Page 1

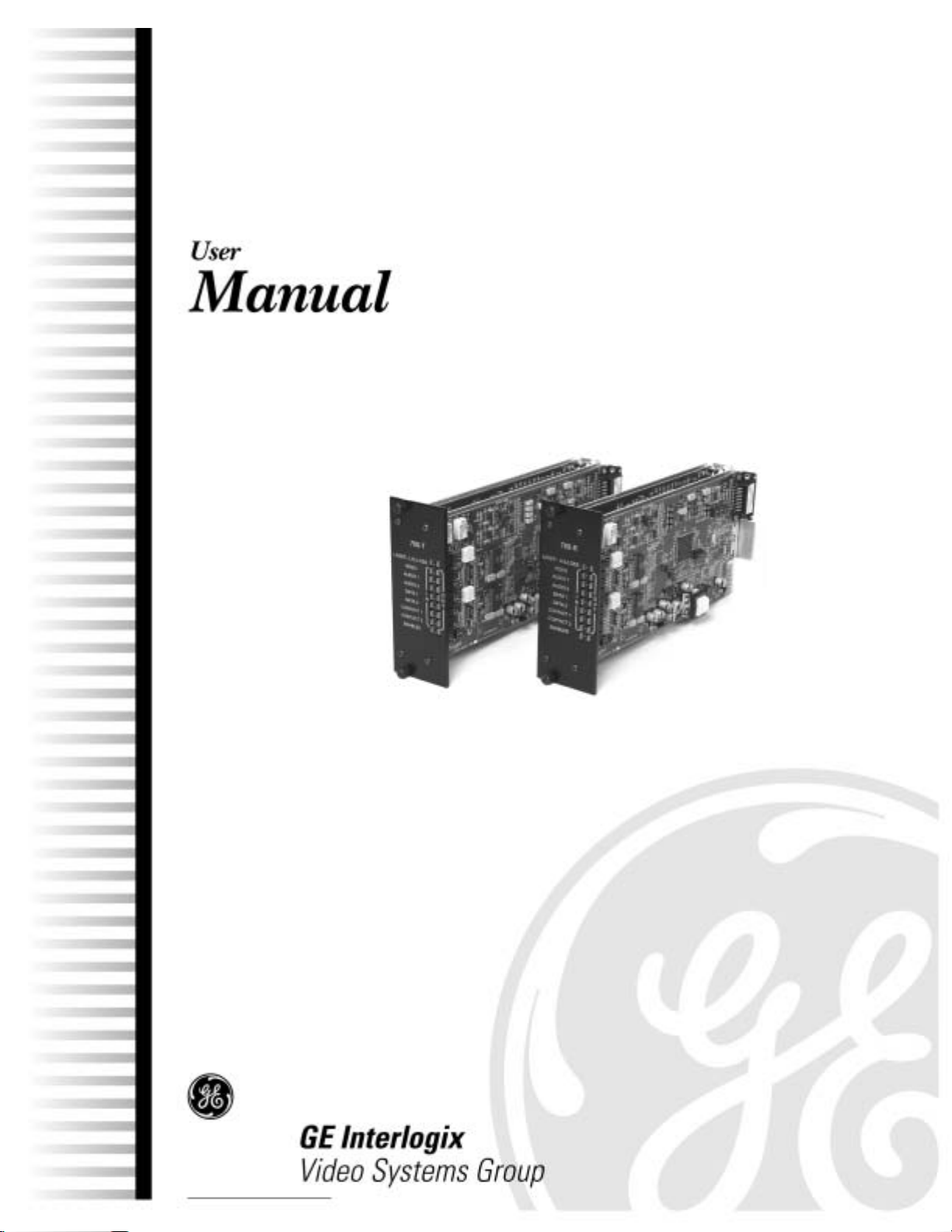

S768DAV – S7768DAV

p

Fiber O

tic Transmission System

Page 2

© 2003 GE Interlogix, Video Systems Group

All Rights Reserved.

Any GE Interlogix, Video Systems Group, software

supplied with GE Interlogix, Video Systems Group,

products is proprietary and furnished under license

and can be used or copied only in accordance with

the terms of such license.

This document contains proprietary information that is

protected by copyright. No part of this document may

be reproduced or transmitted in any form or by any

means without the prior written permission of

GE Interlogix, Video Systems Group.

The information contained in this document is subject

to change without notice. GE Interlogix, Video

Systems Group, in keeping pace with technological

advances, is a company of product innovation.

Therefore, it is difficult to ensure that all information

provided is entirely accurate and up-to-date.

GE Interlogix, Video Systems Group, accepts no

responsibility for inaccuracies or omissions and

specifically disclaims any liabilities, losses, or risks,

personal or otherwise, incurred as a consequence,

directly or indirectly, of the use or application of any of

the contents of this document.

For the latest product specifications, visit

GE Interlogix, Video Systems Group, online at

www.GE-Interlogix.com or contact your GE Interlogix,

Video Systems Group, sales representative.

This equipment has been tested and

found to comply with the limits for a

Class A digital device, pursuant to part

15 of the FCC Rules. These limits are

designed to provide reasonable

protection against harmful interference

when the equipment is operated in a

commercial environment. This

equipment generates, uses, and can

radiate radio frequency energy and, if

not installed and used in accordance

with the instruction manual, may cause

harmful interference to radio

communications.

You are cautioned that any changes or

modifications not expressly approved by

the party responsible for compliance

could void the user's authority to

operate the equipment.

For technical support before and after installation, call 800-469-1676.

Technical support is available 24 hours a day, 7 days a week.

Call: Tech Support 800-469-1676 (6 A.M. – 5 P.M. PST Monday through Friday)

Tech Support 541-740-3589 (all other times)

Main 800-343-3358 or 541-754-9133

Fax: Tech Support 541-752-9096 (available 24 hours a day)

Main 541-754-7162

Web: www.GE-Interlogix.com

11-0768DAV-B / December 2003

Page 3

S768DAV – S7768DAV User Manual Table of Contents

TABLE OF CONTENTS

BEFORE YOU BEGIN ..........................................................................................................5

1 INTRODUCTION ............................................................................................................ 7

2 MODULE SETUP ..........................................................................................................8

2.1 U

2.2 D

2.3 I

NPACKING THE UNIT .......................................................................................... 8

ATA TRANSLATION ............................................................................................ 8

NPUT/OUTPUT DATA FORMAT.............................................................................. 8

2.3.1 MANUAL DATA SELECTION ......................................................................... 9

2.3.2 AUTO DATA CONFIGURATION.................................................................... 10

2.4 OPTICAL/VIDEO ALARMS.................................................................................... 10

2.5 V

2.6 A

2.7 I

IDEO FORMAT/TEST PATTERN GENERATOR....................................................... 11

UDIO LEVEL .................................................................................................... 11

NPUT IMPEDANCE ............................................................................................. 12

3 INSTALLATION ...........................................................................................................13

3.1 RACK CARDS.................................................................................................... 13

3.2 502R R

3.3 C

ONNECTIONS .................................................................................................. 14

3.3.1 BACK PANEL CONNECTIONS ..................................................................... 15

3.3.2 INTERFACE BOARD CONNECTIONS ............................................................ 16

ACK CARD ENCLOSURES ....................................................................... 13

3.3.3 BUILT-IN TERMINATION ............................................................................ 19

3.3.4 VIDEO CABLE CONNECTIONS.................................................................... 20

3.3.5 AUDIO CONNECTIONS .............................................................................. 20

3.3.6 FIBER OPTIC CABLE CONNECTIONS .......................................................... 20

3.3.7 STANDALONE MODULE POWER CONNECTIONS........................................... 21

3.3.8 RACK MODULE POWER CONNECTIONS ...................................................... 21

4 OPERATION...............................................................................................................22

4.1 N

4.2 LED O

11-0768DAV-B/ December 2003 3

ORMAL OPERATION ......................................................................................... 22

PERATION .............................................................................................. 22

4.2.1 LASER INDICATOR ................................................................................. 22

4.2.2 LEVEL/LOSS INDICATOR ....................................................................... 23

4.2.3 VIDEO IN/OUT INDICATORS ................................................................... 23

4.2.4 AUDIO 1, 2 IN/OUT INDICATORS ............................................................ 23

Page 4

Table of Contents S768DAV – S7768DAV User Manual

4.2.5 DATA 1, 2 IN/OUT INDICATORS.............................................................. 23

4.2.6 CONTACT 1, 2 IN/OUT INDICATORS ...................................................... 24

4.2.7 ENABLED 1, 2 INDICATORS.................................................................... 24

4.3 V

4.4 T

IDEO TEST PATTERNS ..................................................................................... 24

EST MODE ...................................................................................................... 24

5 TROUBLESHOOTING...................................................................................................26

A

PPENDIX A: RS485 APPLICATION NOTES....................................................................... 27

A.1 INTRODUCTION ................................................................................................. 27

A.2 C

A.3 CONFIGURATION ............................................................................................... 27

A.4 T

ONNECTION .................................................................................................... 27

ERMINATION.................................................................................................... 27

4 11-0768DAV-B/ December 2003

Page 5

S768DAV – S7768DAV User Manual Before You Begin

BEFORE YOU BEGIN

Read these instructions before installing or operating this product.

Note: This installation should be made by a qualified service person and should conform to local codes.

This manual provides installation and operation information. To use this document, you must have the

following minimum qualifications:

! A basic knowledge of CCTV systems and components

! A basic knowledge of electrical wiring and low-voltage electrical hookups

Intended use

Use this product only for the purpose for which it was designed; refer to the product specification and user

documentation.

Customer Support

For assistance in installing, operating, maintaining, and troubleshooting this product, refer to this

document and any other documentation provided. If you still have questions, please contact

Technical Support and Sales:

GE Interlogix, Video Systems Group

Call: 800-469-1676

Fax: 541-752-9096

Note: You should be at the equipment and ready with details before calling Technical Support.

Conventions Used in this Manual

Boldface or button icons highlight command entries. The following WARNING, CAUTION, and Note

statements identify potential hazards that can occur if the equipment is handled improperly:

* WARNING:

Improper use of this equipment can cause severe bodily injury or equipment damage.

** CAUTION:

Improper use of this equipment can cause equipment damage.

Note: Notes contain important information about a product or procedure.

* This symbol indicates electrical warnings and cautions.

** This symbol indicates general warnings and cautions.

11-0768DAV-B/ December 2003 5

Page 6

Before You Begin S768DAV – S7768DAV User Manual

6 11-0768DAV-B/ December 2003

Page 7

S768DAV – S7768DAV User Manual Introduction

1 INTRODUCTION

This is a guide to the installation and operation of the S768DAV and S7768DAV series fiber optic video,

audio, data, and contact closure transmission system. Please read the entire manual before installing the

equipment.

NOTE: The series numbers S768DAVT and S768DAVR are used to describe all models of transmitters and receivers unless noted

otherwise.

The Series S768DAV and S7768DAV transmission systems offer simultaneous real-time transmission of:

! One channel of two-way 9-bit digital video

! Two channels of two-way high quality audio (HQA)

! Two channels of two-way multi-protocol data (MPD)

! Two channels of two-way relay/contact closures

The S768DAV system operates over one or two multimode fibers and the S7768DAV uses one or two

single-mode fibers. A complete system consists of an S768DAVT transmitter and an S768DAVR receiver.

Units are designed for installation in the 515R1 or 517R1 Card Cages or in the 502R rack card enclosure.

Figure 1 shows a basic system diagram.

Figure 1. S768DAV System Diagram

11-0768DAV-B/ December 2003 7

Page 8

Module Setup S768DAV – S7768DAV User Manual

2 MODULE SETUP

2.1 UNPACKING THE UNIT

In the event that anything is missing from the following list, contact your authorized dealer or

representative.

! S768DAVT (S7768DAVT) Transmitter or S7768DAVR (S7768DAVR) Receiver

! User Manual

Save the original packing materials in case it becomes necessary to return the unit.

CAUTION:

Take all necessary precautions to protect the unit from static electricity during the following procedures.

Equipment damage may result.

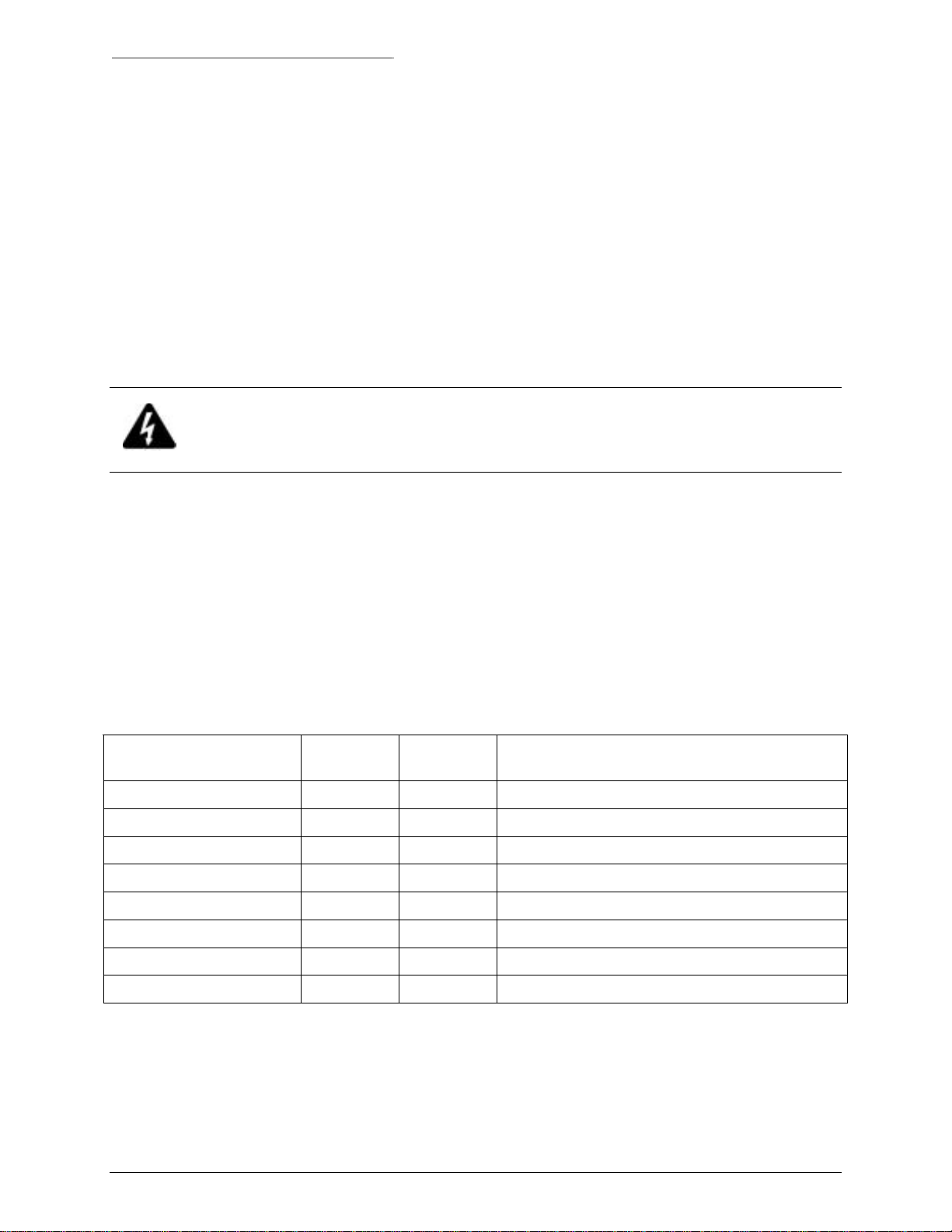

2.2 DATA TRANSLATION

The data translation capability of the S768DAV series is unique in the industry. It enables translation from

one data format to another and eliminates the need for external translation devices.

The translation is in the physical layer only; it cannot interpret specific protocols or translate commands.

Due to the encoding schemes utilized in Manchester and Biphase, these formats are exempt from

translation. Data translation examples are shown in Table 1.

Table 1. Data Translations

Translation TX Switch

Setting

TTL to RS232 three-wire 3 1 Signal level conversion

RS232, three-wire to TTL 1 3 Signal level conversion

TTL to RS422 3 4 Single ended to differential conversion

RS422 to TTL 4 3 Differential to single ended conversion

RS232, three-wire to RS422 1 4 Single ended to differential conversion

RS422 to RS232, three -wire 4 1 Differential to single ended conversion

RS232, five-wire to RS485 2 7 - A RS232 handshaking bit is used to indicate tri-state

RX Switch

Setting

Comments

RS485 to RS232, five-wire 7 – A 2 Tri-State detection circuitry activates handshaking bit

2.3 INPUT/OUTPUT DATA FORMAT

Determine the data formats required for input and output for both data channels. The data formats may

be the same or different for each channel. The data format can also differ from input to output on the

same data channel.

8 11-0768DAV-B/ December 2003

Page 9

S768DAV – S7768DAV User Manual Module Setup

2.3.1 MANUAL DATA SELECTION

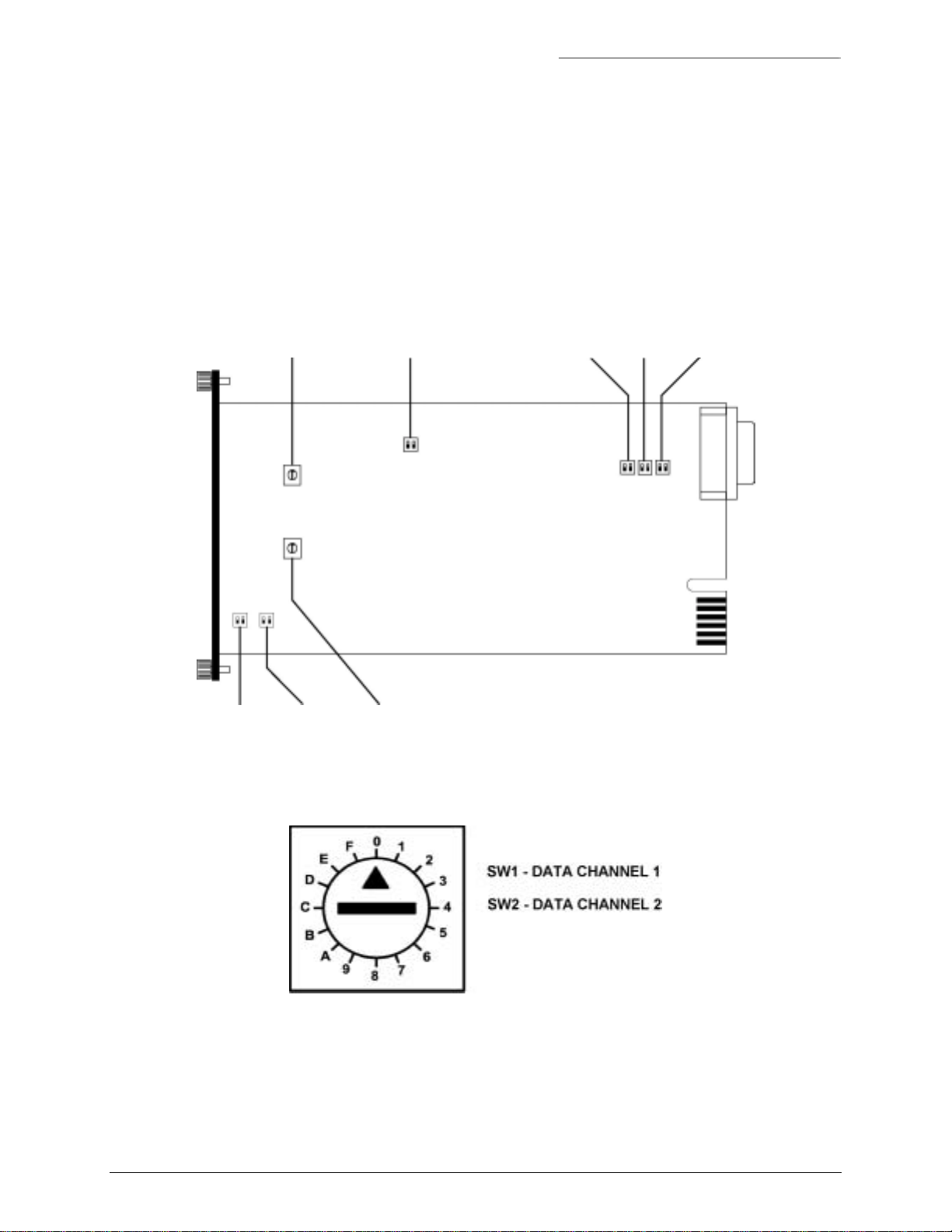

To set the data format for channels 1 and 2, see Figure 2, Figure 3, Table 2 and perform the following.

1) Select a data format for each Data channel on the transmitter using DATA SELECT switch SW1

(channel 1) and SW2 (channel 2).

2) Select a data format for each Data channel on the receiver using DATA SELECT switch SW1

(channel 1) and SW2 (channel 2).

NOTE: The DATA SELECT switches, SW1 and SW2 on the audio/data card, are shipped in the Auto Configure setting (position 0).

SW1 SW7 SW5 SW4 SW6

SW3 SW8 SW2

Figure 2. S768DAV Location of Switches

Figure 3. DATA SELECT Switches SW1 and SW2

11-0768DAV-B/ December 2003 9

Page 10

Module Setup S768DAV – S7768DAV User Manual

Table 2. DATA SELECT SW1/SW2 Settings

Setting Data Mode Setting Data Mode

0 Not Configured or Auto Configuration 8 RS485 two -wire, 2V offset

1 RS232 9 RS485 four-wire standard

2 RS232 with handshake A RS485 four-wire, 1V offset

3 TTL B RS485 four-wire, 2V offset

4 RS422 two-wire C Not used

5 Manchester/Biphase D Not used

6 RS485 two-wire Standard or SensorNet E Receiver Test mode

7 RS485 two -wire, 1V offset F Transmitter Test mode

2.3.2 AUTO DATA CONFIGURATION

The S768DAV modules can be set for Auto Data Configuration, where the format of the data on channel

1 or channel 2 is controlled from one unit, either the transmitter or the receiver. To use the Auto Data

Configuration feature, perform the following.

1) Set the DATA SELECT switches SW1 or SW2 on one unit to position 0 (default setting).

2) Set the DATA SELECT switches SW1 or SW2 on the other unit to the desired format.

3) If the data format needs to be changed for a particular channel, only the DATA SELECT switches

on one unit need to be changed. The other unit remains in position 0 and will auto-configure

according to the selected data format.

2.4 OPTICAL/VIDEO ALARMS

Rack cards are supplied with alarm functions that activate if the optical or video signal input to the module

fails. These alarms can be output to the rack power supply, where an audible alarm and alarm output

contact closure can be activated. The optical and video alarms are controlled using DIP switch SW3 on

the audio/data card. To set the optical and video alarms, see Figure 2 and Figure 4 and perform the

following.

Figure 4. ALARM Switch SW3

1) Set switch SW3-1 to ON to enable the FIBER (optical) alarm.

2) Set SW3-2 to ON to enable the VIDEO alarm.

10 11-0768DAV-B/ December 2003

Page 11

S768DAV – S7768DAV User Manual Module Setup

3) If the optical or video alarm output is not desired, set the corresponding DIP switch (SW3-1 or

SW3-2) to OFF.

NOTE: Setting ALARM switches SW3-1 and SW3-2 to OFF does not affect the operation of the LEVEL/LOSS or VIDEO LEDs. A

red LED always indicates signal loss.

2.5 VIDEO FORMAT/TEST PATTERN GENERATOR

The S768DAV links support both NTSC and PAL video standards without adjustment. DIP switch SW8 on

the S768DAVT transmitter and S768DAVR receiver audio/data cards enable the test pattern generator

and select the video format. To enable the test pattern generator and set the video format, see Figure 2

and Figure 5 and perform the following.

Figure 5. VIDEO FORMAT/TEST PATTERN GENERATOR Switch SW8

1) Set DIP switch SW8 on the transmitter and receiver to the desired position.

2) Ensure the switches on the transmitter and receiver are set to the same video format.

NOTE: In order for the test pattern generator to operate properly, both the transmitter and receiver must be set to the same format.

2.6 AUDIO LEVEL

The S768DAV system features dual audio level operation to meet the system requirements of -10 dBu

audio reference and 0 dBu/+4 dBu audio reference level. All units are shipped with the audio level

switches set to 18 dBu (0 dBu audio reference level). At this setting, the 18 dB of operating range will

support maximum audio levels of +18 dBu. Switches SW4, SW5, and SW7 on the audio/data card select

the input and output audio levels. To set the audio levels, see Figure 2 and Figure 6 and perform the

following.

11-0768DAV-B/ December 2003 11

Page 12

Module Setup S768DAV – S7768DAV User Manual

Figure 6. AUDIO LEVEL Switches SW4, SW5, and SW7

1) If a low audio input level causes the output audio signal to degrade, the input sensitivity of the

S768DAV can be increased by switching to the 8 dBu maximum scale.

2) For systems running at -10 dBu, typical for VCRs and DVD players, switches SW4, SW5, and SW7

should be set to 8 dB.

3) You can set the transmitter input to 8 dBu and the receiver output to 18 dBu to add 10 dB of gain to

the system, however, this also increases system signal-to-noise ratio (S/N).

2.7 INPUT IMPEDANCE

The S768DAV units are shipped with the input impedance set at high impedance (high-Z). To select a

600Ω input impedance in place of the high-Z input, set switch SW6 on the audio/data card to 600. See

Figure 2 and Figure 7.

Figure 7. IMPEDANCE Switch SW6

12 11-0768DAV-B/ December 2003

Page 13

S768DAV – S7768DAV User Manual Installation

3 INSTALLATION

This fiber-optic link is supplied as a rack card. The rack cards can also be used in a standalone

configuration if placed in a 502R rack card enclosure.

Units should be installed in dry locations protected from extremes of temperature and humidity.

3.1 RACK CARDS

Rack cards are installed in a 19-inch (483-mm), EIA standard card-cage rack, either the 515R1 or the

517R1. Follow these guidelines to install rack cards.

CAUTION:

Although rack cards are hot-swappable and can be installed without turning off power to the rack, the

power switch on the rack power supply should be turned off and the rack power supply disconnected

from any power source before installing rack cards.

1) Make sure that the card is oriented right-side up, and slide it into the card guides in the rack until the

edge connector at the back of the card seats in the corresponding slot in the rack’s connector panel.

Seating may require thumb pressure on the top and bottom of the card’s front panel.

CAUTION:

Do not press on any of the LEDs when installing cards into the rack. Equipment damage may result.

2) Tighten the two thumbscrews on the card until the front panel of the card is seated against the front

of the rack.

3.2 502R RACK CARD ENCLOSURES

To install rack cards in the 502R rack card enclosure, see Figure 8 and perform the following.

CAUTION:

The rack card module can be powered only by 13.5 - 16 VDC. AC power must not be used. It is

recommended that the 613P power adapter be used to supply power to the module. Damage to the

equipment may result if AC power is used.

CAUTION:

Complete all instruction steps before supplying power to the unit.

11-0768DAV-B/ December 2003 13

Page 14

Installation S768DAV – S7768DAV User Manual

1) Look inside the enclosure to determine the location of the socket for the edge connector on the

card. Orient the card so that it will seat in the socket, and slide it into the card guides in the

enclosure until the edge connector at the back of the card seats in the socket. Seating may require

thumb pressure on the top and bottom of the card’s front panel.

CAUTION:

Do not to press on any of the LEDs when installing cards into the enclosure. Equipment damage may

result.

2) Tighten the two thumbscrews on the card until the front panel of the card is seated against the front

of the enclosure.

3) Determine where the module will be installed, and ensure that there is adequate space for making

the various cable connections and for reading the diagnostic LEDs.

NOTE: The type of screws chosen must be suitable for the surface on which the module is to be mounted.

4) Standalone modules can be attached to suitable flat surfaces with four No. 6 (3 mm) screws. After

the enclosure is securely attached to a flat surface, the cable connections can be made.

Figure 8. 502R Rack Card Enclosure Mounting Data

3.3 CONNECTIONS

All video, audio, data, contact, and fiber connections are made to the back panel of the S768DAV

module. When connecting audio, data, or contact signals, always wire the signal OUT pins on the

audio/data equipment to the signal IN pins on the fiber links, and the signal IN pins on the audio/data

equipment to the signal OUT pins on the fiber links. See Figure 9.

14 11-0768DAV-B/ December 2003

Page 15

S768DAV – S7768DAV User Manual Installation

Audio/Data Equipment S768DAV Link

Figure 9. S768DAV Fiber Link Audio – Data – Contact Connections

3.3.1 BACK PANEL CONNECTIONS

Audio, data, and contact signals can be connected directly to the unit by wiring a 26-pin male D-connector

(AMP plug part number 748474-1, pin part number 748333-4) and attaching it to audio/data connector J4

on the back panel of the unit. See Figure 10. Table 3 lists the signal and pin information.

Audio/Data

Video Out

Optical In

Optical Out

Video In

Note: Optical In connector is not present on 1-Fiber models.

Figure 10. S768DAV 2-Fiber Module Back Panel Connections

11-0768DAV-B/ December 2003 15

Page 16

Installation S768DAV – S7768DAV User Manual

Table 3. J4 Audio/Data Connections

Pin Signal Pin Signal

1 AUDIO CHANNEL 1 OUT + 14 AUDIO CHANNEL 1 IN -

2 GROUND 15 AUDIO CHANNEL 2 IN +

3 AUDIO CHANNEL 2 OUT - 16 GROUND

4 CONTACT CHANNEL 1 IN + 17 DATA CHANNEL 1 OUT -

5 AUDIO CHANNEL 1 IN + 18 DATA CHANNEL 1 IN -

6 AUDIO CHANNEL 2 IN - 19 CONTACT CHANNEL 2 OUT -

7 DATA CHANNEL 1 OUT + 20 CONTACT CHANNEL 1 OUT +

8 DATA CHANNEL 1 IN + 21 CONTACT CHANNEL 1 OUT -

9 DATA CHANNEL 2 IN - 22 +5 VDC BIAS

10 CONTACT CHANNEL 2 OUT + 23 GROUND

11 AUDIO CHANNEL 1 OUT - 24 DATA CHANNEL 2 OUT +

12 AUDIO CHANNEL 2 OUT + 25 DATA CHANNEL 2 OUT -

13 CONTACT CHANNEL 2 IN + 26 DATA CHANNEL 2 IN +

3.3.2 INTERFACE BOARD CONNECTIONS

The S768DAV units are also supplied with an interface board that attaches directly to the back of the

module. The interface board contains screw terminal connectors for the audio, data, and contact inputs

and outputs. Refer to Figure 11 and Table 4 through Table 14 for interface board wiring information.

J2 J4 J6

J1

Mates with J4

on S768DAV

Back Panel

J3 J5 J7

Figure 11. S768DAV Interface Board

16 11-0768DAV-B/ December 2003

Page 17

S768DAV – S7768DAV User Manual Installation

Table 4. Interface Board Connections

Pin Signal Pin Signal

Connector J2 Connector J3

1 GROUND 1 GROUND

2 DATA CHANNEL 1 OUT + 2 DATA CHANNEL 2 OUT +

3 DATA CHANNEL 1 OUT - 3 DATA CHANNEL 2 OUT -

4 +5 VDC BIAS 4 +5 VDC BIAS

5 DATA CHANNEL 1 IN + 5 DATA CHANNEL 2 IN +

6 DATA CHANNEL 1 IN - 6 DATA CHANNEL 2 IN -

7 TERMINATION 7 TERMINATION

8 GROUND 8 GROUND

Connector J4 Connector J5

1 AUDIO CHANNEL 1 IN + 1 AUDIO CHANNEL 2 IN +

2 AUDIO CHANNEL 1 IN - 2 AUDIO CHANNEL 2 IN -

3 GROUND 3 GROUND

4 AUDIO CHANNEL 1 OUT + 4 AUDIO CHANNEL 2 OUT +

5 AUDIO CHANNEL 1 OUT - 5 AUDIO CHANNEL 2 OUT -

6 GROUND 6 GROUND

Connector J6 Connector J7

1 CONTACT CHANNEL 1 IN + 1 CONTACT CHANNEL 2 IN +

2 CONTACT CHANNEL 1 IN - 2 CONTACT CHANNEL 2 IN -

3 CONTACT CHANNEL 1 OUT + 3 CONTACT CHANNEL 2 OUT +

4 CONTACT CHANNEL 1 OUT - 4 CONTACT CHANNEL 2 OUT -

Table 5. J2/J3 Connections for RS232 Data

SW1 / SW2 – Position 1

Pin Signal

1 GROUND/SHIELD

2 RS232 OUT

3 NO CONNECTION

4 NO CONNECTION

5 RS232 IN

6 NO CONNECTION

7 NO CONNECTION

8 GROUND

Table 6. J2/J3 Connections for RS232 Data with

Handshaking

SW1 / SW2 – Position 2

Pin Signal

1 GROUND/SHIELD

2 RS232 OUT

3 RTS/CTS OUT

4 NO CONNECTION

5 RS232 IN

6 RTS/CTS IN

7 NO CONNECTION

8 GROUND

11-0768DAV-B/ December 2003 17

Page 18

Installation S768DAV – S7768DAV User Manual

Table 7. J2/J3 Connections for TTL Data

SW1 / SW2 – Position 3

Pin Signal

1 GROUND/SHIELD

2 NO CONNECTION

3 TTL OUT

4 NO CONNECTION

5 TIE TO PIN 1

6 TTL IN

7 NO CONNECTION

8 GROUND

Table 9. J2/J3 Connections for Manchester/Biphase Data

SW1 / SW2 – Position 5

Pin Signal

1 MANCHESTER/BIPHASE OUT -

2 MANCHESTER/BIPHASE OUT +

3 NO CONNECTION

4 NO CONNECTION

5 MANCHESTER/BIPHASE IN -

6 MANCHESTER/BIPHASE IN +

7 NO CONNECTION

8 GROUND

Table 8. J2/J3 Connections for RS422 Data

SW1 / SW2 – Position 4

Pin Signal

1 GROUND/SHIELD

2 RS422 OUT -

3 RS422 OUT +

4 NO CONNECTION

5 RS422 IN -

6 RS422 IN +

7 NO CONNECTION

8 GROUND

Table 10. J2/J3 Connections for Manchester/Biphase

Termination Unit Data

SW1 / SW2 – Position 5

Pin Signal

1 MANCHESTER/BIPHASE OUT -

2 MANCHESTER/BIPHASE OUT +

3 NO CONNECTION

4 NO CONNECTION

5 MANCHESTER/BIPHASE IN -

6 MANCHESTER/BIPHASE IN +

7 TERMINIATION - TIE TO PIN 5

8 GROUND

18

11-0768DAV-B/

December 2003

Page 19

Manual title Table of Contents

Table 11. J2/J3 Connections for RS485 2-Wire Data

SW1 / SW2 – Position 6 (standard offset)

Position 7 (1V offset)

Position 8 (2V offset)

Pin Signal

1 GROUND/SHIELD

2 NO CONNECTION

3 NO CONNECTION

4 +5 VDC BIAS OUT

5 RS485 -

6 RS485 +

7 TERMINATION – TIE TO PIN 5

8 GROUND

Table 13. J2/J3 Connections for SensorNet Data

SW1 / SW2 – Position 6

Table 12. J2/J3 Connections for RS485 4-Wire Data

SW1 / SW2 – Position 9 (standard offset)

Position A (1V offset)

Position B (2V offset)

Pin Signal

1 GROUND/SHIELD

2 RS485 OUT -

3 RS485 OUT +

4 +5 VDC BIAS OUT

5 RS485 IN -

6 RS485 IN +

7 TERMINATION – TIE TO PIN 5

8 GROUND

Table 14. J2/J3 Connections for Test Mode Loopback

SW1 / SW2 – Position F

Pin Signal

1 GROUND/SHIELD

2 NO CONNECTION

3 NO CONNECTION

4 +5 VDC BIAS OUT

5 SENSORNET -

6 SENSORNET +

7 TERMINATION – TIE TO PIN 5

8 GROUND

Pin Signal

1 NO CONNECTION

2 TIE TO PIN 5

3 TIE TO PIN 6

4 NO CONNECTION

5 TIE TO PIN 2

6 TIE TO PIN 3

7 NO CONNECTION

8 GROUND

3.3.3 BUILT-IN TERMINATION

The S768DAV features a built-in termination on the Interface Board for RS485, Manchester, Biphase, and

SensorNet installations. Refer to Table 4, and Table 10 through Table 13.

11-0768DAV-B/ December 2003 19

Page 20

Installation S768DAV – S7768DAV User Manual

3.3.4 VIDEO CABLE CONNECTIONS

CAUTION:

Make sure all peripheral equipment that will be connected to the fiber unit is turned OFF during

installation. Damage to equipment may result.

NOTE: Belden number 9259 or equivalent RG59/U coaxial cable should be used between the video equipment and the fiber units.

Do not exceed the maximum distance recommended by the manufacturer of the video equipment.

Coaxial cable must be terminated with female BNC connectors to properly connect with the fiber links.

NOTE:

Connect the video equipment, such as a camera and monitor, to the input and output BNC jacks on the

S768DAV transmitter and receiver using terminated coaxial cable. See Figure 10.

3.3.5

AUDIO CONNECTIONS

Audio input and output signals are connected to the 26-pin connector located on the back of the module,

or to the screw terminal connectors on the Interface board supplied with the unit. See Figure 10 and

Figure 11. Refer to Table 3 and Table 4 for wiring information.

NOTE: Signal strength remains the same regardless of type of connection.

Audio connection options include:

! Balanced transmitter input to balanced receiver output

! Balanced transmitter input to unbalanced receiver output

! Unbalanced transmitter input to unbalanced receiver output

! Unbalanced transmitter input to balanced receiver output

1) For a balanced connection, connect the external equipment to the (+) and (-) pins of the desired

channel.

2) For an unbalanced connection, add a short jumper between the (-) pin and the ground pin.

3.3.6

FIBER OPTIC CABLE CONNECTIONS

Most cable manufacturers identify the individual fibers in the cable. Select appropriately terminated fiber

and mark both ends with a unique identification label (e.g. for cable no. 03, fiber no. 08) to ensure that the

fiber connected to the near end is the same as the one connected to the far end.

The proper optical connection will link the transmitter's TRANSMIT (OUT) port to the receiver's RECEIVE

(IN) port. See Figure 10.

1) Wipe the inside of the port’s sleeve with a lint-free pipe cleaner moistened with reagent-grade

isopropyl alcohol. Blow dry with dry air.

2) Clean the connector using a lint-free cloth dampened with reagent-grade isopropyl alcohol.

Thoroughly wipe the side and end of the ferrule. Blow the ferrule dry with dry air. Visually inspect

the ferrule for lint.

3) Fasten the fiber optic cable to the port.

20 December 2003

11-0768DAV-B/

Page 21

S768DAV – S7768DAV User Manual Installation

3.3.7 STANDALONE MODULE POWER CONNECTIONS

CAUTION:

Standalone modules can be powered only by 13.5 - 16 VDC. AC power must not be used. Damage to

the equipment will result.

The 502R rack card enclosure has a removable screw terminal connector for the electrical input

connection. Pin 1 of this connector is the GROUND terminal, pin 2 is not used, and pin 3 is the +DC

terminal as marked on the enclosure. Connect the input power as follows.

1) Identify the power connector and remove it from the module.

2) Make sure the power supply is not connected to any power source, and strip approximately 0.25

inches (6 mm) of insulation from the ends of the cable.

3) Taking care to observe the correct polarization of the cable, insert one lead into one of the screw

sockets and tighten the screw. Confirm the security of the connection with a light pull on the cable.

4) Repeat step 3 for the other conductor.

5) Seat the connector in its position in the fiber unit.

6) Plug the power supply into a suitable outlet.

7) Power up the peripheral equipment and verify system operation by observing video on the monitor

at the receiver end.

3.3.8

RACK MODULE POWER CONNECTIONS

Power connections are made automatically when the card is installed. To supply power to the rack,

connect the rack power supply to an AC outlet and set the power switch to ON.

December 2003 21 11-0768DAV-B/

Page 22

Operation S768DAV – S7768DAV User Manual

4 OPERATION

4.1 NORMAL OPERATION

S768DAV fiber links operate automatically after installation. Refer to paragraph 4.4 for details on how to

execute the test mode. For description of LED color codes and an explanation of how to diagnose system

faults using the LEDs built into the units, refer to section 5, Troubleshooting.

4.2 LED OPERATION

The S768DAV modules have built-in Status Monitoring And Reliability Test System (SMARTS)

diagnostic capabilities that include LED indicators for monitoring data and optical status. The S768DAV

fiber units have nine pairs of LED indicators that describe the current state of operation; the current status

of video, audio, and data signals; and fiber optic signal strength.

These indicator pairs are LASER and LEVEL/LOSS, VIDEO IN/OUT, AUDIO 1 IN/OUT, AUDIO 2

IN/OUT, DATA 1 IN/OUT, DATA 2 IN/OUT, CONTACT 1 IN/OUT, CONTACT 2 IN/OUT, ENABLED 1,

and ENABLED 2. See Figure 12. The operation of the front panel LEDs is described in the following

paragraphs.

Figure 12. Front Panel LEDs

4.2.1 LASER INDICATOR

A green LASER LED indicates the laser is operating normally. A red LASER LED indicates the laser is

malfunctioning.

22

11-0768DAV-B/ December 2003

Page 23

S768DAV – S7768DAV User Manual Operation

4.2.2 LEVEL/LOSS INDICATOR

This LED indicates the relative optical signal strength received at the module. When sufficient optical

power is being received, the LED is green. As the optical power decreases, as happens through long fiber

runs, splices or connections, the LEVEL/LOSS LED stays green until the optical power drops below the

minimum level.

The LEVEL/LOSS LED will turn bright red to indicate an insufficient amount of optical power is being

received. All data will default to its failure state level to eliminate bus contention.

4.2.3

VIDEO IN/OUT INDICATORS

The VIDEO IN (or OUT) LED indicates the strength of the video signal. The VIDEO IN LED on the module

remains green as long as an adequate video signal is being input to the unit. If the video input becomes

too weak, the LED will turn red. The VIDEO OUT LED on the module performs a similar function, except

that it refers to the video output from the unit.

Note: The S768DAV monitors the video sync signals to determine the strength of the signal. It does not monitor the brightness

signal. Thus, if the scene in front of a camera is totally dark, producing a blank monitor screen, the VIDEO IN and OUT LEDs can

still be green.

4.2.4 AUDIO 1, 2 IN/OUT INDICATORS

The AUDIO IN (or OUT) LED indicates the strength of the audio signal by varying in intensity. The AUDIO

IN LED remains green as long as an adequate audio signal level is being input to the module.

If the audio input becomes too weak, the LED will turn off. The LED will be red when the audio level is

clipped.

The AUDIO OUT LED performs a similar function, except that it refers to the audio output from the

module.

4.2.5

DATA 1, 2 IN/OUT INDICATORS

The DATA IN LED indicates the level of the data signal being input to the S768DAV over copper. A green

DATA IN LED indicates a logic HIGH is present on the data inputs.

An amber DATA IN LED indicates a logic LOW is present on the copper. No color (OFF) indicates a tristate or high impedance input.

This LED can be used to determine the resting state of your equipment and, in the RS485 states, verify

that a tri-state is being detected properly.

The S768DAV has special circuitry to capture data transitions and make them visible on the LEDs. Highspeed bursts of activity, previously undetectable by standard LED circuits, are easily seen by this special

circuitry.

The DATA OUT LED functions identically to the DATA IN LED except that the LED represents data that is

being output from the unit. This LED has the same high-speed capture circuitry as the DATA IN LED.

11-0768DAV-B/ December 2003 23

Page 24

Operation S768DAV – S7768DAV User Manual

4.2.6 CONTACT 1, 2 IN/OUT INDICATORS

The CONTACT IN/OUT LEDs indicate the presence of relay/contact closure signals. A green CONTACT

IN/OUT LED indicates a closed relay contact, and a red LED indicates an open relay contact.

4.2.7

ENABLED 1, 2 INDICATORS

The ENABLED 1 (left) and ENABLED 2 (right) LEDs monitor the selected mode of Data channels 1 and

2. They have five states as follows:

! Green indicates a valid mode has been selected.

! Red indicates an invalid mode (spare or TEST mode) has been selected.

! Flashing red/green indicates that no mode has been selected.

! Flashing green/off indicates a valid mode is configured remotely.

! Flashing red/off indicates either an invalid mode or the Test mode is configured remotely.

4.3 VIDEO TEST PATTERNS

The S768DAV includes an internal video test pattern generator that can ease installation and

troubleshooting. The test patterns generated can notify the user of a fiber or video source failure by

outputting specific test patterns on the user’s monitor. This mode verifies proper functionality of the digital

decoding process and the fiber-optic interconnections.

Follow the procedures described in paragraph 2.5 to enable the test pattern generator. Figure 13 shows

the test patterns displayed on the monitor.

Disabling the test pattern generator causes no on-screen display during failure conditions.

Single White Bar Double White Bar Ramp Test Pattern

No Video Input No Optical Input Test Mode Selected

to Transmitter to Receiver at Transmitter

Figure 13. On-Screen Monitor Displays

4.4 TEST MODE

The Test mode enables you to verify the operation of the video, audio, and data circuits in the S768DAV

units, as well as the fiber connection from the S768DAV transmitter to the S768DAV receiver. To execute

the test mode, perform the following.

Note: Either DATA SELECT switch (SW-1 or SW-2) can be set to position F to enable the video ramp test pattern and the 1 kHz

test tone generator to verify video and audio operation.

24 11-0768DAV-B/ December 2003

Page 25

S768DAV – S7768DAV User Manual Operation

1) Set the DATA SELECT switch on the S768DAV you are testing to F (TX Test Mode). At this end

only, wire the data connections as follows (refer to Table 14):

• Connect the DATA IN+ pin to the DATA OUT+ pin.

• Connect the DATA IN- pin to the DATA OUT- pin.

2) At the opposite end, set the DATA SELECT switch on the S768DAV to E (RX Test Mode).

3) The transmitting unit should operate as follows:

• ENABLED LED is RED, indicating that a valid data format has not been selected.

• DATA OUT LED is slowly flashing between amber, green, and off. This indicates that the test

mode is generating an output pattern and sending it out on copper.

• DATA IN LED should mimic the DATA OUT LED. This indicates a good, proper loopback

connection, and proves that the data transmit/receive circuitry is working properly.

• LEVEL/LOSSTM might be red or green indicating received fiber signal strength.

4) The receiving unit should operate as follows:

• ENABLED LED is GREEN indicating a valid data format is selected.

• DATA OUT LED should slowly flash amber, green, off. This indicates that the fiber path from the

unit set for Test mode is reliable.

• DATA IN LED should be OFF indicating there is no input copper connection made.

• LEVEL/LOSS LED should be green to off (but not red), indicating that sufficient optical power is

being received.

• The AUDIO OUT LEDs should be green indicating sufficient audio output signal level.

5) In addition to the LED operation described above, verify the following:

• The monitor displays a ramp test pattern as shown in Figure 13.

• A 1 kHz test tone is emitted on the audio system connected to the receiving unit.

After the test has been performed at one end, swap switch positions and connectors to perform the test

on the other end. If the test is successful, the copper-in-to-fiber-to-copper-out conversion is working in

both directions.

11-0768DAV-B/ December 2003 25

Page 26

Troubleshooting S768DAV – S7768DAV User Manual

5 TROUBLESHOOTING

Table 15 contains troubleshooting information for the S768DAV units.

Table 15. Troubleshooting

Problem Probable Cause Solution

Red LASER LED Laser is malfunctioning Replace module

Fiber not connected Connect fiber to receiver and transmitter Red LEVEL/LOSS LED

Transmitter/Receiver not powered up Connect and apply power to module

VIDEO IN/OUT LED is OFF

AUDIO IN/OUT LED is OFF

DATA IN LED is OFF

Video input not connected to module Connect video input to module

Video source not powered up Apply power to video source

Video source not transmitting Check video source and cabling

Audio input not connected to module Connect audio input to module

Audio source not powered up Apply power to audio source

Audio source not transmitting Check audio source and cabling

Tri-state condition No action required

Data input not connected to module Connect data input to module

Data source not powered up Apply power to data source

Data source not transmitting Check data source and cabling

Red ENABLED 1 and/or 2 LED Test or invalid mode selected Set DATA SELECT switch to valid format

ENABLED 1 and/or 2 LED

flashing red/green

ENABLED 1 and/or 2 LED

flashing red/off

26 11-0768DAV-B/ December 2003

Both Transmitter and Receiver set to

Auto Configure mode

Invalid or Test mode configured

remotely

Set Transmitter or Receiver DATA

SELECT switch to valid format

Set DATA SELECT switch to valid format

if not in Test mode

Page 27

S768DAV – S7768DAV User Manual RS485 Application Notes

APPENDIX A: RS485 APPLICATION NOTES

A.1 INTRODUCTION

The S768DAV is configurable for both full-duplex (four-wire) and half-duplex (two-wire) operation. It can

be used for interfacing to systems adhering strictly to the RS-485 specification and for use with systems

that use a modified, "fail-safe biased" RS-485 bus.

A.2 CONNECTION

Use high-quality twisted-pair wiring, and make sure all connection points are clean and tight. A loose

connection on one of the wires can appear to function, yet cause intermittent errors: DATA LEDs may be

flashing as signals pass through the system, but those signals will be corrupt.

A.3 CONFIGURATION

The S768DAV multi-protocol data (MPD) units are designed to work with virtually any RS485 system.

Unfortunately, some systems operate on a "modified" version of RS485 that use a fail-safe biasing to pull

up/down their bus during a tri-state condition. In a standard RS485 system, when a driver on a properly

terminated bus goes into tri-state, the voltage between the differential outputs should be less than

200 mv.

(This is considered "standard offset" in the product instruction manuals.) A differential output tri-state

voltage this small can cause some non-standard systems to latch up, because they are designed for

much larger, "fail-safe," offsets.

To be able to interface to such equipment, the S768DAV MPD units offer two more "offset" level modes.

In most cases, the S768DAV unit should be configured for "standard offset" operation.

When the system is operating properly, the DATA IN and DATA OUT LEDs are off when there is no

communication (tri-state) and flash when data is being sent or received. If the link is not functioning

properly (LEDs will most likely not turn off), change the DATA SELECT switch on the unit to a higher

offset mode.

First try 1 V, then 2 V. If switching the mode switch does not prove effective, the offset level may have to

be emulated at one end of the system by using pull-up/down resistors on the data connector. The

S768DAV has a +5 V bias pin and ground pins on the connector for this purpose. Contact the equipment

manufacturer's technical support for recommended resistor values and configuration.

A.4 TERMINATION

RS485 systems need to be properly terminated in order to work reliably. Two terminating resistors are

used on each RS485 bus, at the farthest ends of the link.

These resistors should be attached to the data/audio connector on the back of the unit if the S768DAV

link is at one end of the bus. If the terminating resistors are left out, the tri-state condition will not be

detected, and the bus might lock up. If there are too many terminations on the bus, signal levels might

drop too low, or driver circuitry might fail. The standard value of terminating resistors for RS485 is 120Ω.

11-0768DAV-B/ December 2003 27

Page 28

RS485 Application Notes S768DAV – S7768DAV User Manual

28 December 2003 11-0768DAV-B/

Loading...

Loading...