Page 1

GE Healthcare

Instructions 71-5017-88 AC Ion Exchange Columns

Mono Q 5/50 GL and

Mono S 5/50 GL

Quick information

Mono Q™ 5/50 GL and Mono STM 5/50 GL are TricornTM high per formance columns.

The columns are pre-packed glass columns for high performance ion exchange

chromatography of proteins, peptides, polynucleotides and other biomolecules.

The columns are supplied with two union M6 female/1/16” male for connection

TM

to FPLC

System, two fingertight connector 1/16” for connecting 1/16” tubing

to column and ÄKTA, two stop plugs 1/16” male to seal the column (attached to

column when delivered) and instruction.

Column data

Matrix Polystyrene/divinyl benzene

Bead form Rigid, s pherical, po rous monodis perse

Particle size 10 μm

Column dimensions 5 × 50 mm

Bed volume 1 ml

Average loading capacity 50 mg

(will var y depending on s ample and loa ding conditi ons)

pH stability

regula r use 2–12

cleani ng 1–14

Tem pera tur e

operating 4 to 40 ºC

Flow rate (water at room temperature)

recommended 0.5–3.0 ml /min

maximum 3 ml/m in

Pressure over column

maximum 4 MPa, 40 bar, 580 psi

Mono Q Mono S

Type of exchanger Strong anion Strong cation

Charge d group -CH

Ionic capacity 0.27–0.37 mmol 0.12–0.15 mmol

Cl

Note: Before co nnecting th e column to a chrom atography sys tem, start t he pump and remo ve all air

and debr is in the syste m, particul arly in the tubi ng and valves.

-N+(CH3)3 -CH2-SO

2

-

/ml mediu m H+/ml mediu m

-

3

First-time use

Equilibrate the column for first-time use or after long-term storage as follows:

a) 5 column volumes (CV) distilled water at 1 ml/min at room temperature.

b) 5 CV star t buffer at 2 ml/min at room temperature.

c) 5 CV elution buffer at 2 ml/min at room temperature.

d) 5 CV star t buffer at 2 ml/min at room temperature.

Try these conditions fi rst

Start buffer (Mono Q)*: 20 mM Tris-HCl, pH 8.0

Elution buffer (Mono Q)*: 20 mM Tris-HCl + 1.0 M NaCl, pH 8.0

Star t buffer ( Mono S) *: 20 mM 2-[N-morpholino] ethanesulphonic acid ( MES), pH 6.0

Elution buffer (Mono S)*: 20 mM MES + 1.0 M NaCl, pH 6.0

* Users of Ä KTATM design s ystem may sele ct one of the buf fer recipes re commended fo r anion

exchange chromatography at pH 8 or cation exchange chromatography at pH 6.

Separation by gradient elution

Flow: 2 ml/min at room temperature

1. Equilibrate column with 5–10 column volumes (CV) of start buffer or until

baseline, eluent pH and conductivity are stable.

2. Adjust the sample to the chosen starting pH and ionic strength and apply to

the column (see sample recommendations).

3. Wash with 5–10 CV of start buffer or until the baseline, the eluent pH and the

conductivity are stable i.e. when all unbound material has washed through

the column.

4. Begin elution using a gradient volume of 10–20 CV and an increasing ionic

strengt up to 0.5 M NaCl (50% elution buffer).

5. Wash with 2–5 CV of 1 M NaCl (100% elution buffer) to elute any remaining

ionically-bound material.

6. Requilibrate with at least 5–10 CV of start buff er or until eluent pH and

conductivity reach the required values.

Read the section ”Optimization” for information about how to optimize a

separation.

Buff ers and solvent resistance

Recommended to have an on-line filter upstream of the injection valve. Buffers

and solvents with increased viscosity will affect the back-pressure and flow rate.

▼

De-gas and filter all solutions through a 0.22 μm filter.

Daily use

All commonly used aqueous buffers, pH 2–12

Urea, up to 8 M

Guanidine hydrochloride, up to 6 M

Acetonitrile, up to 30% in aqueous buffers

Non-ionic detergents

Cationic detergents (Mono Q)

Anionic detergents (Mono S)

Cleaning

Acetonitrile, up to 100%

Sodium hydroxide, up to 2 M

Ethanol, up to 100%

Methanol, up to 100%

Acetic acid, up to 75%

Isopropanol, up to 100%

Hydrochloric acid, up to 1 M

1% Trifluoroacetic a cid

Avoid:

Oxidizing agents

Anionic detergents (Mono Q)

Cationic detergents (Mono S)

Sample recommendations

Net charge of target molecule negative (Mono Q), positive (Mono S)

Recomm ended initial sample load ≤ 45 mg

Prepar ation Disso lve the sample i n start buf fer,

filter throu gh a 0.22 μm filte r or

centri fuge at 10 000 × g for 10 min

In-depth information

Delivery/storage

The column is delivered in degassed 20% ethanol sealed with two stop plugs to

prevent the column from drying out. For column storage, wash with 5 column

volumes of distilled water followed by 5 column volumes of 20% ethanol. Degas

the ethanol/water mixture thoroughly and apply at a low flow rate to avoid overpressuring the column. Store at room temperature or, for long periods, store at +4°

C to +8 °C. Ensure that the column is sealed well to avoid drying out. Do not freeze.

Choice of eluent

To avoid local disturbances in pH caused by buf fering ions par ticipating in the ion

exchange process, select an eluent with buffering ions of the same charge as the

substituent groups on the ion exchanger.

Choose the start buf fer pH so that substances to be bound to the ion exchanger

are charged, e.g. at least 1 pH unit above the isoelectric point for anion exchangers

and at least 1 pH unit below the isoelectric point for cation exchangers. Figure 2

and Figure 3 list a selection of standard aqueous buffers.

Piperidine

BICINE

(25 ˚C)

pKa

(25 °C)

3.13

3.86

4.21

4.75

5.76

6.27

7.20

7.56

8.33

pKa

4.75

5.33

6.48

6.65; 9.10

7.76

8.07

8.52

8.88

9.50

9.73

10.55

11.12

5

467891011pH

N-methyl piperazine

Piperazine

bis-Tris

Fig 2. Recommen ded buffer s for anion excha nge chromatog raphy.

Triethhanolamine

Tris

N-methyldiethanolamine

bis-Trispropane

Propane-1,3-diamino

Ethanolamine

Piperazine

Propane-1,3-diamino

▼

pH 2.5 3 4 5 6 7 8 9

Citric acid

Lactic acid

Butanedioic acid

Acetic acid

Methyl Malonic acid

MES

Phosphate

HEPES

Fig 3. Recommen ded buffers f or cation excha nge chromato graphy.

Table 1 lists suggested volatile buffers that can be used in cases where the purified

substance has to be freeze-dried.

Table 1. Volatile buffer systems.

pH Substance

3.3–4.3; 4.8–5.8 Pyridine/formic acid

3.3–4.3; 9.3–10.3 Trimethylamine/formic acid

4.3–5.8 Pyridine/acetic acid

3.3–4 .3; 8.8–9.8 A mmonia/formic acid

4.3–5. 3; 8.8–9.8 Ammonia /acetic acid

5.9–6.9; 9.3–10.3 Trimethylamine/carbonate

5.9–6.9; 8.8–9.8 A mmonium carb onate/ammonia

4.3–5.3; 7.2–8.2 N-ethylmorpholine/acetate

▼

Fig 1. Illustration of how to lock the upper adapter. The locking ring (black) must be

in down position to prevent uncontrolled adjustment of the column’s bed height.

Tricorn

™

Page 2

Optimization

Perform a first run as described in the section “Try these conditions first”. If the

results obtained are unsatisfactory, consider the following:

Action Eff ect

Change pH/buf fer salt (see Changes selectivity, gives

Figure 1 and Figure 2 for buf fers) weaker/stronger binding.

Change salt, counter ions Changes selectivity.

and/or co-ions

Decrease the sample load Improves resolution.

Decrease the flow rate Improves resolution.

Change gradient slope Shallower gradients improve selectivity but

broaden peaks (decrease efficiency).

A steeper gradient will sharpen peaks, but

move them closer together.

For more information, please refer to the handbook “Ion exchange

chromatography, Principles & Methods”, which can be ordered from GE Healthcare

or downloaded from our web site.

Cleaning

It is recommended to reverse the direction of flow during column cleaning so that

contaminants do not need to pass through the entire length of the column.

Regular cleaning

Flow: 0.5 ml/min at room temperature

1. Wash with 2 column volumes (CV) of 2 M NaCl.

2. Wash with 4 CV of 1 M NaOH

3. Wash with at least 2 CV of 2 M NaCl

4. Rinse with at least 2CV of distilled water until the UV-baseline and the eluent

pH are stable.

4. Wash with at least 4 CV of start buffer or storage buf fer until pH and

conductivity values have reached the required values.

More rigorous cleaning

Remove strongly hydrophobically bound proteins, lipoproteins and lipids by

washing with 4 column volumes (CV) of 30% isopropanol or 70% ethanol at

0.25 ml/min. Remove precipitated proteins with 1 CV of 1 mg/ml pepsin in

0.5 M NaCl, 0.1 M acetic acid (leave overnight) or wash with 2 CV of 6 M Guanidine

hydrochloride at 0.25 ml /min.

Depending on the nature of contaminant cleaning solution in the section ”Buffers

and solvent resistance” may be appropriate. After cleaning the column wash

with at least 2 CV of distilled water and 4 CV of star t buffer or storage buffer. For

more information on how to clean your column, please refer to the handbook ”Ion

exchange chromatography & Chromatofocusing, Principles & Methods”.

As an alternative to more rigorous cleaning or if column performance still not

restored change the filter at the top of the column. (Since contaminants are

introduced with the liquid flow, many of them are caught by the filter.) Instructions

for changing the f ilter are supplied with the Filter Kit. Clean the column after filter

change according to regular cleaning.

Troubleshooting

Symptom Remedy

Increased back-pressure Reverse the flow direction and pump 5 ml elution

over the column buffer at a flow rate of 0.5 ml/min through the

column. Return to normal flow direction and run for

5 minutes at 1 ml/min through the column. If high

backpressure persists, clean the column.

Loss of resolution and/or Clean the column according to the procedure

decreased sample recovery described in the section “More rigorous cleaning”.

Air in the column Reverse the flow direction and pump 10 ml well de-

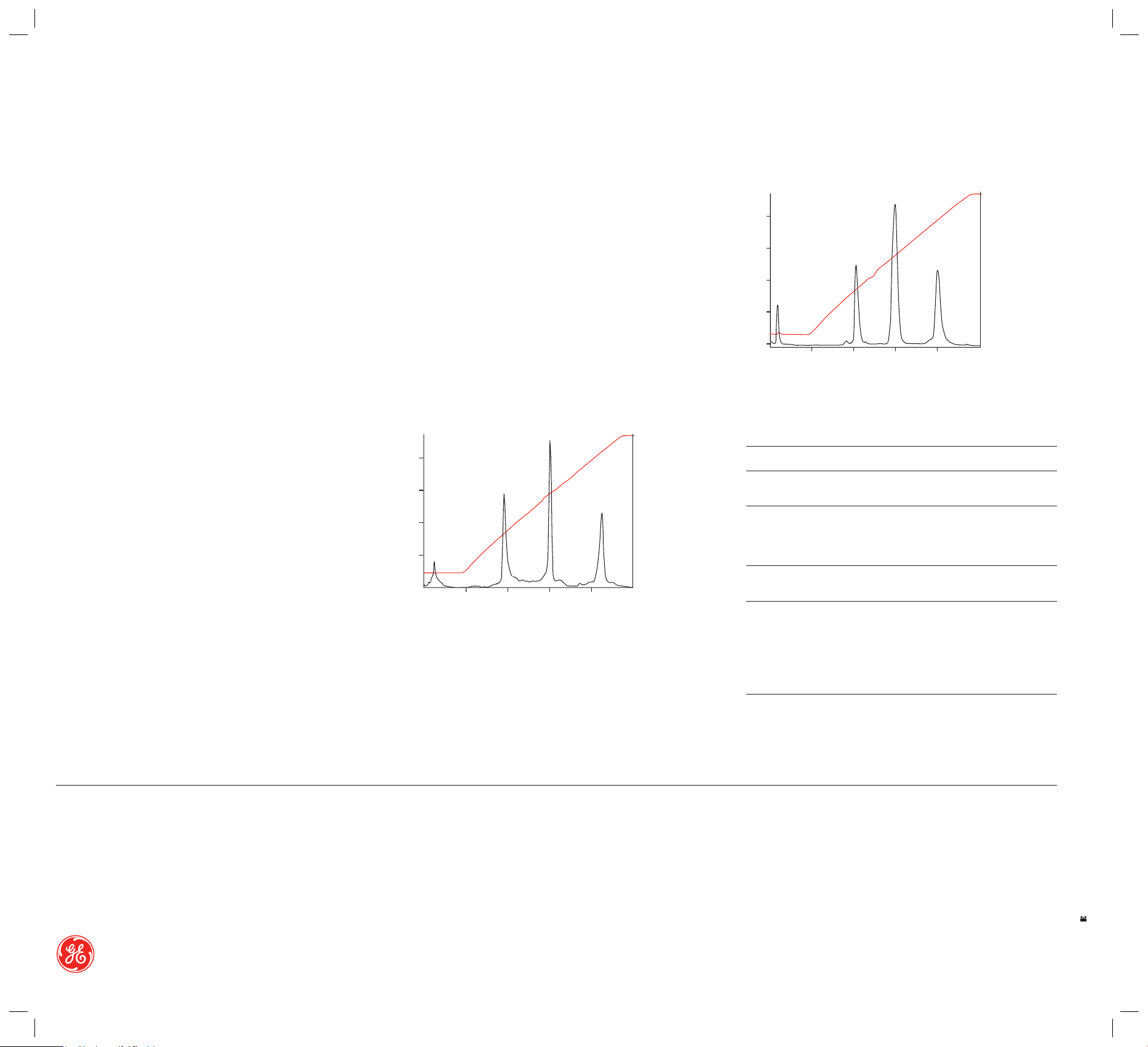

Function test of Mono S 5/50 GL

Sample: 1 . Ribonuclease A (1.5 mg/m l)

2. Cytochrome C (0.4 mg /ml)

3. Lysozyme ( 0.4 mg/ml)

Sample volume : 100 μl

Gradie nt: 0–100% elution b uffer in 20 CV

Start buffer: 20 mM so dium phospha te, pH 6.8

Elution buf fer: 20 mM sodiu m phosphate + 0.4 M N aCl, pH 6.8

Flow rat e: 1.0 ml/min (r oom temperatu re)

mAU (280 nm) % Elution Buffer

100

gassed start buffer through the column at a flow

rate of 0.5 ml/min.

200

Column performance control

Check the performance of the column when new by running the separation

described in Figures 4 and 5. Figures 4 and 5 shows a typical chromatogram run

on an optimized system. Since the system can profoundly affect the resolution,

it is meaningful to compare runs done on the same system. Check the column at

regular intervals and whenever you suspect a problem.

Function test of Mono Q 5/50 GL

Sample: 1. Conalbumin (3 mg/ml)

2. α-lactalbumin, bovine milk (4 mg/ml)

3. Soyb ean trypsin inhibit or (6 mg/ml)

Sample volume: 200 μl

Gradient: 0–100% elution buffer in 20 CV

Start buffer: 20 mM Tris-HCl, pH 7.0

Elution buf fer: 20 mM Tris-HCl + 0.25 M NaCl, pH 7.0

Flow rat e: 1.0 ml/min (r oom temperatu re)

mAU (280 nm) % Elution Buffer

200

150

▼▼

100

50

0

0.0 5.0 10.0 15.0 20.00ml

100

Fig 4. Typical chromatograms from a function test of Mono Q 5/50 GL.

150

100

50

0

0.0 5.0 10.0 15.0 20.00ml

Fig 5. Typical chromatograms from a function test of Mono S 5/50 GL.

Ordering information

Product No. per pack Code No.

Mono Q 5/50 GL 1 17-5166-01

Mono S 5/50 GL 1 17-5168-01

Related products

Product No. per pack Code No.

Mono Q 10/100 GL 1 17-5167-01

Mono Q 4.6 /100 PE 1 17-5179-01

Mono S 10/100 GL 1 17-5169-01

Mono S 4.6 /100 PE 1 17-5180-01

TM

HiTrap

Desal ting 5 × 5 ml 17-1408-01

Accessories

Product No. per pack Code No.

Tubing connectors:

Fingertig ht connector 1 /16” male 10 18-1112-55

Tricorn 5 f ilter kit* 1 18-1153-02

Filter Too l 1 18-1153-20

Union M6 fe male/1/16” male 8 18-1112-58

On-li ne filter (1/16”) 1 18-1118-01

Handbook:

Ion Exchange Chromatography & Chromatofocusing,

Princi ples and Methods 1 11-0004 -21

* includes t op and bottom f ilters and O- rings, 5 of each .

▼

www.gehealthcare.com/protein-purifi cation

www.gehealthcare.com

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

GE Healthcare Europe GmbH

Munzinger Strasse 5, D-79111 Freiburg, Germany

GE Healthcare UK Ltd

Amersham Place, Little Chalfont, Buckinghamshire, HP7 9NA, UK

GE Healthcare Bio-Sciences Corp

800 Centennial Avenue, P.O. Box 1327, Piscataway, NJ 08855-1327, USA

GE Healthcare Bio-Sciences KK

Sanken Bldg, 3-25-1, Hyakunincho, Shinjuku-ku, Tokyo 169-0073, Japan

71-5017-88 AC 03/2006

Tricorn, Mono Q, Mono S, HiTrap, ÄKTA and Drop Design are trademarks of GE Healthcare

companies. GE and GE Monogram are trademarks of General Electric Company.

The Tricorn column and components are protected by US design patents USD500856, USD506261,

USD500555, USD495060 and their equivalents in other countries.

All goods and services are sold subject to the terms and conditions of sale of the company within

GE Healthcare which supplies them. General Electric Company reserves the right, subject to any

regulatory and contractual approval, if required, to make changes in specifi cations and features

shown herein, or discontinue the product described at any time without notice or obligation.

© 2006 General Electric Company – All rights reserved.

GE Healthcare Bio-Sciences AB, a General Electric Company.

Elanders Östervåla 2006

Loading...

Loading...