GE SEER Light, SEER Light Extend Ambulatory Recorder, SEER Light Extend Ambulatory Controller, SEER Light Connect Device Service Manual

Page 1

SEER® Light

Ambulatory Recorder/Controller

Service Manual

Software Version 1

2019818-008 Revision B

Service Instructions for:

SEER Light/SEER Light Extend Compact Digital Holter Recorder

SEER Light/SEER Light Extend Controller

SEER Light Connect

Page 2

NOTE: The information in this manual only applies to SEER Light devices software version 1. It does not

apply to earlier software versions. Due to continuing product innovation, specifications in this manual are

subject to change without notice.

Marquette®, MARS®, MUSE®, and SEER® are trademarks owned by GE Medical Systems Information

Technologies, a General Electric Company going to market as GE Healthcare. All other marks are owned by

their respective owners.

© 2005 General Electric Company. All rights reserved.

T-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008 15 July 2005

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Disposal of the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Information Technology Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2 SEER Light/SEER Light Extend Recorder . . . . . . . . . . . 2-1

Component Names and Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Self-Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

No Buzzer Sound After Installing the Batteries . . . . . . . . . . . . . . . . . . . . . . .2-6

Beep Sound Will Not Stop After Installing the Batteries . . . . . . . . . . . . . . . .2-7

ECG Cannot Be Previewed with Controller (I.R.) . . . . . . . . . . . . . . . . . . . . .2-8

ECG Cannot be Previewed with Controller (Cable) . . . . . . . . . . . . . . . . . . . .2-9

ECG Cannot Be Previewed with SEER Light Connect Device . . . . . . . . . .2-10

Recording Cannot Start with the Controller (I.R.) . . . . . . . . . . . . . . . . . . . .2-11

Recording Cannot Start with the SEER Light Connect Device . . . . . . . . . .2-12

Cannot Start by Pressing the Start Button . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Cannot Record for 24 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Cannot Record for 48 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Cannot Transfer Data from the Controller . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Revision B SEER Light Ambulatory Recorder/Controller i

2019818-008

Page 4

Cannot Transfer Data from the Recorder to the

SEER Light Connect Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Record Start Date/Time is Initialized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Artifact on ECG Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Cannot Detect Pacemaker Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

3 SEER Light/SEER Light Extend Controller . . . . . . . . . . . 3-1

Component Names and Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

No Operation After Inserting Batteries and Pressing Power Button . . . . . . . . . . .3-6

ECG Cannot be Previewed with the Controller (I.R.) . . . . . . . . . . . . . . . . . . . . . . .3-7

ECG Cannot be Previewed by the Controller (Cable) . . . . . . . . . . . . . . . . . . . . . .3-8

Cannot Start Recording (I.R.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Pressing the Appropriate Key(s) Does Not Start Operation . . . . . . . . . . . . . . . . .3-10

Beep Sounds While the Flash Card is Inserted . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Data Cannot be Transferred from the Recorder . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Recording Start Date/Time is Not Correct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Time is Not Correct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

4 SEER Light Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Component Names and Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

ECG Cannot Be Previewed with SEER Light Connect Device . . . . . . . . . . .4-5

Recording Cannot Start with the SEER Light Connect Device . . . . . . . . . . .4-6

Cannot Transfer Data from the Recorder to the

SEER Light Connect Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Recording Start Date/Time is Not Correct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

ii SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Cleaning Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Storing the Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Maintenance/Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Maintenance/Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

SEER Light/SEER Light Extend Ambulatory Recorder . . . . . . . . . . . . . . . . . . . . .A-3

SEER Light Ambulatory Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A -4

SEER Light Connect Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . .B-1

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions . . . . . . .B-3

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity . . . . . . . .B-4

Recommended Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Compliant Cables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

Revision B SEER Light Ambulatory Recorder/Controller iii

2019818-008

Page 6

iv SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 7

1 Introduction

Revision B SEER Light Ambulatory Recorder/Controller 1-1

2019818-008

Page 8

For your notes

1-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 9

Introduction: Manual Information

Manual Informatio n

Revision History

Each page of the document has the document part number followed by a

revision letter at the bottom of the page. This letter identifies the

document’s update level. The latest letter of the alphabet corresponds to

the most current revision of the document.

The revision history of this document is summarized in the table below.

Table 1. Revision History 2019818-008

Revision Date Comment

A 15 May 2005 Initial release of manual.

B 15 July 2005 Manual updated for clarity.

Manual Purpose

Definitions

This manual supplies technical information for service representative

and technical personnel so they can maintain the equipment. Use it as a

guide for maintenance and electrical repairs considered field repairable.

Where necessary the manual identifies additional sources of relevant

information and or technical assistance.

See the operator manual for the instructions necessary to operate the

equipment safely in accordance with its function and intended use.

Items shown in Black text are keys on the keyboard, text to be

entered, or hardware items such as buttons or switches on the

equipment.

Items shown in Italicized text are software terms which identify

menu items, buttons, or options in various windows.

To perform an operation which appears with a plus (+)sign between

the names of two keys, you press and hold the first key while

pressing the second key once. This is called a keystroke combination.

For example, “Press Ctrl + Esc” means to press and hold down the

Ctrl key while pressing the Esc key.

When instructions are given for typing a precise text string with one

or more spaces, the point where the spacebar must be pressed is

indicated as:

you press the spacebar when required.

Revision B SEER Light Ambulatory Recorder/Controller 1-3

<Space>. The purpose of the < > brackets is to ensure

2019818-008

Page 10

Introduction: Manual Information

Enter means to press the “Enter” or “Return” key on the keyboard.

Do not type “enter”.

1-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 11

Introduction: Related Manuals

Related Manuals

See the documents listed below for additional information.

Table 2. SEER Light Documents

Part Number Name

2019818-007 SEER Light Ambulatory Recorder/Controller Operator’s Manual

Revision B SEER Light Ambulatory Recorder/Controller 1-5

2019818-008

Page 12

Safety Information

Intended Use

The SEER Light recorder is a two and three channel digital Holter ECG

recorder that records the electrical signals associated with cardiac

activity fo r 24 or 48 h our s . It i s u se d in diagnosing card i ac a bno r mal i t ie s

and revealing trends or changes in heart function. This device is for the

use of trained personnel only.

This device is not intended for use on infants weighing less than 10 kg

(22 lbs).

Definitions

The terms danger, warning, and caution are used throughout this

manual to point out hazards and to designate a degree or level of

seriousness. Familiarize yourself with their definitions and significance.

Introduction: Safety Information

Warnings

Hazard is defined as a source of potential injury to a person.

DANGER indicates an imminent hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or product/property

damage.

NOTE provides application tips or other useful information.

WARNINGS

ACCIDENTAL SPILLS — If liquids have entered a

device, take it out of service and have it checked by a

service technician before it is used again. To avoid

electric shock or device malfunction liquids must not be

allowed to enter the device.

CABLES — To avoid possible strangulation, route all

cables away from patient's throat.

CARDIAC APPLICATION — This device cannot be used

for direct cardiac application.

CONDUCTIVITY — Keep the conductive parts of lead

electrodes and associated parts away from other

conductive parts, including earth.

DEFIBRILLATOR PRECAUTIONS — Do not come into

1-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 13

Introduction: Safety Information

contact with patients during defibrillation. Otherwise,

serious injury or death could result. Patient signal inputs

labeled with the CF and BF symbols wi th paddles are

protected against damage resulting from defibrillation

voltages. To ensure proper defibrillator protection, use

only the recommended cables and leadwires. Proper

placement of defibrillator paddles in relation to the

electrodes is required to ensure successful defibrillation.

ELECTROSURGERY — If an electrosurgery device is

used, it is necessary to disconnect the patient cable from

the SEER Light recorder. Take precautions to reduce

risks of burns and injury to the patient.

LEAKAGE CURRENT — Electrical shock to patient

could result from component failure and lack of power

isolation.

In the event this syste m is used in the patient vicinity, it

must be configured in such a way that it and all of its

electrically-connecte d peripheral devices ar e isolated from

mains power to prevent excessive leakage current to the

patient. This can be accomplished through the use of

isolated mains power, or a medical grade isolation

transformer (in compliance with UL 60601, CAN/CSA

C22.2 No. 601.1, IEC 60601-1) with this system. All nonmedical peripheral devices shall comply with IEC and ISO

safety standards that are relevant to that equipment (i.e.,

IEC 60950, UL 60950).

Cautions

Use of the SEER Light Connect device in the patient

vicinity requires that these measures are observed.

PACEMAKER PATIENTS — Take precautions to avoid

risks of hazard due to the operation of a cardiac

pacemaker or other electrical stimulators.

SUPERVISED USE — This device is intended for use

under the direct supervision of a licensed health care

practitioner.

CAUTIONS

RESTRICTED SALE — U.S. federal law restricts this

device to sale by or on the order of a physician.

BEFORE OPERATION — Check that the instrument

operates properly.

DISPOSAL — At the end of its service life, the product

described in this manual, as well as its accessories, must

be disposed of in compliance with local, state, or federal

Revision B SEER Light Ambulatory Recorder/Controller 1-7

2019818-008

Page 14

Introduction: Safety Information

A

guidelines regulating the disposal of such products. If you

have questions concerning dispos al of the product , please

contact GE or its representatives.

MODIFICATIONS — Do not make an y modifications to

the device.

AFTER DEVICE USE — Clean the device after each use

to ensure trouble-free op eration for the next use.

Use a piece of damp cloth with alcohol to clean the

device and the patient cable.

The device cannot be sterilized.

Do not use xylene and petrol related liquid for

cleaning the device.

To ensure proper operation of the device, it is

necessary to periodically have the device checked by

authorized service personnel.

Check the patient cable and connectors every month

by connecting them to an ECG simulator.

Serial Number

INSTALLATION — Adhere to the following

recommendations during installation:

Install and keep device away from splashing water.

Do not install the device where it may be affected by

humidity, ventilation, direct sunlight, air

conditioning, dust, salt, sulfur, etc.

Prevent the device from ti lting, and protect it from

the possibility of vibration or shock.

Do not install the device in a chemical storage area or

where gas is generated.

Every GE Medical Systems Information Technologies device has a

unique serial number for identification. The serial number appears on

the device label similar to the one shown below

.

50

1-8 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 15

Disposal of the Device

Introduction: Safety Information

When disposing the device, follow the applicable national rules and

regulations of disposal of medical equipment.

When disposing the recyclable battery, follow the applicable national

rules and regulations concerning the environmental issues.

Revision B SEER Light Ambulatory Recorder/Controller 1-9

2019818-008

Page 16

Introduction: Responsibility of the Manufacturer

Responsibility of the Manu facturer

GE is responsible for the effects of safety, reliability, and performance

only if:

Assembly operations, extensions, readju stments, modifications, or

repairs are carrie d out by persons aut horized b y GE Medica l Systems

Information Technologies.

The equipment is used in accordance with the instructions for use.

General

Refer equipment servicing to GE authorized service personnel only. Any

unauthorized attempt to repair equipment under warranty voids that

warranty.

It is the user’s respons ibility t o report the need for se rvice to GE or to one

of its authoriz ed agents.

This device is intended for use under the direct supervision of a licensed

health care practitioner.

To ensure patient safety, use only parts and access ories manufactured or

recommended by GE.

Contact GE for information before connecting any devices to this

equipment that are not recommended in this manual.

Parts and accessories used must meet t he requireme nts of t he appli cable

IEC 60601 series sa fety st andard s, and/ or t he sy stem co nfigura tion mus t

meet the requirements of the IEC 60601-1-1 medical electrical systems

standard.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the choice shall

include:

use of the accessory in the PATIENT VICINITY; and

evidence that the safety certification of the ACCESSORY has been

performed in accordance with the appropriate IEC 60601-1 and/or

IEC 60601-1-1 harmonized national standard.

1-10 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 17

Introduction: Responsibility of the Manufacturer

Information Technology Equipment

The hardware components supplied by GE for the MARS® Holter

analysis workstation, on which the SEER Light Connect application

runs, are considered to be Information Technology Equipment (ITE).

These individual components have been found to comply with the

standard for Safety of Information Technology Equipment, including

Electrical Business Equipment EN60950 (UL 60950).

The software used in the MARS® Holter analysis workstation is

considered as medical software. The software has been designed and

manufactured to the appropriate medical regulations and controls.

In order for the MARS® Holter analysis workstation to comply with

medical equipment standard leakage current requirements, a medical

grade uninterruptible power supply (UPS) must be used (UL 60601-1,

CSA 22.2 No. 60601-1, EN 60601-1) to power all non-medical equipment.

In addition, non-medical electrical equipment must comply with IEC and

ISO safety standards that are relevant to that equipment (i.e., IEC

60950, Safety of Information Technology Equipment.)

Revision B SEER Light Ambulatory Recorder/Controller 1-11

2019818-008

Page 18

Equipment Symbols

The following symbols may appear on the equipment.

Attention. Consult accompanying documents.

Event.

This symbol indicates the polarity orientation that each battery should have when you insert it

into the unit. This unit requires you to insert the batteries so that the polarities are oriented in

alternating directions.

Power.

Introduction: Equipment Symbols

Stop.

Input connector.

Output connector.

This symbol indicates that the waste of electrical and electronic equipment must not be

disposed as unsorted municipal waste and must be collected separately. Please contact an

authorized representative of the manufacturer for information concerning the

decommissioning of your equipment.

1-12 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 19

2 SEER Light/SEER Light

Extend Recorder

Revision B SEER Light Ambulatory Recorder/Controller 2-1

2019818-008

Page 20

For your notes

2-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 21

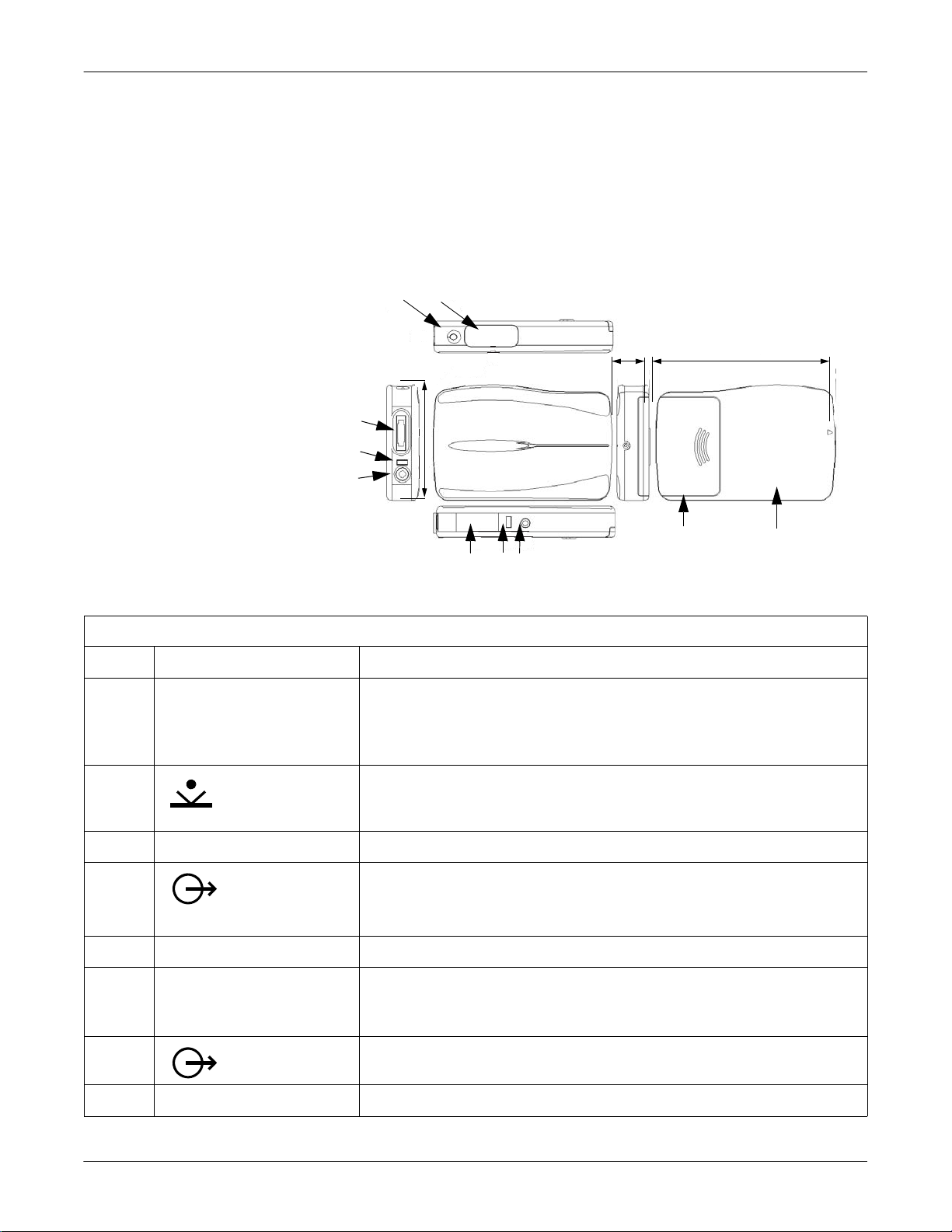

SEER Light/SEER Light Extend Recorder: Component Names and Locations

Component Names and Locations

Structure

The SEER Light ambulatory recorder is shown and described below.

A B

.60 in.

(15 mm)

I

H

G

2.17 in.(55 mm)

F E D

Table 3. SEER Light Ambulatory Recorder

Item Name Description

A REC LED To display operation conditions:

After pressing the start/event button, the LED will flash twice per second for three

minutes. During this time data is not recorded.

During reco rding, the LED will flash every second.

C

3.35 in.

(85 mm)

J

017A

B

start/event button

Use to start recording.

Use to mark events during recording.

C battery compartment cover Slide the cover to open and set the batteries in the battery compartment.

D

A data output

For transfer of data to the SEER Light controller or to the SEER Light Connect device.

connector

E access LED Will flash during communication with the SEER Light controller.

F infrared terminal (I.R. Window) Used to receive the signal from the SEER Light controller to begin ECG recording.

Used to receive patient information and ECG recording starting time.

Used to confirm the ECG waveform recorded by the recorder (ECG preview).

G

B output connector

Not used.

H DATA LED The LED flashes while transferring data to the SEER Light controller.

Revision B SEER Light Ambulatory Recorder/Controller 2-3

2019818-008

Page 22

SEER Light/SEER Light Extend Recorder: Component Names and Locations

Table 3. SEER Light Ambulatory Recorder (Continued)

I patient cable connector Used to connect patient cable for ECG input.

J Stop button Push to stop recording

2-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 23

SEER Light/SEER Light Extend Recorder: Troubleshooting

Troubleshooting

Self-Test Mode

A self-test can be done on the following functions.

1. Self-test I (pacemaker detection check mode)

Provide a pacemaker signal to the recorder with an ECG simulator.

To enter the pacemaker detection mode, set the batteries while

pressing the STOP button.

Confirm the audible sound synchronizes with the pacemaker

signal input through the patient input connector.

Remove the batteries to end the self-test.

2. Self-tes t II (accelerometer sensor check mode)

After setting the batteries, press the STOP button three times

within a second.

Confirm the audible so und synchronizes as the recorder is moved

around.

Remove the batteries to end the self-test.

Revision B SEER Light Ambulatory Recorder/Controller 2-5

2019818-008

Page 24

SEER Light/SEER Light Extend Recorder: Troubleshooting

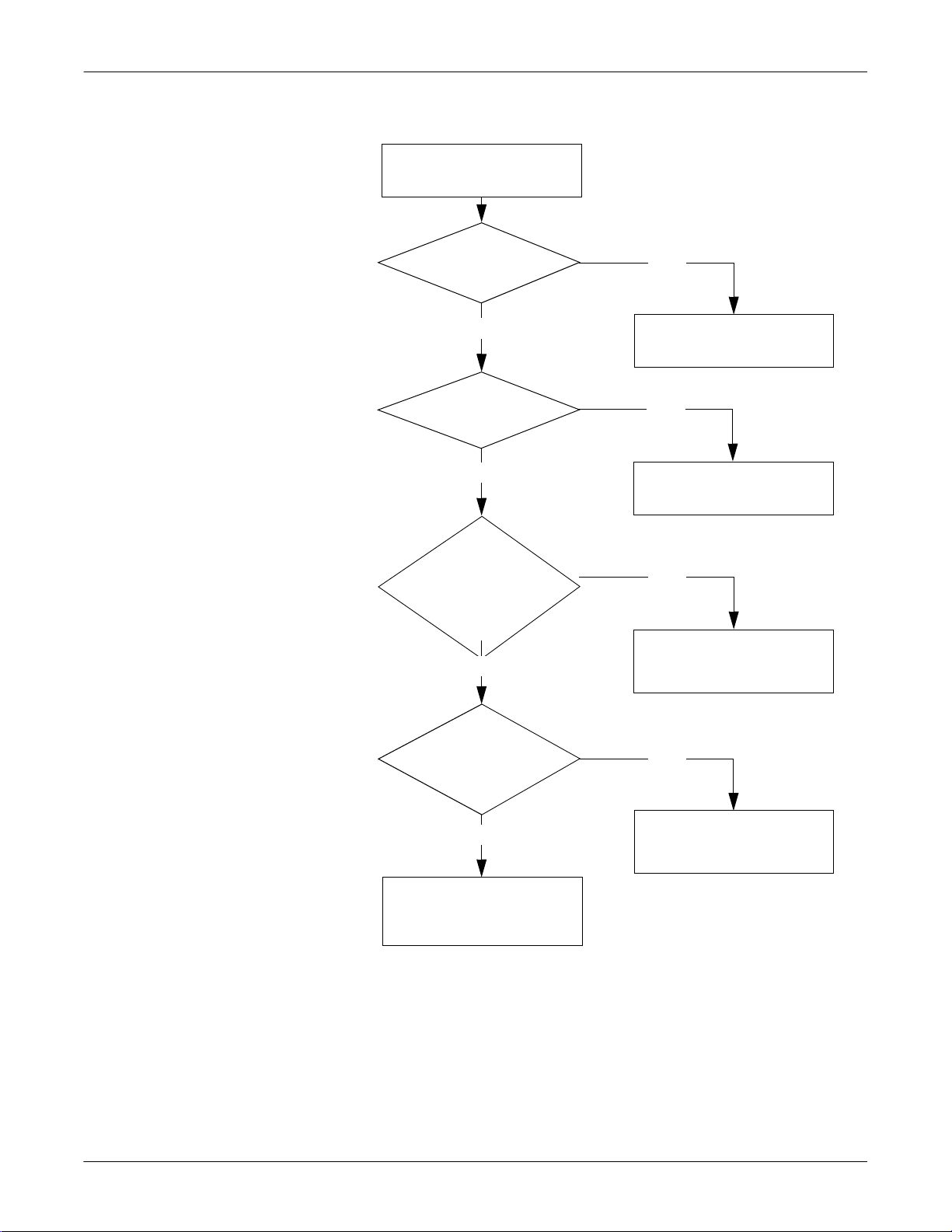

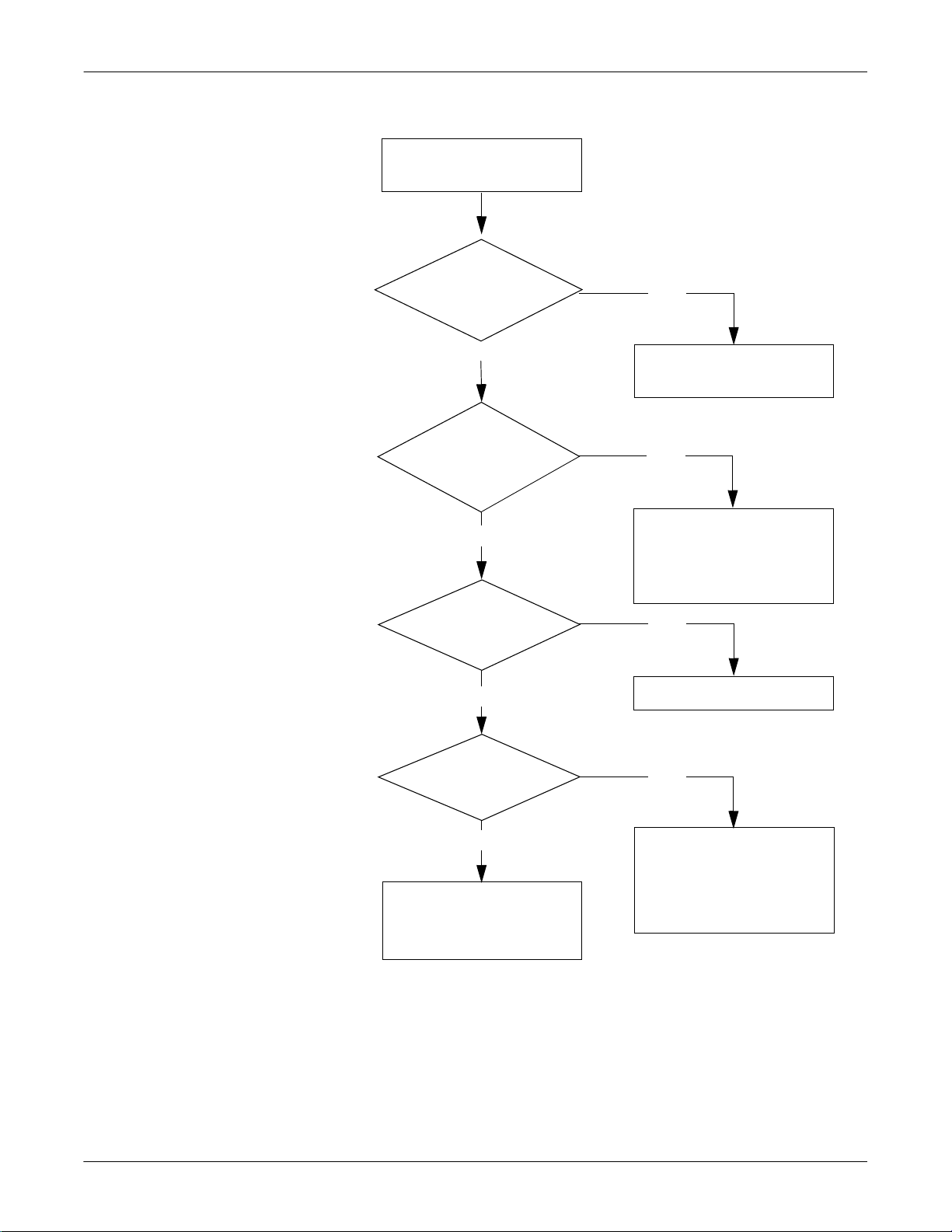

No Buzzer Sound After Installing the Batteries

No buzzer sound after

installing the batteries.

Are the batteries

installed properly?

Yes

Are the batteries

new?

Yes

Were the batteries

reinstalled over 10

seconds after the

batteries were

removed?

Yes

No

Install the batteries

properly.

No

Replace with new

batteries.

No

Reinstall the batteries

over 10 seconds after

removing them.

Are the battery

electrodes clean and

properly soldered?

Yes

Call GE service.

2-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

No

Call GE service.

Page 25

SEER Light/SEER Light Extend Recorder: Troubleshooting

Beep Sound Will Not Stop After Installing the Batt eries

Beep sound will not stop

after installing the batteries.

Are the batteries new?

Yes

Are the alkaline

batteries

installed?

Yes

Call GE service.

No

Replace with new

alkaline batteries.

No

Set new alkaline

batteries.

Revision B SEER Light Ambulatory Recorder/Controller 2-7

2019818-008

Page 26

SEER Light/SEER Light Extend Recorder: Troubleshooting

ECG Cannot Be Previewed with Controller (I.R.)

ECG cannot be previewe d

with the controller (I.R.).

Is the dista nce from

the controller withi n

4.9 ft. (1.5 m)?

No

Yes

Is the I.R.

window facing the

controller properly?

Yes

Were the batteries

set within one hour?

Yes

Has recording

already started?

Position the controller

within 4.9 ft (1.5 m).

No

Reposition the I.R . window

properly to the controller,

or remove any obstacle

between the recorder and

the controller.

No

Reset the batteries.

Yes

No

Call GE service.

2-8 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Preview ECG with the cable.

Cannot preview ECG by I.R.

operation if more than 3

minutes has elapsed since

recording started.

Page 27

SEER Light/SEER Light Extend Recorder: Troubleshooting

ECG Cannot be Previewed with Controller (Cable)

ECG cannot be previe wed

with the controller

(by the preview cable).

Is cable connection

proper?

Yes

Is the cable

damaged?

No

Call GE service.

No

Connect the

cable properly.

Yes

Replace with a

new cable.

Revision B SEER Light Ambulatory Recorder/Controller 2-9

2019818-008

Page 28

SEER Light/SEER Light Extend Recorder: Troubleshooting

ECG Cannot Be Previewed with SEER Light Connect Device

ECG cannot be previewe d

with the SEER Light

Connect Device.

Is the USB cable

from the Connect

plugged in?

No

Yes

Is the orange LED

on the Connect on?

Yes

Is the dista nce from

the controller withi n

4.9 ft. (1.5 m)?

Yes

Is the I.R.

window facing the

controller properly?

Yes

Plug it in.

No

Call GE Service.

No

Position the controller

within 4.9 ft (1.5 m).

No

Reposition the I.R . window

properly, or remove any

obstacle between the

recorder and the controller.

Were the batteries

installed within one

hour?

Yes

Has recording

already started?

No

Call GE service.

2-10 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

No

Reinstall the batterie s.

Yes

Cannot preview ECG by I.R.

operation if more than 3

minutes has elapsed since

recording started.

Page 29

SEER Light/SEER Light Extend Recorder: Troubleshooting

Recording Cannot Start with the Controller (I.R.)

Recording cannot start

with the controller (I.R.).

Does the controller

display “untransmitte d

data?”

No

Does

the controller display

“Already started?”

No

Is the distance

from the controller

within 4.9 ft

(1.5 m?)

Yes

Yes

Transfer previous data or

press the START button

when the controller displays

“Data still remains.”

Yes

Reset the batteries over 30

seconds after removing them.

No

Adjust the position

within 4.9 ft. (1.5 m)

from the controller.

Does the I.R. wind ow

face the controller

properly?

Yes

Call GE Service.

Revision B SEER Light Ambulatory Recorder/Controller 2-11

2019818-008

No

Reposition the I.R . windows

to face each other prop erly.

Remove any obstacles

between the recorder and

the controller.

Page 30

SEER Light/SEER Light Extend Recorder: Troubleshooting

Recording Cannot Start with the SEER Light Connect Device

Recording cannot start

with the Connect.

Is the USB cable

from the Connect

plugged in?

No

Yes

Is the orange LED

on the Connect on?

Yes

Does the controller

display “untransmitte d

data?”

No

Does

the controller display

“Already started?”

No

Plug it in.

No

Call GE Service.

Yes

Transfer previous data or

press the START button.

Yes

Reinstall the batteries over 30

seconds after removing them.

Is the distance

from the Connect

within 4.9 ft

(1.5 m?)

Yes

Does the I.R. window

face the Connect

properly?

Yes

Call GE Service.

2-12 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

No

Adjust the position

within 4.9 ft. (1.5 m)

from the Connect.

No

Reposition the I.R. windows

to face each other properl y.

Remove any obstacles

between the recorder and

the Connect.

Page 31

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Start by Pressing the Start Button

Cannot start by p r es sin g

the START button.

Was

the START button

pressed over 1.5

seconds?

No

Yes

Is it within

one hour of setting the

batteries?

Yes

Call GE Service

Press the START button

longer than 1.5 seconds.

No

Reset the batteries.

Revision B SEER Light Ambulatory Recorder/Controller 2-13

2019818-008

Page 32

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Record for 24 Hours

Cannot record for

24 hours.

Are there many

artifacts in the ECG

recording?

No

Were the batteries

removed before record ing

for 24 hours?

No

Were alkaline

batteries used?

Yes

Yes

Refer to flow chart on

artifact later in this chapter.

Yes

Don’t remove the batteries

before recording for 24 hours.

No

Use alkaline

batteries.

Are the

battery electrodes dirty

or improperly

soldered?

No

Call GE Service.

2-14 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Yes

Clean the battery electrod es

or improve soldering.

Page 33

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Record for 48 Hours

Cannot record for

48 hours.

Is the recorder

labeled “SEER Light

Extend?”

Yes

Are there many

artifacts in the ECG

recording?

No

Were the batteries

removed before record ing

for 48 hours?

No

No

The recorder does not ha ve

48-hour recording

capability.

Yes

Refer to flow chart on

artifact later in this chapter.

Yes

Don’t remove the batteries

before recording for 48 hours.

Were alkaline

batteries used?

Yes

Are the

battery electrodes dirty

or improperly

soldered?

No

Call GE Service.

Revision B SEER Light Ambulatory Recorder/Controller 2-15

2019818-008

No

Use alkaline

batteries.

Yes

Clean the battery electrod es

or improve soldering.

Page 34

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Transfer Data from the Controller

Cannot transfer data

from the controller.

Is the transfer

cable properly connected?

Yes

Does the

controller display “No data

in the recorder?”

No

Does the

controller display

“Recorder contains data

error?”

No

Is the data output

connector clean?

No

Connect the

cable properly.

Yes

No data in the recorder.

Record ECG again.

Yes

Call GE Service.

No

Yes

Is the transfer

cable damaged?

No

Call GE Service.

2-16 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Clean the data output

connector.

Yes

Call GE Service.

Page 35

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Transfer Data from the Recorder to the SEER Light Connect Device

Cannot transfer data to

the Connect.

Is the USB cable

No

Plug it in.

Is the orange LED

on the Connect on?

from the Connect

plugged in?

Yes

No

Yes

Attach the Connect to the

recorder.

Is the green LED on

the Connect on?

Yes

Is the transfer

cable properly

connected?

Yes

Does the

controller display “No data

in the recorder?”

No

Is the data output

connector clean?

Yes

No

Call GE Service.

No

Connect the

cable properly.

Yes

No data in the recorder.

Record ECG again.

No

Clean the data output

connector.

Is the transfer

cable damaged?

No

Call GE Service.

Revision B SEER Light Ambulatory Recorder/Controller 2-17

2019818-008

Yes

Call GE Service.

Page 36

SEER Light/SEER Light Extend Recorder: Troubleshooting

Record Start Date/Time is Initialized

Record start date/time

is initialized.

Was the recording

started by pressing the

START button?

Yes

Were the batteries

removed during or af ter

recording?

No

Did more than

one week pass from the

last recording?

No

Call GE Service.

No

Call GE Service.

Yes

Record start date/time will be

initialized if the batteries are

removed before transferring the

ECG data after th e START button

is pressed to start recording.

Yes

Replace the batteries.

2-18 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 37

SEER Light/SEER Light Extend Recorder: Troubleshooting

Artifact on ECG Recording

Artifact on ECG

recording.

Are electrodes

connected properly on

the patient?

Yes

Is the patie nt cable

connected properly?

Yes

Is the patient

cable connector

clean?

Yes

No

Attach electrodes properly.

No

Connect the patient cable

properly.

No

Clean the patient

cable connector.

Is the patient cable

damaged?

No

Call GE Service.

Revision B SEER Light Ambulatory Recorder/Controller 2-19

2019818-008

Yes

Call GE Service.

Page 38

SEER Light/SEER Light Extend Recorder: Troubleshooting

Cannot Detect Pacemaker Pulse

Cannot detect

pacemaker pulse.

Insert the batteries while

pressing the STOP button.

Disconnec t the patient ca ble

and touch the electrode

connector with a finger.

Does audible beep

sound?

No

Call GE Medical Systems

Information Technologies

Service.

Yes

Normal pacemaker detection circuit.

Confirm pacemaker pulse detection

by the Preview function of the

controller. Reposition the CH1 if the

pulse signals are too small.

2-20 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 39

3 SEER Light/SEER Light

Extend Controller

Revision B SEER Light Ambulatory Recorder/Controller 3-1

2019818-008

Page 40

For your notes

3-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 41

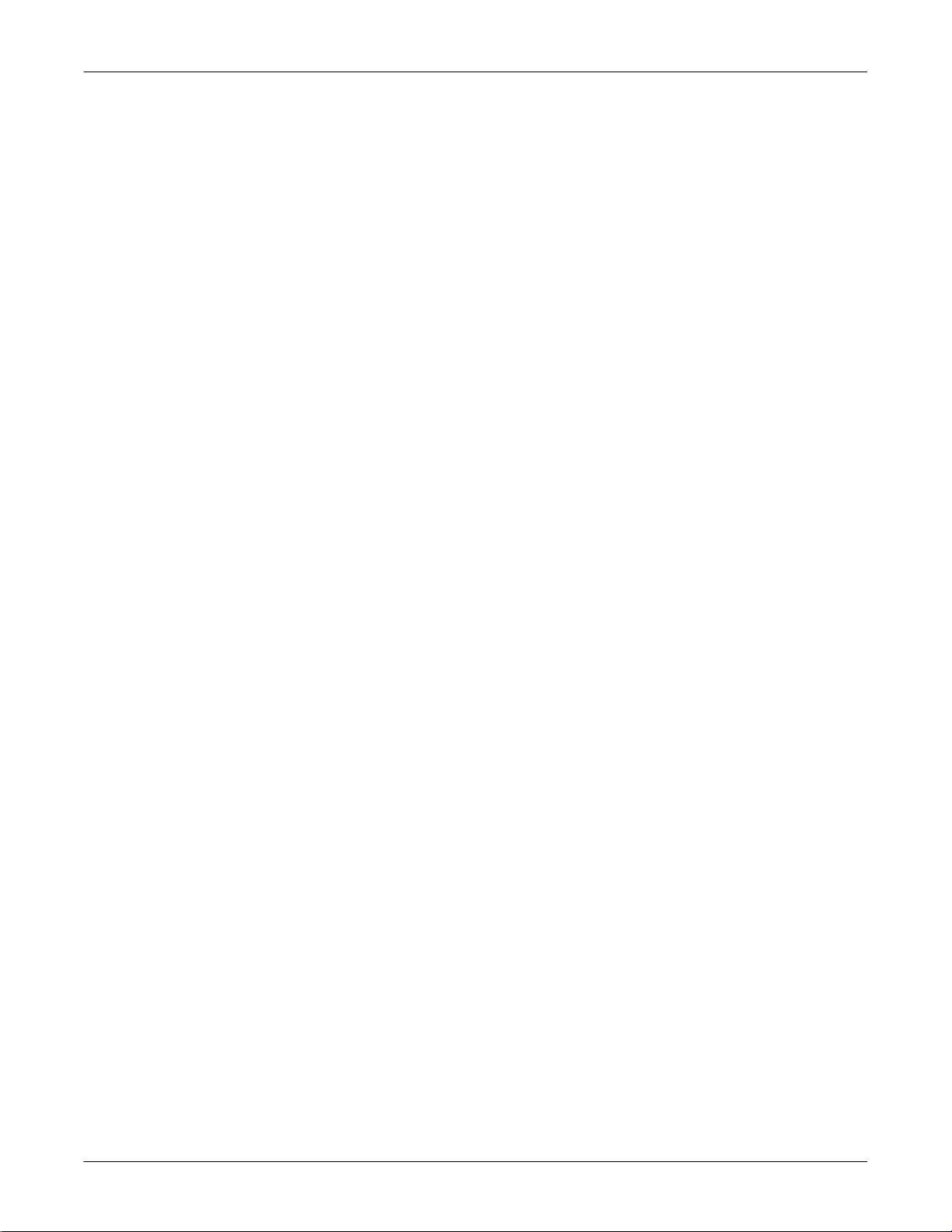

SEER Light/SEER Light Extend Controller: Component Names and Locations

Component Names and Locations

Structure

Below are the names of each part on the SEER Light/SEER Light Extend

Controller.

A

1.2 in.

3.5 in. (90 mm)

7.9 in. (200 mm)

(30 mm)

D

E

F

G

H

I

J

K

B

C

037A

L

Table 4. Controller Parts List

Item Name Description

A

input connector

Used to connect to the SEER Light recorder to check recording conditions.

NOTE This feature is reserved for future use.

B infrared terminal Used to communicate with the SEER Light recorder.

Transfer the instructions to a SEER Light recorder before recording.

Receive ECG waveform recording data from a SEER Light recorder to preview.

Revision B SEER Light Ambulatory Recorder/Controller 3-3

2019818-008

Page 42

SEER Light/SEER Light Extend Controller: Component Names and Locations

Table 4. Controller Parts List (Continued)

Item Name Description

C data transfer cable Used to transfer data from the SEER Light recorder. When not in use, store the cable in

the guide on the backside panel.

D

Used to turn the power on and off.

power button

E Holter card slot Used to insert a Holter card.

F LCD (liquid crystal display) Displays operating conditions.

G F1 button Used to enter the preview mode (wired or wireless) to confirm the quality of ECG

recording.

H F2 button Used to enter the data transfer mode to transmit data to a Holter card.

I F3 button Used to start recording of the SEER Light recorder and to start transferring data to a

Holter card.

J

set-up button (

K patient information entry

)

Used to select settings.

Enter the patient’s alphanumeric information.

buttons

L battery cover In direction indicated, slide the cover open and place four new alkaline AAA type batteries

in the battery box.

3-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 43

SEER Light/SEER Light Extend Controller: Troubleshooting

Troubleshooting

Software Version

Self-Test

The software version of the SEER Light/SEER Light Extend Controller

appears in the lower right hand corner of the display upon start up.

A self-test can be done on the following functions.

1. Button check mode:

Enter the Set-up Condition display mode by pressing the POWER

button and button simultaneously. Continue to hold the button

while releasing the POWER button.

Press the CLEAR button at the Set-up Condition display mode.

Press the number 0 at the Factory Settings display mode.

The name of the button that was pressed will be displayed, and

an audible sound will be heard when the respective button is

pressed once.

NOTE

If the ENTER button is pressed three times the unit will

enter into the LCD check mode.

Turn off the power to end this function test.

2. LCD check mode:

Enter the Set-up Condition display mode by pressing the POWER

button and button simultaneously. Continue to hold the button

while releasing the POWER button.

Press the CLEAR button at the Set-up Condition display mode.

Press the number 0 at the Factory Settings display mode.

In the button check mode display press the ENTER button three

times, and the LCD display will appear darkened.

Press the POWER button to end this function test.

Revision B SEER Light Ambulatory Recorder/Controller 3-5

2019818-008

Page 44

SEER Light/SEER Light Extend Controller: Troubleshooting

No Operation After Inserting Batteries and Pressing Power Button

No operation after insertin g

batteries and pressing the

POWER button.

Are the batteries

set properly?

Yes

Do the

batteries have su f ficient

power of >4.5 V?

Yes

Did the

beep sound when the

POWER button was

pressed?

No

No

Set the batteries

properly.

No

Replace with new

batteries.

Yes

Call GE service.

Call GE service.

3-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 45

SEER Light/SEER Light Extend Controller: Troubleshooting

ECG Cannot be Previewed with the Controller (I.R.)

ECG cannot be previewe d

with the controller (I.R.)

Communication Error

Is the dista nce from

the recorder within

4.9 ft. (1.5 m)?

No

Yes

Is the I.R.

window facing the

recorder properly?

Yes

Has recording

already started?

No

Call GE service.

Position the recorder

within 4.9 ft. (1.5 m).

No

Reposition the I.R . window

properly to the recorder,

or remove any obstacle

between the recorder and

the controller.

Yes

Preview ECG with the cable.

Cannot preview ECG by I.R.

operation over 3 minutes after

recording started.

Revision B SEER Light Ambulatory Recorder/Controller 3-7

2019818-008

Page 46

SEER Light/SEER Light Extend Controller: Troubleshooting

ECG Cannot be Previewed by the Controller (Cable)

ECG cannot be previe wed

by the controller

(by the preview cable).

Is cable connection

proper?

Yes

Is the cable

damaged?

No

Call GE service.

No

Connect the

cable properly.

Yes

Call GE service.

3-8 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 47

SEER Light/SEER Light Extend Controller: Troubleshooting

Cannot Start Recording (I.R.)

Cannot start recording

(I.R.).

Does

the controller display

“Already started?”

Yes

No

Is the distance from

the recorder within

4.9 ft. (1.5 m)?

Yes

Does the I.R. window

face the controller

properly?

Yes

Has

over 60 minutes

passed since recording

started?

Reset the batteries over 30

seconds after removing them.

No

Adjust the position within

4.9 ft. (1.5 m) from the

recorder.

No

Reposition the I.R. windo ws

to face each other properly.

Remove any obstac les

between the recorder and

the controller.

Yes

No

Call GE service.

Revision B SEER Light Ambulatory Recorder/Controller 3-9

2019818-008

If over 60 minutes have

passed, the SEER Light

cannot start by I.R.

operation.

Page 48

SEER Light/SEER Light Extend Controller: Troubleshooting

Pressing the Appropriate Key(s) Does Not Start Operation

Pressing the appropriate

key(s) does not start op erat ion .

Can

the operation panel

key(s) be pressed

properly?

No

Yes

Is there

debris between PC

board and key sheet

panel?

No

Call GE service.

Call GE service.

Yes

Call GE service.

3-10 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 49

SEER Light/SEER Light Extend Controller: Troubleshooting

Beep Sounds While the Flash Card is Inserted

Beep sounds while the

flash card is inserted.

The display is distorted.

Is the flash card

inserted completely?

Yes

Is the

card inserted in the

opposite direction?

No

Call GE service.

No

Insert the card

completely.

Yes

Insert the card

properly.

Revision B SEER Light Ambulatory Recorder/Controller 3-11

2019818-008

Page 50

SEER Light/SEER Light Extend Controller: Troubleshooting

Data Cannot be Transferred from the Recorder

Data cannot be transferred

from the recorder .

Is the data output

connector clean?

Yes

Is the connector

damaged?

No

Has

the compact flash card

been formatted?

Yes

Is the card defective?

No

No

Clean the

connector.

Yes

Replace th e

connector.

No

Format the compact

flash card.

Yes

Replace with a

new card.

Does data remain on

the card?

No

Are

there distorted card

connector pins?

No

Call GE service.

Yes

Transfer the

data to the PC.

Yes

Call GE service.

3-12 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 51

SEER Light/SEER Light Extend Controller: Troubleshooting

Recording Start Date/Time is Not Correct

Recording start date/ time

is not correct.

Time is Not Correct

Is date within

one month?

Yes

See next flowchart.

Time is not correct.

Is it within 5 years

of use?

Yes

No

Adjust date.

No

Call GE service.

Are the

battery electrodes

clean or properly

solder?

Yes

Replace the PC boards.

Revision B SEER Light Ambulatory Recorder/Controller 3-13

2019818-008

No

Clean the electrodes

or improve soldering.

Page 52

SEER Light/SEER Light Extend Controller: Inspection

Inspection

Production process inspection sheet and inspection procedure.

M. No.

Product Model Name SEER Light Controller Date (Start Inspection) Approval Audit

Serial No. Board No.

Production Lot No.

Program Version Production Specification

High temperature heat run (40 to 48 hours) Start and End Date

Inspection Before Heat-Run Staff

No. Item Inspection Procedures Result Accept Reject

1 Appearance Check paint condition, no scratches or stains on LCD and cases, clear wording,

etc. Check connector pin of memory card for breaks, bends, etc.

2 Power switch Turn ON the power switch. Ensure there are buzzer sounds and the factory reset

menu appears on the LCD. Confirm program version number.

3 Set the time Set year, month, date, and time. Turn off the Auto Power function for heat-run

inspection.

4 Key/LCD check Under the inspection mode, ensure the key input and LCD display are normal,

LCD backlight is lit, and the keys should not stick when pressed.

5 Leakage current Patient leakage current is less than 10 µA. µA

6 Power ON Insert the batteries and confirm buzzer one time. Press start switch, confirm to buzzer and

blink red LED. Then press stop switch and check buzzer sound and LED blinking are

stopped.

7 Start test Ensure that the SEER Light is starting (straight line: 1.5 m).

8 IrDA preview

check

9 Preview check

with cable

10 Analog output Using inspection contr ol ler with c able , conf i rm ana log wavef orm s 1 ch, 2 ch, and 3 ch are

11 Transfer test Connect the SEER Light. Ensure that data is transferred and that the data can be

12 Check settings Check the year, month, date, and time (with ±1 minute).

13 Reset menu Used to initialize the settings (menu).

14 Auto Power Off

function

15 Appearance Check painting conditions such as no scratches stains on LCD cases, clear wording,

16 Supply current Start at 6 V. The supply current is 60 ±6 mA. mA

No. Visual Inspection Accept Reject No. Visual Inspection Accept Reject

1 Battery mark 1 place 4 Electrode welding 2 places

2 Ribbon 1 place 5 LCD boards, connector cutting 1 place

3 Board installation 1 place 6 Main body assembly 4 places

Notes:

Use SEER Light, which is pre-installed with ECG wave, and ensure that the

displayed waveform of 1 ch, 2 ch, and 3 ch are normal under the preview function.

Use SEER Light, which is pre-installed with ECG wave, and ensure that the

displayed analog waveform of 1 ch, 2 ch, and 3 ch are normal.

normal.

installed onto the Holter card.

Turn ON the power switch. Check that the power is automatically switched off if no

operation for 15 minutes continuously.

etc. Check ser ia l pl at e and ba tt e r y ma r k se al (v er s io n nu m be r ) is se cu re ly af fixed.

Ver. No.

3-14 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 53

4 SEER Light Connect

Revision A SEER Light Ambulatory Recorder/Controller 4-1

2019818-008

Page 54

For your notes

4-2 SEER Light Ambulatory Recorder/Controller Revision A

2019818-008

Page 55

SEER Light Connect: Component Names and Locations

Component Names and Locations

The SEER Light Connect is shown and described below. It is used as a

direct interface connection between the recorder and the Holter analysis

system. This device is also referred to as “the connect” in this document.

Structure

Below are the names of each part on the SEER Light Connect.

D

A

C

B

Name Function

A data transfer cable Used to transfer data from the SEER Light recorder

to the SEER Light Connect.

B infrared terminal Used to communicate with the SEER Light

recorder.

Receives ECG waveform data from a SEER

Light recorder to preview.

Transfers patient demographics to the SEER

Light recorder.

Starts the SEER Light recorder.

C USB Connection Uses a USB patch cord to transfer data from the

SEER Light Connect to the Holter analysis system.

084A

D LED indicator Flashes when data is transferring.

Lights without flashing when a proper connection

exists.

Revision A SEER Light Ambulatory Recorder/Controller 4-3

2019818-008

Page 56

Troubleshooting

SEER Light Connect: Troubleshooting

WARNING

LEAKAGE CURRENT—Electrical shock to patient could

result from component failure and lack of power

isolation.

In the event this syste m is used in the patient vicinity, it

must be configured in such a way that it and all of its

electrically-connecte d peripheral devices ar e isolated from

mains power to prevent excessive leakage current to the

patient. This can be accomplished through the use of

isolated mains power, or a medical grade isolation

transformer (in compliance with UL 60601, CAN/CSA

C22.2 No. 601.1, IEC 60601-1) with this system. All nonmedical peripheral devices shall comply with IEC and ISO

safety standards that are relevant to that equipment (i.e.,

IEC 60950, UL 60950).

Software Version

Use of the SEER Light Connect device in the patient

vicinity requires that these measures are observed.

To view the software version of the SEER Light Connect device, click

About in the SEER Light Hookup window.

4-4 SEER Light Ambulatory Recorder/Controller Revision A

2019818-008

Page 57

SEER Light Connect: Troubleshooting

ECG Cannot Be Previewed with SEER Light Connect Device

ECG cannot be previewe d

with the SEER Light

Connect Device.

Is the USB cable

from the Connect

plugged in?

No

Yes

Is the orange LED

on the Connect on?

Yes

Is the dista nce from

the controller withi n

4.9 ft. (1.5 m)?

Yes

Is the I.R.

window facing the

controller properly?

Yes

Plug it in.

No

Call GE Service.

No

Position the controller

within 4.9 ft (1.5 m).

No

Reposition the I.R . window

properly, or remove any

obstacle between the

recorder and the controller.

Were the batteries

installed within one

hour?

Yes

Has recording

already started?

No

Call GE service.

Revision A SEER Light Ambulatory Recorder/Controller 4-5

2019818-008

No

Reinstall the batterie s.

Yes

Cannot preview ECG by I.R.

operation if more than 3

minutes has elapsed since

recording started.

Page 58

SEER Light Connect: Troubleshooting

Recording Cannot Start with the SEER Light Connect Device

Recording cannot start

with the Connect.

Is the USB cable

from the Connect

plugged in?

No

Yes

Is the orange LED

on the Connect on?

Yes

Does the controller

display “untransmitte d

data?”

No

Does

the controller display

“Already started?”

No

Plug it in.

No

Call GE Service.

Yes

Transfer previous data or

press the START button.

Yes

Reinstall the batteries over 30

seconds after removing them.

Is the distance

from the Connect

within 4.9 ft

(1.5 m?)

Yes

Does the I.R. window

face the Connect

properly?

Yes

Call GE Service.

4-6 SEER Light Ambulatory Recorder/Controller Revision A

2019818-008

No

Adjust the position

within 4.9 ft. (1.5 m)

from the Connect.

No

Reposition the I.R. windows

to face each other properl y.

Remove any obstacles

between the recorder and

the Connect.

Page 59

SEER Light Connect: Troubleshooting

Cannot Transfer Data from the Recorder to the SEER Light Connect Device

Cannot transfer data to

the Connect.

Is the USB cable

No

Plug it in.

Is the orange LED

on the Connect on?

from the Connect

plugged in?

Yes

No

Yes

Attach the Connect to the

recorder.

Is the green LED on

the Connect on?

Yes

Is the transfer

cable properly

connected?

Yes

Does the

controller display “No data

in the recorder?”

No

Is the data output

connector clean?

Yes

No

Call GE Service.

No

Connect the

cable properly.

Yes

No data in the recorder.

Record ECG again.

No

Clean the data output

connector.

Is the transfer

cable damaged?

No

Call GE Service.

Revision A SEER Light Ambulatory Recorder/Controller 4-7

2019818-008

Yes

Call GE Service.

Page 60

SEER Light Connect: Troubleshooting

Recording Start Date/Time is Not Correct

Recording start date/ time

is not correct.

Is date correct on

the PC?

Yes

Call GE Service.

No

Adjust date/time on the PC.

4-8 SEER Light Ambulatory Recorder/Controller Revision A

2019818-008

Page 61

5 Maintenance

Revision B SEER Light Ambulatory Recorder/Controller 5-1

2019818-008

Page 62

For your notes

5-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 63

Maintenance

Visual Inspection

Maintenance: Maintenance

Perform a visual inspection daily. If you notice any items that need

repair, contact an authorized GE Medical Systems Information

Technologies service person to make the repairs.

Check the case and display screen for cracks or other damage.

Regularly inspect all cords and cables for fraying or other damage.

Inspect all plugs, cables, and connectors for bent prongs or pins.

Verify that all cords and connectors are securely seated.

Inspect controls for proper operation.

Inspect the LCD to make sure all the segments function.

Precautions

Cleaning

Cleaning Frequency

Do not immerse any part of the equipment in water.

Do not use organic solvents, ammonia based solutions, or abrasive

cleaning agents which may damage equipme nt surfaces.

NOTE

Remove the batteries before cleaning

Clean the exterior surfaces with a clean, soft cloth and a mild

dishwashing detergent diluted in water.

Wring the excess water from the clot h. Avoid contact with open

vents, plugs, or connectors.

Do not spray or spill fluid directly on the reco rder/controller.

Dry the surfaces with a clean cloth or paper towel.

With each new patient use, clean the SEER Light Recorder/Controller

and the SEER Light recorder pouch, leadwires, and patient cable.

Revision B SEER Light Ambulatory Recorder/Controller 5-3

2019818-008

Page 64

Maintenance: Storing the Recorder

Storing the Recorder

When the SEER Light Recorder/C ontrol ler wi ll not be in use fo r a period

of time:

Remove the batteries

Disconnect and properly store any patient cables.

Memory card may remain in the recorder.

5-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 65

Maintenance: Maintenance/Repair Log

Maintenance/Repair Log

Unit Serial Number:

Institution Name:

Date Maintenance/Repair Technician

Revision B SEER Light Ambulatory Recorder/Controller 5-5

2019818-008

Page 66

Maintenance: Maintenance/Repair Log

Maintenance/Repair Log

Unit Serial Number:

Institution Name:

Date Maintenance/Repair Technician

5-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 67

Appendix A —

Technical Specifications

Revision B SEER Light Ambulatory Recorder/Controller A-1

2019818-008

Page 68

For your notes

A-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 69

Appendix A: Technical Specifications

Technical Specifications

SEER Light/SEER Light Extend Ambulatory Recorder

The following table lists the specifications for the SEER Light/

SEERLight Extend Ambulatory Recorder.

Description Specification

Dimensions Height: 54 mm (2.1 in)

Width: 85 mm (3.35 in)

Depth: 15 mm (0.6 in)

Weight 72 g (2.5 oz) including batteries

Operating temperature 0 to 45°C (32 to 113°F)

Operating humidity 10 to 95% relative humidity (no condensation

allowed)

Storage temperature –20 to 65° C (-4 to 149°F)

Storage humidity 5 to 90% relative humidity (no condensation

allowed)

Material Aluminum ABSPC (main body)

Recording time within 24 hours — SEER Light

within 48 hours — SEER Light Extend

Recording method Digital memory

Power supply 2 x AAA Alkaline battery

Recording channel ECG: 3 channels

Movement level: 1 channel

Pacemaker pulse: 1 channel

Pacemaker detection channel CH1

Memory 32 Mbyte

Input level 16 mV p-p

A/D converter 10 bit, 8 ms sampling

Frequency response 0.05 to 40 Hz

Safety Type B

Input impedance Over 10 M Ohms

Time data backup Within 1 week (when started by the Cardy 301

recorder)

Revision B SEER Light Ambulatory Recorder/Controller A-3

2019818-008

Page 70

Appendix A: Technical Specifications

SEER Light Ambulatory Controller

The following table lists the specifications for the SEER Light

Ambulatory Controller.

Description Specification

Dimensions Height: 200 mm (7.9 in)

Weight 285 g (9.9 oz) including batteries

Operating temperature 10 to 35°C (50 to 95°F)

Operating humidity 10 to 95% relative humidity (no condensation

Storage temperature –20 to 65° C (-4 to 149°F)

Storage humidity 5 to 90% relative humidity (no condensation

Power supply 4 x AAA Alkaline battery

Width: 90 mm (3.5 in)

Depth: 25 mm (1.2 in)

allowed)

allowed)

Vibration endurance Operation: 0.5 G (10 to 20 Hz)

Non operation: 3.0 G (100 to 300 Hz)

Data transfer medium Compact flash card

Time accuracy + 60 seconds per month

A-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 71

Appendix A: Technical Specifications

SEER Light Connect Device

The following ta ble lists the specifications for the SEER Light Connect

device.

Dimensions Height: 13 mm (.51 in)

Weight 87 g (.19 lbs)

Operating temperature 10 to 35°C (50 to 95°F)

Operating humidity 10 to 95% relative humidity (no condensation

Storage temperature –20 to 65° C (-4 to 149°F)

Storage humidity 5 to 90% relative humidity (no condensation

Description Specification

Width: 90 mm (3.54 in)

Depth: 51 mm (2.01 in)

Cable length: 260 mm (10.24 in)

allowed)

allowed)

Power supply DC 5V

Recorders SEER Light Recorder

SEER Light Extend Recorder

Revision B SEER Light Ambulatory Recorder/Controller A-5

2019818-008

Page 72

For your notes

Appendix A: Technical Specifications

A-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 73

Appendix B —

Electromagnetic

Compatibility

Revision B SEER Light Ambulatory Recorder/Controller B-1

2019818-008

Page 74

For your notes

B-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 75

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC)

Changes or modification to this system not expressly approved by GE

Medical System could cause EMC issues with this or other equipment.

This system is designed and tested to comply with applicable regulation

regarding EMC and needs to be installed and put into service according

to the EMC information stated as follows.

WARNING

Use of portable phones or other radio frequency (RF)

emitting equi pment near the sys te m may cau s e

unexpected or adverse operation.

WARNING

The equipment or system should not be used adjacen t to ,

or stacked with, other equipment. If adjacent or stacked

use is necessary, the equipment or system should be

tested to verify normal operation in the configuration in

which it is being used.

Guidance and Manufacturer’s Declaration – Electromagnetic

Emissions

The SEER Light recorder and controller are intended for use in the

electromagnetic environment specified below. It is the responsibility of

the customer or user to ensure that the SEER Light recorder and

controller are used in such an environment.

Emissions Test Compliance Electromagnetic Environment - Guidance

The equipment uses RF energy only for its

RF emissions

CISPR11

RF emissions

CISPR11

Harmonic Emissions

EN 61000-3-2

Voltage fluctuations/

Flicker emissions

EN 61000-3-3

Group 1

Class A

Class A

Complies

internal function. Therefore, its RF emissions

are very low and are not likely to cause any

interference in nearby electronic equipment.

The equipment is suitable for use in all

establishments including domestic

establishments and those directly connected to

the public low-voltage power supply network

that supplies buildings used for domestic

purposes.

Revision B SEER Light Ambulatory Recorder/Controller B-3

2019818-008

Page 76

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

Guidance and Manufacturer’s Declaration – Electromagnetic

Immunity

The SEER Light recorder and controller are intended for use in the

electromagnetic environment specified below. It is the responsibility of

the customer or user to ensure that the SEER Light recorder and

controller are used in such an environment.

Immunity Test EN 60601 Test Level Compliance Level

Electrostatic

discharge (ESD)

EN 61000-4-2

Electrical fast

transient/burst

EN 61000-4-4

Surge

EN 61000-4-5

Voltage dips, short

interruptions and

voltage variations on

power supply input

lines

EN 61000-4-11

Power frequency

(50/60 Hz) magnetic

field

EN 61000-4-8

± 6 kV contact

± 8 kV air

± 2 kV for power supply lines

±1 kV for input/output lines

± 1 kV differential mode

± 2 kV common mode

<5% Ut (>95% dip in Ut)

for 0.5 cycles

40% Ut (60% dip in Ut)

for 5 cycles

70% Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

for 5 sec

3 A/m 3 A/m Power frequency magnetic fields should be

± 6 kV contact

± 8 kV air

± 2 kV for power supply lines

±1 kV for input/output lines

± 1 kV differential mode

± 2 kV common mode

<5% Ut (>95% dip in Ut)

for 0.5 cycles

40% Ut (60% dip in Ut)

for 5 cycles

70% Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

for 5 sec

Electromagnetic Environment -

Guidance

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Not applicable. The SEER Light recorder

and controller are not powered by Mains

power.

Not applicable. The SEER Light recorder

and controller are not powered by Mains

power.

Not applicable. The SEER Light recorder

and controller are not powered by Mains

power.

at levels characteristics of a typical location

in a typical commercial or hospital

environment.

NOTE

Ut is the AC mains voltage prior to application of the test level.

B-4 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 77

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

PPP

Guidance and Manufacturer’s Declaration – Electromagnetic

Immunity

The SEER Light recorder and controller are intended for use in the

electromagnetic environment specified below. It is the responsibility of

the customer or user to assure that the SEER Light recorder and

controller are used in such an environment.

Immunity Test EN 60601 Test Level Compliance Level Electromagnetic Environment – Guidance

Portable and mobile RF communications equipment should not

be used closer to any part of the equipment, including cables,

than the recommended separation distance calculated from the

equation applicable to the frequency of the transmitter.

Recommended separation distance

Conducted RF

EN 61000-4-6

Radiated RF

EN 61000-4-3

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by reflection from structures, objects,

and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radio, AM

and FM radio broadcast, and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured field strength

in the location in which the equipment is used exceeds the applicable RF compliance level above, the equipment should be

observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as

re-orienting or relocating the equipment.

b

Over the frequency range 150 KHz to 80 MHz, field strengths should be less than 3 V/m.

3 Vrms

150 KHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

3 V rms

3 V/m

d = 1.2

d = 1.2 80 MHz to 800 MHz

d = 2.3 800 MHz to 2.5 GHz

where P is the maximum output power rating of the transmitter

in watts (W) according to the transmitter manufacturer, and d is

the recommended separation distance in meters (m).

Field strengths from fixed RF transmitters, as determined by an

electromagnetic site survey

compliance level in each frequency range

Interference may occur in the vicinity of equipment marked with

the following symbol:

a

, should be less than the

b

.

Revision B SEER Light Ambulatory Recorder/Controller B-5

2019818-008

Page 78

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

PPP

P

Recommended Separation Distances

The table below provides the recommended separation distances (in

meters) between portable and mobile RF communication equipment and

the SEER Light recorder and controller.

The SEER Light recorder and controller are intended for use in the

electromagnetic environment on which radiated RF disturbances are

controlled. The customer or the user of the SEER Light recorder and

controller are can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the SEER Light recorder

and controller as recommended below, according to the maximum output

power of the communications equipment.

Separation Distance in Meters (m) According to Frequency of Transmitter

Rated Maximum Output

Power of Transmitter in

Watts

0.01 0.12 0.12 0.12 0.23

0.1 0.38 0.38 0.38 0.73

1 1.2 1.2 1.2 2.3

10 3.8 3.8 3.8 7.3

100 12 12 12 23

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

150 kHz to 80 MHz

outside ISM bands

d = 1.2

For transmitters rated at a maximum ou tp ut po wer n ot lis ted ab ove , the

recommended separation distance [d] in meters (m) can estimated using

the equation applicable to the frequency of the transmitter, where P is

the maximum output power rating of the transmitter in watts (w)

according to the transmitter manufacturer.

NOTE

These guidelines may not apply in all situations. Electromagnetic

propagation is affected by absorption and reflection from structures,

objects, and people.

150 kHz to 80 MHz

in ISM bands

d = 1.2

80 MHz to 800 MHz

d = 1.2

800 MHz to 2.5 GHz

d = 2.3

B-6 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 79

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

Compliant Cables and Accessories

WARNING

The use of accessori es, tra nsducers and cable s other t han

those specified may result in increased emissions or

decreased immunity performance of the equipment or

system.

The table below lists cables, transducers, and other applicable

accessories with which GE Medical Systems claims EMC compliance.

NOTE

Any supplied accessories that do not affect EMC compliance are not

included.

Part No Description Maximum Lengths

2008750-002 SEER Light 64MB Compact Flash NA

2008751-001 Compact Flash to PC Adapter NA

2008594-00X SEER Light Patient Cable 1m

3801-005 Battery Alkaline 1.5V AAA NA

Revision B SEER Light Ambulatory Recorder/Controller B-7

2019818-008

Page 80

For your notes

Electromagnetic Compatibility: Electromagnetic Compatibility (EMC)

B-8 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 81

Index

Revision B SEER Light Ambulatory Recorder/Controller Index-1

2019818-008

Page 82

Index-2 SEER Light Ambulatory Recorder/Controller Revision B

2019818-008

Page 83

A

abrasive cleaning agents 3

Access LED 3

Accessories 10

Accidental spills warning 6

Alphanumeric

keypad 4

Authorized service 10

B

Battery box

controller

cover 4

recorder

cover 3

C

Cables warning 6

Cardiac application warning 6

Caution definition 6

certification

CSA 22.2 No. 601 11

EN 60950 (UL 950) 11

IEC 601-1 11

UL 2601-1 11

Cleaning 3

cleaning

what to use 3

Conductivity warning 6

D

Danger definition 6

DATA LED 3

Data transfer

data transfer cable 4

Defibrillation warning 6

Definition

danger, warning, caution, note 6

Disposal 9

caution 7

E

Electrosurgery warning 7

Equipment Symbols 12

Equipment symbols 9

Event 12

F

Function buttons (F1, F2, F3) 4

H

Holter card slot 4

I

IEC 10

immersion in water 3

information technology equipment 11

Infrared terminal 3

Input connector 12, 3

Intended use 6

L

LCD 4

Leakage current warning 7, 4

M

Maintenance 5, 3

manual

definitions 3

purpose 3

revision history 3

manuals

related 5

Modifications caution 8

N

Note definition 6

O

Output connector 12, 3

P

Pacemaker

warning 7

Patient cable

connector 4