Page 1

GE Consumer & Industrial

Technical Service Guide

September 2008

GE Profile

Wall Oven

PT925

31-9176

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2008

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

Table of Contents

Bake Element ...................................................................................................................................................................... 36

Broil Element ....................................................................................................................................................................... 35

Component Locator Views ........................................................................................................................................... 25

Control Features ................................................................................................................................................................ 6

Control Voltage .................................................................................................................................................................. 48

Convection Bake Element .............................................................................................................................................37

Convection Fan Blade .....................................................................................................................................................36

Convection Fan Motor .................................................................................................................................................... 37

Convection Fan Troubleshooting ..............................................................................................................................53

Cooling Fan ..........................................................................................................................................................................41

Diagnostics and Service Information ...................................................................................................................... 48

Door Assemblies ................................................................................................................................................................28

Door Hinge Receivers ..................................................................................................................................................... 42

Electronic Oven Control ................................................................................................................................................. 32

Electronic Oven Control ................................................................................................................................................. 45

Error Codes .......................................................................................................................................................................... 57

General Troubleshooting ............................................................................................................................................... 54

Introduction ......................................................................................................................................................................... 4

Lock Assembly ...................................................................................................................................................................38

Lock Out Relay ................................................................................................................................................................... 40

Meat Probe and Outlet ................................................................................................................................................... 42

Nomenclature .................................................................................................................................................................... 5

Oven Component Access Chart ................................................................................................................................ 27

Oven Components ...........................................................................................................................................................28

Oven Light Assembly ...................................................................................................................................................... 42

Oven Light Bulbs ............................................................................................................................................................... 43

Oven Removal .................................................................................................................................................................... 32

Oven Sensor Ohmmeter Test ...................................................................................................................................... 53

Oven Temperature Sensor............................................................................................................................................35

Rear Access Panels .......................................................................................................................................................... 34

Relay Boards ....................................................................................................................................................................... 38

Ribbon Cable Assembly ................................................................................................................................................. 41

Sail Switch Assembly ...................................................................................................................................................... 40

Schematics and Wiring Diagrams ............................................................................................................................ 58

Service Mode ......................................................................................................................................................................50

Side Access Panels ........................................................................................................................................................... 33

Smoke Eliminators ............................................................................................................................................................ 44

Thermal Cut Outs .............................................................................................................................................................. 39

Top Access Panels ............................................................................................................................................................ 34

Using the Ribbon Cable for Troubleshooting ....................................................................................................... 51

Warranty .............................................................................................................................................................................. 62

– 3 –

Page 4

Introduction

The new 30-in. wall ovens have superior style and performance. These ovens feature electronic controls that

utilize the precision of modern digital technology. Additional features include:

Glass Touch LCD Controls - Combine a smooth, easy-to-clean glass design with large, easy-to-read •

graphics to facilitate easier usage

Flat Back Convection Fan - Features a more streamlined convection fan that better accommodates •

baking and roasting pans

Convection Bake - Provides ideal airflow •

throughout the oven cavity, ensuring better

baking results

Convection Roast - Provides even cooking and •

consistent results, roasting meats faster than a

traditional oven

Closed Door Broiling - Provides cleaner broiling •

with lower wattage heating elements

Self Clean Oven - Conveniently cleans the oven •

cavity without need of scrubbing

– 4 –

Page 5

Model Number

Nomenclature

P T 9 2 5 B R B B

GE Cooking Product

P = Profile

Configuration

T = 30-in. Wall Oven

Feature Pack

Designates features–the higher

the number, the more features.

Product Color

SS = Stainless Steel

BB = Black

WW = White

Model Year Designator

Glass Color

S = Integrated Stainless

B = Integrated Black

W = Integrated White

Serial Number

The first two characters of the serial number

identify the month and year of manufacture.

Example: AR123456S = January, 2008

Nomenclature

The nomenclature plate is located on the front

right behind the oven door.

The mini-manual is attached to the right side

wall of the oven.

A - JAN 2008 - R

D - FEB 2007 - M

F - MAR 2006 - L

G - APR 2005 - H

H - MAY 2004 - G

L - JUN 2003 - F

M - JUL 2002 - D

R - AUG 2001 - A

S - SEP 2000 - Z

T - OCT 1999 - V

V - NOV 1998 - T

Z - DEC 1997 - S

– 5 –

The letter designating

the year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Page 6

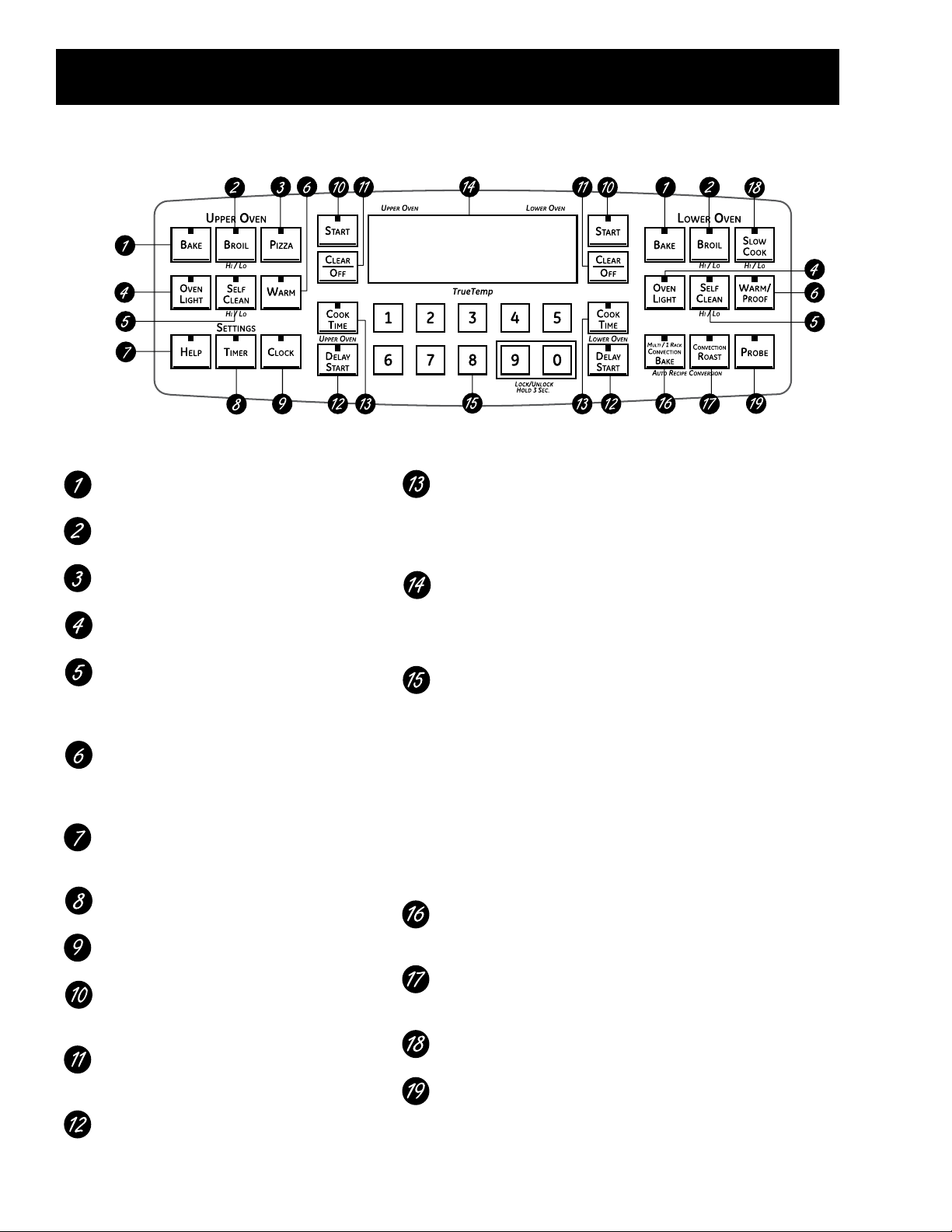

Features and appearance

may vary.

Control Features

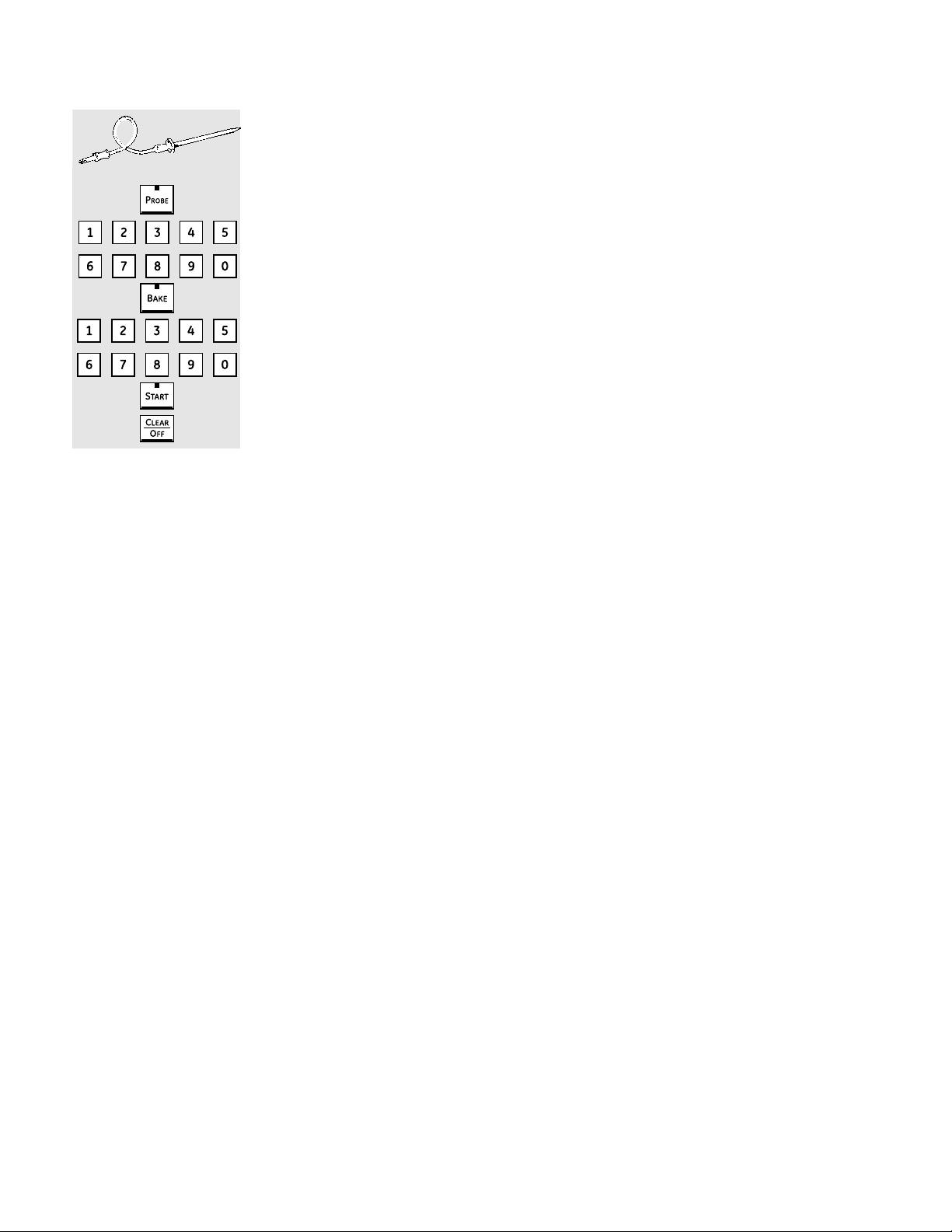

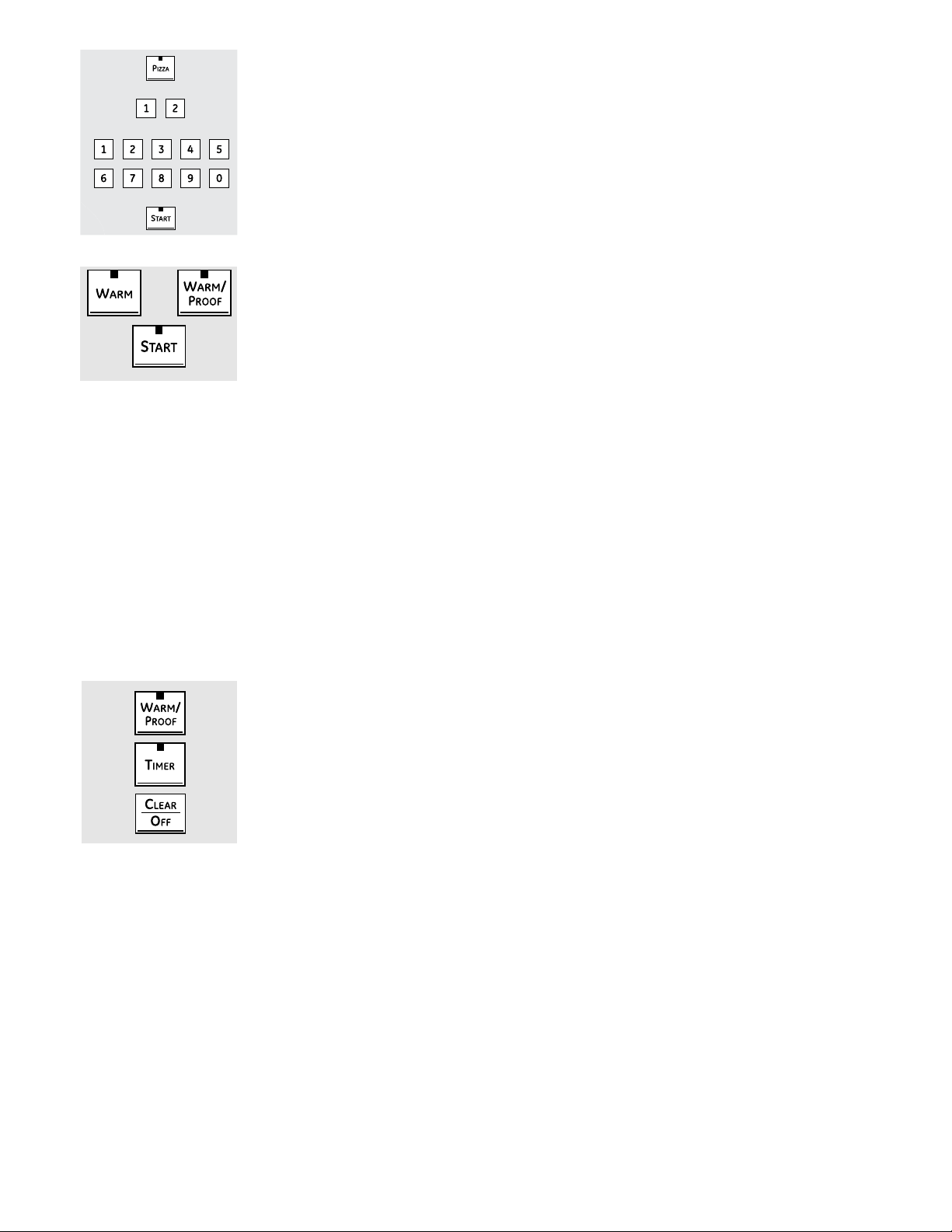

BAKE Pad

Touch to select the bake function.

BROIL HI/LO Pad

Touch to select the broil function.

PIZZA Pad

Touch to select the Pizza function.

OVEN LIGHT Pad

Touch to turn the oven light on or off.

SELF CLEAN HI/LO Pad

Touch to select self-cleaning function.

See the Using the self-cleaning upper

and lower ovens section.

WARM/PROOF Pad

Touch to keep cooked foods warm.

See the How to Set the Lower and Upper

Ovens for Warming section.

HELP Pad

Touch to get help on a specific function

or to change options.

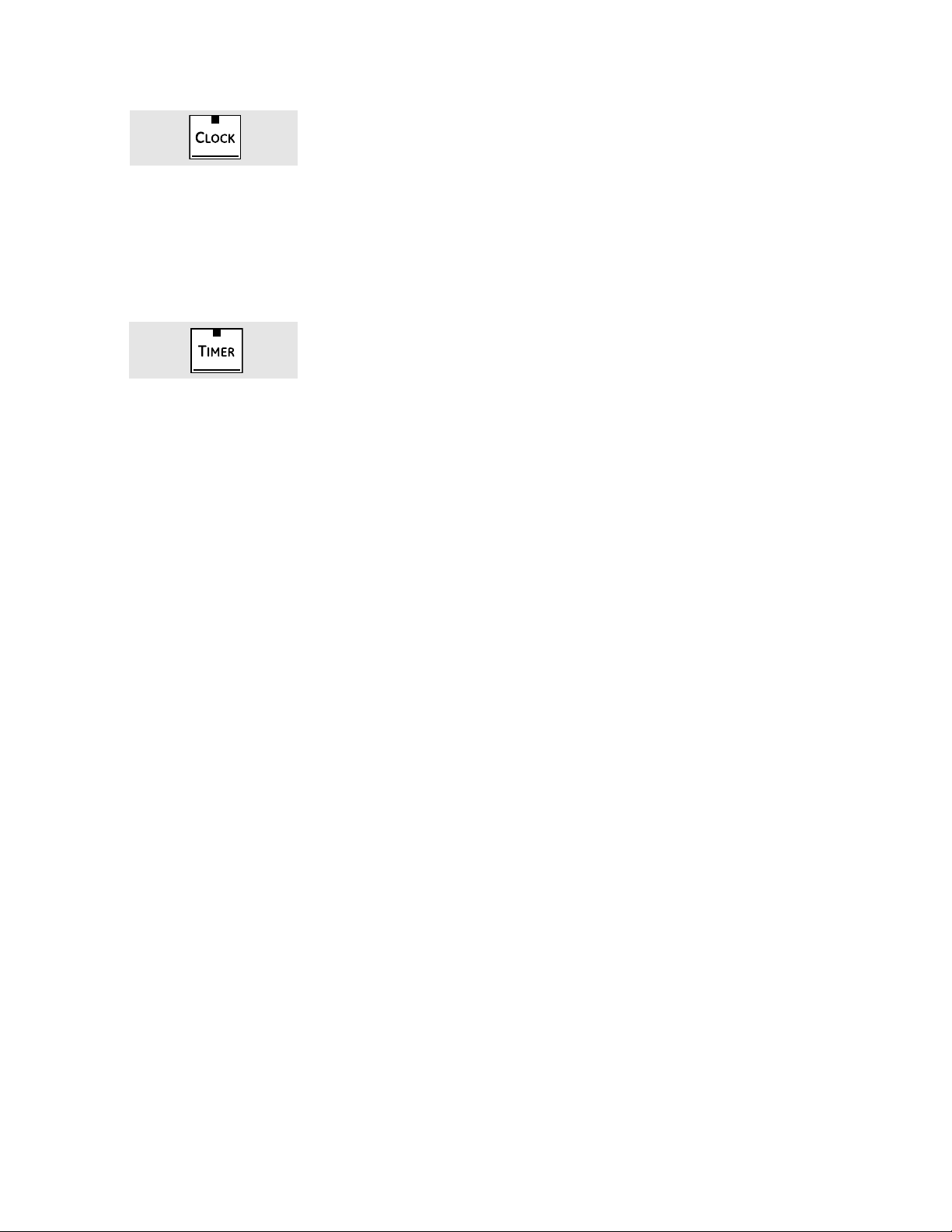

TIMER Pad

Touch to select the timer feature.

CLOCK Pad

Touch to set the clock.

START Pad

Must be touched to start any cooking

or cleaning function.

CLEAR/OFF Pad

Touch to cancel ALL oven operations except

the clock and timer.

DELAY START Pad

Use along with COOK TIME or SELF CLEAN

HI/LO pads to set the oven to start and stop

automatically at a time you set.

COOK TIME Pad

Touch this pad and then touch the number

pads to set the amount of time you want

your food to cook. The oven will shut off

when the cooking time has run out.

Display

Shows the time of day, oven temperature,

whether the oven is in the bake, broil

or self-cleaning mode and the times set

for the timer or automatic oven operations.

Number Pads

Use to set any function requiring numbers

such as the time of day on the clock,

the timer, the oven temperature,

the internal food temperature,

the start time and length of operation

for timed baking and self-cleaning.

If your oven was set for a timed oven operation

and a power outage occurred, the clock and all

programmed functions must be reset.

The time of day will flash in the display when

there has been a power outage.

CONVECTION BAKE Pad

Touch to select baking with the convection

function.

CONVECTION ROAST Pad

Touch to select roasting with the convection

function.

SLOW COOK Pad

Touch to select the Slow Cook function.

PROBE Pad

Touch when using the probe to cook food.

NOTE: When setting times, you are setting hours

and minutes only. The lowest time you can set is

one minute.

(Continued next page)

– 6 –

Page 7

Using the Upper and Lower Ovens

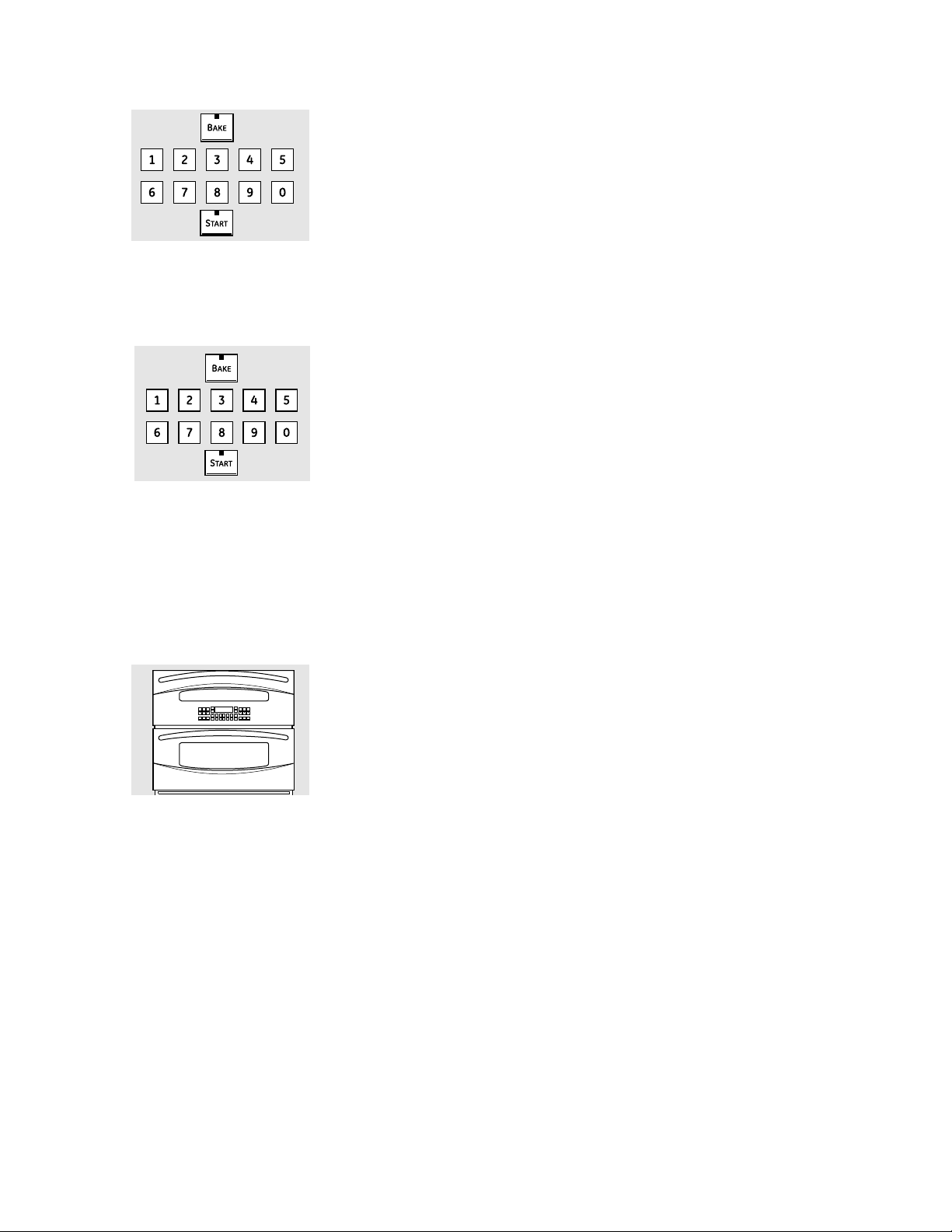

How to Set the Upper Oven for Baking

Touch the 1. BAKE pad.

Touch the number pads to set the desired temperature.2.

Touch the 3. START pad.

Check if food is done at minimum time of the recipe. Cook longer if 4.

necessary.

_________________________________________________________________________________________

_________________________________________________________________________________________

Touch the 5. CLEAR/OFF pad when cooking is complete.

How to Set the Lower Oven for Baking or Roasting

Touch the 1. BAKE pad.

Touch the number pads to set the desired temperature.2.

Touch the 3. START pad.

Note: You will hear the convection fan running while the oven is

preheating. The fan will stop after the oven is preheated and the display

shows your set temperature. This is normal.

Check if food is done at minimum time of the recipe. Cook longer if 4.

necessary.

Touch the 5. CLEAR/OFF pad when cooking is complete.

How to Set the Upper and Lower Ovens

Note:

Close the doors. Always broil with the doors closed.•

If your oven is connected to 208 volts, rare steaks may be broiled •

by preheating the broiler and positioning the oven rack one position

higher.

Place the meat or fish on a broiler grid in a broiler pan.1.

Follow suggested rack positions in the 2. Broiling Guide.

Touch the 3. BROIL HI/LO pad once for HI Broil.

To change to LO Broil, touch the BROIL HI/LO pad again.

Use LO Broil to cook foods such as poultry or thick cuts of meat

thoroughly without over-browning them.

Touch the 4. START pad.

When broiling is finished, touch the CLEAR/OFF pad.5.

Note: Broil and self-clean settings will not work if the temperature probe is

plugged in.

– 7 –

Page 8

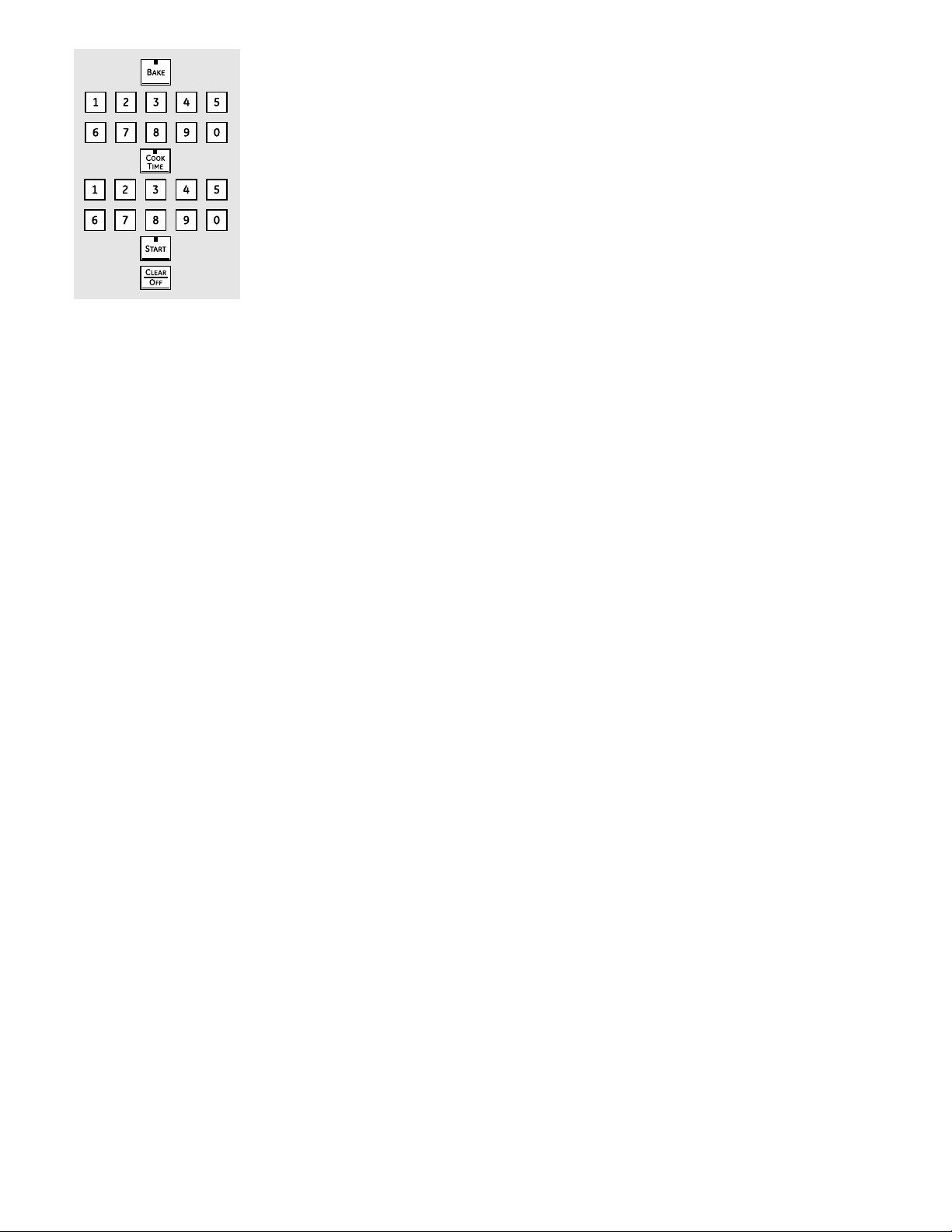

How to Set an Immediate Start and Automatic Stop

The oven will turn on immediately and cook for a selected length of time.

At the end of the cooking time, the oven will turn off automatically.

Touch the 1. BAKE pad.

Touch the number pads to set the desired oven temperature.2.

Touch the 3. COOK TIME pad.

Note: If the recipe requires preheating, you may need to add time to the

cooking time.

Touch the number pads to set the desired length of cooking time. The 4.

minimum cooking time you can set is 1 minute.

The oven temperature that you set and the cooking time that you

entered will be in the display.

Touch the 5. START pad.

Note: An attention tone will sound if you are using timed baking and do

not touch the START pad.

The oven will turn on, and the display will show the cooking time

countdown and the changing temperature starting at 100°F. (The

temperature display will start to change once the oven temperature

reaches 100°F.) When the oven reaches the temperature you set, 3 beeps

will sound.

The oven will continue to cook for the set amount of time, then turn off

automatically, unless the WARM feature was set. See the How to Set the

Lower and Upper Ovens for Warming section.

Touch the 6. CLEAR/OFF pad to clear the display, if necessary. Remove

the food from the oven. Remember, even though the oven turns off

automatically, food left in the oven will continue cooking after the

oven turns off.

– 8 –

(Continued next page)

Page 9

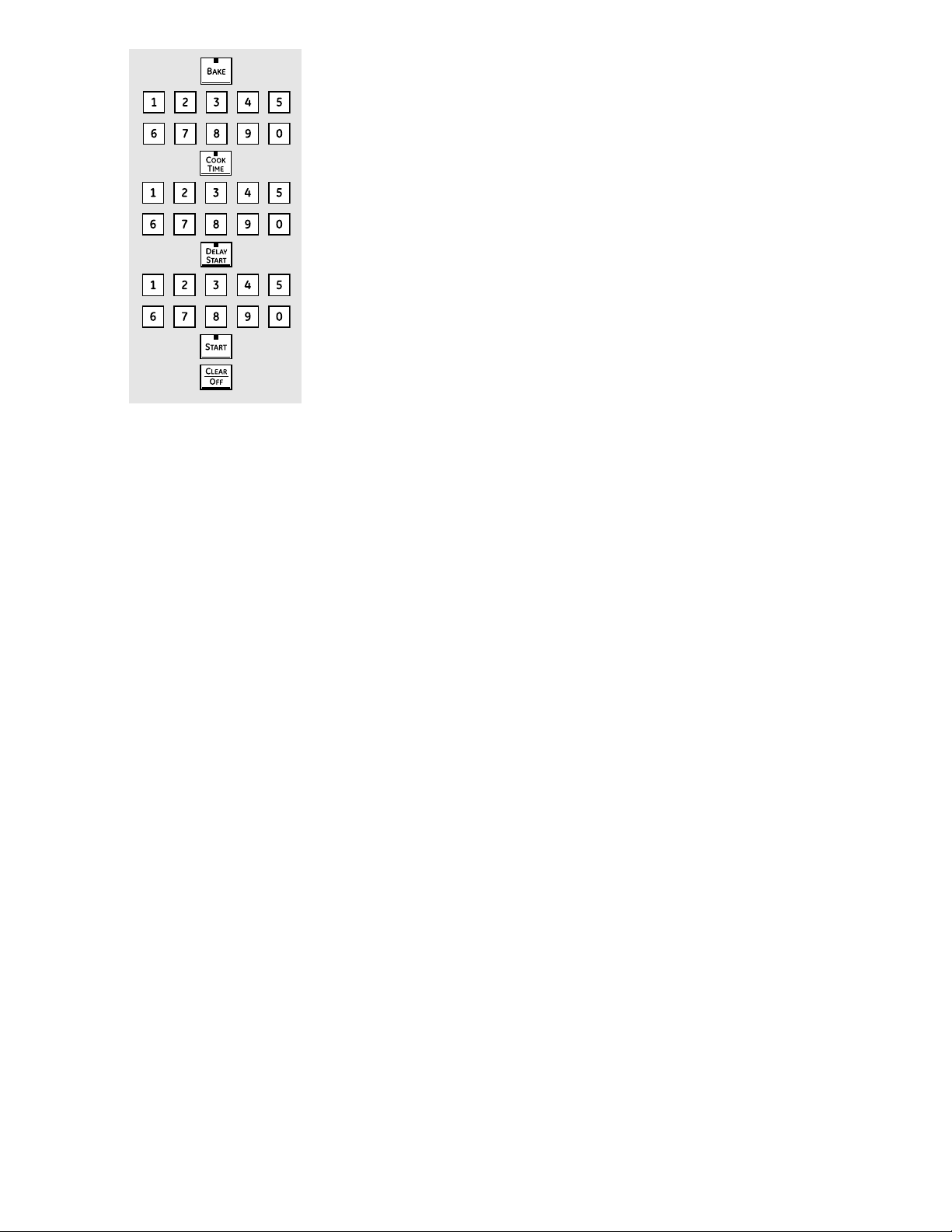

How to Set a Delayed Start and Automatic Stop

The oven will turn on at the time of day you set, cook for a specific length

of time, and then turn off automatically.

Make sure the clock shows the correct time of day.

Touch the 1. BAKE pad.

Touch the number pads to set the desired oven temperature.2.

Touch the 3. COOK TIME pad.

Note: If the recipe requires preheating, you may need to add time to the

cooking time.

Touch the number pads to set the desired length of cooking time. The 4.

minimum cooking time you can set is 1 minute.

The oven temperature that you set and the cooking time that you

entered will be in the display.

Touch the 5. DELAY START pad.

Touch the number pads to set the time of day you want the oven to 6.

turn on and start cooking.

Touch the 7. START pad.

Note:

An attention tone will sound if you are using timed baking and do not •

touch the START pad.

If you would like to check the times you have set, touch the • DELAY

START pad to check the start time you have set or touch the COOK

TIME pad to check the length of cooking time you have set.

When the oven turns on at the time of day you set, the display will show

the cooking time countdown and the changing temperature starting

at 100°F. (The temperature display will start to change once the oven

temperature reaches 100°F.) When the oven reaches the temperature you

set, 3 beeps will sound.

The oven will continue to cook for the set amount of time, then turn off

automatically, unless the WARM feature was set. See the How to Set the

Lower and Upper Ovens for Warming section.

Touch the 8. CLEAR/OFF pad to clear the display, if necessary. Remove

the food from the oven. Remember, even though the oven turns off

automatically, food left in the oven will continue cooking after the

oven turns off.

– 9 –

Page 10

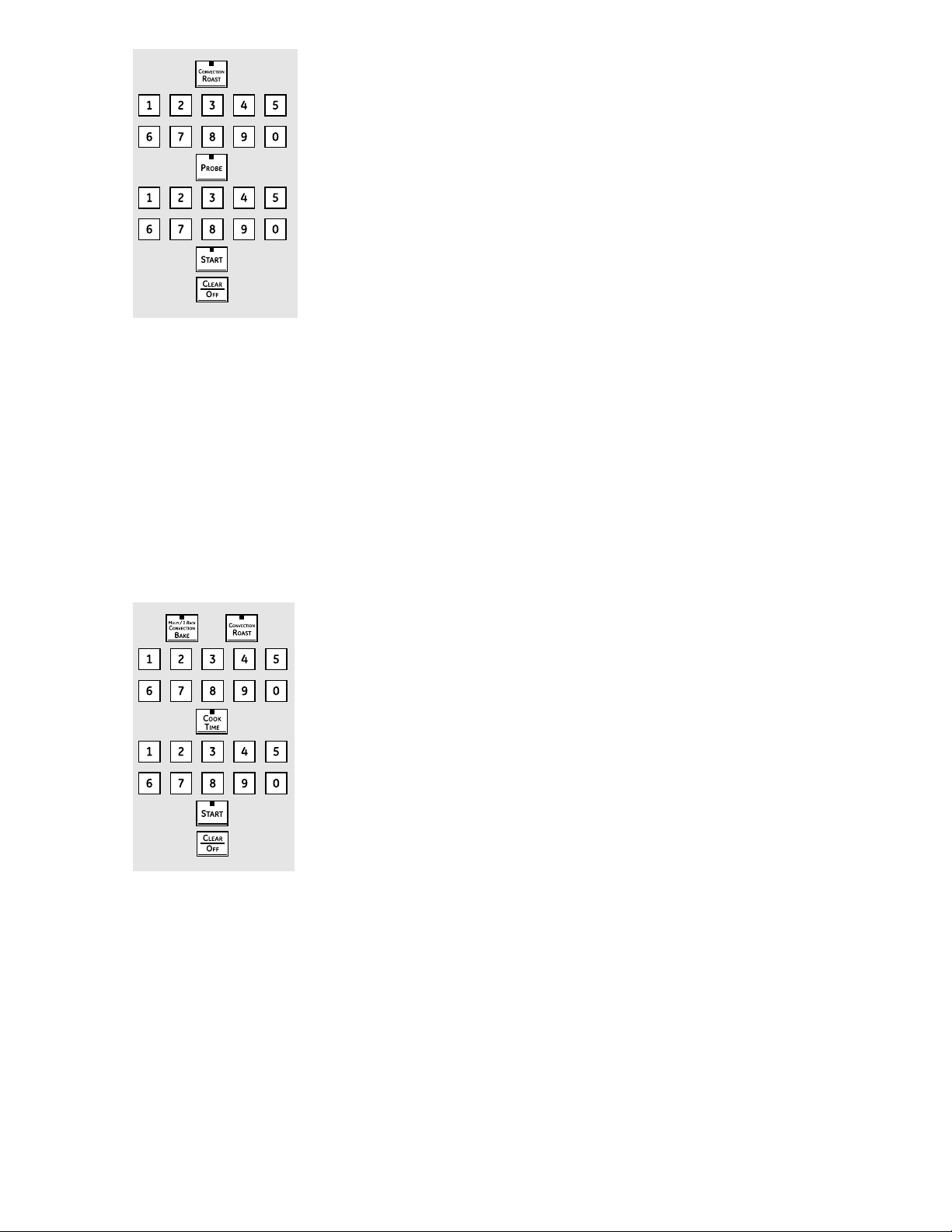

Using the Probe on the Lower Convection Oven

How to Set the Lower Oven for Baking/Roasting When Using the Probe

Insert the probe fully into the food.1.

Plug the probe into the outlet in the oven. Make sure it’s pushed all the 2.

way in. Close the oven door. Make sure the probe cable is not touching

the broil element.

Touch the 3. PROBE pad. Display will show “Set Probe Temperature.”

Touch the number pads to set the desired internal food or meat 4.

temperature. The maximum internal temperature for the food that

you can set is 200ºF.

Touch the 5. BAKE pad.

Touch the number pads to set the desired oven temperature.6.

Touch the 7. START pad.

After the internal temperature of the food reaches 100°F, the changing

internal temperature will be shown in the display.

When the internal temperature of the food reaches the number 8.

you have set, the probe and the oven turn off, and the oven control

signals. To stop the signal, touch the CLEAR/OFF pad. Use hot pads to

remove the probe from the food. Do not use tongs to pull on the probe

― they might damage it.

Note: If the probe is removed from the oven while the probe is still

cooking, the oven will not automatically turn off.

To change the oven temperature during the Bake/Roast cycle, touch the

BAKE pad and then the number pads to set the new temperature.

Note: You can use the Kitchen Timer even though you cannot use timed

oven operations while using the probe.

– 10 –

Page 11

Using the Clock, Kitchen Timer, and Control Lock

To Set the Clock

The clock must be set to the correct time of day for the automatic oven

timing functions to work properly. The time of day cannot be changed

during a timed baking or self-cleaning cycle.

Touch the 1. CLOCK pad.

Touch the number pads.2.

Touch the 3. START pad.

_________________________________________________________________________________________

To Set the Kitchen Timer

Touch the 1. TIMER pad.

Touch the number pads until the amount of time you want shows in 2.

the display. For example, to set 2 hours and 45 minutes, touch 2, 4

and 5 in that order. If you make a mistake, touch the TIMER pad and

begin again.

Touch the 3. START pad.

After touching the START pad, SET disappears; this tells you the time is

counting down, although the display does not change until one minute

has passed. Seconds will not be shown in the display until the last minute

is counting down.

When the Kitchen Timer reaches :00, the control will beep 3 times 4.

followed by one beep every 6 seconds until the TIMER pad is touched.

The 6-second tone can be canceled by following the steps in the Special

features of your oven control section under Tones at the End of a Timed

Cycle.

_________________________________________________________________________________________

To Reset the Kitchen Timer

If the display is still showing the time remaining, you may change it by

touching the TIMER pad, then touch the number pads until the time you

want appears in the display.

If the remaining time is not in the display (clock, delay start or cooking

time are in the display), recall the remaining time by touching the TIMER

pad and then touching the number pads to enter the new time you want.

_________________________________________________________________________________________

To Cancel the Kitchen Timer

Touch the TIMER pad twice.

– 11 –

(Continued next page)

Page 12

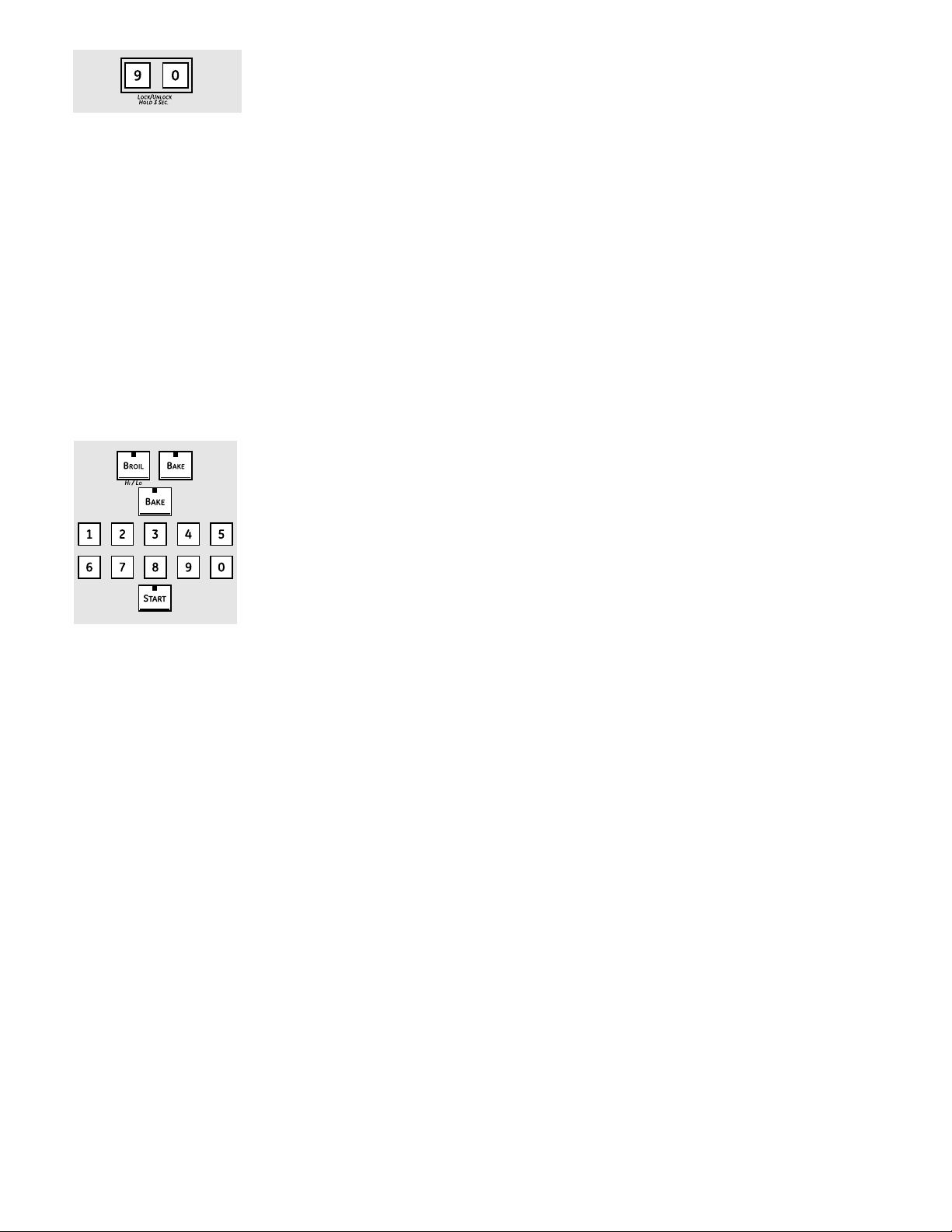

Control Lock

Your control will allow you to lock out the touch pads so they cannot be

activated when touched.

To lock/unlock the controls:

Touch and hold the 9 and 0 pads for 3 seconds.1.

The oven display will show “Oven controls locked” for several seconds,

then “Locked.”

To unlock the control, touch and hold the 9 and 0 pads for 3 seconds.2.

Note: The CONTROL LOCK mode affects all touch pads. No touch pads will

work when this feature is activated.

Adjusting the Upper or Lower Oven Thermostat

To Adjust the Thermostat

+

Note: This adjustment will only affect baking and roasting temperatures;

it will not affect broiling or self-cleaning temperatures. The adjustment will

be retained in memory after a power failure.

Touch the 1. BROIL HI/LO and BAKE pads at the same time until the

display shows "SF".

Touch the 2. BAKE pad. A two-digit number shows in the display.

Touch the BAKE pad again to alternate between increasing and

decreasing the oven temperature.

To adjust the upper oven thermostat, touch the upper oven BAKE pad. To

adjust the lower oven thermostat, touch the lower oven BAKE pad.

The oven temperature can be adjusted up to (+) 35ºF hotter or (-) 35ºF 3.

cooler. Touch the number pads the same way you read them. For

example, to change the oven temperature 15ºF, touch 1 and 5.

When you have made the adjustment, touch the 4. START pad to go

back to the time of day display. Use your oven as you would normally.

– 12 –

Page 13

Using the Convection Oven

Convection Fan Operation

In a convection oven, a fan circulates hot air over, under, and around the

food.

This circulating hot air is evenly distributed throughout the oven. As a

result, foods are evenly cooked and browned ― often in less time than

with convection heat.

Note: To maximize cooking evenness, the fan is designed to rotate in both

directions, with a pause in between. This is normal.

The convection fan shuts off when the oven door is opened. DO NOT leave

the door open for long periods of time while using convection cooking or

you may shorten the life of the convection heating element.

_________________________________________________________________________________________

Introduction

The convection oven comes with two convection baking modes:

Multi and 1 Rack:

MULTI ― for convection cooking on more than one rack. Touch the

CONVECTION BAKE pad and then the 2 pad. See the Multi-Rack

Convection Baking section below.

1 RACK ― for convection cooking on one rack only. Touch the

CONVECTION BAKE pad and then the 1 pad. See the 1 Rack Convection

Baking section below.

_________________________________________________________________________________________

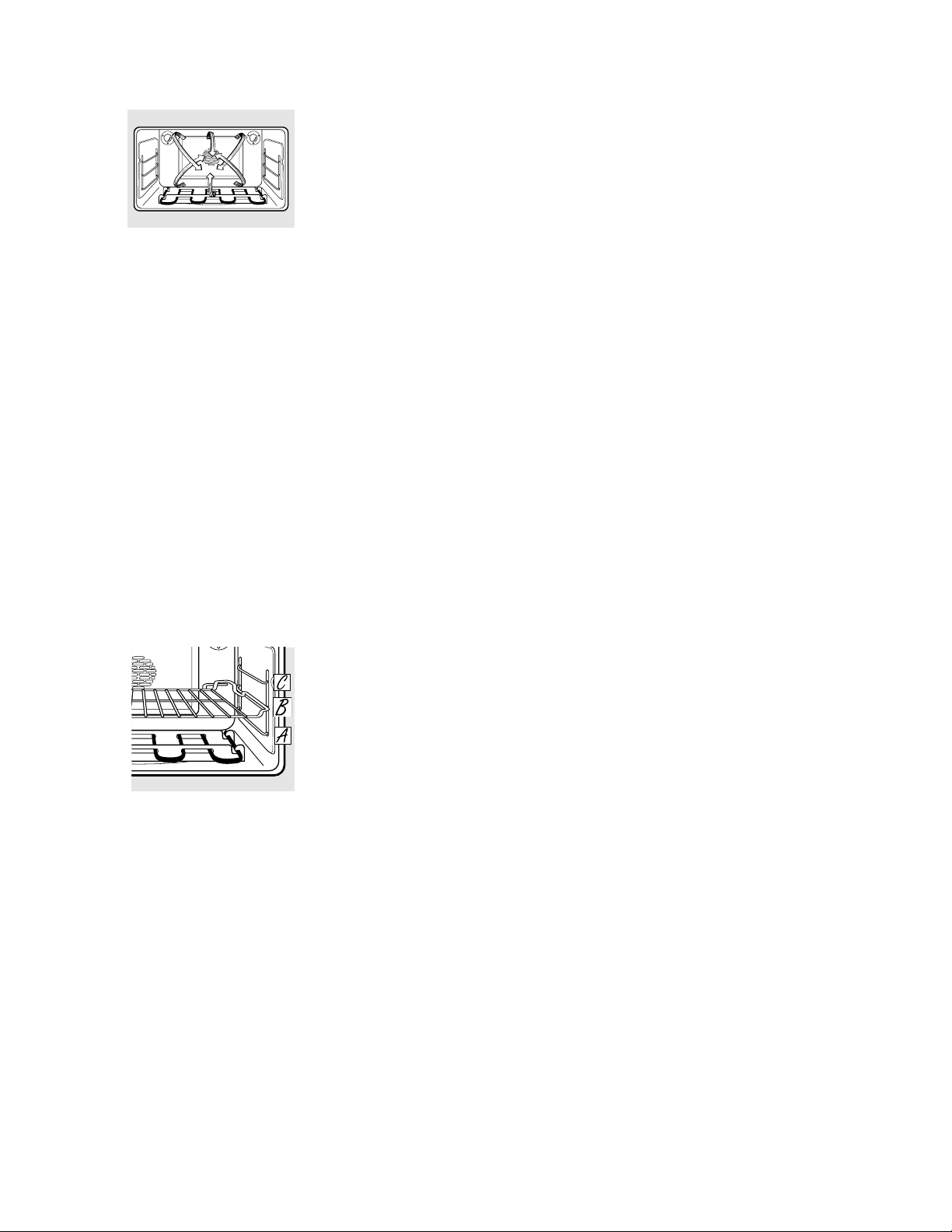

Multi-Rack Convection Baking

Because heated air is circulated evenly throughout the oven, foods can be

baked with excellent results using multiple racks.

Multi-rack baking may increase cook times slightly for some foods, but

the overall result is time saved. Cookies, muffins, biscuits, and other

quickbreads give very good results with multi-rack baking.

To cook food on more than one rack in convection bake, use CONVECTION

BAKE MULTI.

For multi-rack baking, place the flat rack in the highest (C) position and the

_________________________________________________________________________________________

offset rack in the middle (B) position.

1 Rack Convection Baking

When convection baking with only 1 rack, use CONVECTION BAKE 1 RACK

and follow the rack positions recommended in the Using the Oven section

of the Owner's Manual.

Note: Ideal for baked foods cooked on 1 rack.

– 13 –

(Continued next page)

Page 14

OR

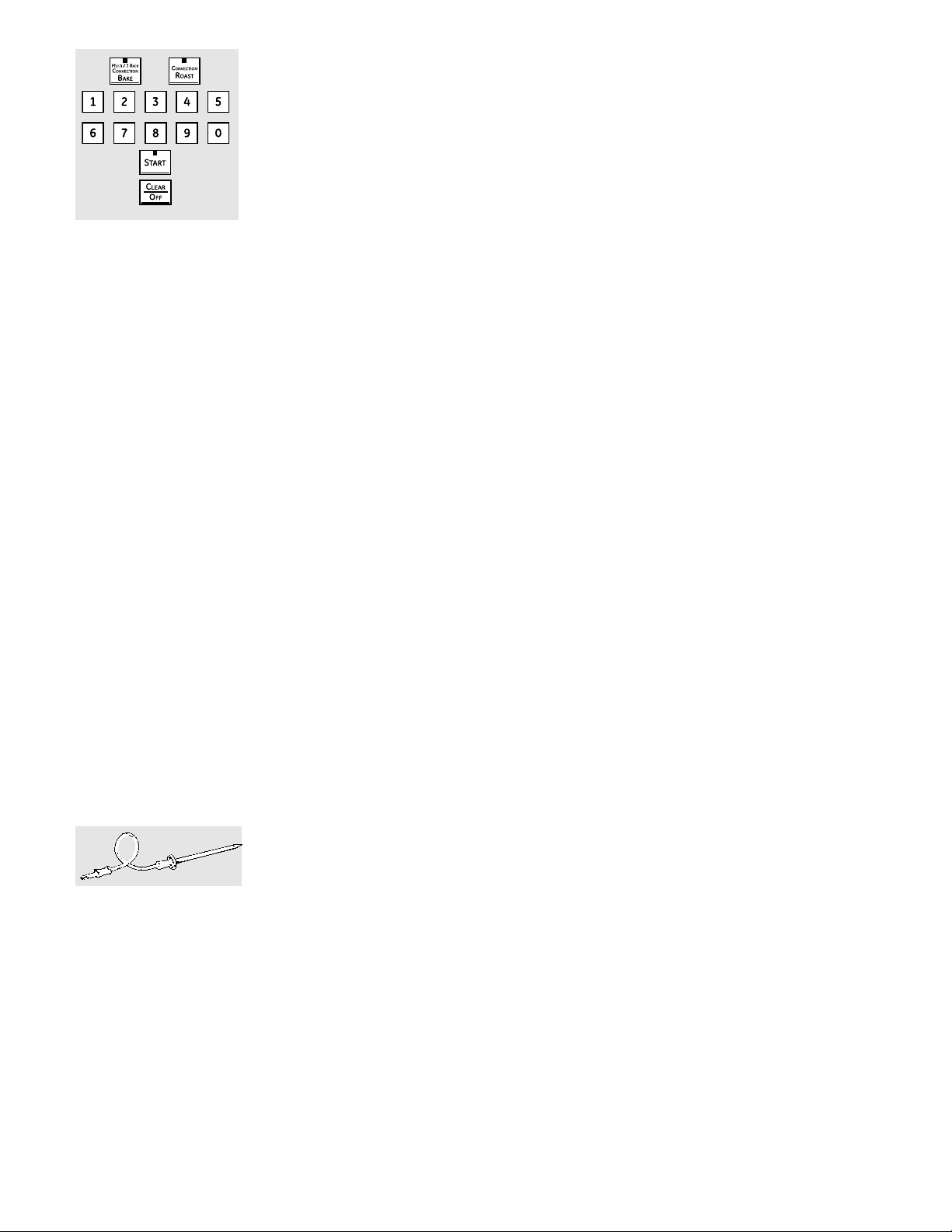

How to Set the Lower Oven for Convection Baking or Roasting

Touch the 1. CONVECTION BAKE pad and then the 2 pad for multirack convection baking. This mode is used for cooking food items

on more than one rack (i.e., 2, 3, or more racks) at the same time in

convection bake. See the Multi-Rack Convection Baking section for

more information.

Touch the CONVECTION BAKE pad and then the 1 pad for one-rack

convection baking. This mode is used for cooking food items on only

one rack in convection bake.

Touch the CONVECTION ROAST pad for convection roasting.

Touch the number pads to set the oven temperature.2.

Touch the 3. START pad.

Note: If the Auto Recipe™ Conversion Feature is on, it will automatically

reduce the set regular baking temperature by 25°F to the appropriate

convection temperature in convection bake mode. See Auto Recipe™

Conversion in the Special Features section.

To change the oven temperature, touch the CONVECTION BAKE or

CONVECTION ROAST pad and then the number pads to set the new

temperature.

When the oven starts to heat, the changing temperature, starting at

100°F, will be displayed. When the oven reaches the temperature you set,

3 beeps will sound.

Touch the 4. CLEAR/OFF pad when finished.

Note:

You will hear a fan while cooking with convection. The fan will stop •

when the door is opened, but the heat will not turn off.

You may hear the oven clicking during baking. This is normal.•

In convection bake modes, for maximum cooking evenness, the fan is •

designed to rotate in both directions, with a pause in between. This is

normal.

_________________________________________________________________________________________

How to Set the Lower Oven for Convection Roasting when Using the

Probe

Note: For best results when roasting large turkeys and roasts, we

recommend using the probe included in the convection oven

Place the oven rack in the position that centers the food between the 1.

top and bottom of the oven. Insert the probe into the meat. Make sure

it is pushed all the way in.

Plug the probe into the outlet in the oven. Make sure it is pushed all the 2.

way in. Close the oven door.

Touch the 3. CONVECTION ROAST pad.

Touch the number pads to set the desired oven temperature. 4.

Touch the 5. PROBE pad.

Touch the number pads to set the desired internal meat temperature.6.

– 14 –

(Continued next page)

Page 15

Note: The maximum internal temperature that you can set is 200°F.

7. Touch the START pad.

The display will flash "PROBE", and the oven control will signal if the probe

is inserted into the outlet and you have not set a probe temperature and

pressed the START pad.

When the oven starts to heat, the word "LO" will be in the display.

After the internal temperature of the meat reaches 100°F, the changing

internal temperature will be shown in the display.

Note: To change the oven temperature during the Convection Roast cycle,

touch the CONVECTION ROAST pad and then touch the number pads to

set the new desired temperature.

8. When the internal temperature of the meat reaches the number

you have set, the probe and the oven turn off, and the oven control

signals. To stop the signal, touch the CLEAR/OFF pad. Use an oven

mitt to remove the probe from the food. Do not use tongs to pull on

the probe ― they might damage it.

Note: If the probe is removed from the oven while the probe is still

cooking, the oven will not automatically turn off.

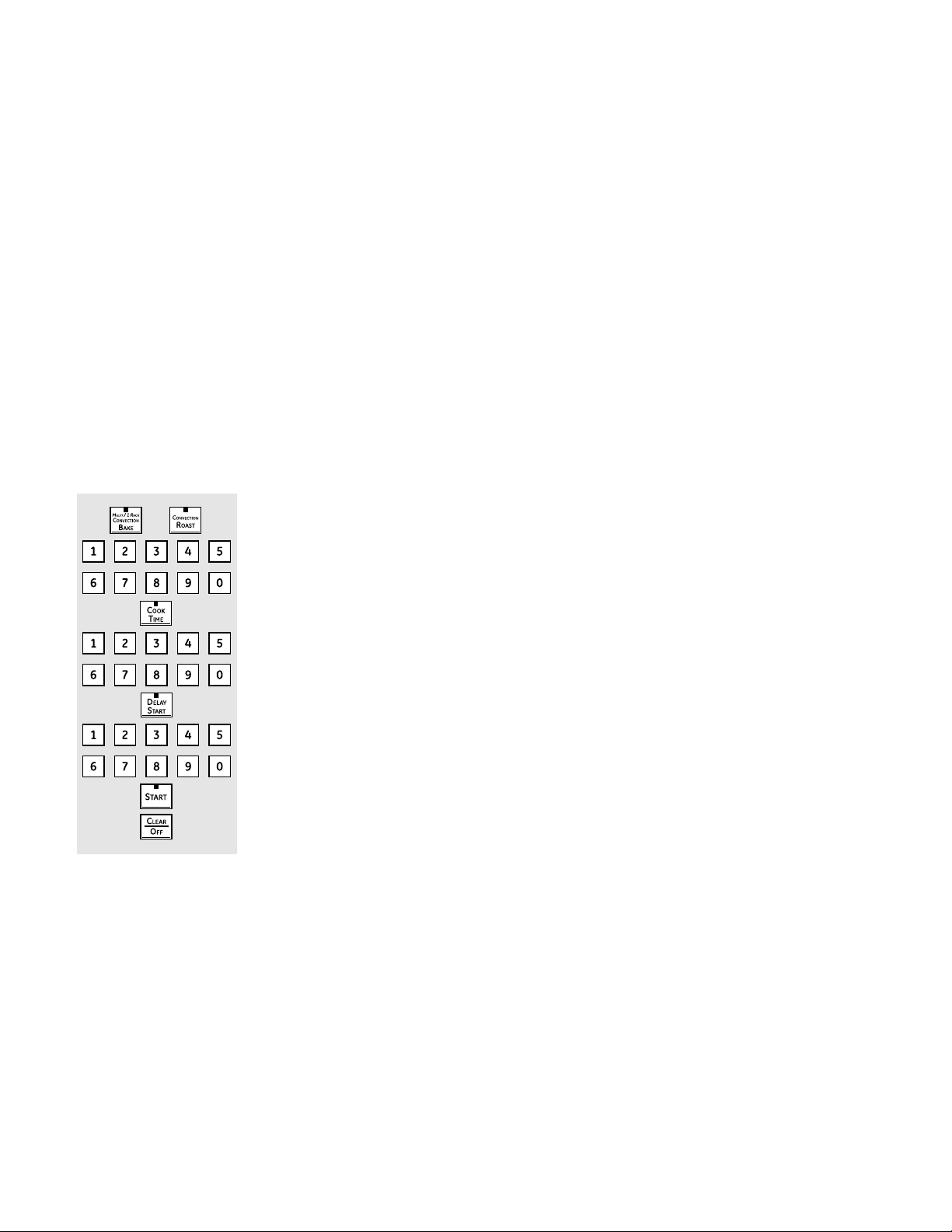

Using the Timed Features for Convection Cooking

How to Set an Immediate Start and Automatic Stop

OR

The lower oven will turn on immediately and cook for a selected length of

time. At the end of the cooking time, the oven will turn off automatically.

Make sure the clock shows the correct time of day.

Touch the 1. CONVECTION BAKE pad and then the 2 pad for multi-rack

convection baking. This mode is used for cooking food items on more

than one rack (i.e., 2, 3, or more racks) at the same time in convection

bake. See the Multi-Rack Baking section for more information.

Touch the CONVECTION BAKE pad and then the 1 pad for one-rack

convection baking. This mode is used for cooking food items on only

one rack in convection bake.

Touch the CONVECTION ROAST pad for convection roasting.

Touch the number pads to set the oven temperature.2.

Touch the 3. COOK TIME pad.

Note: If the recipe requires preheating, you may need to add time to the

cooking time.

Touch the number pads to set the desired length of cooking time. The 4.

minimum cooking time you can set is 1 minute. The oven temperature

that you set and the cooking time that you entered will be in the

display.

(Continued next page)

– 15 –

Page 16

5. Touch the START pad.

The oven will turn on, and the display will show the cooking time

countdown and the changing temperature starting at 100°F. (The

temperature display will start to change once the oven temperature

reaches 100°F.) When the oven reaches the temperature you set, 3 beeps

will sound.

Note: If the Auto Recipe™ Conversion Feature is on, it will automatically

reduce the set regular baking temperature by 25°F to the appropriate

convection temperature in convection bake mode. See Auto Recipe™

Conversion in the Special Features section.

The oven will continue to cook for the set amount of time, then turn off

automatically, unless the WARM feature was set. See the How to Set the

Oven for Warming section.

After the oven turns off, the end-of-cycle tone will sound.

6. Touch the CLEAR/OFF pad to clear the display, if necessary. Remove

the food from the oven. Remember, even though the oven turns off

automatically, food left in the oven will continue cooking after the

oven turns off.

_________________________________________________________________________________________

How to Set a Delayed Start and Automatic Stop

OR

The lower oven will turn on at the time of day you set, cook for a specific

length of time, and then turn off automatically.

Make sure the clock shows the correct time of day.

Touch the 1. CONVECTION BAKE pad and then the 2 pad for multi-rack

convection baking. This mode is used for cooking food items on more

than one rack (i.e., 2, 3, or more racks) at the same time in convection

bake. See the Multi-Rack Baking section for more information.

Touch the CONVECTION BAKE pad and then the 1 pad for one-rack

convection baking. This mode is used for cooking food items on only

one rack in convection bake.

Touch the CONVECTION ROAST pad for convection roasting.

Touch the number pads to set the oven temperature.2.

Touch the 3. COOK TIME pad.

Note: If the recipe requires preheating, you may need to add time to the

cooking time.

Touch the number pads to set the desired length of cooking time. The 4.

minimum cooking time you can set is 1 minute.

The oven temperature that you set and the cooking time that you

entered will be in the display.

Touch the 5. DELAY START pad.

Touch the number pads to set the time of day you want the oven to 6.

turn on and start cooking.

– 16 –

(Continued next page)

Page 17

7. Touch the START pad.

Note:

An attention tone will sound if you are using timed baking or roasting •

and do not touch the START pad.

If you would like to check the times you have set, touch the • DELAY

START pad to check the start time you have set, or touch the COOK

TIME pad to check the length of cooking time you have set.

When the oven turns on at the time of day you set, the display will show

the cooking time countdown and the changing temperature starting

at 100°F. (The temperature display will start to change once the oven

temperature reaches 100°F.) When the oven reaches the temperature you

set, 3 beeps will sound.

Note: If the Auto Recipe™ Conversion Feature is on, it will automatically

reduce the set regular baking temperature by 25°F to the appropriate

convection temperature in convection bake mode. See Auto Recipe™

Conversion in the Special Features section.

The oven will continue to cook for the programmed amount of time, then

shut off automatically, unless the WARM feature was set. See the How to

Set the Oven for Warming section.

After the oven turns off, the end-of-cycle tone will sound.

8. Touch the CLEAR/OFF pad to clear the display, if necessary. Remove

the food from the oven. Remember, even though the oven shuts off

automatically, food left in the oven will continue cooking after the

oven turns off.

Using the Slow Cook, Pizza, Warming, and Proofing Features

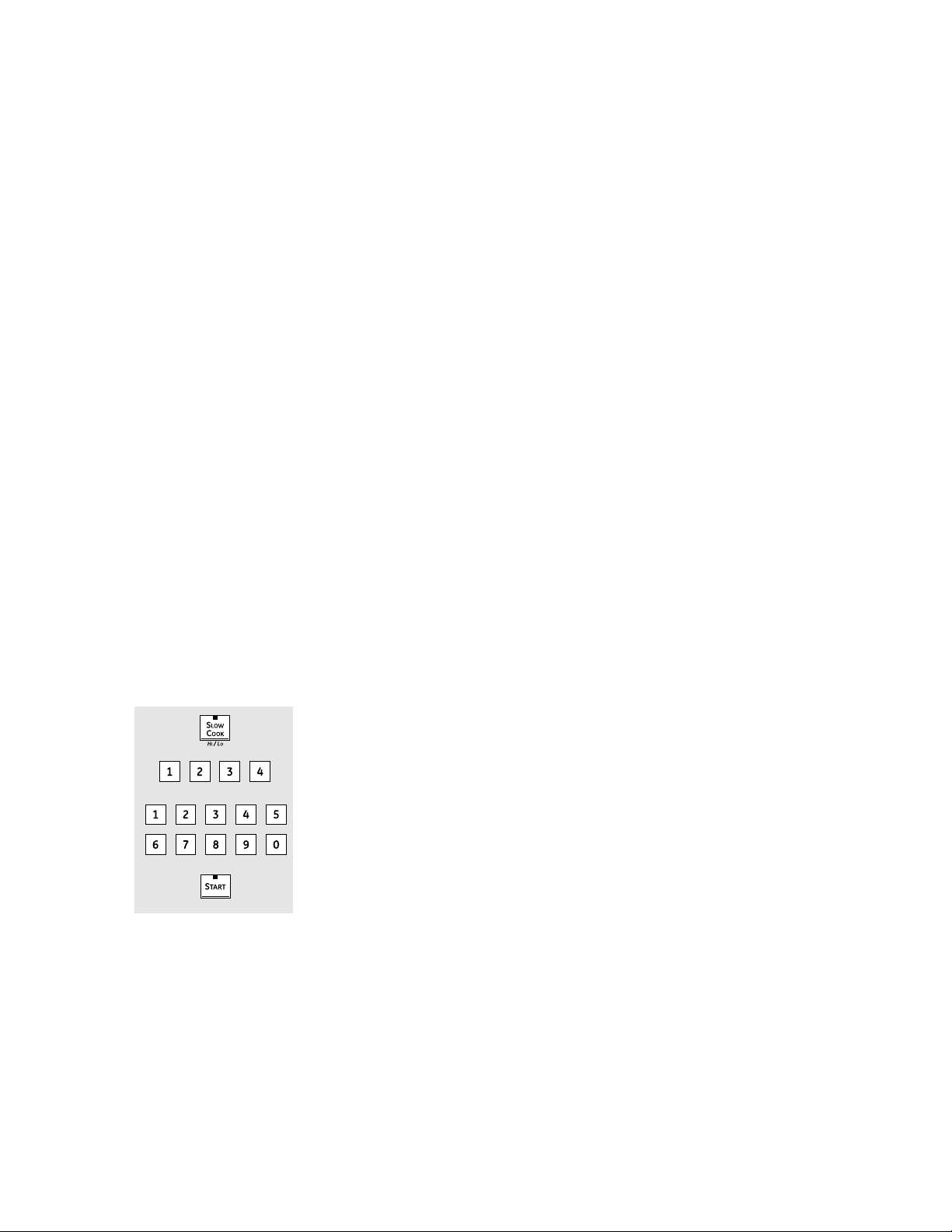

How to Set the Lower Oven For Slow Cook

Slow Cook is designed for long hours of unattended cooking.

Touch the 1. SLOW COOK pad once for HI Slow Cook.

To change to LO Slow Cook, touch the SLOW COOK pad again.

Touch the number pads to select the desired setting – 1 for Beef, 2 for 2.

Poultry, 3 for Pork, or 4 for Stews. Use the 1–Beef setting if you are

unsure which setting to use.

Touch the number pads to set the desired length of cooking time. For 3.

the HI setting, the cooking time must be between 3 and 8 hours. For

the LO setting, the cooking time must be between 3 and 12 hours.

Touch the 4. START pad.

When the Slow Cook function has completed, the oven will go into the

Warm mode. The display will say “Cooking Complete Keeping Warm.”

The total time the oven will be on (Slow Cook time plus Warm time) is 12

hours. This is because of the 12-Hour Shutdown feature See the 12-Hour

Shutdown section.

Note: If a power outage occurs while the oven is in Slow Cook, the oven

will shut off.

(Continued next page)

– 17 –

Page 18

How to Set the Upper Oven For Pizza

Adjust rack position for type of pizza tray being used.

Touch the 1. PIZZA pad.

Touch the number pads to select 1 for fresh or 2 for frozen pizza.2.

Touch the number pads to set the baking temperature.3.

Touch the 4. START pad.

_________________________________________________________________________________________

How to Set the Lower and Upper Ovens for Warming

OR

The WARM feature keeps cooked foods hot.

This feature is not designed to reheat cold food.

To use the WARM feature, touch the WARM pad or the WARM/PROOF pad

once and then the START pad.

To use the WARM feature after Timed Baking or Roasting, complete the

following steps:

Touch the mode of cooking that you want to use (BAKE, CONVECTION 1.

BAKE MULTI, CONVECTION BAKE 1 RACK, or CONVECTION ROAST).

Touch the number pads to set the oven temperature.2.

Touch the 3. COOK TIME pad.

Touch the number pads to set the desired length of cooking time.4.

Touch the 5. WARM pad or the WARM/PROOF pad once.

Touch the 6. START pad.

_________________________________________________________________________________________

How to Set the Lower Oven for Proofing

The proofing feature maintains a warm environment useful for rising

yeast-leavened products.

Place the covered dough in the oven on rack B or C.1.

Note: For best results, cover the dough with a cloth or with greased plastic

wrap (the plastic may need to be anchored underneath the container so

the oven fan will not blow it off).

Touch the 2. WARM/PROOF pad twice.

The display will read "PrF" (proof).

The oven interior light turns on and remains on during proofing.

The proofing feature automatically provides the optimum temperature

for the proofing process, and therefore, does not have a temperature

adjustment.

Set the TIMER for the minimum proof time.3.

When proofing is finished, touch the 4. CLEAR/OFF pad.

– 18 –

Page 19

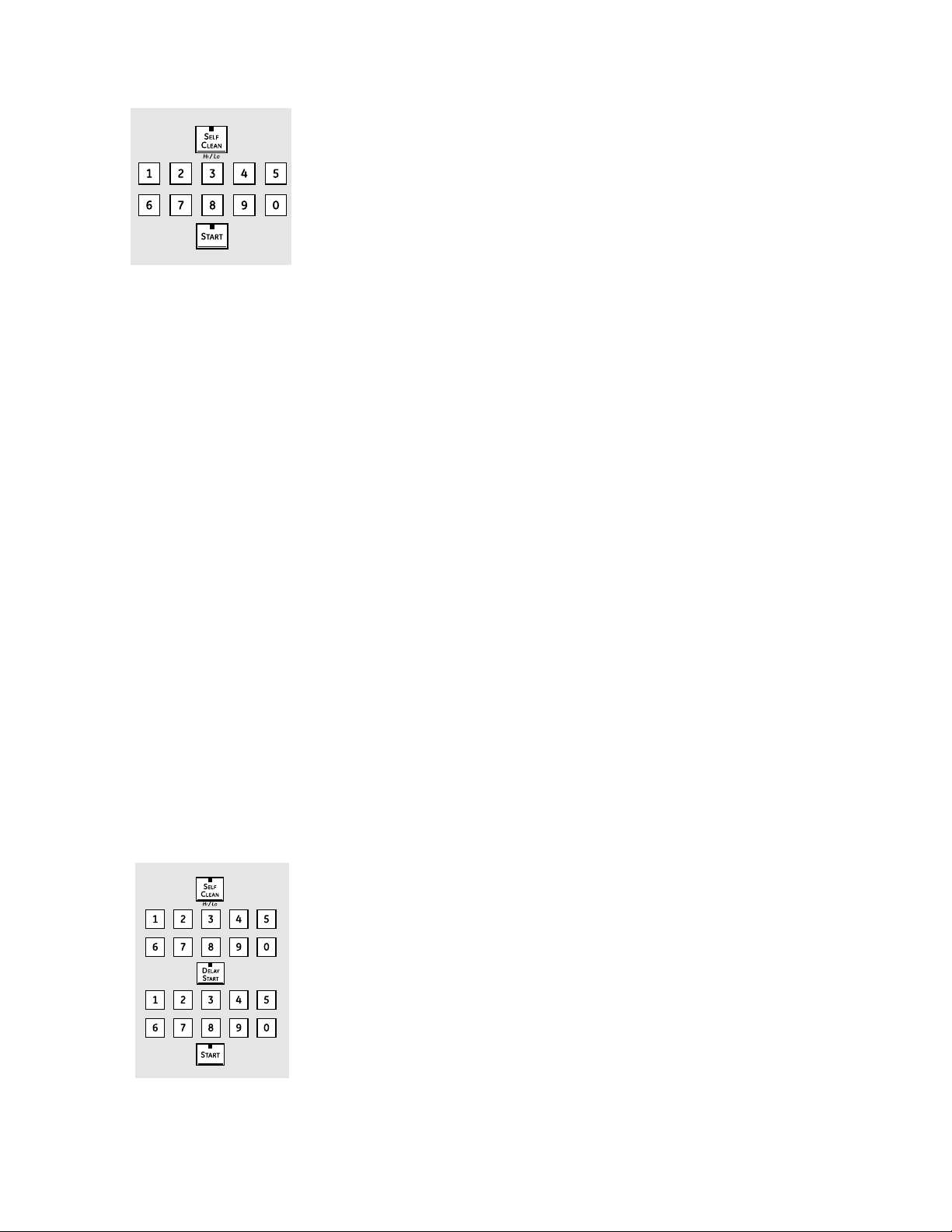

Using the Self-Cleaning Upper and Lower Ovens

How to Set the Upper/Lower Oven for Cleaning

The oven doors must be closed and all controls set correctly for the cycle

to work properly.

Touch the 1. SELF CLEAN HI/LO pad once for a 5-hour clean time or

twice for a 3-hour clean time.

A 3-hour self-clean time is recommended for use when cleaning small,

contained spills. A self-clean time of 5 hours is recommended for a

dirtier oven.

If a time other than 5 hours or 3 hours is needed, use the number pads 2.

and enter the desired clean time.

You can change the clean time to any time between 3 hours and 5 hours,

depending on how dirty your oven is.

Touch the 3. START pad.

The upper and lower oven doors lock automatically. The display will show

the clean time remaining. It will not be possible to open the oven doors

until the temperature drops below the lock temperature and LOCKED goes

off in the control display.

When LOCKED goes off, you will be able to open the doors.

Note:

The word LOCKED will flash and the word door will display if you set •

the clean cycle and forget to close the oven doors.

To stop a clean cycle, touch the • CLEAR/OFF pad. When LOCKED goes

off, indicating the ovens have cooled below the locking temperature,

you will be able to open the doors.

You can set a clean cycle in both ovens at the same time; however, they

will not self-clean at the same time. The last oven set will automatically

delay its start until the end of the first oven’s clean cycle.

When either oven is set to self-clean, both oven doors will lock. The ovens

_________________________________________________________________________________________

cannot be used when one of the ovens is set to self-clean.

How to Delay the Start of Cleaning

Touch the 1. SELF CLEAN HI/LO pad once for a 5-hour clean time or

twice for a 3-hour clean time.

A 3-hour self-clean time is recommended for use when cleaning small,

contained spills. A self-clean time of 5 hours is recommended for a

dirtier oven.

If a time other than 5 hours or 3 hours is needed, use the number pads 2.

and enter the desired clean time.

You can change the clean time to any time between 3 hours and 5 hours,

depending on how dirty your oven is.

Touch the 3. DELAY START pad.

(Continued next page)

– 19 –

Page 20

4. Using the number pads, enter the time of day you want the clean

cycle to start.

5. Touch the START pad.

The upper and lower oven doors lock automatically. The display will show

the start time. It will not be possible to open the oven doors until the

temperature drops below the lock temperature and LOCKED goes off in

the control display.

When LOCKED goes off, you will be able to open the doors.

Special Features of the Oven Control

The special feature modes can only be activated while the display is showing the time of day. They remain in

the control’s memory until the steps are repeated.

To enter a special feature for either oven, you must first touch the upper oven BROIL HI/LO and BAKE pads

at the same time. The lower oven BROIL HI/LO and BAKE pads will not activate special features. When the

display shows your choice, touch the START pad. The special features will remain in memory after a power

failure, except for the Sabbath feature, which will have to be reset.

Help Function

Touch the HELP pad to get additional information on the keypad of your

choice.

Touch the HELP pad and the display will show “Press keypad for help on

that feature or 1 for options.”

The following options can be adjusted using the method described here or

through HELP.

_________________________________________________________________________________________

12-Hour Shutdown

+

With this feature, should you forget and leave the oven on, the control will

automatically turn off the oven after 12 hours during baking functions or

after 3 hours during a broil function.

If you wish to turn off this feature, follow the steps below.

Touch the upper oven 1. BROIL HI/LO and BAKE pads at the same time

until the display shows "SF".

Touch the 2. DELAY START pad until "no shdn" (no shut-off) appears in

the display.

Touch the 3. START pad to activate the no shut-off and leave the control

set in this special features mode.

– 20 –

(Continued next page)

Page 21

Fahrenheit or Celsius Temperature Selection

+

Your oven control is set to use the Fahrenheit temperature selections, but

you may change this to use the Celsius selections.

+

Touch the upper oven 1. BROIL HI/LO and BAKE pads at the same time

until the display shows "SF".

Touch the 2. COOK TIME and BROIL HI/LO pads at the same time. The

display will show "F" (Fahrenheit).

Touch the 3. COOK TIME and BROIL HI/LO pads again at the same time.

The display will show "C" (Celsius).

_________________________________________________________________________________________

+

_________________________________________________________________________________________

+

Touch the 4. START pad.

Tones at the End of a Timed Cycle

At the end of a timed cycle, 3 short beeps will sound followed by one

beep every 6 seconds until the CLEAR/OFF pad is touched. This continual

6-second beep may be canceled.

To cancel the 6-second beep:

Touch the upper oven 1. BROIL HI/LO and BAKE pads at the same time

until the display shows "SF".

Touch the 2. BROIL pad. The display shows "CONTI BEEP" (continuous

beep). Touch the BROIL pad again. The display shows "SINGLE BEEP".

(This cancels the one beep every 6 seconds.)

Touch the 3. START pad.

Tone Volume

This feature allows you to adjust the tone volumes to a more acceptable

volume. There are three possible volume levels.

Touch the upper oven 1. BROIL HI/LO and BAKE pads at the same time

until the display shows "SF".

Touch the 2. COOK TIME pad. The display will show "2 BEEP". This is the

middle volume level.

Touch the COOK TIME pad again. The display will show "3 BEEP". This

is the loudest volume level.

Touch the COOK TIME pad again. The display will show "1 BEEP". This

is the quietest volume level.

For each time the level is changed, a tone will sound to provide an

indication of the volume level.

Choose the desired sound level (1 BEEP, 2 BEEP, or 3 BEEP).3.

Touch the 4. START pad to activate the level shown.

(Continued next page)

– 21 –

Page 22

12-Hour, 24-Hour or Clock Blackout

+

_________________________________________________________________________________________

+

Your control is set to use a 12-hour clock.

If you would prefer to have a 24-hour military time clock or black out the

clock display, follow the steps below.

Touch the upper oven 1. BROIL HI/LO and BAKE pads at the same time

until the display shows "SF".

Touch the 2. CLOCK pad once. The display will show "12 hr". If this is the

choice you want, touch the START pad.

Touch the CLOCK pad again to change to the 24-hour military time clock.

The display will show "24 hr". If this is the choice you want, touch the

START pad.

Touch the CLOCK pad again to black out the clock display. The display will

show "OFF". If this is the choice you want, touch the START pad.

Note: If the clock is in the black-out mode, you will not be able to use the

Delay Start function.

Auto Recipe™ Conversion

When using convection bake, the Auto Recipe™ Conversion feature will

automatically convert entered regular baking temperatures to convection

baking temperatures.

This feature is activated so that the display will show the actual converted

(reduced) temperature. For example, if you enter a regular recipe

temperature of 350°F and touch the START pad, the display will show

"CON" and the converted temperature of 325°F.

To deactivate the feature:

Touch the upper oven 1. BAKE and BROIL HI/LO pads at the same time

until the display shows "SF".

Touch the 2. CONVECTION BAKE pad. The display will show "CON ON".

Touch the CONVECTION BAKE pad again. The display will show "CON

OFF".

Touch the 3. START pad.

To reactivate the feature, repeat steps 1–3 above, but touch the START

pad when "CON ON" is in the display.

– 22 –

Page 23

Using the Sabbath Feature (lower oven only)

(Designed for use on the Jewish Sabbath and Holidays)

The Sabbath feature can be used for baking only. It cannot be used for convection, broiling, self-cleaning, or

delay start cooking.

+

How to Set for Regular Baking

Make sure the clock shows the correct time of day and both ovens are off.

On the upper oven, touch and hold both the 1. BROIL HI/LO pad and the

BAKE pad, at the same time, until the display shows "SF".

Note: If bake or broil appears in the display, the BROIL HI/LO pad and

the BAKE pad were not touched at the same time. Touch the upper oven

CLEAR/OFF pad and begin again.

Tap the 2. DELAY START pad until "SAb bAtH" appears in the display.

Touch the 3. START pad twice and "]" will appear in the display.

Touch the lower oven 4. BAKE pad. No signal will be given.

Using the number pads, enter the desired temperature between 170°F 5.

and 550°F. No signal or temperature will be given.

Touch the lower oven 6. START pad.

After a random delay period of approximately 30 seconds to 1 minute, 7.

"] [" will appear in the display indicating that the oven is baking. If

"] [" doesn’t appear in the display, start again at Step 4.

Note: When the display shows "]", the oven is set in Sabbath. When the

display shows "] [", the oven is baking.

To adjust the oven temperature, touch the lower oven BAKE pad, enter the

new temperature using the number pads and touch the START pad.

Note: The CLEAR/OFF pad and the COOK TIME pad of the lower oven are

_________________________________________________________________________________________

+

active during the Sabbath feature.

How to Set for Timed Baking―Immediate Start and Automatic Stop

Make sure the clock shows the correct time of day and both ovens are off.

On the upper oven, touch and hold both the 1. BROIL HI/LO pad and the

BAKE pads, at the same time, until the display shows "SF".

Note: If bake or broil appears in the display, the BROIL HI/LO pad and

the BAKE pad were not touched at the same time. Touch the upper oven

CLEAR/OFF pad and begin again.

Tap the 2. DELAY START pad until "SAb bAtH" appears in the display.

Touch the 3. START pad twice and "]" will appear in the display.

Touch the lower oven 4. COOK TIME pad.

Touch the number pads to set the desired length of cooking time 5.

between 1 minute and 9 hours and 59 minutes. The cooking time that

you entered will be displayed.

– 23 –

(Continued next page)

Page 24

6. Touch the lower oven START pad.

7. Touch the lower oven BAKE pad. No signal will be given.

8. Using the number pads, enter the desired temperature. No signal or

temperature will be given.

9. Touch the lower oven START pad.

10. After a random delay period of approximately 30 seconds to 1 minute,

"] [" will appear in the display indicating that the oven is baking. If "] ["

does not appear in the display, start again at Step 7.

To adjust the oven temperature, touch the lower oven BAKE pad, enter the

new temperature using the number pads and touch the START pad.

When cooking is finished, the display will change from "] [" to "]" and

0:00 will appear, indicating that the oven has turned off but is still set in

_________________________________________________________________________________________

Sabbath. Remove the cooked food.

How to Exit the Sabbath Feature

Touch the lower oven 1. CLEAR/OFF pad.

+

If the oven is cooking, wait for a random delay period of 2.

approximately 30 seconds to 1 minute, until only "]" is in the display.

On the upper oven, touch and hold both the 3. BROIL HI/LO pad and the

BAKE pad, at the same time, until the display shows "SF".

Tap the 4. DELAY START pad until "12 shdn" or "no shdn" appears in the

display.

Choose "12 shdn", indicating that the oven will automatically turn 5.

off after 12 hours or "no shdn", indicating that the oven will not

automatically turn off after 12 hours.

Touch the 6. START tab twice when the option that you want is in the

display ("12 shdn" or "no shdn").

Note: If a power outage occurs while the oven is in Sabbath, the oven will

automatically turn off and stay off even when the power returns. The oven

control must be reset.

– 24 –

Page 25

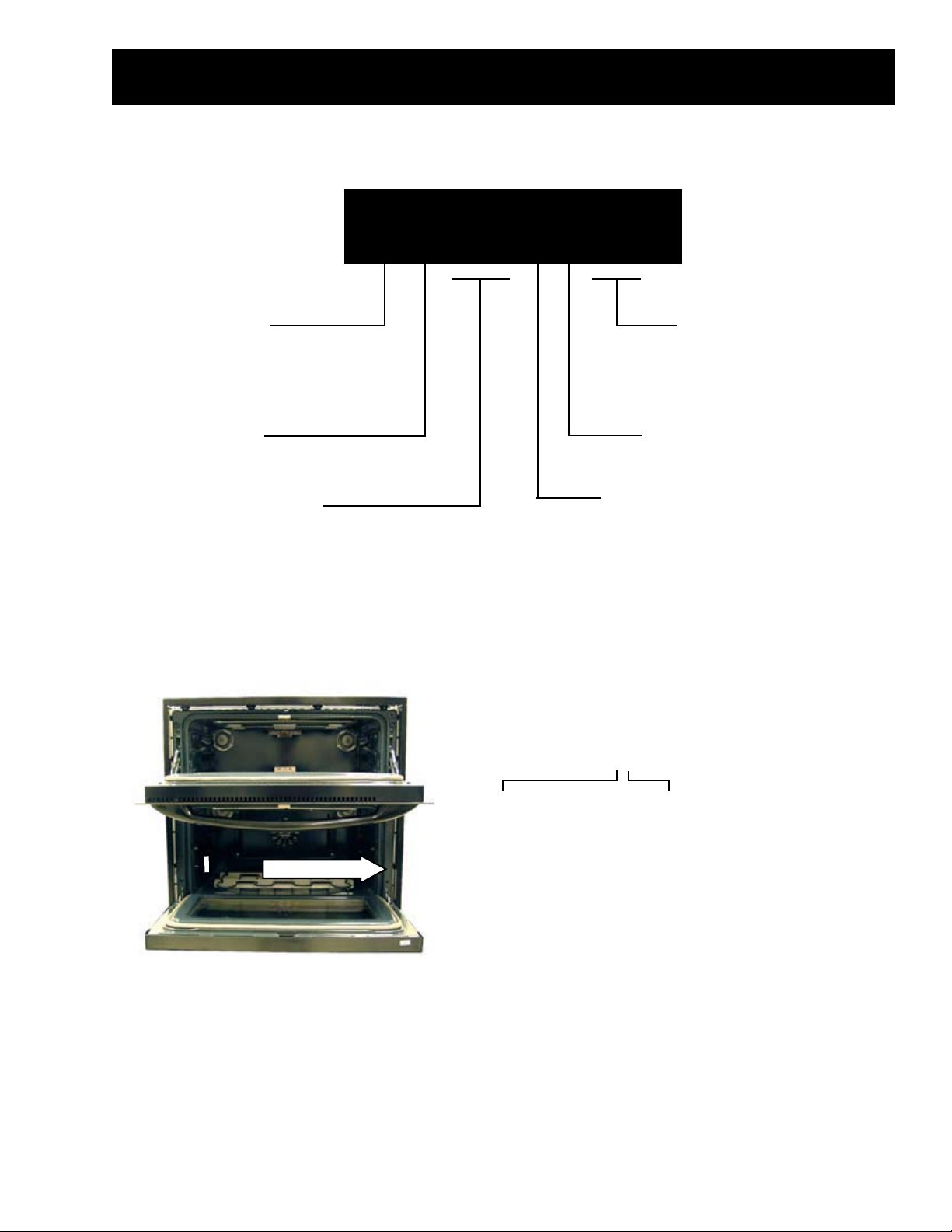

Component Locator Views

Single Double Wall Oven (Profile shown)

Door Lock

Broil Element

Oven Temperature Sensor

Light

Ribbon Cable

Meat Probe Outlet

Convection Fan

Bake Element

Upper Oven Door Control System (Door shown with inner door assembly removed)

Slider Assembly

Display/Logic Board

(Continued next page)

– 25 –

Page 26

Control Compartment

Back of Oven (Main Rear Panel Shown Removed)

Lock Out Relay

Upper Oven Relay Board

Broil Element

Lower Oven Relay Board

Thermal Cut Out

Thermal Cut Out

Convection Element

Convection Fan

Bake Element

Sail Switch

Cooling Fan

– 26 –

(Continued next page)

Page 27

Oven Component Access Chart

WARNING:

The wall oven is heavy and requires two people to remove it from the installation. Care should be taken •

when removing and installing.

Sharp edges may be exposed when servicing. Use caution to avoid injury. Wear Kevlar gloves or •

equivalent protection.

Components Requiring Oven Removal

Front Serviceable Oven Components

Lower

Upper

Bake Element

Broil Element

Convection Bake Element

Convection Fan Blade

Convection Fan Motor

Cooling Fan

Display/Logic Board

Door Assembly

Door Hinge Receiver

Lock Assembly

Lock Out Relay

Meat Probe Outlet

Oven Light Assembly

Oven Temperature Sensor

Relay Boards

Sail Switch Assembly

Thermal Cut Outs

Vent Tube/Smoke Eliminator

– 27 –

Page 28

Oven Components

Door Assemblies

The upper door contains many of the electronics

and controls for the oven.

Caution: The doors are heavy. Use the correct lifting

procedure. Do not lift the doors by the handles.

To remove the lower door:

Open the door fully.1.

Push the hinge locks down toward the door 2.

frame, to the unlocked position. (This may

require a flat-blade screwdriver to start the

hinge locks moving.)

Slot

Hinge

lock

Pull down

to access

Slider Assembly

Upper

Oven

Lower

Oven

Snap engages

with door

frame

3. Pull the tab forward to release the ribbon cable

assembly from the door.

Pull down to

Press tab

to release

ribbon

disconnect

ribbon cable

assembly

cable

3. Firmly grasp both sides of the door at the top.

4. Close the door to the door removal position.

5. Lift the door up and out until the hinge arm is

clear of the slot

To remove the upper door:

Fully open or remove the lower door.1.

4. Fully open the upper oven door.

5. Lift up on the hinge locks toward the oven frame

until they stop.

Hinge Lock

(Unlocked Position)

Slot

Hinge

Lock

6. Close the door to 45 degrees. The hinge lock will

contact the oven frame.

Removal Position

Pull down on the ribbon cable until the snap 2.

engages with the door frame.

– 28 –

(Continued next page)

Page 29

7. On both sides of the door, press down on the

release buttons on each hinge.

To remove the lower outer door assembly:

Remove the lower door. (See 1.

Door Assemblies.)

Door

Frame

Release buttons

8. Lift the door up until it is clear of the hinge.

To replace the door:

Firmly grasp both sides of the door at the top.1.

With the door at the same angle as the removal 2.

position, seat the indentation of the hinge arm

into the bottom edge of the hinge slot. The

notch in the hinge arm must be fully seated into

the bottom of the slot.

Bottom

edge

of slot

Hinge arm

Place the inner door assembly, gasket side up, 2.

on a protective surface.

Remove the four T15 Torx screws from the 3.

bottom of the outer door assembly.

Remove the two T15 Torx screws (1 on each 4.

side) from the outer door assembly.

1 of 2

Indentation

3. Fully open the door. If the door will not fully

open, the indentation is not seated correctly in

the bottom edge of the slot.

4. Push the hinge locks up against the front frame

of the oven to the locked position.

Hinge

lock

Hinge

arm

5. Close the oven door.

Note: The inner door assembly is heavier than the

outer door assembly.

Separate the inner door assembly from the 5.

outer door assembly.

Remove the four 1/4-in. hex-head screws and 6.

brackets that hold the door handle to the outer

door assembly.

Door Shown with Inner Door Assembly Removed

Outer Door Assembly

Caution: Care must be taken if reinstalling the door

handle. Overtightening the screws can damage the

handle. Hand-tighten the screws and make sure the

handle fits snugly against the door panel. (Do not

use an electric driver.)

– 29 –

(Continued next page)

Page 30

To replace the lower inner door assembly:

To remove the upper outer door assembly:

Remove the outer door assembly. (See 1.

Assemblies.)

Door

2. Remove the four T15 Torx screws (2 on each

side) that attach each door hinge to the inner

door. Carefully turn the door over and remove

both door hinges.

Remove the upper door. (See 1.

Door Assemblies.)

Place the inner door assembly, gasket side up, 2.

on a protective surface.

Remove the two T15 Torx screws from the 3.

bottom of the outer door assembly.

Remove the two T15 Torx screws (1 on each 4.

side) from the outer door assembly.

1 of 2

3. Remove the six 1/4-in. hex-head screws that

hold the insulation retainer to the inner door.

Remove the insulation retainer.

4. Remove the insulation and the inner glass

assembly from the inner door.

Inner Glass Assembly

Note: The inner door assembly is heavier than the

outer door assembly.

Separate the inner door assembly from the 5.

outer door assembly.

Remove the four 1/4-in. hex-head screws and 6.

brackets that hold the door handle to the outer

door assembly.

Door Shown with Inner Door Assembly Removed

Outer Door Assembly

Caution: Care must be taken if reinstalling the door

handle. Overtightening the screws can damage the

handle. Hand-tighten the screws and make sure the

handle fits snugly to the door panel. (Do not use an

electric driver.)

(Continued next page)

– 30 –

Page 31

To replace the upper inner door assembly:

Assembly Notes

Remove the upper door assembly. (See 1.

Assemblies.)

Door

2. Remove the four T15 Torx screws (2 on each

side) that attach each door hinge to the inner

door. Carefully turn the door over and remove

both door hinges.

3. Remove the six 1/4-in. hex-head screws that

hold the insulation retainer to the inner door.

Remove the insulation retainer.

When assembling, make sure the hinges are parallel

to each other and perpendicular to the door liner. If

not, the hinge may bind on the receiving channel of

the door. If the new hinge is not in the cocked and

locked position after installing, place the bottom of

the door against a firm, protected surface and push

the hinge arm down to the cocked position. Pull the

hinge lock back against the door liner surface to

lock the hinge in this position.

Air enters the door assembly through large slots in

the bottom and flows upward between the inner

and outer assemblies, exhausting through slots

in the top of the door. DO NOT INSULATE THIS AIR

CHANNEL.

Door Gasket

The gasket forms a complete seal around the front

edge of the oven liner and the inner door panel. The

door gasket is attached to the inner door panel by

spring clips. When removing the gasket, pull the

ends of the gasket out of the slots at the bottom

of the door. Place a finger under the gasket beside

each clip and pull straight up.

4. Remove the insulation and the inner glass

assembly from the inner door.

Inner Glass Assembly

When installing the door gasket, it is helpful to fold

the gasket in half and locate the center clip. Insert

the clip at the top of the door and work your way

around the door.

Make sure the gasket is cross-tucked in the

bottom slots of the inner door panel. Use a small

screwdriver to tuck the loose ends of the gasket into

the slots. The overlap is required to ensure a proper

door seal.

Cross Tuck

– 31 –

Page 32

Oven Removal

The replacement of certain components require

oven removal. (See Oven Component Access Chart.)

WARNING: The oven is heavy and requires two

people to remove it from the installation.

To remove the oven:

Remove the 2 Phillips-head screws (1 on each 1.

side) that hold the oven in place.

Door Shown with Inner Door Assembly Removed

Outer Door Assembly

1/4-in

Remove the three 3.

. hex-head screws from

the plastic cover that protects the display/logic

boards.

2. Pull the oven forward to remove it. Utilize a table

or platform in front of the oven and pull the oven

completely out.

Note: When reinserting the oven into the cabinet

opening, ensure the conduit is properly positioned

behind the oven. (See the

Installation Instructions

manual.)

Electronic Oven Control

The electronic oven control consists of the touch

glass keyboard, the display/logic board, and the

slider board assembly.

To remove the electronic oven control:

Remove the upper outer door assembly. (See 1.

Door Assemblies.)

Separate the inner door assembly from the 2.

outer door assembly. (See

Door Assemblies.)

4. Lift the bottom edge of the plastic cover to

expose the display/logic boards.

5. Remove the

1/4-in

. hex-head screw from the

logic board that holds the board in place.

6. Disconnect the 2 ribbon cables from the right

side of the board.

7. Disconnect the 2 wire harnesses from the board.

Disconnect

Disconnect

Disconnect

Disconnect

8. Remove the board.

– 32 –

(Continued next page)

Page 33

9. To access the slider board assembly, remove the

3/8-in. nut securing the insulating cover.

Side Access Panels

There are two side panels on each side of the oven.

To remove the side access panels:

10. To remove the board from the slider board

assembly, press the two tabs securing the

board to the slider and lift the board from the

assembly.

Remove the oven. (See 1.

Oven Removal.)

On each side of the oven, remove the four 1/4-2.

in. hex-head screws that hold the side trim in

place.

Panel One

Side Trim

Panel Two

Left Side Shown

3. Remove the two T10 Torx screws that hold the

bracket to the oven.

4. Remove the

1/4-in

. hex-head screws that hold

the two side panels to each side of the oven.

There are 46 hex-head screws on the left side

and 41 screws on the right side.

1 of 46

Torx Screw

Bracket

Torx Screw

– 33 –

Left Side Shown

Page 34

Rear Access Panels

Top Access Panels

There are two rear access panels: the main rear

access panel and the secondary rear access panel.

To remove many of the oven components, it is

necessary to remove one or both of the rear access

panels.

To remove the rear access panels:

Remove the oven. (See 1.

Oven Removal.)

To remove the main rear access panel, remove 2.

the twenty-five 1/4-in. hex-head screws that

hold the main rear panel in place.

Main Access Panel

1 of 25

To remove the top access panels:

Remove the oven. (See1. Oven Removal.)

Remove the four 1/4-in. hex-head screws that 2.

hold the top trim in place.

3. Remove the two 1/4-in. hex-head screws from

the top of the top access panel.

3. To remove the secondary rear access panel,

remove the twenty-five 1/4-in. hex-head screws

that hold the secondary rear panel in place.

Secondary Access Panel

1 of 25

4. Remove the fifteen 1/4-in. hex-head screws

from the sides and back of the oven that hold

the top access panel in place. There are 4

screws on the left side, 3 screws on the right

side and 8 screws on the back of the oven.

1 of 15

Right Side Shown

– 34 –

(Continued next page)

Page 35

5. Remove the thirteen 1/4-in. hex-head screws

from the top of the heat shield.

1 of 13

6. Lift up the top heat shield.

4. Carefully pull the sensor and sensor wiring

harness from the oven liner.

Note: When reinstalling the sensor, use a small flatbladed screwdriver to push and guide the sensor

wire harness into the oven liner.

Oven Temperature Sensor

The resistance of the temperature sensor is:

1080 • Ω at room temperature

2650 • Ω at clean temperature

To remove the oven temperature sensor:

Remove the main rear access panel. (See 1.

Access Panels.)

Remove the two 1/4-in. hex-head screws that 2.

attach the sensor to the broiler element bracket.

Rear

Broil Element

The broil element will not work if the temperature

probe is plugged in. The broil element terminals are

located behind the main rear access panel.

The broil elements are rated at:

Upper oven broil element (inner) - 1700 watts•

Upper oven broil element (outer) - 1050 watts•

Lower oven broil element (inner) - 2200 watts•

Lower oven broil element (outer) - 750 watts•

To remove the broil element:

Remove the main rear access panel. (See 1.

Access Panels.)

IMPORTANT: The lower wattage elements use

3/16-in. terminal connections. The higher wattage

elements use 1/4-in. terminal connections.

Rear

Disconnect the sensor wiring harness from the 3.

back of the oven.

Disconnect

2. Disconnect the wires from the broil element.

Disconnect

Disconnect

Disconnect

3. Remove the two 1/4-in. hex-head screws that

attach the temperature sensor to the broiler

element bracket.

(Continued next page)

– 35 –

Disconnect

Page 36

4. Remove the three 1/4-in. hex-head screws

that attach the broiler element to the oven

cavity.

5. Carefully pull out the sensor approximately 2

inches from the broiler element bracket.

6. Remove the four 1/4-in. hex-head screws that

attach the broil element to the top of the oven.

3. Remove the two 1/4-in hex-head screws that

hold the bake element to the back of the oven.

4. Carefully pull the bake element out through the

front of the oven.

Convection Fan Blade

The convection fan blade is located on the back wall

of the oven cavity and is removed separately from

the convection fan motor.

7. Carefully pull, then lower the broiler element

towards the front of the oven to remove.

Bake Element

The upper bake element is rated at 1700 watts, and

the lower element is rated at 2200 watts.

The bake element terminals are located behind the

main rear access panel.

To remove the bake element:

Remove the main rear access panel. (See 1.

Access Panels.

)

IMPORTANT: The lower wattage elements use

3/16-in. terminal connections. The higher wattage

elements use 1/4-in. terminal connections.

Rear

To remove the convection fan blade:

Remove the oven racks.1.

Remove the four 1/4-in. hex-head screws that 2.

hold the convection cover to the back wall of the

oven cavity.

3. The fan blade is attached to the motor shaft

with a reverse-threaded 1/2-in. hex-nut. Turn

the nut clockwise to remove.

2. Disconnect the wires from the bake element.

Disconnect

Disconnect

– 36 –

Page 37

Convection Bake Element

Convection Fan Motor

The inner convection element is rated at 655 watts

and the outer convection element is rated at 645

watts.

The convection bake element is located on the back

wall of the oven.

To remove the convection bake element:

Remove the oven. (See 1.

Remove the main rear access panel. (See 2.

Access Panels.)

Oven Removal.)

Rear

IMPORTANT: The lower wattage elements use

3/16-in. terminal connections. The higher wattage

elements use 1/4-in. terminal connections.

3. Disconnect the wires from the convection bake

element.

The convection fan motor is located on the back

wall of the oven cavity.

The convection fan will turn on (after a short delay).

The fan may cycle on and off, and change direction,

to best distribute hot air in the oven. The convection

fan shuts off when the door is opened.

The convection fan motor has approximate

resistance values between the following wires:

• Red and Blue: 168 Ω

• Red and Gray: 75 Ω

• Blue and Gray: 93 Ω

To remove the convection fan motor assembly:

Remove convection fan blade. (See 1.

Fan Blade

.)

Convection

Remove the rear access panel. (See 2. Rear Access

Panels.)

4. Remove the oven racks.

5. Remove the four 1/4-in. hex-head screws that

hold the convection cover to the back wall of the

oven cavity. (See

Convection Fan Blade.)

6. Remove the five 1/4-in. hex-head screws that

hold the convection bake element to the back

wall of the oven cavity.

Disconnect the convection fan motor wire 3.

harness.

Remove the three 1/4-in. hex-head screws that 4.

hold the convection fan motor to the back of the

oven.

Disconnect

7. Carefully pull the convection bake element

toward the front of the oven.

– 37 –

Page 38

Relay Boards

Lock Assembly

The relay boards can be accessed by removing the

main rear access panel. The top relay board controls

the lower oven, and the bottom relay board controls

the top oven.

The lower oven relay board contains the power

supply module, which provides power to the rest of

the control system.

Lower Oven Relay Board

Upper Oven Relay Board

To remove the relay boards:

Remove the main rear access panel. (See 1. Rear

Access Panels.)

Mark and disconnect all connectors from the 2.

relay boards.

The motorized door lock assembly is located above

the oven and comes as a complete assembly.

Door Locking/Unlocking Strip Circuit

LOCK RELAY

L

J14 J7

ALL OTHER MODES WITH DOOR CLOSED

LOCK RELAY

L

J14 J7

LOCK

MOTOR

LOCK

MOTOR

SWITCH

NO

NC

SWITCH

NO

NC

DOOR

DOOR

N

C

N

C

The cam on the motor performs two functions:

Positions the lock hook in the door to prevent 1.

opening during clean operation.

Operates the lock switches, which tell the 2.

control if the door is unlocked or locked and

ready for clean operation.

Remove the four 1/4-in. hex-head screws (2 on 3.

each side) that hold each relay board in place.

Note: When the door is either being locked or

unlocked, both the lock and unlock switches will

be in the open position. The upper oven latch is

controlled by the upper oven relay board. The lower

oven latch is controlled by the lower oven relay

board.

Strip Circuit

LOCKED

J16

5

4

3

2

1

J17-Pin9

– 38 –

(Continued next page)

Page 39

Strip Circuit

Thermal Cut Outs

UNLOCKED

J16

5

4

3

2

1

J17-Pin9

To remove the lock assembly:

Remove the main rear access panel. (See 1.

Access Panels.)

Remove the two T15 Torx screws from the front 2.

of the oven that secure the lock assembly in

place.

Rear

When either of the 2 thermal cut outs are open, L2 is

cut off from the oven.

The thermal cut outs are rated at:

Upper oven TCO = 177°C/350°F•

Lower oven TCO = 150°C/302°F•

Upper Oven Thermal Cut Out

Lower Oven Thermal Cut Out

3. Disconnect the motor and switch wiring

harnesses from the lock assembly.

Disconnect

Lock Assembly

Disconnect

4. Slide the lock assembly through the channel and

out through the back of the oven.

To remove the thermal cut outs:

Remove the main rear access panel. (See 1.

Access Panels.)

Disconnect the wires, and remove the two 1/4-2.

in. hex-head screws that attach the thermal

switch to the oven.

Disconnect

Disconnect

Rear

Disconnect

Disconnect

– 39 –

Page 40

Lock Out Relay

The L2 DLB lockout relay opens the L2 side of the

line to the upper oven heating elements if the upper

oven door is opened.

Micro Switch

Sail

To remove the lock out relay:

Remove the main rear access panel. (See 1.

Access Panels.)

Mark and disconnect the wiring to the lock out 2.

relay.

Remove the two 1/4-in. hex-head screws that 3.

attach the lock out relay to the oven frame.

Disconnect

Rear

Disconnect

Airflow from the

Cooling Fan Pulls

the Sail Closed

Cooling Fan

To remove the sail switch:

Remove the main rear access panel. (See 1. Rear

Access Panels.)

Disconnect the wires from the sail switch.2.

Disconnect

Sail Switch Assembly

The sail switch assembly is located on the back of

the unit, above the cooling fan, and is operated by

the airflow of the fan.

When the cooling fan is in high speed, the sail

should be closed. When the cooling fan is off, the

sail should be open. When the cooling fan is in low

speed, the sail may be open or closed, and the

control ignores the output of the micro switch.

3. Remove the two 11/4-in. hex-head screws that

attach the sail switch assembly to the left side

access panel.

Sail Switch

– 40 –

Page 41

Cooling Fan

Ribbon Cable Assembly

The cooling fan is located in a recess in the back of

the oven. It is necessary to remove the oven from

the installation to access the cooling fan.

The fan will begin to operate when the oven is in

any cooking mode. The fan may continue to operate

even after the oven is turned off.

To remove the cooling fan:

Remove the main rear access panel. (See 1.

Access Panels.)

Rear

Disconnect the wire harness and the ground 2.

wire from the cooling fan.

Disconnect

Disconnect

Cooling Fan

To remove the ribbon cable assembly:

Open or remove the lower door.1.

Release the ribbon cable assembly from the 2.

door. (See

Door Assemblies.)

Remove the secondary rear access panel. (See 3.

Rear Access Panels.)

Disconnect the back of the ribbon cable from 4.

the mating connector.

Disconnect

5. Remove the 4 screws and nuts from the front

end of the ribbon cable housing.

3. Remove the four 1/4-in. hex-head screws (2

on each side) that hold the cooling fan to the

control compartment.

Carefully grasp the assembly and tilt the unit 4.

back, up, and out of the oven frame.

6. Remove the ribbon cable by sliding it out of the

ribbon cable sleeve.

Note: When installing the new ribbon cable, ensure

that the new cable is positioned between the wings

of the ribbon guide located between the oven

cavities.

– 41 –

Page 42

Door Hinge Receivers

To remove the door hinge receivers:

Remove the side access panels. (See 1.

Panels.)

Carefully lift the insulation from the outside of 2.

the oven.

Remove the two T20 Torx screws that hold each 3.

hinge receiver to the oven frame.

Side Access

3. Pull the outlet and wiring down from the oven

wall.

Note: When replacing the meat probe outlet, cut

the probe wires and splice the new probe using

approved heat-resistant connectors.

4. Push the hinge receiver through the opening in

the oven frame and remove from the rear.

Note: Upon reassembly, ensure the displaced

insulation around the oven and components is

returned to its original position.

Meat Probe and Outlet

The meat probe outlet is located on the top of the

oven cavity, near the front. The meat probe outlet is

connected to the electronic oven control. The meat

probe has a resistance value of 30K-50K Ω at room

temperature.

To remove the meat probe outlet:

Open the lower oven door.1.

Cut Here

Cut Here