GE SCA1000HBB01, SCA1000HBB02, SCA1000HBB04, SCA1000HCC01, SCA1000HCC02 Installation Guide

...Page 1

I

sta

I

structi kto Ove

JVM1490,JVM1790,SCAI000,SCAI001

j Ouestions? Call 800-GE=CARES(800-q32=2737)or Visit our Website at: go.corn j

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT - S_ve_l_ese

instructions fbr local inspector's use.

• IMPORTANT - Obse,ve_,ll

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Constuner.

Note to Consumer - Keep these

instructions for filture reference.

* Skill level - Installation of this appliance requires

basic mechanical and electrical skills.

* Proper installation is the responsibility of the installer.

* Prodt_ct fhilure due to improper installation is not

covered under the Warranty.

LA SECCiON EN ESPANOL

EMPiEZA EN LA PAGiNA 25.

READ CAREFU LLY.

KEEP THESE iNSTRUCTiONS,

Page 2

Installation instructions

CONTENTS

General information

Important Safety Instructions .................................. 3

Electrical Requirements .......................................... 3

Hood Exhaust ...................................................... 4, 5

Damage - Shipment/Installation .............................. 6

Parts Included .......................................................... 6

Tools You Will Need ................................................ 7

Mounting Space ...................................................... 7

Step-by-step installation guide

Placement of Mounting Plate ............................ 8-10

Removing the Mounting Plate ...................... 8

Finding the Wall Studs .................................. 8

Determining Wall Plate Location .................. 9

Recirculating ........................................ 19-22

Attach Mounting Plate to Wall ............ 19

Preparation of Top Cabinet ................ 19

Adapdng Blower

fin Recirculation .......................... 20, 21

Mount the Oven ............................ 21, 22

Installing the Charcoal Filter. ............. 22

Before You Use Your Oven .................................. 23

Seccidn en Espafiol ........................................ 25-47

Aligning the Wall Plate ................................ 10

Installation Types .............................................. 11-22

_ Outside Top ............................

Attach Mounting Plate to Wall ............ 12

Preparation of Top Cabinet ................ 13

Checking for Proper Damper

Operation ............................................ 13

Mount the Oven ............................ 13, 14

Adj ust the Exhaust Adaptor ................ 14

Connecting Ductwork .......................... 14

_ Outside Back Exhaust 15-18

Preparing Rear Wall fin.

Outside Back Exhaust .......................... 15

Attach Mounting Plate to Wall ...... 15, 16

Preparation of Top Cabinet ................ 16

Adapting Blower fin Outside

Back Exhaust .................................... 16, 17

Exhaust

12-14

Mount the Oven .................................. 18

2

Page 3

Installation instructions

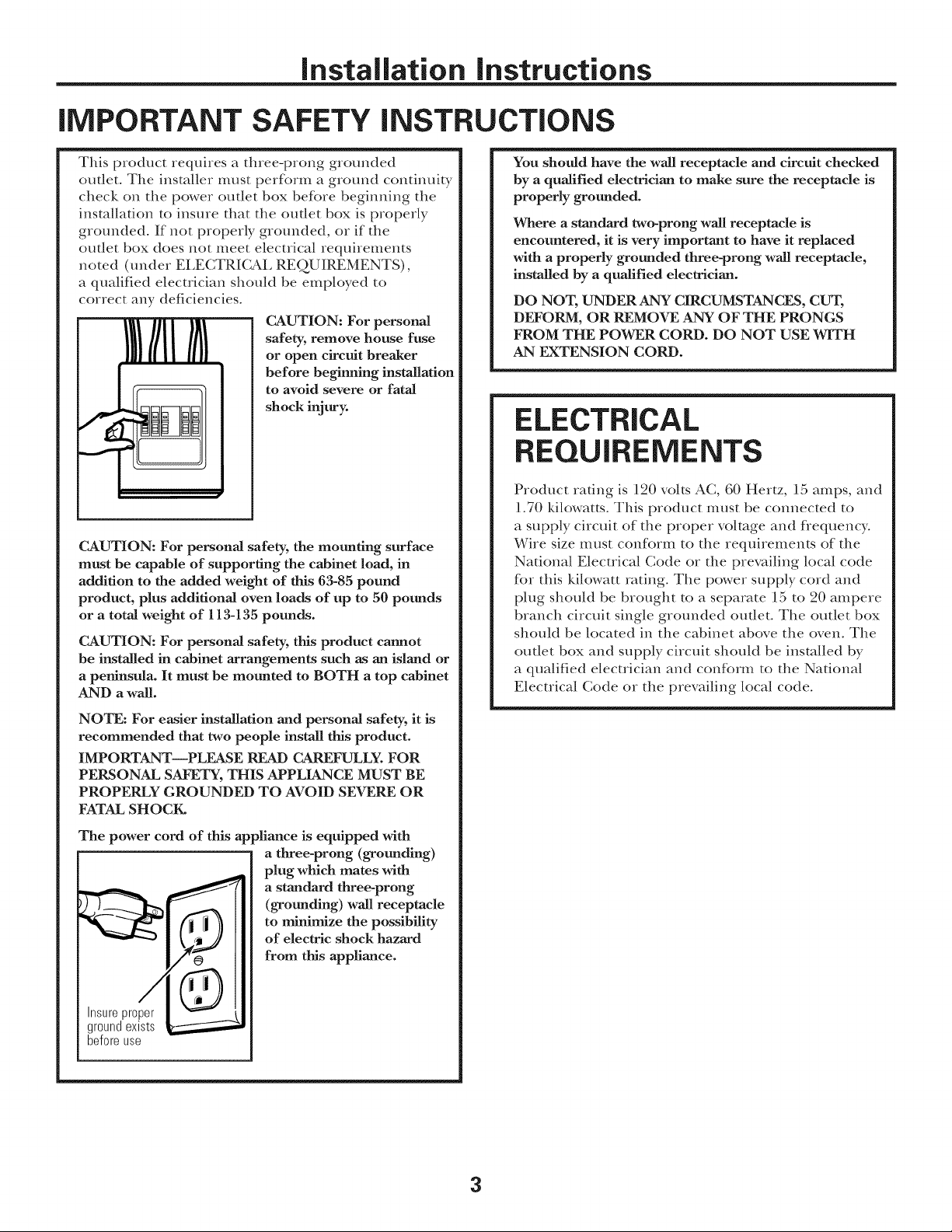

iMPORTANT SAFETY iNSTRUCTiONS

This product requires a three-prong grounded

out|et. The installer must perform a ground continuity

check on the power outlet box before beginning the

installation to instue that the out|et box is properly

grounded. If not properly grounded, or if the

outlet box does not meet electrical requirements

noted (under ELECTRICAl, REQUIREMENTS),

a qualified electrician should be employed to

correct any deficiencies.

i_1/[ CAUTION: For personal

CAUTION: For personal safety, the mounting surface

must be capable of supporting the cabinet load, in

addition to the added weight of this 63-85 pound

product, plus additional oven loads of up to 50 pounds

or a total weight of 113-135 pounds.

CAUTION: For personal safety, this product cannot

be installed in cabinet arrangements such as an island or

a peninsula. It must be mounted to BOTH a top cabinet

AND a wall.

i or open circuit breaker

w

safety, remove house fuse

before beginning installation

to avoid severe or fatal

shock injury.

You should have the wall receptacle and circuit checked

by a qualified electridan to make sure the receptade is

properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is very important to have it replaced

with a properly grounded three-prong wall receptacle,

installed by a qualified electrician.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT,

DEFORM, OR REMOVE ANY OF THE PRONGS

FROM THE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Product radng is 120 volts AC, 60 Hertz, 15 amps, and

1.70 ldlowatts. This product IllUSt be connected to

a supply circuit of the proper voltage and fiequenc>

Wire size must conform to the requirements of the

National Electrical Code or the prevailing local code

for this kilowatt rating. The power supply cord and

plug should be brought to a separate 15 to 20 ampere

branch circuit single grounded outlet. The outlet box

should be located in the cabinet above the oven. The

outlet box and supply circuit should be installed by

a qualified electrician and confbrm to the National

Electrical Code or the prevailing local code.

NOTE: For easier installation and personal safety, it is

recommended that two people install this product.

IMPORTANT--PLEASE READ CAREFULLY. FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVERE OR

FATAL SHOCK.

The power cord of this appliance is equipped with

a three-prong (grounding)

plug which mates with

a standard three-prong

(grounding) wall receptacle

to minimize the possibility

of electric shock hazard

from this appliance.

Insure proper

ground exists

before use

3

Page 4

Installation instructions

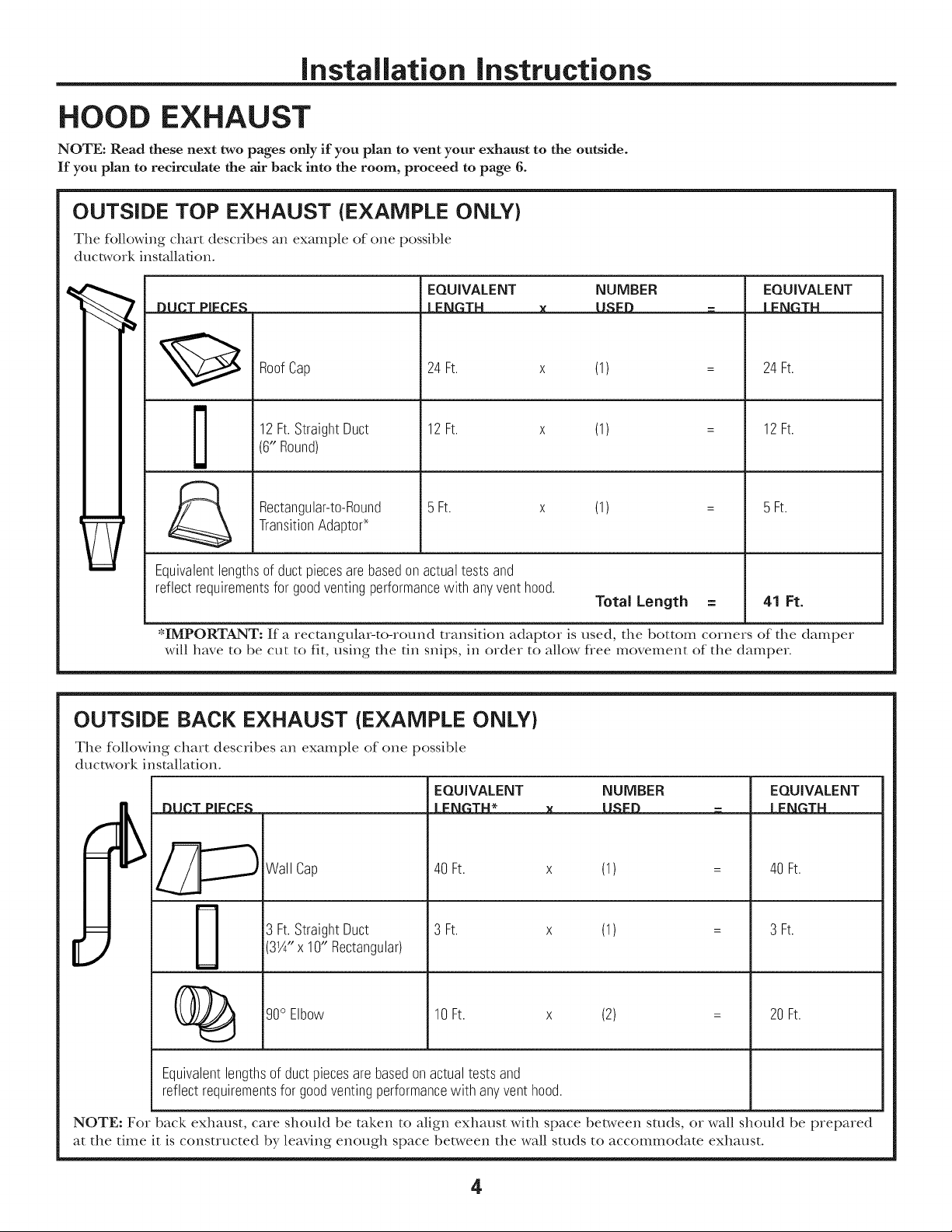

HOOD EXHAUST

NOTE: Read these next two pages only if you plan to vent your exhaust to the outside.

If you plan to redrculate the air back into the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY}

The fbllowing chart describes an example of one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

IDDCI PIECES =LENGTH x USED = J LENGTH

24Ft. x (1) = 24Ft.

12Ft.StraightDuct

RoofCap

(6" Round)

TransitionAdaptor*

Rectangular-to-Round

Equivalentlengthsof ductpiecesarebasedon actualtests and

reflectrequirementsfor goodventingperformancewith anyventhood.

*IMPORTANT: If a rectangular-to-round transition adaptor is used, the bottom corners of the damper

will have to be cut to fit, using the tin snips, in order to allow flee movement of the damper.

12Ft. x (1) = 12Ft.

5 Ft. x (1) = 5 Ft.

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible

ductwork installation.

EQUIVALENT

13|lP.T PIFP.I:N

Wall Cap

I I::N_TM*

40 Ft.

Total Length = 41 Ft.

EQUIVALENT

I FN_TM

(1)

40 Ft.

3 Ft.StraightDuct

3W' x 10" Rectangular)

(_ go° Elbow 10 x (2) = 20

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent hood.

NOTE: For back exhaust, care should be taken to align exhaust with space bet_,veen studs, or wall should be prepared

at the time it is constructed by leaving enough space between the wall studs to accommodate exhaust.

3 Ft.

Ft. Ft.

(1)

3 Ft.

4

Page 5

Installation instructions

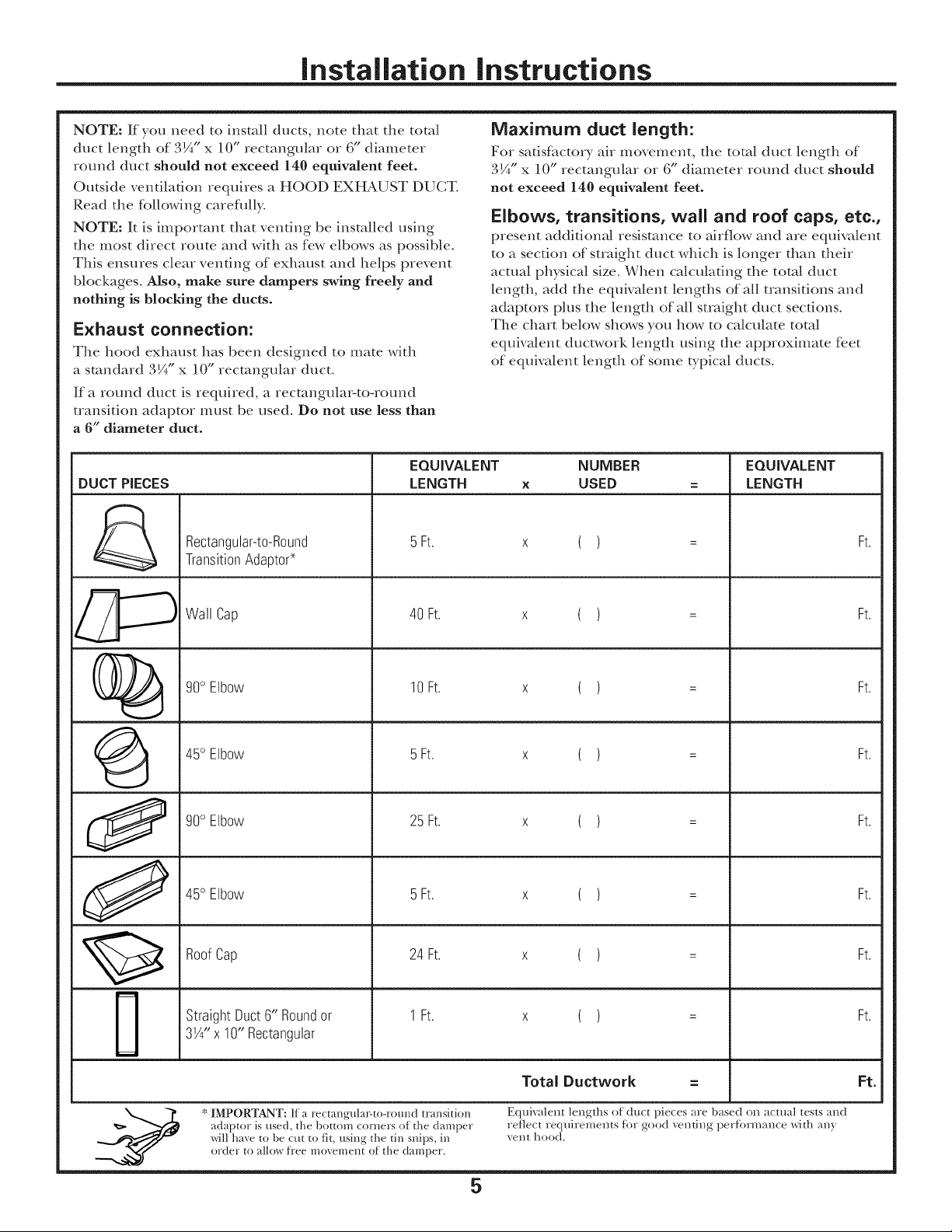

NOTE: If you need to install ducts, note that the total

duct length of 3¼" x 10" rectangular or 6" diameter

round duct should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the fbllowing careflflly:

NOTE: It is important that venting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and

nothing is blocMng the ducts.

Exhaust connection:

The hood exhaust has been designed to mate with

a standard 3¼" x 10" rectangular duct.

If a round duct is required, a rectangular-to-round

transition adaptor must be used. Do not use less than

a 6" diameter duct.

EQUIVALENT

DUCT PIECES

&

Rectangular-to-Round

TransitionAdaptoP

LENGTH

5Ft.

Maximum duct length:

For safisfhctory air movement, the total duct length of

3¼"x 10" rectangular or 6" diameter round duct should

not exceed 140 equivalent feet.

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equivalent

to a section of straight duct which is longer than their

actual physical size. When calculating the total duct

length, add the equNa/ent lengths of all transitions and

adaptors plus the length of all straight duct sections.

The chart below shows you how to calculate total

equiwdent ducta, vork length using the approximate feet

of equivalent length of some typical ducts.

NUMBER

X

USED

( )

EQUIVALENT

LENGTH

Ft.

Wall Cap

90° Elbow

45° Elbow 5Ft. x ( ) = Ft.

90° Elbow 25 Ft. x ( ) = Ft.

45° Elbow 5Ft. x ( ) = Ft.

RoofCap 24 Ft. x ( ) = Ft.

Straight Duct 6" Roundor 1Ft. x ( ) = Ft.

3X" x 10" Rectangular

40 Ft.

10 Ft.

( )

( )

Ft.

Ft.

* IMPORTANT: If a rectangula>to-round transition

adaptor is used, the bottom corners of the damper

will ha_e to be cut to fit, using the tin snips, in

order to allow ti'ee movement of the damper.

Total Ductwork = Ft.

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good velltillg performance x_dth any

Vellt hood.

5

Page 6

Installation instructions

DAMAGE - SHIPMENT/

iNSTALLATiON

• If the unit is damaged in shipment, return the

unit to the store in which it was bought for repair

or replacement.

• If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

• If the unit is damaged by the installer (if other

than the customer), repair or replacement must

be made by arrangement bet_,veen customer and

installer.

PARTS iNCLUDED

HARDWARE PACKET

PART QUANTITY

WoodScrews 2

(Yg'x2")

PARTS iNCLUDED

ADDITIONAL PARTS

PART

TopCabinet

TOPCABINET TEMPLATE

I

INSTALLATION

INSTRUCTIONS

Template

RearWall

Template

installation

instructions

m

QUANTITY

1

wingnuts)(1A"x

ToggleBolts(and3,,) 4

Self-aligningMachine

Screws(W'-28x 3W')

/

J

You will find the installation hardware contained in

a packet with the unit. Check to make sure you have

all these parts.

NOTE: Some extra parts are included.

Self-aligningMachine

Screw(W'-28x 2%")

NylonGrommet

(formetalcabinets)

ExhaustAdaptor 1

Damper 1

Metal Screws 1black

(1/8"xY2") 2 bronze

PowerCordStrap 1

(plastic)

3

2(JVM1790only)

1(JVM1790only)

2

Separately

Packed

Grease

Filters

6

Page 7

Installation instructions

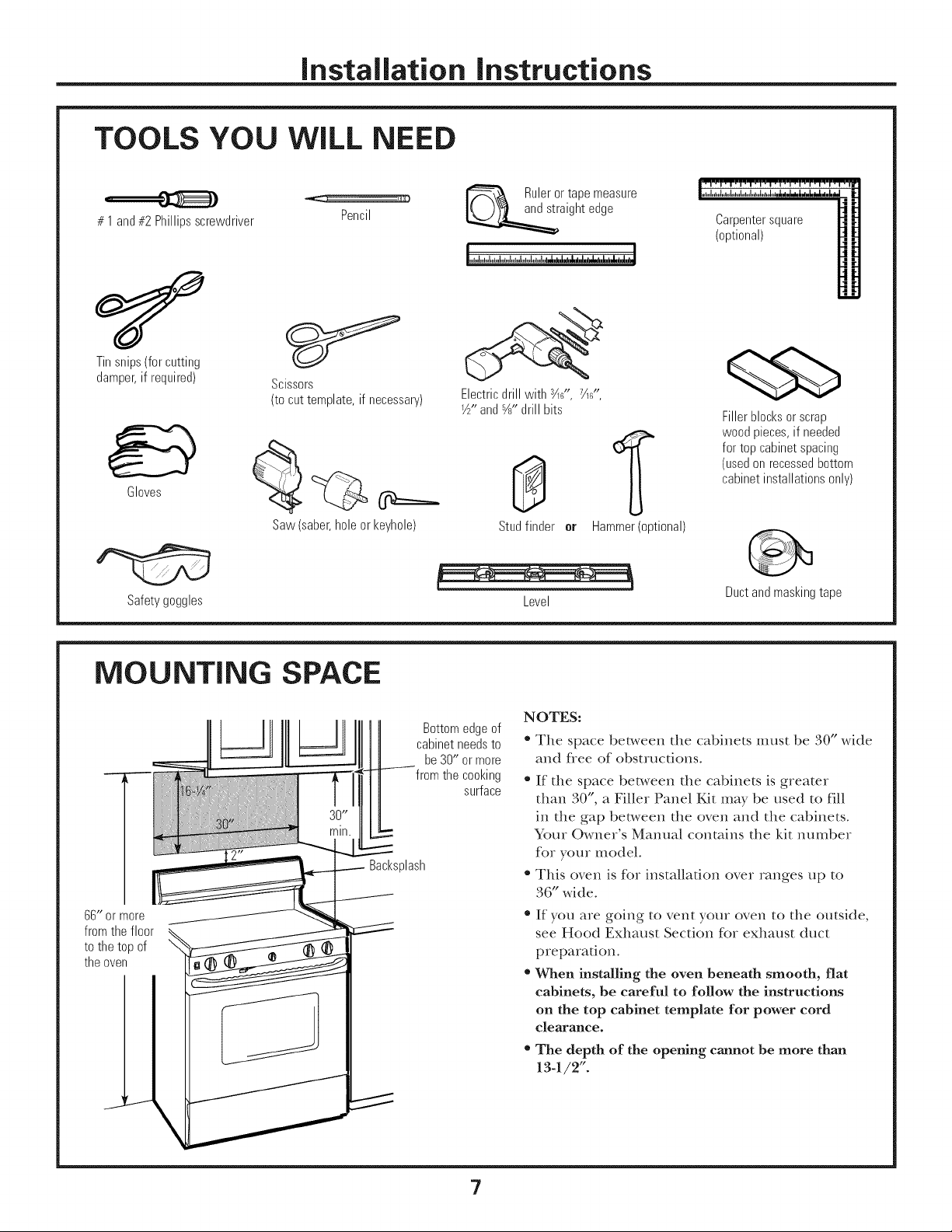

TOOLS YOU WiLL NEED

# 1 and#2 Phillipsscrewdriver

Tinsnips(forcutting

damper,if required)

Gloves

Scissors

(tocuttemplate,if necessary)

Pencil

Ruleror tapemeasure

aightedge

Electricdrill with _6 , X_ ,

_" and%" drill bits

3 ,1 7 /z

8

Carpentersquare

(optional)

Fillerblocksor scrap

woodpieces,if needed

fortop cabinetspacing

(usedonrecessedbottom

cabinetinstallationsonly)

Saw(saber,holeor keyhole)

Safety goggles

MOUNTING SPACE

66" or more

fromthe floor

tothe top of

theoven

Bottomedgeof

cabinetneedsto

fromthe cooking

Bacl<splash

be30" or more

surface

Studfinder or

Level

NOTES:

• The space bet_,veen the cabinets must be , u wide

and f}ee of obstructions.

• If the space between the cabinets is g;eate;

than 30", a Filler Panel Kit may be used to fill

in the gap belween the oven and the cabinets.

Your Owner's Manual contains the kit numbe;

for your model.

• This oven is fbr installation over ranges up to

36" wide.

• If you are going to vent your oven to the outside,

see Hood Exhaust Section for exhaust duct

preparation.

• When installing the oven beneath smooth, fiat

cabinets, be careful to follow the instructions

on the top cabinet template for power cord

clearance.

• The depth of the opening cannot be more than

13-1/2".

Hammer(optional)

Duct and masking tape

\

7

Page 8

Installation instructions

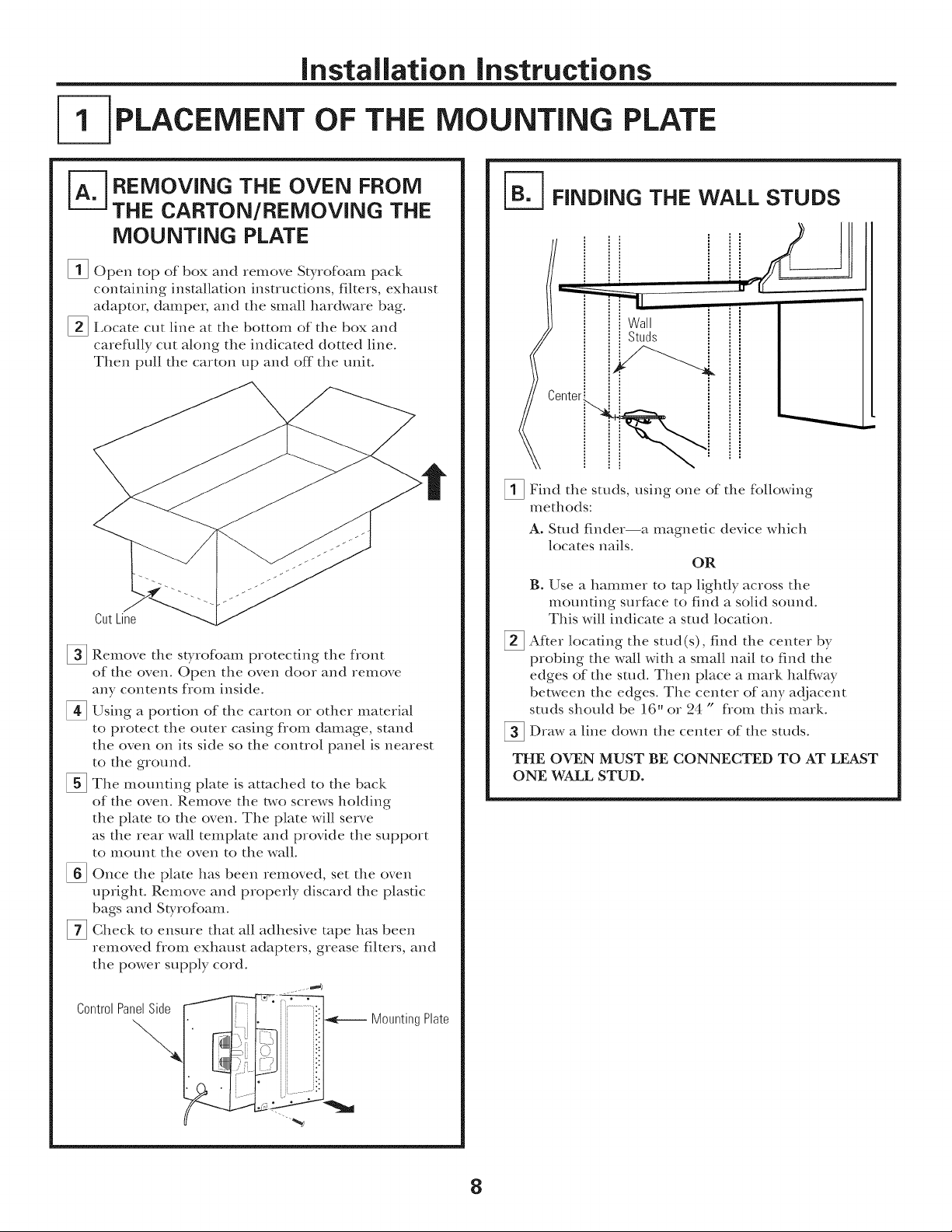

[- PLACEMENT OF THE MOUNTING PLATE

A--71 EMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

[] Open top of box and remove Styrofoam pack

containing installation instructions, filters, exhaust

adaptor, damper, and the small hardware bag.

[]Locate cut line at the bottom of the box and

carefully cut along the indicated dotted line.

Then pull the carton up and off the unit.

[]Remove the the front

of the oven. Open the oven door and remove

any contents f}om inside.

[_ Using a portion of the carton or other material

to protect the outer casing flom damage, stand

the oven on its side so the control panel is nearest

to the ground.

]The mounting plate is attached to the back

of the oven. Remove the two screws holding

the plate to the oven. The plate will serve

as the rear wall template and provide the support

to mount the oven to the wall.

]Once the plate has been removed, set the oven

upright. Remove and properly discard the plastic

bags and Styrofbam.

[_ Check that all adhesive has been

removed flom exhaust adapters, grease filters, and

the power supply cord.

St'_7I'O f}jaill protecting

to enstlie

tape

IB,---1FINDING THE WALL STUDS

l i i

Wall

Studs

i

Centeri_i

[_ Find the studs, using one of the fbllowing

methods:

A. Stud finder--a magnetic device which

locates nails.

OR

g. Use a hammer to mp lighdy across the

mounting surf_ce to find a solid sound.

This will indicate a stud location.

[_ After locating the stud(s), find the center by

probing the wall with a small nail to find the

edges of the stud. Then place a mark halfk,vW

between the edges. The center of any adjacent

studs should be 16" or 24 " f]om this mark.

[_ Draw line down the center of the studs.

THE OVEN MUST BE CONNECTED TO AT LEAST

ONE WALL STUD.

a

ControlPanelSide "" [ ................".

-- MountingPlate

8

Page 9

Installation instructions

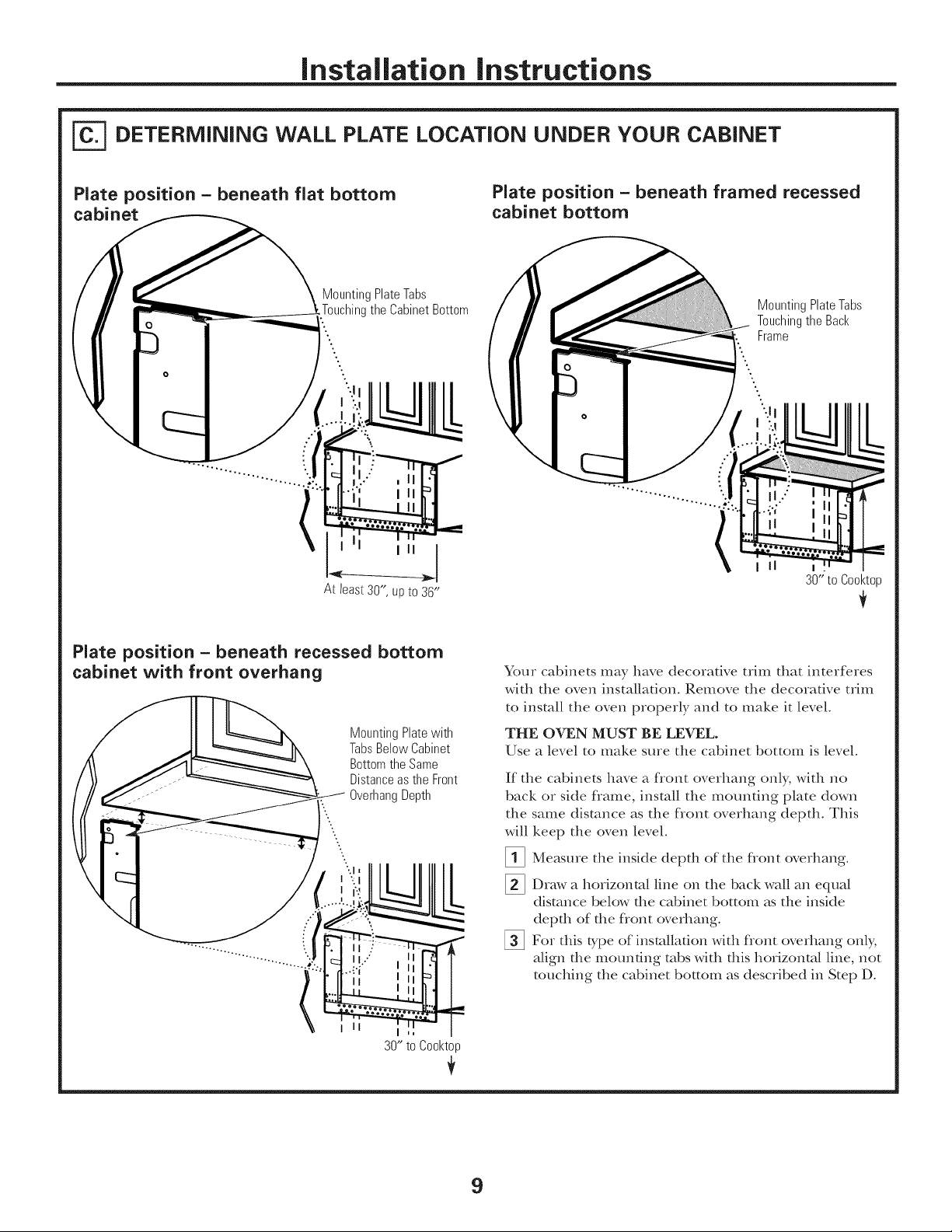

DETERMiNiNG WALL PLATE LOCATION UNDER YOUR CABINET

Plate position - beneath flat bottom

cabinet

MountingPlateTabs

ig the CabinetBottom

':o

o,

Plate position - beneath framed recessed

cabinet bottom

MountingPlateTabs

Touchingthe Back

Frame

II1

30"to Cool<top

Plate position - beneath recessed bottom

cabinet with front overhang

MountingPlatewith

TabsBelowCabinet

BottomtheSame

Distanceasthe Front

OverhangDepth

"-..

I II

30" to Cool<top

L

Your cabinets may have decorative trim that interferes

with the oven installation. Remove the decorative trhn

to install the oven properly and to make it level.

THE OVEN MUST BE LEVEL.

Use a level to make sure the cabinet bottom is level.

If the cabinets have a front overhang only, with no

back or side fiame, install the mounting plate down

the same distance as the front overhang depth. This

will

keep the oven level.

Measme the inside depth of the flont overhang.

%

Draw a horizontal line on the back wall an equal

distance below the cabinet bottom as the inside

depth of the fiont overhang.

%

For this t),pe of installation with fiont overhang only;

align the mounting robs with this horizontal line, not

touching the cabinet bottom as described in Step D.

9

Page 10

Installation instructions

ALiGNiNG THE WALL PLATE

HoleA

HoleD

0 0 0 0 0 0 0 0 0 0 0 0 0

0 010 0 0 0 0 0 0 0

CAUTION: Wear gloves

to avoid cutdng fingers on

sharp edges.

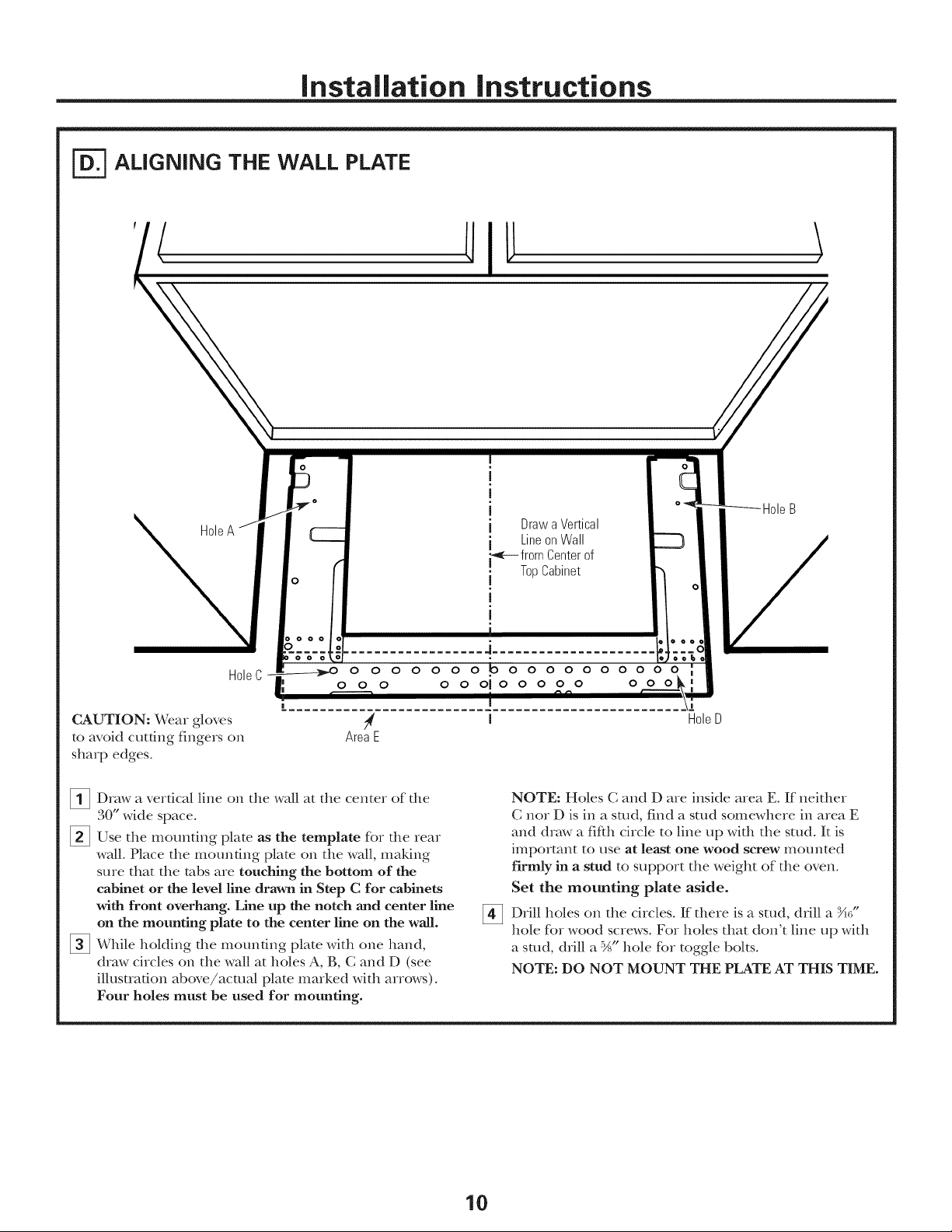

[]Draw a vertical line on the wall at the center of die

30" wide space.

[_] Use the mounting plato as the template for the rear

wall. Place the mounting plato on the wall, maMng

sure that the robs are touching the bottom of the

cabinet or the level line drawn in Step C for cabinets

with front overhang. Line up the notch and center line

on the mounting plate to the center line on the wall.

[] While holding the mounting plate with one hand,

draw circles on the wall at holes A, B, C and D (see

illustration above/actual plate marked with arrows).

Four holes must be used for mounting.

0 0 0 b

0 0

I

I

I

I

I DrawaVertical

i_ LineonWall

from Centerof

TopCabinet

I

I

I

I

0

j

I nn

I

NOTE: Holes C and D are inside area E. If neither

C nor D is in a stud, find a stud somewhere in area E

and draw a fifth circle to line up with the stud. It is

important to use at least one wood screw mounted

firmly in a stud to support the weight of the oven.

Set the mounting plate aside.

Drill holes on the circles. If there is a stud, drill a NJ'

hole for wood screws. For holes that don't line up with

a stud, drill a %" hole for toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

HoleD

10

Page 11

Installation instructions

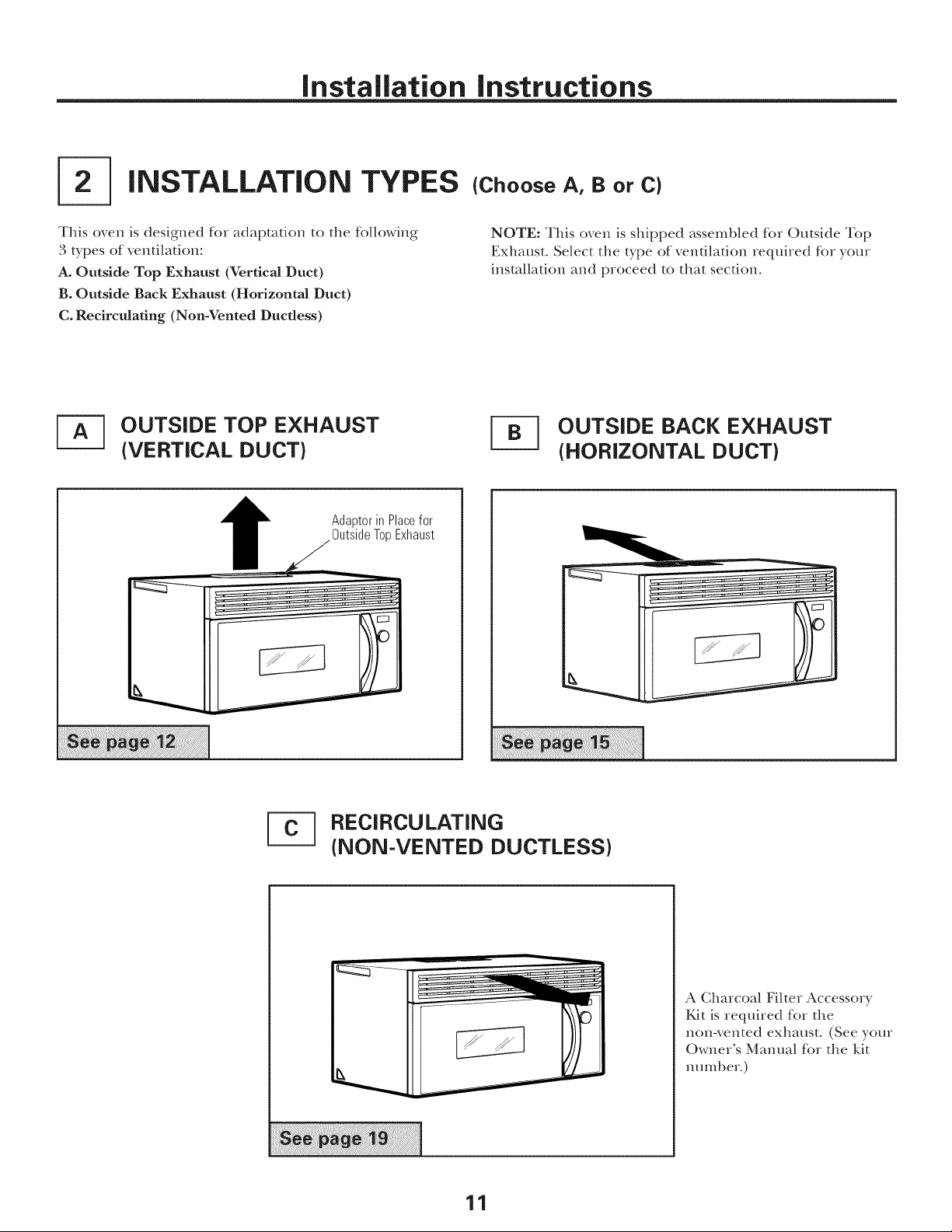

INSTALLATION TYPES

This oven is designed for adaptation to the following

3 types of ventilation:

A. Outside Top Exhaust (Vertical Duct)

B. Outside Back Exhaust (Horizontal Duct)

Co Recirculating (Non-Vented Ductless)

OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

Adapterin Placefor

OutsideTopExhaust

/

(Choose A, B or C}

NOTE: This oven is shipped assembled for Outside Top

Exhaust° Select the type of ventilation required for your

installation and proceed to that section.

OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

RECIRCULATING

{NON-VENTED DUCTLESSi

11

A Charcoal Filter Accessory

Kit is required fin the

non-vented exhaust. (See your

Owner's Manual for the kit

number.)

Page 12

Installation instructions

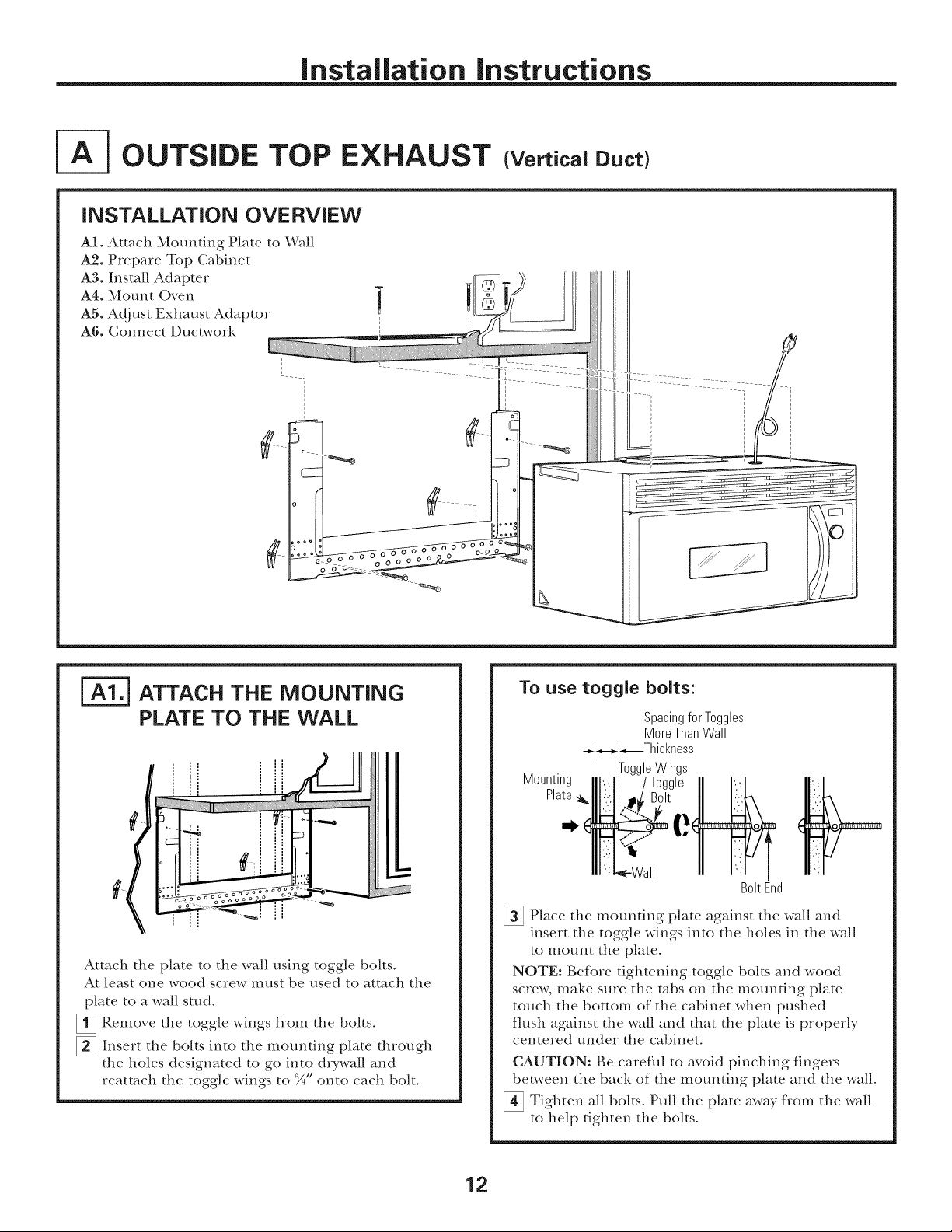

OUTSIDE TOP EXHAUST (VerticalDuctl

iNSTALLATiON OVERVIEW

A1. Attach Mounting Plate to Wall

A2. Prepare Top Cabinet

A3o Install Adapter

A4. Mount Oven

AS. Adjust Exhaust Adaptor

A6. Connect Ductwork

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to tile wall using toggle bolts.

At least one wood screw must be used to attach tile

plate to a wall stud.

_ Remove tile toggle wings flom tile bolts.

_ Insert tile bolts into the mounting plate through

tile holes designated to go into drywall and

reatmch the toggle wings to ¾" onto each bolt.

To use toggle bolts:

SpacingforToggles

MoreThanWall

+l_.!.,,_Th icl<ness

Mounting

Plate

_ Place the mounting plate against tile wall and

insert tile toggle wings into the holes in the wall

tO IIIOtlnt the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the robs on the mounting plate

touch the bottom of the cabinet when pushed

flush against tile wall and that tile plate is properly

centered under tile cabinet.

CAUTION: Be careful to avoid pinching fingers

between tile back of tile mounting plate and the wall.

_ Tighten all bolts. Pull the plate away from tile wall

to help tighten tile bolts.

Wings

BoltEnd

12

Page 13

Installation instructions

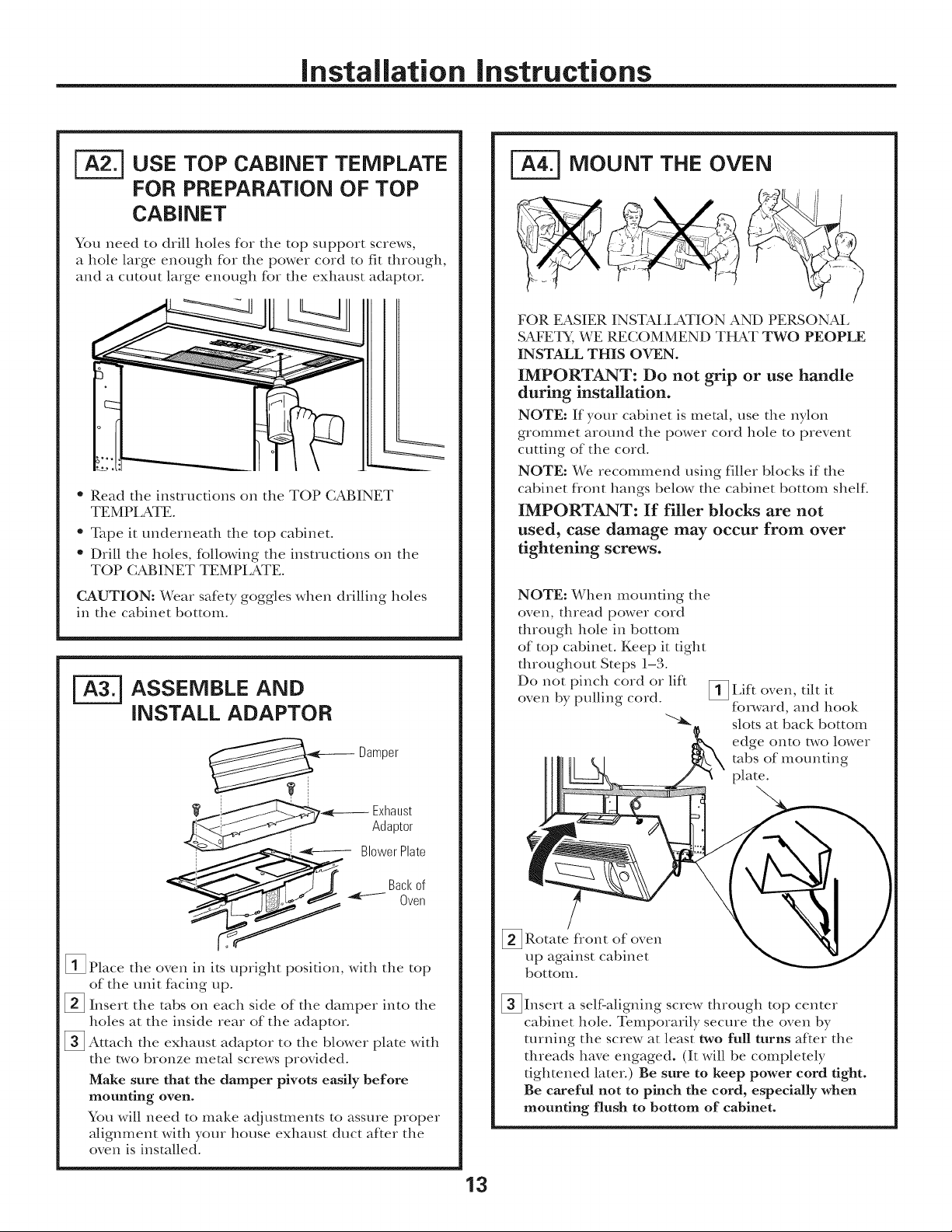

[-_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws,

a hole large enough for the power cord to fit through,

and a CUtOUt large enough for tile exhaust adaptor.

• Read the instructions on tile TOP CABINET

TEMPI ATE.

• Tape it underneath the top cabinet.

• Drill the holes, tbllowing the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling boles

in the cabinet bottom.

ASSEMBLE AND

iNSTALL ADAPTOR

Damper

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around tlle power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet f?ont bangs below tile cabinet bottom shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting tile

oven, thread power cord

through hole in bottom

of top cabinet. Keep it fight

throughout Steps 1-3.

Do not pinch cord or lift

oven by pulling cord.

_Lift tilt itoven,

forward, and hook

slots at back bottom

edge onto two lower

robs of mounting

plate.

-- Exhaust

Adaptor

_,_2_ BlowerPlate

-I

[]Place tile oven in its upright position, with the top

of the unit fi_cing up.

[]Insert tile tabs on each side of the damper into tile

boles at tile inside rear of tile adaptor.

_ Attach the exhaust adaptor to the blower plate with

tile two bronze metal screws provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make adj usunents to assure proper

alignment with your house exhaust duct af_er the

oven is installed.

[] Rotate flont of

up against cabinet

bottom.

_Insert a self:aligning screw through top center

cabinet hole. Temporarily secure tlle oven by

turning the screw at least two full turns after the

threads have engaged. (It will be completely

tightened later.) Be sure to keep power cord tight.

Be careful not to pinch the cord, especially when

mounting flush to bottom of cabinet.

oven

13

Page 14

Installation instructions

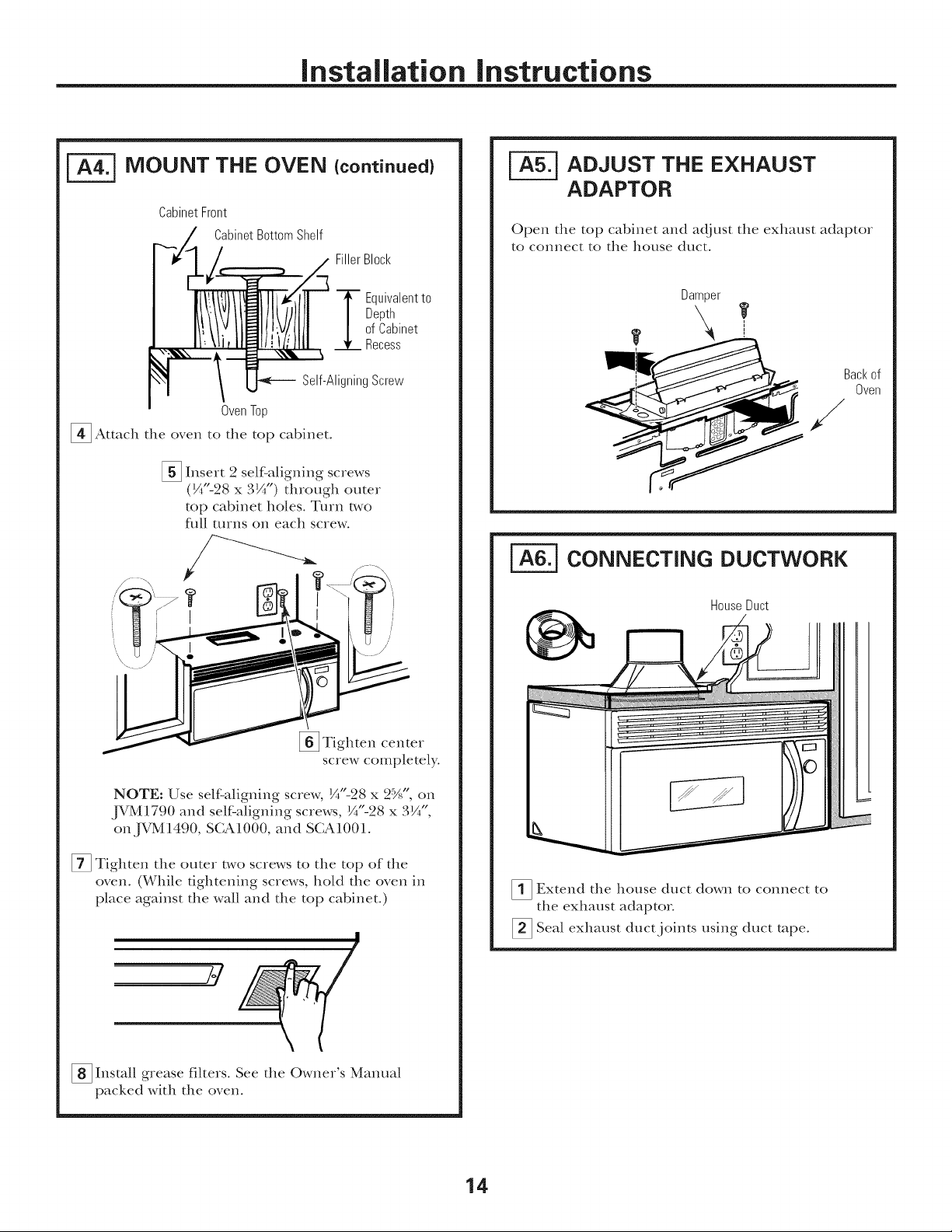

_] MOUNT THE OVEN {continuedl

Cabinet Front

Cabinet Bottom Shelf

Filler Block

Depth

ofCabinet

i quivalentto

Recess

Self-AligningScrew

Oven Top

[]Attach the oven to the top cabinet°

Insert 2 self aligning screws

(¼"-28 x . ¼ ) through outer

top cabinet holes. Turn t_,vo

full turns on each screw.

,_l pt

t

I

/

L===========_

ADJUST THE EXHAUST

ADAPTOR

Open the top cabinet and adjust the exhaust adaptor

to connect to the house duct.

Damper

CONNECTING DUCTWORK

HouseDuct

[]Tighten center

screw completely.

NOTE: Use self:aligning screw, ¼"-28 x 2_ , on

t ,_ l/'",_qVl1790 and self aligning screws, ¼"-28 x, y4 ,

on J\qV/1490, SCA1000, and SCA1001.

[] Tighten the outer la,vo screws to the top of the

oven. (While tightening screws, hold the oven in

place against the wall and the top cabinet.)

c5 rz

/o/

[] Install grease filters. See the Owner's Manual

packed with the oven.

[]Extend the house duct down to connect to

the exhaust adaptor

[] Seal exhaust duct joints using duct rope.

14

Page 15

installation instructions

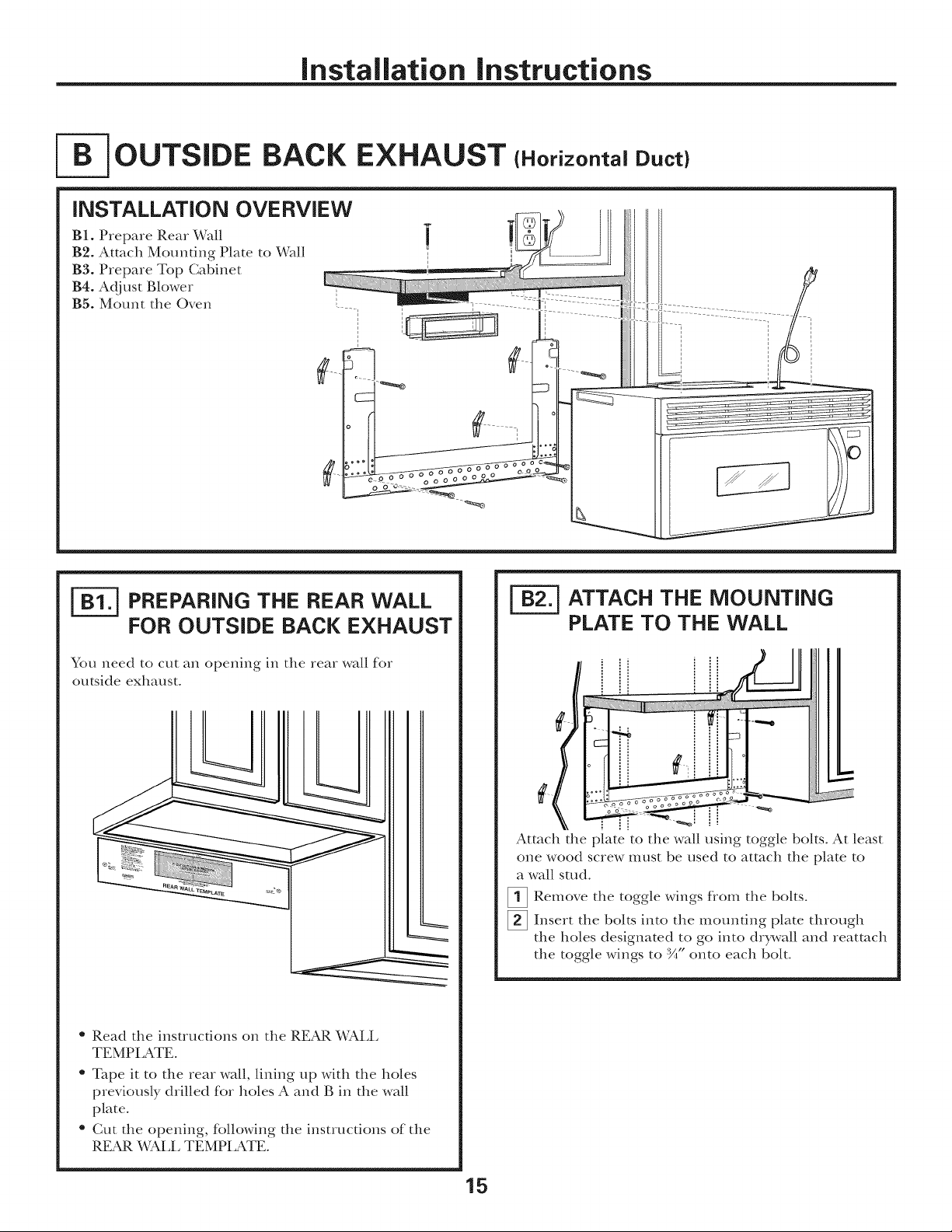

OUTSIDE BACK EXHAUST IHorkontalDuctl

iNSTALLATION OVERVIEW

B1. Prepare Rear Wall

B2. Attach Mounting Plate to Wall

B3. Prepare Top Cabinet

B4. Adjust Blower

BS. Mount the Oven

_=_ PREPARING THE REAR WALL

llaaaaaaaaaai=

FOR OUTSIDE BACK EXHAUST

You need to cut an opening in the rear wall for

outside exhaust.

* Read the instructions on the REAR WALL

TEMPI ATE.

. Tape it to the rear wall, lining up with the holes

previously drilled fbr holes A and B in the wall

plate.

. Cut the opening, following the instructions of the

REAR WALL TEMPLATE.

_-] ATTACH THE MOUNTING

I_==========,_

PLATE TO THE WALL

i

, i

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to

a wall stud.

_ Remove the toggle wings flom the bolts.

_ Insert the bolts into the mounting plate through

the holes designated to go into drywall and reatmch

the toggle wings to ¾" onto each bolt.

15

Page 16

Installation instructions

To use toggle bolts:

SpacingforTogglesMore

-*@-@,_ ThanWall Thickness

IVl " IToggleWings

ountmg •

" '."i Toggle .,:

Platedllii':l, }/Bolt ]l I;':.ilk

III : I_-Wall II I:1 [

[]Place the mounting plate against the wall and

insert the toggle wings into the boles in the wall

to mount the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed flush

against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careflfl to avoid pinching fingers

between the back of the moundng plate and the wall.

[]Tighten all bolts. Pull the plate away from the wall

to help dghten the bolts.

BoltEnd

_-_ ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

_ Remove the three that hold the blower

plate to the oven. Slide blower plate flom under

its retaining flange. Remove and save the screw

that holds blower motor to oven.

Retaining _:_:_..._

FIange-..` ._...._.__-,____ BlowerPlate

__ e___BlowerMotor

_-yy Screw

_ Careflflly the blower unit. The wirespull

will extend far enough to allow you to adjust

the blower unit.

EndA

screws

()lit

EndB

_-_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill boles for the top support screws and

a hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPI ATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safe b, goggles when drilling boles

in the cabinet bottom.

[Rotate blower unit counterclockwise 180 °.

BeforeRotation

Oven

_ Gently the wires flom the

Reroute the wires through grooves on other side

of the blower unit.

WiresRoutedThroughRightSide Wires RoutedThroughLeftSide

reInove

BeforeRerouting After Rerouting

After Rotation

Oven

grooves.

16

Page 17

Installation instructions

]Roll the blower unit 90 ° so that fan blade

openings are facing out the back of the oven.

BeforeRolling

Backof

Oven

Locate the t_,vo"knockout" plates, on the rear

%

oven panel, near the top of the oven.

Using un snips, carefhlly cut tile web area f}om

the two boles side-by-side (that secure tile

knockouts to tile oven). Cut all fore webs on both

rear knockouts; this will allow the vendlauon fan

airflow to exhaust out the rear of tile oven.

CAUTION: Be sure to trim the sharp edges from

the openings after removing the knockout plates.

Oven Rear Panel

Snipall 4webs

oneachknockout

panelandremove

themetalknockouts

[] Replace the blower plate in the same position

as befbre with the screws.

BlowerPlateScrews

g g_/ Blower Plate

•i<-- / BackofOven

_ Insert tile tabs each side of tile intodamper

the boles at the inside rear of the adapton

_ Attach tile exhaust adaptor to the _ear of the

oven by sliding it into the guides at tile top

center of tile back of tile oven.

ExhaustAdaptor

on

l

-_-----__Exhaust

Adaptor

Damper

sideup)

forrearairflow.

[]Place tile blower unit back into the opening.

EndA

CAUTION: Do not pull or stretch the blower

unit wiring. Make sure the wires are not pinched.

NOTE: The blower unit exhaust openings should

match exhaust openings on rear of oven.

Slideexhaust

adaptorinto

guideson

ovenrear.

o

Push in securely until it is in the lower locking

tabs. Take care to assure tile damper binge is

installed so that it is at tile top and that tile

damper swings f_eel>

BackofOven

Guides

_ Secu,e the exhaust adaptoI to tile oven with the

two bronze metal screws provided.

17

Page 18

Installation instructions

_=_ MOUNT THE OVEN

Cabinet Front

Cabinet Bottom Shelf

Filler Block

i quivalent

to Depth

ofCabinet

Recess

FOR EASIER INSTALLATION AND PERSONAL

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet fiont bangs below the cabinet bottom shelfi

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting

the oven, thread power

cord through hole in

bottom of top cabinet.

Keep it tight throughout

Steps 1-3. Do not pinch

cord or lift oven by

pulling cord.

[]Lift oven, tilt it

forward, and hook

slots at back bottom

edge onto two lower

robs of mounting plate.

Self-AligningScrew

0venTop

_ Attach the oven to the top cabinet.

Insert 2 self'aligning screws

(¼"-28 x , ¼ ) through outer

,_1 pt

top cabinet boles. Turn two

full ttlrns on each screw.

g

I

_ Tighten center

screw completely.

NOTE: Use self'aligning screw, ¼"-28 x 2_ , on

JVM1790 and self'aligning screws, ¼"-28 x, y4 ,

on ,_/M 1490, SCA1000, and SCA1001.

c 5 ii

,_IX pt

[]Rotate flont of oven up

against cabinet bottom.

[]Insert a self'aligning screw through top center

cabinet hole. Temporarily secure the oven by

turning the screw at least two full turns after the

threads have engaged. (It will be completely

tightened later) Be sure to keep power cord tight.

Be careful not to pinch the cord, especially when

mounting flush to bottom of cabinet.

[] Tighten the outer ta,vo screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

_ Install grease filters. See the Owner's Manual

packed with the oven.

18

Page 19

Installation instructions

RECIRCULATING

iNSTALLATiON OVERVIEW

C1. Attach Mounting Plate to Wall

C2. Prepare Top Cabinet

C3. A(0 ust Blower

C4. Mount the Oven

C5. Install Charcoal Filter (not supplied)

ATTACH THE MOUNTING

PLATE TO THE WALL

(Non-Vented Ductless)

_ Place the mounting plate against the wall and

insert the toggle wings into tile boles in tile wall

to I'tlOllllt the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the robs on the mounting plate

touch the bottom of the cabinet when pushed flush

against tile wall and that tile plate is properly

centered under the cabinet.

CAUTION: Be careflfl to avoid pinching fingers

between the back of tile mounting plate and tile wall.

_ Tighten all bolts. Pull the plate away from tile wall

to help tighten tile bolts.

Attach tile plate to the wall using toggle bolts. At

least one wood screw must be used to attach tile

plate to a wall stud.

[]Remove tile toggle wings f_om the bolts.

[]Insert the bolts into tile mounting plate through

the holes designated to go into drywall and

reatmch the toggle wings to ¾" onto each bolt.

To use toggle bolts:

SpacingforToggles

MoreThanWall

-_l_i_--Thicl<ness

Mounting

Plate

Wings

BoltEnd

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill boles for the top support screws and

a hole large enough for the power cord to fit through.

* Read the instructions on the TOP CABINET

TEMPI ATE.

* Tape it underneath the top cabinet.

o Drill the boles, fbllowing the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safeb_ goggles when drilling boles

in the cabinet bottom.

19

Page 20

Installation instructions

ADAPTING BLOWER

FOR RECIRCULATION

NOTE: The exhaust adaptor with damper is not

needed for recirculating models. You may want to

save them for possible future use.

[]Remove and save screws that hold blower plate to

the oven°

_'; _ _ SlowerPlateScrews

[]Slide the blower from under itsplate retaining

flange and lift it off. Remove and save screw that

holds the blower motor to oven°

Retaining __

[] Careflflly pull out the blower unit. The wires

will extend far enough to allow you to adjust the

blower unit.

[]Roll the blower trait 90 ° so that fan blade openings

are fi_cing toward the flont of the oven.

"-'_e _ BlowerMotor

[ ;_ Screw

R011

ower te

NOTE: Make sure wires remain routed in the

grooves of the motor flame.

20

Page 21

Installation instructions

ADAPTING BLOWER FOR

RECIRCULATION (continued)

_ Place the blower unit back into the opening.

CAUTION: Do not pull or stretch the blower unit

wiring. Make sure the wires are not pinched.

J

[]Secure blower unit to oven with the screw

removed in Step 2. Insert the screw in bottom

right screw hole on the back of the oven.

[]Replace blower plate with the screws removed in

Step 1.

_---- SlowerPlateScrews

BackofOven

-----------4

_o,55:___ _qq[:_-Blower Motor

I _,r Screw

MOUNT THE OVEN

NOTE: When mounting

the oven, thread power

cord through hole in

bottom of top cabinet.

Keep it tight throughout

Steps 1-3. Do not pinch

cord or lit* oven by

pulling cord.

_Liff oven, tilt it

forward, and hook

slots at back bottom

edge onto two lower

tabs of mounting plate.

/

_Romte front of oven

up against cabinet

bottom.

_Insert a self'aligning screw through top center

cabinet hole. Temporarily secure the oven by

turning the screw at least two full turns after the

threads have engaged. (It will be completely

tightened later.) Be sure to keep power cord tight.

Be careful not to pinch the cord, especially when

mounting flush to bottom of cabinet.

CabinetFront

CabinetBottomShelf

FillerBlock

FOR EASIER INSTALLATION AND PERSONAL

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet flont hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used,

case damage may occur from over tightening

screws.

Equivalentto Depth

of CabinetRecess

Self-AligningScrew

Oven Top

_Attach the oven to the top cabinet.

21

Page 22

Installation instructions

MOUNT THE OVEN

{continuedl

Insert 2 self'aligning screws

(¼"-28 x, ¼ ) through outer

top cabinet boles. Turn two

full turns on each screw.

NOTE: Use self:aligning screw, ¼"-28 x 2%", on

JVM1790 and self:aligning screws, ¼"-28 x , '/4 ,

on ._/M 1490, SCA1000, and SCA1001.

[] Tighten the outer two screws to the top of the

oven. (While tightening screws, hokt the oven

in place against the wall and the top cabinet.)

,_1 ,t

screw completely.

_K 't

iNSTALLiNG THE

CHARCOAL FILTER

[] Remove 2 screws on top of oven, j ust above the

grille panel, using a Phillips screwdriver. Remove

one screw on the leR side.

[]Open the door.

[] Remove the grille.

screws

Scre_ -

[]Insert the filter into the sho\,vn,

maneuvering it behind the plastic grille tmtil it fits

squarely into place. It will rest at an angle behind

the plastic grille on two side support robs and in

fiont of the right rear rob. When properly

installed, the wire mesh of the filter should be

visible fiom the fiont.

oven as

[ Install grease filters. See the Owner's Manual

packed with the oven.

,/

[]Replace the grille and the 2 top screws.

Close the door and replace left side screw.

Insertmesh-sidedown

22

Page 23

Installation instructions

BEFORE YOU USE YOUR OVEN

Make sure the oven has been installed

according to instructions.

_ Remove all packing material flom the oven.

= m

_7] Read the Owner's Manual.

[=_ KEEP INSTALLATION INSTRUCTIONS

FOR THE LOCAL INSPECTOR'S USE.

_V] Replace house fuse or mrn breaker back on.

Plug power cord into a dedicated 15 to 20 amp

electrical outlet.

F

t

F

.I

23

Page 24

49-405901 (07-08 JR)

P_inted in Ko_ea

24

Page 25

me

|

sta

ANTES DE ENIPEZAR

orno para

[]

encim8 e

colocar

aest a

JVM1490,JVM1790,SCA1000ySCA1001

Lea estas instrucciones completa y cuidadosamente.

• IMPORTANTE - Gu_-_t__

instrucciones para el uso del inspector local.

• IMPORTANTE - c_,mp_,.,.

todos los c6digos y ordenanzas gubernamentales.

• Nota para el instalador - Asegfiresede dejar

esms instrucciones con el consumidor.

* Nora para el consumidor - Guarde esms

instrucciones pare flm_ra referencia.

* Nivel de destrezas - La insmlacidn de este aparato

requiere de destrezas bdsicas de mec_inica y electricidad.

* La instalacidn apropiada es responsabilidad

del insmlador.

* La falla del producto debido a una insmlacidn

inapropiada no est:i cubierm pot la garantia.

25

LEA CUIDADOSAMENTE.

GUARDE ESTAS INSTRUCCIONES.

Page 26

Instrucciones de instalaci6n

CONTENIDO

Informaci6n general

Instrucciones de seguridad importantes ................ 27

RequMtos el_ctricos .............................................. 27

Campana de escape .......................................... 28, 29

Dafios - Envio / Instalad6n .................................. 30

Partes incluidas ...................................................... 30

Herramientas que necesitarfi .................................. 31

Espado de montaje ................................................ 31

Guia de instalaci6n paso pot paso

C6mo colocar el plato de montaje .................... 32-34

C6mo remover el plato de mon@e ............ 32

Cdmo encontrar madera s61ida

en la pared .................................................. 32

C6mo determinar la localizaci6n

de las placas de la pared ............................ 33

[] Recirculacidn ........................................ 43-46

Cdmo adherir el plato de

mont_tje a la pared .............................. 43

Cdmo preparer el gabinete superior....43

Cdmo adaptar el calefactor

para la recirculacidn ...................... 44, 45

Cdmo monmr el homo .................. 45, 46

Cdmo insmlar el filtro de carbonilla....46

Antes de comenzar a usar su horno ...................... 47

C6mo alinear la placa de la pared .............. 34

Tipos de instalaci6n .......................................... 35-46

_ Escape superior .......................

C6mo adherir la placa de

mont:_je a la pared .............................. 36

Preparaci6n del gabinete superior ...... 37

Cdmo inspeccionar si la operacidn

del regulador de fifo es apropiada ...... 37

Cdmo montar el homo .................. 37, 38

Cdmo _jusmr el adapmdor de escape ..38

Cdmo conecmr la red de conductos .... 38

_] Escape posterior externo ......................

Cdmo preparar la pared posterior

pare el escape posterior exterior ........ 39

Cdmo adherir el plato de

mont:tje a la pared ........................ 39, 40

Cdmo preparar el gabinete superior....40

exterior. 36-38

39-42

Cdmo adaptar el calefactor para

el escape exterior posterior. ........... 40, 41

Cdmo montar el homo ........................ 42

26

Page 27

Instrucciones de instalacion

INSTRUCCIONES DE SEGURIDAD IIVIPORTANTES

Este producto requiere un tomacorriente el_ctrico

de tres paras conecmdo a fierra. E1 instalador debe

llevar a cabo tma inspeccidn de confinuidad a fierra

en la c_ia el_ctrica antes de comenzar la instalacidn

para asegurar que la c_ja tomacorriente estg conecmda

a tierra de manera apropiada. Si no lo est_i, o si el

tomacorriente no cumple con los requisitos

el_ctricos indicados (b_io la seccidn REQUISITOS

ELt_CTRICOS), se deber_i recurrir a un t_cnico

calificado pare corregir cualquier deficiencia.

i remueva el fusible de

w

PRECAUCI()N: En pos de la seguridad personal,

la superfide de montaje debe ser capaz de soportar

la carga del gabinete, ademfis del peso adicional

(de 63 a 85 fibras) de este producto, mAs las cargas

adicionales del horno de hasta 50 fibras o un peso total

entre ll3 y 135 fibras.

PRECAUCION: En pos de la seguridad personal,

este producto no puede ser instalado en sistemas de

gabinetes tales como los llamados "islas" o "peninsulas".

Este debe ser montado tanto a un gabinete superior

como a una pared.

NOTA: Para una instalacidn mAs filch yen pos de la

seguridad personal, se recomienda que dos personas

instalen este producto.

IMPORTANTE: POR FAVOR, LEA

CUIDADOSAMENTE. EN POS DE LA SEGURIDAD

PERSONAL, ESTE APARATO DEBE SER

CONECTADO A TIERRA APROPIADAMENTE PARA

EVITAR DESCARGAS SEVERAS O FATALES.

Asegdrese de

que existe una

conexidn a

tierra apropiada

antes del uso

Para seguridad personal,

la casa o abra el interruptor

de circuito antes de

eomenzar la instalaeidn

para evitar descargas

el_ctricas severas o fatales.

E1 cable el6ctrico de este

aparato estfi equlpado con

un enchufe de tres paras

(con conexidn a tierra),

lo cual requiere que el

mismo encaje con un

tomacorriente para tres

paras (con conexi6n a tierra)

de pared para minimizar

la posibilidad de

descargas el_ctricas.

Deberi hacer que un t_cnico calificado inspeccione el

tomacorriente de pared y el circulto para asegurarse de

que el tomaeorriente est_ conectado a tierra de manera

apropiada.

Donde nsted encuentre un tomacorriente esffmdar de

dos paras, es muy importante que haga que el mismo se

carnble por uno de tres paras apropiadamente coneetado

a fierra, instalado por un electridsta calificado.

BAJO NINGUNA CIRCUNSTANCIA NO CORTE,

DEFORME, O REMUEVA NINGUNA DE LAS PATAS

DEL CABLE ELt_CTRICO. NO LO USE CON UNA

EXTENSION ELI_CTRICAo

REQUISITOS

f

ELECTRICOS

La clasificacidn del prodt_cto es de 120 ratios CA

(AC), 60 hertz, 15 amperios, y 1.70 kilovafios. Este

prodt_cto debe esmr conectado a un circt_ito de

suministro del voltx_ie y fiecuencia apropiados. E1

mmafio del alambre debe conf_rmarse a los requisitos

del National Electric Code o al cddigo local en efecto

para este fndice de kilovafios° E1 cable eldctrico de

alimenmcidn y el interruptor deberfin llevarse a un

tomacorriente dnico conecmdo a tierra de 15 a

20 amperios. La c_ja del tomacorriente deberfi esmr

localizada en el gabinete encima del homo. La

c_ja del tomacorriente debe set instalada pot un

electricism calificado y debe confk_rmarse al National

Electrical Code o al cddigo local en efecto.

27

Page 28

Instrucciones de instalaci6n

CAMPANA DE ESCAPE

NOTA: Lea las Mguientes dos pfiginas solamente si planea ventilar el escape hacia el exterior.

Si pot el contrario planea recircular el aire de vuelta hada el sal6n, continfie en la pfigina 30.

ESCAPE SUPERIOR EXTERNO (EJEIViPLO SOLAIVIENTE)

La siguiente tabla describe un ejemplo de una posible

insta/aci6n de red de conductos.

LONGITUD NOMERO LONGITUD

PARTES DEL ONDUCTO

EOUIVALENTE × USADO = EOUIVALENTE

24pies x (1)

Conducto recto de 12 pies

(redondo de 6")

• . _

Adaptador de transici6n 5 pies x (1) = 5 pies

de rect_finguloa redondo_

12pies x (1)

LaIongitudde las partesde losconductosequivalentesest8basadaen pruebasrealesy reflejanlos

requisitosparaIograrunabuenaventilaciOnconcualquiercampanade escape.

Longitud total =

*IMPORTANTE: Si se usa un adapmdor de transicidn de rect_ingtflo a redondo, las es(

del regulador de tiros deber_n cormrse para que enc_jen, usando las tijeras de corte

movimiento libre del regulador de tiros.

ESCAPE POSTERIOR EXTERNO (EJEIVIPLO SOLAIVIENTE)

La siguiente tabla describe un ejemplo de una posible

insmlacidn de red de conductos.

LONGITUD N01VIERO

PARTES DEL CONDUCTO

EOUIVALi_NTE x USADO

24pies

12pies

41 pies

uinas del f_mdo

para permitir el

LONGiTUD

EOUIVALENTE

Tapadepared 40pies x (1)

Conductorectode3 pies

3 pies x (1)

40pies

3 pies

(rectangularde31A" x 10")

Codode90°

10pies x (2)

20pies

LaIongituddelas partesde losconductosequivalentesest8basadaenpruebasrealesy reflejan los

requisitosparaIograrunabuenaventilaciOnconcualquiercampanadeescape..

NOTA: Para el escape posterior, se debe tenet cuidado al alinear el escape entre los espacios de los postes de xiga de la pared,

o la pared deberfa set preparada en el momento de su construccidn dejando suficiente espacio entre los postes de xiga de la

pared para acomodar el escape.

28

Page 29

Instrucciones de instalaci6n

NOTA: Si usted necesita instldar conductos, tenga

pendiente que la longimd total del conducto rectangular

de 3¼" x 10" o el conducto redondo de 6" de di_metro

no debe sobrepasar 140 pies equivalentes.

La venfilacidn externa requiere un CONDUCTO DE

CAMPANA DE ESCAPE. Lea lo siguienm cuidadosamente.

NOTA: Es impormnm que la venfilacidn sea insta/ada

usando la mm mAs direcm y con la menor canfidad de codos

posible° Esto asegma la venfilacidn del escape y ayuda a

prevenir bloqueoso Tambi6n, cerddrese de que el regulador

de tiro pende libremente y nada bloquea los conductos.

Conexiones de escape:

i_ campana de escape ha sido diseflada para enc_iar con

un conducto rectangular de 3¼" x 10" est_inda_:

N un conducto redondo es necesafio, se debe usar un

adapmdor de transicidn de rectangular a redondoo

No use un conducto menor de 6" de difimetro.

LONGITUD NOMERO

PARTES DE CONDUCTO

&

Adaptadordetransici0n de

reckinguloa redondo_

EQUIVALENTE x USADO

5pies

Longitud maxima del conducto:

Para lograr un movimiento satisfi_ctorio del aire, la

longimd total del conducto rectangular de 3¼" x 10"

o el conducto redondo de 6" de di;imetro no debe

sobrepasar 140 pies equivalentes.

Los codos, transiciones, paredes y tapas

de techo, etc., presenmn resistencia adicional al

flt{io de aire y son equivalentes a una seccidn de

conducto recto el cual es m_is largo que su tamafio fl'sico

real Cuando calcule la longimd total del conducto,

agregue las longitudes equivalentes de todas las

transiciones y adaptadores, m_is la longimd de todas

las secciones de conducto recmso La tabla re;is adelante

muestra cdmo puede calcular la longimd aproximada

de Ia red de conductos usando pies aproximados de

longitudes equivalentes de algm_os conductos tfpicoso

LONGITUD

EQUIVALENTE

( )

pies

Tapadepared

(_ Codode90 °

Codo de 45° 5 pies x ( ) = pies

Codo de 90° 25 pies x ( ) = pies

Codo de 45° 5 pies x ( ) = pies

Tapa de techo 24 pies x ( ) = pies

Conducto recto de 6" redondo 1 pies x ( ) = pies

o rectangular de 3W' x 10"

40 pies

10pies

( )

( )

pies

pies

* IMPORTANTE: Si se usa tm adaptador de transici6n de

rect_ingulo a redondo, las esquinas del iondo del regulador

de tiros deber_in set cortadas para clue encaien, usando las

tijeras de corte, para permitir el movimient_ libre del

regulador de tiros.

29

Total red de conductos = pies

La longimd de las partes de conductos equivalentes est_ basada

en pruebas reales y refleian los requisitos para lograr tma bueml

ventilacidn con cualquier campana de escape.

Page 30

Instrucciones de instalaci6n

DAI OS - ENViO /

INSTALACION

• Si la unidad se dafia durante el envio, devuelva la

unidad al almac&l donde la adquiri6 para su

reparaci6n o reemplazo.

• Si el diente dafia la unidad, la reparaci6n o el

reemplazo es responsabilidad del cliente.

• Si el instalador dafia la unidad (si no es el cliente),

la reparaci6n o reemplazo se debe hacer pot

medio de un arreglo entre el cliente y el insmlador.

PARTES iNCLUIDAS

PAQUETE DE ELEMENTOS

PARTE CANTIDAD

(Y4"xT°rnill°2!')demadera 2

(ytuercasdemariposa)

Tornillosbasculantes 4

(Y4"x3")

Tornillosdem_iquina

autoalineables

(Yg'-28x 3Yg')

3

2(JVM1790SOlo

PARTES IRCLUIDAS

PARTES ADICIONALES

PART

Plantillapara

TOPCABINET TEMPLATE

INSrALLA;qON

INSTRUCTf0N$

el gabinete

superior

Plantillapara

lapared

)osterior

Instrucciones

de instalaciOn

Filtrosde

grasa

empacados

porseparado

m

CANTIDAD

1

m

2

Tornillosdem_iquina

autoalineables

(Yg'-28x 2%")

Arandelaaislantede

j 2

Usted encontrar_ los elementos de insmlacidn en

un paquete jtmto con la unidad. Inspeccione para

cerciorarse de que dene todas las partes.

NOTA" Se incluyen algunas partes adicionales.

nil@(paragabinetes

metNicos)

Adaptadordelescape

Reguladordetiro

Tornillosparametal 1negro

(Y¢'xW') 2 debronce

elOctrico(pl_istica)

Abrazaderadelcable 1

1(JVM1790SOlo

30

Page 31

Instrucciones de instalacion

HERRAMIENTAS QUE NECESITARA

Destornilladoresdeestrella

#1 y#2

Tijeras para cortar lat6n

(para cortar el regulador

de tiro, si es necesario)

Guantes

Gafasdeseguridad

L@iz

1-ijeras(paracortarla

plantilla,si esnecesario)

Sierra(desable,agujero,ode

ojode cerradura)

recta y cinta m6trica

Taladroel6ctricoconbrocasde

3 ,1 7 ,1

_, _ ,Wly_ '1

8

Detectorde

postesdeviga e un martillo (opcional)

I_ !

Nivel

Escuadra de

carpintero

(opcional)

Bloques de relleno o

pedazos de madera, si son

necesarios para rellenar el

gabinete (usades selamente

en la instalaci6n de

gabinetes apoyados)

Cintadeconductoso

cintaadhesivaprotectora

ESPAClO DE IVIONTAJE

Protectorpostenor

desalpicaduras

66'1omSs

desdeel

pisohasta

la parte

superiordel

home

Elextremedel

fondodel gabinete

necesitaestara

30'1e m_sa partir

de la superficiede

laestufa

NOTAS:

• E1 espacio entre los gabinetes debe set de 30"

de ancho y debe estar libre de obstrucciones.

• Si el espacio entre los gabinetes es mayor de

30", un "Fillet Panel Kit" podrfa sex necesario

para rellenar las brechas entre el horno y los

gabinetes. Su Manual del Propietario confiene

el nfimero de kit para su modelo.

• Este horno es para sex insmlado por encima de

estufas hasm 36" de ancho.

Si usted se dispone a venfilar su horno hacia el

extericm vex la Seccidn de Campana de Escape

pata la preparacidn del conducto de escape.

Cuando se instale el horno debajo de gabinetes

de rondos lisos y planos, tenga euidado de seguir

euidadosamente las instrueeiones en la plantilla

del gabinete superior para el espaeio de

toleranda del cable el6etrieo.

• La profundidad de la abertura no puede ser

superior a 13-1/2".

31

Page 32

Instrucciones de instalaci6n

-_ 61VIO QUITAR EL HORNO DE

LA CAJA / COiVlO QUITAR LA

PLACA DE MONTAJE

Abra la parte superior de ][acaja y quite elipaquete

de po][iesfireno que contiene ][asinstrucciones de

insm][acidn, filtros, adapmdor de sa][ida, regu][ador

de aire y ][abo][sa de piezas pequeflas.

Ubique ][a][fnea de corte en ][aparte inferior de

][ac_ja y con cuidado corte a ][olargo de ][alfnea

punteada indicada. Luego fire dell cartdn hacia

arriba y fuera de ][aunidad.

Linea de corte

Quite eli po][iestireno que protege el flente

dell homo. Abra ][a puerto dell homo y saque

][os contenidos.

_l'_ Uti][izando una porcidn del cartdn u otro material[

para proteger ][a carcasa extericm pare el homo

sobre su lado de modo que el pane][ de control[

se encuentre lo mils cerca del piso.

[] La p][aca de mont:_je se encuentra st{jeta a][a parte

tmsera dell homo. Quite los dos torni][][os que

sosfienen ][a p][aca all homo. La p][aca flmcionar_i

como ][a p][anfil][a de pared trasem y brindar_i

el soporte para monmr el homo a][a pared.

Una vez que se ha quimdo ][a p][aca, co][oque

eli homo en posicidn verOca][. Quite y descarte

adecuadamente ][as bo][sas de p][_isdco y po][iesdreno.

[] Asegfirese de quitar toda ][a cinta adhesiva

de ][os adaptadores de sa][ida, fi][tros de grasa

y eli cab][e de smninistro de energfa.

F_ C(SNIO ENCONTRAR LOS

POSTES DE VIGA EN LA PARED

i

Postesdeviga

i

enla pared

i

i

i

i

i

i

1

_ Encuentre

los m&odos siguientes:

A. Use un detector de postes--un dispositivo

magnifico que loca][iza c][avos.

B. Use un marfil][o para go][pear ][igeramente

a tray, s de ][a superficie de monti_je basra

encontrar un sonido sd][ido. Esto indicar_i que

hay un poste de riga en ese ][ugar.

Despu_s de ][oca][izar el poste o ][os postes de riga,

encuentre eli centro mediante eli an_i][isis de ][a pared

usando un c][avo pequefio para darse cuenta de

ddnde est_in los bordes dell poste. Luego co][oque

una marca en eli centro de ][os bordes. E1 centro

de cua][quier poste adyacente deber_i set entre

16" d 24" desde esm marca.

Trace una ][fnea hacia a]b_tjo indicando eli centro

dell poste.

EL HORNO DEBE CONECTARSE POR LO MENOS

A UN POSTE DE LA PARED.

][os posies, usando {lno de

O

Ladodelpanel

de control

. _i ii _ Placade montaje

\ ::

32

Page 33

Instrucciones de instalacion

C. COMO DETERMINAR LA LOCALIZACION DEL PLATO DE MONTAJE

DEBAJO DE SU GABINETE

Posicion del plato - debajo de gabinetes de

fondo piano

Lasorejillasdelplato de

montajetocanel fondo

delgabinete

,,,J

Por Io menos 30", hasta 36"

Posicion del plato - debajo de gabinetes de

fondo apoyado en un marco

Lasorejillasdelplato

demontajetocanel

marcoposterior

II1

30" hasta la estufa

Posicion del plato - debajo de gabinetes de

fondo apoyado con frente saliente

Platodemontajecon

orejillaspordebajo

delfondo delgabinete

ala mismadistancia

quela profundidad

delsaliente

II

30" hasta la estufa

Sus gabinetes podrfan tenet marcos de decoraci6n

que interfieran con la insmlaci6n del homo.

Remueva los marcos decorafivos para insmlar el homo

apropiadamente y para hacer que quede nivelado.

EL HORNO DEBE QUEDAR NIVELADO.

Use un nivel para cerciorarse de que el rondo del

gabinete estli nivelado.

Si los gabinetes tienen tm saliente flontal solamente,

sin marco posterior o lateral, insmle el plato de

mont_tje a la misma dismncia de la profimdidad

del saliente. Este mantendr_ el homo nivelado.

Mida la proflmdidad interna del flente del saliente.

%

Trace una lfnea horizontal en la pared posterior a

una distancia deb_jo del rondo del gabinete igua/

a la proflmdidad interna del flente saliente.

%

Para este fipo de insta/aci6n con salienm fionta[

sohmente, a/inee las orejillas de mont_je con la lfnea

horizontal, sin tocar el rondo del gabinem como se

describi6 en el Paso D.

33

Page 34

Instrucciones de instalaci6n

']C6MO ALINEAR EL PLATO DE MONTAJE SOBRE LA PARED

AgujeroA

Agujer0C

PRECAUCION: Use

guantes de protecciOn

para evimr cortaduras

en sus dedos con los

ex{reIIlos f]]osos.

[] Trace una lfnea vertical en la pared en el centro del

espacio de 30" de ancho.

Use el plato de mont_je como la plantilla para la pared

posterior Coloque el plato de mont_je en la pared,

cercior_ndose de que las orejillas se encuentran

toeando el rondo del gabinete o la linea mareada en

el Paso C para los gabinetes con salientes frontales.

Alinee la muesea y linea dd eentro en el plato de

montaje con la linea de eentro en la pared.

[] Mientras sosdene el plato de mont_{je con una mano,

uace cfrculos en la pared en los agt0eros A, B, C y D

(vex la ilustraci6n anterior / la placa real est:i marcada

con flechas). Deben usarse euatro agujeros para el

montaje.

0 0 0 0 0 0 .b o o o o o o o

o o o olo o o o o

I

I

I

I

I TRACEUNAL[NEA

" VERTICALENLA

iI_e_ PAREDA PARTIR

DELCENTRODEL

I GABINETESUPERIOR

I

I

I

O

er0B

j,

o o o

o o o

I nn

I

NOTA: Los agt{jeros C y D van en el interior del Area

E. Si ni el C ni el D est_in en un poste de riga,

encuentre un poste en a/gfin otto lugar en el _rea E y

marque un quinto cfrculo para alinearse con el poste.

Es impormnte usar pot lo menos un tornillo de madera

monmdo firmemente en un poste para apoyar el peso

del homo.

Aparte el plato de montaje.

Perfore agt{jeros en los cfrculos. Si hay un posm de

[]

riga, perfore un agt{jero de 3/16" pare los tornillos de

madera. Para los agt{jeros que no quedaron a/ineados

con el poste de riga, perR)re un agt{jero de 5/8" pare

los tornillos basculanms.

NOTA: TODAV[A NO MONTE EL PLATO.

!

AgujeroD

34

Page 35

Instrucciones de instalaci6n

_ TIPOS DE INSTALACION IEscoiaA,BoCI

Este homo estli disefiado para adaptarse a los siguientes

tres fipos de ventilaci6n:

A. Escape superior exterior (Conducto vertical)

B. Escape posterior exterior (Conducto horizontal)

C. Recirculaci6n (Sin conducto de ventilaci6n)

ESCAPE SUPERIOR EXTERIOR

(CONDUCTO VERTICAL}

lugar para el escape

El adaptador est_ en su

superior exterior

NOTA: Este homo es enviado ya ensamblado para un

escape superior exterior. Seleccione el tipo de ventilaci6n

requerido para su instalaci6n y proceda a ml secci6n.

ESCAPE POSTERIOR EXTERIOR

{CONDUCTO HORIZONTAL}

_-_C. RECIRCULACI()N {SIN

CONDUCTO DE VENTILACI()N}

35

Un Kit de accesorios de filtro

de carbonilla es necesario

para el sistema sin ventilacidn.

(Consulte su Manual del

Propietario para obtener

el nfimero del kit.)

Page 36

Instrucciones de instalacion

ESCAPE SUPERIOR EXTERIOR (conauctoverticall

PERSPECTIVA GENERAL DE

LA INSTALACION

A1. Como adherir el plato de

mont_je a la pared

A2. Prepare el gabinete superior

A3. Instale el adapmdor

A4. Monte el homo

AS. Aj uste el adapmdor

de escape

A6. Conecte el conducto

[==_ CI3MO ADHERIR LA PLACA

DE MONTAJE A LA PARED

Pegue el plato a la pared usando los tornillos

basculantes. Pot lo menos tm tornillo de madera debe

sex usado pare pegar el plato al poste de la pared.

Remueva las mariposas del basculante de los

tornillos.

Inserte los tornillos en el plato de mont_je a tray,s

de los agt{jeros diseflados para sex insertados en la

pared de mamposterfa seca y pegue otra vez las

mariposas de ¾" en cada tornillo.

Para usar los tornillos basculantes:

Espaciadoresparalos

basculantes mayores

--,-I-_-_!_,_queelanchodelapared

Platode

montaje

Coloque el plato de mont_je contra la pared e

inserte las alas de mariposa en los agt{jeros de la

pared para montar el plato.

NOTA" Antes de apremr los tornillos basculantes y los

tornillos de madera, cercidrese de que las or@llas en el

plato de monti_je toquen el rondo del gabinete cuando

son empt{jadas contra la pared y de que el plato est5

cenuado apropiadamente deb_jo del gabinete.

PRECAUCI6N: Tenga cuidado de evimr pellizcar sus

dedos entre la parte posterior del plato de mont:_je y

la pared.

Apriete todos los tornillos. Tire del plato en

direccidn opuesm a la pared para ayudar a apremr

los tornillos.

_lasdemariposa

.Pared

Extremodeltornillo

36

Page 37

Instrucciones de instalaci6n

USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA LA

PREPARACION DEL GABINETE

Deberfi perR_rar ag_{ieros pata los tornillos de

apoyo superiores, tm agt{iero suficientemente

grande para que el cable el_ctrico quepa, y un

recorte lo suficientemente grande como para

que el adapmdor de escape pueda sex introducido.

* i,ea las instrucciones sobre la PI,ANTII,I,A DEI,

(;ABINETE SUPERIOR.

* P4guelo deb_jo del gabinete superior:

* Taladre los agt_jeros, siguiendo las instrucciones en

la PI,ANTII,I,A DEI, (;ABINETE SUPERIOR.

PRECAUCION: Use gafi_s de seguridad cuando

perfore los agt{jeros en el rondo del gabinete.

ENSAlViBLAJE E INSTALACI()N

DEL ADAPTADOR

Reguladordetiro

C()iVIO MONTAR EL HORNO

PARA OBTENER UNA INSTAI,ACI6N MAS FACII,

Y EN POS DE I,A SEGURIDAD PERSONAl,, SE

RECOMIENDA QUE DOS PERSONAS INSTALEN

ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante la instalacidn.

NOT_&: Si su gabinete es de metal, use la arandela de

nildn ahededor del cable elSctrico pata evimr que el

IlliSIIIO sea cortado.

NOTA: Recomendamos el uso de bloques de relleno

si el fiente del gabinete cuelga por deb_io del

estante del Rmdo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrian ocurrir dafios por apretar

demasiado los tornillos.

NOTA: Cuando se encuentre

montando el homo, enrosque

el cable eldctrico a travds del

agt_iero en el tkmdo del gabinete

superior. Mant_ngalo

traxds de los Pasos del 1-3. No mchnelo hacm

pellizque el cable ni tire del

homo pot el cable.

tenso I exante el homo

adelante, y enganche

las rannras en el

extremo interior

posterior en dos

oreiillas int_riores del

plato de montaje.

de escape

__e--_-_ L Platodel

_____ _ calefactor

__ delhorno

[_ Coloque el horno en su posicldn vertical, con la

parte superior hacia arriba.

[_ Inserte las oreiillas en cada lado del regulador de tiro

en los ag_{ieros en el interior posterior del adapmdot:

[_ Pegue el adapmdor de escape al plato calefitctor con

los dos tornillos de bronce que le proporcionamos.

Cereidrese de que el regulador de tiro gira

fficilmente antes de montar el horno.

Deber_i hacer _iustes para asegurarse de que existe

alineacidn apropiada con el sistema de condttctos

de su casa despuSs de la insmlacidn del horno.

[ Parte

[_ (;ire el tkente del homo

contra el tondo del gabinete.

_Inserte tornillo de antoalineacidn del

ag/_iero central superior del gabinete. Asegnre el

dos vneltas completas despnds de que las roscas hayan

agarrado. (i,uego qnedarfin totahnente apretadas).

Tenga cnidado de no pellizcar el cable, especiMmente

cuando se monte al nivel del fondo del gabinete.

/ln

homo temporahnente girando el tornillo pot lo menos

Cercidrese de mantener el cable el_ctrico estirado.

37

tI'_ es

Page 38

Instrucciones de instalaci6n

C0MO MORTAR EL BORNO

(continuaci6n)

Frente del gabinete

Estante del fondo del gabinete

Bloque de relleno

T quivalente a

Tornillo autoalineable

Parte superior del homo

_ Pegue el horno a la parte superior del gabinete.

_ Inserte (K_"-2S x 3V/')

2 tornillos

autoalineables a trav_s de los agujeros

exteriores superiores del homo. Gire

dos wleltas completas en cada tornillo.

COMO AJUSTAR EL

ADAPTADOR DE ESCAPE

Abra el gabinete superior y _juste el adapmdor de

escape para conecmrlo al conducto de ]a casa.

Regulador de tiro

la profundidad

del retroceso

del gabinete

° del horno

__ Parteposterior

F_ COMO CONECTAR

EL CONDUCTO

Conducto de la casa

I

]Apriete el tornillo del

centro coil/pletall/ente.

NOTA: Use Tornillos autoalineables (W'-28 x 2%")

en JVM 179(} y Tornillos autoalineables (1A"-28 x 3_")

en IVM] 490 SCA1000, y SCA1001.

[] Apriete los dos tornillos exteriores hacia la parte

de arriba del homo. (Mientras aprieta los tornillos,

mantenga el homo en su lugar contra la pared y el

gabinete superior.)

Extienda el conducto de la casa hacia

ab_jo

conecmrlo con el adapmdor de escape.

_2_ Selle lasj untas del conducto de escape usando

cinta adhesiva de conductos.

para

_ Instale los filtros de Ver el Manual del Propietariograsa.

que xiene con el homo.

38

Page 39

Instrucciones de instalacion

ESCAPE POSTERIOR EXTERNO ICo.d.ctohorkomall

PERSPECTIVA GENERAL DE

LA INSTALACION

B1. Prepare la pared posterior

B2. Pegue el plato de mont_ie

a la pared

}{3. Prepare el gabinete superior _.,

g4. A)uste el calefactor

BS. Monte el homo

_-_ C(31ViO PREPARAR LA PARED

POSTERIOR PARA EL ESCAPE

POSTERIOR

Necesita cortar una abertura en la pared posterior

para el escape exterior.

• Lea las instmcciones en la PLANTILLA PARA IA

PARED POSTERIOR.

• P_guela con cinm adhesiva a la pared postericm

aline_indola con los ag_jeros previamenm perfbmdos

para los ag_{jeros A y Ben el plato de la pared.

• Corte la apermra, siguiendo las instrucciones de la

PIANTILLA PARA LA PARED POSTERIOR.

| COIVIO ADHERIR EL PLATO DE

IVIONTAJE A LA PARED

[

. i

o_ _._1,..O

Pegue el plato a la pared usando los tornillos basculantes.

Pot lo menos un tornillo de madera debe set usado pare

pegar el plato a[ posm de riga de la pared°

Remueva las mariposas de los tornillos.

Inserte los tornillos en el plato de mont_je a tray&

de los agt{ieros disefiados para colocarse contra la

pared de mamposterfa seca y pegue otra vez las

mariposas de ¾" a cada tornillo.

39

Page 40

Instrucciones de instalaci6n

Para usar los tornillos basculantes:

Espaciadoresparalosbasculantes

-@*-@,_ mayoresqueel anchodela pared

IAlasdemariposa

PlatodeII1'"1 /T°rnin°dellI"'1 II::/:L

montaje_MII:.::IIlll_,mariposa II I:.:.b,

III _ I_<-Pared II I;I I

[] Coloque el plato de mont_je contra la pared e

inserte las alas de mariposa en los agt{jeros de

la pared para monmr el plato.

NOT_k; Antes de apremr los tornillos basculantes y el

mrnillo de madera, cercidrese de que las orejillas en

el plato de mom_tie mquen el rondo del gabinete

cuando se empt{ien conl:ra la pared y de que el plato

est6 cenuado apropiadamente deb_tio del gabinete.

PRECAUCI()N: Tenga cuidado de evimr pellizcar sus

dedos enue la parte posterior del plato de mont_tie y

la pared.

[] Ap_Jem todos los tornillos. Tire del plato en direccidn

opuesm a la pared pare ayudar a apremr los tornillos.

Extremodel tornillo

COMO ADAPTAR ELCALEFACTOR

PARA EL ESCAPE EXTERIOR

_1_ Remueva y guarde los tornillos que sostienen el

plato del calefitctor en el homo. Deslice el plato

del calefitctor de ab_io de su reborde de retencidn.

Remueva y gumde los tornillos que sosfienen el

motor del calef_tctor en el homo.

Rebordede !_, I_

retenci6n _ _<<_::::::_

caleTactor

_J__e _ Tornillodelmotor

_r _''_ _---- delcalefactor

_ Cuidadosamente dre del calefitcto_: Los alambres

se extenderfin lo suficiente como para permitirle

que usted ajuste la unidad del calef_tcmr.

ExtremoB

Extremo

USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA

PREPARAR EL GABINETE

SUPERIOR

Necesim perforar agt{jeros para los tornillos de apoyo

superiores y un agt{iero suficientemente grande para

que el cable el6cuico quepa.

• Lea las insuucciones sobre la PLANTILLA DEL

(;ABINETE SUPERIOR.

• PSguela deb_tjo del gabinete superior.

• Taladre los agt{jeros, siguiendo las instrucciones en

la PLANTILLA DEL GABINETE SUPERIOR.

]Rote la unidad iS0 ° en sentido contrario a las

agt_jas del reloj.

Antesdela rotaci6n

Parteposterior

del homo

_4_ Suavemente remueva los alambres de las ranHras.

Redirija los alambres a trav6s de las ram]ms en el

ouo lado de la unidad del calef_tcmr.

Antesde redirigirlos Despu6sderedirigirlos

Despu6sdela rotaci6n

Parteposterior

delhomo

PRECAUCI()N: Use gafits de segmidad cuando

perfore los agt{jeros en el rondo del gabinete.

Alambresdirigidosa trav6sdel Alambresdirigidosa trav6sdel

ladoderecho ladoizquierdo

40

Page 41

Instrucciones de instalacion

[] Ruede la unidad del calefactor 90 ° de forma ml

que las aberturas de la palem del ventilador est_n

orientadas hacia la parte posterior del homo.

Antesdela rotaci6n Despu6sde la

rotaci6n

_arte posterior

delhomo

Localice los dos platos removibles en el panel

%

posterior del homo, cerca de la parte superior

del homo.

Usando tijelas, cuidadosamente corte el 4rea

de telarafia de los dos agt{ieros lado a lado (que

asegumn los platos removibles al homo). Corte

las cuatro telarafias en ambos platos removibles

posteriores; esto permitir_i que el flt{jo de aire

del venfllador escape hacia la parte posterior

del homo.

PRECAUCI6N: Cercidrese de recortar los

extremos filosos de las aberturas despurs de

remover los platos.

Parteposterior

delhomo

Coloque el plato calefactor en la misma

posicidn como esmba antes con los tornillos.

g i_eI_ Tornillosdel plato calefactor

_:___r_ Platocalefactor

Parteposterior

__ delhomo

Inserte las orejillas en cada lado del regulador

de tiro en los agt{jeros en el lado interior

posterior del adaptador.

I

i

r_ _-_r_--..___ Adaptador

deescape

Pegue el adapmdor de escape a la parte posterior

del homo desliz_ndolo en las gufas en la parte

superior central de la parte posterior del homo.

Adaptador _ Reguladordetire

Parte posterior del homo

Coloque la unidad del calefilctor

la abertma.

Extreme B

PRECAUCI6N: No tire ni estire los cables del

calefactor. Cercidrese de que los alambres no

estfin pellizcados.

NOTA: Las aberturas del escape del calefactor

deberfin encajar con las aberturas del escape en

la parte posterior del horno.

Cortecontijeras las

cuatrotelara_asde

cadapanelremovible

y remuevalosdiscos

removiblesdemetal

parapermitirel flujo

deaire posterior.

de nLlevo en

ExtremeA

adaptadorde -- _1_I_ .a[, e posterior

escapeenlas _j-1.,d .>_-..r_. _ uel norno

gu asdela

parteposterior .,f/_ llldS_ _'Y/ h Tormllos

_"%_ _ decierre Guias

o

Empt{je firmemente hasm que estd en las orejillas

de cierre inferiores. Tanga cuidado de asegurarse

de que la bisagra del regulador de tiro est_

insmlada de forma que est_ en la parte superior

y que el regulador de tiro gire libremente.

Asegure el adapmdor de escape al homo

con los dos tornillos metfilicos de bronce

que proporcionamos.

41

Page 42

Instrucciones de instalaci6n

IViONTAJE DEL HORNO

Frentedelgabinete

Estantedelfondodel gabinete

Bloquederelleno

i_ Equivalentea

la profundidad

delretroceso

delgabinete

PARA UNA INSTMACION MAS FACIL Y EN POS

DE i_ SEGURIDAD PERSONM,, SE RECOMIENDA

QUE DOS PERSONAS INSTALEN ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante la instaladdn.

NOTA" Si su gabinete es de metal, use la arandela de

nildn ahededor del cable el_ctrico para evimr que el

IlliSlllO sea cortltdo.

NOTA: Recomendamos el uso de bloques de relleno

si el ffente del gabinete cuelga pot deb_jo del

estante del rondo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrian oeurrir dafios por apretar

demasiado los tornillos.

NOTA: Cuando se encuentre

montando el homo, enrosque el

cable eldctrico a travds del

agt_jero en el fimdo del gabinete

superior. Mantdngalo tenso a

travds de los Pasos del 1-3. No

pellizque el cable ni tire del

homo pot el cable.

_ Lexante el homo,

inclfnelo hacia adehmte, y

enganche las r_lnnras en e

extremo inl>rior posterior

en dos oreiillas inl>riores

del plato de montaje.

\

Tornillosautoalineables

Partesuperiordelhorno

Pegue el homo a la parte superior del gabinete.

_ Inserte 2 tornillos (_¢'-28 x 3V/')