Page 1

INSTALLATION INSTRUCTIONS FOR YOUR NEW

•

STOP!

TOOL LIST

• 1/8" drill bit

• Electric or hand drill

• No. 1 or No. 2 Phillips

screwdriver

• Pencil

• Ruler and straightedge

• Hand or saber saw

• Pipe wrench

• Adjustable wrench

• 3/16" hex socket

driver

• 12" spirit level

ADDITIONAL MATERIAL YOU MAY NEED:

• Gas line shut-off valve

• Pipe joint sealant

• 1/2" pipe nipple

For flexible connection where local codes

permit:

• Coated and approved flexible metal tubing (same

3/4" or 1/2" I.D. as gas supply line)

• Adaptor or connector

For rigid connection:

• Pipe fittings or union as required

229C

4053P085

Pub. No. 31-10253

IMPORTANT:

Remove all packing material

and literature from the cooktop before

connecting gas and electrical supplies.

STOP!

30" SEALED GAS COOKTOPS

Before you begin: Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

INSTALLER: Be sure to leave these instructions with the Consumer.

CONSUMER: Keep these instructions with your Use and Care Book for future

reference.

This appliance must be properly grounded.

Installation of this cooktop must conform with local

FOR YOUR SAFETY

WARNING!! If the information in

this manual is not followed

exactly, a fire, explosion, or gas

leak may result causing property

damage, personal injury, or

death.

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE!

WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light any

appliance.

• Do not touch any electrical

switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

codes or in the absence of local codes with the

National Fuel Gas Code, ANSI Z223. 1-Latest edition.

• Be sure your cooktop is installed properly by a qualified

installer or service technician.

• To eliminate reaching over surface burners, cabinet

storage above burner should be avoided.

• Do not install the unit near an outside door or where a

draft may affect its use.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

This cooktop has been design certified by the American

Gas Association. You’ll find safety precautions in your

Use and Care book. Read them carefully.

1

Page 2

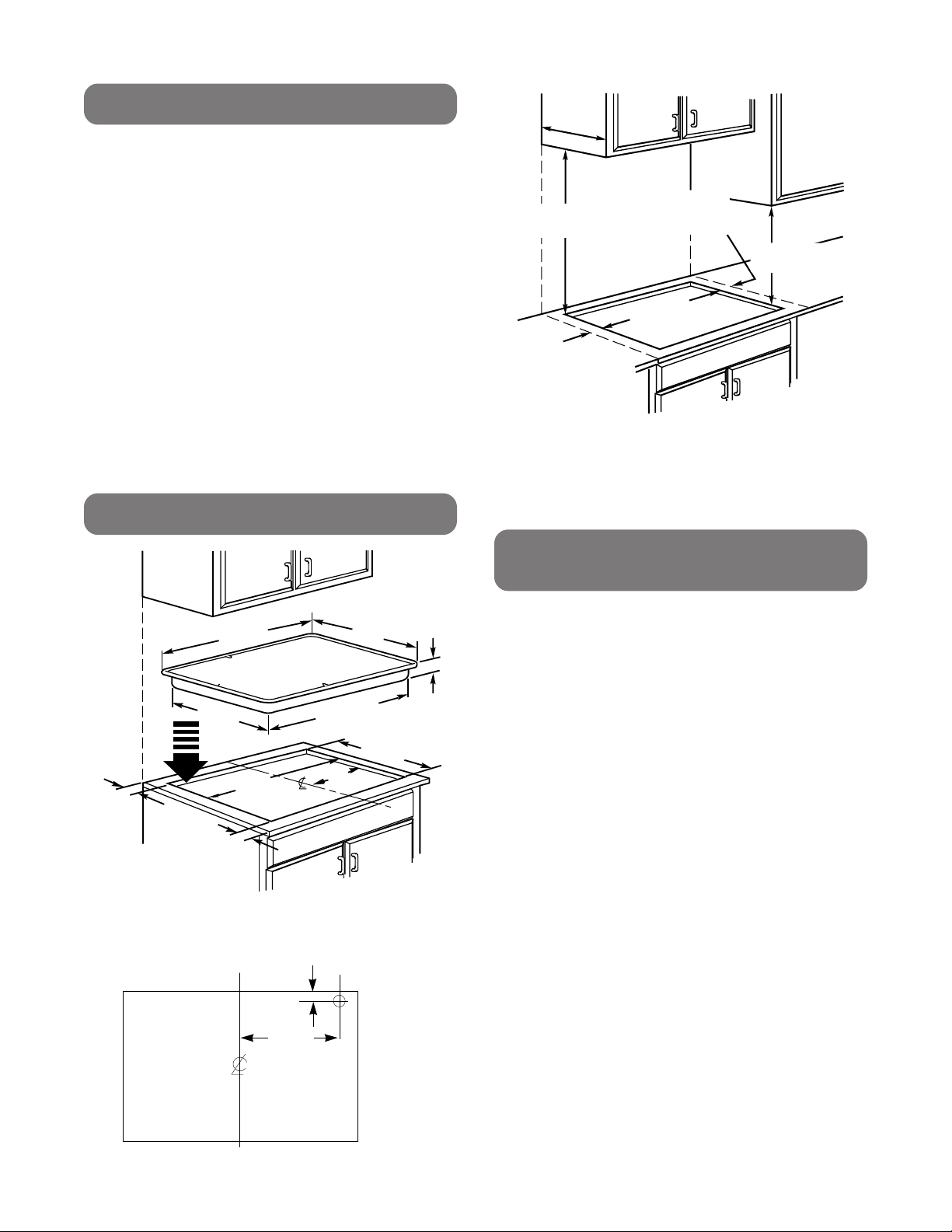

ELECTRICAL REQUIREMENTS

19 3/8"

28 3/8"

21"

30"

28 1/2"

3"

2 1/4"

MIN.

3 1/4" MIN.

19 5/8"

14 1/4"

COOKTOP

FROM CUTOUT

CENTER LINE

1" FROM BACKWALL

3 3/4" MIN.

CLEARANCE

TO SIDE WALL

30" MIN.

TO CABINET

3 3/4" MIN.

CLEARANCE

TO SIDE WALL

13"

MAX.

DEPTH

18" MIN.

TO CABINET

PROVIDE ADEQUATE

GAS SUPPLY

This cooktop is designed to operate on natural gas at 4"

of water column pressure. It is shipped from the factory

set for natural gas.

A convertible pressure regulator is connected in series

with the manifold of the cooktop and must remain in

series with the supply line regardless of whether natural

or L.P. gas is being used.

FOR PROPER OPERATION, THE MAXIMUM

INLET PRESSURE TO THE REGULATOR MUST

BE NO MORE THAN 14" OF WATER COLUMN

PRESSURE.

For checking the regulator, the inlet

pressure must be at least 1" (or 3.4 KPA) greater than

the regulator output setting. If the regulator is set for 4"

of water column pressure, the inlet pressure must be at

least 5". If the regulator is set for 10", the inlet pressure

must be at least 11".

The gas supply line to the cooktop should be 1/2" or

3/4" pipe.

This Appliance must be electrically grounded. Check

with your local codes which apply in your area. If no

local codes apply, the National Electrical Code, ANSI/

NFPA No. 70-Latest Edition must be followed. Write to:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Be sure the installation of this cooktop in a mobile home

conforms with the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280. If this

standard does not apply, you must follow the standard

for Manufactured Home Installations, ANSI A225. 1 and

Manufactured Home Installations, Sites, and

Communities and ANSI/NFPA 501A or with local codes.

You can get a copy of the Federal Standard by Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

PREPARE THE OPENING

Fig. 3

• Make sure the wall coverings, countertop and

cabinets around the cooktop can withstand the heat

(up to 200°F) generated by the cooktop.

• Provide adequate clearances between cooktop and

adjacent combustible surfaces.

Fig. 1

Fig. 2

12 1/2"

2

Page 3

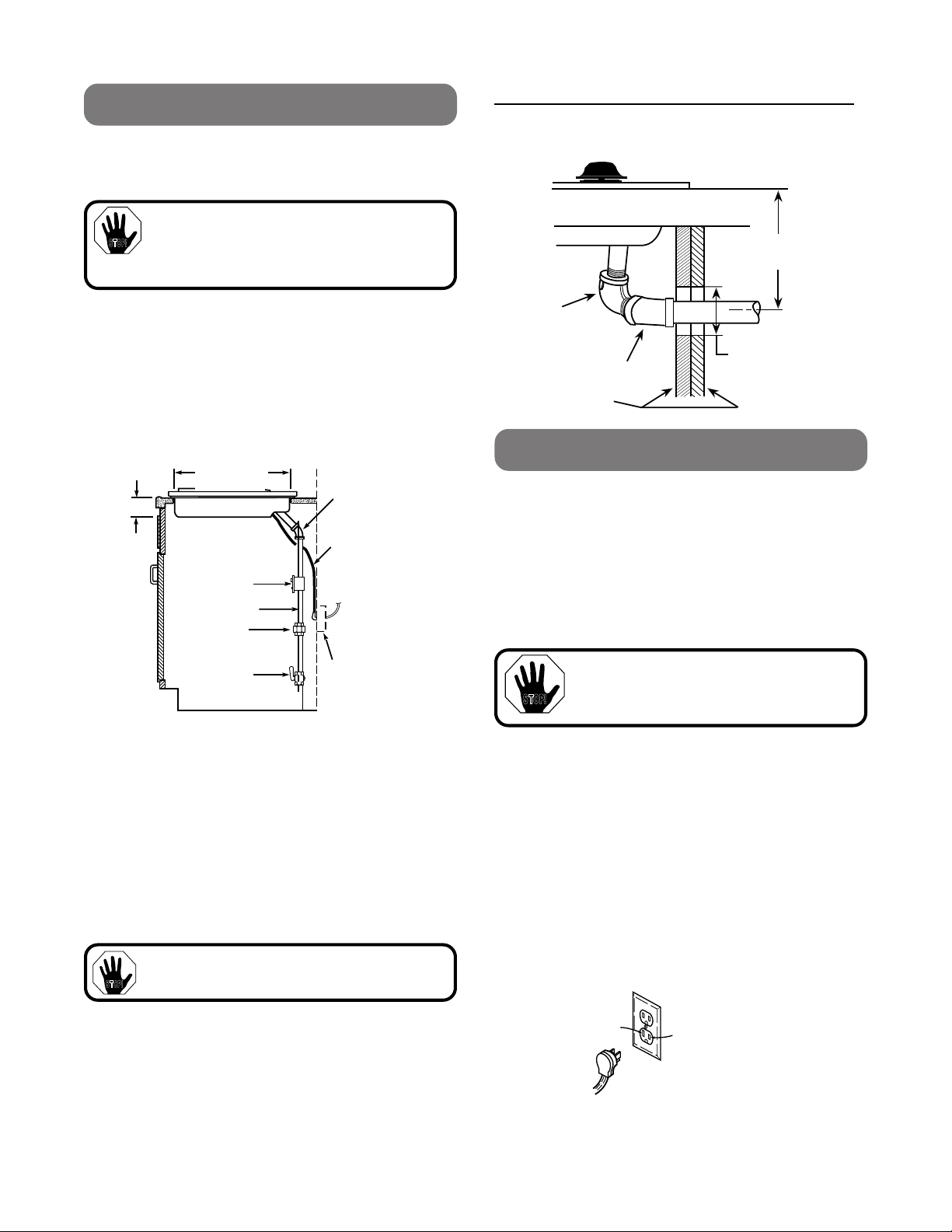

GAS CONNECTIONS

90°

STREET EL

45°

ELBOW

CABINET SIDES

2" DIA. HOLE (20 7/8"

FROM FRONT OF

COUNTERTOP TO

HOLE CENTER)

5" TO CENTER

OF 2" DIA. HOLE

FROM COUNTERTOP

ELECTRICAL CONNECTION

Because of potential safety hazards under certain

conditions we strongly recommend against the use of

an extension cord. However, if you still elect to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance extension cord

and that the current carrying rating of the cord in

amperes be equivalent to or greater than the branch

circuit rating. Such extension cords are obtainable

through your local appliance dealer.

IMPORTANT:

(Please read carefully) FOR

PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED.

STOP!

Insure proper

ground and

firm connection

before use

L

N

STOP!

3" MIN.

19 1/2"

CUTOUT

45°

PRESSURE

REGULATOR

SHUT OFF

VALVE

1/2" PIPE

COUPLING

ELECTRICAL

CORD

34"LONG

ELECTRICAL

OUTLET

12" BELOW

COUNTERTOP

19 5/8"

CUTOUT

Fig. 4

5.

Check for leaks. After connecting cooktop to gas,

check system for leaks with a manometer. If a

manometer is not available, turn the gas supply on

to the cooktop and use a liquid leak detector at all

joints and connections to check for leaks.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the cooktop

to the gas supply to be sure the manifold pipe has not

been moved. A misalignment could cause the valve

knob stem to rub on the control panel, resulting in a gas

leak at the valve.

DO NOT USE OPEN FLAME TO CHECK FOR

LEAKS!

STOP!

1.

Connect the cooktop to the gas supply line.

2. NEVER REUSE OLD CONNECTORS WHEN

INSTALLING THIS COOKTOP.

INSTALLATION OVER BUILT-IN OVEN

See built-in oven installation for complete installation

instruction.

3.

4.

Disconnect this cooktop and its individual

shutoff valve

during any pressure testing of that system at test

pressures greater than 1/2" psig.

Isolate the cooktop

system by closing its individual shutoff valve during any

pressure testing of the gas supply system at test

pressures equal to or less than 1/2" psig.

WARNING:

Never reuse old flexible connectors.

The use of old flexible connectors can cause

gas leaks and personal injury. Always use new

flexible connectors when installing a gas appliance.

The regulator supplied with the unit must be installed in the gas supply line between the shut-off

valve and the unit connection. The top of the regulator should face toward the cabinet front and easily

accessible through the cabinet doors.

Install a manual shutoff valve in the gas line in an

easily accessible location outside the cooktop. Be

sure you know how and where to shut off the gas

supply to the cooktop.

from the gas supply piping system

from the gas supply piping

An adequate electrical supply and outlet must be used

to operate the electrical parts of your cooktop.

1.

The power cord of this appliance is equipped with

a three-prong (grounding) plug which must be

used with a properly grounded three-hole outlet

with a standard 120 Volt, 60 cycle AC household

current.

2.

If you do not have a three-hole grounded outlet,

have a qualified electrician change your old one.

3.

A grounding adaptor will be needed to convert the

old one until the outlet can be replaced. This method

is only temporary, and a qualified electrician should

test it to be sure it meets requirements.

3

Fig. 5

Page 4

Where a standard two-prong wall receptacle is

STOP!

CAUTION:

Attaching the adaptor ground

terminal to the wall receptacle cover screw

does not ground the appliance unless the

screw is metal, and not insulated, and the

wall receptacle is grounded through the housewiring.

The customer should have the circuit checked by a

qualified electrician to make sure the receptacle is

properly grounded.

STOP!

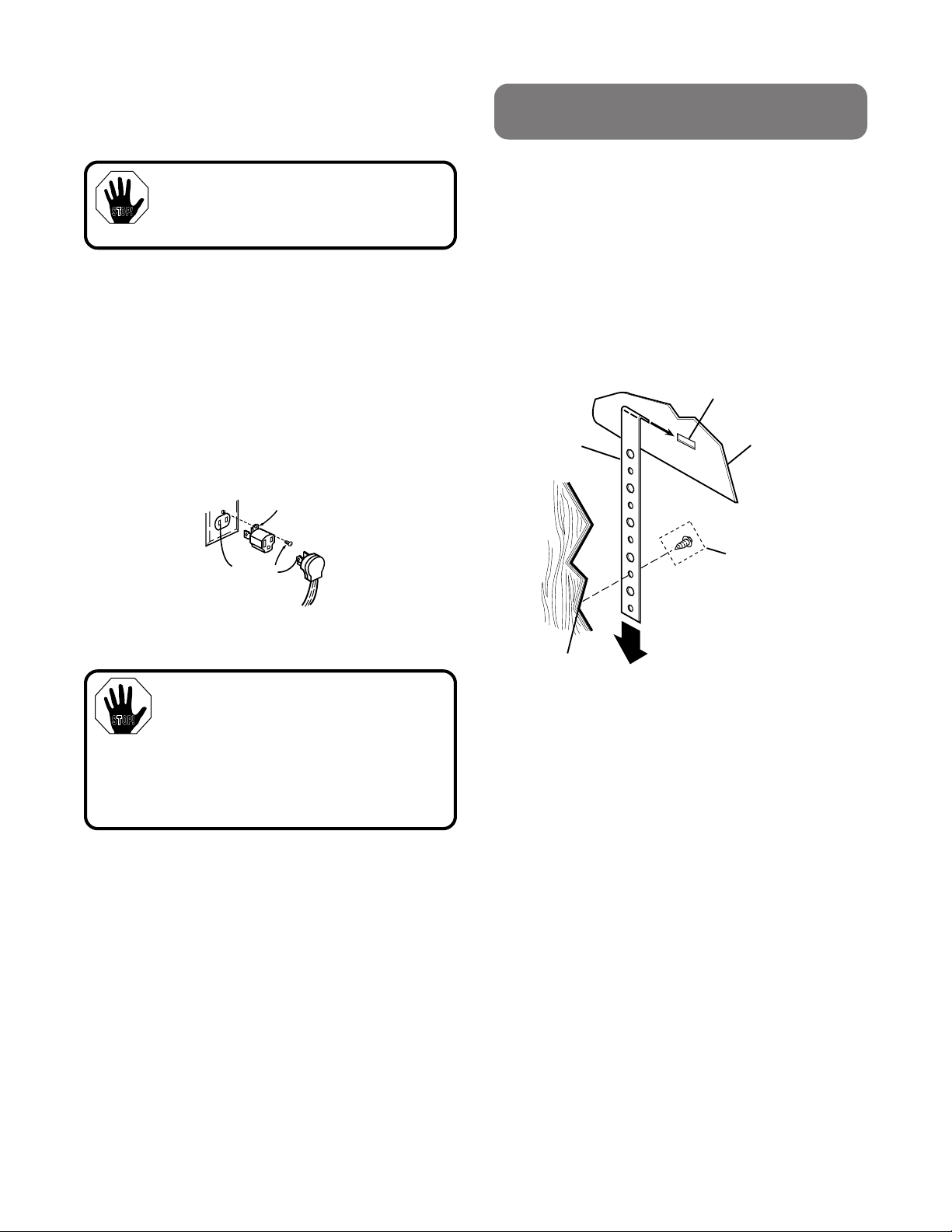

INSTALLING UNIT IN A

STANDARD OR TILE COUNTER

1.

Before installing the unit in the cutout, attach the

adhesive backed foam tape (shipped with unit). For

the Glass Cooktops attach the strip around the

bottom surface of the glass, near the edge of the

maintop. For Porcelain Cooktops attach the strip

around the edge of the metal flange.

2.

Attach the unit to the counter. Insert the hold down

brackets in the slots on each side of the unit.

3.

Use the screws supplied to attach unit to counter as

shown.The unit must rest on the metal flange around

the burner box and not on the glass.

HOLD DOWN

BRACKET

MOUNTING

SLOT

BURNER BOX

SIDES

USE SUITABLE

FASTENERS FOR

ANCHORING IN

CABINET SIDES

CABINET

SIDES

encountered, it is the personal responsibility and obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

Do not under any circumstances cut or remove grounding prong from cooktop cord.

Failure to provide proper polarization may

create a hazardous condition.

USAGE SITUATIONS WHERE APPLIANCE

POWER CORD WILL BE DISCONNECTED FREQUENTLY.

For 15 amp circuit only.

amp circuit. Where local codes permit, a

CONNECTION

Do not

use an adaptor on a 20

TEMPORARY

may be made to a properly grounded

two-prong wall receptacle by the use of a UL listed

adaptor available at most hardware stores. The larger

slot in the adaptor must be aligned with the large slot in

the wall receptacle to provide proper polarity in the

connection of the power cord.

Insure proper ground and

firm connection before use

When disconnecting the power cord from the adaptor,

always hold the adaptor with one hand. If this is not done

the adaptor ground terminal is very likely to break with

repeated use. Should this happen, DO NOT USE the

appliance until a proper ground has again been established.

Do not use an adaptor plug in these situations because

disconnection of the power cord places undue strain on

the adaptor and leads to eventual failure of the adaptor

ground terminal. The customer should have the twoprong wall receptacle replaced with a three-prong

(grounding) receptacle by a qualified electrician before

using the appliance.

Align large

prongs/slots

Temporary method

(Adaptor plugs not permitted

in Canada)

4

Page 5

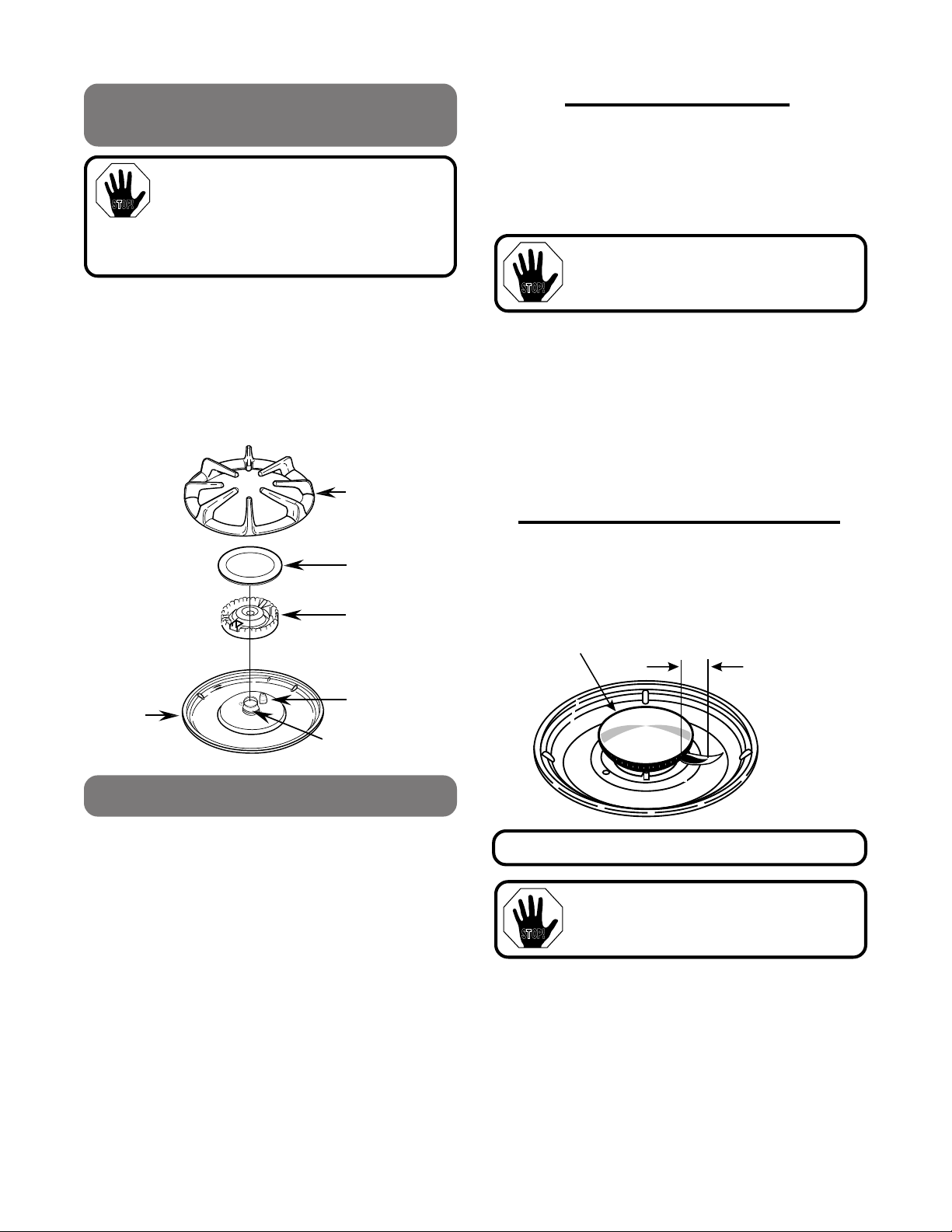

ASSEMBLING THE COOKTOP

STOP!

BURNER

BOWL

SPARK IGNITER

BURNER GRATE

BURNER CAP

BURNER HEAD

MIXER TUBE

(CHIMNEY)

CHECK THE IGNITERS

Operation of electric igniters should be checked after

cooktop and supply line connectors have been carefully checked for leaks and cooktop has been connected to electric power.

1.

Push and turn a burner valve to the LITE position.

a.

The burner valve should light when gas is

available to burner.

b.

Once the burner lights, it should be turned

out of the LITE position.

2.

Try each valve separately until all burners have

been checked.

BURNER IGNITION

COOKTOP SPARK IGNITION

- When you turn the

cooktop knob to LITE, the spark igniter makes a series

of electric sparks (ticking sounds) which light the burner.

During a power failure the burners will not light

automatically. In an emergency, a cooktop burner may

be lit with a match by following the steps below.

WARNING:

Lighting gas burners with a

match is dangerous. You should match light

the cooktop burners only in an emergency.

STOP!

Turn each burner on. Flames should be blue in color

with no trace of yellow. The burner flames should not

flutter or blow away from the burner. The inner cone of

the flame should be between 1/2" to 3/4" long.

1/2" to 3/4"

COOKTOP

BURNER

BURNERS SHOULD BE CHECKED FREQUENTLY

WARNING:

If you attempt to measure the

inner cone of the flame, please use caution.

Burns could result.

STOP!

BURNERS

The electrode of the spark igniter is exposed.

Be careful not to push any cooktop controls

while the top of the burner is removed. Do not

remove the top or touch the electrode of any

burner while another burner is turned on. Electrical

shock might result.

1.

Place the burner head on the burner bowl, so that

the location of the spark igniter matches up with

the opening in the burner head.

2.

Position the burner cap on the burner head.

3.

Place the burner grate over the burner assembly

and into the burner bowl. The bottoms of the

burner grates have fingers that fit into the

corresponding indentations in the burner bowl.

1.

Light a match and hold the flame near the burner

you want to light. Wooden matches work best.

2.

Push in and turn the control knob slowly. Be sure

you are turning the correct knob for the burner you

are lighting.

NOTE: If the burner does not light within five

seconds, turn the knob off and wait one

minute before trying again.

ABOUT THE BURNER FLAMES

5

Page 6

WHEN ALL HOOKUPS ARE

STOP!

COMPLETED

MAKING THE L.P.

Double check to make sure everything in this guide has

been completed. Rechecking steps will ensure safe

use of the cooktop.

MAKE SURE ALL CONTROLS ARE LEFT IN

THE OFF POSITION.

MAKE SURE THE FLOW OF COMBUSTION

AND VENTILATION AIR TO THE COOKTOP IS

UNOBSTRUCTED.

The serial plate for your cooktop is located on the

bottom of the burner box. In addition to the model and

serial numbers, it tells you the ratings of the burners and

type of fuel and pressure the cooktop was adjusted for

when it left the factory.

When ordering parts, always include the serial number,

model number and code letter to ensure proper replacement parts. Parts may be obtained through Sears

Service Centers or retail stores.

RECHECK STEPS

Double check to make sure everything in this guide has

been completed. Rechecking steps will ensure safe

use of the cooktop.

CONVERSION

The pressure regulator and the burner orifices are set

for natural gas. To use Propane Gas, the regulator and

burner orifices must be converted. The L.P. orifice

spuds for the cooktop burners can be located within a

bracket attached to the pressure regulator of this unit.

CAUTION:

the factory, is set for use with natural gas. If

you wish to use your unit with Liquefied

Petroleum (Propane) gas, you must first replace the

orifices and convert the pressure regulator.

WARNING:

This conversion must be performed by a

qualified installer or gas supplier in

accordance with the manufacturer's

instructions and all codes and requirements

of the authority having jurisdiction. Failure to

follow instructions could result in serious

injury of property damage. The qualified

agency performing this work assumes

responsibility for the conversion.

To adjust your cooktop for use with L.P. gas, follow

these instructions:

1.

Disconnect all electrical power, at the main circuit

breaker or fuse box.

2.

Shut off the gas supply to the cooktop by closing the

manual shut-off valve.

3.

Adjust the Pressure Regulator:

A.

Unscrew the cap.

B.

Place your thumb against the flat side of the

spring retainer and press down to remove the

retainer.

C.

Carefully look at the spring retainer to locate the

NAT or LP position.

The counter unit, as shipped from

6

Page 7

D.

NAT.

POSITION

L.P.

POSITION

CAP

SPRING

RETAINER

DOWN

FOR OFF

NAT

LP

LP

NAT

GASKET

PRESSURE REGULATOR

LP

NAT

NAT

LP

BURNER

BOWL

SPARK IGNITER

BURNER GRATE

BURNER CAP

BURNER HEAD

MIXER TUBE (CHIMNEY)

MIXER TUBE (CHIMNEY)

RETAINER

RING

GLASS COOKTOP

PORCELAIN COOKTOP

Turn the spring retainer over so that LP is

showing on the bottom.

E.

Snap the retainer back into position.

4.

Change the cooktop burner orifices:

A.

Remove the top grates, burner caps and burner

head.

IMPORTANT: Save these

orifices for future conversion

back to natural gas.

5.

Locate the L.P./Propane orifices.

The L.P./Propane orifices are shipped in the literature

package. They will have a digit number and the

letter “L” on one side.

Each orifice will also show a series of engraved

marks, (I, II or III), located on the top.

These marks denote the precise location of each orifice

to the cooktop burner.

B.

Using a 7mm or 9/32" nut driver, remove the top

burner orifices. These may be accessed

through the burner air/gas mixer tube (chimney).

NOTE: The orifices have a spring loaded retaining ring around the hex head to hold the

orifice in the nut driver during installation and

removal. A slight amount of force is required

to push the nut driver down over the ring.

6.

Install the L.P./Propane orifices in their precise

locations.

Return the natural orifices to the bracket and reattach

the bracket and the instruction sheet to the pressure

regulator using the screw previously removed.

7

Page 8

ADJUSTING BURNER FLAMES

STOP!

L

O

HI

OFF

LITE

RIGHT

BY-PASS SCREW

STOP!

CAUTION:

be made before turning on the burner. Failure

to do so could result in serious injury. Be

sure pressure regulator has been converted.

1.

Turn all burners full on and check the flames.

A.

They should be blue in color with no trace of

yellow. Foreign particles in the gas line may

cause an orange flame at first, but this will soon

disappear.

2.

To make adjustments, remove the control knobs

and panel. Insert a screwdriver in the shaft to

adjust the valve by-pass screw.

The following adjustments must

Once the conversion is complete

and checked ok, fill out the L.P.

sticker and include your name,

organization and date conversion was

made. Apply the sticker near the cooktop

gas inlet opening to alert others in the

future that this appliance has been

converted to L.P. If converting back to

natural gas from L.P., please remove the

sticker so others know the appliance is

set to use natural gas.

A.

If the flames were yellow or fluttered, open the

valve more than the original setting.

B.

If the flames blew away from the burner, close

the valve more than the original setting.

3.

Make the adjustment, by slowly turning the screw

until flame appearance is correct.

Adjust the low flame setting using the valve by-pass

screw as follows:

A.

Low setting adjustments must be made with

two other burners in operation on a medium

setting.

B.

This procedure prevents the low flame from

being set too low resulting in the flame being

extinguished when other burners are turned on.

TO CONVERT THE COOKTOP BACK

TO NATURAL GAS, REVERSE THE

STEPS UNDER MAKING THE L.P.

CONVERSION.

8

Pub. No. 31-10253

229C

4053P085

Page 9

INSTRUCCIONES PARA LA INSTALACION DE SU NUEVA

NO ALMACENE O USE GASOLINA U OTROS

GASES O LÍQUIDOS INFLAMABLES

CERCA DE ESTE O DE CUALQUIER OTRO

APARATO ELÉCTRICO.

QUE HACER SI HUELE GAS:

• No trate de encender ningún

aparato eléctrico.

• No toque ningún interruptor

eléctrico; no use ningún

teléfono en su edificio.

• Inmediatamente llame a su abastecedor de

gas desde el teléfono de un vecino. Siga las

instrucciones de su abastecedor de gas.

• Si no se puede comunicar con su

abastecedor de gas, llame a la compañía de

bomberos.

La instalación y el servicio debe hacerse por

un técnico calificado, agencia de servicio o el

abastecedor de gas.

STOP!

LISTA DE HERRAMIENTAS

• Punta de taladro de 1/8"

• Taladro eléctrico o manual

• Destornillador Phillips No.1

o No. 2

• Lápiz

• Regla

• Sierra manual o eléctrica

MATERIALES ADICIONALES QUE PODRIA

NECESITAR:

• Válvula de cierre para la línea del gas

• Sello para las uniones de cañerías

• Tubo de 1/2"

Para conexiones flexibles donde las permitan

los códigos locales:

• Tubería de metal flexible (3/4" o 1/2" igual que I.D. como

la línea del gas).

• Adaptador o unión.

Para conexión rígida:

• Encajes para tuberías que se requieran.

IMPORTANTE:

Saque todos los materiales de

empaque y la literatura de la cubierta para cocinar

antes de conectar el gas y la electricidad a la

estufa.

STOP!

CUBIERTA PARA COCINAR A GAS SELLADA DE 30"

Antes de empezar - Lea estas instrucciones completa y cuidadosamente.

IMPORTANTE - Guarde estas instrucciones para el uso del inspector local.

IMPORTANTE - CUMPLA CON TODOS LOS CODIGOS Y ORDENANZAS VIGENTES.

Nota al instalador - Asegúrese de dejar estas instrucciones con el consumidor.

Nota al consumidor - Guarde estas instrucciones con su Manual de Uso y Cuidado para referencia

futura.

Este aparato debe hacer tierra adecuadamente.

• La instalación de esta cubierta para cocinar debe cumplir

PARA SU SEGURIDAD

¡¡ADVERTENCIA!! Si la información

en este manual no se sigue

exactamente, podría resultar en

un incendlo o una explosión que

cause daño a la propiedad, heridas

personales o muerte.

con los códigos locales, o en la ausencia de códigos

locales con el National Fuel Gas Code, ANSI Z223, 1Latest edition.

• Asegúrese que su estufa sea instalada adecuandamente

por un instalador competente o por un técnico de servicio.

• Para eliminar tener que alcanzar algo por encima de los

quemadores de la superficie, se debería evitar guardar

cosas en los gabinetes que están encima de la cubierta.

• No instale la unidad cerca de una puerta que dé hacia

afuera o donde una corriente de aire pueda afectar su uso.

• Llave inglesa para

cañerías

• LLave inglesa

ajustable

• Soquete hexagonal de

3/16"

• Nivel de espíritu de 12"

El diseño de esta cubierta para cocinar ha sido certificado por

la Asociación de Gas Americana. Usted encontrará

precauciones de seguridad en su libro de Uso y Cuidado.

Léalas cuidadosamente.

Pub. No. 31-10253

229C

4053P085

1

Page 10

REQUERIMIENTOS ELECTRICOS

28 3/8

21

30

28 1/2

14 1/4

3

2 1/4

3 1/4

19 1/2

CUBIERTA PARA COCINAR

19 3/8

12 1/2"

DESDE LINEA

DE CENTRO

DEL CORTE

1" DESDE PARED TRASERA

30" MIN AL

GABINETE

.

3 3/4" MIN. DE

ESPACIO A PARED DEL LADO

18" MIN.

AL GABINETE

13" PROFUNDIDAD MAX.

3 3/4" MIN. DE

ESPACIO A PARED

DEL LADO

PROVEA UN ABASTECIMIENTO

DE GAS ADECUADO

Esta cubierta está diseñada para funcionar con gas natural a 4"

de presión columna de agua. Sale de fábrica programada para

gas natural.

Un regulador de presión convertible está conectado en series

con el conjunto de cañerías de la cubierta y debe permanecer

en series con la línea abastecedora sin importar si el gas que

se está usando es natural o L.P.

PARA UN FUNCIONAMIENTO ADECUADO, LA

PRESION MAXIMA DE ENTRADA AL REGULADOR

NO DEBE SER MAYOR A 14" DE PRESION COLUMNA

DE AGUA.

Para probar el regulador, la presión de entrada

debe ser por lo menos 1" (o 3.4 KPA) más que la posición de

salida del regulador. Si el regulador está puesto para 4" de

presión columna de agua, la presión de entrada debe ser de

por lo menos 5". Si el regulador está puesto para 10", la

presión de entrada debe ser de por lo menos 11".

La línea abastecedora del gas a la cubierta debería ser una

cañería de 1/2" o 3/4".

"

"

"

"

"

"

" "

"

5/8

"

Este aparato debe hacer tierra. Consulte los códigos

locales que se aplican en su área. Si no existen códigos

locales, debe cumplir con el National Electrical Code,

ANSI/NFPA No. 70-Latest Edition. Escriba a:

NATIONAL FIRE PROTECTION ASSOCIATION

BATTERYMARCH PARK

QUINCY, MA 02269

Asegúrese que la instalación de esta cubierta para cocinar en

una casa móvil cumpla con el Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280. Si

esta norma no es aplicable, usted debe cumplir con las

normas para Manufactured Home Installations 1982

(Manufactured Home Site, Communities and Set-ups, ANSI

A225.1-Latest Edition) o códigos locales. Escriba a:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

COMO PREPARAR LA ABERTURA

• Asegúrese que todos los revestimientos de paredes,

mesón y gabinetes alrededor de la cubierta para cocinar

°

pueden soportar el calor (hasta 200

F) generado por la

cubierta para cocinar.

• Provea espacios adecuados entre la cubierta para cocinar

y las superficies combustibles adyacentes.

2

Page 11

CONEXIONES DEL GAS

ELE DE 90°

CODO DE 45°

LADOS DEL

GABINETE

HOYO DE 2" DE DIAM.

(20 7/8" DEL FRENTE

DEL MESON AL

CENTRO DEL HOYO)

5" AL CENTRO DEL

HOYO DE 2" DE DIAM.

DESDE SUPERFICIE

DEL MESON

REQUERIMIENTOS ELECTRICOS

Debido al posible peligro bajo ciertas condiciones,

recomendamos categóricamente no usar un cordón de

extensión. Sin embargo, si usted aún decide usar un cordón

de extensión, es absolutamente necesario que sea un cordón

de extensión para aparatos eléctricos de 3 alambres que

haga tierra que esté en la lista de UL, y que la capacidad de

conducción de corriente en amperes sea equivalente o

mayor a la capacidad del circuito. Tales cordones de extensión

se pueden obtener a través del vendedor de aparatos

eléctricos de su localidad.

IMPORTANTE:

(Por favor lea cuidadosamente)

PARA SU SEGURIDAD PERSONAL, ESTE APARATO

DEBE HACER TIERRA ADECUADAMENTE.

STOP!

L

N

STOP!

3" MIN.

CORTE DE

19 5/8"

CODO DE 45°

REGULADOR

DE PRESION

VALVULA

DE CIERRE

CAÑERIA

DE 1/2"

UNION

CORDON

ELECTRICO

RECEPTACULO

ELECTRICO

¡NO USE UNA LLAMA PARA VER SI

EXISTEN ESCAPES!

STOP!

1.

Conecte la cubierta a la línea abastecedora de gas.

2. NUNCA REUSE CONECTORES VIEJOS O

USADOS CUANDO INSTALE UNA ESTUFA

NUEVA.

PARA LA INSTALACION SOBRE UN

HORNO EMPOTRADO (BUILT-IN):

Vea cómo se instala un Horno de tipo “Built-In” (Empotrado)

para instrucciones completas.

PRECAUCION:

Nunca reutilice conectores flexibles

viejos. El uso de conectores flexibles viejos puede

causar escapes de gas y heridas personales. Siempre

utilice conectores nuevos cuando instale una estufa a gas.

3.

El regulador que se provee con la unidad debe ser

instalado en la línea del gas entre la válvula de cierre y

la conexión de la unidad. La parte superior del regulador

debería mirar hacia el frente del gabinete y tener un fácil

acceso a través de las puertas del gabinete.

4.

Instale una válvula de cierre manual en la línea

abastecedora en un lugar fácilmente accesible.

Asegúrese de saber cómo y dónde cerrar el paso del

gas a la cubierta para cocinar.

5.

Revise que no hayan escapes. Después de conectar la

estufa al gas, revise el sistema para que no hayan

escapes con un manómetro. Si no tiene un manómetro

disponible, abra el paso del gas a la estufa y use un

detector de escapes líquido en todas las uniones y

conexiones para ver que no existan escapes.

Apriete todas las conexiones si es necesario para prevenir

escapes de gas en la cubierta o en la línea abastecedora de

gas.

Revise el alineamiento de las válvulas después de conectar

la estufa a la línea del gas para estar seguro que el tubo del

conjunto de cañerías no ha sido movido. Un mal alineamiento

podría causar que el tallo de la válvula roce contra el panel

de control, resultando en un escape de gas en la válvula.

Desconecte la estufa del sistema abastecedor de

gas cerrando su válvula de cierre individual

cualquier prueba del sistema abastecedor de gas a presiones

de prueba igual o menor de 1/2" psig.

La estufa debe ser aislada del sistema

abastecedor

durante cualquier prueba de presión al sistema abastecedor

de gas a presiones de prueba igual o menor de 1/2" psig.

durante

de gas cerrando su válvula de cierre individual

Se debe usar una línea de corriente y un receptáculo adecuado

para operar las partes eléctricas de su estufa.

1.

El cordón eléctrico de este aparato está equipado con un

enchufe de tres patas (para hacer tierra) el cual se debe

usar con un receptáculo de tres hoyos que haga tierra

adecuadamente con corriente alterna normal de casa de

120 voltios, 60 ciclos.

2.

Si usted no tiene un receptáculo de tres hoyos que haga

tierra adecuadamente, haga que un electricista le cambie

el viejo.

3.

Se necesitará un adaptador para convertir el viejo hasta

que el receptáculo pueda ser reemplazado. Este método

es solamente provisorio, y un electricista calificado

debería probarlo para estar seguro que cumple con los

requerimientos.

Asegúrese que haga

tierra bien y que esté

conectado firmemente

antes de usarlo.

3

Page 12

Donde exista un receptáculo de pared para un enchufe de

STOP!

STOP!

COMO INSTALAR UNA UNIDAD

EN UN MESON NORMAL O DE

BALDOSA

1.

Antes de instalar la unidad en el corte, pegue la cinta

adhesiva de espuma (viene con la unidad) alrededor de

la superficie del fondo del vidrio, cerca de la orilla de la

superficie principal.

2.

Pegue la unidad al mesón como se muestra. Inserte las

abrazaderas para sujetarla en las ranuras a cada lado

de la unidad.

3.

Use los tornillos que se le proveen para pegar la unidad

al mesón como se muestra. La unidad debe descansar

sobre la falange de metal alrededor de la caja del

quemador y no sobre el vidrio.

ABRAZADERA

RANURA DE MONTAJE

LADOS DE LA CAJA

DEL QUEMADOR

USE SUJETADORES

ADECUADOS PARA

ANCLAR EN LOS

LADOS DEL GABINETE

LADOS DEL

GABINETE

dos patas, es la responsabilidad y la obligación del cliente

de reemplazarlo con un receptáculo de pared para tres

patas que haga tierra adecuadamente.

NO, BAJO NINGUNA CIRCUNSTANCIA, CORTE O SAQUE

LA TERCERA PATA (QUE HACE TIERRA) DEL CORDON

ELECTRICO. LA FALLA DE PROVEER UNA

POLARIZACION ADECUADA PODRIA CREAR UNA

CONDICION PELIGROSA.

SITUACIONES DE USO CUANDO EL CORDON

ELECTRICO DE LA ESTUFA SE DESCONECTARA

FRECUENTEMENTE.

Para circuitos de 15 amp. solamente. No use un adaptador

en un circuito de 20 amp. Donde los códigos locales lo

permitan, se puede hacer una

conexión provisoria

a un

receptáculo de pared de dos patas que haga tierra

adecuadamente con un adaptador aprobado por UL que se

puede obtener en la mayoría de las ferreterías. La ranura más

grande del adaptador debe estar en línea con la ranura

grande del receptáculo de pared para proveer una polaridad

adecuada en la conexión del cordón eléctrico.

Asegúrese que

haga tierra bien y

que esté conectado

firmemente antes

Ponga en línea las

patas/ranuras

grandes

de usarlo.

Método provisorio

(Los adaptadores de enchufes no se permiten en

Canadá)

PRECAUCION:

El conectar el terminal para

hacer tierra del adaptador al tornillo de la cubierta

del receptáculo de pared no hace que la estufa

haga tierra a menos que el tornillo sea de metal

y no esté aislado, y que el receptáculo de pared haga tierra

a través del alambrado de la casa. El cliente debería hacer

que un electricista competente revise el circuito para estar

seguro que el receptáculo hace tierra adecuadamente.

Cuando desconecte el cordón eléctrico del adaptador, siempre

sujete el adaptador con una mano. Si esto no se hace, es

posible que el terminal para hacer tierra del adaptador se

quiebre con el uso repetido. Si esto sucede, NO USE el aparato

hasta que nuevamente haga tierra adecuadamente.

SITUACIONES DE USO CUANDO EL CORDON

ELECTRICO DE LA ESTUFA SE DESCONECTARA

FRECUENTEMENTE.

No use un adaptador para el enchufe en estas situaciones

porque la desconexión del cordón eléctrico ejerce demasiado

trabajo sobre el adaptador y conduce a la falla del terminal

para hacer tierra del adaptador. El cliente debería hacer

reemplazar el receptáculo de pared para dos patas con un

receptáculo de pared para tres patas (que haga tierra) a

través de un electricista competente antes de usar la estufa.

4

Page 13

COMO ARMAR LOS

STOP!

REVISE LOS ENCENDEDORES

El funcionamiento de los encendedores debería ser revisado

después que la cubierta para cocinar y la línea abastecedora

de gas hayan sido cuidadosamente revisadas para que no

existan escapes de gas y la cubierta para cocinar haya sido

conectada a la electricidad.

1.

Empuje y haga girar la válvula de un quemador a la

posición LITE (ENCENDIDO).

A.

La válvula de quemador se debería encender cuando

el gas pasa al quemador.

B.

Una vez que el quemador se encienda, se debería

sacar de la posición LITE.

2.

Pruebe cada válvula separadamente hasta que todos los

quemadores hayan sido revisados.

ENCENDIDO DE LOS QUEMADORES

ENCENDIDO A CHISPA DE LOS QUEMADORES —

Cuando usted coloca la perilla de la cubierta en LITE, el

encendedor a chispa produce una serie de chispas eléctricas

(sonidos tic tac) que encienden el quemador.

Durante un corte de corriente, los quemadores no se

encenderán automáticamente. En caso de emergencia, un

quemador de superficie puede ser encendido con un fósforo

siguiendo los pasos de más abajo:

1.

Prenda un fósforo y sujete la llama cerca del quemador

que desea encender. Los fósforos de madera funcionan

mejor.

2.

Empuje y haga girar la perilla de control lentamente. Esté

seguro de hacer girar la perilla del quemador que está

encendiendo.

NOTA: Si el quemador no se enciende dentro

de cinco segundos, apague la perilla y espere

un minuto antes de tratar nuevamente.

LLAMAS DE LOS QUEMADORES

Encienda cada uno de los quemadores. Las llamas deberían

ser de color azul sin muestras de amarillo. Las llamas no

deberían pestañear o soplar en dirección opuesta al quemador.

El cono interno debería tener entre 1/2" a 3/4" de longitud.

1/2" to 3/4"

QUEMADOR DE SUPERFICIE

LOS QUEMADORES DEBERIAN SER REVISADOS

FRECUENTEMENTE

STOP!

RECIPIENTE

DEL QUEMADOR

ENCENDEDOR A CHISPA

PARRILLA DEL QUEMADOR

TAPA DEL QUEMADOR

CABEZA DEL QUEMADOR

TUBO DE MEZCLA (CHIMENEA)

STOP!

QUEMADORES DE LA

SUPERFICIE

El electrodo del encendedor a chispa está

expuesto y el tubo de mezcla podría tener orillas

afiladas. Tenga cuidado de no empujar ninguno

de los controles de la cubierta cuando se saca la

tapa del quemador. No saque la tapa o toque el

electrodo de ningún quemador mientras otro quemador está

encendido. Podría resultar en un golpe de corriente.

1.

Coloque la cabeza del quemador sobre el recipiente del

quemador, de manera que la posición del encendedor a

chispa coincida con la abertura en la cabeza del quemador.

2.

Coloque la tapa del quemador sobre la cabeza del

quemador.

3.

Coloque la parrilla del quemador sobre el conjunto del

quemador y sobre el recipiente del quemador. Los fondos

de las parrillas de los quemadores tienen puntas que

encajan en las indenciones correspondientes en los

recipentes de los quemadores.

ADVERTENCIA: El encender los quemadores a gas

con un fósforo es peligroso. Usted debería prender los

quemadores de la cubierta para cocinar con un fósforo

sólo en caso de emergencia

ADVERTENCIA:

de la llama, por favor tenga cuidado.

Podría quemarse.

Si trata de medir el cono interior

5

Page 14

CUANDO TODAS LAS

STOP!

CONEXIONES HAYAN SIDO

COMPLETADAS

Revise bien para estar seguro que todo en esta guía ha sido

completado. Revisando los pasos asegurará el uso seguro

de la estufa.

ASEGURESE QUE TODOS LOS CONTROLES SE DEJEN EN

POSICION DE APAGADO.

ASEGURESE QUE EL PASO DE LA COMBUSTION Y LA

VENTILACION NO ESTEN OBSTRUIDOS.

La placa con el número de serie de su cubierta para cocinar

está ubicada en el fondo de la caja del quemador. Además

del número de modelo y serie, le dice los valores de los

quemadores y el tipo de combustible y presión a los cuales

la cubierta de cocinar fue ajustada cuando salió de la fábrica.

Cuando ordene partes, siempre incluya el número de serie,

número de modelo y la letra de código para estar seguro de

obtener las partes de repuestos correctas. Las partes se

pueden obtener a través de los Centros de Servicio o Tiendas

Sears.

REVISE LOS PASOS

Revise bien para asegurarse que todo en esta guía ha sido

completado. La revisión de los pasos asegurará el uso seguro

de la cubierta para cocinar.

COMO AJUSTAR PARA

USAR GAS PROPANO

El regulador de presión está programado para gas natural.

Para usar gas propano, el regulador debe ser convertido.

Los orificios para gas L.P. para los quemadores de la

cubierta pueden ser localizados dentro de una abrazadera

pegada al regulador de la presión de esta unidad.

PRECAUCION:

fábrica, está programada para funcionar con gas

natural. Si desea usar su unidad con gas de Petróleo

Liquido (Propano), usted debe primeramente

reemplazar los orificios y convertir el regulador de presión

como se describe más abajo.

ADVERTENCIA:

Esta conversión debe ser hecha por un instalador

competente o por el abastecedor de gas de acuerdo

con las instrucciones del fabricante y todos los

códigos y requerimientos de las autoridades que

tienen jurisdicción. El no seguir las instruccion es

podría resultar en serias heridas o en daño a la

propiedad. La agencia competente que hacer este

trabajo asume la responsabilidad por la conversión.

Para ajustar su estufa para ser usada con gas L.P., siga estas

instrucciones:

1.

Desconecte todo el poder eléctrico, en el interruptor del

circuito principal o la caja de los fusibles.

2.

Corte el paso del gas a la estufa cerrando la válvula de

cierre manual.

3.

Ajuste el regulador de presión como sigue:

A.

Desatornille la tapa.

B.

Coloque el pulgar contra el lado plano del sujetador

del resorte y empuje hacia abajo para soltar el

sujetador.

C.

Mire cuidadosamente para ubicar las posiciones

NAT o L.P.

La unidad de mesón, como sale de

6

Page 15

7

D.

Haga girar el sujetador del resorte hasta que

L.P. se vea en el fondo.

E.

Ponga nuevamente el sujetador en posición.

POSICION NAT

POSICION L.P./PROPANO

TAPA

SUJETADOR

DE RESORTE

DOWN

FOR OFF

NAT

LP

LP

NAT

SELLO

REGULADOR DE PRESION

LP

NAT

NAT

LP

RECIPIENTE

DEL QUEMADOR

ENCENDEDOR A CHISPA

PARRILLA DEL QUEMADOR

TAPA DEL QUEMADOR

CABEZA DEL QUEMADOR

TUBO DE MEZCLA (CHIMENEA)

MIXER TUBE (CHIMNEY)

NOTA: Los orificios tienen un anillo de retención

alrededor de la cabeza hexagonal cargado con un

resorte para sujetar el orificio en el apretador de

tuercas cuando se instala o se saca. Una leve

fuerza se requiere para empujar el apretador de

tuercas sobre el anillo.

RETAINER

RING

ANILLO DE RETENCION

IMPORTANTE:

Guarde estos

orificios para una futura

conversión de vuelta a gas

natural.

5.

Ubique los orificios L.P.

Los orificios se envían en el paquete de la literatura.

Tendrán un número y la letra “L” en un lado.

Cada orificio también tendrá una serie de marcas

grabadas, (I, II, III), ubicadas en la parte superior.

4.

Cambie los orificios de los quemadores de la cubierta:

A.

Sacando las parrillas, las tapas y las cabezas de los

quemadores.

B.

Usando un apretador de tuercas de 7mm o 9/32",

saque los orificios de los quemadores superiores.

Estos se pueden alcanzar a través del tubo de

mezcla de aire/gas (chimenea).

Estas marcas indican la ubicación precisa de cada orificio en

el quemador de la cubierta.

CUBIERTA DE VIDRIO

6.

Instale los orificios L.P. en sus lugares precisos.

CUBIERTA DE PORCELANA

TUBO DE MEZCLA

(CHIMENEA)

Coloque los orificios para gas natural de vuelta en la

abrazadera y pegue nuevamente la abrazadera y la hoja

con las instrucciones al regulador de la presión usando el

tornillo que se sacó previamente.

Page 16

STOP!

COMO HACER LOS AJUSTES

A LA LLAMA DEL QUEMADOR

L

O

HI

OFF

LITE

RIGHT

BYPASS SCREW

TORNILLO DE PASO DE

VALVULA

A.

Si las llamas son amarillas y pestañean, abra el

obturador más que la posición original.

B.

Si las llamas soplan en dirección opuesta al

quemador, cierre el obturador más que la posición

original.

3.

Haga los ajustes haciendo girar lentamente el tornillo

hasta que la apariencia de la llama sea correcta.

Ajuste la posición baja de la llama usando el tornillo de la

válvula de paso como sigue:

A.

Los ajustes de llama baja se deben hacer con

los otros dos quemadores operando a llama

mediana.

B.

Este procedimiento previene que la llama baja

se ponga en una posición demasiado baja que

resulte en que la llama se apague cuando los

otros quemadores se enciendan.

El regulador de presión está programado para

gas natural. Para usar gas propano, el

regulador debe ser convertido.

229C

4053P085

Pub. No. 31-10253

STOP!

PRECAUCION:

hacer antes de encender el quemador. Si no los

hace podría resultar en heridas de gravedad.

Asegúrese que el regulador de la presión ha sido

convertido.

1.

Encienda completamente todos los quemadores y revise

las llamas.

A.

Deberían ser de color azul sin muestras de

amarillo. Las partículas extrañas en la línea del gas

podrían causar una llama anaranjada al

principio, pero esto desaparecerá pronto.

2.

Para hacer los ajustes, saque las perillas de control y el

panel. Inserte un destornillador en el tallo para ajustar el

tornillo de la válvula de paso.

Los siguientes ajustes se deben

Una vez que la conversión haya sido

completada y esté funcionando bien,

llene la etiqueta L.P. e inculya su

nombre, organización y la fecha en

que la conversión fue hecha. Pegue la

etiqueta cerca de la entrada de la línea del gas

a la estufa para advertir a otros en el futuro que

esta estufa ha sido convertida para funcionar

con gas L.P. Si se convierte de gas L.P. para ser

usada nuevamente con gas natural, por favor

saque la etiqueta para que otros sepan que esta

estufa está programada para funcionar con gas

natural.

8

Loading...

Loading...