Page 1

ReadyToProcess WAVE

Operating Instructions

Original instructions

™

25

Page 2

Page intentionally left blank

Page 3

Table of Contents

Table of Contents

51 Introduction ..........................................................................................................

61.1 About this manual ................................................................................................................................

71.2 Important user information .............................................................................................................

91.3 Regulatory information ......................................................................................................................

101.3.1 EU Directives ....................................................................................................................................

111.3.2 Eurasian Customs Union ............................................................................................................

121.3.3 Regulations for USA and Canada ...........................................................................................

131.3.4 Other regulations and standards ............................................................................................

151.4 Important concepts .............................................................................................................................

161.5 User documentation ...........................................................................................................................

172 Safety instructions ...............................................................................................

182.1 Safety precautions ...............................................................................................................................

262.2 Labels .........................................................................................................................................................

272.2.1 Instrument labels ...........................................................................................................................

312.2.2 Safety labels .....................................................................................................................................

332.2.3 Additional labels .............................................................................................................................

352.3 Emergency procedures ......................................................................................................................

382.4 Recycling information .........................................................................................................................

392.5 Declaration of Hazardous Substances (DoHS) ........................................................................

413 System description ..............................................................................................

423.1 System overview ...................................................................................................................................

443.2 ReadyToProcess WAVE 25 rocker .................................................................................................

523.3 ReadyToProcess CBCU .......................................................................................................................

553.4 ReadyToProcess Pump 25 ................................................................................................................

583.5 Cellbag bioreactor ................................................................................................................................

613.6 UNICORN software overview ..........................................................................................................

623.6.1 General UNICORN operation .....................................................................................................

653.6.2 Administration .................................................................................................................................

663.6.3 System control ................................................................................................................................

723.6.4 Evaluation .........................................................................................................................................

734 Installation ............................................................................................................

744.1 Site preparation .....................................................................................................................................

754.1.1 Delivery and storage ....................................................................................................................

764.1.2 Site requirements ...........................................................................................................................

814.1.3 Client computer specifications .................................................................................................

834.2 Hardware installation .........................................................................................................................

844.2.1 Unpack the system units ............................................................................................................

864.2.2 Connect the system components ...........................................................................................

904.3 Software installation ...........................................................................................................................

914.3.1 Install UNICORN software ..........................................................................................................

944.3.2 Configure an e-license .................................................................................................................

1014.3.3 Define the system ..........................................................................................................................

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 3

Page 4

Table of Contents

1035 Operation ..............................................................................................................

1045.1 Set up the system .................................................................................................................................

1055.1.1 Select the tray and Cellbag bioreactor .................................................................................

1065.1.2 Attach and detach tray ................................................................................................................

1095.1.3 Prepare pH and DO sensors ......................................................................................................

1125.1.4 Attach the Cellbag bioreactor ...................................................................................................

1145.1.5 Prepare the pump ..........................................................................................................................

1195.1.6 Connect gas to the system ........................................................................................................

1235.2 Start and configure the system .....................................................................................................

1245.2.1 Start the system and log on to UNICORN ...........................................................................

1255.2.2 Connect to the system .................................................................................................................

1275.2.3 Configure system properties .....................................................................................................

1295.2.4 Configure system settings ..........................................................................................................

1315.2.5 Start a run .........................................................................................................................................

1355.3 Prepare for cultivation ........................................................................................................................

1365.3.1 Inflate the Cellbag bioreactor ...................................................................................................

1375.3.2 Adjust pump parameters ...........................................................................................................

1385.3.3 Add and equilibrate culture medium .....................................................................................

1415.3.4 Prepare the sensors ......................................................................................................................

1445.4 Perform cultivation ..............................................................................................................................

1455.4.1 Inoculate the culture .....................................................................................................................

1465.4.2 Monitor the run ...............................................................................................................................

1485.4.3 End a run ...........................................................................................................................................

1506 Maintenance .........................................................................................................

1516.1 Calibration ................................................................................................................................................

1536.2 Cleaning ....................................................................................................................................................

1546.3 Cleaning before planned service ...................................................................................................

1557 Troubleshooting ...................................................................................................

1567.1 ReadyToProcess WAVE 25 system ................................................................................................

1577.2 ReadyToProcess WAVE 25 rocker .................................................................................................

1617.3 ReadyToProcess CBCU .......................................................................................................................

1627.4 ReadyToProcess Pump 25 ................................................................................................................

1637.5 UNICORN System Control .................................................................................................................

1658 Reference information ........................................................................................

1668.1 Chemical resistance ............................................................................................................................

1678.2 Health and Safety Declaration Form ...........................................................................................

169Index .......................................................................................................................

4 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 5

1 Introduction

About this chapter

This chapter contains important user information, the intended use of ReadyToProcess

WAVE 25, description of safety notices, and regulatory information.

In this chapter

This chapter contains the following sections:

1 Introduction

See pageSection

61.1 About this manual

71.2 Important user information

91.3 Regulatory information

151.4 Important concepts

161.5 User documentation

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 5

Page 6

1 Introduction

1.1 About this manual

1.1 About this manual

Purpose of this manual

The Operating Instructions provide you with the information needed to install, operate

and maintain the product in a safe way.

Scope of this document

This manual covers the entire ReadyToProcess WAVE 25 system,including the main unit

(rocker), CBCU and pump, as well as accessories.

Typographical conventions

Software items are identifiedin the textby bold italic text. A colonseparates menu levels,

thus File:Open refers to the Open command in the File menu.

Hardware controls, indicators and connections are identified in the text by bold text (for

example, Power switch).

Text entries that UNICORN™ generates or that the user must type are represented by a

monospaced typeface(for example, \Program Files\GE Healthcare\UNICORN\).

6 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 7

1.2 Important user information

Read the Operating Instructions

before operating the product

All users must read the entire separate Operating Instructions before installing, operating, or maintaining the product.

Always keep the Operating Instructions at hand when operating the product.

Do not operate the product in any other way than described in the userdocumentation.

If you do, you may be exposed to hazards that can lead to personal injury and you may

cause damage to the equipment.

Intended use

The ReadyToProcess WAVE 25 system is intended to be used as laboratory and manufacturing equipment for cell cultivation. The system may not be used for clinical or diagnostic purposes.

1 Introduction

1.2 Important user information

Prerequisites

In orderto follow this manual and use the system in the intended manner, itis important

that:

•

you have a general understanding of how the client computer and Microsoft®Windows®operating systems work.

•

you areacquainted with the use of general laboratory equipment and with handling

of biological materials.

•

you have read and understood the Safety instructions chapter in these Operating

Instructions.

•

the system is installed according to the instructions in these Operating Instructions.

•

a useraccount has been created according to UNICORN Administrationand Technical

manual.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 7

Page 8

1 Introduction

1.2 Important user information

Safety notices

This user documentation contains safety notices (WARNING, CAUTION, and NOTICE)

concerning the safe use of the product. See definitions below.

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could resultin death orserious injury. Itis important notto proceed

until all stated conditions are met and clearly understood.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury. It is important not to proceed until all stated conditions are met and clearly understood.

NOTICE

NOTICE indicates instructions that must be followed to avoid

damage to the product or other equipment.

Notes and tips

Note:

Tip:

8 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

A note is used to indicate information that is important for trouble-free and

optimal use of the product.

A tip contains useful informationthat can improve or optimizeyour procedures.

Page 9

1.3 Regulatory information

Introduction

This section lists the regulations and standards that apply to ReadyToProcess WAVE 25.

Manufacturing information

The table below summarizes the required manufacturing information.

In this section

1 Introduction

1.3 Regulatory information

InformationRequirement

GE Healthcare Bio-Sciences AB,Name and address of manufacturer

Björkgatan 30, SE 751 84 Uppsala, Sweden

See pageSection

101.3.1 EU Directives

111.3.2 Eurasian Customs Union

121.3.3 Regulations for USA and Canada

131.3.4 Other regulations and standards

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 9

Page 10

1 Introduction

1.3 Regulatory information

1.3.1 EU Directives

1.3.1 EU Directives

Conformity with EU Directives

This product fulfills the European Directives listed below. See the EU Declaration of

Conformity for the directives and regulations that apply for the CE marking.

If not included with the product, a copy of the EU Declaration of Conformity is available

on request.

CE marking

TitleDirective

Machinery Directive (MD)2006/42/EC

Electromagnetic Compatibility (EMC) Directive2014/30/EU

Low Voltage Directive (LVD)2014/35/EU

Restriction of Hazardous Substances (RoHS) Directive2011/65/EU

The CE marking and the corresponding EU Declaration of Conformity is valid for the instrument when it is:

•

used according to the Operating Instructions or user manuals, and

•

used in the same state as it was delivered from GE, except for alterations described

in the Operating Instructions or user manuals.

10 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 11

1.3.2 Eurasian Customs Union

Introduction

This section contains additional regulatory information to comply with the Eurasian

Customs Union technical regulations.

Manufacturer and importer

information

The table below summarizes the manufacturer and importer information required by

the Eurasian Customs Union.

ing information about importer

1 Introduction

1.3 Regulatory information

1.3.2 Eurasian Customs Union

InformationRequirement

See Manufacturing informationName and address of manufacturer

Telephone: + 46 771 400 600Telephone number of manufacturer

GE Healthcare LLCImporter and/orcompany for obtain-

GE Healthcare Life Sciences

Presnenskaya nab., 10C, 12th floor

RU-123 317 Moscow, Russian Federation

Telephone 1: + 7 495 411 9714

Fax nr: + 7 495 739 6932

Email: LSrus@ge.com

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 11

Page 12

1 Introduction

1.3 Regulatory information

1.3.3 Regulations for USA and Canada

1.3.3 Regulations for USA and Canada

NRTL certification

This symbol indicates that Ready to Process bioreactor has been certified by Intertek,

which is a US Occupational Safety and Health Administration Nationally Recognized

Testing Laboratory (NRTL).

This product Conforms to UL 61010-1, and is Certified to CAN/CSA-C22.2 No. 61010-1.

CAN ICES/NMB compliance

This product complies with the Canadian standard ICES-001/NMB-001 concerning

electromagnetic compatibility.

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must acceptany interferencereceived, including interference thatmay cause undesired

operation.

Note:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipmentgenerates, uses,and can radiateradio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

12 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

The user is cautioned that anychanges or modifications not expressly approved

by GE could void the user’s authority to operate the equipment.

Page 13

1.3.4 Other regulations and standards

Environmental conformity

This product conforms to the following environmental requirements.

TitleRequirement

1 Introduction

1.3 Regulatory information

1.3.4 Other regulations and standards

China RoHS

Standards, machinery and

electrical equipment

Standard requirements fulfilled by this product are summarized in the table below.

EN ISO 12100

EN 61010-1, IEC 61010-1,

UL 61010-1, CAN/CSAC22.2 No. 61010-1

IEC/EN 61010-2-010

EN 61326-1

Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products.

DescriptionStandard

Safety of machinery. General principles for design. Risk

assessment and risk reduction.

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 1: General

requirements.

Particular requirements for laboratory equipment for

the heating of materials

Electrical Equipment for Measurement, Control, and

Laboratory Use-EMC requirements-Part 1: General requirements

(Emission according to CISPR 11, Group 1, class A)

NOTICE

This equipmentis not intended for

use in residential environments

and may not provide adequate

protection to radio reception in

such environments.

ICES-001/NMB-001

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 13

Industrial, Scientific and Medical (ISM) Radio Frequency

Generators (Canada)

Page 14

1 Introduction

1.3 Regulatory information

1.3.4 Other regulations and standards

Software declaration of

conformity

UNICORN 6.3,7.0 and laterversions are technicallycompatible with all relevant sections

of FDA 21 CFR Part 11.

A part 11-system assessment checklist is available on request from your local GE representative.

14 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 15

1.4 Important concepts

Concepts and abbreviations used in this manual are explained in the table below.

abbreviation

1 Introduction

1.4 Important concepts

ExplanationConcept/

Cellbag™ bioreactor

DO sensor

Single mode

Dual mode

pH sensor

rocker

Tray

ReadyToProcess WAVE 25

The ReadyToProcess WAVE

25 system

The bioreactor system

The disposable container in which the cells are cultured.

Dissolved oxygen.DO

Optical sensorfor measurementof dissolved oxygen.

Attached to DO configured Cellbag bioreactors.

Operating mode with one Cellbag bioreactor on the

rocker.

Operating modewith two Cellbag bioreactors on the

same rocker. Cultivation is monitored and controlled

independently in the two bioreactors.

Optical sensor forpH measurement. Attached to pH

configured Cellbag bioreactors.

Control unit for gas mix, pH and DO control.ReadyToProcess™ CBCU

The pump.ReadyToProcess Pump 25

The rocker.ReadyToProcess WAVE 25

Tray for Cellbag, mounted on the rocker. Different

tray sizesare available for different culture capacities.

The entire bioreactor system, including rocker,

CBCU(s), andpump(s), together with Cellbagbioreactor(s) and filter heater(s).

UNICORN

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 15

The software used for controlling andmonitoring the

system.

Page 16

1 Introduction

1.5 User documentation

1.5 User documentation

The table below describes the user documentation for ReadyToProcess WAVE25, which

is available from the Help menu in UNICORN or on the user documentation CD.

Main contentsDocument

ReadyToProcess WAVE 25

Operating instructions

ReadyToProcess WAVE 25

System Handbook

ReadyToProcessWAVE25 Cue

Card

UNICORN Administration and

Technical manual

User Documentation CD

Instructions neededto install,operate andmaintain

ReadyToProcess WAVE 25 in a safe way. Includes

basic UNICORN 7.0 system control functions.

Detailed system descriptions and instructions on

how to run, maintain and troubleshoot

ReadyToProcess WAVE 25. Includes UNICORN 7.0

system control functions, method creation and

handling, togetherwith evaluationand presentation

of data.

Brief instructions providing an overview of how to

run the system.

Overview and detailed description of networksetup

and complete software installation. Administration

of UNICORN and the UNICORN database.

Dialog descriptions for UNICORN 7.0.UNICORN Online Help

CD containing the listed manuals and translated

versions of ReadyToProcess WAVE 25 Operating

instructions.

16 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 17

2 Safety instructions

About this chapter

This chapter describes safety precautions, labels and symbols that are attached to the

equipment. In addition, the chapter describes emergency shutdown procedures, and

provides recycling information.

Important

WARNING

Before installing, operating or maintaining the product, all users

must read and understand the entire contents of this chapter

to become aware of the hazards involved.

2 Safety instructions

In this chapter

This chapter contains the following sections:

See pageSection

182.1 Safety precautions

262.2 Labels

352.3 Emergency procedures

382.4 Recycling information

392.5 Declaration of Hazardous Substances (DoHS)

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 17

Page 18

2 Safety instructions

2.1 Safety precautions

2.1 Safety precautions

Introduction

ReadyToProcess WAVE 25 is powered by mains voltage andhandles materials that may

be hazardous.Before installing,operating or maintainingthe system, you must beaware

of the hazards described in this manual.

Follow the instructions provided to avoid personal injuries, damage to the cell cultures, to the product, or to other personnel and equipment in the area.

The safety precautions in this section are grouped into the following categories:

•

General precautions

•

Flammable liquids and explosive environment

•

Personal protection

•

Installing and moving the equipment

•

Power supply

•

System operation

•

Maintenance

Some of the safety precautions in this chapter concern situations that are described in

other manuals.

General precautions

WARNING

Do not operate the product in any other way than described in the

user documentation.

WARNING

Only properly trained personnel may operate and maintain the

product.

WARNING

Do not use any accessories not supplied or recommended by GE.

18 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 19

WARNING

Do not use ReadyToProcess WAVE 25 if it is not working properly,

or if it has suffered any damage, for example:

•

damage to the power cord or its plug

•

damage caused by dropping the equipment

•

damage caused by splashing liquid onto it

NOTICE

Any computer used with the equipment must comply with EN/IEC

60950-1, andbe installed and used accordingto the manufacturer's

instructions.

Flammable liquids and explosive

environment

2 Safety instructions

2.1 Safety precautions

WARNING

ReadyToProcess WAVE 25 is not designed to handle flammable

liquids.

WARNING

ReadyToProcess WAVE 25 is not approved for work in a potentially

explosive atmosphere.

Personal protection

WARNING

Always useappropriate PersonalProtective Equipment(PPE) during

operation and maintenance of this product.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 19

Page 20

2 Safety instructions

2.1 Safety precautions

Installing and moving the

equipment

WARNING

Hazardous substances. When using hazardous chemical and

biological agents, take all suitable protective measures, such as

wearing protective glasses and gloves resistant to the substances

used. Follow local and/or national regulations for safe operation,

maintenance and decommissioning of the system.

WARNING

Spread of biological agents. The operatormust take all necessary

actions toavoid spreading hazardous biological agents.The facility

must comply with the national code of practice for biosafety.

CAUTION

Heavy object. Because of the significantweight of ReadyToProcess

WAVE 25 rocker, assistance from another person is highly recommended when lifting or moving the equipment. Use the handles

on thesides of therocker when possible. Do notlift ReadyToProcess

WAVE 25 rocker with tray attached.

CAUTION

Due to the size and weight of Tray 50, at least two persons are

recommended for installing the tray.

CAUTION

Falling equipment. Do not stack more than one ReadyToProcess

CBCU and/or ReadyToProcess Pump 25 unit on top of each other.

20 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 21

Power supply

2 Safety instructions

2.1 Safety precautions

WARNING

Supply voltage. Before connectingthe powercord, make sure that

the supply voltage at the wall outlet corresponds to the marking

on the instrument.

WARNING

Protective ground. bioreactor stand-alone instruments must al-

ways be connected to a grounded power outlet.

WARNING

Only use grounded power cords delivered or approved by GE.

WARNING

Access to power switch and power cord with plug. Do not block

access to the power switch and power cord. The power switch

must always be easy to access. The power cord with plug must

always be easy to disconnect.

WARNING

Disconnect power. Always disconnect power from the equipment

before connecting the ReadyToProcessWAVE 25 units toany other

instrument.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 21

Page 22

2 Safety instructions

2.1 Safety precautions

System operation

WARNING

Suffocation hazard. ReadyToProcess WAVE 25 equipment must

only be used in locations with forced ventilation. When N2and/or

CO2are connected, make sure that:

•

the pressure overthe gasconnections does not exceed 1.5 bar.

•

the gas connections are tightly secured.

•

Inlet tubing and connections are subject to regular visual inspection.

Exceeding pressure or loose connections maycause the gas tubing

to disconnect, resulting in dangerous leakages.

WARNING

Prevent gas leakage. To prevent any gas leakage, always switch

off all gas supplies when the system is not in use.

WARNING

Fire hazard. O2leakage in combination with heat may cause igni-

tion. To avoid O2leakages, make sure that:

•

the pressure overthe gasconnections does not exceed 1.5 bar.

•

the gas connections are tightly secured. Visually inspect the

inlet tubing regularly.

CAUTION

Only Cellbagbioreactors approvedby GE for ReadyToProcess WAVE

25 may be used together with the equipment.

CAUTION

Heavy object. The filled Cellbag bioreactor is heavy and must be

lifted with care. This also applies to optional equipment such as

calibration weights.

22 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 23

2 Safety instructions

2.1 Safety precautions

CAUTION

Leakage risk of biological substances. Before every use, check

the integrity of all tubing and connections.

CAUTION

Leakage risk of biological substances. Always enter the correct

Cellbag bioreactor size in the system software settings. Failure to

do this may cause overpressure and subsequent rupture of the

Cellbag bioreactor.

CAUTION

Pinch hazard. Body parts maybe caught between therocker base

and tray.

CAUTION

Pinch hazard. Be careful not to trap any fingers between the

rocker platform and tray when repositioning Tray 10 from tilt position. Move the tray by firmly gripping both sides of the tray.

CAUTION

Pinch hazard. Moving parts in [[ProductName7]]. Do not open any

pump head flip tops during operation.

CAUTION

Falling equipment. To prevent the bioreactor system units from

accidentally being pulledfrom thebench, makesure thatall tubing

is kept inside the bench area.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 23

Page 24

2 Safety instructions

2.1 Safety precautions

Maintenance

NOTICE

If UniNet cables are disconnected during a run, the run will be interrupted and must be restarted. Make sure that cables are properly secured before starting a run and avoid moving system units

during a run.

WARNING

Electrical shock hazard. All repairs should be done by service

personnel authorized by GE. Do not open any covers or replace

parts unless specifically stated in the user documentation.

WARNING

Disconnect power. Always disconnect power from the instrument

before performing any maintenance task.

WARNING

Always clean the equipment in a well ventilated area. Never

immerse any part of the equipment in liquid or spray liquid on the

equipment. Always make sure that the equipment is completely

dry beforeconnecting to a mains powersource. Make sure to follow

all environmental, health, and safety guidelines pertaining to the

materials used.

WARNING

Use only approved parts. Only spare parts and accessories that

are approved or supplied by GE may be used for maintaining or

servicing the product.

24 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 25

2 Safety instructions

2.1 Safety precautions

CAUTION

Falling equipment. Due to pinch and crush hazards, calibration

weights should not be stacked on top of each other. Remove calibration weights before the power is turned off.

CAUTION

Hazardous substances. Before maintenance,service and decom-

missioning, clean the ReadyToProcess WAVE 25 system with an

appropriate cleaningagent to removeany hazardous substances.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 25

Page 26

2 Safety instructions

2.2 Labels

2.2 Labels

About this section

This section describes the various labels that are attached to the system units. The illustrations in this section are examples of labels found on various parts of the system. For

information aboutmarking of the client computerequipment, refer to the manufacturer's

instructions.

In this section

See pageSection

272.2.1 Instrument labels

312.2.2 Safety labels

332.2.3 Additional labels

26 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 27

2.2.1 Instrument labels

29044471 Filter Heater

Code no: 29036750

Mfg Year: YYYY/MM

Voltage: 32 V DC

Max Power: 4 W

Made in Sweden

GE Healthcare Bio-Sciences AB

751 84 Uppsala Sweden

ReadyToProcessWAVE 25 rocker

label

The following illustration shows an example of the label located on the back of the

rocker and underneath the rocker platform.

Filter heater label

The following illustration shows an example of the label attached to the filter heater.

2 Safety instructions

2.2 Labels

2.2.1 Instrument labels

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 27

Page 28

2 Safety instructions

2.2 Labels

2.2.1 Instrument labels

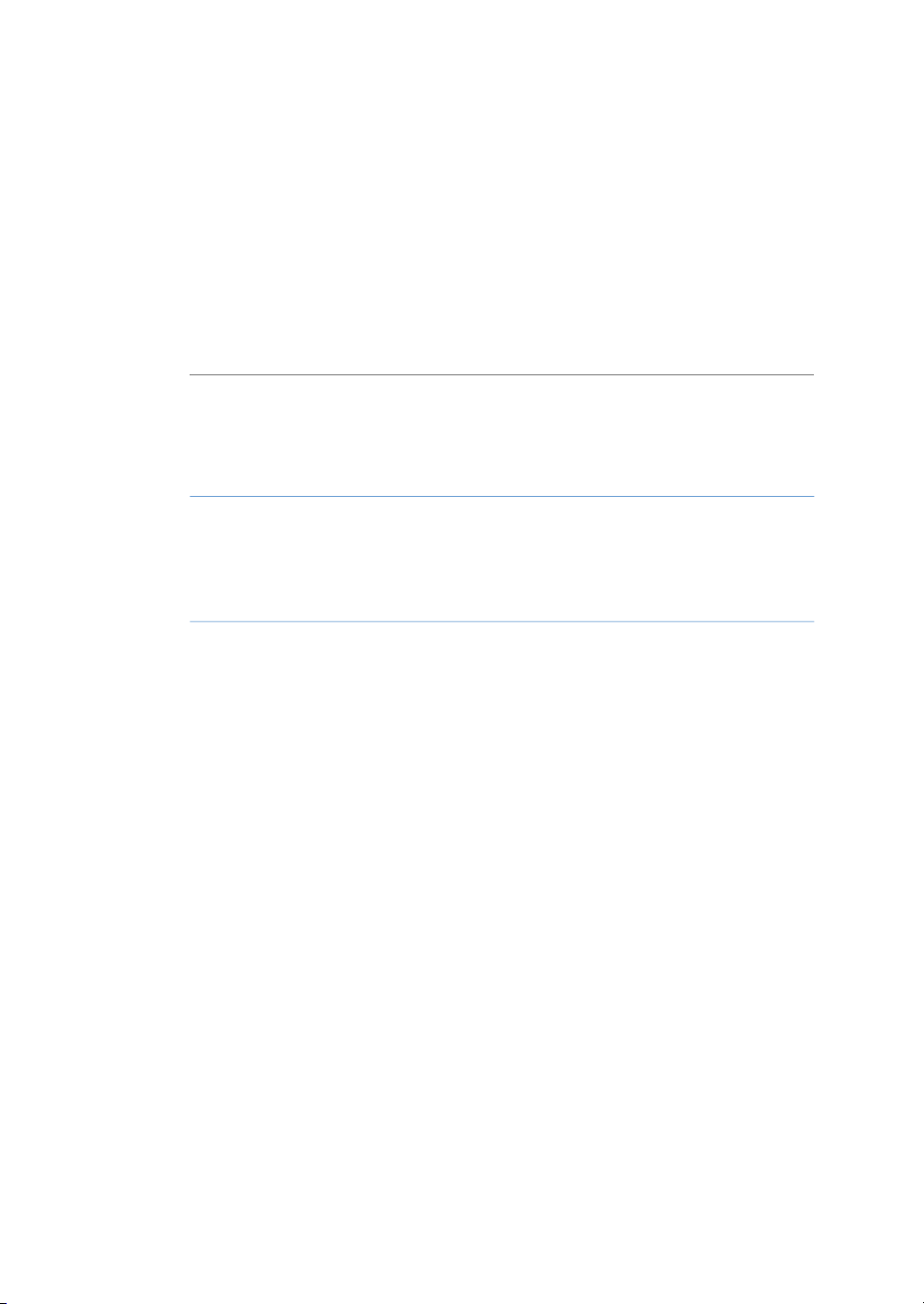

Tray and lid labels

The following illustrations show examples of the labels attached to the trays and lids.

Tray label

Lid label

ReadyToProcess CBCU label

The instrument label on the CBCU is located on the underside of theunit. The illustration

below isan example of the label attached to aCBCU with full configuration. Corresponding

labels are attached to the CBCU units with alternative configurations.

28 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 29

ReadyToProcess Pump 25 label

The following illustraton shows an example of the label located on the rear panel of the

pump.

Symbol description

The following symbols are used in the labels.

2 Safety instructions

2.2 Labels

2.2.1 Instrument labels

DescriptionLabel

Warning! Read the user documentation before using the sys-

tem. Donot open anycovers or replace partsunless specifically

stated in the user documentation.

This symbol indicates that electrical and electronic equipment

must notbe disposed of as unsorted municipal waste andmust

be collectedseparately. Please contact an authorizedrepresentative of the manufacturer for information concerning the decommissioning of equipment.

This symbol indicates that the product contains hazardous

materials in excess of the limits established by the Chinese

standard GB/T 26572 Requirements for Concentration Limits

for Certain Hazardous Substances in Electrical and Electronic

Products.

This symbolindicates thatthe systemcomplies withapplicable

European directives.

This symbolindicates thatthe systemcomplies withapplicable

requirements for Australia and New Zealand.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 29

Page 30

2 Safety instructions

2.2 Labels

2.2.1 Instrument labels

Frequency

Max. Power

DescriptionLabel

Eurasian Conformitymark: the singleconformity markindicates

that the product is approved for circulation on the markets of

the member states of the Eurasian Customs Union.

This symbol indicates that ReadyToProcess WAVE 25 hasbeen

certified by a Nationally Recognized Testing Laboratory (NRTL).

This product Conforms to UL 61010-1, and is Certified to

CAN/CSA-C22.2 No. 61010-1.

Electrical requirements:Voltage

Voltage (VAC )

•

Voltage (VDC )

•

Frequency (Hz)

•

Max. power (VA)

•

Degree of protection provided by the enclosure.Protection Class

CAN ICES-1/NMB1

Year (YYYY) and month (MM) of manufactureMfg. Year

CAN ICES-1/NMB-1 indicates that this product complies with

the Canadianstandard ICES-001 concerning technical requirements relative to radiated noise emissions from Industrial, Scientific and Medical radio frequency generators.

30 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 31

2.2.2 Safety labels

Safety labels on ReadyToProcess

WAVE 25 rocker

The following symbols can be found on the rocker.

DescriptionLabel

Warning! Read the user documentation before using the sys-

tem. Donot open anycovers or replace partsunless specifically

stated in the user documentation.

Indicates a risk for body parts getting caught between two

parts of the system andthat care must betaken to avoidinjury.

Safety labels on ReadyToProcess

Pump 25

The following symbols can be found on the pump.

2 Safety instructions

2.2 Labels

2.2.2 Safety labels

Safety labels on filter heater

The following symbols can be found on the filter heater.

DescriptionLabel

Warning! Indicates a risk for fingers getting caught between

moving partsin thepump andthat caremust be taken to avoid

injury.

DescriptionLabel

Warning! Indicates a hot surface and that care must be exer-

cised to prevent injury.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 31

Page 32

2 Safety instructions

2.2 Labels

2.2.2 Safety labels

Safety labels on tray

The following symbols can be found on the tray.

DescriptionLabel

Warning! Indicates a hot surface and that care must be exer-

cised to prevent injury.

LEFT indicates the left side of the tray.

Warning! Indicates a hot surface and that care must be exer-

cised to prevent injury.

RIGHT indicates the right side of the tray.

32 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 33

2.2.3 Additional labels

Illustration of Cellbag label

The following image is an example of the label attached to the cellbag.

2 Safety instructions

2.2 Labels

2.2.3 Additional labels

Illustration of DO sensor label

The following image is an example of the DO sensor label attached to the cellbag next

to the DO sensor.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 33

Page 34

2 Safety instructions

2.2 Labels

2.2.3 Additional labels

Illustration of pH sensor label

The following image is an example of the pH sensor label attached to the cellbag next

to the pH sensor.

Illustrations of fiber cable labels

The following image shows the label to be attached to the optical fiber cable of the DO

sensor.

The following image shows the label to be attached to the optical fiber cable of the pH

sensor.

Illustration of pump head label

The following image shows the label attached to the pump head.The label indicates the

pumping direction of the pump.

34 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 35

2.3 Emergency procedures

Introduction

This section describes how to perform an emergency shutdown of ReadyToProcess

WAVE 25. This section also describes the result in the event of power failure or network

interruption.

WARNING

Access to power switch and power cord with plug. Do not block

access to the power switch and power cord. The power switch

must always be easy to access. The power cord with plug must

always be easy to disconnect.

Emergency shutdown

In an emergency situation, stop the run in one of the following ways:

•

Stop the run from System Control by clicking the Stop icon, if UNICORN is in control

of the system.

Result: Thecurrent run isended and theinstrument will go to Ready state, indicating

that it is ready for a new run.

2 Safety instructions

2.3 Emergency procedures

.

or

•

Switch off power by pressing the Power button on the rocker front panel.

Result: The run is interrupted. The light in the Power button is turned off.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 35

Page 36

2 Safety instructions

2.3 Emergency procedures

Normal and forced shutdown

If the Power button is pressed once, a normal shutdown is performed. If the button is

pressed and held, a forced shutdown is performed.

The following table describes normal shutdown and forced shutdown.

No light: power is OFF.Green light: power is ON.

DescriptionType of shutdown

Normal shutdown: pressthe Power

button once.

Forced shutdown: press and hold

the Power button.

All processes are stopped. The system waits

for acknowledgement from the processes before shutting down the instrument.

All processes are stopped. The instrument is

shut down immediately.

Power failure

The result of a power failure or emergencyshutdown depends on which unit is affected.

will result in...Power failure to...

ReadyToProcess WAVE 25

36 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

The run is interrupted immediately.

•

The data collected before the power failure is

•

stored in the instrument and can be saved when

power returns.

Page 37

2 Safety instructions

2.3 Emergency procedures

will result in...Power failure to...

Client computer

Restart after emergency

shutdown or power failure

If System Settings:Auto start:Rocker and System Settings:Auto start:CBCU are set to

Resume activity, the following will happen when the system is re-energized:

•

The rocker and the CBCU(s) will restart using the same values as before the power

inerruption.

•

UNICORN will ask if you want to save or discard the run data collected before the

power interruption.

Note:

Data collection, media control, and regulation of pHand DO must be reinitiated

manually by reconnecting to the system and starting a new run.

Uninterruptible power supply

(UPS)

A UPS can postpone power failure, which allows time for a controlled shut-down of the

bioreactor system and prevents data loss.

For UPS power requirements, see the system specifications in ReadyToProcess WAVE 25

System Handbook. Take the specifications for the client computer and monitor into account. Refer to the manufacturers' documentation.

The cellcultivation run continueswithout interruption.

The operatorwill not, however, beable to view system

status, change settings or send manual instructions

during power failure of client computer. The software

retains the run settings when the power is restored.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 37

Page 38

2 Safety instructions

2.4 Recycling information

2.4 Recycling information

Introduction

This section contains information about the decommisioning of ReadyToProcess WAVE

25.

Decontamination

The product must be decontaminated before decommissioning. All local regulations

must be followed with regard to scrapping of the equipment.

Disposal of the product

When taking the product out of service, the different materials must be separated and

recycled according to national and local environmental regulations.

Recycling of hazardous

substances

The product containshazardous substances.Detailed information is available from your

GE representative.

Disposal of electrical

components

Waste electricaland electronicequipment must notbe disposed of as unsorted municipal

waste and must be collected separately. Please contact an authorized representative

of themanufacturer for information concerning the decommissioning of the equipment.

38 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 39

2 Safety instructions

2.5 Declaration of Hazardous Substances (DoHS)

2.5 Declaration of Hazardous Substances (DoHS)

根据SJ/T11364-2014《电子电气产品有害物质限制使用标识要求》特提供如下有关污染控制方面的

信息。

The following product pollution control information is provided according to SJ/T11364-2014 Marking

for Restriction of Hazardous Substances caused by electrical and electronic products.

电子信息产品污染控制标志说明

Explanation of Pollution Control Label

该标志表明本产品含有超过中国标准GB/T 26572 《电子电气产品中限用物质的限

量要求 》中限量的有害物质。标志中的数字为本产品的环保使用期,表明本产品

在正常使用的条件下,有毒有害物质不会发生外泄或突变,用户使用本产品不会

对环境造成严重污染或对其人身、财产造成严重损害的期限。单位为年。

为保证所申明的环保使用期限,应按产品手册中所规定的环境条件和方法进行正

常使用,并严格遵守产品维修手册中规定的定期维修和保养要求。

产品中的消耗件和某些零部件可能有其单独的环保使用期限标志,并且其环保使

用期限有可能比整个产品本身的环保使用期限短。应到期按产品维修程序更换那

些消耗件和零部件,以保证所申明的整个产品的环保使用期限。

本产品在使用寿命结束时不可作为普通生活垃圾处理,应被单独收集妥善处理。

This symbolindicates the product contains hazardous materials inexcess of the limits

established by the Chinese standard GB/T 26572 Requirements of concentration

limits for certain restricted substances in electrical and electronic products. The

number in the symbol is the Environment-friendly Use Period (EFUP), which indicates

the period during which the hazardous substances contained in electrical and electronic products will notleak or mutate under normal operating conditions so that the

use ofsuch electrical andelectronic productswill not result in any severe environmental pollution,any bodily injuryor damage toany assets. Theunit of theperiod is “Year”.

In order to maintain the declared EFUP, the product shall be operated normally according to the instructions and environmental conditions as defined in the product

manual, and periodic maintenance schedules specified in Product Maintenance Procedures shall be followed strictly.

Consumables or certain parts may have their own label with an EFUP value less than

the product. Periodic replacement of those consumables or parts to maintain the

declared EFUP shallbe done in accordance withthe ProductMaintenance Procedures.

This product must not be disposed of as unsorted municipal waste, and must be

collected separately and handled properly after decommissioning.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 39

Page 40

2 Safety instructions

2.5 Declaration of Hazardous Substances (DoHS)

有害物质的名称及含量

Name and Concentration of Hazardous Substances

产品中有害物质的名称及含量

Table of Hazardous Substances’ Name and Concentration

部件名称

Component name

本表格依据SJ/T 11364的规定编制。

This table is prepared according to SJ/T 11364.

0:

X:

•

0:

表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572规定的限量要求以下。

表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572规定的限量要

求。

此表所列数据为发布时所能获得的最佳信息.

Indicates that this hazardous substance contained in all of the homogeneous materials for

this part is below the limit requirement in GB/T 26572.

有害物质

Hazardous substance

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

OOOOOX28988000

OOOOOX29032003

OOOOOX29044213

OOOOOX29044216

OOOOOX29044081

X:

•

40 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Indicates that this hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in GB/T 26572.

Data listed in the table represents best information available at the time of publication.

Page 41

3 System description

About this chapter

This chaptergives a brief overview ofReadyToProcess WAVE25. For more detailed information, refer to ReadyToProcess WAVE 25 System Handbook.

In this chapter

This chapter contains the following sections:

3 System description

See pageSection

423.1 System overview

443.2 ReadyToProcess WAVE 25 rocker

523.3 ReadyToProcess CBCU

553.4 ReadyToProcess Pump 25

583.5 Cellbag bioreactor

613.6 UNICORN software overview

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 41

Page 42

3 System description

3.1 System overview

3.1 System overview

Introduction

ReadyToProcess WAVE 25 is intended for cell cultivation.

A disposable Cellbag bioreactor is placed on a rocker and filled with gas, partially filled

with culture medium, and inoculated with cells. Gas transfer and mixing of culture is

accomplished by wave-induced agitation, performed by the rocker unit.

The cell culture volume range per Cellbag bioreactor is 0.3 to 25 L depending on bioreactor size, and working volume may be expanded up to 10 times during one cultivation.

The system, composed of the rocker, ReadyToProcess CBCU andReadyToProcess Pump

25, enables measurement and control of pH, DO, weight and media distribution, and

provides different gas flow and gas mixing possibilities.

•

In single mode, the system supports culture in one Cellbag bioreactor at one time.

The rocker is connected to one ReadyToProcess CBCU and up to three

ReadyToProcess Pump 25 units.

•

In dual mode, the system supports culture in two Cellbag bioreactors placed on the

same tray. Therocker is connected to up to two ReadyToProcess CBCU units and up

to threeReadyToProcess Pump 25units for independentcontrol ofculture conditions

in the two bioreactors.

The system is controlled from a PC running UNICORN software version 7 or later. The

system can also be controlled from a supervisory control and data acquisition (SCADA)

system, such as the Emerson DeltaV™ control system, using the integrated OPC server.

Contact GE for instructions and guidance for OPC.

42 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 43

Illustration of the system

1 432

58 7 6

The illustration below shows the main system units for use in single mode with one

ReadyToProcessPump 25. Dual mode usestwo ReadyToProcessCBCU unitsfor controlling

the two Cellbag bioreactors independently. Both single and dual modes can support up

to three ReadyToProcess Pump 25 units.

3 System description

3.1 System overview

DescriptionPart

Hatch1

Filter heater2

Cellbag bioreactor3

ReadyToProcess Pump 254

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 43

ReadyToProcess CBCU5

ReadyToProcess WAVE 25 rocker6

Tray7

Lid8

Page 44

1

3

4

5

2

3 System description

3.2 ReadyToProcess WAVE 25 rocker

3.2 ReadyToProcess WAVE 25 rocker

Introduction

The rocker is the main unit of the system. Through the rocker, weight is measured, and

temperature, rocking speed, rocking angle and rocking motion are controlled.

The rocker contains four load cells for monitoring the weight of the Cellbag bioreactor

and content. The placement of the load cells allows independent weight measurement

of the two Cellbag bioreactors in dual mode.

The rocker also contains an embedded microprocessor, which allows the system to be

controlled independently of the performance of the connected network and client

computer.

For specifications of the rocker, refer to the ReadyToProcess WAVE 25 System Handbook

or the data file for ReadyToProcess WAVE 25, available for download from

www.gelifesciences.com/wave.

Front view of the rocker

The illustration below shows the front view of the rocker.

44 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 45

3 System description

3.2 ReadyToProcess WAVE 25 rocker

DescriptionPart

Rocker platform1

Temperature sensors2

Rocker base3

Power button4

Location of adjustable foot5

Power button

The Power button indicates the status of the rocker according to the list below.

DescriptionImageLight indicator

The power is OFF.No light

The rocker is starting up.Green flashing light

Green steady light

The poweris ON andthe rocker is operational.

Red flashing light

The rocker failed to connect to other

components in the system.

Indicates an error of the rocker.Red steady light

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 45

Page 46

1 2 4

3

5 6 7

3 System description

3.2 ReadyToProcess WAVE 25 rocker

Adjustable foot

The adjustable foot is placed in the front right corner of the rocker base when viewed

from the front. It is used to distribute weight evenly over the four rocker feet.

Use the supplied adjustable foot wrench to adjust the foot.

Rear view of the rocker

The illustration below shows the rear panel of the rocker.

DescriptionPart

15-pin D-sub connector, used for digital and analog I/O signals1

Filter heater connectors2

Tray connector3

UniNet-9 ports4

USB ports5

Ethernet connector6

7

46 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Power connector

Note:

The rocker is fitted with internal electrical fuses that arenot user-replaceable.

Page 47

Tray and lid sizes

1

2

3

4

Trays and lids are available in the different sizes listed below:

Illustrations of tray and lid

The illustration below shows the rocker with Tray 50 attached.

3 System description

3.2 ReadyToProcess WAVE 25 rocker

LidsTrays

Lid 10Tray 10

Lid 20Tray 20

Lid 50Tray 50

DescriptionPart

Bag clamp (upper)1

Bag clamp opener (one in each upper corner)2

Bag clamp opener (one in each lower corner)3

Bag clamp (lower)4

The illustration below shows the rocker with Tray 50 and Lid 50 mounted.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 47

Page 48

54

3

2

1

3 System description

3.2 ReadyToProcess WAVE 25 rocker

DescriptionPart

Rocker base1

Lid2

Tray3

Tubing exit4

Hatch5

48 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 49

Prepare for tilt

When the system enters END mode, the tray prepares for tilt if System Settings:Rocker:Prepare for tilt at END is set to Yes. This moves the rocker to the mechanical end

position, which is 14 degrees from horizontal. This position can also be set by executing

the manual instruction Rocker:Prepare for tilt. See illustration below.

Tilt position

In order to facilitate tray change in system setup and sampling and harvest during and

after cell cultivation, it is possible to position the tray with the attached Cellbag bioreactor(s) into an upright position called tilt position. Follow the instructions below to put the

tray into tilt position.

The tray is shown without attached Cellbag bioreactor in the images below.

3 System description

3.2 ReadyToProcess WAVE 25 rocker

NOTICE

Take care when tiltingthe rocker tray with fullCellbag bioreactor(s)

attached.

ActionStep

1

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 49

Prepare for tilt as described above or select the largest possible angle in

UNICORN. Do not tilt the tray from an angle lower than 12°.

Page 50

1

2

3

3 System description

3.2 ReadyToProcess WAVE 25 rocker

ActionStep

2

Hold thetextured grip area on eachside of thetray and pullthe tray towards

you.

The illustration below shows the tilt position:

Filter heater

The filter heater prevents condensation and clogging of the outlet vent filter on the

Cellbag bioreactor.

50 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 51

3 System description

3.2 ReadyToProcess WAVE 25 rocker

DescriptionPart

Filter heater1

Connector for connection to the rocker2

Filter heater stand3

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 51

Page 52

1

4

2

3

3 System description

3.3 ReadyToProcess CBCU

3.3 ReadyToProcess CBCU

Introduction

The control unit, ReadyToProcess CBCU, is connected to the rocker via a UniNet-9 connector. The full configuration mixes air/N2, O2, and CO2gas, and contains O2and CO

sensors, a mass flow controller, an optical pH sensor reader, and an optical DO sensor

reader. Three configurations are available:

•

ReadyToProcess CBCU pH: CO2, O2and pH.

•

ReadyToProcess CBCU DO: CO2, O2and DO.

•

ReadyToProcess CBCU Full: CO2, O2, pH and DO.

For specifications of the CBCU, refer to the ReadyToProcess WAVE 25 System Handbook

or the data file for ReadyToProcess WAVE 25, available for download from

www.gelifesciences.com/wave.

Front view of ReadyToProcess

CBCU

The illustrationbelow shows thefront panel of a fullyconfigured CBCU. The configuration

of your CBCU may vary from the configuration shown below.

2

52 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 53

1

2

3

6

5

4

3 System description

3.3 ReadyToProcess CBCU

DescriptionComponentPart

Connector for pH sensor fiber cable.pH port1

Gas outlet for connection to Cellbag bioreactor.GAS MIX OUT2

Indicates the CBCU operating status.Status LED3

Connector for DO sensor fiber cable.DO port4

Status LED

The status LED indicates the CBCU operating status according to the following table.

DescriptionLight indicator

The CBCU is ready for operation.Steady green light

The CBCU is operating.Green flashing light

Indicates an internal error, but the CBCU is still operating.Red flashing light

Indicates an internal error, and the CBCU is not operating.Steady red light

Rear view of ReadyToProcess

CBCU

The illustration below shows the rear panel of a fully configured CBCU.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 53

Page 54

3 System description

3.3 ReadyToProcess CBCU

DescriptionComponentPart

Power connection to the rocker.UniNet-9 port1

Indicates system connection status.CAN indicator LED2

CAN ID switch3

CAN ID

The CAN ID is a unit number used by UNICORN to recognize the CBCU that is connected

to the system.

The CAN ID is set by turning a switch on the CBCU rear panel (see illustration above). The

CAN ID should always be set to position 1 for use in single mode. For dual mode, set the

CAN ID to 1 for the CBCU connected to the left Cellbag bioreactor, and to 2 for the CBCU

connected to the right Cellbag bioreactor.

Tubing and connectors

Tubing andconnectors for gas flow aslisted below are deliveredwith the ReadyToProcess

CBCU. Tubing and connectors for liquid flow must be obtained separately.

Tubing

Switch for setting the CBCU unit number for system

recognition.

Inlet connection for O2supply.O2 IN4

Inlet connection for CO2supply.CO2 IN5

Inlet connection for air or N2supply.AIR/N26

LengthOuter diameterInner diameterItem

147.6" (375 cm)1/4" (6.4 mm)1/8" (3.2 mm)Tygon™ E3603

7.9" (20 cm)3/8" (9.5 mm)3/16" (4.8 mm)Silicone

Connectors

Inner diameterItem

1/8" to 3/16" (3.2 to 4.8 mm)Reducer connector, gas tubing

1/8" (3.2 mm)Connector, CBCU

54 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 55

3.4 ReadyToProcess Pump 25

1

2

3

Introduction

The ReadyToProcess Pump 25 is a peristaltic pump unit that includes two roller pump

heads. The function of a given pump head is set in the UNICORN software. Up to three

pump units are supported in both single and dual mode.

For specifications of the pump, refer to the ReadyToProcess WAVE 25 System Handbook

or the data file for ReadyToProcess WAVE 25, available for download from

www.gelifesciences.com/wave.

Front view of the pump

The illustration below shows the front panel of the pump.

3 System description

3.4 ReadyToProcess Pump 25

DescriptionPart

Pump head flip top1

Pump head2

Status LEDs for pumping function per pump head3

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 55

Page 56

3

2

1

3 System description

3.4 ReadyToProcess Pump 25

Status LEDs

The status LEDs indicate the pumping function status according to the following table.

DescriptionLight indicator

The pumping function is ready for operation.Steady green light

Pumping is ongoing.Green flashing light

Indicates an internal error, but the pump is still operating.Red flashing light

Steady red light

Rear view of the pump

The illustration below shows the rear panel of the pump.

Indicates an internal error, and the pump is not operating

properly.

DescriptionComponentPart

Power connection to the rocker.UniNet-9 port1

Indicates system connection status.CAN indicator LED2

CAN ID switch3

56 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Shows the unit number of the pump for recognition

by the system.

Page 57

CAN ID

3 System description

3.4 ReadyToProcess Pump 25

The CAN ID is a unit number used by UNICORN to recognize the particular pump unit

that is connected. If more than one pump unit is connected, the units are distinguished

by their CAN IDs.

The CAN ID is set by turning a switch on the pump rear panel (see illustration above).

The switch has four CAN ID positions, marked 1, 2, 3, and 4, respectively. The CAN ID

should be set to position 1 for the first pump, position 2 for the second pump and so on.

Tip:

The pumps are identified in UNICORN by their CAN ID. Label each pump unit

with its CAN ID to simplify identification of the physical pump.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 57

Page 58

3 System description

3.5 Cellbag bioreactor

3.5 Cellbag bioreactor

Introduction

Cell cultivation is performed inside the Cellbag bioreactor. The Cellbag bioreactor is delivered gamma irradiated and ready for use. It is intended for single use only and should

be discarded after use.

Cellbag bioreactor options

The Cellbag bioreactors are available in different configurations, of varying sizes and

equipped with various ports. Cellbag bioreactors with internal cell retention filters are

available for perfusion culture. If required, it is possible to customize the Cellbag bioreactors. The following bag sizes are available for ReadyToProcess WAVE 25:

•

2 L

•

10 L

•

20 L (single mode only)

•

22 L

•

50 L (single mode only)

58 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 59

Illustration of Cellbag bioreactor

1

678

5432

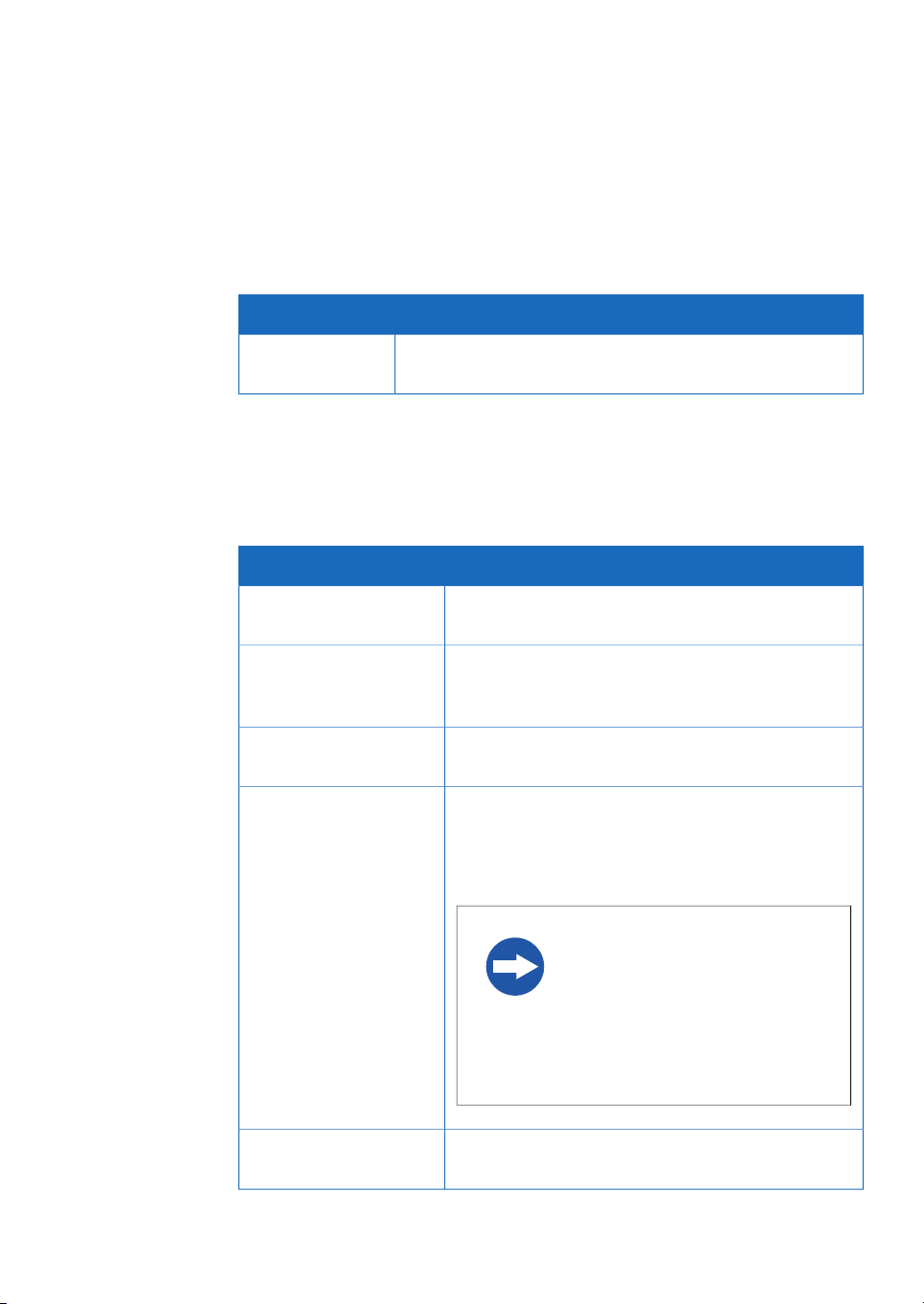

9

The illustration shows a general Cellbag bioreactor. The configuration of your Cellbag

bioreactor may vary from the configuration shown below.

3 System description

3.5 Cellbag bioreactor

DescriptionPart

pH bag sensor port, located on the underside of the bag1

Outlet vent filter with pressure control valve2

Inlet vent filter3

Addition port4

DO bag sensor port, located on the underside of the bag5

Cellbag rod6

Clave™ sampling port7

Note:

Addition port8

Addition/harvest port9

The inlet and outlet vent filters are distinguished by the pressure control valve

on the outlet filter.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 59

Page 60

1

2

3 System description

3.5 Cellbag bioreactor

pH and DO sensors

The Cellbag bioreactor may be equipped with optical sensors for monitoring pH and

dissolved oxygen (DO). The sensors are light sensitive and should be protected from excessive light. The sensors are located in the center of a sensor port on the Cellbag

bioreactor and must be coupled to a sensor adapter, see table below.

DescriptionPart

Bag sensor

port

Sensor

adapter

The sensor port is located onthe underside ofthe Cellbag bioreactor.

The actual sensor (white/yellow for pH, pink/black for DO is located

in the center (1) of the sensor port, see image below.

The sensor adapter is attached to the sensor port by the four pins (2).

The sensor adapter is located at one end of an optical fiber cable.

The opticallens of thefiber cable islocated in thecenter of thesensor

adapter. The fiber cable is connected to a sensor reader in the CBCU.

The fiber cable is connected to the pH or DO port on the CBCU front

panel.

60 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 61

3.6 UNICORN software overview

In this section

This section gives an overview of the general operation of the UNICORN software: a

complete package for control, supervision and evaluation of cell cultivation runs. It also

describes how to access the help utility that is included in UNICORN.

This section contains the following subsections:

3 System description

3.6 UNICORN software overview

See pageSection

623.6.1 General UNICORN operation

653.6.2 Administration

663.6.3 System control

723.6.4 Evaluation

Note:

Software illustrations in these instructions are examples, and may differ from

your software in some details.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 61

Page 62

3 System description

3.6 UNICORN software overview

3.6.1 General UNICORN operation

3.6.1 General UNICORN operation

UNICORN modules overview

UNICORN consists of four modules: System Control, Evaluation, Administration and

Method Editor.

The main functions of the modules are described in the table below.

Main functionsModule

Start, view and control runs.System Control

Open results, evaluate runs and create reports.Evaluation

Administration

Enter a UNICORN module

To enter a module:

•

click the Taskbar button of the module of interest,

or

•

choose themodule of interest in the Tools menu in any of the othersoftware modules.

The illustration below shows the Tools menu of the Evaluation module.

Perform userand systemsetup, systemlog and database

administration.

Create and edit methods.Method Editor

62 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 63

Access the help utility

A comprehensive help utility is included in the UNICORN software. The table below describes how to access the different parts of the help utility.

a UNICORN module

3 System description

3.6 UNICORN software overview

3.6.1 General UNICORN operation

then...If you want to...

select Help:Help for... in the UNICORN module of interestfind information about

find information about

the itemcurrently selected and in focus (e.g., a

pane, a dialog, or a

method phase)

navigate theonline help

search for a specific

term in the online help

access manuals in PDF

format

press theF1 key with theitem of interest selectedand

•

in focus

or

click the Help icon in the open dialog

•

select Help:Helpfor... in anyof the UNICORN modules

•

(see illustration above)

in the TOC (Table of contents) pane, expand the

•

headings ofinterest tonavigate the content structure

click the heading of interest to open a section

•

select Help:Helpfor... in anyof the UNICORN modules

•

(see illustration above)

in the Search pane, enter the term of interest in the

•

input field

click the Search button

•

select Help:Helpfor... in anyof the UNICORN modules

•

(see illustration above)

in the TOC pane, expand the heading UNICORN 7.0

•

online documentation portal and select Documentation overview

in the PDF manuals section, click one of the text links

•

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 63

Page 64

3 System description

3.6 UNICORN software overview

3.6.1 General UNICORN operation

an instruction

then...If you want to...

In the Method Editor module:find information about

open a method

•

select theinstruction of interest in theInstruction box

•

in the Text instruction pane

press the F1 key

•

In the System Control module:

select Manual:Execute Manual Instructions

•

expand aheading and select the instruction of interest

•

press the F1 key

•

or

click the Help icon in the dialog

64 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 65

3.6.2 Administration

Introduction

The Administration module is used to manage all functions of the UNICORN software.

Refer to UNICORN Administration and Technical manual for more information.

Icons in the Administration

module

The table below shows the Administration module icons.

FunctionIcon

User Setup is used to manage user access to UNICORN.

Access Groups and Network Users is used to manage access groupsand

network users.

3 System description

3.6 UNICORN software overview

3.6.2 Administration

E-mail Setup is used to set up an e-mail account for automated system

messages.

UNICORN and System Log providesthe system administrator with records

of usage and activity.

System Properties isused to define thesystem and editsystem properties.

Database Management is used for maintenance of the database.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 65

Page 66

3 System description

3.6 UNICORN software overview

3.6.3 System control

3.6.3 System control

Introduction

The System Control module is used to start, view, and control a manual or method run.

System Control panes

As illustrated below, two tabs are available in the System Control module by default.

The Process Picture tab allows manual interactions with the system and provides

feedback on run parameters. The Chart tab shows a graphical presentation of data

throughout therun. Process picture, charts, runlogs, and rundata can be displayedeither

as separate tabs or as docked panes in the same window.

Refer to Section 5.4 Perform cultivation, on page 144 for information on how to perform

a run.

Tip:

To get more information than isshown in the Process Picture, select View:Run

Data to open the Run Data pane which presents current data in numerical

values.

Items in the process picture reflect the components includedin the system(for example,

the illustration above shows a system in single mode equipped with three pumps).

66 ReadyToProcess WAVE 25 Operating Instructions 29009597 AD

Page 67

3 System description

3.6 UNICORN software overview

3.6.3 System control

In dual mode, the process picture shows two Cellbag bioreactors on the rocker picture,

with separatecontrol iconsfor the individually controlled parameters in each bioreactor.

Icons for the left-hand bioreactor are in the upper half of the process picture and icons

for the right-hand bioreactor in the lower half.

Identifying system components in the process picture

This section describes how to identify the units in the process picture with respect to the

Cellbag bioreactors in single and dual mode.

•

The left-and right-hand Cellbag bioreactorsin dual mode are controlledby the CBCU

units with CAN ID 1 and 2 respectively. They are shown on the left and right sides of

the tray in the process picture. To avoid confusion, place the physical CBCU units on

the left and right sides of the tray as viewed from the front of the rocker.

•

Connections betweenthe Cellbag bioreactor(s) and therespective monitorand active

control units are indicated by connection lines in the process picture.

•

Pump units are identified in the process picture as 1, 2 or 3 according to their CAN

ID setting, and the pump heads on each unit are designated A (left) and B (right).

In dual mode, pump rolesfor the leftand right Cellbagbioreactors are labelled L and

R respectively.

Examples:

Pump 25: 1B refers to the right-hand pump head on the pump unit with CAN ID 1.

ReadyToProcess WAVE 25 Operating Instructions 29009597 AD 67

Page 68

3 System description

3.6 UNICORN software overview

3.6.3 System control

Pump 25: 2A refers to the left-hand pump head on the pump unit with CAN ID 2.

Tip:

Label the CBCU and pump unitswith their CANID settings to simplify correlation

of the physical units with the process picture.

In dual mode, place the pumps connected to the left and right Cellbag bioreactors on the left and right sides of the rocker respectively.

Actions in the Process Picture

pane

It is possible to interact with the Process Picture pane in the following ways:

then...If you want to...

Activate or deactivate

pH and DO measurement and control

Activate or deactivate

other functions

Hold the cursor over the right-hand side of the button,

and turn Reading and/or Control on or off as required.

You can only switch the Control setting if Reading is on,

and you cannot turn Reading off if Control is on.

Click on the right-hand side of the button. The text on the

button shows the current value of the function.