Page 1

GE

g

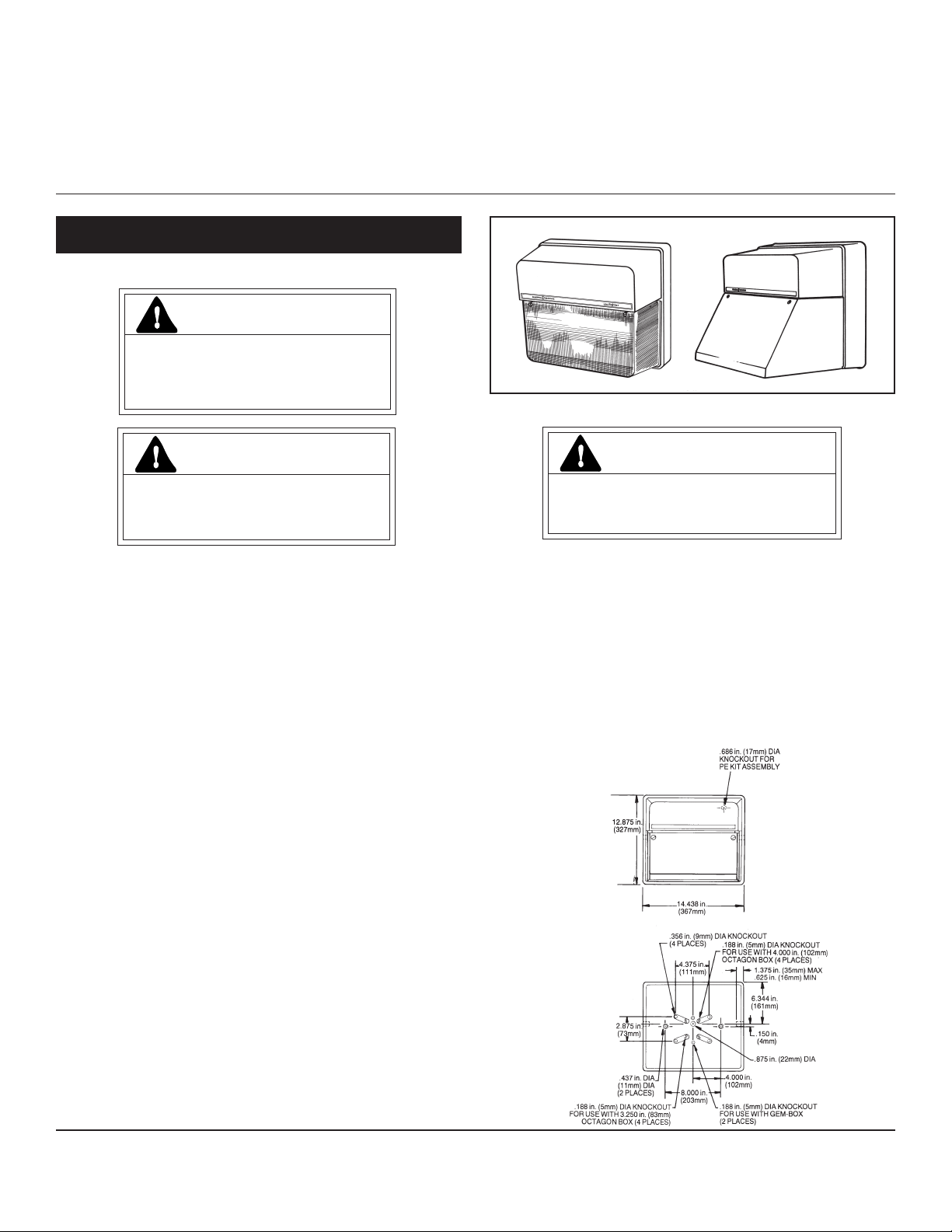

W1LR, W1SR, W1LG, W1SG, W25C (cutoff optics)

Lighting Solutions

READ THOROUGHLY BEFORE INSTALLING

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

GEH-3932C

INSTRUCTIONS

Wallighter 175 and

Wallighter 250 Cutoff Luminaires

A. MOUNTING

WARNING

Risk of fire

• Use supply wire specified on

nameplate

GENERAL

This luminaire is designed for outdoor lighting applications, and

should not be used in areas of limited ventilation, or in high

ambient temperature enclosures. For optimum performance, it

should be installed and maintained according to the following

recommendations.

UNPACKING

This luminaire has been properly packed so that no parts should

have been damaged during transit. Inspect to confirm.

INSTALLATION

The refractor must be removed to access two bolts (on each

side of the reflector) which secures front housing to back plate.

Removal of the front housing allows access for mounting and

wiring.

NOTE: For units marked W25C having socket mounted in front

housing, plug wire assembly located in center top of back plate

must be unplugged while removing front housing.

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

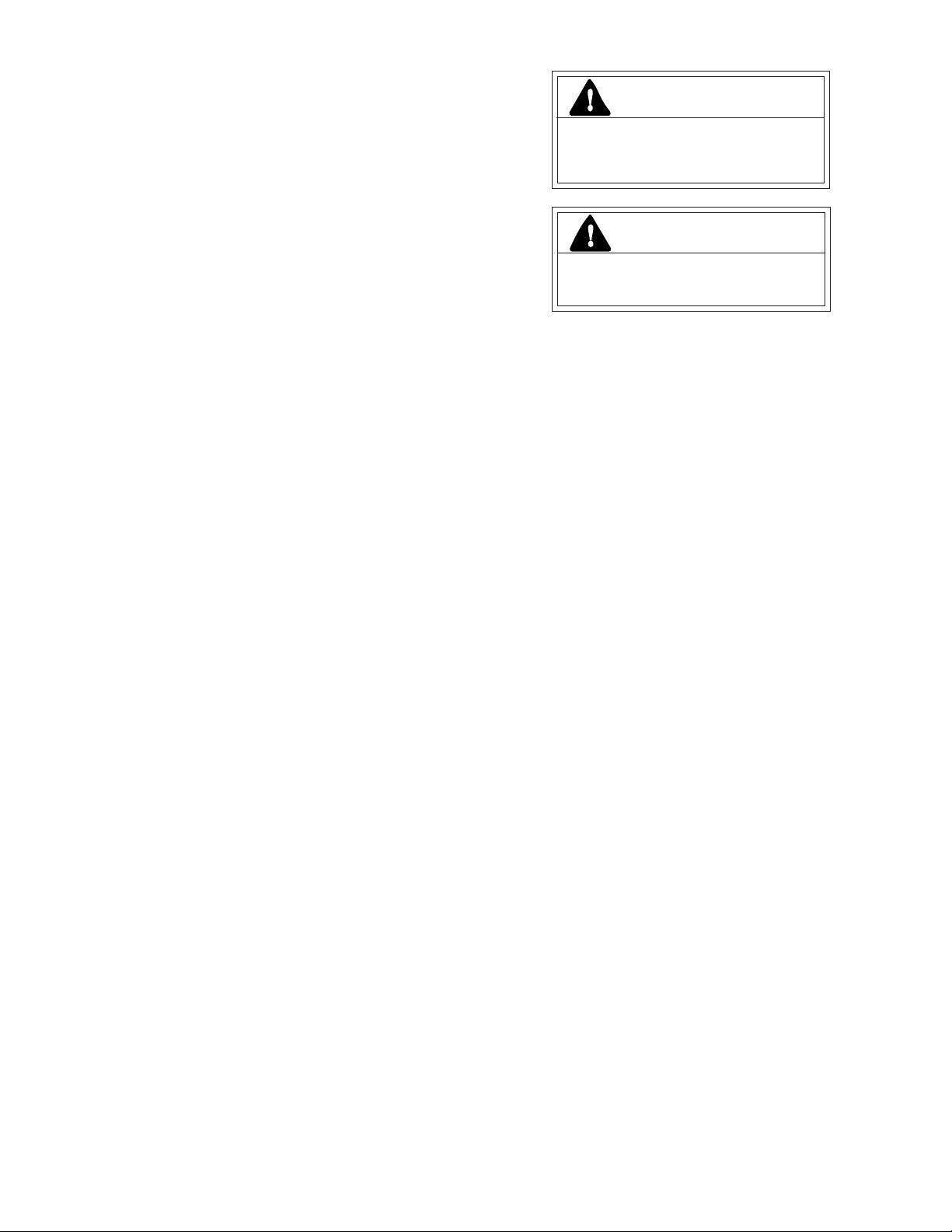

Outlet Box Mounting: The luminaire can be mounted to a

suitable surface-mounted outlet box (3'’ or 4'’ octagon, or 2'’x4'’

rectangular). The back plate may be attached to the outlet box with

two 10-24 screws (not provided), approximately ‘’ long. An alternate

method of mounting the back plate over a surface-mounted outlet

box is to position back plate over box and mount with two 3/8'’ bolts

(not provided) through the knock-out holes provided in the back

plate (see figure 2). Wire the unit (see Wiring). Reattach the front

housing/reflector over the back plate. For W25C having socket

mounted in front housing, plug wire assembly must be

re-connected as front housing is installed.

Figure 1

A gasket is provided with the unit to be used when mounting

over an outlet box, and should be installed between rear of back

plate and the mounting surface. If additional sealing is desired,

caulk back of housing with generic non-hardening sealant (not

provided) across the top and down both sides.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Figure 2

Page 2

Through-Feed Conduit:

Note: Some units may not allow this mounting or may require

special high temperature cable. See labels on back plate for

instruction.

Knock-out holes are provided to permit mounting of the back

plate on vertical surfaces with two 3/8'’ bolts (not provided). The

-inch conduit is then positioned in the cradles on each side of back

plate and secured to back plate with clips and screws provided

(see figure 2). The conduit may also be secured to the wall on either

side of the fixture with conduit straps (not provided). Wire the unit

(see Wiring). Knock-out the sections on each side of the front

housing using pliers, twisting inwardly. Re-attach the front

housing/reflector over the back plate. For W25C having socket

mounted in front housing, plug wire assembly must be

re-connected as front housing is installed.

Install lamp (see LAMP INSTALLATION) and re-install refractor

or cut-off optical assembly.

NOTE: Do not overcompress the gasket on acrylic lens units as

this may cause the lens to crack around the screw holes.

B. WIRING

Make all electrical connections in accordance with the National

Electrical Code and any applicable local code requirements.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

WARNING

Risk of burn

• Do not touch operating luminaire

Use only lamps specified on nameplate. Observe lamp

manufacturer’s recommendations and restrictions on lamp

operation, particularly ballast type, burning position, etc.

Lamp Tightness-Mogul Base Lamp: The lamp should be securely

inserted to the NEMA-EEI specified torque of 35 inch-pounds,

which is best achieved by very firm tightening sufficient to fully

depress and load the center contact of the socket.

Lamp Tightness-Medium Base Lamp: The lamp should be

tightened to a light firmness sufficient to depress the center

contact.

Verify that supply voltage is correct by comparing it to

nameplate.

Customer wiring enters either through the center hole in the

back plate or through the conduit entrance knock-outs on the sides

of the front housing. In either case, an easy access wiring area

(see figure 2) is provided for electrical connections.

Route incoming supply conductors through clips provided and

maintain half inch minimum spacing from ballast and reflector.

NOTE: Connect ground lead to ground (gnd) screw on the back

plate.

Do not remove insulated connectors from wires not needed for

required voltage connection.

IF SINGLE VOLTAGE:

All single voltage ballasts are pre-wired such that user need

only connect the supply conductors.

IF MULTIVOLT: (120/208/240/277 volts)

Connect the ballast lead with the insulated terminal to the

desired voltage terminal as indicated on the ballast terminal

nameplate.

IF MULTIWATT:

Multiwatt ballasts are available in various combinations of

wattage. See wiring instructions on wiring tag inside the

luminaire.

MAINTENANCE AND CLEANING

It will occasionally be necessary to clean the outside of the

refractor to maintain light levels. Frequency of cleaning will

depend on ambient dirt level and minimum light level which is

acceptable to the user. The refractor should be washed in a

solution of warm water and any mild, nonabrasive household

detergent, rinsed with clean water and wiped dry. Should the

optical assembly become dirty on the inside, wipe the reflector

and clean the refractor in the above manner.

The light output of a luminaire is dependent on the age of the

lamp. In applications where the light level is critical, it may be

desirable to replace lamps before they burn out. The lamp

manufacturer can provide data showing how the lamp light output

decreases with use.

To complete installation refer to MOUNTING.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

g

16943533----888

35-201578-M3 (11/99)

Loading...

Loading...