GE SCA2000FBB02, SCA2000FBB03, SCA2000FCC02, SCA2000FCC03, SCA2000FWW02 Installation Guide

...Page 1

Installation

Speedcook Oven

Instructions

Questions?Call 800.GE.CARES(800.432.2737)or Visit,,,H-x_ebsite_,t:www.GEAppliances.com I

BEFORE YOU BEGIN

Read these hlstructions completely mid ca_refully.

• IMPORTANT - S_,,etheseinstructions

lot local inspector's use.

• IMPORTANT - Obse,,e_,ll_o,eH,in_

codes and ordinances.

• Note to Installer - Be sure to leaxe these instructions

with the Consume_:

• Note to Consumer - Kee I) these instructions fi_r

fllttu'e reterence.

• Sldll level - Installation of this appliance requires basic

mechanical and electrical skills.

• Proper installation is the responsibilit} of the installe_:

• Product thiltu'e due to improper installation is not

coxered trader the _n'rant_.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

Page 2

Installation Instructions

CONTENTS

General information

lmporta_t Safety h_structions ........................................ 3

Electrical Requirements .................................................. 3

Hood Exhattst ............................................................ 4, 5

Dmnage_hipment/h_staJlation .................................... 6

Parts Included ................................................................ 6

Tools You Will Need ...................................................... 7

Mounting Space .............................................................. 7

Step-by-step installation guide

Placement of Momlthag Plate .................................. 8-10

I_em_wing the Mounting Plate ........................ 8

Finding the _Mdl Studs ...................................... 8

Detemfining Wall Plate I,ocation .................... 9

_Migning the Wall Plate .................................. 10

[] Recirculafing ............................................ 19-22

Attach Mounting Plate to Wall .............. 19

Preparation of Top Cabinet .................. 19

Adapting Blower fl)r

Recirculation .................................... 20, 21

Mount the Oven .............................. 21, 22

Installing the Charcoal [qlter ................ 22

Before You Use Your Oven ........................................ 23

Installation Types .................................................... 11-22

_] Outside Top Exhaust ................................ 12-14

Attach Mounting Plate to Wall .............. 12

Preparation of Top Cabinet .................. 13

Assemble and Install Adaptor. ............... 13

Mount the Oven .............................. 13, 14

At!just the Exhaust Adaptor .................. 14

Connecting Ductwork ............................ 14

_] Outside Back Exhaust .............................. 15-18

Preparing Rear _4hll fin.

Outside Back Exhaust ............................ 15

Attach Mounting Plate to X_hll .............. 16

Preparation of Top Cabinet .................. 16

Adapting Blower fin" Outside

Back Exhaust .................................... 16, 17

Mount the Oven .............................. 17, 18

2

Page 3

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

This product requires a 4-i)ron_*_grounded outlet. The

installer must perlimn a ground continui_, check on the

power outlet box before beginning the installation to

insure that the outlet box is properl) grounded. If not

properl} grounded, or if the outlet box does not ineet

electrical requirements noted (under EI,ECTRICAI,

REQUIREMENTS), a qualified electrician should be

emplo} ed to correct any deficiencies.

I 1//11/ l

For personal safety, remove

house fuse or open circuit

breaker before beghl_fing

hlstallation to avoid severe

or fatal shock injury.

f

CAUTION: Vorpe onaJsafety, the mom,th,g

surface must be capable of supporthlg the cabinet load,

in addition to the added weight of this 70-85 pound

product, plus additional oven loads of up to 50 pounds

or a total weight of 120-135 pounds.

CAUTION: Forpe onaJsafety, this product

cmmot be h_stalled in cabinet axrmlgements such as an

islmld or a pe_finsuia. It must be mounted to BOTH a

top cabinet AND a wall

NOTE: For easier installation m_d personal safety, it is

recommended that two people install this product.

IMPORTANT PLEASE READ CAP&:FULLY. FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVFI_: OR

FATAL SHOCK.

You should have the wall receptacle mad circuit checked

by a qualified electricim_ to make sure the receptacle is

properly grounded.

Where a standard 3-prong wall receptacle is encountered,

it is very hnportaalt to have it replaced with a properly

grounded NEMA # 14-30R wall receptacle, installed by

a qualified electriciml.

DO NOT, UNDER ANY CIRCUMSTANCILS, CUT,

DI?_'ORM, OR REMOVE ANY OF THE PRONGS

FROM TFIE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Product rating is 240/208 w_lts AC, 60 Hertz, 30 amps

and 6.5 kilowatts. This product must be connected to an

individual properly grounded branch circuit, protected

b)' circuit breake_ or time delay fllses. _,\]re size must

confimn to the requirements of the National Electrical

Code or the pre\;filing local code fin" this kilowatt rating.

The outlet box should be located in the cabinet above

the oven. The outlet box and supply circuit should be

installed by a qualified electrician and cont0nn to the

National Electrical Code or the pre\;filing local code.

groundexists

beforeuse.

NEMA14-30R

Wall Receptacle

The wall outlet receptacle

recommended for this

applim_ce is NEMA #

14-30R m_d accepts the

4-prong grounded plug

of this applimlce.

3

Page 4

Installation Instructions

HOOD EXHAUST

NOTE: Read these next two pages only if you plml to vent your exhaust to the outside. If you plma to recirculate the air back into

the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The fi>llowing chart describes an example of one possible ductwork installation.

EQUIVALENT NUMBER

DUCT PIECES

12Ft.StraightDuct 12Ft. x

RoofCap 24 Ft. x

(6" Round)

TransitionAdaptor*

Rectangular-to-Round 5 Ft. x

Equivalentlengthsofductpiecesare basedon actualtestsand

reflectrequirementsfor goodventingperformancewith anyventhood.

*IMPORTANT: If a rectangtflm_to-rom_d transition adaptor is used, the bottom corners of the damper will have

to be cut to fit, usino._ the fin snips, in order to allow fl'ee moxement of the dampe_;

LENGTH x USED

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

EQUIVALENT

LENGTH

(1)

(1)

(1)

Total Length = 41 Ft.

24 Ft.

12Ft.

5Ft.

The following chart describes an example ot one possible dtu'twork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH* x USED = LENGTH

_) Wall Cap 40Ft. x (1) = 40Ft.

3 Ft.StraightDuct 3R. x (1) = 3 Ft.

(3W'x 10"Rectangular)

(_ 90° Elbow 10Ft. x (2) = 20Ft.

Equivalentlengthsof ductpiecesare basedonactualtestsand

reflectrequirementsforgoodventingperformancewith anyventhood.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall should be

prepared at the time it is constructed by, leaving, enouoh_ space between the wall studs to accommodate exhaust.

4

Total Length = 63 Ft.

Page 5

Installation Instructions

NOTE: If wm need to install ducts, note that the total duct

length of 3¼" x ] 0" rectangular or 6" dianmter round duct

should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the following careflflly.

NOTE: It is important that venting be installed using

the most direct route and with as tew elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, lllaJ_e sure dmnpers swing freely and

nothing is blocking the ducts,

Exhaust connection:

The hood exhaust has been designed to mate with

a standard 3¼"x 10" rectangular duct,

If a r(mnd duct is required, a rectangula>to-rom_d

transition adaptor must be used. Do not use less thml

a 6" diameter duct.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Rectangular-to-Round 5Ft. x ( ) = Ft.

TransitionAdaptor*

Maximum duct length:

For satisfi_ctory air movement, the total duct length of

3/(' x ] 0" rectangular or 6" diameter round duct should not

exceed 140 equivalent feet.

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equi\_flent

to a section ol straight duct which is longer than their actual

ph):sical size. When calculating the total duct length, add

the equivalent lengths of all transitions and adapt(n_ plus

the length ot all straight duct sections. The chart below

sho_vs you how to calculate total equi\;flent ductwork length

using the approximate teet ol equivalent length ol some

Q'pical ducts.

Wall Cap 40 Ft. x ( ) = Ft.

G)_ 90° Elbow 10Ft. x ( ) = Ft.

(_ 45° Elbow 5Ft. x ( ) = Ft.

90° Elbow 25 Ft. x ( ) = Ft.

45° Elbow 5Ft. x ( ) = Ft.

RoofCap 24 Ft. x ( ) = Ft.

StraightDuct6" Roundor 1Ft. x ( ) = Ft.

3W' x 10" Rectangular

* IMPORTANT: If'a rectangular-to-round transition adaI)mr

is used, the bottom comers of the dami)er will ha_e to be

cut to fit, using Ihe tin snips, in order to allow fi-ee moxenlent

of the damper.

5

Total Ductwork = Ft.

Equivalent lengths of duct pi< c<s at< based on actual t<sts

and r( flect re(luir( merits for good venting l)( rlormance with

_]I]V V(}llt hoo([.

Page 6

Installation Instructions

DAMAGE--SHIPMENT/

INSTALLATION

* If the unit is dmnaged in shipment, return the unit

to the store in which it was bought fin" repair or

replacement.

• If the refit is dmnaged by the customer, repair or

replacenmnt is the responsibility of the customer;

• If the unit is dmnaged by the installer (if other than

the customer), repair or replacement must be made

by arrangement between customer and installe_:

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

WoodScrews 2

(1/4"x 2")

ToggleBolts(and 4

wing nuts)(1/4" x3")

PARTS INCLUDED

ADDITIONAL PARTS

PART

TopCabinet

TOPCABINETTEMPLATE

Template

Installation

Instructions

Separately

Packed

Grease

Filters

QUANTITY

1

Self-aligningMachine

Screws(1/4"-28x 3Y4")

NylonGrommet

(formetalcabinets)

ExhaustAdaptor

with Damper

Metal Screws

} (1/8"x 1/2")

PowerCordStrap

(plastic)

You will find the installation hardware contained in a

packet with the trait. Check to make sure w)u have all

these parts.

NOTE: Some extra parts are included.

3

2

1

1 black

2 bronze

1

6

Page 7

Installation Instructions

TOOLS YOU WILL NEED

# 1 and#2Phillipsscrewdriver

Tinsnips(for cutting

damper,if required)

Gloves

Scissors

(to cut template, if necessary)

Pencil

Ruler ortape measure

aight edge

LEd.,E&,_&,_d,J._.,I.,_d.,b,h,,h,l,,,h._,,h,,l,,h,,h,h,,I,,d,,,I,,,l,,I,,,iJ

Electric drill with 3/167 7/16,"

1/2" and 5/8" drill bits

0

Carpentersquare

(optional)

Filler blocks or scrap

wood pieces, if needed

for top cabinet spacing

(used on recessed bottom

cabinet installations only)

Saw (saber, hole or keyhole)

Safety goggles

MOUNTING SPACE

66" or more

fromthefloor

to thetop

of theoven

Bottomedgeof

cabinetneedsto

be30" ormore

fromthecooking

Backsplash

surface

Stud finder or

Level

NOTFS:

• The space between the cabinets must be 30" wide

and fl'ee of obstructions.

If the space between the cabinets is greater than

30'_ a Filler Panel Vdt may be used to fill in the gap

between the oven and the cabinets. Your Owner's

Manual contains the kit nmnber fi)r vom" model.

• This oven is for installation oxer ranges up to

_tt• r) wide,

" lfw)u are going to vent yore" oven to the outside,

see Hood Exhaust Section ti)r exhaust duct

preparation.

• When h_stallh_g the oven beneath smooth, flat

cabinets, be careful to follow the h_structions on

the top cabinet template for power cord dem'mlce.

• For best installation results, we recolnmend a

maxim um cabinet depth ot 12".

Hammer (optional)

Duct and masking tape

7

Page 8

Installation Instructions

PLACEMENT OF THE MOUNTING PLATE

I-A--1REMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

_ Remoxe the box containing the instnllation

instructions, filte_, exhaust adaptor and the

small hardware bag.

_] Stnnd the oxen on its control panel side. Use a portion

ot the carton or some other material to protect the

outer case fl'om being dama ,ed

e:=..... HI Ili Mounting

IID: lllI1:!1

0@ii :!

I-_ FINDING THE WALL STUDS

J

_Find the studs, using one otthe fi_llowing methods:

A. Stud finde_a magnetic device which locates nails.

OR

B. Use a hammer to trip lightly across the motmting

sudime to find a solid sound. This will indicate a

stud location.

ControlPanelSide

_]The motmting plate is attached to the back of the

oven. Remove the 2 screws holding it to the oven.

The plate will be used as the rear wall template and

fiw motmting the oven to the wall.

_] Set the oxen uptight. Remoxe and properly discard

plastic bags and Styrofl_am. Remove an) adhesixe tape

(if there is any) on the exhaust adaptor; the grease

filte_ and the power supply cord.

] (-)pen the ox, en dooi" _111(1reliloxe _lny accessolJes

fl'om inside the oxen.

[_ _Mter locating the stud(s), find the center by )robing

the wall with a small nail to find the edges of the stud.

Then place a mark halfway between the edges. The

center of any ac!iacent studs shouM be 16" or 24" fi'om

this mark.

[3] Draw a line down the center oI the studs.

THE OVEN MUST BE CONNECTED TO AT LI_ST

ONE WALL STUD.

• [

8

Page 9

Installation Instructions

_--] DETERIVIINING WALL PLATE LOCATION UNDER YOUR CABINET

Plate positionmbeneath flat bottom

cabinet

i the Cabinet

Bottom

At least 30", up to 36"

PlateTabs

Plate positionmbeneath framed recessed

cabinet bottom

Mounting Plate Tabs

the Back

Frame

30" to

Cooktop

Plate position_beneath recessed bottom

cabinet with front overhang

Plate with

TabsBelow Cabinet

Bottom the Same

Distance as the Front

Overhang Depth

II

II

II 30"to

Cooktop

_4mr cabinets may have decorative trim that intetteres

with the oven installation. Remove the decorative trim

to install the oven properly and to make it level.

TI_ OVEN MUST BE LEYEL Use a level to make

sm'e the cabinet bottom is level.

If the cabinets have a fl'ont overhang onl); with no back

or side fl'ame, install the motmting plate down the same

distance as the fl'ont overhang depth. This will kee I) the

oven level.

[_ Measm'e the inside depth of the fl'ont overhang.

[] Draw a horizontal line on the back wall an equal

distance below the cabinet bottom as the inside

depth of the fl'ont overhang.

_]For this bpe of installation with front oxerhang

only; align the mortaring tabs with this horizontal

line, not touching the cabinet bottom as described

in Step D,

9

Page 10

Installation Instructions

i--_ ALIGNING THE WALL PLATE

I/

HoleA-[

HoleC/

CAUTION:

on shaq) edges.

_j_ Draw a xertical line on the wall at the center of the

50" wide space.

_]Use the mounting plate as the template for the rear

wall. Place tile mo/mfing plate on tile wall, making sm'e

that tile tabs are touching the bottom of the cabinet or

the level line dxawn in Step C for cabinets with front

overhm_g. Line up the notch and center line on the

momlthag plate to the center line on the wall,

[] _qfile holding tile molmfing plate with one hand,

draw circles on the wall at holes A, B, C and D (see

illustration above/actual plate marked with arro_vs).

Four holes must he used for mom_thlg,

NOTE: Holes C and D are inside area E. If neither

C nor D is ill a stud, find a stud SOlnewhere ill area E

and draw a fifth drcle to line up with tile stud. It is

important to use at least one wood screw motmted

firmly in a stud to support tile weight of tile oxen.

Set the mom_thag plate aside.

Drill holes on the circles. If there is a stud, drill a :_A(_"

[]

hole for wood screws. For holes that don't line up with

a stud, drill a %" hole fin" toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

10

Page 11

Installation Instructions

INSTALLATION TYPES (Choose A, B or C)

This oven is designed fi)r adaptation to the fi)llowing

3 types of ventilation:

A. Outside Top Exhaust (Vertical Duct)

B. Outside Back Exhaust (Horizontal Duct)

C. Recirculathlg (Non-Vented Ductless)

V-_ OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

Adaptorin Placefor

1

Exhaust

NOTE: This ()veil is shipped assembled tot Outside Top

Exhaust. Select the type of ventilation required tot vour

installation and proceed to that section.

I--_ OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

V_ RECIRCULATING

(NON-VENTED DUCTLESS)

11

A Charcoal Filter Accessory Kit

is required tot the non-vented

exhaust. (See your Owner's

Manual fi)r the kit numl_e_:)

Page 12

Installation Instructions

_ OUTSIDE TOP EXHAUST (Vertical Duct)

INSTALLATION OVERVIEW

A1. Mmch Morn]ring Plate to Will

A2. Prepare Top Cabinet

A3. Install Adaptor

A4. M(mnt the (-)yen

AS, A(!iust Exhaust Adaptor

A6, Connect Ductwork

|

VA-_ ATTACH THE MOUNTING

PLATE TO THE WALL

, , i

Attach the plate to the wall using toggle bolts, At least one

wood screw m ust be used to attach the plate to a wall stud.

_ Remoxe the toggle wings fl'om the bolts.

_] Insert the bolts into the mortaring plate through the

holes designated to go into drywall, and reattach the

toggle wings to 3/4" onto each bolt,

To use toggle bolts:

Spacingfor TogglesMore

+]*,-,..j*,_ThanWall Thickness

i Toggle . i, i

7Jags II I;:kMounting--->- ..

Toggle !

'll

Bolt o

Wall

_] Place the IllOtlnting plate against the wall and insert

the toggle wings into the holes in the wall to motmt

the plate.

NOTE: Befin'e tightening toggle bolts and wood scre_;

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: Be carefl,1 to avoid )iilchiilg

finge_s between the back of the motmting plate and

the wall.

[_] Tighten all bolts. Pull the plate awa) fl'om the wall

to help tighten the bolts.

End

I

12

Page 13

Installation Instructions

VK_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

Ybu need to drill holes for the top support screws, a hole

lmge enough fin" tile power cord to fit through, and a

ctltotlt lmge enough fin" tile exhatlst adaptor:

%

" Read tile instructions on tile TOP CABINET

TEMPI ATE.

• Tape it tmderneath tile top cabinet.

• Drill the holes, tollowing the instructions on the TOP

CABINET TEMPLATE.

CAUTION: l.llin

holes in the cabinet bottom.

VA-3-]ASSEMBLE AND INSTALL

ADAPTOR ,_

I

ExhaustAdaptor

V_ MOUNT THE OVEN

FOR EASIER INS%M,I ATION AND PERSONAl, SPd;ETY,

X4E RECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use hmldle dttrhlg

installation.

NOTE: If w)ur cabinet is metal, use tile nylon grommet

arom_d tile power cord hole to prevent cutting of tile cord.

NOTE: _'e recommend using filler blocks it tile cabinet

fl'ont hangs below tile cabinet bottom shell

IMPORTANT: If filler blocks axe not used, case da_mage

may occur from over tightenh_g screws.

NOTE: When motmting tile oven,

thread power cord through hole

in bottom of top cabinet. Kee I) it

tight throughout Steps 1-3.

Do not pinch cord or lilt oven

by pulling

_i,ifl tilt it

oven_

forward, and

hook slots at back

bottom edge onto

9 lower tabs ot

molmfing plate.

BlowerPlate

of Oven

If you have a fiat bottom cabinet, tile exhaust adaptor will

be installed later through tile cutout in tile cabinet bottom.

[_ Place tile oxen in its u )fight position, with tile top of

tile trait fi_cin *lm

_] Attach the exhaust adaImn; hinge side toward the back

of the oxen, to the blower plate with the 2 bronze

metal scre_:s provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make ac!justments to assure proper

alignment with your house exhaust duct alter tile

oven is installed.

_] Rotate oven up

_] Inset* a sel6aligning screw through top center cabinet

fl'ont of

against cabinet bottom.

hole. Temporarily secme tile oven by tm'ning tile

screw at least two full tur_s after tile threads have

engaged. (It will be completely tightened late_:)

Be sure to keep power cord tight. Be careful not to

pinch the cord, espedally when mom_th_g flush to

bottom of cabinet.

Page 14

Installation Instructions

IA4-1MOUNT THE OVEN (cont.)

If your cabinet fl'ont hangs more than 2'_A" below tile

cabinet bottom, you may need to use longer screws than

tile ones provided with this product. Tile screws pro\ided

with this product (hardware item 3) are self:aligning,

lmge-head machine screws 1/4" diameter; 3¼" long,

with SAE 28 threads per inch. It is important that )_)u

use replacement screws just long enough to attach the

product to tile cabinet. Tile length can be detemfined

by measm_ing tile height of tile overhang fl'om tile top

ot tile cabinet floor to tile bottom of tile overhang and

adding 1" to that length. This will be the length of the

1/4" SAE 28 threads per inch screws w)u need.

You will also need to tlse washe_ 3/4" diameter to fit tile

screws you pro'chase. This will prevent the screw heads

fl'om pulling through tile bottom of tile cabinet when

tightening dm_ing installation.

CabinetFront

CabinetBottomShelf

FillerBlock

[]

Install grease filte_5.

See tile Owner's Manual

packed with the oven.

Remove tile tape fl'om tile

cooktop lan/p covei3 on

tile bottolil of tile oven.

Secm'e tile power cord to tile cabinet wall, as desired

[]

to kee I) excess length out of the way using the power

cord strap and the black metal screw.

ADJUST THE EXHAUST

ADAPTOR

Open tile top cabinet and a(!iust tile exhaust adaptor to

connect to tile house duct.

For top exhaust on tile fiat-bottomed cabinets, open tile

top cabinet and attach tile exhaust adaptor to tile oven

through tile cabinet bottom with tile 2 bronze metal

screws provided.

Damper '_

-Eq uivalent

to Depth

of Cabinet

Recess

gningScrew

OvenTop

_] Attach tile oxen to tile top cabinet.

_] Insert 2 self:alignim* screws throtu*h outer top cabinet

holes. Turn two flfll turns on each screw.

_] Tighten center

screw completely:,

I-A- CONNECTING DUCTWORK

HouseDuct

-1

_] Tighten tile outer 2 screws to tile to I) of tile oxen.

(X4q/ile tightening screws, hold the oxen in place

against tile wall and tile top cabinet.)

_ Extend tile house duct down to connect to tile

exhaust adaptm;

t_aV_Seal exhaust duct ioints using duct ta• , I)e ,

14

Page 15

Installation Instructions

OUTSIDE BACK EXHAUST (Horizontal Duct)

INSTALLATION OVERVIEW

B1. Prepare Rear Wall

B2. Attach Mounting Plate to XMfll

B3. Prepare Top Cabinet

B4. A(!iust Blower

B5. Mount tile Oven

[-B-_ PREPARING THE REAR WALL

FOR OUTSIDE BACK EXHAUST

[]Place tile mounting plate against tile rear wall and

align it with the holes drilled earlier:

_] Using a pencil, put dots through slots F and G, and

through holes H and I. Remove tile mortaring plate

and draw lines extending through the p()ints. This will

give the lcoadon and size ot the box cutout ti)i" the

rear wall duct.

_] Attach tile exhaust adaptor to tile rear mortaring plate

b) sliding it into the gukles at the top center of the

plate on the wall side,

ExhaustAddptor_.........__-,_ Damper

SlideExhaust (o_t.__...,_ (wall side)

AdaptorInto [___

Guideson _ ...._( _:_

/_.,_/_/.._ _ MountingPlate

(hingesideup)

e0rPane,

U';_P-_ Locki'/

_° Tabs Guides

Push in secm'ely tmtil it is past tile top locking tabs and

in the lower locking tabs. Take care to assm'e the damper

hinge is installed so that it is at tile top and that tile

damper swings fl'eely.

[] (_arefully guide tile exhaust adaptm, now drenched to

the motmting plato, into the house duct, l)etk)i'e using

tile screws to attach tile plate to tile wall.

15

Page 16

Installation Instructions

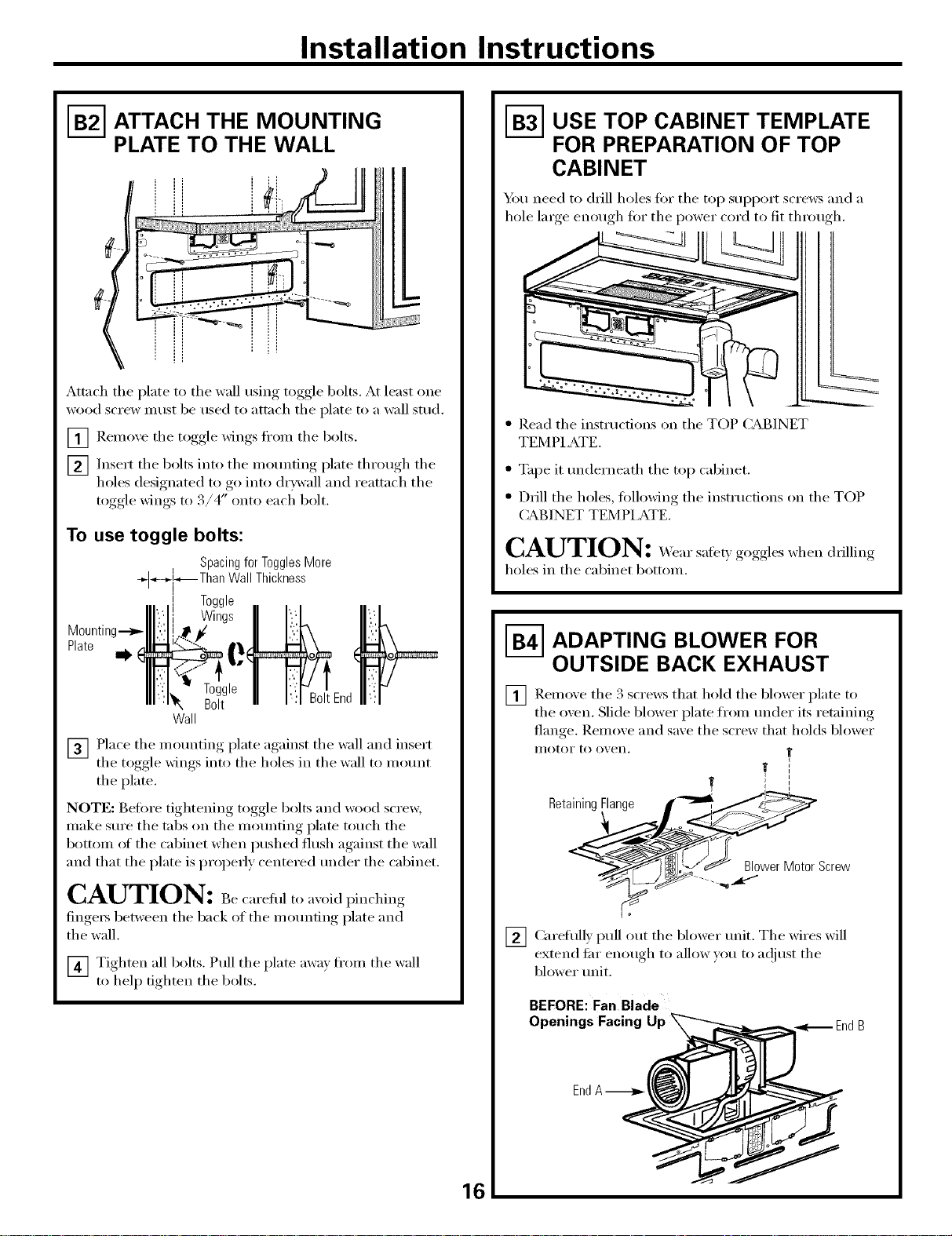

FB--_ATTACH THE MOUNTING

PLATE TO THE WALL

i = il

::::::::i

Attach the plate to the wall using toggle bolts. At least one

wood screw must be used to attach the plate to a wall stud.

_ Remme the toggle wings fi'om the bolts.

_] Insert the bolts into the motmting plate through the

holes designated to go into drywall, and reattach the

toggle wings to 3/4" onto each bolt.

To use toggle bolts:

Spacingfor TogglesMore

_*--_-[_,_Than Wall Thickness

= Toggle

Wings

Mounting.-->_

Plate

VB-3-]USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

Ym need to drill holes for the top support screws and a

hole large enough t0r the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPI ATE.

• Tape it underneath the top cabinet.

• Drill the holes, tollowing the instructions on the TOP

CABINETTEMPI ATE.

CAUTION: d, .in

holes in the cabinet bottom.

VB--_ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

Bolt

Wall

[_ Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to motmt

the plate.

NOTE: Before tightening toggle bolts and wood scrm_;

make sure the tabs on the mounting plate touch the

bottom oI the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: Bec .ef.1 pinching

finge_ between the back of the motmfing plate and

the wall.

[4] Tighten all bolts. Pull the plate axvav fl'om the wall

to help tighten the bolts.

_ Remove the 3 that hold the blower to

the o;en. Slide blower plate from under its retaining

flan ,e Remoxe and saxe the screw that holds blower

II/OtoI" to ox, eil.

sciews

plate

@_10_er MotorScre_

%j_ ...._,.--"

[2] Carefiflly pull out the blower unit. The wires will

extend en- enough to allow xou to at!just the

bl(mer unit.

BEFORE: Fan Blade

Facing Up

Openings _nd B

EndA-_-_ I

16

Page 17

Installation Instructions

_] (;enfly tile wires fl'(nn tile Reroute

WiresRoutedThroughRightSide Wires RoutedThroughLeft Side

[_] Rotate blower unit counterclockwise 180°

i'ei//ove

the wires through grooxes on other side of the

blower unit.

Before Rerouting After Rerouting

BeforeRotation After Rotation

gi'oox es.

Backof Oven

_] Place the blower unit back into tile oi)ening,.

AFTER: Fan Blade

Openings Facing Back

EndB._>-

CAUTION: Do not pull or stretch the blower

unit wiring, Make sure the wires axe not pinched,

NOTE: The blower trait exhaust openings should match

exhaust openhigs on rear of oven.

_] Secure tile blower trait to tile oven with tile screw

_emoved earlier: Replace tile blower plato in tile same

position as before with tile screws.

Retaining g

Flange 2 i

) II BlowerPlate

_] Roll tile blower trait 90 ° that tim blade openings

are ti_cing out the back of the oxen.

BeforeRolling After Rolling

Backof Oven

_] I,ocate tile 2 "knockout" plates, on tile rear oxen

panel, near tile top of tile oxen.

Using tin snips, carefifllv cut tile web area fl'om tile

2 holes side-by-side (that secm'e the knockouts to the

oven). Cut all 4 webs on both rear knockouts; this will

allow the ventilation tim airflow to exhaust out the

i'eai" of tile o'_ eil.

Oven Rear Panel

S

so

Backof Oven

Snipall 4webs

on eachknockout

panelandremove

the metalknockouts

for rearairflow.

_,_ Screw

VB-5 MOUNT THE OVEN

FOR EASIER INS%M.IATION AND PERSONAl. SM,_ETY,

X._ERECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use hmldle during

installation,

NOTE: If w)m" cabinet is metal, use tile m'lon grommet

aro/md tile power cord hole to prevent cutting ot tile cord.

NOTE: We recoi/li/lend rising filler blocks it tile cabinet

fl'ont hangs below tile cabinet bottom shelfi

IMPORTANT: If ftller blocks are not used, case dm_rmge

may occur from over tightenh_g screws.

CAUTION: Be sure to trim the sharp edges

from the openings after removh_g the knockout plates.

17

Page 18

Installation Instructions

MOUNT THE OVEN (cont.)

NOTE: When mounting the oven,

thread power cord through hole

in bottom ot top cabinet. Kee I) it

fight throughout Steps 1-3.

Do not pinch cord or lift oven

b) pulling cord.

_] Rotate _wen u l)

_] Insert a self:aligning screw through top center cabinet

If yore" cabinet fl'ont hangs more than 2_A" below the

cabinet bottom, you may need to use longer screws than

the ones provided with this product. The scre_vs provided

with this product (hardware imm 3) are self:aligning,

lmge-head machine screws 1/4" diamem_; 3¼" long,

with SAE 28 threads per inch. It is important that you

use replacement screws just long enough to attach the

product to the cabinet. The length can be detemfined

by measmJng the height ot the overhang fl'om the top

of the cabinet floor to the bottom of the overhang and

adding l" to that length. This will be the length of the

1/4" SAE 28 threads per inch scrmvs you need.

Ybu will also need to use washe_ 3/4" diameter to fit the

scrmvs wm pro'chase. This will prevent the screw heads

fl'om pulling through the bottom of the cabinet when

tightening dtwing installation.

front OJ[

against cabinet bottom.

hole. Temporarily secm'e the oven by turning the

screw at least two full turns alter the threads have

engaged. (It will be completely tightened late_:)

Be sure to keep power cord tight. Be careful not to

pinch the cord, especially when mounting flush to

bottom of cabinet.

[]i Jfi oven, tilt it

_ forward, and

/ hook slots at back

bottom edge onto

2 lower tabs of

_ mortaring plate.

Cabinet Front

Cabinet Bottom Shelf

Filler Block

T quivalent

to Depth

of Cabinet

Recess

gning Screw

OvenTop

r4] Attach the o_en to the top cabinet.

_] Insert 2 self=aligning screws through outer top cabinet

holes. Turn two flfll turns on each screw.

[]Tighten center

screw completely.

Tighten the outer 2 screws to the top of the oven.

[]

(X._qfiletightening screws, hold the oxen in place

against the wall and the top cabinet.)

Install grease filte_s.

[]

See the Owner's Manual

packed with the oven.

Remove the tape fl'om the

cooktop lalllp covelB on

the bottom of the oven.

Secm'e the power cord to the cabinet wall, as desired

[]

to kee I) excess length out of the way using the power

cord strap and the black metal screw,

_....mJ.

18

Page 19

Installation Instructions

RECIRCULATING (Non-Vented Ductless)

INSTALLATION OVERVIEW

C1. Mmch Mounting Plate to _4"dl

C2. Prepare Top Cabinet

C3. A(!iust Blower

C4. Mount the (-)\'en

C5. Install Charcoal Filter

]-€-_ ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one

wood screw must be used to attach the plate to a wall stud.

[_ Remoxe the toggle wings fl'om the bolts.

_] Insert the bolts into the mounting plate through the

holes designated to go into drywall, and reattach the

toggle wings to 3/4" onto each bolt.

To use toggle bolts:

Spacingfor TogglesMore

+]_--_]_._Than Wall Thickness

= Toggle

Wings

Mounting---_

Plate

NOTE: Befi)re tightening toggle bolts and wood scre_;

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: )inchinotinge,s

between the back ot the mounting plate and the wall.

_] Tighten all bolts. Pull the plate awa) fl'om the wall

to help tighten the bolts.

]-€--_USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to (h_ll holes fin" the top support screws and a

hole large enough fin" the power cord to fit throu ,h

" Read the instrucdons on the TOP CABINET

TEMPI ATE.

Bolt

Wall

_] Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to mount

the plate.

• Tape it underneath the top cabinet.

• Drill the holes, tollowing the instructions on the TOP

CABINET TEMPLATE.

CAUTION:

holes in the cabinet bottom.

Page 20

Installation Instructions

[-C--_ADAPTING BLOWER FOR

RECIRCULATION

NOTE: Tile exhaust adaptor with damper is not needed

tor recirculating models. Y_m mm want to sa_e them tor

possible fllture use.

_ Remoxe and saxe screws that hold tile blower plate

to tile oxen.

Retaining

Flange _' i

_' \ I I BlowerPlate

___j I[ je IBack OfOven

_-] Slide tile blower plate fl'om trader its retaining flange

and 1N it off. Remme and saxe screw that holds tile

blower ii/otoi" to o_en.

,_<[-_ Blower Plate Screws

_Roll tile blower trait 90 ° so that tim blade openings

are lacing toward tile fl'ont of tile oxen.

BEFORE: Fan Blade

Openings Facing_

R011 4_

AFTER: Fan Blade

Openings Facing _"----.-...._

RetainingFlange __BIo!er

_7 _._ BlowerMotor

Screw

[_ Careflfll) pull out tile blower trait. Tile wires will

extend fin"enough to allow )ou to a(!iust tile

blower trait.

Forward

NOTE: Make sure wires remain routed in tile grooxes of

the Illotor fKlI/le,

_] Place tile blower trait back into tile oi)ening,.

CAUTION: Donoti,/,llstretchtileblower

trait wiring. Make sure tile wires are not pinched.

2O

Page 21

Installation Instructions

_] Secure blower unit to oxen with the screw remoxed

in Step 2.

F7] Replace blower plate with the screws remoxed

in Step 1.

Retaining

Flange _'

_,_---Blower PlateScrews

_ BlowerPlate

_ •

_._ Backof Oven

"_-_-- Blower Motor

Screw

I-C- MOUNT THE OVEN

FOR EASIER INS%MLA, TION AND PERSONAL SMCETY,

X4'ERECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use hm_dle during

h_staJlation.

NOTE: If w)m" cabinet is metal, use the nylon grommet

around the power cord hole to prevent cutting oI the cord.

NOTE: _e recommend using filler blocks if the cabinet

fl'ont hangs below the cabinet bottom shel£

IMPORTANT: If f'filer blocks axe not used, case dmnage

may occur from over tightenh_g screws.

NOTE: X,_q_enmotmting the oven,

thread power cord through hole

in bottom of top cabinet. Kee I) it

tight throughout Steps 1-3.

Do not pinch cord or lift oven

by pulling

[]

Rotate fl'ont _ff oven up

against cabinet bottom.

[]

Insert a self aligning screw through top center cabinet

hole. Temporarily secme the oven by tm'ning the

screw at least two full tur_s alter the threads have

engaged. (It will be completely tightened late_:)

Be sure to keep power cord tight. Be careful not to

pinch the cord, espedaJly when momathag flush to

bottom of cabinet.

If your cabinet fl'ont hangs more than 2:"A"below the

cabinet bottom, you may need to use longer screws than

the ones provided with this product. The screws provided

with this product (hardware item 3) are self:aligning,

lmge-head machine screws 1/4" diameter; 3¼" long,

with SAE 28 threads per inch. It is impommt that you

use replacement screws just long enough m attach the

product to the cabinet. The length can be detemfined

by measuring the height ot the overhang fl'om the top

of the cabinet floor to the bottom of the overhang and

adding l" to that length. This will be the length ot the

1/4" SAE 98 threads per inch screws w)u need.

You will also need to use washers 3/4" diameter to fit the

scre_:s wm l)m'chase. This will prevent the screw heads

fl'om pulling through the bottom ot the cabinet when

tightening dm-ing installation.

[_I,ifl flit it

oven,

torward, and

hook slots at back

bott()n} edge onto

2 lower tabs ot

inounfing plato.

21

Page 22

Installation Instructions

I-€--_MOUNT THE OVEN (cont.)

Cabinet Front

Cabinet Bottom Shelf

Filler Block

T quivalent

to Depth

of Cabinet

Recess

gningScrew

OvenTop

_ Attnch the o_en to the top cabinet.

_] Insert 2 self:aligning screws through outer top cabinet

holes. Turn two fl/ll turns on each screw.

VC--_INSTALLING THE CHARCOAL

FILTER

[] Remo'_e 2 ,_ci'ews on top of grille using a Phillips

screwdriver: You may need to open the cabinet doo_s

1o i'eillo&e the scI'ews,

_] Open the dora:

[] Remme the

[z[-] ]nstnll the charcoal filte_; _,_hen propefl) installed,

the wire mesh of the filter should be visible fl'om

the fl'ont,

[] Replace the grille and the 9 screws,

[_ Close the dora:

S

grille.

_] Tighten center

screw completely.

F7-] Tighten the outer 2 screws to the top of the o_en.

(_4_file tightening screws, hoM the o_en in place

against the wall and the top cabinet.)

_-] ]nstnll grease filte_.

See the Owner's Manual

packed with the oven.

Remove the tape fl'om the

cooktop lalllp covels on

the bottom of the oven.

_] Secure the power cord to the cabinet wall, as desired

to kee I) excess length out of the way, using, the l)°wer

cord strap and the black metnl screw.

......................//

Insert mesh-side down

22

Page 23

Installation Instructions

BEFORE YOU USE YOUR OVEN

_Make the has been installed according to

I [] Remo_e all packing material fl'om the o_en.

I [] Install o_en rack (mrntnble) in cavity.

[] Replace house fllse or mrn breaker back on.

Stli'e oxen

instructions.

IllIIIIIIII

_] Read the Owner's Manual.

[_ KEEP INSTAI,LATION INSTRUCTIONS FOR THE

I

I,OCAI, INSPECTOR _ USE.

J

f

I

L............-----_

_] Plug cord into dedicated NEMA 14-30Rpower

wall receptncle.

Insureproper

groundexists

beforeuse.

Wall Receptacle

NEMA14-30R

23

Page 24

164D3370P269

49-40339-1

3828W5U0315

o7-o3JR

Printed in Korea

Loading...

Loading...