Page 1

GE

Intelligent Platforms

High

Performance

Embedded

Computing

Page 2

introduction

Parallelism has been at the

heart of supercomputing since

the term was first used in the

1960s. Today, supercomputing

has, in many instances, become

high performance computing

but instead of vast rooms full

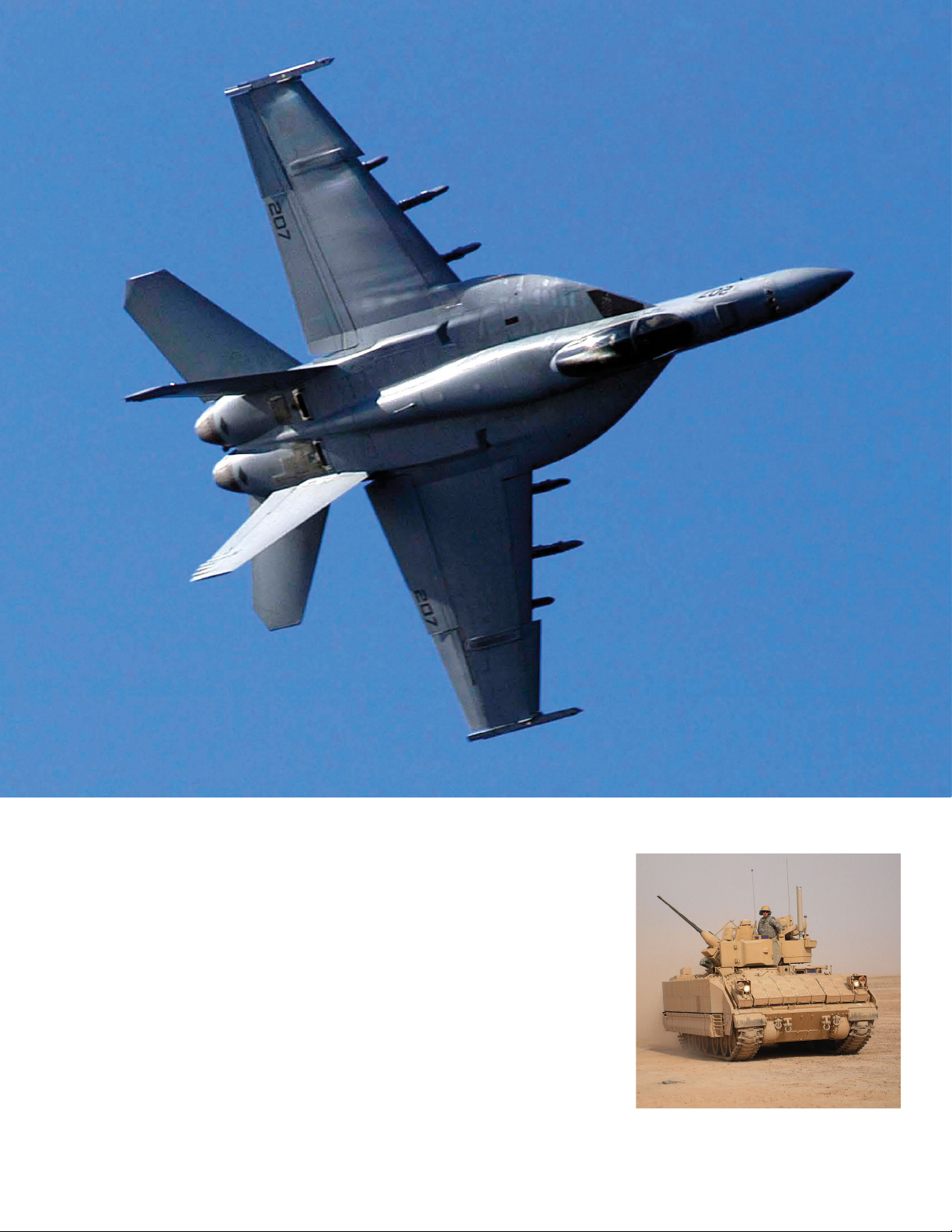

And now, high performance computing has

come to the world of embedded systems –

and, especially, to the systems being

developed and deployed by the world’s

armed forces. To address the most

demanding and sophisticated applications,

such as ISR and electronic warfare, high

performance embedded computing – HPEC –

uses the power, not just of multiple single

board computers working together, but also

of multi-core and many-core processors.

of mainframe computers all

working together on the same

problem, high performance

computing sees the deploy-

ment of numbers of server-class

machines, each featuring

multiple high performance

processors configured in parallel.

Unique challenges

But HPEC in the military arena presents a

unique set of challenges in two key areas as

a result of how and where these solutions will

be deployed. The first of these is the need to

ensure 100% reliability – in what are often,

literally, life-and-death situations – in the face

of extremes of shock, vibration, temperature

and contaminants. The second is that, increasingly, these solutions are being deployed in

environments that are small, and that need to

minimize weight, power and heat .

Both are fields in which GE Intelligent Platforms is an acknowledged leader. No other

company has GE’s pedigree in the devel-

GE’s HPEC Center of Excellence

GE has established a High Performance Embedded Computing Center of Excellence (CoE)

specifically to support customer demand for high TRL (technology readiness level) COTS

(commercial off-the-shelf) solutions that can shorten time-to-market, minimize cost and

help to eliminate program risk, allowing prime contractors, system integrators and OEMs

to focus on value-add and create competitive advantage. The Center takes advantage of

GE’s COTS Rugged Systems (CRS) capability to support the rapid deployment of systems

to the field.

The HPEC CoE also provides a focus for the future development of a range of powerful, flexible products and solutions for military/aerospace embedded computing.

opment of systems that are truly rugged,

capable of withstanding the rigors of deployment in the harshest environments. And no

other company is able to better GE’s expertise in developing HPEC solutions that are

small, lightweight, consume minimal power

and dissipate minimal heat.

GE is well-known for its ability to develop and

deliver leading-edge single board computers,

multiprocessors, high speed switches and so

on. Much less well known is GE’s ability as a

systems company, able to provide complete,

rugged, ready-to-run subsystems – and a

broad range of supporting services.

Meeting new realities

It’s not just about hardware. In an era of

acquisition reform, without the luxury of

extended, government-funded development

cycles, the onus on development exists with

the supplier. To meet these new realities, GE

provides a complete development environment – AXIS – that reduces development time

and cost and accelerates time to market.

There’s more to GE’s HPEC offering than just

hardware and software, however. GE also

has an unmatched understanding of, and

commitment to, long term support – recognition of the multi-year (multi-decade, even)

lifecycle of the typical military program. That

understanding and commitment is backed

by one of the world’s most respected, most

secure companies.

GE Intelligent Platforms has been a long time

champion of COTS – commercial of-the-shelf –

solutions, because of what they bring to

customers in terms of faster access to new

technologies, high technology readiness levels

(TRL), ease of interoperability through the use

of open standards, reduced program risk and

lower lifetime cost of ownership. Today, GE

02

high performance embedded computing

Page 3

readily works with customers to create

custom variants of those solutions – variants

that combine the advantages of COTS with the

benefits of custom development.

GE is in the business of developing innovative solutions all the time, every time – for the

long term. In an unpredictable world, only

a company of GE’s size, stature, resources

and experience can work with customers to

anticipate needs – and minimize the impact

of the unforeseen.

At the heart of everything GE does is the

deep understanding of what is most important to customers: bringing value-added,

differentiated, high performance, reliable

and cost-effective solutions to market in the

fastest time, at the lowest cost and with the

minimum of risk – thereby creating competitive advantage.

GE knows that this goal is only achieved

through a mutual investment in the relationship and a shared commitment to success.

defense.ge-ip.com/hpec

03

Page 4

software

Overarching GE’s comprehensive

high performance embedded

computing offering is AXIS, an

integrated, sophisticated yet

easy to use software develop-

ment environment that has led

to software development time

being halved, and to software

testing beginning 30% sooner

than would have been achieved

with a ‘hand-crafted’ solution.

AXIS reduces the time taken to develop, test,

debug and optimize complex DSP software

applications based on multiprocessor platforms. Because of the high level of hardware

abstraction it provides, it requires little or

no developer knowledge of the underlying

platform, freeing developers to focus on the

application. As such, it reduces program risk;

it increases productivity; it reduces costs; and

it reduces time-to-market, creating competitive advantage.

Easy, fast, cost-effective

Not only this: AXIS is highly portable, allowing

the easy, fast and cost-effective migration

of a software solution to multiple hardware

platforms as well as simplifying technology

insertion during the lifetime of a program.

AXIS provides support for GE’s latest multicore and many-core hardware platforms

including single board computers featuring

th

4

Generation Intel® Core™ i7 processors as

well as those featuring the latest Power Architecture processors from Freescale, and those

featuring NVIDIA’s CUDA GPGPU (general

purpose processing on graphics processing

units) technology, providing customers with

a highly integrated hard- ware and software

platform that uniquely enables them to take

maximum advantage of the enormous benefits of the latest processing technologies.

As well as support for OpenVPX, AXIS provides

support for VME and VXS systems.

Tuning to meet performance requirements

The AXISPro software suite includes an integrated graphical user interface. AXISView

provides tools for application development

and system visualization. The developer

exploits an iterative application development cycle allowing the user to benchmark

routines and tune the application to meet

performance requirements.

In addition, AXISFlow provides a high performance interprocessor communication library

for high throughput , low latency data movement across multiple fabrics (PCI Express

Gigabit Ethernet , 10 Gigabit Ethernet , InfiniBand and Serial RapidIO etc.) scaling from

one to many CPU cores and nodes across a

single board, multiple boards in and multiple

system chassis.

If open standards are required, then AXISmpi

offers an embedded computing focused MPI

library that will operate across heterogeneous systems.

AXISLib provides DSP and math function

libraries to support very high performance

signal and data processing routines with a

standard VSIPL interface as well as a faster

proprietary API for optimum performance

and portability across multiple processor

platforms. Generic C versions of the libraries

are also available.

®

,

04

high performance embedded computing

Software: The GE Advantage

6

High performance, low overhead RDMA capability using AXISFlow and OFED

software stack.

6

Open standard VSIPL and MPI support.

6

AXISView GUI enables system visualization and rapid prototyping.

6

Signal processing algorithm optimization services.

Page 5

TO FIND OUT MORE:

http://defense.ge-ip.com/products/axis-multiprocessing-software/c153

defense.ge-ip.com/hpec

05

Page 6

Embedded Rugged Systems

Naval Applications

Integrated Display Units

Communications and IFF

Shipboard Network Control

Target Detection & Tracking

Fire Control Computers

Sensor Processing

Aerospace Applications

Remote Interface Units

Network Switch Units

Radar Warning Receivers

Stores Management Computer

Integrated Display Processing

SBCs, DSPs, Graphics, I/O Cards

Mission Management Computers

Navigational Control Units

IFF Controllers

Flight Management Computer

solutions

Few, if any, embedded computing

companies can offer the range of

HPEC solutions that are available

from GE Intelligent Platforms.

In line with GE’s strategy of

enabling customers to enjoy –

and maximize – the benefits that

accrue from COTS solutions, all

of GE’s HPEC offerings are built

around technologies that are

industry standards and that

represent ‘best in class’.

Demanding military applications

Processors come from Intel

industry-leading second generation Core

dual- and quad-core technology, and from

Freescale, a long time significant contributor

to embedded computing. From NVIDIA comes

its CUDA architecture and many-core GPU

(graphic processing unit) processors – not just

for graphics applications, but also for general

purpose use in the most demanding military

applications that can benefit from a high

degree of parallelism, such as radar.

From Mellanox comes InfiniBand and

10 Gigabit Ethernet, switched fabric

communications links used extensively in

high performance computing and enterprise

data centers.

®

, with its

Ground Vehicle Applications

Network Switch Units

Target Tracking

Embedded Training

Integrated Display Processing

SBCs, DSPs, Graphics, I/O Cards

Situational Awareness

Remote Interface Units

Launcher Control Units

Fire Control Computers

Hull/Turret Compters

Mission Control

Flight Control

Sensor Processing

Vehicle Management

As part of its unwavering commitment to

open industry standards, GE also supports

OpenVPX, an architecture framework that

defines system-level VPX interoperability.

Specifically developed for deployment in

rugged environments, it is the natural heir

to VME, the computer bus standard that has

been at the heart of embedded computing

since the 1980s, and which GE also supports,

along with the CompactPCI industry standard.

Support for industry standards

Along with hardware and technology standards, GE’s range of HPEC solutions also

support industry software standards, such

as Microsoft Windows and Linux, along

with industry standard real-time operating

systems such as VxWorks from Wind River

Systems, Integrity from Green Hills Software

and LynxOS and LinuxWorks.

Software support also comes in the form of

AXIS, GE’s Advanced Multiprocessor Integrated Software development environment

which has been shown to substantially

shorten the development, debug and optimization cycle.

The OFED software stack from the Open

Fabric Alliance is also fully supported,

providing drivers and open standards

interfaces along with RDMA-enabled communications protocols such as OpenMPI, uDAPL

and sockets direct. This allows developers to

leverage the extensive landscape of commercial HPC software.

Extensive HPEC offering

GE’s extensive HPEC offering includes single

board computers such as the SBC626, Based

on the high performance fourth generation Intel Core i7 processor, it features fully

integrated graphics and memory controller

together with dual or quad core processing

up to 2.4 GHz and offers outstanding performance per watt. Coupled with the Intel QM87

chipset, this provides an unmatched level

of I/O bandwidth for both on-board and offboard functions.

06

high performance embedded computing

Page 7

Naval Applications

Integrated Display Units

Communications and IFF

Shipboard Network Control

Aerospace Applications

Remote Interface Units

Network Switch Units

Target Detection & Tracking

Fire Control Computers

Sensor Processing

Radar Warning Receivers

Stores Management Computer

Integrated Display Processing

SBCs, DSPs, Graphics, I/O Cards

Mission Management Computers

Navigational Control Units

IFF Controllers

Flight Management Computer

sonar, image and sensor processing across

a wide range of platforms including manned,

unmanned airborne, ground and naval vehicles. Multiple DSP281s can be interconnected

via InfiniBand or 10 Gigabit Ethernet fabric

switches to create powerful HPEC clusters.

For applications that demand an even higher

degree of parallelism, GE has introduced

the IPN251 platform. Each is based around

GE’s DSP281 is the latest in a long line of

multiprocessors designed for the most

demanding ISR applications. Like the SBC626,

it is based on Intel second generation Core

processor technology – but features a dual

quad core architecture, delivering, in effect,

eight CPU cores on a single board and

making it ideal for demanding DSP, radar,

the NVIDIA CUDA GK107 GPU, with its 384

cores. In the case of the IPN251, the GK107

is augmented by an Intel Core i7 processor

operating at 2.4 GHz to create a heteroge-

neous and computationally-dense processing

platform for demanding applications that

are constrained in terms of size, weight and

power (SWaP).

Solutions: The GE Advantage

6

HPEC CoE helps with architecture definition, application development and

performance optimization

6

Able to deliver short lead time software development platforms with a path to fully

ruggedized deployable systems

6

Provide fully software integrated and tested ‘application ready’ solutions

6

Provide ‘getting started’ support and training

The IPN251 provides over 750 GFLOPS of

combined CPU and GPU compute power.

They can be built into a multi-board clusters

providing TERAFLOPS of processing power.

Switches, subsystems and more

The other key members of GE HPEC solution

set are the GBX460 10Gigabit Ethernet and the

IBX400 InfiniBand 6U OpenVPX switch fabric

modules (SFMs).

The NETernityTM GBX460 SFM is a fully

managed layer 2/3+ Ethernet switch

supporting up to sixteen payload slots via

10GE data plane (DP) at up to wire speed along

with full control plane(CP) GbE connectivity.

Alternatively, system architects can benefit

from increased bandwidth and reduced latencies by selecting the IBX400 SFM that is slot

compatible with the GBX460 platform. IBX400

can support up to 16 pay load slots with

double data rate (DDR) Infiniband providing

up to 1.8GBytes/s throughput across the

data plane along with the a fully managed

GbE CP interface. Both solutions benefit from

GE’s OFED RDMA enabled processor modules

yielding unprecedented levels of performance

within a standard 6U OpenVPX single or dual

star system architecture scaling to multi-TeraFLOP parallel computing within fully rugged,

deployable platform.

The most recent addition to GE’s HPEC range

is the rapidly-growing family of COTS Rugged

Systems (CRS). Designed for customers who

need to eliminate the expense, time and

risk of custom sourcing and development,

these preconfigured, pretested, ready-torun systems can be deployed in the field as

soon as the application is ready, or used as a

starting point for multiple application-specific

configurations.

GE’s comprehensive HPEC product and system

offering is backed by an extensive infrastructure of customer support programs designed to

ensure that high performance, reliable systems

are deployed in the minimum time, at minimum

cost and with minimum risk.

defense.ge-ip.com/hpec

07

Page 8

technology

GE Intelligent Platforms has long

been a leader in taking COTS

– commercial off-the-shelf –

technologies and adapting them

for the rigorous requirements of

military organizations around

the world.

COTS: faster access to technology,

lower cost of ownership

The advantages of COTS are many. COTS

solutions allow military organizations to

leverage the latest in commercial technologies far faster than would otherwise be the

case. COTS solutions are significantly more

cost-effective, because they obviate the

need for extensive upfront investment in

development – and they take advantage

of technologies that are produced on a

commercial scale. A COTS solution can typically be deployed more quickly, shortening

time-to-market.

Lifetime cost of ownership of a COTS solution

is lower because the vendor takes responsibility for long term support – and COTS

solutions are designed to ease technology

insertion, maximizing performance over the

lifetime of a program. Because COTS solutions are derived from commercially-proven

technologies, they typically feature a high

Technology Readiness Level (TRL) and minimize program risk.

An example of the COTS paradigm in action

is Intel’s range of processors, and notably its

second generation Core processors. Within

nine months of its announcement , Intel

had shipped more than 75 million devices,

widely implemented in servers, desktops and

laptops – as well as in military embedded

computing applications on platforms such

as GE’s Intel Core i7-based SBC626 single

board computer and DSP281 multiprocessor.

GPGPU solves complex problems faster

GPGPU – general purpose computing on a

graphics processing unit – technology is an

excellent example of how military organizations can leverage technologies originally

designed for commercial and consumer

applications. PC-based game playing has

long driven advances in GPU technology as

gamers strive for ever-greater realism – and

that same search for enhanced realism

has seen GPU technology widely deployed

in military display applications such as

embedded training.

But the inherent high degree of parallelism

that brings ultimate graphics performance

can also be used to deliver other types of

processing – types of processing widely

required in military applications such as

radar, where the requirement is to process

multiple streams of data simultaneously.

Customers using NVIDIA’s CUDA GPU architecture – such as the 384-core GK107 – for

applications such as SAR simulation, pattern

recognition, object detection and cryptography are reporting performance increases

of between 10x and 500x. Using a GPU

to augment the capability of a traditional

CPU can therefore bring real size, weight

and power (SWaP) advantages to high-end

processing systems.

08

high performance embedded computing

Fourth generation Intel Core i7 processors

bring unprecedented performance to a wide

range of applications and, by integrating

advanced graphics – and other – capabilities, enable high performance embedded

computing solutions to be smaller, lighter,

consume less power and dissipate less heat.

Dual NVIDIA CUDA GK107 GPUs are featured

in the GE Intelligent Platforms IPN251 multiprocessor, combining the power of a GK107

with the performance of a 3

i7 processor for maximum application integration and flexibility.

rd

generation Intel

Page 9

The most demanding C4ISR and EW applications demand high performance embedded

computing which sees the deployment of

multiple processors of either homogeneous

or heterogeneous types, either on a single

silicon devices, on a single board – or on

multiple boards.

Serial switched fabrics for

high system throughput

This presents two key challenges. The first

is in the intercommunication between the

processors – but here too, GE provides solutions. GE was among the first embedded

computing companies to commit wholeheartedly to the interconnect technology

that has rapidly become the standard for

demanding military applications. VPX – and,

subsequently, OpenVPX – grew out of the

pervasive and hugely successful VME standard, and is an open standard which utilizes

the familiar 3U and 6U card sizes of VME.

It offers true rugged capabilities, including

conduction cooling and resistance to shock

and vibration. At the same time, it offers

higher power budgets, more signal density

and a far faster serial backplane.

GE has also chosen to standardize on two

other open interconnect standards: 10

Gigabit Ethernet and InfiniBand. 10 Gigabit

Ethernet was chosen not only for its high

performance, but because it is ubiquitous,

supported by a substantial ecosystem of

products, technologies and expertise.

Technology: The GE Advantage

6

100% commitment to COTS, industry standards

6

Innovator in key technologies such as truly rugged GPGPU, InfiniBand

6

Leadership in ruggedization

6

Focus on compelling SWaP characteristics, high performance

The Intel/InfiniBand combination is dominant

in the high performance computing clusters

that are often called ‘server farms’ – installa-

tions which deliver massive computing power

by coupling together multiple servers or

blades. With the growing requirement in the

military/aerospace market to gather, process

and disseminate huge volumes of data, those

server farms are increasingly being repli-

cated in defense applications. For customers

looking to create similar profiles, there are

sound commercial as well as technical

reasons why the Intel/InfiniBand combination

is a compelling one.

Software rises to the development challenge

The second challenge is in managing the

multi-faceted complexity of developing

challenging, mission-critical applications on

hardware platforms that can themselves be

complex to master – and to do so in minimum

time and at minimum cost.

Here, GE offers the AXIS – Advanced Multipro-

cessor Integrated Software – development

environment. AXIS is a set of software modules

that can be used to accelerate the design,

development, testing and deployment of

complex DSP and multiprocessing platforms

for real-time applications such as radar, sonar,

communications and image processing.

AXIS allows tough questions – about system

sizing, data movement, algorithm performance, configuration, application mapping

and so on – to be answered quickly and easily,

speeding the cycle of design, development,

test, optimization and validation and reducing

time to market.

GE’s high performance embedded computing

solutions combine the best in COTS technologies with open standards and advanced tools

to make the development and deployment of

demanding ISR applications easier, faster and

more cost-effective.

defense.ge-ip.com/hpec

09

Page 10

applications

Radar

Developers of today’s radars demand that their processing systems be founded

upon the principles of Modular Open System Architecture. Designs must be

scalable, open architecture and capable of sustainment for the long term with

technology insertion plans.

In response, GE has adopted OpenVPX as the primary form-factor, using widely

adopted processors from Intel and NVIDIA, connecting processing clusters with

standard interconnects like Ethernet and InfiniBand, and providing support for

Linux, Open Fabrics Enterprise Distribution, MPI, DDS and so on.

Signal Processing

By using the rapid prototyping capabilities of AXISView along with

quick implementation of radar algorithms with VSIPL and VSIPL++,

a signal processing system can readily be modeled to determine

how many processors are needed. GE can produce standard or

custom radar backend processors scalable to dozens of TFLOPS.

Such systems can extend from sensor input via standard interfaces

such as serial FPDP and 10GbE, through processing on clusters

of Intel processors with optional NVIDIA GPGPU co-processing, to

output to a backend system via standard Gigabit Ethernet.

Electronic Warfare

Electronic Countermeasure Systems are typically defined by their need

for low-latency processing. To date this has often required FPGAs to

meet the latency constraints.

Now, GPUs can be considered for such applications. GPUdirect allows

sensor data to be transferred straight into GPU memory, bypassing the

multiple copies and host processor involvement that were previously

required. Testing has shown a reduction in latency of better than 25x,

opening up the use of GPUs in applications that were previously not

candidates. Development time and cost are also reduced.

10

high performance embedded computing

Page 11

Targeting

Targeting pods require increasing processing power to keep up with

increased sensor resolution and added sensors. Typically the system size

is restricted by the existing pod profile and power.

GE’s range of OpenVPX products, spread across 3U and 6U form factors

allow for highly scalable solutions from the smallest to the largest pods.

The AXIS software tools allow seamless scalability of the application

to match the hardware. Gigabit and 10Gigabit Ethernet offer standard

connections between subsystems and to sensor suites.

ISR Visualization

Increasing focal plane array size, faster frame rates and more sensors

being fused mean that more capability is being demanded in the same

or lower size, weight, and power.

GPUs are particularly well suited to processing the large volumes of pixel

data present on today’s ISR platforms. Given the shock and vibration

levels that many ISR platforms are subjected to, GE’s policy of using chipdown designs fits well. The use of high speed fabrics with RDMA allows

the sensor data to be efficiently spread to the processing nodes.

360 Degree Situational Awareness

To acquire, convert, stitch and display video streams from multiple HD

cameras requires considerable compute power. Typically these systems

must be capable of being retrofitted into spaces on vehicles that offer severe

restrictions on size and cooling paths.

By offering a complete range of SBCs, GPUs, Manycore processors

and network interfaces, GE can supply the building blocks for the most

demanding of SA systems. The availability of middleware and application

frameworks speeds the development of the solution.

defense.ge-ip.com/hpec

11

Page 12

product examples

SBC626

6U OpenVPX 4th Gen Intel Core i7-based

Single Board Computer

FEATURES

6

6U OpenVPX SBC

6

Quad core, 4th Gen Intel Core i7

processor @ up to 2.4 GHz

6

Intel QM87 Express Chipset

6

Up to 32 GB of DDR SDRAM w/ECC

6

Up to 32 GB NAND Flash

6

Dual on-board expansion sites

(XMC/PMC)

6

Air and conduction cooled versions

6

Comprehensive Deployed

Test Software

6

Comprehensive Operating

System support

DSP281

6U OpenVPX Deployed Server Platform

FEATURES

6

Two Intel Core i7-4700EQ CPUs:

– Four cores, eight threads per CPU

– Two channels ECC 1600-DDR3L

– 16GBytes DDR3L, 32GB future option

– AVX2.0 Advanced Vector Extensions

– HD-4600 on-chip graphics

6

Two platform controller hubs:

– 16MBytes BIOS Flash per PCH

– 16GB SATA Nand Flash

– 512KB NVRAM

6

Platform Security:

– Configurable Security Hub FPGA

– Intel Trusted Execution

– Intel vPRO / AMT technology

– Intel AES new instructions

6

Firmware support:

– Built-in Test

– UEFI BIOS

6

Operating System Support:

®

– Linux

– Windows

– WRS VxWorks

– WRS Hypervisor

6

Middlewares and Libraries:

– AXISPro application development

– AXISLib VSIPL and RSPL multi

– GE signal- and image processing

quick start examples

– Intel OpenCL SDKs, IPP and MKL

SDK

®

SDK

®

BSP

framework

threaded DSP and math libraries for

VxWorks, Linux & Windows

IPN251

6U OpenVPX GPGPU Multiprocessor

FEATURES

6

Open VPX: 6U rugged VITA46/VITA48

REDI/AFT

– Multi-fabric data, expansion and

control planes

– 2x 10 Gigabit Ethernet/InfiniBand

– x16 PCIe Gen 2

– 4x 1-Gigabit Ethernet

6

CPU: 3rd Gen Intel Core i7

6

GPU: NVIDIA 384-core

“Kepler” EXK107

6

XMC Site

6

Software

– BIOS, Linux, Windows

– NVIDIA CUDA, OpenCL, OpenGL

– AXISLib-VSIPL Math & DSP libraries

– NVIDIA PhysX

– Matlab

12

high performance embedded computing

Page 13

IBX400

6U OpenVPX InfiniBand Switch

Fabric Module

GBX460

OpenVPX Fully Managed Layer

2/3 10 GigE Switch Module

SCVPX6U-95 series

HPEC Application Ready Platforms

FEATURES

6

6U OpenVPX VITA65 Switch Profile

– SLT-SWH-16U20F-10.4.2

– MOD6-SWH-16U20F-12.4.2-10

6

DDR InfiniBand Data Plane

– 20 x Fat Pipes

– High throughput, low latency

– In-band subnet management

6

Gigabit Ethernet Control Plane

– 16 x Ultra Thin Pipes

– Fully managed layer 2/3

– Ethernet Switch Fabric

6

Management Plane

– I2C/BMM Controller

6

OpenWare Control Plane

Switch Management

–

Layer 2 and layer 3 packet switching

– QoS Priority (IEEE802.1D)

– IPv6 & IPv4 Switching

6

End to end RDMA solutions

– 6U OpenVPX SBCs, Multiprocessors,

GPGPU blades and I/O

6

Application Ready Platforms

– Fully integrated & tested Linux

clusters for radar, image, signal and

data processing

FEATURES

6

6U OpenVPX Compliant: (VITA 65.0)

6

VITA 48 (REDI)

6

VITA 46.0-2007 (VPX Baseline Standard)

6

Switch Profile: SLT6-SWH-16U20F-10.4.2

Data Plane: 20 x 10GigE Ports

Control Plane: 16 x 1 GbE Ports

6

Optional Profile: SLT6-SWH-24F-10.4.3

Data Plane: 24 x 10GigE Ports

6

Non-Blocking

6

Front I/O: Up to four 10GigE Fiber Ports

available for slot profile SLT6-SWH-

16U20F-10.4.2

6

Full wire-speed 10GigE Performance

6

Ruggedization Build Levels:

– Level 1, 2 & 3 Air Cooled

– Level 4 & 5 Conduction Cooled

– Level 8 Air Cooled VITA 48.5

6

RoHS 2002/95/EC Compliant

6

Based on high-performance Low

Latency, Ethernet switch fabric from

Fulcrum Microsystems

6

IEEE 802.3-2005

6

Option for Unmanaged operation

6

Hardware enabled IPv6 and

IPv4 support

6

OpenWare Switch Management

environment

6

Multi-cast Support: IGMP Snooping

Querier and MLD Snooping Querier

6

Allows up to 4096 VLANS

6

L-3 Protocol support including OSPF,

RIP and VRRP

FEATURES

6

6U OpenVPX 5 slot lab

development system

6

Single star BK6-CEN05-11.2.5-3

Backplane

6

Flexible configuration options with

GE Processors and I/O

6

Supports 10GE or InfiniBand data plane

6

Fully integrated & tested Linux cluster

with application examples

CRS 48.5

Rugged VITA48.5 Subsystem

FEATURES

6

6U OpenVPX 5 slot deployable system

6

Modular design supports 10GE or

InfiniBand data plane

6

4 payload processor cards with

SSD options

6

Fully integrated and tested Linux

cluster with application examples

defense.ge-ip.com/hpec

13

Page 14

support

GE’s Program Management

(PM) service rigorously strives

to eliminate the risk in HPEC

program development and

deployment. From development

of the product requirements and

program schedule to product

qualification and release for

production, GE works closely with

its customers to demonstrate

design and manufacturing prog-

ress as measured against the

program baselines and forecasts.

In the event that stock products cannot meet

customer specifications, GE’s PM staff will

develop a customer-centric plan to shepherd

the product development from prototype to

production. Price change risk is eliminated

because GE’s initial quote remains the price

until delivery.

Reduction of risk and cost

In addition, GE’s contract change management service reduces costly change orders

by ensuring that every change has been

formally approved by the customer and that

a separate purchase order has been issued

to reflect that change.

The PM service also provides the documentation of risk management that contractors can

provide to higher-tier contractors who want

to know that systems will be delivered on

time and exactly to specification.

Effective Product Lifecycle management (PLM)

ensures that parts are available to service

routine and emergency maintenance – whatever the duration of the proposed deployment.

A PLM program can also anticipate technology

advances and thus allow for upgrades to

embedded technology with a minimum of

hardware or software disruption.

The result is the highest level of repeatable

performance at the lowest possible cost

of ownership across a program’s lifecycle.

GE’s long-established PLM team maintains

close contact with component suppliers and

industry groups such as the Component

Obsolescence Group to constantly monitor

technology developments and component

obsolescence issues.

Progressive and defensive

long term support

At the heart of the program is a dedication

to providing both progressive and defensive

long term support. ‘Progressive’ support

begins on the design table, with embedded

products being designed for maximum

compatibility or upgradability even before

they are qualified for a system.

The list of critical components will include

only those elements for which vendors have

committed to a long-term production run. After

a product is launched, ‘defensive’ PLM provides

the technical support and service to keep

the product running, as well as ensuring that

sufficient stores of spare parts are available to

avoid the premature shutdown of a system or

even the entire platform.

When technology obsolescence occurs in

the marketplace, GE’s Health Check program

will alert the customer and provide possible

solutions such as a last-time buy of the

components, an appropriate replacement

component, a redesign of the original product

for form, fit, or function compatibility, technology insertion earlier than planned or a

lifetime purchase of the components.

When components are purchased in bulk, GE

also can provide secure, climate-controlled

storage for as long as required by the

customer. Long-term product lifecycles

demand that critical engineering knowledge

is available regardless of personnel changes

or corporate restructures. Similarly, testing,

diagnostic and repair capabilities must be

maintained. GE Intelligent Platforms’ PLM

program ensures that such knowledge,

protocols and capabilities are available

throughout the lifecycle of any program.

14

high performance embedded computing

Page 15

TO FIND OUT MORE:

http://defense.ge-ip.com/support/embeddedsupport

Support: The GE Advantage

6

Unrivaled expertise in support of multi-decade program deployments

6

Tailored to specific customer needs

6

Makes significant contribution to lower lifetime cost-of-ownership

6

Range of support strategies help reduce risk

defense.ge-ip.com/hpec

15

Page 16

GE Intelligent Platforms Contact Information

Americas: 1 800 433 2682 or 1 434 978 5100

Global regional phone numbers are listed by location on our web site at defense.ge-ip.com/contact

defense.ge-ip.com

©2014 General Electric Company. All Rights Reserved. *Trademark of GE Intelligent Platforms, Inc.,

a wholly-owned subsidiary of General Electric Company. All other brands, names or trademarks are

property of their respective owners. Specifications are subject to change without notice.

12.14 GFA-1921B

Loading...

Loading...