Page 1

Installation

Instructions

Downdraft Vent Systems

PVB94

PVB98

ZVB30

ZVB36

Page 2

Safet Information

BEFORE YOU BEGIN

Read these instructions completelg and carefullg.

"IMPORTANT- Savetheseinstructions

for local inspector's use.

"IM PORTANT- Observeallgoverning

codes and ordinances.

, Note to Installer- Be sureto leavethese

instructionswiththe consumer.

, Note to Consumer - Keep these instructions

for future reference.

, Skill Level- Installation of these vents require

basic mechanical and electrical skills.

, Completion Time- 1to 3 hours.

. Proper installation is the responsibility of the

installer. Product failure due to improper

installation is not covered under the warranty.

If you received a damaged vent, you should

immediately contact your dealer or builder.

For Monogram local service in gour area,

1.800.444.1845.

For Monogram service in Canada,

1.800.561.3344.

For Monogram Parts and Accessories,

call 1.800.626.2002.

--_WARNING: SHOCKHAZARD

Thisappliancemust be properlygrounded.

A WARNING:

TO REDUCE THE RISK OF FIRE,USE ONLY METAL

DUCTWORK.

A WA RNING:TOREDUCETHERISK

OF FIRE,ELECTRIC SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING.

A. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

BoBefore service or cleaning unit, switch power

off at service panel and lock the service

disconnecting means to prevent power from

being switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag,

to the service panel.

Do not attempt to repair or replace any part of

the downdraft system unless it is specifically

recommended in this book. All other servicing

should be performed by a qualified technician.

. For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and

vapors.

Installation work and electrical wiring must be

done by a qualified person(s), in accordance with

all applicable codes and standards including fire-

rated construction.

• Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent back drafting.

Follow the heating equipment manufacturer's

guidelines and safety standards such as those

published by the National Fire Protection

Association (NFPA),and the American Societg

for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

When applicable, install ang makeup (replacement)

air system in accordance with local building code

requirements. Visit GEApplionces.com for available

makeup air solutions.

ACAUTION: To reduce the risk of fire

and to properly exhaust air, be sure to duct air

outdoors. Do not vent exhaust air into spaces

within walls or ceilings or into attics, crawl spaces

or garages.

Page 3

CONTENTS

Design Information

Product Dimensions ................................................................3

Accessories ..................................................................................3

Advance Planning ...............................................................4, 5

Installation Preparation

Clearances ..............................................................................6, 7

Parts Supplied ............................................................................7

Tools and Materials Required .............................................7

Remove Packaging ..................................................................7

Power Supplg .............................................................................8

Venting Options .........................................................................9

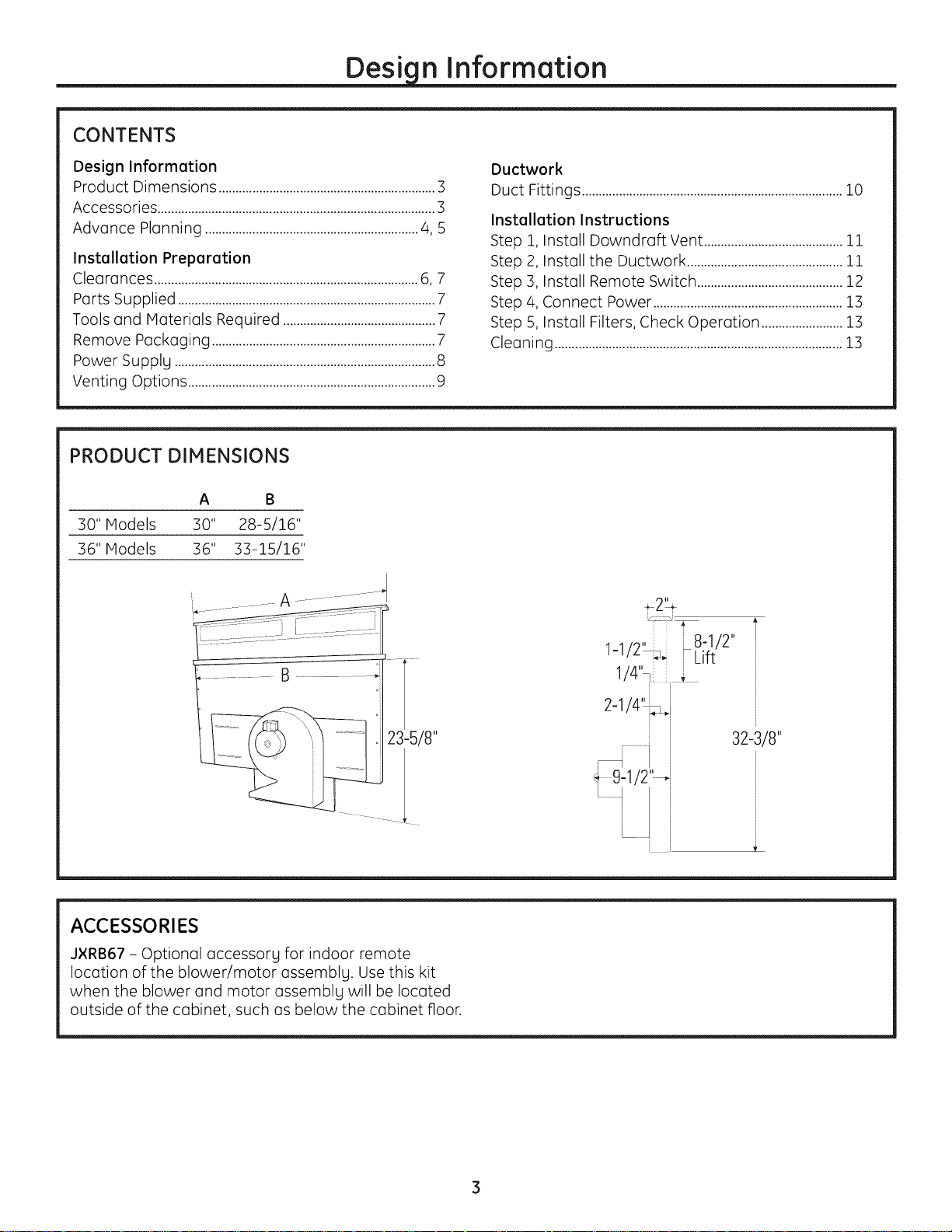

PRODUCT DIMENSIONS

A

30" Models 30"

36" Models 36"

Ductwork

Duct Fittings .............................................................................10

Installation Instructions

Step 1, Install Downdraft Vent .........................................11

Step 2, Install the Ductwork ..............................................11

Step 3, Install Remote Switch ...........................................12

Step 4, Connect Power ........................................................13

Step 5, Install Filters, Check Operation ........................13

Cleaning .....................................................................................13

23-5/8"

ACCESSORIES

J×RB67 - Optional accessorg for indoor remote

location of the blower/motor assemblg. Use this kit

when the blower and motor assemblg will be located

outside of the cabinet, such as below the cabinet floor.

; i

1-1 - 2

I/4_

,i7

2-1/4_j

_ 32-3/8"

Page 4

Desi n Information

ADVANCE PLANNING

Downdraft Vent and Cooktop Cutout

The installation of these downdraft vents with ang GE

or Monogram cooktop requires careful consideration.

Before you begin, review the combination cutout

illustrations on page 6.

Countertop Requirements

The countertop must have a deep flat surface to

accommodate the cooktop and the vent. Countertops

with a rolled front edge and backsplash may not provide

the flat surface area required.

Base Cabinet Requirements

Review the installation preparation on Page 6 to ensure

the base cabinet is deep enough to accommodate the

minimum clearance and that the side and back wall

locations allow the vent to be properlg secured. Ensure

no internal structure elements (such as cabinet corner

braces) interfere with the vent or cooktop.

Before gou begin, gou must:

1. Review countertop dimension illustrations to be

sure gou will have enough flat countertop surface.

2. Check to be sure that the total countertop depth

required (including minimum cutout to front edge

depth) allows enough space for a backsplash.

3. Review the cabinet illustration. Check to be sure

the interior cabinet depth will house the cooktop

burner box, the vent and the cutout clearance from

the front.

4. When countertop and cabinet depth present a

problem, review Creative Solutions.

5. Read this book completelg to accuratelg plan the

installation location, clearances and ductwork

requirements.

With careful planning, gou can achieve acustom look

with minimal adjustments.

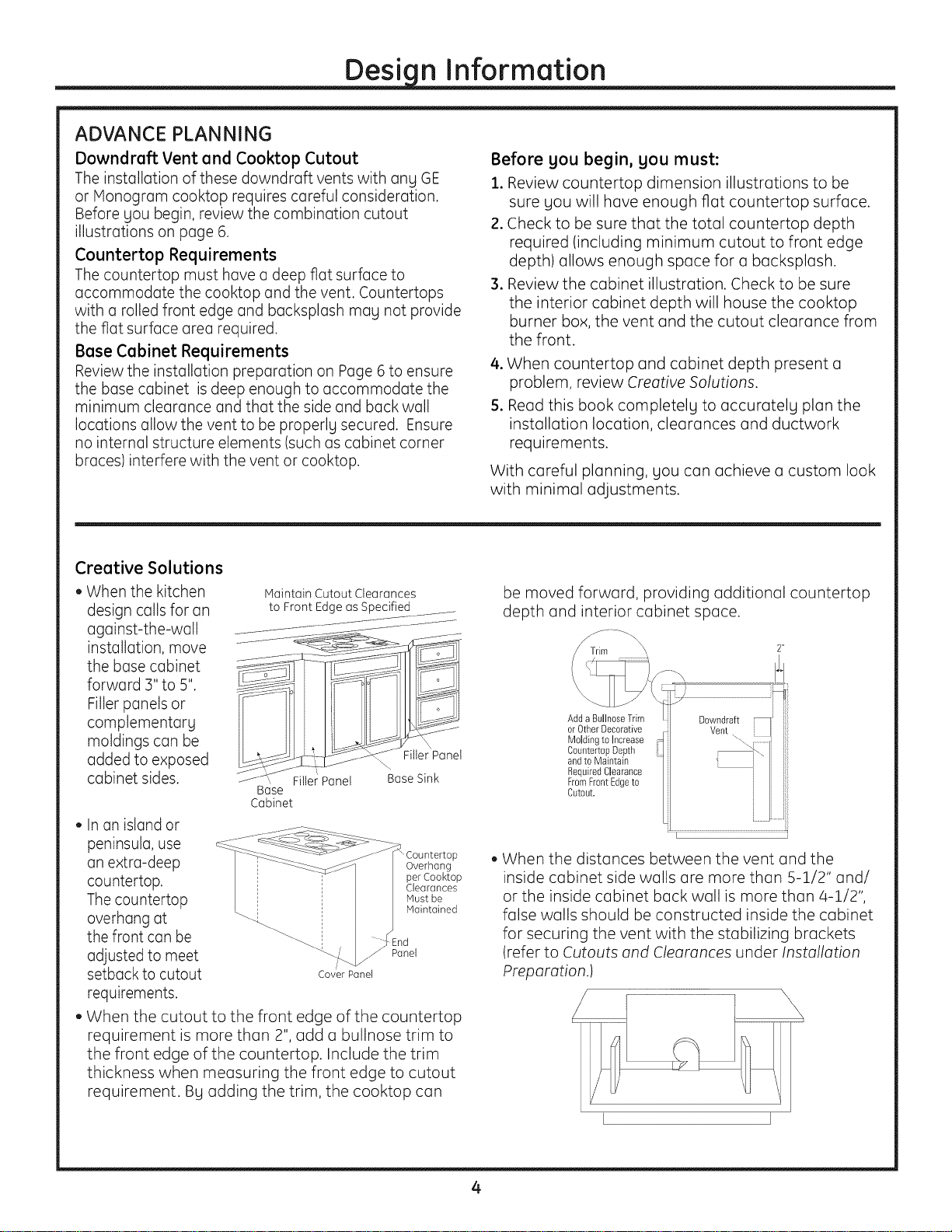

Creative Solutions

. When the kitchen

design calls for an

Maintain Cutout Clearances

to Front Edge as Specified

against-the-watt

installation, move

the base cabinet _!_i

forward 3" to 5".

Filler panels or

complementarg

moldings can be

added to exposed

cabinet sides. ' Filler Panel

Base

Cabinet

\

Filler Panel

Base Sink

. In an island or

peninsula, use

an extra-deep

countertop.

The countertop

Overhang

per Cooktop

Clearances

Must be

Maintained

overhang at

the front can be

adjusted to meet

setback to cutout

CoverPanel

-nd

Panel

requirements.

. When the cutout to the front edge of the countertop

requirement is more than 2", add a bullnose trim to

the front edge of the countertop, include the trim

thickness when measuring the front edge to cutout

requirement. Bg adding the trim, the cooktop can

be moved forward, providing additional countertop

depth and interior cabinet space.

Add a BullnoseTrim

orOtherDecorative

Moldingto Increase

CountertopDepth i

andto Maintain

RequiredClearance

FromFrontEdgeto

Cutout.

. When the distances between the vent and the

inside cabinet side walls are more than 5-1/2" and/

or the inside cabinet back wall is more than 4-1/2",

false walls should be constructed inside the cabinet

for securing the vent with the stabilizing brackets

(refer to Cutouts and Clearances under Installation

Preparation.)

I I

4

Page 5

Desi n Information

Clearances

, The downdraft system with blower, motor and

ductwork will occupy the cabinet below the

countertop and cooktop.

• The blower/motor assembly can be located

below the cabinet floor. The assembly will fit

between 16" floor joists. Order JXRB67 for indoor

remote locations.

Refer to your specific cooktop installation

instruction for appropriate clearances.

, Installation must conform with local codes.

Ductwork

Prepare ductwork to vent to the outdoors.

, Use the shortest and straightest duct run possible.

, The maximum permissible equivalent length for

duct run is 100 feet.

• Refer to "Duct Fittings" chart to calculate

equivalent length for various duct configurations.

o The downdraft blower system is designed to use

3-1/4" x 10" ductwork. It can be transitioned to 6"

round.

, Ductwork MUST be vented to the outside-never

into a crawl space, attic or other enclosed space.

, Determine the need for a wall cap or roof cap.

Order the cap in advance.

• When applicable, install any makeup (replacement)

air system in accordance with local building

code requirements. Visit GEAppliances.com for

available makeup air solutions.

Electricaland Gas Locations

Plan the placement of the electrical outlet and gas

connections (if used) carefully. Electrical outlets and

gas connections cannot be placed on the back wall

of the cabinet because it may interfere with the

downdraft plenum. Refer to POWER SUPPLYsection

for information on location of electrical and gas

connections.

, Install a standard electrical outlet on the right side

of the cabinet within reach of the vent's two-foot-

long power cord.

o The vent and a GE or Monogram gas cooktop

combination can operate from the same 120-volt

standard duplex outlet.

, Electric cooktops must operate from a separate

240-volt junction box.

• A 90 ° elbow (not supplied) can be installed onto

the inlet of the gas cooktop and route the gas

connections to avoid interference when installed

with a downdraft vent or other cabinetry features.

, The hood must vent down or to the left when

installed with a GE or Monogram gas cooktop to

avoid interference with the inlet of the gas cook-

top.

Page 6

Installation Preparation

CUTOUTS AND CLEARANCES

, Measure carefullg when cutting the countertop.

, Make sure sides of the opening are parallel and

rear and front cuts are exactlg perpendicular

(right angles) to the sides.

, Measure to be sure there is room for clearances

to the front edge of the countertop.

, Refer to cooktop installation instructions to be sure

that models fit into the base cabinets being used.

, Draw lines on the countertop to follow as a cutting

guide.

, Measure and mark cooktop and vent overlaps to be

sure there is enough fiat countertop depth.

• The cabinet side walls should be within 5-1/2" of the

vent bodg. The cabinet back wall should be within

4-1/2" of the vent bodg (refer to Creoi:ive Solutions.)

Cooktop Cooktop

o Measure the base cabinet width at the top and

bottom to ensure it meets the minimum width

requirements.

I MODEL I'A'MinimumWidth

PVBg8

ZVB36

PVB94

ZVB30 28-1/2"

]4"

SideView: Installed Vent Front View: Installed Vent

30" COOKTOP AND DOWNDRAFT

COMBINATION

The cooktop must be installed per manufacturer's

installation instructions.

INPORTANT: The countertop cutout depth requires

23-1/2" minimum flat countertop surface and 25"

minimum total countertop depth.

NOTE: Before gou begin, measure and mark depth

to ensure that adequate fiat countertop surface

is available.

For cooktop and downdraft combination depth:

, Follow cooktop installation instructions for cooktop

and downdraft combination installation.

• Otherwise, add 2-]/4" to the cooktop cutout depth.

NOTE: Add 2-7/8" to the cooktop cutout depth for

JP328 and JP626.

8-!/2"

]/8" Minimum fiat counter-

top behind cutout required

Minimum*

*Required to maintain ULor CSAapprovals

Page 7

Installation Preparation

36" COOKTOP AND DOWNDRAFT

COMBINATION

IMPORTANT: The countertop cutout depth requires

23-i/2" minimum flat countertop surface and 25"

minimum total countertop depth.

NOTE: Before you begin, measure and mark depth

to ensure that adequate fiat countertop surface

isavailable.

For cooktop and downdraft combination depth:

, Follow cooktop installation instructions for cooktop

and downdraft combination installation.

• Otherwise, add 2-3/4" to the cooktop cutout depth.

NOTE: Add 2-7/8" to the cooktop cutout depth for

JP328 and JP626.

8-!/2"

3/8" Minimum flat counter-

top behind cutout requirec

Minimum*

*Required to maintain UL or CSA approvals

PARTS SUPPLIED

Open the carton and remove parts package.

Check contents to be sure all pieces are present.

4 Stabilizing Brackets

With Screws

1 Remote Switch

D

2 Filters

i

1 Wire and White

Connector

TOOLS AND MATERIALS REQUIRED

Large flat-blade screwdriver

• Jigsaw

, Carpenter's square

, Ductwork to suit the installation

, Level

REMOVE PACKAGING

, Remove the shipping materials and the carton;

set carton aside. The carton can be used as a pad

when changing or adjusting vent direction.

Page 8

Installation Preparation

POWER SUPPLY

A WARNING: SHOCKHAZARD

FOR PERSONAL SAFETY,THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

Remove house fuse or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug with

this appliance. Follow National Electrical Code or

prevailing local codes and ordinances.

This downdraft vent must be supplied with 120V,

60 Hz. and connected to an individual, properlg

grounded branch circuit, protected bg a 15- or

20-ampere circuit breaker or time-delag fuse.

A properlg grounded 3-prong receptacle should be

located within reach of the vent's two-foot power

cord.

, Gas Cooktops

If this vent is installed in combination with a GE or

Monogram gas cooktop, it mag operate from the

same duplex outlet.

, Electric Cooktops

If this vent is installed in combination with a GE

or Monogram electric cooktop, the vent must

operate from a separate 120V outlet.

Locate the receptacle inside the cabinet on the right

side wall (see illustration). The receptacle cannot be

placed on the back of the cabinet wall where it mag

interfere with the downdraft plenum.

The downdraft vent power cord is to be routed

beneath the cooktop and routed awag from heat

generated bg the cooktop.

Ensure that the cooktop is installed per

manufacturer's installation instructions.

Locate the Gas or Electrical

Connection Onlg Within the

Shaded Area

/

9- "

/

I I

IMPORTANT

(Please read carefullg.)

The power cord of this appliance is equipped with

a three-prong (grounding) plug which mates with

a standard three-prong grounding wall receptacle

to minimize the possibilitg of electric shock. The

customer should have the wall receptacle and

circuit checked bg a qualified electrician to make

sure the receptacle is properlg grounded and has

correct polaritg.

• Where a standard two-prong wall receptacle is

encountered, it is the personal responsibilitg and

obligation of the customer to have it replaced

with a properlg grounded three-prong wall

receptacle.

Do not, under ang circumstances, cut or remove

the third (ground) prong from the power cord.

DO NOT USE AN EXTENSION CORD.

1/2 Gas or Electrical

Connections within

this Area

34" for 36" Models

I J DO NOT Locate

' 28-1/2" for 30" Models

Electrical

Outlet 12"

Cabinet

Floor

Above

Page 9

Installation Preparation

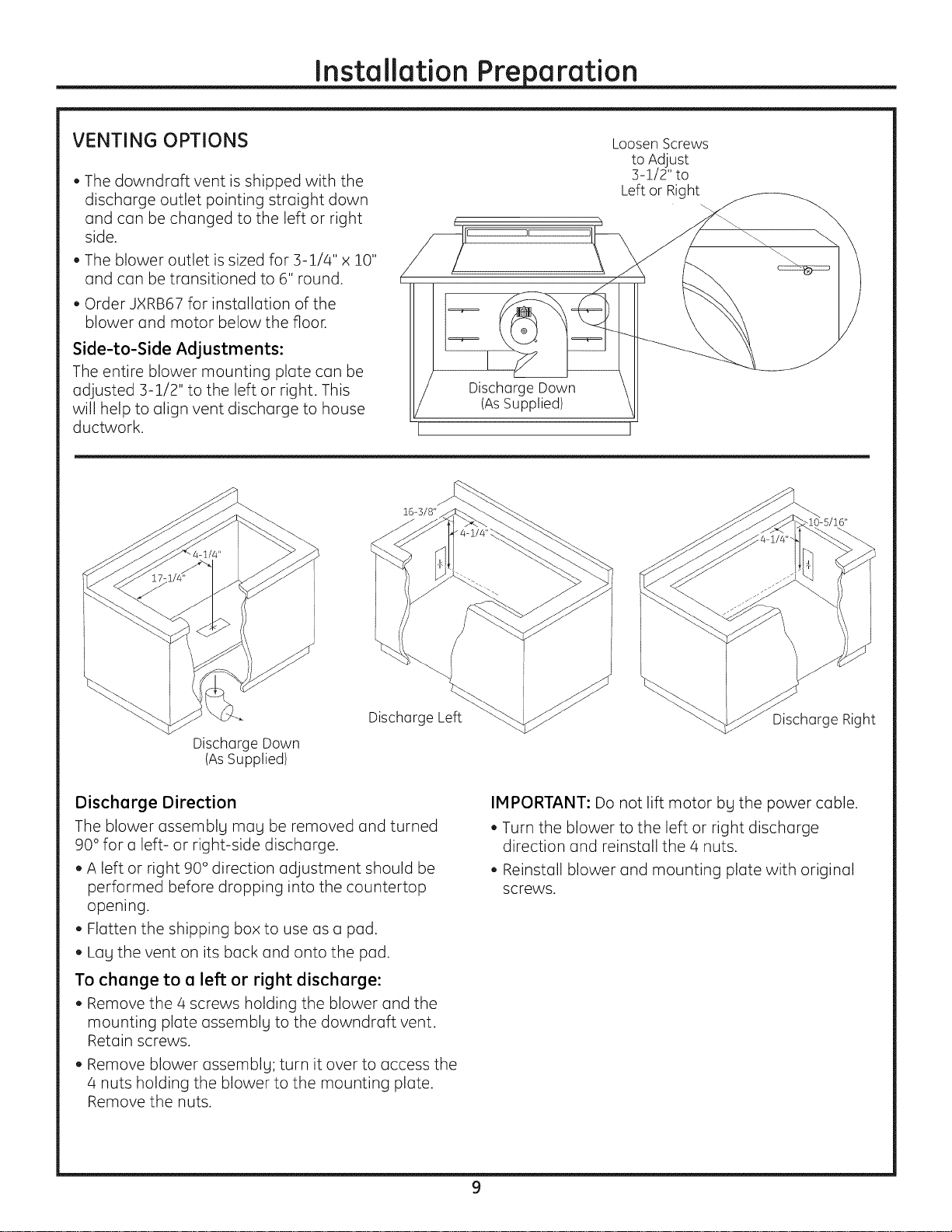

VENTING OPTIONS

, The downdraft vent is shipped with the

discharge outlet pointing straight down

and can be changed to the left or right

side.

• The blower outlet is sized for 3-1/4" x 10"

and can be transitioned to 6" round.

• Order JXRB67 for installation of the

blower and motor below the floor.

Side-to-Side Adjustments:

The entire blower mounting plate can be

adjusted 3-1/2" to the left or right. This

will help to align vent discharge to house

ductwork.

Loosen Screws

to Adjust

3-1/2" to

Left or Right

Discharge Down

(AsSupplied)

16-3/8"

Discharge Left

Discharge Down

(AsSupplied)

Discharge Direction

The blower assemblg mag be removed and turned

90 ° for a left- or right-side discharge.

, A left or right 90 ° direction adjustment should be

performed before dropping into the countertop

opening.

, Flatten the shipping box to use as a pad.

, Lag the vent on its back and onto the pad.

To change to a left or right discharge:

, Remove the 4 screws holding the blower and the

mounting plate assemblg to the downdraft vent.

Retain screws.

, Remove blower assemblg; turn it over to access the

4 nuts holding the blower to the mounting plate.

Remove the nuts.

Discharge Right

IMPORTANT: Do not lift motor bg the power cable.

, Turn the blower to the left or right discharge

direction and reinstall the 4 nuts.

, Reinstall blower and mounting plate with original

screws.

9

Page 10

Installation Preparation

DUCT

FITTINGS

Use this chart to

compute maximum

permissible lengths

for duct runs to

Use 3-1/4" x 10"

outdoors.

duct. It can

transition to 6"

round.

NOTE: Do not exceed

maximum permissible

equivalent lengths!

Downdraft Vent: 1OO'maximum

equivalent length

Flexible ducting:

If flexible metal ducting is used, all the

equivalent feet values in the table should

be doubled. The flexible metal duct should

be straight and smooth and extended as

much as possible.

DO NOT use flexible plastic ducting.

NOTE: Ang home ventilation sgstem, such

us a cooktop with a downdraft exhaust

mechanism, mug interrupt the proper flow

of combustion air and exhaust required bg

fireplaces, gas furnaces, gas water heaters

and other naturallg vented sgstems. To

minimize the chance of interruption of such

naturallg vented sgstems, follow the heating

equipment manufacturer's guidelines and

safetg standards such us those published

bg NFPAand ASHRAE When applicable,

install ang makeup (replacement) air sgstem

in accordance with local building code

requirements. Visit GEAppfiances.com for

available makeup air solutions.

Duct Piece

(_ 6"

(_ 6"

{_ 3-:y/411x 20"

[_,_, 6" round

[_'_/, 3-:Y/4" x 20"

_ 6" round to

[_ 3-:i//4" x 10" to 6"

Dimensions Length*

6" round, (per foot

straight length)

3 -:i//4" x 10" (per foot

straight length)

90 ° elbow Z2 ft.

45° elbow 7 ft.

90 ° elbow 2/4ft.

3-:I//4" x 10"

45° elbow 8 ft.

3-:Y/4" x 10"

90° flat elbow 33 ft.

to 3-:I/4" x 10"

transition 2 ft.

round to 6"

transition 2 ft.

3-:y/411x 20"

transition

90 °elbow /4ft.

round transition

90 °elbow /4ft.

Equivalent

lft.

Zft.

Ouantitg

Used

Total

Equivalent

Length

wall cap

6" round

with damper 2/4ft.

3-:i/4" x 10"wall cap

with damper 2/4ft.

]_ 6" round

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces is based

on actual tests conducted bg GE Evaluation Engineering

and reflect requirements for good venting performance

with ang downdraft cooktop.

roof cap 33 ft.

10

Total Duct Run

Page 11

Installation Instructions

[] INSTALL DOWNDRAFT VENT

(_) Two stabilizing brackets must be installed on

each side of the downdraft vent.

, For right-side or straight-down blower

discharge, fasten the stabilizing brackets at

locations A, B, D and E.

. For left-side blower discharge, fasten the

stabilizing brackets at locations B,C, D and E.

D j

--E

L_w i

..................

A_

C_

C

(_ Place the downdraft vent into the countertop

cutout so that the buck flange of the vent is

sitting on top of the countertop.

Note: The downdraft vent mug need to be

turned at an angle to fit into the countertop

cutout.

(_ Secure the screws for the stabilizing brackets to

the cabinet back and side walls.

Cabinet Back

Bracket

Downdraft Ve_t__ Location A

-B

O Place Cooktop into the countertop cutout. There

should be a 1/8" minimum gap between the

front of the vent trim and the rear of the cooktop.

It mag be necessarg to readjust the cooktop and

repeat steps C and D.

[][] INSTALL DUCTWORK

,,The downdraft blower sgstem is designed for use

with 3-1/4" x 10" ductwork. It can be trunsitioned to

6" round.

• Ductwork MUSTbe vented to the outside-never

in a crawl space, attic or other enclosed space.

6" PVC duct should be used when installing under a

concrete slab.

NOTE: Local building code must be followed for

installation in specifging approved tgpe and schedule

of PVCduct used.

• DO NOT USE flexible plastic ducting.

• Alwmgs use appropriate roof or wall cap with dumper.

Luundrg-tgpe wall cups should never

be used.

,, Usethe straightest duct run possible.

,, For satisfactorg performance, the duct run should

not exceed 100 ft. or its equivalent length when

bends or various fittings are used. Refer to the table

of equivalent lengths to calculate gour installation.

Install ductwork so the piece of duct nearest the

downdruft unit slots INTO the next piece of the duct.

Secure the joints with self-tapping screws and upplg

duct tape around the joints to ensure an airtight seal.

(_ Check that the downdraft vent is verticallg level.

Operate the vent 3 to 5 times to ensure proper

installation.

_Duct Tape

am and Screw

Air

11

Page 12

Installation Instructions

[] INSTALL REMOTE SWITCH

AWARNING: SHOCK HAZARD

Disconnect electrical power from unit before

beginning switch installation. Failure to do so could

result in personal injurg or damage to the electrical

controls.

WARNING: BURNHAZARD

The remote switch must be located so that it can be

operated without reaching over the cooktop. Failure

to do so mug result in ignition of clothing which could

cause serious injurg or death.

Connect Remote Switch to Remote Harness

• Thread the remote harness through the 1/2"-dia.

hole and attach the harness connector to the

remote connector.

Remove the paper backing on the remote switch

foam piece and mount the remote switch on the

countertop such that the switch connectors stag

located in the 1/2"-dim. hole.

• Stick adhesive wire clamp near the 1/2"-dia. hole

and attach the loose wire with a wire tie.

Determine the location for the remote switch.

, The remote switch should be located so that the

vertical distance from the floor to the remote

switch is less than 48" and more than 15".

, The remote switch harness is 68" long and should

be installed so that it is not pinched and is awag

from moving parts.

Remote Switch

Foam Piece With

Adhesive Mounting" _

Surface

_ _-- !/2"-Dio. Hole

Strain Relief I_

(Adhesivewire clamp _, _

withtie) _ _ _x___

f If )? -Remote

\ II :_ Horness_ 1/2"-Dia.

/ II ( Remote

%// switch

_, / F°amtiP_gCserV_heAdhesive

Hating Connectors

Strain Relief

(Adhesive wire

clamp with tie)

Remote Harness

Control

Box

Connect Wire Lead to Control Box

, Connect the mating wire ends.

Place the adhesive wire clumps (provided) near

the mating connector.

Keep approximatelg ]"-long wire and attach

the wire to the clamp with a wire tie. This will act

as a strain relief.

Drill a 1/2"-dia. hole into the desired location. Use

the mounting bracket as a template to locate the

hole accuratelg. Check for interference between

the switch cover, adjacent objects and cooktop/

vent overlaps.

, If switch is mounted into a tile surface, drill the

hole between tiles. Use Iocallg approved caulking

to cover ang gaps.

, If the remote switch is not installed on the coun-

tertop, ensure that it is installed in a location that

meets local codes and is easilg accessible.

12

Page 13

Installation instructions

r4-]CONNECT POWER

Plug power cord into properlg grounded receptacle.

rs] INSTALL FILTERS, CHECK OPERATION

• Press the ON/OFF pad on the control

to raise the vent.

• Slip fingers into the vent holes. Lift the vent

straight up and pull forward.

Retainers

Filter Tabs

• Slide filter into the retainers Grid close the vent.

o Press the Fan Speed HIGHER pad to start the

blower. Adjust the blower bg pressing HIGHER or

LOWER.

, To lower the vent, press the ON/OFF pad.

NOTE: It is not necessorg to turn the fan OFF

before lowering the vent. The fan will automaticallg

turn off when the vent is lowered. When the fan

is not turned off before lowering the vent, it will

automaticallg come on at the previouslg set speed

when the vent is fullg raised.

IMPORTANT: The vent can be activated bg pressing

the pads on the switch. Do not use excessive force

or sharp objects to activate the switch. Damage

could occur and void the warrantg.

13

Page 14

Notes

14

Page 15

Notes

15

Page 16

131-i0728-7 ]

01-13 GE

NOTE:While performing installations described in this book,

safety glasses or goggles should be worn.

NOTE:Product improvement is a continuing endeavor

at Genera] Electric. Therefore, materials, appearance

and specifications are subject to change without notice.

GE Consumer & Industrlel

Appliances

General Electric Comp(]ny

Louisville, K¥ 40225

GEApplionces.com

Loading...

Loading...