Page 1

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT

–

Save these instructions

for local inspector’s use.

•

IMPORTANT

–

Observe all governing

codes and ordinances.

• Note to Installer –Be sure to leave these instructions

with the Consumer.

• Note to Consumer –Keep these instructions for

future reference.

• Skill level – Installation of this appliance requires basic

mechanical and electrical skills.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

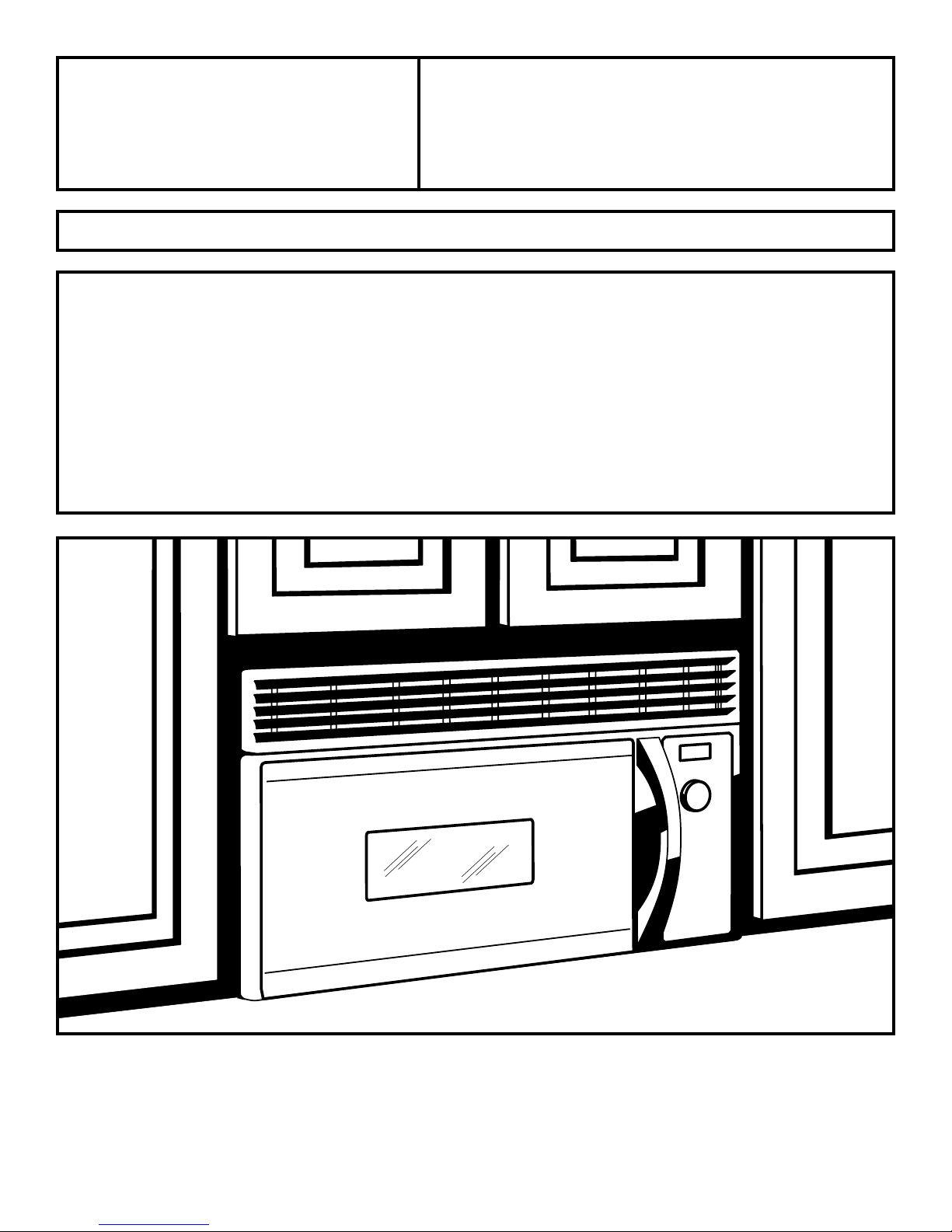

Installation Speedcook Oven

Instructions

Page 2

2

CONTENTS

General information

Important Safety Instructions ........................................ 3

Electrical Requirements.................................................. 3

Hood Exhaust ............................................................ 4, 5

Damage—Shipment/Installation.................................... 6

Parts Included ................................................................ 6

Tools You Will Need ...................................................... 7

Mounting Space .............................................................. 7

Step-by-step installation guide

Placement of Mounting Plate .................................. 8–10

Removing the Mounting Plate ........................ 8

Finding the Wall Studs...................................... 8

Determining Wall Plate Location .................... 9

Aligning the Wall Plate .................................. 10

Installation Types .................................................... 11–22

Outside Top Exhaust ................................ 12–14

Attach Mounting Plate to Wall ..............12

Preparation of Top Cabinet ..................13

Assemble and Install Adaptor ................13

Mount the Oven ..............................13, 14

Adjust the Exhaust Adaptor ..................14

Connecting Ductwork ............................14

Outside Back Exhaust .............................. 15–18

Preparing Rear Wall for

Outside Back Exhaust ............................15

Attach Mounting Plate to Wall ..............16

Preparation of Top Cabinet ..................16

Adapting Blower for Outside

Back Exhaust ....................................16, 17

Mount the Oven ..............................17, 18

B

A

Recirculating ............................................ 19–22

Attach Mounting Plate to Wall ..............19

Preparation of Top Cabinet ..................19

Adapting Blower for

Recirculation ....................................20, 21

Mount the Oven ..............................21, 22

Installing the Charcoal Filter ................22

Before You Use Your Oven ........................................ 23

C

Installation Instructions

Page 3

3

IMPORTANT SAFETY INSTRUCTIONS

Installation Instructions

This product requires a 4-prong grounded outlet. The

installer must perform a ground continuity check on the

power outlet box before beginning the installation to

insure that the outlet box is properly grounded. If not

properly grounded, or if the outlet box does not meet

electrical requirements noted (under ELECTRICAL

REQUIREMENTS), a qualified electrician should be

employed to correct any deficiencies.

CAUTION:

For personal safety, remove

house fuse or open circuit

breaker before beginning

installation to avoid severe

or fatal shock injury.

CAUTION: For personal safety, the mounting

surface must be capable of supporting the cabinet load,

in addition to the added weight of this 70–85 pound

product, plus additional oven loads of up to 50 pounds

or a total weight of 120–135 pounds.

CAUTION: For personal safety, this product

cannot be installed in cabinet arrangements such as an

island or a peninsula. It must be mounted to BOTH a

top cabinet AND a wall.

NOTE: For easier installation and personal safety, it is

recommended that two people install this product.

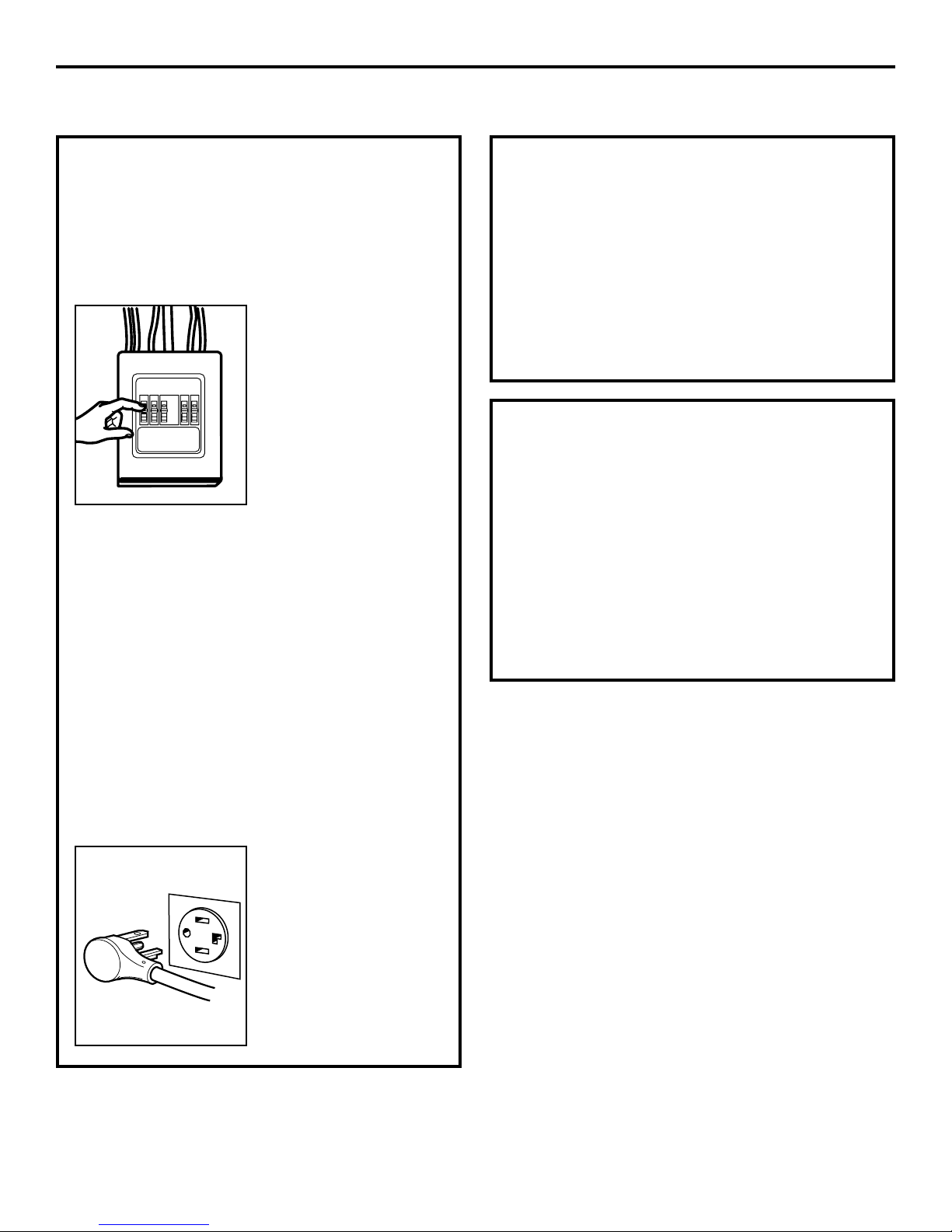

IMPORTANT—PLEASE READ CAREFULLY. FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVERE OR

FATAL SHOCK.

The wall outlet receptacle

recommended for this

appliance is NEMA #

14–30R and accepts the

4-prong grounded plug

of this appliance.

Insure proper

ground exists

before use.

NEMA 14–30R

Wall Receptacle

You should have the wall receptacle and circuit checked

by a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 3-prong wall receptacle is encountered,

it is very important to have it replaced with a properly

grounded NEMA # 14–30R wall receptacle, installed by

a qualified electrician.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT,

DEFORM, OR REMOVE ANY OF THE PRONGS

FROM THE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Product rating is 240/208 volts AC, 60 Hertz, 30 amps

and 6.5 kilowatts. This product must be connected to an

individual properly grounded branch circuit, protected

by circuit breakers or time delay fuses. Wire size must

conform to the requirements of the National Electrical

Code or the prevailing local code for this kilowatt rating.

The outlet box should be located in the cabinet above

the oven. The outlet box and supply circuit should be

installed by a qualified electrician and conform to the

National Electrical Code or the prevailing local code.

Page 4

4

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible ductwork installation.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Roof Cap 24 Ft. x (1) = 24 Ft.

12 Ft. Straight Duct 12 Ft. x (1) = 12 Ft.

(6″ Round)

Rectangular-to-Round 5 Ft. x (1) = 5 Ft.

Transition Adaptor*

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent hood.

Total Length = 41 Ft.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall should be

prepared at the time it is constructed by leaving enough space between the wall studs to accommodate exhaust.

*IMPORTANT: If a rectangular-to-round transition adaptor is used, the bottom corners of the damper will have

to be cut to fit, using the tin snips, in order to allow free movement of the damper.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH* x USED = LENGTH

Wall Cap 40 Ft. x (1) = 40 Ft.

3 Ft. Straight Duct 3 Ft. x (1) = 3 Ft.

(31⁄4″ x 10″ Rectangular)

90° Elbow 10 Ft. x (2) = 20 Ft.

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent hood.

Total Length = 63 Ft.

Installation Instructions

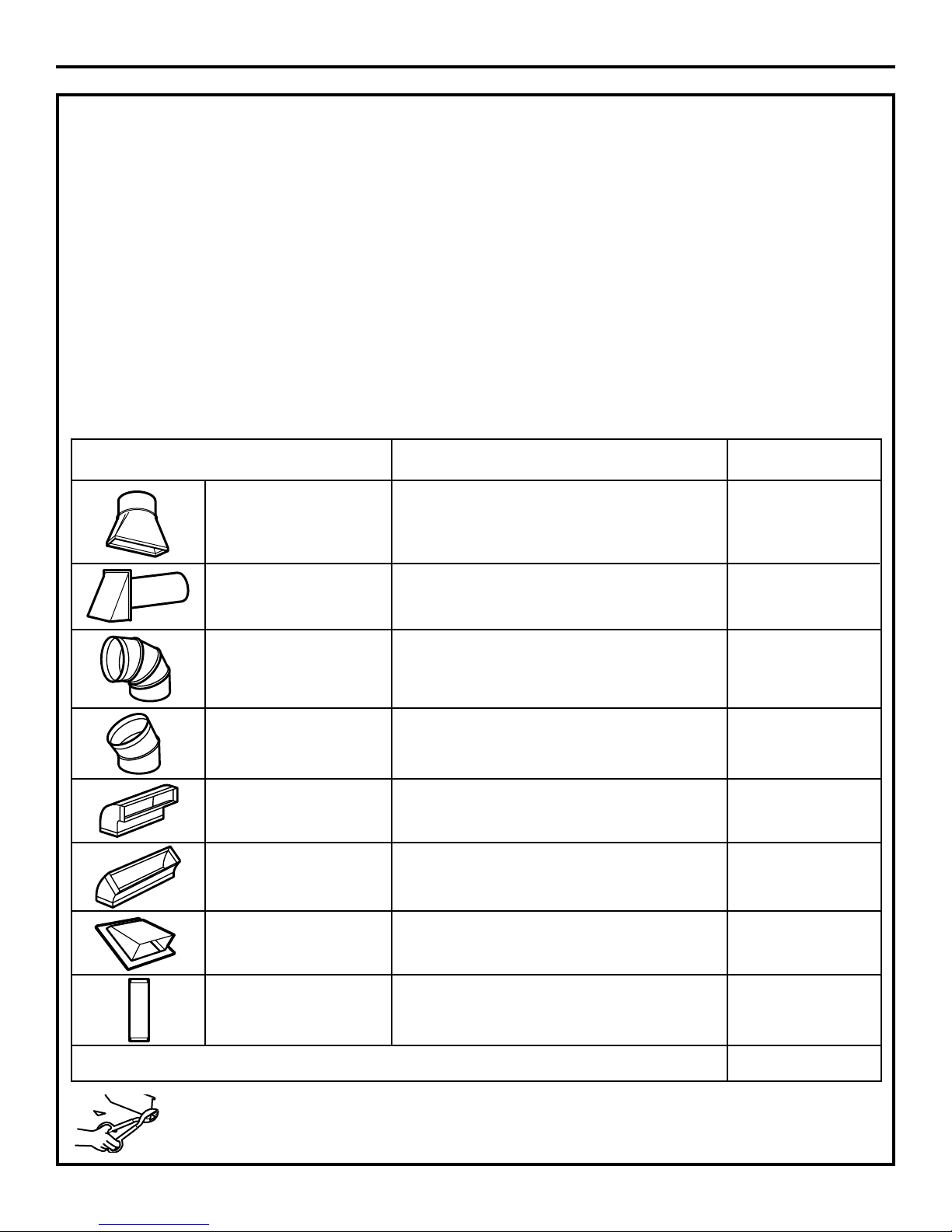

HOOD EXHAUST

NOTE: Read these next two pages only if you plan to vent your exhaust to the outside. If you plan to recirculate the air back into

the room, proceed to page 6.

Page 5

5

NOTE: If you need to install ducts, note that the total duct

length of 31⁄4″ x 10″ rectangular or 6″ diameter round duct

should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the following carefully.

NOTE: It is important that venting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and

nothing is blocking the ducts.

Exhaust connection:

The hood exhaust has been designed to mate with

a standard 31⁄4″ x 10″ rectangular duct.

If a round duct is required, a rectangular-to-round

transition adaptor must be used. Do not use less than

a 6″ diameter duct.

Maximum duct length:

For satisfactory air movement, the total duct length of

31⁄4″ x 10″ rectangular or 6″ diameter round duct should not

exceed 140 equivalent feet.

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equivalent

to a section of straight duct which is longer than their actual

physical size. When calculating the total duct length, add

the equivalent lengths of all transitions and adaptors plus

the length of all straight duct sections. The chart below

shows you how to calculate total equivalent ductwork length

using the approximate feet of equivalent length of some

typical ducts.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Rectangular-to-Round 5 Ft. x ( ) = Ft.

Transition Adaptor*

Wall Cap 40 Ft. x ( ) = Ft.

90° Elbow 10 Ft. x ( ) = Ft.

45° Elbow 5 Ft. x ( ) = Ft.

90° Elbow 25 Ft. x ( ) = Ft.

45° Elbow 5 Ft. x ( ) = Ft.

Roof Cap 24 Ft. x ( ) = Ft.

Straight Duct 6″ Round or 1 Ft. x ( ) = Ft.

31⁄4″ x 10″ Rectangular

Total Ductwork = Ft.

Installation Instructions

* IMPORTANT: If a rectangular-to-round transition adaptor

is used, the bottom corners of the damper will have to be

cut to fit, using the tin snips, in order to allow free movement

of the damper

.

Equivalent lengths of duct pieces are based on actual tests

and reflect requirements for good venting performance with

any vent hood.

Page 6

6

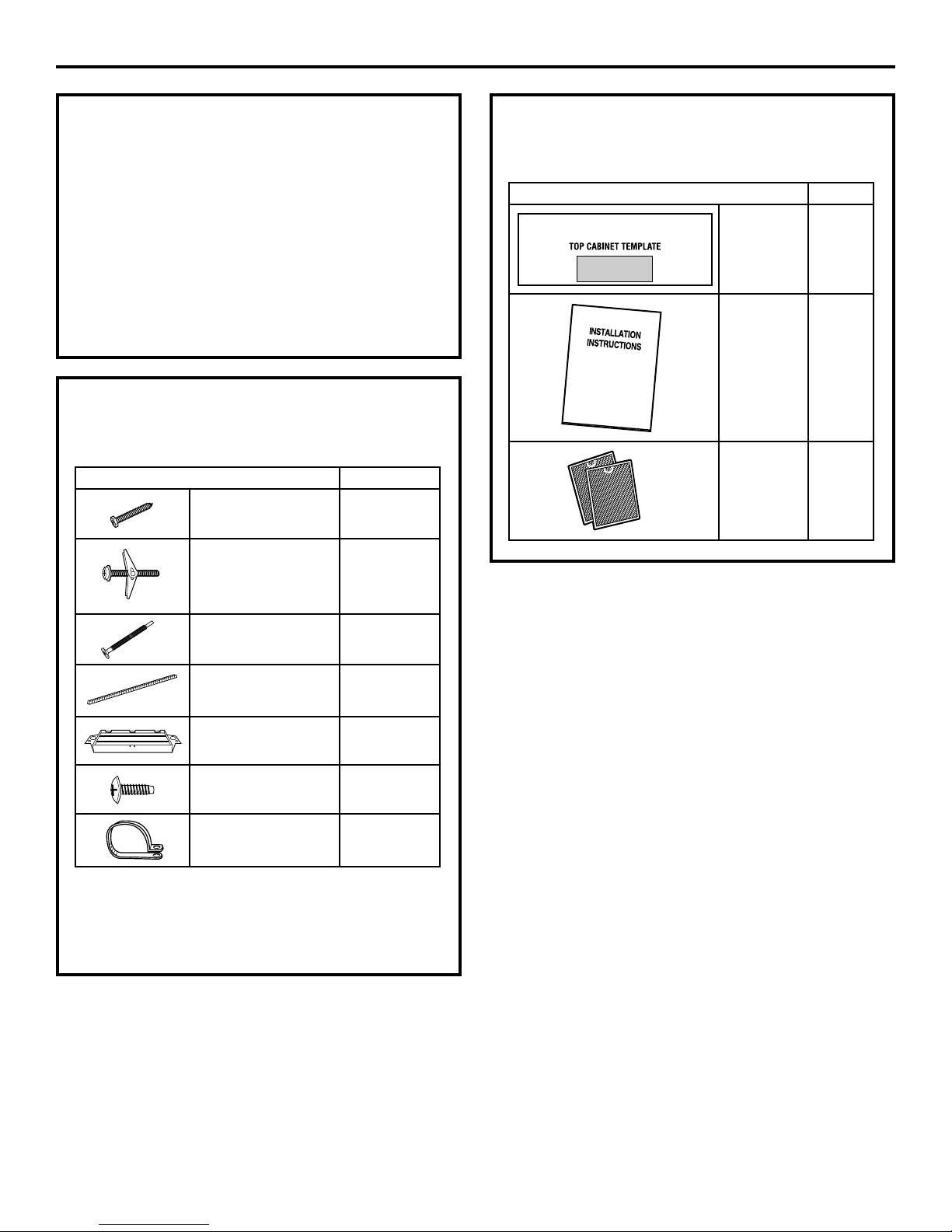

PARTS INCLUDED

ADDITIONAL PARTS

PAR T

QUANTITY

Top Cabinet 1

Template

Installation 1

Instructions

Separately 2

Packed

Grease

Filters

Installation Instructions

DAMAGE—SHIPMENT/

INSTALLATION

• If the unit is damaged in shipment, return the unit

to the store in which it was bought for repair or

replacement.

• If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

• If the unit is damaged by the installer (if other than

the customer), repair or replacement must be made

by arrangement between customer and installer.

PARTS INCLUDED

HARDWARE PACKET

You will find the installation hardware contained in a

packet with the unit. Check to make sure you have all

these parts.

NOTE: Some extra parts are included.

PART QUANTITY

Wood Screws 2

(1/4″ x 2″)

Toggle Bolts (and 4

wing nuts) (1/4″ x 3″)

Self-aligning Machine 3

Screws (1/4″–28 x 31⁄4″)

Nylon Grommet 2

(for metal cabinets)

Exhaust Adaptor 1

with Damper

Metal Screws 1 black

(1/8″ x 1/2″) 2 bronze

Power Cord Strap 1

(plastic)

Page 7

7

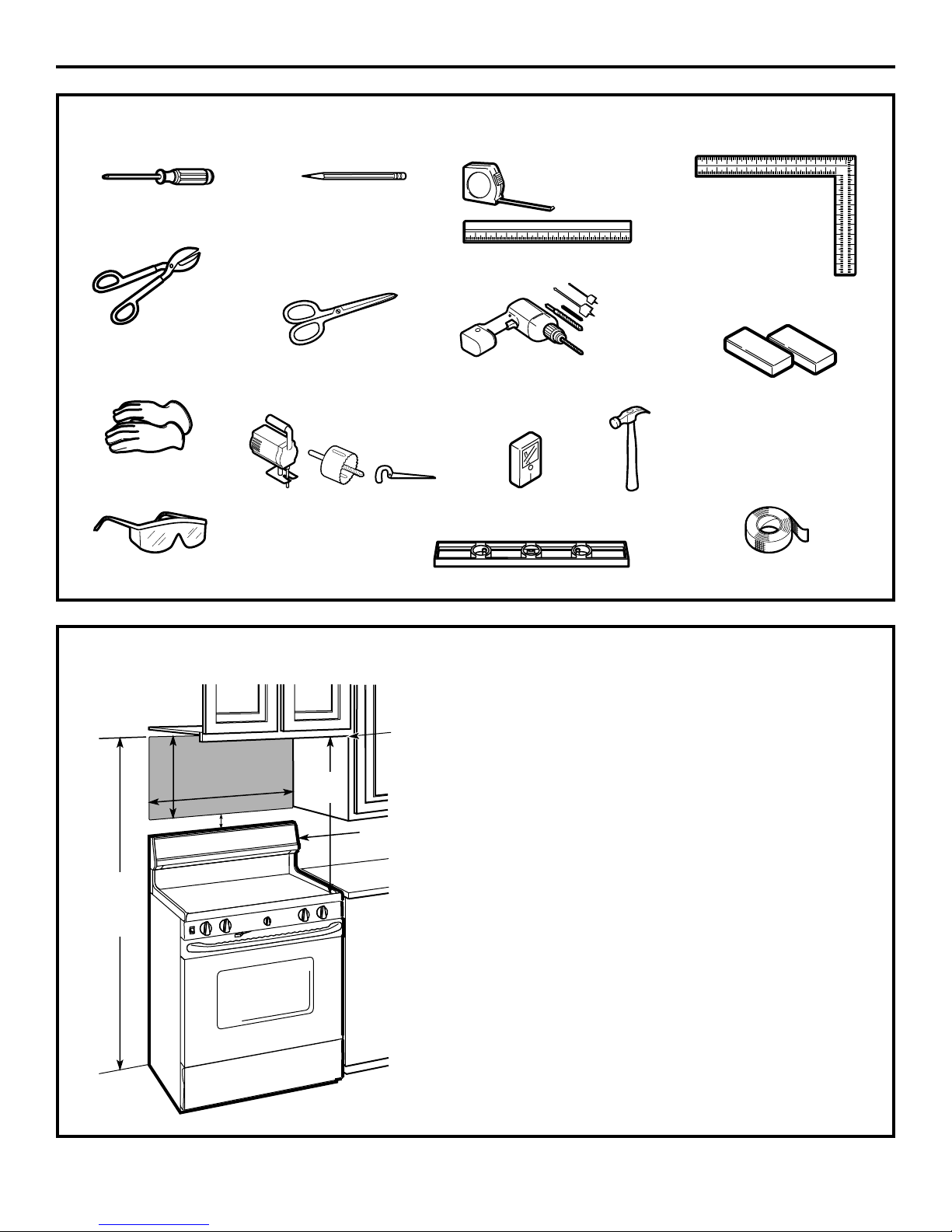

MOUNTING SPACE

TOOLS YOU WILL NEED

# 1 and #2 Phillips screwdriver

Pencil

Ruler or tape measure

and straight edge

Carpenter square

(optional)

Tin snips (for cutting

damper, if required)

Electric drill with 3/16,″ 7/16,″

1/2″ and 5/8″ drill bits

Hammer (optional)

Stud finder or

Filler blocks or scrap

wood pieces, if needed

for top cabinet spacing

(used on recessed bottom

cabinet installations only)

Gloves

Saw (saber, hole or keyhole)

Level

Duct and masking tape

NOTES:

• The space between the cabinets must be 30″ wide

and free of obstructions.

• If the space between the cabinets is greater than

30″, a Filler Panel Kit may be used to fill in the gap

between the oven and the cabinets. Your Owner’s

Manual contains the kit number for your model.

• This oven is for installation over ranges up to

36″ wide.

• If you are going to vent your oven to the outside,

see Hood Exhaust Section for exhaust duct

preparation.

• When installing the oven beneath smooth, flat

cabinets, be careful to follow the instructions on

the top cabinet template for power cord clearance.

• For best installation results, we recommend a

maximum cabinet depth of 12″.

Backsplash

30″

2″

30″

min.

16-1⁄8″

Bottom edge of

cabinet needs to

be 30″ or more

from the cooking

surface

Scissors

(to cut template, if necessary)

Safety goggles

Installation Instructions

66″ or more

from the floor

to the top

of the oven

Page 8

8

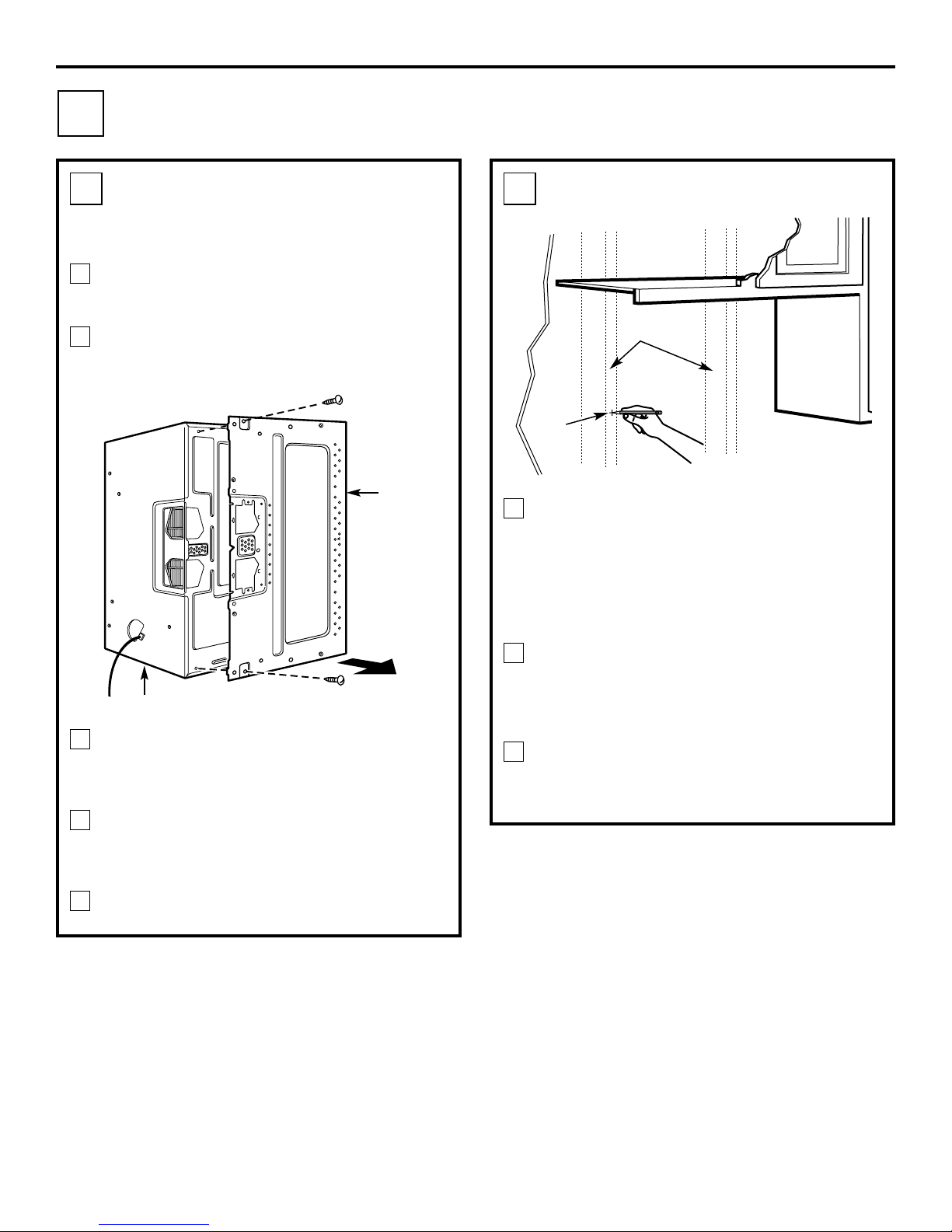

PLACEMENT OF THE MOUNTING PLATE

1

Installation Instructions

REMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

Remove the box containing the installation

instructions, filters, exhaust adaptor and the

small hardware bag.

Stand the oven on its control panel side. Use a portion

of the carton or some other material to protect the

outer case from being damaged.

The mounting plate is attached to the back of the

oven. Remove the 2 screws holding it to the oven.

The plate will be used as the rear wall template and

for mounting the oven to the wall.

Set the oven upright. Remove and properly discard

plastic bags and Styrofoam. Remove any adhesive tape

(if there is any) on the exhaust adaptor, the grease

filters and the power supply cord.

Open the oven door and remove any accessories

from inside the oven.

5

4

3

2

1

A

Mounting

Plate

Control Panel Side

FINDING THE WALL STUDS

Find the studs, using one of the following methods:

A. Stud finder—a magnetic device which locates nails.

OR

B. Use a hammer to tap lightly across the mounting

surface to find a solid sound. This will indicate a

stud location.

After locating the stud(s), find the center by probing

the wall with a small nail to find the edges of the stud.

Then place a mark halfway between the edges. The

center of any adjacent studs should be 16″ or 24″ from

this mark.

Draw a line down the center of the studs.

THE OVEN MUST BE CONNECTED TO AT LEAST

ONE WALL STUD.

3

2

1

B

Wall

Studs

Center

Page 9

9

DETERMINING WALL PLATE LOCATION UNDER YOUR CABINET

C

Plate position—beneath flat bottom

cabinet

Plate position—beneath recessed bottom

cabinet with front overhang

Mounting Plate Tabs

Touching the Cabinet

Bottom

Mounting Plate with

Tabs Below Cabinet

Bottom the Same

Distance as the Front

Overhang Depth

A

t

l

e

a

s

t

3

0

″,

u

p

t

o

3

6

″

Plate position—beneath framed recessed

cabinet bottom

Mounting Plate Tabs

Touching the Back

Frame

Installation Instructions

Your cabinets may have decorative trim that interferes

with the oven installation. Remove the decorative trim

to install the oven properly and to make it level.

THE OVEN MUST BE LEVEL. Use a level to make

sure the cabinet bottom is level.

If the cabinets have a front overhang only, with no back

or side frame, install the mounting plate down the same

distance as the front overhang depth. This will keep the

oven level.

Measure the inside depth of the front overhang.

Draw a horizontal line on the back wall an equal

distance below the cabinet bottom as the inside

depth of the front overhang.

For this type of installation with front overhang

only, align the mounting tabs with this horizontal

line, not touching the cabinet bottom as described

in Step D.

3

2

1

30″ to

Cooktop

30″ to

Cooktop

Page 10

10

ALIGNING THE WALL PLATE

D

Installation Instructions

Draw a Vertical Line

on Wall from Center

of Top Cabinet

Area E

Hole A

Hole B

Hole D

CAUTION: Wear gloves to avoid cutting fingers

on sharp edges.

Draw a vertical line on the wall at the center of the

30″ wide space.

Use the mounting plate as the template for the rear

wall. Place the mounting plate on the wall, making sure

that the tabs are touching the bottom of the cabinet or

the level line drawn in Step C for cabinets with front

overhang. Line up the notch and center line on the

mounting plate to the center line on the wall.

While holding the mounting plate with one hand,

draw circles on the wall at holes A, B, C and D (see

illustration above/actual plate marked with arrows).

Four holes must be used for mounting.

NOTE: Holes C and D are inside area E. If neither

C nor D is in a stud, find a stud somewhere in area E

and draw a fifth circle to line up with the stud. It is

important to use at least one wood screw mounted

firmly in a stud to support the weight of the oven.

Set the mounting plate aside.

Drill holes on the circles. If there is a stud, drill a 3⁄16″

hole for wood screws. For holes that don’t line up with

a stud, drill a 5⁄8″ hole for toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

4

3

2

1

Hole C

Page 11

11

This oven is designed for adaptation to the following

3 types of ventilation:

A. Outside Top Exhaust (Vertical Duct)

B. Outside Back Exhaust (Horizontal Duct)

C. Recirculating (Non-Vented Ductless)

NOTE: This oven is shipped assembled for Outside Top

Exhaust. Select the type of ventilation required for your

installation and proceed to that section.

See page 12 See page 15

A Charcoal Filter Accessory Kit

is required for the non-vented

exhaust. (See your Owner’s

Manual for the kit number.)

Adaptor in Place for

Outside Top Exhaust

Installation Instructions

INSTALLATION TYPES (Choose A, B or C)

2

OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

A

OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

B

See page 19

RECIRCULATING

(NON-VENTED DUCTLESS)

C

Page 12

12

To use toggle bolts:

Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to mount

the plate.

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: Be careful to avoid pinching

fingers between the back of the mounting plate and

the wall.

Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

4

3

INSTALLATION OVERVIEW

A1. Attach Mounting Plate to Wall

A2. Prepare Top Cabinet

A3. Install Adaptor

A4. Mount the Oven

A5. Adjust Exhaust Adaptor

A6. Connect Ductwork

OUTSIDE TOP EXHAUST (Vertical Duct)

A

Installation Instructions

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one

wood screw must be used to attach the plate to a wall stud.

Remove the toggle wings from the bolts.

Insert the bolts into the mounting plate through the

holes designated to go into drywall and reattach the

toggle wings to 3/4″ onto each bolt.

2

1

A1

Wall

Mounting

Plate

Spacing for Toggles More

Than Wall Thickness

Bolt End

Toggle

Bolt

Toggle

Wings

Page 13

13

Installation Instructions

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws, a hole

large enough for the power cord to fit through, and a

cutout large enough for the exhaust adaptor.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling

holes in the cabinet bottom.

A2

ASSEMBLE AND INSTALL

ADAPTOR

If you have a flat bottom cabinet, the exhaust adaptor will

be installed later through the cutout in the cabinet bottom.

Place the oven in its upright position, with the top of

the unit facing up.

Attach the exhaust adaptor, hinge side toward the back

of the oven, to the blower plate with the 2 bronze

metal screws provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make adjustments to assure proper

alignment with your house exhaust duct after the

oven is installed.

2

1

A3

Damper

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY,

WE RECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use handle during

installation.

NOTE: If your cabinet is metal, use the nylon grommet

around the power cord hole to prevent cutting of the cord.

NOTE: We recommend using filler blocks if the cabinet

front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used, case damage

may occur from over tightening screws.

NOTE: When mounting the oven,

thread power cord through hole

in bottom of top cabinet. Keep it

tight throughout Steps 1–3.

Do not pinch cord or lift oven

by pulling cord.

Rotate front of oven up

against cabinet bottom.

Insert a self-aligning screw through top center cabinet

hole. Temporarily secure the oven by turning the

screw at least two full turns after the threads have

engaged. (It will be completely tightened later.)

Be sure to keep power cord tight. Be careful not to

pinch the cord, especially when mounting flush to

bottom of cabinet.

3

2

A4

Lift oven, tilt it

forward, and

hook slots at back

bottom edge onto

2 lower tabs of

mounting plate.

1

Exhaust Adaptor

Blower Plate

Back of Oven

Page 14

14

ADJUST THE EXHAUST

ADAPTOR

Open the top cabinet and adjust the exhaust adaptor to

connect to the house duct.

For top exhaust on the flat-bottomed cabinets, open the

top cabinet and attach the exhaust adaptor to the oven

through the cabinet bottom with the 2 bronze metal

screws provided.

A5

Back of Oven

Damper

Installation Instructions

MOUNT THE OVEN (cont.)

If your cabinet front hangs more than 23⁄4″ below the

cabinet bottom, you may need to use longer screws than

the ones provided with this product. The screws provided

with this product (hardware item 3) are self-aligning,

large-head machine screws 1/4″ diameter, 31⁄4″ long,

with SAE 28 threads per inch. It is important that you

use replacement screws just long enough to attach the

product to the cabinet. The length can be determined

by measuring the height of the overhang from the top

of the cabinet floor to the bottom of the overhang and

adding 1″ to that length. This will be the length of the

1/4″ SAE 28 threads per inch screws you need.

You will also need to use washers 3/4″ diameter to fit the

screws you purchase. This will prevent the screw heads

from pulling through the bottom of the cabinet when

tightening during installation.

Attach the oven to the top cabinet.

Insert 2 self-aligning screws through outer top cabinet

holes. Turn two full turns on each screw.

Tighten the outer 2 screws to the top of the oven.

(While tightening screws, hold the oven in place

against the wall and the top cabinet.)

7

5

4

A4

CONNECTING DUCTWORK

Extend the house duct down to connect to the

exhaust adaptor.

Seal exhaust duct joints using duct tape.

2

1

A6

House Duct

Cabinet Front

Cabinet Bottom Shelf

Filler Block

Oven Top

Equivalent

to Depth

of Cabinet

Recess

Self-Aligning Screw

Install grease filters.

See the Owner’s Manual

packed with the oven.

Remove the tape from the

cooktop lamp covers on

the bottom of the oven.

Secure the power cord to the cabinet wall, as desired

to keep excess length out of the way using the power

cord strap and the black metal screw.

9

8

Tighten center

screw completely.

6

Page 15

15

Attach the exhaust adaptor to the rear mounting plate

by sliding it into the guides at the top center of the

plate on the wall side.

Push in securely until it is past the top locking tabs and

in the lower locking tabs. Take care to assure the damper

hinge is installed so that it is at the top and that the

damper swings freely.

Carefully guide the exhaust adaptor, now attached to

the mounting plate, into the house duct, before using

the screws to attach the plate to the wall.

4

3

INSTALLATION OVERVIEW

B1. Prepare Rear Wall

B2. Attach Mounting Plate to Wall

B3. Prepare Top Cabinet

B4. Adjust Blower

B5. Mount the Oven

Installation Instructions

OUTSIDE BACK EXHAUST (Horizontal Duct)

B

PREPARING THE REAR WALL

FOR OUTSIDE BACK EXHAUST

Place the mounting plate against the rear wall and

align it with the holes drilled earlier.

Using a pencil, put dots through slots F and G, and

through holes H and I. Remove the mounting plate

and draw lines extending through the points. This will

give the lcoation and size of the box cutout for the

rear wall duct.

2

1

B1

F

I

H

G

Slide Exhaust

Adaptor Into

Guides on

Rear Panel

Exhaust Adaptor

Damper

(hinge side up)

Locking

Tabs

Guides

Mounting Plate

(wall side)

Page 16

16

Installation Instructions

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one

wood screw must be used to attach the plate to a wall stud.

Remove the toggle wings from the bolts.

Insert the bolts into the mounting plate through the

holes designated to go into drywall and reattach the

toggle wings to 3/4″ onto each bolt.

To use toggle bolts:

Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to mount

the plate.

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: Be careful to avoid pinching

fingers between the back of the mounting plate and

the wall.

Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

4

3

2

1

B2

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws and a

hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling

holes in the cabinet bottom.

B3

ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

Remove the 3 screws that hold the blower plate to

the oven. Slide blower plate from under its retaining

flange. Remove and save the screw that holds blower

motor to oven.

Carefully pull out the blower unit. The wires will

extend far enough to allow you to adjust the

blower unit.

2

1

B4

Retaining Flange

Blower Motor Screw

End B

End A

BEFORE: Fan Blade

Openings Facing Up

Wall

Mounting

Plate

Spacing for Toggles More

Than Wall Thickness

Bolt End

Toggle

Bolt

Toggle

Wings

Page 17

Gently remove the wires from the grooves. Reroute

the wires through grooves on other side of the

blower unit.

Rotate blower unit counterclockwise 180°.

Roll the blower unit 90° so that fan blade openings

are facing out the back of the oven.

Locate the 2 “knockout” plates, on the rear oven

panel, near the top of the oven.

Using tin snips, carefully cut the web area from the

2 holes side-by-side (that secure the knockouts to the

oven). Cut all 4 webs on both rear knockouts; this will

allow the ventilation fan airflow to exhaust out the

rear of the oven.

CAUTION: Be sure to trim the sharp edges

from the openings after removing the knockout plates.

6

5

4

3

17

Before Rerouting After Rerouting

Wires Routed Through Right Side

Wires Routed Through Left Side

Installation Instructions

Before Rotation After Rotation

Back of Oven

Back of Oven

Place the blower unit back into the opening.

CAUTION: Do not pull or stretch the blower

unit wiring. Make sure the wires are not pinched.

NOTE: The blower unit exhaust openings should match

exhaust openings on rear of oven.

Secure the blower unit to the oven with the screw

removed earlier. Replace the blower plate in the same

position as before with the screws.

8

7

Back of Oven

Back of Oven

Before Rolling After Rolling

End A

End B

AFTER: Fan Blade

Openings Facing Back

Snip all 4 webs

on each knockout

panel and remove

the metal knockouts

for rear airflow.

Oven Rear Panel

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY,

WE RECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use handle during

installation.

NOTE: If your cabinet is metal, use the nylon grommet

around the power cord hole to prevent cutting of the cord.

NOTE: We recommend using filler blocks if the cabinet

front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used, case damage

may occur from over tightening screws.

B5

Retaining

Flange

Blower Plate

Back of Oven

Blower Motor

Screw

Page 18

18

MOUNT THE OVEN

(cont.)

NOTE: When mounting the oven,

thread power cord through hole

in bottom of top cabinet. Keep it

tight throughout Steps 1–3.

Do not pinch cord or lift oven

by pulling cord.

Rotate front of oven up

against cabinet bottom.

Insert a self-aligning screw through top center cabinet

hole. Temporarily secure the oven by turning the

screw at least two full turns after the threads have

engaged. (It will be completely tightened later.)

Be sure to keep power cord tight. Be careful not to

pinch the cord, especially when mounting flush to

bottom of cabinet.

If your cabinet front hangs more than 23⁄4″ below the

cabinet bottom, you may need to use longer screws than

the ones provided with this product. The screws provided

with this product (hardware item 3) are self-aligning,

large-head machine screws 1/4″ diameter, 31⁄4″ long,

with SAE 28 threads per inch. It is important that you

use replacement screws just long enough to attach the

product to the cabinet. The length can be determined

by measuring the height of the overhang from the top

of the cabinet floor to the bottom of the overhang and

adding 1″ to that length. This will be the length of the

1/4″ SAE 28 threads per inch screws you need.

You will also need to use washers 3/4″ diameter to fit the

screws you purchase. This will prevent the screw heads

from pulling through the bottom of the cabinet when

tightening during installation.

3

2

B5

Lift oven, tilt it

forward, and

hook slots at back

bottom edge onto

2 lower tabs of

mounting plate.

1

Installation Instructions

Attach the oven to the top cabinet.

Insert 2 self-aligning screws through outer top cabinet

holes. Turn two full turns on each screw.

Tighten the outer 2 screws to the top of the oven.

(While tightening screws, hold the oven in place

against the wall and the top cabinet.)

Install grease filters.

See the Owner’s Manual

packed with the oven.

Remove the tape from the

cooktop lamp covers on

the bottom of the oven.

Secure the power cord to the cabinet wall, as desired

to keep excess length out of the way using the power

cord strap and the black metal screw.

9

8

7

5

4

Cabinet Front

Cabinet Bottom Shelf

Filler Block

Oven Top

Equivalent

to Depth

of Cabinet

Recess

Self-Aligning Screw

Tighten center

screw completely.

6

Page 19

19

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one

wood screw must be used to attach the plate to a wall stud.

Remove the toggle wings from the bolts.

Insert the bolts into the mounting plate through the

holes designated to go into drywall and reattach the

toggle wings to 3/4″ onto each bolt.

To use toggle bolts:

Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to mount

the plate.

3

2

1

C1

Installation Instructions

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the wall

and that the plate is properly centered under the cabinet.

CAUTION: Be careful to avoid pinching fingers

between the back of the mounting plate and the wall.

Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

4

INSTALLATION OVERVIEW

C1. Attach Mounting Plate to Wall

C2. Prepare Top Cabinet

C3. Adjust Blower

C4. Mount the Oven

C5. Install Charcoal Filter

RECIRCULATING (Non-Vented Ductless)

C

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws and a

hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling

holes in the cabinet bottom.

C2

Wall

Mounting

Plate

Spacing for Toggles More

Than Wall Thickness

Bolt End

Toggle

Bolt

Toggle

Wings

Page 20

ADAPTING BLOWER FOR

RECIRCULATION

NOTE: The exhaust adaptor with damper is not needed

for recirculating models. You may want to save them for

possible future use.

Remove and save screws that hold the blower plate

to the oven.

Slide the blower plate from under its retaining flange

and lift it off. Remove and save screw that holds the

blower motor to oven.

Carefully pull out the blower unit. The wires will

extend far enough to allow you to adjust the

blower unit.

3

2

1

C3

20

Installation Instructions

Retaining Flange

Roll the blower unit 90° so that fan blade openings

are facing toward the front of the oven.

NOTE: Make sure wires remain routed in the grooves of

the motor frame.

Place the blower unit back into the opening.

CAUTION: Do not pull or stretch the blower

unit wiring. Make sure the wires are not pinched.

5

4

BEFORE: Fan Blade

Openings Facing Up

Roll

AFTER: Fan Blade

Openings Facing

Forward

Retaining

Flange

Blower Plate

Back of Oven

Blower Plate Screws

Blower Motor

Screw

Blower Plate

Page 21

21

Installation Instructions

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY,

WE RECOMMEND THAT TWO PEOPLE INSTALL

THIS OVEN.

IMPORTANT: Do not grip or use handle during

installation.

NOTE: If your cabinet is metal, use the nylon grommet

around the power cord hole to prevent cutting of the cord.

NOTE: We recommend using filler blocks if the cabinet

front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used, case damage

may occur from over tightening screws.

C4

Secure blower unit to oven with the screw removed

in Step 2.

Replace blower plate with the screws removed

in Step 1.

7

6

Blower Motor

Screw

NOTE: When mounting the oven,

thread power cord through hole

in bottom of top cabinet. Keep it

tight throughout Steps 1–3.

Do not pinch cord or lift oven

by pulling cord.

Rotate front of oven up

against cabinet bottom.

Insert a self-aligning screw through top center cabinet

hole. Temporarily secure the oven by turning the

screw at least two full turns after the threads have

engaged. (It will be completely tightened later.)

Be sure to keep power cord tight. Be careful not to

pinch the cord, especially when mounting flush to

bottom of cabinet.

If your cabinet front hangs more than 23⁄4″ below the

cabinet bottom, you may need to use longer screws than

the ones provided with this product. The screws provided

with this product (hardware item 3) are self-aligning,

large-head machine screws 1/4″ diameter, 31⁄4″ long,

with SAE 28 threads per inch. It is important that you

use replacement screws just long enough to attach the

product to the cabinet. The length can be determined

by measuring the height of the overhang from the top

of the cabinet floor to the bottom of the overhang and

adding 1″ to that length. This will be the length of the

1/4″ SAE 28 threads per inch screws you need.

You will also need to use washers 3/4″ diameter to fit the

screws you purchase. This will prevent the screw heads

from pulling through the bottom of the cabinet when

tightening during installation.

3

2

Lift oven, tilt it

forward, and

hook slots at back

bottom edge onto

2 lower tabs of

mounting plate.

1

Retaining

Flange

Blower Plate

Back of Oven

Blower Plate Screws

Page 22

INSTALLING THE CHARCOAL

FILTER

Remove 2 screws on top of grille using a Phillips

screwdriver. You may need to open the cabinet doors

to remove the screws.

Open the door.

Remove the grille.

Install the charcoal filter. When properly installed,

the wire mesh of the filter should be visible from

the front.

Replace the grille and the 2 screws.

Close the door.

6

5

4

3

2

1

C5

22

Screws

Insert mesh-side down

Installation Instructions

MOUNT THE OVEN (cont.)

Attach the oven to the top cabinet.

Insert 2 self-aligning screws through outer top cabinet

holes. Turn two full turns on each screw.

Tighten the outer 2 screws to the top of the oven.

(While tightening screws, hold the oven in place

against the wall and the top cabinet.)

Install grease filters.

See the Owner’s Manual

packed with the oven.

Remove the tape from the

cooktop lamp covers on

the bottom of the oven.

Secure the power cord to the cabinet wall, as desired

to keep excess length out of the way using the power

cord strap and the black metal screw.

9

8

7

5

4

C4

Cabinet Front

Cabinet Bottom Shelf

Filler Block

Oven Top

Equivalent

to Depth

of Cabinet

Recess

Self-Aligning Screw

Tighten center

screw completely.

6

Page 23

23

Read the Owner’s Manual.

6

Replace house fuse or turn breaker back on.

4

Installation Instructions

BEFORE YOU USE YOUR OVEN

Make sure the oven has been installed according to

instructions.

1

Remove all packing material from the oven.

2

Install oven rack (turntable) in cavity.

3

Plug power cord into a dedicated NEMA 14–30R

wall receptacle.

5

Insure proper

ground exists

before use.

NEMA 14–30R

Wall Receptacle

KEEP INSTALLATION INSTRUCTIONS FOR THE

LOCAL INSPECTOR’S USE.

7

Page 24

164D3370P269

49-40339-1

3828W5U0315

07-03 JR Printed in Korea

Loading...

Loading...