Page 1

How to get the best from

Your

Contents

~ ]

,

Aluminum Foil

Anti-Tip Device

Appliance Registration

Care and Cleaning

Clock

and Timer

Consumer Services

lmportmt

(lmverting to I.P or

Phone

Numbers

~~. 25, 30

2, 3, 35, 43

28–33

12, 13

51

51

Oven

Vents

Ro&sling,

~

Self-Cleatling

Shelves

Power

Problem Solver

Thermostat

lx)

Roasting

Outage

It

Yol(r.wlf

Adjustmm-

I

5,33

Guide 21, 22

~5_?7

Is,

16

13

49,

50

Z()

use

and

&Installation

of Models

RGB744

RGB745

care

Natural

Features

Installation Instructions

Air

Flooring Under

Leveling

Model and Serial Numbers 2

oven

Biking

Broiling, Broiling

Control

Door Removal

Light;

Oven

Gas

Adlustnlent

Se[tings

BLIlb

Replacement 14,

Botmn

Range

Guide

44.48

6,

34Lt3

42

36

43

14-27

1619

23, 24

31

32

30

Safety Instructions

7 Surface Cooking

Burners

Control Settings

Cooktop

Cookware

Flame Size

lighting Instructions

Warranty

II

GE Answer Center

800.626.2000

Comparison

Tips

3-5

8-I()

8- I ()

x, g

x

10

g

8

Back cover

(]

ttcnFolNr

Page 2

HELP US HELP YOU...

Read this guide carefully.

It is intended to help you operate and

Ilcw’ l“:in:L! pl”opc’l”ly.

Keep it hmdy for

If

yoLI d(m’(

wrik

(

inc]udc y(~LIr

CYollsumer

t+c~tpoint

Appli:lncc

l.(~uis~illc,

tinswcrs [o

Llndcrstancl something or

phone

Affdirs

Park

KY

40225

your questions.

numb”):

Write down the model and serial numbers.

Depending

scri:il llulllbCI”S

behind

‘“1’hcsc

Ownership

r:Inge. Fkforc

Ilumbcl’s here:

Model Number

on your

the

kick

IIUlllbC1’S :II”C :1[S() 011 (hC

Rcgis(ration Cd

sending in this

on

panel,

rmge, you’ll

ii

Iilhel

011

s[(mge drawer

the front of the

~ollSLltllCl”

(hot

cm{, pleaw wrik

Serial Number

m~lint:lin

need

find

the mode! dnd

or

c:unc

your

more

range.

hroikr

drdwer.

[>rOLiLld

with yoLIr

these

help,

WARNING: If

the information in this

guide is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

●

Do not try to light any appliance.

●

Do not touch any electrical switch; do

not use any phone in your building.

●

Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

●

If you cannot reach your gas supplier,

call the fire department.

USC Ihcsc numbcls

cdl

Is

Collccrll

It’

you received a damaged range . . .

lmndi~l(ely

you

tllc

r:ulge.

in

any CI)I”J-CS}30tlCiCllCC

i

ng

Y(JLI1° I“:U1:C

c(mt:ict the dcder

(or builder)

Save time and money. Before you

request service . .

ChCC!i ~he

1(

]iStS

call

——

Problcm

CLILISCS of lllill(M” Opcra(in:

Col”rcc( youl”scl f.

Solver in the

back 01’

pr(~h]enls thu(

●

IN.IURY TO

COIJLD

●

INSTALL

this

PERSONS

RESULT

ANTI-TIP

DEVICES PACKED

WITH RANGE

●

SEE

1NSTALLATION

lNSTRUCTIONS

1

/)

Ah!)

b.-

2’

or

scrvicc

th:l( sold

guide.

J’OLI

— Installation and service must be

performed by a qualified installer, service

or

the

gas

agency

supplier.

IF YOU NEED SERVICE

To obtain service,

(he back

To

Service Centers.

We’re

pleased. If for some

service

further help.

FIRST, contact the

appliance. Explain why you are not

cases,

NEXT,

details—including your phone number-to:

FINALLY, it’ your problem is still

of this

obtain

replacement parts,

proud

you

receive, here are three steps to

this will solve the problem.

if

you

Manager, Consumer Relations

Hotpoint

Appliance Park

Louisville, KY 40225

Major Appliance Consumer Action

z() Nor[h Wacker

Chicago, IL.

scc

the Consumer

guide.

of our service

reason

people

are

still

not

pleased, write all

Drive

60606”

Services piigc

contact CiE/Hotpoint

and

want you to

you

arc

not happy with

who

serkicd

your

pletised.

not

resolved, write:

Panel

he

follow

for

I n most

the

in

[he

‘*”

@).4pPR0uED

0

Page 3

IMPORTANT SAFETY NOTICE

●

The

California Safe Drinking Water and Toxic

Enforcement Act

to publish a list of substances known to the state

to cause cancer, birth defects or other reproductive

harm, and requires businesses to warn customers

of potential exposure to such substances.

Gas appliances can cause minor exposure to

four of these substances,

monoxide, formaldehyde and soot, caused primarily

by the incomplete combustion of natural gas or

LP

fuels. Properly adjusted burners, indicated by a

bluish rather than a yellow flame, will minimize

incomplete combustion. Exposure to these

substances can be minimized by venting with an

open window or using a ventilation fan or hood.

●

Fluorescent light

standing pilot ranges contain mercury.

model has these features, they must be recycled

according to local, state and federal codes.

When You Get Your Range

●

Have the installer show you the location of the

range gas cut-off valve and how to shut it off

if necessary.

●

Have your range installed and properly

grounded by a qualified installer,

with the Installation Instructions. Any adjustment

and service should be performed only by qualified

gas range installers or service technicians.

●

Do not attempt to repair or replace any part of

your range unless it is specifically recommended

in this guide.

to a qualified technician.

●

Plug your range into a 120-volt grounded

outlet only.

prong from the plug. If in doubt about the grounding

of the home electrical system, it is your personal

responsibility and obligation to have an ungrounded

outlet replaced with a properly grounded,

prong outlet in accordance with the National

Electrical Code. In Canada, the appliance must be

electrically grounded in accordance with the

Canadian Electrical Code. Do not use an extension

cord with this appliance.

●

Locate the range out of kitchen

and out of drafty locations to prevent pilot

outage (on standing pilot models) and poor

air circulation.

requires the Governor of California

namely benzene, carbon

bulbs

and safety valves on

If your

in accordance

AH other servicing should be referred

Do not remove the round grounding

three-

traff]c

path

●

Be sure all packing materials are removed from

the range

before operating it to prevent fire or

smoke damage should the packing material ignite.

●

Be sure your range is correctly adjusted by a

qualified service technician or installer for the

type of gas (natural or LP) that is to be used.

Your range can be converted for use with either

type of gas. See the Installation Instructions.

WARNING: These adjustments must be made by

qualified service technician in accordance with the

manufacturer’s instructions and all codes

znd

requirements of the authority having jurisdiction.

Failure to follow these instructions could result in

serious injury or property damage. The qualified

agency performing this work assumes responsibility

for the conversion.

●

After prolonged use of a range, high floor

temperatures may result and many floor

will

coverings

not withstand this kind of use.

Never install the range over vinyl tile or linoleum

that cannot withstand such type of use. Never

install it directly over interior kitchen carpeting.

Using Your Range

A

VVM?RJING-AII

can tip and injury could result. To

prevent accidental tipping of the

range,

attach it to the wall and

installing the Anti-Tip device supplied.

To check if the device is installed and

engaged properly, carefully tip the

range forward. The Anti-Tip device should engage

and prevent the range from tipping over.

pull

If you

the range out from the wall for any

reason, make sure the device is properly engaged

when you push the range back against the wall.

If it is not, there is a possible risk of the range

tipping over and causing injury if you or

stand, sit or lean on an open door.

Please refer to the Anti-Tip device information

in this guide. Failure to take this precaution could

result in tipping of the range and injury.

●

Do not leave children alone or unattended

where a range is hot or in operation.

They could be seriously burned.

●

For your safety, never use your appliance for

warming or heating the room.

ranges

floor

by

@

(&)

a

child

,4

i.

a

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

(continued)

“

CAUTION: ITEMS OF INTEREST TO

CHILDREN SHOULD NOT BE STORED IN

CABINETS ABOVE A RANGE OR ON THE

BACKSPLASH OF A RANGE—CHILDREN

CLIMBING ON THE RANGE TO REACH

ITEMS COULD BE SERIOUSLY INJURED.

●

Do not allow anyone to climb, stand or hang

on the door, broiler drawer or cooktop. They

could damage the range and even tip it over,

causing severe personal injury.

●

Let the burner grates and other surfaces cool

before touching them or leaving them where

children can reach them.

●

Never wear loose fitting or hanging garments

while using the appliance.

Be careful when

reaching for items stored in cabinets over the

cooktop. Flammable material could be ignited if

brought in contact with flame or hot oven surfaces

and may cause severe burns.

●

Do not use water on grease fires. Never pick up

a flaming pan.

Turn the controls off. Smother a

flaming pan on a surface unit by covering the

pan completely with a well-fitting lid, cookie sheet

tlat

tray. Use a multi-purpose dry chemical or

or

foam-type fire extinguisher.

Flaming grease outside a pan can be put out by

covering it with baking soda or, if available, by

using a multi-purpose dry chemical or foam-type

fire extinguisher.

Flame in the oven can be smothered completely by

closing the oven door and turning the oven off or

by using a

tnulti-purpose

dry chemical or

foam-

type fire extinguisher.

●

Do not store flammable materials in an oven, a

range broiler or storage drawer or near a cooktop.

●

DO NOT STORE OR USE COMBUSTIBLE

MATERIALS, GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

●

Do

not let cooking grease or other flammable

materials accumulate in or near the range.

●

When cooking pork,

follow the directions exactly

and always cook the meat to an internal temperature

of at least

17(PF.

This assures that, in the remote

possibility that trichina may be present in the meat,

it will be killed and the meat will be safe to eat.

Surface Cooking

●

Always heat fat slowly, and watch as it heats.

4

s

Always use the LITE position (on electric

ignition models) or the HI position (on standing

pilot models) when igniting the top burners

and

make sure the burners have ignited.

●

Never leave the surface burners unattended at

high flame settings.

Boilovers

cause smoking

and greasy spillovers that may catch on fire.

●

Adjust the top burner flame size so it does not

extend beyond the edge of the cookware.

Excessive

●

Use only dry pot holders—moist

tlame

is hazardous.

or damp pot holders

on hot surfaces may result in burns from steam.

●

Do not let pot holders come near open flames

when lifting cookware.

Do not use a towel or other

bulky cloth in place of a pot holder.

●

To minimize the possibility of burns,

ignition

of flammable materials and spillage, turn cookware

handles toward the side or back of the range

without extending over adjacent burners.

●

Always turn the surface burners to

of”f bef’ore

removing cookware.

●

Carefully watch foods being fried at a

high

flame setting.

●

Never block the vents (air openings) of the

range.

They provide the air inlet and

outlet

that

are necessary for the range to operate properly

with correct combustion. Air openings are located

at the rear of the cooktop, at the top and bottom

ot

the oven door, and at the bottom of the range under

the broiler drawer.

●

Do not use a wok on models with sealed burners

if the wok has a round metal ring that is placed

over the burner grate to support the wok.

This

ring acts as a heat trap, which may damage the

burner grate and burner head. Also, it may cause

the burner to work improperly. This may cause a

carbon monoxide level above that allowed by

current standards, resulting in a health hazard.

●

Foods for frying should be as dry as possible.

on frozen foods or moisture on fresh foods can

Frost

ctiuse

hot fat to bubble up and over the sides of the pan.

●

Use the least possible amount of fat for effective

shallow or deep-fat frying.

of

fat

can cause spillovers when food is added.

●

Use a deep fat thermometer

Filling the pan

too full

whenever possible to

prevent overheating fat beyond the smoking point.

●

Never try to move a pan of hot fat,

deep fat fryer. Wait until the

o

When using glass cookware,

fat

make sure it is

especially a

is cool.

designed for top-of-range cooking.

Page 5

●

If a combination of oils or fats will be used

in frying,

stir together before heating or as fats

melt slowly.

●

Use

proper pan

size—Avoid pans that are

unstable or easily tipped. Select cookware having

flat bottoms large enough to properly contain food

and avoid

boilovers

and spillovers and large

enough to cover burner grate, This will both save

cleaning time and prevent hazardous accumulations

of food, since heavy spattering or spillovers left

on range can ignite. Use pans with handles that

can be easily grasped and remain cool.

●

Keep all plastics away from the top burners.

●

Do not leave plastic

items on the cooktop-

they may melt If left

‘OOclOsetOthevent m

●

Do not leave any items

Vent appearance and

Iocatlon

vary

on the cooktop.

The hot air from the vent may ignite flammable

items and will increase pressure in closed

containers, which may cause them to burst.

●

To avoid the possibility of a burn, always be

certain that the controls for all burners are at

the off position and all grates are cool before

attempting to remove them.

●

When flaming foods are under the hood, turn

the fan off. The fan, if operating, may spread

the flames.

●

If range is located near a window,

do not hang

long curtains that could blow over the top burners

and create a fire hazard.

●

When a pilot goes out

(on standing pilot models),

you will detect a faint odor of gas as your signal

to relight the pilot. When relighting the pilot,

make sure burner controls are in the off position,

and follow instructions in this book to relight.

●

If you smell gas,

and you have already made sure

pilots are lit (on standing pilot models), turn off the

gas to the range and

call

a qualified service technician.

Never use an open flame to locate a leak.

Baking, Broiling and Roasting

●

Do not use the oven for a storage area.

Items stored in the oven can ignite.

●

Place the oven shelves in the desired position

while the oven is cool.

●

Stand away from the range when opening the

door of a hot oven.

escapes can cause burns to hands, face and eyes.

The hot air and steam that

i

●

r!

●

Keep the oven free from grease buildup.

●

Pulling out the shelf to the shelf-stop is

convenience in lifting heavy foods. It is also

precaution against burns from touching hot

surfaces of the door or oven walls. The lowest

position “R” is not designed to slide.

●

Do not heat unopened food containers. Pressure

could build up and the container could burst,

causing an injury.

●

Do not use aluminum foil anywhere in the oven

except as described in this guide.

result in a fire hazard m- damage to the range.

●

When using cooking or roasting bags in the

follow the manufacturer’s directions.

oven,

●

Use only glass

cookware that is recommended

for use in gas ovens.

●

Always remove the broiler pan from range as

soon as you finish broiling.

con

catch fire if oven is used without removing

Grease

the grease from the broiler pan.

●

When broiling, if meat is too close to the flame,

the fat may ignite.

excessive

●

Make sure the broiler pan is in place correctly

tlare-ups.

Trim excess fat to prevent

to reduce the possibility of grease fires.

●

If you should have a grease fire in the broiler pan,

turn off oven control,

and

keep broiler drawer and

oven door closed to contain fire until it burns out.

Self-Cleaning

Q

Clean only parts listed in this Use and

●

Do not clean door gasket.

(lven

The

door gasket is

essential for a good seal. Care should

[he

to rub, damage or move

●

Do not use oven cleaners. No

cleaner or oven

shou]d

be used in or

liner

protective coating of any kind

w-ouncl

Residue from oven cleaners

the

of the oven when

●

Before self-cleaning the oven, remove broiler

self-clean cycle is used.

gasket.

com

any part of the oven.

will

damage the inside

pan and rack and other cookware.

●

Be sure to wipe up excess spillage before

starting the self-cleaning operation.

●

If

the self-cleaning mode malfunctions, turn

the oven off and disconnect the power supply.

Have it serviced by a qualified Technician.

SAVE THESE

INSTRUCTIONS

a

Misww could

left

in the pan

Care Guide,

be

taken not

mere id oven

a

5

Page 6

FEATu~s

OF YOUR RANGE

f

!

II

6

I

Features and

,/”

‘ ‘----’>

,—

(’

— -.

-.,, .-.

/

/

/ i

T.... (

1[’

1

Your range is equipped with one of the two types of surface burners shown above.

&

,.

,

L_.,,,,,”

‘

.-J

(on some

‘y,, ~~~~~~~ase

‘ 2.\

(

[-~>~B”rner

$:~j;,

appearance

)

\,

m

Page 7

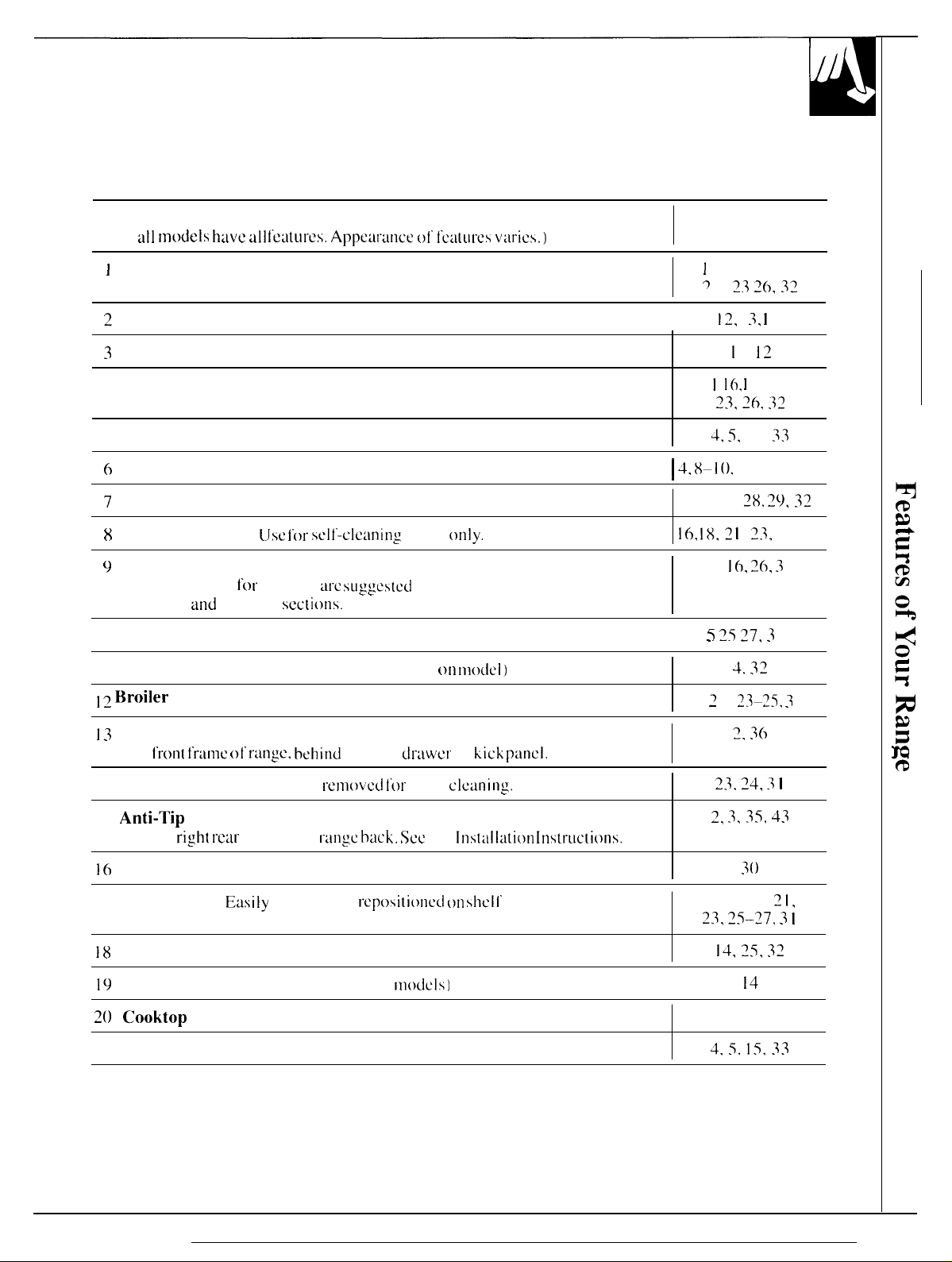

Feature Index

(Not

all models have all

I

OVEN SET Knob

2

Clock and Minute Timer

3

OVEN CYCLE Light

4 OVEN TEMP Knob

5 Oven Vent

6

Grates, Drip Pans (on some models) and Surface Burners

feLItLIres.

Appcw:mce 01” I’C:NUI-CS vmics.)

Explained

on page

I

1, 16.18, 19,

~

I 33

12,

I(3, I

I 3,

I

1,

~6, 32

I

12

X-2 I .

- , -. . -

I

I I ,

~~, ~(,, :{?

4, 5.

Is.

I 4.

8-I(). 25,28-30

x

33

7

Surface Burner Control Knobs

8

Oven Door Latch

9

Oven Shelf Supports

Shelf’ positions

Roasting

10 Oven Door Gasket

11 Storage Drawer or Kick Panel (depending

12

~roiler pan and Rack

13

Model and Serial Numbers

On

I 4 Lift-off Oven Door Easily

15

Anti-1’ip

Lower

16

Removable Oven Bottom

17 Oven Shelves

18

Oven Interior Light

and

f’ron( frame of” range, behind

Device

righ[ I-car

(Jsc for sell’-cleanin:

i“or

cooking wc

Broiling

Easily

sections.

corner on

removed or

cycle

slrgges[cd

storage

r“enlovccf f’t)r

range hack. Scc

reposi[i~)nd on shell’

in the Baking.

dr-:iwcr

oven

only.

(~n

rn(del)

or

kick panel.

c]cdning.

the Instdla[ion tnstrudions.

supports.

4, 8.9,

16,

18.2 I ,

Is,

T ~’i 77, 3

-

, -. . -

I

5, 2 I ,

~j.

2,

3.35,

5. 14–18.

~J, ~5–?7, J I

14, 25, 32

28,

29.32

23,

25–27

I(3, 26, 3

4. 32!

23–25, 3

2, 36

~q, j I

30

I

I

I

43

21,

19

Oven Light On/Ofmf Switch (on some

20 Cooktop

Air Vents

in(xlcls)

I

14

30.33

4.5. 15, 33

7

Page 8

Your

11(2W

cook(op” has

to cooking wi(h

Llnils. yoLl

gas

burrlcl”s.

‘I~pC

(;as

~+

Wi] i llo(icc SOI1lC

of’

Cooktop”

Burners

,.0,

Radiant

(Glass (’manic)

C()()kt()p

o

Solid Disk

--

\

\

[-.)

HOW DOES THIS COOKTOP COMPARE

TO YOUR OLD ONE?

gas

indLlction or

di

Description

[<t~llkll” 01” SCa]LXt

gas burners

c ilhcr I

01” natul”al

I

li:h I’rcqucncy

i

miuct

~lndcr:1

slil’kl!.

F’la(lcnd

1

L[bi n: contain

c

IcL’( ric

w’ ire

SLl>pClldL’d

()~cr a drip pan.

Solid

i

I i SL scaled

l’m)k(op

burllcl-s.

other electric

ft’crcnces

.1)

ion coi

glass

resistance

cast

(ISC

gas

gas.

Is

Inclal

i

Ilg

iron

[()

the

Sul”t’acc.

It’

yoU

tit-c

USed

surface

when yoLl Llse

The best types

of

cookware to use, plus heat-Lip and

coot-down times, depend upon the type

sLlrface unit you have.

The following chart will help you to understand the

differences be{ween gas

other type

of’

cooktop yOLI may

burner

cooktops and

have

used in the past,

How it Works

I:l:uncs heti[

pans should

heat sc((ings

Iicat

(he bottom

cx)ntinue cooking

you

Pans tnusl be made of’ Icrrx)us

pr(duccd by a magnetic circuit between the coil and the pan. Heats up right away

and changes heat settings

01’1’, the gl~iss cxx)k[op

Heats

cook ing l“c?suits, LISC

warped pans than radiant or solid disks.

heat sct(ings

Lx)n[inuc

Heats by direct contact

cooking”

Liisk skrys

I’IX)II) {hc

the

pans directly. Pan

be

well balanced.

right away.

[ravc]s

to

[hc giass suri’x?c and then

(or

good

w’an(

cooking to stop.

by direct contact with the

as quickly as

cooking for a short time after (hey m

results.

hot enough to continue cooking alter it is

solid disk it’ you

When you turn the control

cooking results, The glass

after it is turned oft.

metals

right

is

hoI [’mm

good qud ity pans. ~]ectric coils are more forgiving

gas

wi(h

Hca(s

up and cools down more slowly than electric coils. The

wunt (1w

I’lattwss

GLIS

burners

to

Rcmove (he pan

(metal

awuy, 1

ikc a

the

heal of’

pan

and by heating the air

or induction. Electric coils stay hot

(he

pan, so

pans

cooking to stop.

is not critical to cooking results, but

heat

the pan right away and

off,

cooking stops right away.

the

cookware, so pans must be flat on

Lxmktop

that attracts a magnet). Heat is

gos

the pan,

Heats

up quickly but does not change

must be flat on the bottom for good

stays

hol

from [he surface unit if”

cooktop.

turned

A1’ter

hut

cooking stops right

under

off.

lurnuf

off. Remove the pan

enough to

turning the control

the pan. For best

of:

burner or

any

change

of

enough to

away.

I.ighting Instructions

Your

surt’acc

e]

im ina[ ing the need

constant Iy burn i 0:

[n case

burncl”s on

match

position. [Jse

burners

of” a

power-

your t“an.gc

I\J

the burner, then turn the knob to

are lighted

for

standing pi

1’1 aINcs.

failure,

with a match. }qold a

extreme caution when lighting

burners this way.

Suri’acc burners in

t’ailurc

(lccur-s

usc

whco an

will

con[inuc 10 opcr-a(c normally.

8

SURFACE COOKING

by electric ignition,

Io(

I ights

with

yt~u c;]n

light the surl’acc

L21cctrical

lighted

(IIC

LITE

power

The electrode ot’ the spark igniter is exposed.

When one burner is turned to LITE, all the burners

spark.

Do

not attempt to disassemble or clean

around any burner

An

electric shock may result, which could cause

you

to knock over hot cookware.

while

another burner is on.

Page 9

Surface Burner Controls

The

knobs tha(

located on the

The two

let-t rear

the right front

bLIrncrs.

control

knobs

and right

turn the

on

The two knobs

surface

panel

[he left

rear

in

control

on the right control

burners,

burners on

front

of the burners.

the left front

and

off are

and

ranges

On

●

The smaller burner (right

the best simmer results. [t

performance

foods

long time.

simmer setting.

●

The right i’rent burner is higher powered than the

others and will bring liquids to a boil quicker

(natural gas installations only).

with sealed burners:

rear

position) wi II give

offers

precise cooking

I’or

delicate

which need to

It cm be turned down to u very low

cook

foods.

such as sauces

over

low

heat

for a

or

Before Lighting a Burner

●

[ 1’

drip pans

they should be used tit al I

● M akc

bel’orc using

arc supplied

sure

al I grates on the rungc

any burner.

with

times.

After Lighting a Burner

●

Af’ter the hurncr ignites,

flame size.

●

Check to be

yoLl

Want to

sure

USC.

turn the knob to

the burner you

How to Select Flame Size

To Light a Surface Burner

you[”

range, Push the control knob in

LITE.

ittle

hand, a pot holder. cleaning

w-c

i n pldce

a(ijust

the ● Do not operate a burner

turned on is the one

and turn it to

will hear a I

noise-the sound

spark igniting the burner.

time

withou[ cookww-e

grate may chip without cookware to absorb

● Be sure the burners

place

y(JLIr

other materials on them.

YOLI

“cl icking”

ot’

the electric

on the

and grates

+

P

for

an

extended period ot”

grtite.

are

coo] bei’orc

1111

j

The

finisb

on the

the heat.

you

cloths

or

Watch the I’lame.

The [’lame

cookware

FOR

LET THE FLAME EXTEND

THE COOKWARE.

Any

wasted

size on a

yoLI are Llsi ng.

SAFE HANDLING OF COOKWARE NEVER

I“lame larger [hat] {he

and only serves to heat

not the knob,

burner

gas

bottom

as

y(JLI redLu heat.

shouid tnawh the

~JP

THE

S[DES

of’ the cm~kwarc

the

handle.

(jF

is

(Cil){litiflc{l II(.II p(i,qc)

9

Page 10

Top-of-Range Cookware

SURFACE COOKING

(continued)

Aluminum: Medium-weight cookware is

recommended because it heats quickly and evenly.

Most

foods

brown evenly in an

Use

saucepans with tight-fitting lids when cooking

with minimum

amounts

of

alulminum

water.

skillet.

Cast-iron: If heated slowly, most skillets will give

sa(isl’ac[ory l“CSUit

I+;namelware: Under

some cookware

IIl:itllll’;lctllt-ei”’s recotnlllendzltions” for

Stove Top Grills (on

[]() Ilot

LISe StOVC [Op gl”i]]S

on

ytmr sealed

11’

you

LISe

the stove top

gri ] I 011 the SeUILXI gLIS

burner

it

will

S.

some conditions. the

may

melt. Follow cookware

models

with sealed burners)

gw burners.

CilLISC

enamel ot’

cooking methods.

incomplete combustion and

can l“CiLl

carbon

above

standards. This

hUdl-dollS

It in

Cxposllre

nlonox” icic levels

to

al lowablc current

can be

to

~OUI”

health.

Glass:

There are two types of

for

oven use only and those for top-of--range cooking

(saucepans,

coffee

and teapots). Glass conducts heat

glass

cookware—those

very slowly.

Heatproof Glass Ceramic:

Can

be used

t’or

either

surface or oven cooking. It conducts heat very slowly

and cools very slowly. Check cookware manufacturer’s

directions to be sure it can be used on gas

Stainless Steel: This metal

properties

and

is usually combined with copper.

aluminum or other metals

distribution. Combination

alone

has poor heating

for

improved heat

[metal

skillets usually work

rmlges.

satisfactorily if they are used with medium heat as the

manufacturer recommends.

Wok Cooking (on models with sealed burners)

We recommend that

use only a flat-bottomed wok.

They are available at your local

retail store.

Do not use woks that have

support

rings.

types of woks, with or

without the ring in place,

can be

the ring

dan.zerous. Placing

ov~r

the burner g-rate may cause the burner

to work improperly resulting in carbon monoxide

levels above allowable current standards. This could

be dangerous to your health. Do not try to

woks without the ring. You could be seriously burned

if the wok tipped over.

yOLI

Use of these

w

usc

such

m

Page 11

FEATURES OF YOUR OVEN CONTROLS

OVEN SET

The OVEN

BAKE.

When

the proper

BAKE-UW

opcr~ltions-tor exwnplc.

cwscroles. Only

during

BROII,-Use

(broil ) burner will operate.

TIME BAKE—UW this setting to turn

and oil’ :it

st:ll”t :lIILI slop.

CLEAN-USC

I’utlction

Oven section.

BROIL,

yc)LI tLlt”n

burner is

baking.

specified times when you want cooking

only.

Control Knob

SET

control

TIME BAKE

the

knt~b to the

acliv:itccl for

this

sc[ting for

[he bottom oven

this setting

his sc[ting for the

See

the

Oper~l[ing

knoh Ims

all normal oven

for

for

settings

Jlld

CLEAN.

desired setting.

that operation.

cooking masts or

burner operates

broiling. Only the top

the

oven on

sell-cleaning

the Self-Cleaning

t’or

OVEN TEMP Control Knob

The OVEN TEMP control maintains the

temperature you

m WC I I m

temperature or [o

OFF—Shuts

will not operate.

turned to

For normal oven operation, push in

knob

30-90” WXX)IldS

After the oven reaches the selected temperature,

[he oven burner

21 t“Llli f]:lnlC-tO

The

the burner.

OFF whenever the

to the desired

OVEN CYCI.E light will

sel for

normal

for broi

I i

ng.

Push i n

set to lhc

off’ power to the

The

OVEN TEMP knob

temperature. It will normally take

before

the

cycles—off completely, then on with

kee

p the oven temperature controlled.

oven

operation

and

turn to

CLEAN position.

oven controls. The oven

oven

is not in USC.

flame

comes [)n

cycle on :md ofl’

and

set

should be

turn the

the

with

OVEN SET

T

(1

v

@

to

I

11

Page 12

FEATURES OF YOUR OVEN CONTROLS,

CLOCK AND TIMER

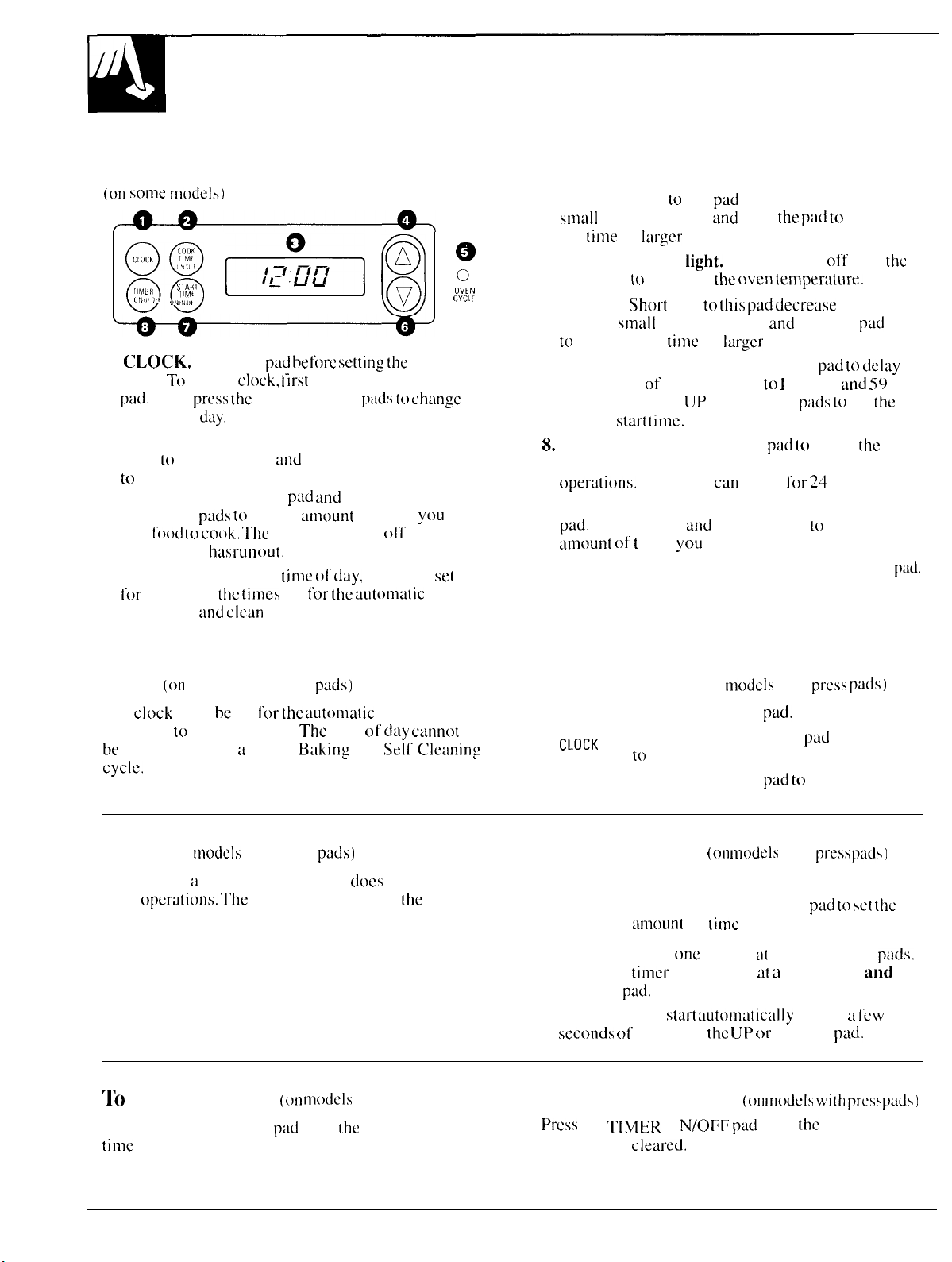

Clock and Timer with Press Pads

(on some m(xlels)

(38

HMt

R

(ON [,,6

1.

CLOCK.

clock. To set the

pad.

Then

the time of’

2. COOK TIME ON/OFF. Turn the OVEN SET

knob

to

the desired cooking temperature. Press the

COOK TIME ON/OFF

or DOWN

food

your

Cook Time

3. DISPLAY. Shows the

t’or

the timer,

operations

~+,

SIAII1

TIM(

,,,

,,,,

Press this pxl

press the

day.

to

TIME BAKE

pxls to set the

to

cook. The

has

the tilnes

:md clean

.—

—

before setting [he

clock. I“irst

UP or DOWN

rLIn oLII.

press the CLOCK

p~~ds to chtinge

and

the OVEN TEMP knob

pxl

und

then press the UP

mount

oven will shut off after

time

set

cycle.

ot’ time

of

ckiy,

the times

i’or the automutic

@

o

(1

yOLI

set

oven

:

OVkN

CYC1 t

want

4.

UP.

Short taps to this

smtill

amounts. Press

the

~ime

by

tal”gcr

5.

OVEN CYCLE

burner(s) to maintain

6. DOWN.

time by

to

decrease the

7. START TIME ON/OFF. Press this

the starting of your oven up to 1 I hours

minutes. Use the

desired

8.

TIMER ON/OFF. Press this

timer feature. The timer does not control oven

oper~tions.

To set the timer, first press the TIMER ON/OFF

pad.

mount

To

cancel the timer,

Short

taps to

small

amounts. Press

start time.

The timer

Press the UP

of 1 i me

pud

increase the time by

and

hold

the

amounts.

light.

Cycles on and

the oven temperi~ture.

[his p:ld decrease

and

hold the

time

by

Iargcr

amounts.

[JP

and DOWN

pad to

can

be set

and

DOWN pads to set the

yOLI

want.

press the TIMER ON/OFF

for 24

pxl to increase

oft’

with

the

pad to clclay

:md 59

pwls to

set

select

hours.

the

pad

the

the

pud.

Clock

The

functions

be

cycle.

Timer

The timer is a minute timer only: it

oven

is 24 hours.

TO

Press the UP or DOWN pxl until

time

(on

models with press

clock

must bc set

to

work properly.

changed during a Timed

(on

models

opcrdtions. The

Reset the Timer

is set.

I’or the automdtic

with press

maximum setting on

(w1

pads)

The

time of

Buking

ptids)

mOdCIS

oven timing

day cannot

or a

Self’-Cleaning

dtws

not control

[he

timer

with press pads)

the

desired

TO Set the Clock (on

1. Press the CLOCK

~LoCK

2. Press the UP or DOWN

to

o

set the time ot’ day.

3. Press the CLOCK

To Set the Timer

1. Press the TIMER ON/OFF pad.

TIMER 2. Press the UP or DOWN

ON/OFF

mount

ot’

modeIs

(on

mode]s

time

on the timer.

pad.

pad to

o

To set the timer

To set the

hold

the

pad.

The timer will

seconds

of releasing

To Cancel the Timer

press

the T[MER (] N/oFF

remaining is

one

minute at a time, tap the pxls.

timer

ten minutes at a time press

sturt uutornatically

[hc LJP or

(otl

pad

until

cleared.

with

ptid

start.

with

pxl to

within a

DOWN

IINMS

the

press

pxis)

press

pXIS)

set the

few

pad.

with press

time

and

PXIS)

12

Page 13

Powt!r outage

(on models with press

pads)

End of Cycle Tones

(on

mode]s

with press

pads)

When

power is restored, you will need to reset

The end of cycle tone is a series of three beeps.

the clock. Reminder beeps continue until the oven is turned off.

All other functions that were in operation when the

power went out will have to be programmed again.

Clock and Minute Timer with Dials

To set the clock, push the knob

in and turn the clock hands to

the correct time. Then let the

knob out and continue turning

to OFF.

\

12 ,

\ =.<’’”O %“’>,, 0

9

:10

-~

‘.,

20 40

0 ~,,,,

,,,, ,,\\\’

/\

(on some models)

:3

:

?“ \

b

60

on

the

Minutes are marked up to

center

ring of the clock.

To

set the

wirhu[ pushing in,

minute timer,

until the pointer reaches the number

turn the knob to the

left,

of minutes you want to time.

At the end of the set time, a buzzer sounds to tell

you time is up. Turn the knob,

without

pushin,q it?,

until the pointer reaches OFF and the buzzer stops.

The minute timer

has been combined with the range

clock. Use it to time cooking operations. You’ll

recognize it as the pointer that is different in color

from the clock hands.

Automatic Oven Timers with Dials

(on some models)

These timers will STOPTIME DELAY START

automatically start and

stop

your oven for you.

Here’s what you do:

~..,~’’:$’,,,,,

:9

~.

---

,..

3-:

..-.,

,,

,/, ,, ,,

\\.’

? -

PUSH TO TURN

\\.\ ’’’112” Z,

:, G;

,,

,/, ,, :,,\\.’

7

1. Make sure both your range clock and the DELAY

START dial show the correct time of day. When

either the DELAY START dial or STOP TIME dial

is pushed in and turned, it will “pop” into place

when the time shown on the range clock is reached.

2. Set the DELAY START dial. Push in and turn the

DELAY START dial to the time you want the oven

to turn itself on. (If you want it to start cooking

immediately, do not set DELAY START time. )

3. Set the STOP TIME dial. Push in and turn the

STOP TIME dial to the time you want the oven to

turn itself off.

NOTE:

There must be at least a half-hour difference

between the DELAY START and STOP TIME dials,

and times can be set only up to 11 hours

and

45

minutes in advance.

4. Set the OVEN SET knob to TIME BAKE (or

CLEAN).

5. Set the OVEN TEMP knob

10

the desired cooking

temperature (or CLEAN).

The oven will turn itself on immediately unless you

have set the DELAY START dial for a later starting

time. It will operate at the temperature you selected

and turn itself off at the Stop Time you selected.

Turn the OVEN TEMP knob to OFF and then take

your food out of the oven.

13

Page 14

USING YOUR OVEN

Before Using Your Oven

Bc

sure you understand how to set the controls

properly.

while the oven is

on

yoLI

using your new range.

Electric Ignition

V.1-

......— 1-... . . . . . ..—

I

ue

electric ignition.

To light either burner, turn

the

knob to

igni[e

After the

oven burner cycles—off’ completely, then on with a

full tlanle-to Iicep

Pructice

the t’ol

lowing

can

rel’cr (o

WeII uurmr WIU uruu uurnw

removin:

coo].

puges.

and

Read

the

Keep this

it, especially during the

J

L.-.. !1 t-....-. . . –—-

the

desired

oven

oper:ltion and [he

the

desired temperature. The burner should

within

S()-9()

seconds.

oven

reaches the selected

the oven temperature controlled.

replacing the shelves

information

guide

and

tips

handy where

first weeks of”

1? —[.

&..

J

are

IIgnLeu uy

L..

OVEN SET knob to

OVEN TEMP

temperature,

[he

Power Outage

CAUTION: DO

the electric ignition

power

fdilure.

The oven or broiler

f“;lilure. G~s

If’ the

oven

the

oven

burrwr

power is restored.

no[

will not flow

is in use

shuts

nuke any

LI[(cmp(

to

opcrutc

oven during an elcc[rical

cannot be

when a

lit

clur-ing a

unless the

power

off’

and cannot be

glow

t’aiiure

power

bar

occurs,

re-]it

is hot.

Llntil

Oven

Use

Light

the

switch on the control panel to turn the oven light on or

Oven Moisture

As your oven heats Lip, the temperature change OF the

air in

dle oven

door

glass.

evaporate as the oven continues to heat Lip.

may

c:wse

These droplets

water droplets to

are

harmless and will

f’orm

on

oil’.

the

14

Page 15

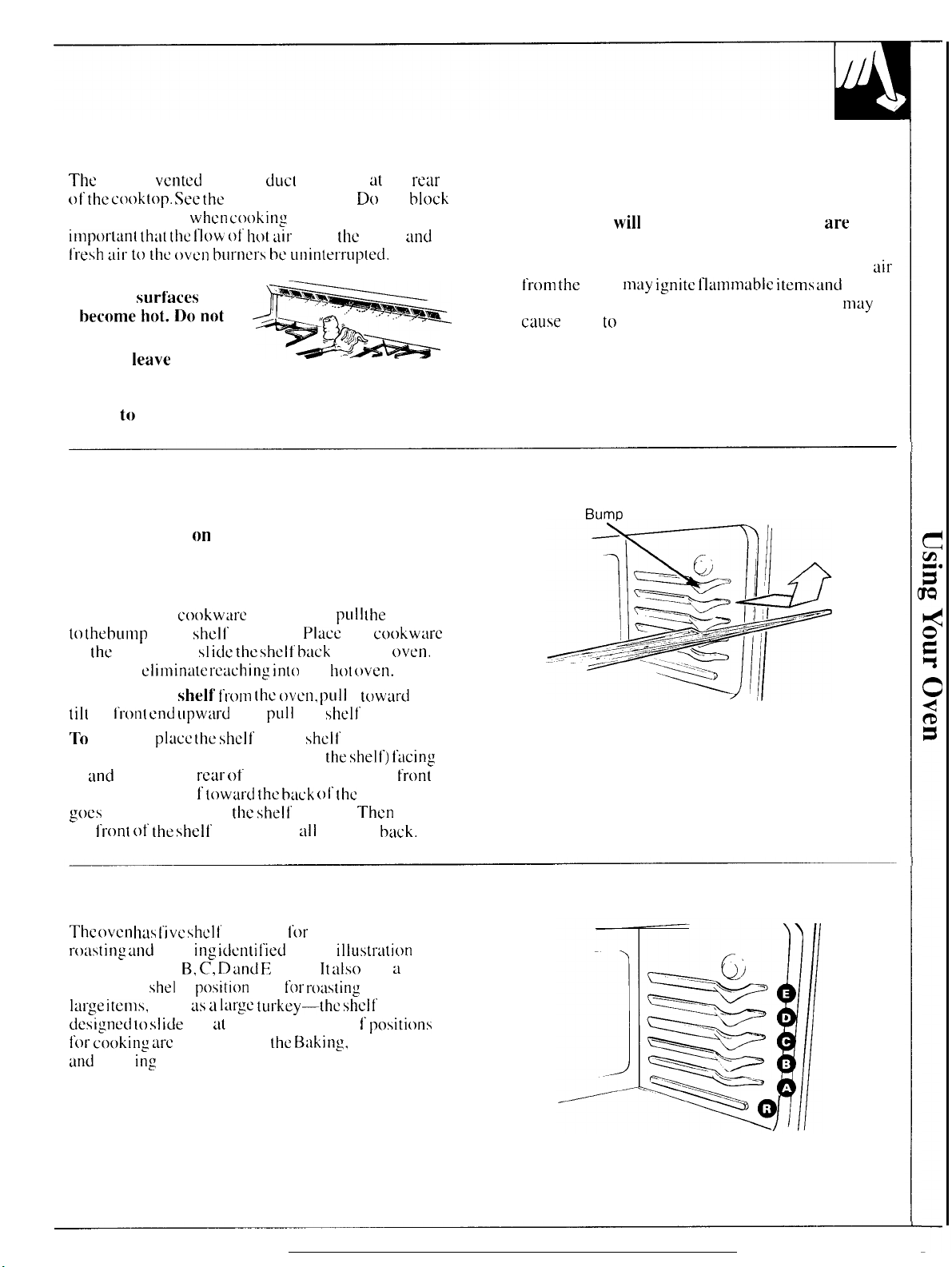

Oven Vents

The

oven is

of’ the cooktop. See the

these

impot-ltint th:lt [he l-low’

vented

openings

through

duc[

openings

Features section. Do not

when cooking

of

in the oven-it is

hot iiir

from

the

tit

the

oven

retu

block

and

fresh uil- tt) the oven burncl”s be Llllilltel’rll}lteci.

● The vent openings and

nearby

become,l(,~~{,not

touch them.

● Do not

items on the cooktop-

surf’aces

le~ve

plastic

may

j~=

9*=

Vent appearance and location vary

they may melt if left too

close

to

the vent.

Oven Shelves

The shelves are designed with stop-locks so when

placed correctly on the shelf’ supports, they will

stop before coming completely out of the oven and

will not tilt when you are removing food from them

or placing food on them.

When placing

to the bLInlp on the

on

the

shell’, then SI

This will

To remove a

tilt the

I’1”011( end

To

replace,

the stop-lochs (curved extension of

up

ond

toward the

and push the shel t’

goes

post the bump on

the

front of’ the

cookware

shelf

on a shell’.

support.

idc the shell’ tmck

climin~lte reaching in(o

shelf’ frotn the oven,

upww”d

plucc the shelf

and

pLl]l

on the

rear

of the oven. Tilt up the

toward the buck

the shell’

shelf and push it

pLIll

Pl~cc

the

into the

the

hot ~)ven.

pLIli

it

the

shelf

shclt’

support with

the shelf) t’acing

of

the

oven until it

support.

all

Then

the way

the shelf out

cookware

oven.

towtird

you,

out.

front

lower

back.

● Handles of pots and pans on the cooktop may

become hot if left too close to the vent.

● Metal items

will

become very hot if they

are

left

on the cooktop and could cause burns.

● Do not leave any items on the cooktop. The hot

from the

increase pressure in closed containers, which

cause

vent

may ignite Ilammablc items and

them to burst.

13umD

will

nmy

.

air

Shelf Positions

The oval Ims l’ivc shclt’

r(wting

as A (bottom). B, C, D

special low

lw”ge itcms,

designed to s] icie

for cooking ure

and

Broil

and

broil

she]

such m a

suggested in

in,g

sections.

i[lg identi I’ied

1’

position

out at this position. Shel 1“

supports

and E

(top). It

( R )

large

tul”key-the

the B:lking,

I’m

t-inking.

in this

illustr~ltion

also

for roasting

shelf

has

a

extra

is not

positions

Roasting

15

Page 16

BAKING

[f ycm

Do

not lock the oven door with the latch during

baking. The latch is used for self-cleaning only.

Your oven temperature is controlled very accurately

using an oven control system. It is recommended that

you operate the oven for a number of weeks to

become familiar with your new oven’s performance.

How to Set Your Range for Baking

To avoid possible burns, place the shelves in the 2. Check the food for doneness at the minimum time

correct position before you turn the oven on. on the recipe. Cook longer if necessary.

1. Close the oven door. Turn the OVEN SET knob to 3. Turn the OVEN TEMP knob to OFF and

BAKE

desired temperature.

tind

then turn the OVEN TEMP knob to the

Oven Shelves

think an adjustment is necessary, see the Adjust

the Oven

Yourself

Thermostat section. It gives easy

instructions on how to adjust the thermostat.

then remove the food.

Do It

Arrange

shelf or shelves in

the

locations while

the oven is

The correct shelf

position depends

on the kind of

food

browning desired.

As a

Dlacc”most foocfs

either shelf position B or C. See the chart for

stlggcsteci

the

desired

and

the

general rule,

shelf positions.

oven

coo].

in

the

middle of the oven. on

Preheating

Preheat the oven if the recipe calls for it. Preheat

means bringing the oven up to the specified

[temperature before putting the food in the oven.

To preheat, set the oven at the correct

selecting a higher temperature does not shorten

preheat time.

Preheating is necessary for good results when baking

cakes, cookies, pastry

and

r(ms(s,

preheating is not necessary. For ovens

without a

minutes. After the oven is preheated

in the oven as

f’rom

prehetit

q(lickly as

escaping.

and

breads. For most casseroles

indicator light or tone, preheat

possible to prevent heat

temperature-

place

the food

1()

Type

of Food

Angel

food cake

Biscuits or muffins

Cookies or cupcakes

Brownies

I

Layer cakes

I

Bundtor~ound cakes I A orB

I

Pies or pie shells

Frozen pies

Casseroles

I

Roasting

Shelf Position

A

B or C

B or C

B or C

B or C

I I

I

B or C

A (on cookie sheet)

B or C

]

B orR

Pan Placement

For even cooking and proper browning, there must be

enough room for air circulation in the oven. Baking

results will be better if baking pans are centered as

much as possible rather than being placed to the front

or to the back of the oven.

Pans should not touch each other or the walls of the

oven.

Allow

1 – to 1 ‘/~–inch space between pans as

well as from the back of the oven, the door and the

sides. If

so one is not directly above the other.

yoLl

need to use two shelves, stagger the pans

I

I

I

16

Page 17

Baking Guides

When

instructi(ms f’or best

using

prepared

baking results.

baking

Cookies

When

b~~king

cookies,

flat cookie

(without sides)

produce

cookies. Cookies

baked

pan

around

darker edges

or light browning may occur.

DO not Llse

wtil

Is or the door of

For best results,

at a (i

sheets

bet[ct--looking

in a

.jclly

(short sides

)

m:iy h:lvc

and pale

a

cookie

me.

roll

id]

LISC

sheet so

the

oven.

only one

Pies

mixes,

large that

cookie

f(Jllow

package recipe

it touches the

sheet in the oven

or

Aluminum Foil

Never

entirely cover

~1

shelf’ with duminun]

foil.

This will disturb

the heat circulation and

result in poor baking. A

slmaller

may be used to

spil]over

on a lower shelf’ several

inches

sheet of

by placing

below the

f“oi

catch

Cakes

I

il

food.

f

I

a

\

I

For best

to

produce a browner, crisper crust.

p~ms should be placed

for

from

resLIlls, bi~ke

baking since the shiny foil pan reflects

the

pie

crust; the

pies in dark, rough or dull

on an

uluminum cookie

cookie

sheet helps

Baking Pans

Use [he

the pan Lfetermincs

will

●

● Shiny, bright and smooth

“ CJl:iss baki tlg dishes :tlso absorb heal.

proper

OCCLI1”.

Dark. rol]gll

browner, crisper

in a lighter,

cookies require this type of pan.

in

glass buking

be l“dUd

bilking pun.

the amount of browning

or

dLIl 1

crust.

more de] icatc

dishes,

by 25( ’F.

The

pans absorb

Use this type

p~ms

browning.

the [emperaturc may

[ype

heut

reflect hwt,

Frozen

pies in

sheet A cake

heat

away

rettiin

it.

of finish on

thut

resu

Iti ng

in

for

pies.

rcsulti ng

Cakes

and

When bilking

need

pans

foil

u

to

When baking cakes,

uneven baking results and poorly shaped products.

b;lked

in a pan larger

recommends

than it

recommended. it may be undercooked and

overflow. Check the recipe to

used is the

will

should be. If btiked

onc

warped

usLIally

recommended.

be crisper, thinner

in a pan smaller

or bent pans will

than

the

recipe

th:m

baltcr may

m~~ke

sure

the pan

ctiuse

:md

drier

size

Don’t Peek

Set the

not open the door to look at your

provide minimum

as

DO NOT open the

time. Opening the oven door

cooking

longer.

timer for

“bake 30-40 minutes.”

allows

YoLIr

the estimated cooking time

and muximum

door to

heat to

baking

escape and

results

food. Mwst

baking

check until

I’rcyuen[ly

nukes baking times

may tilso be tifl’ectcd.

times

the

minimum

during

and do

recipes

such

17

—

Page 18

a

/“

For models with DELAY START and STOP TIME dials, see the

Automatic Oven Timers section in Oven Controls, Clock and Timer.

Automatic Oven Timer (on models with press pads)

TIMED BAKING

How to Time Bake

Do not lock the oven door with the latch during

regular timed baking. The latch is used for

cleaning only.

Your oven

NOTE: Before beginning, make sure the oven

shows the correct time of day.

can

be set to turn on

and of’f

automatically.

self-

CLOCK

o

clock

How to Set Immediate Start and Automatic Stop

To avoid possible burns, place the shelves in the

correct position before you turn the oven on.

The

oven will turn on immediately and cook

selected length of time. At the end

oven will

@@

1. Turn the OVEN SET knob to TIME BAKE.

2. Turn the OVEN TEMP knob to the desired

turn off automatically.

OVEN SET

temperature.

3.

COOK

TIME

ON/OFF

Press the COOK TIME ON/OFF pad.

OVEN TEMP

fq~-1~

of’

Cook Time the

t’or

a

S. The oven will

Cook Time remaining.

au[omatical Iy.

6.

When the

control

signal.

7. Remove the

foods

after the controls

NOTE: Foods that

fish, stuffings,

to sit for

Room temperature promotes

bacteria.

from the

o

Set the desired amount of cooking time

using the UP and DOWN pads.

To set the clock,

CLOCK pad. Press the UP or DOWN pad

until correct

the

CLOCK

tLIrn on.

set temperature, a

continue to cook

time up to I 1

oven

will

that

are left

nl& ihan O;C Imir- bcfor-c or after

Be

sure that oven light is off

bulb

for the

hours and

automatically turns

signal. Turn

Iood from

in the oven continue

arc oft.

spoil cxsiiy

poultry

will speed

first

press the

time

of

ciay

is displayed, Press

pad again to start.

The

display will show the

When ~he ~Jven

tone

sounds. The

programmed amount

50 minutes,

the

‘oven off to stop

the oven. Remember,

such

and pork

harmf’ul

should

the

growth of

bacteria growth,

reaches

oven

will

[hen shu[

off,

the oven

its

milk,

not be allowed

because heat

off

the

cooking”

eggs,

cooking.

harn]ful

the

ot’

18

Page 19

How to Set Delay Start and Automatic Stop

Quick Reminder

1. Turn the OVEN SET knob to TIME BAKE.

2.

Turn [he

desired

3. Press the

4.

Press the

desired length of cooking

5.

Press the

6.

Press the UP or DOWN

time

To avoid possible burns, place the shelves in the

correc{

position

You

c:m

automatically,

turn

off

For example:

shortly after

time

at

OVEN SET

@@

1. Turn

2.

TuI”n the

temperature (in this

COOK

TIME

ONIOFF

o

OVEN

tcmperiiturc.

COOK TIME ON/OFF pad.

UP or DOWN

START TIME ON/OFF pacf.

of

day

set

the oven

cook for a

lmtomatica]ly.

Let’s

7:()(). The

325°F.

Here’s how:

the

OVEN SET knob to TIME BAKE.

OVEN TEMP knob to the desired

3.

Press the

TEMP

knob to the

p~d to

set the

lime.

pad

to set the

yoLI

ww?t c(wking to

bef’orc

you

progrum

control to turn the oven on

specific length of time and

say it’s

COOK TIME ON/OFF

2:()()

recipe

OVEN TEMP

ivv339

exmnple 325[’F).

the

and dinner time is

suggests 3

start.

oven.

hours

baking

pfid.

4. For 3 hours

press the UP pad until

appears in the display.

@

of’

cooking time.

“3:()()”

5. Press the START TIME ON/OFF

START

TIME

n

w

6. Press the UP

display. The

2 hours,

Once the oven begins cooking, the Cook

remaining will be displayed.

At the

end

the oven will automatically turn oil’.

7. When the oven automatically turns

control

to OFF to stop the signal.

the oven. Remember, even

oft’

automatically,

controls

NOTE:

● The low temperature zone of

150”F and

f’oods

warm. Food kept in the oven

hours at these low temperatures may

●

Foods that spoi I

stuffings, poultry

to sit out for more than

cooking. Room temperature promotes the

of

harmful bacteria. Be sure the oven I

because heat from the bulb will

bacteria growth.

pad unlil “4:()()”

t;rner

is now set

at 4:()().

of’

the 3

hour cooking time

wil

I signal. Turn the OVEN TEMP knob

foods

tire

off.

2000 F)” is

tivailable

easi Iy

such as m i I k,

and

pork

appears in

to”start baking

RCITK)YC

though the oven

continue

this rwlgc

to

should

one

hour

speed hwmll’ul

oN.

the

cxx)king :tt’tcr the

p hot cooked

kcc

longer [him two

eggs,

not he

before

the

in

Time

(7:()()).

the

()\Jcn

food from

shuts

(between

spoil.

fish,

ill

lowed

or

~lftcr

yowth

ight

is oil’

pad.

Questions and Answers

~.

Can

I use the minute timer during oven

cooking?

A.

The

minute

cook in:

(imcr can

function.

he

Llseci

ciuring

my

Q.

Can I change the time of’ day on the

I’m Time Baking in the oven?

A. The time of

changed during

timer. You must either stop those programs or

until they

day

tire

finished

on the

clock

any

program

bel’ore ch:mging the [

should

thut

LIses the

nt)[ be

clock

(JVCI1

i me.

while

w:li[

19

Page 20

ADJUST THE OVEN THERMOSTAT—

DO IT YOURSELF!

You may feel that your new oven cooks differently

than the one it replaced.

LISC

your new oven

for o few

We

recommend that you

weeks to become more

fimiliar with it, following the times given in your

recipes

us

a guide.

If you think your new oven is too hot or too cold,

you can adjust the thermostat yourself.

it is too hot.

Ii’

you think it is too

make

it hotter.

We

do not recommend the use of inexpensive

thermometers, such

[o

check the temperature setting of your new oven.

These thermometers may vary

adjust [he

thermostat to make it cooler,

cool, acijust

:1s (hose found

the

in grocery stores.

2040” degrees.

OVEN TEMP

OFF

~v+

03

+

‘&e

@

Front of the OVEN TEMP knob

(1

Osv

T

v

#’

w

E

It’

yOLI

lhermmstat

think

to

Ad.iust

-

To

the Thermostat:

Note the position of the pointer to the screw

before making the adjustment.

Cooler Hotter

(appearance may vary)

Pull the OVEN TEMP knob off the range and look

at the back side.

To make adjustment. loosen (approximately

but

do

not completely remove, the two screws on the

back

of’

the knt~b.

you,

hold

the outer

und

turn the front of the knob with

To raise the oven temperature, move the top

towmd the right. You’ II

you move the knob.

screw

the top

the oven temperature approximately

plus or minus

We

suggest

from the original

betorc making

After the adjustment is

screws so they are

overtighten.

and check

pertorm:mce.

With

the btick of”

edge ot’ the

the knob

knob with one

the other

toward

the left.

600F

from the arrow. )

that

you

make

se[ting and check

hew-:1 click

To

lower

the adjustment onc

for

the

temperature, move

Each c1 ick

oven performance

my additional adjustments.

nmde, retighten

snug,

but be careful not to

Re-i

nstal I

the knob on the range

10OF.

cfich

will

the

one

facing

hand.

screw

notch

(

Ran,ge

turn),

hand

ch~nge

is

click

20

Page 21

ROASTI

Do not lock the oven door with the latch duri]lg

roasting. The latch is used for selt’-cletining (ml}.

Rowting is

poultl”y

R021sting

stexiy,

The oven

low

shelt’

just

tib(~vc

bottoln, Usc

extra cm~k

needed, fm

when

lLIrkey. The

designed to

this

position.”

1.

Position” the ()~en

at shelf’

fOr small

(~ 1(J

(R)

larger row(s.

cwoking by

C;lI1 IX! roas[cd

temperatures.

keep

simttcri n:

has a speci:~l

(R)

pwsirion

the

(JWI)

it

when

i ng

space

example,

rwasti ng ii Im-ge

shclt’

is

slide out :M

( B )

positit)n

size

r(Mst

5

Ibs.

) Wld at

position

t’or

dry

he:i[,

Tender

Un(’ovel”cd in

which sho[lld he low

to :1 m i n i

is

n(~[

Yolll”

Illum.

nlc:l[ or

()\

’cll.

ancl

Roils{

ill:

is

1“1::111)’ :1 hakit)g [31”OCCdUI”C

‘l”IIC1” CI’O1°C [Ilc (1~’cn Con[rols” :uc sc[ [’or

‘l-il]l~’d B:lkin:.

i

ndic:i[

i

IIakillg wi

Alost

IncaIs con(

al’t(’r

hciny

s(ilnd

i ny t i

ii

I I

(Jv,s ro~l$ls 10 [’i ml

L:ir\c.

‘rk

1 ()’ F. I 1’

( You

I]: (Ilc (J\cn

II

lLIrIl

removed I’rom the

tnc I’(JI” ro:lsts

In:ly

is

w{)rki n: ptx)pcrly.

the ()\cn on aI)d 011”

inue [() L(x)I< SI i~h(l~ w’hilc standin~z

is I ()

up

i

ntcrml [cmpctwurc w

)’OU

\\isll [() Colllpcllsa[c (’01” [Ilc

hew a

()\Tcn. “RCCOIIIIIICIl(

(() 20

:In(l nlakcs t heln e;tsicr {0

llWd

13Ain:

slight clicking

)

:iLl(oill:ltic:illJ,

m i

nu{cs.

i 11

ri

sc

t-i sc, rcnl~)tc [he ro:lsl l’r~)lll (he t)\’C:ll Wllcll

lclllpcl”illut”c

sholvn

dcsi

red i

3. “1’UIN

(

)VIIN

S(K-’

:Ipprox

&

When

‘1’I{M P

1’1”0111

i s 5[

{()

I ()’

i II t

Ilc R(Ms(

n[crnal tcnlpcr:lturc h~Is

IIlc (

‘l’l{jNl 1)

[Ilc l<():~sliny (;

i I1):IIc cook” i ng t i

I“(xlstin:

1<11012 [() ()[t

(I)c

)VI;~

()\

i n: (; u

SET

is

’cll.

kiloh 10 tllc

Lli&! 1’01” [ClllpCl”JtUl”L!S

I’inishcd.

and then rclllo\L! the

‘1. ICss 111;1[1 [Ilc

idc.

been

hi]oh

to

13A K[;

desired

Incs.

turn

lilt

OVEN

(ClllpC1”21t L11’C

rcachcd.

and

tcnlpcruturc,

f’ol” IIMMIS.

Or

sound

Ti]ncd

iCCi-

This

:Lboul

5(’

to

[Cll)~Cl”21[L11°C

i [s i

IltCl”ll:il

(I]c

ilnd

I’()()d

2.

C~heck the weight ot’

fat-Si&-LIp

rousting

baste

metit

gOOd pan for

01” the

rack

the

Incil[. Sclcc( a

m possible. (The

this. )

the

poLdh

in

:1

sII:IIIOW pat).

ro:~s[. Pl:icc tlw nlcat

’y bl”eaSt-SiLh-Llp

The

mcltin:

pm as

htx)i Icr pan

I:IOSC to (I1c six 01”

with

Dual Shelf Cooking

This allows more

stirne

time.

FOr Cxtunple:

turkey on shell’ pOsition

equipped) may be

seal

IOpLXI pOtatoes c:ul be u~x)!icd :11 (Iw willlc (i tlw.

C:dculate

the

tO complete c(mking at

m

inutcs 0[’

:ddit

tlmn onc I’o(d tt) hc cot)licd at (Iw

Whi Ic

R, a second

r(msl

shei 1’

i n: a

;Lddcd on p~)silit)l} [) so th:ll

10t;ll c(x)kiny (inlc 10 Cnul)ic Iootll disllcs

the

same tilnc. Allow

iOn:d c(N~k

i n: t i

]l)c I’or (I]c Ix)t:l((ws.

r;~c’k

20-11].

( i 1’

011

the

I’:1[

uil I

is

so

I 5-20

ii

Use of

You ciin usc :Iluminutll l’(~il [()

‘1’his tlldkcs

Ill:ll”illil(i Ily. c(x)kiny, wit]) Ii-u

cured

(Ilc I’oi

~::”i>,; x”

y==$$J?

\

\

.A1uminum

clew-up cmicr

tllea(s or b:ls[i ny

I (i: hi

“-

‘\,\ “’

‘,, =

<&.L.:”/

.---7/

,~’

1]

woLInd Il)c

“i- !.+/

..d,-.5--

Foil

I

in~ the

wIIc]l

its.

cook”

I’(xxi

‘1

~~~ “ ‘ ?;, z

‘“:~~-$”’

““”

.... ---””

duri n: c’()()k ing. Press

i

nsidc 01” (I]c

,

/’

..----”

‘“

broiler

using

i

11: Iledvi 1>

( ( ‘(11!

lhc [Mn for

pan.

//11/{(>(/

p:m,

//(.\/

/)(/,yl>)

2]

Page 22

Questions and Answers

().

1s it necessary to check for doneness with a

meat thermometer?

A. Checking the

completion of cooking time is recommended.

Temperatures are

roasts

over 8

hour intervals

f’inished

internal tempmtture at

shown in Roasting

lbs.,

check with thermometer at

after htilf’

the time

has passed.

Guide.

Q. Why is my roast crumbling when I try to

carve it?

A.

Romts m easier to slice if ol]owed to coo]

z() IIlinutes ~ftcl,

cut across the grain of the meat.

removing from

oven. Be

ROASTING GUIDE

Frozen Roasts

ROASTING

(corltinLled)

Q.

Do 1 need to preheat my oven each time I cook

a

the

For

half-

10

sure to

to

A. It is not

Q. When buying a roast, are there any special tips

that would help me

A.

Yes.

01”

Q.

Can I seal

roasting a turkey?

A. Sealing

it unsealed

(I1C

roast or poultry?

necessury to

Buy :1

ro:Ist

as

even

buy

rolled

roasts.

the

sides of’ my

the

f’oil will steam [he

al ILJWS the

rncat.

prehwt

cook

yoLIr

oven.

it

more evenly?

in thickness m possible,

foil

“tent” when

met~t. Le~~ving

air (o

circulate and

brown

Frozen roasts

of’

beef,

without thawing, but

xiditiorral

5 pounds,

Type

Meat

Tender cuts: rib, high

tip,

Lamb

Veal sht)utdcr, lcg

pork

Ham,

Poultry

Chicken or

Chicken pieces

Tul”lwy

‘1’

F’or”

“1”’rhe

some food poisoning”

time ( I 5 minutes per

rn(me

time

rLImp

or

top

round’]

leg

or born-in

\c)lIl,

rib or shoulder”:

precooked

borwlcss rolled roosts

[1. S. Deparlmen[

or

Duck

pork,

Iwnb,

allow

15 to 25 minutes per pound

for larger

qutili(y

”

shoulder’1’

loin’)’

of’

(M”gwl isms

roasts. )

sirloin

over

6 inches thick, Jdd 5

Agricul(urc siIys

etc., can be

pound for roasts

325”

350[

325”

Indy

“Rw-c

survi}c.”

stw%xl

under

Doneness

Rdrc:

Mcdiuln:

Well

Done:

Rwc:

Medium:

Wcil Dollc:

well I“)onc:

well Done:

T() Wm”In:

WL!II

)

becl’ is

(!+)uIu: w F(Nd ~~

Well

well

(()

1 () mi

popui:it”,

Ix)nc:

Done:

[)

OIIC:

nutts

bLIt yoLI ShtJLIld know” [h:I[

Make

sure poultry is thawed

Unthtiwed

Some commercial

poultry

often does

frozen

poultry

successfully without thawing.

given on

.Approximate

in Minutes

3

24-35

35-30

39-.45

i

25–30

30-35

35-45

35--45

I 8

3

.3s

35–’40

10 to 15

1

pcr

package

Libel.

Roasting Time

per

Pound Temperature

to 5 tbs.

6

1

2-3

3 I ..3.?

I –25

--?3

to 5

tninu(cs

It)s.

pet”

40

11)s.

()--22

pound to (i nws gi vcn :lbo~’c,

Y~)LIr

Ki(chcn

~iLlid~,

20-23

24–28

28

30--$()

30-40”

[1011[11]

(Wly weight)

over 5 Ibs.

.30-.35

over

I ~- I

cooking” i[

LISDA

bel’(xc

roosting.

not

cook

evenly.

can be cookd

F’ol]ow Lfircctions

Internal

to 8 Ibs.

8–25

I

--3.? I 70( ’-- I

15

Ihs.

()

[() only I -$()’’};. nwarls

I<c\r.

IL(IW

1

40”- 1

150( ’-1 60’”

I 70<’-

140(’- 1

I 50’”

I 70”- 1 X()”

1

70(’-

11

5“-

I

85”-

1 85”- I 90’”

In thigh:

1

85”-

[9X5. ]

I

I 60”

I

I 90’”

1 90(

50<’”;”

X5’

S()’’”i”

X5’

I

X()’

25”

”

“F.

22

Page 23

BROILING

Do

not lock the oven door with the latch during

broiling. The latch is used for self-cleaning

13roiling

food.

broiled,

smoking

is cooking fiml by

Most fish :Ind

Follow” these

(t)

a m i n i mum.

direc[

tender cLrts

directions

heat

of’

meat c;ul bc

(()

kwp spatter-in: and

I’he oven door should be closed during broiling.

only.

f’rorn :ibovc the

food

Turn the

during cooking.

f’o(ds

for

according to the Broil i

GLli(le.

Turn

{he food.

the times given

second

the

preferred doneness.

only once

the

first side

then use

side as a

Time

for

the

guide to

the

n,g

1. If the

20 pl:lce

mea[ hus [’LI[

vertical sl:ishcs

desired,

:lboLlt l/X” thick.

the Illcil[

comes

which

so

1’;1[

drips

may

bccomc ho[ enough (o catch

or gristle around the edge.

throLrgh

(hc

tat may bc

011 (llC broiler r;lck

with the

into (he

broi

h(~th

ahoLrt ~“ LIpar[. 11’

[rimmed, lca\ing tI layer

in the broiler p:ltl

rungc.

Always mw

Icr

pan: otherwise

fire.

3. Posi(ion the shell” on [he rccommcndcd

position as

Use

of’

You

c:m use aluminum f’(~i]

broiler

to the r;lck and

Without

juices

I’r”oln draining to

WLl[d

become

not cut the slits,

sLI,ggcslcd in

Broi]ing Guide.

Aluminum Foil