GE Lumination RC Series, RC6, Lumination RX Series, Lumination LRC Series, LRC6 Installation Manual

...Page 1

Installation Guide

LuminationTM LED Luminaire

RC/LRC/RX/LRX Series - New Construction Frame

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING/AVERTISSEMENT

RISK OF ELECTRIC SHOCK

• Turn power off before inspection, installation or removal.

• Properly ground electrical enclosure.

RISK OF FIRE

• Follow all NEC and local codes.

• Use only UL approved wire for input/output connections.

Minimum size 18 AWG or 14 AWG for continuous runs.

RISQUES DE DÉCHARGES ÉLECTRIQUES

• Coupez l’alimentation avant d’’inspecter, installer ou déplacer le luminaire.

• Assurez-vous de correctement mettre à la terre le boîtier d’alimentation électrique.

RISQUES D’INCENDIE

• Respectez tous les codes NEC et codes locaux.

• N’utilisez que des ls approuvés par UL pour les entrées/sorties de

connexion. Taille minimum 18 AWG ou 14 AWG pour les rangées continues.

NOTICE

Lamp Housings RC6, RC8 or LRC6, LRC8 or RX6, RX8 or LRXR4, LRXR6, LRXR8 may be assembled with part FRAMExR. When Lamp Housings RC6,

RC8 or LRC6, LRC8 or RX6, RX8 or LRXR4, LRXR6, LRXR8 is assembled with Part FRAMExR the nal assembly complies with UL 1598 category IFAO

recessed luminaire requirements. LRX products are suitable for wet location covered ceiling only.

Les boîtiers de lampes RC6, RC8 ou LRC6, LRC8 ou RX6, RX8 ou LRXR4, LRXR6, LRXR8 peuvent être montés avec la pièce FRAMExR. Lorsque les

boîtiers des lampes RC6, RC8 ou LRC6, LRC8 ou RX6, RX8 ou LRXR4, LRXR6, LRXR8 sont montés avec la pièce FRAMExR, le montage nal respecte

les exigences des luminaires encastrés de la catégorie IFAO de la norme UL 1598. LRX produits conviennent pour emplacement humide couverte

au plafond uniquement.

Save These Instructions

Use only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

Prepare Electrical Wiring

Electrical Requirements

The LED luminaire must be connected to the mains

supply according to its ratings on the product label.

Grounding Instructions

The grounding and bonding of the overall system

shall be done in accordance to local electric code of

the country where the luminaire is installed.

1

Page 2

1

2 3 4

5

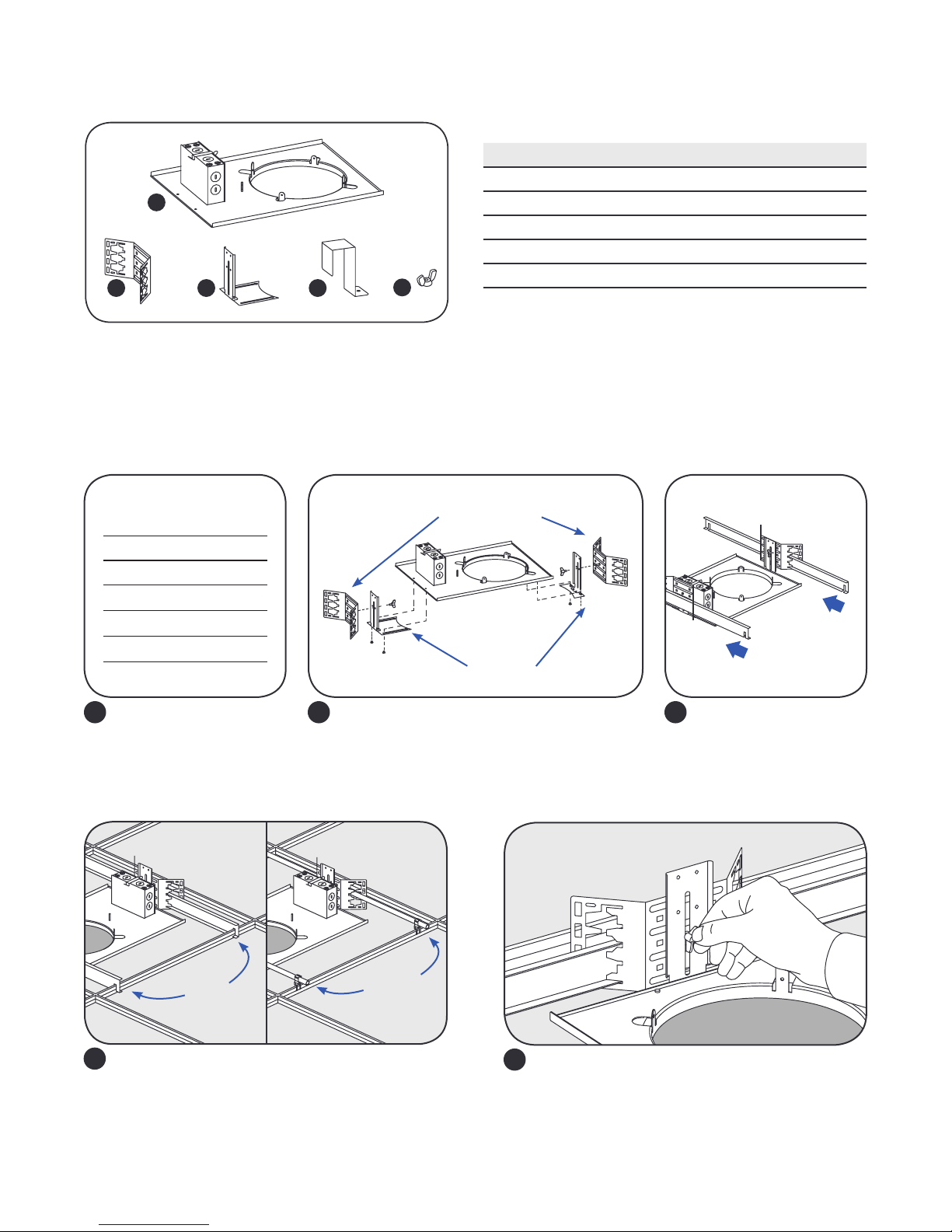

Components

Frame Installation

Provided Item Qty.

1 Frame (4-inch, 6-inch or 8-inch) 1

2 Mounting brackets 2

3 L-Bracket 2

4 U-Bracket (used only with RC/LRC Series Installs) 1

5 Wing nut 3

NOTE: Part 4 and 5 are only for RC/LRC product.

Fixture

Diameter

LRXR4 4.9–5.2 in.

RC6/LRC6 6.4–7.2 in.

RX6/LRXR6 5.91–6.60 in.

RC8/LRC8 7.5–8.9 in.

RX8/LRXR8 7.68–8.27 in.

Cut the appropriate size

1 2

hole into ceiling tile.

Hole

Diameter

Mounting brackets

L-brackets

Place side L-brackets on existing frame screws

and tighten with screwdriver on both sides of

the frame. Then attach mounting brackets to

both L-brackets with wing nuts (provided).

Adjust height and

tighten wing nut

Slide hanger bars through

3

adjustable mounting

brackets.

Bars

A B

Option A: Mount xture by attaching hanger bars

4

to T-Grid ceiling (BH3 SKU 94890).

Option B: Mount xture with ½” EMT conduit.

Note: Supplied by 3rd party.

Conduit

Adjust xture height to be ush with ceiling and

5

tighten both mounting bracket wing nuts.

2

Page 3

RC/LRC-Series Mounting

(RX-Series Mounting skip to step 15. LRXR-Series Mounting skip to step 18)

Through Wiring for RC-series 15A Circuit

Lumen Level

Maximum Number of Fixtures

(120V Input / 277V Input)

Minimum Spacing Requirements

for all Fixture Congurations

1000 84 / 195

1500 77 / 179

2000 59 / 138

3000 38 / 89

Center to center of adjacent luminaires 24”

Top of Luminaire to overhead building member 3”

Luminaire center to side building member 12”

4000 24 / 57

(For any other information refer to RC-series or LRC-series Installation Guides)

Remove cover

AC conduit

Screwdriver tip

Remove

AC wires

Open RC or LRC PSU box cover, disconnect AC conduit. Remove AC conduit wire from PSU box knockout hole using

6

at head screw driver.

AC line (Line, Neutral and Ground)

Insert AC line wires into the PSU box through

7

the knockout hole and connect wires (see wiring

diagrams at right).

LRC Wiring Diagram

Black /Red (+) Lead

White (-) Lead

TPC

Blue (+) Lead

*NOTE:

Black Lead - 120V ONLY

Red Lead - 277V ONLY

RC Wiring Diagram

Black (+) Lead

White (-) Lead

TPC

*Blue/Red (+) Lead

*NOTE:

Blue Lead - 120V ONLY

Red Lead - 277V ONLY

L N G

(0-10V) Purple (+) Dimming Lead

(0-10V) Grey (-) Dimming Lead

L N G

(0-10V) Purple (+) Dimming Lead

(0-10V) Grey (-) Dimming Lead

PSU Enclosure

White (-) Lead

Black (+) Lead

PSU Enclosure

Black (+) Lead

DRIVER

DRIVER

3

Page 4

Loop around

L-bracket

Wing nut

Place PSU box onto frame next to unused junction

8 9

U-bracket

box and secure with U-bracket by tightening wing nut.

Safety

tether

Feed button stop

and toggle through

hole in bracket

Toggle

Button stop

Attach the other end of the safety tether to the

1110

xture using one of the three holes located on the

xture brackets. Feed the button stop and toggle

through the hole and slide into the hole in the

bracket. Allow the xture to hang freely .

Take the provided safety tether and loop one end

of the tether around the L-bracket.

Connect two

quick connects

Assembled connector

housing

Plug together the light xture to the driver enclosure

with the supplied quick connects and assemble the

connector housing when nished.

Cut cable tie on light xture.

12

Position xture so

L-bracket does not

interfere with springs

Align the xture so that two of the three springs are

13

on each side of the L-bracket. This is necessary in

order to make sure that when the springs release,

the L-bracket does not interfere and prevent the

springs from making contact with the top of the

ceiling for proper support.

4

Page 5

installation

position for

14

Push xture through the hole in the ceiling. This will

engage the protruding arms, thus, releasing the

springs. The springs will draw the xture up into the

ceiling and hold it their tightly.

RX-Series Mounting

Final

springs

CAUTION

RISK OF PERSONAL INJURY - Operators shall ensure no

appendages are in the path of the torsion springs

as they are a pinch hazard when released. The

springs will release when the arm is exed downward.

Be cautious that no body part is in the path of the

spring when released.

RISQUE DE BLESSURE CORPORELLE - Les techniciens

veilleront à ce qu’aucun appendice ne se trouve sur

le chemin des ressorts de torsion, car ils présentent

un risque de pincement lorsqu’ils sont libérés. Les

ressorts seront libérés au moment de échir le bras vers

le bas. Faites attention à ce qu’aucune partie du corps

ne se trouve sur le chemin du ressort à sa libération.

Wiring Diagram

Line (black)

Neutral (white)

Ground (green)

AC line

Connect AC line to existing junction box. Connect conduit tting to the existing junction box. Connect the black,

15

Black

White

Green/Yellow

DRIVER

white and green/yellow wires of the input leads to the black, white and green AC line wires using UL Listed twist-on

wire connectors and close the junction box (see wiring diagram).

Springs up

Connect plugs

16

Connect the two quick connectors and reassemble

the connector box.

Reassembled

connector box

17

Load springs into upright position by twisting the

springs upward and carefully insert the xture to

the hole of the frame. Ensure xture is secure.

RISK OF PERSONAL INJURY - Operators shall ensure no appendages are in the path of the torsion springs as they are a pinch hazard when

released. The springs will release when the arm is exed downward. Be cautious that no body part is in the path of the spring when released.

RISQUE DE BLESSURE CORPORELLE - Les techniciens veilleront à ce qu’aucun appendice ne se trouve sur le chemin des ressorts de torsion, car

ils présentent un risque de pincement lorsqu’ils sont libérés. Les ressorts seront libérés au moment de échir le bras vers le bas. Faites attention à

ce qu’aucune partie du corps ne se trouve sur le chemin du ressort à sa libération.

CAUTION

5

Page 6

LRX-Series Mounting

Wiring Diagram

AC line

Connect conduit end with input leads to existing

18

junction box and make proper connections. Connect

the black, white, and green/yellow wires of the input

leads to the black, white and green wires using twiston wire connectors and close junction box.

Optional dimmer: When connecting with dimming

controller, wires must be run through another

separate knockout hole. Connect the violet (dimming

+) and gray (dimming -) wires to the violet and gray

wires of the xture.

NOTE: Please cover dimming leads with wire nuts if

you won’t connect with dimming leads.

Dimming compatibility for both 0-10V and phase cut,

please refer to GE website:

www.gelighting.com/dimming.

L

N

Dimming +

Dimming –

Ground

0-10 Volt Dimming

LED

Driver

Gray

Violet

Black

White

Violet

Gray

Green/Yellow

0-10V –

0-10V +

LRX

Fixture

To 0-10V

Dimmer

Lumens Setting Switch

NOTE: For 1000/650lm and 4000/3000lm, default output lumen is 1000lm and 4000lm respectively. Push switch up or

left to activate 650lm and 3000lm respectively.

6

Page 7

Springs up

Connect plugs:

3 pole to 3 pole

2 pole to 2 pole

19

Connect the two quick connectors and

reassemble the connector box.

Reassemble

connector box

20

Load springs into upright position by twisting the

springs upward and carefully insert the xture to

the hole of the frame. Verify reector trim is ush

with ceiling.

CAUTION

RISK OF PERSONAL INJURY - Operators shall ensure no

appendages are in the path of the torsion springs

as they are a pinch hazard when released. The

springs will release when the arm is exed downward.

Be cautious that no body part is in the path of the

spring when released.

RISQUE DE BLESSURE CORPORELLE - Les techniciens

veilleront à ce qu’aucun appendice ne se trouve sur

le chemin des ressorts de torsion, car ils présentent

un risque de pincement lorsqu’ils sont libérés. Les

ressorts seront libérés au moment de échir le bras vers

le bas. Faites attention à ce qu’aucune partie du corps

ne se trouve sur le chemin du ressort à sa libération.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesired operation. CAN ICES-005 (A) / NMB-005 (A).

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

All trademarks are the property of their respective owners. Information provided is subject to

change without notice. All values are design or typical values when measured under laboratory

conditions. Current, powered by GE is a business of the General Electric Company.

© 2018 GE.

www.currentbyge.com

IND259 (Rev 08/15/18) GE2029-8519

Loading...

Loading...