Page 1

SPECIFICATIONS

ROOTS™RAM™-DVJ WHISPAIR

™

Dry Vacuum Exhausters

Frames 406J, 412J & 616J

DESIGN AND CONSTRUCTION FEATURES

1. Single stage operation to 27” HgV

2. No valves, vanes or Teflon rings to wear

3. Alloy steel timing gears

4. Cylindrical roller bearings

5. Piston ring air seals

6. Lip-type oil seals (optional mechanical seal)

7. Splash oil lubrication

8. Horizontal and vertical configurations available

RAM™ stands for Reliability, Availability and

Maintainability. Today, more than ever, ROOTS is

committed to supplying our customers with reliable

products manufactured with state-of-the-art CNC

machine tools. Production and inventory are being

scheduled and controlled to ensure these units will be

available when you need them. Design improvements

such as repositionable rugged steel mounting feet and

die-cast aluminum drive end covers and gear covers

help to reduce installation costs and make normal

maintenance easier.

BASIC BLOWER DESCRIPTION

ROOTS™ RAM™-DVJ WHISPAIR™ dry exhausters

have an exclusive discharge jet plenum design which

allows cool, atmospheric air to flow into the cylinder.

This unique design permits continuous operation at

vacuum levels to blank-off with a single stage unit.

Standard dry vacuum exhausters are limited to

approx. 16” Hg vacuum because operation at higher

vacuum levels can cause extreme discharge temperatures resulting in casing and impeller distortion and

possible failure. The RAM™ vacuum exhauster’s

integral cooling design eliminates the problems

caused by high discharge temperatures at vacuum

levels beyond 16” Hg.

The basic model is designed using integral-shaft

ductile iron impellers with an involute profile. the

casing and headplates are grey iron, while the drive

end cover and gear cover are aluminum. Carburized

and ground alloy steel spur timing gears are taper

mounted on the shafts, secured with a locknut.

Cylindrical roller bearings are splash lubricated at

both the gear end and the drive end.Piston rings

reduce air leakage through the head-plate bores

and lip-type oil seals prevent lubricants from

entering the air chamber. Units can be equipped

with mechanical seals for gas applications.

All units are designed with rugged steel mounting

feet which permit in-field adaptability to either vertical

or horizontal installation requirements.

ROOTS™ DVJ WHISPAIR™ exhausters can be

arranged to operate in two and three stage systems to

achieve vacuum levels down to 1 Torr.

OPERATING PRINCIPLE

Position 1: Incoming air is trapped between the impellers.Simultaneously,

pressurized air is being discharged. Position 2: As the upper impeller passes

the jet plenum, cooled, pressurized air flows into the space between the impeller

and cylinder. This cools the trapped air, helps control thermal growth and allows

higher discharge pressures. Position 3: The trapped air is then moved into the

discharge flange (left). Backflow is reduced, resulting in lower operating noise

level and reduced shock loading on the impellers.

S-58F97 rev.0608

POSITION 2POSITION 1

POSITION 3

Page 2

D

D

DISCH.

DISCH.

P

AA

INLET

INLET

A

AA'

AB

P

AA

AA'

AB

A

O

R'

R

C

B

U

+.000

-.001

AF - INLET

AF' - DISCHARGE

AW – SYSTEM AIR INLET

Horizontal Orientation

Top Discharge Only

Counter Clockwise Rotation

Furnished Unless Otherwise

Specified

Clockwise Rotation

Furnished Only

When Specified

+.000

-.001

O'

D1

B

U

AA

AF – INLET

AA'

C

R '

R '

R '

AA

INLET

A'

AX AX

IDISCH.

AF' – DISCHARGE

AW – SYSTEM

AIR INLET

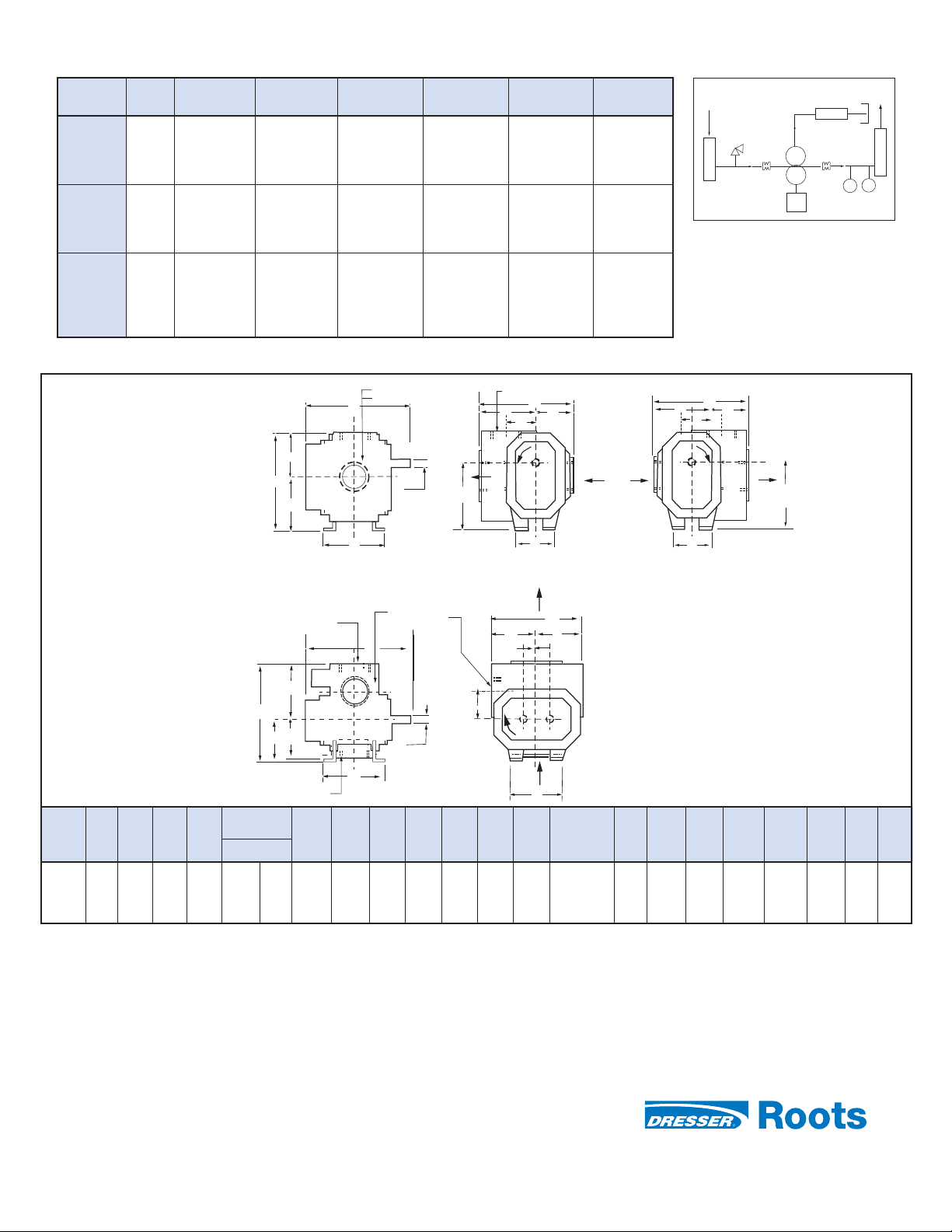

FRAME SPEED Maximum 12” HgV 16” HgV 20” HgV 24” HgV 27” HgV

SIZE RPM Free Air CFM CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP

2320 266 10.3 228 13.5 177 16.7 78 20.0 * 22.4

406J 2695 329 12.2 291 15.9 240 19.5 140 23.2 * 26.0

3564 474 16.7 436 21.5 385 26.2 286 30.9 38 34.5

4000 668 547 19.2 509 24.4 458 29.6 358 34.9 111 38.8

2320 530 20.2 456 26.7 353 33.2 155 39.7 * 44.5

412J 2695 655 23.6 580 31.1 478 38.6 280 46.1 * 51.8

3564 945 32.0 870 41.7 767 51.5 569 61.3 77 68.6

4000 1332 1090 36.3 1015 47.2 912 58.0 715 68.9 222 77.0

1750 1015 35.8 902 47.5 747 59.1 448 70.8 * 79.6

616J 2124 1310 43.7 1197 57.8 1042 71.9 743 86.0 * 96.6

2437 1557 50.5 1444 66.6 1289 82.7 990 98.8 245 110.9

2860 1891 59.8 1777 78.6 1622 97.4 1323 116.2 579 130.2

3000 2367 2001 63.0 1888 82.6 1733 102.3 1434 121.9 689 136.7

PERFORMANCE TABLE

WARRANTY PERIOD

Twelve (12) months from date of original unit start-up or 18 months from date of original shipment, whichever occurs first.

OUTLINE DRAWING & DIMENSIONAL TABLE

VERTICAL CONFIGURATION

(Horizontal Air Flow)

FRAME A A’ B C O O’ P P’ R R’ U Keyway AA AA’ AB AF AF’ AW AX WGT.

SIZE D D1

406J 8.00 11.00 10.75 20.50 11.25 7.50 16.38 18.00 17.75 14.75 9.00 7.38 1.500 .375x .188 7.25 10.50 6.75 4 NPT 5 NPT 4 NPT 2.25 365

412J 8.00 11.00 16.75 26.50 11.25 7.50 16.63 19.25 17.75 15.25 9.00 7.63 1.500 .375 x .188 6.00 11.75 6.50 6 FLG 6 FLG 5 FLG 2.25 575

412J 10.00 16.00 21.44 32.50 15.00 9.00 21.63 22.75 21.25 19.25 12.00 9.63 2.000 .500 x .250 7.50 13.75 6.75 8 FLG 10 FLG 8 FLG 3.00 975

Drive Shaft

Location

HORIZONTAL CONFIGURATION

(Vertical Air Flow)

NOTES:

1. All dimensions are in inches

2. Weights are in pounds, and are approximate

NOTES:

1. Vacuum ratings bases on inlet and jet

air at standard temperature of 68°F,

discharge and jet pressure of 30” Hg

and specific gravity of 1.0.

2. Refer to Factory for performance

guarantee above 24” HgV.

* Denotes blank-off.

From

Process

VRV

TS TG

Motor

Filter

I

N

S

I

L

S

I

L

E

N

C

E

R

SILENCER

S-58F97 rev.0608

Dresser Roots

Houston, Texas Headquarters • U.S. Toll Free Phone: 1-877-363-ROOT(S) (7668) • Direct Phone: +1 832-590-2600

Connersville, Indiana Operations • U.S. Toll Free Phone: 1-877-442-7910 • Direct Phone: +1 765-827-9285

United Kingdom Operations • Phone: +44 (0) 1484 422 222

USA/Canada Sales • Phone: +1 773-444-3360

Houston, Texas Factory Service • Phone: +1 713-896-4810

Mexico City Sales and Factory Service • Phone: +52 55 5889 5811

Dubai Sales and Factory Service • Phone: +971 4-8830831

Malaysia Sales • Phone: +60 3 2163 0480

China Sales • Phone: +86 10 8486 2440

Shanghai Factory Service • Phone: +86 21 5858 7638

©2007 Dresser, Inc. all rights reserved. • Printed in the U.S.A. • All information subject to change

without notice. • Universal RAI and EasyAir are registered trademarks of Dresser, Inc. • ROOTS,

RAM X, and WHISPAIR, are trademarks of Dresser, Inc.

www.dresser.com

Loading...

Loading...