GE IC755CxW07CD SERIES, IC755CxS10CD SERIES, IC755CxS12CD SERIES, IC755CxS15CD SERIES, QuickPanel+ User Manual

Page 1

GE

Intelligent Platforms

QuickPanel+ Operator Interface

IC755CxW07CDx (7” Display)

IC755CxS10CDx (10" Display)

IC755CxS12CDx (12” Display)

IC755CxS15CDx (15” Display)

User Manual

GFK-2847F

For public disclosure

Page 2

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met during installation, operation, and maintenance. The information is supplied for informational

purposes only, and GE makes no warranty as to the accuracy of the information included herein. Changes, modifications,

and/or improvements to equipment and specifications are made periodically and these changes may or may not be reflected

herein. It is understood that GE may make changes, modifications, or improvements to the equipment referenced herein or to

the document itself at any time. This document is intended for trained personnel familiar with the GE products referenced

herein.

This document is approved for public disclosure.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing of this

document does not provide any license whatsoever to any of these patents.

GE provides the following document and the information included therein as is and without warranty of any kind, expressed

or implied, including but not limited to any implied statutory warranty of merchantability or fitness for particular purpose.

For further assistance or technical information, contact the nearest GE Sales or Service Office, or an authorized GE Sales

Representative.

Revised: Sept 2014

Issued: Nov 2013

Copyright © 2013 - 2014 General Electric Company, All rights reserved.

___________________________________

* Indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

Refer to the section, Contact Information for support on this product.

Please send documentation comments or suggestions to controls.doc@ge.com

For public disclosure

Page 3

Safety Symbol Legend

Indicates a procedure, condition, or statement that, if not

strictly observed, could result in personal injury or death.

Warning

Indicates a procedure, condition, or statement that, if not

strictly observed, could result in damage to or destruction of

equipment.

Caution

Indicates a procedure, condition, or statement that should be

strictly followed to improve these applications.

Attention

For public disclosure

Page 4

Contact Information

If you purchased this product through an Authorized Channel Partner, then contact the seller directly.

General Contact Information

Online technical support and GlobalCare http://support.ge-ip.com

Additional information http://www.ge-ip.com/

Solution Provider solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please contact us by

telephone or email, or on the web at http://support.ge-ip.com

Americas

Online Technical Support http://support.ge-ip.com

Phone 1-800-433-2682

International Americas Direct Dial

Technical Support Email support.ip@ge.com

Customer Care Email

Primary language of support English

1-780-420-2010 (if toll free 800 option is unavailable)

customercare.ip@ge.com

Europe, the Middle East, and Africa

Online Technical Support http://support.ge-ip.com

Phone + 800-1-433-2682

EMEA Direct Dial

Technical Support Email support.emea.ip@ge.com

Customer Care Email

Primary languages of support English, French, German, Italian, Czech, Spanish

+ 420-23-901-5850 (if toll free 800 option is unavailable or dialing from

a mobile telephone)

customercare.emea.ip@ge.com

Asia Pacific

Online Technical Support http://support.ge-ip.com

Phone

Technical Support Email

Customer Care Email

+ 86-400-820-8208

+ 86-21-3217-4826 (India, Indonesia, and Pakistan)

support.cn.ip@ge.com (China)

support.jp.ip@ge.com (Japan)

support.in.ip@ge.com (remaining Asia customers)

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

4 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 5

Contents

1 Introduction ....................................................................................................................................... 7

1.1 Specifications .. ....................... .............................................. .............................................. .................... 7

1.1.1 General Specifications .................. ....................... ....................... .............................................. .........7

1.1.2 Physical Specifications and Mounting Options.................. ....................... ....................... ..................... .. .8

1.1.3 Environmental Specifications .............................. .............................................. ..................... .............9

1.2 QuickPanel

1.2.1 Physical Overview .................. ..................... .. .............................................. ................................... 10

1.2.2 Status Indicators ................................... .. ..................... .............................................. ..................... 14

2 Pre-installation Checks.................................................................................................................15

2.1 Unpacking and Inspection ........ .............................................. .. ..................... .......................................... 15

2.2 Basic Setup .................... ..................... .. ............................................ .. .............................................. ... 17

2.3 Initial Startup................... ..................... .............................................. .............................................. .... 18

2.3.1 Connecting Input Power ......... ....................... ....................... .............................................. .............. 18

2.3.2 Initial Configuration .................................. ..................... .. .............................................. ................. 19

2.4 Runtime Setup ........ .. .............................................. ................................................................... ........... 19

2.5 Firmware Updates.. .............................................. .............................................. ....................... ............. 19

2.6 Shutdown......................................... .............................................. ....................... ............................... 20

3 Software............................................................................................................................................ 21

3.1 Operating System ....................... .............................................. ....................... ....................... ............... 21

3.2 Backup Utility.. ....................... .............................................. .............................................. .................. 21

3.3 Storage Manager ....................................... .............................................. ..................... ......................... 21

3.4 Copying Project to SD Card .... ....................... ....................... .............................................. ..................... 22

3.5 Updating a Machine Edition Project .......... .............................................. ..................... ............................. 23

3.6 FTP Server .............. .............................................. ....................... ....................... ....................... .......... 24

3.6.1 Authentication of Remote Users.... .. .............................................. .............................................. ....... 24

3.6.2 FTP with Removable Flash Devices ...... ....................... ....................... ..................... .. ........................ 24

3.7 HTTP Server .............. .. ............................................ .. ..................... .............................................. ....... 25

3.8 SNTP Server............................. .. .............................................. ..................... ....................................... 25

+

Hardware User Features ............ .............................................. .............................................. 10

4 Installation........................................................................................................................................27

4.1 Installing the Protective Sheet ...... .. ..................... .............................................. ....................................... 27

4.2 Choosing a Mounting Location................ .. ............................................ .. .............................................. ... 28

4.3 Panel Mounting ....................... .............................................. .............................................. .................. 29

4.4 Installation Procedure ............................. .............................................. ..................... ............................. 31

4.5 Mounting on a VESA Arm .............. ....................... .............................................. ................................... 33

4.6 Installing and Replacing the Battery .......... .............................................. ..................... ............................. 34

4.6.1 IC755CxW07CDx................................. .. .............................................. ..................... ..................... 35

4.6.2 IC755CxSxxCDx .... ....................... ..................... .. .............................................. ............................ 37

4.7 Connectors ....................................... .............................................. ....................... ....................... ........ 39

4.7.1 Power Connector Pin-out for IC755CxW07CDx and IC755CxSxxCDx .................. ..................... .............. 39

4.7.2 Ethernet for IC755CxW07CDx and IC755CxSxxCDx.................. .. ..................... ................................... 39

4.7.3 Serial Port .. ....................... ....................... .............................................. ....................................... 40

4.7.4 Universal Serial Bus (USB) Ports ......................... .............................................. ..................... ........... 44

4.7.5 Audio (LINE OUT) Details for IC755CxW07CDx and IC755CxSxxCDx ........................................... ....... 45

GFK-2847F User Manual 5

For public disclosure

Page 6

4.7.6 Audio (MIC IN) Details (only applicable to IC755CxW07CDx)............ .. .............................................. ... 45

4.7.7 SD Card Slot ..................................... .............................................. .. ..................... ....................... . 46

5 Operation.......................................................................................................................................... 47

5.1 Touchscreen Display ............................................ .............................................. ..................... .. ............. 47

5.1.1 Adjusting the Display Brightness ..................... .............................................. ....................... ............. 47

5.1.2 Configuring the Backlight......... ..................... .. .............................................. ................................... 47

5.1.3 Re-calibrating the Touchscreen ...... .............................................. .............................................. .. ...... 48

5.2 Keyboard ............................................. .............................................. ..................... ............................. 49

5.2.1 External Keyboard (Optional)................................ .. ................................................................... ....... 49

5.2.2 Soft Input Panel ...................... ....................... ....................... ....................... ................................... 49

5.3 Mouse ........................ .............................................. ..................... .............................................. .. ...... 49

5.4 Memory. .............................................. .............................................. ..................... ............................. 50

5.4.1 Dynamic RAM Memory.................................... .............................................. .. ..................... .......... 50

5.4.2 Modifying Memory Allocation ....................... .. ..................... .............................................. .............. 51

Appendix A Product Certifications and Installation Guidelines............................................... 53

Appendix B Orderable Part Numbers ..............................................................................................55

Appendix C IC755CxS12CDA Serial Port Details .........................................................................57

Index......................................................................................................................................................... 59

6 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 7

1 Introduction

The QuickPanel+Operator Interface is an all-in-one microcomputer designed for

maximum flexibility. The design is based on an advanced ARM core microprocessor to

combine a high-resolution touchscreen operator interface with a variety of

communications options. Users can connect to most industrial equipment through the

LCD

+

communications ports.

+

is equipped with several memory types to satisfy the most demanding

Freescale i.MX535 (1 GHz ARM Cortex A8)

DDR3 SDRAM 1 GB

512 KB (with battery backup)

10.4" Standard TFT LCD

800(W) x 600(H) pixels SVGA

2

400 cd/m

2

Projected capacitive

Two-point

1x 10/100BaseT (RJ-45) for IC755CxS12CDA

(1x 10-pin connector for IC755CxS12CDA)

2x USB 2.0 (Type-A)

Max power (5 V at 0.5 A)

1x USB 2.0 (Mini Type-B)

1x SD/SDHC card slot

12.1" Standard TFT

LCD

65,536

450 cd/m

LED

2x 10/100BaseT (RJ-45)

1x RS-232 UART port,

1x RS-232/485 port

(2x 5-pin connector)

2

QuickPanel

The QuickPanel

applications. A section of DRAM is split between the operating system, an object store,

and application memory. A section of non-volatile flash memory functioning as a virtual

hard drive is divided between the operating system and persistent storage for application

programs. Retentive memory is a battery-backed SRAM to store and protect valuable data

during a power failure.

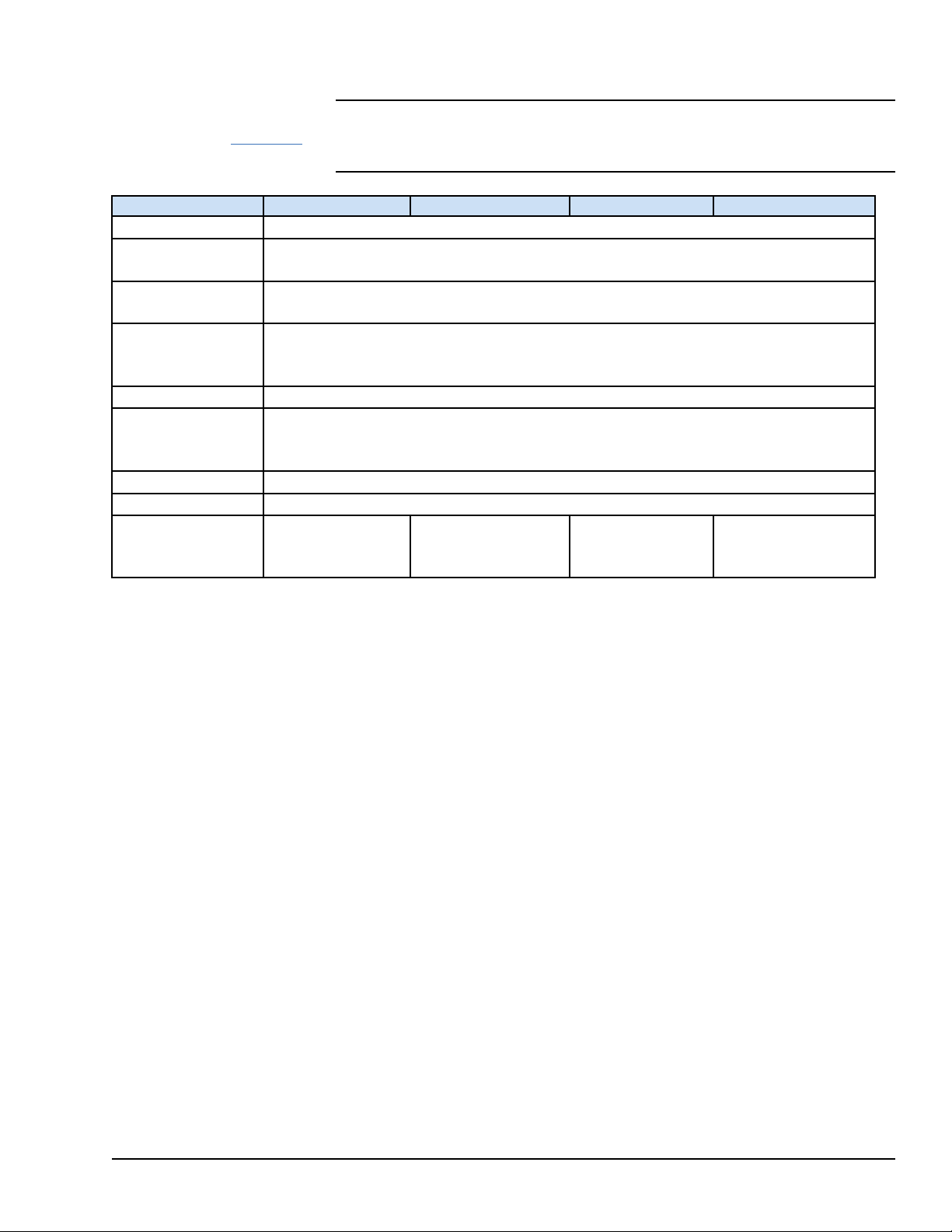

1.1 Specifications

1.1.1 General Specifications

Item IC755CxW07CDx IC755CxS10CDx IC755CxS12CDx IC755CxS15CDx

Processor

RAM

Memory

Operating System Microsoft Windows Embedded Compact 7

Display

Touchscreen

Communications

Storage

ROM SLC NAND 256 MB SLC NAND 512 MB

SRAM

Type

Resolution

Color

Brightness

Backlight

Touch Panel

Type

Multi-touch

Ethernet Port

Serial Port

USB, Host

USB, Device

DDR2 SDRAM

512 MB

7" Widescreen TFT

800(W) x 480(H)

pixels WVGA

310 cd/m

1x 10/100BaseT

(RJ-45)

1x RS-232 UART port

(5-pin connector)

15" Standard TFT

LCD

1024(W) x 768(H)

pixels XGA

310 cd/m

2

Introduction GFK-2847F User Manual 7

For public disclosure

Page 8

Item IC755CxW07CDx IC755CxS10CDx IC755CxS12CDx IC755CxS15CDx

1x Mic In (Mono)

Audio

Noise Immunity

Input power

Rated Voltage

Power

Consumption

Frame Ground

(FG)

(3.5 mm jack)

1x Line Out (Stereo)

(3.5 mm jack)

+24 V dc ±20%

(3-pin connector)

15 W (max), 0.625 A 18 W (max), 1.5/0.75 A 30 W (max), 2.5/1.25 A

Frame GND is connected to Signal GND internally

1x Line Out (Stereo) (3.5 mm jack)

Noise voltage: 1500 V p-p

Pulse duration: 1µs

Rise time: 1ns

+12/24 V dc ±20% (3-pin connector)

1.1.2 Physical Specifications and Mounting Options

Item IC755CxW07CDx IC755CxS10CDx IC755CxS12CDx IC755CxS15CDx

Dimensions (L×W×D)

Weight 0.80 kg (1.76 lbs) 2.40 kg (5.29 lbs) 3 kg (6.61 lbs) 4.46 kg (9.83 lbs)

Panel cutout

Mounting

Options

dimensions

VESA

mount

192 × 137 × 36 mm

(7.56 × 5.39 × 1.42 in)

183.50 × 128.50 mm

(7.22 × 5.06 in)

75 x 75 mm

(2.95 x 2.95 in)

278 × 222 × 65 mm

(10.95 × 8.74 × 2.56 in)

266 × 210 mm

(10.47 × 8.27 in)

314 × 248 × 65 mm

(12.36 × 9.76 × 2.56 in)

302 × 228 mm

(11.89 × 8.98 in)

100 x 100 mm

(3.94 x 3.94 in)

399 × 323 × 70 mm

(15.71 × 12.72 × 2.76 in)

379 × 305 mm

(14.92 × 12.01 in)

8 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 9

For additional product

standards and agency

approvals, refer to Appendix A.

Item IC755CxW07CDx IC755CxS10CDx IC755CxS12CDx IC755CxS15CDx

Cooling

Ambient Operating

Temperature

Ambient Storage

Temperature

Ambient Humidity

(Operating and

Storage)

Environment

Vibration Resistance

Altitude

ROHS

Enclosure Rating

IP65 in panel mount

1.1.3 Environmental Specifications

Note Install the QuickPanel+in a well-ventilated location that is not exposed to dust,

corrosive gases or liquids, rain, strong ultraviolet light or direct sunlight, and meets the

specifications listed in the following table.

Natural convection

0 to +55°C (32 to 131 °F)

-10 to +60°C (14 to 140 °F)

85% RH

Non-condensing, wet-bulb temperature: 30°C (86 °F) or less

Pollution Degree 2, Indoor use only

5 to 9 Hz single-amplitude 3.5 mm; 9 to 150 Hz constant-accelerated velocity 9.8 m/s

X, Y, Z directions 10 time (100 minutes)

(Compliance 3502, IEC61131-2 JIS B)

800~1114 hPa, altitude up to 2000 m (6561.68 ft)

Compliant with EU RoHS Directive 2011/65/EU

only

UL Type 4X rating;

IP65 in panel mount

only

IP65 in panel mount

only

UL Type 4X rating;

IP65 in panel mount only

2

;

Introduction GFK-2847F User Manual 9

For public disclosure

Page 10

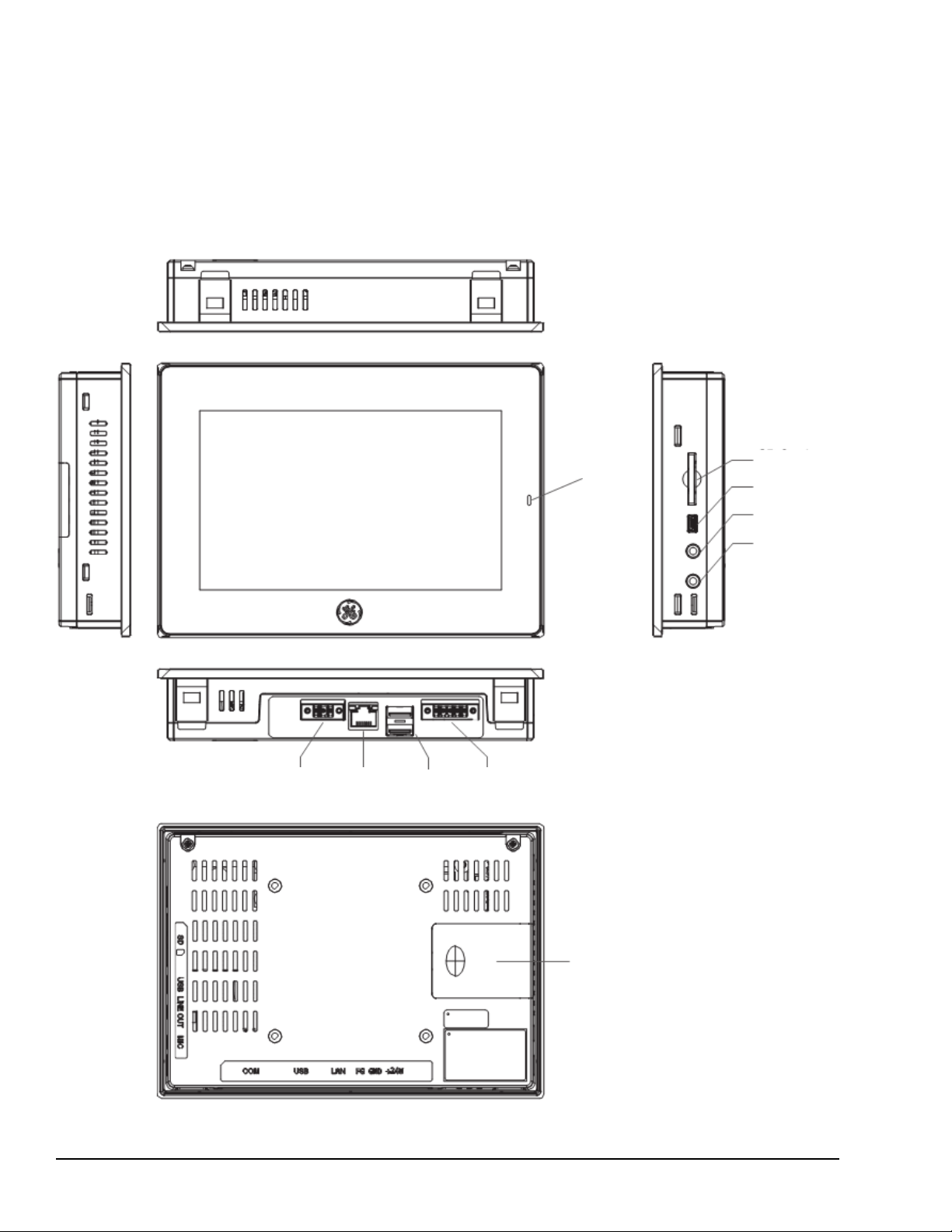

1.2 QuickPanel+Hardware User Features

Battery

Cover

COM

USB Host

Ports

LAN

Input

Power

SD Card

MICRO USB

LINE OUT

MIC IN

Status

Indicator LED

Touchscreen

LCD

In addition to the primary touchscreen interface, the QuickPanel+Operator Interface

supports a variety of communication ports.

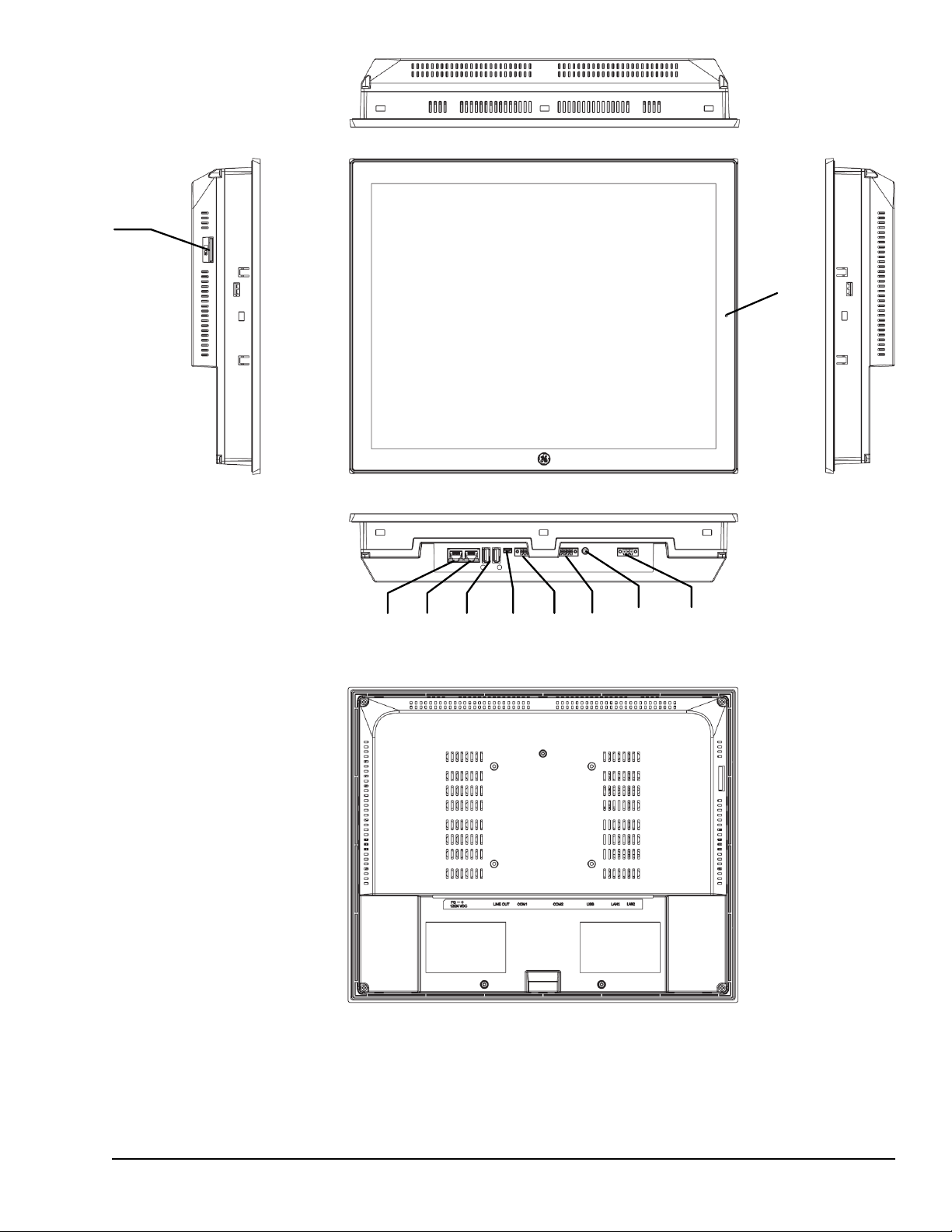

1.2.1 Physical Overview

The following diagrams display the physical layout of the QuickPanel+, including

locations of status LEDs, communications ports, and connectors.

IC755CxW07CDx Hardware Features

10 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 11

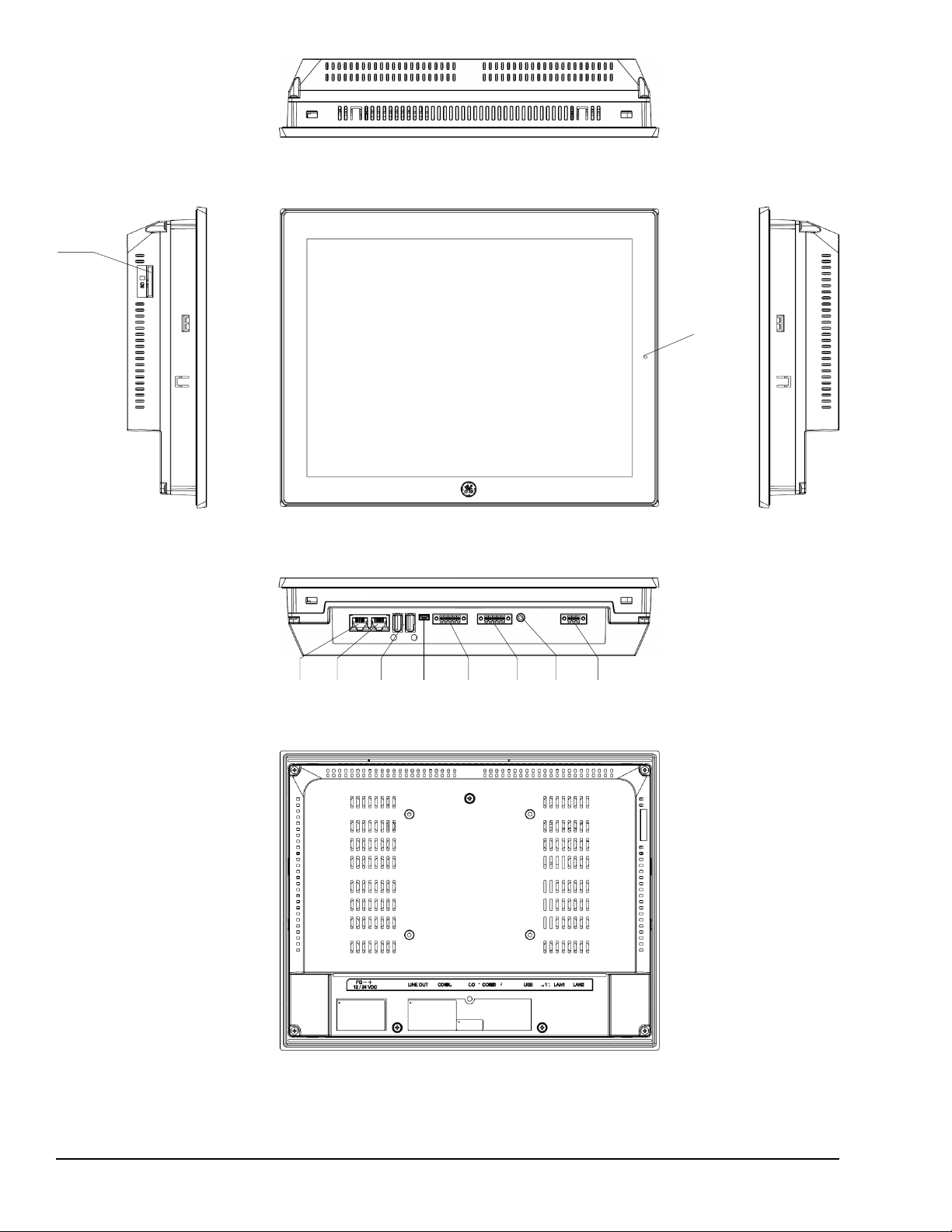

Status

Indicator LED

Touchscreen

LCD

SD Card

USB

Host

Ports

MICRO

USB

LAN2

COM1LAN1

Input

Power

LINE

OUT

COM2

IC755CxS10CDx Hardware Features

Introduction GFK-2847F User Manual 11

For public disclosure

Page 12

!

!

IC755CxS12CDx Hardware Features

12 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 13

Touchscreen

LCD

Status

Indicator

LED

SD Card

Input

Power

LINE

OUT

USB

Host

Ports

MICRO

USB

COM2

LAN2

COM1

LAN1

IC755CxS15CDx Hardware Features

Introduction GFK-2847F User Manual 13

For public disclosure

Page 14

1.2.2 Status Indicators

Speed Link Activity

The QuickPanel+has a tri-color LED that provides visual status indications for

IC755CxW07CDx and IC755CxSxxCDx units.

1.2.2.1 Status LED Operation

+

LED State

Amber, solid

Green, solid

Green, blinking Backlight off

Red, blinking Backlight failure

Off

QuickPanel

Operating system starting

Normal operating state

Power not applied to the unit

1.2.2.2 Ethernet Port LED Operation

The Ethernet port has two LED indicators: Speed and Link Activity.

LED LED State Operating State

Speed On, Yellow 10/100

Link Activity On, Green Link status

State

14 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 15

2 Pre-installation Checks

This chapter provides information for performing a pre-installation check of the

QuickPanel

Before installing and using the QuickPanel

• Unpacking and Inspection

• Basic Setup

• Initial Startup

• Runtime Setup

• Firmware Updates

• Shutdown

2.1 Unpacking and Inspection

Upon receipt of the QuickPanel+Operator Interface, carefully inspect all shipping

containers for damage. If any part of the system is damaged, notify the carrier

immediately. The damaged shipping container should be saved as evidence for inspection

by the carrier. It is the consignee’s responsibility to register a claim with the carrier for

damage incurred during shipment. However, we will fully cooperate should such action

be necessary.

+

Operator Interface.

+

, complete the following procedures:

For phone numbers and email

addresses, refer to the section,

Contact Information.

After unpacking the unit, record all serial numbers. Serial numbers are required if you

need to contact Customer Care during the warranty period. Shipping containers and

packing material should be saved in case it is necessary to transport or ship the unit.

Verify that all system components have been received and agree with the order. If the

system received does not agree with your order, contact Customer Care.

Before initial powerup, inspect the unit for loose or damaged components. If damage is

found (such as bent component leads or loose components), contact GE Intelligent

Platforms for additional instructions.

Do not apply power to the unit if it has visible damage.

Applying power to a unit with damaged components

may cause additional damage.

Caution

Pre-installation Checks GFK-2847F User Manual 15

For public disclosure

Page 16

Battery (Qty 1) (pre-installed)

Serial Port Connector (Qty 1)

Power Connector (Qty 1)

Mounting Brackets (Qty 4)

Protective Sheet (Qty 1) (not shown)

Gasket (Qty 1) (not shown, pre-installed)

QuickPanel +

Operator Interface

IC755CxW07CDx Example Package Contents

16 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 17

2.2 Basic Setup

Power Supply

Optional Ethernet

Connection

Optional USB Keyboard and Mouse

Serial I/O

Optional Serial I/O

The QuickPanel+Operator Interface is shipped ready for use after initial configuration.

To power up the unit, connect a dc power supply using the supplied quick-connect plug.

Depending on the application, you may also want to connect and configure optional input

devices, communications ports, and expansion adapters.

ELECTRICAL SHOCK HAZARD — To avoid

personal injury or damage to equipment, ensure that

the dc supply is disconnected from power and that the

leads are not energized before attaching them to the

Warning

unit's power supply plug.

If this equipment is used in a manner not specified by

the manufacturer, the protection provided by the

equipment may be impaired.

Warning

Basic Setup Diagram

Pre-installation Checks GFK-2847F User Manual 17

For public disclosure

Page 18

2.3 Initial Startup

M2.5

Mounting clamps

M2

Screw clamps

Power Connector

FG

GND +24 V dc

You will need the following:

• A Safety Extra Low Voltage (SELV) and Limited Energy Circuit or SELVand Class

• The power terminal block is supplied with the product. For voltage and requirements,

• The mating power terminal block supports stranded 30 – 14 AWG (0.05 – 2.00 mm

• At a minimum, the cable must be rated for 75°C (167 °F) or more.

• USB-compatible keyboard (optional)

• USB-compatible mouse (optional)

2.3.1 Connecting Input Power

�� To connect input power

1. Verify that the power cable is not energized.

2 dc power supply.

refer to the Input Power specifications in the table, General Specifications.

wires. The user calculates proper gauge wiring for current carrying capacity and loss

according to local regulations.

2

)

2. Loosen the screw clamps on the mating power

connector.

3. Strip the insulation from the power cables.

4. Secure the power cable to the mating connector,

noting polarity, and tighten the screw clamps. The

torque for the attaching screws is 0.3 Nm (2.66

in-lb).

5. Apply dc power to the unit. During normal startup

and operation, the QuickPanel

+

status LED indicator

displays as follows:

• Solid amber while the QuickPanel

+

is starting

up

• Solid green during normal operation

+

6. Once power is applied, the QuickPanel

begins

initializing. The first thing to display is the splash

screen.

To skip running any programs included in the

StartUp folder, tap Don’t run Startup programs.

The Microsoft Windows Embedded Compact 7

starts automatically.

18 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 19

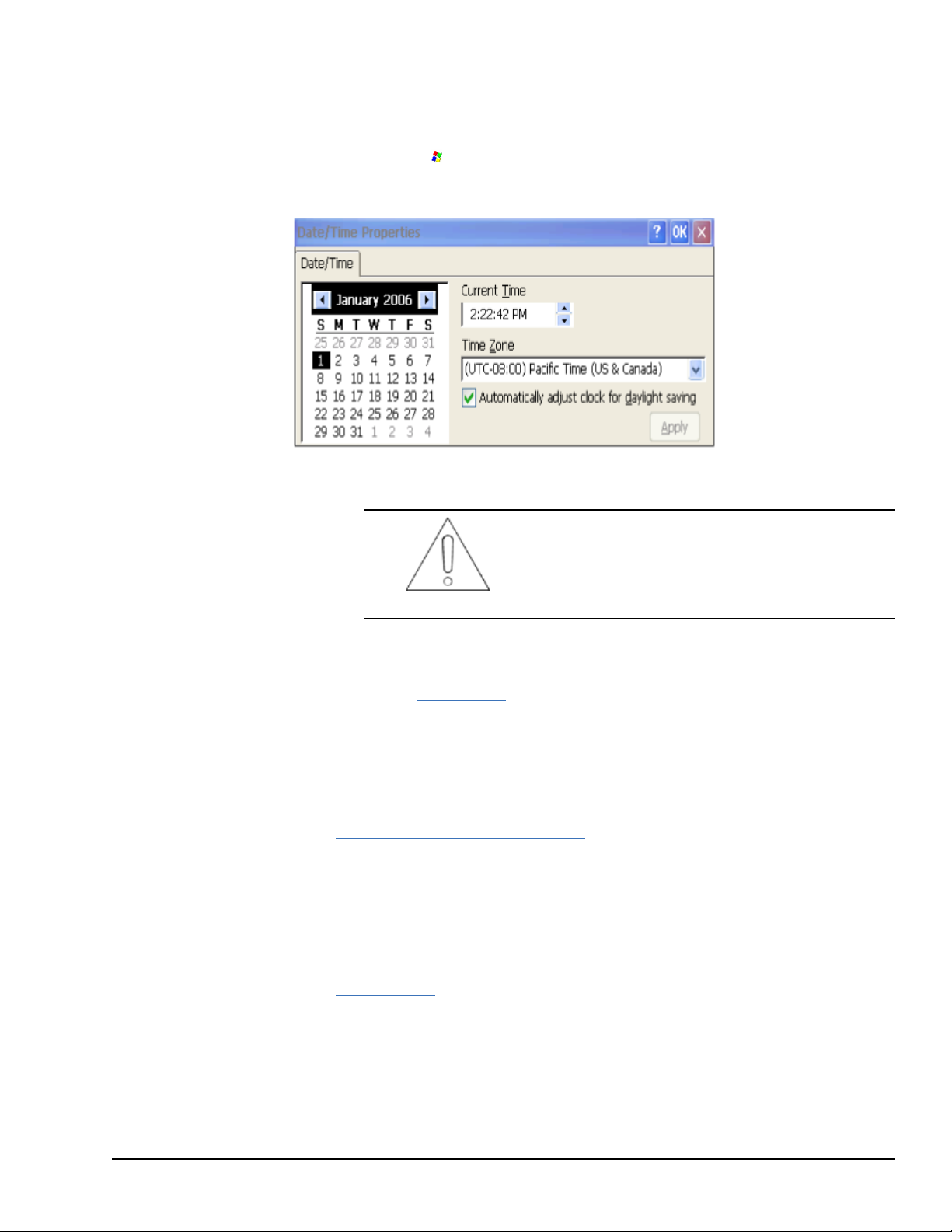

2.3.2 Initial Configuration

When you first start up the QuickPanel+, a few configuration steps are necessary.

�� To configure the QuickPanel

1. Tap Start, point to Settings, then tap Control Panel.

2. From the Control Panel, double-tap Date and Time to configure the system clock.

3. From the Control Panel, double-tap System to configure a Network Device Name.

Many applications, including Proficy Historian, require a unique Device Name.

+

It is recommended to set a unique Device Name for

+

the QuickPanel

to avoid future conflicts.

Attention

4. From the Control Panel, double-tap Network and Dial-up Connectionsto

configure network settings.

5. Run the Backup Utility to save the settings.

2.4 Runtime Setup

To download an application to a QuickPanel+Operator Interface, set up a data link

between the unit and your development workstation. Refer to the section Ethernet for

IC755CxW07CDx and IC755CxSxxCDx, and the Proficy Machine Edition (PME) online

help, Downloading a Machine Edition Project.

2.5 Firmware Updates

Update the unit to the most recent released version of the firmware with the latest feature

upgrades and issues addressed. Firmware updates for the QuickPanel

Support website.

+

are available on the

Pre-installation Checks GFK-2847F User Manual 19

For public disclosure

Page 20

2.6 Shutdown

There are no specific dangers associated with a power failure or other unplanned

shutdown of the QuickPanel

+

. In general, programs are retained in flash memory and user

data can be retained in battery-backed SRAM. Some operating system settings are

retained only with user intervention. We recommend the following procedure to shut

down the QuickPanel

+

.

�� To shut down the QuickPanel

+

1. Quit any programs that are running and wait for all file operations to complete.

2. If you have not changed operating system settings (for example, brightness or

touchscreen sensitivity) or do not want to save the changes, remove ac power from

the dc supply.

3. To save changes to operating system settings run Backup. When the Backup dialog

box displays Completed Successfully, remove power from the dc power supply

connected to the QuickPanel

+

.

20 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 21

3 Software

This chapter provides general information on the QuickPanel+software and procedures

for completing some of the most common tasks.

3.1 Operating System

Refer to http://windows.

microsoft.com.

Microsoft Windows Embedded Compact 7 is the operating system for the QuickPanel+. It

is a full 32-bit O/S with a graphical user interface. The QuickPanel

stored in flash memory and copied to a block of DRAM for execution. The operating

system starts automatically following a powerup or reset of the QuickPanel

3.2 Backup Utility

The Backup Utility saves the changes made to the Windows Registry or Desktop to Flash

Memory. This is required because the QuickPanel

the Backup Utility achieves the following:

• Stores the Windows Embedded Compact 7 registry (including any control panel

• Stores any changes (or additions) made to the \Windows sub-tree of the file system in

Run the Backup Utility whenever you make

configuration changes to the operating system or

installed applications, and before shutting down the

QuickPanel

Attention

settings) in Flash memory.

the user block of flash memory.

+

Operator Interface.

+

is not battery powered. Specifically,

+

operating system is

+

.

3.3 Storage Manager

Storage Manager, accessed

from the Control Panel folder,

is a Microsoft product for

which online help is available.

Software GFK-2847F User Manual 21

For public disclosure

Use Storage Manager to repair or format lost or corrupted data volumes. Storage Manager

can repair data volumes existing either in SD Card, battery-backed SRAM (BBSRAM),

or USB Flash Keys (thumb drives). Data volumes existing in the main flash file system of

the QuickPanel

+

may not be repaired by Storage Manager.

Page 22

3.4 Copying Project to SD Card

This is a custom utility for transferring Proficy Machine Edition View and Control

projects between compatible QuickPanel

Ensure that the copy or update operation is complete

such as no busy or wait cursor displays) before

disconnecting power.

Caution

�� To copy a Machine Edition project to SD card

1. Ensure there is a blank SD card in the SD card port.

2. Double tap the Copy Project to SD Card icon on the desktop.

3. Tap Yes when the Copy Project Query confirmation dialog box appears.

Copying a project while the Proficy Machine Edition

runtimes are active may cause an incomplete copy to be

created if the runtimes are also writing to files in the

project folders. The utility can detect this situation and

will notify you to stop the runtimes before making the

Caution

backup. You will not be able to create a backup while

the runtimes are writing files.

+

units via SD cards.

22 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 23

3.5 Updating a Machine Edition Project

You can update a Machine Edition application currently stored on the QuickPanel+with a

revision stored on a flash device, such as a SD card.

�� To update a Machine Edition project

1. Insert the flash device containing an upgraded version of the Machine Edition project

into the appropriate port.

2. Reboot the machine.

Note Depending on options set, the update may or may not be enabled, or may

automatically update. If there is more than one flash device with a valid project copy

present, a Select Media confirmation dialog displays, allowing you to choose which

flash device to update with. Select the device from the list and select OK to continue.

When a valid project is found on the flash device, you will be prompted to install the

project or skip it. Tap OK to install or Cancel to skip the install and continue to

boot. If an invalid project is found, an error message appears in a dialog box. This

dialog box must be closed before boot will continue.

3. Remove the flash device from the port.

Software GFK-2847F User Manual 23

For public disclosure

Page 24

3.6 FTP Server

The FTP server included with the QuickPanel+supports standard (RFC 959). It does not

support SFTP or implicit FTPS, which uses different ports and is based on SSH rather

than SSL.

The FTP server is configured with the Quick Panel+ Setup Tool. By default, the server is

not enabled. Once enabled, a background program will run, waiting for clients to connect.

Up to ten connections are supported. Sessions that are idle for five minutes are terminated

by the server.

The server supports non-secure operation. All information including username, password,

and data is transmitted with no encryption and susceptible to packet sniffing and various

FTP attacks.

Note If the server status is changed, the QuickPanel+must be re-booted before changes

take effect.

3.6.1 Authentication of Remote Users

The FTP root directory is

available from the QuickPanel

+

as \ and is the root of the

flash device.

The server only supports anonymous login: Anonymous with password requested (but not

validated). This may prevent some types of attacks and is required by some clients. Once

connected, a remote user is logged into the FTP root directory.

3.6.2 FTP with Removable Flash Devices

All removable flash devices appear to remote FTP users as directories off the FTP root

directory. Computer Flash card partitions display as directories such as \SDMemory and

USB Flash Keys as directories such as \Hard Disk. Full access privileges are granted for

the client in these folders/devices.

Removable flash device directories are captured when a session is opened and are not

changed while the session exists. If you start without an SD Card installed, you will have

to close your session and login again to see the SD Card directory. If the SD Card existed

when you logged in and is removed and inserted, it will still work, provided the SD

Card’s device name did not change during reinsertion.

24 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 25

3.7 HTTP Server

3.8 SNTP Server

The HTTP server included with the QuickPanel+supports standard (RFC 2616). The

HTTP server is configured with the Quick Panel+ Setup Tool. By default, the server is not

enabled. Once enabled, a background program will run, waiting for clients to connect.

The default web page is located in \Windows\www\wwwpub on the QuickPanel

Interface.

The server supports non-secure port 80 operation.

Note If the server status is changed, the QuickPanel+must be re-booted before changes

take effect.

The SNTP server included with the QuickPanel+supports SNTP Version 4 for IPv4, IPv6

and OSI. The SNTP server is configured with the Quick Panel+ Setup Tool. By default,

the server is not enabled. Once enabled, the server will refresh the time specified in the

setup tool configuration. Pressing the Update Now button immediately obtains the time

from the configured time server.

The SNTP server supports non-secure UDP port 123 operation.

+

Operator

Software GFK-2847F User Manual 25

For public disclosure

Page 26

Notes

26 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 27

4 Installation

This chapter provides the following procedures for installing the QuickPanel+Operator

Interface:

• Installing the Protective Sheet

• Choosing a Mounting Location

• Panel Mounting

• Mounting on a VESA Arm

• Installing and Replacing the Battery

• Connectors

4.1 Installing the Protective Sheet

�� To install the protective sheet

1. Remove the protective film on the screen of the QuickPanel

2. Wipe the display of any dust or fingerprints.

3. Peel a corner of the clear side of the protective sheet.

+

.

4. Begin applying the corner to the display.

5. Slowly apply the rest of the protective sheet, smoothing out as you go.

6. Peel the green curing film from the protective sheet.

Installation GFK-2847F User Manual 27

For public disclosure

Page 28

4.2 Choosing a Mounting Location

Refer to the section,

Environmental Specifications.

When mounting the QuickPanel+Operator Interface, make sure the mounting area allows

room to insert and remove the SD card, cables, and mounting brackets. Choose a location

that will allow natural convection air flow from bottom to top of the QuickPanel

enclosure. Do not mount the QuickPanel+at an angle more than 30° from the vertical, as

illustrated in the following figure.

+

Mounting Angle

28 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 29

4.3 Panel Mounting

To mount the QuickPanel+in an enclosure, you will need:

• One #2 Phillips head screwdriver

• Mounting brackets (supplied)

The IC755CxW07CDx, IC755CxS10CDx, and IC755CxS12CDx mounting holes are

located on the top and bottom sides of the unit.

IC755CxW07CDx Mounting Holes

IC755CxS10CDx and IC755CxS12CDx Mounting Holes

Installation GFK-2847F User Manual 29

For public disclosure

Page 30

The IC755CxS15CDx mounting holes are located on the top, bottom, and sides of the

unit.

IC755CxS15CDx Mounting Holes

30 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 31

4.4 Installation Procedure

Panel Thickness:

1.0 to 5.0 mm

(0.04 to 0.20 in)

128.50 mm (5.06 in)

183.50 mm (7.22 in)

Panel Thickness:

1.6 to 5.0 mm

(0.06 to 0.20 in)

266 mm (10.47 in)

210 mm (8.27 in)

Panel Thickness:

1.6 to 5.0 mm

(0.06 to 0.20 in)

228 mm (8.98 in)

302 mm (11.89 in)

Panel Thickness:

1.6 to 5.0 mm

(0.06 to 0.20 in)

379 mm (14.92 in)

305 mm (12.01 in)

Observe the following guidelines to properly mount and install the QuickPanel+Operator

Interface:

• To properly mount the QuickPanel

• The metal enclosure panel should ensure proper thickness and rigidity suitable to

To order replacement gaskets,

refer to the part number listed

in Appendix B.

minimize impact to the QuickPanel

• To avoid gasket degradation, limit repeated insertions or removals of the unit and

retightening of the mounting clips. For full protection, always use a fresh gasket.

• The unit will not fit through the cutout with any cables connected, or with the power

supply plug inserted in the socket.

Caution

+

, the enclosure should be of metal material.

+

.

When installing the QuickPanel+into the panel, pay

careful attention while handling the unit so it does not

drop and damage the unit.

�� To install the QuickPanel

1. Cut an opening in the panel according to the specifications in the following figures.

Note Panel cutout tolerances are +0.50, –0.00 mm (+0.02, –0.00 in).

IC755CxW07CDx Panel Cutout Dimensions

+

IC755CxS10CDx Panel Cutout Dimensions

IC755CxS12CDx Panel Cutout Dimensions

Installation GFK-2847F User Manual 31

For public disclosure

IC755CxS15CDx Panel Cutout Dimensions

Page 32

2. Verify that the gasket is present and properly seated in the bezel channel located on

the sides of the unit.

3. Insert the QuickPanel

+

into the mounting panel cutout.

4. Insert the hook of the mounting bracket into the mounting hole as displayed in the

following figure.

5. Tighten the screws on the mounting bracket in a clock-wise direction.

Torque Range for Mounting Clamp Screws

Unit Torque Range

IC755CxW07CDx 0.3 Nm (2.66 in-lb)

IC755CxS10CDx 0.7 Nm (6 in-lb)

IC755CxS12CDx 1.0 to 1.2 Nm (8.9 to 10.6 in-lb)

IC755CxS15CDx 1.0 to 1.2 Nm (8.9 to 10.6 in-lb)

32 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 33

4.5 Mounting on a VESA Arm

75

m

m

7

5

m

m

75 mm

(2.95 in)

75 mm

(2.95 in)

100 mm

(3.94 in)

100 mm

(3.94 in)

The QuickPanel+can be installed on a commercially available Video Electronics

Standards Association (VESA) MIS-D arm, stand, or apparatus that is listed to comply

with the UL1678 standard.

Refer to the mounting arm

manual for instructions.

�� To mount the QuickPanel

unit as displayed in the following figures.

The IC755CxW07CDx mounting holes attach with M4 screws that are 6 mm

(0.24 in) or less in length.

The IC755CxSxxCDx mounting holes attach with M4 screws that are 8 mm

(0.32 in) or less in length.

Torque Range for Mounting M4 Screws

Unit Torque Range

IC755CxW07CDx 0.7 to 0.8 Nm (6.2 to 7.1 in-lb)

IC755CxSxxCDx 1.0 to 1.2 Nm (8.9 to 10.6 in-lb)

+

: use the mounting holes located on the back of the

IC755CxW07CDx VESA Mounting Holes

Installation GFK-2847F User Manual 33

For public disclosure

IC755CxSxxCDx VESA Mounting Holes

Page 34

4.6 Installing and Replacing the Battery

Batteries may present a risk of fire, explosion, or

chemical burn if mistreated. Do not crush, disassemble,

short-circuit, or dispose of in fire.

Use of batteries not specified for use with the

Warning

Warning

QuickPanel

explosion.

Do not recharge, disassemble, heat or incinerate lithium

batteries.

Dispose of lithium batteries in accordance with federal,

state, and local regulations. Be sure to consult with the

appropriate regulatory agencies before disposing of

batteries.

1) Replacing the battery should only be performed by

trained personnel and in a non-hazardous location.

+

product may present a risk of fire or

Caution

2) If the QuickPanel

mounted, detach from the VESA arm when replacing

the battery.

3) The battery should only be replaced when the unit is

powered off.

4) Care should be taken to protect and insert the battery

with correct polarity.

5) Do not use any metallic item to remove the battery

(such as screwdrivers, knives, pliers, and so forth).

6) Be careful to not drop the battery or any associated

screws into the unit.

7) Be careful of edges on internal sides of the enclosure

and frame.

+

Operator Interface is VESA

34 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 35

4.6.1 IC755CxW07CDx

Battery Part Number IC755ACCBATT

�� To install or replace the battery for the IC755CxW07CDx

Replace the battery for the IC755CxW07CDx only with

battery part number IC755ACCBATT.

Caution

1. Remove the battery cover by pressing down while sliding outward.

IC755CxW07CDx Battery Cover Removal

2. Connect the battery harness connector to the header, noting keyed orientation.

Battery Harness Connection

3. Verify that positive (red) is down and negative (black) is up.

Installation GFK-2847F User Manual 35

For public disclosure

Page 36

4. Wrap the harness connector around to match the following figure. Do not let the

harness connector go above the tab.

Harness Connector Orientation

5. Slide the battery cover into place, taking care not to pinch the harness connector.

36 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 37

4.6.2 IC755CxSxxCDx

�� To install or replace the battery for the IC755CxSxxCDx

Replace the battery for the IC755CxSxxCDx only with

battery part number IC755ACCBATTNL.

Caution

1. Remove seven screws from the back cover.

IC755CxSxxCDx Screw Locations (Back Cover)

2. Gently press on either side tab to release the back cover.

Side Tab for Cover Release

3. Lift up the back cover to remove.

Installation GFK-2847F User Manual 37

For public disclosure

Page 38

The battery will be exposed on the back of the unit.

Battery Part Number IC755ACCBATTNL

IC755CxSxxCDx Battery

4. Gently remove the coin battery and replace with a new one, noting the polarity of the

battery.

5. Replace the battery cover and tighten all screws to 0.5 Nm (4.4 in-lb).

38 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 39

4.7 Connectors

1 3

8 1

Yellow Green

4.7.1 Power Connector Pin-out for IC755CxW07CDx and IC755CxSxxCDx

To connect the power supply,

refer to the section, Connecting

Input Power.

Refer to the section, Ethernet

Port LED Operation.

Connector: Terminal Euro (Tyco Electronics 284539-3)

Mating Connector: (Tyco Electronics 284510-3)

Pin # Signal Name Pin-out

1 +24 V dc

2 GND

3 FG

†

IC755CxSxxCDx supports both +12 V dc or +24 V dc IN

†

4.7.2 Ethernet for IC755CxW07CDx and IC755CxSxxCDx

The QuickPanel+is equipped with 10BaseT/100-BaseTX Ethernet port(s). You can

connect an Ethernet network cable (unshielded, twisted pair, UTP CAT 5) to the unit

through the RJ-45 connector(s) on the bottom of the enclosure. LED indicators on the port

indicate channel status. The port can be accessed by Windows Embedded Compact 7

network communications or by your application.

4.7.2.1 Ethernet Port Details

Interface: Ethernet 10BASE-T/100BASE-TX

Pin # Signal Name Pin-out

1 TX+

2 TX3 RX+

4 NC

5

6 RX7

8 NC

NC

NC

Installation GFK-2847F User Manual 39

For public disclosure

Page 40

4.7.2.2 Setting an IP Address

5 1

The QuickPanel+Operator Interface provides two methods to set an IP address:

• DHCP (Dynamic Host Configuration Protocol)

The network server assigns an IP address during QuickPanel

+

initialization. (You

must be connected to the network.) There must be a DHCP server on the connected

network for a valid IP address to be assigned. Contact your network administrator to

ensure correct DHCP server configuration.

• Manual Method

Specify the numeric addresses obtained from your network administrator for the

QuickPanel

+

IP Address, Subnet Mask and Default Gateway (if applicable).

Note Run the Backup utility to save the settings.

4.7.3 Serial Port

4.7.3.1 IC755CxW07CDx Serial Port Details

• A terminal block is supplied.

• The mating terminal block supports stranded 30-14 AWG (0.05 – 2.00 mm

2

) wires.

• At a minimum, the cable must be rated for 75°C (167 °F) or more.

• Secure the serial cable to the mating connector while noting signal orientation and

tighten the screw clamps.

• The torque for the attaching screws is 0.3 Nm (2.66 in-lb).

Interface: x1 RS-232

Connectors: Euro Terminal (Tyco Electronics 284539-5)

Mating Connector: (Tyco Electronics 284510-5)

COM1 Pin Details

Pin # Signal Name Pin-out

1 TXD

2 RXD

3 RTS

4 CTS

5

SGND

40 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 41

4.7.3.2 IC755CxSxxCDx Serial Port Details

5 1

5 1

For an IC755CxS12CDA serial

port, refer to

Appendix C IC755CxS12CDA

Serial Port Details.

• Terminal blocks are supplied.

• The mating terminal blocks support stranded 30 to 14 AWG (0.05 to 2.00 mm

2

)

wires.

• At a minimum, the cable must be rated for 75°C (167 °F) or more.

• Secure the serial cable to the mating connector while noting signal orientation and

tighten the screw clamps.

• The torque for the attaching screws is 0.3 Nm (2.66 in-lb).

Connectors: Euro Terminal (Tyco Electronics 284539-5)

Mating Connectors: Tyco Electronics 284510-5

4.7.3.2.1 Serial Port COM1

Interface: RS-232

COM1 Pin Details

Pin # Signal Name Pin-out

1 TXD

2 RXD

3 RTS

4 CTS

5

SGND

4.7.3.2.2 Serial Port COM2

Interface: RS-232C/485 (default is RS-485 Half-duplex)

COM2 Pin Details

RS–232 RS–485

Pin #

1 TXD

2 RXD

3 RTS

4 CTS

5

†

Full-duplex RS–485 is backwards compatible to RS–422 mode.

‡

Pins 1-3 and 2-4 are connected internally.

Signal Name

SGND SG SG

Signal Name

(Full-duplex

TXD+

TXD-

RXD+

RXD-

†

)

Signal Name

(Half-duplex†)

‡

DATA+

‡

DATA-

‡

DATA+

‡

DATA-

Pin-out

Installation GFK-2847F User Manual 41

For public disclosure

Page 42

Example of Full-duplex (RS–485 Mode) Connection

COM2 DIP Switch Setting

DIP SW Bit ON/OFF DIP SW Bit ON/OFF

1 OFF

1 ON

2 OFF 2 ON

3 OFF 3 OFF

SW2

4 OFF 4 OFF

5 ON 5 ON

SW4

6 ON 6 ON

7 OFF 7 OFF

8 ON 8 OFF

SW3

1 OFF

2 ON 2 OFF

3 OFF 3 OFF

SW5

1 OFF

4 OFF 4 OFF

42 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 43

Example of Half-duplex (RS–485 Mode) Connection

COM2 DIP Switch Setting

DIPSW Bit ON/OFF DIPSW Bit ON/OFF

1 OFF

1 ON

2 OFF 2 ON

3 ON 3 ON

SW2

4 OFF 4 ON

5 ON 5 ON

SW4

6 ON 6 ON

7 OFF 7 OFF

8 ON 8 OFF

SW3

1 OFF

2 ON 2 OFF

3 OFF 3 OFF

SW5

1 OFF

4 ON 4 OFF

Installation GFK-2847F User Manual 43

For public disclosure

Page 44

4.7.4 Universal Serial Bus (USB) Ports

5 1

4.7.4.1 USB Host Port Details for IC755CxW07CDx and IC755CxSxxCDx

The QuickPanel+has two full-speed USB 2.0 host ports. A variety of third party USB

peripheral devices are also available. Each connected USB device requires a specific

driver. The driver supplied with the QuickPanel

support; other devices require installation of the custom driver software.

Interface: USB 2.0

Number of Ports: Two

Connectors: Type-A connector

Maximum Supply Current: 0.5 A (per port)

Pin # Signal Name Pin-out

1 USB_VCC

2 USB_D-

3 USB_D+

4 USB_GND

+

is for optional keyboard or mouse

4.7.4.2 USB Device Port Details for IC755CxW07CDx and IC755CxSxxCDx

The USB device port allows the QuickPanel+Operator Interface to be used as Slave

device.

Interface: USB 2.0

Number of Ports: One

Connectors: Type-B Mini connector

Pin # Signal Name Pin-out

1 VCC

2 D3 D+

4 NC

5

GND

44 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 45

4.7.5 Audio (LINE OUT) Details for IC755CxW07CDx

1

2

3

1

2

3

and IC755CxSxxCDx

Interface: LINE OUT (stereo)

Number of Ports: One

Connectors: φ3.5 mm jack

Maximum output level: 1 Vrms

Pin # Signal Name Pin-out

1 GND

2 Lineout R

3 Lineout L

4.7.6 Audio (MIC IN) Details (only applicable to IC755CxW07CDx)

Interface: MIC IN (monaural)

Number of Ports: One

Connectors: φ3.5 mm jack

Maximum output level: 250 mVrms

Pin # Signal Name Pin-out

1 GND

2 Lineout R

3 Lineout L

Installation GFK-2847F User Manual 45

For public disclosure

Page 46

4.7.7 SD Card Slot

The QuickPanel+is equipped with one standard SD Card port. SD/SDHC memory cards

are supported. The SD card slot is spring-loaded for easy insertion and removal.

4.7.7.1 SD Card Storage Details

Connectors: SD card slot (push in-push out method)

Card support: SD/SDHC memory card

Maximum capacity: 32 GB

Note During insertion, observe the orientation of the SD card as displayed in the

following figures.

IC755CxW07CDx SD Card Location

IC755CxSxxCDx SD Card Location

46 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 47

5 Operation

5.1 Touchscreen Display

The QuickPanel+Operator Interface features a LED Backlit LCD touchscreen display

with two-point touch technology. The touch technology is based on projected capacitance,

which allows tracking of the finger without pressured contact and is conducive to smooth

scrolling and multi-touch gesturing capability. Display brightness and backlight operation

can be set using the operating system Control Panel.

Caution

5.1.1 Adjusting the Display Brightness

�� To adjust the brightness of the display

1. From the Control Panel, double-tap Display and select the Brightness tab to

display the Brightness window.

Although we recommend the use of the protective sheet,

do not operate the touchscreen with any hard materials,

such as a screwdriver. This could damage the

touchscreen display.

2. Drag the Brightness slider bar between Lowest and Highest.

3. Tap OK to exit the control panel.

4. Run the Backup Utility to save the settings.

5.1.2 Configuring the Backlight

�� To configure the backlight

1. From the Control Panel, double-tap Display and select the Backlight tab to display

the Backlight Display Properties window.

2. Select Automatically turn off backlight while on external power.

Backlight Display Properties

3. Tap OK to exit the control panel.

4. Run the Backup Utility to save the settings.

Operation GFK-2847F User Manual 47

For public disclosure

Page 48

5.1.3 Re-calibrating the Touchscreen

Battery

Cover

Switch

The QuickPanel+touchscreen is shipped pre-calibrated. However, If there are any issues

with touchscreen responsiveness, it may need to be re-calibrated.

�� To re-calibrate the touchscreen

1. Open the QuickPanel+ Setup tool.

2. Select the TouchPanel tab.

3. Select Recalibrate Touch Screen.

4. Select Recalibrate Touch Sensor.

Note During IC755CxW07CDx touchscreen sensor re-calibration, the user is

prompted to activate a switch located in the battery compartment. This is not

applicable to any other panel sizes.

5. Remove the battery cover and press the switch.

Touchscreen Sensor Calibration Switch

6. Replace the battery cover.

48 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 49

5.2 Keyboard

The QuickPanel+Operator Interface can be configured to use either or both a hardware

keyboard and a software emulation keyboard as operator data input devices. Typically, an

optional external hardware keyboard is used when in development mode, while the

included Soft Input Panel (SIP) is more applicable in an operational environment.

5.2.1 External Keyboard (Optional)

Any USB-compatible keyboard may be used as an input device for the unit. The USB

driver for the keyboard is included with the operating system and no configuraton is

required. To use an external keyboard, simply plug and play.

5.2.2 Soft Input Panel

The Soft Input Panel (SIP) is a touchscreen version of a standard keyboard that may be

used in place of a standard hardware keyboard. An icon in the system tray enables the

user to view or hide the SIP.

�� To show or hide the SIP: from the system tray located on the task bar, tap the

icon and select Hide Input Panel.

Note When visible, the SIP can be moved around the screen by dragging the title bar to

reveal parts of the screen that would be obstructed from view by the SIP.

5.3 Mouse

Any USB-compatible mouse may be used as an input device for the unit. The USB driver

for the mouse is included with the operating system and no configuration is required. To

use an external mouse, plug it into the appropriate port.

Operation GFK-2847F User Manual 49

For public disclosure

Page 50

5.4 Memory

5.4.1 Dynamic RAM Memory

The QuickPanel+Operator Interface is equipped with dynamic RAM (DRAM). Part of the

DRAM is reserved for the Windows operating system and is not accessible by user

applications. The remaining memory is split between two functions: an object store for

temporary file storage and the main memory for running programs.

Typically, compressed programs stored in flash memory are expanded and moved to

DRAM for execution. Temporary storage of program variables or data files is also

provided by DRAM. Any data stored in DRAM is not retained through a power cycle or

reboot.

The split between program memory and storage memory can be adjusted as necessary to

make more room for one or the other, depending on your specific application needs. For

example, if you find that an application is short of memory, alter the DRAM memory

allocation from the System Properties window.

Setting the Program Memory too low may prevent

additional applications from starting, or may cause

currently running applications to fail due to lack of

memory.

Caution

Setting the Storage Memory too low may prevent the

saving of files into the object store portion of the file

system, which may also cause application failures.

50 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 51

5.4.2 Modifying Memory Allocation

�� To change the memory allocation

1. From the Control Panel, double-tap System to display the System Properties

window.

2. From the Memory tab, drag the slider bar to divide into Storage and Program

memory. The amount of memory allocated to and used by each area is displayed in

the window. The blue slider bar indicates the current amount of unallocated SDRAM

and determines the boundaries within which the slider can move.

System Memory Slider Bar

Note Storage memory is limited to a maximum of 128 MB. Using the slider bar to

increase storage memory will provide more RAM-based storage in the folder \Object

Store.

3. Tap OK to apply the new setting.

4. Run the Backup Utility to save the settings.

Operation GFK-2847F User Manual 51

For public disclosure

Page 52

Notes

52 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 53

Appendix A Product Certifications and Installation Guidelines

The QuickPanel+Operator Interface is intended for use in industrial environments and,

when properly installed, shall comply with the agency approvals listed in this chapter.

Agency Approvals

Note The agency approvals listed in the following table and on the Declaration of

Conformities are believed to be accurate; however, the product’s agency approvals should

be verified by the marking on the unit itself.

Description Agency Marking

N.A. Safety for Programmable

Controller for use in Hazardous

locations

Class I Division 2 Groups A,B,C,D

Electromagnetic Compatibility

Directive

European Electromagnetic

Compatibility (EMC) for Industrial

Control Equipment

Conditions of Safe Use for Installation in Hazardous Locations

The following information applies to products bearing the UL marking for Hazardous

areas for explosive atmospheres:

Suitable for use in Class I Division 2 Groups A, B, C, D.

Comments

Certification by Underwriter's Laboratories to UL 61010-1;

UL61010-2-201;

CSA C22.2 No 142 – M1987; CSA 61010-1; CSA 61010-2-201

ISA 12.12.01 standard and CSA C22.2 No 213-M1987

Self-declaration in accordance with European Directives

EN61000-6-2, EN61000-6-4

EXPLOSION HAZARD — Class I Division 2 Groups

A, B, C, D; do not disconnect equipment unless power

has been removed or the area is known to be

non-hazardous.

EXPLOSION HAZARD — Substitution of components

may impair suitability.

Warning

EXPLOSION HAZARD — DO NOT VESA MOUNT.

Panel mount only with enclosures that shall only be able

to be opened with the use of a tool.

Appendix A Product Certifications and Installation Guidelines GFK-2847F User Manual 53

For public disclosure

Page 54

Government Regulations

The FCC requires the following note to be published according to FCC guidelines:

Note This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Changes or modifications to this unit that are not expressly approved by GE Intelligent

Platforms could void the user’s authority to operate the equipment.

Industry Canada requires the following note to be published:

Note This Class A digital apparatus complies with Canadian CAN ICES 3 (A)/NMB 3

(A).

EMC Installation and Operation Considerations

This equipment has been tested and found to comply with a minimum level of EMC

performance as defined by EN 61000-6-2 and EN 61000-6-4 standards. To meet these

requirements, the following installation and operation considerations were taken into

account:

• Shielding USB cables

• Limiting RS-232 cables to 15 m (49.2 ft) in length

• Using Audio ports only during operational maintenance

Although these considerations were deliberated during testing, actual EMC environments

vary greatly. Therefore, these considerations may not be necessary. Likewise, additional

measures, such as filtering, wire separation, and cable routing, may need to be considered

to ensure intended operation of the overall system.

54 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 55

Appendix B Orderable Part Numbers

QuickPanel+Operator Interface Part Numbers

Part Number

IC755CSW07CDx

IC755ACC07GAS

IC755ACC07MNT

IC755ACC07PRO

IC755ACC07ADP

IC755ACCBATT

IC755CSS10CDx

IC755ACC10GAS

IC755ACC10MNT

IC755ACC10PRO

IC755CSS12CDx

IC755ACC12GAS

IC755ACC12MNT

IC755ACC12PRO

IC755CSS15CDx

IC755ACC15GAS

IC755ACC15MNT

IC755ACC15PRO

IC755ACCBATTNL

Description

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

QuickPanel

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

7” Color TFT Widescreen with Multi-touch Projected Capacitive Screen, 24 V dc Powered

7” Replacement Gasket

7” Accessory Kit - Replacement Mounting Clips, Power and Serial Port Connectors

7" Replacement Screen Protectors (Qty 3)

Panel Adapter Kit - 8" QuickPanel View/Control to QuickPanel+ 7"

7” Replacement Battery Pack

10" Color TFT with Multi-touch Projected Capacitive Screen, 12/24 V dc Powered

10” Replacement Gasket

10" Accessory Kit - Replacement Mounting Clips, Power and Serial Port Connectors

10" Replacement Screen Protectors (Qty 3)

12" Color TFT with Multi-touch Projected Capacitive Screen, 12/24 V dc Powered

12” Replacement Gasket

12" Accessory Kit - Replacement Mounting Clips, Power and Serial Port Connectors

12" Replacement Screen Protectors (Qty 3)

15" Color TFT with Multi-touch Projected Capacitive Screen, 12/24 V dc Powered

15” Replacement Gasket

15" Accessory Kit - Replacement Mounting Clips, Power and Serial Port Connectors

15" Replacement Screen Protectors (Qty 3)

10”, 12”, 15” Replacement Battery Pack

Appendix B Orderable Part Numbers GFK-2847F User Manual 55

For public disclosure

Page 56

Notes

56 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 57

Appendix C IC755CxS12CDA Serial Port

10 1

Details

• A terminal block is supplied.

• The mating terminal block supports stranded 30-14 AWG (0.05 – 2.00 mm

• At a minimum, the cable must be rated for 75°C (167 °F) or more.

• Secure the serial cable to the mating connector while noting signal orientation and

tighten the screw clamps.

• The torque for the attaching screws is 0.3 Nm (2.66 in-lb).

Interface: x1 RS–232, x1 RS-232/485 (default is RS-485)

Connectors: Euro Terminal (Tyco Electronics 1-284539-0)

Mating Connector: (Tyco Electronics 1-284510-0)

Pin # Signal Name Pin-out

COM1

1 TXD

2 RXD

3 RTS

4 CTS

5

COM2 (RS-232/485

6 TXD/TXD+/DATA+

7

8 RTS/RXD+/DATA+

9 CTS/RXD-/DATA-

10 SG

†

RS-485 mode shorts pins 6-8 and 7-9

SGND

†

)

RXD/TXD-/DATA-

2

) wires.

Appendix C IC755CxS12CDA Serial Port Details GFK-2847F User Manual 57

For public disclosure

Page 58

Notes

58 GFK-2847F QuickPanel+ Operator Interface User Manual

For public disclosure

Page 59

Index

A

Accessories

part numbers 55

Audio

LINE OUT 45

MIC IN 45

B

Backlight

adjusting 47

configuring 47

Backup 7

Backup Utility 21

Battery

Installing/Replacing 34

part number 55

C

Calibration

touchscreen 48

Configuration

initial 19

Conformance 53

Connecting Input Power 18

Contact Information 4

protective sheet 27

IP Address 40

K

Keyboard 49

external 49

SIP 49

L

LED Operation

status 14

M

Machine Edition 22

updating a project 23

Memory 50

DRAM 50

Modifying allocation 51

Mounting

VESA Arm 33

Mounting Angle 28

mounting location

protective sheet 28

Mounting location 28

Mouse 49

N

Network device name 19

E

Ethernet

C755CxW07CDx and IC755CxSxxCDx 39

port LED operation 14

F

Firmware Updates 19

Flash devices 24

FTP

with removable Flash devices 24

FTP Server 24

H

HTTP Server 25

I

Installation 27

battery 34

guidelines 53

Installing

panel mounting 29

O

Operating Sytsem 21

P

Package Contents 16

Panel Cutout

dimensions 31

Panel Mounting 29

Part numbers 55

Power Connector 18

C755CxW07CDx and IC755CxSxxCDx 39

Product Certifications 53

R

Remote Users

authenication 24

Runtime Setup 19

S

SD Card

copy project to 22

GFK-2847F Index 59

For public disclosure

Page 60

storage details 46

SD Card Slot 46

Serial Port 40

IC755CxS12CDA 41

IC755CxS12CDx 57

Serial Port Details

IC755CxW07CDx 40

Setup

basic 17

runtime 19

Shutdown 20

Soft Input Panel 49

Software 21

Specifications 7

environmental 9

general 7

physical and mounting 8

Startup 18

Status Indicators 14

Store Manager 21

T

Touchscreen

calibrating 48

display 47

U

Universal Serial Bus (USB) Ports 44

Unpacking and Inspection 15

USB

device port details 44

host port details 44

V

VESA Arm

mounting 33

60 QuickPanel+ Operator Interface User Manual

For public disclosure

Page 61

Page 62

GE Intelligent Platforms

1-800-433-2682

1-434-978-5100

www.ge-ip.com

GFK-2847F For public disclosure

Loading...

Loading...