Page 1

ProSys™ Lighting Control System Relay Panels

DEH40212 Installation Instructions

GE Total Lighting Control

ProSys Lighting Control System

Catalog Number RINTERxxxPS(P)

RINTER2424PSP 24-Relay Interior shown with RTUB24

DESCRIPTION

The ProSys Lighting Control System is a small network of

relay panels and occupant control switches linked by a 4-wire

dataline. Together, these devices form a reconfigurable

switching platform — one that uses “softwiring” instead of

hardwiring to link occupant switches to relays. Scheduling

capability can be readily added by simply mounting an

RCLK8PS Softwired Clock to the DIN rail in any relay panel.

The RINTERxxxxPS(P)

Lighting Control System Relay Panel. The complete relay

panel assembly will include the following:

1. Tub (RTUBxx)

2. Interior (RINTERxxxxPS or RINTERxxxxPSP)

3. Power Supply (RPWRxxx)

4. Cover (RCOVxxxx)

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met in connection with

installation, operation or maintenance. Should further information be desired or should particular problems arise that are not covered for the purchaser's purposes,

the matter should be referred to the GE Company.

1

is the interior for a ProSys

This instruction sheet will show you how to:

1. Install the Relay Panel(s)

2. Install and Test the Dataline

3. Document the Relay Panels

Full descriptions of the installation and operation of Softwired

Switches and the Softwired Clock and other optional

automation devices are located in other sections of this

manual and are provided with each hardware unit.

Before starting, read the following installation

instructions. If you have questions, call GE Total

Lighting Control Service at:

1-877-584-2685 (LTG-CNTL) in the USA and Canada.

1

Page 2

DEH40212 Installation Instructions

RELAY PANEL INSTALLATION

CAUTION: Make sure all power is OFF before wiring.

Do not energize wiring until the unit is fully assembled.

Conform to all applicable codes.

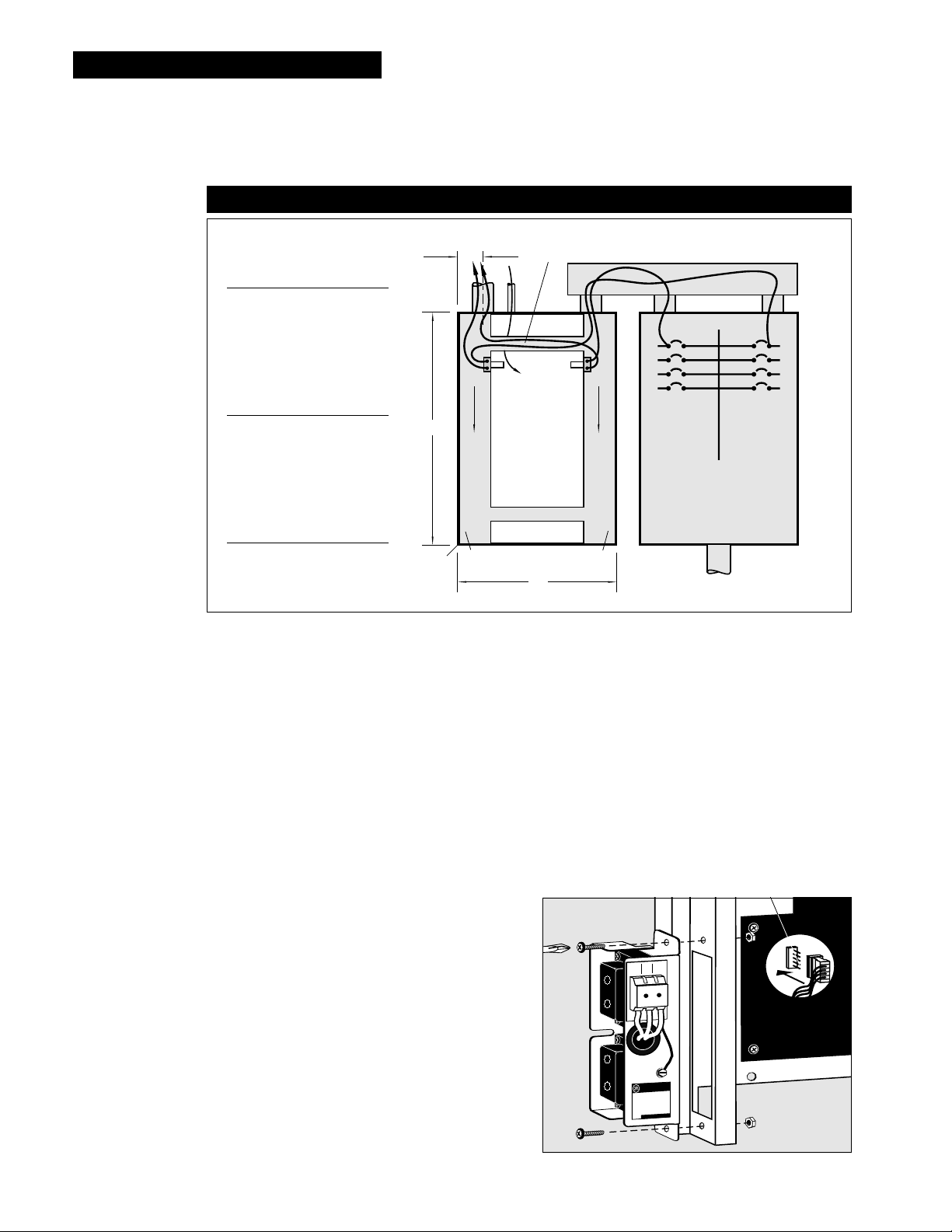

Figure 1

SWITCHED LIGHTING CIRCUITS

2" TYP.

Dimensions (A x B)

RINTER1212PS(P)

16.0" (406mm) x 16.5" (419mm)

RINTER2424PS(P)

22.5" (572mm) x 24.0" (610mm)

RINTER4848PS(P)

36.0" (914mm) x 24.0" (610mm)

Relay Capacities (C)

RINTER1212PS 12 RR7 relays

RINTER1212PSP 12 RR9 relays

RINTER2424PS 24 RR7 relays

RELAYS RELAYS

CLASS 2

LOW-VOLTAGE

WIRING SECTION

A

CC

DIN RAIL

RINTER2424PSP 24 RR9 relays

RINTER4848PS 48 RR7 relays

RINTER4848PSP 48 RR9 relays

DIN Rail Capacities

RINTER1212PS(P) One module

4.5" D

RINTER2424PS(P) Two modules

RINTER4848PS(P) Two modules

If you have purchased the ProSys II Lighting Control System

(the stand-alone system), the devices (panels, switches and

clock) will be in self-install mode, which means that as soon

as they are connected to the network, they are operational

and can communicate with each other.

If you have purchased the ProSys LM Lighting Control System

along with the ProSys LM software, the devices will be in

software-install mode. This means that in order for them to

function on the network you must:

• assign network addresses to the devices and

• bind network variables and message tags using your

network management tool.

Addresses and binding are necessary for the devices to function on

the network. ProSys LM users please refer to the ProSys LM

Software User Guide for instructions on installing devices.

LINE-VOLTAGE WIRING SECTIONS

5" WIDE

B

Rough-In Tub

• Environment

• Mounting

• Pulling Wires

o

32 to 131

F (0 to 50oC), 0 to 95% relative humidity,

stationary applications

The tub should be level, plumb and rigidly installed with

hardware sufficient to hold 100 lbs. (48kg). For flush-mount

panels, the front flange should be flush with the final

finished surface. For multiple panels, allow

1

⁄4” minimum

between panels for showbox cover clearance.

Route line-voltage wiring through the 2

1

⁄2” knockouts in

either the top or bottom of the tub. Route Class 2 lowvoltage dataline from the remote switches or other controls

through the

3

⁄4” knockouts in either end.

1.5" x 1.5" CROSSOVER WIRING CHANNEL (TOP AND BOTTOM)

CIRCUIT BREAKER PANEL

ILLUSTRATION NOT TO SCALE

Install Interior

• Power Supply

Attach the power supply to the frame (bottom of 12-relay

interior and left side of 24- or 48-relay interiors) and plug

the low-voltage connector to the terminal marked “POWER”

as shown in Figure 1 above.

• Interior

Mount the interior in the tub and secure it to the studs with

the hardware provided. Make sure that all line- and lowvoltage wiring is confined to the appropriate areas.

Wire Line Voltage

Before making any connections to the relays, make sure that

none of the load circuits are shorted. Wire from the circuit

breaker through each relay’s SPST output terminals, and from

there to the loads. Confirm that each circuit is wired to the

relay specified in the drawings. Wire the power supply.

Figure 2

D

R

G

U

E

N

5

1

1

C

A

V

ls

o

r

t

n

o

C

g

in

t

h

ig

L

E

G

J2

RINTER2424PS

shown

2

Page 3

POWER UP AND TEST RELAYS

DEH40212 Installation Instructions

1. Apply power to the power supply only. As shown in

Figure 3, to the right, press the Relay Control Button next

to each relay’s yellow plug-in termination to toggle it ON/

OFF. The relay should “click” and the LED status indicator

should change state. Confirm the operation by measuring

the continuity at the line-voltage terminations of each

relay.

2. Apply power to the relays. Being careful not to touch

any line-voltage wiring, toggle each relay ON/OFF again

and confirm that each relay controls the appropriate load.

DOCUMENT RELAY WIRING

Record the circuit controlled by each relay on the RELAY

SCHEDULE which was shipped with the interior. The relays

Figure 4

PROSYS RELAY SCHEDULE

PANEL #

01

RELAY # SUPPLY LOAD DESCRIPTION

Figure 3

TO RELAY

RR7P RELAY SHOWN

LED INDICATOR

RELAY

CONTROL

BUTTON

associated with automation channels A-H are recorded later.

-01

-02

-03

-04

-05

LP1-1 OPEN OFFICE - FIRST FLOOR NW

LP1-2 "

LP1-3 OPEN OFFICE - FIRST FLOOR NE

LP1-4 "

LP1-5 OPEN OFFICE - FIRST FLOOR SW

SOFTWIRING A RELAY GROUP TO A CHANNEL

Figure 5 – Softwiring a Relay Group

HH

HH

PRESS

AND

HOLD

CHANNEL

PUSH

BUTTON

FLASHING

RED LED

1 Press and hold the

Channel Push Button

for several seconds.

2 Select the relays to

be controlled.

3 Press the Channel

FLASHING

LED

Push Button again.

Test. Press the

Channel Push Button

to toggle the group

ON/OFF/ON.

Each ProSys panel includes eight “channels” (A-H) which may

be softwired to relays within the panel. Channels are used to

group relays for common control.

When a ProSys system includes an automation module

(RCLK8PS Softwired Clock), we strongly recommend you turn

to the installation instructions for that automation module and

complete the documentation before softwiring any

relays to channels.

However, if automation is to be provided by an interface to

another system, or by using manual switches only, the

channels may be used simply for grouping relays. Follow the

instructions in Figure 5 to the left.

3

Page 4

DEH40212 Installation Instructions

DATALINE INSTALLATION

GLOBAL (PANEL-TO-PANEL) DATALINE

PANEL 01 PANEL 02 PANEL XX

The dataline connects the relay panels, switches and optional

control modules. Within the 4-wire dataline are two twisted

pairs: the red and black wires, carrying data; and the blue and

white wires, providing power to the dataline switches and

control modules.

For simplicity, we refer to a 4-wire dataline running between

a relay panel and the dataline switches as a “Local Dataline”.

The relay panel provides the low-voltage power to all of the

intelligent devices on that section of the dataline.

The dataline running between relay panels is known as the

“Global Dataline,” and it uses only the red and black data

wires. The blue and white wires are not connected and should

be trimmed.

Panel Addressing

The two rotary switches on each relay panel set its address,

allowing the differentiation between relays in different panels.

NOTE: The first panel address must be set at 01 and the others

numbered sequentially 02, 03, and so on, between 02 and 30 as

shown to the right. If the panel address is set higher than 30, the

channel LEDs in the panel will flash. Setting the panel address to 30

or below will return the panel to normal operation. If a panel is set to

the same address as another panel, then the two panels will not

operate properly. The ProSys LM panels can be setup in groups of 30

where the panels in a group can be numbered from 00 to 30.

Note: To ensure good communications between panels,

GE RLONWIREP-S4 Dataline Wire Specifications

• #18 AWG (7 strands x 26 AWG)

• 2 independent twisted pairs – black/red, blue/white

• Unshielded copper conductors

• 2 inch twist lay on pairs, 6 inch twist lay on cable

• Plenum-rated copolymer jacket, 0.230" O.D.

• FEP 0.010" insulation, 0.060" O.D.

• 30 pF/foot maximum capacitance

• -20°C to 150°C operating temperature range

• 17 lbs. per 500 foot reel

• UL rated

the installer must comply with the dataline specification.

GE will not warrant a system using a dataline that does

not meet our specification. To avoid questions, use GE

RLONWIRE-4P (plenum rated). Do not run the dataline

in conduit or wiring trays with power wires. Do not

4

connect the local datalines from two different panels.

Page 5

HARDWIRE LOW-VOLTAGE SWITCHES (OPTIONAL)

Each of the ProSys panel’s eight channels has a single switch

input which will accept any of the dry-contact configurations

shown in Figures 6 and 7, and also provides status feedback

for that channel.

DEH40212 Installation Instructions

Figure 7 – Hardwired Switch Configurations

RED/BLACK JUMPER

ProSys panels whose catalog numbers end in “P” also include

inputs for each relay. Like the channel inputs, these support

all of the dry-contact configurations shown.

Figure 6 – Hardwired Switch Inputs

HARDWIRED CHANNEL SWITCHES

HARDWIRED RELAY SWITCHES*

* The ability to hardwire a 2- or 3-wire

switch directly to a relay is an option in

ProSys system panels. For panels with relay

inputs, order interiors with catalog

numbers ending in P.

PANEL TESTING AND TROUBLESHOOTING

Panel Testing

The panel-to-panel dataline should be tested for continuity

and isolation from ground.

To test for continuity, remove the red and black dataline wires

at panel 01 and wire nut together (short the wires together).

Go to the last panel in the series and measure the resistance

between the red and black terminals. It should be less than 3

ohms. Return to panel 01 and restore the red and black wires

to their associated terminals.

MAINTAINED

ISOLATED CONTACT

2-WIRE MOMENTARY

PUSH BUTTON

STANDARD 3-WIRE

MOMENTARY

STANDARD 3-WIRE

MAINTAINED

R B Y W

BLACK/WHITE JUMPER

R B Y W

R B Y W

R B Y W

For shorts, test from red to white and black to white

anywhere in the low-voltage section of the panel. You should

see an open circuit.

5

Page 6

DEH40212 Installation Instructions

DEH40212 BL 0700 R02

6

GE Total Lighting Control

GE Total Lighting Control

41 Woodford Avenue, Plainville, CT 06062

©2000 General Electric Company

Loading...

Loading...