Page 1

4XLN%ULGJH(XUR5HSHDWHU

'

ZZZ*(,QWHUORJL[FRP

Product Summary

0RGHO1R

*(,QWHUORJL[

The purpose of the Qui k B ridge® Euro Repeater SA W is to extend the range of wireless security

systems. The repeater accomplishes this by receiving and retransmitting signals from Learn

Mode™ sensors, wireless touchpads, and other repeaters. The repeater is ideal for the following

applications:

• Installations where sensors are either beyond panel reception or cannot pass the sensor test.

• As a substitute for preamps in installations where panel antennas ar e shielded by metal.

The repeater will retransmit all signals received from compatible sensors and wireless touchpads

(see “Compatibility”). It will retransmit signals received from another Euro Repeater SAW if the

DIP switches of both repeaters have been set accordingly (see “Setting the DIP Switches”).

Repeater Features

Repeater features include:

• Supervisory reports to the panel every 15 minutes.

• A tamper switch that causes an alarm transmission if the repeater cover is removed.

• A tamper alarm if the antenna is removed.

• Support for a rechargeable lead acid backup battery.

• A loop-antenna receiver, which improves reception through spatial diversity.

• A low battery trouble report when the backup battery is low.

• An AC power failure alarm when AC power has failed for more than 15 minutes.

• Jam detection, which alerts the panel when the receiver detects “noise” on the same frequency that the transmitters use for alarm transmissions.

6$:

,QVWDOODWLRQ,QVWUXFWLRQV

'RFXPHQW1XPEHU5HY(

$SULO

Powering Options

The repeater must be hardwired into the

electrical system of the premises. Electrical codes will vary depending upon the

country and city where the system is

installed. Have a qualified person connect

the 220-240VAC (50 Hz) power cable to

the power input terminal as shown in Figure 1. A minimum of 14-gauge power

wire must be used. The power wires

should not be routed near the receiver circuitry on the top of the circuit board.

Note

The repeater does not hav e a power switch.

A readily accessible power disconnect

device must be incorporated in the building installation wiring to comply with local safety standards.

A 12 VDC lead acid battery, such as the Panasonic LCR12V1.3P, may be installed as a backup

power source. Connect the battery to the circuit board as shown in Figure 1. The term inals of the

battery should face towards the right side of the enclosure (see Figure 2).

There is a risk of explosion if an incorrect type of battery is installed.

T O A C

P O W E R

S O U R C E

T O E A R T H

G R O U N D

Figure 1. AC Power and DC Battery Connections

T O A C

P O W E R

S O U R C E

T O P O S I T I V E

B A T T E R Y

T E R M I N A L

T O N E G A T I V E

B A T T E R Y

T E R M I N A L

!

Warning

1

Page 2

!

Caution

Observe polarity when installi ng a new battery. Installing the battery backward may

cause damage to the rep eat er.

Dispose of used batteries according to the manufacturer’s instructions and local government authorities.

F u s e H o l d e r

B a t t e r y T e r m i n a l s

B a c k u p B a t t e r y

Tools and Accessories Needed

Figure 2. Installation of Backup Battery

Compatibility

• All GE Interlogix Learn Mode SAW sensors and wireless touchpads at 433 mHz (non

upper device type)

•Euro SX-V

• Euro Commander

• Euro Conco rd

• Euro SuperBus® 2000 RF Receiver Module

®

Special with software version 7.0 or later

®

™

Included with Repeater

• Mounting screws and anchors

• Loop antenna

• Battery cables

• Rose Enclosure (Rose 0312200830 (UL94VO))

Not Included with Repeater

• Phillips screwdriver

• Small standard screwdriver

• 2-conductor, 12–22-gauge, stranded wire

• Silicone sealant (for sealing the antenna holes)

• Backup battery (optional) such as the Panasonic LCD 12V1.3P rechargeable battery

• RF Sniffer (60-401, optional)

2

Quik Bridge® Euro Repeater SAW Installation Instructions

Page 3

Overview of Repeater Components Operation

DIP Switches

There are 8 DIP switches (numbered 1–8 fr om le ft to right) on the repeater circui t board (see Figure 3). DIP switch functions include:

• Setting the repeater identification number

• Enabling (or disabling) jam detecti on and AC power failure

reports

• Configuring the repeater to work with your panel.

A DIP switch is “ON” when flipped left (toward the word “ON”)

or “OFF” when flipped right. The repeater will only “read” the

DIP switches upon power-up.

Figure 3. Setting DIP Switches

8

567

34

2

1

ON

LED Indications

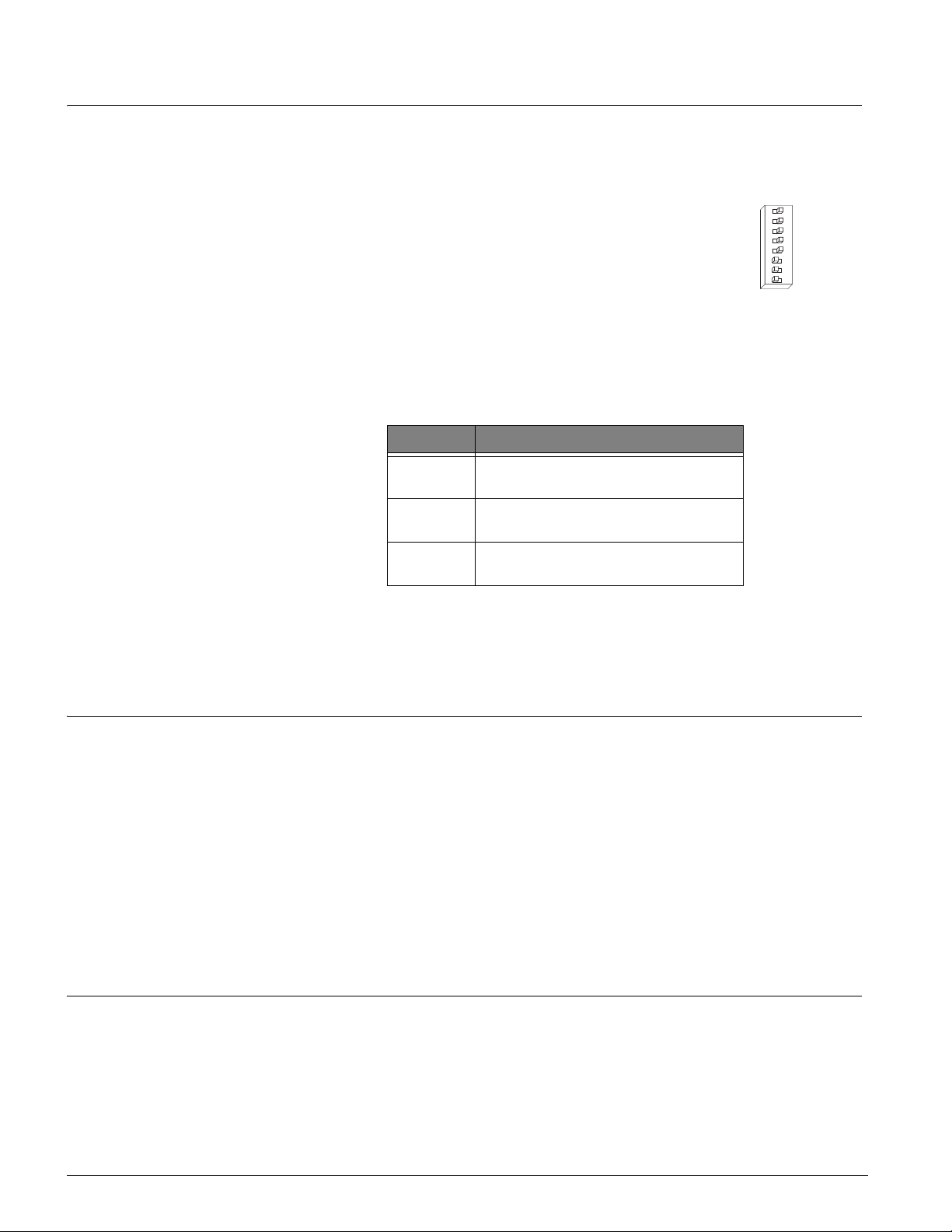

The purpose of the LED is to indicate certain actions of the repeater. Table 1 describes all possible

LED indications.

Table 1: LED Indications

LED Indications

Installation Overview

ON Repeater is powered up and passed

OFF Repeater is not powered or failed to

Single

blink

self-test.

power up.

Repeater received a signal fro m a Learn

Mode transmitter.

Fuse Replacement

The fuse holder is located above the terminal block (see Figure 2). To replace the fuse:

1. Unscrew the top of the fuse holder with a standard screwdriver. Remove the fuse.

2. Insert the new 5 x 20 mm, 32 mA, 250 V fuse into the top of the fuse holder.

3. Insert the fuse and top into the holder and reattach by pressing down and turning clockwise.

Install this repeater by completing these steps in the following order:

1. Perform a Dealer Sensor test to determine which transmitters need a repeater.

2. Connect the antenna.

3. Set the DIP switches on this repeater: a. Set the repeater identification number. b. Configure the repeater to work with your panel.

4. Connect power.

5. Program the repeater into the panel.

6. Choose a location and temporarily mount the repeater.

7. Perform a Dealer Sensor Test between the repeater and the panel (or the receiving repeater).

8. Perform a Repeater Reception Test between the repeater and the transmitters (e.g. sensors, touchpads, or a transmitting repeater).

9. If both tests are successful, permanently mount the r epeater. If either test fails, go back to step

6.

Installing Repeaters

Perform a Dealer Sensor Test

The first step of the installation is to determine which sensors and touchpads are “dis tant.” Distant

sensors are outside th e rang e of the control panel, so they need a repeater to re-transmit the alarm

and supervisory signals they generate.

¾

To determine which sensors and touchpads need a repeater:

1. Mount the sensors and touchpads in the desired locations.

3Quik Bridge® Euro Repeater SAW Installation Instructions

Page 4

2. Remove power from any repeaters that are already installed.

-

3. Perform a Dealer Sensor Test. This test checks the communication link between the control panel and the transmitters (e.g., sensors and touchpads). Refer to the panel installation manual for the Dealer Sensor Test procedure.

If all of the system sensors and touchpads pass this test, a repeater is not necessary with the

system. Distant sensors, however, will need to have their signals retransmitted by one or more

repeaters.

Note

Keep track of which transmitters are “distant.” You will need to perform a Repeater Reception Test for

these transmitters.

Mounting the Repeater in the Housing

¾ To mount the repeater in the housing:

1. Press the threaded inserts into the four mounting holes at the top of the repeater housing.

2. Secure the inserts into the mounting holes with a small punch or scr e wdriver.

3. Place the repeater over the mounting holes in the housing.

4. Attach the circuit board to the housing with the mounting screws and plastic washers.

Connecting the Antenna to the Repeater

¾ To connect the antenna to the repeater:

1. Loosen the inside terminals of the left and right antenna terminal blocks.

2. Insert the ends of the loop antenna into the predrilled holes.

3. Insert one end of the antenna into each inside terminal.

4. Tighten down the terminal screws (see Figure

4).

A n t e n n a e n d s

A n t e n n a

t e r m i n a l

b l o c k s

Setting the DIP Switches

You must set the DIP switches on the repeater circuit board to set the repeater identification

number, to enable or disable supervisory

report transmission, and to configure the repeater

for compatibility with your control panel.

¾

To set the repeater identification number:

1. Remove power from the repeater and disconnect the battery.

Note

The repeater only “reads” th e di p sw i tch settings when power is firs t appl i ed. When you change dip

switch settings, you m ust re m ove power and then re-po w er th e re peater so it can “read” the new settings.

2. Set DIP switches 1-5 to a unique, non-zero repeater identification number (see Figure 4).

Euro Repeater SAW signals “cascade” toward the panel in descending order. Therefore, the

repeater identification number at the receiving or destination repeater must be less than the

repeater identification number of the transmitting or source repeater. For example, repeater “two”

will recognize signals transmitted from repeater “three,” because 3 is greater than 2. Repeater

“two” will not recognize signals transmitted from repeater “one” because 1 is less than 2. Refer to

the installation example at the end of this document (see Figure 8).

If fewer than 16 intelligent mode repeaters are needed for the system, plan to assign only even

numbers to the repeaters. This method allows for an additional repeater to be retro-fitted between

two cascaded repeaters, if necessary.

¾

To configure the repeater to your control panel:

1. To use the repeater with the Euro Commander or the Euro SX-V Special, set DIP switch 8 to the ON position.

Figure 4. Connecting Antenna to inside termi

nals of Antenna Terminal Blocks

4

Quik Bridge® Euro Repeater SAW Installation Instructions

Page 5

Note

When DIP switch 8 is set to O N , the A C Fai lure and Jam Detection feat ur es are disabled.

2. To use the repeater with the Euro Concord, you may set DIP switch 8 to either the OFF or ON position.

8

8

8

8

7

8

8

8

8

7

8

8

Repeater No. 02

ON

1234

567

Repeater No. 05

ON

1

34

2

56

Repeater No. 08

ON

1234

567

Repeater No. 11

ON

1234

567

Repeater No. 14

ON

1

234567

Repeater No. 17

ON

1234

567

Repeater No. 20

ON

1

34

2

56

Repeater No. 23

ON

1234

567

Repeater No. 26

ON

1234

56

Repeater No. 29

ON

1

4

3

2

567

Repeater No. 01

ON

1234

567

Repeater No. 04

ON

1

234567

Repeater No. 07

ON

1234

567

Repeater No. 10

ON

1234

56

Repeater No. 13

ON

1234

567

Repeater No. 16

ON

1234

567

Repeater No. 19

ON

1

234567

Repeater No. 22

ON

1234

56

Repeater No. 25

ON

1

234567

Repeater No. 28

ON

1234

567

Repeater No. 31

ON

1234

56

8

7

Figure 5. DIP Switch Settings for Repeater Identification Numbers

8

8

7

8

8

8

8

8

7

8

8

7

8

Repeater No. 03

ON

1234

567

Repeater No. 06

ON

1

34

2

56

Repeater No. 09

ON

1234

567

Repeater No. 12

ON

1234

567

Repeater No. 15

ON

1

234567

Repeater No. 18

ON

1234

567

Repeater No. 21

ON

1

34

2

56

Repeater No. 24

ON

1234

567

Repeater No. 27

ON

1234

56

Repeater No. 30

ON

1

4

3

2

567

8

8

7

8

8

8

8

8

7

8

8

7

8

Programming the Repeater into the panel

Before the panel can supervise the repeater, the repeater must be programmed into panel memory.

To program the repeater into the panel:

¾

1. Refer to the panel installation instructions for the sensor pro-

gramming procedure.

2. When the panel prompts you for a group number, we recom-

mend that you use group number 4. Group number 4 supervises the repeater and causes an instant alarm if the tamper is

tripped.

3. Trip one of the r epeater tamper switches wh en the procedure

prompts you for sensor activation.

To trip the antenna tamper, remove one end of the antenna

from its terminal.

To trip the cover tamper switch, the switch must first be

closed. T o clo se the switch, insert a wire jumper between the

terminals of the cover tamper switch as shown in Figure 6.

To trip the switch, remove the jumper.

Figure 6. Closing the Cov er

Tamper Switch

5Quik Bridge® Euro Repeater SAW Installation Instructions

Page 6

Choosing a Location for the Repeater

¾ To select a mounting location for a repeater, use the following guidelines

• After a location has been selected, temporarily mount the repeater using a piece of doublesided tape or a single mounting screw (see “Mounting the Repeater”). You may need to test

the transmitter and receiver in several locations before you permanently mount the repeater.

• Select a location with access to 220-240VAC power.

• If this repeater transmits directly to the panel, locate it between the panel and the distant transmitters (but within panel reception range).

• If this repeater transmits to another repeater, locate this repeater between the receiving

repeater and the distant transmitters (but within the reception range of the receiving repeater).

Testing the Repeater Transmitter

After the repeater is temporarily mounted, perform a Dealer Sensor Test to determine whether or

not the signals sent by this repeater are received by the control panel. If the repeater passes this

test, skip to “DOOR/WINDOW SENSORS.”

If the repeater fails this test, it is too far from the control panel and must be relocated. Move the

repeater to a new location perform another Dealer Sensor Test. Continue until the repeater passes

this test.

Note

If this repeater will be transmitting to another repeater, perform a Repeater Reception Test on the destination repeater to ensur e t hat th e si gnals from this repeater ar e re cei ved. If the destination r epeater

does not receive the signals from this repeater, move this repeater to a new location and try again. Continue until the destination r epeater can receive signals from this repeater.

Testing a Repeater Receiver

Distant transmitters (i.e., any transmitter that failed the Dealer Sensor Test) must pass this test.

This test checks the communication link between a transmitter (e.g., sensor or touchpad) and the

repeater that will re-transmit its signal.

Note

This test requires two peo ple. O ne person must activate (trip) th e transmitter while another person

observes the repeater LED .

¾ To perform a repeater reception test:

1. Take the cover off this repeater so you can observe the LED.

2. For sensors with a tamper switch, remove the cover from the sensor to cause an alarm transmission. The repeater LED should flash 7-8 times (indicating reception of the alarm signal).

or-- For sensors without a tamper switch, activate an alarm. The repeater LED should flash 7–8

times.

or-- For panic buttons, hold down the button for 5 seconds and release it. The repeater LED

should flash 14–16 times.

or-- For touchpads, hold down an emergency button for 5 seconds, then release it. The repeater

LED should flash 7–8 times.

or-- If this repeater will receive signals from another repeater, hold down the tamper switch of the

transmitting repeater for 5 seconds and release it. The LED of this repeater shoul d flash 14–

16 times in order to pass this test.

3. If any one of the distant transmitters fails this test, relocate the repeater and retest both the repeater transmitter and receiver.

or--Consider installing additional repeaters.

Adding Additional Repeaters

If there are distant sensors that are not within the reception range of this repeater, you must add

additional repeaters to the system. Perform the above installation procedure for each repeater,

assigning appropriate repeater identification numbers to ensure a “cascade” of repeated signals

(see “Setting the DIP Switches”).

6

Quik Bridge® Euro Repeater SAW Installation Instructions

Page 7

Mounting the Repeater

You must be free of static electricity before handling circuit boards. Wear a

grounding strap or touch a bare metal surface to discharge static electricity.

Static

¾ To disassemble and mount the repeater:

1. Remove the enclosure cover by removing the cover screws. Set the cover aside.

2. Remove the screws securing the circuit board in place. Remove the circuit board from the base and place it in the repeater cover.

Placing the circuit bo ard in direct contact with a metall ic

surface (such as a ladder) can permanently damage

the repeater.

m o u n t i n g

h o l e s

3. Hold the base against the mounting surface and mark the four mounting holes (see Figure 7).

Note

Remember to leave at least 10 inches above the repeater for the

antenna.

4. Remove the base and install anchors (included) where needed.

5. Place the base on the wall and secure it us ing the s crews included.

6. Reattach the circuit board to the base with screws.

7. To enable the cover tamper switch, wire a “normally

Figure 7. Mounting Hole

Locations (view

from back of base)

closed” contact (not included) to the terminals on J6 and glue the contact to the cover.

8. To disable the cover tamper switch, insert a jumper wire between the terminals as shown in Figure 6.

9. Replace the cover.

Repeater Installation Example

Install the control panel and sensors

1. Install the control panel.

2. Add (“learn”) sensors 1–8 into the control

panel memory, then mount them.

3. Determine which sensors are “distant” (outside the control panel reception range) by

performing a Dealer Sensor Test on all of

the sensors.

In this example, sensors 3–8 were determined

to be distant sensors.

Add a repeater to the system

4. Add (“learn”) repeater 1 into the control panel memory.

5. Place repeater 1 between the control panel and a group of distant sensors

For this example, sensors 3 and 4 were chosen

for use with repeater 1.

6. Remove power from the repeater and s et the repeater identification number to “two” (set the DIPs on repeater 1 to 0100000, as shown in Figure 5).

Note

By using only even number s i n the example “cascade,” we are also designing a flexible system . If

necessary, we can expand the system with mor e

sensors and repeaters i n t he f ut ur e ( w ithout re-

REPEATER

1

CONTROL

PANEL

SENSOR

NUMBER 7

REPEATER

3

SENSOR

NUMBER 8

SENSOR

NUMBER 4

SENSOR

NUMBER 2

8854G04C.DS4

SENSOR

NUMBER 6

SENSOR

NUMBER 5

REPEATER

2

SENSOR

NUMBER 3

SENSOR

NUMBER 1

Figure 8. Example Repeater Installation (arrows

denote communications links)

7Quik Bridge® Euro Repeater SAW Installation Instructions

Page 8

configuring all the origin al repeater identification num bers).

7. Configure DIP switch 8 to match your system.

8. Power up the repeater and perform a Dealer Sensor Test (on the repeater).

9. Perform a Repeater Reception Test on all distant sensors to determine which sensor signals this repeater is able to receive and retransmit.

For this example, only sensors 3 and 4 passed the test.

Add a second repeater to the system

10. Add (“learn”) repeater 2 into the control panel memory.

11. Set the identification number for repeater 2 to “four,” which is greater than the identification

number for repeater 1. This ensures that repeater 1 can recognize transmiss ions from repeater

2.

12.Configure DIP switch 8.

13. Place repeater 2 between repeater 1 and a group of distant sensors.

For this example, sensors 5 and 6 were chosen for use with repeater 2.

14. Perform a Repeater Reception Test between repeater 2 and repeater 1.

15. Perform a Repeater Reception Test on all remaining distant sensors (sensors 5 through 8) to

determine which sensor signals this repeater is able to receive and retransmit.

For this example, only sensors 5 and 6 passed the test.

Add a third repeater to the system

16. Add (“learn”) repeater 3 into the control panel memory.

17. Set the identification number for repeater 3 to “six.”

18.Configure DIP switch 8.

19. Place repeater 3 between repeater 1 and the remaining distant sensors (sensors 7 and 8).

20. Perform a Repeater Reception Test between repeater 3 and repeater 1.

21. Perform a repeater reception test on all remaining distant sensors (sensors 7 and 8) to deter-

mine which sensors this repeater is able to repeat.

For this example, sensors 7 and 8 passed the test.

Specifications

Compatibility: Euro SX-V Special (with software 7.0 or later), Euro Concord and

Euro Commander panels,

433 MHz Learn Mode sensors and wireless touchpads.

Power Requirements: 220-240VAC, 50 Hz, 75 mA.

A rechargeable12 V lead-acid backup battery is optional.

Fuse: T32 mA, 250 VAC

Dimensions: 8” x 4.75” x 3.125” (L x W x D), excluding antenna.

Euro SuperBus® 2000 RF Receiver Module,

8

Quik Bridge® Euro Repeater SAW Installation Instructions

Page 9

Declaration of Conformity

Manufacturer’s Name: GE Interlogix

Manufacturer’s Address:2266 North 2nd Street

North St. Paul, MN, USA 55109

EU Representative: GE Interlogix B. V.

Kelvinstraat 7

6003 DH Weert

The Netherlands

Product Identification: Product: Quik Bridge Euro Repeater SAW

Model Number: 60-841-43-EUR, 60-841-43-ITY

Brand: ITI

R&TTE Directive: See all standards used for E.M.C. and L.V.D.

Test Report Reference

60-841-43 CEQP Euro Repeater Rev. B

E.M.C:

EN50130-4 (1995), A1 (1998)

EN61000-3-2 (2000)

EN61000-3-3 (1995), A1 (2001)

EN300 220-3 v. 1.1.1 (2000)

L.V.D: IEC 60950: 3rd Edition (1999)

EN60950 (2000)

Means of conformity

We declare under our sole responsibility that this product is in conformity with Directive 93/68/EEC (Mark-

ing) and/or complies to the essential requirements and all other relevant provisions of the 1999/5/EC

(R&TTE) based on test results using (non) harmoni zed standards in accordance with the Directives mentioned.

Technical Service and Repair

If you experience trouble with this equipment, please contact

GE Interlogix

2266 Second Street North

North Saint Paul, MN, USA 55109

1-800-777-1415

for service and repair information. Changes or modifications not expressly approved by Interactive Technologies, Inc. can void the user’s authority to operate the equipment.

9Quik Bridge® Euro Repeater SAW Installation Instructions

Page 10

)

*(,QWHUORJL[

10

*(,QWH UORJ L[6; 9&R PP DQ GH U 6XSH U %XVDQG 4XLN%U LGJ H DUHUHJLVWHUHG

WUDGHPDUNVRI*(,QWHUORJL[&RQFRUGLVDWUDGHPDUNRI*(,QWHUORJL[

$OOULJKWVUHVHUYHG

Quik Bridge® Euro Repeater SAW Installation Instructions

6HFRQG6WUHHW1RUWK

1RUWK6DLQW3DXO0186$

7HFKQLFDO6XSSRUW

Loading...

Loading...