Page 1

g

GEH-3908F

GE

INSTRUCTIONS

Lighting Solutions

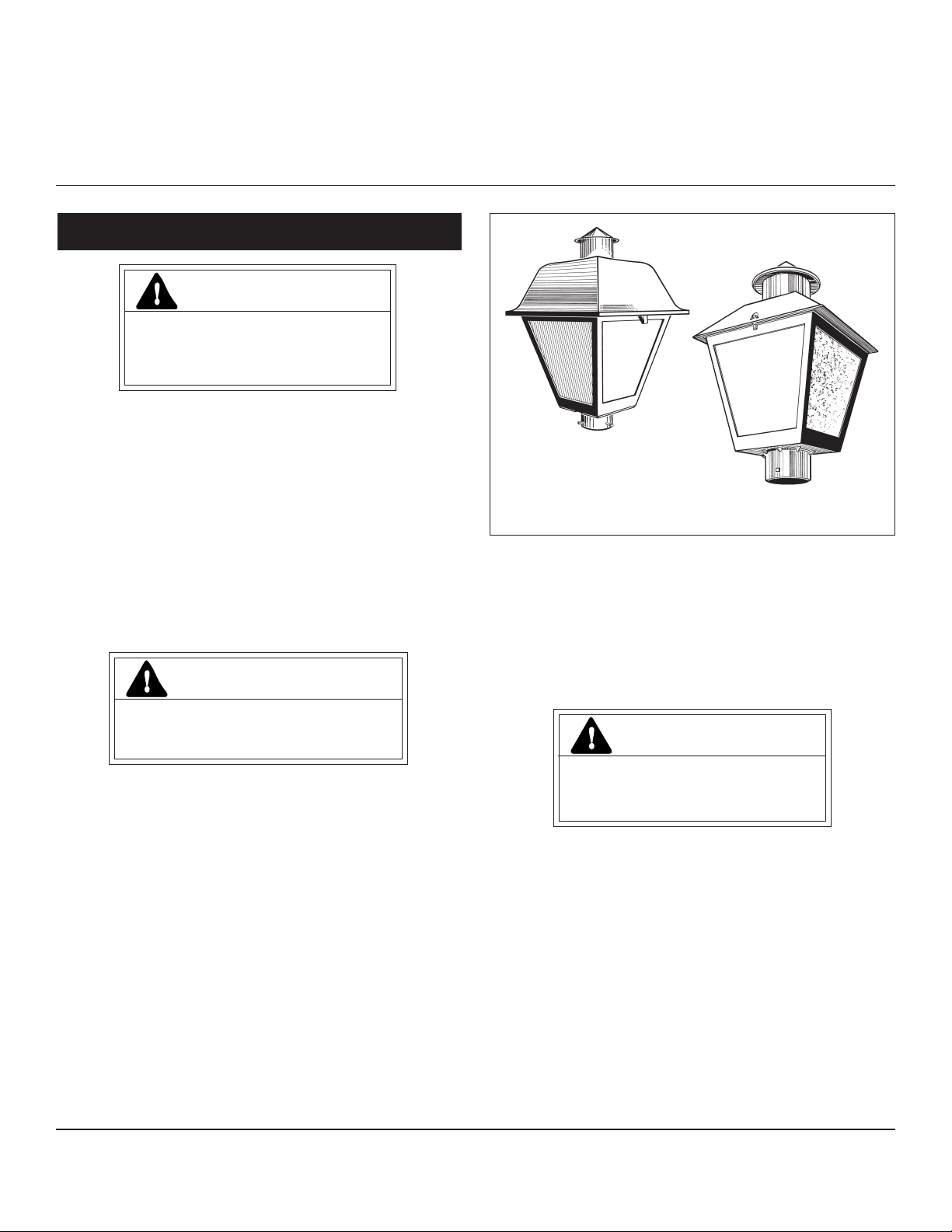

Town and Country,

READ THOROUGHLY BEFORE INSTALLING

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

GENERAL

This luminaire is designed for outdoor lighting service,

and should not be used in areas of limited ventilation, or in

high ambient temperature enclosures. Best results will be

obtained if installed and maintained according to the

following recommendations.

UNPACKING

This luminaire has been properly packed so that no parts

should have been damaged during transit. Inspect to

confirm.

MOUNTING

Salem

Salem

TRCR

TR1C and TR1R

Loosen the captive screw or release the latch which holds

down the canopy, tilt canopy back toward the house side.

Connect power supply leads to the luminaire leads provided

or to the optional terminal board.

NOTE: Connect ground lead to the green ground

screw on the housing or terminal block.

Luminaires

Town and Country

T10C and T10R

™

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

This luminaire is provided with means for mounting on

3.000'' max. outside diameter pole tops.

Feed the power supply leads through the slipfitter wire

access hole as the fixture is installed on the pole.

Orient canopy screw or latch toward street and level by

adjusting the three screws, and tighten.

(CAUTION: Tighten screws to 15 - 20 foot pounds

torque.)

WIRING

NOTE: Make all electrical connections in accordance

with the National Electrical Code and any applicable

local code requirements.

NOTE: Verify that supply voltage is correct by

comparing it to nameplate.

120/240 VOLT field RECONNECTABLE ballasts are

factory connected for 120 volt supply. For 240 volt operation, rewire per attached wiring tag.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

LAMP INSTALLATION – HID

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

NOTE: Use only lamps specified on nameplate.

Observe lamp manufacturer’s recommendations

and restrictions on lamp operation, particularly

ballast type, burning position, etc.

Damage may occur to the fixture if the lamp is inserted

while the power is on, or if the lamp is not tight in the

socket when the power is applied.

Lamp Tightness Mogul Base Lamp: The lamp should be

securely inserted to the NEMA-EEI specified torque of 35

inch-pounds, which is best achieved by very firmly tightening to insure application of sufficient torque. Tightening

must be sufficient to fully depress and load the center

contact of the socket.

Page 2

LAMP INSTALLATION –

INDUCTIVE TECHNOLOGY LAMP

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

NOTE: Use only lamps specified on nameplate.

Observe lamp manufacturer’s recommendations

and restrictions on lamp operation, particularly

ballast type, burning position, etc.

Damage may occur to the fixture if the lamp is inserted

while the power is on.

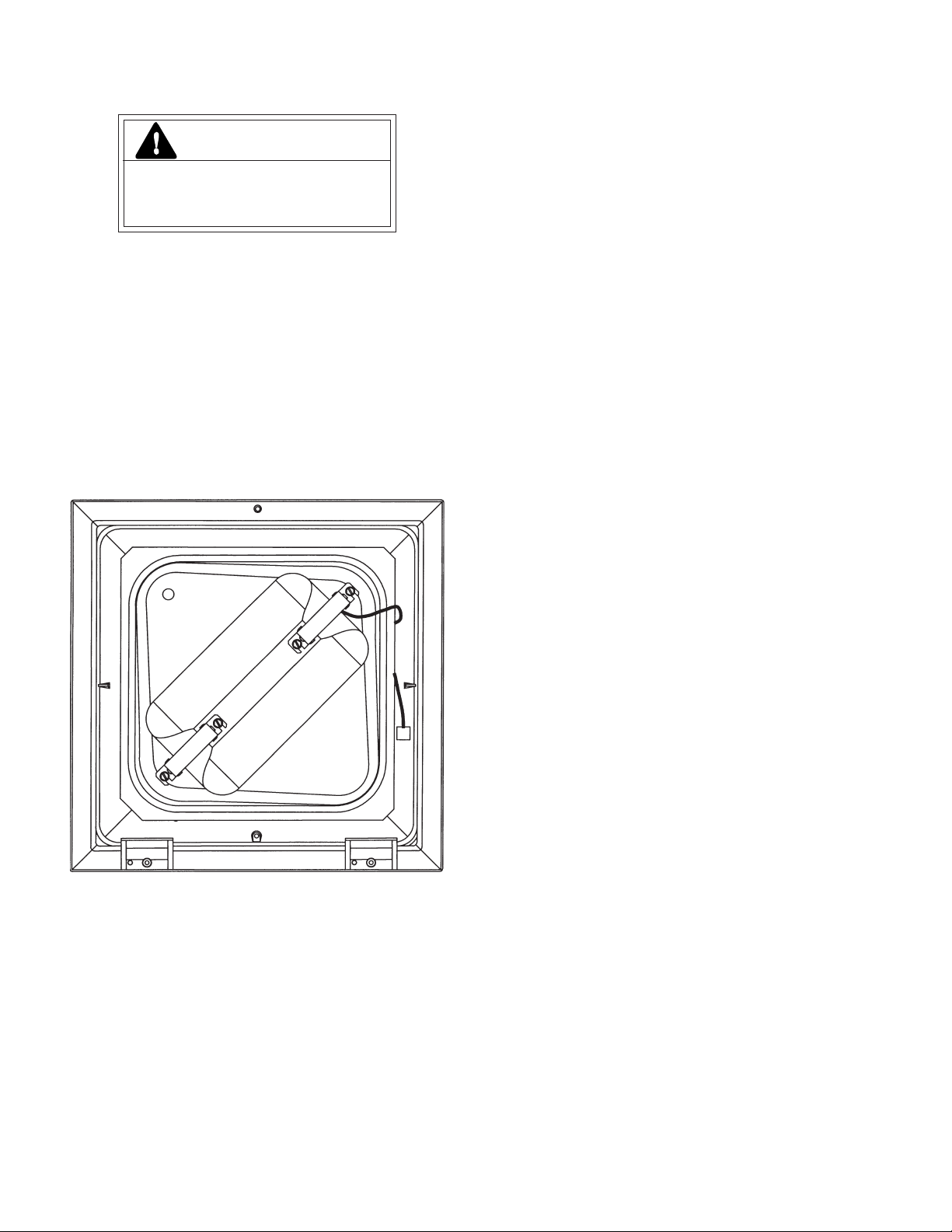

The inductively coupled electrodeless lamps are factory

supplied with the lamp installed. To replace the lamp,

remove the four screws holding the mounting brackets to

the reflector (Figure 1). Disconnect the lamp wiring

harness and attach the new lamp. Secure the new lamp with

the four screws through the mounting bracket and close the

fixture. Use one of the following lamps: OSI 26100 or

OSI 26101.

PHOTOELECTRIC CONTROL

When a photoelectric control is used, the photoelectric

receptacle should be oriented so that the word “North’’ is

directed toward the true north direction. This can be easily

done by seating a photoelectric control into the receptacle,

lifting upward on the photoelectric control (which will lift

the photoelectric receptacle also), and rotating them

clockwise until the word “North’’ is directed toward the true

north direction. Lower the photoelectric control and

receptacle to firmly seat them into position. No tools are

required to make this orienting adjustment.

Alternatively, the photoelectric receptacle can be oriented before the photoelectric control is installed. This is

done by lifting up on the rim of the photoelectric receptacle

and rotating it until the word “North’’ is directed toward

the true north direction. Lower the photoelectric receptacle

to firmly seat it in this position. Install the photoelectric

control.

Because of the shielding of the cupola window by the

cupola top it may be necessary to adjust for an earlier turnon time of the photoelectric control.

ONE PIECE REFRACTOR REPLACEMENT

To remove a textured refractor on this luminaire, loosen

the canopy captive screw or latch and tilt back the canopy.

Remove the refractor assembly unit. To replace refractor

reverse this procedure.

Figure 1

FOUR PIECE REFRACTOR REPLACEMENT

To replace a prismatic refractor on this luminaire,

loosen the canopy captive screw or latch and tilt back the

canopy. Disconnect the photoelectric receptacle plug and

unclip the leads form the house side panel. Remove the

refractor panels as a unit. Release the defective panel from

the tongue and groove. To replace the assembly reverse this

procedure.

MAINTENANCE AND CLEANING

WARNING: MAKE CERTAIN POWER IS OFF

BEFORE ATTEMPTING ANY MAINTENANCE.

It will occasionally be necessary to clean the optical parts

in order to maintain the light level. Frequency of cleaning

will depend on the dirt level in the area and the minimum

light level which is acceptable. Wash with non-abrasive

soap, cleaner or detergent solutions and rinse with cool

water.

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

35-201578-E9 (8/01)

Loading...

Loading...