Page 1

SCOUT & vbSeries

Instrument Reference Guide

SCOUT100-Ex, SCOUT140-Ex

vb5, vb6, vb7, vb8

25 September 2014

Page 2

GE

Measurement & Control

COPYRIGHT © 2014 Bently Nevada, Inc & GE Energy (New Zealand) Ltd.

All rights reserved

No part of this document may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, electronic,

mechanical, photocopy, recording or otherwise without the prior written

permission of Bently Nevada.

The information provided in this document is subject to change without

notice. Names and data used in examples are fictitious unless otherwise

noted. This document is distributed as is, without warranty of any kind,

either expressed or implied, respecting the contents of this document,

including but not limited to implied warranties for the document’s

quality, performance, merchantability, or fitness for any particular

purpose. Neither GE Energy (New Zealand) Ltd, nor its employees,

dealers, agents or distributors shall be liable to the user of this document

or any other person or entity with respect to any liability, loss or damage

caused or alleged to be caused directly or indirectly by this document.

Trademarks

The following are trademarks of Bently Nevada, Inc, a wholly owned

subsidiary of General Electric Company:

• Registered trademarks — Ascent, Bently Nevada, Commtest,

Keyphasor, vbOnline, vbSeries

• Trademarks — Ranger, System 1

Other trademarks and registered trademarks are the property of their

respective owners.

Printed in New Zealand. Uncontrolled when transmitted electronically.

Page 3

GE

Measurement & Control

Additional Information

This manual does not contain all the information required to operate

and maintain the product. Refer to the Ascent Reference Guide for the

required information (available from Help menu in Ascent).

Product Disposal Statement

Customers and third parties, who are not member states of the

European Union, who are in control of the product at the end of its life or

at the end of its use, are solely responsible for the proper disposal of the

product. No person, firm, corporation, association or agency that is in

control of product shall dispose of it in a manner that is in violation of

any applicable federal, state, local or international law. GE Energy (New

Zealand) Ltd is not responsible for the disposal of the product at the end

of its life or at the end of its use.

Page 4

Section 1 — Introduction

i

Contents

SECTION 1 — INTRODUCTION ....................................................................... 1

FLEX FEATURES ...........................................................................................................................2

PRECAUTIONS..............................................................................................................................4

HAZARDOUS LOCATIONS ..........................................................................................................6

CSA Certification — vbSeries Instruments ..........................................................6

IECEx / ATEX Certification — SCOUT Instruments ...........................................8

INSTRUMENT CONNECTIONS ................................................................................................. 11

FRONT PANEL BUTTONS ........................................................................................................ 12

LED INDICATORS ..................................................................................................................... 13

CHARGE BATTERY PACK ......................................................................................................... 14

BATTERY FEATURES ................................................................................................................. 15

REMOVE BATTERY PACK ......................................................................................................... 16

CABLE TEST .............................................................................................................................. 17

OPERATING OVERVIEW ........................................................................................................... 18

Onsite Analysis .............................................................................................................. 19

Recording Routes ......................................................................................................... 20

Balancing ......................................................................................................................... 21

Keypad Entry .................................................................................................................. 22

SECTION 2 — INSTRUMENT FUNDAMENTALS ........................................... 23

SWITCH INSTRUMENT ON OR OFF ....................................................................................... 23

USE MAIN MENU ..................................................................................................................... 24

RETURN TO PREVIOUS MENU ................................................................................................ 24

USE NAVIGATION KEYS AND ICONS ..................................................................................... 24

SELECT MENU ITEMS............................................................................................................... 26

Select Option .................................................................................................................. 26

Jump To End of List ..................................................................................................... 26

Scroll through Multi-column List .......................................................................... 27

Cancel Option ................................................................................................................ 27

Display Hint Labels and Detailed Help .............................................................. 28

Display Alternative Options..................................................................................... 30

Enter Characters........................................................................................................... 31

Example — Rename Folder ..................................................................................... 32

ADDITIONAL ICONS ................................................................................................................. 34

SECTION 3 — SENSORS ................................................................................. 35

CONNECT SENSOR TO INSTRUMENT .................................................................................... 35

MOUNT SENSOR ...................................................................................................................... 35

Page 5

Section 1 — Introduction

ii

SET UP ACCELEROMETER........................................................................................................ 36

Permanent Mounting ................................................................................................. 37

SET UP TACHOMETER .............................................................................................................. 38

TACHOMETER SIGNAL FROM KEYPHASOR® ........................................................................ 40

Manual Keyphasor Threshold settings .............................................................. 42

USE STROBE LIGHT ................................................................................................................. 45

SECTION 4 — MEASUREMENT TYPES AND THEIR USES ........................... 46

SPECTRUM ................................................................................................................................ 46

Strobe Output................................................................................................................. 48

Read Speed of Connected Strobe ........................................................................ 50

WAVEFORM .............................................................................................................................. 51

DEMODULATION ...................................................................................................................... 52

Analyze Demodulation Data .................................................................................. 54

DEMOD SPECTRUM ................................................................................................................. 55

6PACK ....................................................................................................................................... 55

Streamlined Parameter Settings .......................................................................... 56

6Pack Demodulation Processing ......................................................................... 57

TACHOMETER DISPLAY ........................................................................................................... 58

TIME SYNCHRONOUS AVERAGING ........................................................................................ 59

BUMP TEST ............................................................................................................................... 60

COAST-DOWN/RUN-UP ......................................................................................................... 61

Tips for Coast-down/Run-up recordings.......................................................... 61

Deactivate Saving Waveform Data for Coast-down/Run-up

Measurement ................................................................................................................. 62

Take Coast-down/run-up Measurement.......................................................... 63

CROSS CHANNEL PHASE ........................................................................................................ 64

Recommendations for Cross Channel Phase................................................. 65

Fault Types and their Phase Relationships ..................................................... 66

Measuring Cross Channel Phase.......................................................................... 69

Setup .................................................................................................................................. 69

Measure Cross Channel Phase .............................................................................. 70

1 — Plan Cross Channel Spectrum (ODS) Recording Routine ................ 71

2 — Setup ......................................................................................................................... 72

3 — Take Cross Channel Spectrum (ODS) Recording ................................. 75

4 — Review Data .......................................................................................................... 77

REVIEW DATA IN ODS SOFTWARE ....................................................................................... 78

LONG TIME WAVEFORMS ....................................................................................................... 80

Measure Long Time Waveforms........................................................................... 80

View Long Time Waveforms on Computer ..................................................... 82

ORBIT PLOT .............................................................................................................................. 83

Use Orbit Plot Measurement Mode ..................................................................... 86

Page 6

Section 1 — Introduction

iii

Take Orbit Plot Measurement on Route ............................................................ 88

MODAL IMPACT TESTING........................................................................................................ 89

1 — Plan Impact Test Routine ................................................................................ 90

2 — Setup ......................................................................................................................... 90

3 — Perform Trial Impact ......................................................................................... 93

Disable Warning Messages .................................................................................... 95

4 — Perform Actual Modal Impact Test ............................................................ 95

Specify Locations and Directions for Saved Impacts..................................... 97

5 — Review Data .......................................................................................................... 98

KEYPAD ENTRY ......................................................................................................................... 99

ORDER TRACKING................................................................................................................. 101

Take Order Tracked Measurement ................................................................... 102

AVERAGE VALUE MEASUREMENTS .................................................................................... 106

TAKE MULTI-CHANNEL SIMULTANEOUS MEASUREMENTS ............................................ 106

Set up Sensors and Channels ............................................................................. 107

Save Multi-channel Measurements ................................................................. 108

SECTION 5 — SET MEASUREMENT OPTIONS ........................................... 110

SET MEASUREMENT UNITS AND SPECTRUM SCALING ................................................... 110

SET MEASUREMENT PARAMETERS ..................................................................................... 112

CREATE YOUR OWN PARAMETER SETS.............................................................................. 114

ASSIGN SENSORS TO CHANNELS ....................................................................................... 115

SPECTRUM PARAMETERS ..................................................................................................... 116

Fmax ................................................................................................................................ 117

Spectral Lines .............................................................................................................. 118

Fmin ................................................................................................................................. 118

Tach Trigger ................................................................................................................. 118

Averaging ...................................................................................................................... 118

Number of Averages ............................................................................................... 119

Averaging Types ....................................................................................................... 119

Average Overlap....................................................................................................... 119

Windowing ................................................................................................................... 120

Choose Window Type ............................................................................................. 120

WAVEFORM PARAMETERS................................................................................................... 120

Equivalent Fmax ........................................................................................................ 121

Number of Samples ................................................................................................. 121

Duration ......................................................................................................................... 121

ADDITIONAL MEASUREMENT PARAMETERS ..................................................................... 121

SECTION 6 — TAKE RECORDINGS ............................................................. 122

WALKTHROUGH — TAKE RECORDINGS............................................................................ 122

TAKE INDIVIDUAL AND MULTIPLE RECORDINGS.............................................................. 123

Individual recording ................................................................................................. 123

Page 7

Section 1 — Introduction

iv

Multiple recording ..................................................................................................... 123

SAVE RECORDINGS ............................................................................................................... 124

REVIEW RECORDING ............................................................................................................ 125

Review Current Recording .................................................................................... 125

Review Stored Recording ...................................................................................... 126

DELETE RECORDING ............................................................................................................. 127

ATTACH NOTE ....................................................................................................................... 127

BASELINE RECORDINGS ....................................................................................................... 128

SECTION 7 — ANALYZING MEASUREMENTS ONSITE ............................. 129

TIPS FOR TAKING MEASUREMENTS ................................................................................... 130

WALKTHROUGH — TAKE MEASUREMENT ........................................................................ 131

CHANGE DEFAULT MEASUREMENT SETTINGS ................................................................. 133

CHARTS .................................................................................................................................. 134

ANALYZE MEASUREMENTS.................................................................................................. 135

Cursors ........................................................................................................................... 136

Show or Hide Harmonics ...................................................................................... 138

Zoom ............................................................................................................................... 139

VIEW MULTIPLE CHARTS ..................................................................................................... 140

Select Chart .................................................................................................................. 140

Display Single Chart................................................................................................. 140

CHANGE CHART VIEW ......................................................................................................... 141

Select Chart Layout .................................................................................................. 141

Change Multi-chart Layout Display ................................................................... 141

SET Y AXIS (AMPLITUDE) SCALE ......................................................................................... 142

Fixed Y Axis scale options ..................................................................................... 143

AMPLITUDE DISPLAY UNITS ................................................................................................ 144

vdB ................................................................................................................................... 145

adB ................................................................................................................................... 145

SET RPM ............................................................................................................................... 145

Enter RPM manually ................................................................................................ 145

Enter RPM using 1X peak ...................................................................................... 146

VIEW ORDERS ....................................................................................................................... 147

VIEW REVOLUTIONS ............................................................................................................. 148

SAVE MEASUREMENT ........................................................................................................... 148

Save to Existing Machine ...................................................................................... 149

Save to New Machine ............................................................................................. 150

CHANGE SCREEN CONTRAST WHILE IN MEASURE MODE ............................................ 151

SECTION 8 — SEND AND RECEIVE INFORMATION ................................. 152

TRANSFER RECORDINGS FROM INSTRUMENT TO ASCENT ............................................. 152

TRANSFER FOLDERS FROM ASCENT TO INSTRUMENT .................................................... 154

Page 8

Section 1 — Introduction

v

Resend Updated Folder ......................................................................................... 155

Retain Stored Recordings ...................................................................................... 155

Retain Baseline Recordings on Instrument ..................................................... 155

SYNCHRONIZE TIME ZONE ON INSTRUMENT AND COMPUTER ..................................... 156

EXPORT OR IMPORT DATA USING USB FLASH DRIVE .................................................... 157

Export Data using USB Flash Drive .................................................................. 158

Import Data using USB Flash Drive.................................................................. 159

REMOTE COMMS FUNCTIONALITY ...................................................................................... 159

Receive Data from Remote Comms Server .................................................. 160

Send Data from Instrument to Remote Comms Server ......................... 161

CONNECT TO WI-FI NETWORK .......................................................................................... 162

Set up wireless network ........................................................................................ 163

Connect instrument to wireless network ...................................................... 165

Specify preferred wireless connection ........................................................... 166

Using Wi-Fi with your smart phone ................................................................. 167

UFF EXPORT ......................................................................................................................... 168

SECTION 9 — WORKING WITH ROUTES ................................................... 169

WHAT IS A ROUTE? .............................................................................................................. 169

WALKTHROUGH — TAKE RECORDINGS USING ROUTE .................................................. 170

USE BAND ALARMS AND BASELINE OVERALLS ON ROUTE ........................................... 173

View Alarm Bands Configured in Ascent....................................................... 175

RECORD MULTIPLE CHANNELS ON ROUTE ...................................................................... 176

Axis Mode ...................................................................................................................... 177

Point Mode ................................................................................................................... 178

Complete Setup.......................................................................................................... 179

TRIAXIAL MEASUREMENTS .................................................................................................. 179

ENTER MACHINE SPEED ON ROUTE .................................................................................. 182

View Machine and Point Speed Details.......................................................... 184

SKIP ROUTE ENTRIES AND MACHINES .............................................................................. 184

LOCATE SKIPPED ROUTE ENTRIES ..................................................................................... 185

TRACK PROGRESS THROUGH ROUTE ................................................................................ 186

SAVE ROUTE RECORDING ................................................................................................... 187

Select Save mode for recording ......................................................................... 188

Select Recording to Review .................................................................................. 189

RETAKE RECORDING ............................................................................................................ 190

DELETE ROUTE RECORDING ............................................................................................... 191

TAKE OFF-ROUTE RECORDING .......................................................................................... 192

EDIT OR DELETE ROUTE....................................................................................................... 192

SECTION 10 — CREATE, EDIT, AND DELETE ITEMS ................................. 193

STORAGE CAPACITY AND RECORDING VOLUME.............................................................. 193

Page 9

Section 1 — Introduction

vi

ORGANIZE AND STORE RECORDINGS ................................................................................ 194

FOLDERS ................................................................................................................................ 196

Create Folder ............................................................................................................... 196

Change Selected Folder ......................................................................................... 196

Rename Folder ........................................................................................................... 196

Delete Folder ............................................................................................................... 197

Restore Deleted or Overwritten Folder ........................................................... 197

MACHINES ............................................................................................................................. 198

Create Machine Structure ..................................................................................... 199

Create Parameter Set.............................................................................................. 200

Change Sensor ........................................................................................................... 201

Add Structure to Existing Machine ................................................................... 201

Copy Machine Structure ........................................................................................ 202

Rename Machine Structure ................................................................................. 203

Delete Machine Structure...................................................................................... 204

SENSORS ................................................................................................................................ 205

Define or Edit Sensors ............................................................................................. 205

Bias Voltage Check ................................................................................................... 207

Set Default Sensor .................................................................................................... 208

Change Sensor Temporarily ................................................................................. 209

Change Default Sensor .......................................................................................... 209

Delete Sensor .............................................................................................................. 209

NOTES .................................................................................................................................... 209

Create Note .................................................................................................................. 210

Edit Note ........................................................................................................................ 210

Attach Note .................................................................................................................. 211

View Note ...................................................................................................................... 211

Detach Note ................................................................................................................. 211

Delete Note Permanently ...................................................................................... 212

DELETE ALL RECORDINGS IN FOLDER ............................................................................... 212

DELETE ALL STORED INFORMATION .................................................................................. 213

SECTION 11 — BALANCING ROTORS ........................................................ 214

METHODS FOR BALANCING ROTORS ................................................................................ 214

BALANCING PROCESS .......................................................................................................... 215

BALANCING TIPS ................................................................................................................... 216

TACHOMETER ........................................................................................................................ 216

SUGGESTED TRIAL WEIGHT MASS AND LOCATION ........................................................ 217

MANUALLY ENTER BALANCING DATA............................................................................... 217

SET UP BALANCING JOB...................................................................................................... 218

Balance Planes and Weight Positions ............................................................ 219

Balance Planes ......................................................................................................... 219

Page 10

Section 1 — Introduction

vii

Weight Position (Reference Mark) ....................................................................... 219

# Sensors....................................................................................................................... 221

Channel Position ...................................................................................................... 222

Averages ........................................................................................................................ 223

Machine Information ............................................................................................... 224

Rotor Weight, Diameter, and Speed .................................................................. 224

Reference Mark......................................................................................................... 225

Filter Bandwidth ........................................................................................................ 226

Weight Orientation ................................................................................................... 226

Tach Trigger ................................................................................................................. 227

Weight Lin Dist ........................................................................................................... 227

Store Units .................................................................................................................... 227

COMBINE AND SPLIT TRIM WEIGHTS ................................................................................ 227

Combine/Adjust Weights ...................................................................................... 228

Split Weight .................................................................................................................. 229

ADJUST WEIGHTS FOR NEW RADIUS LOCATION ............................................................ 231

REVIEW PREVIOUS BALANCING JOBS ............................................................................... 232

SECTION 12 — BALANCING WALKTHROUGH .......................................... 233

STEP 1 — SET UP NEW BALANCE JOB ............................................................................. 234

STEP 2 — TAKE INITIAL READING ...................................................................................... 235

STEP 3 — TAKE TRIAL READING ........................................................................................ 237

STEP 4 — BALANCE ROTOR................................................................................................ 240

STEP 5 — PERFORM TRIM BALANCING ............................................................................ 241

STEP 6 — VIEW OR SAVE BALANCING JOB ..................................................................... 242

Save balance job ....................................................................................................... 243

SECTION 13 — GENERAL SETUP OPTIONS ............................................... 244

SET DATE AND TIME ............................................................................................................. 244

Adjust Date or Time Format................................................................................. 245

SELECT LOCAL TIME ZONE .................................................................................................. 245

DAYLIGHT SAVING AUTOMATIC ADJUSTMENT ................................................................ 246

ADJUST SOUND VOLUME.................................................................................................... 247

SET INSTRUMENT LANGUAGE ............................................................................................. 247

ADJUST SCREEN CONTRAST ............................................................................................... 247

SWITCH BACKLIGHT ON/OFF ............................................................................................ 248

ESTIMATE REMAINING OPERATING TIME .......................................................................... 248

CONSERVE BATTERY POWER .............................................................................................. 249

Set Backlight Timeout ............................................................................................. 249

Set Sleep Mode Timeout ........................................................................................ 250

Change Default Sleep Mode Timeout ................................................................ 250

Switch Instrument On ............................................................................................. 250

Set Complete Powerdown Timeout ................................................................. 251

Page 11

Section 1 — Introduction

viii

MANAGE INSTRUMENT MEMORY ....................................................................................... 251

Check Available Memory ....................................................................................... 252

Instrument Memory Warnings ........................................................................... 252

80% Memory Capacity Warning ....................................................................... 253

95% Memory Capacity Warning ......................................................................... 254

100% Memory Capacity Warning ...................................................................... 254

Free up Instrument Memory ................................................................................ 255

Reformat Memory Card ......................................................................................... 256

Empty Recycle Bin .................................................................................................... 257

Overwrite Primary Database with Mirror Backup .................................... 258

DISPLAY SYSTEM INFORMATION ........................................................................................ 259

UNLOCKABLE FEATURES ..................................................................................................... 260

UPGRADE INSTRUMENT FIRMWARE — PROFLASH ......................................................... 261

PROFLASH PROCEDURE ....................................................................................................... 262

SECTION 14 – TROUBLESHOOTING .......................................................... 263

RESET INSTRUMENT ............................................................................................................. 263

TROUBLESHOOT NETWORK COMMUNICATIONS ............................................................. 264

Set Ethernet Network Address ........................................................................... 265

Reset Network Values to Factory Default ........................................................ 265

ETHERNET CONNECTION LOST IN WINDOWS VISTA ...................................................... 266

INDEX ............................................................................................................. 267

Page 12

Section 1 — Introduction

1

Section 1 — Introduction

You can use this Reference Guide in conjunction with the Ascent

Reference Guide. Please read this guide before operating your Bently

Nevada SCOUT or Commtest vbSeries Portable Vibration Analyzer and

keep it for future reference. This guide applies to the following

instrument models:

• SCOUT100-Ex

• SCOUT140-Ex

• vb5

• vb6

• vb7

• vb8

Although this guide makes use of common vibration analysis and

balancing concepts, it is not intended as a comprehensive guide or

training manual. Please ensure you have the relevant knowledge and

experience to carry out the procedures described. It is essential to follow

all appropriate safety precautions when working near rotating

machinery.

Page 13

Section 1 — Introduction

2

Flex Features

Some of the features available with the 2013 release are included by

default for some new models, and available for purchase with other

older models. When you purchase an additional Flex feature, you will

receive a license for it which you can activate via Ascent.

If you purchase a Flex feature, you can easily review the licensing status

of these at any time. To do this:

1. Press Options.

2. Press Model + Features.

MORE: Contact your local sales representative to arrange a license

for a feature you wish to add.

MORE: Refer to your Ascent Reference Guide to learn how to apply

our license in Ascent.

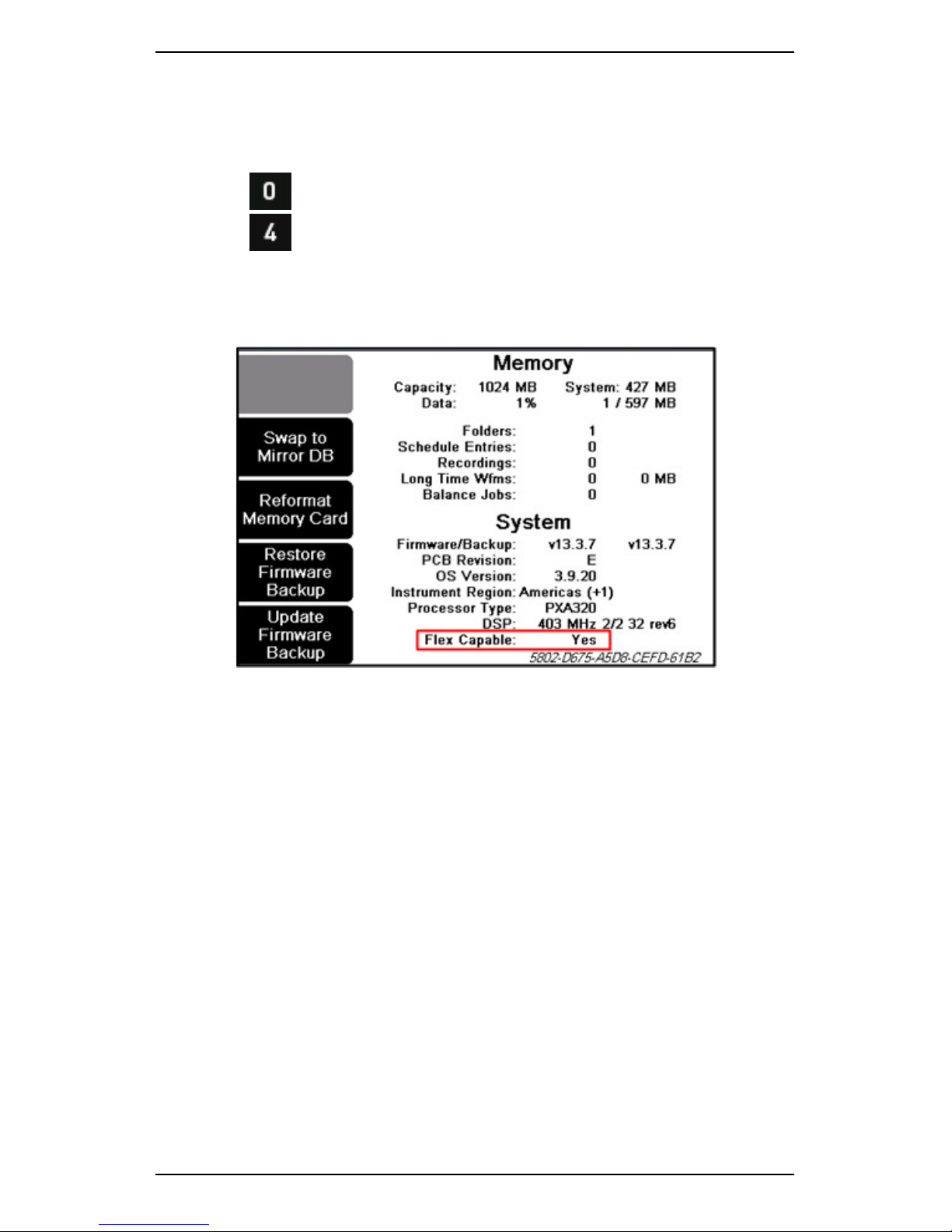

Checking the licensing details for any additional features

Page 14

Section 1 — Introduction

3

Some older instruments are not automatically compatible with Flex

features. To check whether your instrument is currently configured to

support the addition of Flex features:

1. Press Options.

2. Press Memory & System — The Flex Capable listing at the

bottom of the screen indicates either Yes or No.

MORE: Contact Commtest Support if your instrument is currently

not set up to support Flex features.

Determining whether your instrument is currently set up to

support the addition of Flex features

Page 15

Section 1 — Introduction

4

Precautions

Ensure you read and understand this section before operating your

instrument. Pay attention to all warnings and recommendations to

prevent data loss, data inaccuracy, damage to the instrument, or injury

to you.

Do NOT attach sensors to any object with a high

potential voltage — I.e. a voltage that exceeds 50 V DC

or 32 V AC or the Safety Extra Low Voltage (SELV)

defined by your local power authority.

Ensure the cables and neck strap cannot become

entangled with any rotating or moving machinery.

Do NOT bring any objects that are sensitive to

magnetic fields near the magnetic mounting bases

(e.g. cardiac pacemakers, credit cards, floppy disks,

video tapes, audio cassette tapes, or mechanical

watches).

Explosion Hazard — When working in a hazardous

area with risk of flammable gases, all precautions and

limitations explained in the following Hazardous

Locations section must be followed.

Do NOT detach the battery pack from the instrument

for more than 10 minutes. This will erase the

instrument's date and time (it will retain all recordings

and other information).

Neck straps must be connected to the instrument

using the 2.5 turn stainless steel rings provided. The

strap must NOT be connected directly to the unit. This

will defeat the 10 kg safety release provided by the

rings. Replacement rings are available.

Page 16

Section 1 — Introduction

5

Only use an approved power adapter — 12 V 3 A

output, center positive. Do NOT use the plug-pack

transformers supplied with previous instrument

versions. Doing so will damage these transformers.

The cover over the comms and charger connectors

provides an essential seal. The cover must be in place

whenever you use the instrument in an industrial

environment. Failure to comply with this

requirement might void your warranty. IP65 rating

only applies while the cover is securely in place.

Transfer information stored in the instrument to a PC

before reprogramming (PROFLASHING) the instrument

with new firmware. PROFLASHING the instrument will

delete all stored information.

To obtain accurate measurements, ensure the drive

current is switched on when using an IEPE/ICP®-type

accelerometer.

Mount the sensor correctly before taking

measurements. This will ensure your readings are

accurate and consistent.

Use a mild detergent diluted with warm water to

clean your instrument. Do NOT use abrasive or

polishing substances, hydrocarbons, petrochemicals,

or solvents, as these will degrade the plastic casing.

Do NOT place the instrument or magnetic mounting

base where the temperature might exceed 140°F

(60°C). This will degrade the battery pack and magnet.

If your instrument malfunctions, return it to an

authorized dealer. Do NOT attempt to repair the

instrument yourself as this will void your warranty.

Page 17

Section 1 — Introduction

6

Hazardous Locations

SCOUT and vbSeries instruments are rated differently for hazardous

environments — SCOUT instruments hold an IECEx/ATEX rating, while

vbSeries instruments are CSA-certified.

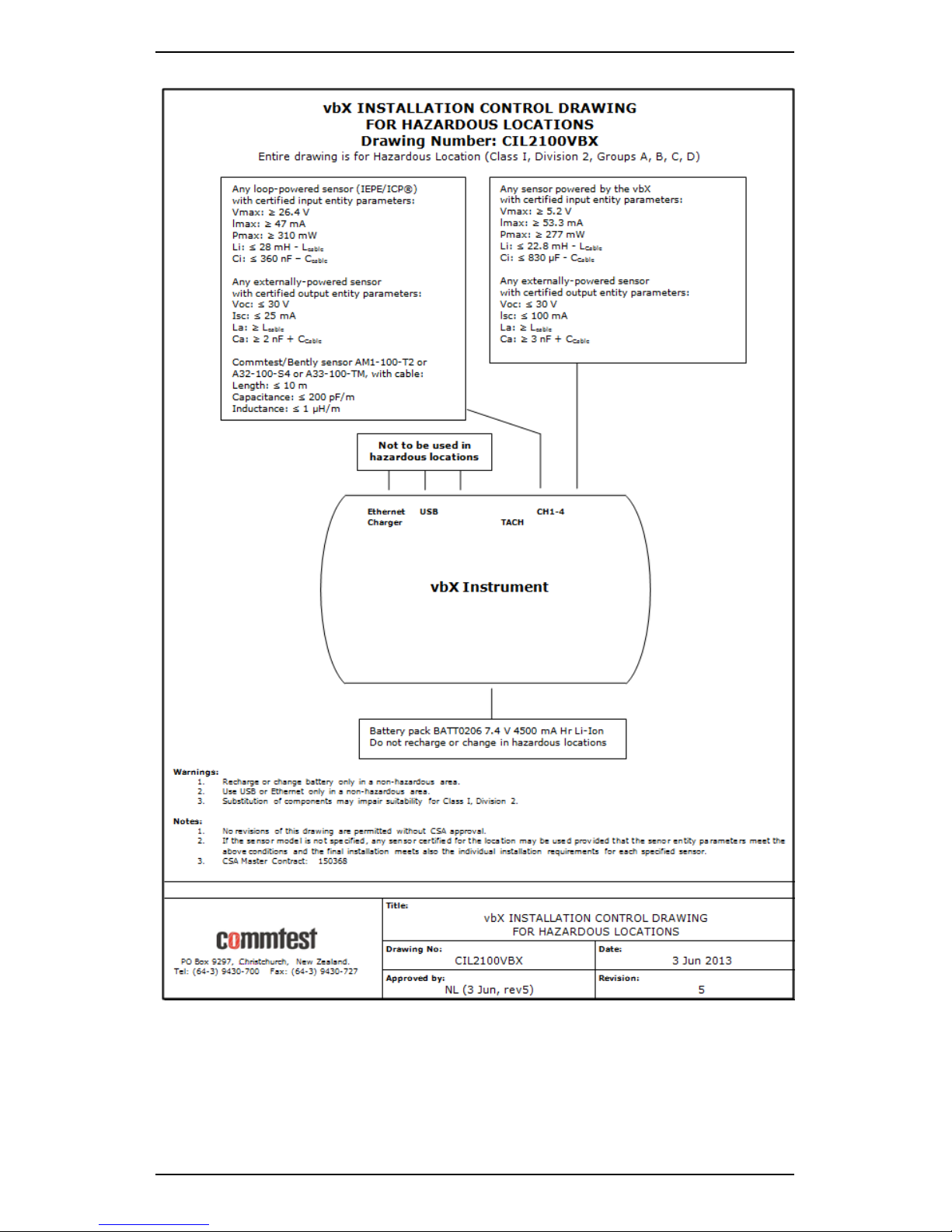

CSA Certification — vbSeries Instruments

Your Portable Vibration Analyzer has been approved by the Canadian

Standards Association (CSA) for use in hazardous locations that meet the

following classifications — Class I; Division 2; Groups A, B, C, and D.

These instruments are clearly identified with the CSA logo and a

Hazardous Locations information panel. The Class I Division 2

classification is officially defined in the Canadian Electrical Code, part 1.

In summary, it is a location in which volatile flammable gases or vapors

are present but confined within closed systems from which they can

escape only in case of accidental rupture or abnormal operation; or in

which ignitable concentrations of gases are normally prevented by

positive pressure or mechanical ventilation, and which might become

hazardous through abnormal operation of the ventilation equipment.

The approval specifically covers use in the United States of America and

any other countries which recognize the CSA certification.

When using a certified instrument in a hazardous location, the

installation must comply with the Installation Control Drawing for

Hazardous Locations, including all its footnotes and warnings.

Your instrument will be supplied, complete with appropriate sensors for

use in Class I Division 2 environments. As indicated in the diagram, you

can use alternative sensors, provided these are certified for use in these

locations, and provided their entity parameters meet the limits shown in

the drawing.

Page 18

Section 1 — Introduction

7

Installation Control Drawing for Hazardous Locations

Page 19

Section 1 — Introduction

8

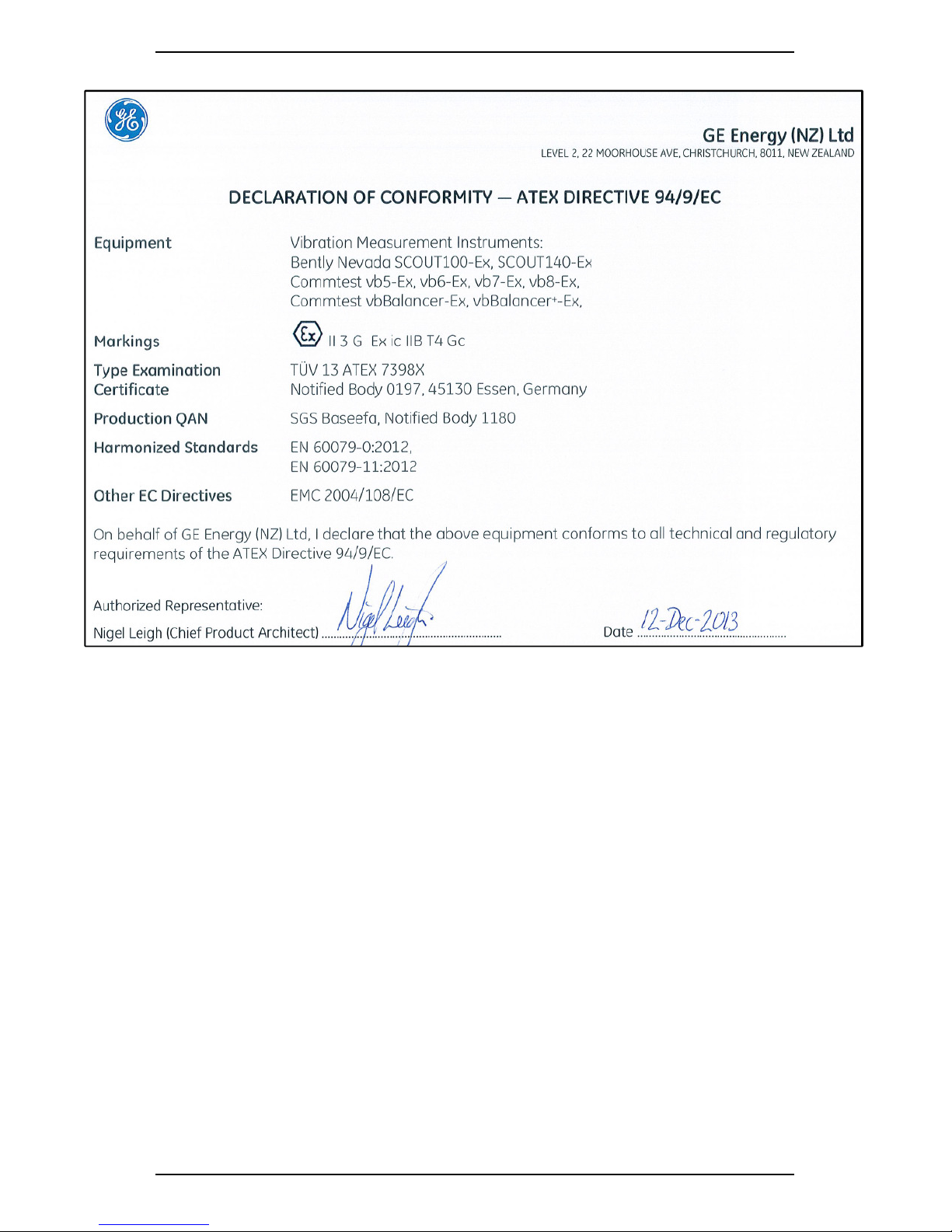

IECEx / ATEX Certification — SCOUT Instruments

SCOUT100-Ex and SCOUT140-Ex portable vibration analyzers are IECEx /

ATEX certified — Identified by the logo on the rear instrument

label.

If you need to use your instrument in hazardous areas, please ensure it

is the appropriate variant for your country. Refer to the following pages

for the hazardous area usage instructions.

The logo on the rear label indicates your instrument has been

approved for use in hazardous locations with the following classification:

II 3 G Ex ic IIB T4 Gc

• Group II = non-mining

• Category 3 = Zone 2

• Atmosphere G = Gas

• Protection method ic = intrinsic safety for zone 2

• Explosion Group IIB = gases such as Ethylene

• Temperature Class T4 = surface will not exceed 135°C

• Protection level c = Zone 2

The approval covers use in Europe (under ATEX) and any other countries

that recognize the IECEx certification.

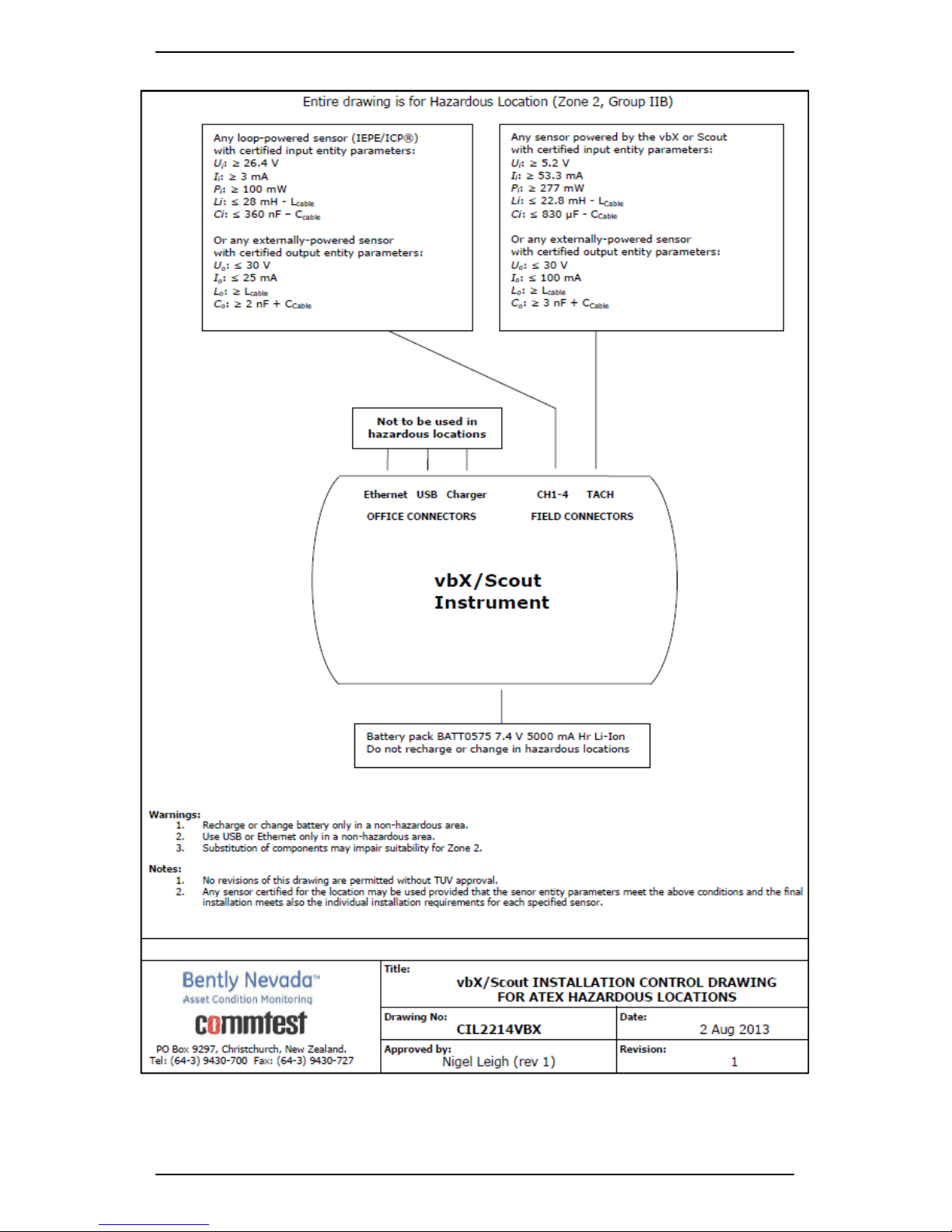

When using a certified instrument in a hazardous location, the

installation must comply with the following Installation Control Drawing

for ATEX Hazardous Locations GE2214VBX , including all its footnotes

and warnings.

Your instrument will be supplied, complete with appropriate sensors for

use in Zone 2 environments. As indicated in the following drawing, you

can use alternative sensors, provided these are certified for use in these

locations, and provided their entity parameters meet the limits shown in

the drawing.

Page 20

Section 1 — Introduction

9

Installation Control Drawing GE2214VBX for ATEX Hazardous Locations

Page 21

Section 1 — Introduction

10

IECEx / ATEX Declaration of Conformity

Page 22

Section 1 — Introduction

11

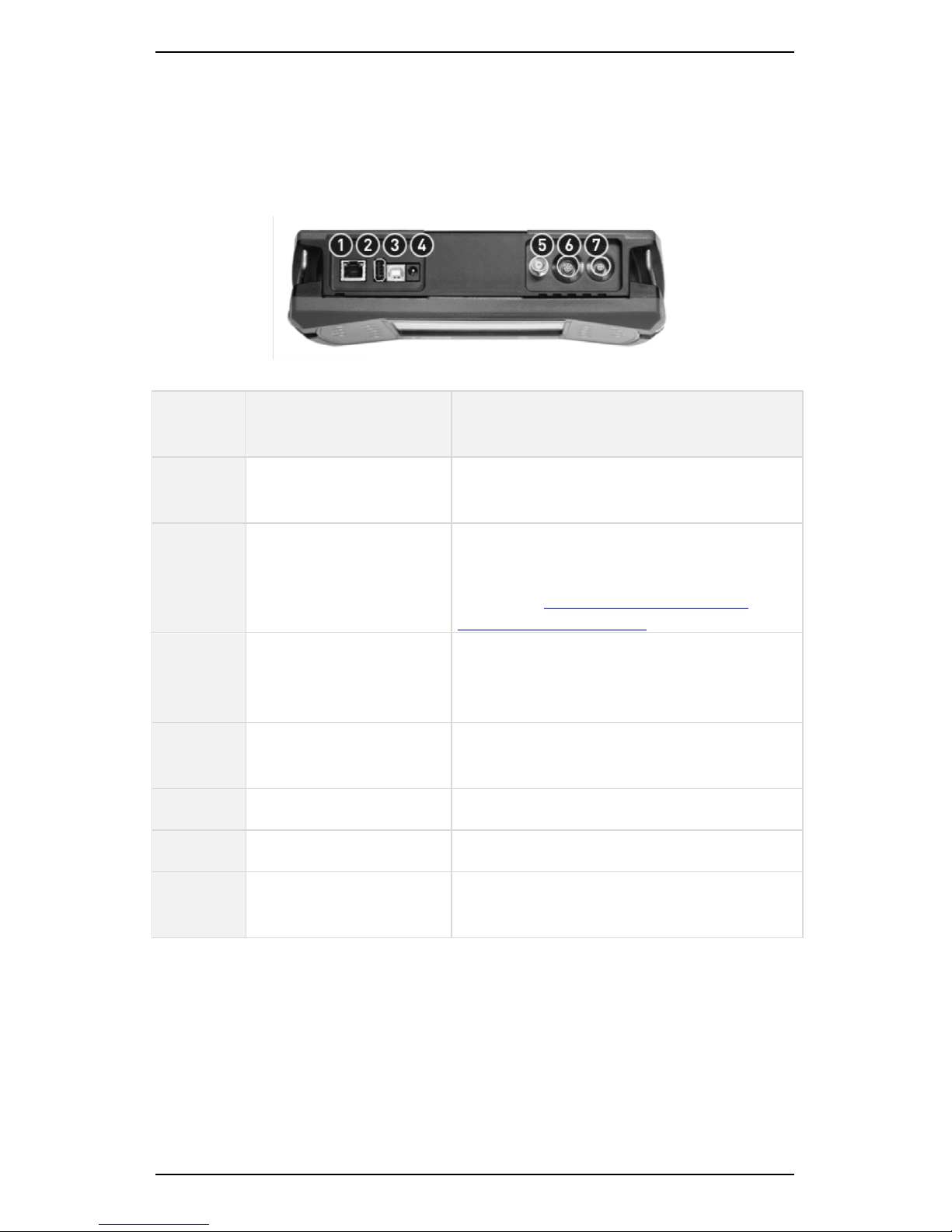

Instrument Connections

The top panel of the instrument is equipped with the following

connectors:

Top panel

Label

number

Feature Description

1 Ethernet port Connects to a standard 8P8C (RJ45)

male plug terminator

2 USB host port Connects to an external USB memory

device for data import and export

MORE: See Export/Import Data via an

External USB Flash Drive.

3 USB socket Provides a data connection between

the instrument and an Ascent

software host computer

4 Charger power socket

(12 Volt 3 Amp input)

Enables you to power the instrument

and charge the its battery pack

5 BNC sensor input Channel 1

6 BNC sensor input Channel 2

7 LEMO four-pin

tachometer input

IMPORTANT! Ensure the protective rubber cover is securely

fastened over the instrument communication ports while you

collect data in the field. Failure to do this may void your warranty.

The IP65 rating only applies while the rubber cover is securely

fastened.

Page 23

Section 1 — Introduction

12

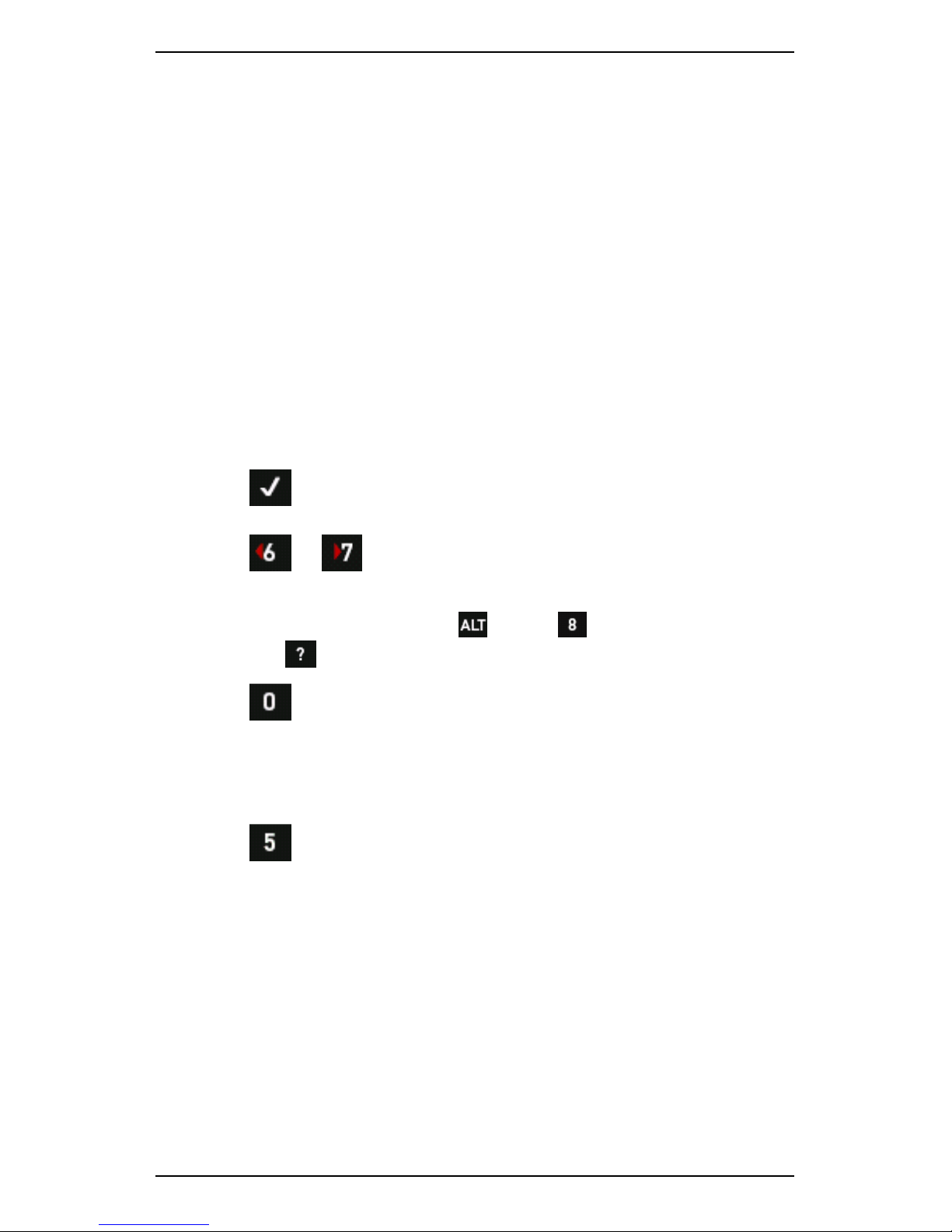

Front Panel Buttons

The table outlines the functions of the buttons on the front panel of your

instrument.

Switch the instrument On/Off.

Cancel/Go Back — A long press takes you back to the main menu.

Accept/Go Forward to the next menu.

Activate alternate functions for each key — In some menus, keys

can perform several functions. To see the available options, press

ALT and toggle the key functions.

Help key — Access easy-to-see hint labels. A long press displays

detailed contextual help text.

Navigate up/down through a list — Press and hold to move more

rapidly through a list.

Navigate left/right — Expands and collapse a level in the navigator

and directs movement between split-screen menus (e.g. Record

Review menu).

Buttons on front panel of your instrument

Page 24

Section 1 — Introduction

13

LED Indicators

There are five LED indicators on the front panel of your instrument.

These indicate the instrument's current state and warn you of any

measurement problems.

Instrument LEDs

Power

supply

(GREEN)

Illuminates when power is supplied to the instrument from

the power adapter.

Charging

(RED)

Indicates the instrument battery is charging.

Danger

(RED)

Illuminates when:

• A DSP or critical error occurs.

• A measurement is less than 25% or greater than

200% of the preset baseline value.

MORE: See Baseline Recordings.

• The sensor bias voltage is outside the specified

range.

Alert

(AMBER)

Illuminates when a measurement is less than 50% or

greater than 150% of the preset baseline value.

OK (GREEN)

Indicates that a measurement is being, or has been,

collected successfully. No error or alert has been triggered.

Page 25

Section 1 — Introduction

14

Charge Battery Pack

To charge your battery pack:

1. Ensure the power adapter you are using is suitable (i.e. 12 Volt, 3

Amp output, center positive).

NOTE: The power adapter supplied with your instrument has the

correct DC voltage.

2. Connect the AC power adapter included with your instrument to a

powered outlet (100-240 Volt, 50/60 Hz).

NOTE: You can also use the optional car adapter charging lead to

charge the battery pack in a vehicle with a 12 V negative-chassis

power system.

3. Connect the adapter's DC output to your instrument's charger

power socket — The instrument's Power Supply and Charging LED

indicators illuminate to indicate that the instrument is charging.

NOTE: The battery will be fully charged in approximately 3 hours.

NOTE: Ensure you charge the fast-charge Lithium Ion battery pack

for at least 1 hour before or during its initial use.

Page 26

Section 1 — Introduction

15

Battery Features

Your instrument is powered by a rechargeable custom Lithium Ion

battery pack with a normal operating range of 6.5 - 8.4 V.

It is equipped with an internal backup energy source to protect your

data and settings in case the battery pack is momentarily removed from

the instrument. The backup remains charged by the battery pack,

provided the battery is functioning correctly. Your instrument includes a

number of features that help ensure the battery pack is always

sufficiently charged.

The table outlines the battery behavior in its different states.

Battery state Behavior

Below 7 Volts Instrument automatically switches off the back

light to prevent further power drainage. It

displays a flashing battery icon to indicate the

battery needs to be recharged.

At 6.5 Volts Instrument automatically powers down.

Charge of 25% or less Instrument enters Complete Powerdown mode

when powered off (rather than Sleep mode).

Page 27

Section 1 — Introduction

16

Remove Battery Pack

To remove the battery pack from your instrument:

1. Use a 2 x Phillips head to loosen the screws that attach the battery

cover to the bottom panel of the instrument.

2. Set the battery cover aside and extract the battery.

WARNING! Do NOT detach the battery pack from the instrument

for more than 10 minutes. This will cause the instrument date/time

to be reset. Stored measurement data or recordings will NOT be

lost.

WARNING! Ensure power is NOT supplied to the instrument when

you remove the battery. Unplug any connected power adapters

before removing the battery.

WARNING! You should NOT re-insert a damaged battery in your

instrument. Dispose of damaged batteries responsibly and in

accordance with local regulations. Do NOT disassemble the

battery or use fire to dispose of it. Replacement batteries are

available from authorized distributors (part number BATT0206).

Page 28

Section 1 — Introduction

17

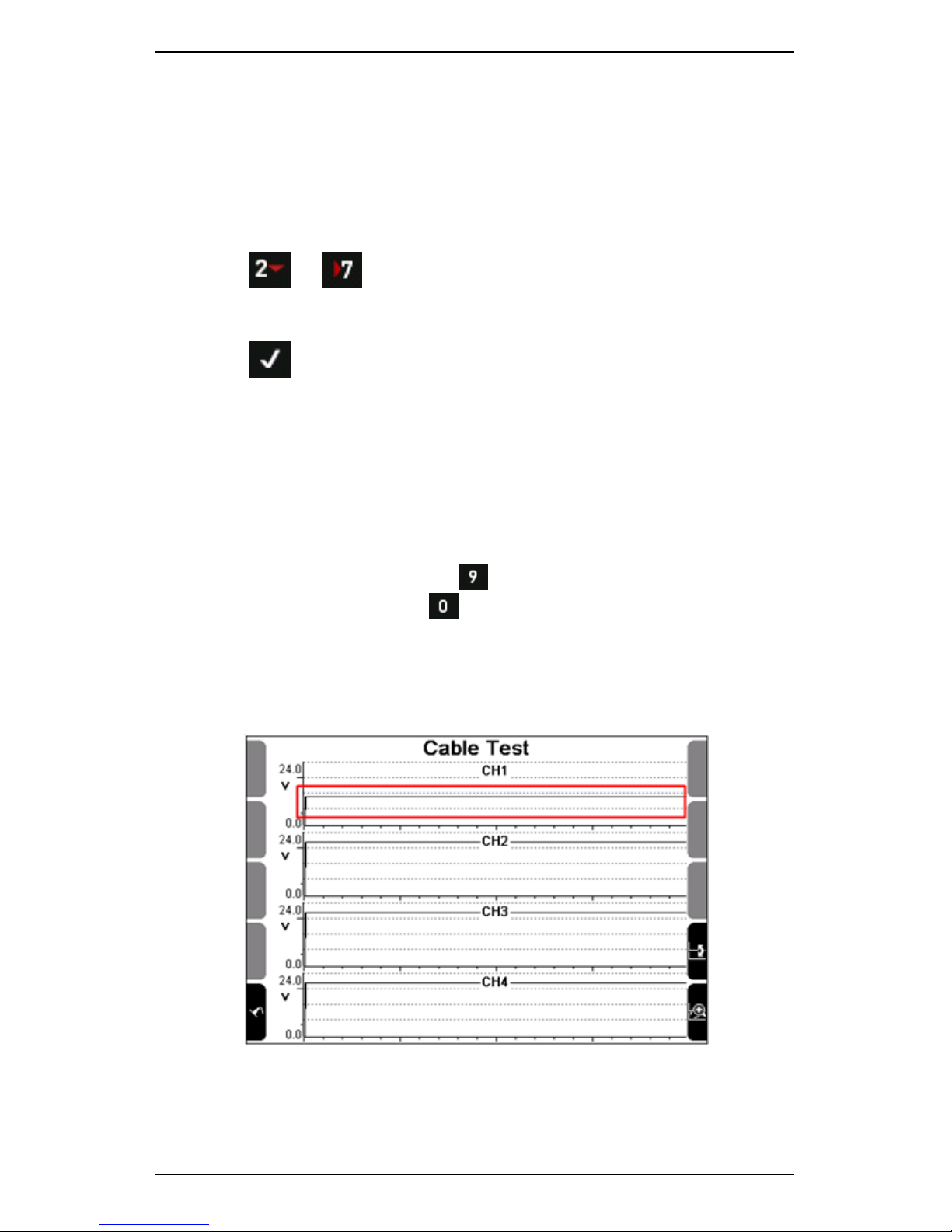

Cable Test

To display a live bias voltage graph of all connected channels and

determine whether your sensors and cables are working correctly:

1. Secure your sensor so that it does not move — You could attach it to

a machine that is not running or hold it with a clamp.

2. Press or Measure.

3. Use the navigation keys provided to scroll down and select Cable

Test.

4. Press — The current voltage displays in real time.

5. Move the cable joints to determine whether there is an intermittent

short:

• Consistent data (e.g. a straight line) indicates the cable is

working correctly.

• Varying data (e.g. a varying line) indicates there is a problem

with the cable.

TIP: You can view the data that displays for a particular channel in

more detail. To do this, press to toggle and select the channel

you wish to view > Press to access an enlarged view of the

data.

NOTE: You can run a cable test for any standard sensor that is

supported by your instrument, including accelerometers, velocity

sensors, and proximity probes.

Cable test reveals sensor is functioning correctly

Page 29

Section 1 — Introduction

18

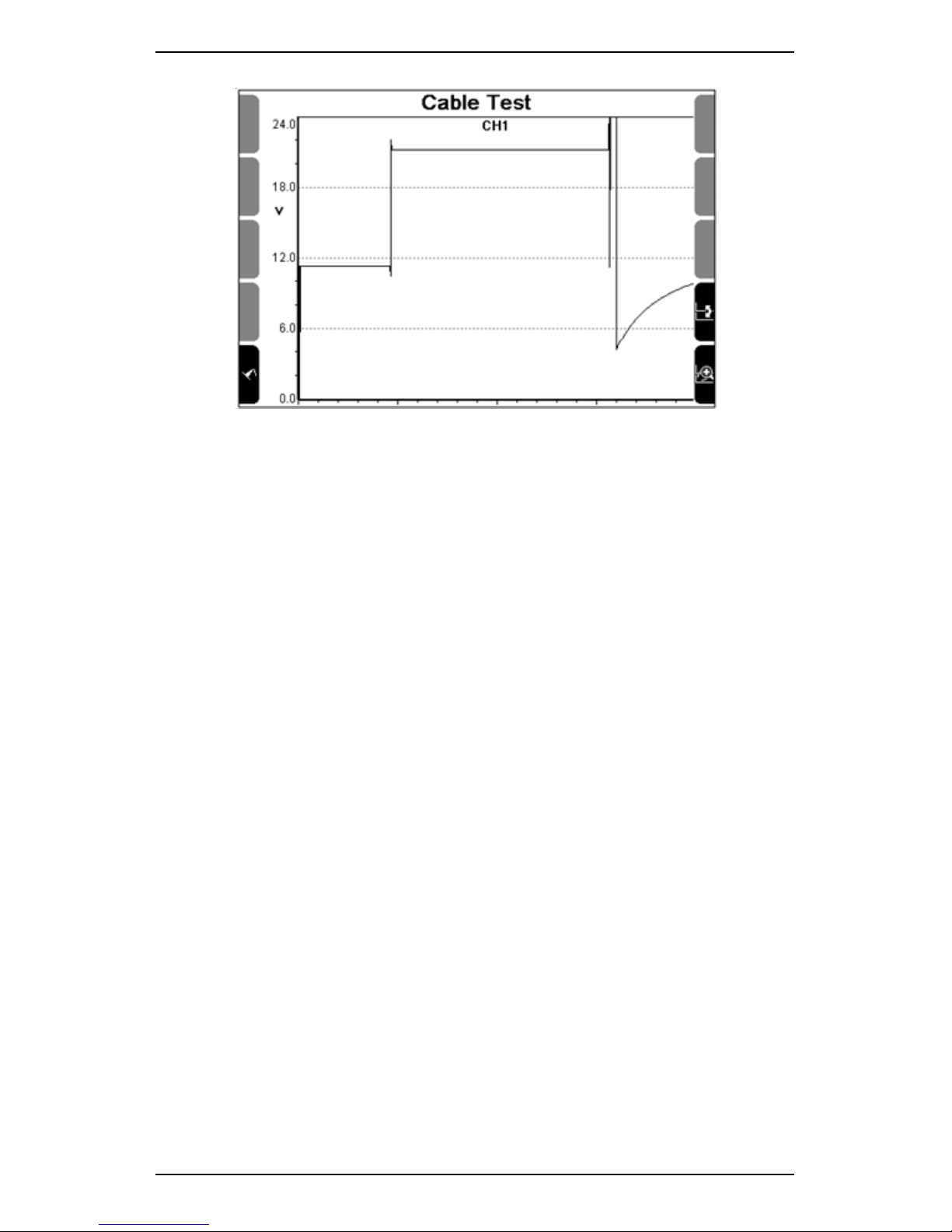

Enlarged view of selected channel reveals problematic sensor connection

Operating Overview

You can use your instrument to:

• Take live, free run measurements for onsite analysis of vibration

spectra and waveforms.

• Record routes and store vibration data for transfer to a PC (off-

site analysis).

• Use keypad entry to enter additional machine information and

process inputs.

• Balance machines using single and dual plane methods.

Page 30

Section 1 — Introduction

19

Onsite Analysis

You can use your instrument to measure vibration spectra and

waveforms. You can then analyze your data onsite immediately. This is

ideal for one-off investigations that fall outside your regular scheduled

monitoring route.

To do an onsite analysis:

1. Set measurement parameters on your instrument.

2. Measure and analyze the spectrum or waveform.

3. Record the data to memory (optional).

4. Transfer the data to your computer for further analysis (optional).

>

>

>

Page 31

Section 1 — Introduction

20

Recording Routes

You can take vibration recordings for all monitored machines and

transfer these to your computer for analysis.

Your instrument can guide you through a predefined data recording

sequence known as a route. You can create a route on your computer

and transfer it to your instrument.

Recording routes is particularly useful if you routinely monitor a large

number of machines. It enables you to build up a history of machine

states and conditions over time.

To record a route:

1. Create a recording route on your computer.

MORE: See the Ascent Reference Guide for instructions.

2. Transfer the route to your instrument.

3. Collect data for each item on the recording route as prompted by

your instrument.

4. Transfer the collected data to your computer for further analysis.

>

>

Page 32

Section 1 — Introduction

21

Balancing

Depending on your instrument, you can analyze and correct rotating

mass imbalance problems where they occur. A rigid rotor can be

balanced in one or two planes. To address a balancing problem where it

occurs:

1. Take an initial measurement of the imbalance.

2. Attach a trial weight to the balancing plane.

3. Take another measurement.

TIP: For dual-plane balancing, do the same for the second plane.

4. Attach correction weights to the balancing planes as recommended

by your instrument.

5. Take a measurement in each plane to confirm the rotor is balanced.

NOTE: You can use Trim Balancing to remove any residual

imbalance.

TIP: You can swap the display so that the rotation shown on the

screen matches the rotation of the shaft you are looking at.

>

>

>

Page 33

Section 1 — Introduction

22

Keypad Entry

You can create keypad entries to define process input values such as

current or flow rates. You can enter process input values manually using

the keypad (instead of attaching a sensor to your machine). You can

then transfer the data you have collected to your computer, along with

your normal measurements.

If you include keypad entries in a route, your instrument will prompt you

to enter values at specific points along the route. Keypad entries can

also be used as onscreen reminders to perform machine checks (e.g. for

checking temperature and pressure).

To collect and record entries using the keypad:

1. Create keypad entries as part of a recording route.

2. Transfer your entries to your instrument.

3. Enter the values for each keypad entry item (when prompted to do

so by your instrument).

4. Transfer the values and recordings you have collected to your

computer for analysis.

>

>

Page 34

Section 2 — Instrument Fundamentals

23

Section 2 — Instrument Fundamentals

This section explains how to:

• Switch your instrument on and off

• Navigate around menus and select menu items

• Enter and edit characters and punctuation

• View hint labels for the buttons on your screen

• Access more detailed help for a feature

Switch Instrument On or Off

You can press the power button to switch your instrument on or

off.

NOTE: If your instrument is switched on and it has a battery state

above 25%, it will enter Sleep mode when you press the power

button. If the battery has less than 25% charge remaining,

your instrument will enter Complete Powerdown Mode when you

switch it off.

When you switch your instrument on, the main menu displays the

following details:

• The remaining battery charge amount

• Today's date and time

• The serial number and firmware version

• Your user-defined description

• The name of the currently selected folder

TIP: You can press and hold either cancel button to return to

the main menu.

Page 35

Section 2 — Instrument Fundamentals

24

Main menu that displays when you switch your instrument on

Use Main Menu

To navigate around the menu, press the key of the task you want to

perform. For example, you can press to take measurements, and

to review recordings.

Return to Previous Menu

You can press the cancel button to return to the previous menu. If

you have opened several submenus, pressing this key will return you to

each previous menu item.

You can press and hold the cancel button to return to the main

menu.

Use Navigation Keys and Icons

You can use the arrow icons on the keypad and screen to:

• Navigate backwards and forwards through menus

• Move up and down and across lists

• Expand and collapse structures that contain other items

Page 36

Section 2 — Instrument Fundamentals

25

The table outlines the functions of the navigation keys and icons.

Move the selection bar in the required direction.

Move the selection bar to the top of a single column list.

Move one column to the left in a multi-column list.

Move the selection bar to the bottom of a single column list.

Move one column to the right in a multi-column list.

Expand the highlighted machine structure to show its points,

locations, and parameter sets.

Move to the right of the screen in a split-screen menu.

Collapse the highlighted machine structure so that only the top

level displays.

Move to the left of the screen in a split-screen menu.

When you are working with large numbers of machines, you can

use the collapse icon to collapse the machine structures

displayed. This will speed up navigation, enabling you to move the

selection bar from machine to machine, instead of scrolling

through each individual parameter set, location, or point.

Using the collapse icon

Page 37

Section 2 — Instrument Fundamentals

26

Select Menu Items

When several menu items are available, these will display in list format,

along with arrows on the screen. You can press the arrow keys to scroll

up, down, or across a multi-column list.

Select Option

To select an option from a list:

1. Use the arrows keys to move the selection bar until your option is

highlighted,

2. Press to select the required option.

Using the arrow keys to navigate to the required menu item

Jump To End of List

Left and right arrows display on the right of your screen when several

menu options are available. If required, you can:

• Press to jump to the first list entry.

• Press to jump to the final list entry.

Page 38

Section 2 — Instrument Fundamentals

27

To jump directly to the end of a list:

1. Open the main menu.

TIP: You can press and hold the cancel button to return to the

main menu from a submenu.

2. Press button to access the Measure menu.

3. Press button to select the Spectrum Waveform menu.

4. Press button to drill down for more details about the Spectrum

Waveform Left and right arrows display on the right of the screen.

5. Press button to select the first list entry, or button to

select the final list entry.

Using the left and right arrows to navigate to the required menu item

Scroll through Multi-column List

You might find lengthy lists displayed in several columns. Where this

happens, you can jump across columns and scroll up or down.

Cancel Option

You can press the cancel button to cancel an option and return

you to the previous menu.

TIP: You can press and hold the cancel button to return to the

main menu.

Page 39

Section 2 — Instrument Fundamentals

28

Display Hint Labels and Detailed Help

The functions on your screen have hidden hint labels and more detailed

snippets of help attached to them. To give you more screen space, the

help is hidden by default.

To access the hint labels and more detailed snippets of help:

1. Open the main menu.

TIP: Press and hold the cancel button to return to the main

menu from a submenu you have open.

2. Open the required menu (e.g. press button to open the Record

Review menu).

3. Press the help key to display the associated hint labels.

4. Press and hold the help key to display more detailed help.

5. Press the help key again to hide the detailed help text.

6. Press any key to hide the hint labels.

Page 40

Section 2 — Instrument Fundamentals

29

Viewing hint labels

Accessing more detailed help

Page 41

Section 2 — Instrument Fundamentals

30

Display Alternative Options

For several of the menu options, one key can perform more than one

function. When an additional menu option is available, an icon will

display at the top of the screen.

You can press the key to access a different set of options.

View of menu before pressing

View of menu after pressing

Page 42

Section 2 — Instrument Fundamentals

31

Enter Characters

The names you enter can be up to 50 characters long. These can contain

a mixture of upper and lower case letters, spaces, numbers, and

punctuation.

To enter letters and numbers, press the keys repeatedly to cycle through

the characters until you reach the one you want to use.

EG: To enter the number 7, press four times.

You can insert spaces between words, change from upper to lower case,

and delete or insert special characters as required.

Pressing to display hint labels will help you use the various editing

commands.

TIP: If you press a different key, the cursor will jump to the next

space. If you need to use a character that is on the same key as

the previous character, pause for a moment until the cursor moves

forward. This will ensure you do NOT overwrite your text.

TIP: Press if you make a mistake and wish to delete a

character.

Page 43

Section 2 — Instrument Fundamentals

32

Example — Rename Folder

This example explains how to rename a folder:

1. Open the main menu.

2. Press Folders & USB Export.

3. Press to change the folder name.

4. Press > Press to clear the current folder name.

5. Press the buttons provided to select the required letter.

EG: Press three times to enter the letter F.

6. Press to enter a space between words.

7. Press to access the punctuation options

8. Press > Press to display the advanced editing menu —

You can use this to change case, delete characters, and more.

9. Press to save your changes once you have finished entering

text.

Entering characters

Page 44

Section 2 — Instrument Fundamentals

33

Using the advanced options

Page 45

Section 2 — Instrument Fundamentals

34

Additional Icons

There are additional icons you can use to manage your machines and

other items.

TIP: Press to display the hint labels for a function.

The table lists the additional icons you can use to manage your

machines.

Icon Function

Create a new machine

Create a new point

Create a new location

Create a new parameter set

The table lists the additional icons you can use to manage any item.

Icon Function

Create a new item

Edit the selected item

Delete the selected item

Copy the selected item into memory

Paste the copied item to the highlighted position

Page 46

Section 3 — Sensors

35

Section 3 — Sensors

This section explains how to use the sensors that are compatible with

your instrument. You will learn:

• How to use the accelerometer and tachometer supplied with

your instrument

• How to mount a sensor correctly

Connect Sensor to Instrument

You can connect a sensor to the instrument via a BNC connector.

BNC connector

To attach a sensor cable plug to a BNC connector, insert the cable and

gently turn it clockwise.

To remove a sensor cable plug from a BNC connector, grip the end of

the cable plug, gently twist it anti-clockwise, and pull it up.

WARNING! Do NOT pull the sensor cable to remove the BNC

connector. Doing this can damage the cable.

Mount Sensor

The sensor mounting you choose will affect the accuracy (and therefore

repeatability) of your vibration measurements.

For walkathon data collection, accelerometers are usually mounted

using the supplied magnetic base. However, for optimal high frequency

results, you can stud-mount these (see Permanent Mounting).

NOTE: Ensure you mount tachometers, displacement sensors,

proximity probes, and current sensors according to the

manufacturer's instructions.

Page 47

Section 3 — Sensors

36

Set up Accelerometer

To set up your accelerometer:

1. Plug the accelerometer connector into the BNC sensor input of your

instrument.

2. Screw the accelerometer into the magnetic base.

3. Attach the accelerometer to the measurement point using these

guidelines:

• Attach the accelerometer to a sturdy, rigidly mounted, non-

flexible structure, where vibration from the rotating part of the

machine will be accurately transmitted.

• Do NOT attach sensors to sheet metal, guards, or any machine

structure that is NOT closely coupled to the source of vibration

in the spinning rotor. The vibration of this kind of structure will

be different to the vibration source.

• The attachment structure must be at least 10 times heavier

than the accelerometer itself. Do NOT mount the accelerometer

on lightweight motors or similar parts as the weight of the

accelerometer will distort the vibration signal. Use a smaller

accelerometer for small structures.

• To avoid distorted signals, attach the accelerometer as closely

as possible to, and in line with, the centerline of the bearings.

• The mounting surface should be flat and smooth where the

accelerometer makes contact. Attach the accelerometer using

the magnetic accelerometer base supplied or a threaded stud

on the machine surface. The accelerometer should NOT move

independently of the machine part it is attached to.

• Ensure the accelerometer is oriented correctly. Vibration can

vary significantly with direction.

• If you are undertaking an ongoing study of a particular

measurement point, always attach the accelerometer at exactly

the same position you used for previous measurements

TIP: Mark the position if necessary.

• Keep the accelerometer clear from other cables to ensure it is

NOT twisted, kinked, or tangled.

Page 48

Section 3 — Sensors

37

Permanent Mounting

To mount a sensor using the stud method:

1. Follow the specifications shown in the diagram below to prepare a

mounting spot on the machine.

2. Unscrew the magnetic base from the sensor.

3. Screw the sensor onto the threaded stud.

TIP: We recommend you use a thread locking compound.

CAUTION! Do NOT use a wrench to tighten the accelerometer. This

may damage the sensor.

Stud mounting spot

Page 49

Section 3 — Sensors

38

Set up Tachometer

A tachometer collects information about a machine's rotation speed. It

provides you with an exact reading of machine speed as a

measurement is taken. This is more accurate than using a default RPM

because a machine's speed can vary significantly under different loads.

The tachometer also provides information on the angle at which the

rotor is vibrating. The angle is measured from a fixed reference mark on

the rotor called the phase angle. To balance a rotor, you need to

consider the amplitude of vibration and the phase angle. The amplitude

shows the severity of the imbalance. The phase angle indicates the

geometry of the imbalance.

WARNING! The laser tachometer is a class 2 laser product. Do

NOT stare into the laser beam.

To set up your tachometer:

1. Screw the block grip extension of the tachometer into the end of the

mounting base articulated arm.

2. Plug the cable socket into the tachometer connecting pins > Turn

the locking ring to make the connection secure.

3. Locate the TACH input on your instrument > Attach the other end of

the cable to this (the LEMO end).

4. Stop the rotor.

5. Cut out a small strip of the reflective tape supplied (approximately 5

mm x 15 mm (0.2" x 0.5").

6. Stick this piece of reflective tape to a machine part that rotates at

the rotor speed (e.g. the shaft).

NOTE: This trigger spot should provide a pronounced increase in

reflection as it passes under the tachometer light beam. The tape

width must be at least double the diameter of the light beam spot.

7. Mount the tachometer magnetic base to a stationary portion of the

machine, close to the trigger spot.

8. Position the tachometer slightly away from the center line of the

rotating machine part so that reflections from the surface of the

machine part do NOT interfere with it.

9. Start the rotor > Wait until it is running at normal running speed.

10. Open the main menu on your instrument.

11. Press to access the Measure menu.

Page 50

Section 3 — Sensors

39

12. Press to access the Tach menu.

13. Press to access the Tach Type > Toggle this setting to

Standard (if you are using the supplied tachometer). — The screen

will display the rotor running speed in RPM and Hz. These values will

continuously update but should stabilize, indicating that the

tachometer is triggering reliably. If the RPM does NOT stabilize,

adjust the position of the tachometer.

Ideal sensor positioning

Preparing to take a tachometer reading

Page 51

Section 3 — Sensors

40

Tachometer Signal from Keyphasor®

If your machine has a proximity-probe-based tachometer (tach) sensor

(e.g. Keyphasor®), you can use this as the tach signal for your

instrument. The sensor should have a buffered front-panel BNC output.

This will ensure your instrument's measurements do NOT interfere with

pre-existing speed measurements.

TIP: You can purchase Keyphasor® LEMO connector tach cables

through your local reseller.

You should adjust the Keyphasor® proximity sensor gap so the driver

box output is -8 V +/- 2 V (i.e. -6 V to -10 V) when the sensor is over the

shaft. This is the normal mid-range position for these sensors. When the

sensor is over the keyway, its output will be -14 V to -22 V (depending on

the make and model).

A number of enhancements are available for instruments with serial

numbers 45000 and higher when taking recordings with a Keyphasor

tachometer:

• There are two additional Keyphasor voltage threshold levels,

making it easier to choose an appropriate threshold for the

machine’s Keyphasor probe gap. The previous single threshold

level was found to be incompatible with some Keyphasors that

had non-standard gap settings. When you take a recording

using a Keyphasor tachometer, your instrument will let you

know if a recording is tach-triggered but no pulses are detected.

You will then be shown the RPM measurements obtained at

each threshold level and be prompted to select the one that

provides the best measurement of the machine’s speed. When

the recording is received into Ascent, your Keyphasor threshold

level selection will be retained for future recordings on that

machine.

• The Tachometer input of these instruments is also sensitive to

both positive and negative signal pulses. Consequently there is

no longer a requirement to use the special Keyphasor Tach

cable (black strain relief, product code KEY70258). Instead you

can use either that cable or the TTL Tach cable (red strain relief,

product code TTL70259).

Page 52

Section 3 — Sensors

41

• In addition to the existing Tach Trigger and Off tachometer

modes, it is possible to set the mode to RPM Only for all

instruments and threshold levels (standard and Keyphasor). You

can use the RPM mode when you need the tachometer to

record machine running speed, but do not require tach

triggering (e.g. when you take coast-down recordings on a

machine with rolling element bearings). The disadvantage of