Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 16i / 18i / 21i / 20i – Model A

Descriptions Manual

GFZ-63002EN/02 August 1999

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1999 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

s–1

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration). Note that some precautions are related only to specific functions, and thus

may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder. Before attempting to operate the machine or create a program to control the operation

of the machine, the operator must become fully familiar with the contents of this manual and relevant manual

supplied by the machine tool builder.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. GENERAL WARNINGS AND CAUTIONS s–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS AND CAUTIONS RELATED TO PROGRAMMING s–5. . . . . . . . . . . . .

4. WARNINGS AND CAUTIONS RELATED TO HANDLING s–7. . . . . . . . . . . . . . . . . . .

5. WARNINGS RELATED TO DAILY MAINTENANCE s–9. . . . . . . . . . . . . . . . . . . . . . . .

Page 4

SAFETY PRECAUTIONS

B–63002EN/02

s–2

1

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into Warning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

Page 5

B–63002EN/02

SAFETY PRECAUTIONS

s–3

2

GENERAL WARNINGS AND CAUTIONS

WARNING

1.

Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

2.

Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

3.

Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

4.

When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

5.

The parameters for the CNC and PMC are factory–set. Usually, there is not need to change them.

When, however, there is not alternative other than to change a parameter, ensure that you fully

understand the function of the parameter before making any change.

Failure to set a parameter correctly may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

6.

Immediately after switching on the power, do not touch any of the keys on the MDI panel until

the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other special operations.

Pressing any of these keys may place the CNC unit in other than its normal state. Starting the

machine in this state may cause it to behave unexpectedly.

7.

The operator’s manual and programming manual supplied with a CNC unit provide an overall

description of the machine’s functions, including any optional functions. Note that the optional

functions will vary from one machine model to another. Therefore, some functions described

in the manuals may not actually be available for a particular model. Check the specification of

the machine if in doubt.

Page 6

SAFETY PRECAUTIONS

B–63002EN/02

s–4

WARNING

8.

Some functions may have been implemented at the request of the machine–tool builder. When

using such functions, refer to the manual supplied by the machine–tool builder for details of their

use and any related cautions.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in the CNC unit.

Usually, they are retained even if the power is turned off. Such data may be deleted inadvertently,

however, or it may prove necessary to delete all data from nonvolatile memory as part of error

recovery.

To guard against the occurrence of the above, and assure quick restoration of deleted data, backup

all vital data, and keep the backup copy in a safe place.

Page 7

B–63002EN/02

SAFETY PRECAUTIONS

s–5

3

WARNINGS AND CAUTIONS RELATED TO

PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to

perform programming, read the supplied operator’s manual and programming manual carefully

such that you are fully familiar with their contents.

WARNING

1.

Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave unexpectedly as a

result of the program issuing an otherwise valid move command.

Such an unexpected operation may damage the tool, the machine itself, the workpiece, or cause

injury to the user.

2.

Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear movement

between the start and end points), the tool path must be carefully confirmed before performing

programming.

Positioning involves rapid traverse. If the tool collides with the workpiece, it may damage the

tool, the machine itself, the workpiece, or cause injury to the user.

3.

Function involving a rotation axis

When programming polar coordinate interpolation or normal–direction (perpendicular) control,

pay careful attention to the speed of the rotation axis. Incorrect programming may result in the

rotation axis speed becoming excessively high, such that centrifugal force causes the chuck to

lose its grip on the workpiece if the latter is not mounted securely.

Such mishap is likely to damage the tool, the machine itself, the workpiece, or cause injury to

the user.

4.

Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement units of data such

as the workpiece origin offset, parameter, and current position. Before starting the machine,

therefore, determine which measurement units are being used. Attempting to perform an

operation with invalid data specified may damage the tool, the machine itself, the workpiece, or

cause injury to the user.

5.

Constant surface speed control

When an axis subject to constant surface speed control approaches the origin of the workpiece

coordinate system, the spindle speed may become excessively high. Therefore, it is necessary

to specify a maximum allowable speed. Specifying the maximum allowable speed incorrectly

may damage the tool, the machine itself, the workpiece, or cause injury to the user.

Page 8

SAFETY PRECAUTIONS

B–63002EN/02

s–6

WARNING

6.

Stroke check

After switching on the power, perform a manual reference position return as required. Stroke

check is not possible before manual reference position return is performed. Note that when stroke

check is disabled, an alarm is not issued even if a stroke limit is exceeded, possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the user.

7.

Tool post interference check

A tool post interference check is performed based on the tool data specified during automatic

operation. If the tool specification does not match the tool actually being used, the interference

check cannot be made correctly, possibly damaging the tool or the machine itself, or causing

injury to the user.

After switching on the power, or after selecting a tool post manually, always start automatic

operation and specify the tool number of the tool to be used.

8.

Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice versa, the machine

may behave unexpectedly.

9.

Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or a canned cycle,

the machine may behave unexpectedly . Refer to the descriptions of the respective functions for

details.

10.

Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip is specified

without the torque limit actually being applied, a move command will be executed without

performing a skip.

11.

Programmable mirror image

Note that programmed operations vary considerably when a programmable mirror image is

enabled.

12.

Compensation function

If a command based on the machine coordinate system or a reference position return command

is issued in compensation function mode, compensation is temporarily canceled, resulting in the

unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel compensation function

mode.

Page 9

B–63002EN/02

SAFETY PRECAUTIONS

s–7

4

WARNINGS AND CAUTIONS RELA TED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting

to operate your machine, read the supplied operator’s manual and programming manual carefully,

such that you are fully familiar with their contents.

WARNING

1.

Manual operation

When operating the machine manually , determine the current position of the tool and workpiece,

and ensure that the movement axis, direction, and feedrate have been specified correctly.

Incorrect operation of the machine may damage the tool, the machine itself, the workpiece, or

cause injury to the operator.

2.

Manual reference position return

After switching on the power, perform manual reference position return as required. If the

machine is operated without first performing manual reference position return, it may behave

unexpectedly . Stroke check is not possible before manual reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine itself, the workpiece,

or cause injury to the user.

3.

Manual numeric command

When issuing a manual numeric command, determine the current position of the tool and

workpiece, and ensure that the movement axis, direction, and command have been specified

correctly, and that the entered values are valid.

Attempting to operate the machine with an invalid command specified may damage the tool, the

machine itself, the workpiece, or cause injury to the operator.

4.

Manual handle feed

In manual handle feed, rotating the handle with a large scale factor , such as 100, applied causes

the tool and table to move rapidly. Careless handling may damage the tool and/or machine, or

cause injury to the user.

5.

Disabled override

If override is disabled (according to the specification in a macro variable) during threading, rigid

tapping, or other tapping, the speed cannot be predicted, possibly damaging the tool, the machine

itself, the workpiece, or causing injury to the operator.

6.

Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is operating under the

control of a program. Otherwise, the machine may behave unexpectedly, possibly damaging the

tool, the machine itself, the tool, or causing injury to the user.

Page 10

SAFETY PRECAUTIONS

B–63002EN/02

s–8

WARNING

7.

Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece coordinate

system. Before attempting to operate the machine under the control of a program, confirm the

coordinate system carefully.

If the machine is operated under the control of a program without making allowances for any shift

in the workpiece coordinate system, the machine may behave unexpectedly, possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the operator.

8.

Software operator ’s panel and menu switches

Using the software operator’s panel and menu switches, in combination with the MDI panel, it

is possible to specify operations not supported by the machine operator’s panel, such as mode

change, override value change, and jog feed commands.

Note, however, that if the MDI panel keys are operated inadvertently, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the workpiece, or causing injury

to the user.

9.

Manual intervention

If manual intervention is performed during programmed operation of the machine, the tool path

may vary when the machine is restarted. Before restarting the machine after manual intervention,

therefore, confirm the settings of the manual absolute switches, parameters, and

absolute/incremental command mode.

10.

Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled using custom macro

system variable #3004. Be careful when operating the machine in this case.

11.

Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry run, the machine

operates at dry run speed, which differs from the corresponding programmed feedrate. Note that

the dry run speed may sometimes be higher than the programmed feed rate.

12.

Cutter and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode, because cutter or tool

nose radius compensation is not applied. When a command is entered from the MDI to interrupt

in automatic operation in cutter or tool nose radius compensation mode, pay particular attention

to the tool path when automatic operation is subsequently resumed. Refer to the descriptions of

the corresponding functions for details.

13.

Program editing

If the machine is stopped, after which the machining program is edited (modification, insertion,

or deletion), the machine may behave unexpectedly if machining is resumed under the control

of that program. Basically, do not modify, insert, or delete commands from a machining program

while it is in use.

Page 11

B–63002EN/02

SAFETY PRECAUTIONS

s–9

5

WARNINGS RELA TED TO DAILY MAINTENANCE

WARNING

1.

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

and

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

Refer to the maintenance section of the operator’s manual or programming manual for details of the

battery replacement procedure.

Page 12

SAFETY PRECAUTIONS

B–63002EN/02

s–10

WARNING

2.

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

and

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

Refer to the maintenance section of the operator’s manual or programming manual for details of the

battery replacement procedure.

Page 13

B–63002EN/02

SAFETY PRECAUTIONS

s–11

WARNING

3.

Fuse replacement

For some units, the chapter covering daily maintenance in the operator’s manual or programming

manual describes the fuse replacement procedure.

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

and fitted with an insulating cover).

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

Page 14

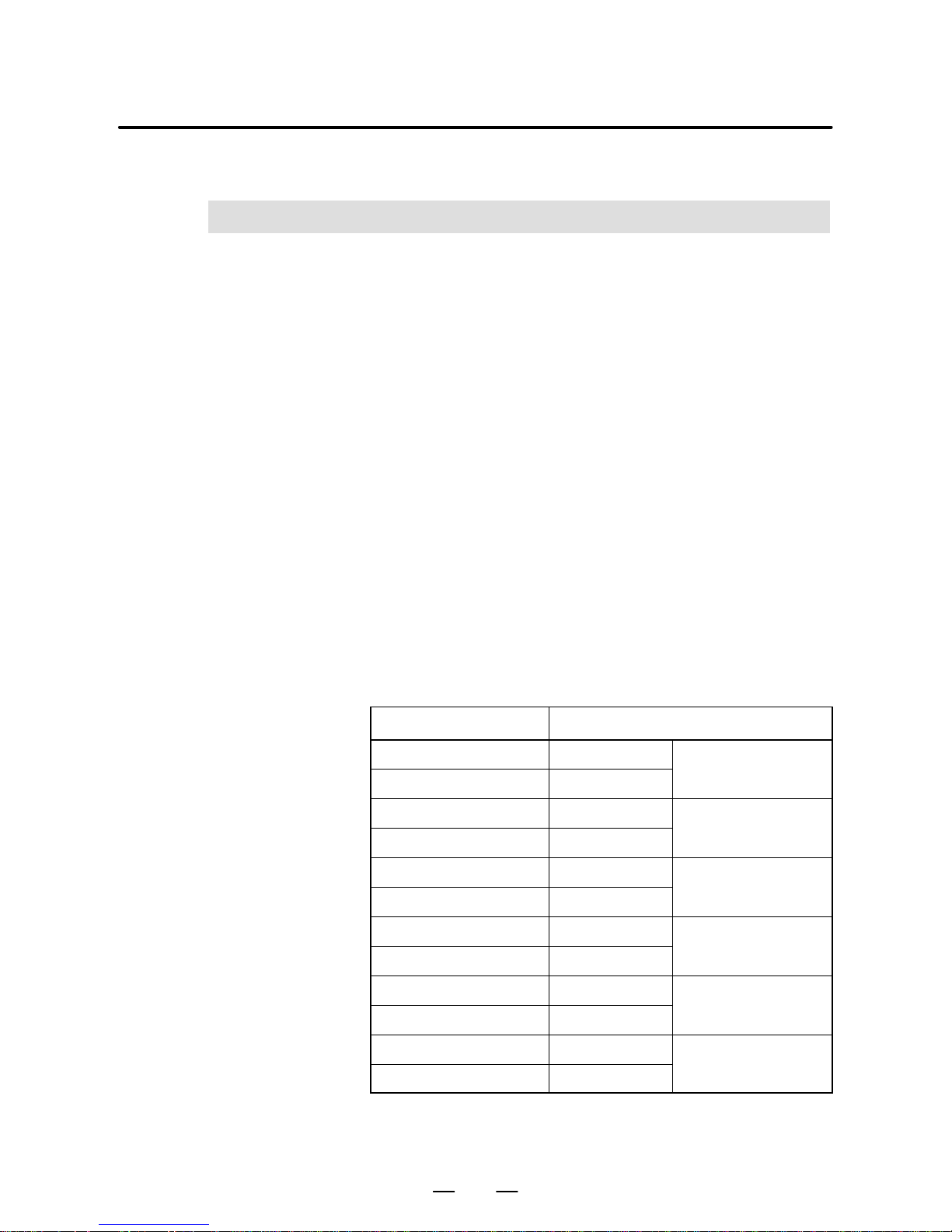

Table of Contents

B–63002EN/02

c–1

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

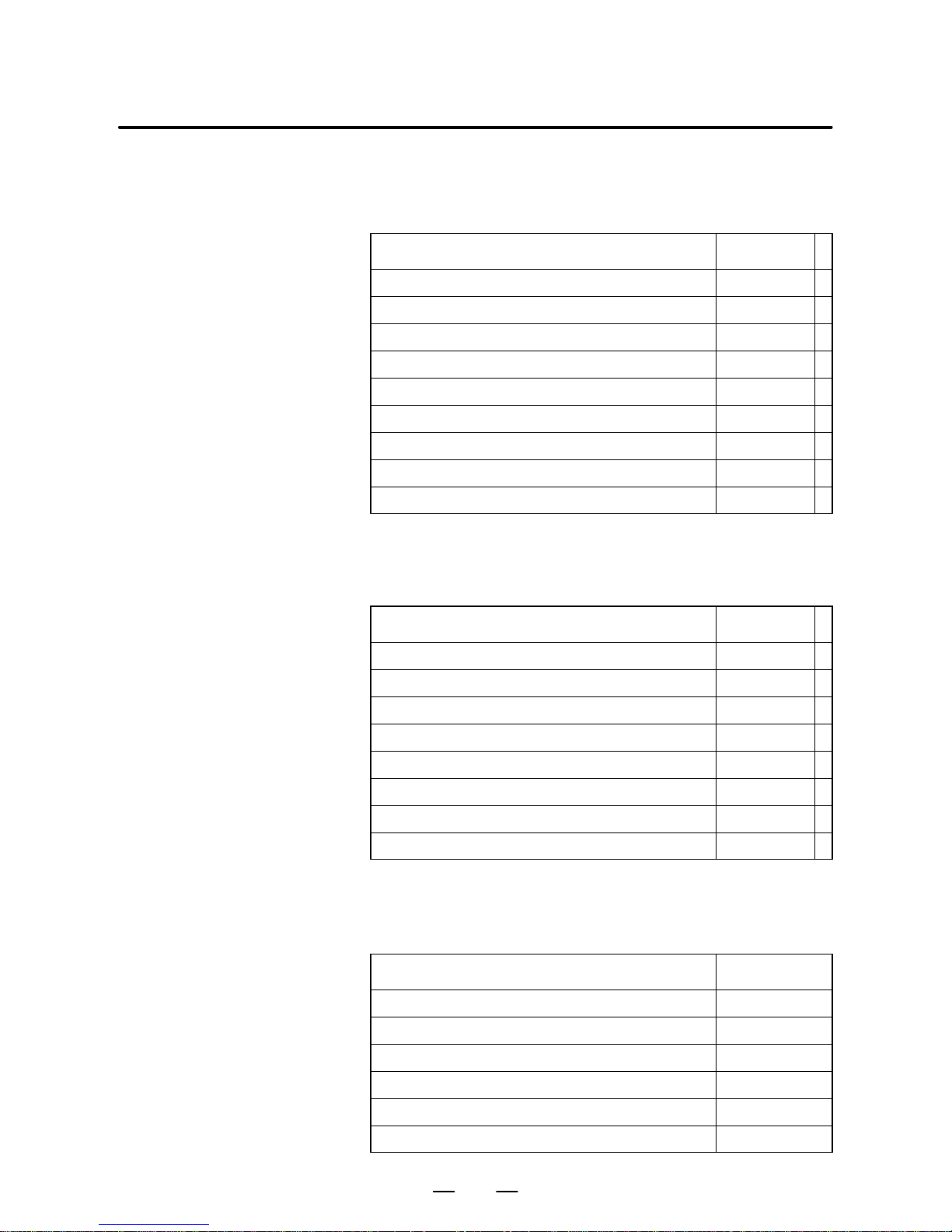

2. LIST OF SPECIFICATIONS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. NC FUNCTION

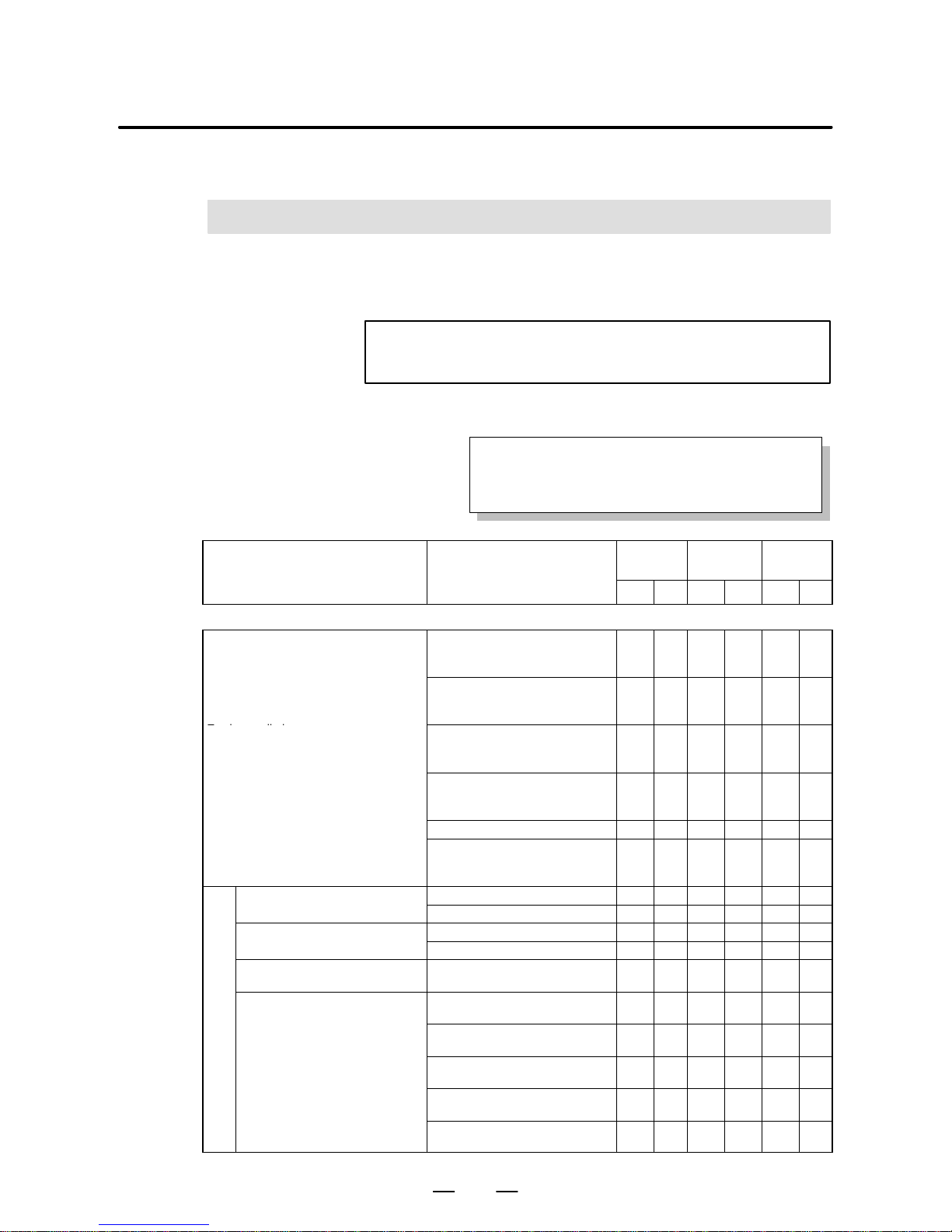

PREFACE 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. CONTROLLED AXES 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 NUMBER OF THE ALL CONTROLLED AXES 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 MACHINE CONTROLLED AXES 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Number of Controlled Paths 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Number of Basic Controlled Axes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Number of Basic Simultaneously Controlled Axes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Number of Controlled Axes Expanded (All) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Number of Simultaneously Controlled Axes Expanded (All) 26. . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Axis Control by PMA 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Cs Contour Control 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 LOADER CONTROLLED AXES 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 AXIS NAMES 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 INCREMENT SYSTEM 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Input Unit (10 Times) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 MAXIMUM STROKE 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PREPARATORY FUNCTIONS 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

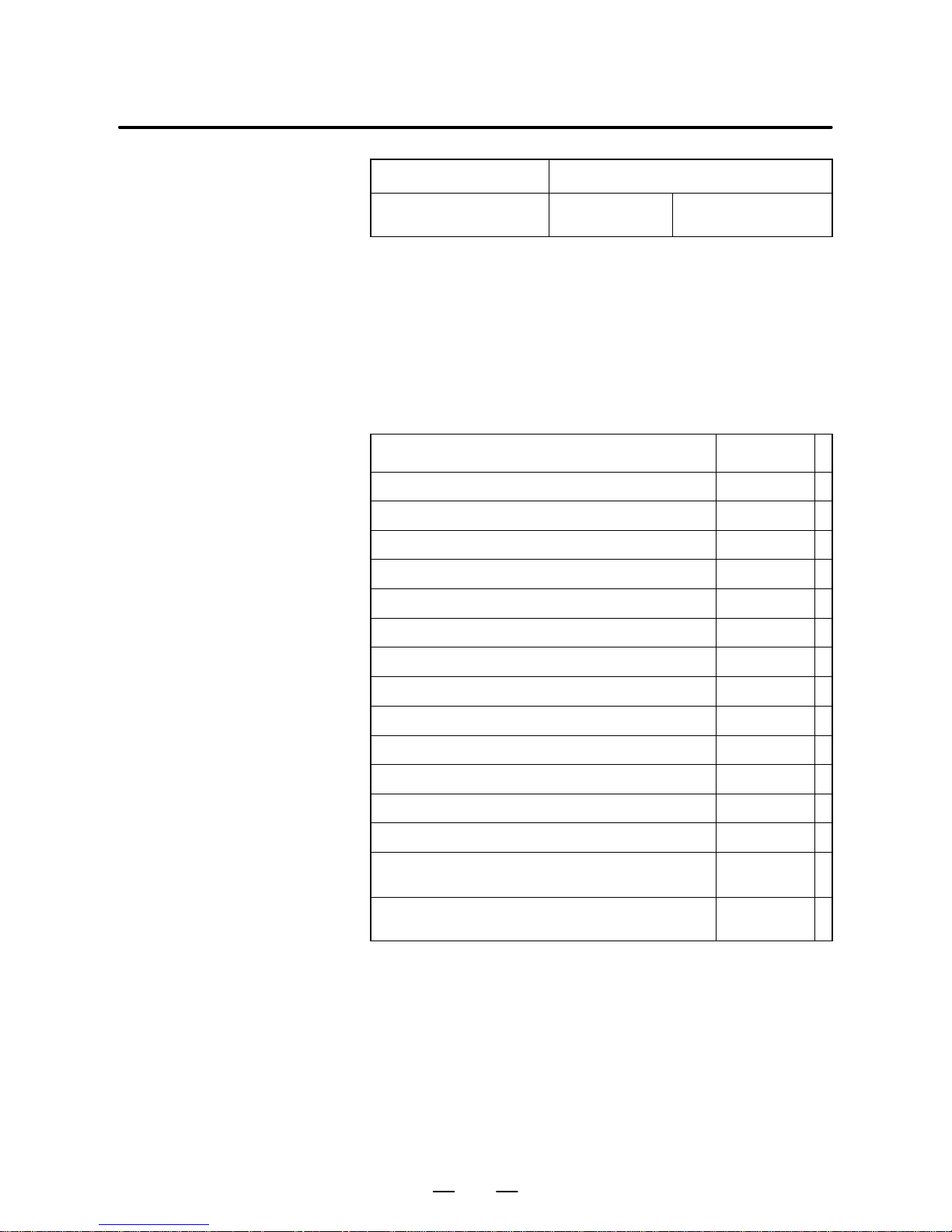

2.1 T SERIES 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 M SERIES 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INTERPOLATION FUNCTIONS 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 POSITIONING (G00) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SINGLE DIRECTION POSITIONING (G60) (M series) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 LINEAR INTERPOLATION (G01) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 CIRCULAR INTERPOLATION (G02, G03) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 HELICAL INTERPOLATION (G02, G03) 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 HELICAL INTERPOLATION B (G02, G03) (M series) 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 POLAR COORDINATE INTERPOLATION (G12.1, G13.1) 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 CYLINDRICAL INTERPOLATION (G07.1) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 INVOLUTE INTERPOLATION (G02.2, G03.2) (M series) 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

TABLE OF CONTENTS

B–63002EN/02

c–2

3.10 EXPONENTIAL FUNCTION INTERPOLATION (G02.3, G03.3) (M series) 51. . . . . . . . . . . . . . . . .

3.11 SMOOTH INTERPOLATION (G05.1) (M series) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 HYPOTHETICAL AXIS INTERPOLATION (G07) 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13 SPIRAL INTERPOLATION, CONICAL INTERPOLATION (M series) 55. . . . . . . . . . . . . . . . . . . . .

3.14 NURBS INTERPOLATION (G06.2) 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. THREAD CUTTING 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 EQUAL LEAD THREAD CUTTING (G33) (WITH G CODE SYSTEM A: G32) 60. . . . . . . . . . . . . .

4.2 MULTIPLE–THREAD CUTTING (G33) (T series) 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 VARIABLE LEAD THREAD CUTTING (G34) (T series) 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CONTINUOUS THREAD CUTTING (T series) 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 CIRCULAR THREADING (G35, G36) (T series) 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. FEED FUNCTIONS 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 RAPID TRAVERSE 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CUTTING FEED RATE 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Tangential Speed Constant Control 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Cutting Feed Rate Clamp 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Per Minute Feed (G94) 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Per Revolution Feed (G95) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Inverse Time Feed (G93) (M series) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 F1–digit Feed (M series) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 OVERRIDE 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Feed Rate Override 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Second Feed Rate Override 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Rapid Traverse Override 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Override Cancel 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Jog Override 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 AUTOMATIC ACCELERATION/DECELERATION 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 RAPID TRAVERSE BELL–SHAPED ACCELERATION/DECELERATION 69. . . . . . . . . . . . . . . . .

5.6 LINEAR ACCELERATION/DECELERATION AFTER CUTTING FEED INTERPOLATION 70. . .

5.7 BELL–SHAPED ACCELERATION/DECELERATION

AFTER CUTTING FEED INTERPOLATION 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 LINEAR ACCELERATION/DECELERATION BEFORE CUTTING FEED INTERPOLATION 72. .

5.9 ERROR DETECTION (T series) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 EXACT STOP (G09) (M series) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 EXACT STOP MODE (G61) (M series) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 CUTTING MODE (G64) (M series) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 TAPPING MODE (G63) (M series) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 AUTOMATIC CORNER OVERRIDE (G62) (M series) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.15 DWELL (G04) 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.16 POSITIONING BY OPTIMUM ACCELERATION 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. REFERENCE POSITION 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 MANUAL REFERENCE POSITION RETURN 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SETTING THE REFERENCE POSITION WITHOUT DOGS 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 AUTOMATIC REFERENCE POSITION RETURN (G28, G29(ONLY FOR M SERIES )) 78. . . . . . .

Page 16

TABLE OF CONTENTS

B–63002EN/02

c–3

6.4 REFERENCE POSITION RETURN CHECK (G27) 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 2ND, 3RD AND 4TH REFERENCE POSITION RETURN (G30) 79. . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 FLOATING REFERENCE POSITION RETURN (G30.1) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 REFERENCE POSITION SHIFT 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 BUTT–TYPE REFERENCE POSITION SETTING 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 LINEAR SCALE WITH ABSOLUTE ADDRESSING REFERENCE MARKS 82. . . . . . . . . . . . . . . .

7. COORDINATE SYSTEMS 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 MACHINE COORDINATE SYSTEM (G53) 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 WORKPIECE COORDINATE SYSTEM 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Setting a Workpiece Coordinate System (Using G92) (with G Code System A: G50) 85. . . . . .

7.2.2 Automatic Coordinate System Setting 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Setting a Workpiece Coordinate System (Using G54 to G59) 88. . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LOCAL COORDINATE SYSTEM (G52) 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 WORKPIECE ORIGIN OFFSET VALUE CHANGE

(PROGRAMMABLE DATA INPUT) (G10) 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 ADDITIONAL WORKPIECE COORDINATE SYSTEMS (G54.1 OR G54) (M series) 91. . . . . . . . .

7.6 WORKPIECE COORDINATE SYSTEM PRESET (G92.1) 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 WORKPIECE COORDINATE SYSTEM SHIFT (T series) 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 PLANE SELECTION (G17, G18, G19) 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. COORDINATE VALUE AND DIMENSION 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91) 96. . . . . . . . . . . . . . . . . . . . . . . .

8.2 POLAR COORDINATE COMMAND (G15, G16) (M series) 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 INCH/METRIC CONVERSION (G20, G21) 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 DECIMAL POINT INPUT/POCKET CALCULATOR TYPE DECIMAL POINT INPUT 98. . . . . . .

8.5 DIAMETER AND RADIUS PROGRAMMING (T series) 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 LINEAR AXIS AND ROTATION AXIS 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 ROTATION AXIS ROLL-OVER FUNCTION 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SPINDLE FUNCTIONS 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 S CODE OUTPUT 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SPINDLE SPEED ANALOG OUTPUT (S ANALOG OUTPUT) 101. . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 SPINDLE SPEED SERIAL OUTPUT (S SERIAL OUTPUT) 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 SPINDLE OUTPUT CONTROL BY THE PMC 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 CONSTANT SURFACE SPEED CONTROL 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 SPINDLE OVERRIDE 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 ACTUAL SPINDLE SPEED OUTPUT (T series) 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 SPINDLE POSITIONING (T series) 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 SPINDLE SPEED FLUCTUATION DETECTION (G25, G26) 104. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10 CS CONTOUR CONTROL 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 MULTI–SPINDLE CONTROL 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12 SPINDLE SYNCHRONIZATION CONTROL 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13 SPINDLE ORIENTATION 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.14 SPINDLE OUTPUT SWITCHING 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.15 THREE–SPINDLE SERIAL OUTPUT (ONLY FOR SINGLE–PATH CONTROL) 108. . . . . . . . . . . .

9.16 SIMPLE SPINDLE SYNCHRONOUS CONTROL 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 17

TABLE OF CONTENTS

B–63002EN/02

c–4

10. TOOL FUNCTIONS 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 T CODE OUTPUT 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 TOOL LIFE MANAGEMENT 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Tool Life Management 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Addition of Tool Pairs for Tool Life Management

<512 Pairs (M series) / 128 Pairs (T series)> 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Extended Tool Life Management (M series) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. MISCELLANEOUS FUNCTIONS 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 MISCELLANEOUS FUNCTIONS 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 1–BLOCK PLURAL M COMMAND 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 SECOND MISCELLANEOUS FUNCTIONS 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 HIGH-SPEED M/S/T/B INTERFACE 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 M CODE GROUP CHECK FUNCTION 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. PROGRAM CONFIGURATION 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 PROGRAM NUMBER 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 PROGRAM NAME 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 MAIN PROGRAM 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 SUB PROGRAM 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 EXTERNAL MEMORY AND SUB PROGRAM CALLING FUNCTION 120. . . . . . . . . . . . . . . . . . .

12.6 SEQUENCE NUMBER 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 TAPE CODES 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 BASIC ADDRESSES AND COMMAND VALUE RANGE 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9 TAPE FORMAT 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.10 LABEL SKIP 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.11 CONTROL-IN/CONTROL-OUT 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.12 OPTIONAL BLOCK SKIP 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.13 ADDITIONAL OPTIONAL BLOCK SKIP 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.14 TAPE HORIZONTAL (TH) PARITY CHECK AND

TAPE VERTICAL (TV) PARITY CHECK 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. FUNCTIONS TO SIMPLIFY PROGRAMMING 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 CANNED CYCLES (G73, G74, G76, G80-G89, G98, G99) (M series) 125. . . . . . . . . . . . . . . . . . . . .

13.2 RIGID TAP 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 EXTERNAL OPERATION FUNCTION (G81) (M series) 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 CANNED CYCLES FOR TURNING (T series) 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.1 Cutting Cycle A (G77) (with G Code System A: G90) 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.2 Thread Cutting Cycle (G78) (with G Code System A: G92) 135. . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.3 Turning Cycle in Facing (G79) (with G Code System A: G94) 137. . . . . . . . . . . . . . . . . . . . . . . .

13.5 MULTIPLE REPETITIVE CYCLES FOR TURNING (G70 - G76) (T series) 138. . . . . . . . . . . . . . . .

13.5.1 Stock Removal in Turning (G71) 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.2 Stock Removal in Facing (G72) 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.3 Pattern Repeating (G73) 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.4 Finishing Cycle (G70) 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.5 Peck Drilling in Z-axis (G74) 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.6 Grooving in X-axis (G75) 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.7 Thread Cutting Cycle (G76) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 18

TABLE OF CONTENTS

B–63002EN/02

c–5

13.6 CANNED CYCLES FOR DRILLING (G80 - G89) (T series) 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 CHAMFERING AND CORNER R (T series) 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 OPTIONAL ANGLE CHAMFERING/CORNER ROUNDING (M series) 152. . . . . . . . . . . . . . . . . . .

13.9 DIRECT DRAWING DIMENSIONS PROGRAMMING (T series) 153. . . . . . . . . . . . . . . . . . . . . . . .

13.10 PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) (M series) 155. . . . . . . . . . . . . . . . . . . . . . . .

13.11 MIRROR IMAGE FOR DOUBLE TURRETS (G68, G69) (T series) 156. . . . . . . . . . . . . . . . . . . . . . .

13.12 INDEX TABLE INDEXING (M series) 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.13 CANNED CYCLES FOR CYLINDRICAL GRINDING (T series) 158. . . . . . . . . . . . . . . . . . . . . . . . .

13.13.1 Traverse Grinding Cycle (G71) 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.13.2 Traverse Direct Gauge Grinding Cycle (G72) 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.13.3 Oscillation Grinding Cycle (G73) 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.13.4 Oscillation Direct Gauge Grinding Cycle (G74) 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.14 SURFACE GRINDING CANNED CYCLE (M series) 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.14.1 Plunge Grinding Cycle (G75) 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.14.2 Plunge Direct Grinding Cycle (G77) 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.14.3 Continuous Feed Plane Grinding Cycle (G78) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.14.4 Intermittent Feed Plane Grinding Cycle (G79) 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.15 INFEED CONTROL (M series) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.16 FIGURE COPYING (G72.1, G72.2) (M series) 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.16.1 Rotation Copy 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.16.2 Linear Copy 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. TOOL COMPENSATION FUNCTION 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOOL OFFSET (T series) 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 Tool Offset (T Code) 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.2 Tool Geometry Compensation and Tool Wear Compensation 175. . . . . . . . . . . . . . . . . . . . . . . . .

14.1.3 Y Axis Offset 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 TOOL NOSE RADIUS COMPENSATION (G40, G41, G42) (T series) 176. . . . . . . . . . . . . . . . . . . . .

14.3 CORNER CIRCULAR INTERPOLATION FUNCTION (G39) (T series) 178. . . . . . . . . . . . . . . . . . .

14.4 TOOL LENGTH COMPENSATION (G43, G44, G49) (M series) 179. . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 TOOL OFFSET (G45, G46, G47, G48) (M series) 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 CUTTER COMPENSATION (M series) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6.1 Cutter Compensation B (G40 - 42) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6.2 Cutter Compensation C (G40 - G42) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7 CORNER CIRCULAR INTERPOLATION FUNCTION (G39) (M series) 183. . . . . . . . . . . . . . . . . . .

14.8 TOOL COMPENSATION MEMORY 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.1 Tool Compensation Memory (M series) 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.2 Tool Offset Amount Memory (T series) 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.9 NUMBER OF TOOL OFFSETS 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.9.1 Number of Tool Offsets (M Series) 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.9.2 Number of Tool Offsets (T Series) 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.10 CHANGING OF TOOL OFFSET AMOUNT (PROGRAMMABLE DATA INPUT) (G10) 188. . . . . .

14.11 GRINDING-WHEEL WEAR COMPENSATION BY CONTINUOUS DRESSING (M series) 190. . .

14.12 THREE–DIMENSIONAL TOOL COMPENSATION (G40, G41) (M series) 191. . . . . . . . . . . . . . . . .

14.13 GRINDING WHEEL WEAR COMPENSATION (G40, G41) (T seriesS) 192. . . . . . . . . . . . . . . . . . . .

Page 19

TABLE OF CONTENTS

B–63002EN/02

c–6

15. ACCURACY COMPENSATION FUNCTION 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 STORED PITCH ERROR COMPENSATION 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 STRAIGHTNESS COMPENSATION 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 BACKLASH COMPENSATION 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 BACKLASH COMPENSATION SPECIFIC TO RAPID TRAVERSE AND CUTTING FEED 195. . .

15.5 PROGRAMMABLE PARAMETER ENTRY (G10, G11) 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16. COORDINATE SYSTEM CONVERSION 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 COORDINATE SYSTEM ROTATION (G68, G69) – (M SERIES)

(G68.1, G69.1) – (T SERIES) 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 SCALING (G50, G51) (M series) 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 THREE–DIMENSIONAL COORDINATE CONVERSION (G68, G69) (M series) 201. . . . . . . . . . . .

17. MEASUREMENT FUNCTIONS 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 SKIP FUNCTION (G31) 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 MULTI-STEP SKIP FUNCTION (G31 P1 - G31 P4) (T series) 204. . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 HIGH-SPEED SKIP SIGNAL INPUT 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 TORQUE LIMIT SKIP (G31 P99, G31 P98) (T series) 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 CONTINUOUS HIGH–SPEED SKIP FUNCTION (G31, P90) (M series) 204. . . . . . . . . . . . . . . . . . .

17.6 TOOL LENGTH AUTOMATIC MEASUREMENT (G37) (M series) 205. . . . . . . . . . . . . . . . . . . . . . .

17.7 AUTOMATIC TOOL OFFSET (G37, G36) (T series) 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8 TOOL LENGTH MEASUREMENT (M series) 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.9 DIRECT INPUT OF TOOL COMPENSATION MEASURED VALUE/DIRECT INPUT OF

WORKPIECE COORDINATE SYSTEM SHIFT AMOUNT (T series) 208. . . . . . . . . . . . . . . . . . . . .

17.10 TOOL COMPENSATION VALUE MEASURED VALUE DIRECT INPUT B (T series) 209. . . . . . .

17.11 COUNT INPUT OF TOOL OFFSET VALUES (T series) 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.12 DIRECT INPUT OF WORKPIECE ZERO POINT OFFSET VALUE MEASURED 212. . . . . . . . . . .

17.13 TOOL LENGTH/WORKPIECE ORIGIN MEASUREMENT B (M series) 212. . . . . . . . . . . . . . . . . .

18. CUSTOM MACRO 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 CUSTOM MACRO 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 INCREASED CUSTOM MACRO COMMON VARIABLES 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 INTERRUPTION TYPE CUSTOM MACRO 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.4 PATTERN DATA INPUT 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.5 MACRO EXECUTER FUNCTION 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6 C LANGUAGE EXECUTER FUNCTION 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19. SERIES 15 TAPE FORMAT/SERIES 10/11 TAPE FORMAT 224. . . . . . . . . . . . . . . . . . . .

19.1 SERIES 15 TAPE FORMAT 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.2 SERIES–10/11 TAPE FORMAT 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20. FUNCTIONS FOR HIGH SPEED CUTTING 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.1 HIGH-SPEED CYCLE MACHINING (ONLY AT 1–PATH CONTROL) 227. . . . . . . . . . . . . . . . . . . .

20.2 AUTOMATIC CORNER DECELERATION (M series) 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3 FEEDRATE CLAMP BY CIRCULAR RADIUS (M series) 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 20

TABLE OF CONTENTS

B–63002EN/02

c–7

20.4 LOOK–AHEAD CONTROL (G08) (M series) 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5 REMOTE BUFFER 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.1 Remote Buffer (Only at 1–path Control) 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.2 High–speed Remote Buffer A (G05) (Only at 1–path Control) 233. . . . . . . . . . . . . . . . . . . . . . . .

20.5.3 High–speed Remote Buffer B (G05) (At 1–path Control) (M series) 234. . . . . . . . . . . . . . . . . . .

20.6 HIGH–PRECISION CONTOUR CONTROL (ONLY FOR ONE SYSTEM) (M series) 235. . . . . . . . .

20.6.1 Acceleration/Decelera–tion Before Interpolation by Pre-reading Multiple Blocks 235. . . . . . . . .

20.6.2 Automatic Velocity Control Function 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.7 SIMPLE HIGH–PRECISION CONTOUR CONTROL (G05.1) (M series) 237. . . . . . . . . . . . . . . . . . .

20.8 HIGH–SPEED LINEAR INTERPOLATION (G05) 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. AXES CONTROL 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1 FOLLOW UP FUNCTION 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2 MECHANICAL HANDLE FEED 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.3 SERVO OFF 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.4 MIRROR IMAGE 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5 CONTROL AXIS DETACH 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6 SIMPLE SYNCHRONOUS CONTROL 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.7 SYNCHRONIZATION CONTROL (ONLY AT 1–PATH CONTROL) (T series) 241. . . . . . . . . . . . . .

21.8 FEED STOP 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.9 NORMAL DIRECTION CONTROL (G40.1,G41.1,G42.1) (M series) 243. . . . . . . . . . . . . . . . . . . . . .

21.10 POLYGONAL TURNING (G50.2, G51.2) (T series) 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.11 POLYGONAL TURNING WITH TWO SPINDLES (T series) 247. . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.12 AXIS CONTROL WITH PMC 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.13 SLANTED AXIS CONTROL 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.14 ARBITRARY AXIS ANGULAR AXIS CONTROL 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.15 B–AXIS CONTROL (T series) 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.16 TANDEM CONTROL 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.17 CHOPPING FUNCTION (G80, G81.1) 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.18 HOBBING MACHINE FUNCTION (G80, G81) (M series) 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.19 SIMPLE ELECTRIC GEAR BOX (G80, G81) (M series) 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. FUNCTIONS SPECIFIC TO 2–PATH CONTROL 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.1 WAITING FUNCTION 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.2 PATH INTERFERENCE CHECK (T series) 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.3 BALANCE CUT (G68, G69) (T series) 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.4 MEMORY COMMON TO PATHS 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.5 SYNCHRONIZATION/MIX CONTROL (T series) 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.6 COPYING A PROGRAM BETWEEN TWO PATHS 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. MANUAL OPERATION 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1 MANUAL FEED 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2 INCREMENTAL FEED 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.3 MANUAL HANDLE FEED (1ST) 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.4 MANUAL HANDLE FEED (2ND, 3RD) (T SERIES: 2ND) 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5 HANDLE FEED IN THE SAME MODE AS FOR JOGGING 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 21

TABLE OF CONTENTS

B–63002EN/02

c–8

23.6 MANUAL PER-ROTATION FEED (T series) 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.7 MANUAL ABSOLUTE ON/OFF 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.8 TOOL AXIS DIRECTION HANDLE FEED AND TOOL AXISDIRECTION

HANDLE FEED B (FOR M SERIES) 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.8.1 Tool Axis Direction Handle Feed 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.8.2 Tool Axis Normal Direction Handle Feed 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.9 MANUAL LINEAR/CIRCULAR INTERPOLATION (ONLY FOR ONE PATH) 266. . . . . . . . . . . . .

23.10 MANUAL RIGID TAPPING (M series) 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.11 MANUAL NUMERIC COMMAND 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24. AUTOMATIC OPERATION 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1 OPERATION MODE 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1.1 DNC Operation 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1.2 Memory Operation 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1.3 MDI Operation 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2 SELECTION OF EXECUTION PROGRAMS 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2.1 Program Number Search 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2.2 Sequence Number Search 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2.3 Rewind 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2.4 External Workpiece Number Search 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.3 ACTIVATION OF AUTOMATIC OPERATION 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.3.1 Cycle Start 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.4 EXECUTION OF AUTOMATIC OPERATION 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.4.1 Buffer Register 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5 AUTOMATIC OPERATION STOP 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.1 Program Stop (M00, M01) 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.2 Program End (M02, M30) 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.3 Sequence Number Comparison and Stop 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.4 Feed Hold 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.5 Thread Cutting Cycle Retract (T series) 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5.6 Reset 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.6 RESTART OF AUTOMATIC OPERATION 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.6.1 Program Restart 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.6.2 Tool Retract & Recover 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.6.3 Manual Intervention and Return 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.7 MANUAL INTERRUPTION DURING AUTOMATIC OPERATION 275. . . . . . . . . . . . . . . . . . . . . .

24.7.1 Handle Interruption 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.8 SCHEDULING FUNCTION 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.9 SIMULTANEOUS INPUT AND OUTPUT OPERATIONS

(AT 1–PATH CONTROL) (M series) 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.10 RETRACE FUNCTION (M series) 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.11 RIGID TAPPING RETURN (M series) 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25. PROGRAM TEST FUNCTIONS 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1 ALL-AXES MACHINE LOCK 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.2 MACHINE LOCK ON EACH AXIS 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.3 AUXILIARY FUNCTION LOCK 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.4 DRY RUN 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.5 SINGLE BLOCK 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 22

TABLE OF CONTENTS

B–63002EN/02

c–9

26. SETTING AND DISPLAY UNIT 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1 SETTING AND DISPLAY UNIT 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.1 CNC Control Unit with 7.2″/8.4″ LCD 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.2 CNC Control Unit with 9.5″/10.4″ LCD 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.3 Separate–Type Small MDI Unit 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.4 Separate–Type Standard MDI Unit (Horizontal Type) 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.5 Separate–Type Standard MDI Unit (Vertical Type) 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1.6 Separate–Type FA Full Keyboard (Vertical Type) (for 160i/180i/210i) 286. . . . . . . . . . . . . . . . .

26.2 EXPLANATION OF THE KEYBOARD 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.2.1 Explanation of the Function Keys 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.2.2 Explanation of the Soft Keys 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. DISPLAYING AND SETTING DATA 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.1 DISPLAY 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.2 LANGUAGE SELECTION 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3 CLOCK FUNCTION 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.4 RUN TIME & PARTS NUMBER DISPLAY 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.5 SOFTWARE OPERATOR’S PANEL 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.6 DIRECTORY DISPLAY OF FLOPPY CASSETTE 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.7 GRAPHIC DISPLAY FUNCTION 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.7.1 Graphic Display Function 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.7.2 Dynamic Graphic Display 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.7.3 Background Drawing (M series) 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.8 SERVO WAVEFORM FUNCTION 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9 SCREENS FOR SERVO DATA AND SPINDLE DATA 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9.1 Servo Setting Screen 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9.2 Servo Adjustment Screen 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9.3 Spindle Setting Screen 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9.4 Spindle Adjustment Screen 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.9.5 Spindle Monitor Screen 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.10 SYSTEM CONFIGURATION DISPLAY FUNCTION 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.11 HELP FUNCTION 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.12 DATA PROTECTION KEY 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.13 DISPLAYING OPERATION HISTORY 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.14 MACHINING TIME STAMP FUNCTION 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.15 REMOTE DIAGNOSIS 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.16 DIRECTORY DISPLAY AND PUNCH FOR A SPECIFIED GROUP 317. . . . . . . . . . . . . . . . . . . . . .

27.17 CLEARING THE SCREEN 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.18 PERIODIC MAINTENANCE SCREEN 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.19 TOUCH PAD 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.20 MAINTENANCE INFORMATION SCREEN 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.21 COLOR SETTING SCREEN 319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.22 CONTRAST ADJUSTMENT SCREEN 319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 23

TABLE OF CONTENTS

B–63002EN/02

c–10

28. PART PROGRAM STORAGE AND EDITING 320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.1 FOREGROUND EDITING 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2 BACKGROUND EDITING 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3 EXPANDED PART PROGRAM EDITING 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.4 NUMBER OF REGISTERED PROGRAMS 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.5 PART PROGRAM STORAGE LENGTH 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.6 PLAY BACK 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.7 EXTERNAL CONTROL OF I/O DEVICE 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.8 CONVERSATIONAL PROGRAMMING OF FIGURES (ONLY AT 1–PATH CONTROL) 323. . . . .

28.9 PASSWORD FUNCTION 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29. DIAGNOSIS FUNCTIONS 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.1 SELF DIAGNOSIS FUNCTIONS 325. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30. DATA INPUT/OUTPUT 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.1 READER/PUNCH INTERFACES 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2 INPUT/OUTPUT DEVICES 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.1 FANUC Floppy Cassette 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.2 FANUC Program File Mate 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.3 FANUC Handy File 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3 EXTERNAL PROGRAM INPUT 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.4 DATA INPUT/OUTPUT USING A MEMORY CARD 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.5 DNC1 CONTROL 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.6 DNC2 CONTROL (ONLY AT 1–PATH CONTROL) 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.7 DATA SERVER 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.8 DATA INPUT/OUTPUT FUNCTION BASED ON THE I/O LINK AND

DATA INPUT/OUTPUT FUNCTION B BASED ON THE I/O LINK 333. . . . . . . . . . . . . . . . . . . . . . .

30.9 POWER MOTION MANAGER 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. SAFETY FUNCTIONS 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.1 EMERGENCY STOP 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2 OVERTRAVEL FUNCTIONS 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.1 Overtravel 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.2 Stored Stroke Check 1 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.3 Stored Stroke Check 2 (G22, G23) (M series) 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.4 Stored Stroke Checks 3 (M series) 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.5 Stored Stroke Checks 2 and 3 (T series) 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.6 Stroke Limit Check Before Movement 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.7 Externally Setting the Stroke Limit 341. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2.8 Chuck/Tail Stock Barrier (T series) 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3 INTERLOCK 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3.1 Interlock per Axis 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3.2 All Axes Interlock 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3.3 Interlock for Each Axis Direction 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3.4 Start Lock 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.4 EXTERNAL DECELERATION 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.5 ABNORMAL LOAD DETECTION 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.6 SERVO/SPINDLE MOTOR SPEED DETECTION 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 24

TABLE OF CONTENTS

B–63002EN/02

c–11

32. STATUS OUTPUT 346. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.1 NC READY SIGNAL 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.2 SERVO READY SIGNAL 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.3 REWINDING SIGNAL 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.4 ALARM SIGNAL 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .