Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 0 / 00 / 0-Mate

Operation and Maintenance Manual

GFZ-61397E/02 June 1996

Page 2

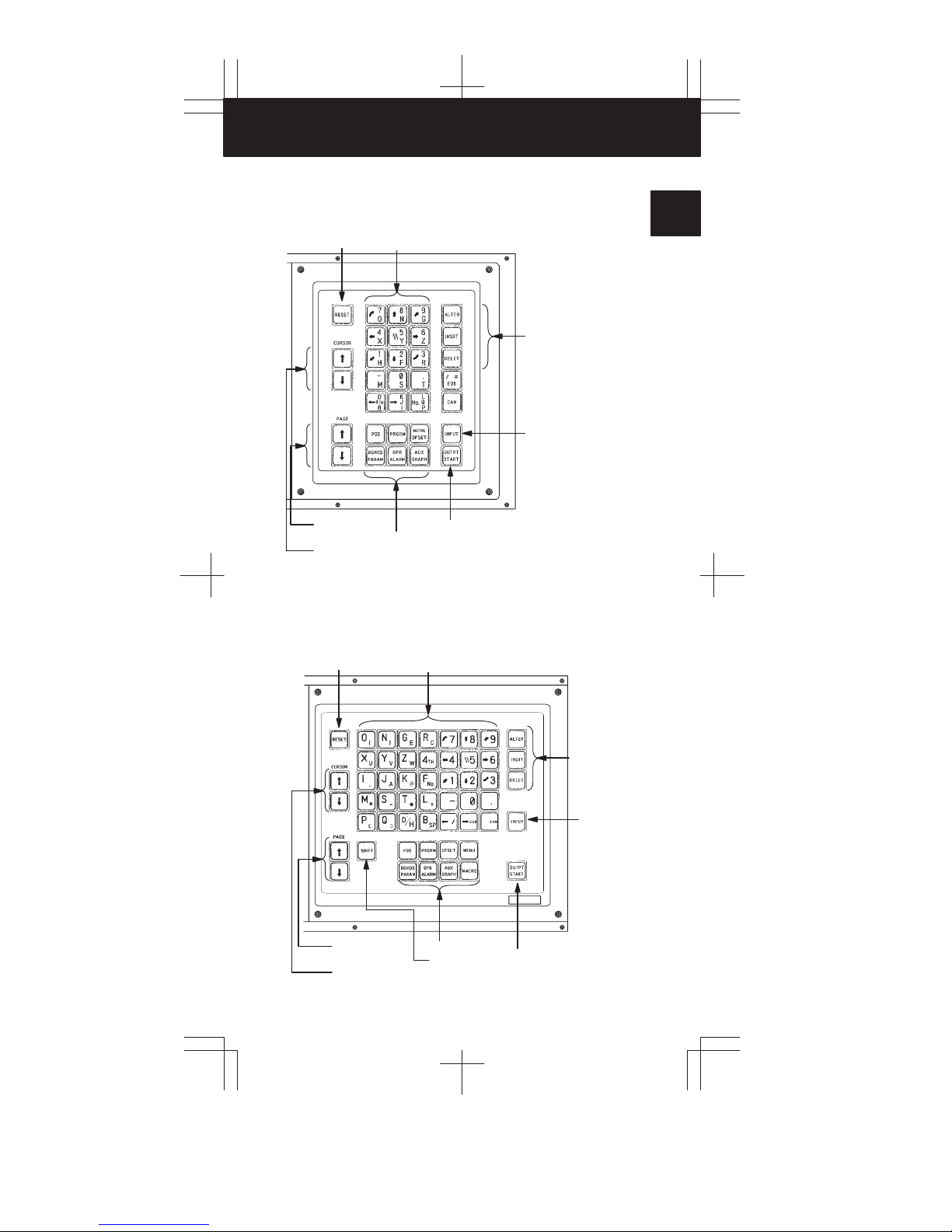

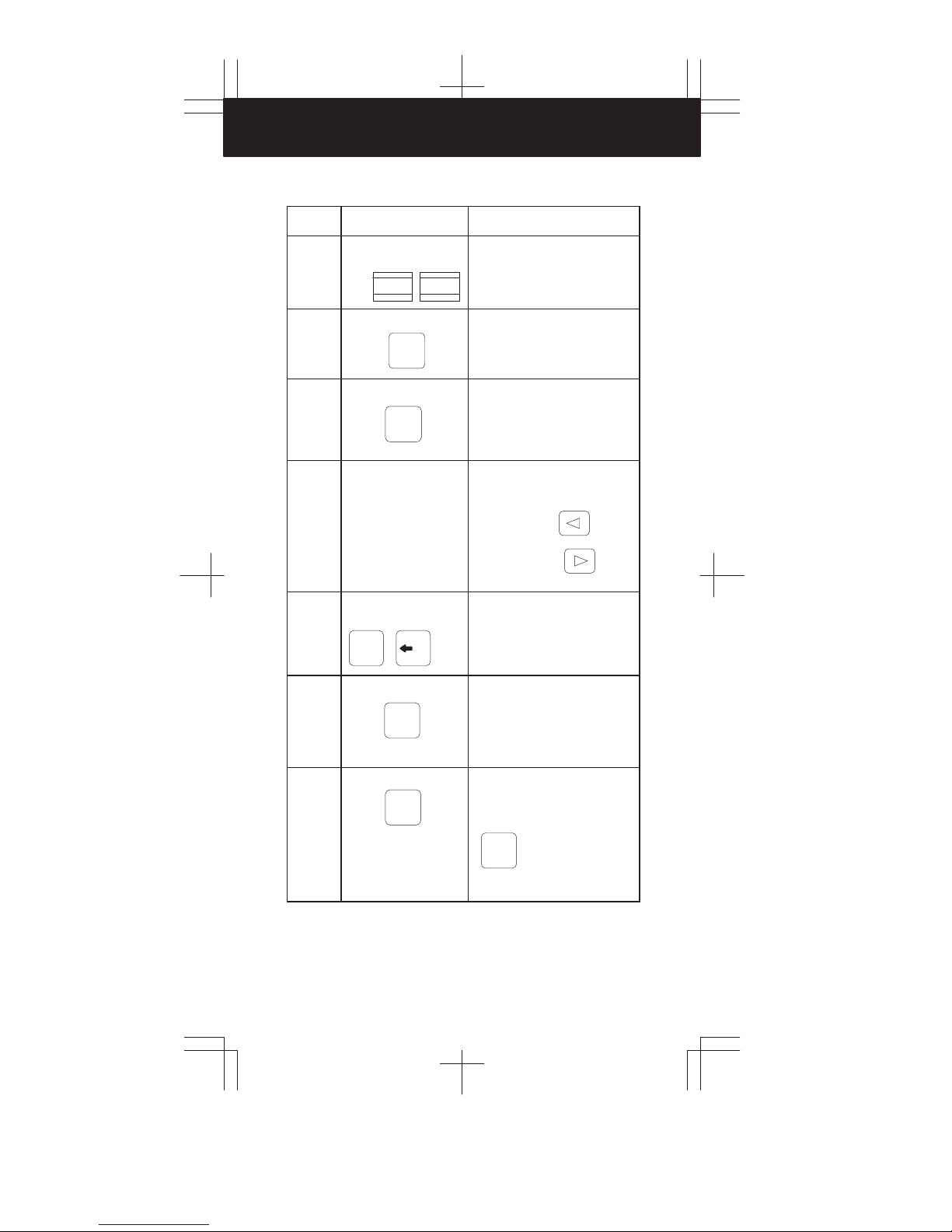

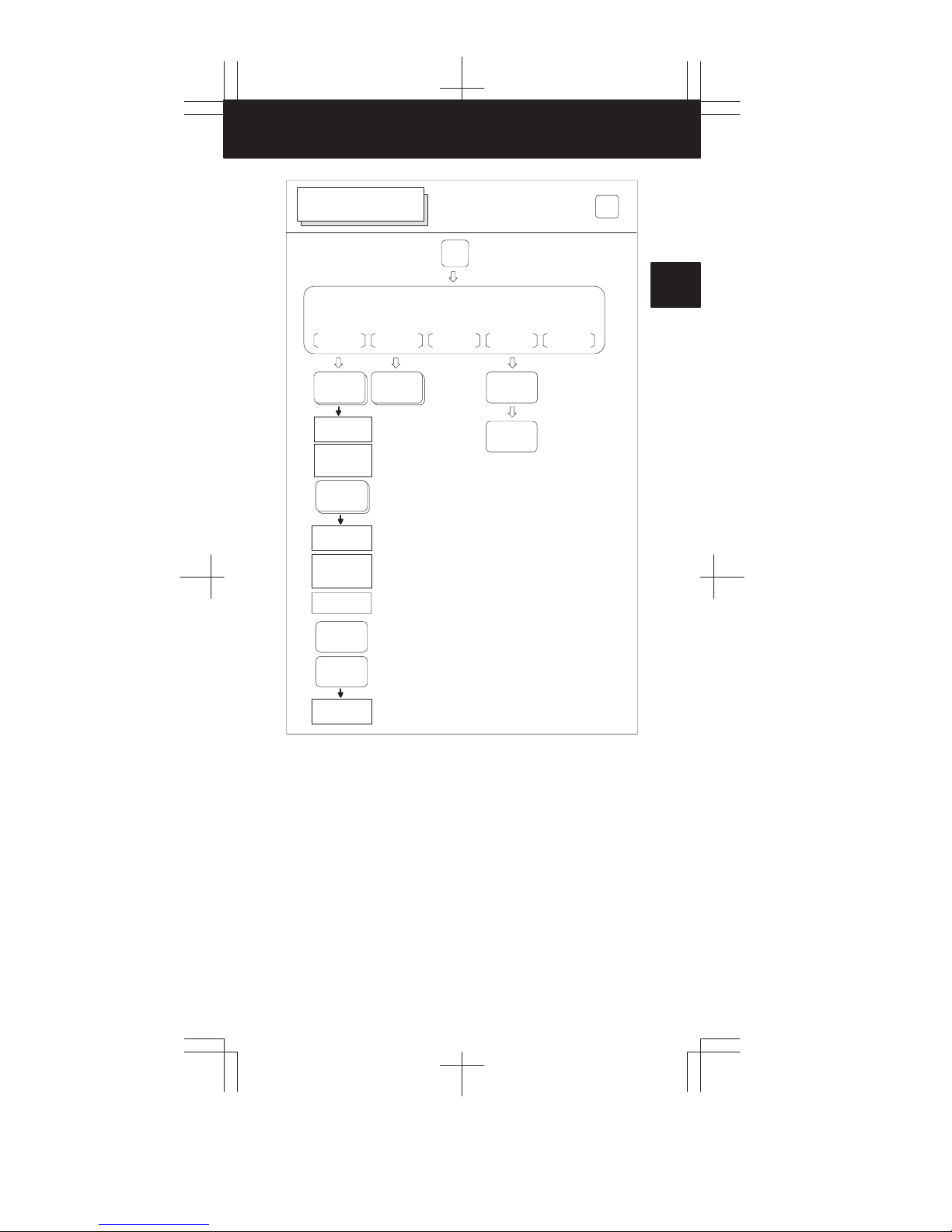

1. CRT/MDI P ANEL

1.1 Standard CRT/MDI Panel

M series

Soft key (Option)

9″ CRT

1.2 Full Key CRT/MDI Panel

M series

POWER

ON

OFF

Soft key

1

9″ CRT

Page 3

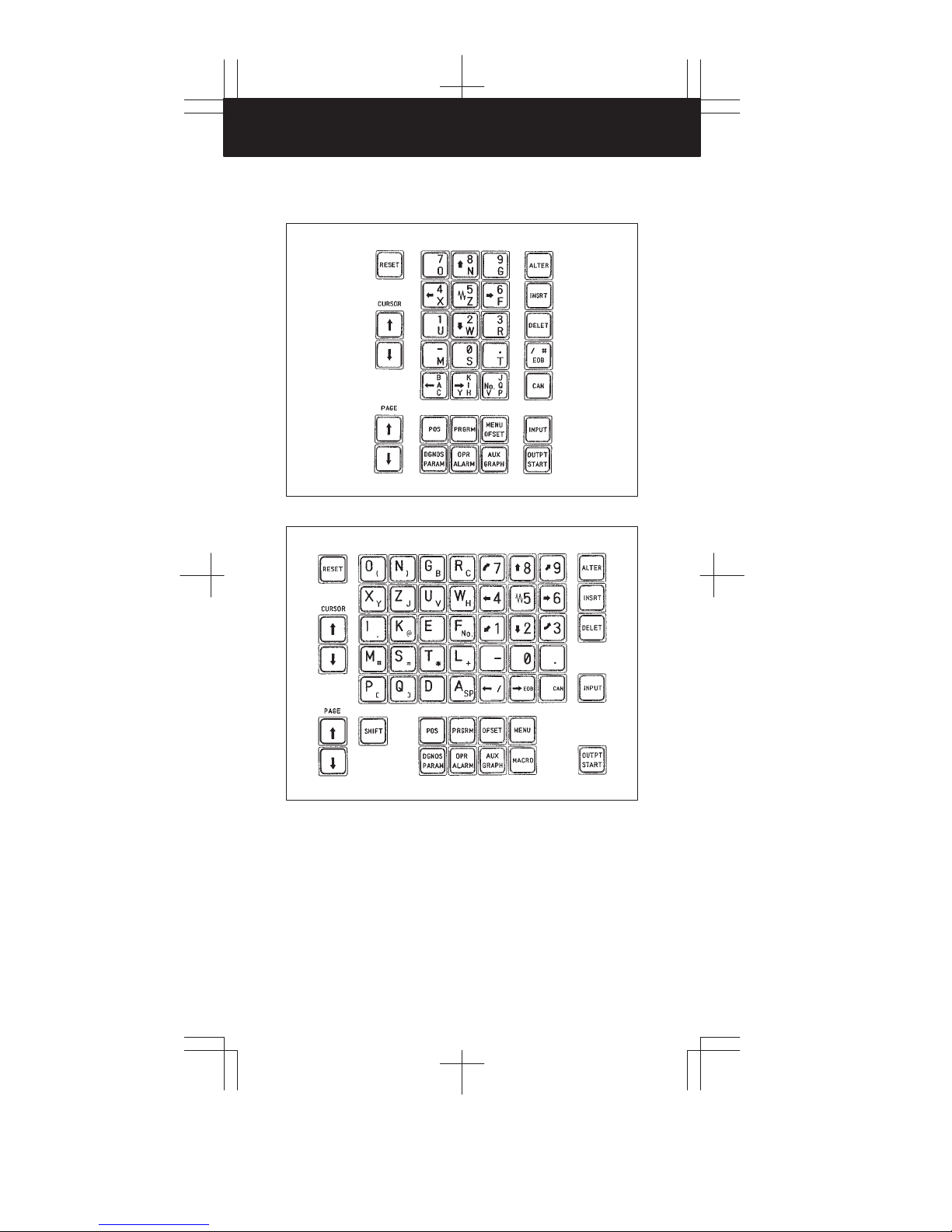

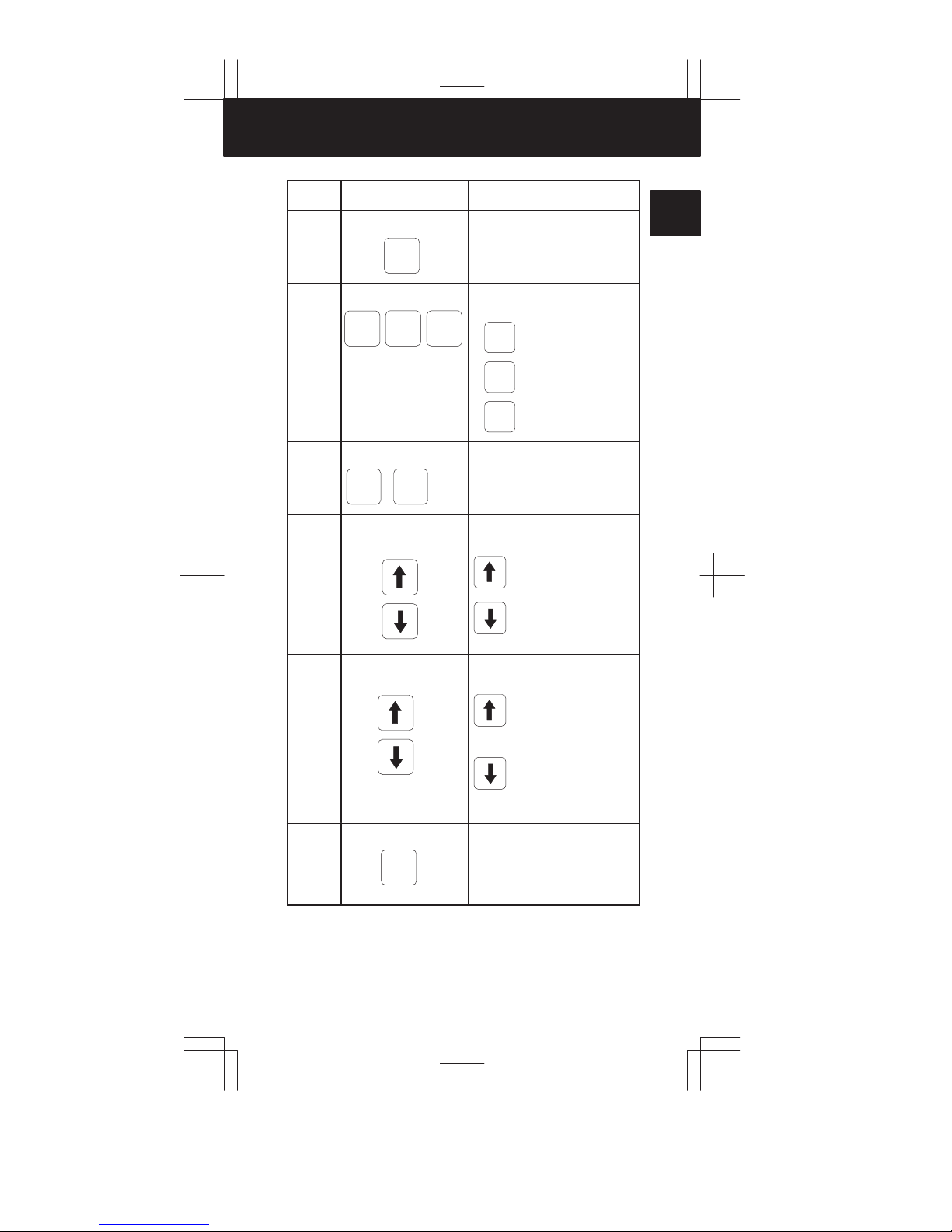

1

Reset button

Page change

keys

Cursor move keys

Reset key

Data input keys

Function keys

Data input keys

Output/Start key

Program edit keys

Input key

2

3

4

5

6

7

Page change

keys

Cursor move keys

Function keys

Shift key

Program edit

keys

Output/Start key

8

9

Input key

10

2

Page 4

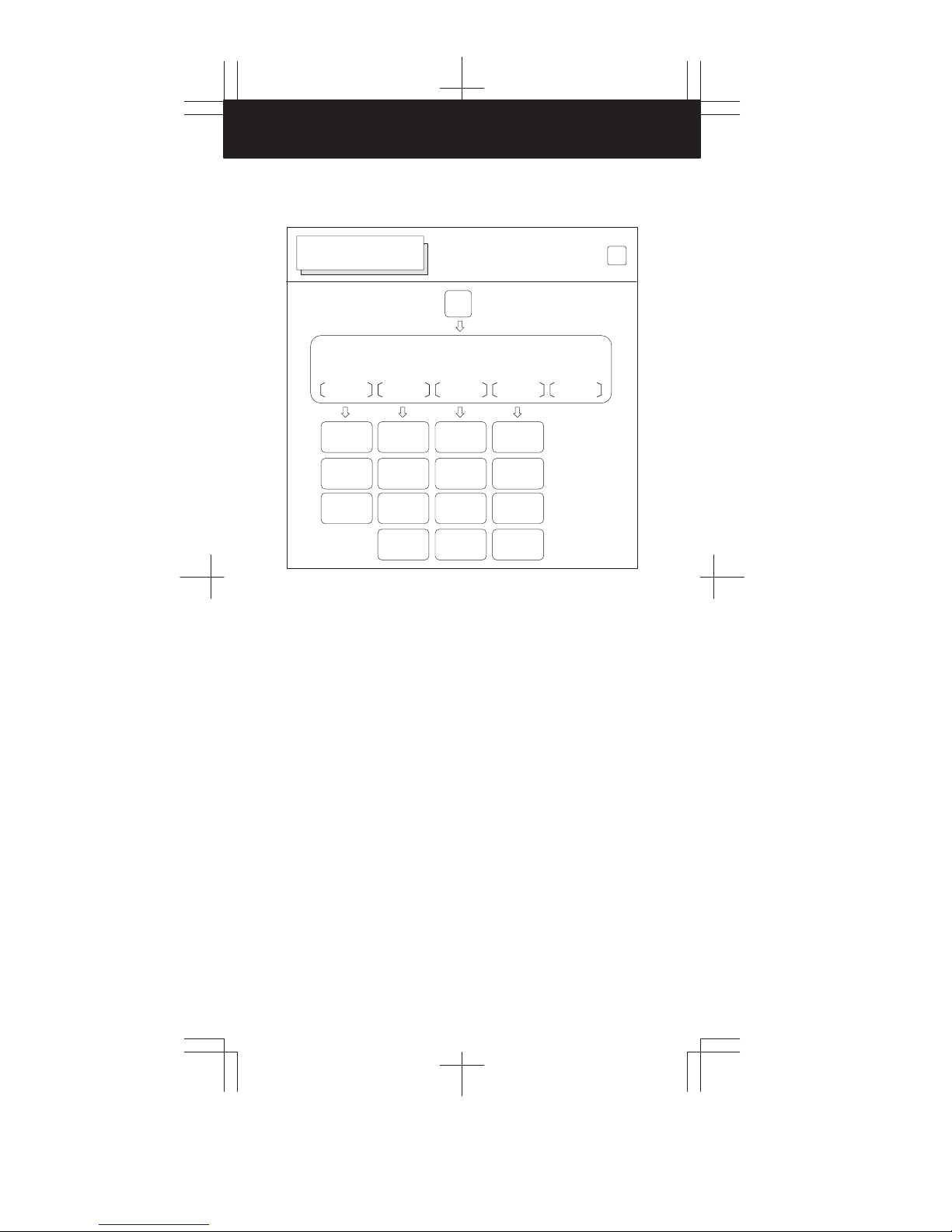

1. CRT/MDI PANEL

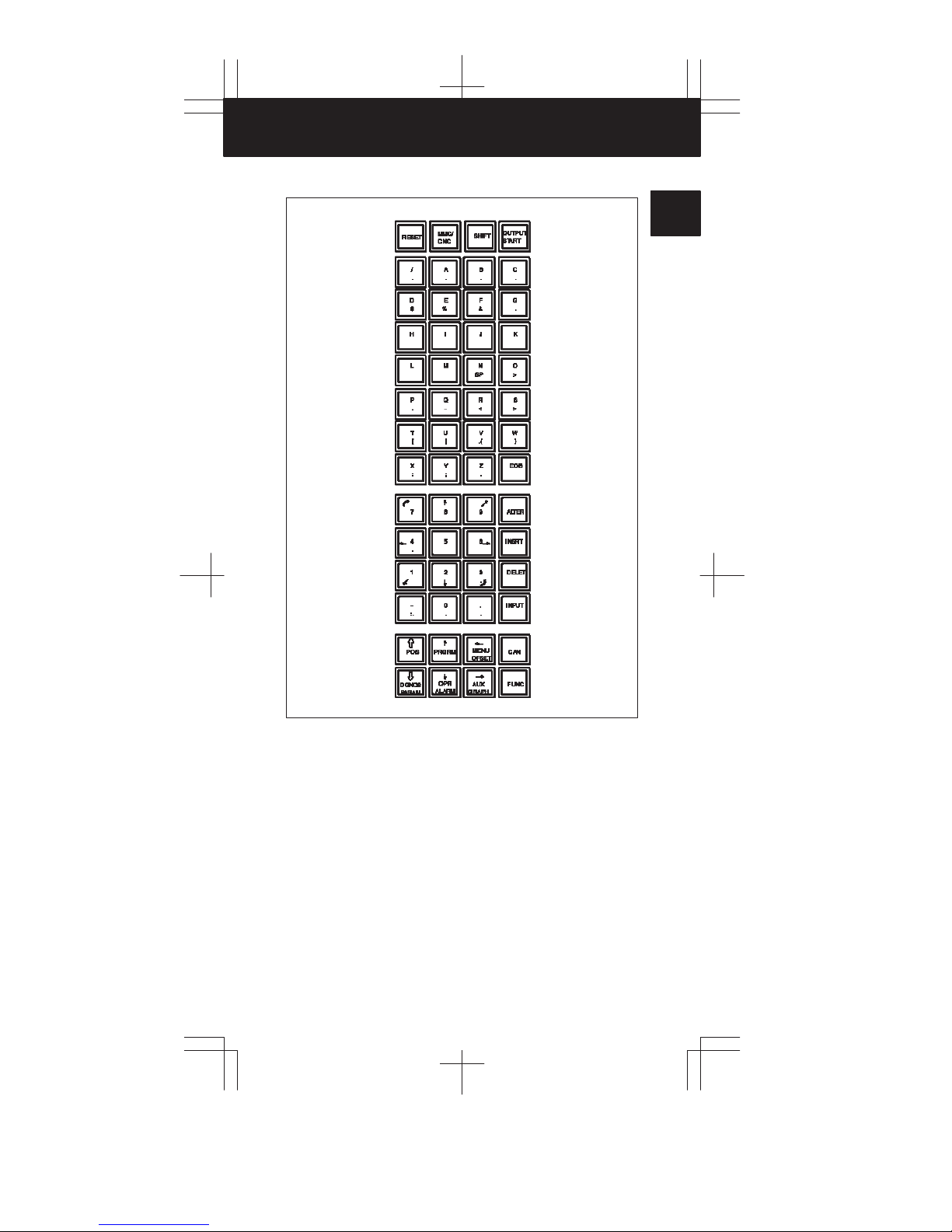

1.3 CRT/MDI with MMC

POWER

I+OFF O+OFF

3

Page 5

MMC/CNC change key

Shift keyReset key

RESET

/.A.B.C

D$E%F&G

H

L M NSPO

P

.Q–R<S>

T

[U]V.{W}

X

:Y;Z.

7 8 9 ALTER

4.5 6 INSRT

1 2 3

–

:.0...

POS PRGRM CAN

DGNOS

PARAM

CNC

I J K

MENU

OFSET

OPR

AUX

ALARM

GRAPH

START

.

.

>

EOB

DELET

.

INPUT

FUNC

OUTPUT

MMC/

SHIFT

Function keys

Start/output key

Program edit keys

Input key

1

2

3

4

5

6

7

8

9

10

4

Page 6

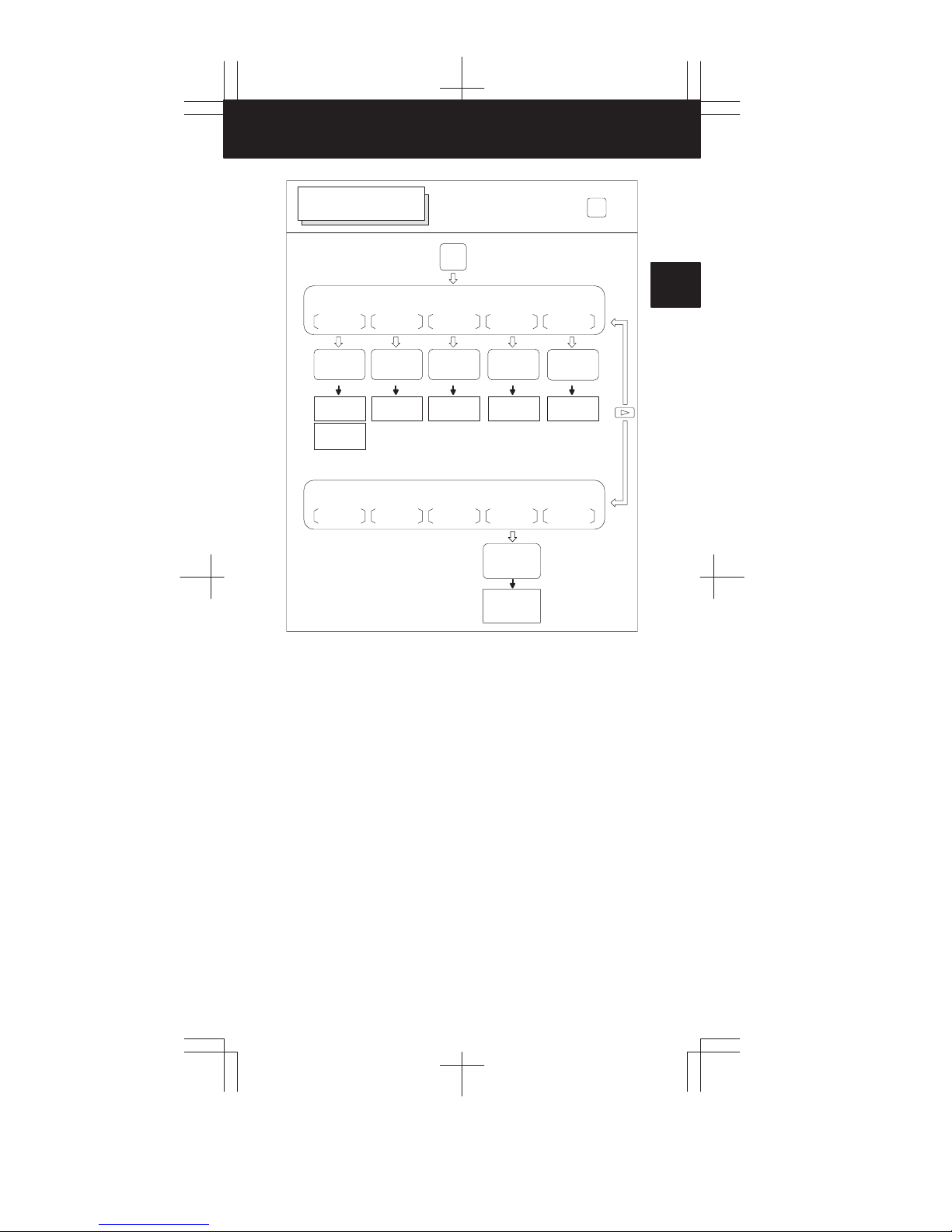

1. CRT/MDI PANEL

1.4 MDI Keyboard

Standard MDI keyboards (T series)

Full MDI keyboards (T series)

5

Page 7

Standard MDI keyboards (M series)

1

2

3

4

Full MDI keyboards (M series)

5

6

7

8

9

10

6

Page 8

1. CRT/MDI PANEL

Full MDI keyboards (14″ CRT for M series)

7

Page 9

MDI keyboards with MMC

1

2

3

4

5

6

7

8

9

10

8

Page 10

1. CRT/MDI PANEL

1.5 Explanation of the Keyboard

Number Name Explanation

1 Power ON and OFF buttons

f OFF | ON

Press these buttons to turn CNC power

ON and OFF.

2 RESET key

RESET

3 START key

OUTPT

START

4 Soft keys (option) The soft keys have various functions,

5 Address and numeric keys

N

6 SHIFT key

SHIFT key

(Full MDI keyboard)

7 INPUT key

4

(

SHIFT

INPUT

Press this key to reset the CNC, to cancel an alarm, etc.

This key is used to start MDI operation

or automatic operation, depending on

the machine. Refer to the manual provided by the machine tool builder. This

key is also used to output data to an input/output device.

according to the applications. The soft

key functions are displayed at the bottom of the CRT screen.

Soft key of left edge :

Soft key of right edge :

Continuous menu key

Press these keys to input alphabetic,

numeric, and other characters.

…

Some keys have two characters on

their keytop. Pressing the <SHIFT>

key switches the characters. Special

character is displayed on the screen

when a character indicated at the bottom right corner on the keytop can be

entered.

When an address or a numerical key is

pressed, the data is input to the buffer,

and it is displayed on the CRT screen.

To copy the data in the key input buffer

to the offset register, etc., press the

key.

INPUT

Return menu key

9

This key is also used to input data from

an input/output device.

Page 11

Number ExplanationName

8 Cancel key

CAN

Press this key to delete the input data

or the last character in the key input

buffer.

1

9 Program edit keys

INSRT

ALTER

10 Function keys

POS PRGRM

11 Cursor move keys

DELET

CURSOR

12 Page change keys

PAGE

13 MMC/CNC change key

MMC/

CNC

Press these keys when editing the program.

ALTER

: Alteration

: Insertion

INSRT

DELET

: Deletion

Press these keys to switch display

screens for each function.

…

There are two different cursor move

keys.

: This key is used to move

the cursor in an upward or

reverse direction.

: This key is used to move

the cursor in a downward

or forward direction.

Two kinds of page change keys are

available.

: This key is used to

changeover the page on

the CRT screen in the reverse direction.

: This key is used to

changeover the page on

the CRT screen in the forward direction.

Selects whether the MMC screen or

CNC screen is displayed on the CRT.

2

3

4

5

6

7

8

9

10

10

Page 12

1. CRT/MDI PANEL

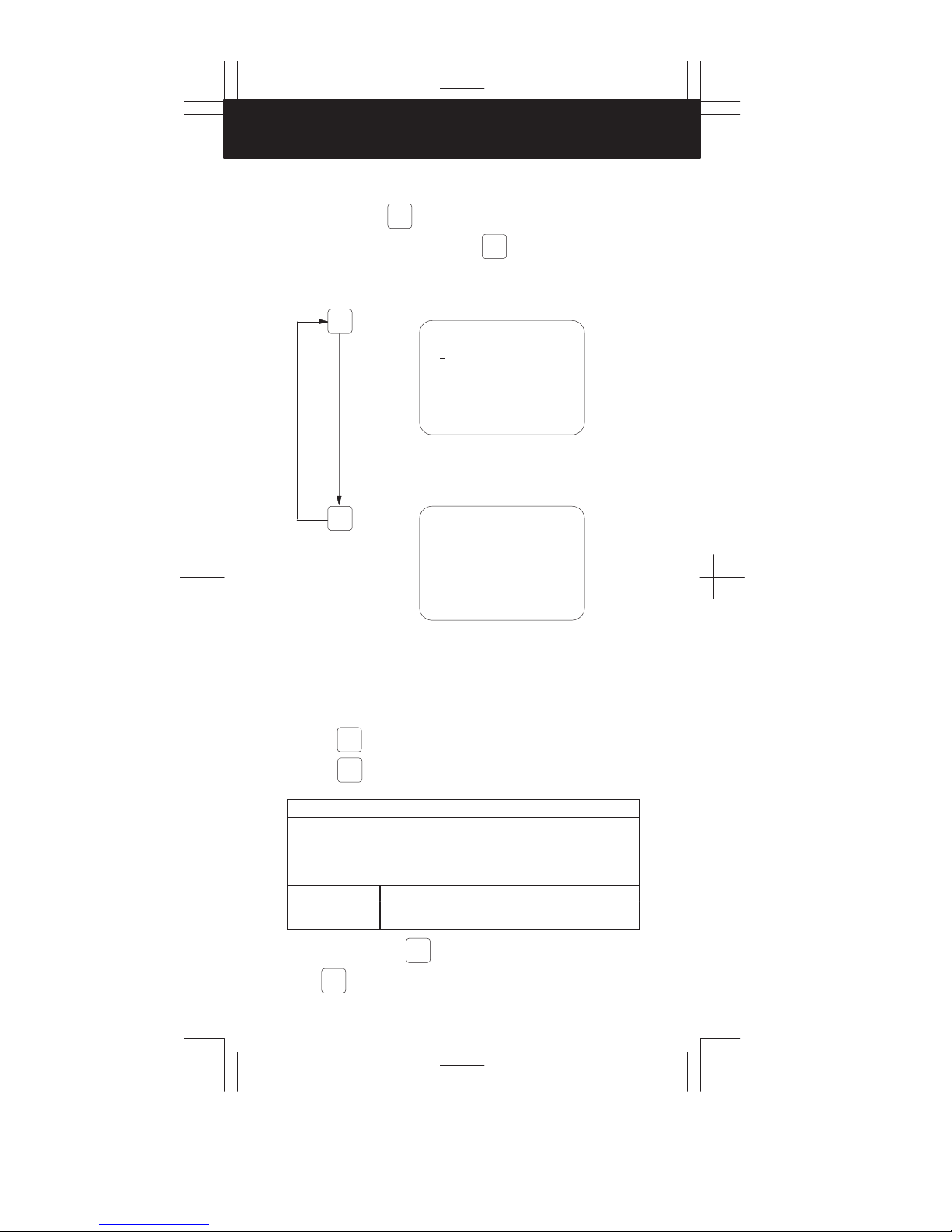

1.6 Key Input

For standard MDI keyboard

On the standard MDI keyboard, the same key is used to input both an

address and a numeric value.

When “ADRS.” is displayed on the top of the key input buffer , addresses can

be input.

When “NUM.” is displayed on the top of the key input buffer, numeric values

can be input.

Press

ADRS.

[ ][ ]

4

X

NUM. X

[ ][ ]

key

Press

NUM. X

[ ][ ]

4

X

NUM. X 4

[ ][ ]

key

The following keys are used for inputting multiple addresses. They may be

not displayed on the screen depending on the options used.

T series

B

A

NO.

V

Y

C

K

I

H

J

Q

P

CA B

IKY

H

JQ P

D

L

V

M series

11

D

4th

B

K

J

I

L

P

NO.

Q

D B 4th

IJK

PQL

Page 13

For full MDI keyboard

A “<” is displayed at the end of the key input buffer indicating the input

position of the next character.

1

Key input

buffer

display

T o input the symbol indicated at the lower part of a key top, press the

key to change the prompt < to ƞ. Then press the key.

N001X100Z<

[ ] [ ] [ ] [ ] [ ]

Key input buffer display

2

3

SHIFT

4

5

6

7

8

9

10

12

Page 14

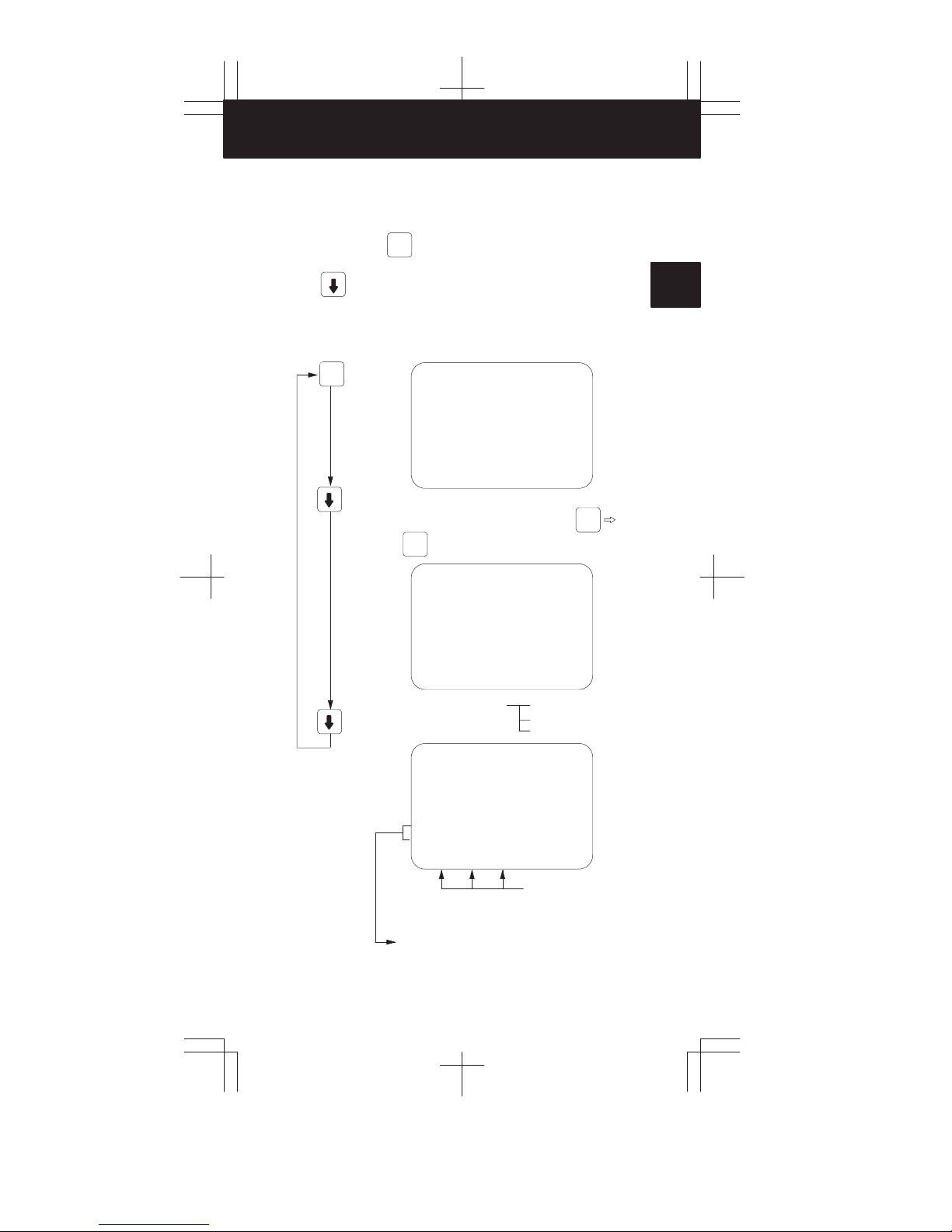

2. CRT/MDI OPERA TION

2.1 Screen Transition Triggered by the Each Function Key

POSITION DISPLAY

SCREEN

Screen transition triggered by the

function key

Current position screen

ABS REL ALL HNDL

Position display

of absolute coordinate system

Display of run

time and parts

count

Display of

actual speed

Position displays

of relative coordinate system

Display of run

time and parts

count

Display of

actual speed

Setting of relative coordinate

values

Total position

display of each

coordinate

system

Display of run

time and parts

count

Display of

actual speed

Display of

distance to go

POS

Manual handle

interruption

Display of run

time and parts

count

Display of

actual speed

Display of

distance to go

POS

13

Page 15

PROGRAM SCREEN

PRGRM

PRGRM

1

Program screen

PRGRM

Display of program contents

Display of program number

and sequence

number

Program screen

BG–EDT

Back ground

editing

screen

CURRNT NEXT

Display of current block and

modal data

Program being

executed

Absolute / relative

coordinate value

Distance to go

Modal values

*1

*2

FL.SDL

Setting of

schedule

Display of current block and

next block

Command

for MDI operation

Displayed in MDI mode

Not displayed in MDI mode

*2

[SCHDUL]

AUTO (MDI)

CHECK

*1

(MDI)

*1

AUTO

2

*1

RSTR

3

Program restart

4

5

6

7

8

9

10

14

Page 16

2. CRT/MDI OPERA TION

PROGRAM SCREEN

PRGRM

Program screen

*1

FLOPPY

PRGRM

Program editing screen

LIB C.A.P.

Display of program directory

on CNC

memory

Condense of

CNC memory

*1

Displayed if the Floppy Cassette is specified as the input/output unit

*2

Displayed if the above conditions are not satisfied

I/O

Display of program directory

on floppy cassette

EDIT

*2

*1

Program screen

EDIT

BG–EDT EX–EDT

Back ground

editing screen

Conversational

programming

screen

Extended part

program editing

PRGRM

15

Page 17

OFFSET SCREEN

Tool offset value

OFFSET

MACRO

Screen transition triggered by

the function key

(M series)

MENU

OFSET

MENU

WORK

TOOLLF

MENU

OFSET

1

2

Display of tool

offset value

Setting of tool

offset value

Tool length

measurement

Tool offset value

Display of

custom macro

variables

Setting of macro

variables

Display of pattern menu

Setting of pattern data

Display of workpiece zero point

offset value

Setting of workpiece zero point

offset value

WORK48

Display of the additional workpiece

zero point offset

value

Setting of the additional workpiece

zero point offset

value

Display of tool

life management data

Preset of tool

life counter

3

4

5

6

7

8

9

10

16

Page 18

2. CRT/MDI OPERA TION

OFFSET SCREEN

Tool offset value

WEAR

OFFSET

Display tool

wear offset

value

Set tool wear

offset value

Tool length

measurement

Tool offset value

TOOLLF

Display tool

life management data

Preset tool life

management

data

GEOM

Display tool

geometry offset value

Set tool geometry offset value

WEAR

Display Y–axis

tool wear offset value

Set Y–axis tool

wear offset

value

Screen transition triggered by

the function key (T series)

MENU

OFSET

W.SHFT

WORK

Display work

shift or workpiece zero point

offset value

Set work shift

or workpiece

zero point offset value

MACRO

Display macro

variables

Set macro variables

GEOM

Display Y–axis

tool geometry

offset value

Set Y–axis tool

geometry offset value

MENU

OFSET

17

Page 19

PARAMETER/DIAGNOSTIC SCREEN

DGNOS

PARAM

DGNOS

PARAM

1

Parameter screen

PARAM DGNOS

Display of parameter

screen

Setting of parameter

Setting of pitch

error compensation data

Display of

setting data

Setting of setting data

Setting of sequence number

comparison and

stop

Setting of parts

count

Display of run

time, parts count

Display of date

and clock

Setting of date

and clock

Display of

diagnosis

screen

*

SV–PRM

Display of

servo setting

screen

Display of

servo tuning

screen

*

The servo setting/tuning screen can be suppressed if bit 0 of

parameter 0389 is specified accordingly.

2

3

4

5

6

7

8

9

10

18

Page 20

2. CRT/MDI OPERA TION

ALARM SCREEN

Alarm screen

ALARM

Display of

alarm screen

OPR MSG

Display of software operator’s

panel general

purpose switch

Setting of software

operator’s panel

general purpose

switch

Screen transition triggered

by the function key

OPR

ALARM

Display of operator’s message

OPR

ALARM

19

Page 21

2.2 CRT/MDI Operation

Command display

Function button

PRGRM

1

During the AUTO mode, press (page) or the corresponding soft

key to cause any of the following four types of displays to appear.

(1) A program being currently executed is displayed.

PRGRM

PAGE

PROGRAM O2000 N0130

O2000 ;

N100 G92 X0 Y0 Z50. ;

N110 G91 G00 Y50. ;

N120 Z–50. ;

130 G41 G17 H1 G01 X20. F3000 ;

N

N140 G02 J–25.5 ;

N150 X20. ;

N160 G02 X12.5 Y12.5 R12.5 ;

N170 G01 Y40. ;

N180 X30. Y30. ;

N190 G40 X50. ;

16:59:40 BUF AUTO

[ PRGRM ] [CURRNT] [ NEXT ] [ CHECK ] [ RSTR ]

S 0 T

The cursor is set to the beginning of the program

being executed.

PAGE

PAGE

(2) The command currently being executed and the

modal values specified before are displayed.

PROGRAM O2000 N00130

(CURRNT) (MODAL)

X 20.000 G67 G01 F 3000

G01 F 3000 G54 G17 R

G17 H 1 G64 G91 P

G41 G49 T

G80 G98 S

02:50:52 BUF AUTO

[ PRGRM ] [ CURRNT ] [ NEXT ] [ CHECK ] [ RSTR ]

G69 G22 Q

G15 G94 H

G25 G21 M

G41 S

G80

G50

S 0 T0000

(3) The command currently being executed and the

next command to be executed are displayed.

PROGRAM O2000 N0130

(CURRNT) (NEXT)

X 20.000 J –25.500

G01 F 3000 G02

G17 H 1

G41

G80 G80

S 0 T

02:52:14 BUF AUTO

[ PRGRM ] [ CURRNT ] [ NEXT ] [ CHECK ] [ RSTR ]

PAGE

(4) Program check

The block currently being executed, the current

position, and the modal values specified before

are displayed.

PROGRAM CHECK O2000 N0130

N130 G41 G17 H1 G01 X20. F3000 ;

N140 G02 J–25.5 ;

N150 X20.0 ;

N160 G02 X12.5 Y12.5 R12.5 ;

(RELATIVE) (DIST TO GO) ( G)

X 17.600 X 2.400 G01 G21 G50

Y 50.000 Y 0.000 G17 G41 G67

Z 0.000 Z 0.000 G91 G49 G54

F 3000 P H 1 S

R Q M T

ACT.F 3000 MM/M S 0 T

02:53:16 BUF AUTO

[ PRGRM ] [ CURRNT ] [ NEXT ] [ CHECK ] [ RSTR ]

G22 G80 G64

G94 G98 G69

* Besides the above displays, the program restart screen is displayed in

some cases. (Option)

20

2

3

4

5

6

7

8

9

10

Page 22

2. CRT/MDI OPERA TION

Program display

Function button

During the EDIT mode, press the

PRGRM

PRGRM

key several times or the

corresponding soft key to cause either of the following two types of

displays to appear.

(1) The program is displayed.

PRGRM

PROGRM

O0100 ;

N10 G92 X0 Y0 Z0 ;

N20 G00 Z10. Y–50. ;

N30 G

01 X200. Y–60. F500 T12 ;

N40

%

< S 0 T

10:39:27 EDIT

[ PRGRM ] [ LIB ] [ FLOPPY ] [ ] [ C.A.P. ]

O0100 N0040

The program and sequence numbers are displayed at

the upper right section of the screen.

(2) The amount of program memory in use is

displayed.

PRGRM

PROGRAM O1224 N0000

SYSTEM EDITION 0466 – 25

PROGRAM NO. USED : 14 FREE : 49

MEMORY AREA USED : 275 FREE : 3820

PROGRAM LIBRARY LIST

O0010 O2000 O0020 O0030 O0200 O0300

O0555 O1200 O0777 O1234 O0040 O0050

O1969 O1224

> S 0 T

03:04:17

[ PRGRM ] [ CONDNS ] [ ] [ ] [ C.A.P. ]

Number of registered programs

Memory area in use

Program list

* If the directory display of floppy cassette is provided, a file list, in addition

to the above displays, appears on the screen.

Reset

Press the

RESET

. This key is usually used to reset the alarm.

When the

A tool movement command continues to be executed.

An M, S, or T continues to be sent

out.

When the buffer is

loaded with one

block

In any case, pressing the

mode,

21

RESET

is pressed, the NC enters one of the states listed below.

Before a reset

The tool decelerates and stops. The unexecuted amount of movement disappears.

A send–out sequence is terminated. Refer

to the machine tool builder’s manual for what

occurs on the machine side.

After a reset

MDI mode The contents of the buffer are not erased.

Other modes The contents of the buffer are erased. The

RESET

causes the labels to be skipped.

BUF display disappears.

RESET

resets the NC. In a mode other than the MDI

Page 23

Custom macro variable display/setting

MENU

Function button

Press the

select the desired screen.

MENU

OFSET

OFSET

MENU

OFSET

key several times or the corresponding soft key to

MENU

OFSET

PAGE

VARIABLE O1234 N1234

NO. DATA NO. DATA

100 123.456 108

101 0.000 109

102 110

103 111

104 112

105 113

106 114

107 115

ACTUAL POSITION (RELATIVE)

X 0.000 Y 0.000

Z 0.000 B 0.000

[OFFSET ] [ MACRO ] [ MENU ] [ WORK ] [ ]

1

2

3

MDI

CURSOR

If a variable is null, the corresponding value

field is left blank. If the absolute value is

greater than 99999999, the corresponding

value field contains ********.

Numeral

INPUT

Tool compensation value display/setting

MENU

OFSET

MENU

OFSET

PAGE

CURSOR

OFFSET O1224 N0000

NO. DATA NO. DATA

001 009 0.000

002 0.000 010 12.269

003 5.000 011 10.230

004 0.000 012 –11.265

005 12.580 013 –8.562

006 0.000 014 0.000

007 0.000 015 0.000

008 0.000 016 0.000

ACTUAL POSITION (RELATIVE)

X 0.000 Y 0.000

Z 0.000

NO. 013 = S 0 T

03:22:13 MDI

[ OFFSET ] [ MACRO ] [ MENU ] [ WORK ] [ TOOLLF ]

Move the cursor to the target offset

number using the cursor keys. Or

press the keys as shown below:

No.

Offset number

4

5

6

7

8

9

INPUT

10

Offset amount

INPUT

22

Page 24

2. CRT/MDI OPERA TION

Alarm display

ALARM MESSAGE O0000 N0000

100P/S ALARM

417SERVO ALARM : X AXIS DGTL PARAM

427SERVO ALARM : Y AXIS DGTL PARAM

OPR

ALARM

NOT READY ALARM MDI

[ ALARM ] [ OPR ] [ MSG ] [ ] [ ]

Software operator’s panel display/setting

OPR

ALARM

Set

4th

B

OPR

key several times or the corresponding soft key to select

ALARM

OPR

ALARM

PAGE

PAGE

K

J

or

I

OPERATOR’S PANEL O1224 N0000

MODE : MDI AUTO EDIT HNDL JOG ZRN

HANDLE AXIS : HX HY HZ

HANDLE MULT. : *1 *10 *100

RAPID OVRD. : 100% 50% 25% F0

JOG FEED : 500 MM/MIN

FEED OVRD. : 100%

ACTUAL POSITION (ABSOLUTE)

X 0.000 Y 0.000

Z 0.000

03:59:30 MDI

[ ALARM ] [ OPR ] [ MSG ] [ ] [ ]

OPERATOR’S PANEL O1224 N0000

BLOCK SKIP : JOFF ON

SINGLE BLOCK : OFF JON

MACHINE LOCK : OFF JON

DRY RUN : OFF JON

PROTECT KEY : PROTECT JRELEASE

FEED HOLD : JOFF ON

ACTUAL POSITION (ABSOLUTE)

X 0.000 Y 0.000

Z 0.000

04:00:18 MDI

[ ALARM ] [ OPR ] [ MSG ] [ ] [ ]

**************

Press the

the target screen.

CURSORorCURSOR

S 0 T

******

S0 T

S 0 T

The switches and controls on the CRT/MDI panel can be used in place of the

counterparts on the machine operator’s panel. (F ANUC MPC is required.)

D Use the buttons shown below for jog feed operations.

23

8

N

5

4

Y

X

1

H

2

F

9

G

6

Z

Page 25

2.3 CRT/MDI Operation and Display (M Series)

Current position display

Function button

POS

1

Press (page) or the corresponding soft key to cause any of the

following three types of displays to appear.

(1) Absolute coordinates

Distance from the programmed zero point

POS

ACTUAL POSITION (ABSOLUTE)

O0010 N0000

X 123.456

Y 363.233

Z 0.000

RUN TIME 0H 1M CYCLE TIME 0H 1M33S

ACT.F 3000 MM/M S 0 T

01:35:22 BUF AUTO

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

PART COUNT 1

(2) Relative coordinates

Any tool position can be set to 0 by

CAN

. This holds true also of Y and Z.

ACTUAL POSITION (RELATIVE)

O0010 N0000

X 123.456

Y 363.233

Z 0.000

RUN TIME 0H 1M CYCLE TIME 0H 1M33S

ACT.F 3000 MM/M S 0 T

01:36:12 BUF AUTO

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

(3) General coordinates

ACTUAL POSITION O1000 N00010

(RELATIVE)

X 246.912

Y 913.780

Z 1578.246

(MACHINE)

X 0.000

Y 0.000

Z 0.000

RUN TIME 0H 4M CYCLE TIME 0H 1M38S

ACT.F 0 MM/M S 0 T

01:54:57 MDI

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

PART COUNT 1

Absolute coordinates

(ABSOLUTE)

X 123.456

Y 456.890

Z 789.123

(DISTANCE TO GO)

X 0.000

Y 0.000

Z 0.000

PART COUNT 1

X

Relative coordinates

Machine coordinates

2

3

4

5

6

7

8

9

The target screen can

be selected directly

by the corresponding

soft key.

The operating time and parts count are displayed.

Two types of operating time and parts count are

displayed on the coordinate display screen.

(position)

10

24

Page 26

2. CRT/MDI OPERA TION

Setting data display/setting

Function button

DGNOS

PARAM

(Parameter pages 1 and 2 are the setting data screens.)

When the title parameter is not on the screen,

press the key or

DGNOS

PARAM

the corresponding soft

key to select the parameter screen.

[Setting]

MDI mode

CURSORorCURSOR

Numeral

INPUT

Display

Item

REVX X–axis mirror image OFF X–axis mirror image ON

REVY Y–axis mirror image OFF Y–axis mirror image ON

TVON No TV check is made. A TV check is made.

ISO EIA code output

INCH Metric input Inch input

I/O (Note) Reader/punch interface channel is selected.

ABS Incremental command (MDI

SEQ Sequence numbers are not in-

PWE Parameter writing is disabled. Parameter writing is enabled.

REV4 Fourth–axis mirror image OFF Fourth–axis mirror image ON

TAPEF F10/11 table format is not used F10/11 table format is used

(during punch)

mode)

serted automatically when a

program is entered from the

MDI.

PARAMETER O1224 N0000

(SETTING 1)

_REVX = 0

REVY = 0

TVON = 0

ISO = 0 (0:EIA 1:ISO)

INCH = 0 (0:MM 1:INCH)

I/O = 0

ABS = 0 (0:INC 1:ABS)

SEQ = 0

NO. REVX = S 0 T

03:30:09 MDI

[ PARAM ] [ DGNOS ] [ ] [ SV–PRM ] [ ]

CLOCK 10/01/10

03:30:18

(page)

PARAMETER O1224 N0000

(SETTING 2)

_PWE = 1 (0:DISABLE 1:ENABLE)

REV4 = 0

TAPEF = 0

(SEQUENCE STOP)

PRGNO = 0

SEQNO = 0

PART TOTA L = 17

PART REQUIRED = 50

PART COUNT = 17

RUN TIME OH 4M CYCLE TIME OH OM 2S

NO. PWE = S 0 T

03:35:07 MDI

[ PARAM ] [ DGNOS ] [ ] [ SV–PRM ] [ ]

0 1

ISO code output

(during punch)

Absolute command (MDI

mode)

Sequence numbers are inserted automatically when a

program is entered from the

MDI.

NOTE See Page 33 for details.

25

Page 27

2.4 CRT/MDI Operation and Display (T Series)

Current position display

Function button POS

1

Press (page) or the corresponding soft key to cause any of the

following three types of displays to appear.

(1) Absolute coordinates

Distance from the programmed zero point

POS

ACTUAL POSITION (ABSOLUTE)

X 200.000

Z 220.000

C 0.000

Y 0.000

RUN TIME 2H47M CYCLE TIME 0H 1M47S

ACT.F 3000 MM/M S 0 T0101

16:14:02 BUF AUTO

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

PART COUNT 1786

(2) Relative coordinates

Any tool position can be set to 0 by

CAN . This holds true also of Z and Y.

ACTUAL POSITION (RELATIVE)

O0001 N0023

X 200.000

Z 220.000

C 0.000

Y 0.000

PART COUNT 23

RUNTIME 3H30M CYCLE TIME 0H 2M14S

ACT.F 3000 MM/M S 0 T0101

20:03:21 AUTO

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

(3) General coordinates

ACTUAL POSITION O0100 N0000

(RELATIVE) (ABSOLUTE)

U 0.000 X 200.179

W 0.000 Z 220.000

H 0.000 C 0.000

V 0.000 Y 0.000

(MACHINE) (DISTANCE TO GO)

X –118.170 X 0.000

Z –21.470 Z 0.000

C 0.676 C 0.000

Y 0.046 Y 0.000

RUN TIME 3H30M CYCLE TIME 0H 2M14S

ACT.F 0 MM/M S 0 T0101

20:04:37 AUTO

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

PART COUNT 23

Absolute coordinates

X

Relative coordinates

Machine coordinates

2

3

4

5

6

7

8

9

10

The target screen can

be selected directly

by the corresponding

soft key.

The operating time and part count are displayed.

Two types of operating time and parts count are

displayed on the coordinate display screen

(position).

26

Page 28

2. CRT/MDI OPERA TION

Setting data display/setting

Function button

DGNOS

PARAM

(Parameter pages 1 and 2 are the setting data screens.)

When the title “parameter” is not on the screen,

press the key or

DGNOS

PARAM

the corresponding soft

key to select the parameter screen.

[Setting]

MDI mode

CURSORorCURSOR

Numeral

INPUT

Display

Item

TVON No TV check is made. A TV check is made.

ISO EIA code output

INCH Metric input Inch input

I/O (Note) Reader/punch interface channel is selected.

SEQ Sequence numbers are not in-

PWE Parameter writing is disabled. Parameter writing is enabled.

TAPEF F10/11 table format is not used. F10/11 table format is used.

(during punch)

serted automatically when a

program is entered from the

MDI.

PARAMETER O0001 N0001

(SETTING 1)

TVON = 1

ISO = 1 (0:EIA 1:ISO )

INCH = 0 (0:MM 1:INCH)

I/O = 0

SEQ = 1

CLOCK 94/05/16

NO. TVON S 0 T0101

21:35:25 MDI

[ PARAM ] [ DGNOS ] [ ] [SV–PRM ] [ ]

12:11:52

(page)

PARAMETER O0001 N0001

(SETTING 2)

_PWE = 0 (0:DISABLE 1:ENABLE)

TAPEF = 0

(SEQUENCE STOP)

PRGNO = 0

SEQNO = 0

PART TOTA L = 2 3

PART REQUIRED = 0

PART COUNT = 23

RUN TIME 3H36M CYCLE TOME 0H 0M 0S

NO. PWE S 0 T0101

21:36:25 MDI

[ PARAM ] [ DGNOS ] [ ] [SV–PRM ] [ ]

0 1

ISO code output

(during punch)

Sequence numbers are inserted automatically when a

program is entered from the

MDI.

NOTE See Page 33 for details.

27

Page 29

2.5 CRT/MDI Operation and Display (with MMC)

(1) Operation

Key operation can only be done when the CNC screen is displayed on

the CRT display of the CRT/MDI panel. Address keys and numerical

keys are independently arranged on 00–C. However, inputting data is

exactly the same as that of 0–C. The page key

, and selection key on the software operator’s

panel are of combined use with the function key. Press the

corresponding key for use as a page key , cursor key , and selection key

on the software operator’s panel. Press the corresponding key while

pressing the “FUNC” key as the function key.

Five keys on the right half ten keys are effective for the variable section,

and the other five keys on the left half are effective for selecting position

display data in the fixed section.

When the number is specified by a method like the parameter screen,

because there is no NO. key use the cursor key

(2) Display

MMC/

Press

key on the CRT/MDI panel to display the CNC screen

CNC

when the MMC screen is displayed on the CRT display of the CRT/MDI

panel.

The CNC screen consists of a variable section and a fixed section. The

variable section is the part that is surrounded by the frame at the bottom

right, and its display contents are the same as displayed on the 9” CRT

display of 0–C. Therefore, the screen selected by function key, page

key, cursor key, and soft key is displayed.

The fixed section is the rest of the above variable section, and its display

contents are position data, operation time (optional), modal data, and

S, T command value, as shown on the screen. Display items of this

section cannot be changed by the screen selection operation. However,

its display contents are always renewed.

, cursor key

instead.

1

2

3

4

5

6

7

Fixed section

ACTUAL POSITION (ABSOLUTE)

X 0.000 O0009

Y 0.000

Z 0.000 N0009

(MODAL)

G64 G00 F

G17 R

G91 P

G22 Q

G94 H

G21 M

G40 S

G49 T

G80

G98

G67

G54

RELABS ALL

PARAMETER

NO. DATA NO. DATA

0001 10000100 0011 00000000

0002 00000011 0012 00000001

0003 00000000 0013 10000000

0004 01110111 0014 00000000

0005 01110111 0015 00000000

0006 01110111 0016 00000000

0007 01110111 0017 01111111

0008 00000011 0018 00000000

0009 01000100 0019 00000000

0010 11000100 0020 00000000

NO. 0001 =

PRGRM

PART COUNT 0

RUN TIME 29H 47M

CYCLE TIME 0H 0M 0S

DGNOS

8

9

Variable

section

10

MDI

+

28

Page 30

2. CRT/MDI OPERA TION

2.6 Data Input/Output (FANUC Cassette)

Setting the beginning of the file

1 Select the EDIT mode

2 Press the

times to select the program list

screen.

3 Key in address N.

4 Key in the target file number.

CNC parameter output

1 Select the EDIT mode

2 Press the

times to select the parameter

screen.

PRGRM

key several

PROGRAM O1224 N0000

SYSTEM EDITION 0466 – 25

PROGRAM NO. USED : 14 FREE : 49

MEMORY AREA USED : 275 FREE : 3820

PROGRAM LIBRARY LIST

O0010 O2000 O0020 O0030 O0200 O0300

O0555 O1200 O0777 O1234 O0040 O0050

O1969 O1224

> S 0 T

03:04:17

[ PRGRM ] [ CONDNS ] [ ] [ ] [ C.A.P. ]

N0 ⇒ Locates the beginning of the cassette.

This is used regardless of whether the file is on the floppy

disk.

N1 ⇒ Locates the beginning of the cassette.

This is used when the file is on the floppy disk.

N2 to N9999 ⇒Locates the beginning of any file.

DGNOS

key several

PARAM

PARAMETER O1224 N0000

(SETTING 1)

_REVX= 0

REVY= 0

TVON = 0

ISO = 0 (0:EIA 1:ISO)

INCH = 0 (0:MM 1:INCH)

I/O = 0

ABS = 0 (0:INC 1:ABS)

SEQ = 0

NO. REVX = S 0 T

03:30:09 EDIT

[ PARAM ] [ DGNOS ] [ ] [ SV–PRM ] [ ]

CLOCK 10/01/10

03:30:18

3 Press the

OUTPT

key, and output begins.

START

NOTE Parameter Nos. nine hundreds (900 to 999) are not output.

PMC parameter output

1 Select the EDIT mode.

DGNOS

2 Press the

key several times to select the DGNOS (diagnose)

PARAM

screen.

OUTPT

3 Press the

key, and output begins.

START

29

Page 31

Program output

1 Select the EDIT mode.

2 Press the

PRGRM

key several

times to select the program list

screen.

3 Key in address O.

4 Key in the target program number.

5 Press the

OUTPT

key, and output begins.

START

* All–program output: 0–9999

Offset output

1 Select the EDIT mode.

MENU

OFSET

2 Press the

times to select the offset

screen.

3 Press the

key several

OUTPT

key, and output begins.

START

PROGRAM O1224 N0000

SYSTEM EDITION 0466 – 25

PROGRAM NO. USED : 14 FREE : 49

MEMORY AREA USED : 275 FREE : 3820

PROGRAM LIBRARY LIST

O0010 O2000 O0020 O0030 O0200 O0300

O0555 O1200 O0777 O1234 O0040 O0050

O1969 O1224

> S 0 T

03:04:17

[ PRGRM ] [ CONDNS ] [ ] [ ] [ C.A.P. ]

OUTPT

START

OFFSET O1224 N0000

NO. DATA NO. DATA

001 009 0.000

002 0.000 010 12.269

003 5.000 011 10.230

004 0.000 012 –11.265

005 12.580 013 –8.562

006 0.000 014 0.000

007 0.000 015 0.000

008 0.000 016 0.000

ACTUAL POSITION (RELATIVE)

X 0.000 Y 0.000

Z 0.000

NO. 013 = S 0 T

03:22:13 MDI

[ OFFSET ] [ MACRO ] [ MENU ] [ WORK ] [ TOOLLF ]

1

2

3

4

5

6

7

Conversational mode data output

[M series]

1 Select the EDIT mode.

MENU

OFSET

2 Press the

data screen.

3 Press the

key several times to select the conversational mode

OUTPT

key, and output begins.

START

8

9

10

30

Page 32

2. CRT/MDI OPERA TION

CNC parameter input

1 Set setting data PWE to 1 (page 2 of the parameter screen).

PARAMETER O1224 N0000

(SETTING 2)

_PWE = 1 (0:DISABLE 1:ENABLE)

REV4 = 0

TAPEF = 0

(SEQUENCE STOP)

This is set in the

MDI mode or at an

emergency stop.

PRGNO = 0

SEQNO = 0

PART TOTA L = 17

PART REQUIRED = 50

PART COUNT = 17

RUN TIME OH 4M CYCLE TIME OH OM 2S

NO. PWE = S 0 T

03:35:07 MDI

[ PARAM ] [ DGNOS ] [ ] [ SV–PRM ] [ ]

NOTE Alarm P/S100 occurs at this point. Press the

DGNOS

PARAM

key again to

cause the parameter screen to appear.

2 Select the EDIT mode.

* Release the emergency stop condition.

3 Press the

INPUT

key, and input begins.

* Alarm P/S000 occurs at this point. Turn the CNC power off and on

again.

* If you want to enter parameters during the emergency stop state,

press and hold down the

Key, then press the

EOB

INPUT

Key. In

this case, it is not necessary to select the EDIT mode.

NOTE It is impossible to enter parameter Nos. nine hundreds (900 to 999).

PMC parameter input

1 Select the EDIT mode.

2 Locate the beginning of the file.

3 Disable program protection (KEY=1).

4 Turn to 1 at setting parameter PWE.

DGNOS

5 Press the

key several times to select the DGNOS (diagnose)

PARAM

screen.

INPUT

6 Press the

key, and input begins.

NOTE PWE should be 1 in case of parameter 393#7=0.

Program input

1 Select the EDIT mode.

2 Locate the beginning of the file.

3 Disable program protection (KEY=1).

PRGRM

4 Press the

times to select the program

screen.

key several

PROGRAM O1224 N0000

SYSTEM EDITION 0466 – 25

PROGRAM NO. USED : 14 FREE : 49

MEMORY AREA USED : 275 FREE : 3820

PROGRAM LIBRARY LIST

O0010 O2000 O0020 O0030 O0200 O0300

O0555 O1200 O0777 O1234 O0040 O0050

O1969 O1224

> S 0 T

03:04:17

[ PRGRM ] [ CONDNS ] [ ] [ ] [ C.A.P. ]

31

Page 33

5 Press the

INPUT

key, and input begins.

* When only one program is entered.

6 Key in address O.

7 Key in the target program number.

8 Press the

INPUT

key, and input begins.

Offset input

1 Select the EDIT mode.

2 Locate the beginning of the file.

3 Disable program protection (KEY=1).

MENU

OFSET

4 Press the

times to select the offset

screen.

key several

OFFSET O1224 N0000

NO. DATA NO. DATA

001 009 0.000

002 0.000 010 12.269

003 5.000 011 10.230

004 0.000 012 –11.265

005 12.580 013 –8.562

006 0.000 014 0.000

007 0.000 015 0.000

008 0.000 016 0.000

ACTUAL POSITION (RELATIVE)

X 0.000 Y 0.000

Z 0.000

NO. 013 = S 0 T

03:22:13 MDI

[ OFFSET ] [ MACRO ] [ MENU ] [ WORK ] [ TOOLLF ]

1

2

3

4

5

5 Press the

INPUT

key, and input begins.

Conversational mode data input

[M series]

1 Select the EDIT mode.

2 Locate the beginning of the file.

3 Disable program protection (KEY=1).

PRGRM

4 Press the

5 Key in address 0.

6 Key in any program number.

7 Press the

8 Select the AUTO mode.

9 A program entered before is executed.

* Be cautious about the following parameter.

PRM, No. 015

CAUTION

When a decimal point is omitted from an address in which it can be

used:

1 : mm, inch, and s units (usually)

0 : Least input increment (at data input time)

key several times to select the program list screen.

INPUT

key, and input begins.

Caution

*******

6

7

8

9

10

32

Page 34

2. CRT/MDI OPERA TION

Function

Parameters related to data input/output

To use the FANUC floppy cassette, set the parameters as follows:

Setting: I/O = 0 (Note)

Parameter: ISO = 1

PRM, No. 002

1****0*1

PRM, No. 552

PRM, No. 010

10 (4800BPS)

* * * Note * * * *

NOTE1 1 : Protects program numbers 9000s (9000 to 9999).

0 : Enables editing of program numbers 9000s (9000 to 9999).

PRM, No. 038

0 1 * * Note * * *

NOTE2 1 : A full keyboard is used.

0 : A standard keyboard is used.

NOTE3 I/O = selects a device used for data input/output through a reader/

punch interface.

Related parameter No.

I/O=0 I/O=1 I/O=2 I/O=3

Feed (NFED) 2.7 12.7 50.7 51.7

20 mA current loop

(ASR33)

Stop bit (STP2) 2.0 12.0 50.0 51.0

I/O device model

specification

Baud rate 552 553 250 251

Connector number

2.2 12.2 Unusable

38.7

38.6

M5

Channel 1M5Channel 1

38.7

38.6

38.5

38.4

M74

Channel 2

38.2

38.1

M77/M73

Channel 3

For M77, either RS–232–C or RS–422 can be selected by parameter No.

55.3.

The connector number is M73 when RS–422 is used with an external clock.

33

Page 35

Displaying the directory of floppy disk files

1

Press the EDIT switch on the machine operator’s panel.

2

Press function

3

Press soft key [FLOPPY].

4

Press page key or .

5

The screen below appears.

PRGRM

key .

1

2

DIRECTORY (FLOPPY)

NO. FILE NAME

0001 PARAMETER

0002 ALL. PROGRAM

0003 O0001

0004 O0002

0005 O0003

0006 O0004

0007 O005

0008 O0100

0009 O0555

19:36:51 EDIT

SRHFIL

[][][][][]

6

Press a page key again to display another page of the directory.

READ PUNCH DELETE

O0555 N0000

(METER) VOL

65.6

1.9

1.3

1.3

1.3

1.3

1.3

1.9

1.3

S0 T

Reading files

1

Press soft key [READ] after directry is displayed.

DIRECTORY (FLOPPY)

NO. FILE NAME

READ

_FILE NO. = PROGRAM NO. =

NUM. S 0 T

19:38:35

EXEC

[][][][][]

CAN STOP

O0555 N0000

(METER) VOL

EDIT

3

4

5

6

7

8

9

2

Enter a file number, then press function

3

T o modify the program number , enter the program number , then press

function

4

Press soft key [EXEC].

5

Press soft key [CAN] to return to the soft key display shown in

the screen of directory display.

INPUT

key.

INPUT

key .

10

34

Page 36

2. CRT/MDI OPERA TION

Outputting programs

1

Press soft key [PUNCH] after directry is displayed.

DIRECTORY (FLOPPY)

NO. FILE NAME

PUNCH

_FILE NO. = _ PROGRAM NO. =

NUM. S 0 T

19:39:17

[][][][][]

2

Enter a program number. To write all programs into a single file, enter

PRG–NOEXEC

CAN STOP

O0555 N0000

(METER) VOL

EDIT

–9999 in the program number field. In this case, the file name

“ALL.PROGRAM” is registered.

Then press function

3

Press soft key [EXEC].

4

Press soft key [CAN] to return to the soft key display shown in

INPUT

key.

the screen of directry display.

Deleting files

1

Press soft key [DELETE] after directry is displayed.

DIRECTORY (FLOPPY)

NO. FILE NAME

O0555 N0000

(METER) VOL

DELETE

_FILE NO. =

NUM. S 0 T

19:39:56

EXEC

[][][][][]

2

Specify the file to be deleted.

CAN STOP

EDIT

When specifying the file with a file number, type the number and

press function

3

Press soft key [EXEC].

4

Press soft key [CAN] to return to the soft key display shown in

INPUT

key.

the screen of directry display.

35

Page 37

Procedure for changing the file name

1

Press soft key [RENAME] after directry is displayed.

2

Position the cursor to FILE NO. then enter the number of the file whose

name is to be changed. Press the

3

Position the cursor to NAME and key in a new file name. Then, press

INPUT

the

4

Press soft key [EXEC].

5

To return to the previous screen, press the [CAN] soft key.

FILE DIRECTORY

NO. FILE NAME

0001 PARAMETER 87.1

0002 ALL.PROGRAM 87.1

0003 O0001 1.9

0004 O0021 7.1

0005 O0041 7.1

0006 O0615 5.8

0007 O0651 9.1

0008 O0601 7.1

0009 O0645 5.8

RENAME

[][][][][]

key.

FILE NO. = NAME=

NUM. S 0 T0101

21:59:53 EDIT

EXEC

CAN STOP

INPUT

key.

O0001 N0000

(METER) VOL

1

2

3

4

5

6

36

7

8

9

10

Page 38

3. OPERATION LIST

Reset

Classifi-

cation

Registration

from MDI

Registration

from NC

tape

SET-

KEY

Function

Resetting of operating time

Resetting of number of machined parts

Resetting of OT alarm At power–up

Resetting of alarm 100 —

Parameter input f MDI mode

Offset input —

Setting data input MDI mode

PMC parameter input

Tool length measurement JOG mode

Parameter input (NC tape

→ memory)

PMC parameter input

Offset input EDIT mode

Program registration f

SW

f

f

TING

PWE=1

f

MDI mode

f EDIT mode

f —

EDIT mode

f

EDIT/AUTO

Mode

—

—

mode

Tape punch

out

37

Parameter punch out EDIT mode

PMC parameter punch out EDIT mode

Offset punch out EDIT mode

All programs punch out EDIT mode

One program punch out EDIT mode

Page 39

Func-

tion

key

POS

R CAN

→

Operation

1

POS

—

—

PARAM

OFSET

PARAM

DGNOS

POS →

OFSET

PARAM

PARAM

DGNOS

OFSET

P CAN

→

P CAN

AND

CAN RESET

AND

No.

Parameter number →→ → Data →

→PWE =0 →

No.

No. 0

No.

POS Z

OFSET

→

→ Offset number →

INPUT

Emergency stop →

INPUT

INPUT

RESET

→ Offset number → → Offset value→

→

INPUT INPUT

→

→ Diagnostic number → → Data →

(Relative coordinate system display)

→ Place tool in measurement position →

INPUT

EOB

INPUT INPUT

INPUT INPUT

→ Data →

INPUT INPUT

EOB Z

→

AND

AND

INPUT

2

3

4

5

CAN

→

No.

6

7

8

PRGRM

PARAM

DGNOS

OFSET

PRGRM

PRGRM

INPUT

OUTPT

OUTPT

OUTPT

O

O

→

OUTPT

–9999 →→

Program number →

9

10

OUTPT

38

Page 40

3. OPERATION LIST

Classifi-

cation

Search

Editing

SET-

KEY

Function

Search for program number

Search for sequence number

Search for address/word EDIT mode

Search for address only EDIT mode

Search for offset number —

Search for diagnostic number

Search for parameter number

Display of memory used EDIT mode

Deletion of all programs f EDIT mode

Deletion of one program f EDIT mode

Deletion of multiple blocks f EDIT mode

Deletion of one block f EDIT mode

SW

TING

PWE=1

Mode

EDIT/AUTO

mode

AUTO mode

—

—

Word deletion f EDIT mode

Word alteration f EDIT mode

Word insertion f EDIT mode

Collation Memory collation

Program registration f

Output of all programs EDIT mode

I/O to and

from

FANUC

Cassette

Output of one program EDIT mode

File head search

File deletion f EDIT mode

Program collation

39

EDIT/AUTO

mode

EDIT/AUTO

mode

EDIT/AUTO

mode

EDIT/AUTO

mode

Page 41

Func-

tion

key

PRGRM

O

Program number →

→

Operation

b

1

(Cursor)

PRGRM

PRGRM

PRGRM

OFSET

DGNOS

PARAM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

DELET

N

b

INPUT

(Cursor)

b

INPUT

INPUT

DELET

DELET

DELET

ALTER

Program number search →→ Sequence number search

(Cursor)

b

→

Data to be searched for →

Address to be searched for → (Cursor)

No.

Offset number →

→

No.

Diagnostic number →

→

Parameter number →

No.

→

PRGRM

O

–9999 →→

O

Program number →

→

O

Sequence number →→

DELET

EOB

→

Search for word to be deleted →

Search for word to be changed → New data →

Search for word immediately before insertion location → New data

INSRT

→

2

3

4

5

6

7

8

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

PRGRM

INPUT

N

File number →

→

O

–9999 →→

O

Program number →

→

N

File number →

→

N

File number →

→

N INPUT INPUT

File number →

→

INPUT INPUT

OUTPT

INPUT

OUTPT

→

OUTPT

→

9

10

40

Page 42

3. OPERATION LIST

Clear

Classifi-

cation

Play–back NC data input

Function

Memory all clear At power–up

Parameter clear f At power–up

Program clear f At power–up

Sub PCB all clear At power–up

KEY

SW

SETTING

PWE=1

Mode

TEACH–IN

JOG/HANDLE

mode

41

Page 43

Func-

tion

key

PRGRM

—

Move machine →

→ NC data →

RESET DELET

AND

Operation

X Y Z

INSRT EOB INSRT

→

or

,

→

1

INSRT

→

2

—

—

—

RESET

DELET

DELET S

AND

3

(However, set PWE on main side to 0.)

4

5

6

7

8

9

10

42

Page 44

4. G CODE LIST

01

00

17

06

04

00

08

00

11

00

M series

G code list (M series) (1/3)

G code Group Function

G00

G01

G02

G03 Circular interpolation/Helical interpolation CCW

G04 Dwell, Exact stop

G05 High speed cycle machining

G08

G09

G10 Data setting

G11 Data setting mode cancel

G15

G16

G17

G18

G19

G20

G21

G22

G23

G27 Reference position return check

G28 Return to reference position

G29 00 Return from reference position

G30 2nd, 3rd and 4th reference position return

G31 Skip function

G33 01 Thread cutting

G37

G39

G40

G41

G42 Cutter compensation right

G43

G44

G45 Tool offset increase

G46

G47

G48 Tool offset double decrease

G49

G50

G51

G52

G53

Positioning

Linear interpolation

01

Circular interpolation/Helical interpolation CW

Advanced preview control

Exact stop

Polar coordinates command cancel

17

Polar coordinates command

XpYp plane selection Xp: X axis or its parallel axis

02 ZpXp plane selection Yp: Y axis or its parallel axis

YpZp plane selection Zp: Z axis or its parallel axis

Input in inch

Input in mm

Stored stroke check function on

04

Stored stroke check function off

Automatic tool length measurement

Corner offset circular interpolation

Cutter compensation cancel

07

Cutter compensation left

Tool length compensation + direction

Tool length compensation – direction

Tool offset decrease

Tool offset double increase

08 Tool length compensation cancel

Scaling cancel

11

Scaling

Local coordinate system setting

Machine coordinate system selection

43

Page 45

G code list (M series) (2/3)

14

15

12

16

09

01

03

05

13

10

G code Group Function

G54

G55 Workpiece coordinate system 2 selection

G56

G57

G58 Workpiece coordinate system 5 selection

G59 Workpiece coordinate system 6 selection

G60 00 Single direction positioning

G61 Exact stop mode

G62

G63

G64

G65 00 Macro call

G66

G67

G68

G69

G73

G74

G75 01 Plunge grinding cycle (0–GSC)

G76 09 Fine boring cycle

G77

G78

G79 Intermittent–feed surface grinding cycle (0–GSC)

G80

G81

G82 Drilling cycle or counter boring cycle

G83

G84 Tapping cycle

G85 Boring cycle

G86 Boring cycle

G87 Back boring cycle

G88 Boring cycle

G89 Boring cycle

G90

G91

G92 00

G94

G95

G96

G97

G98

G99

G107 00 Cylindrical interpolation

Workpiece coordinate system 1 selection

Workpiece coordinate system 3 selection

14

Workpiece coordinate system 4 selection

Automatic corner override

Tapping mode

Cutting mode

Macro modal call

Macro modal call cancel

Coordinate rotation

Coordinate rotation cancel

Peck drilling cycle

Counter tapping cycle

Direct constant–dimension plunge grinding cycle

(0–GSC)

Continuous–feed surface grinding cycle (0–GSC)

Canned cycle cancel/external operation function cancel

Drilling cycle, spot boring cycle or external operation

function

Peck drilling cycle

09

Absolute command

Increment command

Setting for work coordinate system or clamp at maxi-

mum spindle speed

Feed per minute

05

Feed per rotation

Constant surface speed control

Constant surface speed control cancel

Return to initial point in canned cycle

10

Return to R point in canned cycle

1

2

3

4

5

6

7

8

9

10

44

Page 46

4. G CODE LIST

G code list (M series) (3/3)

G code Group Function

G150

G151

G152 Normal direction control right side on

G160

G161 20 In–feed control function (0–GSC)

CAUTION

1. Multiple G codes of different groups can be specified in a single

block. When multiple G codes of one group are specified in a block,

the G code specified last is effective.

2. If any G code of group 01 is specified in a canned cycle mode, the

canned cycle is automatically cancelled and the G80 condition is

entered. However, a G code of group 01 is not af fected by any of

the canned cycle G codes.

NOTE

1. Modal G codes have the following initial conditions when the power is

turned on or the system is reset to the clear state (bit 6 of parameter No.

045).

1) Those G codes marked in Table 3 are specified automatically.

2) G20 and G21 retain their original conditions.

3) When the power is turned on, G22 is specified automatically. When

the system is reset, G22 and G23 retain their original conditions.

4) G00 or G01 is automatically selected depending on the setting of

bit 6 of parameter No. 011.

5) G90 or G91 is automatically selected depending on the setting of

bit 7 of parameter No. 030.

2. The G codes of group 00, except G10 and G11, are one–shot G codes.

3. If a G code that does not appear in the G code list is specified, or a G

code whose options are not supported is specified, alarm No. 010 is

displayed.

4. A G code is displayed from each group.

Normal direction control cancel mode

19

Normal direction control left side on

20 In–feed control function cancel (0–GSC)

45

Page 47

T series

p

06

09

08

00

01

00

00

14

12

04

G code system

(Note 7)

A B C

G00 G00

G01

G01 G01

G02 G02 G02 Circular interpolation CW

G03 G03 G03 Circular interpolation CCW

G04 G04 G04 Dwell

G10 G10 00 Data setting

G10

G11 G11 G11 Data setting mode cancel

G17 G17 G17 XpYp plane selection

G18

G18 G18

G19 G19 G19 YpZp plane selection

G20 G20 G70

G21 G21 G71

G22

G22 G22

G23 G23 G23

G25

G25 G25

G26 G26 G26

G27 G27 G27 Reference point return check

G28 G28 G28

G30 G30 G30

G31 G31 G31 Skip cutting

G32 G33 G33

G34 G34 G34

G36 G36 G36

G37 G37 G37

G40

G40 G40

G41 G41 G41

G42 G42 G42 Tool nose radius compensation right

G50 G92 G92

G52 G52 G52

G53 G53 G53 Machine coordinate system setting

G54

G54 G54

G55 G55 G55 Workpiece coordinate system 2 setting

G56 G56 G56

G57 G57 G57

G58 G58 G58 Workpiece coordinate system 5 setting

G59 G59 G59 Workpiece coordinate system 6 setting

G65 G65 G65 00 Macro calling

G66 G66 G66

G67

G67 G67

G68 G68 G68

G69 G69 G69

G code list (T series) (1/2)

Group Function

G00

Positioning (rapid traverse)

Linear interpolation (feed)

01

16 ZpXp plane selection

Inch data input

Metric data input

Stored stroke check function ON

09

Stored stroke check function OFF

Spindle speed fluctuation detect OFF

08

Spindle speed fluctuation detect ON

Return to reference point

2nd, 3rd, 4th reference point return

Thread cutting

Variable–lead thread cutting

Automatic tool compensation X

Automatic tool compensation Z

Tool nose radius compensation cancel

07

Tool nose radius compensation left

Coordinate system setting, max. spindle

speed setting

Local coordinate system setting

Workpiece coordinate system 1 setting

Workpiece coordinate system 3 setting

14

Workpiece coordinate system 4 setting

Macro modal call

Macro modal call cancel

Mirror image for double turrets ON or balance

cut mode (0–TTC)

Mirror image for double turrets OFF or bal-

ance cut mode cancel (0–TTC)

1

2

3

4

5

6

7

8

9

10

46

Page 48

4. G CODE LIST

p

01

02

05

03

11

21

G code list (T series) (2/2)

G code system

(Note 7)

A B C

G70 G70 G72

G71 G71 G73

G72 G72 G74

G73 G73 G75 00

G74 G74 G76

G75 G75 G77

G76 G76 G78

G71 G71 G72 Traverse grinding cycle (0–GCC, 00–GCC)

G72 G72 G73

G73 G73 G74

G74 G74 G75

G80

G80 G80

G83 G83 G83 Cycle for face drilling

G84 G84 G84 Cycle for face tapping

G86 G86 G86

G87 G87 G87 Cycle for side drilling

G88 G88 G88 Cycle for side tapping

G89 G89 G89 Cycle for side boring

G90 G77 G20

G92 G78 G21

G94 G79 G24 Endface turning cycle

G96 G96 G96

G97

G97 G97

G98 G94 G94

G99

G95 G95

—

G90 G90

—

G91 G91

— G98 G98

— G99 G99

G107 G107 G107

G112 G112 G112

G113

G113 G113

G250

G250

G251 G251 G251

Group Function

Finishing cycle

(other than 0–GCC or 00–GCC)

Stock removal in turning

(other than 0–GCC or 00–GCC)

Stock removal in facing

(other than 0–GCC or 00–GCC)

Pattern repeating

(other than 0–GCC or 00–GCC)

Peck drilling on Z axis

(other than 0–GCC or 00–GCC)

Grooving on X axis

(other than 0–GCC or 00–GCC)

Multiple threading cycle

(other than 0–GCC or 00–GCC)

Traverse direct constant dimension grinding

cycle (0–GCC, 00–GCC)

01

Oscillation grinding cycle

(0–GCC, 00–GCC)

Oscillation direct constant–dimension grinding cycle (0–GCC, 00–GCC)

Canned cycle for drilling cancel

10

Cycle for face boring

Outer diameter/internal diameter cutting

cycle

Thread cutting cycle

Constant surface speed control

Constant surface speed control cancel

Per minute feed

Per revolution feed

Absolute programming

03

Incremental programming

Return to initial level

Return to R point level

00 Cylindrical interpolation

Polar coordinate interpolation mode

G250

Polar coordinate interpolation cancel mode

Polygonal turning cancel

20

Polygonal turning

47

Page 49

CAUTION

1. A number of G codes can be specified in the same block. When

more than one G code of the same group is specified, the G code

specified later is effective.

2. If any G code of group 01 is specified in a canned cycle mode, the

canned cycle is automatically cancelled and the G80 condition is

entered. However a G code of group 01 is not affect4ed by any of

the canned cycle G codes.

NOTE

1. G codes marked

For G20 and G 21, the G code before turning power off remains. G00

or G01 can be selected by parameter setting.

2. G codes of group 00 are not modal. They are only effective in the block

in which they are specified.

3. If a G code not listed on the table of G codes is inputted, or optional G

code not specified in the system is commanded, an alarm (No. 010) is

displayed.

4. A G code is displayed from each group.

5. G code system B and C are options. Whether G code system B or C is

set by parameter No. 0036: GSPC.

are initial G codes when turning power on.

1

2

3

4

5

6

7

48

8

9

10

Page 50

5. PROGRAM FORMAT

Functions Explanation

Positioning (G00)

Start point

Linear interpolation

(G01)

Start point

Circular interpolation

(G02, G03)

P

P

Start point

Helical cutting

(G02, G03)

Center

(x, y)

Center

Start

point

R

J

I

G03

R

I

Z

G02

Start point

J

End point

End point

(x, y)

Tool path

YX

49

The feedrate along the circumference

of two circular interpolated axes is the

specified feedrate.

Page 51

G00P__ ;

Tape format

T

seriesMseries

f f

1

G01P__ ;

G02 R__

G17 Xp__Yp__ F__ ;

G03 I__J__

G02 R__

G18 Xp__Zp__ F__ ;

G03 I__K__

G02 R__

G19 Yp__Zp__ F__ ;

G03 I__K__

Synchronously with arc of XpYp plane

G02 I__J__

G17 Xp__Yp__ α__ F__ ;

G03 R__

Synchronously with arc of ZpYp plane

G02 I__K__

G18 Xp__Zp__ α__ F__ ;

G03 R__

Synchronously with arc of YpZp plane

G02 J__K__

G19 Yp__Zp__ α__ F__ ;

G03 R__

Any one axis where circular interpolation is

not applied.

f f

2

f f

3

4

5

6

f

7

8

9

10

50

Page 52

5. PROGRAM FORMAT

Functions Explanation

Dwell (G04) (Example)

G04 P1000; Dwell by 1 seconds

Exact stop

(G04, G09)

High-speed cycle

machining (G05)

High-speed remote

buffer A (G05)

Speed

Time

(Example)

Cycle 1: connection 2, repetition 1

Cycle 2: connection 3, repetition 3

Cycle 3: connection 0, repetition 1

G05P10001L2;

Cycle is executed as 1, 2, 2, 2, 3, 1, 2, 2, 2, 3

Specify G05 only in a block using normal NC

command format. Then specify move data in the

special format explained next page. When zero is specified as the travel distance along all axes, normal NC

command format can be used again for

subsequent command specification.

High-speed remote

buffer B (G05)

Advanced preview

control (G08)

51

High-speed remote buffer A uses binary data.

On the other hand, high-speed remote buffer B can directly use NC language coded with equipment such as

an automatic programming unit to perform

high-speed machining.

This function can minimize the delay caused by acceleration/deceleration, which increases together with the

feedrate, as well as the delay in the servo system. Tool

movement can thus faithfully follow the command values, reducing the degree of error in the machined figure.

Page 53

Tape format

X__

G04 ; Dwell by second

P__

G04 ;

G09

P

;

T

seriesMseries

f f

f

1

2

3

G05 P10 ×××L∆∆∆ ;

××× : Start program number of called programs

∆∆∆: Repetition time of machining cycle

⋅Binary input operation enabled: G05;

⋅Binary input operation disabled: The travel distance along

⋅Data format for binary input operation

Data

sequence

All data must be specified in binary.

G05P01; Start high-speed machining

X__Y__Z__;

G05P00; End high-speed machining

Byte

High byte

Low byte

High byte

Low byte

:

:

High byte

Low byte

Check byte

all axes are set to zero.

1st axis

2nd axis

Nth axis

f f

f f

4

5

6

7

8

f

9

G08 Pp;

p=1: Advanced preview control mode on

p=0: Advanced preview control mode off

f

10

52

Page 54

5. PROGRAM FORMAT

Functions Explanation

Change of offset value by

program (G10)

Change of offset value by

program (G10)

The tool compensation amount can be set or changed

with the G10 command.

When G10 is used in absolute input (G90), the

compensation amount specified in the command

becomes the new tool compensation amount.

When G10 is used in incremental input (G91), the

compensation amount specified in the command is

added to the amount currently set.

Change of parameter by

program (G10)

Polar coordinate

command mode

(G15, G16)

XpYp plane selection

(G17)

ZpXp plane selection

(G18)

YpZp plane selection

(G19)

Inch/metric conversion

(G20, G21)

Extended stored stroke

limit check on

(G22, G23)

The parameter value can be changed by the

machining program.

Y

x

y

Y

G17

(I, J, K)

X

X

G18 G19

Z

Z

(X, Y, Z)

X>I, Y>J, Z>K

X

Y

53

Page 55

Tape format

G10P__X (U)__Y (V)__Z (W)__R (C)__Q__;

For geometry offset amount

P=10000+geometry offset number

For offset amount

P= wear offset number

R : Tool nose radius offset value

Q : Imaginary tool nose number

T

seriesMseries

f

1

2

G10L__PpRr;

p : Offset No.

r : T ool compensation amount

Format

(1) For tool compensation memory A

G10 L11 P__R__;

(2) For tool compensation memory B

Setting/changing the geometric compensation amount

G10 L10 P__R__;

Setting/changing the wear compensation amount

G10 L11 P__R__;

G10 L50 ;

N__P__ ;

G11

N : Parameter number

P : Parameter value

G16 ; Polar coordinate command

Xx

Yy ;

x: radius, y: angle (*)

G15 ; Polar coordinate command cancel

G17 ;

G18 ;

G19 ;

G20 ; Inch input

G21 ; Metric input

G22X__Y__Z__I__J__K__ ; on

G23 ; off

(X, Z, I and K only for T series)

f f

f f

f f

f f

f

3

4

5

f

6

7

8

9

10

54

Page 56

5. PROGRAM FORMAT

Functions Explanation

Spindle speed

fluctuation detection

on (G26)

Spindle speed

fluctuation detection

off (G25)

(Example)

(1) When an alarm is raised after a specified spindle speed is reached

Spindle speed

Reference for spindle speed at which

check is started

Specified

r

speed

Fluctuation at which

alarm is raised (r)

Check

Specification of

another speed

(2) When an alarm is raised before a specified spindle speed is

reached

Spindle speed

Specification of

another speed

Reference position

return check (G27)

Spindle speed specified by q

q

Check

No check

Alarm

Start of check

Spindle speed specified by r

P

No check

Start of check

Start point

CheckCheck

Alarm

Actual speed

(detected by position

coder)

Time

r

Actual

speed

Time

Reference position

Specified

speed

P

55

Page 57

Tape format

G26PpQqRr ; spindle fluctuation detection on

p: Time (in ms) from the issue of a new spindle rotation

command (S command) to the start of checking whether

the actual spindle speed is so fast that an overheat can

occur. (When a specified speed is reached within the time

period of P, a check is started at that time.)

q: Tolerance (%) of a specified spindle speed (If a specified

spindle speed lies within this range, it is regarded as

having reached the specified value. Then, the checking

of an actual spindle speed is started.)

q = (1 – actual spindle speed/specified spindle speed)

× 100

r: Spindle speed fluctuation (%) at which the actual spindle

speed is so fast that an overheat can occur

r = (1 – speed that can cause overheat/specified spindle

speed) × 100

G26 enables the spindle speed fluctuation detection

function, and G25 disables the spindle speed fluctuation

detection.

G25 ; Spindle fluctuation detection off

T

seriesMseries

f

1

2

3

4

5

6

G27P__ ;

7

8

9

10

f f

56

Page 58

5. PROGRAM FORMAT

F: Lead

Functions Explanation

Reference position

return (G28)

2nd, 3rd, 4th reference

position return (G30)

Reference poisition

Intermediate point

P

Start point

Return to reference

position return start

position (G29)

Skip function (G31)

Multi-step skip function

(G31)

Equal lead thred cutting

(G32)

Thread cutting (G33)

Variable lead thread

cutting

Automatic tool compensation (G36, G37)

Reference position

Start point

Starting point

Specified position

(Xa or Za)

Intermediate position

Skip signal

Measured position

reach signal

Offset value set

by this command

P

P

Measured

position

57

Page 59

G28P__ ;

P2

G30 P3

P4

G29P__ ;

Tape format

P2: 2nd reference position return

P

__ ;

P3: 3rd reference position return

P4: 4th reference position return

T

seriesMseries

f f

f

1

2

3

G31P__F__ ;

Move command

G31

P

__F__P__;

F__: Feedrate

P__: P1-P4

Dwell

G04X (U, P)__(Q__);

X(U, P)__: Dwell time

Q__: Q1-Q4

G32P__F__ ;

G33P__F__ ;

G34P__FfKf ;

f: Longer axis lead at the start position

k: increase/decrease value per spindle revolution

G36X xa ;

G37Z za

;

X xa, Z za: Specified position

f f

GCC

f

f

f

4

5

f

6

7

8

9

10

58

Page 60

5. PROGRAM FORMAT

ÇÇ

ÇÇ

Functions Explanation

Automatic tool length

measurement (G37)

Tool nose radius

compensation

(G40, G41, G42)

Cutter compensation B

(G39 to G42)

Cutter compensation

(G40 to G42)

Tool length

compensation A, B, C

(G43, G44, G49)

Z

Rapid

traverse

Measurement

feedrate

0

Compensation value = (Current compensation value)

+ [(Coordinates of the point at which the tool is

stopped) – (Coordinates of the programmed

measurement position)]

G40

G40 : Programmed path

G41 : Left of programmed path

G42 : Right of programmed path

G40

G40 : Programmed path

G41 : Left of programmed path

G42 : Right of programmed path

A (Start position)

Measurement position is

commanded with G37

B (Deceleration position)

C (Measurement position)

The tool stops when the

approach end signal

goes on.

X

G41

G42

G41

G42

59

G43: + offset

G44: – offset

Offset

Z

Page 61

Tape format

G92P__;Sets the workpiece coordinate system. (It can be

set with G54 to G59.)

Hff; Specifies an offset number for tool length offset.

G90 G37P__; Absolute command

⋅G37 is valid only in the block in which it is

specified.

P__ indicates the X-, Y-, Z-, or fourth axis.

T

seriesMseries

f

1

2

3

G40

G41

P

G42

G39X(I)__Y(J)__ ;

Corner offset circular interpolation

(Cutter compensation B only)

G17 G40

G18 G41 D(H)__ ;

G19 G42

D(H): Tool offset number

G43

G44

G17 X__

G18 Y__ H__ ;

G19 Z__

G43 α__H__ ; Tool length compensation C

G44

H: Offset number

α: Arbitrary one axis

G49 ; T ool length compensation cancel

__ ;

(Z__)H__ ; T ool length compensation A

G43

G44

Tool length compensation B

f

4

5

f

6

7

f

8

9

10

60

Page 62

5. PROGRAM FORMAT

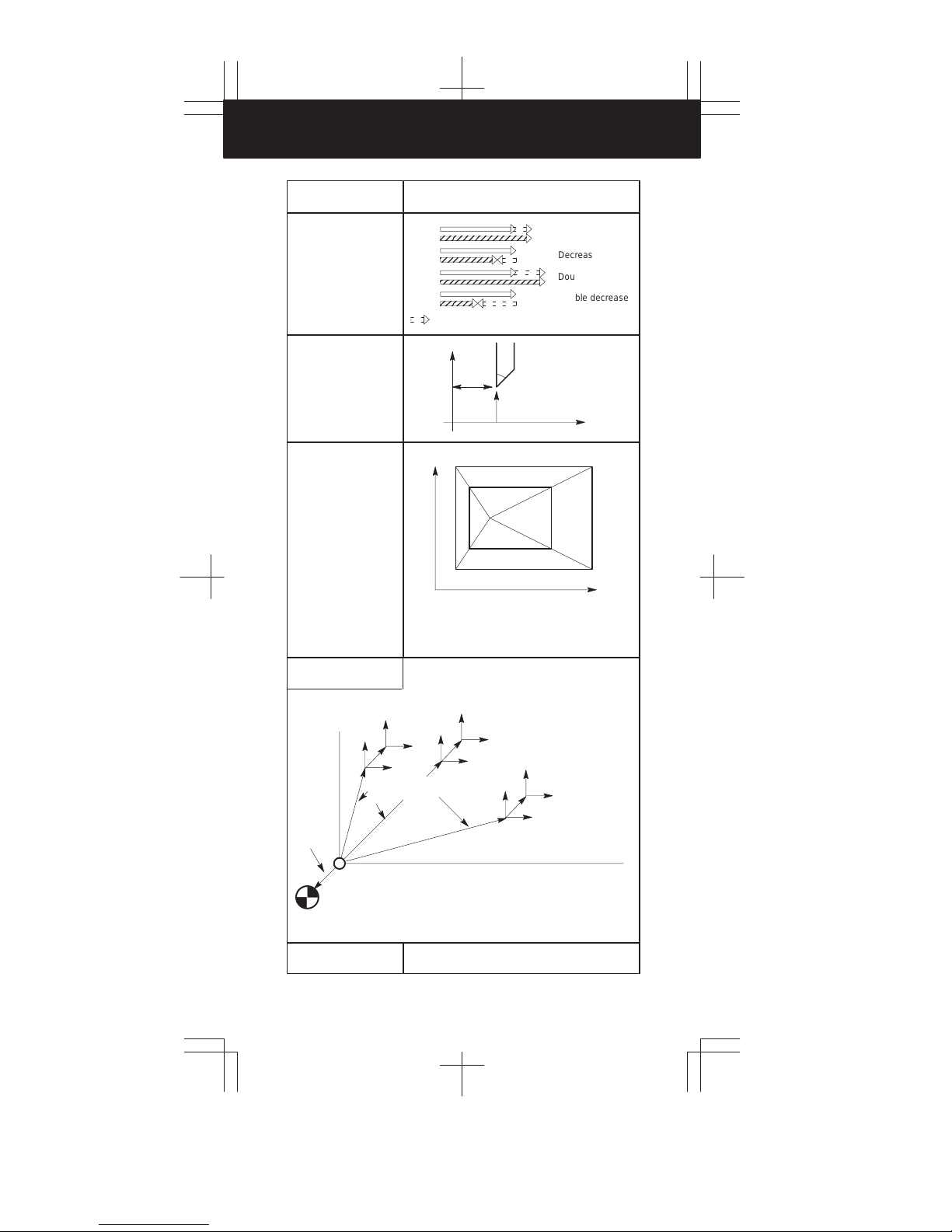

Functions Explanation

Tool offset

(G45 – G48)

Coordinate system

setting

Spindle speed setting

(G50)

G45

G46

G47

G48

: offset value

X

Increases

Decrease

Double increase

Double decrease

P

Z

Scaling (G50, G51)

Local coordinate

system setting (G52)

(Parameter

value)

(Origin of the machine coordinate system)

(Reference position)

P

P

to P4: Programmed shape

1

P

’ to P4’: Scaled shape

1

P0: Scaling center

(Local coor-

dinate system)

(Workpiece

coordinate

system 1:

G54)

(Workpiece reference

position offset)

P

(Machine coordinate system)

P3’

P

3

4

P4’

P

0

P2’

P1’

P

1

(Local coordinate

system)

P

2

(Workpiece coordinate system 2:G55)

(Workpiece

coordinate system)

P

(Workpiece coordinate

system 6:G59)

Machine coordinate

system selection (G53)

61

Page 63

Tape format

G45 (increase)

G46 (decrease)

G47 (double increase)

G48 (double decrease)

X__

Y__ Dxx ;

Z__

T

seriesMseries

f

1

2

G50X__Z__ ; Coordinate system setting

G50S__ ; Spindle speed setting

G51X__Y__Z__P__(or I__J__K__) ;

G50 ; Cancel

X, Y, Z: Scaling center

P: Magnification

(I, J, and K are the scaling magnifications for the X-, Y-, and

Z-axes respectively.)

G52P__ ; Local coordinate system setting

G52

P

0 ; Local coordinate system cancel

f

3

4

f

5

6

7

f f

8

9

G53P__ ;

10

f f

62

Page 64

5. PROGRAM FORMAT

Functions Explanation

Work coordinate

system 1 – 6

selection

(G54 – G59)

Workpiece

coordinate

system 1

ZOFS1: Reference position offset for workpiece coordinate system 1

ZOFS2: Reference position offset for workpiece coordinate system 2

ZOFS3: Reference position offset for workpiece coordinate system 3

ZOFS4: Reference position offset for workpiece coordinate system 4

ZOFS5: Reference position offset for workpiece coordinate system 5

ZOFS6: Reference position offset for workpiece coordinate system 6

Additioonal work

coordinate system

selection (G54P)

Spindle direction

positioning (G60)

Exact stop mode (G61)

Workpiece

coordinate

system 2

ZOFS2 ZOFS3 ZOFS4

ZOFS1

Machine reference

position

(Example)

G54P12 ;

Selecting additional work coordinate system 12

Start point

End point

End point

Speed

Workpiece

coordinate

system 3

ZOFS5

ZOFS6

Overrun

Workpiece

coordinate

system 4

Workpiece