Page 1

GE

Automation & Controls

Programmable Control Products

RX3i PROFINET IO-Scanner User Manual GFK-2737F

PACSystems*

RX3i PROFINET

IO-Scanner

User Manual

GFK-2737F

December 2016

Page 2

Legal Information

Warnings, Cautions, and Notes as Used in this Publication GFL-002

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met during installation, operation, and maintenance. The information is supplied

for informational purposes only, and GE makes no warranty as to the accuracy of the information included

herein. Changes, modifications, and/or improvements to equipment and specifications are made

periodically and these changes may or may not be reflected herein. It is understood that GE may make

changes, modifications, or improvements to the equipment referenced herein or to the document itself at

any time. This document is intended for trained personnel familiar with the GE products referenced herein.

GE may have patents or pending patent applications covering subject matter in this document. The

furnishing of this document does not provide any license whatsoever to any of these patents.

GE provides the following document and the information included therein as-is and without warranty of

any kind, expressed or implied, including but not limited to any implied statutory warranty of

merchantability or fitness for particular purpose.

* indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

©Copyright 2013-2016 General Electric Company.

All Rights Reserved

If you purchased this product through an Authorized Channel Partner, please contact the seller directly.

Page 3

Contact Information

General Contact Information

Online technical support and GlobalCare

www.geautomation.com/support

Additional information

www.geautomation.com

Solution Provider

solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please

contact us by telephone or email, or on the web at www.geautomation.com

Americas

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Customer Care Email

customercare.ip@ge.com

Primary language of support

English

Europe, the Middle East, and Africa

Phone

+800-1-433-2682

EMEA Direct Dial

+420 239015850 (if toll free 800 option is unavailable or

if dialing from a mobile telephone)

Customer Care Email

customercare.emea.ip@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Asia Pacific

Phone

+86-400-820-8208

+86-21-3877-7006 (India, Indonesia, and Pakistan)

Customer Care Email

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

Page 4

GFK-2737F December 2016 i

Table of Contents

RX3i PROFINET IO-Scanner User Manual GFK-2737F

Table of Contents ............................................................................................................................................... i

Table of Figures ................................................................................................................................................ iv

Chapter 1 Introduction ............................................................................................................................ 1

1.1 Revisions in this Manual .............................................................................................................. 3

1.2 RX3i PROFINET Scanner Specifications ..................................................................................... 4

1.3 RX3i PROFINET Scanner Controls and Indicators ................................................................... 5

1.3.1 LEDs on the PROFINET Scanner Module ..................................................................................................................... 6

1.3.2 SD Card Slot ............................................................................................................................................................................... 6

1.3.3 Pushbutton ................................................................................................................................................................................. 6

1.3.4 USB Port ....................................................................................................................................................................................... 6

1.3.5 Ethernet Port Connections ................................................................................................................................................. 6

1.4 PROFINET Communications ........................................................................................................ 7

1.4.1 Notes on Available PROFINET Controllers .................................................................................................................. 7

1.4.2 Operations of the PROFINET Scanner .......................................................................................................................... 8

1.5 PROFINET Redundant Media ....................................................................................................... 9

1.6 System Limits .............................................................................................................................. 10

1.7 Supported Modules, Power Supplies and Backplanes ......................................................... 11

1.8 Glossary ........................................................................................................................................ 16

1.9 Documentation ........................................................................................................................... 18

Chapter 2 LED Operation and Connector Details ............................................................................. 19

2.1 Normal Operation of Individual LEDs ..................................................................................... 20

2.1.1 OK LED........................................................................................................................................................................................ 20

2.1.2 LAN LED ..................................................................................................................................................................................... 20

2.1.3 Status LED ................................................................................................................................................................................ 20

2.1.4 CONN LED................................................................................................................................................................................. 20

2.1.5 Port LEDs ................................................................................................................................................................................... 21

2.1.6 Active LED ................................................................................................................................................................................. 21

2.1.7 USB LED ..................................................................................................................................................................................... 21

2.1.8 Special LED Blink Patterns ............................................................................................................................................... 21

Page 5

Contents

ii PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

2.2 Ethernet Network Ports ............................................................................................................. 24

2.3 SD Card Slot ................................................................................................................................. 25

2.4 USB Port ........................................................................................................................................ 26

Chapter 3 Installation ............................................................................................................................ 27

3.1 Pre-Installation Check ............................................................................................................... 28

3.2 Installation in Hazardous Areas............................................................................................... 29

3.2.1 ATEX Marking .......................................................................................................................................................................... 29

3.3 Module Installation ..................................................................................................................... 30

3.3.1 Power Requiremnents ....................................................................................................................................................... 30

3.3.2 Hot Insertion and Removal ............................................................................................................................................. 30

3.3.3 Removing the Backplane Knockout ........................................................................................................................... 30

3.3.4 Module Installation .............................................................................................................................................................. 31

3.3.5 Module Removal ................................................................................................................................................................... 31

3.4 Replacing a PROFINET Scanner ................................................................................................ 32

3.4.1 Method 1 – Using the SD Card ...................................................................................................................................... 32

3.4.2 Method 2 – Using the DCP Tool .................................................................................................................................... 32

3.5 SFP Modules for Ethernet Ports................................................................................................ 33

3.6 External Switch VLAN Priority Settings ................................................................................... 33

3.7 Installing the USB Port Driver ................................................................................................... 33

3.8 Firmware Updates ...................................................................................................................... 33

Chapter 4 Configuration ........................................................................................................................ 35

4.1 Configuration Overview ............................................................................................................ 36

4.1.1 Basic Configuration Steps ............................................................................................................................................... 36

4.1.2 Configuration Tool ............................................................................................................................................................... 36

4.2 Adding an IO-Device to a PROFINET LAN ............................................................................... 37

4.2.1 Adding an RX3i PROFINET Scanner to the PROFINET LAN .............................................................................. 37

4.2.2 Configuring an RX3i PROFINET Scanner .................................................................................................................. 38

4.2.3 Adding RX3i Modules .......................................................................................................................................................... 40

4.2.4 Support for Analog Modules with HART Features............................................................................................... 44

4.2.5 Configuring Module Parameters .................................................................................................................................. 44

4.3 Assigning Device Names ........................................................................................................... 48

4.3.1 Transferring the Device Name with an SD Card .................................................................................................. 48

Page 6

Contents

GFK-2737F December 2016 iii

4.4 After the Configuration is Stored to the PROFINET Controller........................................... 49

Chapter 5 Operations ............................................................................................................................. 51

5.1 Power-up ...................................................................................................................................... 52

5.2 I/O Scanning ................................................................................................................................ 53

5.2.1 PROFINET Scanner Status and Control Data ......................................................................................................... 53

5.2.2 Data Coherency .................................................................................................................................................................... 54

5.2.3 Sampling Rate ........................................................................................................................................................................ 54

5.2.4 Differences from Main (CPU) Rack ............................................................................................................................... 54

5.2.5 Output Control ....................................................................................................................................................................... 55

5.3 Hot Swap of I/O Modules ........................................................................................................... 56

Chapter 6 Diagnostics ........................................................................................................................... 57

6.1 Configuration Faults .................................................................................................................. 58

6.2 Version Information ................................................................................................................... 59

6.3 Fatal Error Handling ................................................................................................................... 60

6.4 Connection Troubleshooting .................................................................................................... 61

Appendix A PROFINET Specifications .......................................................................................................... 63

A-1 PROFINET Protocol Support ................................................................................................................... 63

A-2 Technical Data .......................................................................................................................................... 63

A-3 Limitations ................................................................................................................................................ 64

A-3.1 PACSystems Features ........................................................................................................................................................ 64

A-3.2 PROFINET Features .............................................................................................................................................................. 64

Page 7

Contents

iv PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

Table of Figures

Figure 1: Front View IC695PNS001 ___________________________________________________________________ 5

Figure 2: Ethernet Port Connectors on IC695PNS001 _____________________________________________________ 6

Figure 3: IC695PNS001 LEDs _______________________________________________________________________ 23

Figure 4: Underside of IC695PNS001 Showing Ethernet Ports _____________________________________________ 24

Figure 5: RX3i Backplane showing Removable Plastic Knockout ___________________________________________ 30

Figure 6: Install Module into RX3i Backplane __________________________________________________________ 31

Figure 7: Remove Module from RX3i Backplane ________________________________________________________ 31

Figure 8: Select System Redundancy Parameters in PME _________________________________________________ 39

Figure 9: Change Submodule List produces list of Eligible SFP Modules _____________________________________ 40

Figure 10: Analog Module with Configurable Parameters ________________________________________________ 42

Figure 11: Analog Module with Multiple Possible Option Settings __________________________________________ 43

Page 8

GFK-2737F December 2016 1

Chapter 1 Introduction

This chapter provides an overview of the PACSystems RX3i PROFINET Scanner (PNS) module and its

operation. The last two pages of this chapter are a glossary that summarizes many terms used in the

manual.

Chapter 2, LED Operation and Connector Details, provides detailed description of the module’s indicators

and ports

Chapter 3, Installation, gives instructions for PNS module installation and replacing a PNS module.

Provides information for selecting SFP modules and network cabling and connectors.

Chapter 4, Configuration, describes how to configure the RX3i PROFINET Scanner and its associated IOdevices.

Chapter 5, Operations, describes powering up and restarting the RX3i PROFINET Scanner, the input status

data, replacing I/O modules while scanning, and how to update the firmware.

Chapter 6, Diagnostics, describes configuration faults, how to check the RX3i PROFINET Scanner version

information, fatal error handling, and some common troubleshooting suggestions.

Appendix A, PROFINET Specifications, summarizes the features specified for PROFINET v2.3 Class A IODevices that are supported by the RX3i PROFINET Scanner module

Page 9

Chapter 1. Introduction

2 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

The PACSystems RX3i PROFINET Scanner (PNS) module, IC695PNS001, connects a remote universal RX3i

I/O rack of Series 90-30 or RX3i modules to a PROFINET I/O Controller. The PROFINET Scanner scans the

modules in its rack, retrieving input data and providing output data, and exchanges that data on the

PROFINET I/O LAN at the configured production rate.

The PNS manages PROFINET communication and module configuration between an I/O Controller and

modules in the remote rack. If network communications are lost, the PNS manages I/O states according

to the individual module configurations.

The PNS supports 10/100/1000 Mbps Copper, 100/1000 Mbps Multi-mode Fiber, and 100/1000 Mbps

Single-mode Fiber. PROFINET communications on the network require 100 or 1000 Mbps link speed.

Although 10 Mbps cannot be used for PROFINET communications, 10 Mbps can be used for other types of

Ethernet traffic such as PING. Features of the RX3i PNS include:

Full programming and configuration services for all supported Series 90-30 and RX3i I/O Modules

using Proficy* Machine Edition. For a list of currently supported I/O modules, refer to the Important

Product Information (IPI) document provided with the firmware version on your PNS module.

Support for daisy-chain/line, star, or ring (redundant media) topologies.

Four switched Ethernet ports - two 8-conductor RJ45 shielded twisted pair 10/100/1000 Mbps copper

interfaces and two Small Form-factor Pluggable (SFP) cages for user-supplied SFP devices.

The network can include media interfaces of more than one type.

Support for transfer of IO-Device Name to another PNS module using an SD card. This eliminates the

need to connect a configuration tool, such as Proficy Machine Edition when replacing a module.

A USB port for field updates of firmware using WinLoader.

Note: The USB port is for firmware upgrades only. It is not intended for permanent connection.

Page 10

Chapter 1. Introduction

GFK-2737F December 2016 3

1.1 Revisions in this Manual

Rev

Date

Description

F

Dec2016

• Updates for CPE400 (new related product).

• Updated list of supported I/O Modules in Section 1.7 per GFK-2738L

• Added footnotes tracking PNS firmware support for various I/O modules.

• Added footnotes tracking PNS firmware support for various features, such as HART Pass

Through.

• Added note on support for Remote Get HART Device Information COMMREQ.

E

Apr2015

In Section 1.7, corrected data for IC695SPF010 in table

D

May2014

In Section 4.2.5, Configuring Module Parameters, added Universal Analog Input Module and

Power Sync and Measurement Module and related rules to the table,

In Section 4.2.5.1, RX3i PROFINET Scanner Configuration Validation, added IC695ALG600 to the

table.

Page 11

Chapter 1. Introduction

4 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.2 RX3i PROFINET Scanner Specifications

PROFINET Support

PROFINET Version 2.3 Class A IO-Device

Redundantly controlled operation conforms to PROFINET V2.3 Type S-2 System

Redundancy.

Controller CPU Version

Required

RX3i CPU315/CPU320 with firmware version 7.10 or later RX3i CPE305/CPE310 with

firmware version 7.10 or later RXi Controller with firmware version 7.80 or later

Proficy Machine Edition

Version Required

Version 8.0 or later

Power Requirements

3.3 Vdc:

1.2 A with no SFP devices installed

1.9 A maximum (two SFP devices installed, 0.35 A per SFP)

5 Vdc:

1.1 A maximum

Operating Temperature

Range

0 to 60°C De-rated to 57°C:

• If 100 Mbps Fiber SFPs installed, or

• If Copper SFPs operating at 1 Gbps

Number of Port

Connectors

Two RJ45 and Two SFP Cages

(SFP devices not included, available separately.)

USB Connector (for

firmware upgrades)

One Micro-B connector. USB 2.0 compliant running at Full-speed

(12 MHz)

SD Card

Supports SD and SDHC cards.

PNS Status and

Control Bits

32 input status bits and 32 output control bits

PROFINET I/O

production rate (ms)

(I/O Update Rate)

Configurable selections: 1, 2, 4, 8, 16, 32, 64, 128, 256 or 512 ms

Number of IP Addresses

Five. One per external port and one internal.

I/O Station Maximum

Limits

Number of

I/O Modules

per station

Number of backplane slots in the host RX3i rack

less one for PNS001 module itself

less the number of slots occupied by the RX3i power supply

I/O data

per station

2880 bytes total

1440 bytes of input data

1440 bytes of output data

Configuration

V2.3 GSDML file.

The file is included with Proficy Machine Edition; available for import into 3rd-Party tools.

Note: Configuration software that supports GSDML V2.3 MenuList elements (such as

Proficy Machine Edition 8.0 or later) is required to display the configuration

parameters of most IC695xxx I/O modules.

For product standards, general operating specifications, and installation requirements, refer to the

PACSystems RX3i System Manual, GFK-2314

Page 12

Chapter 1. Introduction

GFK-2737F December 2016 5

1.3 RX3i PROFINET Scanner Controls and Indicators

Figure 1: Front View IC695PNS001

Page 13

Chapter 1. Introduction

6 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.3.1 LEDs on the PROFINET Scanner Module

LEDs provide an immediate visual indication of the operational state of the PNS and port link status. The

LEDs and their operation are described in Chapter 2 LED Operation and Connector Details.

1.3.2 SD Card Slot

The SD Card Slot supports an SD or SDHC card. It can be used to transfer the IO-Device Name to another

PROFINET Scanner Module unit without a configuration tool such as Proficy Machine Edition.

1.3.3 Pushbutton

The pushbutton adjacent to the USB port is reserved for future use.

1.3.4 USB Port

The USB Port is used for installing new firmware using the WinLoader tool.

1.3.5 Ethernet Port Connections

Each port on an RX3i PNS operates independently, so devices that operate at different speeds and/or

duplex modes may be attached to the ports. By default, all ports, including empty, unconfigured SFP

cages, are set for Automatic, which enables auto negotiation for the widest range of options supported by

the port.

Figure 2: Ethernet Port Connectors on IC695PNS001

Connections to the PROFINET Scanner can be made using standard Cat 5e/6 Ethernet cables. Different

devices on the same network can be connected using the multiple ports on the RX3i PNS (Figure 2).

For other options, refer to Chapter 4, the section Adding and Configuring an Ethernet Port.

Page 14

Chapter 1. Introduction

GFK-2737F December 2016 7

1.4 PROFINET Communications

For a full discussion of PROFINET Communications and interactions with the controlling RX3i CPU, refer to

Chapter 4 of the PACSystems RX3i PROFINET Controller User Manual, GFK-2571. The following topics are

covered:

PROFINET Operation Overview

PROFINET Communications

Application Relationships

Types of PROFINET Communications

Operations of the PROFINET Controller in the RX3i System

Duplicate PROFINET Device IP Address

Duplicate PROFINET Controller IP Address

Resolving Duplicate IP Addresses

I/O Scanning

Data Coherency

Performance Factors

PROFINET IO Update Rate Configuration

RX3i CPU Operations for PROFINET

Reference ID Variables for the RX3i Application

PNIO_DEV_COMM Function Block

Reset Smart Module for the PROFINET Controller

DO I/O for Remote IO Modules

Scan Set I/O for Remote I/O Modules

RX3i CPU Defaults - Inputs

RX3i CPU Defaults – Outputs

1.4.1 Notes on Available PROFINET Controllers

Each PROFINET I/O Network is controlled by one or more PROFINET I/O Controllers. PROFINET I/O

Controllers may be GE products or third-party products.

GE Automation and Control offers the following RX3i PROFINET Controllers:

IC695PNC001: this is a rack-based intelligent module located in a slot of the host RX3i CPU rack.

The host CPU may be equipped with a maximum of four IC695PNC001 modules.

The IC695CPE330 provides an optional embedded PROFINET Controller. To utilize this feature,

LAN2 must be configured as a PROFINET Controller. In addition, the IC695CPE330 may host a

maximum of four IC695PNC001 modules in its CPU rack.

The IC695CPE400 also provides an optional embedded PROFINET Controller. To utilize this feature,

LAN2 must be configured as a PROFINET Controller. Since the IC695CPE400 is a Rackless CPU, it

cannot host any IC695PNC001 modules.

Each of the RX3i PROFINET Controllers mentioned above is capable of controlling a PROFINET I/O Network

containing PROFINET Scanners supplied by GE or by third-party vendors. Many vendors also supply I/O

devices that connect directly to the PROFINET network.

For PROFINET Controller product details, refer to the PACSystems RX3i PROFINET Controller User Manual,

GFK-2571.

Page 15

Chapter 1. Introduction

8 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.4.2 Operations of the PROFINET Scanner

The RX3i PROFINET Scanner (PNS) is the head-end unit responsible for monitoring and controlling I/O

modules installed in its RX3i I/O rack. All PROFINET communications are passed between the PROFINET I/O

Controller and the PNS. The PNS is one type of IO-Device the PROFINET I/O Controller expects to

encounter. Other third-party IO-Devices may also be present on the PROFINET network.

A PNS will normally be present on a PROFINET network controlled by an RX3i PROFINET Controller (PNC).

However, it is possible to use a PNS in conjunction with any qualified PROFINET I/O Controller.

The RX3i PNS performs the following operations:

Consumes PROFINET IO-Device configuration from the PROFINET IO-Controller over the PROFINET

network and applies it to its modules.

Scans input data from each module it manages and produces that data to the PROFINET

IO-Controller.

Consumes the output data that it receives from the PROFINET IO-Controller and applies it to each

module it manages.

GE Automation and Control offers the following types of PROFINET Scanners:

IC695PNS001: the RX3i PROFINET Scanner. It may control a sub-set of RX3i I/O modules located in

the same RX3i I/O rack. This product is discussed in detail in this manual.

IC695CEP001: a PROFINET Scanner which may control a sub-set of RX3i I/O modules in a remote

I/O drop. For product details, refer to the PACSystems RX3i CEP PROFINET Scanner User Manual,

GFK-2883.

Page 16

Chapter 1. Introduction

GFK-2737F December 2016 9

1.5 PROFINET Redundant Media

For a full discussion of PROFINET Redundant Media and interactions with the controlling RX3i CPU, refer to

Chapter 6 of the PACSystems RX3i PROFINET Controller User Manual, GFK-2571. The following topics are

covered:

PROFINET Media Redundancy Protocol

MRP Failover Performance

Bumpless Operation with MRP

MRP Operation for I/O Update Rates of 16ms or Greater

MRP Operation at I/O Update Rates Less Than 16ms

Minimum I/O Rate When Configured in an MRP Ring

Minimum I/O Update Rates for Bumpless Operation in a Ring Topology

Third-party MRP Manager Use with PNC as MRP Client

Ring Topology with One Controller

Ring Topology with Multiple Controllers

Setting Up Media Redundancy Protocol

Media Redundancy Setup for a PROFINET I/O Controller

Sequence for Enabling Media Redundancy

Sequence for Replacing a Media Redundancy Manager

Procedure for Disabling Media Redundancy

Page 17

Chapter 1. Introduction

10 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.6 System Limits

I/O Controllers will have limitations on the system they support. One of these limits is the number of

PROFINET submodules supported. In the RX3i PNS rack, each power supply or I/O module is represented

by one PROFINET submodule. The RX3i PNS uses four to six submodules:

• two submodules for basic operation of the PNS module

• two built-in port submodules that are always configured

• up to two additional port submodules, one for each optional Ethernet port configured

Other limitations, such as the configuration and I/O sizes, are specific to the configuration options chosen.

Note that not every combination of options is supported in every system.

If the configuration uses all slots in every device with a large device count, the memory of the I/O

Controller system will be a limiting resource.

Page 18

Chapter 1. Introduction

GFK-2737F December 2016 11

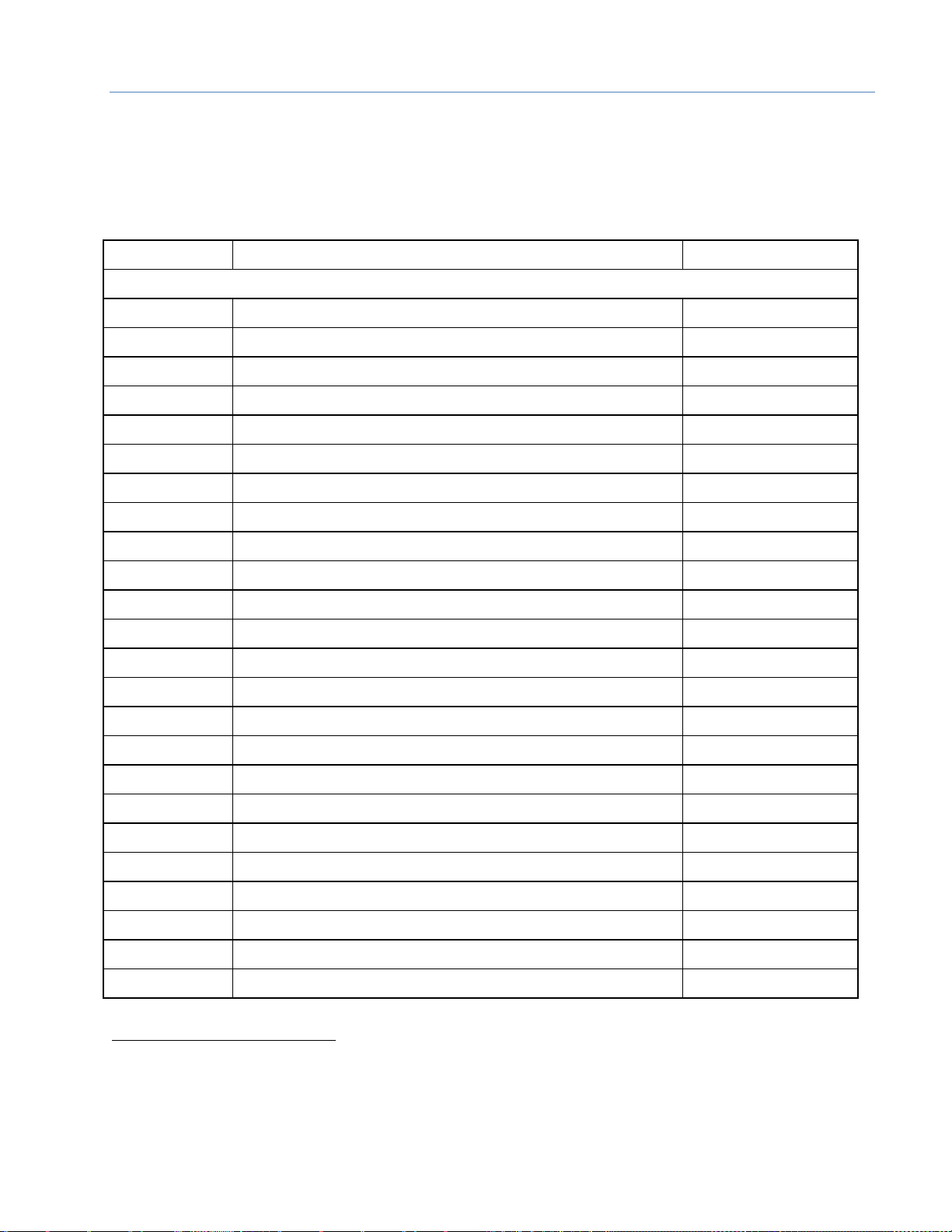

1.7 Supported Modules, Power Supplies and Backplanes

For an updated list of modules, power supplies and backplanes that can be used with an RX3i PROFINET

Scanner, refer to the most recent version of the PACSystems RX3i PROFINET Scanner Important Product

Information, GFK-2738. The list below was published in GFK-2738L (June 2016).

Catalog Number

Module Description

Distinguishing Classes1

Discrete Input Modules

IC693ACC300

Input Simulator Module (8-pt & 16-pt operation)

8 in, 16 in

IC693MDL230

8-Circuit Input 120 Vac Isolated

8 in

IC693MDL231

8-Circuit Input 240 Vac Isolated

8 in

IC693MDL240

16-Circuit Input 120 Vac

16 in

IC693MDL241

16-Circuit Input 24 Vac / Vdc

16 in

IC693MDL250

16-Circuit Isolated Input 120 Vac, Input Filtering Off

16 in

IC693MDL250

16-Circuit Isolated Input 120 Vac, Input Filtering On

none

IC693MDL260

32-Circuit Input 120 Vac, Input Filtering Off

32 in

IC693MDL260

32-Circuit Input 120 Vac, Input Filtering On

32 in/out

IC693MDL632

8-Circuit Input 125 Vdc Positive / Negative Logic

8 in

IC693MDL634

8-Circuit Input 24 Vdc Positive / Negative Logic

8 in

IC693MDL635

16-Circuit Input 125 Vdc Positive / Negative Logic

16 in

IC693MDL645

16-Circuit Input 24 Vdc Positive / Negative Logic

16 in

IC693MDL646

16-Circuit Input 24 Vdc Positive / Negative Logic Fast

16 in

IC693MDL648

16-Circuit Input 48 Vdc Positive / Negative Logic Fast

16 in

IC693MDL654

32-Circuit Input 5/12 Vdc Positive / Negative Logic

32 in

IC693MDL655

32-Circuit Input 24 Vdc Positive / Negative Logic Fast

32 in

IC693MDL660

32-Circuit Input 24 Vdc Positive / Negative Logic, Input Filtering Off

32 in

IC693MDL660

32-Circuit Input 24 Vdc Positive / Negative Logic, Input Filtering On

32 in/out

IC694ACC300

Input Simulator Module (8-pt & 16-pt Mode)

8 in, 16 in

IC694MDL230

8-Circuit Input 120 Vac Isolated

8 in

IC694MDL231

8-Circuit Input 240 Vac Isolated

8 in

IC694MDL240

16-Circuit Input 120 Vac

16 in

IC694MDL241

16-Circuit Input 24 Vac / Vdc

16 in

1

The PNS001 cannot distinguish between modules within the same Distinguishing Class type. This means that any module

physically present that is within the same class as the one configured will not alert the user with a System Configuration

Mismatch fault on the Controller Fault Table. Refer to the section entitled CPU operation during System Configuration Mismatch

Faults in PACSystems RX7i and RX3i CPU Reference Manual, GFK-2222.

Page 19

Chapter 1. Introduction

12 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

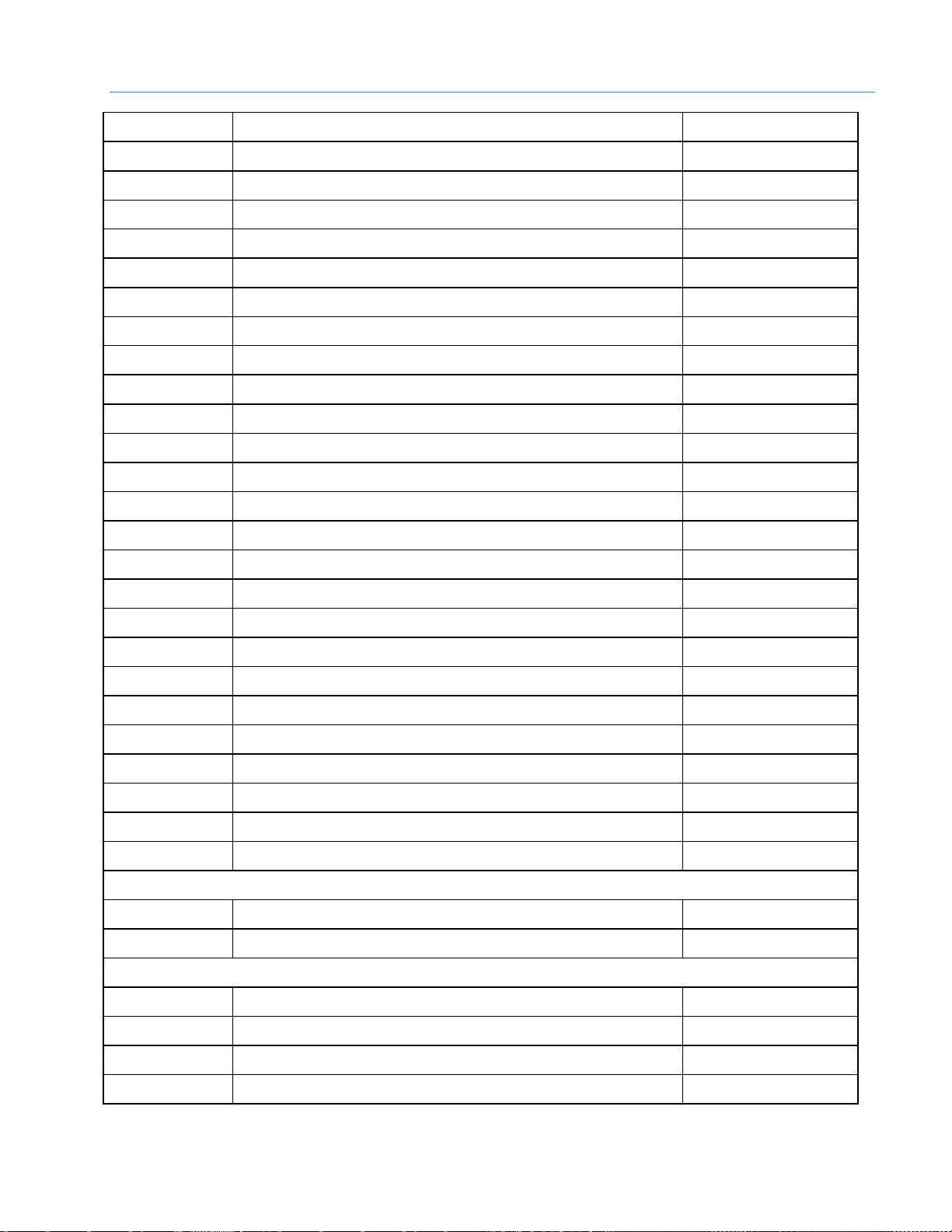

Catalog Number

Module Description

Distinguishing Classes1

IC694MDL250

16-Circuit Input 120 Vac Isolated

none

IC694MDL260

32-Circuit Input 120 Vac

none

IC694MDL632

8-Circuit Input 125 Vdc Positive / Negative Logic

8 in

IC694MDL634

8-Circuit Input 24 Vdc Positive / Negative Logic

8 in

IC694MDL635

16-Circuit Input 125 Vdc Positive / Negative Logic

16 in

IC694MDL645

16-Circuit Input 24 Vdc Positive / Negative Logic

16 in

IC694MDL646

16-Circuit Input 24 Vdc Positive / Negative Logic Fast

16 in

IC694MDL654

32-Circuit Input 5/12 Vdc Positive / Negative Logic

32 in

IC694MDL655

32-Circuit Input 24 Vdc Positive / Negative Logic Fast

32 in

IC694MDL658

32-Circuit Input 48 Vdc Positive / Negative Logic Fast

32 in

IC694MDL660

32-Circuit Input 24 Vdc Positive / Negative Logic

none

IC695MDL664

16-Circuit Smart Input 24 Vdc Positive Logic2

none

Discrete Output Modules

IC693MDL310

12-Circuit Output 120 Vac 0.5A

16 out

IC693MDL330

8-Circuit Output 120/240 Vac 2A

8 out

IC693MDL340

16-Circuit Output 120 Vac 0.5A

16 out

IC693MDL350

16-Circuit Output 120/240 Vac Isolated

16 out

IC693MDL390

5-Circuit Output 120/240 Vac 2A Isolated

8 out

IC693MDL730

8-Circuit Output 12/24 Vdc 2A Positive

8 out

IC693MDL731

8-Circuit Output 12/24 Vdc 2A Negative

8 out

IC693MDL732

8-Circuit Output 12/24 Vdc 0.5A Positive

8 out

IC693MDL733

8-Circuit Output 12/24 Vdc 0.5A Negative

8 out

IC693MDL734

6-Circuit Output 125 Vdc 1A Positive/Negative

8 out

IC693MDL740

16-Circuit Output 12/24 Vdc 0.5A Positive

16 out

IC693MDL741

16-Circuit Output 12/24 Vdc 0.5A Negative

16 out

IC693MDL742

16-Circuit Output 12/24 Vdc 1A Positive

16 out

IC693MDL748

8-Circuit Output 48 Vdc 0.5A Positive

8 out

IC693MDL752

32-Circuit Output 5/24 Vdc 0.5A Negative

32 out

IC693MDL753

32-Circuit Output 12/24 Vdc 0.5A Positive

32 out

IC693MDL754

32-Circuit Output 24 Vdc 0.75A Positive with ESCP, Diagnostics Off

32 out

IC693MDL754

32-Circuit Output 24 Vdc 0.75A Positive with ESCP, Diagnostics On

32 in/out

2

The PNS001 currently does not support Fault Reporting from this module.

Page 20

Chapter 1. Introduction

GFK-2737F December 2016 13

Catalog Number

Module Description

Distinguishing Classes1

IC693MDL758

32-Circuit Output 12/24 Vdc 0.5A Positive with ESCP

2,3

32 out

IC693MDL760

Solenoid Valve Output Module

16 out

IC693MDL916

16-Circuit Output 4A Relay

16 out

IC693MDL930

8-Circuit Output 4A Relay Isolated

8 out

IC693MDL931

8-Circuit Output Relay Form BC Isolated

8 out

IC693MDL940

16-Circuit Output 2A Relay

16 out

IC694MDL310

12-Circuit Output 120 Vac 0.5A

16 out

IC694MDL330

8-Circuit Output 120/240 Vac 2A

8 out

IC694MDL340

16-Circuit Output 120 Vac 0.5A

16 out

IC694MDL350

16-Circuit Output 120/240 Vac Isolated

none

IC694MDL390

5-Circuit Output 120/240 Vac 2A Isolated

8 out

IC694MDL732

8-Circuit Output 12/24 Vdc 2A Positive

8 out

IC694MDL734

6-Circuit Output 125 Vdc 1A Positive/Negative

8 out

IC694MDL740

16-Circuit Output 12/24 Vdc 0.5A Positive

16 out

IC694MDL741

16-Circuit Output 12/24 Vdc 1A Negative

16 out

IC694MDL742

16-Circuit Output 12/24 Vdc 1A Positive

16 out

IC694MDL752

32-Circuit Output 5/24 Vdc 0.5A Negative

32 out

IC694MDL753

32-Circuit Output 12/24 Vdc 0.5A Positive

32 out

IC694MDL754

32-Circuit Output with ESCP

none

IC694MDL758

32-Circuit Output 12/24 Vdc 0.5A Positive with ESCP2

none

IC694MDL916

16-Circuit Output 4A Relay

none

IC694MDL930

8-Circuit Output 4A Relay Isolated

8 out

IC694MDL931

8-Circuit Output Relay Form BC Isolated

8 out

IC694MDL940

16-Circuit Output 2A Relay

16 out

IC695MDL765

16-Circuit Smart Output 24/125 Vdc 2A Positive Logic2

None

Discrete Mixed Modules

IC693MAR590

8-Circuit Mixed 120 Vac Input / Relay Output

8 in/out

IC693MDR390

8-Circuit Mixed 24 Vdc Input / Relay Output

8 in/out

Analog Input Modules

IC693ALG220

4-Point Analog Voltage Input

ALG IN 4

IC693ALG221

4-Point Analog Current Input

ALG IN 4

IC693ALG222

16-Point Analog Voltage Input

ALG IN 16

IC693ALG223

16-Point Analog Current Input

ALG IN 16

Page 21

Chapter 1. Introduction

14 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

Catalog Number

Module Description

Distinguishing Classes1

IC694ALG220

4-Point Analog Voltage Input

ALG IN 4

IC694ALG221

4-Point Analog Current Input

ALG IN 4

IC694ALG222

16-Point Analog Voltage Input

ALG IN 16

IC694ALG223

16-Point Analog Current Input

ALG IN 16

IC695ALG106

6-Point Isolated Analog Input Current/Voltage

3,4

none

IC695ALG112

12-Point Isolated Analog Current/Voltage Input4

none

IC695ALG600

8-Point Universal Analog Input Module4

none

IC695ALG608

8-Point Analog Input Current / Voltage Input

3, 4

none

IC695ALG616

16-Point Analog Current / Voltage Input4

none

IC695ALG626

16-Point Analog Current / Voltage Input4 (HART5 Support)

none

IC695ALG628

8-Point Analog Current / Voltage Input

3, 4

(HART5 Support)

none

Analog Output Modules

IC693ALG390

2-Point Analog Voltage Output

ALG OUT 2

IC693ALG391

2-Point Analog Current Output

ALG OUT 2

IC693ALG392

8-Point Analog Current / Voltage Output

ALG OUT 8

IC694ALG390

2-Point Analog Voltage Output

ALG OUT 2

IC694ALG391

2-Point Analog Current Output

ALG OUT 2

IC694ALG392

8-Point Analog Current / Voltage Output

ALG OUT 8

IC695ALG704

4-Point Analog Current / Voltage Output

3, 4

none

IC695ALG708

8-Point Analog Current / Voltage Output4

none

IC695ALG728

8-Point Analog Current / Voltage Output4 (HART5 Support)

none

IC695ALG808

8-Point Isolated Analog Current / Voltage Output4

none

Analog Mixed Modules

IC693ALG442

4-Input / 2-Output, Current / Voltage

ALG IN 4, ALG OUT 2

IC694ALG442

4-Input / 2-Output, Current / Voltage

ALG IN 4, ALG OUT 2

RTD Input Modules

IC695ALG508

8-Channel Isolated RTD Input4

none

Thermocouple Input Modules

IC695ALG312

12-Point Isolated Thermocouple Input

3, 4

none

IC695ALG412

12-Point Isolated High Speed Thermocouple Input

3, 4

none

3

PNS001 firmware version 2.40 required for this product.

4

PNS001 currently does not support Fault Reporting or Interrupts from this module.

5

PNS001 firmware version 2.30 supports the HART Pass Through capabilities of this module. HART-compatible PNC001 and CPU

versions are also required.

Page 22

Chapter 1. Introduction

GFK-2737F December 2016 15

Catalog Number

Module Description

Distinguishing Classes1

High-Speed Counter Modules

IC695HSC308

High-Speed Counter Module - 8 Counters4

None

Specialty Modules

IC694PSM001

Power Sync and Measurement Module

none

Power Supply Modules

IC695PSA040

Universal 120/240 Vac, 125Vdc 40W Power Supply

none

IC695PSA140

Multifunctional 120/240 Vac, 125Vdc 40W Power Supply

none

IC695PSD040

24Vdc 40W Power Supply

none

IC695PSD140

Multifunctional 24Vdc 40W Power Supply

none

Small Form-Factor Pluggable (SFP) Modules

IC695SPC100

10/100/1000Base-T Copper SFP

none

IC695SPF002

100Base-FX (fiber 2km) SFP

none

IC695SPF010

1000Base-LX (fiber 10km) SFP

none

IC695SPF550

1000Base-SX (fiber 550m) SFP

none

Page 23

Chapter 1. Introduction

16 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.8 Glossary

AR

Application Relationship. PROFINET term for a relationship that is established between an IO-Controller/

IO-Supervisor and IO-Device. For any data to be exchanged between an IO-Controller/IO-Supervisor and a

given IO-Device, an Application Relationship must be established. Within the Application Relationship,

various Communication Relationships (CRs) are then established for the different types of data to be

exchanged.

Broadcast

In Ethernet, the transmission of a network message to all hosts on the network.

CPU Node

In a PACSystems RX3i PROFINET network, a CPU Node is a node in which a PACSystems RX3i CPU is

connected to the PROFINET network.

CR

Communication Relationship. PROFINET term for a channel that is established within an Application

Relationship (AR) to transfer specific data between an IO-Controller/IO-Supervisor and a given IO-Device.

Multiple CRs are established within an AR to transfer data.

DAP

Device Access Point. This access point is used to address an IO-Device as an entity.

Gratuitous ARPs

An Address Resolution Protocol (ARP) request sent by the host to resolve its own IP Address.

GSDML

General Station Description Markup Language - definition of PROFINET Device Characteristics.

IOC

PROFINET IO-Controller

IOD

PROFINET IO-Device

IOCR

Input Output Communication Relationship – describes the type (input/output) and amount of I/O data to be

transferred, the sequence of the transfers and the transfer cycle between a PROFINET IO-Controller (or

IO-Supervisor) and a PROFINET IO-Device.

IOCS

PROFINET Input/Output Consumer Status is transmitted on the PROFINET network to provide feedback on

Input Data for an IO-controller and Output Data for an IO-device.

IOPS

PROFINET Input/Output Provider Status is transmitted on the PROFINET network to provide feedback on

Output Data for an IO-controller and the Input Data for an IO-device.

IOxS

PROFINET abbreviation for the IOCS and/or IOPS (see above).

LLDP

Link Layer Discovery Protocol. IEEE standardized protocol used by network devices to advertise their

identity and capabilities.

LLDPDU

Link Layer Discovery Protocol Data Unit.

MAC

Media Access Control address (MAC address)

MAU

Medium Attachment Unit

MIB

Management Information Basis

MRC

Media Redundancy Client. Within Media Redundancy Protocol, an MRC is responsible for helping the MRM

detect breaks/no breaks in the ring.

MRM

Media Redundancy Manager. Within Media Redundancy Protocol, an MRM is responsible for ensuring that

the ring does not have a closed loop, while simultaneously ensuring maximal connectivity between nodes

on the ring.

MRP

Media Redundancy Protocol. An Ethernet protocol that provides redundant paths for PROFINET-IO cyclic

traffic by supporting a ring topology.

Multicast

In Ethernet, the transmission of a network message to all hosts within a host group.

NOS

Name of Station

OID

Object Identifier

Phase

If the IOCR Update Period is greater than the Send Clock time, the Update Period is divided into multiple

phases where each phase is equal to one Send Clock.

Page 24

Chapter 1. Introduction

GFK-2737F December 2016 17

Glossary, continued

PNC

PROFINET Controller. This could be a separate module, e.g. IC695PNC001 for the RX3i family, or a functional

component of a product such as the PROFINET controller embedded in the ICRXICTL000, IC695CPE330, or

IC695CPE400. Refer to Section 1.4.1.

PNS

PROFINET Scanner. Refer to Section 1.4.2.

RDO

Record Data Object. Services used to read and write structured data stored in a PROFINET IO-Device.

Reduction Ratio

Along with Send Clock determines the Update Period for a PROFINET cyclic data transfer between two

devices (see IOCR). The Update Period equals the Reduction Ratio multiplied by the Send Clock time. For

example, if the Reduction Ratio is 4 and the Send Clock is 1ms, the Update Period is 4ms.

Remote Node

For an RX3i PROFINET network, a Remote Node is any PROFINET IO-Device, such as a rack of I/O modules

with a Remote Scanner or a third party PROFINET IO-Device.

RTA

Real-Time Acyclic. A PROFINET-IO Mechanism used to exchange non-periodic data such as alarms.

RTC

Real-Time Cyclic. A PROFINET-IO Mechanism used to exchange input and output data.

Send Clock

Value between 1 and 128 inclusive in units of 31.25 µs (equivalent to a range of 31.25 µs to 4 ms) used to

calculate the Update Period for a PROFINET cyclic data transfer between two devices (see IOCR). The Send

Clock is the basis for all other scheduling parameters.

Send Offset

The time to delay a scheduled PROFINET cyclic data transfer frame.

Measured in nanoseconds from 0 to 3,999,999. Must be less than the Send Clock time.

SFP

Small Form-factor Pluggable. Pluggable, hot-swappable transceivers.

SNMP

Simple Network Management Protocol. UDP-based network protocol that facilitates the exchange of

management information between network devices.

Submodule

PROFINET-IO representation of the smallest configurable entity of a PROFINET Module.

SVC_REQ

Service Request Function Block. A control system service initiated by the RX3i CPU.

TLV

Type-Length-Value

Unicast

In Ethernet, the transmission of a network message to an individual host.

Update Period

The time between PROFINET cyclic data transfers between an IO-Controller and an IO-Device.

WinLoader

A software utility used to download and install firmware upgrades.

Page 25

Chapter 1. Introduction

18 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

1.9 Documentation

PACSystems Manuals

PACSystems RX7i and RX3i CPU Reference Manual

GFK-2222

PACSystems RX7i and RX3i CPU Programmer’s Reference Manual

GFK-2950

PACSystems Hot Standby CPU Redundancy User Manual

GFK-2308

PACSystems Battery and Energy Pack Manual

GFK-2741

Proficy Machine Edition Logic Developer Getting Started

GFK-1918

Proficy Process Systems Getting Started Guide

GFK-2487

PACSystems RXi, RX3i, and RX7i Controller Secure Deployment Guide

GFK-2830

RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i PROFINET Controller Command Line Interface Manual

GFK-2572

PACSystems RX3i Max-On Hot Standby Redundancy User’s Manual

GFK-2409

PACSystems RX3i PROFINET Controller User Manual

GFK-2571

PACSystems RX3i CEP PROFINET Scanner User Manual

GFK-2883

PACSystems HART Pass Through User Manual

GFK-2929

PACSystems RX3i PROFINET Scanner Important Product Information

GFK-2574

VersaMax Manuals

VersaMax PROFINET Scanner Manual

GFK-2721

In addition to these manuals, datasheets and product update documents describe individual modules

and product revisions. The most recent PACSystems documentation is available on the GE Automation

and Controls support website www.geautomation.com.

Page 26

GFK-2737F December 2016 19

Chapter 2 LED Operation and Connector Details

This chapter describes:

LEDs

Ethernet Network Ports

SD Card Slot

USB Port

Page 27

Chapter 2. LED Operation and Connector Details

20 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

2.1 Normal Operation of Individual LEDs

2.1.1 OK LED

LED

LED Status

Green On

PNS OK

Off

PNS Not OK

2.1.2 LAN LED

The LAN LED indicates access to and activity on the Ethernet network. The LAN LED indicates network

packets are being processed by the network interface (not just passing through the embedded switch).

LED

LED Status

Green Blinking

The corresponding network interface is active.

Off

The corresponding network interface is not active.

2.1.3 Status LED

The STATUS LED stays green during normal operation.

LED

LED Status

Green On

Normal operation

Red Blinking

A MAC address read from non-volatile memory is invalid. Ports with invalid MAC

addresses remain disconnected from the Ethernet network

2.1.4 CONN LED

The CONN LED indicates the status of PROFINET connections.

LED

LED Status

Green On

At least one PROFINET connection (AR) exists with an I/O Controller

Amber Blinking

No Device Name configured.

Off

No PROFINET connection (AR) exists.

Page 28

Chapter 2. LED Operation and Connector Details

GFK-2737F December 2016 21

2.1.5 Port LEDs

The PROFINET I/O Scanner has four Port LEDs, PORT1, PORT2, PORT3, and PORT4 that indicate link speed,

link connection and link activity corresponding to the four possible external Ethernet ports.

LED

LED Status

Blue On

Link connected, 1000 Mbps

Blue Blinking

Port active, 1000 Mbps

Green On

Link connected, 100 Mbps

Green Blinking

Port active, 100 Mbps

Purple On

Link connected, 10 Mbps

Purple Blinking

Port active, 10 Mbps

Off

The associated Ethernet port is not connected to an active link (can be disabled by

configuration)

Red On

Port 3 and port 4 only. Incompatible SFP plugged into port.

2.1.6 Active LED

The Active LED indicates the Scanner is connected to a PROFINET IO-Controller that is controlling the I/O

data for the I/O modules located in the same rack as the PNS001.

LED

LED Status

Green On

PNS is connected to a PROFINET I/O Controller that is controlling IO Module IO

data

Off

PNS is not connected to a PROFINET I/O Controller or no established connection to

an Active I/O Controller

2.1.7 USB LED

LED

LED Status

Green On

A USB cable is connected.

Green Blinking

The corresponding network interface is active.

Off

No USB port activity.

2.1.8 Special LED Blink Patterns

The PNS’s LEDs can operate in tandem to indicate fatal error, module location/identification,

microprocessor over temperature, and update conditions, as described below. There is also a startup

sequence that tracks the startup processing of the module with the LEDs.

Page 29

Chapter 2. LED Operation and Connector Details

22 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

2.1.8.1 Fatal Error Codes

When the PNS encounters a fatal error, it will blink an error code pattern on the OK LED with an Amber

color or on the STATUS LED with a Green color. In this mode all LEDs flash Green once to indicate the start

of the error code. Next the OK or STATUS LED blinks a 4-digit decimal error code. The LED first blinks to

indicate the most significant error digit, then after a brief pause blinks again to indicate the next

significant error digit and so forth. After another brief pause, all LEDs flash Green again and the error code

pattern repeats. Repetitions continue indefinitely until the module is power-cycled.

2.1.8.2 Module Identification

The LEDs on a PNS module can be commanded to repeatedly turn ON and OFF in a special sequence, to

help locate or identify the module:

First the green LEDs are turned on in the following circular order: OK, LAN, STATUS, CONN, PORT 4,

PORT 3, PORT 2, PORT 1. There is a short delay between turning on each LED.

The LEDs are then turned off in the same order. There is a short time delay between turning off each

LED.

The Module Identification LED Pattern is initiated by the PROFINET DCP Identify Device command. Module

Identification can be initiated using the Proficy Machine Edition Discovery Tool by refreshing the device

list, double clicking on the RX3i PNS module, and clicking the Identify Device button on the PNS properties

pop-up window.

2.1.8.3 Microprocessor Over Temperature

If the maximum threshold temperature for the PNS’s microprocessor is crossed, the PNS goes into power-

saving mode. While the PNS is in an over-temperature condition, the following blink patterns are

alternated:

• PORT 1, PORT 2, and STATUS LEDs turn on RED for 0.5 seconds (all other LEDs off)

• Then PORT 3 and PORT 4 LEDs turn on RED for 0.5 seconds (all other LEDs off)

The PNS stays in power-saving mode until the temperature drops to a safer level. Once a safe

temperature is reached, the PNS module restarts.

Note: Under certain ambient operating temperatures, the PNS may momentarily display the over

temperature pattern during power-up while it is calibrating its thermal protection functions. This

indication can be ignored.

2.1.8.4 Firmware Update

While the PNS is in firmware update mode, the OK, LAN, and STATUS LEDs blink Green for 0.5 seconds and

then off for 0.5 seconds in unison. During firmware update operation, the ports are disabled, so all of the

PORT LEDs are off and the CONN LED is off. The USB LED operates normally displaying the condition of the

USB port.

2.1.8.5 Internal Update

Some changes from a firmware update are applied to the system on the next power up. During this

internal update process, the STATUS and LAN LEDs blink Green for 0.5 seconds and then off for 0.5

seconds in unison. At the completion of the internal update process, the PNS restarts and should power

up normally.

Page 30

Chapter 2. LED Operation and Connector Details

GFK-2737F December 2016 23

2.1.8.6 Power-up LED Patterns

At power-up, the LEDs show the patterns described below. The LEDs also blink diagnostic patterns for

certain operating errors and for module identification. See the section on Special LED Blink Patterns above

for a description of the special blink patterns.

Step

LED/Blink Pattern

Description

Figure 3: IC695PNS001 LEDs

1

All LEDs off

Initial state

2

STATUS LED solid green

Normal operation

OK LED blinks amber with

special blink code

Fatal initialization or diagnostics

Failure; Hardware Module Identity

Information not available.

STATUS LED blinks green

with special blink code

Fatal initialization failure.

OK, LAN, and STATUS LEDs

blink green in unison (1 Hz)

Invalid firmware detected or

firmware update initiated. Module is

waiting for firmware update. Blink

pattern continues during firmware

update. After the automatic update

completes, the LAN and STATUS

LEDs blink Amber and the module

resets, which restarts the power-up

process.

STATUS and LAN LEDs blink

green in unison (1 Hz)

Internal update in process following

a firmware update. Unit should

complete update and restart

automatically.

3

LAN and STATUS LED solid

green

Normal operation

4

OK LED solid green

Normal operation. Power-up

completed.

Note: Under certain ambient operating temperatures, the PROFINET Scanner may momentarily display

the over temperature pattern during power up, while it is calibrating its thermal protection

functions. This indication can be ignored. For details, refer to the section Microprocessor Over

Temperature above.

Page 31

Chapter 2. LED Operation and Connector Details

24 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

2.2 Ethernet Network Ports

The four external Ethernet ports (two RJ45 and two SFP Cages) are on the bottom of the module. Figure 4

shows the underside view of the RX3i PNS. Ports 1 and 2 are standard RJ45 connectors. Ports 3 and 4 are

Small Form-factor Pluggable (SFP) ports.

Figure 4: Underside of IC695PNS001 Showing Ethernet Ports

The two RJ45 ports provide 10/100/1000 Mbps copper interfaces. The two SFP cages accommodate usersupplied SFP devices, which can support a number of different media types. Refer to SFP Modules for

Ethernet Ports in the Installation chapter for additional information about SFPs.

The two RJ45 ports support CAT5e/6 cabling of up to 100m. Each Ethernet port automatically senses the

type of network and adjusts speed and connection parameters.

The PROFINET protocol can be sent and received over any or all of the four external ports.

Devices connected to the PROFINET Scanner ports should have Ethernet Autonegotiation enabled. The

Ethernet ports can be disabled to support requirements such as IT policies for unused ports. Disabled

ports do not establish a link on their Ethernet network. RX3i PNS modules and other participating modules

can be connected in a daisy chain/line, or star topology. The ports can also be configured to limit their

advertised Autonegotiation setting. This can be used to force a copper interface to establish a link at

100 Mbps rather than 1 Gbps to have quicker link change detection during MRP operation.

Caution

Multiple ports on the Ethernet Interface must not be connected, directly or indirectly, to

the same device so as to form a circular network.

Caution

Port disable settings are non-volatile. If an SFP port is configured as the only enabled

port and that SFP is removed, the RX3i Scanner will not be accessible until an SFP is

returned to that port.

Page 32

Chapter 2. LED Operation and Connector Details

GFK-2737F December 2016 25

2.3 SD Card Slot

The SD Card Slot, located on the front of the PROFINET Scanner, can be used to transfer the Device Name

from a different PROFINET Scanner without the need for a configuration tool such as PME to commission

the new hardware. A card is not required to be present. Refer to Section 4.3.1, Transferring the Device

Name with an SD Card for more details.

Note that when installing an SD Card, the label should face to the left with the write-protect (Lock) switch

to the bottom. The card should enter easily and click when fully inserted. The spring action will return the

card back slightly from its fully depressed position. Do not force the card into the slot as that can damage

the unit. To release the card, press the card in again until it clicks, and the spring action will eject the card

out enough to easily grab hold of it.

SD and SDHC capacity cards are supported. An SD Card can be formatted as either FAT12 or FAT16 per

the SD Card standard and an SDHC card should be formatted using FAT32 per the SD Card standard.

Page 33

Chapter 2. LED Operation and Connector Details

26 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

2.4 USB Port

The USB port, located on the front of the PROFINET Scanner, can be used to connect a computer for

firmware updates for the PROFINET Scanner. The USB port accepts a standard USB cable (USB Micro B

Male to USB Type A Male, not included). The port must be set up before using it, as described in

Section 3.7, Installing the USB Port Driver.

Note: The USB port is for firmware upgrades only. It is not intended as a permanent connection.

Page 34

GFK-2737F December 2016 27

Chapter 3 Installation

This chapter provides instructions for installing PACSystems RX3i PROFINET Controller modules.

Pre-Installation check

Power Requirements

Hot insertion and removal

Removing the backplane knockout

Module installation and removal

Port connections

Installing SFP devices

Installing the USB Port Driver

Firmware updates

For additional information about system installation, also refer to the PACSystems RX3i Systems Manual,

GFK-2314.

Page 35

Chapter 3. Installation

28 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

3.1 Pre-Installation Check

Upon receiving your RX3i equipment, carefully inspect all shipping containers for damage. If any part of

the system is damaged, notify the carrier immediately. The damaged shipping container should be saved

as evidence for inspection by the carrier.

As the consignee, it is your responsibility to register a claim with the carrier for damage incurred during

shipment. However, GE Automation and Controls will fully cooperate with you, should such action be

necessary.

After unpacking the RX3i equipment, record all serial numbers. Serial numbers are required if you should

need to contact Customer Care during the warranty period. All shipping containers and all packing

material should be saved should it be necessary to transport or ship any part of the system.

Verify that all components of the system have been received and that they agree with your order. If the

system received does not agree with your order, contact Customer Care.

If you need technical help, contact Technical Support. For phone numbers and email addresses, see the

General Contact Information page in the front of this manual.

Page 36

Chapter 3. Installation

GFK-2737F December 2016 29

3.2 Installation in Hazardous Areas

EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 HAZARDOUS LOCATIONS IS

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS LOCATIONS ONLY.

Warning

EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2.

Warning

EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES.

Warning

EXPLOSION HAZARD - DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

Warning

EXPLOSION HAZARD - USB PORT IS ONLY FOR USE IN NON-HAZARDOUS LOCATIONS, DO

NOT USE UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

3.2.1 ATEX Marking

II 3 G Ex nA IIC T5 X Ta: 0 - 60C

Page 37

Chapter 3. Installation

30 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

3.3 Module Installation

3.3.1 Power Requiremnents

More than one power supply may be required to support some configurations. To determine the loading

within the PNS rack, refer to the Module Load Requirement section in the PACSystems RX3i System Manual,

GFK-2314. Calculate the 3.3 Vdc and 5 Vdc needs of the modules within the rack, and select power

supplies accordingly.

3.3.2 Hot Insertion and Removal

The PNS Module does not support hot insertion or removal. Turn power off at the rack before removing or

inserting a PNS.

Certain I/O Modules within the rack may be removed and/or inserted while the rack is powered up. Refer

to Section 5.3, Hot Swap of I/O Modules.

For a full discussion of this topic, refer to the Hot Insertion and Removal section in the PACSystems RX3i

System Manual, GFK-2314.

3.3.3 Removing the Backplane Knockout

The PNS can be installed in slot 1 or slot 2 of a 7-, 12-, or 16-slot RX3i Universal Backplane (IC695CHS007,

CHS012 or CHS016), or in slot 6 of a 7-slot RX3i Universal Backplane. It may not be located in the same

rack as an RX3i CPU module. For details, refer to the PACSystems RX3i System Manual, GFK-2314.

The rear of the PNS module has an exposed heat sink and backplane connector. Before inserting the

module into the backplane, remove the plastic knockout in the slot into which the module will be placed.

The installation slot must match the slot selected for the module in the Proficy Machine Edition (PME)

hardware configuration.

Figure 5: RX3i Backplane showing Removable Plastic Knockout

Page 38

Chapter 3. Installation

GFK-2737F December 2016 31

3.3.4 Module Installation

RX3i rack power must be turned off. The

PNS does not support insertion/removal

while power is applied to the rack.

Figure 6: Install Module into RX3i Backplane

Holding the module firmly, align the module

with the correct slot and connector.

Engage the module’s rear pivot hook in the

notch on the top of the backplane (1).

Swing the module down (2) until the

module’s connector engages the

backplane’s backplane connector.

Visually inspect the module to be sure it is

properly seated.

Secure the bottom of the module to the

backplane using the machine screws

provided with the module (3).

Tighten the heat sink screw on the front of

the module in the threaded hole in the back

plate to 6 in-lbs (0.68 Nm), using a flat-tip

screwdriver.

3.3.5 Module Removal

RX3i rack power must be turned off.

Figure 7: Remove Module from RX3i Backplane

Loosen the heat sink screw on the front of

the module to release the heat sink from

the backplane’s aluminum back plate.

Loosen the screws at the bottom of the

module (1).

Pivot the module upward until its connector

is out of the backplane (2).

Lift the module up and away from the

backplane to disengage the pivot hook (3).

Page 39

Chapter 3. Installation

32 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

3.4 Replacing a PROFINET Scanner

If a PNS module needs to be replaced for any reason, follow these steps to commission a replacement

module.

Note: If the replacement PNS module has no assigned Device Name (the CONN LED is blinking Amber

slowly), the network cabling can be plugged back in and the name assigned over the PROFINET

network.

However, if the replacement PNS module already has an assigned Device Name, there will be a

risk of a duplicate Device Name on the network. This condition cannot be tolerated by the

PROFINET Controller. This situation can be avoided by transferring the Device Name from the

installed PNS to the replacement PNS via the SD Card prior to connecting the replacement unit to

the PROFINET network.

If there is a possibility of duplicate Device Names or duplicate IP Addresses existing on the

network, these should be assigned before inserting the replacement PNS into a working PROFINET

network. The Device Name and IP Address settings can be updated offline (for example, in an

office setting).

Use the Proficy Machine Edition DCP Tool to store the Device Name to the RX3i SD Card installed in

the PNS SD slot. Avoid hand-editing Device Name files contained on the SD Card. Storing an illegal

name to the RX3i PNS will prevent it from connecting to its PROFINET Controller until a valid Device

Name is stored.

3.4.1 Method 1 – Using the SD Card

1) Remove power from the PNS module. This should be done before network cabling is removed,

especially in the case of fiber connections.

2) Remove network cabling from the module.

3) Remove the SD Card from the module.

4) Remove the module.

5) Install the replacement PNS module.

6) Insert the SD Card from Step 3) in the replacement PNS module.

7) Connect network cabling to the replacement PNS module.

8) Apply power to the replacement PNS module hardware. The PROFINET IO-Controller will update

any IP Address settings automatically when it connects.

3.4.2 Method 2 – Using the DCP Tool

Refer to Section 4.3, Assigning Device Names.

1) Remove power from the PNS module. This should be done before network cabling is removed,

especially in the case of fiber connections.

2) Remove network cabling from the module

3) Remove the module.

4) Install the replacement PNS module.

5) Connect network cabling to the replacement PNS module.

6) Apply power to the replacement PNS module hardware.

7) Using the utility PROFINET DCP click on the Refresh Device List command button.

8) Highlight the row representing the newly installed PNS.

9) Click on the Edit Device command button and type in the Device Name.

10) Click on the Set Device Name command button.

Page 40

Chapter 3. Installation

GFK-2737F December 2016 33

3.5 SFP Modules for Ethernet Ports

Refer to Chapter 2 of the PACSystems RX3i PROFINET Controller User Manual, GFK-2571.

3.6 External Switch VLAN Priority Settings

Refer to Chapter 4 of the PACSystems RX3i PROFINET Controller User Manual, GFK-2571.

3.7 Installing the USB Port Driver

The USB port is only used for firmware updates. USB driver files are provided as part of upgrade packages

compatible with the PNS.

With the provided installation files accessible on either a local or network drive, connect the computer’s

USB port to the USB port on the PNS module to be upgraded. When requested, direct the installation to

the proper location of the installation files.

The serial port name is COM followed by the next available number from 1 to 256. After the computer

assigns the USB port a COM port number, that computer uses the same COM port number each time it

connects to that PNS module.

Note: When connecting the USB cable to the PNS, you may receive a warning for installing a driver that

has not passed Windows Logo testing. This warning should be ignored. Because each PNS has a

different serial number, the operating system recognizes each driver installation as different.

3.8 Firmware Updates

Note: The RX3i PNS does not prevent initiation of firmware update when it is actively connected to an

I/O Controller. When the PNS enters firmware update mode, the PNS and its modules go to their

I/O default modes. During the update, the PNS does not drive module outputs or send inputs to

the I/O Controller. When the firmware update is completed and the PNS is rebooted, its previous

connections are re-established and control resumes. Refer to section 2.1.8.6 Power-up LED

Patterns.

The PNS enters firmware update mode when commanded to do so from the WinLoader update utility, or

if a firmware component is corrupted or invalid. In firmware update mode, the PNS module blinks its LEDs

in a special pattern as described previously, and its Ethernet ports are not operational.

If the PNS has experienced a fatal error, the module goes to an LED blink-code error condition and does

not communicate with WinLoader, causing WinLoader to return a timeout failure indication. The module

must be power-cycled before reattempting the update.

Page 41

Page 42

GFK-2737F December 2016 35

Chapter 4 Configuration

This chapter explains how to configure a PROFINET IO-Device consisting of an RX3i PROFINET Scanner

and the I/O modules located in its rack into a PACSystems RX3i system controlled by an RX3i CPU.

Additional information about RX3i configuration is available in other PACSystems documentation (refer to

Section 1.9, PACSystems Manuals) and in the Logic Developer online help.

This chapter discusses the following topics:

Configuration Overview

o Basic Configuration Steps

o Configuration Tools

Adding an RX3i PROFINET Scanner to a LAN

- Configuring RX3i PROFINET Scanner

- Adding RX3i Modules to a Remote Node

o Adding a Power Supply

o Adding and Configuring an Ethernet Port

o Configuring Module Parameters

o Configuring Analog Modules that have DIP Switches

o Configuring Analog Modules that have Jumpers

• Assigning Device Names

- Transferring the IO-Device Name with an SD Card

After the Configuration is Stored to the PROFINET Controller

Page 43

Chapter 4. Configuration

36 PACSystems* RX3i PROFINET IO-Scanner User Manual GFK-2737F

4.1 Configuration Overview

The RX3i PNS receives its configuration from a connected PROFINET Controller (PNC), which has been

configured by a PROFINET configuration tool. The GSDML files required for configuring the PROFINET

Scanner (PNS) are provided with Proficy Machine Edition. For other PROFINET configuration tools, the PNS

GSDML must be imported. The GSDML file for the RX3i PNS can be obtained at www.geautomation.com.

PNS001 GSDML files are also included in all RX3i firmware upgrade kits.

Note: For details on using the Proficy Machine Edition PLC Logic Developer programmer to create and

download the configuration for an RX3i PROFINET network and its IO-Devices, refer to the

PACSystems RX3i PROFINET Controller Manual, GFK 2571.