Installation Instructions

for your new

RAD10

For Installation on an

Before you begin - Read these instructions

completely and carefully.

IMPORTANT – OBSERVE ALL GOVERNING

CODES AND ORDINANCES.

Note to Installer – Be sure to leave these

instructions with the Consumer.

Note to Consumer – Keep these instructions

with your Owner’s Manual for future reference.

NOTE: Parts in this kit will allow for two different types of installations onto the wall sleeve (external or internal.) A

combination of different parts is required. Depending on the type of installation selected, there may be some extra parts.

Parts Included

RAB71* (Steel), or RAB80* (Steel),

RAB81* (Steel), RAB77* (Molded),

RAB26* (Steel), or RAB46B* (Steel), RAB78B*

(Molded) Wall Sleeve, or RAB24* (Steel)

*all versions

Hex Head Screw

for external drains

(4)

Pan Head Screw

for internal drains

(2)

Nut

(2)

3” x 1/2” Straight

Tube

(1)

To Install the External Drain

The External Drain Kit is installed on the Zoneline Sleeve

if it desired to direct the sleeve overflow water to the

exterior and completely away from the installation.

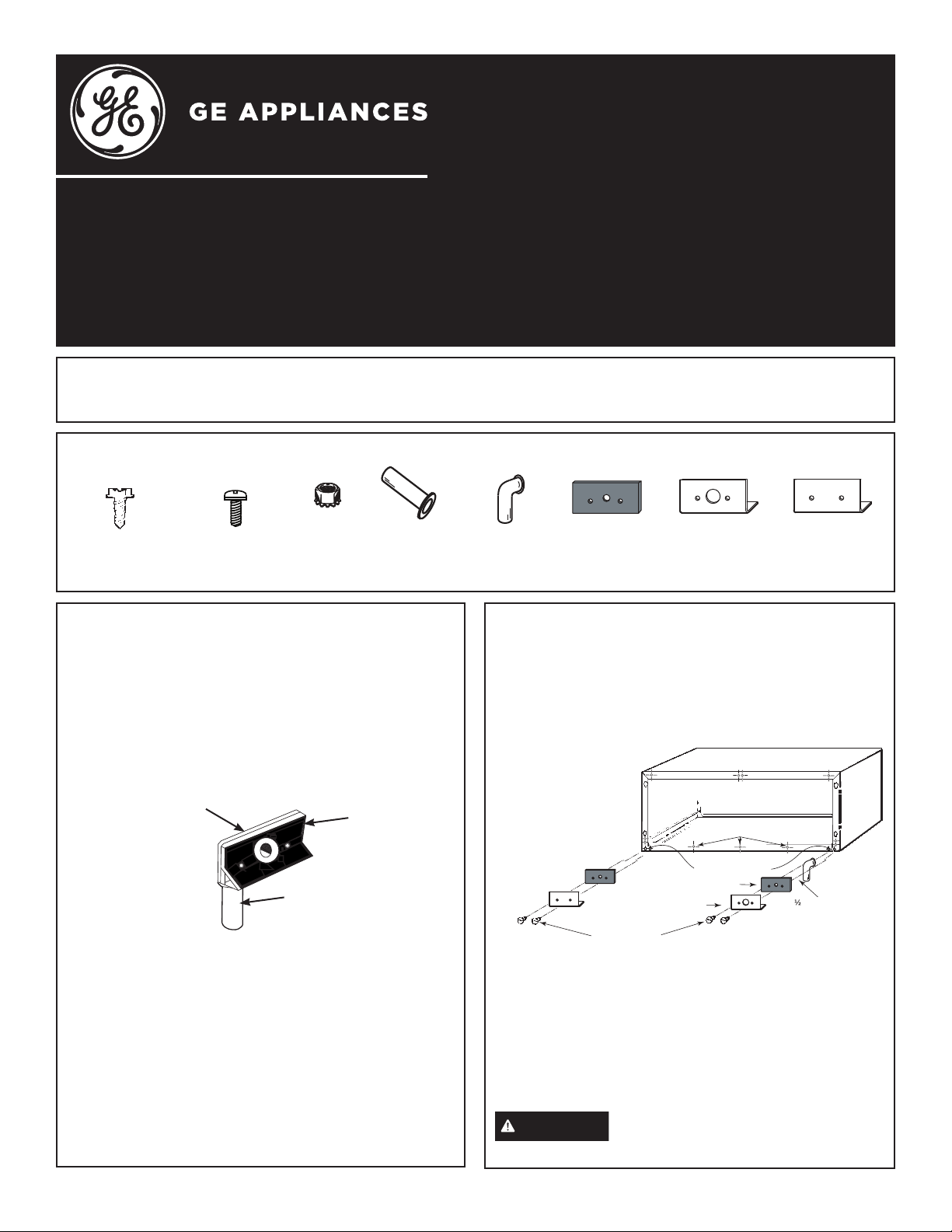

1. The gasket should be placed on the cover plate (with

1/2” hole) with screw holes in the gasket lined up with

screw holes in cover plate. Then insert drain tube

(from gasket side) through gasket and cover plate (see

Fig. 1).

Enter screw

through the back

of mounting plate

Drain Tube

Gasket

Fig. 1

2. This assembly may now be installed into either the

left or right drain holes on the rear flange of the

sleeve, using two (2) of the screws (Type A for Metal

cabinet or Type B for Molded) included.

NOTE: The drain kit may be installed on the sleeve either

before or after the sleeve is installed in the wall, and

with or without the rear protective cover installed on the

sleeve. The stamped rear grille must be removed or the

drain kit installation made before the grille is installed. The

installation of the drain kit may be made from the outside

(rear of sleeve) or from the roomside (inside) by removing

the rear protective cover or rear grille.

Drain Tube

(1)

Neoprene

Foam Gasket

(3)

Steel Mounting

Plate

(1)

Steel Mounting

Plate (2)

To Install the External Drain (cont.)

3. The solid gasket (without hole) should be properly

placed on the rear of the solid cover plate and the

assembly installed over the drain hole in the sleeve

that it is not used to drain. Using two (2) of the

screws included (Type A or B depending on the type

of sleeve, attach to cabinet (see Fig. 2).

2YHUÀRZUHOLHIGUDLQ

6TXDUHGUDLQKROHV

1HRSUHQHIRDPJDVNHW

6WHHOPRXQWLQJSODWH

$OWHUQDWH

)LJ

+H[+HDGVFUHZV

´ORQJ´2'

VWUDLJKWFRSSHUWXEH

4. A tube or hose 1/2” I. D. (obtained locally) may be

installed onto the drain tube to drain any overflow

water away from the installation (to a gutter ot the

ground).

NOTE: To redirect the drain tube to another direction

(toward the side, downward, etc.) merely loosen the two

screws, rotate the drain tube to the desired direction

and retighten the screws.

CAUTION

DO NOT point the drain tube above

the horizontal position.

´2'GUDLQWXEH

31-5000414 Rev. 0 06-20 GEA

Installation Instructions

Install the Internal Drain

Location of the Drain in the Cabinet Bottom

1. The Drain Kit must be installed on the bottom of

the wall sleeve prior to installation of the sleeve in

the wall. The location should not be in the area of

chassis supports or molded ribs (molded sleeve

only).

NOTE: If installation in the wall requires the use of a

sub-base, the location of the drain should be at least

3” from the front edge of the wall sleeve.

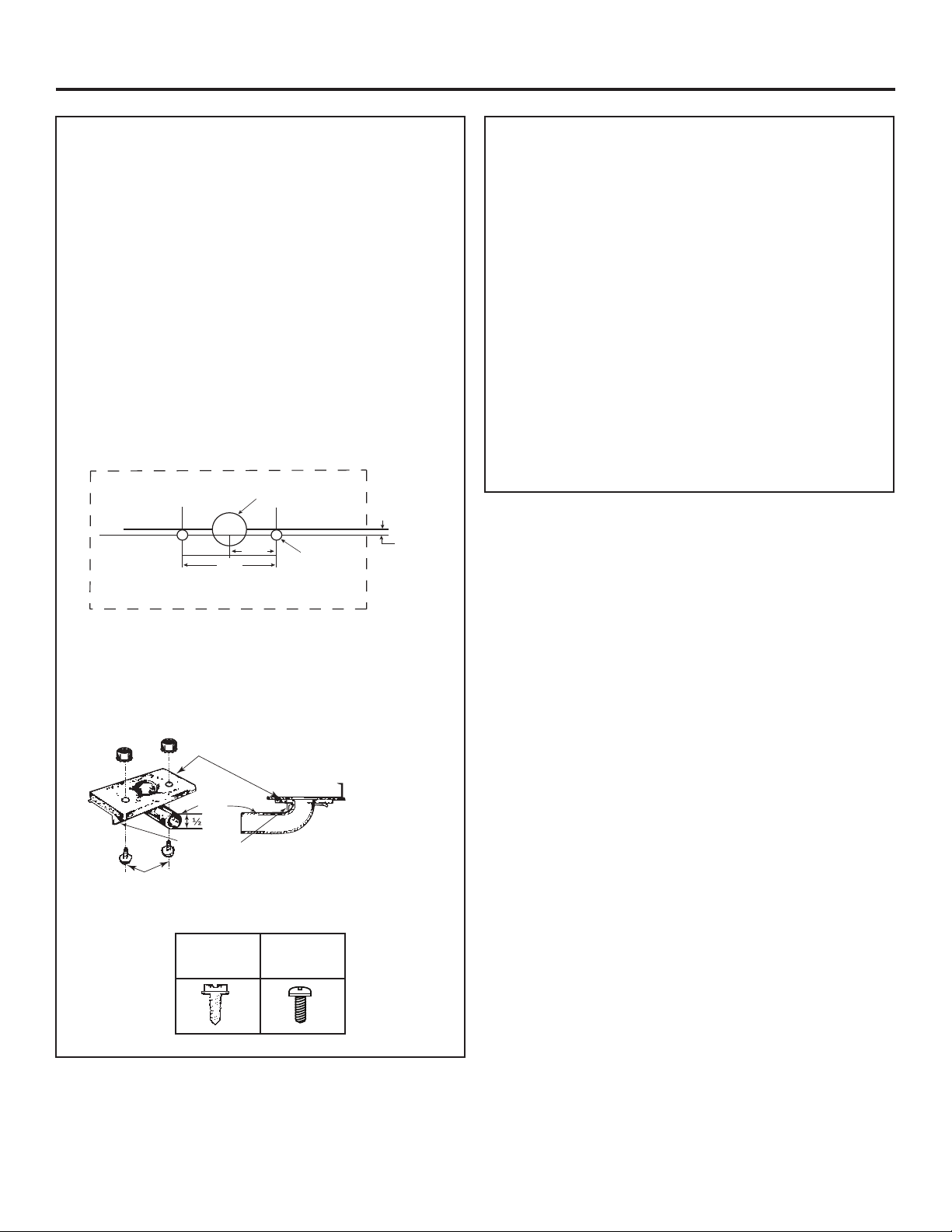

2. After location of Drain Kit is determined, locate and

drill 3 holes per dimensions on Fig. 3. The steel

mounting plate with the 1/2” center hole can also be

used as a template to mark holes. Repaint edges

of drilled holes on metal cabinet to prevent rust or

corrosion.

1/2” Diameter

3/32”

1-3/8”

11/16”

5/32” Diameter

(2 holes)

Install the Internal Drain (cont.)

4. Attach this assembly to bottom of the wall sleeve

with two Type A screws through the cover plate,

gasket, and wall sleeve. On molded sleeve, the 2

speed nuts must be used to secure drain kit wall

sleeve using the two Type A screws.

5. Seal external drain holes. Prepare the remaining

mounting plates/gasket assemblies as shown in Fig.

2. Using the screws (Type A for Steel or Type B for

Molded sleeve) attach plate/gasket assemblies to

the bottom exterior flange over both as shown.

6. Install the wall sleeve into the wall opening (level in

all directions) and secure with adequate fasteners

per instructions packed with the wall sleeve.

7. A tube or hose 1/2” I.D. (obtained locally) must be

installed on the drain and connected to the internal

drain system in the building.

Fig. 3

3. The gasket should be placed on the steel mounting

plate (with 1/2” hole) with screw holes in gasket

lined up with screw holes in steel mounting plate.

Then insert drain tube through gasket and steel

mounting plate, as shown in Fig. 4.

Nuts

Pan Head screws

Gasket

Sleeve bottom

Tube

” O.D.

Steel mounting plate

Fig. 4

Screw “A”

for metal

sleeves

Screw “B”

for molded

sleeves

2

Loading...

Loading...