Page 1

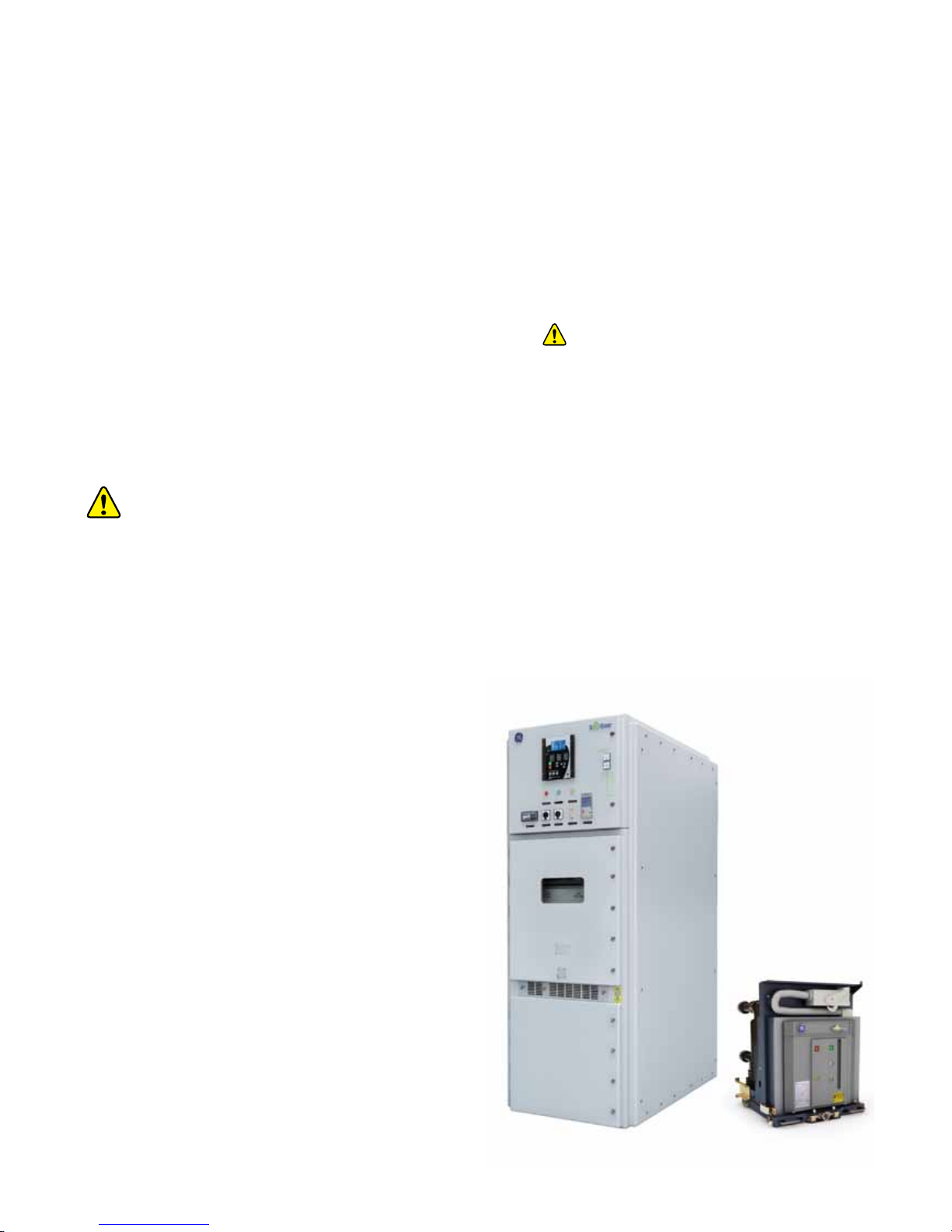

24kV-27kV

Air Insulation Switchgear

User Manual

Gear

GE

Industrial Solutions

Page 2

Index

General

Technical Specification

Enclosure design and equipment

Operations and trouble shooting

Inspection and Maintenance

Summary

Standard and Specification

Operating Conditions

Safety and Environment Protection Requirement

Handling and Storage

Installation of Switchgear

Technical specification for SecoGear Table 1

Technical specification for SecoVac VB2 Plus (Circuit breaker) Table 2

Main circuit resistance

of SecoVac VB2 plus Table 3

Technical specification for Earthing switch Table 4

Resistance to internal arc faults (Optional)

Keylock (Optional)

Padlock (Optional)

Typical Modules (Figures 3/1)

Enclosure and Partitioning (Figure 3/2)

Switchgear Structure

Cable Connections

Operations and trouble shooting

Rack Circuit Breaker out from Service Position to Test / Disconnected Position

Circuit Breaker

Earthing Swit

ch Operation

Interlocking of the Switchgear

Debugging of Combined Overcurrent Relay

Summary

Inspection and Maintenance Interval

Diagnosis and Trouble Shooting for Malfunction During Operations

Maintenance Item and Cycle

Routine Inspection

Service

Repairs

Inspection Items

Performance Test

2

7

11

16

21

2

2

3

3

4

6

7

7

7

8

8

8

10

11

11

12

15

16

17

18

18

19

20

21

21

22

22

22

23

24

24

24

Page 3

Major Repairs and Examples

Spare Parts

Appendix A - Onsite Service Safety Instruction

Inspection and replacement of the main busbar

Inspection and replacement of the fixed contact and spout bushing

Inspection and replacement of the shutter mechanism

Replacing the earthing switch

Replacing the current transformer

Inspection and replacement of the surge arrester

Main Busbar

25

32

32

25

26

27

27

29

30

31

Page 4

SecoGear 24kV-27kV Air Insulation Switchgear

1

Safety first!

Important Recommendations:

• Switchgear should be installed in a clean, dry, ventilated room.

• Switchgear and/or switchboards should be installed in closed rooms suitable for electrical equipment.

• Installation, operation and maintenance should be carried out by licensed electricians.

• Fully comply with the applicable standards (e.g. IEC), the utility connection requirements and the

applicable safety regulations.

• Observe the relevant instructions in the instruction manual for all actions in relation to switchgear and switchboards.

• Pay attention to the hazard notes in the instruction manual marked with this

warning symbol.

• Make sure that the specified data are not exceeded under switchgear or switchboard operating conditions.

• Keep the instruction manual accessible to all personnel involved in installation, operation and maintenance.

• The users must act responsibly in all matters affecting safety at work and correct handling of the switchgear.

Warning

• Always follow the instruction manual and respect the rules for good engineering practice!

• Hazardous voltage can cause electrical shocks and burns.

• Disconnect power, then earth and short-circuit before proceeding with any work on the equipment.

If you have any further questions about this instruction manual,

our field team will be pleased to provide the required information.

GE Energy reserve all

rights to this publication. We do not accept

any responsibility for the information provided, which is subject to

alternation.

Page 5

SecoGear 24kV-27kV Air Insulation Switchgear

2

General

Summary

This publication contains the information required for

installation, commissioning, operation and maintenance

of SecoGear. SecoGear is three-phase, metal enclosed, air-

insulated factory assembled switchgear. SecoGear is type-

tested and suitable for indoor applications up to 27 kV. The

panel is designed with withdrawable modules and is fitted with

a single busbar system. The withdra

wable parts are equipped

with circuit breakers, voltage transformers, fuses or current

transformers.

Details of the technical design and configuration of individual

switchgear, such as the technical data, detailed part lists for the

individual panels and comprehensive circuit documentation etc.,

can be found in the relevant order documents.

For correct usage of the switchgear, please read this manua

l

carefully. It is always advisable to use the manual for all

operations regarding installation, commissioning, operation and

maintenance of SecoGear air-insulated switchgear.

These instructions are also used as references for personnel to

carry on regularly maintenance of the switchgear.

Standard and Specification

• SecoGear complies with the standards and specifications for factory-assembled, metal enclosed and type tested high voltage

switchgears to IEC publications as given below.

IEC62271-100: 2008 …………… High-voltage alternating current circuit breakers.

IEC62271-200: 2003 …………… AC Metal enclosed switchgear and control gear for rated voltages above

1kV and up to 52kV.

IEC62271-102: 2001 …………… High-voltage alternating current Disconnector and Earthing Switches.

IEC62271

-1: 2007 …………… The common specification for high voltage switchgear and control gear

simple Standards

IEC60529:1989 …………… Degrees of protection as provided by enclosures (IP Code)

The switchgear has the following degrees of protection:

IP 4X applies for the enclosure and IP 2X applies for the partitions.

All other corresponding IEC publications, national or local safe

ty regulations must be followed during the installation and operation of

the switchgear. In addition, any project specific advice from GE must be considered.

Page 6

SecoGear 24kV-27kV Air Insulation Switchgear

3

Operating Conditions

Normal operating conditions

The switchgear is fundamentally designed for the normal service conditions for indoor switchgear to IEC Publication 62271-1:2007. The

following limitations apply. (If there are others we should detailthe limitations)

• Ambient temperature

- Maximum + 40℃

- 24h-Medium +35℃

- Minimum -15℃

• The maximum site altitude is 1000 m above

sea level

• The intensity of earthquake should not exceed level 8

• Humidity

- Highest average value measured over 24 hours

o Relative humidity 95 %

- Highest average value measured over 1 month

o Relative humidity 90 %

Special operating conditions

SecoGear is suitable for operation in the climate of indoor

type according to IEC 62271-200 standard. Special operating

conditions must b

e discussed with the manufacturer in advance.

For example: At site altitudes above 1000 m, the effects of the

reduction in density of air on the dielectric properties must be

taken into account.

Increased ambient temperatures must be compensated for in

the design of the busbar and the branch conductors as well as

the withdrawable parts; otherwise the current carrying capacity

will be reduced. Fitting

additional ventilation facilities can assist

heat dissipation in the switchgear panel.

Note on any special climatic operating conditions

When the switchgear is operated in areas with high humidity

and/or major rapid temperature fluctuations, there is a risk

of condensation. Preventive actions (e.g. applying an electric

heater) must be consulted with the manufacturer to avoid

condensation and any re

sulting corrosion or other adverse

effects. The control of the heaters depends on the particular

project are available.

Safety and Environment Protection Requirement

Safety Procedure

• Wear safety uniform according to electric safety regulations before entering the site

• Comply with industry work procedure. Power supply shall be operated by authorized staff.

Environment protection requirements

The manufacturer has a product recycle policy in accordance

with related law and ISO14001. Local laws shall be observed

when the switchgear is due for recycle.

Page 7

SecoGear 24kV-27kV Air Insulation Switchgear

4

Handling and Storage

Condition on delivery

Packing

Transport

At the time of dispatch, the factory assembled SecoGear will

have withdrawable parts either securely locked in the service

position or packed separately, depending on the rating of the

equipment, transport mode and destination.

The SecoGear panels are verified in the factory for completeness

as per order requirement, and also passed routine

testing as per

IEC 62271-200.

The busbars are not assembled, they are packed separately with

fasteners and accessories.

Based on the kind of transportation and country of destination,

the packing may vary. To protect against moisture a drying

agent bag is provided. IEC62271-1:2007 guidelines are followed.

• Panels with basic or no packing

• Panels with seaworthy or similar packing (including packing

for containerized shipments)

o Sealed in polyethylene sheeting

o Transport drying agent bags included

o Moisture indicator included

• Observe the directions for use of the drying agent bags. Note

the following

o Drying agent color observed blue indicates the packaged

equipment is dry condition

o Drying agent color observed pink indicates the packaging

contains m

oisture (relative humidity above 40%). Please

contact the manufacturer in this case before installation

The transport units normally comprise of individual panels and,

in exceptional cases, small groups of panels. The panels are

equipped with four (4) lifting eyebolts.

Only carry out loading operations when all precautionary

measures to protect personnel and materials have been taken,

with t

he following equipment:

• Crane of suitable capacity; the minimum capacity shall be 2

tonnes

• Fork-lift truck and/or manual trolley

• Lifting ropes/slings of appropriate load capacity with shackles

• Maintain an angle of at least 60° from the front for the ropes

leading to the crane hook (Figure 1/1)

HANG THE UNITS USING ALL 4 EYEBOLTS!

Figure 1/1: Handling by crane

(1) Lifting eyebolts (qty.4)

Page 8

SecoGear 24kV-27kV Air Insulation Switchgear

5

Upon Receipt

The responsibilities of the consignee when the switchgear arrives at the site include, but are not limited to, the following:

Check the consignment is complete and without damage (e.g. look for any adverse effect caused by moisture). In case of doubt, the

packing must be opened and then properly resealed with new drying agent bags (when intermediate storage is necessary).

If any quantit

ies are short, or defects or transport damage is noted, these must be;

• Documented on the respective shipping document

• Notified to the relevant carrier or forwarding agent immediately in accordance with the relative liability regulations

Note:

Always take photographs to document any major damage.

Intermediate storage

Intermediate storage should follow the following practices to avoid any negative consequences:

Panels with basic packing or without packing

• A dry well-ventilated storeroom with a climate in accordance

with IEC62271-1:2007

• Store the panels upright

• Do not stack panels

Panels with basic packing;

• Open the packing, at least partially

Panels without packing;

• Loosely covered with polythene

• Ensure that there is sufficient air circulation

Check regularly for any condensation during s

torage.

Panels with seaworthy or similar packing with internal protective

covers

• Store the transport units

a. Protected from the weather

b. In a dry place

c. Safe from any damage

• Check the packing for damage

• Check the drying agent;

d. On arrival of the consignment

e. Subsequently at regular intervals

When the maximum storage period (starting from the date of packing) has been exceeded

• The protective

function of the packing can no longer be guaranteed

• Take suitable action if intermediate storage needs to be continued

Warning

Do not walk on the top of the panels (due to rupture points in pressure

relief devices) ! The pressure relief devices can be damaged!

Page 9

SecoGear 24kV-27kV Air Insulation Switchgear

6

Installation of Switchgear

In order to obtain an optimum installation sequence and ensure

high quality standards, site installation of the switchgear should

only be carried out by specially trained, or at least by supervised

personnel and monitored by responsible persons.

On commencement of installation on site, the switch-room

must be fundamentally finished, provided with lighting and the

electri

city supply, lockable, dry and with facilities for ventilation.

It is also required that the basic frame and indoor ground

for the switchgear should be checked and accepted before

the construction. It must be ensure that the ceiling height is

sufficient for the opening travel of the pressure relief plates.

Tolerances for laying the floor frame are:

Evenness tolerance: ± 1mm within a measuring length o

f 1m.

Straightness tolerance: 1mm per 1m, but not more than 3mm

over entire length of frame.

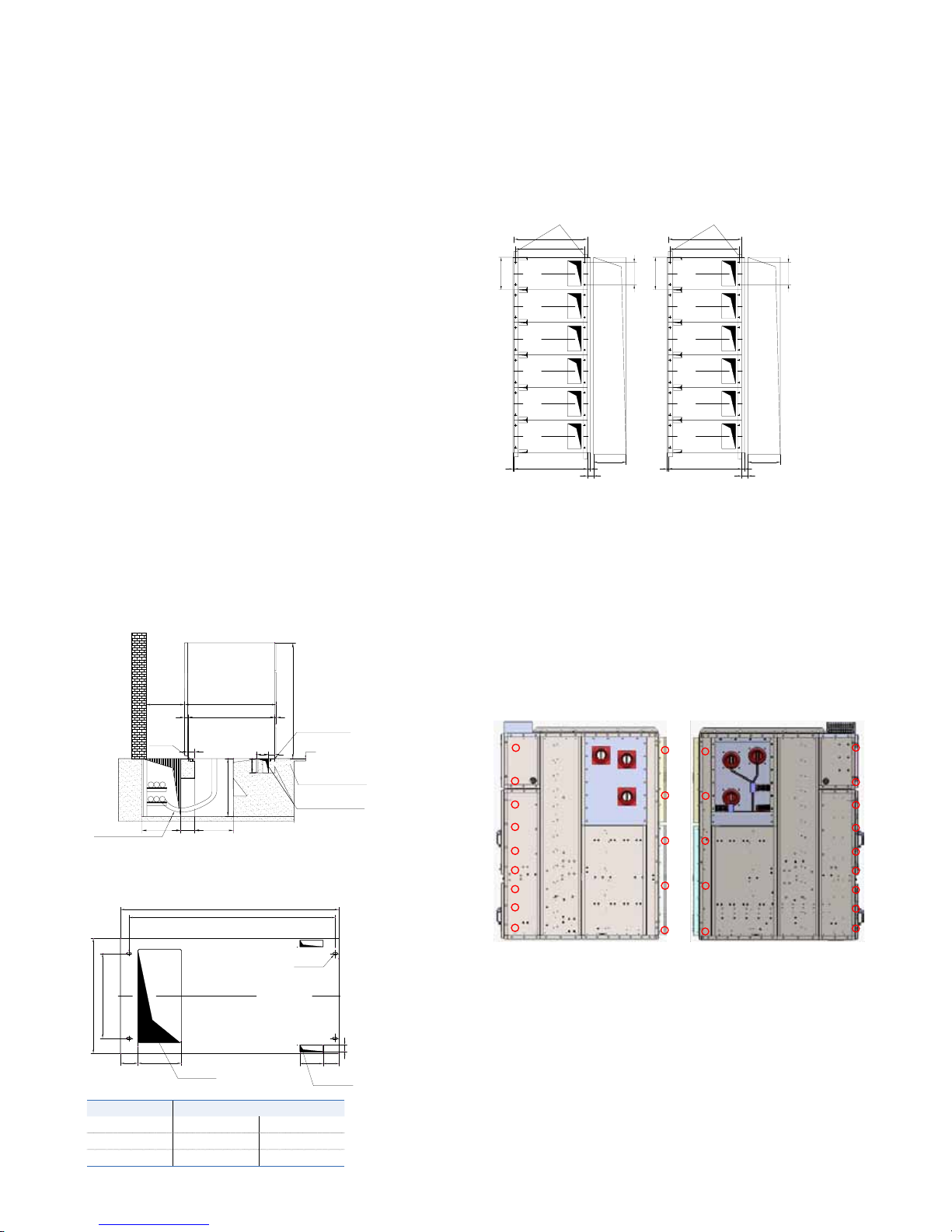

Cross section view of switchgear room layout (plan

view)

Switch room cable duct arrangement (Side elevation)

Detail of switchgear cable access cutout

Width Dimension

A 800 1000

B 600 800

C 595 692

290 800800

140

800 1900

70

1800

30

130

250

2400

Power Cable Duct 800*1000

3~5mm above ground

+5.0m

Figured steel plate (t=5mm)

Top Curface of basic frame

Strap of control cable duct

Control Cable Duct 250*250

Basic Frame

1200

300

A

190 130

1800

358

1700

B

4-15x20

54

Power Cable

Control Cable

144

600

1800

30

1800

70

800

Power Cable Duct

Basic Frame

150

1700

800/1000

800

1800

30

1800

70

800

Power Cable Duct

Basic Frame

150

1700

800/1000

Connection betweenSwitchgears

In order to connect the different switchgears together, here

use bolts of M8×35 to connect the panels together, the torque

requirement for the bolts is 26 N∙m, the connection points on the

switchgear is shown below.

Connection Points betweenSwitchgears

Page 10

SecoGear 24kV-27kV Air Insulation Switchgear

7

Technical Specification

Technical specification for SecoGear -Table 1

Rated voltage kV 24 27

Rated power frequency withstand voltage kV 50 65

Rated lightning impulse withstand voltage kVp 125 125

Rated frequency Hz 50/60

Rated current A 1250/2500

Rated short time withstand current(3s) kA 31.5

Rated peak withstand current1) kAp 82

Resistance u

Ω

≤ 110 ( ≤ 1600A)

≤ 85 ( ≥ 2000A)

IP level for weather protection

Enclosure IP4X

Between compartment IP2X

Technical specification for SecoVac VB2 Plus (Circuit breaker) -Table 2

Main circuit resistance of SecoVac VB2 plus -Table 3

Rated voltage kV 24 27

Rated power frequency withstand voltage kV 50 65

Rated lightning impulse withstand voltage kVp 125 125

Rated frequency Hz 50/60

Rated current A 1250/2500

Rated short-circuit breaking current: kA 31.5s

Percentage of DC component Up to 52%

Rated short-circuit closing current kAp 82

Rated short time withstand current kA 31.5

Rated peak value withstand current kAp 82

Rated duration time for short

-circuit s 3

Opening Time ms 20 ~ 50

Closing Time ms 30 ~ 70

Rated auxiliary control voltage V 24*/30*/36/48/60/110/220 V DC 110/220 V AC

Operation sequence: O-0.3s-CO-15s-CO/ O-0.3s-CO-180s-CO

Mechanical life operations: Times 10000 (M 2)

Electrical Endurance Class E2

Single Capacitor Switching current A 400

*Consult with GE

Item Unit Value

Rated current A 1250 2500

Withdrawable µ

Ω

≤ 45 ≤ 25

Page 11

SecoGear 24kV-27kV Air Insulation Switchgear

8

Technical specification for Earthing switch -Table 4

S/N Specification Unit Data

1 Rated voltage kV 24/27

2 Rated Work frequency withstand voltage (1min) in open condition of switch kV 65

3 Rated Lighting impulse withstand voltage (peak value) in open condition of switch kVp 125

4 Rated short-time withstand current (3s) kA 31.5

5 Rated peak value withstand current kAp 82

6 Rated short circuit making current kAp 82

7 Centre distance between phases mm 220/255

8 Electric endurance Clas

s E1

9 Mechanical endurance Times 2000

Resistance to internal arc faults

Arc release

All three primary compartments of SecoGear switchgear are

provided with pressure relief flaps, which will automatically open

and guide the pressurized gas to the rear side direction if an

internal arc fault occurs in an affected compartment

The pressure relief protects damage to switchgear components

and the risk of injury t

o personnel, which may endanger an

operator or extend the arc fault effect to the entire switchgear

lineup. The relief flap is fixed by 3-M8 steel bolts and the other

side is fixed by plastic M6 screw, The M6 screw will be broken

and flap will open along weakness area( No bend area and part

with oblong holes) when pressure increase quick by internal arc

31.5kA/1s

Keylock (Optional)

The use of key interlocks is to realizing the interlocking logics between units of switchgear, Also the functional truck can be locked in

the racked-out position and the relevant lock key can only be removed with the functional truck in disconnect position. The earthing

switch closing and opening operations can be locked by means of keys. The latter can only be removed with the e

arthing switch in an

opposed position to the lock to be made.

Page 12

SecoGear 24kV-27kV Air Insulation Switchgear

9

Description of the interlock system Key Condition

Functional truck racking-in lock

Key will be free when the truck in the disconnect position

Key will be trapped when the truck in the rack-in position

Earthing switch closing lock

Key will be free when the Earthing switch is open

Key will trapped when the earthing switch in closed position

Earthing switch opening lock

Key will be free when the Earthing swi

tch closed

Key will trapped when the earthing switch in open position

Figure : Functional truck racking-in lock

Figure 2/5: Earthing switch in open position

Figure 2/6: Earthing switch in close position

Key lock is locked, key is free, Truck indisconnect position

Key lock can't be locked when truck in rack in position, and key is trapped

When earthing switch in open position, earthing switch can be locked by closing lock, the key of closing lock can be free. And openi

ng

lock can't be locked, the key of opening lock is trapped.

When earthing switch in close position, earthing switch can be locked by opening lock, the key of opening lock can be free. And closing

lock can’t be locked, the key of closing lock is trapped.

Page 13

SecoGear 24kV-27kV Air Insulation Switchgear

10

Padlock (Optional)

Padlock for Circuit breaker racking-in/out operation

Padlock for Circuit breaker racking-in/out operation will limit the access to insert crank lever to racking-in/out Circuit breaker. Racking-

in/out operation can be done only when lock cover is in the open position.

Figure 2/9: Padlock for Circuit breaker racking-in/out operation

Padlock for earthing switch operation

Padlock for earthing switch operation will limit the access to inserting the operation lever to operate earthing switch. Open/close

button can be operated only when the lock cover is in the open position.

Figure 2/8: Padlock for earthing switch operation

Page 14

SecoGear 24kV-27kV Air Insulation Switchgear

11

Enclosure design and equipment

Typical modules (Figures 3/1)

With withdrawable type SecoVac VB2 Plus Vacuum

Circuit Breaker installed, SecoGear panels are used for

incoming or outgoing feeder. Each unit consists of three

high voltage compartments; Main bus bar, Circuit breaker,

Cable compartment and one Low voltage compartment for

instruments and auxiliary circuits.

For busbar sectionalizing, two

panels are necessary, the

coupling panel with the withdrawable circuit breaker part and

a bus riser panel (available with busbar metering and earthing).

In equipment without busbar sectionalizing, a direct bar

connection between the individual panels will be provided.

Figure 3/1: Typical modules

Enclosure and partitioning

High quality 2mm thick Alu-Zinc steel sheets is used for the

external enclosur

e and internal partitions. Pressure relief

flaps are provided on the top of the panel for all high voltage

compartments. In case of overpressure due to internal arc

inside any of the compartments, these pressure relief flaps are

designed to open quickly to release the pressure. The pressure-

relief flaps are secured with steel screws on one side and

with plastic screws on the other side. In the case o

f internal

overpressure, the plastic screws are the point of rupture caused

by arc conditions. The top mounted pressure relief flaps on the

enclosure are made from mesh metal.

All compartments are accessible from the front, with their

own independent doors. The front doors can be opened up to

an angle of 130° and they are arc resistant. An inspection

window made of security glass is provided on circ

uit breaker

compartment door. The panel design provides an air gap

between two adjacent panels after panels are joined together.

• Figures of the panel (Refer to figure 3/2), the floor of the cable

compartment is fitted with removable non-magnetic metal

(13).

• The rear wall of the busbar compartment (3), intermediate

wall (14), mounting plate with shutters (16) and horizontal

partition (20) form pa

rt of the internal partitioning.

• The earthed internal partitioning ensures safe access to the

circuit breaker and cable compartment (C) even when the

busbars are energized.

• The low voltage compartment (D) is fully protected from the

high voltage area with the earthed steel-sheet casing.

• On the end sides of the switchgear, end cover plates are

provided for consistent appearance, as well as mecha

nical

and thermal strength in case of internal arc fault in the end

panel.

• Doors, rea r walls and cover pla tes are treat ed aga inst

corrosion and then coated with high quality paint. The doors

for circuit breaker and cable compartment are arc resistant

with a mechanical interlock.

Page 15

SecoGear 24kV-27kV Air Insulation Switchgear

12

Switchgear structure

Figure 3/2: Typical feeder panel

A. Main bus compartment

B. Breaker compartment

C. Cable compartment

D. Low voltage compartment

1. Pressure relief plate

2. Enclosure

3. Cover of main busbar compartment (can be removed)

4. Branch busbar

5. Main busbar

6. Primary disconnect spouse

7. Primary disconnect

8. Current transformer

9. Earthing switch

10. Rear door interlock

11. Bottom plate

12. Pa

rtition between breaker compartment and busbar

compartment

13. Terminal block

14. Control plug

15. Shutter

16. Vacuum circuit breaker

17. Drive screw

18. Earthing switch operation mechanism

19. Control wire duct

20. Main earthing busbar

Figure 3/3: Incoming/feeder panel(1250/2500A) Figure 3/4: Incoming With fix VT panel (1250/2500A)

22

40

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A

B

D

C

P30

P32

SCALE 1,000

10

Page 16

SecoGear 24kV-27kV Air Insulation Switchgear

13

Figure 3/5: Busbar tie panel(1250/2500A) Figure 3/6: Riser panel(1250/2500A)

Figure 3/7: Measuring panel(1250/2500A) Figure 3/8: VT Panel (2500A)

P28

SCALE 1,000

10

A

B C

P29

A

B C

SCALE 1,000

P30

10

95.5

76

JSZV17-15R

15

P31

95.5

76

JSZV17-15R

15

P32

Page 17

SecoGear 24kV-27kV Air Insulation Switchgear

14

Figure 3/9: Incoming with ES & VT panel (1250/2500A) Figure 3/10: Riser with ES panel (1250/2500)

Figure 3/11: CPT panel (2500A)

Figure 3/12: Typical dimensions and Weights of SecoGear

(including withdrawable circuit-breaker parts)

Description

Dimension in

mm

27kV

Height A 2400

Width

Rated current of branch 1250A 31.5kA

B

800

VT

Rated current of branch 2500A 31.5kA 1000

Depth C 1800

Rated current Weight

A Kg

1250 800-1000

2500 1000-1200

P30

P31

P32

Page 18

SecoGear 24kV-27kV Air Insulation Switchgear

15

Cable Connections

The cable compartment contains current transformers, voltage transformers (fixed or withdrawable), and earthing switch, depending

on the individual operating requirements.

The cable compartment is constructed for installation of three current transformers. When all the three current transformers are not

required, dummies can be installed in their place to maintain the same instal

lation and connection procedures.

The fixed or withdrawable voltage transformers are connected with busbar on the primary side and fitted with HRC fuses. The earthing

switch can be operated manually, with position indication by mechanical indicator on the driveshaft and auxiliary switch. Three

lightning arrestors (optional) can be mounted in the space available.

Cable connection:

Rated voltage Panel width Max. number of parallel cables Max. cross section of cables Range of cable clamp Range of reducer ring

(kV) (mm ) per Phase (mm

2

) (mm) (mm)

27

800 6

630 35-54 27-62

1000 6

Figure 3/13: Cable compartment layout

NO. Parts Description

1 Cable clamp

2 Main earthing bar

3 Cable connection bar

4 Earthing Switch

1

2

3

4

This cover has been interlocked with the earthing

switch and can be opened only when the earthing

switch is in closed position

Earthing switch can be opened only when rear cover

is closed

Page 19

SecoGear 24kV-27kV Air Insulation Switchgear

16

Operations and trouble shooting

Operations and trouble shooting

Before start up, the following work should be completed:

a. Check the overall condition of the switchgear and clear any

potential risk factor.

b. Check the switch,truck,isolated contactor and insulating

parts etc. by visual inspection.

c. Chec k the co nnect ion betwe en e arthi ng b us b ar a nd

earthing conductor of the transformer substation out

side the

compartment is secure.

d. Remove all of the remaining materials, unnecessary objects

and tools inside of the compartment.

e. Wipe the compartment body and the insulation parts with

a soft cloth that should be clean and dry. Then wipe off any

remaining dust and grease.

f. Clean the surface of earthing busbar. The earthing loop

resistance should be less than 350 micro-ohms.

g. Re-install the cov

er removed during the period of installation,

wiring and commissioning.

Warning

a. Comply with all relevant safety regulations

b. Maintain circuit breakers in disconnection position

c. Remove earth wires and short wires of the hazardous areas

d. Pay attention to any abnormal situations

Use of hand tools

1) Gear door lock key

drawing no: 5GD.253.008

2) Rack handle for truck

drawing no: Y-002

FIG 20 : Hand Tools

h. Remove the shipping cap on the pole of the circuit breaker.

i. When

testing the power frequency withstand voltage of main

circuit, pay particular attention to sensors, cables and other

equipment during the test process.

Attention:

Read the product manual carefully when testing

the VT withstand voltage; use a test voltage of appropriate

frequency to avoid core saturation.

j. Place the Circuit Breaker on auxiliary control power.

k. Perform the operation test of the ci

rcuit breaker by manual or

electric control; observe the corresponding position indicator.

l. Check the interlocking validity, both mechanical and electrical.

m.Conductive paste can be applied on the circuit breaker

primary contacts.

3) Earthin g swit ch operation handle

drawing no: 5GD.253.144

Page 20

SecoGear 24kV-27kV Air Insulation Switchgear

17

Rack Circuit Breaker out from service position to test / disconnected position

Move circuit breaker truck from transfer truck into the switchgear

a. Check the fixed primary contact and apply an adequate

amo unt o f co nductive pa s t e . Check the i n t erlocki ng

mechanism and apply lubricant on the moving parts to ensure

smooth operation.

b. Place the Circuit Breaker on transfer truck and put in lock

posi

tion. (See figure 4/1).

VCB l o c k e d on

the transfer truck

Figure 4/1: VCB truck on the transfer truck

Figure 4/2: Transfer truck lock

with switchgear

Figure 4/3: Lock VCB in

switchgear

Warning

The trolley has four (4) nuts for adjusting the platform, to

the same level of the breaker compartment.

c. Move the transfer truck to the front of the switchgear, turn

the adjusting nut to adjust the height of the transfer truck

platform, (See figure 4/2). Aim the guiding pin at the guiding

jack in front of the switchgear, push and make the transfer

truck engage with the switchgear by using the lock

key. At

the same time, insert the front guide rail of the transfer truck

into the bottom guide rail groove of the switchgear truck. (See

figure 4/3).

d. Push the two sliding cranks inward under the truck to remove

the locked position with the transfer truck, and then push the

truck forward to make it enter the switchgear compartment

and lock it in the disconnect / test position. (See figure 4/4).

e.

Operate the lock key releasing lever of the transfer truck to

Figure 4/4: Lock VCB in switchgear

remove the locked relation between the transfer truck and the

switchgear, and then remove the transfer truck.

Page 21

SecoGear 24kV-27kV Air Insulation Switchgear

18

Move the truck from disconnect / test position to service position

a. Make sure the front and back door of the switchgear are

closed. Make sure the earthing switch is in the open position,

the circuit breaker compartment is clear and without any

unexpected object.

b. Insert the secondary plug of the truck into the socket on the

topside of the switchgear truck compartment and put into the

lock pos

ition. (See figure 4/5 & 4/6)

Figure 4/5: Take off secondary

plug from truck

Figure 4/6: Put the secondary

plug into switchgear socket

Figure 4/7: Rack in the breaker

to work position

c. Make sure the circuit breaker is in the open position.

d. Insert the racking crank of the truck into the rectangular

cranking hole of the screw mechanism of the truck through

the operation hole under the door of the circuit breaker

compartment. (

See figure 4/7).

e. Turn the crank clockwise (approximately 20 turns) until it can't

be moved any more, listen for a strong cranking sound when

the breaker changes into the operating position.

f. The position indicator on the door of the low voltage

compartment shows the breaker is in service position.

g. Take off the racking crank. The racking operation is now

complete.

Warning

The truck is not allowed to be placed in any intermediate

position between disconnect/test position and operating

position.

Move the Circuit Breaker from service position to test

position

Move the Circuit Breaker from switchgear

compartment to transfer truck.

Perform the operating steps for moving the Circuit Breaker truck

from transfer truck into the switchgear in reverse order.

a. Make sure the cir

cuit breaker is in open position.

b. Perform the operating steps for moving the Circuit Breaker

into operation position in reverse order.

Circuit breaker

Earthing switch operation

For operating instructions refer to the Circuit Breaker instruction

manual.

The earthing switch has a rapid close-open mechanism, which

is independent to the rotation speed of the earth switch drive

shaft.

The closing brake

function can be quickly applied through

the rapid close-brake mechanism. The earthing switch, circuit

breaker truck and rear cover behind the panel have a closedown

device to prevent incorrect operation.

The earthing switch can be operated only when the truck is in

disconnect / test position and the rear cover of the switchgear is

in the closed position.

The operating hole of the earthing switch lo

cated in the lower

position of the right side in front of the panel. (See figure 4/8).

Page 22

SecoGear 24kV-27kV Air Insulation Switchgear

19

Figure 4/8: Earthing switch operation warning

Close the earthing switch

Open the earthing switch

• Check that the voltage presence indication on the low voltage

compartment is off.

• Check other electrical interlock, if applicable, to allow the

operation.

• (See figure 4/9) Lower the operating hole shutter and insert

the operating handle, and turn the handle 180° clockwise to

close the earthing switch.

Figure 4/9: Close earth switch Figure 4/10: Open earthing switch

• Ensure the earthing switch is fully closed.

Warning

Warning

Check the position indicator on low voltage compartment

door

Check the flag adjacent to the earthing switch operating

hole

Make sure the cable compartment is clear and without

any unexpected objects

Make sure the cable compartment door is closed

completely

• Insert the earthing switch operating handle, and turn the

handle 180° counterclockwise to open the switch (See figure

4/10)

• Check the mechanical

ly interlocked label and indication light

to ensure the earthing switch is fully open

Interlocking of the switchgear

• The circuit breaker can be closed only when fully engaged in

the test or service position

• The control plug can be released when the circuit breaker is in

test or disconnected position. The secondary plug is latched

when the circuit is in service position (see figure 4/11)

Figure 4/11: Secondary plug latch

• Front Break is released only when operating lever is inserted;

and operating lever cannot be inserted when undercarriage is

in test position

• Undercarriage Interlock is released only when undercarriage

is in test position

• Undercarriage and ES interlock insures undercarriage can be

in service position only when ES is OFF

• Back Break insures ES can be switched on

ly when back door

is closed

• Back Door Interlock is released only when ES is ON

The earthing switch has been interlocked with the rear

cover of cable compartment and can be opened only when

the cover is closed.

If found the operation of earthing switch become hard, do

not apply the excessive force. This can cause damage to

the parts. Ensure the cover is properly secured and then

operate the earthing switch.

Contact the manufacturer, if the problem still exist.

Page 23

SecoGear 24kV-27kV Air Insulation Switchgear

20

Fig 4/12 Earthing switch interlock with rear cover

Fig 4/14: Earthing switch interlock VCB truck and Rear door

Fig 4/13 Breaker interlock with undercarriage

Interlock with Rear door

Interlock with VCB

undercarriage door

Padlock cover for ES operation

1. Operation Lever Insert Socket

2. Front Break

3. Undercarriage Position Interlock

4. Undercarriage and ES Interlock

5. Front Operation shaft

6. Back Break

7. Back Interlock Shaft

8. Back Door Interlock

SEQUENCE OF EARTHING SWITCH OPERATION

Closing the earthing switch:

Press the handle slide downwards; insert earthing switch operation handle

and turn the handle 180 degree clockwise to close the earthing switch,

Opening the earthing switch:

Press the handle flap downward, insert earthing switch operation handle

and turn the handle 180 degree counter clockwise to open earthing switch.

The flap will

be in lower position when earthingn switch is open

Page 24

SecoGear 24kV-27kV Air Insulation Switchgear

21

Inspection and maintenance

Summary

After the process of installation and testing, the switchgear

is available to use. Timely and proper maintenance can keep

the switchgear trouble-free and can prolong the life of the

switchgear as long as possible.

The maintenance work must be carried out by certified persons

who are familiar with the related operations of the switchgear

and understand relevant IE

C and other local safety rules and

important guides established by other technical departments

as well. Allow a GE representative to assist when the switchgear

and its components need to be repaired. Users should think

about the operating environment and the operation frequency

when developing maintenance rules. Usually the inspection of

some equipment / components (such as wearable parts) and

the

maintenance intervals (maintenance period) depend on

the running time, operating frequency and the number of short

circuit cycles. The maintenance period of other parts depends on

the working situation, the degree of the load and environmental

impact (including pollution and corrosive gasses).

Inspection and maintenance interval

The maintenance interval determined by operating conditions of

the swi

tchgear depends on the operating mode, the operating

number of rated current and short circuit current, environment

temperature and pollution.

The recommending maintenance interval is showed in the

following table:

maintenance content interval(years) according to the operation

cycle of circuit breaker

inspection 2~3

1)

5000

3)

care and maintenance 2~3

2)

1) Recommended shorter interval years when operated in very

severe running conditions.

2) According to inspection results.

3) Refer to the VCB manual.

Page 25

SecoGear 24kV-27kV Air Insulation Switchgear

22

Diagnosis and trouble shooting for malfunction during operations

Malfunction Reason Resolution

The circuit breaker can not be racked into service

position from test position

1. The handles on the withdrawable frame is not

in position.

2. The circuit breaker is closed

3. The earthing switch is closed

4. The circuit breaker is electrically interlocked

(electromagnetic Y0 locked)

5. Shutter is not completely open

1. Adjust the frame and handles

2. Open the circuit breake

r

3. Open the earthing switch

4. Unlock /Check electromagnetic Y0

5. Check shutter drive mechanism

The circuit breaker can not be racked out to test

position from service position

1. The circuit breaker is closed

2. The circuit breaker is electrically interlocked

(electromagnetic Y0 locked)

1. Open the circuit breaker

2. Unlock /Check electromagnetic Y0

Can not lower the shutter on the earthing switch

operating hole

1. The circuit breaker is not in test / disconnected

position

2. The earth switch is electrically interlocked

1. Rack the circuit breaker out to test position or

disconnected position

2. Unlock / Check electromagnet

Operating hole shutter can not rise back after

the earthing switch is opened

Drive shaft of earthing switch has not reached

intended position

Turn the crank anticlockwise

to the limit where

the mechanical OPEN indication stays exactly

below the operating hole

The cable compartment door can not be closed /

opened

The earthing switch is not completely

opened

Open the earthing switch

The circuit breaker can not be closed

1. No auxiliary power supply

2. The control plug is not inserted

3. The circuit breaker is not engaged in test /

service position

4. The closing spring has

not been charged

5. The electrical interlocking in position

6. Closing release not working

1. Turn on auxiliary power supply

2. Insert and lock control plug

3. Fully engage the circuit breaker to test /service

position

4. Charge the closing spring

5. Check power supply for interlocking

6. Check power supply for closing release

The circuit breaker can not be opened

1. No auxiliary power supply

2. Opening

release not working

1. Turn on auxiliary power supply

2. Check power supply for opening release

Maintenance item and cycle

Maintenance of the switchgear should be carried out by

trained personnel, who are familiar with the switchgear

characteristics, in accordance to the manufacturer's

instructions and IEC standards.

Safety measure: Routine inspection is to ensure smooth

operation of the switchgear. It does not require power

shutdown, but requires care to prevent incorrect

operations.

It is recommended any major repairs

(if required) shall be

assisted by the manufacturer or a qualified representative.

The purpose for routine inspection is to find issues in advance so

they can be resolved immediately.

Routine Inspection

Page 26

SecoGear 24kV-27kV Air Insulation Switchgear

23

Routine inspection includes:

• Check compartment doors are closed properly

• Verify the control voltage, auxiliary voltage and battery

voltage are in normal condition

• The status indication and position indication for the circuit

breaker and earthing switch etc are normal

• Check ammeter and voltmeter on the display

• Check relay indications. (The power indication should be on

and fault indication

should be off.)

• Check alarm and pre alarm indications

• Partial discharge should not occur on the surfaces of

equipment at operating voltage. This can, for example, be

detected by characteristic noises, a clearly perceptible smell

of ozone, or visible glowing in the dark;

• Check the heater condition, if installed. The relay monitoring

the heater current is in the low voltage compartment. Check

th

e heater circuit if the red current indication turn off due to

the heater losing power supply. (see figure 5/1)

Heater current

indication

Figure 5/1: Heater current monitoring relay

If any abnormal condition is found, then the cause must be

identified in order to restore normal condition.

Service

Safety measure: The power must be shutdown before

scheduled switchgear service, and the work area

must be isolated. Measures must be taken to disallow

the power being switched on. Ensure proper earthing

and padlocks in place. Specially trained personnel are

required to supervise.

It is recommeded to inspect the circuit breaker every 6

months if in stand-by for a significant period of time.

The purpo

se for the service is to guarantee the operation quality

of the switchgear and avoid any possible malfunctions. This

increases the life of the switchgear. The scope of work is as

follows:

• Inspection: Determination of the actual condition

• Servicing: Measures to preserve the specified condition

• Repair: Measures to restore the specified condition

The service interval for the switchgear depends on ext

ernal

factors including the operating environment, the operation

frequency and service age etc.

It is recommended to have switchgear serviced

every 2-3 years, if installed in good environment and

not frequently operated.

It is recommended to have switchgear serviced

every year, if operated more than 10 times a month.

It is recommended to have switchgear serviced

every half year, if installed in adve

rse environment

and frequently operated.

It is recommended to have the circuit breaker

replaced, if reached its mechanicall operating cycles

or rated short circuit breaking times.

Page 27

SecoGear 24kV-27kV Air Insulation Switchgear

24

Repairs

Immediate repairs are required in case of following situation emerges:

• Deteriorated insulation, discharges, flashover and breakdown

• Damaged component in the switchgear

• Any other abnormal observation which may affect safety

Inspection Items

• Check all the compartments and internal components for

dampness, rust and dirt.

• Check the tightening torques of the busbar bolted connections

on select

ed samples.

• Remove the pressure flaps on the busbar compartment and

remove the insulation shield (See fig 5/2). Check the torque is

86 N-m using a torque wrench.

Insulation

shield (for side

panel)

Insulation shield

(Middle panel)

Figure 5/2: Main busbar shield(Need to be replaced)

• Check the fixed contact including its profile for any sign of

sparking or wear-and-tear.

• Chec k th e sh u t ter mechanis m i

n t h e ci r cuit breake r

compartment.

• Check the interlocking between the circuit breaker and the

earthing switch.

• Check the bolted connection betwe en the power cable

connectors and lugs.

• Check earthing switch operation.

• Check the interlocking between the earthing switch and the

cable compartment door.

• Check the interlocking between the circuit breaker and the

breaker compartment door.

• Check liv

e voltage indications.

• Check the heater (If installed).

Performance test

Performance test is to validate the electrical performance of the switchgear. It is recommended to be carried out together with the

scheduled service.

Performance test includes:

• Close and open the circuit break for five times, and check the circuit

• Check all the interlocking mechanism

• Electrical test including power frequency

withstand test, CT/VT ratio and the contact resistance for the circuit break

• Verify mechanical characteristics of the circuit break

Page 28

SecoGear 24kV-27kV Air Insulation Switchgear

25

Major Repairs and examples

Be sure to comply with the applicable safety

regulations when carrying out repairs.

Verify the switchgear is de-energized and the safety

measures are in place.

Pay attention to the direction of the tapered washers

and the bolted connection torque should reach 86 N-m.

• Open the main busbar compartment and check the tightening

torques for the busbar bolted connections

• Check the main busbar and branch

busbar for any dampness

or rust.

• Check all the sidewalls for any dampness or rust.

• Check the main busbar compartment for any unexpected

object.

• Restore the insulation shield and the pressure flap on the top

of the panel.

• Check the fitness of the fixed contact and the surface

condition.

• Open the cable compartment and check the cable connection

as wells as the connectors for color distortion.

• Ch

eck the sealing condition of through holes for the primary

and secondary cables.

• Check the heater condition.

• Check the breaker and cable compartment for unexpected

objects.

• Check the secondary connections of the CTs.

• Check the current terminals in the low voltage compartment

for the close loop of the secondary current circuit. Check

the protection relay, ammeter, energy meter, etc. on the CT

s

econdary are in service.

Inspection and replacement of the

main busbar

Unexpected objects in the busbar compartment, or a loose

bolted connection, may result heated joint or even phase fault.

The procedure to change the main busbar is as follow;

• Remove the rear covers on the busbar compartment, as well

as the same on the adjacent panels. Now the busbar is visible.

(see figure 6/1)

Figure 6/1: Busba

r after opening the rear cover

• Remove the pressure flap on the busbar compartment

• Remove the busbar insulation shield

• Remove the connection bolt on the main bar and branch

busbar

• Remove the busbar from the busbar compartment

• Install the new main busbar and fasten the joints

• Cover the busbar joints with insulation shield

• Reassemble the pressure flaps and rear cover panels for the

busbar compa

rtment

Page 29

SecoGear 24kV-27kV Air Insulation Switchgear

26

Verify the switchgear is de-energized and the safety

measures are in place.

Don't fasten the bolt initially when locking the fixed

contact, Please fasten by applying torque when the

upper branch and main busbar, lower branch and the

current transformer are fixed;

Inspection and replacement of the

fixed contact and spout bushing

It is normal to find the fixed contact surface oxidized due to

current flow an

d environmental factors during period of service.

However if the surface becomes rusty due to wet or corrosive

conditions, the fixed contact must be replaced. The spout

bushing may be replaced depending of its condition.

Clean the contact with a cotton-free paper, and apply some

pure alcohol if necessary. Brush small amount of contact

lubrication grease (DE-G51 for example) on the surface after

wipi

ng. It is important to check any abnormal condition such as

the burning marks on the spout bushing, which may be caused

by the epoxy.

• Check and replace the fixed contact

• Withdraw the circuit break . Open the shutter mechanism, and

insert two M8 bolts into the overlapping holes on the shafts

(See figure 6/2). Then the fixed contact along with the spout

bushing are visible.

Figure 6/2 : shutter mechanism

• Inspect the contacts. Replace the contact if the silver coating

on copper is worn, or the surface is corroded, damaged or

over heated.

• Remove the bolts on the fixed contact, and replace the fixed

contact (see figure 6/3)

• Replace the spout bushing

• Remove the bolt at the joint of the upper branch and main

busbar

• Remove the bolt at the joint of the lower branch busba

r and

the current transformer

• Remove the center bolt of the fixed contact and then remove

the vertical connections

Figure 6/3: Fixed contact and spout bushings

• Remove four fixing screws (M12) of the spout and then the

spout can be removed (see figure 6/3)

• Replace the new spout bushing and fasten the fixing screws

(M12). Inject glass glue in the clearance between the spout

bushing and the mounting m

etal frame

• Insert the upper and lower branch busbar into the spout

bushing, and fix the fixed contact

Attention:

The torque will be different based on different sizes of

the bolt and with/without lubrication. Corresponding torques of

different bolts identified below:

Silver plating fixed contact

Front Rear

Fixing screws

Page 30

SecoGear 24kV-27kV Air Insulation Switchgear

27

Recommend torque (N-m)

Bolt size Without lubrication (oil) With lubrication (oil)

M8 26 10

M10 50 20

M12 86 40

M16 200 80

M20 300 120

• Tighten the bolt on the upper branch and main busbar. Ensure that applied torque is 86 N-m

• Tighten the bolt of the lower branch busbar and the current transformer. Ensure applied torque is 86 N-m

• Remove the inserted bolts on the driving mechanism of the shutter, and then put down

the shutters

Inspection and replacement of the

shutter mechanism

Replacing the earthing switch

In case of distortion or deformation, the driving mechanism of

the shutter shall be replaced.

The steps as follows:

• Remove the split pins of the driving mechanism of the shutters

and connection bar (see figure 6/5)

• Screw off the bolt which is used to fix driving mechanism (see

figure 6/4)

The replacing of th

e earthing switch includes changing the

earthing switch along with labels for ON and OFF position, the

driving mechanism including driving gear assembly and drive

rod.

The steps for replacement are as follows.

Figure 6/4: Driving mechanism of the shutter

• Remove the 5 screws on the earthing bar, then remove the

earthing bar.

• Replace the 4 screws on the side plate of the shutter

mechanism, then remo

ve the side plate.

• Remove the 6 screws which used to fix the shutter

mechanism, replace with the new parts of shutter mechanism.

• Now replacement can be done with the above instructions

following the previous instructions in reverse order.

• Rack out the circuit breaker

• Remove the compartment separating plate

• Remove the cover plate on the right side in the cable

compartment

Ensure switchgear is in Power OFF position and turn

the earthing switch to the ON position.

Remove 6 fixing screws

which used to fix the

ES on the side sheet

Remove 4 fixing screws

Remove 6 fixing screws

• Loosen the fastening screws on the drive rod, but do not

remove completely.

Split pins

Bolt

Earthing bar

Page 31

SecoGear 24kV-27kV Air Insulation Switchgear

28

Both the screws can be accessed only when the

earthing switch is in OPEN position

Attention: Don't fully remove the drive rod, otherwise all

the parts will fall out.

Attention: Replace the bevel gear assembly and

earthing switch in the same way. Use care to avoid

damage as the main body is much heavier.

• Open the padlock on the operating hole of the earthing switch

• Draw out the drive rod forward,

then the parts of the drive rod

in the switchgear can be removed from backwards now.

• Completely draw out the drive rod from another side at a

slight angle.

• Loosen the 4 fixing screws on the fixing bracket (see figure

6/6), and then remove drive rod of the rear door interlock from

rear door, then draw out the drive rod backward.

• Unscrew both of the bolts on the bevel gear (See figure 6/7).

Fixed screw of

the bevel gear

Flexible connection

of the earthing

switch and earthing

busbar

Figure 6/7: Fixing screw of bevel gear

Figure 6/8: Flexible cable between earthing Switch and earthing

busbar

• Unscrew the flexible connections between the earthing switch and common earthing busbar (see figure 6/8)

• Remove the fixing screw of the earthing switch, and then push the bevel gear and the main body of the earthing switch (See figure

6/9)

• Now replacement can be done with the above instruc

tions following the previous instructions in reverse order.

Remove 6 fixing

screws o f the

earthing switch

Figure 6/9: Fixing screw of the earthing switch

Page 32

SecoGear 24kV-27kV Air Insulation Switchgear

29

Replacing the current transformer

Replace the current transformer if the assembled current

transformer cannot meet the function due to a change in the

load conditions. The steps are as follows:

Confirm the equipment be powered off and make sure

to follow proper safety measures.

Confirm the earthing switch is in OPEN position.

Ensure the marking on the mounting plate for the

installing position of the current transformer before

removing the four bolts to avoid the wrong position

with the hole of the copper connections after installing

the new current transformer;

Attention: The weight is heavy

because of the current

transformer installed in the mounting plate. It is

necessary to hold the mounting plate of the current

transformer to avoid the damage for the equipment

and personnel if the mounting plate drops down after

loosening the bolt.

• Remove the back cover of the enclosure

• Remove the connection bolt between the current transformer

and the vertical copper connections (See figure 6/1

0)

• Remove the secondary wires of the current transformer

• Remove the 6 pcs of M8 bolts on the mounting plate of the

current transformer

Figure 6/11: Mounting plate of the current transformer

• Support the mounting plate of the current transformer and

then put on the ground

• Remove the four bolts which are used to fix the current

transformer, and remove the current transformer

• Replace the current tr

ansformer with new one and screw on

with the four bolts

• Assemble the current transformer in its place on mounting

plate and tighten the mounting plate by tightening the 10 pcs

of M8 bolts

• Screw on the bolts on the current transformer and the both

side copper connections

• Fix the bolt of the fixed contact of the earthing switch, but do

not fully tighten.

• Adjust the position of the fixed contact a

fter switching the

earthing switch in ON Position and then fasten

• OPEN the earthing switch

• Fasten the bolts on the copper connections and the current

transformer mounting with a torque wrench at a torque of 86

N-m

• Fix the insulation shield, and make sure it is in a vertical

position

• Connect the secondary connection of the CT and cover it

according to the requirements

• Assemble the back cover

and compartment separating plate

of switchgear

Copper

connections

Figure 6/10: Connection busbar between current transformer

and earthing switch

3 pcs of M8 bolts on each side

Page 33

SecoGear 24kV-27kV Air Insulation Switchgear

30

Inspection and replacement of the

surge arrester

Inspection and replacement of

potential indicator

It is necessary to replace the surge arrester based on big

difference between reference voltage and the test data recorded

on site during the maintenance and recording. The steps are as

follows:

Mounting bracket and

earthing bar for arrester

Figure 6/12: Installing surge arrester

• Remove the cable between the arrester and copper

connection (See figure 6/12)

• Remove the fixed bolts on both sides of the mounting bracket

of the arrester

• Push the three arresters and the bracket

• Remove the fixed bolts on the mounting bracket of the

arrester

Figure 6/13: Surge arrester mounting plate

• Install the new arrester and fasten the bolts with the mounting

bracket

• Screw both side bolts on the brackets

• Fix the connection between the arrester and copper

connection

If the display "Lock" on the potential indicator is flashing, and

an abnormal sound from the relay is continuously heard, there

may be two reasons that can cause this problem. First, t

here

may be a problem with the potential indicator contact. Second,

the display itself may have a fault despite three-phase power

condition.

Both of these situations demand to replace the display. The

steps are as follows:

Lock indicator

Test push button

Three phase c harged

display

Figure 6/14: Potential indicator

There are two types potential indicators. One is with latching

contact, and another is without the latching contact. The

replacement of the two types are the same. (See figure 6/14)

• Cut off the auxiliary power of potential indicator (if any)

• Disconnect all the connection from the back of the indicator

• Remove the lock of the potential indicator, and then push it

ou

t (See figure 6/15)

• Replace with the new one, and fix the lock

• Reconnect the wires at back

• Recover the auxiliary power

Lock to fix of

the potential

indicator

All connection on

the jointing row

Figure 6/15: Removing and installing for the potential indicator

Page 34

SecoGear 24kV-27kV Air Insulation Switchgear

31

Main Busbar

Rule and Note:

Every 3~4 panels use one Main Busbar. The maximum length of Main Busbar should be less than 4m.

Below is a table indicating Busbar sizing;

Rated current Busbar type Cross section (copper)

Main Busbar &

Branch Busbar

(Rectangle)

1250A

Branch 50x8x2

Main 80x10x1

2500A

Branch 120x8x2

Main 120x8x2

Connection mode of Main Busbar / Branch Busbar

Connection mode of Main Busbar and Grading ring

• Main Busbar and Branch Busbar

1. Main busbar

2. Wall bushing

3. Support pad

4. Main Busbar & Branch Busbar

joint insulation boot

In order to better protect the

wall bushing, it is necessary to

add a grading ring in the wall bushing to balance the voltage

between the wall bushing and main busbar. So the grading ring

and the main busbar should be connected before doing the

routine tests and installation of the Switchgear in the field. As

the grading ring is casted into the wall bushing, the wall bushing

and the main busbar should be connected by conductor.

Here, choose connect the bushing and the main busbar on

the outward side of the switchgear for convenience of the

connection. (See Figure 6/16 )

Wall Bushing

Grading Ring

Conductor

Main Busbar

Figure 6/16: Grading Ring and Connecting conductor

Before the connection of grading ring and main busbar, make

sure the through threaded ho le (M5) on the centerline of

main busbar which close the conductor have already tapped

according to the length of the conductor. The length between

the two hole's center of the conductor is 200mm. The distance

between

the center of threaded hole and the outer surface of

the wall bushing is 150mm ( See Figure 6/17).

150

Figure 6/17:Position of the threaded hole

5. Branch busbar

6. Insulation Cover

7. Support insulator

8. Spout

1

2

3

4

5

6

7

8

Page 35

SecoGear 24kV-27kV Air Insulation Switchgear

32

Spare parts

Please refer to recommended spare parts list below. Other spare parts are also available based on customer's requirement.

S/N Name Unit Comments

1 Heater Piece

2 Key for door lock Piece

3 Earthing switch operating handle Piece

4 27KV Service Truck T800 Set

5 27KV Service Truck T1000 Set

Appendix A - Onsite service safety instruction

Before operating the equipment, please check and make sure to

follow all safety requirement.

If for any reason the work is interrupted, please make sure site

safety procedure is followed when restarting the

work.

• Before operating, please check site layout, both inside

and outside of the electrical operating area, earthing line

layout, ON or OFF condition of the control power, state of

the temporary power, and if any personnel is present and all

safety/emergency exits are clear.

• Ensure if safety procedures on working sheet are well

implemented, recheck if the safety procedures comply with

requiremen

ts, if isolation procedure between live equipment

and test equipment is established, and there are clear

instructions on the product labels.

The connection sequence as follows:

Confirm the equipment be powered off and make sure to

follow proper safety measures.

• One side of conductor is connected with wall bushing

by using one screw(M5X8) and a flat washer, required

torque is 5Nm.

• Another side of connecting conductor is connected

with main busbar by using another screw(M5X10) and

a flat washer, required torque is 5Nm.

• Replacement can be d

one with the above instructions

following the previous instructions in reverse order.

• Once equipment is in power off phase, it is strictly forbidden

to operate the circuit breaker or switch. Please switch OFF

circuit breaker and move VCB to test or withdrawn position.

Instrument and power transformer to power of the equipment

shall be switched off in order to avoid any unintended

charging of the eq

uipment.

• Please confirm the switchgear reference data and series

number to avoid working on the wrong equipment.

• All current transformer and voltage transformer secondary

winding shall only have one permanent and reliable protective

earthing.

• If it is necessary that personnel must service the switchgear,

please make sure to contact GE or that site personnel is

properly trained and are capable of

following proper safety

measures.

Cut off the heat-shrinkable tube (the surface side which close

the conductor) with the area of 30x30mm around the threaded

hole (See Figure 6/16).

Figure 6/17

Threaded Hole (M5)

Page 36

Japan

11F, Akasaka Park Bldg.,5-2-20, Akasaka, Minato-ku

Tokyo 107-6111

T : +81 3 3588 5288

F : +81 3 3585 3010

North Asia

Korea

22, Daewangpangyo-ro 712 beon-gil, Bundang-gu,

Seongnam-si, Gyeonggi-do, 463-400, Korea

T: +82-31-620-6000

F: +82-31-620-7070

Malaysia

Level 6, 1 Sentral, Jalan Travers, Kuala Lumpur Sentral

Kuala Lumpur, Malaysia 50470

T : +603 2273 9788

F : +603 2273 7988

Thailand

25th floor, CRC Tower, All Seasons Place, 87/2 Wireless

Road, Lumpini, Pathumwan, Bangkok 10330

T : +66 2 648 0240

F : +66 2 648 0200

Indonesia

BRI II Tower, 27th floor, Jl. Jend. Sudirman No. 44-46

Jakarta 10210

T: +62 21 573 0430

F: +62 21 574 7089

Singapore

240 Tanjong Pagar Road, #06-00 GE Tower

Singapore 088540

T : +65 6326 3718

F : +65 6326 3015

Philippines

8F Net Cube Building, 30th Street, Corner 3rd Avenue,

Crescent West Park, Global City Taguig 1634

T : +63 2 877 7000

F : +63 2 846 0629

Vietnam

Saigon Centre, Unit 1, Floor 7, Le Loi Boulevard, District 1

HoChiMinh City

T : +84 8 3914 6700

F : +84 8 3827 8229

South East Asia

Australia

125-127 Long Street, Smithfield, Sydney, NSW 2164

T : +61 2 8788 6911

F : +61 2 8788 7224

Australia & New Zealand

New Zealand

Level 1, 8 Tangihua Street, Auckland, North Island

T : +64 9 353 6706

F : +64 9 353 6707

India

Polt No. 42/1 & 45/14, Electronic City-Phase II

Bangalore-560100

T: (080) 41434000

F: (080) 41434199

India

Shanghai

4F, Building 2, CTP, No.1 Hua Tuo Rd. Zhang Jiang Hi-Tech

Park, Shanghai, China 201203

T : +86 21 3877 7888

F : +86 21 3877 7600

Taiwan

6F, No. 8, Min Sheng E. Rd., Sec. 3, Taipei 10480

T : +886 2 2183 7000

F : +886 2 2516 6829

Greater China

Spain

P.I. Clot del Tufau, s/n, E-08295 Sant Vicenç de Castellet

T: +34 900 993 625

Belgium

Nieuwevaart 51, B-9000 Gent

T: +32 (0)9 265 21 11

Finland

Kuortaneenkatu 2, FI-00510 Helsinki

T: +358 (0)10 394 3760

France

Paris Nord 2, 13, rue de la Perdrix

F-95958 Roissy CDG Cédex

T: +33 (0)800 912 816

Poland

Ul. Odrowaza 15, 03-310 Warszawa

T: +48 22 519 76 00

and

Ul. Leszczyńska 6, Bielsko-Biała 43-300

T: +48 33 828 62 33

Europe & Middle East

Italy

Centro Direzionale Colleoni

Via Paracelso 16, Palazzo Andromeda B1

I-20864 Agrate Brianza (MB)

T: +39 039 637 3701

Netherlands

Parallelweg 10, Nl-7482 CA Haaksbergen

T: +31 (0)53 573 03 03

Germany

Robert-Bosch Str. 2a, 50354 Hürth-Efferen

T: +49 (0) 2233/ 9719-0

Portugal

Rua Camilo Castelo Branco, 805, Apartado 2770

4401-601 Vila Nova de Gaia

T: +351 22 374 60 00

Hungary

Vaci ut 81-83. H-1139 Budapest

T: +36 1 447 6050

Russia

27/8, Electrozavodskaya street, Moscow, 107023

T: +7 495 937 11 11

South Africa

Unit 4, 130 Gazelle Avenue, Corporate Park Midrand 1685

P.O. Box 76672 Wendywood 2144

T: +27 11 238 3000

United Arab Emirates

Injaz Building, 3rd Floor

Dubai Internet City, PO Box 11549, Dubai

T: +971 4 4546912

United Kingdom

2 The Arena, Downshire Way

Bracknell, Berkshire

RG12 1PU

T: +44 (0) 800 587 1239

Latin America

790 N.W. 107th Avenue, Suite 200, Miami, Fl 33172 USA

T: +1 305 551 5155

Chile

Vespucio Norte, Avenida Presidente Eduardo Frei

Montalva 6001, Edificio N° 66

Comuna: Conchalí, Sector el Cortijo, Santiago

T: (56 2) 928-4700

Latin America

Brazil

Av. María Coelho Aguiar, 215, Bloco C - 6.Andar

Jd.São Luiz, 05804-900, São Paulo

T: +55 11 36141900

Mexico

Av. Churubusco 3900 Nte, Col. Industrial Benito Juárez

Monterrey, N.L. 64517

T: (01-800) 800-1968

USA

41 Woodford Avenue, Plainville CT, USA 06062

and

12305 Kurland Drive, Houston, TX USA 77034

T: +1 800-431-7867

North America

Shanghai GE Guangdian Co., Ltd

No.3, Lane 123, East Huancheng Rd,

Fengxian District, Shanghai, China 201401

T : +86 21 6710 1888

F : +86 21 6710 1901

Printing Code: GE/PV2/MU/2013/01

Loading...

Loading...