Page 1

SE 250/260 Mighty Small II

Operating Instructions

Original instructions

Page 2

Table of Contents

31 Introduction ..........................................................................................................

41.1 About this manual ................................................................................................................................

51.2 Important user information .............................................................................................................

71.3 Regulatory information ......................................................................................................................

81.3.1 EU directives .....................................................................................................................................

91.3.2 Eurasian Customs Union ............................................................................................................

101.3.3 Regulations for USA and Canada ...........................................................................................

111.3.4 Other regulations and standards ............................................................................................

122 Safety information ...............................................................................................

132.1 Safety precautions ...............................................................................................................................

202.2 Labels .........................................................................................................................................................

222.3 Emergency procedures ......................................................................................................................

232.4 Recycling information .........................................................................................................................

242.5 Declaration of Hazardous Substances (DoHS) ........................................................................

263 System description ..............................................................................................

284 Installation ............................................................................................................

295 Operation ..............................................................................................................

315.1 Preparations ............................................................................................................................................

345.2 Assembly ..................................................................................................................................................

405.3 Electrophoresis run ..............................................................................................................................

426 Maintenance .........................................................................................................

447 Troubleshooting ...................................................................................................

478 Reference information ........................................................................................

488.1 Specifications .........................................................................................................................................

498.2 Ordering information ..........................................................................................................................

508.3 Health and Safety Declaration Forms .........................................................................................

52Index .......................................................................................................................

2 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

Table of Contents

Page 3

1 Introduction

About this chapter

This chaptercontains importantuser information,descriptions ofsafety notices,regulatory information, and intended use of the SE 250/260 Mighty Small II.

In this chapter

See pageSection

41.1 About this manual

51.2 Important user information

71.3 Regulatory information

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 3

1 Introduction

Page 4

1.1 About this manual

Purpose of this manual

The Operating instructions provide you with the information needed to install, operate

and maintain the product in a safe way.

Scope of this manual

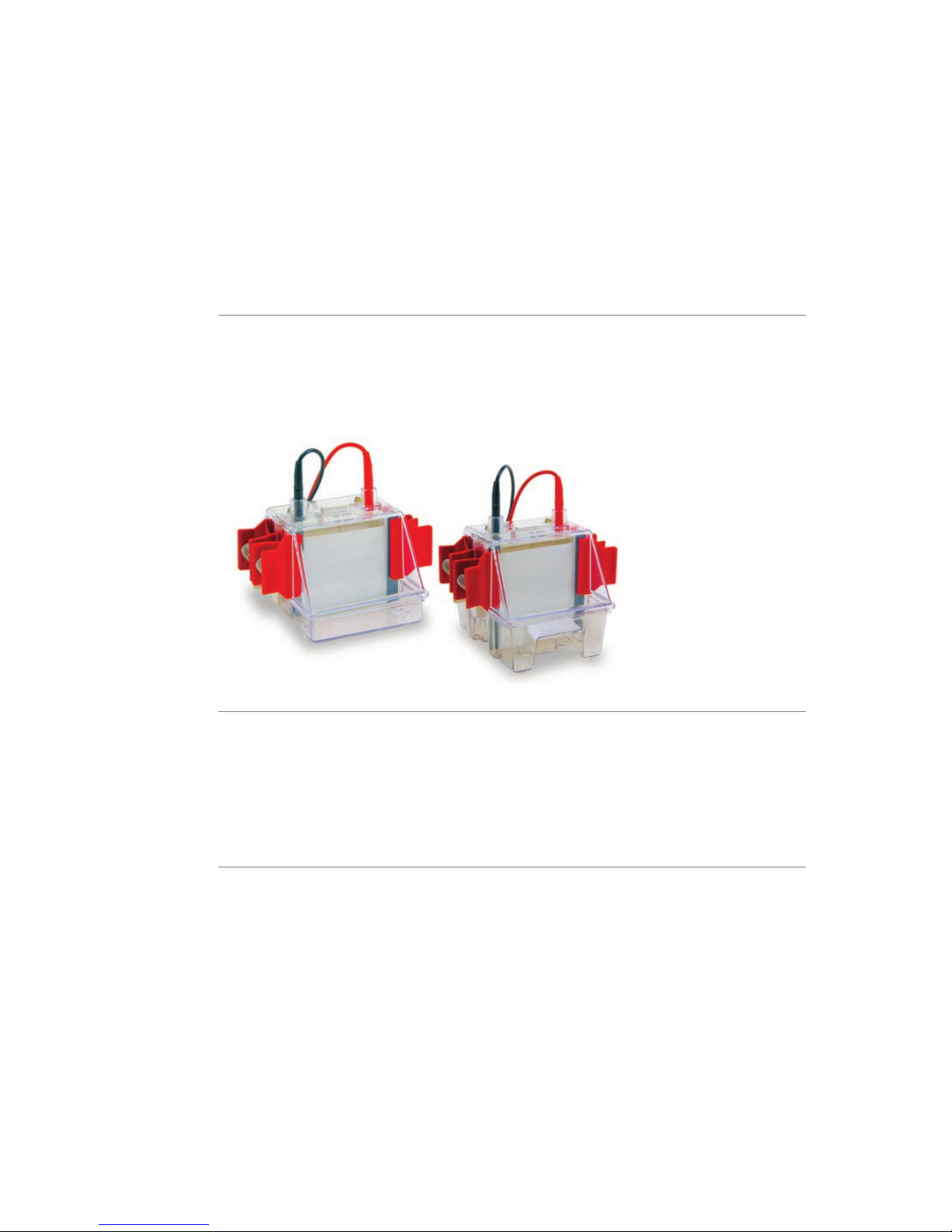

The Operating Instructions covers the SE 250/260 Mighty Small II. The illustration below

shows the SE 250/260 Mighty Small II.

Illustrations

The images and annotations in this document are for illustrative purposes only. The

configuration of individual products mayvary, andtherefore illustrations maynot reflect

the actual system delivered.

4 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

1 Introduction

1.1 About this manual

Page 5

1.2 Important user information

Read this before operating the

product

All users must read the entire Operating instruction before installing, operating or

maintaining the product.

Always keep the Operating instruction at hand when operating the product.

Do not operate the product in any other way than described in the user documentation.

If you do, you may be exposed to hazards that can lead to personal injury and you may

cause damage to the equipment.

Intended use of the product

The SE 250/260 Mighty Small II small format vertical slab gel unit is intended for rapid

electrophoresis of proteinor nucleicacid samples.Most samplescan berun in 45 minutes,

and only a minimal amount of sample is required.

The SE 250/260 Mighty Small II accommodates one or two 10 × 8 cm gel sandwiches.

The SE 250/260 Mighty Small II accommodates one or two 10 × 8 cm or 10 × 10.5 cm

gel sandwiches. In both SE 250/260 Mighty Small II units, the upper buffer chamber is

formed when the notched side of a gel sandwich is sealed against the silicone rubber

gasket.

The upper buffer chamber core serves as a heat exchanger if cooling is required. The

core is hollow and equipped with ports on either side for coolant circulation.

Prerequisites

In order to operate the SE 250/260 Mighty Small II in the way it is intended:

•

The user must have a general understanding of gel electrophoresis.

•

The user must read and understand theSafety Instructions chapter in the Operating

Instructions.

•

The SE 250/260 Mighty Small II must be installed in accordance with the instructions

in the Operating Instructions.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 5

1 Introduction

1.2 Important user information

Page 6

Safety notices

This user documentation contains safety notices (WARNING, CAUTION, and NOTICE)

concerning the safe use of the product. See definitions below.

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could result indeath or serious injury. It is importantnot to proceed

until all stated conditions are met and clearly understood.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury. It is important not to proceed until all stated conditions are met and clearly understood.

NOTICE

NOTICE indicates instructions that must be followed to avoid

damage to the product or other equipment.

Notes and tips

A note is used to indicate information that is important for trouble-free and

optimal use of the product.

Note:

A tip contains useful information that can improve or optimize your procedures.

Tip:

6 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

1 Introduction

1.2 Important user information

Page 7

1.3 Regulatory information

Introduction

This section lists the regulations and standards that apply to the SE 250/260 Mighty

Small II.

Manufacturing information

The table below summarizes the required manufacturing information.

InformationRequirement

GE Healthcare Bio-Sciences AB,Name and address of manufacturer

Björkgatan 30, SE 751 84 Uppsala, Sweden

In this section

See pageSection

81.3.1 EU directives

91.3.2 Eurasian Customs Union

101.3.3 Regulations for USA and Canada

111.3.4 Other regulations and standards

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 7

1 Introduction

1.3 Regulatory information

Page 8

1.3.1 EU directives

Introduction

This section describes the EU Directives that apply to SE 250/260 Mighty Small II.

Conformity with EU Directives

This product fulfills the European Directives listed below. See the EU Declaration of

Conformity for the directives and regulations that apply for the CE marking.

If not included with the product, a copy of the EU Declaration of Conformity is available

on request.

TitleDirective

Low Voltage Directive (LVD)2014/35/EU

Restriction of Hazardous Substances (RoHS) Directive2011/65/EU

CE marking

The CE marking and the corresponding EU Declaration of Conformity is valid for the instrument when it is:

•

used according to the Operating Instructions or user manuals, and

•

used in the same state as it was delivered from GE, except for alterations described

in the Operating Instructions or user manuals.

8 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

1 Introduction

1.3 Regulatory information

1.3.1 EU directives

Page 9

1.3.2 Eurasian Customs Union

Introduction

This section contains additional regulatory information to comply with the Eurasian

Customs Union technical regulations.

Manufacturer and importer

information

The table below summarizes the manufacturer and importer information required by

the Eurasian Customs Union.

InformationRequirement

See Manufacturing informationName and address of manufacturer

Telephone: + 46 771 400 600Telephone number of manufacturer

GE Healthcare LLCImporter and/orcompany forobtain-

ing information about importer

GE Healthcare Life Sciences

Presnenskaya nab., 10C, 12th floor

RU-123 317 Moscow, Russian Federation

Telephone 1: + 7 495 411 9714

Fax nr: + 7 495 739 6932

Email: LSrus@ge.com

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 9

1 Introduction

1.3 Regulatory information

1.3.2 Eurasian Customs Union

Page 10

1.3.3 Regulations for USA and Canada

Introduction

This section describes the regulations that apply to SE 250/260 Mighty Small II in the

USA and Canada.

NRTL certification

This symbol indicates that the product has been certified by Intertek, which is a US Occupational Safety and Health Administration Nationally Recognized Testing Laboratory

(NRTL).

10 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

1 Introduction

1.3 Regulatory information

1.3.3 Regulations for USA and Canada

Page 11

1.3.4 Other regulations and standards

Introduction

This section describes the standards that apply to the SE 250/260 Mighty Small II.

Environmental conformity

This product conforms to the following environmental requirements.

TitleRequirement

Waste Electrical and Electronic Equipment (WEEE) Directive2012/19/EU

Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products.

China RoHS

Standards, applied to this

product

Standard requirements fulfilled by this product are summarized in the table below.

DescriptionStandard

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 1: General

requirements.

IEC/EN 61010-1, UL

61010-1, CAN/CSA-C22.2

No. 61010-1

Technical documentation forthe assessmentof electrical

and electronic products with respect to the restriction

of hazardous substances

EN 50581

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 11

1 Introduction

1.3 Regulatory information

1.3.4 Other regulations and standards

Page 12

2 Safety information

About this chapter

This chapter describes safety precautions, labels and symbols that are attached to the

equipment. In addition,the chapterdescribes emergency and recovery procedures, and

provides recycling information.

Important

WARNING

Before installing, operating or maintaining the product, all users

must read and understand the entire contents of this chapter

to become aware of the hazards involved.

In this chapter

See pageSection

132.1 Safety precautions

202.2 Labels

222.3 Emergency procedures

232.4 Recycling information

242.5 Declaration of Hazardous Substances (DoHS)

12 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

Page 13

2.1 Safety precautions

Introduction

The SE 250/260 Mighty SmallII ispowered by anexternal power supply. Before installing,

operating or maintaining the system, you must be aware of the hazards described in

this manual.

Follow the instructions provided to avoid injury to the operator or other personnel,

to the product, or to other equipment in the area.

The safety precautions in this section are grouped into the following categories:

•

General precautions

•

Personal protection

•

Using flammable liquids

•

Installing and moving the product

•

Power supply

•

System operation

•

Maintenance

Always follow the instructions below to avoid injury when using the SE 250/260 Mighty

Small II.

General precautions

WARNING

Before installing, operating or maintaining the product, all users

must read and understand the entire contents of this chapter

to become aware of the hazards involved.

WARNING

Only properly trained personnel may operate and maintain the

product.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 13

2 Safety information

2.1 Safety precautions

Page 14

WARNING

Do not operate the SE 250/260 Mighty Small II in any other way

than describedin theSE 250/260Mighty SmallII OperatingInstructions.

WARNING

Do notdamage thepower supply cord by bending, twisting, heating

or allowing them to become pinned under the equipment. Using

damaged power cords could result in fire or electric shock.

If the power supply cords are damaged, contact your local GE

representative for replacements.

WARNING

The safety lid must be in place before connecting the power leads

to a power supply.

WARNING

Any liquid on the equipment must be dried off before connecting

the power supply.

CAUTION

Circulate only water or 50/50 water/ethylene glycol through the

heat exchanger. Never use anti-freeze or any organic solvent in

the heat exchanger.

CAUTION

Never introduce anti-freeze or any organic solvent into any part

of the instrument. Organic solvents will cause irreparable damage

to the instrument.

14 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.1 Safety precautions

Page 15

Personal protection

WARNING

Always use appropriate Personal ProtectiveEquipment (PPE)during

operation and maintenance of this product.

WARNING

Hazardous substances and biological agents. When using haz-

ardous chemical and biological agents, take all suitable protective

measures, such as wearing protective clothing,glasses and gloves

resistant to the substances used. Follow local and/or national

regulations for safe operation and maintenance of this product .

WARNING

Spread of biological agents. The operator must take all necessary

actions toavoid spreading hazardous biological agents.The facility

must comply with the national code of practice for biosafety.

CAUTION

Handle theglass components with care! Wearappropriate personal

protective equipment (PPE).

Using flammable liquids

WARNING

A fume hood or similar ventilation system shall be installed when

flammable or noxious substances are used.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 15

2 Safety information

2.1 Safety precautions

Page 16

Installing and moving the

product

CAUTION

When lifting and moving the instrument be careful not to drop it.

This may cause injury.

CAUTION

Make sure that the system is placed on a stable, level bench with

adequate space for ventilation.

CAUTION

Turn off the power switch and remove connecting cables before

moving the equipment.

CAUTION

The electrophoresis unitis heavy,especially when filled with buffer.

Handle the unit with care to avoid personal injury.

Power supply

WARNING

Power cord. Only use power cords with approved plugs delivered

or approved by GE.

WARNING

The safety lid must be in place before connecting the power leads

to a power supply.

16 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.1 Safety precautions

Page 17

WARNING

Make sure that there isaccess tothe instrument power supplycord

at all times.

Operation

WARNING

The highvoltage power supply must always be disconnectedwhen

the safety lid of the electrophoresis unit is taken off. The high voltage power supply must never be switched on unless the safety lid

is on the electrophoresis unit.

WARNING

Acrylamide is a neurotoxin. Always wear gloves and observe all

laboratory safety procedures.

WARNING

Never exceed the operating limits stated in this document and on

the system label. Operation of the productoutside these limits can

damage equipment and cause personal injury or death.

WARNING

Turn all power supply controls off and disconnect the power leads

before removing the safety lid.

WARNING

Always disconnect the high voltage leads from the power supply

before removing the lid from the unit.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 17

2 Safety information

2.1 Safety precautions

Page 18

CAUTION

Circulate coolant throughthe heat exchanger to minimizeheating.

Overheating will cause irreparable damage to the unit! Do not

connect the heat exchanger to a water tap or any coolant source

where the water pressure is unregulated.

CAUTION

Do not operate with buffer temperatures above the maximum

specified technicalspecifications. Overheating will cause irreparable

damage to the unit!

CAUTION

Devices must only be operatedwith acertified power supply capable of limiting the voltage and current to specified ratings.

NOTICE

After initial monitoring, do not leave the unit unattended for more

than 45 min before checking the progress of the bands and the

buffer level.

NOTICE

If running only one gel, block off the unused part of the core with

a glass plate. Do not fill this side with buffer.

Maintenance

WARNING

Decontaminate before maintenance. To avoid personnel being

exposed to potentially hazardous substances, make sure that the

SE 250/260 Mighty Small II is properly decontaminated and sanitized before maintenance or service.

18 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.1 Safety precautions

Page 19

WARNING

Use only approved parts. Only spare parts and accessories that

are approved or supplied by GE may be used for maintaining or

servicing the product.

WARNING

Disconnect power. Always disconnect power from the instrument

before performing any maintenance task.

WARNING

Decommissioning. Decontaminatethe equipment before decom-

missioning to make sure that hazardous residues are removed.

NOTICE

Cleaning. Keep the exterior of the instrument dry and clean. Wipe

regularly with a soft damp tissue and, if necessary, a mild cleaning

agent. Let the instrument dry completely before use.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 19

2 Safety information

2.1 Safety precautions

Page 20

2.2 Labels

Introduction

This section describes the system label and other safety or regulatory labels that are

attached to the product.

Description of symbols on the

system label

The table below describes the various symbols that may be found on the system label.

MeaningLabel

Warning! Read the user documentation before using the system.

Do not open any covers or replace parts unless specifically stated

in the user documentation.

This symbol indicates that the waste of electrical and electronic

equipment must not be disposed as unsorted municipal waste and

must be collected separately. Please contact an authorized representative of the manufacturer for information concerning the decommissioning of equipment.

This symbol indicates that the product does not contain toxic or

hazardous materials in excess of the limits established by the Chinese standard GB/T 26572 Requirements of concentration limits for

certain hazardous substances in electrical and electronic products,

and can be recycled after being discarded, andshould not be casually discarded.

The system complies with applicable European directives.

Eurasian Conformity mark: the single conformity mark indicates

that the product is approved for circulation on the markets of the

member states of the Eurasian Customs Union.

20 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.2 Labels

Page 21

MeaningLabel

This symbolindicates thatthe product hasbeen certified by Intertek,

which is a US Occupational Safety and Health Administration Nationally Recognized Testing Laboratory (NRTL).

Serial number of the productSerial no.:

Year (YYYY) and month (MM) of manufactureManufac-

tured:

Safety labels

The table below describes the various symbols that may be found on the product.

DescriptionSymbol/text

Warning! Read the user documentation before using

the system. Do not open any covers or replace parts

unless specifically stated in the user documentation.

Warning! High Voltage. Always make sure that the

system is disconnected from electric power before removing the lid.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 21

2 Safety information

2.2 Labels

Page 22

2.3 Emergency procedures

Introduction

This section describes how to shut down of the SE 250/260 Mighty Small II in an emergency situation, and the procedure for restarting the SE 250/260 Mighty Small II.

The section also describes the result in the event of power failure.

Precautions

WARNING

Make sure that there isaccess tothe instrument power supplycord

at all times.

Emergency shutdown

In anemergency situation, shut down the power supply in accordancewith itsemergency

procedure.

Power failure

In case of power failure to the SE 250/260 Mighty Small II, the run is interrupted immediately.

Restart after emergency

shutdown or power failure

To restart the run after an emergency shutdown or power failure, follow these steps:

ActionStep

Make sure all connections are in place.1

Start the power supply as described in the power supply's User Manual.2

22 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.3 Emergency procedures

Page 23

2.4 Recycling information

Introduction

This section contains information about the decommissioning of the product.

Decontamination

The product must be decontaminated before decommissioning. All local regulations

must be followed with regard to scrapping of the equipment.

Disposal of the product

When taking the product out of service, the different materials must be separated and

recycled according to national and local environmental regulations.

Disposal of electrical

components

Waste electricaland electronic equipment mustnot bedisposed ofas unsortedmunicipal

waste and must be collected separately. Please contact an authorized representative

of the manufacturerfor information concerningthe decommissioning ofthe equipment.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 23

2 Safety information

2.4 Recycling information

Page 24

2.5 Declaration of Hazardous Substances (DoHS)

根据SJ/T11364-2014《电子电气产品有害物质限制使用标识要求》特提供如下有关污染控制方面的

信息。

The following product pollution control information is provided according to SJ/T11364-2014 Marking

for Restriction of Hazardous Substances caused by electrical and electronic products.

电子信息产品污染控制标志说明

Explanation of Pollution Control Label

该标志表明本产品不含有超过中国标准 GB/T 26572 《电子信息产品中有毒有害物

质的限量要求》中限量的有毒有害物质,报废后可以进行回收处理,不能随意丢弃。

This symbol indicates that this electrical and electronic product does not contain any

hazardous substances above the maximum concentration value established by the

Chinese standard GB/T26572 , and can berecycledafter being discarded,and should

not be casually discarded.

24 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

2 Safety information

2.5 Declaration of Hazardous Substances (DoHS)

Page 25

有害物质的名称及含量

Name and Concentration of Hazardous Substances

产品中有害物质的名称及含量

Table of Hazardous Substances’ Name and Concentration

有害物质

Hazardous substance

部件名称

Component name

多溴二苯醚

(PBDE)

多溴联苯

(PBB)

六价铬

(Cr(VI))

镉

(Cd)

汞

(Hg)

铅

(Pb)

OOOOOO80614745

OOOOOO80614935

本表格依据SJ/T 11364的规定编制。

This table is prepared according to SJ/T 11364.

0:

表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572规定的限量要求以下。

X:

表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572规定的限量要

求。

•

此表所列数据为发布时所能获得的最佳信息.

0:

Indicates that this hazardous substance contained in all of the homogeneous materials for

this part is below the limit requirement in GB/T 26572.

X:

Indicates that this hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in GB/T 26572.

•

Data listed in the table represents best information available at the time of publication.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 25

2 Safety information

2.5 Declaration of Hazardous Substances (DoHS)

Page 26

3 System description

About this chapter

This chapter gives an overview of the SE 250/260 Mighty Small II.

Illustration of the instrument

The illustration below shows the SE 250/260 Mighty Small II instrument.

1

2

3

4

5

6

8

7

FunctionPart

Color-coded leads (2)1

26 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

3 System description

Page 27

FunctionPart

Safety lid2

Upper buffer chamber core3

Foam gasket4

Coolant port (2)5

Spring clamps (4)6

Positioning tabs7

SE 250/260 Mighty Small II Lower buffer chamber8

The following parts are included, but not shown in the illustration:

•

Glass plates

•

Notched alumina plates

•

Gel seal, 1/4 oz.

•

Spacer-Mate

•

Well-locating decal

Power supply with a minimum rating of 250 V, 50 mA, constant current or

constant voltage is required, but not included.

Note:

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 27

3 System description

Page 28

4 Installation

About this chapter

This chapter provides required information to enable users and service personnel to

unpack the SE 250/260 Mighty Small II instrument.

Safety precautions

CAUTION

When lifting and moving the instrument be careful not to drop it.

This may cause injury.

CAUTION

Make sure that the system is placed on a stable, level bench with

adequate space for ventilation.

Unpacking procedure

Unwrap all packages carefully.

Inspect all visible parts for damage or missing pieces. If any damage is observed, record

this on the receiving documents and inform your GE representative. Make sure to keep

all packing material for damage claims or to use should it become necessary to return

the unit.

28 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

4 Installation

Page 29

5 Operation

About this chapter

This chapter gives instructions on how to operate the product in a safe way.

Safety precautions

WARNING

The highvoltage power supply must always be disconnectedwhen

the safety lid of the electrophoresis unit is taken off. The high voltage power supply must never be switched on unless the safety lid

is on the electrophoresis unit.

WARNING

Acrylamide is a neurotoxin. Always wear gloves and observe all

laboratory safety procedures.

WARNING

Never exceed the operating limits stated in this document and on

the system label. Operation of the productoutside these limits can

damage equipment and cause personal injury or death.

CAUTION

Do not operate with buffer temperatures above the maximum

specified technicalspecifications. Overheating will cause irreparable

damage to the unit!

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 29

5 Operation

Page 30

CAUTION

Circulate only water or 50/50 water/ethylene glycol through the

heat exchanger. Never use anti-freeze or any organic solvent in

the heat exchanger.

CAUTION

Devices must only be operatedwith acertified power supply capable of limiting the voltage and current to specified ratings.

NOTICE

After initial monitoring, do not leave the unit unattended for more

than 45 min before checking the progress of the bands and the

buffer level.

NOTICE

If running only one gel, block off the unused part of the core with

a glass plate. Do not fill this side with buffer.

In this chapter

See pageSection

315.1 Preparations

345.2 Assembly

405.3 Electrophoresis run

30 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

Page 31

5.1 Preparations

Prepare the gel sandwich

Both precast and self-cast gels can be run in the SE 250/260 Mighty Small II units. This

unit accepts gels in 10 × 8 cm plates, which can be cast in SE215, SE245, or SE275 gel

casters.

Each unit includes notched alumina plates and rectangular glass plates. If casting your

own polyacrylamide gels, we recommend using a notched alumina ceramic back plate

because it transfers heat 40 times more rapidly than glass. For applications that are not

heat sensitive, a notched glass plate is available.

Before installingthe gels into the electrophoresis unit, the separating gel should already

be completely polymerized. Clean away any gel adhering to the notched alumina back

plate. The stacking gel (if applicable) can be cast in place on the electrophoresis unit.

Load liquid samples after the gel sandwich is installed.

Maintenance before use

Rinse the instrument before each use. Before using the first time, disassemble the unit

completely and wash with a dilute solution of a laboratory detergent and thoroughly

rinse with water and distilled water.

Check the gasket. Periodically remove the gray silicone rubber gasket from the core. Inspect for nicks and wear. If the gasket is intact, apply a light film of Gel seal, and replace

it inthe groove.Avoid stretching thegasket. Lay it onto the groove and pressit into place.

Disassemble a fully assembled

unit

ActionStep

Remove the safety lid by pressing on the handle at the top of the upper

buffer chamber core while lifting the lid by the bottom edges.

1

Empty all buffer chambers and remove any gel sandwiches.2

Depress both release tabs and lift out the upper buffer chamber core.3

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 31

5 Operation

5.1 Preparations

Page 32

Optional cooling

Circulating pressure must not exceed 0.8 bar (12 psi) above ambient pressure. Do not

connect the cooling core to an unregulated coolant source such as a water tap.

To connect the cooling core to a circulator bath, follow these steps:

ActionStep

Slide hose clamps (4 in total) onto each end of two lengths of 8 mm (5/16")

vinyl or silicone tubing.

1

Attach one end of each length of tubing to a cooling core port.2

Attach the free ends of each length of tubing to the circulator bath ports;

one to the inlet and the other to the outlet.

3

Secure the connections with the hose clamps.4

Install the upper buffer chamber

core

CAUTION

Circulate only water or 50/50 water/ethylene glycol through the

heat exchanger. Never use anti-freeze or any organic solvent in

the heat exchanger.

ActionStep

Steady the lower chamber with one hand and then hold the core with the

other hand.

1

Position the lower chamber on the positioning tabs.2

Press down, listening for the core to snap into place. (Alternatively, depress

both release tabs at either side, position the core on the positioning tabs,

press into place, and release the tabs. Check that the core is secure.)

3

32 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

5.1 Preparations

Page 33

ActionStep

To remove the core, depress both release tabs and lift.4

1

2

3

DescriptionPart

Handle1

Release tabs (2)2

Coolant port (2)3

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 33

5 Operation

5.1 Preparations

Page 34

5.2 Assembly

Place the gel sandwich in the SE

250/260 Mighty Small II

WARNING

Acrylamide is a neurotoxin. Always wear gloves and observe all

laboratory safety procedures.

ActionStep

Rinse away the gel overlay with distilled water and drain any excess water.1

If installinga self-castor precast10 ×8 cm gel sandwich, orient the sandwich

so thatthe notchedplate facesthe gasket, notches at the top. Set the bottom

of thesandwich onthe supportingledges inthe bottomof thelower chamber

and center the plate so that the gasket seals both sides.

2

Place the gel sandwich in the SE

250/260 Mighty Small II

WARNING

Acrylamide is a neurotoxin. Always wear gloves and observe all

laboratory safety procedures.

34 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

5.2 Assembly

Page 35

ActionStep

Rinse away the overlay with distilled water and drain any excess water.1

If installing a self-cast or precast 10 × 8 cm gel sandwich, align the bottom

of the plate with the bottom of the core (see figure below). The bottom of

the notched plate must cover the silicone rubber gasket. The 10 × 8 cm gel

sandwich fits flush with the bottom of the upper buffer chamber core.

2

If installing a self-cast or precast 10 × 10.5 cm gel sandwich, orient the

sandwich so that the notched plate faces the gasket, notches at the top.

Set the bottom of the sandwich on the supporting ledges in the bottom of

the lower chamber and center the plate so that the gasket seals both sides

(see figure below). The 10 × 10.5 cm gel sandwich fits against the bottom of

the lower buffer chamber.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 35

5 Operation

5.2 Assembly

Page 36

Clamp the sandwich in place

Cooling is optional. If desired, attach tubing to ports on both sides of the core

before attaching gel sandwiches. Circulate coolant. See Optional cooling, on

page 32.

Note:

ActionStep

Lightly press the sandwich against the gasket and secure it to the core with

one spring clamp on each side.

1

Position the jaw so that the shorter rounded jaw edge fits into the core

groove and the longer edge sits on the glass plate.

2

Slide the clamps down to the stop.

Note:

Proper positioning is important to achieve a seal and to minimize glass

breakage.

3

Repeat step 1-3 for the second sandwich, or, if running only one gel, clamp

a plain glass plate on the unused side of the core to prevent a possible short

circuit with the unused electrode. Do not fill this chamber with buffer if no

gel sandwich is in place.

4

Sample preparation and loading

If applicable, cast the stacking gel in the unit.

Calculate the stacking gel monomer solution volume:measure the distance, in cm, from

the top of the resolving gel to the notch in the alumina plate. (This should be at least 2

cm—more if the sample depth in the well is unusually high.) Multiply this distance by the

gel width (8.3 cm) and the gel thickness (cm). This product is the required volume in ml.

If wells are already in place, start at with preparing the sample.

36 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

5.2 Assembly

Page 37

To prepare the wells, follow these steps:

ActionStep

De-aerate the stacking gel monomer solution.1

Add catalyst and initiator to the stacking gel monomer solution and then

pour.

2

Use a pipette to deliver the solution into one corner of the plate, taking care

not to trap any bubbles.

3

Insert a comb (at a slight angle to prevent trapping air) into the sandwich,

allowing the comb sides to rest on the spacers.

4

Overlay each gel with a thin layer of water-saturated n-butanol, water, or

diluted gel buffer to prevent gel exposure to oxygen. Slowly deliver the

overlay solution from a glass syringe fitted with a 22-gauge needle. Apply

the solution near the spacer at the side of the sandwich and allow it to flow

across the surface unaided.

5

Allow a minimum of one hour for the gel to polymerize.6

To prepare the sample, follow these steps:

ActionStep

Increase liquid sample density with 10% glycerol or sucrose.1

Add a tracking dye.2

For SDS protein gels, use 2× treatment buffer to denature both liquid and

dry samples in a test tube.

3

To liquid protein solutions, add an equal volume of 2× buffer.

To dry protein samples, add equal volumes of buffer and ddH2O to achieve

the desired concentration.

Heat the tube in boiling water for 90 seconds, then chill it in ice until ready

to use.

4

Treated samples can be stored at -40°C to -80°C for future runs.

To load samples, follow these steps:

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 37

5 Operation

5.2 Assembly

Page 38

ActionStep

To aid in loading samples, wet the well-locating decal and apply it to the

front of the glass plate so that the appropriate edge outlines the sample

wells.

Note:

The side wells for standards of a preparative comb correspond to the outermost wells formed by the 10-well comb.

1

Fill the sample wells and each upper buffer chamber that will be used with

running buffer. One upper buffer chamber holds approximately 75 mL.

2

Load the sample into the wells using a fine-tipped microsyringe. The width

of the wells depends on the number of wells per comb.For the volume required to fill to 1mm well depth, see the table below.

3

Volume of sample (µL) per 1 mm depth

Comb thickness (mm)No. of wells

1.51.00.75

19.112.79.55

5.89

7.24.83.610

4.42.92.215

2.918

Final assembly

CAUTION

Devices must only be operatedwith acertified power supply capable of limiting the voltage and current to specified ratings.

38 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

5.2 Assembly

Page 39

ActionStep

Fill the lower buffer chamber with running buffer.1

The SE 250/260 Mighty Small II holds about 250 mL. Make sure that the

lower electrode (running along the bottom of the the upper buffer chamber

core) is completely submerged.

Note:

If using precast gels, check that the lower gel/buffer contact surface is exposed

(the colored plastic tape must be removed).

Place the safety lid on the unit.2

Plug the color-coded leads into the jacks of an approved power supply. The

red lead plugs into the red output jack, and the black lead plugs into the

black output jack.

3

Optional cooling:Begin circulating coldwater ora chilled 50/50 water/ethylene glycol solution.

4

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 39

5 Operation

5.2 Assembly

Page 40

5.3 Electrophoresis run

Running the gel

Gels maybe run at either constant currentor constantvoltage. Aconstant current setting

is traditionallyused witha discontinuous buffer system so that the rate of electrophoretic

migration remains unchanged throughout the run. Under these conditions, voltage increases as the run proceeds. A lower current setting is recommended for higher resolution. Precast gels are run under the same current and voltage conditions as self-cast

gels.

It takes about one hour to run two 7 cm × 0.75 mm Laemmli gels at 40 mA (20 mA per

gel, constant current). Check band progress after 5 minutes, and again after half an

hour, keeping an eye on the position of the tracking dye. The run is complete when the

tracking dye reaches the bottom of the gel. Watch the buffer level in the upper buffer

chamber and, if necessary, replenishit before itfalls below the level of the notchedplate.

A small volume of buffer may leak past a chipped plate or nicked gasket, or it may wick

out through the gel.

NOTICE

After initial monitoring, do not leave the unit unattended for more

than 45 min before checking the progress of the bands and the

buffer level.

After the run

WARNING

Always disconnect the high voltage leads from the power supply

before removing the lid from the unit.

ActionStep

Once the tracking dye reaches the bottom of the gel, turn off the power

supply, disconnect the leads, and remove the safety lid as described in Dis-

assemble a fully assembled unit, on page 31

1

If coolant is circulating, stop the flow and disconnect the fittings or tubing.2

40 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

5 Operation

5.3 Electrophoresis run

Page 41

ActionStep

Remove the core assembly with gels attached by squeezing the release tabs

and lift out the core assembly.

3

Pour outthe bufferby inverting the core assembly,then remove bothclamps,

and lift away gel sandwich(es) from the upper buffer chamber core.

4

Gently loosen and then slide away both spacers.5

Slip an extra spacer or a Wonder Wedge into the bottom edge (to prevent

breaking the ears of the notched plates) and separate the plates. The gel

usually adheres to the alumina plate.

6

Carefully lift the gel from the plate and lay it into a tray of stain or fixative.7

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 41

5 Operation

5.3 Electrophoresis run

Page 42

6 Maintenance

About this chapter

This chapter provides information to enable users and service personnel to clean and

maintain the product.

Precautions

WARNING

Decontaminate before maintenance. To avoid personnel being

exposed to potentially hazardous substances, make sure that the

SE 250/260 Mighty Small II is properly decontaminated and sanitized before maintenance or service.

WARNING

Use only approved parts. Only spare parts and accessories that

are approved or supplied by GE may be used for maintaining or

servicing the product.

WARNING

Disconnect power. Always disconnect power from the instrument

before performing any maintenance task.

General procedures

Immediately after each use, rinse the unit with water and then rinse thoroughly with

distilled water. Do not use organic solvents, abrasives, strong cleaning solutions, or

strong acids or bases to clean the chambers. Handle the upper buffer chamber core

with care to prevent damage to the banana plugs. Allow to air dry.

Clean glassand aluminaplates andspacers witha dilutesolution ofa laboratory cleanser,

then rinse thoroughly with tap and distilled water. Glass plates can also be treated with

(but notstored in) acid cleaning solutions. Do not autoclave or heat any part above 45°C.

42 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

6 Maintenance

Page 43

Cleaning before planned

maintenance/service

To ensure the protection and safety of service personnel, all equipment and work areas

must be clean and free of any hazardous contaminants before a Service Engineerstarts

maintenance work.

Please complete the checklist in the On Site Service Health and Safety Declaration Form

or the Health and Safety Declaration Form for Product Return or Servicing, depending on

whether theinstrument isgoing to be serviced on site or returned for service, respectively.

Copy theform you needfrom Section 8.3 Health and Safety Declaration Forms, on page 50.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 43

6 Maintenance

Page 44

7 Troubleshooting

About this chapter

This chapter provides information to assist users and service personnel to identify and

correct problems that may occur when operating the product.

If the suggested actions in this guide do not solve the problem, or if the problem is not

covered by this guide, contact your GE representative for advice.

Safety precautions

CAUTION

Circulate only water or 50/50 water/ethylene glycol through the

heat exchanger. Never use anti-freeze or any organic solvent in

the heat exchanger.

CAUTION

Never introduce anti-freeze or any organic solvent into any part

of the instrument. Organic solvents will cause irreparable damage

to the instrument.

Potential problems

Corrective actionError description

To reduce the running temperature:Smile effect on the

buffer front

•

Circulate coolant throughthe upper buffer chamber core.

•

Prechill the buffer.

•

Decrease the current or voltage setting. (10 mA per 0.75

mm gel, 15 mA per 1.5 mm thick gel.)

•

Run the gel in the cold room.

44 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

7 Troubleshooting

Page 45

Corrective actionError description

Centrifuge or filter sample before loading to remove particulates.

Protein streaks vertically

Dialyze or desalt the sample.

To increase ordecrease the migrationrate, adjust the voltage

or current by 25% to 50%.

Unusually slow (or

fast) run

Adjust the solutions:

•

Check recipes, gelconcentrations, solutions,and dilutions.

(For instance, do not use Tris-HCl instead of Tris.)

•

If the required pH of a solution is exceeded, do not backtitrate. Prepare a fresh buffer.

•

Dispose of older acrylamide solutions and use only stock

of the highest quality.

•

Only use freshly deionized urea.

Check gel preparation and polymerization.Bands are skewed

or distorted

De-gas the stacking gel solution and avoid trapping air bubbles under the comb teeth.

Overlay therunning gelwith water-saturated n-butanolbefore

polymerization begins to avoid forming an uneven gel surface.

Check sample preparation.

Dialyze or desalt the sample.

Centrifuge or filter sample before loading to remove particulates.

Near the buffer front:Stained sample col-

lects

•

Protein is not sufficiently restricted by the resolving gel;

increase the % T.

Near the top of the gel when the buffer front has reached the

bottom:

•

The gel pore size is too small. Decrease the % T of the resolving gel.

•

The protein has precipitated. Heat the sample at a lower

temperature (70°C or less) for 1–2 minutes.

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 45

7 Troubleshooting

Page 46

Corrective actionError description

Use only the highest quality reagents.Poor band resolu-

tion

Conduct the separation at a lower current or voltage setting.

Dialyze or desalt the sample.

Reduce the sample volume or concentration.

Only use freshly deionized urea.

Improve dissociation of subunits by heating sample in SDS

sample buffer 1–2 minutes at 100°C.

Add more mercaptoethanol or dithiothreitol; check sample

treatment.

Only use gels that were recently prepared.

Check pHvalues of the separating and stacking gel solutions.

Do not back-titrate buffers.

Sample preparation:

•

Heat samples for no more than 1–2 minutes at 100°C.

Store on ice after heating.

•

Store sample on ice before it is denatured.

•

Add protease inhibitorsif necessary to preventproteolytic

degradation of sample.

•

Store samples to be frozen in aliquots to prevent repeated

freezing and thawing. (Store at -40% to -80%.)

Pour a taller stacking gel. (For best results, allow a stacking

gel height of 2.5 times the height of the sample in the well.)

Bromophenol blue

does not sharpen

into a concentrated

zone in the stacking

gel

Dispose of outdated acrylamide solutions and use only the

highest grade of acrylamide.

When preparing samples, avoid using solutions with a high

sodium or potassium concentration.

46 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

7 Troubleshooting

Page 47

8 Reference information

About this chapter

This chapter lists the technical specifications of the SE 250/260 Mighty Small II. The

chapter also includes ordering information, and the Health and Safety Declaration form

for service.

In this chapter

See pageSection

488.1 Specifications

498.2 Ordering information

508.3 Health and Safety Declaration Forms

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 47

8 Reference information

Page 48

8.1 Specifications

SpecificationParameter

10 × 8 cmGel plate size

8 × 7 cmApproximate gel size

12 WMaximum power

500 VMaximum voltage

500 mAMaximum current

45°CMaximum gel temperature

Indoor use: 4°C to 40°CEnvironmental operating

conditions

Humidity up to 80%

Altitude up to 2000 m

IIInstallation category

2Pollution degree

16.5 × 16 × 16 cmDimensions (W × H × D)

(6.5 × 6.3 × 6.3 in.)

2.7 kgWeight

48 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

8 Reference information

8.1 Specifications

Page 49

8.2 Ordering information

For product codes and information about how to order, please see

www.gelifesciences.com

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 49

8 Reference information

8.2 Ordering information

Page 50

8.3 Health and Safety Declaration Forms

On site service

On Site Service Health &

Safety Declaration Form

Service Ticket #:

To make the mutual protection and safety of GE service personnel and our customers, all equipment and work areas must be

clean and free of any hazardous contaminants before a Service Engineer starts a repair. To avoid delays in the servicing of your

equipment, please complete this checklist and present it to the Service Engineer upon arrival. Equipment and/or work areas

not sufficiently cleaned, accessible and safe for an engineer may lead to delays in servicing the equipment and could be subject to

additional charges.

Yes

No

Please review the actions below and answer “Yes” or “No”.

Provide explanation f or any “No” answers in box below.

Instrument has been cleaned of hazardous substances.

Please rinse tubing or piping, wipe down scanner surfaces, or otherwise ensure removal of any dangerous

residue. Ensure the area around the instrument is clean. If radioactivity has been used, please perform a

wipe test or other suitable survey.

Adequate space and clearance is provided to allow safe access for instrument service, repair or

installation. In some cases this may require customer to move equipment from normal operating location

prior to GE arrival.

Consumables, such as columns or gels, have been removed or isolated from the instrument and from

any area that may impede access to the instrument .

All buffer / waste vessels are labeled.

Excess containers have been removed from the area to provide access.

Provide

explanation

for any “No”

answers here:

Equipment type / Product No:

Serial No:

I hereby confirm that the equipment specified above has been cleaned to remove any hazardous substances and that the

area has been made safe and accessible.

Name:

Company or institution:

Position or

job title:

Date (YYYY/MM/DD):

Signed:

GE and GE monogram are trademarks of General El ectri c Company.

GE Healt hcare Bio-Scien ces Corp, 800 Centennial Avenue, P.O. Box 1327, Piscataway,

NJ 08855-1327

© 2010-14 General Electric Company—All rights reserved. First pub lis hed April 2010.

DOC114954 2/28-9800-26 AC 05/201 4

50 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

8 Reference information

8.3 Health and Safety Declaration Forms

Page 51

Product return or servicing

Health & Safety Declaration

Form

for Product Return or

Servicing

Return authorization

number:

and/or

Service Ticket/Request:

To make sure the mutual protection and safety of GE personnel, our customers, transportation personnel and our environment,

all equipment must be clean and free of any hazardous contaminants before shipping to GE. To avoid delays in the processing of

your equipment, please complete this checklist and include it with your return.

1. Please note that items will NOT be accepted for servicing or return without this form

2. Equipment which is not sufficiently cleaned prior to return to GE may lead to delays in servicing the equipment and

could be subject to additional charges

3. Visible contamination will be assumed hazardous and additional cleaning and decontamination charges will be applied

Yes

No

Please specify if the equipment has been in contact with any of the following:

Radioactivity (please specify)

Infectious or hazardous biological substances (please specify)

Other Hazar

dous

Chemicals (please specify)

Equipment must be decontaminated prior to service / return. Please provide a telephone number where G E can

contact

you for additional information concerning the system / equipment.

Telephone No:

Liquid and/or gas in equipment is:

Water

Ethanol

None, empty

Argon, Helium, Nitrogen

Liquid Nitrogen

Other, please

specify

Equipment type / Product No:

Serial No:

I hereby confirm that the equipment specified above has been cleaned to remove any hazardous substances and that the

area has been made safe and accessible.

Name:

Company or

institution:

Position or job title:

Date (YYYY/MM/DD)

Signed:

To receive a return authorization num ber or service number,

please call local technical support or customer service.

GE and GE monogram are trademarks of General El ectri c Company.

GE Healt hcare Bio-Scien ces Corp, 800 Centennial Avenue, P.O. Box 1327, Piscataway,

NJ 08855-1327, US

© 2010-14 General Electric Company—All rights reserved. First pub lis hed April 2010.

DOC114954 4/28-9800-27 AC 05/201 4

SE 250/260 Mighty Small II Operating Instructions 29281629 AA 51

8 Reference information

8.3 Health and Safety Declaration Forms

Page 52

Index

C

CE

conformity, 8

marking, 8

Cleaning, 42

Before service, 43

D

Decommisioning, 23

E

Emergency

procedures, 22

Emergency procedures

emergency shutdown, 22

power failure, 22

restart, 22

G

Gel

running, 40

Gel sandwich

assembly, 34, 36

preparation, 31

I

Important user information, 5

Intended use, 5

L

Labels, 20

Safety labels, 21

System label, 20

M

Maintenance, 42

Manufacturing information, 7

N

Notes and tips, 6

NRLT, 10

O

On site service, 50

Operation, 29

Ordering information, 49

P

Prerequisites, 5

Product return or servicing, 51

Purpose of this manual, 4

R

Recycling information

decontamination, 23

disposal ofelectrical components, 23

Regulatory information, 7, 10

S

Safety information, 12

Safety label

Description, 21

Safety notices, 6

Safety precautions

Installation, 16

introduction, 13

Maintenance, 18

Power supply, 16

System operation, 17

Samples

loading, 36

preparation, 36

SE 250/260 Mighty Small II

illustration, 26

main components, 26

Service

Cleaning before, 43

Specifications, 48

Standards, 11

System label

Description, 20

T

Troubleshooting, 44

U

Unpacking, 28

Unpacking procedure, 28

52 SE 250/260 Mighty Small II Operating Instructions 29281629 AA

Index

Page 53

GE and the GE Monogram are trademarks of General Electric Company.

© 2004-2018 General Electric Company

All goods and services are sold subject to the terms and conditions of sale of

the company within GE Healthcare which supplies them. A copyof these terms

and conditions is available on request. Contact your local GEHealthcare representative for the most current information.

GE Healthcare Bio-Sciences AB

Björkgatan 30, 751 84 Uppsala, Sweden

GE Healthcare Europe GmbH

Munzinger Strasse 5, D-79111 Freiburg, Germany

GE Healthcare Bio-Sciences Corp.

100 Results Way, Marlborough, MA 01752, USA

HyClone Laboratories, Inc.

925 W 1800 S, Logan, UT 84321, USA

GE Healthcare Japan Corporation

Sanken Bldg. 3-25-1, Hyakunincho Shinjuku-ku, Tokyo 169-0073, Japan

For local office contact information, visit

www.gelifesciences.com/contact

GE Healthcare UK Limited

Amersham Place

Little Chalfont

Buckinghamshire, HP7 9NA

United Kingdom

www.gelifesciences.com

29281629 AA 03/2018 a155

Loading...

Loading...