GE SABA Brochure

Technical Data

GE Inspection TechnologiesGE Inspection Technologies

SEIFERT SABA 3000 XCR

XrayXray

Font ISO Standard Type in accordance with DIN 6776 B vertical, with the following deviation:

Space between numeric characters = three times the line width, user scalable,

starting from 10 mm height at 100 µm/pixel.

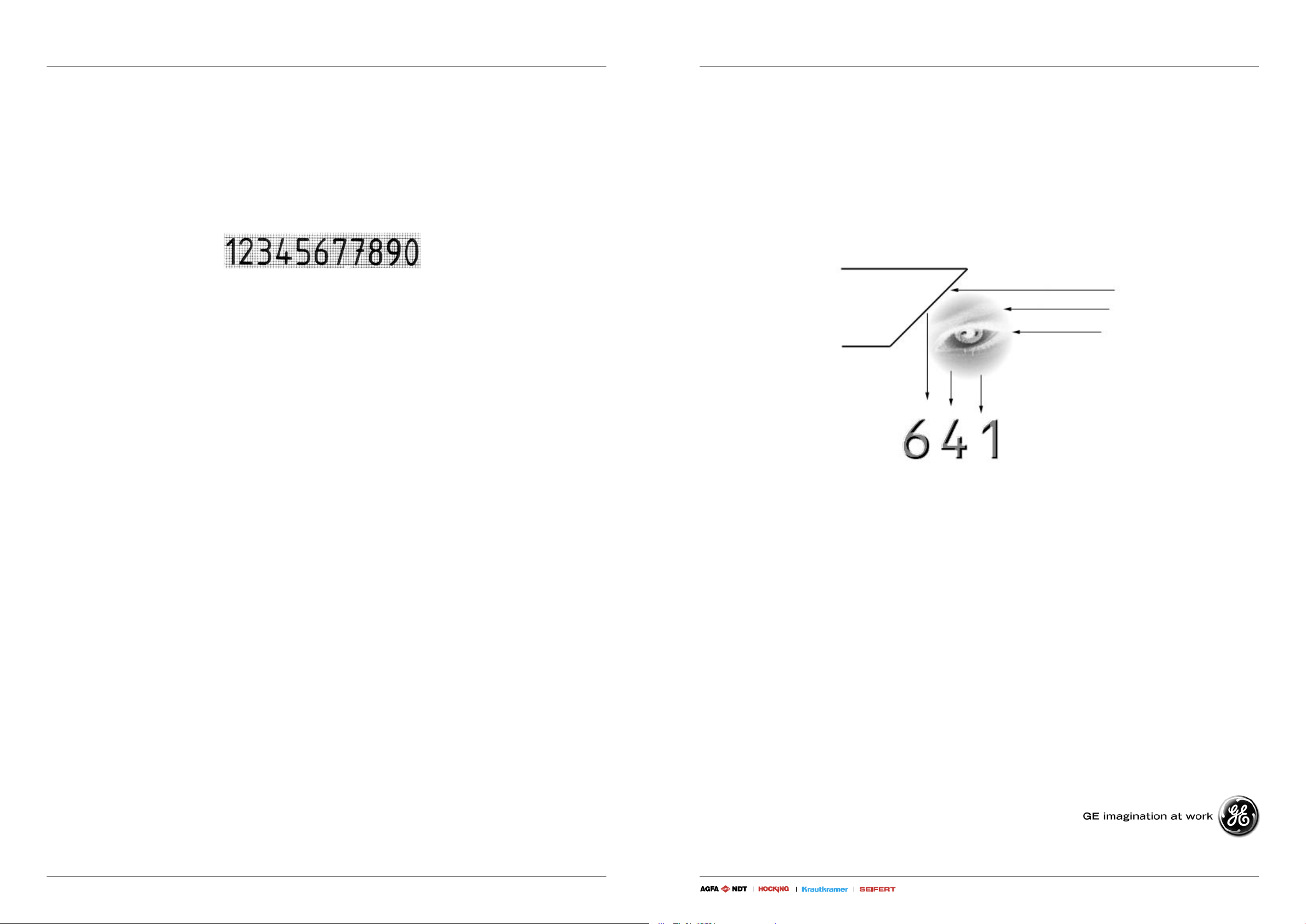

Font sample:

Allowable numeric characters: 0, 1, 2, 3, 4, 5, 6, 7, 8 ,9

Minimum values of numeric characters, based on an image resolution of 100 µm/pixel

and an X-ray tube current of 4 mA:

Height (nominal size) 10 mm

Width (at nominal size) 5 mm, the numeric character 1 having a 3 mm width

Line width 1 mm, (-0.1 mm, +0.4 mm)

Minimum distance between numeric characters 3 mm

X-ray Character Recognition

Required type elevation (minimum values) with given material thickness

Material thickness [mm] 5 10 20 30

Type elevation [mm] 0.75 1 1.6 >2.4

Numeric character slant approximately 3°

Numeric character arrangement in the image rectangular relative to the image border (0°, 90°, 180°, 270°)

Deviation of the character string position from the nominal position ± 2 mm

Deviation of the rotation (within the string) from the nominal position ± 2 °

Application

The SABA 3000 XCR software for X-ray Character Recognition acts as an additional

module within the SABA 3000 image evaluation system. It is designed for automatic

numeric character recognition.

The cast-on clear text information (e.g. mould numbers) is read from

the X-ray radioscopic image.

• Produced under ISO 9001 certified quality management system.

We reserve the right to technical modifications without prior notice.

GEInspectionTechnologies.com

©2004 General Electric Company. All rights reserved.

GEIT-30068GB (6/04)

GE Inspection Technologies

Description

Xray

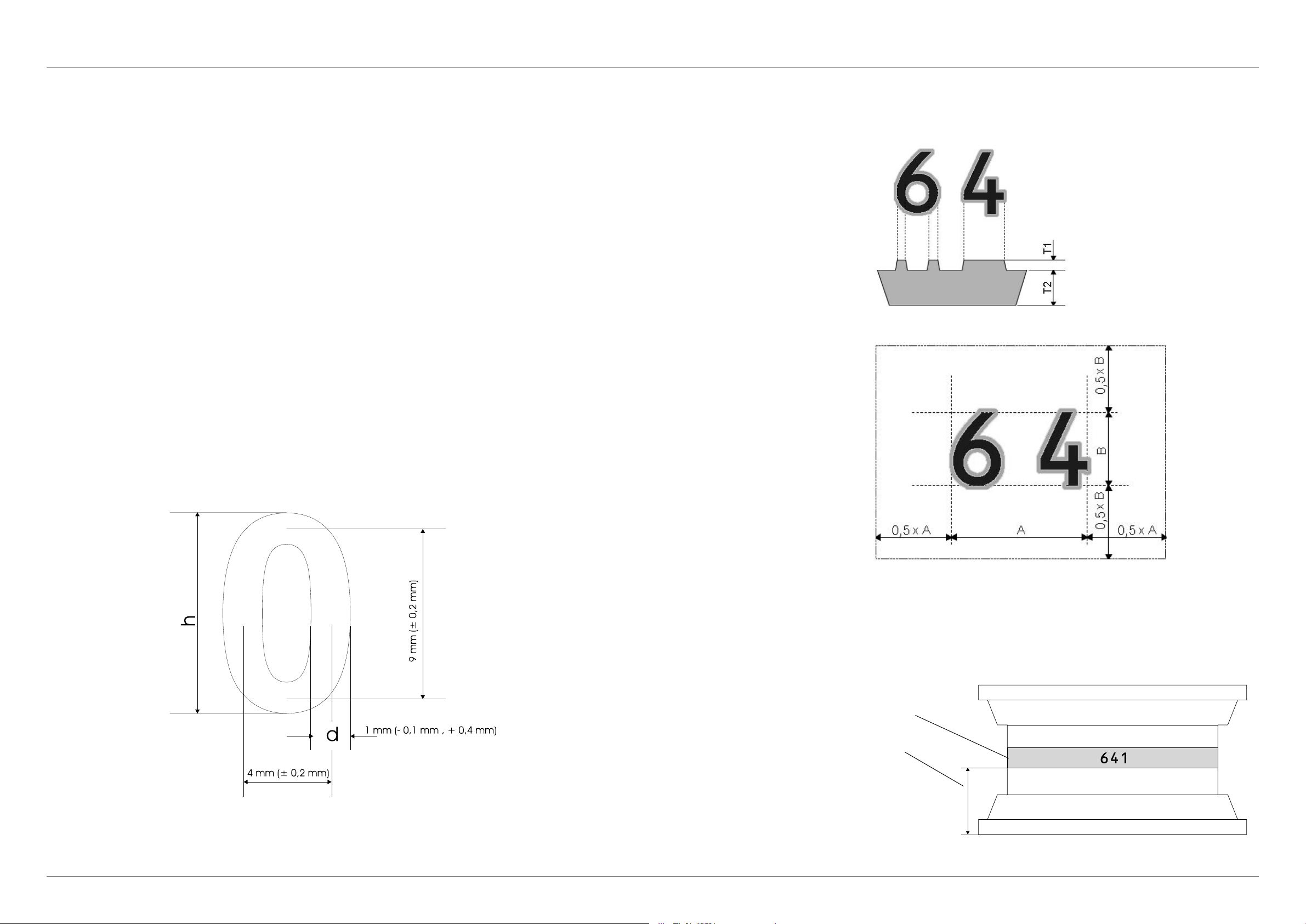

In order to obtain accurate character rec-

ognition results the following prerequisites

have to be met:

• The font to be used is the ISO Stan-

dard Type for drawings in accordance

with DIN 6776 B vertical. This type is

characterized by high legibility.

• Each individual numeric character

must be distinct in shape to prevent

confusion with others.

• The distance between two numeric

characters must be three times the

line width (d).

• The numeric character height (h)

must be at least 10 mm (see

Figure 1).

• For serial inspection the numeric

characters in the image must always

appear in the same place.

• The arrangement of the numeric char-

acters in the image must be rectangu-

lar. A diagonal arrangement prevents

them from being recognized.

• The type must be highly contrastive.

The proportion of the type elevation

T1 to the material thickness T2 (see

Figure 2) must be constant through-

out the entire numeric character area

(see Figure 3) and be at least 1:10

given a numeric character height of

10 mm.

Example:

Given a 10 mm material thickness the

type elevation must be 1 mm (-0.2

mm, +0.8 mm).

• No further structures (e.g. cooling

fins) must be in the numeric character

area as they will affect results.

• In the numeric character area the

material thickness must be constant.

• As the type elevation is limited for

reasons inherent in the casting pro-

cess, the numeric characters should

be placed in workpiece areas with the

least possible material thickness. This

is the only way to ensure a sufficiently

high contrast in the X-ray radioscopic

image.

Figure 2 - Proportion T1/T2

Figure 1 - Dimensions for 10 mm numeric character size

Figure 3 - Numeric character area

The following points are important for X-ray character recognition on wheels:

• The strip must not contain any other information

except for the numeric characters.

• For all wheels of one type the strip must have the

same height position.

• The number of numeric characters (3 in the example

on the right) must be the same for all wheel types to

be inspected in one plant.

Loading...

Loading...