Page 1

GE

Grid Solutions

GE Reason H49

PRP/HSR/QuadBox Ethernet Switches

Te

chnical Manual

Publication Reference: H49/EN M/C22

Page 2

WARNING

This guide gives instructions for installation, commissioning and operation of the Reason H49.

However, the guide can not cover all conceivable circumstances or include detailed information on all topics. In the

event of questions or specific problems, do not take any action without proper authorization. Please contact the

appropriate GE Grid Solutions technical sales office and request the necessary information.

Refer to the System Release Notes for new features.

Any agreements, commitments, and legal relationships and any obligations on the part of GE Grid Solutions,

including settlement of warranties, result solely from the applicable purchase contract, which is not affected by the

contents of the guide.

LICENSES

The Reason H49 software may contain open source licensed code. For more information and to obtain the source

code, please contact the appropriate GE Grid Solutions technical sales office.

Page 3

GE Reason H49

Technical Manual

H49/EN M/C22

3

Table of Contents

CHAPTER 1: INTRODUCTION 8

1.1 Key Features 8

1.2 Ordering Options 10

CHAPTER 2: SAFETY INFORMATION 11

2.1 Health and Safety 11

2.2 Symbols 11

2.3 Installation, Commissioning and Servicing 12

2.3.1 Lifting Hazards 12

2.3.2 Electrical Hazards 1

2.4 Decommissioning and Disposal 13

CHAPTER 3: COPYRIGHTS & TRADEMARKS 14

3.1 Copyrights 14

3.2 Warnings Regarding Use of GE Grid Solutions Products 14

CHAPTER 4: FUNCTIONAL DESCRIPTION 16

4.1 Hardware 16

4.1.1 Front Panel 16

4.1.2 Bottom view 1

4.2 Parallel Redundancy Protocol (PRP) 20

4.3 High-availability Seamless Redundancy (HSR) Protocol 22

4.4 HSR Quadbox 24

4.5 PRP-HSR Coupling 26

4.5.1 Connecting several PRP Networks to an HSR Ring 28

4.5.2 Connecting one PRP Networks to several HSR Rings 2

4.6 Standard Switch 30

4.7 Time Synchronization 30

4.7.1 Precision time synchronization (PTP) 31

4.7.2 NTP time synchronization 3

4.8 SNMP 33

4.8.1 Supported MIB 33

4.8.2 SNMP Traps 3

2

8

9

2

4

CHAPTER 5: INSTALLATION 35

CHAPTER 6: CONNECTION 41

5.1 Dimensions 35

5.2 Device Labeling 36

5.2.1 Manufacturing Label 37

5.2.2 Firmware Label 3

5.2.3 Manufacturer Label 3

5.3 Mounting 39

5.3.1 Recommendations for Electromagnetic compatibility 40

6.1 General Wiring 41

6.1.1 Well-organized Wiring 41

6.2 Earth Wiring 42

6.2.1 Protective Earth Wiring 42

6.2.2 Casing / Earth Interconnection 4

8

8

3

Page 4

Technical Manual

GE Reason H49

4

H49/EN M/C22

6.3

Power Supply Wiring 44

6.4 Alarm Relay Wiring 47

6.4.1 Using Terminal Blocks 47

6.5 Ethernet Connections 49

6.5.1 RJ45-Type Connection 51

6.5.2 Optical LC-type Connections 52

6.6 Fiber Optic Budget Calculations 53

6.7 Power up 54

CHAPTER 7: SETTINGS 55

7.1 Connecting to Reason H49 55

7.2 Accessing the Web User Interface 55

7.3 Logging In 57

7.4 Feature Overview 58

7.4.1 System 59

7.4.2 Network 81

7.4.3 Security 93

CHAPTER 8: CYBER SECURITY 103

8.1 Reason H49 Cyber Security Implementation 103

8.1.1 Encryption and Credentials 103

8.1.2 Secured File Transfer 104

8.1.3 Authorization 104

8.1.4 Authentication 106

8.1.5 Password Management 108

8.1.6 Security Logs 110

8.1.7 Local Logs 110

8.1.8 Remote Logs 110

8.1.9 Other Security Measures 111

CHAPTER 9: MAINTENANCE 112

9.1 Maintenance period 112

9.2 Product checks 113

9.2.1 Visual checks 113

9.2.2 Functional checks 113

9.3 Firmware Upgrade 113

9.4 Error detection 113

9.5 Testing the LEDs 114

9.6 Method of Repair 114

9.6.1 Replacing Reason H49 114

9.6.2 Repair and Modification Procedure 115

CHAPTER 10: TECHNICAL DATA 117

10.1 Conformity 117

10.2 Environmental conditions 117

10.3 IEC61850-3 Certification 118

10.3.1 Dielectric 118

10.3.2 Electromagnetic Compatibility 118

10.3.3 Safety tests 123

10.3.4 Environmental tests 123

10.4 IEEE1613 Certification 125

10.5 General Characteristics 128

10.5.1 Mechanical 128

10.5.2 Auxiliary Power Supply 128

Page 5

GE Reason H49

Technical Manual

H49/EN M/C22

5

10.5.3 Auxiliary Fault Relays (Optical Port Alarm) 128

10.5.4 BIU261D 129

10.6 Ethernet Management 129

10.7 Manufacturer 130

CHAPTER 11: GLOSSARY 131

CHAPTER 12: APPENDICES 133

12.1 Appendix 1 Configuring Reason H49 from command lines 133

12.1.1 Prerequisites 133

12.1.2 Accessing the SSH configuration interface 133

12.1.3 Login to the H49 135

12.1.4 CLI Commands 137

12.2 Appendix 2 Command Line Use Cases 149

12.2.1 System Commands 149

12.2.2 Networks Commands 151

12.2.3 Security Commands 154

Table of Figures

Figure 1: Front View and Rear View 16

Figure 2: Reason H49 Bottom View 18

Figure 3: Example PRP Redundant Network 20

Figure 4: Reason H49 connecting up to four SANs to the PRP Network 21

Figure 5: Example HSR Redundant Network 22

Figure 6: Two QuadBoxes linking two HSR Rings 24

Figure 7: Coupling two PRP LANs to an SRS Ring 26

Figure 8: Coupling an HSR Ring to two PRP LANs 27

Figure 9: Coupling one HSR ring to several PRP Networks 28

Figure 10: Coupling Several HSR Rings to a PRP Network 29

Figure 11: Example of PRP/HSR Architecture with the Precision Time Protocol (PTP) 31

Figure 12: Example of NTP Synchronization 32

Figure 13: Front Face and side with dimensions 35

Figure 14: Example of Device Labeling 36

Figure 15: Manufacturing Label 37

Figure 16: Firmware Label 38

Figure 17: Manufacturer Label 38

Figure 18: H49 DIN Rail Mounting Details - Rear View with Mounting Rack 39

Figure 19: H49 DIN Rail Mounting Details - Rear View with Weidmuller Clip 39

Figure 20: Protective Earth Screw 42

Figure 21: Example of Earth Cable 43

Figure 22: Recommended mounting and Casing / Earth interconnection 43

Figure 23: Reason H49 Power Supply Wiring 44

Figure 24: Typical 24-way Female Connector 44

Figure 25: Typical 2-way Female Connector 45

Figure 26: Relay Alarm Wiring 47

Figure 27: Pluggable Terminal Block 47

Figure 28: Pluggable Terminal Block 48

Figure 29: SFP Module Connection 49

Figure 30: RJ45 SFP Module 51

Figure 31: Ethernet Fiber Optic – LC-type Module 52

Page 6

Technical Manual

GE Reason H49

6

H49/EN M/C22

Figure 32: Example of Optical Patch Cord (Multimode Duplex LC/ST) 52

Figure 33: Fiber Budget 53

Figure 34: Reason H49 Web User Interface - Error during Login Process 57

Figure 35: Reason H49 Web User Interface - Agreement Conditions 57

Figure 36: Reason H49 Web User Interface – Start Page 58

Figure 37: H49 Web User Interface – Power Supply Status 59

Figure 38: H49 Web User Interface – Interfaces Status 60

Figure 39: H49 Web User Interface – Statistics of a Connected Interface 61

Figure 40: Reason H49 Web User Interface – Time Synchronization Status 61

Figure 41: Reason H49 Web User Interface – Logs Status 63

Figure 42: Reason H49 Web User Interface – Logs Status 64

Figure 43: Reason H49 Web User Interface – PTP Settings 66

Figure 44: Reason H49 Web User Interface – No Redundancy Mode Selected 68

Figure 45: Reason H49 Web User Interface – PRP RedBox Mode Selected 69

Figure 46: Reason H49 Web User Interface – SNMP Page 70

Figure 47: Reason H49 Web User Interface – SNMP Version Section 71

Figure 48: Reason H49 Web User Interface – SNMP Community Section 72

Figure 49: Reason H49 Web User Interface – SNMP Group Section for SNMP v1/v2c 72

Figure 50: Reason H49 Web User Interface – SNMP User Section for SNMP v3 73

Figure 51: Reason H49 Web User Interface – SNMP Group Section for SNMP v3 74

Figure 52: Reason H49 Web User Interface – SNMP View Section 74

Figure 53: Reason H49 Web User Interface – SNMP Access Configuration Section 75

Figure 54: Reason H49 Web User Interface – Device Management 76

Figure 55: Reason H49 Web User Interface – Select a Firmware File 77

Figure 56: Reason H49 Web User Interface – Start the Upgrade Process 77

Figure 57: Reason H49 Web User Interface – Firmware Upload Confirmation 77

Figure 58: Reason H49 Web User Interface – Select the Configuration File to be imported 78

Figure 59: Reason H49 Web User Interface – Start the Upgrade Process 78

Figure 60: Reason H49 Web User Interface – New Configuration Notification 79

Figure 61: Reason H49 Web User Interface – New Configuration Notification 79

Figure 62: Reason H49 Web User Interface – Downloading Running or Startup Configuration 79

Figure 63: Reason H49 Web User Interface – Configuration Export 80

Figure 64: Reason H49 Web User Interface – Reboot Button 80

Figure 65: Reason H49 Web User Interface – Confirmation Button 80

Figure 66: Reason H49 Web User Interface – Interface Configuration 81

Figure 67: Reason H49 – Location of M6 Screws to be removed 83

Figure 68: Reason H49 – Location of the Micro SD Card 84

Figure 69: Win32DiskImage Program – Select the SD Card Driver 84

Figure 70: Win32DiskImage Program – Select the Raw Image of the Switch 85

Figure 71: Win32DiskImage Program – Start the File Copy 85

Figure 72: Win32DiskImage Program – Confirm Overwrite process 85

Figure 73: Win32DiskImage Program – Overwrite process in progress 86

Figure 74: Win32DiskImage Program – Overwrite process done successfully 86

Figure 75: Reason H49 Web User Interface – VLAN Configuration 89

Figure 76: Multicast Filtering Principles 91

Figure 77: Reason H49 Web User Interface – Multicast Filtering Configuration 91

Figure 78: Reason H49 Web User Interface – Priority Configuration 92

Figure 79: Reason H49 Web User Interface – Security Configuration 93

Figure 80: Reason H49 Web User Interface – Certificate Management 94

Figure 81: Reason H49 Web User Interface – Local User Account Configuration 95

Figure 82: Reason H49 Web User Interface – User Account Settings Icon 99

Page 7

GE Reason H49

Technical Manual

H49/EN M/C22

7

Figure 83: Reason H49 Web User Interface – Account Settings 99

Figure 84: Reason H49 Web User Interface – LDAP Server Settings 100

Figure 85: Reason H49 Web User Interface – Syslog Server Settings 102

Figure 86: Network Architecture with Centralized Authentication 106

Figure 87: Reason H49 Web User Interface – User Account Settings Icon 109

Figure 88: SSH Console – Establish the connection with the H49 134

Figure 89: SSH Console – Add the SSH Key 134

Figure 90: SSH Console – Error during the Login Process 135

Figure 91: SSH Console – Enforced Password Policy 135

Figure 92: SSH Console – Agreement Conditions 136

Figure 93: SSH Console – H49 Main Menu 136

Figure 94: SSH Console – Information about the account configuration 154

Figure 95: SSH Console – Information about the security configuration 156

Page 8

Technical Manual

GE Reason H49

8

H49/EN M/C22

Chapter 1: Introduction

The DS Agile Ethernet products and software applications are designed to meet the

needs of a wide range of electrical substations. Emphasis has been placed on

compliance with standards, scalability and modularity.

These features mean that the products can be used in most applications, from the

most basic to the most demanding. They also ensure interoperability with other

vendors.

GE Grid Solutions provides a range of Ethernet products such as switches, which take

into account the compulsory requirements of electrical substations, including power

supply and immunity to environmental constraints.

GE Grid Solutions provides solutions to specific requirements such as network

redundancy management.

The products can be used independently, or can be integrated to form a DS Agile

system, which is a Digital Control System (DCS).

1.1 Key Features

Ports:

• Up to 6 1Gbps ports, copper or fiber

Redundancy Communication Protocols:

• Parallel Redundancy Protocol accordingly to IEC 62439-3 (2016) Clause 4 (PRP)

• High Availability Seamless Redundancy Protocol accordingly to IEC 62439-3

• PRP and HSR RedBox, HSR QuadBox and PRP-HSR coupling

Network Protocols:

• Simple Network Management Protocol an Internet protocol for managing and

(2016) Clause 5 (HSR)

monitoring devices on IP networks (SNMP)

• Network Time Protocol (NTP) and Precision Time Protocol (PTP) according to IEEE

1588 V2/IEC61588 Ed.2 (2009) provides highly accurate time synchronization

• Usual secured network protocols are supported: SSH, SFTP, HTTPS. Non-secured

protocols are disabled by default

Page 9

GE Reason H49

Technical Manual

H49/EN M/C22

9

Network standards:

• IEEE 802.1Q (2014): Networking standard that supports virtual LANs (VLANs) on

an Ethernet network

• IEEE 802.1p defined in IEEE 802.1Q (2014): Class of service (CoS), is a 3-bit field

called the Priority Code Point (PCP) within an Ethernet frame header when using

VLAN tagged frames.

• C37.238 (2011): IEEE Standard Profile for use of PTP (Precision Time Protocol) in

power system applications

Cyber security:

• NERC CIP (North American Electric Reliability Corporation - Critical Infrastructure

Protection): set of requirements designed to secure the assets required for

operating North America's bulk electric system

• IEEE 1686 (2013): Standard for IED Cyber security capabilities

• WIB 2.0: Process industry security standard; Working-party on Instrument

Behavior. The main parts of the WIB requirements will be merged under the roof

of IEC 62443 Industrial Network and System Security

• CIS: Hardened following Center for Internet Security recommendations.

Safety and environment:

• IEC 61850-3 (2013): General requirements for communication networks and

systems for power utility automation

• IEC 60255-27 (2013): Product safety requirements for measuring relays and

protection equipment

• IEEE 1613 (2009): Environmental and testing requirements for communications

networking devices installed in electric power substations.

• IEEE 1613-1 (2013): Environmental and testing requirements for communications

networking devices installed in transmission and distribution facilities.

Page 10

Technical Manual

GE Reason H49

10

H49/EN M/C22

1.2 Ordering Options

Page 11

GE Reason H49

Technical Manual

H49/EN M/C22

11

Chapter 2: Safety Information

2.1 Health and Safety

Personnel associated with the equipment must be familiar with the contents of this

Safety Section, or the Safety Guide (SFTY/4L M).

When electrical equipment is in operation, dangerous voltages are present in certain

parts of the equipment. Improper use of the equipment and failure to observe

warning notices will endanger personnel.

Before working on the equipment, it must first be electrically isolated.

Only qualified personnel may work on or operate the equipment. Qualified personnel

are individuals who:

2.2 Symbols

• Are familiar with the installation, commissioning, and operation of the equipment

and the system to which it is being connected.

• Are familiar with accepted safety engineering practices and are authorized to

energize and de-energize equipment in the correct manner.

• Are trained in the care and use of safety apparatus in accordance with safety

engineering practices

• Are trained in emergency procedures (first aid).

Although the documentation provides instructions for installing, commissioning and

operating the equipment, it cannot cover all conceivable circumstances. In the event

of questions or problems, do not take any action without proper authorization. Please

contact the appropriate technical sales office and request the necessary information.

Throughout this manual, you will come across the following symbols. You will also

see these symbols on parts of the equipment.

Caution:

Refer to equipment documentation. Failure to do so could result in

damage to the equipment

Caution:

Risk of electric shock

Page 12

Technical Manual

GE Reason H49

12

H49/EN M/C22

Earth terminal

Protective Earth terminal

2.3 Installation, Commissioning and Servicing

2.3.1 Lifting Hazards

Plan carefully, identify any possible hazards and determine whether the load needs to

be moved at all. Look at other ways of moving the load to avoid manual handling. Use

the correct lifting techniques and Personal Protective Equipment to reduce the risk of

injury.

Many injuries are caused by:

• Lifting heavy objects

• Lifting things incorrectly

• Pushing or pulling heavy objects

• Using the same muscles repetitively

2.3.2 Electrical Hazards

Caution:

All personnel involved in installing, commissioning, or servicing this

equipment must be familiar with the correct working procedures.

Caution:

Consult the equipment documentation before installing, commissioning,

or servicing the equipment.

Caution:

Always use the equipment in a manner specified by the manufacturer.

Failure to do so will jeopardize the protection provided by the equipment.

Caution:

Removal of equipment may expose hazardous live parts. Please refer to

user documentation before disassembly.

Caution:

Isolate the equipment before working on the terminal strips.

Caution:

Use a suitable protective barrier for areas with restricted space, where

there is a risk of electric shock due to exposed terminals.

Page 13

GE Reason H49

Technical Manual

H49/EN M/C22

13

the equipment

Caution:

Disconnect power before disassembling. Disassembly of the equipment

may expose sensitive electronic circuitry. Take suitable precautions

against electrostatic voltage discharge (ESD) to avoid damage to the

equipment.

Caution:

NEVER look into optical fibres. Always use optical power meters to

determine operation or signal level.

Caution:

Insulation testing may leave capacitors charged up to a hazardous

voltage. At the end of each part of the test, discharge the capacitors by

reducing the voltage to zero, before disconnecting the test leads.

Caution:

Operate the equipment within the specified electrical and environmental

limits.

Caution:

Before cleaning the equipment, ensure that no connections are

energised. Use a lint free cloth dampened with clean water.

2.4 Decommissioning and Disposal

Caution:

Before decommissioning, completely isolate the equipment power

supplies (both poles of any Vdc supply). The auxiliary supply input may

have capacitors in parallel, which may still be charged. To avoid electric

shock, discharge the capacitors using the external terminals before to

decommissioning.

Caution:

Avoid incineration or disposal to water courses. Dispose of

in a safe, responsible an environmentally friendly manner, and if

applicable, in accordance with country-specific regulations.

Page 14

Technical Manual

GE Reason H49

14

H49/EN M/C22

3.1 Copyrights

Chapter 3: Copyrights &

Trademarks

Under the copyright laws, this publication may not be reproduced or transmitted in

any form, electronic or mechanical, including photocopying, recording, storing in an

information retrieval system, or translating, in whole or in part, without the prior

written consent of GE Grid Solutions Trademarks.

DS Agile, DS Agile SCE, DS Agile ES, DS Agile OI, DS Agile SMT, GE Grid Solutions - are

trademarks of GE Grid Solutions. Product and company names mentioned herein are

trademarks or trade names of their respective companies.

3.2 Warnings Regarding Use of GE Grid Solutions Products

GE Grid Solutions products are not designed with components and testing for a level

of reliability suitable for use in connection with surgical implants or as critical

components in any life support systems whose failure to perform can reasonably be

expected to cause significant injuries to a human.

In any application, including the above reliability of operation of the software

products can be impaired by adverse factors, including - but not limited to fluctuations in electrical power supply, computer hardware malfunctions, computer

operating system malfunctions, software suitability, suitability of compilers and

development software used to develop an application, installation errors, software

and hardware compatibility problems, malfunctions or failures of electronic

monitoring or control devices, transient failures of electronic systems (hardware

and/or software), unanticipated uses or misuses, or errors by the user or application

designer (adverse factors such as these are collectively termed "System failures").

Any application where a system failure would create a risk of harm to property or

persons (including the risk of bodily injuries and death) should not be reliant solely

upon one form of electronic system due to the risk of system failure to avoid damage,

injury or death, the user or application designer must take reasonable steps to

protect against system failure, including - but not limited - to back-up or shut-down

mechanisms, not because the end-user's system is customized and differs from GE

Grid Solutions testing platforms but also because a user or application designer may

use GE Grid Solutions products in combination with other products.

These actions cannot be evaluated or contemplated by GE Grid Solutions.

Page 15

GE Reason H49

Technical Manual

H49/EN M/C22

15

Thus, the user or application designer is ultimately responsible for verifying and

validating the suitability of GE Grid Solutions products whenever they are

incorporated in a system or application, even without limitation of the appropriate

design, process and safety levels of such system or application.

Page 16

Technical Manual

GE Reason H49

16

H49/EN M/C22

(2

)

(

1

)

(

3)

(

9)

S1601ENb

(*)

(*)

(19)

(20)

(21)

(22)

(23)

(18)

(A)

(B)

4.1 Hardware

4.1.1 Front Panel

Chapter 4: Functional

Description

The following section show different views of the device together with its

components.

Figure 1: Front View and Rear View

Page 17

GE Reason H49

Technical Manual

H49/EN M/C22

17

1 LED (boot, ok, alarm)

The front panel of the Reason H49 switch contains the following items:

Item Description

Liquid crystal display (LCD) with 4 lines of 16 characters:

Line 1: Empty

A

B Navigation buttons to access and browse the device menu

Line 2: H49

Line 3: IP address (255.255.255.255)

Line 4: Empty

Reason H49 is configured through the web application user interface (detailed later in

this document) or using configuration file.

Signification of the LEDs

Light Emitting Diodes (LEDs) and alarm contacts indicate the status of the product

and its ports:

LED

rank

1

2

3

4 to 9

18

19

20

21

22

Signification Color Description Activity

Power

1 LED

Operating state

Time

Synchronization

1 LED

Port activity

6 LEDs

Alarm

1 LED

HSR RedBox

1 LED

PRP RedBox

1 LED

PRP-HSR Coupling

1 LED

HSR QuadBox

1 LED

Green Powered on

Off Switch is off

Amber

(default)

Green

Green PTP or NTP synchronization

Red

Green 1Gbits/s

Amber 100Mbits/s

Red

Red (default) Power redundancy alarm

Green

Green

Green

Green

As long as the CPU board has not

booted.

Healthy (board works, no contact

alarm)

No synchronization or Switch in

Grandmaster

Not forwarding (access violation,

wrong MAC address)

No traffic On

Signs of activity Blinking

Not plugged or disabled by

configuration

Off

Page 18

Technical Manual

GE Reason H49

18

H49/EN M/C22

Alternatively,

S1602ENa

Alarm

Relay

Slot A

Slot B

Slot C

4.1.2 Bottom view

LED

rank

23

*

Signification Color Description Activity

Standard Switch

1 LED

Green

Red, Green

and Amber

LED chaser

Reason H49 is a 6-port switch, supporting any combination of 100Mbps and 1Gbps

RJ45 copper or LC optical fiber ports.

The following figure presents the bottom view of the device together with its

components.

Figure 2: Reason H49 Bottom View

Page 19

GE Reason H49

Technical Manual

H49/EN M/C22

19

Multi-mode SFP transceivers are used for connections up to 2km, and single-mode

SFP transceivers can be used for distances up to 15km.

Description of the slots

Slot Board Description

Communication port

• Port 1 to port 6: SFP transceiver optical/copper

Alarm Relay Connector

A SRPV3

• Pin1: Normally Open

• Pin2: Common

• Pin3: Normally Closed

Secondary Power Supply

B BIU261D

• Pin2: In-

• Pin1: In+

Primary Power Supply

• Pin1 to Pin21: Not Connected

C BIU261D

• Pin22: Earth

• Pin23: In-

• Pin24: In+

Page 20

Technical Manual

GE Reason H49

20

H49/EN M/C22

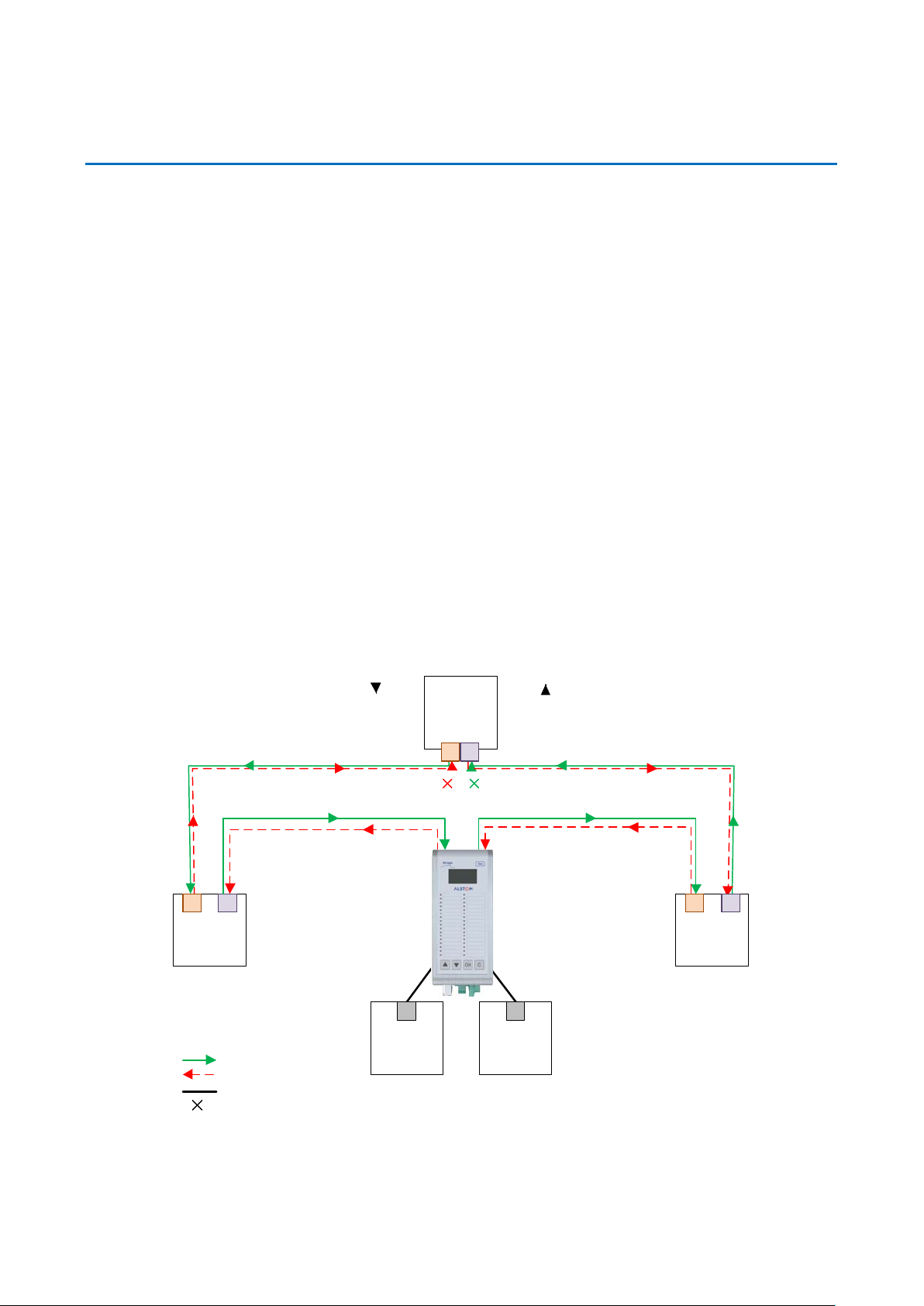

DANP 3

H49

RedBox

DANP 2

SAN 1

SAN 4SAN 2

SAN 3

S1603ENa

LAN A Switch LAN B Switch

DANP 1

4.2 Parallel Redundancy Protocol (PRP)

The Parallel Redundancy Protocol (PRP) is implemented according to the definition in

the standard IEC 62439-3 (2016) Clause 4.

PRP allows seamless switchover and recovery in case of network disruption (for

instance cable, driver, switch or controller failure).

A PRP compatible device has two ports operating in parallel, each port being

connected to a separate local area network (LAN) segment. IEC 62439-3 (2016)

Clause 4 assigns the term DANP (Doubly Attached Node running PRP) to such

devices. Critical devices should be doubly attached using two ports. The two LANs

have no connection between them and are assumed to be fail-independent.

A source DANP sends the same frame over both LANs and a destination DANP

receives it from both LANs within a certain time, consumes the first frame and

discards the duplicate. In the following figure, DANP1 and DANP2 implement this

redundancy.

Figure 3: Example PRP Redundant Network

Singly Attached Nodes (SAN) are connected to only one LAN (see SAN 1 and SAN 4 in

previous figure) and they do not implement any redundancy. They can, however, be

Page 21

GE Reason H49

Technical Manual

H49/EN M/C22

21

DANP 2

DANP 1

SAN 1 SAN 4

SAN 3

S1604ENa

LAN A Switch LAN B Switch

H49 - RedBox

SAN 2

connected to both LANs, via the Reason H49 switch that converts a singly attached

node into a doubly attached node. It acts as a redundancy box or RedBox.

Devices with single network cards such as personal computers, printers, etc., are

singly attached nodes that may be connected into the PRP network via a RedBox as

shown in the following figure.

This is the case for SAN2 and SAN3. Because these SANs connect to both LANs, they

can be considered as Virtual Doubly Attached Nodes and described as VDANs.

Reason H49 can be configured as PRP RedBox and connect up to four SANs to the PRP

network as shown in the following figure:

Figure 4: Reason H49 connecting four SANs to the PRP Network

Page 22

Technical Manual

GE Reason H49

22

H49/EN M/C22

DANH 3

DANH 2

SAN 1

SAN 2

S1605ENa

"C" frame

from SAN

"D" frame

to SAN

"A" frame "B" frame

Returning "B" frame is stopped Returning "A" frame is stopped

“A” frames

“B” frames

non-HSR frames exchanged between ring and host

frame is removed from the ring by the node

H49

HSR RedBox

DANH 1

4.3 High-availability Seamless Redundancy (HSR) Protocol

The HSR protocol is implemented accordingly to IEC 62439-3 (2016) Clause 5.

HSR allows seamless communication in case of a single network disruption (for

instance cable, driver, switch or controller failure).

An HSR-compatible device has two ports operating simultaneously, both ports being

connected to the same LAN. IEC 62439-3 (2016) Clause 5 assigns the term DANH

(Doubly Attached Node running HSR) to such devices. Reason H49 is a DANH.

The figure below shows an example of an HSR network. The doubly attached nodes

HSR RedBox, DANH 1 and DANH 2 send and receive HSR frames in both directions,

while the singly attached nodes SAN 1 and SAN 2 can only send and receive frames

without HSR header.

Singly attached nodes can, however, be connected to HSR ring, via a device which

converts a singly attached node into a doubly attached node. Devices performing this

function are often referred to as redundancy boxes or RedBoxes. Thus, devices with

single network cards such as personal computers, printers, etc., are singly attached

nodes that may be connected to the HSR network via a RedBox as shown in the

figure.

Because these SANs are connected to the HSR network, they can be considered as

Virtual Doubly Attached Nodes and described as VDANs.

Figure 5: Example HSR Redundant Network

Page 23

GE Reason H49

Technical Manual

H49/EN M/C22

23

HSR is based on a ring-type architecture to achieve its network path redundancy.

Duplicate packets, identified as “A” and “B”, are sent in opposite directions of the ring

to achieve redundancy down to the packet level. When a packet arrives at a DANH

node, the node will determine if the packet is addressed to it or to another

destination.

• If the packet is addressed to the node, then

It will process it or

It will discard it if it is a duplicate packet

• If the packet is for another destination, then

If the DANH device receives a frame that it originally sent, it does not

forward it

Otherwise, it will simply forward the packet on to the next node in the

network.

Frames sent by a SAN device (see “C” frames in the following figure) are converted

into two “A” and “B” frames and sent over the HSR network.

Received frames that are addressed to a SAN managed by a Redbox (such as MMS

messages) are not forwarded on to the HSR network.

There are two basic operation principles, depending on whether the broadcasted

frames are multicast (e.g. GOOSE) or unicast (e.g. MMS reports).

• Multicast (e.g. GOOSE): A source DANH sends a frame over both ports (“A”-

frame and “B”-frame). The destination DANH receives, in a fault-free state, two

identical frames from each port within a certain interval, passes the first frame on

to its higher layers. A source DANH discards any duplicate multicast frame from

the ring.

• Unicast (e.g. REPORT): A destination node of a unicast frame does not forward a

frame for which it is the only destination. It removes the unicast frame from the

ring.

Page 24

Technical Manual

GE Reason H49

24

H49/EN M/C22

DANH

S1606ENa

DANH

DANH DANH

H49

QuadBox

H49

QuadBox

DANH

DANH

DANH

DANH

DANH

"A"

"B"

Source

Destination

“A” frames

“B” frames

frame is removed from the ring by the node

4.4 HSR Quadbox

It is possible to connect two HSR rings when the traffic flow exceeds the capabilities

of a single ring. However, transmission delays from end to end are not improved. This

connection is possible thanks to quadruple port devices with forwarding capabilities

called QuadBoxes as shown in the following figure.

Although one QuadBox is sufficient to forward traffic, two QuadBoxes are used to

prevent a single point of failure. A QuadBox forwards frames over each ring as any

HSR node, and passes the frames unchanged to the other ring, except if the frame can

be identified as a frame not to be forwarded to the other ring. To this effect, a

QuadBox is expected to filter traffic based for instance on multicast filtering or on

VLAN filtering. There is no learning of MAC addresses in a QuadBox, though, since the

learning of MAC addresses on specific ports of a QuadBox device could lead to a short

break in communication if the QuadBox that has learned an address and is

forwarding network traffic fails.

With QuadBoxes realized as single physical entities, the two interconnected rings

share the same redundancy domain concerning fault tolerance. If one QuadBox

breaks down, both interconnected rings are in a degraded state and cannot tolerate a

further fault.

Figure 6: Two QuadBoxes linking two HSR Rings

The presence of two QuadBoxes on the same ring causes that two copies of the same

frame are transferred from the first ring to the second, each generating other two

copies.

This does not cause four frames to circulate on the second ring, since, when a copy

from a first QuadBox reaches the second QuadBox on the same second ring, the

second QuadBox will not forward it if it already sent a copy that came from its

interlink.

Page 25

GE Reason H49

Technical Manual

H49/EN M/C22

25

Conversely, if the second QuadBox did not yet receive a copy from its interlink, it will

forward the frame, but not the copy that comes later from the interlink.

When a QuadBox receives a frame that it itself injected into the ring or a frame that

the other QuadBox inserted into the ring, it forwards it to the interlink and to its other

port if it did not already send a copy. This duplicate will be discarded at the other end

of the interlink. This scheme may cause some additional traffic on the interlink, but it

allows to simplify the design of the logic.

Note:

The maximum time skew between two frames of a pair is about the same as if all nodes were on the same ring

Page 26

Technical Manual

GE Reason H49

26

H49/EN M/C22

DANH

S1607ENa

DANH DANH DANH

"A"

"B"

H49

RedBox

“A“

Destination

LAN A

LAN B

"AB"

"BA"

DANP

DANP

Source

“A” frames

“B” frames

duplicated redundant frames

frame is removed from the ring by the node

DANH

H49

RedBox

“B“

4.5 PRP-HSR Coupling

A HSR may be coupled to a PRP network through two RedBoxes, one for each LAN as

shown in the figure here below. In this case, the RedBoxes are configured to support

PRP traffic on the interlink and HSR traffic on the ring ports.

The sequence number from the PRP RCT is reused for the HSR tag and vice versa, to

allow frame identification from one network to the other and to identify pairs and

duplicates on the HSR ring, introduced by a twofold injection into the ring through the

two HSR RedBoxes.

Figure 7: Coupling two PRP LANs to an SRS Ring

Page 27

GE Reason H49

Technical Manual

H49/EN M/C22

27

DANH

S1608ENa

DANH

DANH

DANH DANH

"B"

Destination

LAN A

LAN B

"BA"

DANP

DANP

Source

“A” frames

“B” frames

duplicated redundant frames

frame is removed from the ring by the node

"A"

"AB"

H49

RedBox

“A“

H49

RedBox

“B“

The HSR RedBoxes for connecting the ring to a PRP network operate identically to

those used to attach SANs, except that they are configured as RedBox “A” or RedBox

“B” to accept PRP frames on their interlink. In the figure here above, RedBox A and

RedBox B would send the same frame (A and AB, respectively B and BA), but if a

RedBox receives the frame before it could send it itself, it refrains from sending it.

In the figure here above, RedBox A will not generate an “A“ frame on behalf of LAN A if

it previously received the same frame as “AB“ from the ring, or conversely, RedBox “B”

will generate an “AB” frame if it did not previously receive an “A” frame from the ring,

which is the case whenever frame “A” is not a multicast frame.

Multicast frames or unicast frames without a receiver in the ring (see figure here

above) are removed by the RedBox that inserted them into the ring, if they originated

from outside the ring.

The following figure shows the same coupling when the source is within the ring.

Figure 8: Coupling an HSR Ring to two PRP LANs

Page 28

Technical Manual

GE Reason H49

28

H49/EN M/C22

DANH

S1609ENa

DANH DANH

DANH

H49

RedBox

“1A“

LAN A

LAN B

H49

RedBox

“1B“

DANP

DANP

DANH DANH

DANH DANH

H49

RedBox

“2A“

LAN A

LAN B

H49

RedBox

“2B“

DANP

DANP

DANH DANH

To avoid reinjecting a frame into the PRP network through the other RedBox, each

HSR frame carries the identifier of the PRP network from which the frame came

originally. Therefore, RedBoxes are to be configured with the NetId of the PRP

network to which they are attached.

Other combinations of PRP and HSR networks are allowed. Some of them are

explained in the following sections.

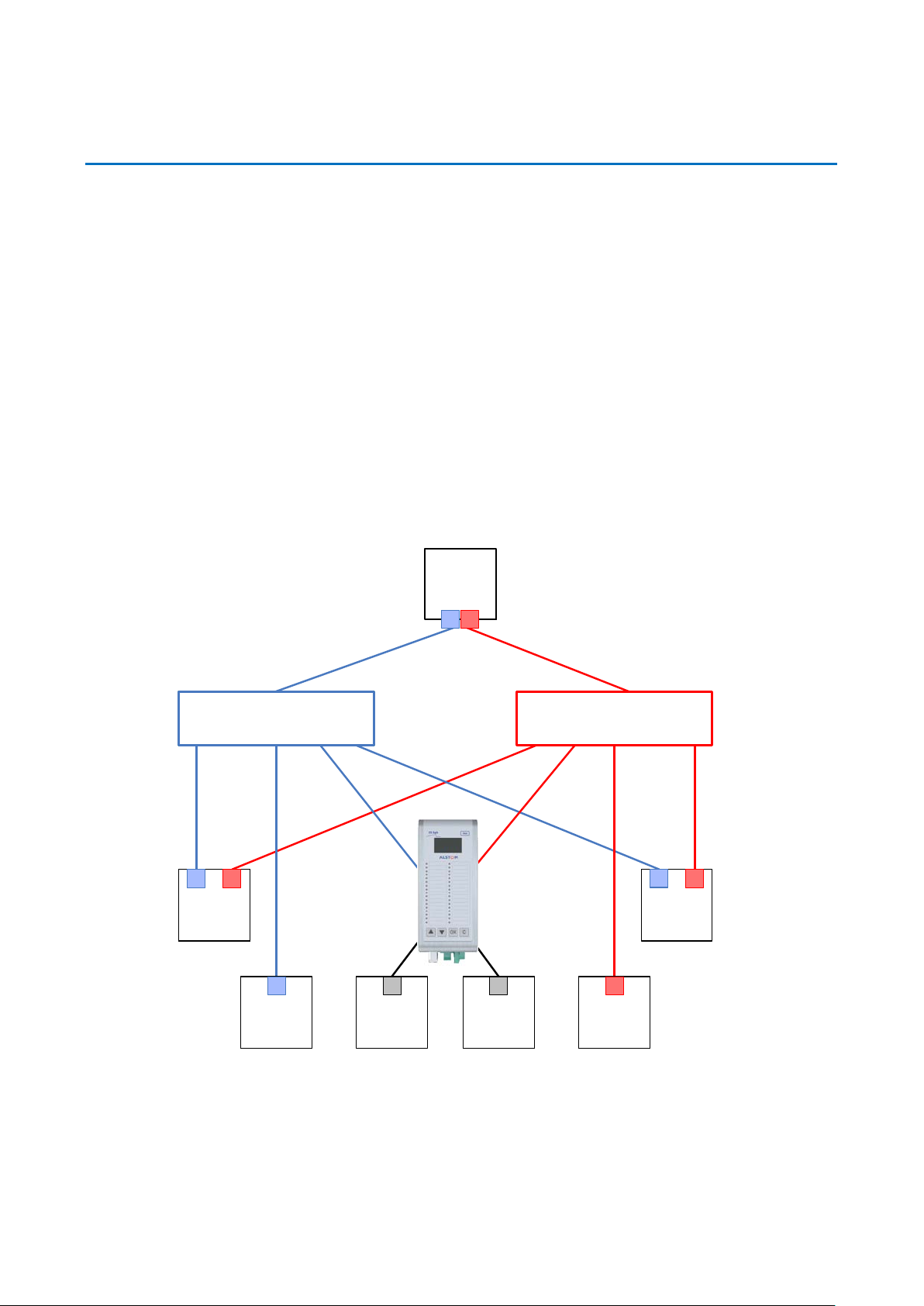

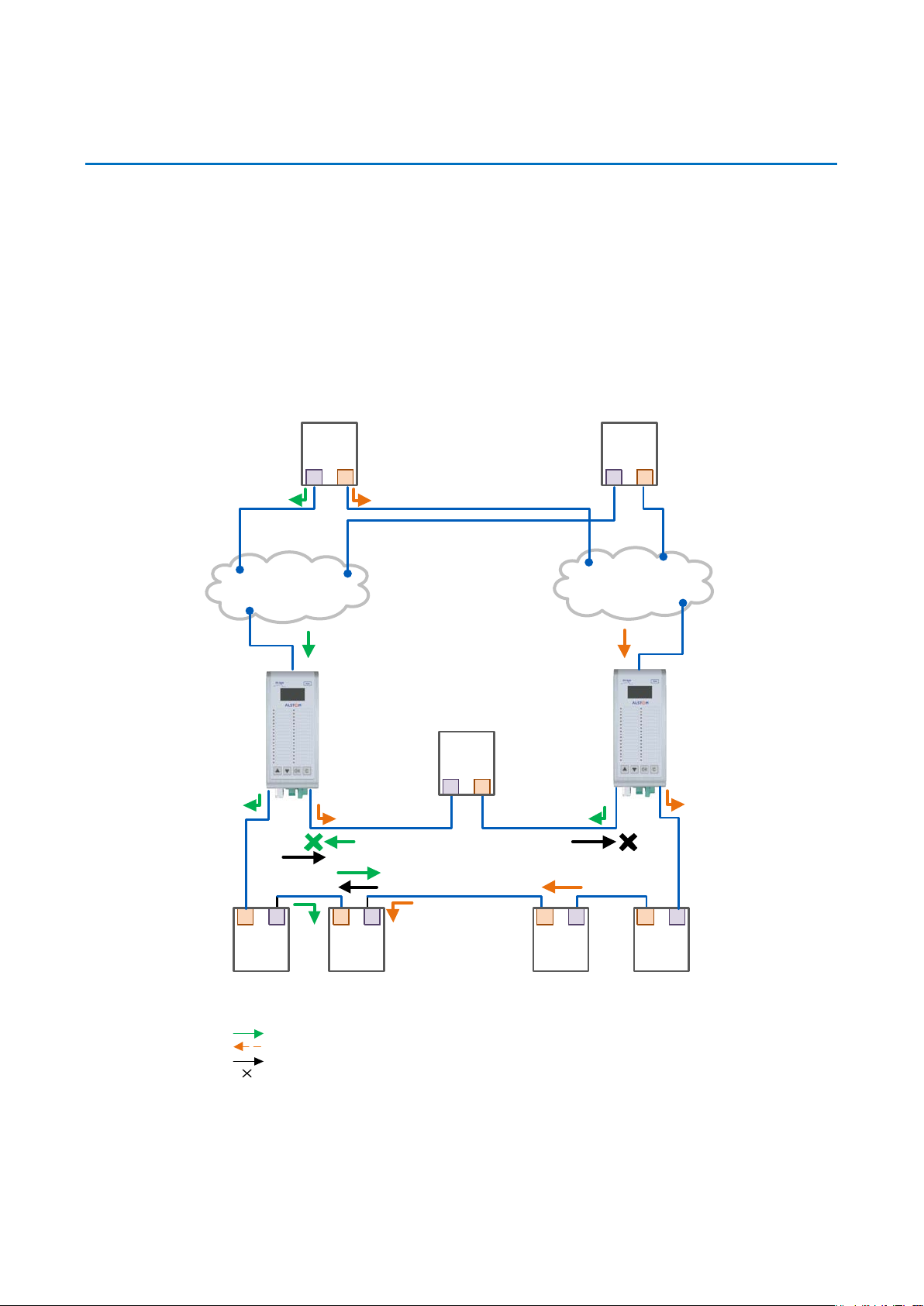

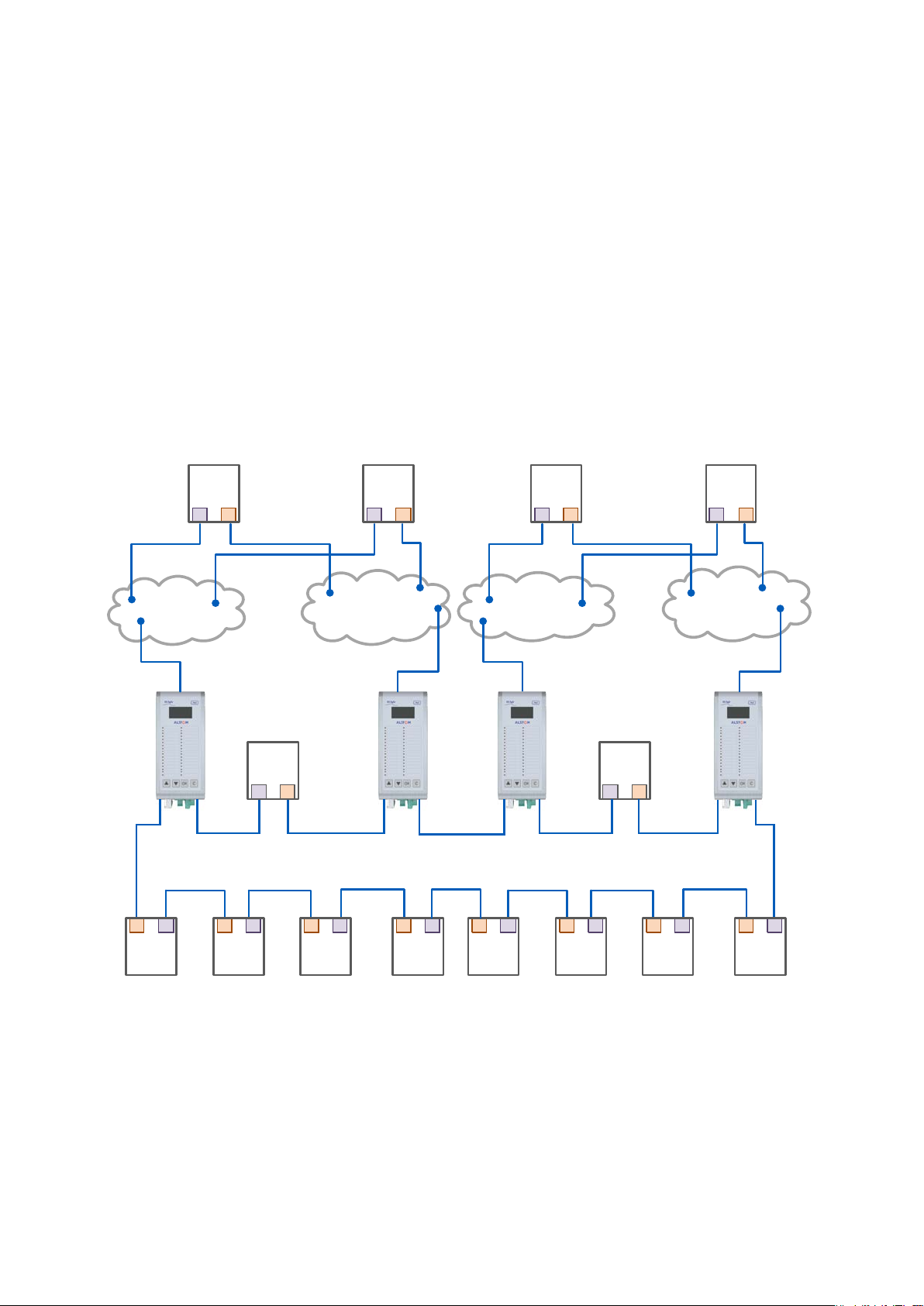

4.5.1 Connecting several PRP Networks to an HSR Ring

Up to six PRP networks can be connected to the same HSR ring, each being identified

by a 3- bit NetId.

The two RedBoxes that connect a PRP network with an HSR ring are configured with

the NetId (1..7) and the LanId (A=0/B=1), see the following figure.

Figure 9: Coupling one HSR ring to several PRP Networks

To prevent reinjection of frames coming from one PRP network into another PRP

network or from the same, a RedBox only forwards from the HSR ring frames that do

not carry its own NetId. When inserting into the ring a PRP frame from LAN A or from

LAN B of a PRP network with a given NetId, a RedBox inserts into the PathId of the

HSR tag its own NetId and the LanId, i.e. one of “2”/”3”, “4”/”5”, “6”/”7”, “8”/”9”, “A”/”B”,

“C”/”D” or “E”/”F”, depending if it is RedBox A or B.

Page 29

GE Reason H49

Technical Manual

H49/EN M/C22

29

DANH

S1610ENa

DANH

DANH

DANH DANH

H49

RedBox

“A“

LAN A

LAN B

H49

RedBox

“B“

DANP

DANP

Source

DANH DANH

DANH

DANH DANH

H49

RedBox

“A“

H49

RedBox

“B“

Source

Ring A Ring B

Conversely, when forwarding a frame from the ring to a PRP network, a RedBox insert

the LanId “A” or ”B” into the RCT, depending if it is RedBox A or RedBox B.

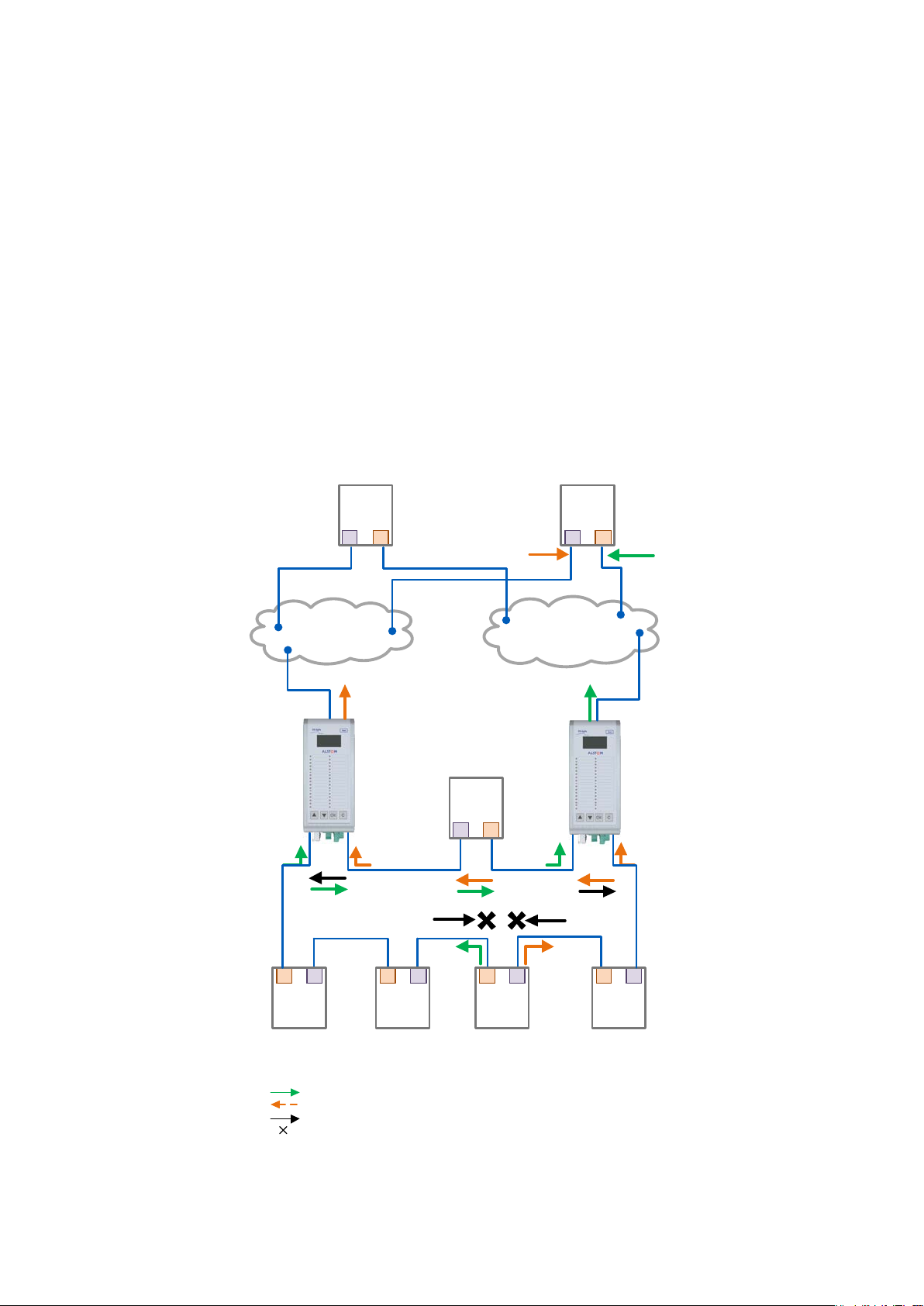

4.5.2 Connecting one PRP Networks to several HSR Rings

A PRP network can be connected to any number of HSR rings, but these rings cannot

be connected between themselves, neither by QuadBoxes nor by another PRP

network since this would create loops.

Figure 10: Coupling Several HSR Rings to a PRP Network

Page 30

Technical Manual

GE Reason H49

30

H49/EN M/C22

4.6 Standard Switch

Reason H49 can be configured as a standard Ethernet Switch. In this case, it manages

up to six Ethernet ports.

Reason H49 using auto-negotiation:

• Automatically determines the speed of transmission on the 10/100/1000 Base

ports according to the following standards:

IEEE 802.3u – 100BaseTX, 100BaseFX

IEEE 802.3ab – 1000BaseTX

IEEE 802.3z – 1000BaseLX, 1000BaseSX

• Determines whether communication is half-duplex or full-duplex, and adapts

accordingly.

Addressing:

• Each Ethernet device inserts its unique “MAC address” into each message it

sends.

• The receiving port automatically recognizes the MAC address in a received frame

and stores it.

• Once an address is recognized and stored, the switch will forward frames to the

appropriate port.

• Up to 512 MAC addresses can be stored and monitored at any time.

4.7 Time Synchronization

Reason H49 supports real-time clock synchronization for the timestamp of logs or

events through the following network protocols:

• Precision Time Protocol (PTP in accordance with IEEE/IEC 61588 (2009))

• Network Time Protocol (NTP).

Note:

The Reason H49 switch does not support Spanning Tree Protocol (STP, RSTP, MSTP).

The time protocol used is independent of the network architecture (HSR or PRP).

Thus, the time server can be placed in either the HSR ring or one of the PRP LANs.

It is important to emphasize that the time server shall be placed in a VDAN device; in

other words, it shall be linked to the network through a RedBox.

Page 31

GE Reason H49

Technical Manual

H49/EN M/C22

31

4.7.1 Precision time synchronization (PTP)

Time synchronization from a master clock synchronized to the global positioning

satellite (GPS) system is accepted over the network according to IEEE/IEC61588 Ed.2.

(2009).

PTP synchronizes all clocks within a network by adjusting distributed clocks to a

grandmaster clock. PTP enables distributed clocks to be synchronized and maintained

to sub-microsecond accuracy.

Note:

On PTP protocol, a time discrepancy of 60 milliseconds per 24h is reported on Reason H49 (equipped with a SRPv3 version x) and

used as Master Clock (M1) (case VDAN-P Grandmaster Clock not available).

Figure 11: Example of PRP/HSR Architecture with the Precision Time Protocol (PTP)

Page 32

Technical Manual

GE Reason H49

32

H49/EN M/C22

4.7.2 NTP time synchronization

Network Time Protocol (NTP) is a networking protocol for clock synchronization

between computer systems over packet-switched, variable-latency data networks.

Reason H49 supports NTP as shown in the figure below.

4.7.2.1 Time Zone

Figure 12: Example of NTP Synchronization

The internal clock of Reason H49 can be synchronized using NTP protocol, which

sends the UTC time (Greenwich Mean Time). When using the equipment in other

regions, the time zone may be set manually to correct the internal clock.

Page 33

GE Reason H49

Technical Manual

H49/EN M/C22

33

4.8 SNMP

Simple Network Management Protocol (SNMP) is the network protocol developed to

manage devices on an IP network.

To exchange information, SNMP relies on a Management Information Base (MIB)

that contains information about parameters to supervise. A MIB format is a tree

structure, with each node identified by a numerical Object Identifier (OID). Each OID

identifies a variable that can be read or set via SMP with the appropriate software.

4.8.1 Supported MIB

The SNMP MIB consists of distinct OIDs, each of which refers to a defined collection of

specific information used to manage devices over the network.

GE Grid Solutions management information bases (MIB) use the following types of

object identifiers (OID):

• BRIDGE-MIB (RFC 1493)

• SNMPv2-MIB (RFC 1907)

• TCP-MIB (RFC 2012)

• UDP-MIB (RFC 2013)

• SNMPv2-SMI (RFC 2578)

• SNMPv2-TC (RFC 2579)

• RMON-MIB (RFC 2819)

• IF-MIB (RFC 2863)

• PRP/HSR MIB (IEC 62439-3)

• Power Profile MIB (IEEE C37.238)

Page 34

Technical Manual

GE Reason H49

34

H49/EN M/C22

4.8.2 SNMP Traps

The SNMP agent in the Reason H49 switch can send SNMP traps to the management

station. Traps are change-of-state messages alerting the SNMP manager to a

condition on the network. A trap message is sent to alert the management station to

some event or condition on the switch such as:

• Loss of communication on one port

• Loss of power supply input

• Loss of time synchronization (PTP)

• Resource exhaustion

Page 35

GE Reason H49

Technical Manual

H49/EN M/C22

35

5.1 Dimensions

Chapter 5: Installation

Figure 13: Front Face and side with dimensions

Page 36

Technical Manual

GE Reason H49

36

H49/EN M/C22

S1616ENa

Manufacturer Label Firmware Label Manufacturing Label

5.2 Device Labeling

The figure below shows an example of the standard labels stuck to the Reason H49

switch:

Figure 14: Example of Device Labeling

Main information present in these labels includes:

• Company

• Product name

• Cortec code

• Voltage range

• Serial number

• Caution notice

• Firmware version

• MAC address

The following tables give the details of the label components.

Page 37

GE Reason H49

Technical Manual

H49/EN M/C22

37

5.2.1 Manufacturing Label

Figure 15: Manufacturing Label

Label 20x94mm

Diagram number:

Reference of the product: GP0067001

Version of the product: B

Serial number:

Unique serial number: 8 numerical digits: 11111158

Date of manufacturing /MM/YY: /06/16

Barcode content description:

Cortec number: DSAGILEH4900000000000B

Serial number without the manufacturing date: 11111158

MAC Address: 80B32AFF0000

Label1 - Manufacturing Label

GP0067001_B

11111158/06/16

DSAGILEH4900000000000B_11111158_80B32AFF0000

Page 38

Technical Manual

GE Reason H49

38

H49/EN M/C22

5.2.2 Firmware Label

Label 10x27mm

Firmware version:

Name of the product: H49

First digit: Major functional version (2)

Second digit: Compatibility indicator version (0)

Third digit: Maintenance/Evolution/Bug fix version (0)

Fourth digit: Second level maintenance version (0)

Figure 16: Firmware Label

Label2 - Firmware Label

H49_2.0.0.0

Note:

Firmware label is given as an example. Check last issue of datapack for correct firmware label.

5.2.3 Manufacturer Label

Figure 17: Manufacturer Label

Label3 - Manufacturer Label

Label 28x50mm

Font: Alstom regular, black

Content: manufacturer contact information

Page 39

GE Reason H49

Technical Manual

H49/EN M/C22

39

5.3 Mounting

Reason H49 is designed to be mounted vertically on a standard DIN Rail.

For this purpose, two adjustable mounting brackets are located on the back of the

H49, one at the top and one at the bottom of the rear face as shown below:

Figure 18: H49 DIN Rail Mounting Details - Rear View with Mounting Rack

Optional Weidmuller FM4 TS35 mounting clip can also be used, as shown in the

following figure (to be ordered separately).

Figure 19: H49 DIN Rail Mounting Details - Rear View with Weidmuller Clip

Page 40

Technical Manual

GE Reason H49

40

H49/EN M/C22

5.3.1 Recommendations for Electromagnetic compatibility

Caution:

Reason H49 operates within -25°C/+55°C in normal conditions. As heat

within Reason H49 switches is channeled to the enclosure, it is

recommended that 1,5 cm of space be kept between each switch mounted

within the DIN Rail to allow for a small amount of airflow.

A closer spacing will result in higher device operating temperature.

Caution:

The orientation in which the Reason H49 is fitted on the DIN Rail is a key

factor to optimal performance. Reason H49 requires to be installed

vertically on the DIN rail. Other position would lead to inadequate

ventilation and result in increased heat generation.

Page 41

GE Reason H49

Technical Manual

H49/EN M/C22

41

Chapter 6: Connection

As well as connections to the Ethernet network, Reason H49 requires auxiliary power

supply connection and safety earth connection. Alarm outputs are provided and

these should be connected for system supervision.

The locations of the various connection points are detailed section Bottom view.

6.1 General Wiring

Only two wires can be screwed together on any one connector. The AC and DC signal

and communication wires should use separate shielded cable.

Wires should be connected with the power supply connectors unplugged. Each wired

signal has to be tested before plugging and fixing the connectors. The connectors

have to be fixed on the H49 case with the screws available at each extremity of the

connector.

Caution:

A high rupture capacity (HRC) fuse must be used for auxiliary supplies (for

example Red Spot type NIT or TIA) with the following characteristics:

• Current rating: 16 Amps

• Minimum dc rating: 220 V dc

• gG operating class in accordance with IEC 60269

The fuses must be connected in series with the positive auxiliary supply input

connections for both primary (Pin 23) and secondary (Pin 1) BIU261D inputs.

For connection of the protective (earth) conductor, refer to chapter 6.2 Earth Wiring

page 42.

6.1.1 Well-organized Wiring

Caution:

Improperly installed cabling can affect device performance and generate

interferences.

To avoid interferences, careful placement of cables is required. The principle

consists in physically separating power sources (AC/DC) and communications

cables (i.e. high voltage from RJ45/Copper). This is even more important

when devices receive time synchronization from PTP master clock.

Whenever possible, use cableways or troughs.

Page 42

Technical Manual

GE Reason H49

42

H49/EN M/C22

6.2 Earth Wiring

6.2.1 Protective Earth Wiring

This equipment requires a protective conductor (earth) to ensure user safety

according to the definition in the standard IEC 60255-27: 2005 Insulation Class 1.

Warning:

– To preserve the device's safety features, the protective conductor (earth)

MUST not BE disturbed when connecting or disconnecting functional earth

conductors, such as cable screens, to the PCT stud.

– The protective conductor must be connected first, in such a way that it is

unlikely to be loosened or removed during installation, commissioning or

maintenance. This MAY be achieved by use of an additional locking nut.

Caution:

Always place the protective conductor (earth) as shown on the diagram

below.

Figure 20: Protective Earth Screw

The protective conductor (earth) must be as short as possible, with low impedance.

The best electrical conductivity must be maintained at all times, particularly the

contact resistance of the plated steel stud surface.

Page 43

GE Reason H49

Technical Manual

H49/EN M/C22

43

C0047ENb

Good conductor surface

Cable crimp

Copper cable

minimum section: 2.5mm²

S1645

ENa

1,

5 cm

1,

5 cm

1,

5 cm

1,

5 cm

Figure 21: Example of Earth Cable

6.2.2 Casing / Earth Interconnection

To protect against disturbances, each Reason H49 must be carefully and correctly

interconnected.

Within Reason H49 equipment, earth and casing must be connected to a grid-like

grounding system in the shortest possible way using low impedance (at high

frequencies), wide and short electrical connections (wires or braids) as specified in

the IEC 61000-5 standard.

Figure 22: Recommended mounting and Casing / Earth interconnection

Page 44

Technical Manual

GE Reason H49

44

H49/EN M/C22

S1613ENa

6.3 Power Supply Wiring

Reason H49 contains a Basic Interface Unit (BIU261D) board, which includes two

redundant power supply inputs, as shown in the following figure:

Figure 23: Reason H49 Power Supply Wiring

BIU261D primary power supply

The primary power supply is connected using a 24-way connector block:

Figure 24: Typical 24-way Female Connector

Page 45

GE Reason H49

Technical Manual

H49/EN M/C22

45

BIU261D primary power supply

Pin n° Description

1 to 21 Not used

22 Voltage input: GND

23 Voltage input: AC/DC ( + )

24 Voltage input: AC/DC ( - )

Note:

Inputs must be connected to the specified pins. Other pins must remain unused and no other connection has to be made.

The 24-way connector block characteristics are as follows:

• Continuous rating 10A

• Connection method M3 screws

• Cable section 2.5mm2

• Connection pitch 5.08mm

• Insulation between terminals and to the earth 300 V basic insulation

• Standards UL, CSA

Note:

The connector is fixed using 2 M3 screws located at each end of the connector.

BIU261D secondary power supply

The secondary power supply is connected using a 2-way connector block:

Figure 25: Typical 2-way Female Connector

1 Voltage input: DC ( + )

2 Voltage input: DC ( - )

Pin n° Description

Page 46

Technical Manual

GE Reason H49

46

H49/EN M/C22

The 2-way connector block characteristics are as follows:

• Continuous rating 10A

• Connection method M2.5 screws

• Cable section 2.5mm2

• Connection pitch 5.08mm

• Insulation between terminals and to the earth 300 V basic insulation

• Standards UL, CSA

If the primary power supply input is lost while being used, the BIU261D switches to

the secondary power supply input. It will switch back to the primary power supply

when the latter becomes available again and has been stable for a few seconds.

If the secondary power supply is lost while being used, the BIU261 instantly switches

to the primary power supply. It will continue to use the primary power supply source

as long as it is available, even when the secondary power supply becomes available

again.

Reason H49 supports the following power supply use cases:

Primary source Secondary source

Use case 1 DC DC

Use case 2 DC OFF

Use case 3 OFF DC

Use case 4 AC DC

Use case 5 AC OFF

Nominal Power supply range

85Vac to 230Vac

85Vdc 220Vdc

85Vdc 220Vdc

Page 47

GE Reason H49

Technical Manual

H49/EN M/C22

47

S1351ENa

6.4 Alarm Relay Wiring

The 3-pin connector of the relay alarm on the SRPV3 board allows the following H49

statuses:

Figure 26: Relay Alarm Wiring

Pin Signal Description

1 Normally Open

2 Common

3 Normally Closed

Closed=Normal Operation

Open= Power supply defect (both input voltage sources are

down) / Operating System defect (Kernel crash, processor

overload, memory leak)

Closed= Power supply defect (both input voltage sources are

down) / Operating System defect (Kernel crash, processor

overload, memory leak)

Open= Normal Operation

6.4.1 Using Terminal Blocks

Printed-circuit board connectors can be used:

Figure 27: Pluggable Terminal Block

The relay alarm connector shall be plugged with MSTB 2,5 HC/ 3-ST-5,08 - 1911978

manufactured by Phoenix Contact.

6.4.1.1 Recommended Wire Size

The minimum recommended wire size for terminal blocks is 2.5mm2.

Page 48

Technical Manual

GE Reason H49

48

H49/EN M/C22

6.4.1.2 Crimped Ferrule

For safety reasons, wire terminations must be insulated using an insulated crimped

ferrule, suitable for 2,5mm

2

wire size.

Figure 28: Pluggable Terminal Block

Insulated wire ferrules must be slipped over the stripped cable and crimped to

prevent stranded wire from fraying.

Caution:

Refer to section 10.5.3 Auxiliary Fault Relays (Optical Port Alarm) page 128 for

electrical characteristics of alarm circuit.

Page 49

GE Reason H49

Technical Manual

H49/EN M/C22

49

S1353ENa

6.5 Ethernet Connections

Reason H49 is easy to install and operate. It is designed to work in an electrical plant

environment and it is fully certified IEEE 1613 series, IEC 61850-3 and IEC 60255-27.

Reason H49 connects to the network through a Small Form-factor Pluggable module

(SFP), which can be inserted and removed safely while the switch is powered and

operating:

Figure 29: SFP Module Connection

The SFP module is a hot-swappable connector that provides high-speed performance.

Reason H49 supports two kinds of modules:

• Optical LC-type SFP

• RJ45-type SFP.

The table below lists the supported LC-type SFP and references:

Reference Manufacturer Description Connector Type Image

AFBR-5715ALZ fit-foxconn

HFBR-57E0APZ AVAGO

1Gbps Multimode

850nm wavelength

100Mbps Multimode

1300 nm wavelength

LC Duplex

LC Duplex

100Mbps Single-mode SR

AFCT-5765ALZ fit-foxconn

(up to 2 km)

1300 nm wavelength

LC Duplex

Page 50

Technical Manual

GE Reason H49

50

H49/EN M/C22

mode (up to

Reference Manufacturer Description Connector Type Image

1Gbps Single-

AFCT-5715ALZ fit-foxconn

AFCT-5765ATLZ fit-foxconn

10km)

1310 nm wavelength

100Mbps Single-mode IR1 (up to 15 km)

1300 nm wavelength

LC Duplex

LC Duplex

The table below lists the supported RJ45-type SFP and references:

Reference Manufacturer Description

ABCU-5741ARZ fit-foxconn 10/100/1000Mbps RJ45

Connector

Caution:

Reason H49 is delivered with SFP cap inserted in each SFP

cage.

The cap must be inserted in each SFP cage unused. It is a

protection against dust.

Type

Image

Page 51

GE Reason H49

Technical Manual

H49/EN M/C22

51

6.5.1 RJ45-Type Connection

S1355ENa

The following figure shows the RJ45-type module used by the Reason H49 switch and

its corresponding RJ45 connector.

Insulated cable category 6 or 5e (FTP: Foil Twisted Pair) or insulated (STP – Shielded

Twisted Pair) with RJ45 connectors are mandatory.

Note: Do not use RJ45 UTP cable. This kind of cable may disrupt time synchronization.

Figure 30: RJ45 SFP Module

Caution:

When SFP Copper Ethernet modules are used, the connected cables shall

be shortened to minimum possible length. We recommend that cables

(such as RJ45 category 6 or 5e) do not exceed 3 meters to comply with

Electromagnetic compatibility (EMC) requirements.

Connected cables shall not extend beyond the cabinet where the product

is used. The equipment connected to both ends of the cable shall be

connected directly to a common protective earth point within the same

cabinet.

Page 52

Technical Manual

GE Reason H49

52

H49/EN M/C22

6.5.2 Optical LC-type Connections

S1354ENa

The following figure shows the optical LC-type module used by the Reason H49

switch and its corresponding LC-type connector.

Figure 31: Ethernet Fiber Optic – LC-type Module

Warning about Laser Rays

Caution:

NEVER look into optical fibers. Always use optical power meters to

determine operation or signal level.

Non–observance of this rule could possibly result in personal injury.

Signals transmitted via optical fibers are unaffected by interference. The

fibers guarantee electrical isolation between the connections.

If electrical to optical converters are used, they must have management of

character idle state capability (for when the fiber optic cable interface is

"Light off").

-type small form-factor pluggable (SFP) modules shall be used. LC/ST or LC/SC

LC

optical patch cords may be used to connect the board to devices fitted with ST or SC

connectors.

Figure 32: Example of Optical Patch Cord (Multimode Duplex LC/ST)

Page 53

GE Reason H49

Technical Manual

H49/EN M/C22

53

6.6 Fiber Optic Budget Calculations

Transmitted Power

Received Power

S0525ENb

Optical

Transmitter

Optical loss:

Connectors, fibers

Optical Receiver

Optical power is expressed in Watts. However, the common unit of power

measurement is the dBm, defined by the following equation: Power (dBm) = 10 log

Power (mW) / 1 mW.

The fiber optic budget is the difference between the power emitted into the fiber and

the sensitivity (minimum amount of power required) of the receiver connected

through the fiber optic cable.

Link Power Budget = Transmitter Power (dBm) - Receiver Sensitivity (dBm). The

distance over which the signals can be transmitted and successfully received is

affected by the optical loss as shown in the figure below.

Figure 33: Fiber Budget

For this product, the optical budget is given in the table below.

Fiber type

Power coupled into fiber -19 dBm -15 dBm

Sensitivity -31 dBm -34 dBm

In calculating the maximum distance, the following figures can be used as a guide, but

you should check with your supplier for precise figures.

Fiber type Multimode Single mode

Link budget 12 dB 19 dB

Typical connector loss

(1 per receiver, 1 per transmitter)

Safety Margin 4 dB 4 dB

Allowed link attenuation 6.4 dB 13.4 dB

Typical cable attenuation 1 dB/km 0.4 dB/km

Maximum range 2 km 15 km

Insertion of a patch panel (per panel) 2 dB 1 db

Multimode

62.5/125 micron

0.8 dB 0.8 dB

Single mode

9/125 micron

Page 54

Technical Manual

GE Reason H49

54

H49/EN M/C22

6.7 Power up

During the power up process the following indicators are displayed:

• LED 1 is green

• LED 2 is amber

• LED 18 indicates the state of the redundant power supply

At the end of the power-up process, the following indicators are displayed:

• The LCD screen displays “H49” and the device’s IP address

• LED 1 is green

• LED 2 is green

Refer to section 4.1.1 Front Panel page 16 for LEDs indications.

Page 55

GE Reason H49

Technical Manual

H49/EN M/C22

55

Chapter 7: Settings

To take full advantage of all the features available from the Reason H49 switch, the

device must properly be configured for your network.

There are several ways to configure the Reason H49 switch:

• A web user interface, accessible via the switch’s built-in web server.

• An SNMP interface can be used to read/write some settings

• CLI (command Line Interface) can be used to read/write most settings (SSH).

Note:

This chapter only explains how to configure the Reason H49 switch through the embedded web server. However, an appendix, at

the end of this document, describes the command lines supported by the SSH service.

7.1 Connecting to Reason H49

To access the embedded web server from a PC connected to the same LAN as the

Reason H49 switch, the PC and the H49 must be on the same subnet.

The default IP address of the Reason H49 switch is 192.168.254.254 and the sub

mask is 255.255.0.0.

Your PC IP address must be set in the same LAN for initial configuration.

Note:

The device connects to the network through a Small Form-factor Pluggable module (SFP). Refer to the Ethernet Connections

section to see the references of the supported RJ45-type SFP module.

7.2 Accessing the Web User Interface

The H49 web user interface provides an easy way to modify the switch’s configuration

settings and access the built-in network and security administration functions.

The web user interface can be accessed via a web browser.

Once your PC is connected to the same LAN and subnet as the H49, open the switch’s

web user interface as follows:

1 Open one of the following recommended web browsers:

Page 56

Technical Manual

GE Reason H49

56

H49/EN M/C22

Browser name Manufacturer

Chrome Google

Internet Explorer Microsoft

Mozilla Firefox

Safari Apple Inc.

n the web browser’s address bar, type the default H49’s IP address:

2 I

Mozilla Foundation

Mozilla Corporation

192.168.254.254 and press Enter on your keyboard.

Note:

The embedded web server only supports the secure HTTPS protocol. When you access the server via https, you may see a

warning dialogue indicating that the certificate was signed by an unknown authority. This is expected as the certificate provided

by default is self-signed. To avoid this message in the future, you can choose to install a properly signed certificate.

Page 57

GE Reason H49

Technical Manual

H49/EN M/C22

57

7.3 Logging In

The web login window prompts you for a login name and password.

Use the following default values:

• Login: user

• Password: user

Note: See the Cyber Security section for more information on user accounts.

If an error occurs during the authentication process, an information message appears

on screen, as shown in the following figure.

Figure 34: Reason H49 Web User Interface - Error during Login Process

When connecting to Reason H49 for the first time, the system prompts the user to

change the default password.

• Enter a new password and confirm.

Note:

The new password must match the Password complexity parameter, which is enabled by default in H49 web user

interface. Refer to section 8.1.5 Password Management, page 108 for more information.

Upon successful authentication, the user is granted authorization for access.

Read the Software License agreement and click Yes to agree to the terms:

Figure 35: Reason H49 Web User Interface - Agreement Conditions

Page 58

Technical Manual

GE Reason H49

58

H49/EN M/C22

7.4 Feature Overview

The embedded web user interface consists of two areas:

• A configuration menu, on the left side of the window, which is organized into

three main sections;

System

Network

Security

• A setting panel, on the right.

Navigate through the configuration menu to access each of the switch’s functions.

Figure 36: Reason H49 Web User Interface – Start Page

Page 59

GE Reason H49

Technical Manual

H49/EN M/C22

59

7.4.1 System

7.4.1.1 Status

The System section provides the current configuration of the Reason H49 switch

together with its status.

It also allows the user to update the main system attributes.

To get the global status of the Reason H49 switch, click Status in the System

section:

The top part of the page shows the following information:

Attribute Description

Redundancy mode Selected redundancy mode

IP address Device’s IP address

MAC address Device’s MAC address

Date & Time Device’s clock date and time

Uptime Elapsed time since last reboot

Firmware Version Version of the firmware currently running on the device

L

ED Chaser

The LED chaser of the H49 is a function used to identify correctly a given device

amongst others.

It consists in sequentially lighting all the LEDs in the front panel one after the other,

eight at a time.

• Click Enable LED Chaser to activate the LED chaser and make the device’s LEDs

b

link in sequence.

• Click again to stop the LED chaser (Disable LED Chaser button), or press the “C”

button on the device front panel.

Alternatively, the LED chaser can be stopped by pressing the “C” button in the front

panel.

Supply Status

This area shows information about the input voltage sources (Primary voltage

source/Secondary voltage source):

Figure 37: H49 Web User Interface – Power Supply Status

Page 60

Technical Manual

GE Reason H49

60

H49/EN M/C22

Interfaces

This area displays the interface status:

Figure 38: H49 Web User Interface – Interfaces Status

Note:

The interface configuration is done in the System > Redundancy Mode page.

Each interface has a colored button and some details:

Attribute Description

Display the port type in accordance of colors.

• Red: Redundant interface Port A

• Green: Redundant interface Port B

Button color

• Blue: PRP coupling interface

• White: Standard interface

• Grey: The port is not available in the selected redundancy mode.

• Copper 10/100/1000 Mbps

Media and speed state

of interfaces X1 to X6

• Fiber 100 Mbps

• Fiber 1000 Mbps

• Green: Connected

Connection state of

interfaces X1 to X6

• Yellow: Disconnected

• Red: Disabled

These settings can be modified in the Network > Interface page.

Page 61

GE Reason H49

Technical Manual

H49/EN M/C22

61

Click a connected interface to get the status of the packets sent:

Figure 39: H49 Web User Interface – Statistics of a Connected Interface

Time Synchronization

This area displays read-only information about the device’s time synchronization

protocol.

Figure 40: Reason H49 Web User Interface – Time Synchronization Status

This information comes from the configuration done in the System > Global

Settings page.

The following attributes are also displayed according to the selected value.

Note:

when the device uses its Local clock as time source, then no other attribute is displayed in this section.

Page 62

Technical Manual

GE Reason H49

62

H49/EN M/C22

NTP attributes

Attribute Description

System's time synchronization mode:

• Disable

Mode

• Client

• Client/Server

• Server

Time synchronization status:

Status

• Synchronized

• Not synchronized

PTP attributes

Attribute Description

Synchronization mode of the system:

• Disable

• Boundary clock

Mode

• Transparent clock - E2E

• Transparent clock - P2P

A label “Slave” or “Master” indicates the current state as time

Master or Slave.

• Synchronized to a Master clock

Status

• Not synchronized to a Master clock

Grandmaster ID Grandmaster MAC address

• Atomic clock

• GPS

• Terrestrial radio

Time Source

• Hand set

• Internal oscillator

• Other

Clock Accuracy Case time error (its magnitude) between time that the

device provided a traceable time (Applicable only for PTP

clock mode)

25ns | 100ns | 250ns | 1us | 2.5us | 10us | 25us | 100us |

250us | 1ms | 2.5ms | 10ms | 25ms | 100ms | 250ms | 1s |

10s | >10s

Page 63

GE Reason H49

Technical Manual

H49/EN M/C22

63

Logs

This area displays the log messages in a Syslog format. The syslog level is divided in 4

categories: error, warning, notice and information:

Figure 41: Reason H49 Web User Interface – Logs Status

The following table gives a description of each table columns:

Attribute Description

Date & Time Date and time of log generation

Log’s severity level:

• Alert

• Critical

• Debugging

Severity

• Emergency

• Error

• Informational

• Notice

• Warning

Group name of the Syslog message defined in the Cyber

Security system specifications

• Authentication

Group

• Security

• System

• Command

Login Username at the origin of the Syslog message.

Message Message content

Page 64

Technical Manual

GE Reason H49

64

H49/EN M/C22

7.4.1.2 Global Settings

To configure the global settings of the Reason H49 switch, click Global Settings in

the System section.

Figure 42: Reason H49 Web User Interface – Logs Status

Page 65

GE Reason H49

Technical Manual

H49/EN M/C22

65

Network

The Network area allows the user to modify the usual TCP/IP network parameters.

An explanation of each configuration item is given in the following table:

Attribute Description Factory Default

Name Name of the system Undefined

VLAN ID

IP Address

Subnet Mask

Gateway

DNS

Default VLAN ID. It identifies the individual

VLANs you create on your network.

IP address in IPV4 format which identifies the

switch on a TCP/IP network.

Identifies the type of network to which the

H49 is connected.

IP address of the router that connects the

LAN to an outside network.

IP address of the DNS Server used by your

network.

192.168.254.254

255.255.0.0

(Class B network)

0.0.0.0

10.5.6.78

Time

The Time area allows the user to set the time, date and other time source attributes

for the system and the PTP settings:

Attribute Description

Timezone

Allows conversion from GMT (Greenwich Mean Time) to local time.

Use the drop-down list to select the time zone of the system.

Note:

Changing the time zone will automatically correct the current time. You should configure the time zone before

setting the time.

Synchronization

The H49 time synchronization mode can be:

• Manual (the device uses its Local clock as time source)

• NTP

• PTP

Page 66

Technical Manual

GE Reason H49

66

H49/EN M/C22

PTP Configuration

Figure 43: Reason H49 Web User Interface – PTP Settings

Set the PTP settings as detailed below:

Attribute Description Factory Default

Use the drop-down list to select the PTP switching

mode:

• Disable

Clock Mode

• Boundary clock

Transparent clock E2E

• Transparent clock - E2E

• Transparent clock - P2P

Set Reason H49 as a PTP slave-only. It means that

Slave Only

Domain Enter the PTP domain between 0 and 255 0

Priority 1

Priority 2

Step Number Select the device’s step synchronization mode. One-step

Profile

the device will not postulate as time master during

a selection campaign.

Enter the priority level to turn the H49 as the

Master clock. Priority 1 goes from 0 to 255.

Lowest values increase the probability for the

device to be elected Master clock.

Enter the priority level to turn the H49 as the

Master clock. Priority 2 goes from 0 to 255.

Lowest values increase the probability to be

elected Master clock.

Selects the PTP profile

• Default L2

Enabled

255

255

Power Profile

• Power profile

Page 67

GE Reason H49

Technical Manual

H49/EN M/C22

67

VLAN Tag

Enable or disable the VLAN tag for PTP messages.

VLAN ID

PCP ID

7.4.1.3 Redundancy Mode

Setting up communication redundancy on your network provides a backup data

transmission route in the event that the communication is lost.