Page 1

Installation Instructions

for your new

RAK204U, RAK204E15, RAK204E20,

RAK204E30, RAK204D15P, RAK204D20P,

RAK204D30P, RAK204D15PA, RAK204D15C,

RAK204D20PA, RAK204D20C, RAK204D30PA,

RAK204D30C

Sub-base

Before you begin - Read these instructions completely and carefully.

IMPORTANT – OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer – Be sure to leave these instructions with the Consumer.

Note to Consumer – Keep these instructions with your Owner’s Manual for future reference.

Tools Needed

• 5/16" nut driver

• Pliers

• Slotted screwdriver

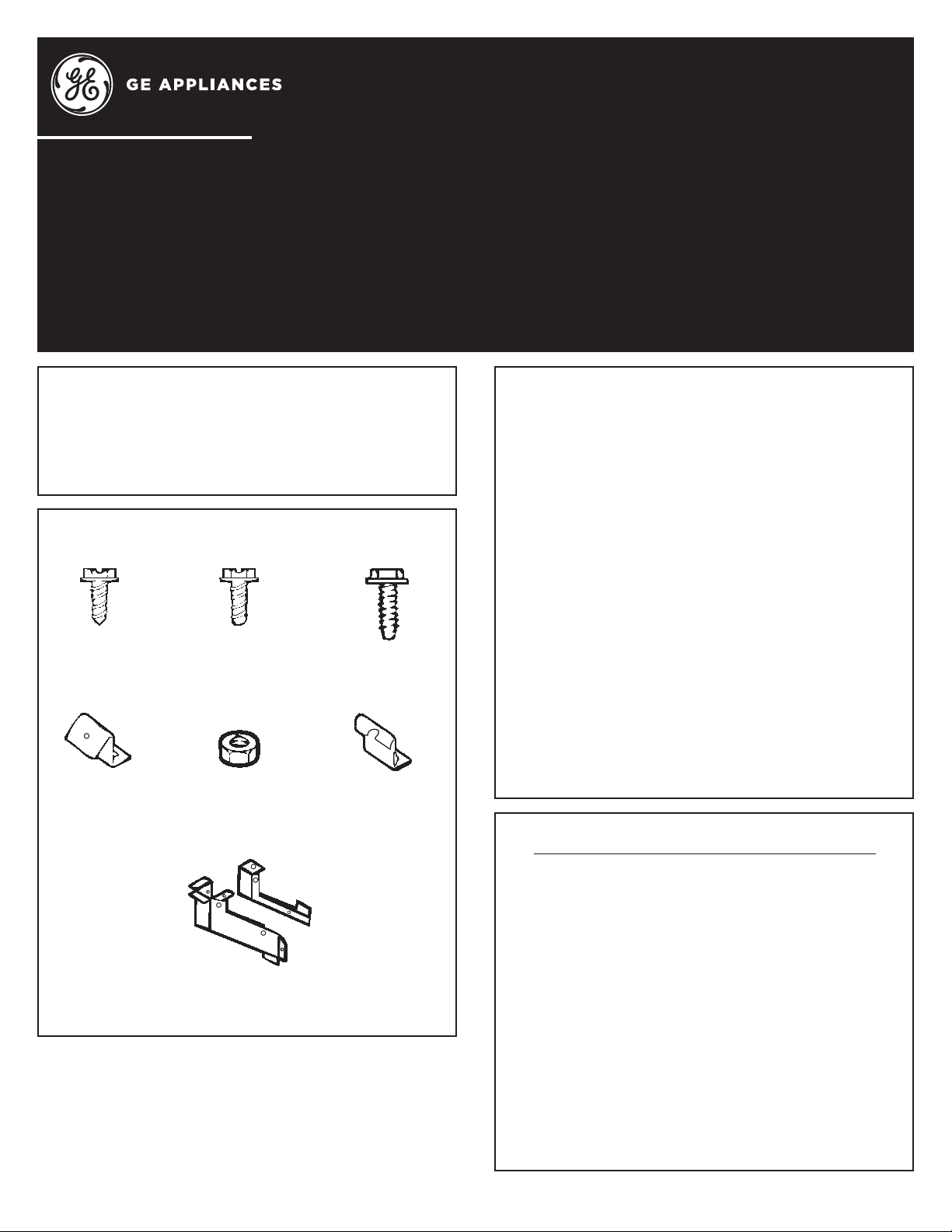

Parts Included In Bag with Sub-Base

Type A

10 required

Type D

2 mounting clips

for metal case

Type B

2 required

4 nuts

Chaseway

and cover

Type C

2 required

Type E

2 mounting clips

for molded case

Important Notes

• This unit must be properly grounded.

• Read this instruction before installing the

sub-base to the molded or metal case.

• CAUTION: The sub-base must be assembled to

the case before securing the case in the wall.

• ELECTRICAL REQUIREMENTS:

1. Electrical wiring may enter the sub-base

through any of the knockout holes provided in

the sub-base bottom or rear.

2. Refer to the unit nameplate for branch circuit

requirements.

3. All wiring should be done in accordance with

the local electrical codes and regulations.

4. Not approved for aluminum wire application.

5. If electrical wiring is placed in or against

the sub-base enclosure, the sub-base must

be grounded. Grounding holes have been

provided in the back surface of the enclosure.

See diagram. Green grounding screws and

securing nuts are included.

Kit Number Description

RAK204U NON-ELECTRICAL SUB-BASE

RAK204E15 265/277V 15A

RAK204E20 265/277V 20A

RAK204E30 265/277V 30A

RAK204D15P 230/208V 15A

RAK204D20P 230/208V 20A

RAK204D30P 230/208V 30A

RAK204D15PA 230/208V 15A

RAK204D15C 230/208V 15A

RAK204D20PA 230/208V 20A

RAK204D20C 230/208V 20A

RAK204D30PA 230/208V 30A

RAK204D30C 230/208V 30A

RAK205CW CHASEWAY

RAK4002A JUNCTION BOX

RAK4002C JUNCTION BOX

(For use with RAK204U)

1

Pub No. 30-7774-6 03-16 GE

Page 2

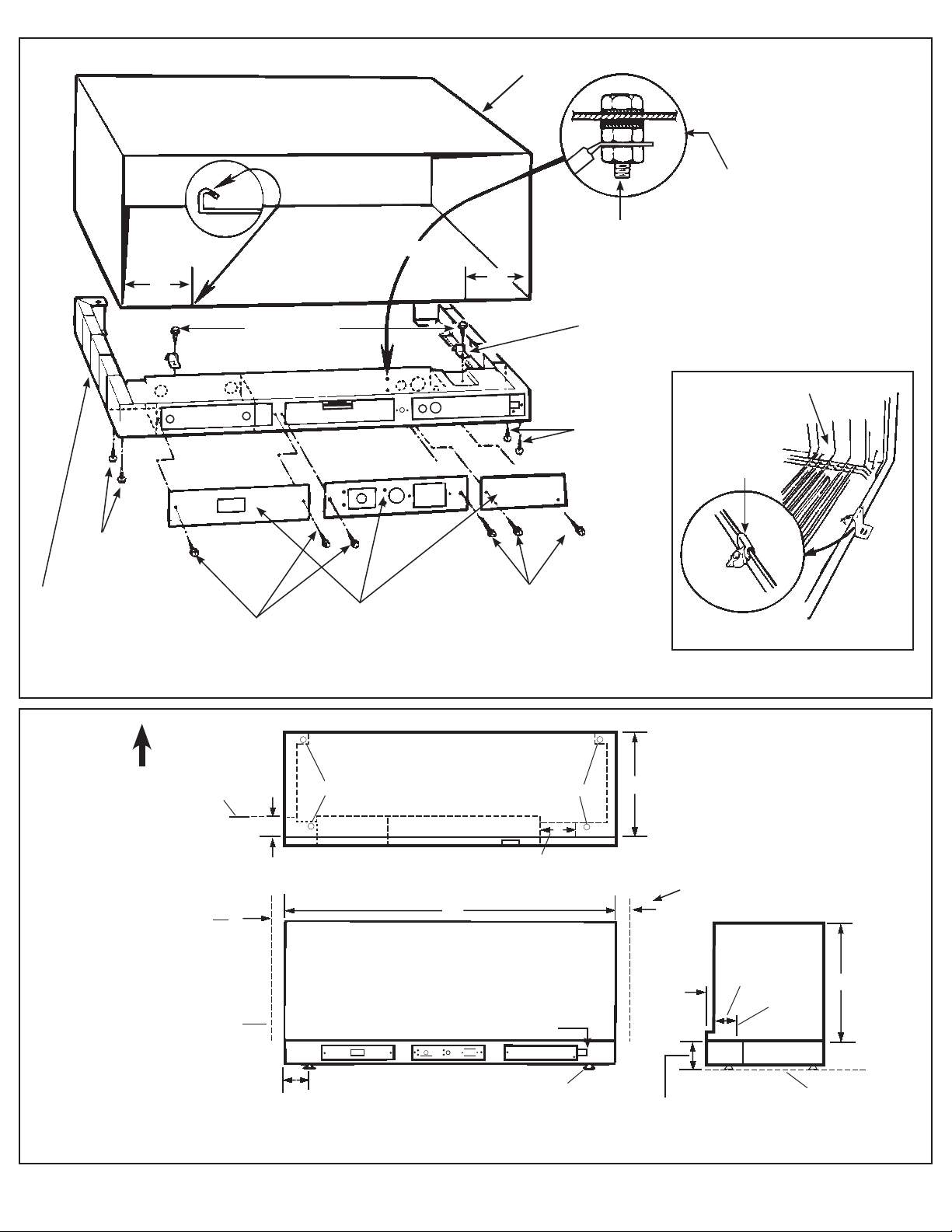

Metal Case (RAB71)

Install ground screw from the

rear and secure from the inside

of the sub-base using a nut.

Secure branch circuit (or other)

ground wire using a second nut.

5/32“ DIA. HOLES (SEE NOTE)

Green ground

screw (type C)

For securing type D clips

6"

to sleeve using type A

screws

6"

Type B screws

Mounting

clip for

metal case

type D

Type A

screws

Type A

screws

Side channels are

adjustable from 13¾” to

2¾” in length by breaking

of sections of side channels.

Access plates

Type C screws

Type C screws

NOTEIf the case does not have screw holes, 5/32” dia. holes must be drilled 6” from each side in the

front flange. (See insert)

OUTSIDE

Finished

interior

wall

23/8”

min.

Leveling screw Leveling screw

Top view

13

Molded case (RAB77)

Mounting

clip for

molded case

type E

3

/4”

Bottom of sub-base is cut out on right end

to permit electrical circuit entry.

Recommend 2"

Recommend 2” to

clearance to interior

interior adjacent

wall both sides.

adjacent wall both

sides.

Interior adjacent

wall

2”

31/2”

42”

Front view

Chaseway knockout

Leveling screw

NOTE: Remove knockouts from inside out. Knockouts (enclosure) 4 rear, 4 bottom.

Use as required for branch circuit wire entrance.

2

3”

See note

left side

2”

Side view

15/16”

3” min.,

adjustable

to 5”

23/8”

Interior

wall

16”

Finished floor

Page 3

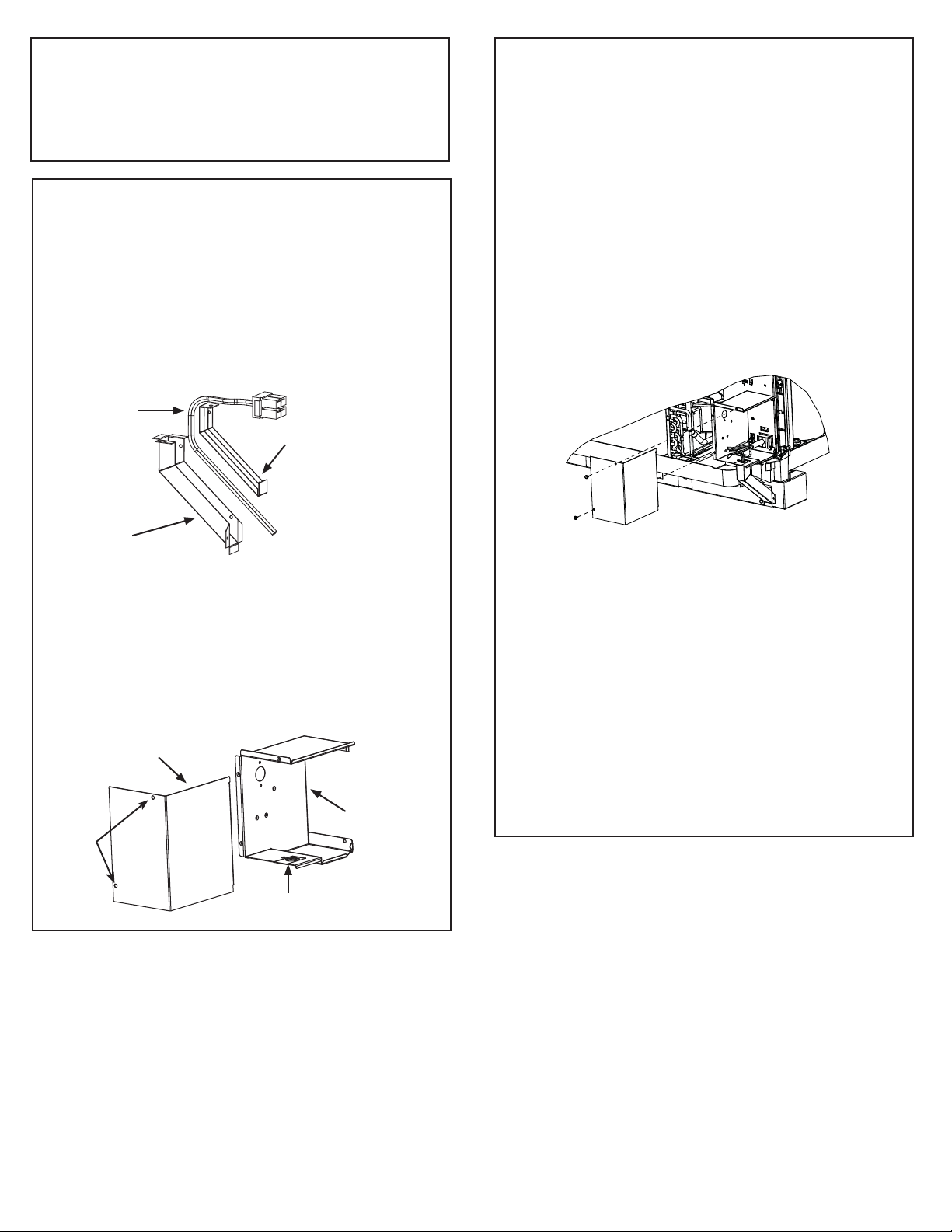

INSTALLATION for 230/208v Models:

Follow the Installation Instruction with the Power

Supply Kit or Junction Box Kit to install junction box

and all unit wiring.

INSTALLATION for 265v Models:

The chaseway can be used several ways in

conjunction with the associated knockouts in the

junction box and sub-base to protect and conceal

wiring (cordsets/power supply kits and branch

circuit wiring).

1. Wiring is placed between the two halves of

the chaseway. Observe the orientation of the

chaseway.

Wiring

Chaseway cover

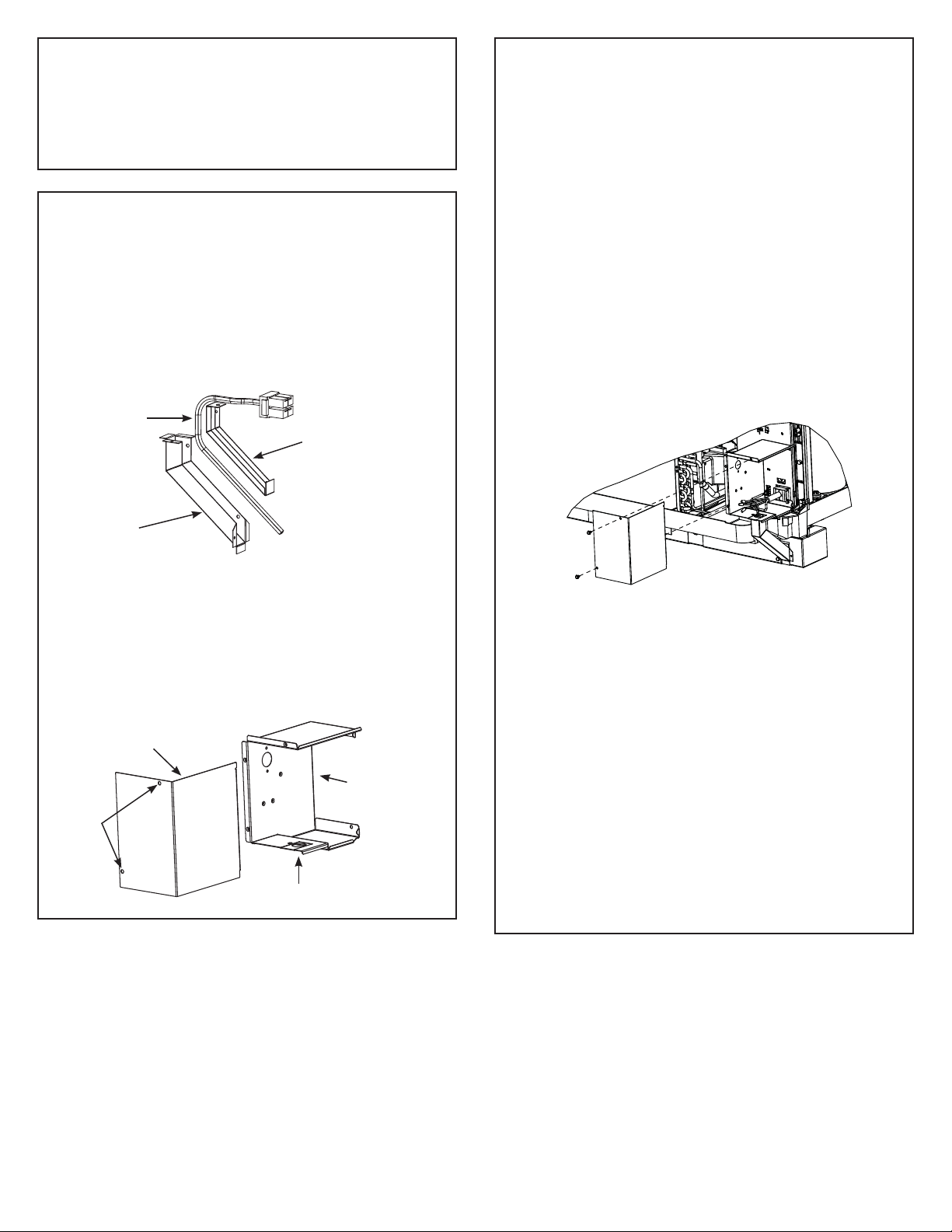

5. Slide the upper end of chaseway with wiring

protruding into rectangular knockout opening

in the junction box. Be sure chaseway “ears”

are on the inside of the box. Drive one type A

screw through the junction box bottom into

the chaseway “ear” hole. Insert lower end of

chaseway into rectangular hole in sub-base

and slide to right into the rectangular knockout

making sure chaseway “ears” are inside the

sub-base. Route wire toward the center of the

sub-base. Fit junction box into place on chassis

and secure at top with original mounting screw.

Be sure the slot at the lower right rear corner of

the box engages the protruding flange from the

chassis. Drive one type A screw through the subbase slotted hole into chaseway “ear” hole.

Chaseway

2. Align the screw holes and secure the halves

together using two type A screws.

3. Remove the junction box and cover.

4. Remove the rectangular knockout at the bottom

of the junction box. Remove the rectangular

knockout at the right end of the sub-base.

Junction box

cover

Junction box

Screws

Knock out

6. Recheck to be sure the chaseway “ears” are

inside the junction box and the sub-base and that

no wiring is pinched.

7. Complete the connection of wiring inside the

sub-base either by fully inserting the plug into

the receptacle or attaching to the branch circuit

wiring or other field installed devices. Coil up any

excess wiring inside the sub-base.

8. Complete connections inside the junction box.

See the Installation Instructions in the Owner’s

Manual (pages 14-16) for chassis or junction box

kit for additional information.

9. Replace and secure all front covers. Do not pinch

any wires.

3

Page 4

NOTES

4

Page 5

Instructions d’installation

pour votre nouveau

RAK204U, RAK204E15, RAK204E20,

RAK204E30, RAK204D15P, RAK204D20P,

RAK204D30P, RAK204D15PA, RAK204D15C,

RAK204D20PA, RAK204D20C, RAK204D30PA,

RAK204D30C

Sub-base

Avant de commencer – Lire attentivement ces instructions dans leur intégralité

IMPORTANT – OBSERVER TOUTES LES RÉGLEMENTATIONS ET ORDONNANCES EN VIGUEUR.

Remarque pour l’installateur – S’assurer de laisser ces instructions au client.

Remarque pour le consommateur – Garder ces instructions avec le manuel utilisateur pour

référence ultérieure.

Outils nécessaires

• Tournevis à douille de 5/16 po

• Pinces

• Tournevis bout plat

Pièces fournies dans le sac de visserie

du socle

Type A

10 requises

2 brides de fixation

pour le coffret

métallique de type D

Type B

2 requises

4 écrous

Chaseway

et couvercle

Type C

2 requises

2 brides de fixation

pour le coffret

moulé de type E

Remarques importantes

• Ce modèle doit être correctement mis à la terre.

• Lisez ces instructions avant d’installer le socle sur le

coffret métallique ou moulé.

• ATTENTION : Le socle doit être assemblé sur le

coffret avant de bloquer le coffret dans le mur.

• SPÉCIFICATIONS ÉLECTRIQUES:

1. Le câblage électrique peut entrer dans le socle

par une des découpes fournies dans le dessous ou

l’arrière du socle.

2. Voir la plaque signalétique du module pour les

spécifications de circuit de dérivation.

3. Tout le câblage doit être effectué conformément

aux réglementations et codes électriques en

vigueur.

4. Pas approuvé pour les installations à fil en aluminium.

5. Si du fil électrique est placé dans ou contre le

recouvrement du socle, le socle doit être mis à la

terre. Les trous de mise à la terre ont été fournis

dans la surface arrière du recouvrement, Voir le

schéma. Des vis de mise à la terre vertes et des

écrous de blocage sont fournis.

Numéro du kit Description

RAK204U SOCLE NON-ÉLECTRIQUE

RAK204E15 265/277V 15A

RAK204E20 265/277V 20A

RAK204E30 265/277V 30A

RAK204D15P 230/208V 15A

RAK204D20P 230/208V 20A

RAK204D30P 230/208V 30A

RAK204D15PA 230/208V 15A

RAK204D15C 230/208V 15A

RAK204D20PA 230/208V 20A

RAK204D20C 230/208V 20A

RAK204D30PA 230/208V 30A

RAK204D30C 230/208V 30A

RAK205CW CHASEWAY

RAK4002A BOÎTE À BORNES

RAK4002C BOÎTE À BORNES

(À utiliser avec RAK204U)

1

Pub No. 30-7774-6 03-16 GE

Page 6

Coffret métallique

(RAB71)

Installer une vis de terre de

l’arrière et bloquer de l’intérieur

du socle avec un écrou. Bloquer

TROUS DE 5/32 PO

DE DIAMÈTRE (VOIR

REMARQUE)

Pour bloquer les

brides du type D sur le

6"

manchon à l’aide des

vis du type A

6"

Vis de terre verte

(type C)

le file de terre du circuit de

dérivation (ou autre) avec un

second écrou.

Vis du type B

métallique D

Vis du

type A

Les montants latéraux sont

réglables de 13 3/4” à 2 3/4” de

long en brisant des sections de

montants latéraux.

Plaques d’accès

Vis du type C

Vis du type C

REMARQUE : Si le coffret ne présente pas de trou de vis, il faut percer des trous de 5/32 po de

diamètre à 15 cm de chaque côté de la bride avant. (Voir encart)

EXTÉRIEUR

Mur

Finished

intérieur

interior

terminé

wall

23/8”

min.

Vis de réglage Vis de réglage

Leveling screw Leveling screw

Vue du dessus

Top view

Bride de

fixation

pour le type

de coffret

Vis du

type A

13

Coffret moulé (RAB77)

Bride de

fixation pour

coffret moulé

Type E

3

/4”

3”

Le dessous du socle est découpé du côté droit

Bottom of sub-base is cut out on right end

pour permettre l’entrée de circuit électrique.

to permit electrical circuit entry.

Espacement de 5

Recommend 2” to

cm recommandé

interior adjacent

wall both sides.

par rapport au mur

adjacent intérieur

2”

42”

Vue de face

Front view

des deux côtés

Mur intérieur

Interior adjacent

Découpe de Chaseway

wall

31/2”

Rasant de la vis

Leveling screw

REMARQUE : Retirer les découpes en poussant de l’intérieur. Découpes (recouvrement) 4 à l’arrière,

4 sur le dessous. Utiliser selon les besoins pour l’entrée de fil dans le circuit de dérivation.

2

Voir la remarque sur le

See note

côté gauche

left side

2”

Vue de côté

Side view

15/16”

3” min.,

7,5 cm min,

adjustable

réglable à 12,5

to 5”

cm

23/8”

Mur in-

Interior

wall

térieur

16”

Sol terminé

Finished floor

Page 7

INSTALLATION pour les modèles de

230/208V :

Suivez les instructions d’installation avec le kit

d’alimentation ou le boîte

boîte

à bornes et tout le cablage du climatiseur.

à bornes pour installer la

INSTALLATION pour les modèles de 265V :

Le Chaseway peut être utilisé de plusieurs manières

en conjonction avec les découpes associées dans la

boîte à bornes et le socle pour protéger et cacher le

câblage (kits d’alimentation/cordons et câblage de

circuit de dérivation).

1. Le câblage est placé entre les deux moitiés du

Chaseway. Observer l’orientation du Chaseway.

Câblage

Couvercle de

Chaseway

5. Glisser l’extrémité supérieure du Chaseway

avec le câblage dépassant dans l’ouverture

de découpe rectangulaire dans la boîte à

bornes. S’assurer que les oreilles du Chaseway

sont à l’intérieur de la boîte. Visser une vis du

type A dans le dessous de la boîte à bornes

dans le trou d’oreille du Chaseway. Insérer

l’extrémité inférieure du Chaseway dans le trou

rectangulaire du socle et glisser vers la droite

dans la découpe rectangulaire en s’assurant

que les oreilles du Chaseway sont à l’intérieur du

socle. Passer le fil vers le centre du socle. Ajuster

la boîte à bornes en place sur le châssis et

bloquer en haut avec une vis de fixation d’origine.

S’assurer que la fente dans le coin inférieur

arrière droit de la boîte engage la bride qui

dépasse du châssis. Visser une vis du type A dans

le trou en fente du socle dans le trou d’oreille du

Chaseway.

Chaseway

2. Aligner les trous de vis et bloquer les moitiés

ensemble avec deux vis du type A.

3. Déposer la boîte à bornes et le couvercle.

4. Retirer la découpe rectangulaire en bas de la

boîte à bornes. Retirer la découpe rectangulaire

sur la droite du socle.

Couvercle

de la boîte à

bornes

Boîte à

bornes

Vis

Découpe

6. Revérifier que les oreilles du Chaseway sont à

l’intérieur de la boîte à bornes et du socle et

qu’aucun câblage n’est pincé.

7. Terminer la connexion du câblage à l’intérieur

du socle en insérant complètement la fiche dans

la prise ou en fixant au câblage du circuit de

dérivation ou tout autre appareil installé sur le

terrain. Enrouler le câblage en excès à l’intérieur

du socle.

8. Terminer les connexions à l’intérieur de la boîte

à bornes. Voir les instructions d’installation dans

le manuel utilisateur (pages 14-16) pour des

renseignements supplémentaires sur le châssis et

le kit de boîte à bornes.

9. Remettre en place et bloquer tous les couvercles

avant. Ne pas pincer de fil.

3

Page 8

NOTES

4

Loading...

Loading...