Page 1

INSTRUCTIONS

GEK-90636D

Static

Frequency

SFF2O1A,

SFF2O2A,

SFF2O4A,

Relays

B

B

B

Page 2

GEK-90636

Description

Application

Under

Rate

of

Over

Load

Specifications

DC

Control

AC

Control

Measurement

AC

Settings

Environmental

Ratings

Burden

Contact

Settings

Displays

Functional

Construction

Receiving,

Acceptance

General

Visual

TestEquipment

General

Relay

Tests

Over

Under

of

Rate

Restore

Installation

Surge

Electrical

Settings

Trouble

Servicing

Periodic

Renewal

Shooting

Checks

Parts

Frequency

Change

Frequency

Restoration

Voltage

Voltage

Input

Ratings

Description

Handling

Tests

Testing

Outputs

Frequency

Over

Over

Frequency

Under

Under

Change

RateofChange

Rate

Relay

Restore

Restore

Procedure

Ground

Tests

and

Considerations

Relay

Frequency

Frequency

Relay

Frequency

Frequency

for

of

Change

Tests

With

Test

Test

With

and

Routine

Storage

Tests

Test

Test

Tests

Test

Test

Multiple

Test

Test

Variable

Single

Maintenance

rrabl

With

With

With

With

Setpoint

for

Variable

for

Single

of

Variable

Single

Variable

Single

or

Frequency

or

Line

Contents

Frequency

or

Line

Frequency

or

Line

Models

Frequency

Line

Frequency

Frequency

Frequency

Only

Generators

Frequency

Generator

Generator

Generator

Page

3

4

4

5

5

6

7

7

7

7

7

7

8

8

8

8

9

9

10

10

10

10

11

11

11

11

12

12

12

13

14

14

14

15

15

16

16

17

17

17

18

18

18

18

19

19

20

Cover

2

Photo:

8043796

Page 3

GEK-90636

The

frequency.

frequency

can

and

ranse

independently

be

has

of 40

SFF2O(-)B.Ifa

frequency

A

simple

models.

frequencyifthe

with

the higher

SUP

type

Three

setpoints.

I

form

C

79.9

to

will

rate-of-change

When

this

relays

are

versions

EachSthe

for

set

output

contact.

Nzin0.1 Hz

frequency

be

prevented

setting

featureisenabled,

next

lower frequency

frequency

set

digital

of

the

under

from

(ROC)

can

relayissettooperateat59Hzwith

delay.

associated

the

second

setpoint

output

frequency

under

whereasitis

Timer

full

and

The

minimum

to

frequency

ranges

If

58

with

0.75

seconds

third

relay.

occuris3

setpoint

used

are

Hzisreached

the

59

has

Hz

setting

expired.

setpoints

operating

cycles.

wherein

or

over

frequency

prolong

to

shown

below:

0.5

and

between

time

In

addition, an adjustable

a delay

the

output

DESCRI

frequency

5FF

are

frequency

frequency,

Each

element

steps

in

outside

operating.

feature

an

setpoint

time

out.

an

0.75

seconds

will

operateatthat

Similar

for

an

under

can

be

mode

when

PTION

relays

available

measuring

over

providinç

elements

frequency,

maybeset

the

SFF2O(-)A

of

the acceptable range

can

output

For

second

after

enabled

be

will

be

is

reached

example,

delay.

59

Hzisreached,

and

time

performance

the

third

canbeobtained

and

fourth

frequency,

addedtothe

this

the

time

function

is

that

measure

is

or

for

any

and

0.01

on

the

produced

before

the

assume

at

58

rather

setpoints

over

frequency,orrestore

timer

is provided for

output.

used

to

is

usedinthe

the

one,

two,

independent,

restore

freQuency

Hz

is

operation,

over

steps

made,

multi-frequency

at

the

higher

timer

thatatwo

Hz

the

than

with

output

waiting

associated

setpoint

aIsecond

between

in

the

When

delay

usedinthe

the

restore

system

or

four

and

the

in

the

that

set

relay

until

the

four

each

output,

mode.

Mpdel

Sfl20(-)A:

SF’F20(-)B: 1.0to255

The

AC

undervoltage

input

time

cycle.

Note

voltageisless

Sapproximately

The

function

that

the

percentage

example,ifthe input

cutoff

evely

Should

sufficiently

Company.

standards,

vaiy

will

These

instructionsdonot

possible

funher

To

the

extent

gnat4y.

occurat60

contingencytobe

information

flu’

the

purchaseri

required

butnosuch

Timer

0to1.55

0.lto

cutoff

than

the

undervoltage

one-half

is

adjustable

voltage

volts

purport

be

the

products

assuranceisgiven with

(1/2)

is

based

is 110

(50

to

cover

metinconnection

desired

purposes.

25.5

function

cycle

over

on

volts,

percentof120)

all

or

should

the

described

Ranae

seconds

milliseconds

seconds

operatestoblock

the

120

cutoff

and a

range

volts,

and

setting.

pickup

535

the

the

rather than

details

or variationsinequipment

with

installation,

particular

matter

herein

respect

should

meet

to

local

The

time

to

95

nominal

cutoff

problems

referred

be

applicable

codes

SteDs

second

.05

1

millisecond

0.lsecond

all

outputs

function

dapproximately

percent

rating

level

is

55

volts

operationormaintenance.

arise

which

to

ANSI,

ordinances

and

whenever

hasadropout

inS

percent

d’the

set

to

50

(50

nortoprouide

are

not

the

General

IEEE

and

because

one

relay.

percent,

percent

covered

Electric

NEMA

the

(1)

stçps.

For

of

for

they

a

Page 4

The

relays

can

powered

be

from

GEK-90636

either

a

DC

or

AC

source.

External

Figures

1, 2

Table

The

SFF

device

is

conditions.

Under

Krequency

connections

and

3,

I

summarizes

series

required

to

the

respectively.

the

models

Model

SFF

201

202

204

of

frequency

for

the

accurate

SFF2O1,

SFF2O2

available.

Table

Case

Size

S2

M2

M2

APPlICATION

relays

can

detection

I

be

and

applied

of

under

SFF2O4

Set

Points

1

2

4

wherever

frequency

relays

an

or

can

be

extremely

over

frequency

seen

stable

in

under

The

conservation

important.

load

exceeds

in

danger

used

to

detect

the

loss

of

of

the

system

of

the

entire

overall

An

different

a.

ways:

Disconnect

successively

b.

Disconnect

so

that

Any

c.

Each

frequency

of

the

voltage

under

distorted

total

Longer

the

or

over

so

time

time

frequency

frequency

schemes where

If

a

system

generation,

of

collapsing.

this

condition

generation.

to

recovertonormal,

system

load

blocks

lower

blocks

some

load

combination

measuring

wave

frequency

as

to

affect

setting,

delay

settings

exceeds

trip

accuracy

disturbance

system

Under

and

Sufficient

will

be

facilitated.

conservation

of

load

frequency.

of

load

is

disconnected

of

the

against

a

crystal

before

the

period

is

possible

it

will

the

setting

feature

results

frequency

frequency

to

disconnect

load

or

near

scheme

in

in

several

above.

element

reference and

delay

the

of

for

the

make

for

of

and

repeatability

relays

must

normal

can

several

steps

as

each

in

the

timer

the

wave,

relay

this

at

the

in

loss

will

start

distributed

selected

disconnected

be

be

steps

on

time

SFF

is

and

to

less

likely

least

SFF

relays

of

generating

to

frequency.

arranged

with

a

time

step

compares

requires

started.

if

this

make

to

one

cycle

of

frequency

decay

system

to

each

basis

reached.

is

If

the

distortion

an

occur.

after

may

and

around

load

enable

to

In

this

trip

off

step

at

one

period

the

three

successive

input

incorrect

On

the

be

used

measurement

capacity

system

the

the

system

to

compensate

the

way,

selected

occurring

frequency

of

voltage

persists

measurement.

the

other

delay

in

load

such

that

may

can

remainder

restoration

load

at

level

cycle

each

cycles

wave

for

the

hand,

timer

is

be

be

for

in

a

of

is

if

is

4

Page 5

GEK-90636

started,

a

new

measurement

An

of

the

potential

not

good

section

voltage

when

to

the

this

the

zero

load.

condition

setting

then

this

A

substation

time

coordination

substation

frequency

the

combined

to

trip

and

load

would

sources.

of

the

under

The

power

For

high

the

down

drop

The

the

company

faults

speed

reclosure

during

in

relay

power

analyzed

the

open

arid

before

important

practice

and

use

and

frequency

circuits

and

often

A

frequency

any).

(if

load

are

decreased

with

lock

not

‘This

problem

frequency

SFF

relay

on

the

reclose.

to

the

frequency

could

system

to

determine

circuit

the

will

consideration

source

supply

to

that

relay

are

de-energized.

different

at

if

the

voltage

the

If

will

be

inadvertently

which

in

load

tripped

fast

a

out

operating

unnecessarily.

then

may

transmission

line,

Itisimportant

prevent

interruption.

that

be

used

before

period.

time

delay

be

started.

from

which

relay

a

to

disconnect

of

circuits

relay

stays

relay

has

is

a

shedding

out,

the

as

the

be

accomplished

could

also

both

trip

be

and

be

ends

damage

might

to

occur

trip

reclosing

the

amount

is

reached,

in

the

the

from

supplying

Rather,

rates

depending

connected

above

connected

disconnected.

large

amount

applications.

motor

motors

under

In

avoided

the

level

in

used

circuit

of

the

for

to

motors

An

SFF

during

incoming

the

takes

of

application

relay

makes

a

potential

load

on

motor

both

such

to

the

voltage

to

disconnect

of

load

would

were

slowing

frequency

an

unattended

simply

by

coordinating

by

of

the

an

industrial

that

utilizes

will

line

the

industrial

andlor

relay

the

breaker

place.

frequency

the

timer

of

frequency

its

source

another

load

the

voltage

on

the

characteristics

a

circuit

cutoff

load

motor

load

If

the

tend

down.

relay

may

station,

reenergizing

undervoltage

installation

high

be

tripped.

load

generators

at

the

plant

time

that

to

Each

decay,

will

immediately

be

relays

measurement.

that

is

connected

bus

section.

do

not

go

to

and

the

could

produce

setting

on

a

separate

may

present

transmission

maintain

to

This

slow

cause

restoration

the

settings

cutoff

that

speed

to

automatic

This

will

disconnected

be

that

could

the

the

be

transmission

plant

application

if

any,

that

is

It

For

zero

frequency

the

of

for

the

sources

the

decay

the

motor

the

of

the

function.

is

tapped

be

may

used

to

separate

will

will

reset

the

location

is

generally

to

one

example,

immediately

decay

circuit

an

output

time

delay

bus

section,

problem

a

to

voltage

of

voltage

while

breakers

of

the

motor

transmission

time

delay

off

reclosing.

followed

by

prior

have

to

occur

detect

line

have

slowed

is

open.

it

from

to

during

and

bus

the

and

for

the

of

the

be

of

a

a

to

Rate

of

Change

The

rate

relays,

or

a

The

F3

rate

and

rate

and

faster

of

position.

Over

over

Frequency

The

over

frequency

operation

load

rejection.

schemes

to

synchronous

would

during

be

used

off-line

of

change

usable

is

F4.

This

than

change

frequency

condition.

at

frequencies

be

used

speeds

to

operation.

only

feature

was

feature

Another

to

or

remove

feature

between

will

anticipated

is

enabled

function

For

example,

above

possible

protect

on

turning

supplemental

available

is

two

allow

when

may

rated

application

generator

a

gear.

adjacent

load

to

the

by

setting

be

used

it

can

speed

In

protection

5

only

shed

be

delay

the

anywhere

be

that

of

against

such

in

multi-setpoint

setpoints;

faster

timer

appropriate

that

used

to

could

the

be

over

accidental

schemes

that

is

i.e.,

if

the

settings

it

protect

caused

frequency

the

over

required

models

Fl

and

F2,

frequency

were

ROC

switch

is

desired

generator

a

by

an

function

energization

frequency

to

be

of

the

F2

and

decays

determined.

the

to

detect

to

against

inadvertent

at

function

enabled

SFF

is

sub

only

F3

at

IN

an

in

Page 6

It

should

fashion

enabling

be

that

the

recognized

a

loss

of

associated

I)C

when

the

to

off-line

GEK-90636

CAUTION

applying

relay

protection.

will

the

cause

over

frequency

the

output

function

relay

to

in

reset,

this

thus

Load

frequency

recovery

minutes.

can

that

Restoration

If

a

load

be

used

can

to

be

availability

determines

restoration

provided

related

by

to

emergency

setpoints

time.

the

system

Since

they

should

Reconnecting

the

do

not

momentarily

is

provided

whenever

below

enough

the

to

shedding

will

stabilize,

normal

the

As

to

automatically

restored

of

generation,

whether

program

a

timer

the

amount

conditions.

and

thereby

restoration

reset

reset

with

function

the

setpoint.

ride

over

program

likely

is

frequency

is

or

usually

external

of

staggered

be

loads

minimizes

as

a

result

restore

the

an

adjustable

is

This

momentary

and

through

to

be

approaches

begin

determined

either

not

the

incorporates

to

the

time

required

Also,

both

so

on

a

distributed

timers

will

of

output

time

subjected

delay

is

under

has

been

system

quite

the

by

slow

normal

load

the

locally

shed

load

SFF

to

the

time

all

that

the

possibility

be

set

transient

function.

delay

to a

frequency

adjustable

frequency

successfully

control

and

the

restoration

ability

ol-

through

can

substantial

relay.

add

generation

delay

of

the

basis

for

long

system

For

reset

and

will

may

extend

restore

process.

of

the

be

successfully

time

The

amount

and

load

is

not

also

minimizes

of

initiating

time

frequency

this

before

change

should

be

conditions.

implemented,

recover

over

a

function

The

system

system

interconnections,

restored.

delay,

of

time

or

to

close

the

restoration

reconnected

power

new

a

delays,

it

oscillations

reason,

the

from

contacts

kept

the

above

very

the

to

normal.

period

in

to

the

amount

serve

of

SFF

which

delay

tie

lines

frequency

at

the

swings

disturbance.

essential

is

that

restore

change

the

setpoint

brief,

only

system

The

several

relay

of

load

it.

The

A

load

must

to

use

during

same

across

that

may

function

state

long

be

is

to

The

rated

frequency.

restore

relay

may

provided

after

load

kept

energized

should

after

an

has

been

the

restore

restore

frequency

function

be

shortened.

to

control

shedding

de-energized.

be

under

frequency

restored.

function

If

output

until

continuous

the

the

has

all

During

will

setting

relay

To

restore

occurred

of

the

In

this

condition

normal

not

operate

of

will

prevent

output.

and

load

way,

has

frequency

the

function

variations

pick

up

this,

CC

when

that

was

the

restore

been

due

to

minor

6

will

most

in

normal

and

drop

contact

a

is

to

be

energized

it

is

desired

shed

has

output

detected and

conditions,

changes

likely

frequency

continually,

out

converter

to

restore

been

relay

until

CC

in

be

at

designated

by

an

load.

restored

will

the

load

will

be

frequency.

or

very

are

such

that

the

life

external

CC

should

which

at

only

be

operated

that

was

de-energized

close

of

CC

device

time

shed

and

to

the

the

is

be

it

Page 7

GEK-90636

SPECIFICATIONS

DC

Control

Nominal

Minimum

Maximum

AC

Control

Nominal

Minimum

Maximum

AC

Measurement

Nominal

Minimum

Maximum

Settings

Frequency

SFF2O(-)A:

SFF2O(-)B:

Repeatability

Timing

SFF2O(-)A:

SFF2O(-)B:

Repeatability

Voltage

48,

110,

Volts

37

280

Voltage

110-120

45

Vrms

132

120

Vrms

42

Vrms

132

125,

Volts

Vrms

Vrms

Input

Vrms

±0.002

±

220,

(35%

(110%

3%

250

of

nominal)

of

Hz

nominal)

Setpoint

Setpoint

Setpoint

Setpoint

Setpoint

40.0

40.0

to 1.55

0

1

to

0.lto

to

79.9

to

79.9

seconds

255

milliseconds

25.5

Hz

in

Hz

in

seconds

0.1

0.01

in

in

Hz

0.05

in

0.1

steps

Hz

steps

second

1

millisecond

second

steps

steps

steps

Undervoltage

Setpoint

Setpoint

Repeatability

Rate

change

of

Frequency

Frequency

Frequency

Environmental

Operating

-20°C

will

not

malfunction,

Storage

-40°C

Surge

ANSI

IEC 255

GE

RFI

35%

Accuracy

(multi-setpoint

1

to

2

to

3

to

to

+55°C

to+75°C

C37.90

(SWC

to

95%

±5%

±3%

frequency

frequency

frequency

95%

nor

95%

in

5%

of

setting

relative

be

relative

and

Fast

steps

from

models

2:

IN

or

IN

3:

4:

IN

or

or

humidity

damaged,

humidity

Transient)

based

35%

only)

OUT

OUT

OUT

in

on

l2OVrms

to

90%

(noncondensing).

ambient

up

to

(noncondensing)

nominal

65°C

+

Note

that

the

unit

7

Page 8

Burden

Model

SFF

Case

Size

Set

Points

GEK-9063

RATINGS

Table

48

II

Power

DC

125

Burdens

Supply

250

AC

VA

120

Measurement

AC

VA

Contact

Make

DC

AC

Target

amps.

The

front

of

only

is

necessary

Frequency

frequency

stated

201

202

204

Ratings

and

carry

Break

Break

277

Volts

supervision

following

relay

the

A

of

each

range,

60

25

to

three

that

S2

M2

M2

30

amps

Watts

VA

maximum

settings,

without

remove

or

setpoint

frequency

Resistive

ms

(40

unit

which

the

four

for

0.1

the

digit

to

1

2

4

1

second.

L/R)

Amperes

5

amp

must

need

front

thumbwheel

be

set.

setpoint

operate

SWFTI

be

for

pulling

cover

3.2

4.9

8.4

set

from

Note:

will

level

NGS

in

if

be

3.5

5.2

8.7

with

each

boards

the

relay.

switch

setting

a

prevented

6.3

8.0

11.5

than

less

application,

or

removing

on

the

is

front

made

from

8.1

10.6

15.7

0.6

are

the

operating.

volt

made

nameplate.

panel

outside

1

1

1

drop

from

allows

of

at

30

the

It

the

the

Function

modes

delay

Rate

the

It

of

rate

is

disabled

and

Time

delay.

Voltage

used

to

the

switches

A

of

operation.

the

Change

of

change

Delay

setting

The

Cutoff

choose

three

contact

(Multi

when

An

the

in

the

position

When

the

converter

frequency

function.

over

frequency

array

is

An

of

equal

array

undervoltage

UP

position.

slide

switch

restore

input

models

This

function

or

two-position

the

to

of

sum

two-position

cutoff

permits

mode

is

enabled.

restore

of

the

level.

is

only)

only

is

modes

toggle

switches

toggle

The

8

the

chosen

A

two

valid

switches

switches

cutoff

choice

the

position

are

in

of

timer

under

for

chosen.

allows

UP

the

calibrated

setting

under,

is

switched

recessed

frequency

setting

position.

is

equal

over,

switch

in

to

or

restore

dropout

to

selects

operation.

the

output

5%

steps

the

sum

is

of

Page 9

jp

current.

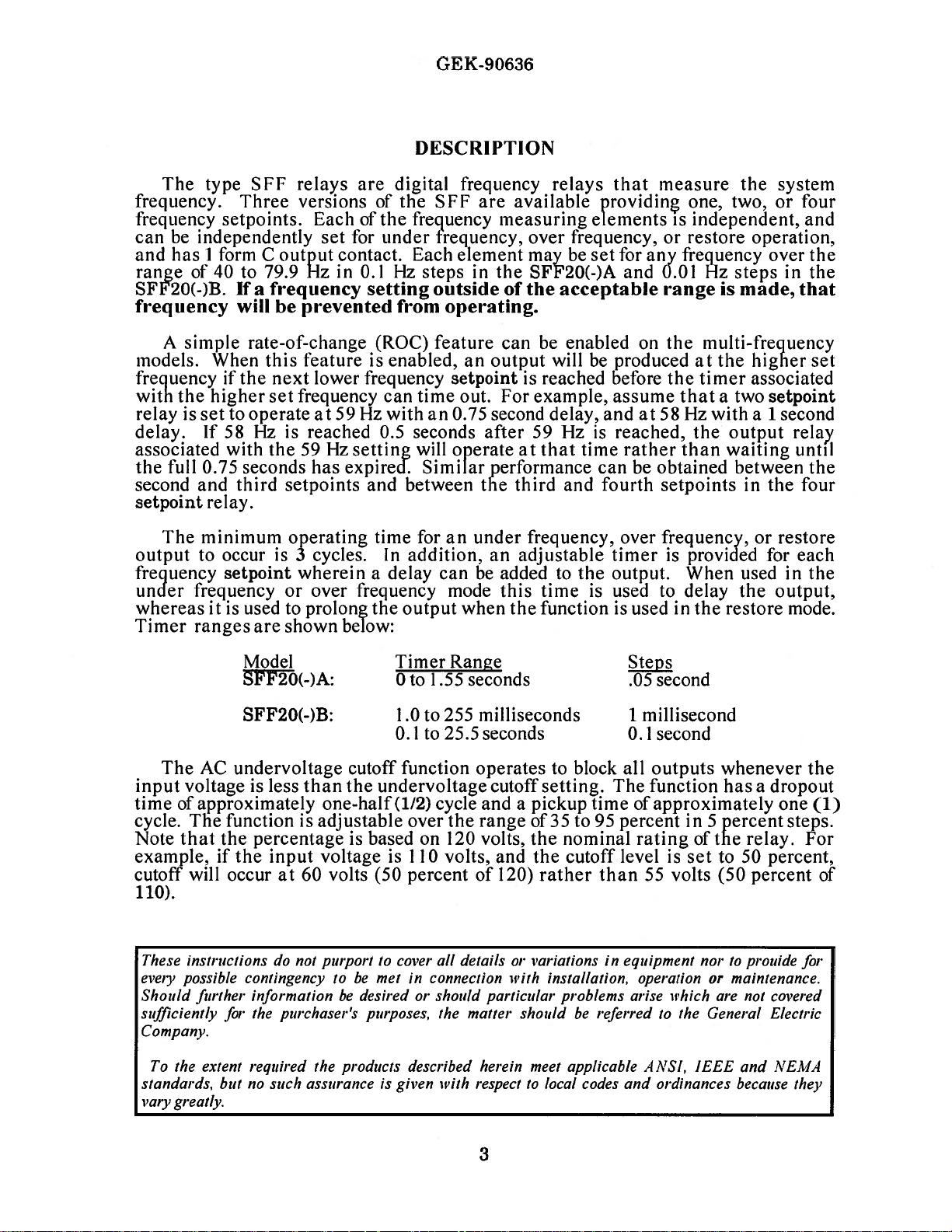

The

trip

One

indicators

provided

is

are

for

red

each

GEK-

DISPLAYS

LED’s

tripping

90636

which

element.

are

supervised

by

the

passage

of

trip

Test

output

In

Service

are

operational.

Model

Amber

and

Target

201

202

ROC

204

ROC

ROC

LED’s

ifanoutput

A

normally

Fl

Fl

F2

Fl

F2

F3

ROC

F4

light

to

relay

lit

green

FUNCTIONAL

Table

Description

Frequency

Frequency

Rate

of

change

Frequency

Frequency

of

Rate

change

Frequency

of

Rate

change

Frequency

of

Rate

change

Frequency

indicate

is

energized

LED

indicates

HI

1

output

I

output

caused

2

output

1

output

caused

2

output

caused

3

output

caused

4

output

when

the

(TB).

the

DESCRIPTION

contact

contact

Fl

contact

contact

contact

Fl

contact

contact

F2

contact

contact

F3

contact

contact

frequency

regulated

operated

operated

to

operated

operated

to

operated

to

operated

to

operated

detection

DC

operate

operate

operate

operate

and

circuit

start-up

has

circuity

an

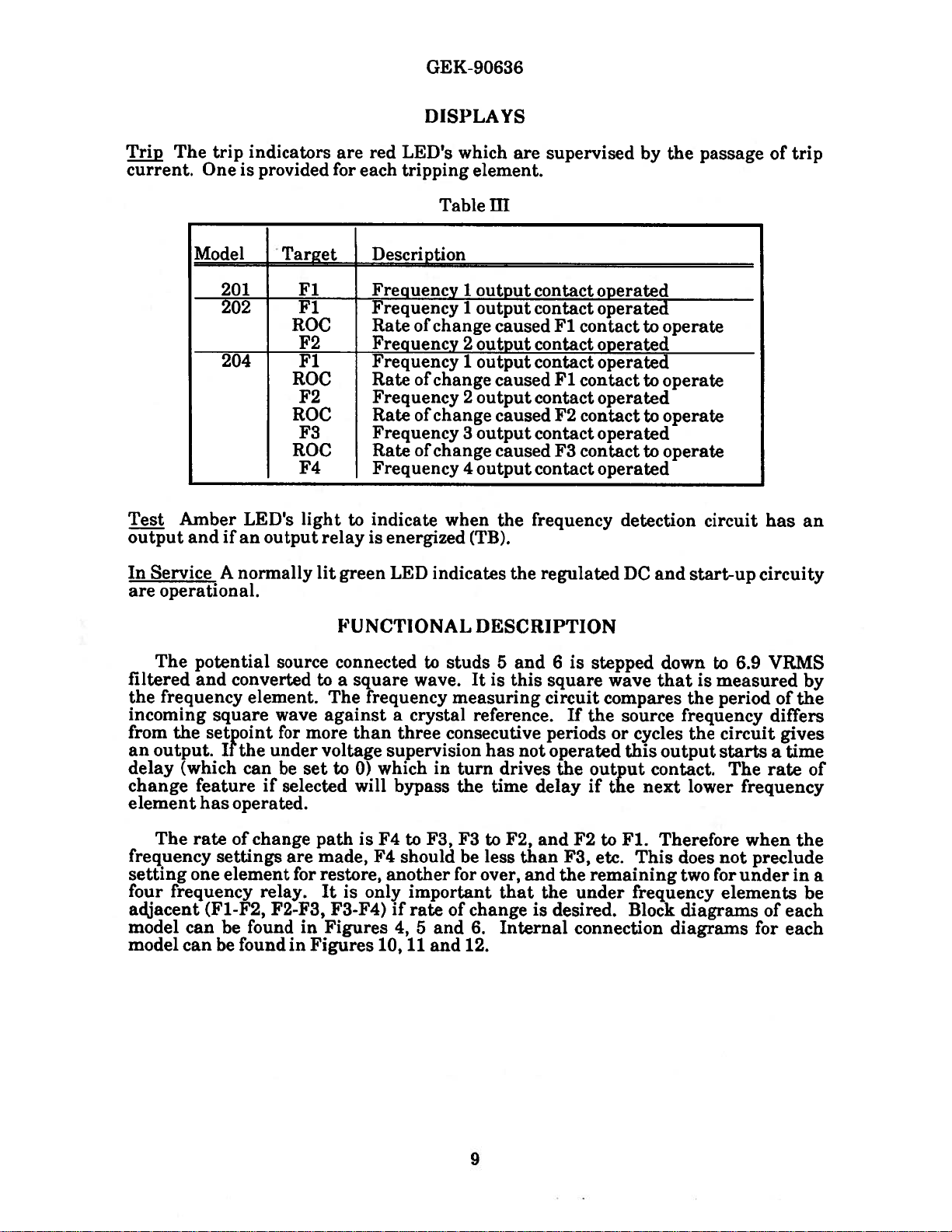

The

potential

filtered

the

and

frequency

incoming

from

the

an

output.

delay

change

(which

feature

element

The

rateofchange

frequency

setting

four

one

frequency

adjacent

model can

model

can

converted

square

setpoint

If

the

has

operated.

settings

element

(F1-F2,

be

be

found

source

element.

wave

for

under

be

can

if

selected

are

relay.

F2-F3,

found

in

connected

to

The

against

more

voltage

set

to

pathisF4

made,

for

restore,

It

F3-F4)

in

Figures

Figures

a

square

frequency

than

0)

will

only

is

to

wave.

a

crystal

three

supervision

which

in

bypass

to

F3,

F4

should

another

important

if

rate

4,

and

5

10,

11

and

studs

5

and

It

is

this

measuring

reference.

consecutive

has

not

turn

drives

the

time

F3

to

F2,

be

less

for

over,

that

of

change

6.

Internal

12.

delay

and

than

and

the

is

6

is

stepped

square

circuit

If

the

periods

operated

the

output

if

F2

F3,

etc.

the

remaining

under

desired.

connection

wave

that

compares

source

or

cycles

this

contact.

next

the

to

Fl.

This

frequency

Block

down

to

is

measured

the

frequency

the

output

lower

Therefore

does

two

for

diagrams

diagrams

6.9

VRMS

period

circuit

starts

The

rate

frequency

when

not

preclude

under

elements

of

for

by

of

the

differs

gives

a time

the

in

be

each

each

of

a

9

Page 10

GEK-90636

CONSTRUCTION

The

components

removed

bottom.

from

The

completed

The

cover

prevent

all

unless

SFF2O1

by

the

The

case

panel

otherwise

are

The

printed

removing

horizontally

GE

part

circuit

boards.

components

The

output

cradle.

out

of

The

If

the

input

the

electrical

through

is

attached

from

cover

is

suitable

thicknesses

specified

shown

circuit

the

in

guides.

number

If

you

when

relays

a

relay

socket.

transformer

of

relay

the

case.

relay

connections

removable

the

front

to

being

for

semi-flush

to

two

up

on

in

figure

8

boards

four

screws

Each

286A2847P1

not

do

removing

are

mounted

requires

replacement

is

mounted

RECEIVING,

are

The

cradle

connection

of

replaced

inches.

the

order.

and

for

are

mounted

securing

board

card

have

a

the

boards.

HANDLING

mounted

is

between

the

case

until

mounting

A

Outline

SFF2O2

the

the

is

labeled

puller

puller,

card

in

sockets

unclip

on

the

on

locked

the

plugs

and

the

panel

behind

nameplate.

to

or

bottom

a

cradle

in

the

case

blocks

to

permit

includes

connection

on

panels.

thickness

and

panel

and

204

the

nameplate

correspond

other

be

on

the

suitable

careful

board

a

retaining

plate

AND

STORAGE

assembly

by

case

and

testing

two

plugs

Hardware

of

1/8

drilling

figure

The

to

not

fixed

of

the

that

latches

the

cradle

the

relay

interlocking

have

will

inch

dimensions

7.

and

can

boards

a

given

means

to

damage

to

the

and

wire

relay

cradle.

can

at

the

in

been

available

is

be

be

are

location.

remove

to

or

back

pull

easily

top

b1ocks

its

case.

arms

inserted.

assumed

for

accessed

mounted

bend

of

the

relay

be

and

are

that

for

the

Use

the

any

the

relay

This

discharge

components.

and

the

conditions

to

care

on

their

touching

generation

the

should

the

body

internal

any

These

cartons

relay

handling

promptly

installed

The

designed

examine

is

notify

relays

immediately,

chips.

General

The

relay

has

been

sustained

contains

currents

The

be

has

of

relays,

evident,

should

main

of

of

electrostatic

exercised

switches.

been

discharged,

components

the

when

to

protect

for

it

file

the

nearest

should

be

in

electronic

if

those

source

low

humidity,

when

The

not

any

damage

damage

a

General

be

stored

and

examined

shipment

components

currents

of

electrostatic

carpeted

discharge

removing

persons

by

on

included

them

handling

touching

the

modules.

as

against

sustained

claim

Electric

in

their

inaplace

that

ACCEPTANCE

and

tested

and

that

flow

floors

currents.

handling

and

some

part

damage.

once

at

Sales

original

is

upon

the

relay

that

could

through

discharge

and

the

surface

of

a

control

in

transit.

with

the

Office.

cartons.

free

from

TESTS

delivery

is

functioning

damaged

be

certain

currents

isolating

Where

the

module

these

modules

should

ground

at

panel,

Immediately

If

damage

transportation

If

the

moisture,

to

insure

by

terminals

is

the

shoes

are

conditions

to

make

make

potential,

will

be

upon

resulting

relays

dust

that

correctly.

electrostatic

of

human

body,

conducive

exist,

settings

sure

before

shipped

receipt

company

are

not

to

and

metallic

no

damage

the

that

in

of

from

and

be

a

10

Page 11

Visual

Remove

broken

Every

important

high

enough

brushes

circuited

A

drawout

12XLAI3A

a

disturb

Although

connections

‘Pest

any

Equipment

the

cracked

or

circuit

on

do.

during

shorting

this

are

relay

circuits

to

This

case

test

plug

made

parts.

in

the

engage

will

insertion

relay

plug.

bars

allows

to

from

drawout

may

This

both

its

with

the

prevent

of

in

greater

the

case

case

shorting

connecting

the

be

tested

plug

makes

the

case.

relay

GEK-90636

and

check

CAUTION:

has

bars

the

secondary

connection

without

connection

The

flexibility,

and

the

for

signs

an

auxiliary

that

the

plug

or

plug.

removing

12XLA12A

it

requires

external

of

auxiliary

test

circuits

it,

to

the

test

circuits.

physical

brush.

plug

from

from

relay

plug

shorting

damage

it

brush

before

the

panel,

only

may

jumpers

is

especially

the

being

and

also

such

be

by

does

be

as

bent

main

open-

using

not

used.

since

1

DC

2.

Variable

70

3.

Limiting

3KQ,

General

The

line

Each

generators.

When

manufactures

Testing

above

set

Relay

Test

Targets

The

panels).

frequency

frequency

lights

voltage

hertz

25

Testing

relay

can

frequency.

has

test

utilizing

with

or

Outputs

target

test

The

measuring

deviates

when

source

frequency

resistor,

Watts.

Considerations

be

tested

The

acceptance

a

section

variable

manual

line

frequency

below

the

LEDs

targets

test

from

the

timer

at

load

with

48V

box for

a

variable

rated

generator

or

test

for

line

frequency

frequency/voltage

for

specific

requires

line

frequency

are labled

indicatEWe

element

the

is

producing

(F-).

setpoint

to

250V

or

line

trip

have

operation

that

depending

Fl,TB

Test

status

The

for

3

an

output

with

less

than

frequency

target

rated

indicator

voltage/frequency

taken

into

testing

generators

account

and

refer

instructions

the

frequency

on

the

fault

F4,TB,

to

of

the

output

“F”

test

indicator

consecutive

to

operate

cycles.

the

ripple

5%

at

48

test.

generator

or

for

to

of

the

setpoints

being

see

output

to

Rated

both

variable

the

test

figure

relay

will

The

l2OVrms,

from

or

100Q-

with

contingencies.

frequency

equipment

test

apparatus.

of

the

relay

simulated.

19

17,

and

(TB)

“TB”

when

indicator

light

relay.

40

the

be

(front

the

the

to

Trip

Targets

The

the

are

trip

relay

reset

target

trips

with

LEDs

and

the

are

there

target

labeled

is

over

reset

lOOma

switch

F1,RC

through

or

by

11

to

the

F4,RC.

the

normally

removal

They

of

the

will

open

relay

latch

contacts.

power.

“on”

when

They

Page 12

GEK-90636

Relay

The

contacts

Tests

For

for

the front

SFF204

Test

the

Under

Note:

output

Over

The

relay

more

SFF2O1

SFF2O2

SFF2O4

The

T

Contacts

relay

for

the

following

front

relay

Frequency,

The

trip

contacts.

Frequency

will

than

three

Set

Point

Fl

Fl

F2

Fl

F2

F3

F4

relay

contacts

eachofthe

test.s

viewsofthe

view.

in

accordance

RateofChange

LEDs

will

Relay

trip

when

cycles.

Frequency

t

5Oor6Ohz

50

50

50

50

50

50

can

be

tested

and

consist

of

frequency

refertofigure

SFF2O1,

with

only

light

Tests

the

frequency

60hz

or

or

60hz

60hz

or

60hz

or

60hz

or

or

60hz

at

other

adjust

the

normally

measuring

9

for

and

204

respectively.

the function

or

Restore.

and

sealinif

under

Table

Switch

Settings

Mode

over

over

over

over

over

over

over

frequencies

inputs

based

open

(NO)

units.

test

connections,

set

for.

it

is

lOOma

test

exceeds

IV

ROC

-

out

-

out l.5sec

out

out

-

if

desired.

on

that

and

normally

and

For

the

SFF202

Such

as

of

current

the frequency

Time

Delay

1.5sec

1.5sec

1.5sec

1.Ssec

1.5sec

1.5sec

To

do

so,

setting.

to

flows

set

figure

Over

the

closed

17

and

refer

Frequency,

through

setpoints

Under

Voltage

Cutoff

35%

35%

35%

frequency

(NC)

to

20

the

the

for

Over

1.

Apply

2.

Set

the

frequency

frequency

setting

Verify

LEDs

to

have

Frequency

the

the

frequency

frequency

for

that

“Fl”

“F4”

light

tripped,

Test

rated

to

source

(0.5hz)

3

cycles

the

“F4”

to

after

as

With

supply

voltage

generator

59.5hz

115

at

above

plus

following

light.

the

indicated

Variable

at

for

60hz

Vrms

the

setpoint.

1.5sec

occurs

The

1.5

second

by

the

Frequency

between

(0.5hz)

and

between

to

produce

during

“TB”

time

trip

12

stud(1)

below

49.5hz

stud(5)

Maintain

test

delay.

targets.

Generator

for

an

output.

the

targets

and

the

50hz

and

over

and

And

stud(2)

setpoints.

rated

stud(6).

the

frequency

frequency.

the

trip

the

output

(either

For

setpoints.

Then

The

target

relay

polarity).

example,

Apply

increase

the

at

test

LEDs

contacts

set

the

the

higher

target

“Fl”

Page 13

3.

4.

5.

Remove

dropped

Reset

Remove

the

the

out.

target

the

input

LEDs.

supply

test

frequency,

voltage.

GEK-90636

and

note

that

the

contacts

and

LEDs

have

6.

Set

at

LEDs

outputs.

Over

Before

(0.5hz)

49.5hz

Apply

1.

2.

Apply

line

the

second

indicated

Remove

3.

have

4.

Reset

Remove

5.

undervoltage

the

step

1.

on

during

Frequency

applying

below

for

50hz

rated

the

frequency

“TB”

test

time

by

the

dropped

the

targets.

the

With

the

rated

supply

test

delay

the

input

supply

the

the

Test

With

the

line

frequency

line.

line

is

applied

targets

trip

out.

switch

undervoltage

over

frequency.

Single

or

single

input

This

simulates

voltage

between

frequency

verify

and

the

setting.

targets.

test

frequency,

voltage

setting

set

or

Line

frequency

that

at

ll5vrms

that

trip

And

to

at

you

stud(1)

the

target

the

and

95%,

and

there

95%

The

undervoltage

Frequency

source,

use.

an

over

and

between

test

LEDs

output

that

note

repeat

should

set

the

Such

frequency.

stud(2),

stud(5)

target

relay

“Fl”

LEDs

to

contacts

the

the

above

be

cutoff

frequency

59.5hz

as

non

and

“Fl”

“F4”

contacts

no

trips,

will

polarity

stud(6).

to

light

have

and

test

or

disable

setpoint(s)

for

60hz

sensitive.

“F4”

after

tripped,

test

starting

target

and

As

the

light,

the

1.5

LEDs

all

as

Set

6.

at

LEDs

outputs.

3I’F1J1

SFF2O2

204

SFF

.—.

The

relay

r

the

step

Set

Point

Fl

Fl

F2

Fl

F2

F3

F4

undervoltage

1.

With

during

the

T

Frequency

t

50

50

50

50

50

50

50

I

can

ne

tested

and

switch

the

undervoltage

over

or

60hz

60hz

or

or

60hz

or

60hz

or

60hz

or

60hz

or

60hz

at

adjust

frequency.

I

other

frequencies

the

setting

Table

Switch

Mode

under

under

under

under

under

under

under

inputs

to

set

The

Settings

-

based

95%,

at

95%

undervoltage

V

ROC

out

-

out

out

out

---

if

desired.

on

-

and

there

-

that

repeat

shouki

-I

—

To

setting.

the

cutoff

Time

Delay

l.5sec

l.5sec

l.5sec

1.5sec

l.5sec

1.Ssec

l.5sec

do

be

so,

above

no

trips,

will

set

the

test

disable

Under

Voltage

Cutoff

35%

35%

35%

frequency

starting

or

target

all

13

Page 14

GE

K-90

636

Under

rphe

than

Under

1.

2.

3.

4.

Frequency

relay

three

Frequency

Apply

Set

the

frequency

frequency

lower

Verify

LEDs

“F4”

to

have

Remove

LEDs

Reset

will

trip

cycles.

rated

the

frequency

frequency

source

setting

that

“Fl”

light

tripped,

the

have

the

targets.

Relay

when

Test

supply

to

(0.5hz)

to

the

to

“F4”

after

as

input

dropped

‘l’ests

the

frequency

With

Variable

voltage

generator

60.5hz

ll5Vrms

at

below

produce

following

light.

the

indicated

test

out.

between

at

for

60hz

between

the

rated

an

output.

occurs

“TB”

The

1.5

second

by

the

frequency,

under

test

Frequency

stud(1)

(0.5hz)

and

50.5hz

setpoints.

during

test

time

trip

targets.

and

is

Generator

above

for

stud(5)

the

targets

delay.

note

below

and

the

50hz

and

Maintain

under

that

the

stud(2).

setpoints.

rated

stud(6).

frequency.

and

And

the

setpoint(s)

the

the

trip

the

output

contacts

For

setpoints.

Then

frequency

The

target

relay

and

for

more

example,

Apply

decrease

test

LEDs

contacts

test

the

the

at

the

target

“Fl”

target

set

5.

Remove

6.

Set

at

target

all

Under

Before

above

Appiy

1.

2.

Apply

the

light,

the

as

Remove

3.

LEDs

4.

Reset

Remove

5.

the

undervoltage

the

1.

step

LEDs

outputs.

Frequency

applying

the

frequency

the

the

line

frequency

the

1.5

second

indicated

the

have

the

the

supply

With

during

the

rated

test

“TB”

by

input

dropped

targets.

supply

Test

supply

or

test

time

the

voltage.

switch

the

undervoltage

the

With

line

input

line

frequency

applied

is

targets

delay

trip

test

out.

voltage

setting

under

Single

or

single

used.

This

voltage

and

setting.

targets.

frequency,

to

set

frequency.

or

Line

frequency

simulates

between

at

ll5vrms

verify

the

that

trip

And

and

100%,

at

100%

The

Frequency

source.

an

stud(1)

the

target

the

output

note

that

and

repeat

there

undervoltage

Set

under

and

(2).

between

target

test

LEDs

relay

the

the

above

should

cutoff

the

setpoint(s)

frequency.

stud(S)

LEDs

“Fl”

to

contacts

contacts

be

and

“F4”

and

test

no

will

stud(6).

“Fl”

light

have

test

starting

trips,

disable

(0.5hz)

to

“F4”

after

tripped,

target

or

As

6.

Set

at

step

target

all

outputs.

the

undervoltage

1.

LEDs

With

during

switch

the

undervoltage

the

under

setting

frequency.

14

to

set

100%,

at

The

and

100%

undervoltage

repeat

there

the

should

above

be

cutoff

test

no

will

starting

trips,

disable

or

Page 15

GEK-90636

Rate

The

of

rateofchange

frequency

frequency

Example:

1.5

delay

a

seconds

change

F’F2U2

SFF2O4

The

t

relay

Change

change

setpoints.

seconds.

of

the

from

Set

Point

El

F2

Fl

F2

F3

F4

can

Fl

1.5

relay

Fl

(ROC)

feature

is

faster

is

set

If

the

seconds.

would

to

F2

[

Frequency

t

5Oor6Ohz

50or60hz

50

50

50

I

50

tested

be

and

for

Multiple

allows

and

to

59.8,

frequency

But

trip

was

faster

or

60hz

or

60hz

or

60hz

or

60hz

at

other

adjust

the

larger

F2

is

were

if

the

without

Switch

F

frequencies

the

Setpoint

relay

set

to

to

frequency

than

Table

Mode

under

under

under

under

under

under

inputs

to

in

magnitude

58.0,

from

go

waiting

the

time

VI

Settings

based

Models

trip

and

60

was

delay

ROC

in

-

in

in

in

-

if

desired.

on

faster

the

to

to

for

that

Only

than

the

time

59.7hz

change

the

of

Fl.

Delay

1.5sec

0.Osec

1.5sec

1.2sec

0.8sec

0.Osec

I

To

setting.

its

limits

delays

only

time

Time

do

set

from

delays.

so,

Fl

set

time

set

on

would

60

delay

on

Fl

and

to

58hz

The

Under

Voltage

Cutoff

35%

35%

H

the

frequicy

if

the

successive

F2

are

trip

after

.25

in

rate

of

It

is

essential

normally

Rate

1.

Apply

2.

Set

the

frequency

frequency

When

test

(The

The

“F4”

After

Remove

3.

LEDs

4.

Reset

5.

Remove

open

of

Change

rated

the

frequency

the

target

rate

“RC”

light

1.5

have

the

the

that

relay

contacts

Test

supply

frequency

to

source

(0.5hz)

frequency

LEDs

of

change

trip

targets

in

delayed

a

seconds

the

input

dropped

targets.

the

supply

trip

targets

for

Variable

voltage

generator

60.5hz

115

at

below

has

“Fl”

has

LEDs

all

test

out.

voltage

are

for

this

test.

Frequency

between

at

for

60hz

Vrms

the

between

setpoint

been

“F4”

to

overridden

light

with

sequence

should

frequency,

enabled

stud(1)

(0.5hz)

and

50.5hz

with

reduced,

the

and

the

no

according

lit.

be

and

by

Generators

above

stud(5)

zero

verify

“TB”s

set

delay,

note

and

for

time

and

to

the

time

their

that

lOOma

stud(2).

the

50hz

and

that

light

delays

the

of

setpoints.

rated

stud(6).

delay.

the

following

with

on

trip

time

the

contacts

current

For

setpoints.

Then

with

the

TB

target

delay

through

example,

Apply

decrease

occurs.

time

no

outputs).

LEDs

settings.

and

test

delay.

“Fl”

Note:

target

the

set

the

the

The

to

15

Page 16

6.

Rate

the

Set

step

at

LEDs

outputs.

of

Change

undervoltage

With

1.

during

the

‘Pest

switch

undervoltage

the

under

for

Single

GEK-90636

setting

frequency.

Line

or

100%,

to

at

set

The

Frequency

and

100%

there

undervoltage

repeat

should

the

be

cutoff

above

no

will

test

trips

starting

or

disable

target

all

Before

above

Apply

1.

Apply

2.

the

target

change

The

to

After

Remove

3.

4.

5.

6.

the

frequency

“RC”

“F4”

1.5

LEDs

Reset

Remove

the

Set

step

at

LEDs

outputs.

applying

frequency

the

LEDs

has

supply

test

“Fl”

overridden

rated

trip

in

light

seconds

input

the

dropped

have

targets.

the

supply

the

undervoltage

With

1.

during

the

input

voltage

frequency

line

been

has

to

target

delayed

all

test

voltage

undervoltage

the

under

the

lineorsingle

used.

between

at

applied

the

and

“F4”

set

light

time

the

LEDs

sequence

LEDs

should

frequency,

out.

switch

setting

frequency.

frequency

stud(1)

ll5vrrns

verify

“TB”s

delays).

with

according

be

and

to

set

Table

no

lit.

100%,

at

The

VII

that

light

delay,

note

100%

source.

and

stud(2),

between

the

with

stud(5)

following

no

and

their

to

the

that

repeat

and

there

should

undervoltage

Set

time

the

time

contacts

the

non

and

trip

delay

the

be

cutoff

setpoint(s)

polarity

stud(6).

occurs.

delay.

(The

target

settings.

and

above

no

test

trips

will

(0.5hz)

sensitive.

When

The

rate

LEDs

Note:

target

test

starting

or

target

disable

test

of

“Fl”

all

SFF’20

SFF2O2

SFF2O4

The

t

Restore

The

pins

to

Set

Point

1

Fl

Fl

F2

Fl

F2

F3

F4

relay

Relay

restore

10

and

can

circuit

20

t

tested

be

Tests

energized.

is

Frequency

60hz

or

50

5Oor6Ohz

60hz

or

50

or

60hz

50

or

60hz

50

60hz

or

50

5Oor6Ohz

at

and

adjust

only

will

other

the

produce

Switch

Settings

Mode

restore

restore

restore

restore

restore

restore

restore

frequencies

an

based

output

inputs

16

ROC

-

out

-

out

out

out

-

if

desired.

on

if

that

the

Time

Delay

1.5sec

1.5sec

1.5sec

1.5sec

l.5sec

1.5sec

1.5sec

To

setting.

contact

so,

do

converter

set

Under

Voltage

Cutoff

35%

35%

35%

the

frequency

connected

Page 17

GEK-90636

Restore

L

Apply

2.

Connect

power

3.

Set

the

frequency

test

Next,

“Fl”

are

4.

Remove

5.

Remove

6.

Set

at

LEDs

Restore

Test

rated

supply

the

frequency

targets

decrease

to

“F4”

closed)

the

undervoltage

step

1.

during

Test

With

supply

a

DC

source

voltage

frequency

to

source

‘Ti”

the

will

for

the

the

input

the

supply

With

the

the

With

Single

Variable

voltage

rated

will

generator

60.5hz

at

ilSVrms

to

“F4”

frequency

go

out

1.5

second

test

voltage

switch

undervoltage

test.

or

Frequency

between

at

48V

suffice

at

for

60hz

and

“TB”

(0.5hz)

but

the

delay

frequency.

setting

The

undervoltage

Line

Frequency

Generator

to

if

it

(0.5hz)

and

between

LEDs

“TB”

setting.

to

set

stud(1)

250V

is

DC.

above

50.5hz

stud(5)

are

below

LEDs

95%,

at

95%

cutoff

and

between

the

for

50hz

and

lit.

the

setpoint.

will

and

there

will

stud(2).

stud(10)

setpoints.

rated

stud(6).

remain

repeat

should

disable

setpoints.

The

lit

the

above

be

all

and

stud(20).

For

And

test

(output

no

trips

outputs.

example,

Apply

note

that

target

contact(s)

test

starting

or

Your

set

the

the

LEDs

target

1.

2.

3.

4.

5.

Before

setpoints

Apply

Connect

power

Apply

note

that

With

(0.5hz)

go

out

closed

Remove

Remove

Set

the

at

step

LEDs

applying

(0.5hz)

rated

supply

the

for

a

the

the

test

above

but

the

the

the

supply

DC

voltage

test

test

or

the

the

1.5

input

supply

undervoltage

1.

With

during

the

the

line

below

the

voltage

source

rated

will

line

frequency

targets

line

rated

“TB”

second

test

“F”

frequency

line

LEDs

time

frequency.

voltage.

switch

the

undervoltage

test.

The

INSTALLATION

or

single

frequency

between

at

48V

to

suffice

and

if

at

still

it

li5vrms

“TB”

applied,

frequency.

will

remain

delay

setting.

setting

set

undervoltage

frequency

used.

stud(1)

250V

is

and

between

DC.

between

LEDs

are

increase

The

test

lit

and

to

95%,

and

at

95%

there

cutoff

will

PROCEDURE

source.

stud(2).

stud(10)

stud(5)

lit.

the

target

the

output

repeat

should

disable

Set

and

and

frequency

LEDs

contacts

the

above

be

no

all

the

stud(20).

stud(6).

setpoints

“Fl”

to

test

trips

outputs.

frequency

Your

And

“F4”

will

will

stay

starting

or

target

to

The

relay

vibration.

dimensions

It

are

should

should

shown

be

installed

be

mounted

in

figures

in

on

7

a

a

and

clean,

vertical

8.

17

dry

surface.

location,

The

free

from

outline

dust

and

and

panel

excessive

drilling

Page 18

GEK-90636

Surge

than

relay

should

protection

positionofthe

Electrical

The

The

Ground

case

AWG

case

be

test

No.

and

as

from

Tests

establishment

Settings

Frequency

Mode

of

Rate

Time

Change

Delay

stud

short

case

given

of

should

12

copper

the

surges.

your

Set

buttons

Choose

position

ON

switch.

Set

UP

be

wire

surge

grounding

suppression

as

possible,

Figure

in

the

procedure.

the

desired

on

Under,

multi-setpoint

the

desired

position.

permanently

or

equivalent.

preferably

23

showsarear

stud.

Acceptance

frequency

the

switch.

Over

slide

switch.

time

connected

networks

Section

or

models,

by

summing

This

in

10

inches

viewofan

for

each

Restore

select

ground

to

connection

the

relay.

or

can

be

setpoint

operation

INorOUT

the

setting

byaconductor

is

made