Page 1

GE Consumer & Industrial

Technical Service Guide

JUNE 2006

Advantium 120

31-9141

SCB 1000

SCB 1001

ZSC 1000

ZSC 1001

GE Appliances

General Electric Company

Louisville, Kentucky 40225

– 1 –

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2006

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

(Continued next page)

Page 3

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY.

A. DO NOT OPERATE OR ALLOW THE OVEN TO BE OPERATED WITH THE

DOOR OPEN.

B. IF THE OVEN OPERATES WITH THE DOOR OPEN, INSTRUCT THE USER

NOT TO OPERATE THE OVEN AND CONTACT THE MANUFACTURER

IMMEDIATELY.

C. MAKE THE FOLLOWING SAFETY CHECKS ON ALL OVENS TO BE

SERVICED BEFORE ACTIVATING THE MAGNETRON OR OTHER

MICROWAVE SOURCE, AND MAKE REPAIRS AS NECESSARY:

1. INTERLOCK OPERATION.

2. PROPER DOOR CLOSING.

3. SEAL AND SEALING SURFACES (ARCING, WEAR AND OTHER

DAMAGE).

4. DAMAGE TO OR LOOSENING OF HINGES AND LATCHES.

5. EVIDENCE OF DROPPING OR ABUSE.

D. BEFORE TURNING ON MICROWAVE POWER FOR ANY TEST OR

INSPECTION WITHIN THE MICROWAVE GENERATING COMPARTMENTS,

CHECK THE MAGNETRON, WAVE GUIDE OR TRANSMISSION LINE AND

CAVITY FOR PROPER ALIGNMENT, INTEGRITY AND CONNECTIONS.

E. ANY DEFECTIVE OR MISADJUSTED COMPONENTS IN THE INTERLOCK

MONITOR, DOOR SEAL AND MICROWAVE GENERATION AND

TRANSMISSION SYSTEMS SHALL BE REPAIRED, REPLACED OR

ADJUSTED BY PROCEDURE DESCRIBED IN THIS MANUAL BEFORE THE

OVEN IS RELEASED TO THE OWNER.

F. A MICROWAVE LEAKAGE CHECK TO VERIFY COMPLIANCE WITH THE

FEDERAL PERFORMANCE STANDARD SHOULD BE PERFORMED ON

EACH OVEN PRIOR TO RELEASE TO THE OWNER.

– 3 –

Page 4

Table of Contents

Blower Assembly ..............................................................................................................................................................32

Capacitor and Diode .......................................................................................................................................................30

Cavity Light ..........................................................................................................................................................................29

Components ........................................................................................................................................................................22

Component Access Chart ............................................................................................................................................22

Component Locator Views ...........................................................................................................................................15

Control Boards and Panel Connections .................................................................................................................19

Control Panel Assembly .................................................................................................................................................25

Control Features ............................................................................................................................................................... 8

Convection Heater Assembly and Thermistor ....................................................................................................35

Damper Assembly ............................................................................................................................................................ 32

Demo Mode .........................................................................................................................................................................42

Diagnostics and Service Information ......................................................................................................................41

Door Assembly ...................................................................................................................................................................24

Fault Codes ..........................................................................................................................................................................42

Fuse ........................................................................................................................................................................................29

High Voltage Transformer ............................................................................................................................................31

Humidity Sensor ................................................................................................................................................................37

Installation ...........................................................................................................................................................................14

Introduction ......................................................................................................................................................................... 6

Left and Right Door Switch Assemblies ..................................................................................................................38

Lower Heater Assembly ................................................................................................................................................35

Low Voltage Transformer .............................................................................................................................................28

Magnetron and Magnetron TCO ................................................................................................................................31

Microwave Leak Test .......................................................................................................................................................43

Noise Filter ........................................................................................................................................................................... 30

Nomenclature .................................................................................................................................................................... 5

Oven Removal / Partial Removal ............................................................................................................................... 23

Proof Feature ......................................................................................................................................................................43

Schematics and Wiring Diagrams ............................................................................................................................44

Speed Cook System .........................................................................................................................................................10

Standard Test Load ..........................................................................................................................................................42

Turntable Motor ................................................................................................................................................................. 37

Upper Heater and Oven Cavity TCOs ...................................................................................................................... 33

Upper Heater Assembly ................................................................................................................................................ 34

Warranty .............................................................................................................................................................................. 46

– 4 –

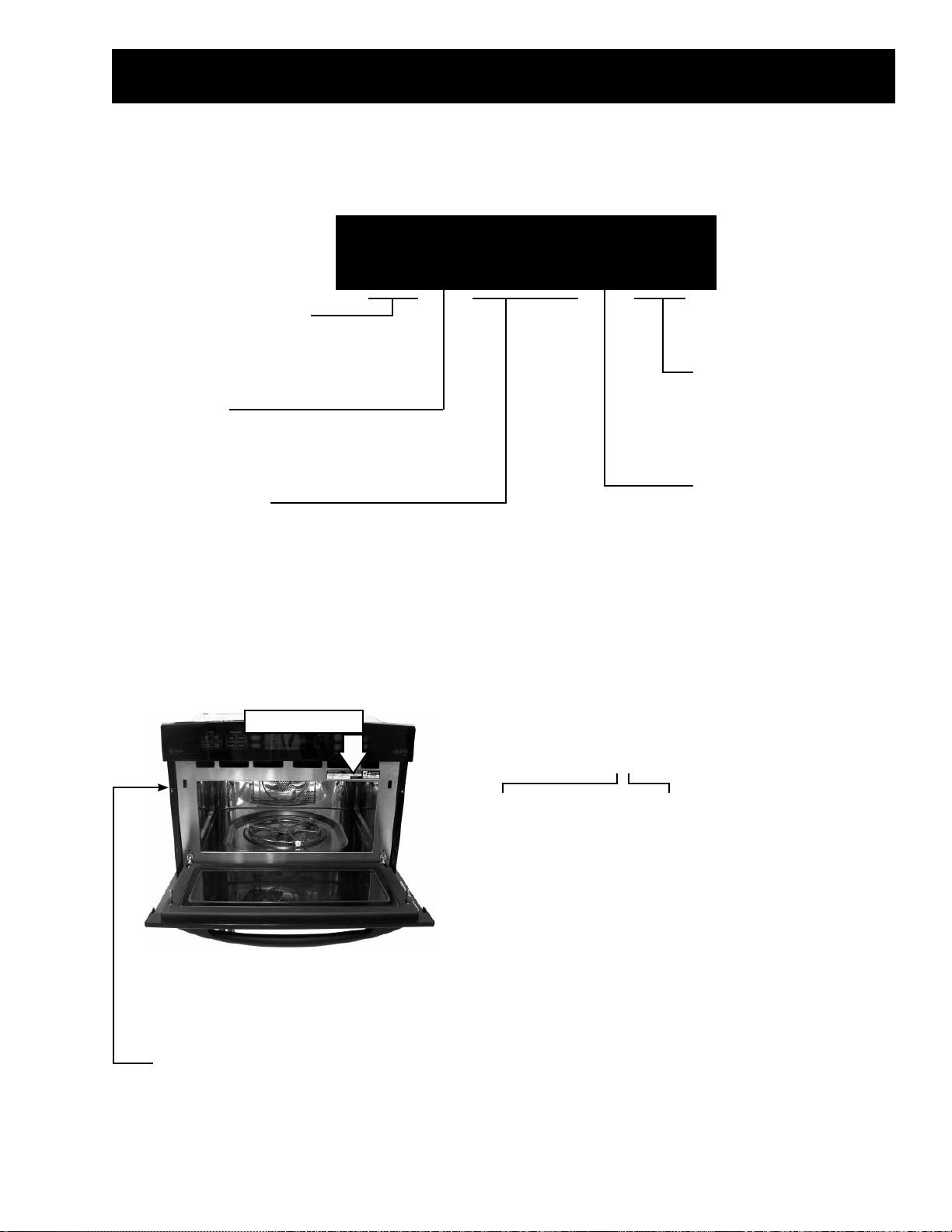

Page 5

Model Number

Nomenclature

S C B 1 0 0 0 D B B

GE Speedcook Technology

SC =GE Profi le

ZS = Monogram

Confi guration

B = Wall Oven

C = Monogram Wall Oven

Model Designator

1000 = Color Model

1001 = Stainless Steel Model

Nomenclature

Exterior Color

BB = Black

CC = Bisque

SS = Stainless Steel

WW = White

Model Year Designator

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example: AL123456S = January, 2006

The nomenclature plate is lo cat ed

on the inside door frame.

The mini-manual is located behind

the small access panel on the left

side of the oven.

A - JAN 2006 - L

D - FEB 2005 - H

F - MAR 2004 - G

G - APR 2003 - F

H - MAY 2002 - D

L - JUN 2001 - A

M - JUL 2000 - Z

R - AUG 1999 - V

S - SEP 1998 - T

T - OCT 1997 - S

V - NOV 1996 - R

Z - DEC 1995 - M

– 5 –

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Page 6

Introduction

The new Advantium oven uses breakthrough Speedcook technology to harness the power of light. The

Advantium oven cooks the outside of foods much like conventional radiant heat, while also penetrating the

surface so the inside cooks simultaneously. While halogen light is the primary source of power, a "microwave

boost” is added with certain foods. Foods cook evenly and fast, retaining their natural moisture.

Features and Benefi ts

Speedcook Oven - Delivers oven quality food up to four times faster than a conventional oven. No

preheating required.

True European Convection Oven - 1500 watt convection oven mode bakes and roasts at temperatures

ranging from 80 to 450°F.

Sensor Microwave Oven - 975 watt sensor microwave oven mode automatically delivers perfect cooking

results.

Warming Oven - Keeps prepared foods warm and fresh, and retains perfect moistness and crispness.

Proof Feature - Specialized mode allows dough to rise quickly.

16-in. Turntable - Removable metal and glass trays easily handle large casserole dishes.

Rounded Rear Wall - Allows complete turntable rotation of 9-in. x 13-in. casserole dish for even cooking.

Installation Flexibility - Fits either a 27-in. x 30-in. wall oven cabinet (installation kit included).

Pre-programmed Recipes - Provide quick and easy programming of over 175 speedcook food selections.

Multi-Level Cooking - Removable rack allows cooking of multiple dishes at once.

Non-Stick Cooling Tray - 16-in. Speedcook tray cleans up easily.

– 6 –

(Continued Next Page)

Page 7

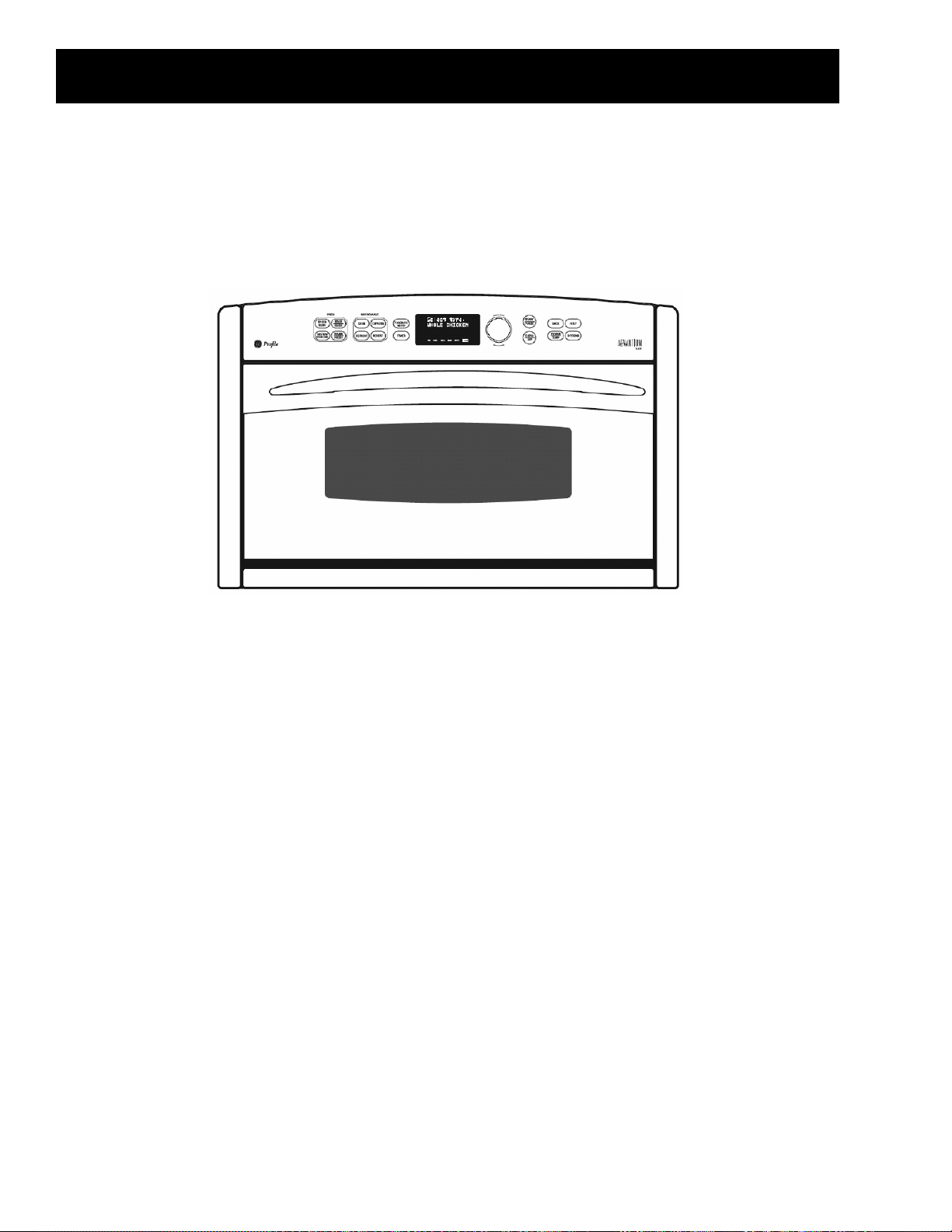

OPTIONS

HELP

POWER

TEMP

BACK

CLEAR

OFF

START

PAUSE

T

U

R

N

T

O

S

E

L

E

C

T

P

R

E

S

S

T

O

E

N

T

E

R

FAN MSG REM MUTE TIMER

TIMER

FAVORITE

RECIPES

MICROWAVE

REHEAT

EXPRESS

DEFROST

COOK

OVEN

WARM

PROOF

BAKE

BROIL

CUSTOM

SPEED COOK

SPEED

COOK

Turntable

The turntable must always be in

place, on the oven floor, for all

cooking. Be sure the turntable is

seated securely over the spindle

in the center of the oven.

Non-stick Metal Tray

Put food directly on the non-stick

metal tray and place on the turntable

when using the speedcook and bake

features.

Wire Oven Rack and Aluminum

Baking Sheet

Put food directly on the aluminum

baking sheet on the wire oven rack,

and place them on the non-stick

metal tray, when baking on two levels,

broiling or toasting foods.

Clear Glass Tray

Place on the turntable when using

the microwave features. Place food or

microwave-safe cookware directly on

the tray.

Upper Halogen Lamp/Ceramic Heater

Operates when using speedcook or

broil.

Window

Allows cooking to be viewed while

keeping microwaves confined in

the oven.

Door Handle

Pull to open the door. The door

must be securely latched for the

oven to operate.

Door Latches

Lower Ceramic Heater

Operates when using speedcook.

Control Panel

The pads used to operate the oven

are located on the control panel.

Rear Convection Heat Element

Operates when using bake.

– 7 –

Page 8

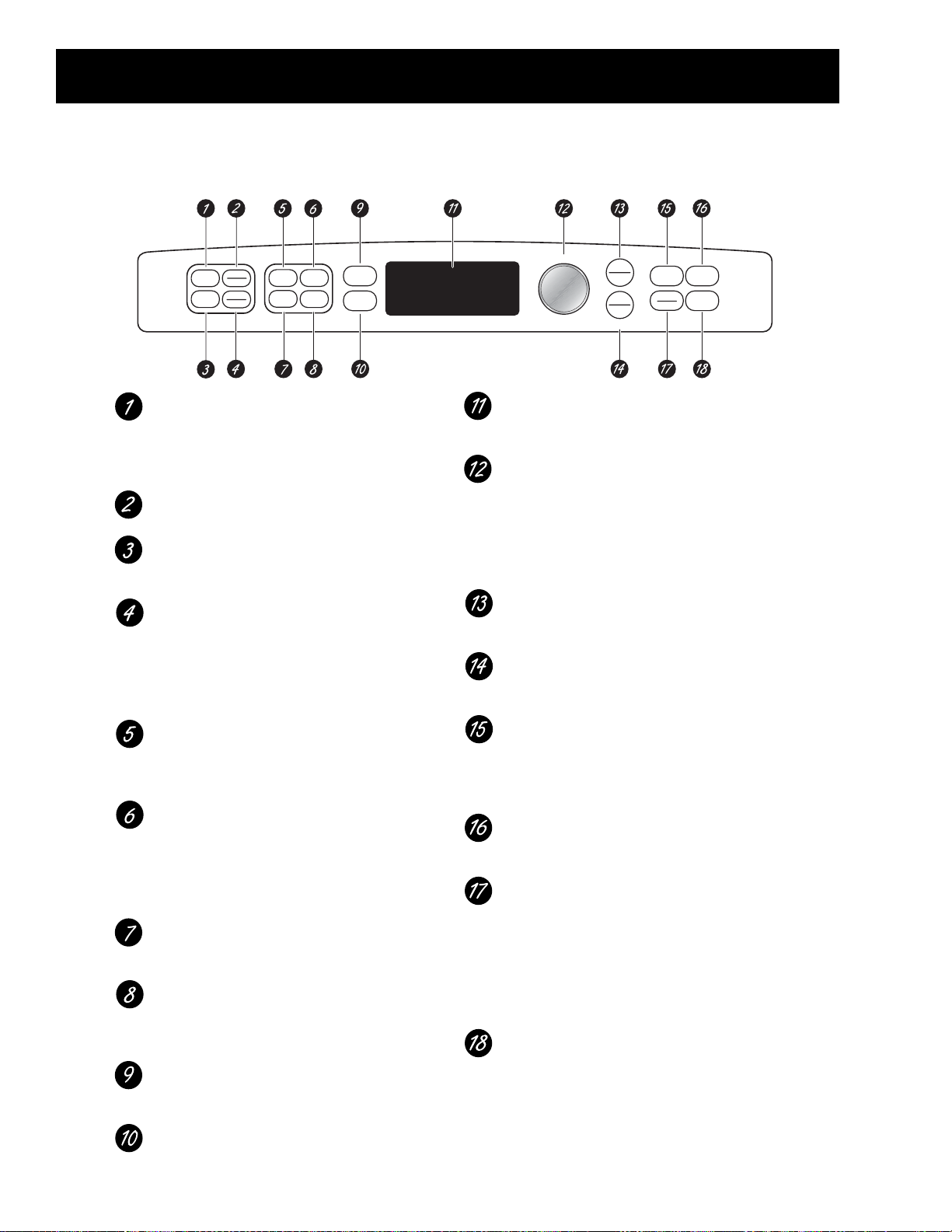

Control Features

With your Advantium oven, you can cook with high-intensity halogen lights, ceramic heaters and convection heating

element, and/or conventional microwave energy.

SPEEDCOOK/Repeat Last

Press this pad to access the pre-set

speedcook menu. Press and hold for

3 seconds to repeat the last cooking

selection.

BAKE/BROIL

Press this pad to bake, broil or toast.

CUSTOM SPEEDCOOK

Press this pad to set your own

speedcook program.

WARM/PROOF

Select WARM to keep hot, cooked

foods at serving temperature.

Select PROOF to set for a warm

environment useful for rising

yeast-leavened products.

COOK (Microwave)

Press this pad to microwave food that

is not in the FAVORITE RECIPES

section.

EXPRESS (Microwave)

Press for 30 seconds of microwave

cooking time. Each time the pad

is pressed adds an additional 30

seconds to the remaining cooking

time. The oven starts immediately.

DEFROST (Microwave)

Press this pad to defrost, soften or

melt frozen foods.

REHEAT (Microwave)

Press this pad to reheat servings of

previously cooked foods or a plate of

leftovers.

FAVORITE RECIPES

Press this pad to add, edit (change)

or remove a recipe from the memory.

TIMER

Press this pad to set the minute

timer.

Display

Shows and instructs the use of all

features on the oven.

SELECTOR DIAL–Turn to select, Press

to enter First turn, then press the dial

to make option, food power level or

temperature selections. Also use the

dial to increase (turn clockwise) or

decrease (turn counterclockwise)

cooking times.

START/PAUSE

Press this pad to start or pause any

cooking function.

CLEAR/OFF

Press this pad to cancel ALL oven

programs except the clock and timer.

BACK

Press this pad to step back one or

more levels in the program process,

such as when entering custom

recipes.

HELP

Press this pad to find out more about

your oven’s features.

POWER/TEMP

During cooking, press this pad

and turn/press the selector dial

to change the microwave power

level, the convection bake

temperature or the speedcook

temperature by adjusting the upper

and lower lamp and heater settings.

OPTIONS

Press this pad to set the Clock

and access the Beeper Volume, Clock

Display ON/OFF, Display Scroll Speed,

Delay Start and Reminder features.

O

S

T

E

N

L

E

R

C

U

T

T

P

R

E

S

S

T

START

PAUSE

CLEAR

OFF

R

E

T

N

E

O

LOCK/UNLOCK

HOLD 5 SECONDS

BACK

POWER

TEMP

HELP

OPTIONS

SPEED

COOK

CUSTOM

SPEED COOK

OVEN

BAKE

BROIL

WARM

PROOF

MICROWAVE

COOK

DEFROST

EXPRESS

REHEAT

FAVORITE

RECIPES

TIMER

FAN MSG REM MUTE TIMER

(Continued Next Page)

– 8 –

Page 9

Cooking Times

■ When speedcooking preprogrammed

foods, you may see OPTIMIZING COOK

TIME in the display several seconds after

you press START/PAUSE. The oven

automatically senses the electrical

voltage level in your home and

adjusts the cooking time up or

down for proper cooking.

Fan/Vent

■ The fan will be on during cooking. At

the end of cooking, the automatic fan

may continue to run for a short time, and

the display will read Oven is Cooling. The

fan will automatically shut off when the

internal parts of the oven have cooled.

■ The oven vent will emit warm air while

the oven is on.

Lights

■ When the oven is on, light may be visible

around the door or outer case.

■ The halogen lights will dim and cycle

on and off during a speedcook cycle,

sometimes even at full power levels.

This is normal. The oven senses the

heat level and adjusts automatically.

To remind you that you have food in the oven, the

Oven Heat

■ No preheating time is required during

Speedcook cycles. The oven begins

cooking immediately.

■ The door and inside of the oven will be

very hot. Use caution when opening the

door and removing food.

■ Do not use cookware or coverings made

of paper, plastic, or foil when cooking

during a speedcook cycle.

■ When cooking for an extended period

of time, the oven may automatically

reduce the power levels to maintain

the appropriate level of oven heat.

Sounds

■ Clicks and a fan blowing are normal

sounds during cooking. The relay board

is turning components on and off.

oven will display COOK TIME COMPLETED and beep

once a minute until you either open the oven door

or press the CLEAR/OFF pad.

RITE

IPES

ER

FAN MSG REM MUTE TIMER

* This occurs during speed cook only when the

cavity temperature approaches 425°F.

*

– 9 –

Page 10

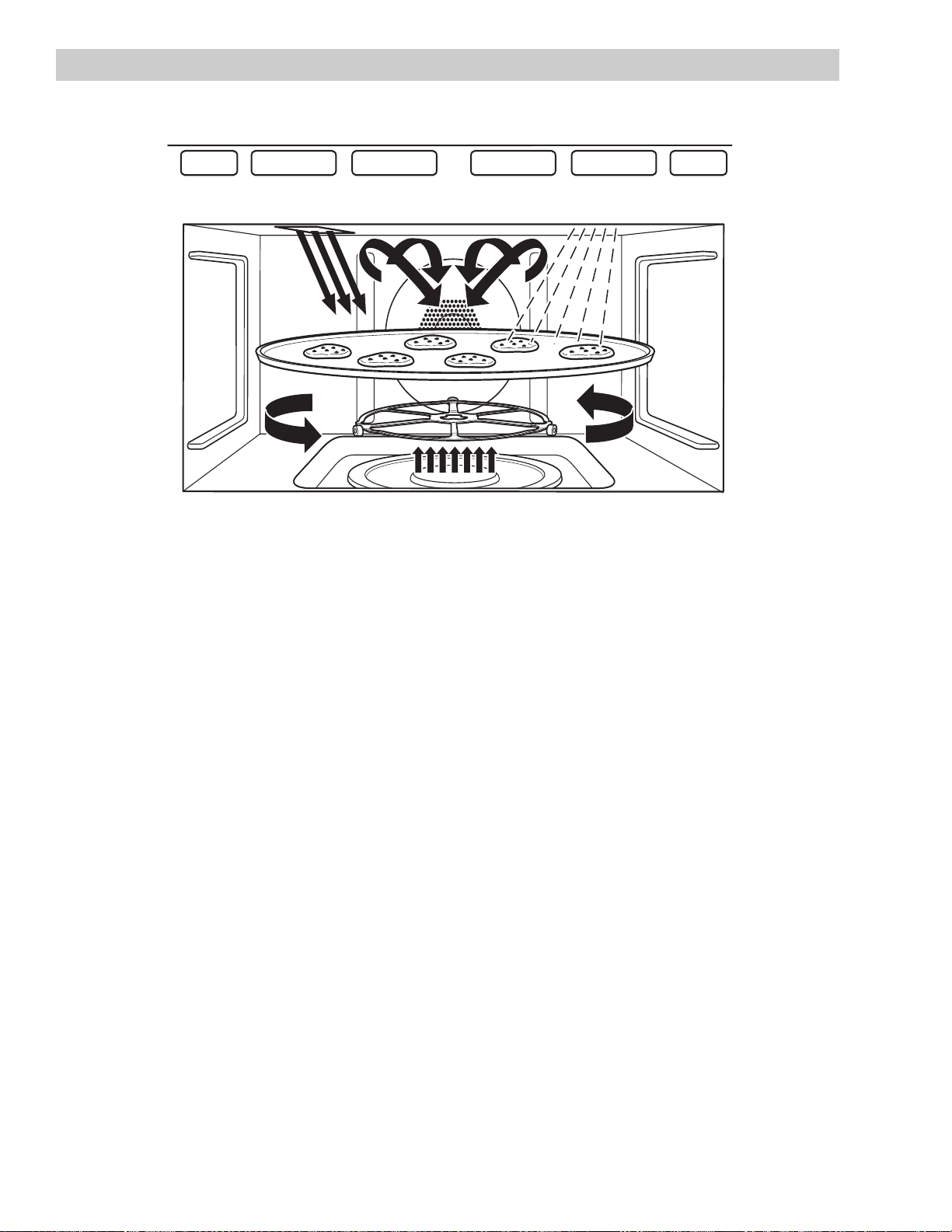

Speed Cook System

Halogen Lamp and Ceramic Heaters

One 500 watt halogen bulb and one 700 watt ceramic heater cook food from above.

•

One 375 watt ceramic heater cooks food from below.

•

Rear Convection Heat Element

Operates when using bake.

•

Microwave

A microwave “boost” is automatically added with certain foods.

•

The oven can also be used as a 975 watt microwave oven

•

– 10 –

(Continued Next Page)

Page 11

Speedcook Power Levels

Lower Heater

Advantium uses power from a high-intensity

halogen light, ceramic heaters, and microwaves

to cook food from the top, bottom, and interior

simultaneously, sealing in moisture and fl avor.

When using preset Speedcook recipes on the food

menu, power levels are preselected. However, these

power levels can be adjusted before or during

cooking. Also, the manual cook feature allows you

to speed cook items not on the preset food menu

by selecting your own cook time and power level

settings.

Each power level alternates heater power and

microwave energy throughout the cook time.

Percentage times of each power source vary,

dependant upon which power level has been

selected. The halogen light and ceramic heaters will

cycle on and off during a speedcook cycle, even

when full power has been selected.

UPPER POWER (U) controls both the upper heating

assembly and microwave power. A higher UPPER

POWER setting will utilize more upper heater power,

browning food faster on top. A lower UPPER POWER

setting utilizes more microwave power, causing food

to cook more evenly throughout. Select a higher

setting for such foods as pizza and baked goods.

Select a lower setting for foods such as casseroles,

meats, and fi sh.

LOWER POWER (L) controls the lower heater. Select a

higher setting to brown foods more on the bottom.

Select a lower setting for less browning on the

bottom.

Refer to the Speedcook Power Level Chart in

this chapter for specifi c power source operating

percentages.

Upper Heaters

The upper heating assembly consists of a 500 watt

halogen heater and a 700 watt ceramic heater. The

halogen and ceramic heaters provide radiant heat,

which browns the outside of the food while sealing

in moisture and fl avor. These heaters only operate in

the speedcook mode and always cycle on and cycle

off at the same time.

The lower heater is a 375 watt ceramic heater.

It operates in speedcook, oven/bake, and warm

modes. The lower heater assists in browning foods

on the bottom.

Microwave Energy

Caution: When cooking in Microwave mode, always

use the glass tray.

The Advantium 120 provides 975 watts of

microwave power, which is delivered directly

into the oven cavity to work independently, or in

conjunction with other cooking cycles. As the food

rotates on the oven turntable, microwave energy is

evenly distributed to all portions of the food.

Sensor Cooking

Advantium’s Microwave mode features sensor

cooking, which automatically selects cook times

and power levels. A humidity sensor detects the

increasing humidity released during cooking, senses

when the food is done, and shuts the oven off at the

appropriate time. Sensor cooking is not available for

5 minutes immediately following Speedcook.

Voltage Compensation

Note: Voltage compensation only occurs when

using a preselected menu item in Speedcook. These

items require compensation for accurate and

consistent cooking results.

Voltage fl uctuations in the power supply can cause

inconsistencies in cooking. The main PCB measures

line voltage at the start of each Speedcooking

selection and adjusts the cooking time to achieve

consistent results. Optimal line voltage, where no

voltage compensation occurs, is 120 VAC. Above

120 VAC, time is subtracted from the recipe. Below

120 VAC, time is added to the recipe. The amount of

voltage compensation required is dependent upon

the incoming voltage at the start of the cooking

cycle and the particular speedcooking selection that

is chosen.

The convection heater, located at the rear of the

oven, operates when using bake mode.

(Continued Next Page)

– 11 –

Page 12

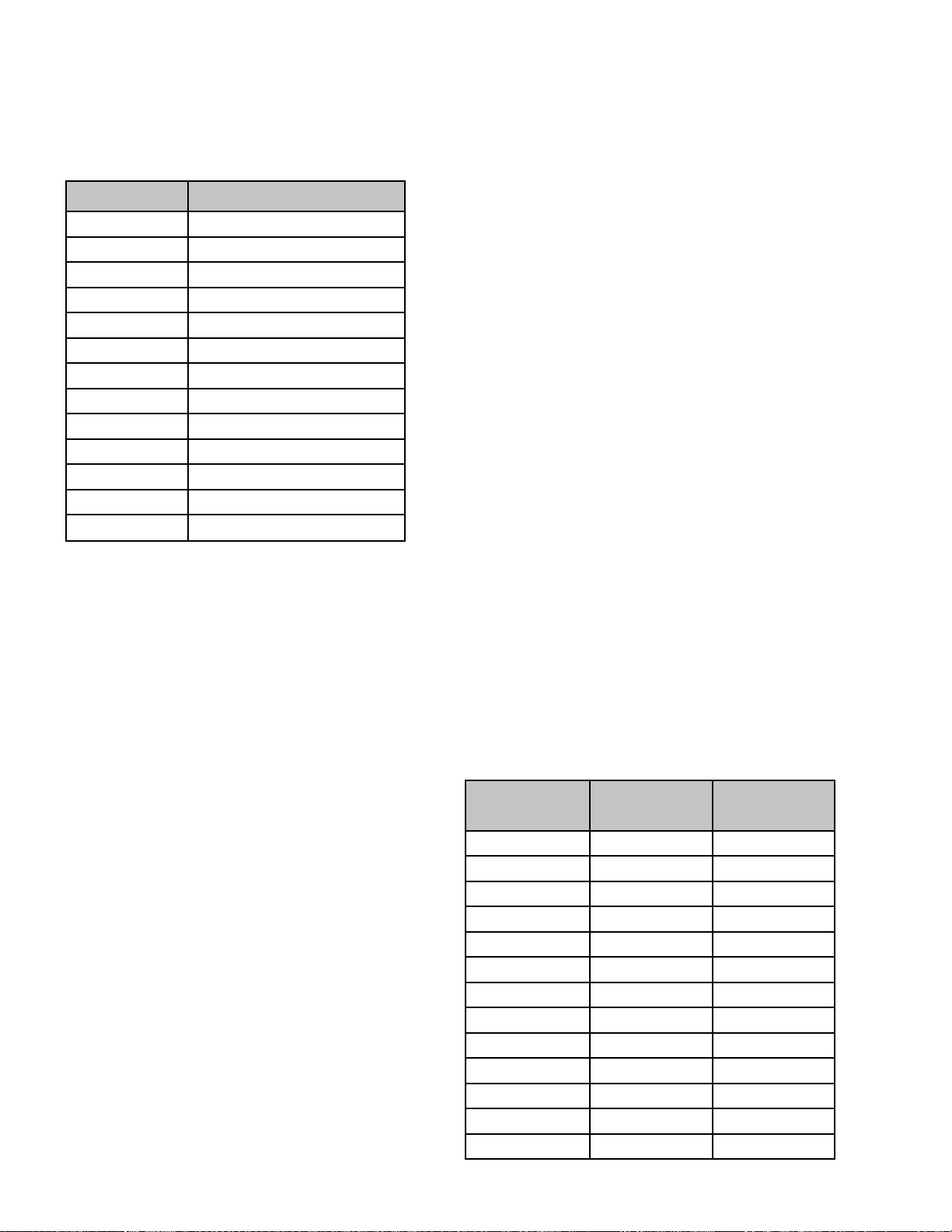

The following chart shows the predicted

compensation times based on a 12-minute

speedcook selection (such as Biscuits, Refr; Large).

Voltage Compensation Chart

Thermal Compensation

Note: Thermal compensation only occurs when

using a preselect menu item in Speedcook. These

items require compensation for accurate and

consistent cooking results.

Voltage Time Change (Seconds)

108 +180

110 +150

112 +120

114 +90

116 +60

118 +30

120 0

122 -21

124 -42

126 -63

128 -84

130 -105

132 -126

Note: Voltage compensation should be within 20

seconds of values in table.

Voltage compensation occurs after approximately 5

seconds of cooking operation. The display will show

OPTIMIZING COOK TIME. The time will fl ash and

then display the new adjusted time, based on the

amount of voltage compensation required.

When cooking several food items consecutively, the

temperature in the oven may become very high.

When Speedcooking, the Advantium automatically

compensates for the increased temperature by

reducing the amount of time the upper and lower

heaters are on during each 32-second duty cycle.

At the start of each new Speedcooking operation,

the cavity thermistor reads the oven temperature

and sends this information to the main PCB board.

If the oven temperature is 150°F or higher, the

main PCB board will initiate thermal compensation.

Thermal compensation will reduce the amount of

time the heaters are on in each 32-second duty

cycle. The reduction in heater time is based on the

oven temperature at the start of Speedcook. The

higher the initial cavity temperature, the less time

the heaters will be on per duty cycle.

Thermal compensation occurs only once, at the

beginning of a Speedcook cycle. In the following

thermal compensation chart, the fi rst column lists

the initial cavity temperature, the second and third

columns list the number of minutes and seconds the

unit will have thermal compensation active.

Thermal Compensation Chart

Voltage compensation only occurs during

Speedcook operation and only occurs once during

the cooking cycle (at initial start of Speedcook

operation).

Thermal Protection

Thermal protection is a safety feature built into the

Advantium’s software. In the event that the internal

oven temperature reaches 500°F, the thermistor will

communicate this information to the main PCB and

thermal protection will be initiated. While in thermal

protection mode, cooking cycles will be maintained;

however, heaters will not be utilized until the oven

reaches the proper operating temperature.

– 12 –

Initial Cavity

Temperature

150°F 2 7

175°F 2 33

200°F 3 0

225°F 3 27

250°F 3 53

275°F 4 20

300°F 4 47

325°F 5 13

350°F 5 40

375°F 6 7

400°F 6 33

425°F 7 0

450°F 7 27

Compensation

Time Minutes

(Continued Next Page)

Compensation

Time Seconds

Page 13

Speedcook Power Level Chart

Upper Power

Level

Hi

Medium Hi

Med

Lower Power

Level

Hi 100% 100% 0%

Lo 100% 80% 0%

Hi 100% 70% 0%

Lo 100% 65% 0%

Hi 90% 90% 10%

Lo 90% 65% 10%

Hi 80% 70% 20%

Upper Heater

On Time

Lower Heater

On Time

Microwave On

Time

Med Lo

Lo

Lo 70% 70% 30%

Hi 60% 60% 40%

Lo 30% 30% 70%

– 13 –

Page 14

Installation

Locate outlet box in the shaded area

6”

9”

Advance Planning

These ovens may be installed directly into a 27-

•

in. or 30-in. wide oven cabinet.

The front surface of the oven will be nearly fl ush

•

with surrounding cabinet doors.

This oven can be installed over any GE or

•

Monogram single electric built-in oven, or a

warming drawer or both.

Color matched side trim pieces are provided

•

for installation into a 30-in. wide space. Use the

side trim when installing the oven above a 30”

wide wall oven or warming drawer. Discard the

side trim pieces if you are installing over a 27-in.

wide oven.

Cutout dimensions are the same for both 27-in.

•

or 30-in. wide cabinet installations.

IMPORTANT: This oven is not approved for use

above another built-in Speedcook oven, a side by

side installation or below a countertop.

Electrical Requirements

Single Advantium 120 Installation

This product requires a 120 volt, 60 Hz, 15 amp

circuit and draws 1.8 kilowatts. This product must be

connected to a supply circuit of the proper voltage

and frequency.

Wire size must conform to the requirements of

•

the National Electrical Code or the prevailing

local code for this kilowatt rating.

The power supply cord and plug should be

•

brought to a separate 15 or 20 ampere branch

circuit single grounded receptacle. The outlet

box should be located within reach of the 48-in.

power cord.

Electrical Location

For personal safety, this oven cannot be

•

installed in a cabinet arrangement such as an

island or peninsula.

The oven must be installed at least 36 3/4 in.

•

above the fl oor.

Allow for clearance to adjacent corners, walls,

•

drawers, etc.

Cabinets installed adjacent to wall ovens

•

must have an adhesion spec of at least 194ºF

temperature rating.

The oven must be securely installed in a cabinet

•

that is fi rmly attached to the house structure.

Weight on the oven door could cause the oven

to tip and result in injury. Never allow anyone to

climb, sit, stand or hang on the oven door.

IMPORTANT: (Please read carefully). The power cord

of this appliance is equipped with a three-prong

(grounding) plug that mates with a standard threeprong grounding wall receptacle to minimize the

possibility of electric shock. The customer should

have the wall receptacle and circuit checked by a

qualifi ed electrician to make sure the receptacle is

properly grounded and has the correct polarity.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with

a properly grounded three-prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord. DO NOT

USE AN EXTENSION CORD.

– 14 –

Page 15

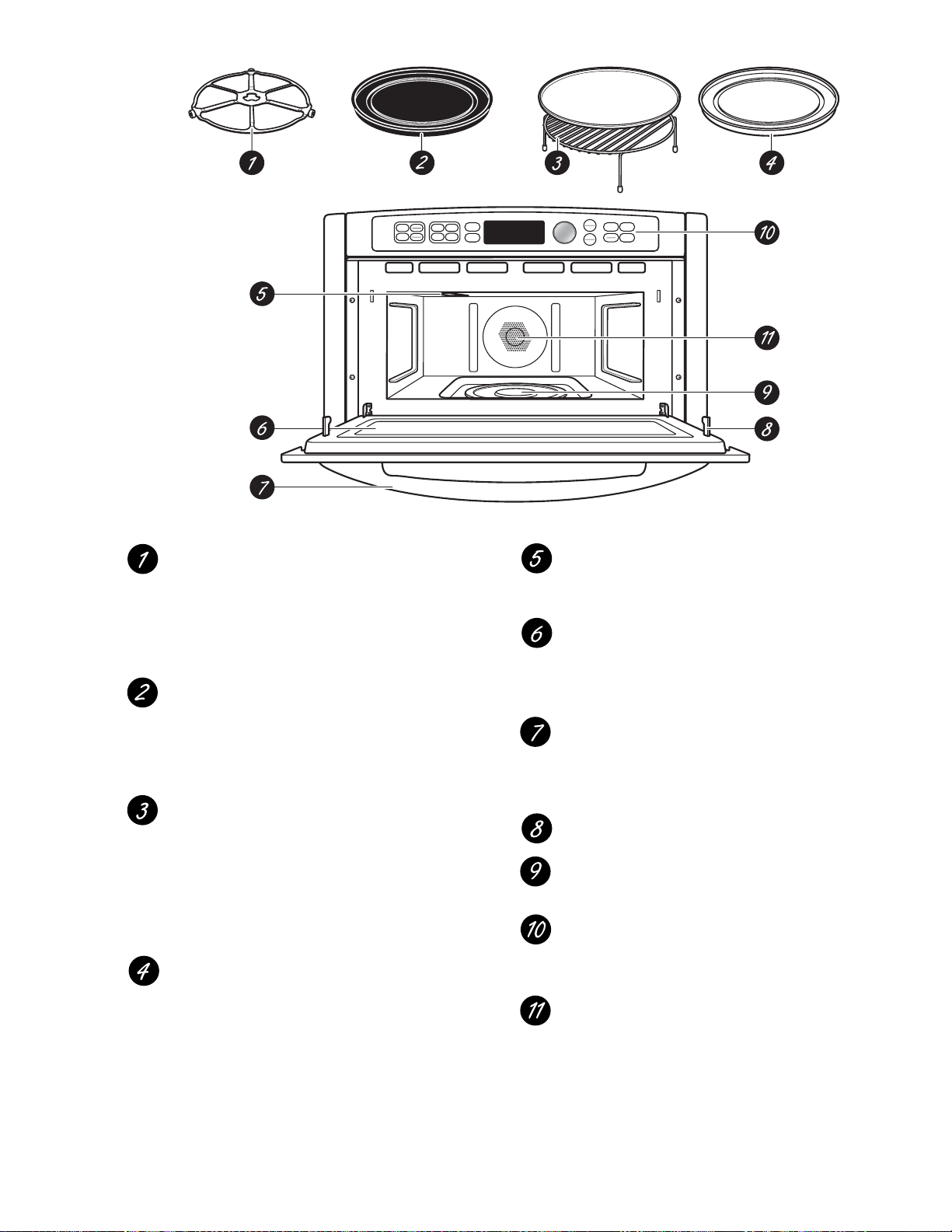

Front View

Control Panel Assembly

Component Locator Views

Convection Fan Assembly

Turntable

Main Component Locator View

Blower Motor

Capacitor

Power

Transformer

Convection Heater

Assembly

Damper

Assembly

Thermistor

Magnetron

Fuse and Noise Filter

– 15 –

(Continued Next Page)

Page 16

Top View

High Voltage Transformer

Upper Heater Assembly

Upper Heater TCO

Bottom View

Low Voltage Transformer

Power Board

Capacitor

Diode

Blower Assembly

Relay Board

Damper Assembly

Magnetron

Fuse

Turntable Motor

Lower Heater Assembly

– 16 –

(Continued Next Page)

Page 17

Left Side View

Control Panel Assembly

Low Voltage Transformer

Humidity Sensor

Oven Cavity TCO

Right Side View

Lower Heater Assembly

Control Panel Assembly

Blower Assembly

Right Side Door Switch Assembly

Fuse

Noise Filter

– 17 –

(Continued Next Page)

Page 18

Control Panel Assembly (Shown separated)

Control Panel

Selector Board

Display Board

Control Board

Control Panel Bracket

Relay Board

Power Board

Low Voltage Transformer

– 18 –

Page 19

Power Board

Control Boards and Panel Connections

CN5 CN8 CN6

CN11

CN4

CN4 - Control Board

CN5 - Humidity Sensor

CN6 - Door Secondary Sensing Switch and Damper Door Sensing Switch

CN7 - Low Voltage Transformer (Secondary Windings)

CN7

CN8 - Thermistor

CN11 - Relay Board

– 19 –

(Continued next page)

Page 20

Relay Board

RY2

RY9

RY8

RY7

RY11

CN3

CN1 - Low Voltage Transformer (Primary Winding)

CN2 - Connection to Door Switch, Heater, and Turntable Motor

CN3 - Control Board

RY2 - High Voltage Transformer

RY7 - Convection Heater

RY8 - Upper Heater (Ceramic)

RY9 - Lower Heater

RY11 - Upper Heater (Halogen)

CN2

CN1

Control Board

CN3 - Relay Board

CN4 - Power Board

CN9 - Selector Board

CN13

CN10

CN9 CN4

CN3

CN10 - Display Board 20-Pin Connector

CN13 - Selector Board

(Continued next page)

– 20 –

Page 21

Display Board

20-Pin

Connector

to CN10

on Control

Board

Selector Board

CN14

CN13

CN9 - Control Board

CN13 - Control Board

CN14 - Control Panel

Control Panel

CN14 to

Selector

Board

CN9

– 21 –

Page 22

Component Access Chart

WARNING:

The oven is heavy and requires two

•

people to remove from the cabinet or

wall opening. Care should be taken when

removing and installing.

Sharp edges may be exposed when

•

servicing. Use caution to avoid injury.

Wear Kevlar gloves or equivalent

protection.

Blower Assembly

Capacitor and Diode

Components

Serviceability - Unit Partially Removed

Serviceability - Unit Installed

Serviceability - Unit Removed

Cavity Light

Cavity TCO

Control Panel Assembly

Convection Fan Motor

Convection Heater Assembly

Damper Assembly

Door

Door Assembly

Fuse

High Voltage Transformer

Humidity Sensor

Left and Right Door Switch Assemblies

Lower Heater Assembly

Low Voltage Transformer

Magnetron and Magnetron Thermostat

Noise Filter

Thermistor

Turntable Motor

Turntable Support

Upper Heater Assembly

Upper Heater TCO

– 22 –

Page 23

Oven Removal / Partial Removal

To remove the oven from cabinet or wall opening:

WARNING: This oven requires 2 people for complete

oven removal. Grasp the bottom of the oven at the

front and rear on each side.

Caution: Do not use the oven handle to lift or lower

the oven. Damage will occur.

Open the door and remove the wire rack,

1.

aluminum baking sheet, glass tray, metal tray,

and turntable.

Remove 4 screws from the side trims

2.

Slide the oven forward approximately 11 inches

3.

to access some components, or remove it

completely from the cabinet or wall opening.

Access Cover

To remove the access cover, the oven must be at

least partially removed from the installation.

The access cover is attached to the outer cover by 2

Phillips-head screws.

Outer Cover

To remove the outer cover, the oven must be

removed from the installation.

The outer cover is held in place by 21 Phillips-head

screws.

Unplug the power cord, and lower the oven onto

4.

a protected surface.

– 23 –

Page 24

Door Assembly

WARNING: A microwave leakage test must be

performed any time a door is removed, replaced, or

adjusted for any reason. (See Diagnostic and Service

Information

Door Removal

Caution: Do not close the door beyond the door

removal position. Damage to the inner door panel

will occur.

To remove the door, open the door fully and insert a

door removal tool (Part # WB01X10318) in each door

hinge opening. The door can then be slowly closed

a few inches to the door-removal position and lifted

from the oven.

.)

To disassemble the door:

Remove the 4 screws from the glass mount.

1.

Remove the choke cover.

2.

Remove the 4 screws from the door frame, and

3.

remove door frame from the glass supporter.

Remove the 4 screws from the glass supporter,

4.

and remove the door handle and vent trim from

the glass supporter.

SCB1000K and SCB1001K

Latch

Latch

Spring

Glass

Supporter

Choke Cover

Tool

Door Hinge Opening

Door-Removal Position

Tool

Door

Handle

Glass Mount

Latch

Spring

Door

Handle

Door

Frame

Door Glass

Door Deco

ZSC1000K and ZSC1001K

Latch

Door

Frame

Latch

Spring

Choke Cover

Latch

Spring

– 24 –

Door Glass

Door Panel

Page 25

Control Panel Assembly

The control panel assembly consists of an outer

control panel and an inner control panel bracket.

The outer control panel contains the control, display,

and selector circuit boards. The power and relay

circuit boards, and the low voltage transformer are

attached to the control panel bracket. Removing the

control panel allows access to the oven lamp.

The control panel is held in place with 7 Phillipshead screws and 4 tabs. Two of the screws are

recessed from the top of the outer cover. Access

holes are provided. A magnetic screwdriver is

necessary to capture these screws.

To remove the control panel assembly:

Place the oven in a partially removed position.

1.

(See Oven Removal / Partial Removal.)

Remove the 3 Phillips-head screws from the top

2.

front of the outer cover.

4. Remove the 2 Phillips-head screws that attach

the control panel assembly to the side of the

frame.

5. Open the oven door.

Grasp the bottom of the control panel assembly

6.

and lift to release the 4 tabs that hold the

bottom of the control panel assembly to the

oven frame.

3. Remove the 2 recessed Phillips-head screws

that attach the control panel assembly to the

top of the frame.

Disconnect wire harnesses from the power

7.

board at locations CN5, CN6, and CN8.

Disconnect wire harnesses from the relay board

8.

at locations RY2, RY7, RY8, RY9, RY11, and CN2.

– 25 –

(Continued Next Page)

Page 26

To remove the power board:

Remove the control panel assembly. (See Control

1.

Panel Assembly.)

Disconnect wire harnesses from the power

2.

board at locations CN4, CN7, and CN11.

Remove the 4 Phillips-head screws that attach

3.

the power board to the control panel bracket.

Lift the power board to clear the retaining tab.

4.

Tab

CN7

CN11

CN4

To remove the relay board:

Remove the control panel. (See Control Panel

1.

Assembly.)

Peel back the foam tape.

2.

Disconnect the wire harness from the power

3.

board at location CN11 and release the harness

from the wire retainer.

Disconnect wire harnesses from the relay board

4.

at locations CN1 and CN3.

Remove the 5 Phillips-head screws that attach

5.

the relay board to the control panel bracket.

Lift the relay board to clear the retaining tab.

6.

Wire Retainer

CN11

CN3

Foam Tape

Tab

CN1

– 26 –

(Continued Next Page)

Page 27

To remove the control panel bracket:

1.

Remove the control panel. (See

Assembly.)

Disconnect wire harnesses from the relay board

2.

Control Panel

at location CN3 and from the power board at

location CN4.

Peel back the foam tape and release the wire

3.

harness to CN4 from the wire retainer.

Remove the 4 Phillips-head screws (2 on each

4.

side) from the control panel bracket.

Slide the control panel bracket to the right then

5.

lift the control panel bracket from the control

panel.

Guide the disconnected harnesses through the

6.

wire entry hole in the control panel bracket.

To remove the control board:

Remove the control panel bracket. (See Control

1.

Panel Assembly.)

Disconnect the 20-pin harness connector from

2.

the display board.

Disconnect the wire harnesses from the selector

3.

board at locations CN9 and CN13.

Remove the 4 Phillips-head screws that hold the

4.

control board to the control panel.

Wire Retainer

Wire Entry Hole

Foam Tape

To remove the display board:

The display board is attached to the control panel

by 2 Phillips-head screws and positioned by 2 pins.

The display board connects to the control board

with a 20-pin wire harness. To access the display

board it is necessary to remove the control panel

bracket. (See Control Panel Assembly.)

Pin

20-Pin Wire Harness

Pin

– 27 –

(Continued Next Page)

Page 28

To remove the selector board:

Remove the control panel bracket. (See Control

1.

Panel Assembly.)

Pull the dial straight out from the control panel.

2.

Disconnect wire harnesses from the selector

3.

board at locations CN9 and CN13.

Low Voltage Transformer

The low voltage transformer is held in place by 2

Phillips-head screws.

The control panel must be removed to access

the low voltage transformer. (See Control Panel

Assembly.)

Disconnect the wire harness from the control

4.

panel at location CN14.

Remove the 6 Phillips-head screws that attach

5.

the selector board to the control panel.

CN13

CN9

To remove the control panel:

To access the control panel it is necessary to remove

the control panel bracket, control, display, and

selector boards. (See Control Panel Assembly.)

The low voltage transformer is connected to the

power board at location CN7 and on the relay board

at location CN1.

Resistance Check

1.

Disconnect the harness from the relay board at

location CN1.

2.

Check the primary winding for approximate

resistance value between the white and black

wires of 23.2 Ω.

3.

Disconnect the harness from the power board

at location CN7.

4.

Check the secondary windings for approximate

resistance value between:

•

Yellow to black - 1.5 Ω

•

Black to white - 5.2 Ω

•

Red to brown - 1.1 Ω

Note: Voltage check for the transformer is:

•

Yellow to black - 13 VAC

•

Black to white - 20 VAC

•

Red to brown - 8 VAC

– 28 –

Page 29

Cavity Light

Fuse

The oven lamp is inserted in a socket that is

attached to the lamp housing with 2 Phillips-head

screws. The screws are recessed from the top of the

outer cover. Access holes are provided. A magnetic

screwdriver is necessary to capture these screws.

It is necessary to remove the control panel to access

the oven lamp. (See Control Panel Assembly.)

The oven cavity light will come on during a

microwave cooking cycle.

Important Note: The primary interlock, monitor

interlock, door sensing (secondary interlock)

switches, and the relay board must all be replaced

when the 20 amp fuse opens due to operation of the

monitor interlock switch.

The unit is equipped with a 20 amp fuse (Part #

WB27X10388).

The fuse is located in a receptacle near the top of

the noise fi lter and is common to all functions and

door switches.

Fuse

Caution: Do not twist the lamp.

The oven lamp is a 130-VAC, 20-watt lamp (Part #

WB08X10050). It is a plug-in type lamp.

Note: If the fuse opens, it will disable all oven

functions including the display. The oven must be

partially removed to access the fuse. (See Oven

Removal / Partial Removal.)

– 29 –

Page 30

Noise Filter

Capacitor and Diode

The noise fi lter is located behind the blower

assembly on the right side of the oven. The noise

fi lter is held in place by a single Phillips-head screw.

The fi lter ground wire is attached to the oven

chassis near the noise fi lter by a single Phillips-head

screw. The outer cover must be removed to access

the noise fi lter. (See

Oven Removal / Partial Removal.)

Note: When installing the noise fi lter, ensure all fi lter

wiring is connected to the correct terminals.

Top View of Noise Filter

Ground Wire Screw

Screw

WARNING: Always be certain the capacitor is

discharged before servicing. Mechanically discharge

by placing an insulated handle screwdriver between

the diode connection of the capacitor and the oven

chassis ground.

Note: The capacitor has an internal discharge

resistor that automatically discharges the capacitor

when the oven turns OFF. Under normal operation,

capacitor should fully discharge within 30 seconds.

The oven must be

partially removed to

Diode

access the capacitor. (See

Oven Removal / Partial

Removal.) The capacitor

Screw

is located behind the top

access cover and is held

in place by 2 Phillips-head

screws. A single Phillipshead screw attaches the

capacitor and diode to

the oven chassis.

Noise Filter

Check to make sure the fuse is good. Check the

noise fi lter for approximate resistance value at the

following locations:

White (neutral input) to white (neutral output) - 0 Ω

Black (line input) to black/brown (line output) - 0 Ω

White (neutral input) to black (line input) - 23 Ω

Front View of Noise Filter

Input

Wire

Harness

Note: When disconnecting the wires and diode from

the capacitor, note wire and diode locations.

The capacitor wires have locking tabs. Remove

the capacitor, capacitor bracket, and diode as one

assembly.

Output-N

Output-L

– 30 –

Page 31

Magnetron and Magnetron TCO

High Voltage Transformer

WARNING: Always be certain the capacitor is

discharged before servicing. (See Capacitor and

Diode.) Mechanically discharge by placing an

insulated handle screwdriver between the diode

connection of the capacitor and the oven chassis

ground.

Note: The capacitor has an internal discharge

resistor that automatically discharges the capacitor

when the oven turns OFF. Under normal operation,

the capacitor should fully discharge within 30

seconds.

The oven must be removed to access the

magnetron. (See Oven Removal / Partial Removal.)

The magnetron is located behind the top access

cover. The top access cover is held in place by 2

Phillips-head screws. The magnetron is held in

place by 4 Phillips-head screws. The magnetron

thermostat must be disconnected before removing

the magnetron.

WARNING: Always be certain the capacitor is

discharged before servicing. (See Capacitor and

Diode.) Mechanically discharge by placing an

insulated handle screwdriver between the diode

connection of the capacitor and the oven chassis

ground.

Note: The capacitor has an internal discharge

resistor that automatically discharges the capacitor

when the oven turns OFF. Under normal operation,

the capacitor should fully discharge within 30

seconds.

The oven must be removed to access the high

voltage transformer. (See Oven Removal / Partial

Removal.) The high voltage transformer is located

behind the top access cover. The top access cover is

held in place by 2 Phillips-head screws.

The transformer is held in place with 4 Phillips-head

screws. Two of the screws are recessed from the

top of the outer cover. Access holes are provided. A

magnetic screwdriver is necessary to capture these

screws.

Magnetron

Magnetron TCO

Magnetron TCO

The magnetron TCO is attached to a bracket

mounted to the magnetron. The magnetron bracket

is held in place by a single Phillips-head screw.

This position of the magnetron TCO allows it to

sense the temperature of the magnetron.

The magnetron TCO opens at 302°F and cannot be

reset. If the magnetron TCO opens, it will disable all

oven functions including the display.

Transformer

When disconnecting the primary and secondary

wire connections, note the wire locations. The wire

connectors use releasing locking tabs.

ELECTRICAL TERMINAL

RELEASE/LOCKING TAB

Check the high voltage transformer windings for

approximate resistance value between:

Red to white (primary) - .5 Ω

Red/Black to chassis ground (secondary) - 87 Ω

Magnetron harness (fi lament high voltage) - .2 Ω

– 31 –

Page 32

Damper Assembly

Blower Assembly

The damper assembly is on the top right side of

the oven cavity. When the damper door is closed,

moisture is retained in the oven cavity. When the

damper door is open, moisture is released, allowing

food to be more crisp.

The outer cover must be removed to access or

observe operation of the damper assembly. (See

Oven Removal / Partial Removal.)

The damper assembly is held in place by 2 pins

and 3 Phillips-head screws that attach the damper

assembly to the oven chassis. When removing,

move the damper assembly inward to disengage

the 2 pins from the vent tube.

Pin

Pin

A blower protects the oven from too much heat

inside the oven cavity. It automatically turns on at

low speed if it senses too much heat. The blower will

automatically turn off when the internal parts are

cool. It may stay on for 30 minutes or more after the

oven control is turned off.

The blower motor has an approximate resistance

value of 14 Ω.

Blower Assembly

Damper Door Switch

The damper door sensing switch is mounted to the

damper assembly. The switch monitors the damper

door position and provides this information to the

main PCB, which controls the operation of the

damper

door motor.

When the

Damper Door Motor

damper

door is

closed, the

switch is

open. The

motor will

run until

Damper Door Switch

the switch

sends the door closed signal. If the damper door

sensing switch circuit shorts (or opens), the damper

motor will run continually. The damper motor has

an approximate resistance value of 3.36 K Ω.

To remove the blower assembly:

Remove the oven from cabinet or wall opening

1.

and remove the outer cover. (See Oven Removal /

Partial Removal.)

Disconnect the blower motor wiring and the

2.

oven lamp wire harness.

Lamp

Wire

Harness

Blower Motor Wires

Damper Door Operating Modes

Cooking

Mode

Damper

Position

Switch Plunger

Position

Switch

Contacts

Microwave Open Not Depressed Closed

Speedcook Closed Depressed Open

– 32 –

Remove the foam seal from the blower bracket.

3.

Remove wiring from the guides in the blower

4.

bracket and from the retainers on the blower

housing.

(Continued Next Page)

Page 33

Disconnect wire harnesses on the relay board at

5.

locations CN2, RY2. RY7, RY8, RY9, and RY11.

Disconnect

Remove the single Phillips-head screw that

6.

Disconnect

attaches the fi lter ground wire to the oven

chassis.

Remove the 5 Phillips-head screws that attach

7.

the blower bracket to the oven chassis.

Upper Heater and Oven Cavity TCOs

The TCOs automatically shut off the oven in the

event of excessive temperatures. When replacing,

be sure to determine the cause of failure. If a TCO

opens, it will disable all oven functions except

the oven light. The outer cover must be removed

to access the TCOs. (See Oven Removal / Partial

Removal.)

The upper heater TCO is mounted on the heat

•

shield above the upper heater assembly.

The oven cavity TCO is mounted to the exhaust

•

duct on the left side of the oven.

Both TCOs are held in place by a singe Phillips-

•

head screw.

Both TCOs open at 293°F and cannot be reset.

•

Upper Heater TCO

Ground Wire

Carefully lift the blower assembly from the oven

8.

chassis.

Remove the 6 Phillips-head screws that hold the

9.

blower housing to the bracket.

Oven Cavity TCO

Note: When installing the blower assembly, ensure

that the fi lter ground wire is secured to the oven

chassis.

– 33 –

Page 34

Upper Heater Assembly

The halogen heater has an approximate resistance

value of 1.8 to 3.7 Ω. It is connected using a white

wire harness.

The ceramic heater has an approximate resistance

value of 15 to 25 Ω. It is connected using a yellow

wire harness.

To remove the upper heater assembly:

Straighten the 4 folded lock tabs.

5.

Remove the 8 Phillips-head screws that attach

6.

the heater cover. Lift off the cover.

Caution: Mark each of the wire harnesses

before disconnecting. The connectors could be

interchanged, causing an adverse effect in cooking

performance.

Remove the oven from cabinet or wall opening

1.

and remove the outer cover. (See Oven Removal /

Partial Removal.)

Disconnect the heater assembly wire harnesses

2.

and pull them through the wire guide.

Disconnect wires from the upper heater TCO.

3.

Lock Tabs

Remove the 3 Phillips-head screws that attach

7.

the heater assembly to the oven chassis.

Remove the 2 Phillips-head screws, wire retainer,

4.

and the heater shield from the heater assembly.

– 34 –

Carefully lift the heater assembly from the oven

8.

chassis.

Page 35

Lower Heater Assembly

Lower heater

Heater

bracket

Reflector

Base plate

Convection Heater Assembly and Thermistor

The lower ceramic heater has an approximate

resistance value of 32 to 42 Ω.

To remove the lower heater assembly:

Remove the oven from cabinet or wall opening.

1.

(See Oven Removal / Partial Removal.)

Remove the 2 Phillips-head screws from the

2.

bottom of each side of the outer cover.

Remove the 6 Phillips-head screws that attach

3.

the bottom to the oven.

The oven must be removed from the cabinet or wall

opening to access the convection heater assembly.

(See Oven Removal / Partial Removal.)

The convection heater assembly is composed of an

inner and outer fan blade, motor, heating element,

and thermistor.

Remove the rear cover. Three Phillips-head screws

hold the cover in place.

Thermistor

Thermistor

Disconnect the bottom heater and turntable

4.

wire harnesses.

Straighten the 4 folded tabs and remove the

5.

3 Phillips-head screws that hold the heater

assembly to the oven chassis.

Bottom View with Baseplate Removed

Tabs

The thermistor must be removed before removing

the convection heater assembly. The thermistor is

attached to the convection heater assembly by a

single Phillips-head screw.

The thermistor is connected to the power board

at location CN8. The approximate values at room

temperature are: Red - Blue = 400K Ω; Red - White

= 290K Ω; Blue - White = 110K Ω.

Convection Heater Assembly Shown with

Rear Cover Removed

Thermistor

(Continued Next Page)

– 35 –

Page 36

Convection Heater Element

Convection Fan Motor

The convection heater assembly is held in place

by two 7-mm hex-nuts and 4 Phillips-head screws

The convection heater element has an approximate

resistance value of 9.5 Ω. Two Phillips-head screws

connect the power wires to the element terminals.

The convection fan motor wire leads have locking

tabs that must be depressed to be disconnected.

To remove each wire from the fan motor, depress

the clip using a small blade screwdriver and pull the

wire off the terminal as shown.

ELECTRICAL TERMINAL

RELEASE/LOCKING TAB

The outer convection fan must be removed before

removing the motor. The outer convection fan is

held in place by a 7-mm nut, lockwasher, spacer

and fl at washer.

Front View of Outer Convection Fan

The convection heater

element is held in place

by 4 Phillips-head

screws. (Three screws on

the front, and 1 screw

on the end.)

The convection fan motor is held in place by 3

Phillips-head screws .

Rear View of Convection Fan

Convection Fan Motor

End View of Element

– 36 –

Page 37

Humidity Sensor

r

Turntable Motor

The humidity sensor is mounted to the exhaust duct

on the left side of the oven. The outer cover must be

removed to access the humidity sensor. (See Oven

Removal / Partial Removal.) The humidity sensor is

connected to the power board at location CN5. The

humidity sensor is held in place by 2 Phillips-head

screws.

The humidity sensor detects the increasing humidity

released during cooking. The oven automatically

adjusts the cooking time to various types and

amounts of food.

The turntable motor is held in place with 2 Phillipshead screws. To replace it requires removing the

turntable, turntable support, and the oven from the

cabinet or wall opening. (See Oven Removal / Partial

Removal.) A single Phillips-head screw attaches an

access panel to the bottom of the oven. A single

wire harness is connected to the turntable motor.

Note: When replacing the turntable support, ensure

it is fully seated into the "D" shaped shaft of the

turntable motor and is fl ush with the oven fl oor.

Humidity Sensor

Humidity Sensor Test

Note:

The oven should be plugged in at least 5

•

minutes before test.

Room temperature should not exceed 95°F.

•

Be sure the interior of the oven is dry.

•

No sensor cooking is available for 5 minutes

•

immediately after speedcook.

Access the control panel.

Disconnect the humidity sensor wire harness from

the power board at location CN5.

On the humidity sensor wire harness check for

approximate resistance values between:

The turntable motor has an approximate resistance

value of 2.6 K Ω.

Base plate cove

Wire leads

Turntable motor

Black-Red = 6.5 k Ω

•

Red-White = 3.25 k Ω

•

Black-White = 3.25 k Ω

•

– 37 –

Page 38

Monitor interlock

switch

Door sensing

(Secondary

Interlock)

Primary interlock

switch

Left and Right Door Switch Assemblies

The primary interlock, monitor interlock, and

door sensing (secondary interlock) switches are

mounted on plastic latch boards. The latch boards

are attached to the left and right side of the oven

cavity. The left side latch board contains the door

sensing (secondary interlock) switch. The right side

latch board contains the primary interlock and the

monitor interlock switches.

Remove the single Phillips-head screw that

2.

holds each door switch access cover to the

outer cover.

Remove the primary interlock and door sensing

3.

switch leads to isolate each switch.

Check continuity of each switch with door open

4.

and door closed. Normal readings are as follows:

• Door Closed: 0 Ω

• Door Open: Infi nity

How to Test the Monitor Switch:

Note: The right side latch pawl pushes horizontally

and actuates the lever of the monitor interlock,

opening the switch.

Disconnect power and partially remove the

1.

oven from it’s installation. (See

Partial Removal.)

Remove the single Phillips-head screw that

2.

Oven Removal /

holds the right side door switch access cover to

the outer cover.

Right side Latch Board Shown

Monitor Interlock Switch

Primary Interlock Switch

Remove the monitor switch leads to isolate the

3.

switch.

Check continuity of the switch with door open

4.

and door closed. Normal readings are as follows:

• Door Closed: Infi nity

• Door Open: 0 Ω

How to Test Interlock System:

1. Disconnect power, remove the outer cover (See

Oven Removal / Partial Removal) and discharge

capacitor.

2. Check 20 amp fuse for continuity and proper

size. Do not use any other fuse or size except 20

amp.

3. Remove monitor switch leads to isolate switch.

Check continuity of switch with door open and

door closed.

• Door Closed: Infi nity Ω

How to Test Primary Interlock and Door Sensing

Switches:

1.

Disconnect power and partially remove the

oven from it’s installation. (See

Partial Removal.)

Oven Removal /

• Door Open: 0 Ω

4. Reconnect switch wiring.

(Continued Next Page)

– 38 –

Page 39

5. Test Circuit Operation.

a. Connect temporary jumper leads across

relay contacts, primary interlock and door

sensing switches to simulate shorted switch

contacts. Locate convenient connections in

circuit to be certain COM and NO terminals

are used.

b. Connect ohmmeter (Rx1) across the line

terminals of the appliance cord. Continuity

must show the following:

• Door Closed : Some Ω

• Door Open : .3 Ω

c. Remove 20 amp fuse. Circuit must open

(infi nity

and interlock circuits.

WARNING: After test, remove temporary jumper

leads from interlock and relay.

WARNING: Primary interlock, door sensing switch,

monitor switch, and relay board must be replaced

when the 20 amp fuse is blown due to operation of

monitor switch.

Ω). If not, check wiring of monitor

To replace the door switches:

1.

Place the oven in a partially removed position.

Oven Removal / Partial Removal.)

(See

Open the oven door.

2.

Remove the single Phillips-head screw that

3.

holds the door switch access cover to the outer

cover.

Disconnect the switch wiring.

4.

Using a fl at blade screwdriver, carefully press

5.

the lock tab until fl ush with the surrounding

area of the latch board.

Using the mounting pin as a pivot, carefully

6.

rotate the switch past the lock tab and

Remove the switch from the mounting pin.

Rotate Switch

Note: Perform microwave leakage test when

replacing or adjusting interlock switches or latch

board.

How to Adjust the Interlocks:

The latch board is adjustable for proper door closure

and switch operation.

Disconnect power and partially remove the

1.

oven from it’s installation. (See Oven Removal /

Partial Removal.)

Note: Each latch board is held in place and adjusted

with 2 Phillips-head screws. The screws are recessed

from the top of the outer cover. Access holes are

provided.

2. Loosen the 2 Phillips-head screws that attach

the latch board to the oven chassis.

3. Adjust each latch-board for proper door closure

and switch operation, retighten screws.

Note: Perform microwave leakage test when

replacing or adjusting interlock switches or latch

boards.

Pivot Pin

Lock Tab

– 39 –

(Continued Next Page)

Page 40

To replace the latch boards:

Place the oven in a partially removed position.

1.

(See Oven Removal / Partial Removal.)

Open the oven door.

2.

Remove the single Phillips-head screw that

3.

holds the door switch access cover to the outer

cover.

Disconnect the switch wiring.

4.

Note: Each latch board is held in place with 2

Phillips-head screws. The screws are recessed

from the top of the outer cover. Access holes are

provided. A magnetic screwdriver is necessary to

capture these screws.

5. Remove the 2 Phillips-head screws that attach

the latch board to the oven chassis.

6. Remove the door switches from the latch board.

– 40 –

Page 41

Diagnostics and Service Information

USE ONLY HEAT AND MICROWAVE RESISTIVE GLASS BOWL

– 41 –

Page 42

Demo Mode

Standard Test Load

The Sales Demo mode will allow dealers to

demonstrate all oven functionality with one

exception: No power is ever applied to any of the

halogen lamps, heaters, mag HVT or inrush relays

while the control is in sales mode.

The sales mode will be initiated by holding the

“POWER / TEMP” and “START” pads down at the

same time for a full 3 seconds. This mode can only

be entered during the initial “SELECT TIME” display

that occurs when the unit powers up after a long

(>60 seconds) power outage. When sales mode

is initiated, a 2 short-beep signal is sounded and

all oven functions will operate with the following

exceptions;

1. No power shall ever be applied to any the

heaters, Halogen lamps, magnetron HVT or

Inrush control relays. The control relays for

any of these loads shall not be switched during

sales mode.

2. The DEMO icon will be lit whenever the unit is in

sales mode regardless of settings or the feature

being selected.

The standard test load is one liter (1000 ml) water

with starting temperature of 59°F ~ 75°F in a 1000

ml beaker. (DO NOT USE ANY OTHER LOAD OR DISH

AS RESULTS WILL VARY FROM STANDARD.)

PERFORMANCE TEST FOR MICROWAVE

Use Clear Glass Tray and the beaker.

1.

(Part # WB64x0073)

Record initial water temperature.

2.

Run at high power for 2:03.

3.

Record end water temperature. The minimum

4.

difference between the initial and ending

temperature should be: 32°F @ 120V.

Fault Codes

The smart board monitors various operations and

can detect certain failure modes. In the event of

specifi c failures, cooking will be terminated, a four

beep signal will be heard, and a fault code will be

displayed.

The sales mode is cleared by holding the “POWER

/ TEMP” and “START” pads down at same time for a

full 3 seconds. The sales mode can only be cleared

during the same initial “SELECT TIME” display that

occurs when the unit powers up after a long (>60

seconds) power outage. After 5 seconds elapse, all

functions of the oven will return to normal operation.

When power-up occurs, software will check the

special sales demo identifi er code. If the code is

set, then the oven will stay in the sales demo mode.

This will prevent the unit from powering back up to

a normal mode if power to the salesroom had gone

off .

Pressing the CLEAR pad will remove the fault code

display, unless the failure is a shorted keypanel

switch. Detection of a failed sensor will have no

effect on features that do not use that sensor.

F4 (open or shorted humidity sensor) and F6 (high

cavity temperature during microwave cooking)

codes apply only to microwave cooking. The

chart below indicates failure modes which can be

detected and displayed.

Display Failure Detected

F1 Oven cavity thermistor open

F2 Open cavity thermistor shorted

F3 Key panel shorted (> 60 seconds)

F4 Humidity sensor open or shorted

F6

High cavity temperature detected

during microwave oven cooking

– 42 –

Page 43

Microwave Leak Test Proof Feature

To test the performance of the proof feature, press

the WARM/PROOF pad, then turn the dial to PROOF

BREAD and press the dial to start. The following will

occur:

• The convection fan and interior lamp come on

immediately, and stay on.

• There is an immediate start-up burst (about 1.5

second duration at 75°F ambient) of heat from

the convection heater.

• The convection fan and interior lamp continue

Place 275 ml water in 600 ml beaker.

1.

(Part # WB64x5010)

Place beaker in center of Clear Glass Tray.

2.

Set meter to 2450 MHz scale.

3.

Turn “ON” for 5 minute test.

4.

to operate and, if needed, the convection heater

will cycle on.

Note: Oven proof temperatures range from 75-

95°F. At ambient temperatures above 75°F, heat

generated by the interior lamp may be suffi cient to

maintain proof temperatures, and the heater may

not cycle again after start-up.

Hold probe perpendicular to surface being

5.

tested. Scan surfaces at the rate of one inch per

second. Scan entire perimeter of door, control

panel, viewing surface of door window, and

exhaust vents.

Maximum leakage is 4 MW/CM2.

6.

Record data on service invoice and microwave

7.

leakage report.

Note:

Maximum allowable leakage is 5 MW/CM2. Four

•

MW/CM2 is used to allow for measurement and

meter accuracy.

Inform the manufacturer of any oven found to

•

have emission in excess of 5 MW/CM2. Make

repairs to bring the unit into compliance at

no cost to owner and try to determine cause.

Instruct owner not to use oven until it has been

brought into compliance.

If an inoperative convection heater in the proof

mode is suspected:

1. Disconnect power.

2. Remove the rear access cover.

3. Remove the thermistor from the convection

heater assembly.

4. Lower the thermistor temperature by placing a

chilled or frozen item against the thermistor.

5. Connect power and enter proof mode.

6. Check for approximately 120 VAC (12.3 Amps) at

the convection heater.

– 43 –

Page 44

Schematics and Wiring Diagrams

WARNING: POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLIANCE

– 44 –

(Continued Next Page)

Page 45

W3

BK2

OVEN TCO

GROUND

HARNESS LEADS

PARTS LEADS

R1

R7

BK6

BL3

BN3

BN3

GN1

C11

BK

WR

CN11

R6

LVT

W

YLBK W R BN

BK

HUMIDITY

SENSOR

PK1

W4

W2

R4

BL2

YL1

W4

W9

W6

MGT

RY2

RELAY PCB POWER PCB

L-H

RY9

MAIN

CN2

CN1

1713

13

CN7

11

13

5

SENSOR

CN5

THERMISTOR

CN8

13

DOOR

CN6

3

CONV

RY7

U-H(C)

RY8

U-H(H)

RY11

YL3

THERMISTOR

SECONDARY

SENSING S/W

D.MOTOR

SENSING S/W

D.MOTOR

SENSING

SWITCH

P/CORD

NOISE

FILTER

BK5

YL4

PK2

W8

BK2

BK

GN

GN

W

W1

BN4

YL4

W8

BK1

BK9

R10

W9

W10

HTR TCO

R1

BN4

OVEN

LAMP

BL3

W2

YL3

W1

MGT

TCO

W5

BL2

UPPER HEATER

(CERAMIC)

YL2

BL5

BN3

R5

BK3

BL5

UPPER HEATER

(HALOGEN)

BLOWER

MOTOR

R7

YL2

R3

MONITOR

SWITCH

CONVECTION

MOTOR

CONVECTION

SHEATH

HEATER

DAMPER

MOTOR

CROUND

H.V. DIODE

HVC

W

R

5

3

4

12

MGT TUBE

FA F

PRIMARY

INTERLOCK

SWITCH

R2

BN1

BK6

BK1

LOWER CERAMIC

HEATER

TURNTABLE

MOTOR

PK1

BL1BL

BK

YL

BL

R

1

4

BL1

BK3

R4

GN1

R5

W

R6

BN2

BN1

BN2

BK4

BK4

BK5

YL1

YL

R

BL

1

4

PK2

R2

R3

W3

W5

DOOR SENSING

SWITCH

COLOR

RED

WHITE

BLACK

BROWN

BLUE

GREEN

YELLOW

PINK

SYMBOL

R

W

BK

BN

BL

GN

YL

P

GROUND

HARNESS LEADS

PARTS LEADS

– 45 –

Page 46

Warranty

For The Period Of: GE Will Replace:

One Year Any part of the oven which fails due to a defect in materials or

From the date of the workmanship. During this full one-year warranty, GE will also provide,

original purchase free of charge, all labor and in-home service to replace the

defective part.

Three Years The heating system, if any heater or lamp fails due to a defect

F

rom the second through

in materials or workmanship. During this full three-year warranty, GE

the third year from the will also provide, free of charge, all labor and related service costs to

date of original purchase

replace the defective part.

Ten Years The magnetron tube, if the magnetron tube fails due to a defect in

From the second through

materials or workmanship. During this additional nine-year limited

the tenth year from the

date

warranty, you will be responsible for any labor or in-home service

of original purchase

costs.

■ Service trips to your home to teach you how

to use the product.

■ Improper installation, delivery or

maintenance.

■ Failure of the product if it is abused,

misused, or used for other than the

intended purpose or used commercially.

■ Replacement of house fuses or resetting of

circuit breakers.

■ Damage to the product caused by accident,

fire, floods or acts of God.

■ Incidental or consequential damage caused

by possible defects with this appliance.

■ Damage caused after delivery.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products

purchased for home use within the USA. In Alaska, the warranty excludes the cost of shipping or

service calls to your home. Proof of the original purchase date is needed to obtain service under

the warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state. To know what your legal rights are, consult your local or state consumer

affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

– 46 –

Loading...

Loading...