Page 1

GE

Power Conversion

Quantum™LMV

Low and Medium Voltage AC Induction

Totally Enclosed Fan Cooled Motors

NEMA 500 Frames

IEC 315 Frames

200-800 HP

150-600 kW

2-12 Pole

Page 2

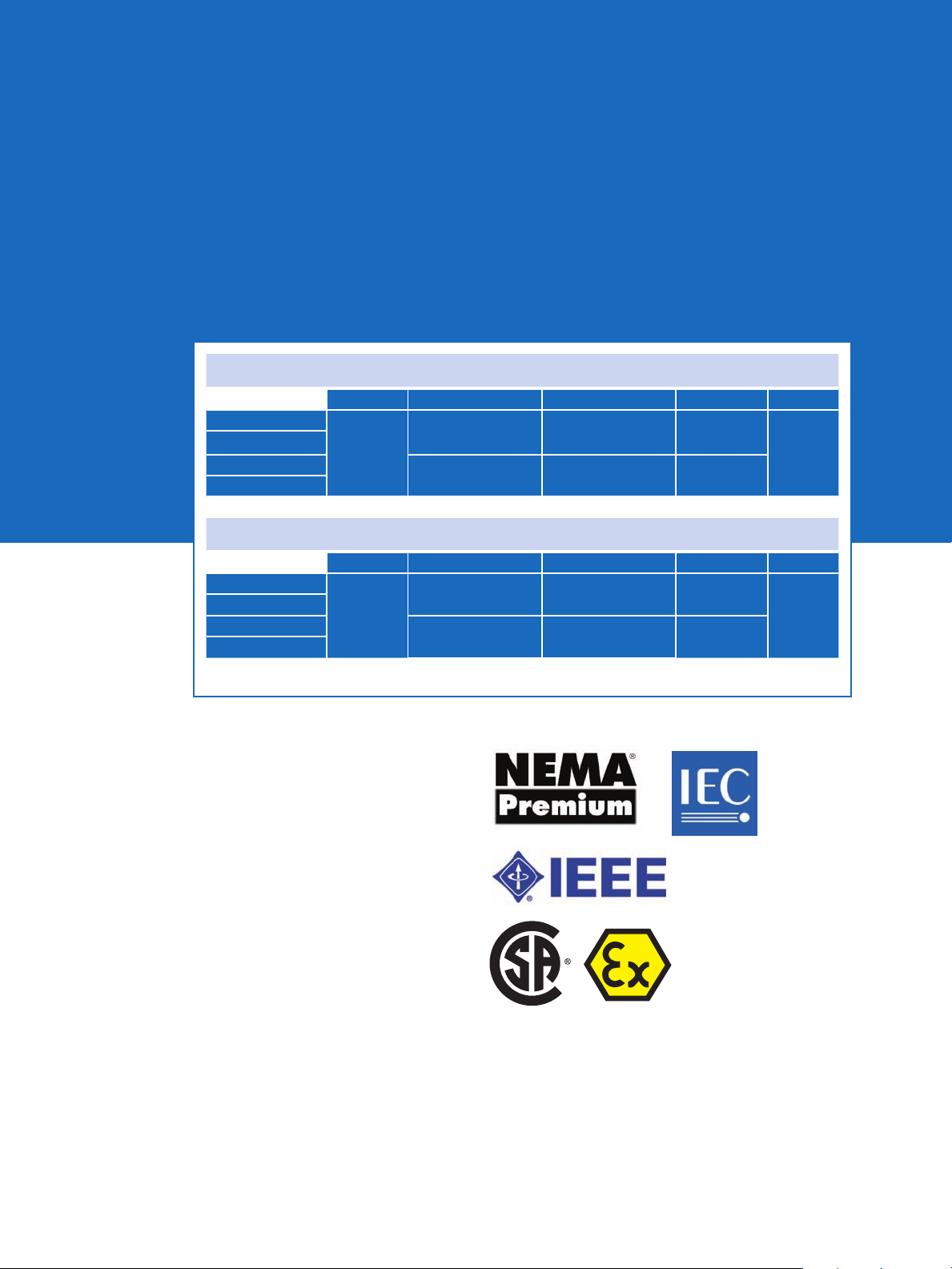

Ratings to Fit Your Applications

NEMA

Frame Size

Severe Duty

IEEE-841

API-547

API-541

509 - 5013

IEC

Frame Size

Severe Duty

IEEE-841

API-547

API-541

* Listed voltages are standard. Other voltages are available.

For your application requirements, contact your GE sales representative.

315

60 Hz* 50 Hz*

460V - 6900V 380V - 6600V 200 - 800

2300V - 6600V 3300V - 6600V 250 - 500

60 Hz* 50 Hz*

460V - 6900V 380V - 6600V 150 - 600

2300V - 6600V 3300V - 6600V

180 - 370

Hp

kW

Poles

2 - 12

Poles

2 - 12

Quantum LMV motors comply

with the following standards

and certifications:

NEMA

IEC

IEEE 841

CSA

API 547 and 541

Division 2

Zone 2 AEx nA

02 GE I Quantum LMV

Page 3

Proven Reliability

GE’s Quantum LMV-TEFC motors are

designed and built to operate under

extreme and harsh conditions in

industries including Petrochemical,

Power Generation, Mining and

General Process.

Operating in applications that

include pumps, blowers,

compressors, crushers and

conveyors, Quantum LMV TEFC

motors meet these industry

demands with superior features.

• Unique frame design, incorporating

D-Ducts to dramatically

increase airflow.

• Trapezoidal rotor vents for superior

cooling and heat distribution.

• External fan, cover and enclosure

engineered for low noise and

maximum heat transfer.

• Specially designed internal fan and rotor

ducts increase airflow allowing more

power in smaller frame sizes.

• Adjustable speed option.

• Sound pressure levels:

88 dBA with an option for 85 dBA (2-pole);

85 dBA with an option for 80 dBA (4-pole);

80 dBA (6-pole)

03GE I Quantum LMV

Page 4

What makes

Quantum LMV better?

Unique Design

The Quantum frame design utilizes an

internal air circuit with patent pending

frame D-Ducts and trapezoidal rotor

vents. This unique shape found in GE

motors dramatically increases airfl ow

for a cooler operating motor at a lower,

more versatile shaft height.

Increased airfl ow

and cooler operating

temperatures extend

motor life and

increase reliability.

• Superior cooling and heat distribution

• Low surface temperatures for

Division 2 and Zone 2 environments

Inverter Duty Reliability

Insulated drive and/or non-drive end

bearings with an Aegis shaft grounding

ring on the drive end, are optional. This

decreases the possibility of bearing fl uting and minimizes the impact of harmful

shaft voltages. A separate blower is available for constant torque applications.

Superior Bearings

Available self-aligning spherically seated

sleeve bearings allow the motor to adapt

to the best position for the load. The shaft

is allowed to adjust without increasing

temperature, vibration or noise levels.

04 GE I Quantum LMV

Page 5

Reliability Inside and Out

C

A

B

D

A

Rotor

The Quantum LMV rotor features

multiple oversized vents for maximum

cooling, resulting in a low temperature

rise. The rotor and internal fan are

shrink-fit onto the shaft, meeting

API specifications. Default material

is cast aluminum, however fabricated

copper bar is optional.

B

Frame

A stiff frame and increased foot

strength leads to a lower vibration

and increased horsepower capability.

Rigid feet, constructed using class 30

cast iron, offer solid mounting and

a high degree of safety during the

starting cycle of the machine. This

rugged construction also allows the

motor to run in extreme environments -40OC to 40OC.

C

Insulation

Quantum LMV motors feature an

epoxy solvent-less resin vacuumpressure-impregnation (VPI) process

to combine superior insulation

materials into a complete insulation

system to assure long and reliable

operation. The insulation system is

subjected to rigorous testing

according to applicable IEEE, IEC,

and NEMA standards.

D

Bearings

Self-aligning spherically seated sleeve

bearings per DIN 31693 are an available option for all ratings on Quantum

LMV 315/500 frames (pictured).

Ball bearings are standard. Roller bearings for severe belted applications are

also available.

05GE I Quantum LMV

Page 6

A wide range of catalog motors.

These pre-engineered NEMA ratings offer reduced cycle times

and stock level pricing to save you time and cost.

06 GE I Quantum LMV

Page 7

Global Expertise

Rotating Machine Factories

Converter Factories

Business Centers

Proven

Experience

Innovative

Technology

The GE

Advantage

Complete

Product

Offering

World-Class

Service

Few manufacturers can claim the depth and

breadth of experience that GE has in building

and delivering electrical and mechanical

solutions for customers.

GE offers a complete portfolio

of rotating machines.

GE has the global resources and capabilities

to maximize the performance and reliability

of your machines.

GE is constantly innovating product

technologies to meet and exceed

customer expectations.

07GE I Quantum LMV

Page 8

MAIN OFFICES

Australia, Botany

Tel: +61 (0) 2 8313 9980

Brazil, São Paulo

Tel: +55 11 3614 1930

Canada, Mississauga

Tel: + 1 905 858 5100

Chile, Santiago

Tel: + 56 2 271 92200

China, Shanghai

Tel: +86 21 6498 2600

France, Massy

Tel: +33 1 77 31 20 00

Germany, Berlin

Tel: +49 30 7622 0

Japan, Tokyo

Tel: +81 3 5544 3852

Russia, Moscow

Tel: +7 495 981 13 13

Singapore

Tel: +65 6332 0940

South Africa, Midrand

Tel: +2711237 0000

South Korea, Busan

Tel: +82 51 710 9015

UAE, Dubai

Tel: +971 44296161

UK, Rugby

Tel: +44 1788 563 563

India, Chennai

Tel: +91 44 4968 0000

USA, Pittsburgh

Tel: +1 412 967 0765

www.gepowerconversion.com

Quantum is a Trademark of General Electric Company

Copyright © 2014 General Electric Company and/or its affiliates. All rights reserved.

GEA31442A-EN (09/2014)

Loading...

Loading...