Page 1

g

GE Consumer Home Services T raining

TECHNICAL SERVICE GUIDE

Arctica Side-By-Side Refrigerator

Inverter Compressor

Low Noise - High Performance

MODEL SERIES:

PSH23SGNAFBS

PUB # 31-9090 02/02

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2002

All rights reser ved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Table of Contents

Introduction ..........................................................................................................2

Specifications.......................................................................................................3

Nomenclature ....................................................................................................... 4

Component Locator Views..................................................................................5

Principals of Refrigeration .................................................................................. 6

Phases of Refrigeration .................................................................................. 6

Dryer..................................................................................................................8

Filter .................................................................................................................. 8

Capillary ............................................................................................................9

Heat Exchanger ................................................................................................ 9

Refrigeration System ......................................................................................... 10

System Pressure............................................................................................ 11

Refrigerant Charge ........................................................................................ 11

Inverter Compressor ..................................................................................... 12

Inverter ........................................................................................................... 14

Adaptive Defrost ................................................................................................ 16

Fans.....................................................................................................................18

Evaporator Fan ...............................................................................................18

Condenser Fan ............................................................................................... 20

Fresh Food Fan .............................................................................................. 21

Main Control Board ........................................................................................... 22

Diagnostics ......................................................................................................... 29

Compressor Not Running Flowcharts ......................................................... 29

Fresh Food Warm - Freezer Normal Flowchart...........................................30

Fresh Food Too Cold - Freezer Normal Flowchart ..................................... 31

Fresh Food Warm - Freezer Warm Flowchart ............................................. 32

Freezer Warm - Fresh Food Normal Flowchart...........................................33

Refrigerator Dead - No Sound, No Cooling Flowchart .............................. 34

Damper Not Operating Flowchart ................................................................35

Heavy Frost on Evaporator Flowchart.........................................................36

Evaporator Fan Not Running Flowchart......................................................37

Condenser Fan Not Running Flowchart......................................................38

Thermistors .................................................................................................... 39

Schematic ........................................................................................................... 40

Wiring Diagram ............................................................................................... 41

Parts List.............................................................................................................42

Warranty .............................................................................................................. 43

– 1 –

Page 4

Introduction

This new Arctica refrigerator is similar to previous Arctica models with the following exceptions:

• Compressor type

• Compressor control

• 3-speed condenser fan

• 3-speed fresh food fan

The new inverter compressor has 3 speeds and is not controlled from the 120 VAC side of the main

control board. The compressor is controlled by an inverter that receives input from the low voltage DC

side of the main control board. The main control board still makes compressor decisions based on the

input of 4 thermistors, door-open time, and input from the temperature control panel.

The other significant difference from previous models is that the main control board now operates the

condenser fan and fresh food fan at three different speeds. Both fans are actually the same fans found

on previous models.

The new Arctica with inverter compressor is also more efficient than previous models. The increased

efficiency provided by the inverter compressor allows this refrigerator to receive an Energy Star rating.

The Energy Star rating means the refrigerator consumes 10% less energy than the Department of

Energy standard for the specific cabinet size.

This refrigerator is also 5 to 7 decibels quieter than previous models.

This technical service guide covers the new features of this new Arctica refrigerator. For information on

features and components that are common to previous Arctica refrigerators, refer to pub #31-9072.

– 2 –

Page 5

Specifications

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL GROUNDING DEVICES

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to

complete a path to ground are removed for service,

they must be returned to their original position and

properly fastened.

ELECTRICAL SPECIFICATIONS

Temperature Control (Position 5) ......................... 7-(-11 )°F

Defrost Control .......................................... 60hrs @ 45 min

w/ no door openings

Overtemperature Thermostat ..............................140-110°F

Defrost Thermistor ........................................................ 70°F

Electrical Rating: 115V AC 60 Hz ......................... 11.6 Amp

Maximum Current Leakage ................................... 0.75 mA

Maximum Ground Path Resistance .................. 0.14 Ohms

Energy Consumption . ..................................... 51 KWH/mo

NO LOAD PERFORMANCE

Control Position MID/MID

and Ambient of: ............................................... 70°F 90°F

Fresh Food, °F ................................................ 34-40 34-40

Frozen Food, °F .............................................. (-3) 3 (-3) 3

Run Time, % ...................................................... <80 <100

REFRIGERATION SYSTEM

Refrigerant Charge (R134a) ............................... 6.0 ounces

Compressor ....................................................833 BTU/hr @

3000 RPM

Minimum Compressor Capacity ......................... 22 inches

Minimum Equalized Pressure

@ 70°F ....................................................................... 45 PSIG

@ 90°F ....................................................................... 57 PSIG

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation of

this information, nor can it assume any liability in

connection with its use.

INSTALLATION

Minimum clearance required for air circulation:

TOP ............................................................................................. 1"

SIDES ................................................................................... 0.125"

REAR ........................................................................................ 0.5"

REPLACEMENT PARTS

Temperature Control ...................................... WR55x10023

Inverter ............................................................. WR55x10155

Overtemperature Thermostat ........................ WR50x10015

Defrost Heater Harness & Thermostat ......... WR23x10142

Defrost Heater & Bracket ............................... WR51x10030

Condenser Fan Motor ..................................... WR60x10042

Evaporator Fan Motor .................................... WR60x10043

Main Board ...................................................... WR55x10156

Dispenser Board.............................................. WR55x10029

Thermistor (EV) ............................................... WR55x10025

Thermistor (FZ) ............................................... WR55x10026

Thermistor (FF)................................................ WR55x10027

Thermistor (FF)................................................ WR55x10028

Thermistor (CC) ............................................... WR55x10030

Compressor ..................................................... WR87x10064

FF Fan Motor ................................................... WR60x10051

Damper ............................................................ WR60x10052

AIR FLOW

– 3 –

Page 6

Nomenclature

P S H 23 S G N A F BS

Brand/Product

G - GE

H - Hotpoint

P - Profile

E - Eterna

S - GE Select

Configuration

S - Side by Side

T - Top Mount

Depth/Power

H - Inverter Compressor

S - Standard Depth

T - Tropical

G - Global

Capacity

(cubic feet) AHAM Rated Volume

Interior Features/Shelves

A - Leader Wire

D - Deluxe Wire

I - Deluxe Glass

K - Spillproof/Slideout Glass F - 6 Month filter

S - Stainless S teel Doors

Q - Showcase Derivative

U - A VB Derivative

W - HPS Derivative

X - Regional Derivative

Exterior Color

BS - Black on Stainless

WW - White on White

AA - Almond on Almond

BB - Black on Black

CC - Bisque on Bisque

WH - White on Black

Door T ype

F - Flat

R - Right

L - Left Door Swing

Engineering

A - Initial Design

B - 1st Revision

Model Year

N - 2002

Icemaker/Exterior

B - Non Dispenser

IM Ready

D - Cubed Ice/Water

E - Cubed/Crushed/Water

F - 6-Month Filter

Cubed/Crushed

G - 1-Y ear Filter

Cubed/Crushed

I - In-line Filter/Indicator

Cubed/Crushed/Water

The rating plate, located on the upper left

wall of the fresh food compartment,

contains the model and serial numbers.

Additionally , the rating plate specifies the

minimum installation clearances,

electrical voltage, frequency, maximum

amperage rating, and refrigerant charge,

and type.

– 4 –

Page 7

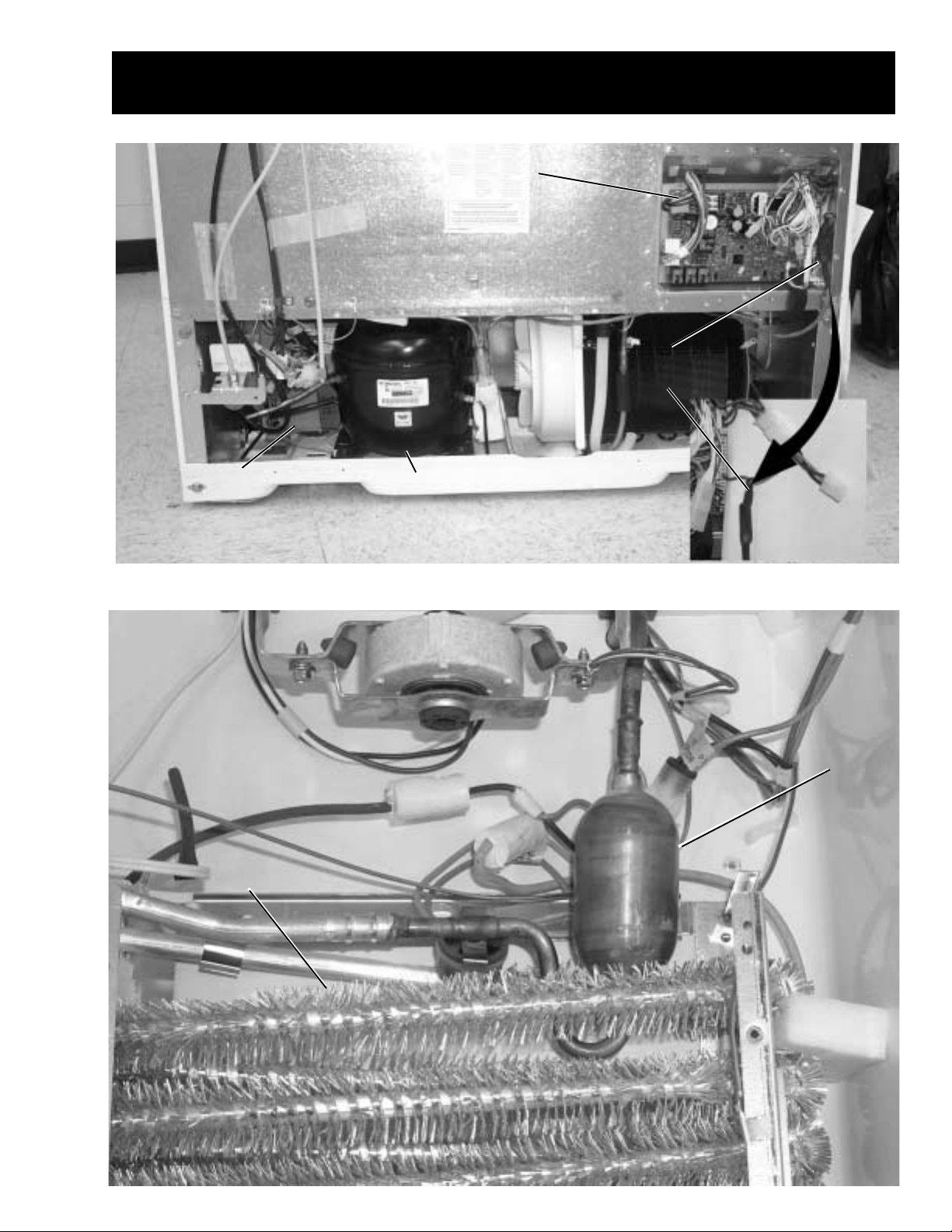

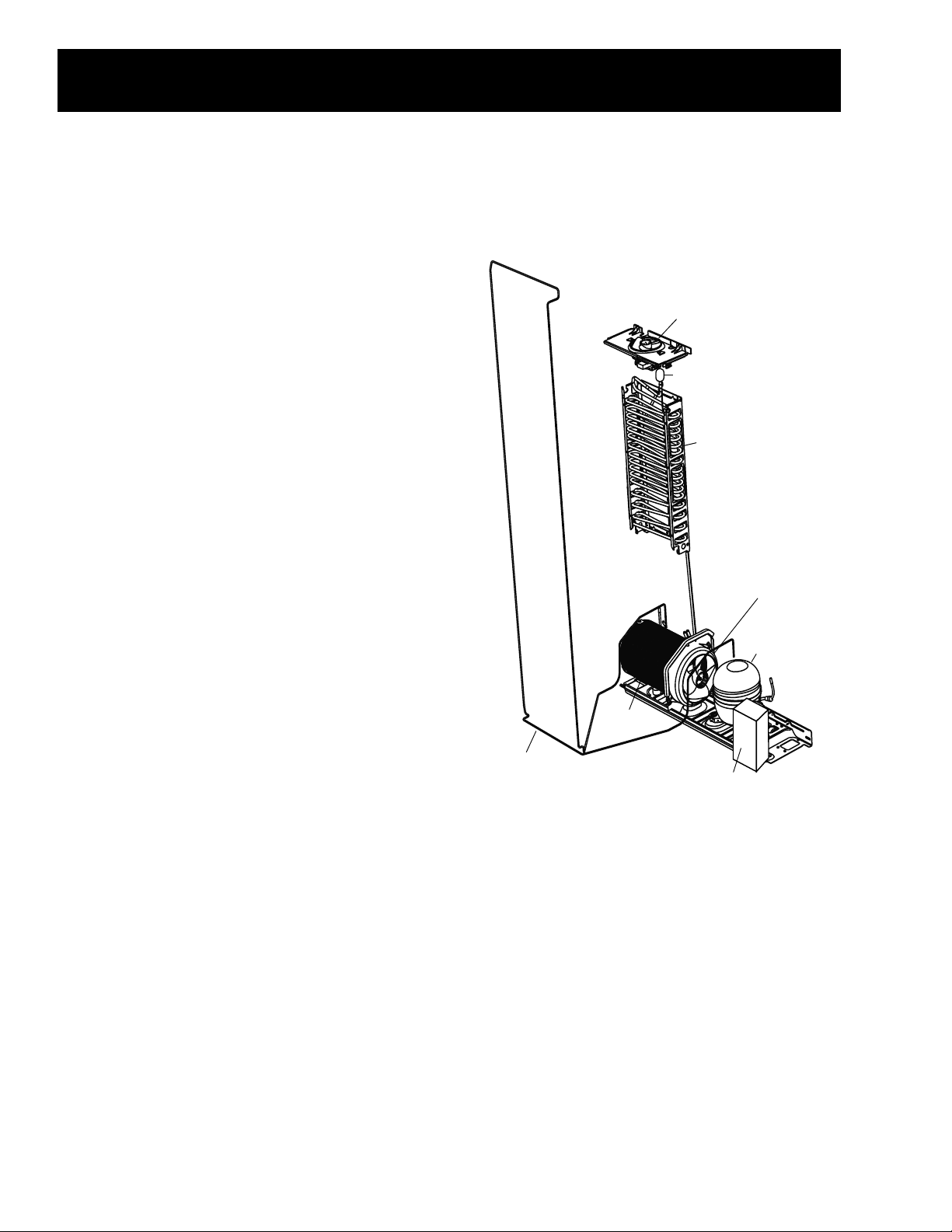

Inverter

Inverter

Component Locator Views

Main Control Board

Main Control Board

Current-Source

Current-Source

Circuit Board

Circuit Board

Inverter CompressorInverter Compressor

Evaporator

Evaporator

– 5 –

Accumulator

Accumulator

Page 8

Principals of Refrigeration

Phases of Refrigeration

The compressor is the heart of any refrigeration system. It serves as a pump to circulate the refrigerant

and create pressure within the system. When the compressor is operating, one side of the system is at

high pressure and the other side is at low pressure. This difference in pressure creates a temperature

difference that allows heat to be removed from inside the cabinet and transferred to the outside of the

cabinet.

The 3 phases of the refrigeration system are:

• Compression

• Condensation – occurs on the “high side” of the system

••

• Evaporation – occurs on the “low side” of the system

••

Compression

While the compressor is operating, refrigerant vapor is discharged into the condenser. A capillary (small

diameter tube) is connected to the outlet of the condenser . The capillary tube restricts the amount of

refrigerant that leaves the condenser . As the compressor continues to pump refrigerant into the

condenser, this restriction causes pressure to build in the condenser. Typical operating pressure in the

condenser in the inverter compressor system is 85 to 90 psig in an ambient temperature of 75 °F.

Condensation

The compressed refrigerant vapor entering the condenser is warmer than the temperature of the room.

As the refrigerant travels though the condenser , the heat from the high-pressure vapor is transferred to

the condenser , which transfers heat to the surrounding air (by convection). As heat is removed from the

high-pressure vapor, it begins to condense into a high-pressure liquid. This high-pressure liquid

refrigerant flows to the end of the condenser and is forced into the capillary tube.

Evaporation

High-pressure liquid refrigerant travels through the capillary and exits at a very high rate of speed into the

much-larger tubing of the evaporator . Low pressure in the evaporator, caused by the suction of the

compressor (typically 0 to 5 psig in the inverter compressor) causes the liquid refrigerant to vaporize.

Approximately 30% of the refrigerant will vaporize immediately upon exiting the capillary . The remaining

refrigerant will vaporize as it travels through the evaporator . As the refrigerant vaporizes, it absorbs

heat. Heat inside the cabinet is transferred (by convection) to the evaporator because the evaporator

temperature is lower than the cabinet air temperature. Refrigerant exiting the evaporator should have

completely vaporized so that only vapor is returned to the compressor through the suction line.

However , under certain conditions some refrigerant may remain in liquid form as it exit s the evaporator.

The mixture of refrigerant (vapor and liquid) is known as “refrigerant quality .” Refrigerant that has a

higher ratio of vapor to liquid has a higher quality . Completely vaporized refrigerant has a quality rating of

100%. Refrigeration that is completely liquid has a quality rating of 0%. Refrigerant that is exiting the

evaporator should have a quality rating of 100%. Refrigerant that is exiting the condenser should have a

quality rating of 0%. Refrigerant quality is an important part of refrigeration system efficiency.

– 6 –

Page 9

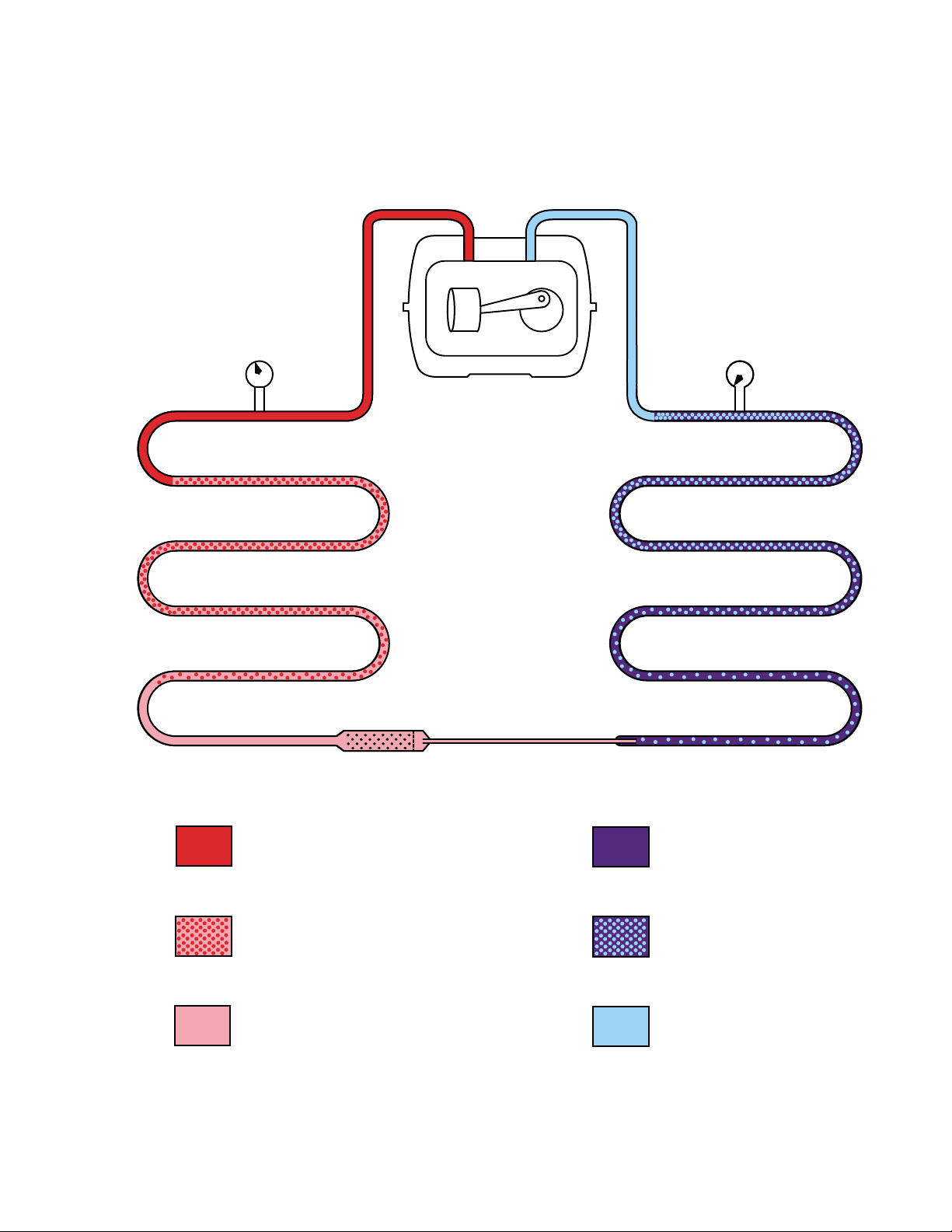

SINGLE-SPEED COMPRESSOR

70-135 PSIG

85-90 PSIG at

75 ˚F Ambient

CONDENSER

FILTER-DRYER

COMPRESSOR

CAPILLARY

0-5 PSIG

1-2 PSIG at

75 ˚F Ambient

EVAPORATOR

HIGH PRESSURE VAPOR

MIX OF LIQUID AND VAPOR

HIGH PRESSURE LIQUID

LOW PRESSURE LIQUID

MIX OF LIQUID AND VAPOR

LOW PRESSURE VAPOR

GEA01261

– 7 –

Page 10

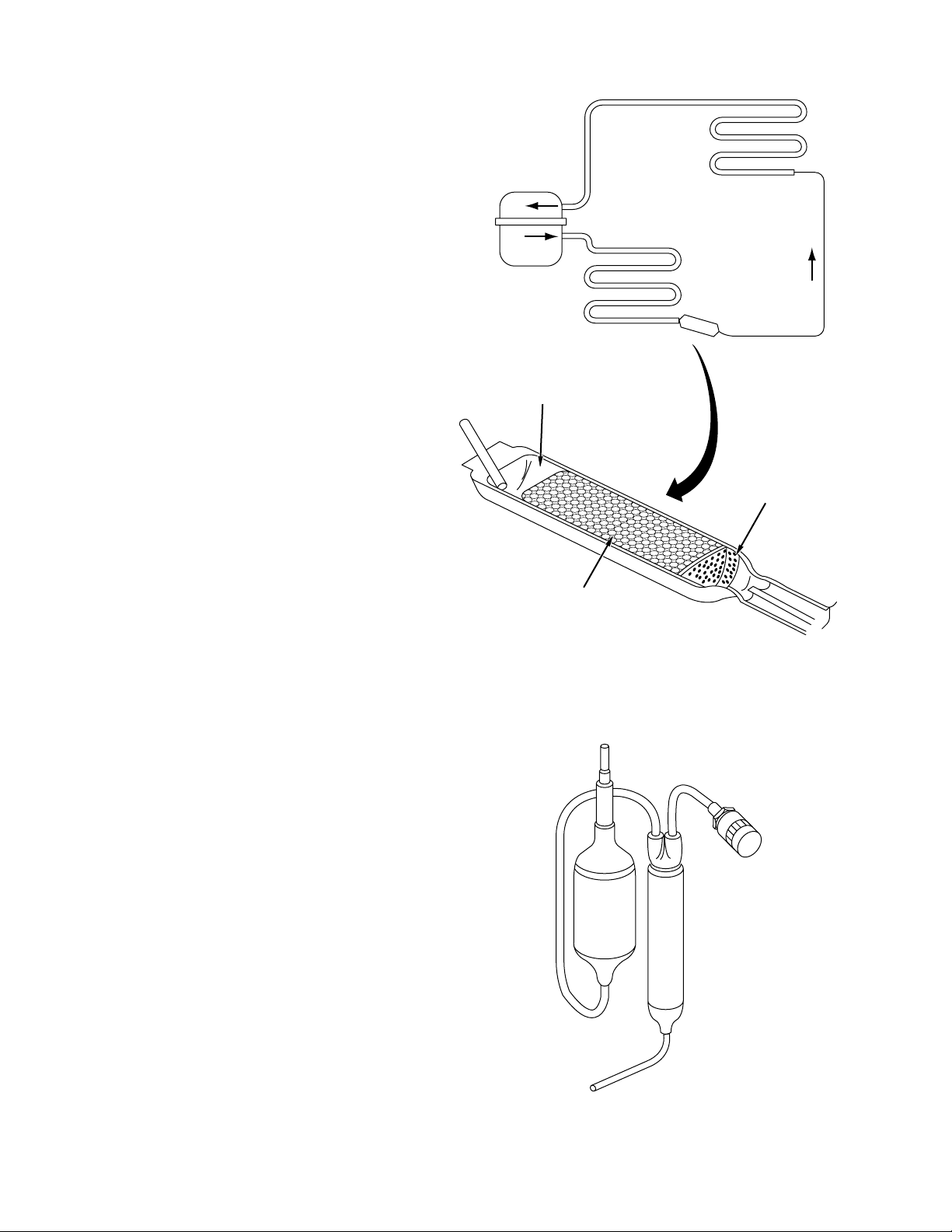

Dryer

The refrigeration system must be free from dirt

and moisture. A single particle of dirt, or one drop

of water, can cause the system to fail. For this

reason, a dryer is a necessary component of the

refrigeration system. The dryer consists of a

strainer at the inlet, a molecular sieve of beads,

and a screen at the outlet. The beads have the

ability to attract and absorb molecules of water but

reject the molecules of refrigerant, oil, nitrogen,

and most other substances. The strainer prevents

the beads from spilling into the inlet. The fine

mesh screen prevents particles (including crushed

beads) from plugging the capillary tube. The dryer

is normally located between the outlet of the

condenser and the inlet of the capillary .

SUCTION TUBE

EVAPORATOR

COMPRESSOR

DRYER

CONDENSER

CAPILLARY

SCREEN

STRAINER

Filter

A filter is provided in some refrigeration systems

and furnished with some replacement

compressors. The filter has the appearance of a

large diameter dryer. It has a very fine mesh

screen located at the outlet and a solid core, made

of a special porous material, that is capable of

chemically removing contaminants from the

system. An arrow, stamped on the body of the

filter, indicates the proper direction of flow.

A filter/dryer combination is furnished with

replacement compressors for systems using

R134a refrigerant. A new filter/dryer must be

installed any time an R134a system is repaired.

An additional 0.5 oz of refrigerant is required when

a filter/dryer is added to the high side of the

system.

MOLECULAR

SIEVE OF BEADS

GEA01257

– 8 –

GEA01258

Page 11

Capillary

GEA01256

CAPILLARY

CONDENSER

COMPRESSOR

SUCTION TUBE

EVAPORATOR

DRYER

The capillary is a very small diameter tube that is

about 6 to 8 feet long. Its primary function is to

control the flow of refrigerant into the evaporator .

The flow rate of a capillary is determined by its

diameter and is critical to the proper operation of

the refrigeration system. If a capillary is

shortened, the flow rate will increase. Likewise, if

it is lengthened the flow rate will decrease.

Therefore, when repairing a refrigeration system it

is very important to cut the capillary as close as

possible to the outlet of the dryer . The capillary is

not replaceable separately .

Heat Exchanger

The function of the heat exchanger is to transfer

heat from the warm liquid flowing through the

capillary to the cool vapor flowing through the

suction tube. The heat exchange occurs where

the capillary is soldered to the outside of the

suction tube. This arrangement improves the

efficiency of the system. By reducing the heat of

the capillary , the boiling point of the liquid entering

the evaporator is lowered. Increasing the heat of

the suction tube increases the density of the vapor

entering the compressor and also helps to prevent

the suction tube from sweating.

– 9 –

Page 12

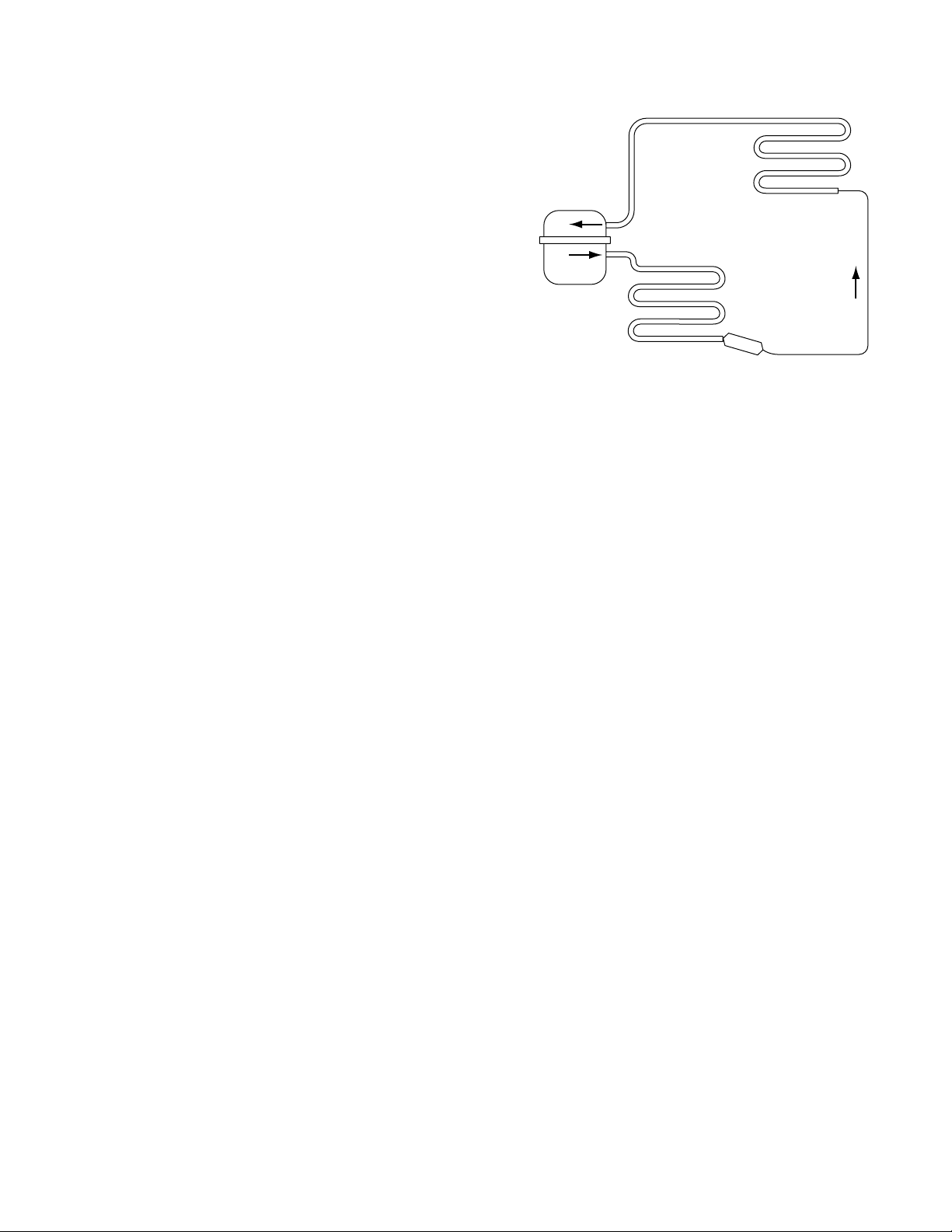

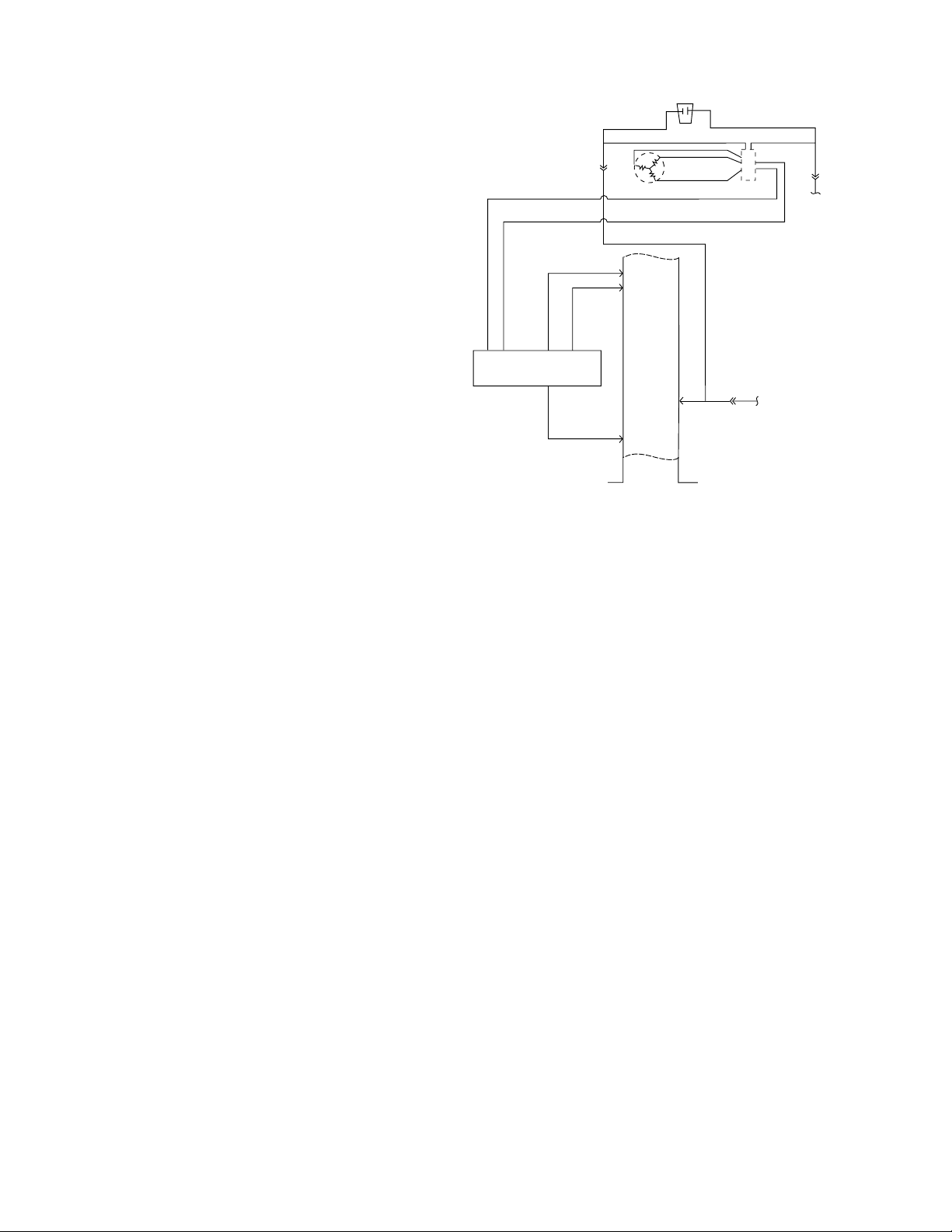

Refrigeration System

The refrigeration system has several new components as well as several familiar ones. New

components include:

• Inverter compressor

• Inverter

• 3-speed condenser fan

• Accumulator at the outlet of the evaporator

Familiar components include:

• Condenser

• Condenser loop

• Dryer

• Evaporator

• Evaporator fan

The refrigeration system operates with optimum

efficiency and economy by changing the speed of

the compressor (and condenser fan) to meet

demand. During times of high usage, or in

extremely warm ambient conditions, the 3-speed,

inverter compressor will increase speed to meet

greater refrigeration requirements. When usage is

low, the compressor will operate at a slower

speed, reducing its energy requirement.

In the new system with the inverter compressor,

the flow of refrigerant through the components in

the system is the same as previous models with

the following exception: an accumulator has been

added to the outlet side of the evaporator.

EVAPORATOR FAN

ACCUMULATOR

EVAPORATOR

3-SPEED CONDENSER FAN

INVERTER

COMPRESSOR

CONDENSER

CONDENSER LOOP

INVERTER

– 10 –

GEA01262

Page 13

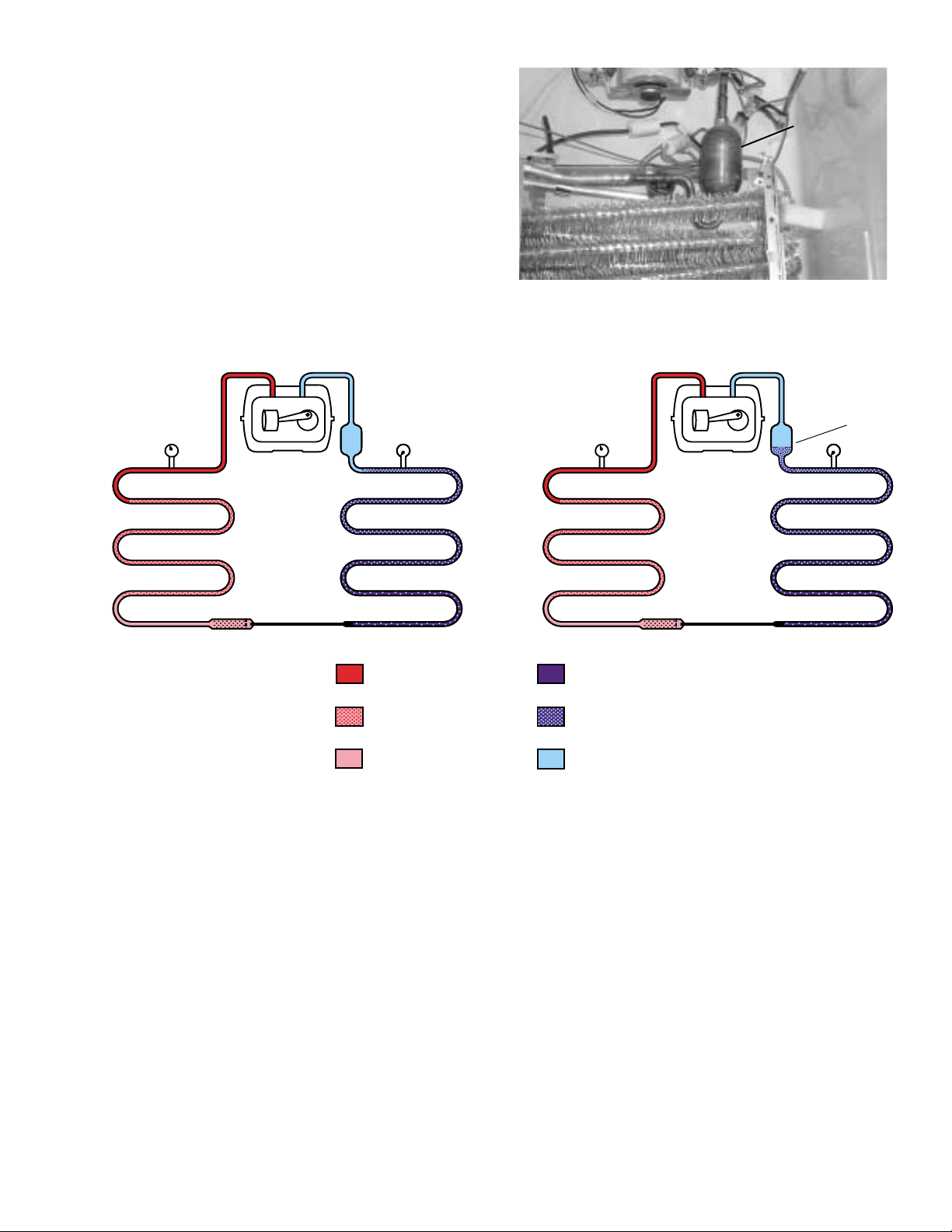

An accumulator has been installed at the outlet of

the evaporator to prevent liquid refrigerant (low

quality) from entering the suction line. Changes in

compressor speed (transition state) can

temporarily reduce refrigerant quality . The

accumulator compensates for this by collecting

and holding up to 2 oz of liquid while allowing

vapor to pass. Within minutes after the

compressor speed change, the system attains a

steady state (becomes stabilized), the liquid

refrigerant in the accumulator vaporizes, and

refrigerant quality returns to normal.

Accumulator

Steady State

INVERTER COMPRESSOR

70-135 PSIG

85-90 PSIG at

75 ˚F Ambient

CONDENSER EVAPORATOR

FILTER-DRYER

COMPRESSOR

CAPILLARY

ACCUMULATOR

HIGH PRESSURE LIQUID

0-5 PSIG

1-2 PSIG at

75 ˚F Ambient

HIGH PRESSURE VAPOR

MIX OF LIQUID AND VAPOR

Transition State

INVERTER COMPRESSOR

70-135 PSIG

85-90 PSIG at

75 ˚F Ambient

CONDENSER EVAPORATOR

FILTER-DRYER

LOW PRESSURE LIQUID

MIX OF LIQUID AND VAPOR

LOW PRESSURE VAPOR

COMPRESSOR

CAPILLARY

ACCUMULATOR

LIQUID ENTERS

THE ACCUMULATOR

0-5 PSIG

1-2 PSIG at

75 ˚F Ambient

GEA01263

System Pressure

The refrigeration system should maintain a consistent pressure regardless of compressor speed.

Pressure variations, due to changing compressor speed, are minimized by matching the condenser fan

speed and evaporator fan speed to the compressor speed. The condenser and evaporator fans will

always operate at the same speed (low, medium, or high) as the compressor.

Low side system pressure should be between 0 and 5 psig dependant on ambient temperature.

System pressures in an ambient temperature of 75 °F should be:

••

• High Side – 85 to 90 psig

••

••

• Low Side – 1 to 2 psig

••

Refrigerant Charge

The refrigerant used in the sealed system is R134a. Proper system charge is 6 oz; however, an

additional 0.5 oz is required when adding a filter/dryer . Proper system charge is critical to the operation

of this unit.

– 11 –

Page 14

Inverter Compressor

The new inverter compressor is not controlled by

120 VAC output from the main control board, as in

previous models. The compressor is controlled by

the inverter.

Warning: Disconnecting the 6-pin connector

does not disconnect power (120 VAC) from the

inverter. The refrigerator must be unplugged

before servicing the inverter or compressor.

Caution: Do not attempt to direct-start the

compressor. The compressor operates on a

3-phase power supply . Applying 120 V AC to the

compressor will permanently damage the unit.

It is not possible to start the compressor

without an inverter.

The compressor is a reciprocating, variable speed,

4-pole type. It operates on 3-phase, 80 to 230 V AC

within a range of 57 to 104 Hz. Compressor speed

is controlled by voltage frequency and pulse width

modulation. Increasing frequency from the inverter

will produce an increase in compressor speed.

6-PIN

CONNECTOR

CURRENT-SOURCE

CIRCUIT BOARD

LOW VOLTA GE DC

CIRCUIT

CLASS 2

+12 VDC

CO

AC

INVERTER

ORANGE

ANGE

R

O

GE

N

A

R

O

BROWN

B

A

L

C

K

10Ω

Ω

0

1

COMPRESSOR

LUE

B

PURPLE

2

J4-

ON

M

M

J4-3

K

B

A

L

C

B

L

E

U

10Ω

BROWN

TAB 4

N

W

BRO

MAIN CONTROL BOARD

10

J3-

S

LINE VOLTAGE

GEA01260

• Frequency of 57 Hz will produce low speed operation at 1710 rpm.

• Frequency of 70 Hz will produce medium speed at 2100 rpm.

• Frequency of 104 Hz will produce 3120 rpm.

Note: Certain voltmeters will not be able to read voltage output or frequency from the inverter.

Compressor wattages at various speeds are:

• LOW - 65 watts

• MED - 100 watts

• HIGH - 150 watts

BTU rating also varies according to operating speed.

Compressor speed is based on the temperature setpoint in conjunction with the cabinet temperature.

Speeds are selected according to the following cabinet temperatures:

• 8 °F to 19.5 °F above setpoint = high speed

• 3.5 °F to 7.5 °F above setpoint = medium speed

• 1 °F to 3 °F above setpoint = low speed

Note: The compressor will run at medium speed if the cabinet temperature is 20 °F or more above the

setpoint.

The use of 3-phase power eliminates the need for the PTCR relay , cap acitor, and individual start and run

windings; therefore the start, run, and common pins found on conventional compressors are not

applicable on this 3-phase model. Compressor pin functions are identical and compressor lead wire

configuration is of no importance. A resistance of 9 to 1 1Ω should be read between any 2 of the 3 pins.

Should an open occur in the compressor winding or should one of the compressor lead wires become

open or disconnected, the inverter will stop voltage output to the compressor .

– 12 –

Page 15

High compressor torque enables the compressor to start against high pressure in the sealed system.

When power has been disconnected from an operating unit, the high torque will enable the compressor

to start immediately upon power restoration.

Compressor and sealed system operation is extremely smooth and cool. The compressor exterior may

be room temperature while operating; therefore a running unit may be difficult to detect.

To verify that the compressor is running:

Disconnect power from the unit and place a hand on the compressor. Reconnect power and feel for a

vibration when the compressor tries to start. It may take up to 8 seconds before the compressor

attempts to start.

To determine motor rpm:

Measure the frequency of the voltage being applied to the compressor and multiply this number by 30.

For example, a frequency measurement of 70 Hz would show a compressor speed of 2100 rpm (30 x

70 = 2100).

Note: If the compressor fails to start, the inverter will briefly stop voltage output. The inverter will make

12 consecutive attempts to start the compressor (once every 12 seconds). If, after 12 attempts, the

compressor has not started, an 8-minute count will occur. After 8 minutes, the inverter will attempt to

start the compressor again. If the compressor starts, normal operation will resume. If the compressor

fails to start, the process will be repeated.

Removing power from the unit will reset the

inverter count. When power is restored, the

inverter will attempt to start the compressor within

8 seconds.

Note:

• When ordering a replacement compressor,

6-PIN

CONNECTOR

BLU

PURPLE

E

BROWN

B

L

A

COMPRESSOR

AC

INVERTER

ORANGE

ORANGE

GE

N

A

R

O

C

K

10Ω

B

A

L

C

K

B

L

E

10Ω

U

10Ω

BROWN

order both the compressor and inverter.

Replace the compressor first. If, after

compressor installation, the compressor fails

to start, replace the inverter.

+12 VDC

CO

2

J4-

ON

MM

J4-3

• When servicing the compressor, it is important

to dress the wiring to keep low voltage DC

wiring and 120 V AC wiring separate.

CURRENT-SOURCE

CIRCUIT BOARD

LOW VOLTA GE DC

CIRCUITS

CLASS 2

TAB 4

BROWN

MAIN CONTROL BOARD

10

J3-

LINE VOLTAGE

GEA01260

– 13 –

Page 16

Inverter

Warning: Disconnecting the 6-pin connector does not disconnect power (120 VAC) from the

inverter. The refrigerator must be unplugged before servicing the inverter.

Note: Certain voltmeters will not be able to read voltage output from the inverter . If no voltage or erratic

voltage is measured, it does not necessarily indicate a faulty inverter.

The inverter receives 120 VAC line-in from the power supply. The inverter converts this single-phase,

60 Hz, 120 VAC into 3-phase, 230 V AC, with frequency variations between 57 Hz and 104 Hz. This

voltage is delivered to the compressor through 3 lead wires. Each wire will carry identical voltage and

frequency. When checking inverter voltage output, connect the test-meter leads to any 2 of the 3

compressor lead wires. The same reading should be measured between any 2 of the 3 wires.

Note: The compressor leads must be connected to measure voltage output. If the compressor wires

are not connected, or if an open occurs in one of the 3 lead wires or in the compressor , the inverter will

stop voltage output.

The inverter controls compressor speed by frequency variation and by pulse width modulation (PWM).

Changing frequency and PWM will cause an effective voltage between 80 and 230 VAC to be received at

the compressor.

• Low speed (1710 rpm) - 57 Hz

• Medium speed (2100 rpm) - 70 Hz

• High Speed (3120 rpm) - 104 Hz

The inverter receives commands from the main control board. The main control board will send a

(PWM) run signal between 1.5 and 3.5 VDC

effective voltage to the inverter. In the circuit

between the main control board and the inverter, a

current-source circuit board is used to amplify the

pulse width modulated voltage. The signal voltage

at the inverter should be higher than the signal

voltage sent by the main control board. The

inverter will select compressor speed (voltage

Current-Source

Current-Source

Circuit Board

Circuit Board

output) based on this signal. A signal voltage from

the main control board (J3-10 to J2-3) lower than

1.5 VDC or greater than 3.5 VDC indicates a faulty

main control board. The main control board will only send a run signal to the inverter when the

compressor should be on.

Note: When measuring signal voltage (from the main control board) at the inverter , disconnect the wire

harness connector at the inverter and measure the voltage at the connector .

The inverter will monitor compressor operation and if the compressor fails to start or excessive current

draw (4 amps maximum) is detected, the inverter will briefly stop voltage output. The inverter will then

make 12 consecutive compressor start attempts (once every 12 seconds). If after 12 attempts the

compressor has not started, an 8-minute count will initiate. After the 8-minute count, the inverter will

attempt to start the compressor again. If the compressor starts, normal operation will resume. If the

compressor fails to start, this process will be repeated. Removing power to the unit will reset the

inverter count. When power is restored, the inverter will attempt to start the compressor within 8

seconds.

The inverter has a built-in circuit protection to guard against damage from a failed or shorted

compressor. However, if a failed compressor is diagnosed, order a new compressor and inverter. If the

compressor fails to start after replacement, replace the inverter.

– 14 –

Page 17

Note: When servicing the inverter, it is import ant

to dress the wiring to keep low-voltage DC wiring

and 120 V AC wiring separate.

To remove the inverter:

1. Unplug the unit.

2. Remove the rear access cover.

3. Remove the screw securing the water valve

and position to access the inverter .

4. Remove 1 screw (1/4 in) securing the inverter.

Slide the inverter forward to release the back

tab from the machine compartment bottom.

Note: It may be necessary to bend the process

tube in order to remove the inverter. If it is

necessary to bend the process tube, use extreme

care.

5. Turn the inverter horizontally and slide out of

the machine compartment.

Water Valve

To remove the inverter cover:

Use a small screwdriver to release the two small

tabs and carefully remove the inverter cover.

Inverter

Inverter

Line-In (L1)

Line-In (L1)

Inverter

Tabs

Signal Wire Connector

Signal Wire Connector

(From Main Control Board)

(From Main Control Board)

Compressor Lead

Compressor Lead

Wires

Wires

– 15 –

Page 18

Adaptive Defrost

Adaptive Defrost

Adaptive Defrost can be described as a defrost

system that adapts to a refrigerator’s surrounding

environment and household usage.

Unlike conventional defrost systems that use

electromechanical timers with a fixed defrost cycle

time, Adaptive Defrost utilizes an intelligent,

electronic control to determine when the defrost

cycle is necessary. In order to accomplish the

correct defrost cycle time, the main control board

monitors the following refrigerator operations:

• Length of time the refrigerator doors were open

since the last defrost cycle

• Length of time the compressor has run since

the last defrost cycle

• Amount of time the defrost heaters were on in

the last defrost cycle

Adaptive Defrost is divided into 5 separate cycles.

Those operations are:

• Cooling Operation

• Pre-Chill Operation

• Defrost Heater Operation

• Dwell Period

• Post Dwell

(See Pub. #31-9062 for more information on

Adaptive Defrost.)

Adaptive Defrost (Cooling Operation)

During the cooling operation, the main control

board monitors door opening (fresh food and

freezer doors) and compressor run times. The

length of time between consecutive defrosts is

reduced by each door opening. If the doors are not

opened, the compressor will run up to 60 hours

between defrosts. If the doors are opened

frequently and/or for long periods of time, the

compressor run time between defrosts will be

reduced to as little as 8 hours.

Adaptive Defrost (Pre-Chill Operation)

When the main control board determines that

defrost is necessary, it will force the refrigerator

into a continuous cool mode (pre-chill). During prechill, the freezer temperature may be driven below

the set point. However , the fresh food temperature

will be regulated by the damper . Pre-chill will

continue until one of the following 3 conditions

have been met.

• freezer temperature of -9 °F

• evaporator temperature of -25 °F

• 110 minutes of continuous run time with no

door openings

The average pre-chill is complete within 30 to

40 minutes. This model does not have a defrost

holdoff.

Adaptive Defrost (Defrost Heater Operation)

After pre-chill has concluded, the main control

board turns off the compressor, condenser fan,

and evaporator fan.

During defrost operation, the main control board

monitors the evaporator temperature using

evaporator thermistor inputs. Typically, the

evaporator thermistor will sense a temperature of

70 °F within 20 to 30 minutes. When the

thermistor senses 70 °F, the main control board

will terminate defrost heater operation. Maximum

defrost cycle (heater on) time is 40 minutes (main

control board time out).

The defrost system is protected by a defrost

termination thermostat (bimetal switch). The

thermostat opens when the evaporator

temperature raises to 140 °F and closes when the

evaporator temperature lowers to 110 °F.

– 16 –

Page 19

Adaptive Defrost (Dwell Period)

After defrost heater operation has been terminated

by the main control board, a 5-minute dwell period

occurs. During this period, the compressor,

condenser fan, and evaporator fan remain off. The

remaining frost melting from the evaporator will

continue to drip and drain so that, prior to the

cooling operation, the evaporator will be totally

clear of any moisture. After the 5-minute dwell

period, the unit goes into post dwell.

Abnormal Operating Characteristics

(Incorrect Operation)

• Rapid fan speed changes. Fan takes at least

1 minute to change speeds.

• Compressor running without the condenser

fan. The compressor and condenser fan

should always run at the same time.

Liner Protection Mode

Adaptive Defrost (Post Dwell)

The post dwell period is designed to cool the

evaporator before circulating air within the

refrigerator . This prevent s any residual heat on the

evaporator from being distributed in the freezer .

During this period, the compressor and the

condenser fan are on, but all interior fans are off

and the damper is closed. Post dwell will last 20

minutes or until the evaporator temperature

reaches 0 °F on this model.

Normal Operating Characteristics That Are

Different from Previous Models

• Compressor changes speed.

• Condenser fan changes speed.

• Fresh food fan changes speed.

• Compressor and fans can run continuously for

more than 8 hours.

The liner protection mode will activate if either of

the doors has been open for 3 minutes. This

mode will start the evaporator fan on high speed.

This mode is controlled by 2 timers. Timer #1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If

3 minutes elapse before the door is closed, the

liner protection mode will become active. Once

the door is closed, timer #1 resets and liner

protection mode goes into standby. In standby,

normal fan and damper operations resume and

timer #2 begins a 3-minute door-closed count.

If 3 minutes elapse without a door opening, liner

protection mode will completely deactivate. If a

door is opened within the timer #2 door-closed

count, the remaining time in the door-closed count

will be deducted from the timer #1 door-open

count.

– 17 –

Page 20

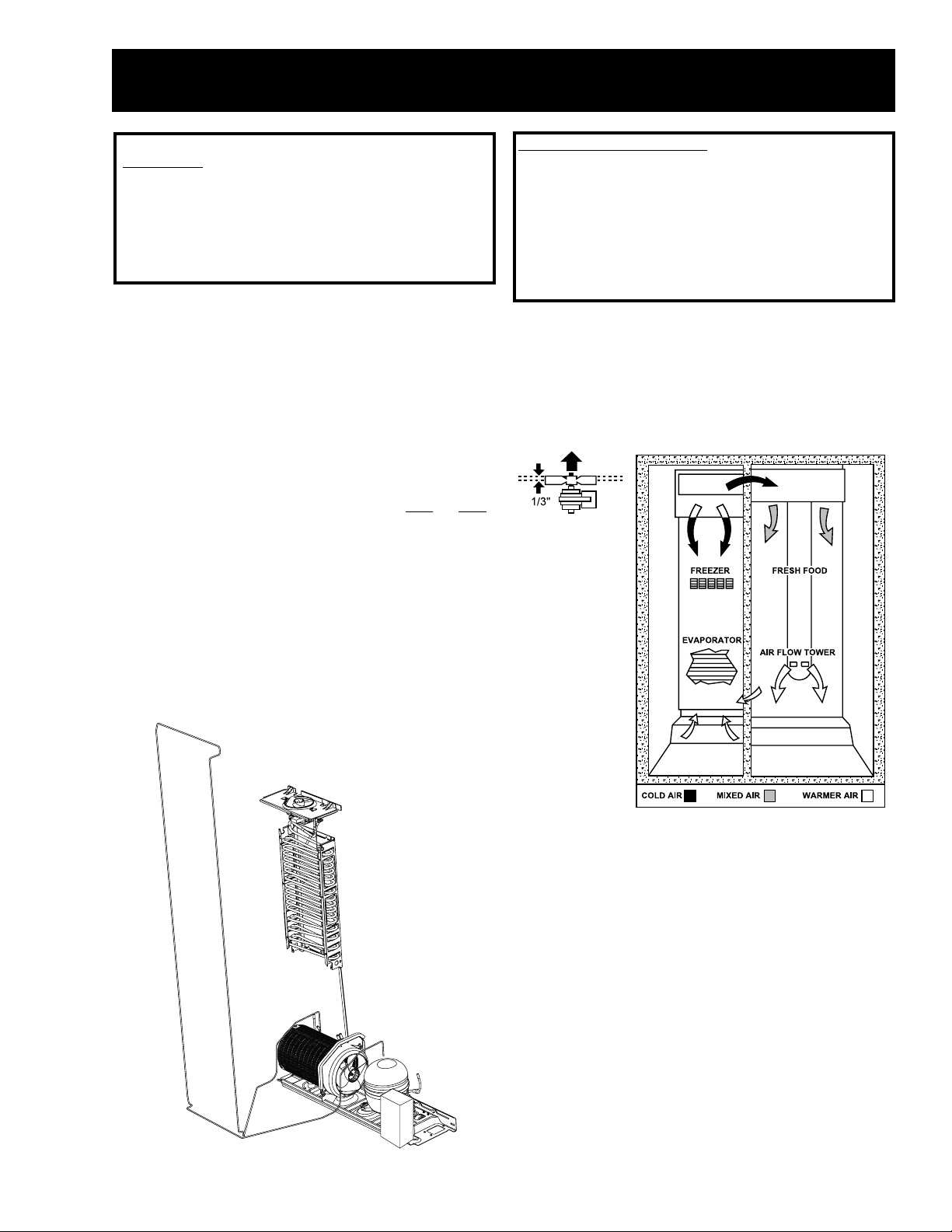

Fans

Evaporator Fan

The position of the fan blade in relation to the shroud is important. Refer to illustration for specifications.

5/16" ± 0.03

1.0" ± 0.05 Target

Blade tip

Orifice

Air Flow

Motor

GEA01149

The evaporator fan is the same fan used on previous models; however a significant difference is that the

main control board does not require, nor receive, input from the fan feedback/rpm (blue) wire. The fan

utilizes a permanent magnet, 4-pole, DC motor that operates at three different speeds: high, medium,

and low . The speed of the fan is controlled by the voltage output from the main control board. V o ltage

output from the control board to the fan is 13.2 VDC; however to regulate the speed of the fan, the main

control board uses pulse width modulation (PWM). When operating, voltage is sent in pulses (much like

a duty cycle) as opposed to an uninterrupted flow. This pulsing of 13.2 VDC produces ef fective volt age

being received at the motor, which is the equivalent to a reduction in volt age. Fan speed will be selected

and maintained by the main control board regulating the length and frequency of the 13.2 VDC pulse.

One complete revolution of the motor is comprised of all 4 poles. To determine the rpm of the fan, do

the following: Measure the frequency being applied to the motor. Multiply this number by 15 (60 seconds

divided by 4 poles). For example, a frequency measurement of 200 Hz multiplied by 15 would show a

fan speed of 3000 rpm (15 x 200 = 3000). Temperature may cause some fan speed variation. Fan

speed may vary +/- 5%, depending on the temperature, with higher temperatures causing slightly higher

speeds.

9.5 VDC

8 VDC

6.5 VDC

12 VDC

0 VDC

High Speed (9.5 VDC measured)

12 VDC

0 VDC

Medium Speed (8 VDC measured)

12 VDC

0 VDC

Low Speed (6.5 VDC measured)

– 18 –

Page 21

The evaporator fan has a 4-wire connection:

White Wire (DC Common)

The white wire is the DC common wire used for

testing. During repairs, DC polarity must be

observed. Reversing the DC polarity will cause a

shorted motor and/or board.

Red Wire (Supply)

Each motor uses an internal electronic controller

to operate the motor. Supply volt age from the

main control board remains at a constant 12 VDC.

Blue Wire (Feedback/RPM)

On previous Arctica models, the blue wire

reported rpm (speed) information to the main

control board for speed control purposes. On this

model, the board does not require nor read any

feedback information from the fan motor.

Yellow Wire (Signal)

The yellow wire is the input wire from the main

control board. The main control board provides

6.5 VDC effective voltage for low speed, 8 VDC

effective voltage for medium speed, and 9.5 VDC

for high speed. The fan will operate in low speed

only when the fresh food thermistor is satisfied.

Note: When testing these motors:

• You cannot test with an ohmmeter.

• DC common is not AC common.

• Verify 2 volt age potentials:

a. Red to white - power for internal controller

b. Yellow to white - power for fan

• Observe circuit polarity.

• Motors can be run for short periods using a

9-volt battery . Connect the white wire to the

negative (-) battery terminal only. Connect the

red and yellow wires to the positive (+) battery

terminal.

– 19 –

Page 22

Condenser Fan

The fan is mounted in the machine compartment

with the No-Clean condenser. The fan and fan

shroud are mounted on one end of the condenser,

and the other end of the condenser is blocked.

When the fan is operating, air is pulled from the

center of the condenser , drawing air in through the

coils. The air is then exhausted over the

compressor and out the right side of the

refrigerator.

Inlet air is available through the left front and left

rear of the machine compartment. A rubber divider

strip underneath the refrigerator divides the inlet

and outlet sides of the machine compartment.

Rear

Baffle

Front

GEA01152

The rear access cover must be tightly fitted to

prevent air from being exhausted directly out of the

rear of the machine compartment, bypassing the

compressor.

The condenser fan is mounted with screws to a

fan shroud and mounting bracket that is attached

to the condenser .

Refer to the illustration for fan blade adjustment.

The condenser fan is the same permanent-

magnet, 4-pole, DC motor used in previous Arctica

models; however a significant difference is that the

fan will operate at 3 speeds. Fan speed (low,

medium, high) corresponds with compressor

speed to minimize pressure variations in the

sealed system. The speed of the fan is controlled

by the voltage output from the main control board.

Voltage output from the control board to the fan is

13.2 VDC; however to regulate the speed of the

fan, the main control board uses pulse width

modulation (PWM). When operating, voltage is

sent in pulses (much like a duty cycle) as opposed

to an uninterrupted flow . This pulsing of 13.2 VDC

produces effective voltage being received at the

motor , which is the equivalent to a reduction in

voltage. Fan speed will be selected and

maintained by the main control board regulating the

length and frequency of the 13.2 VDC pulse.

1/2"

Housing

Fan

0.375"

Motor

Air Flow

Bracket

0.50" ± 0.05

GEA01148

– 20 –

Page 23

One complete revolution of the motor is comprised of all 4 poles. To determine the rpm of the fan, do

the following: Measure the frequency being applied to the motor. Multiply this number by 15 (60 seconds

divided by 4 poles). For example, a frequency measurement of 200 Hz multiplied by 15 would show a

fan speed of 3000 rpm (15 x 200 = 3000). Temperature may cause some fan speed variation. Fan

speed may vary +/- 5%, depending on the temperature, with higher temperatures causing slightly higher

speeds. Condenser fan speed is controlled by the same method (Pulse Width Modulation) used to

control evaporator fan speed. The condenser fan and evaporator fan will usually operate at the same

speed. No rpm/feedback wire is used for the condenser fan.

12 VDC

10.5 VDC

0 VDC

High Speed (10.5 VDC measured)

12 VDC

7.5 VDC

0 VDC

Medium Speed (7.5 VDC measured)

12 VDC

5.5 VDC

0 VDC

Low Speed (5.5 VDC measured)

Fresh Food Fan

A variable speed fresh food fan is located in the top of the fresh food section. When activated, the fresh

food fan will draw cool air from the freezer compartment into the fresh food compartment, providing

cooling independent of evaporator fan operation.

The main control board gathers information from the fresh food thermistors to determine when, and at

what speed, fan operation should occur . A constant 12 VDC is provided to the fan from the main control

board and switching occurs on the neutral side. S peed is regulated by Pulse Width Modulation on the

common side of the fan. When operating, the common side of the circuit is pulsed open and closed.

This pulsing produces effective voltage being received at the motor, which is the equivalent to a

reduction in voltage. Fan speed will be selected and maintained by the main control board regulating the

length and frequency of the 12 VDC pulse.

12 VDC

12 VDC

0 VDC

High Speed (12 VDC measured)

12 VDC

10 VDC

0 VDC

Medium Speed (10 VDC measured)

9 VDC

12 VDC

0 VDC

Low Speed (9 VDC measured)

– 21 –

Page 24

The main control board is located at the back of the refrigerator, above the machine comp artment on the

right-hand side.

It controls all refrigerator operations except the fresh food lights, freezer lights, and icemaker .

– 22 –

GEA00859

Pin 1 J8

Pin 1 J9

Pin 1 J11

Pin 1 J12

Pin 9 J7

Pin 8

Pin 7

Pin 6

Pin 5

Pin 4

Pin 3

Pin 2

Pin 1

Compressor

Defrost Heater

Line

Monogram Drain Pan Heater

Neutral

NIC

FZ Door Switch

FF Door Switch

QuickChill Heater

Auger Motor Interlock

Water Valve

Crusher Solenoid

Auger Motor

Pin 1

Pin 2

QuickChill Htr.

QuickChill Htr.

Evaporator Fan Tach.

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

FF Fan

QuickChill Fan

Fan +12V

Low V oltage DC

120 V AC

J2 Pin 1

QuickChill Damper1 +

QuickChill Damper1 QuickChill Damper2 +

QuickChill Damper2 +5V

QuickChill Thermistor

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

J5 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Comm. Tx/Rx

Comm. +12V

Comm. Common

Discrete Disp. Input 1

Discrete Disp. Input 2

Damper - Blue

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

FF1 Thermistor

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

J4 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Main Control Board

J3 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

J1 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Page 25

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

1J1CDV

1J2CDV

1J3CDV

1J4CDV

1J5 CDV .1JnosnipytilanosrepdnasrotsimrehtrofCDV5sedivorP

SNOITINIFEDNIPDRAOBLORTNOC

,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtdoofhserffokcabdeeF

elcycotdesusieulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulavecnatsiser

sikcabdeeF.nafrosnednocdna,rosserpmoc,nafrotaropave,)desunehw(nafdoofhserf

.etunimrepegnahcfoseerged8otdnopserotderetlif

nehw,CTNsirotsimrehT.)desunehw(eulavrotsimrehtdoofhserfdnocesfokcabdeeF

eulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulavecnatsiser,sporderutarepmet

rosnednocdna,rosserpmoc,nafrotaropave,)desunehw(nafdoofhserfelcycotdesusi

.etunimrepegnahcfoseerged8otdnopserotderetlifsikcabdeeF.naf

,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtrezeerffokcabdeeF

elcycotdesusieulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulavecnatsiser

nehw(nafdoofhserfelcyctonlliwdna,nafrosnednocdna,rosserpmoc,nafrotaropave

.etunimrepegnahcfoseerged8otdnopserotderetlifsikcabdeeF.)desu

,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtrotaropavefokcabdeeF

desusieulavrotsimrehtsihT.noitcuderegatlovnrutergnisuac,sesaercnieulavecnatsiser

nehwffodnaeulavtsorfedwolebsierutarepmetnehwtsorfedgnirudnoretaehehtelcycot

otpu-rewopgniruddaeroslasieulavsihT.eulavtsorfedevobasierutarepmeteht

sikcabdeeF.noitaunitnocelcycroedomnwodllupotniseogrotaregirferfienimreted

.yletaidemmisdnopser,deretlifnu

1J6CDV

1J8CDV

1J9CDV

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

2J1zH .noitacilppasihtrofdaertonsikcabdeefnafrotaropavE.nafrotaropavemorfkcabdeeF

2J2 CDV.nipnoitcelesledoM

2J3 CDV .dnuorgCDV-nommocnafresnednocdnanafrotaropavE

2J4 CDV .MWPybdenimretedsiegatlovevitceffE.noitareporotomrofnafrotaropaveottuptuO

2J5 CDV .MWPybdenimretedsiegatlovevitceffE.noitareporotomrofnafrosnednocottuptuO

2J6 CDV

senimreted,snipytilanosreprehtohtiwnoitanibmocnidetcennocnehw,tahtnipnoitceleS

.ylnopu-rewopnonoitanibmocsdaeR.desugnimmargorpdnaledom

senimreted,snipytilanosreprehtohtiwnoitanibmocnidetcennocnehw,tahtnipnoitceleS

.ylnopu-rewopnonoitanibmocsdaeR.desugnimmargorpdnaledom

senimreted,snipytilanosreprehtohtiwnoitanibmocnidetcennocnehw,tahtnipnoitceleS

.ylnopu-rewopnonoitanibmocsdaeR.desugnimmargorpdnaledom

SNOITINIFEDNIPDRAOBLORTNOC

.lortnocdeepsnafMWProfdehctiwS.noitareporotomrofnafdoofhserfotnommoC

.MWPybdenimretedsiegatlovevitceffE

2J7 CDV .naf)looCmotsuC(llihCkciuQotmommocdehctiwS

2J8 CDV .egatlovtnatsnoc,snafllaotegatlovylppusCDV-21sedivorP

– 23 –

Page 26

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

3J1 CDV.rotomreppetsrepmaD

3J2 CDV.rotomreppetsrepmaD

3J3 CDV.rotomreppetsrepmaD

3J4 CDV.rotomreppetsrepmaD

SNOITINIFEDNIPDRAOBLORTNOC

3J01CDV

SNOITINIFEDNIPDRAOBLORTNOC

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

4J1

4J2 CDV.ylppusCDV21

4J3 CDV.nommocCD

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

latigiD

noitacinummoC

latigiD

noitacinummoC

SNOITINIFEDNIPDRAOBLORTNOC

deepsrosserpmoc,sesaercniegatlovsA.lortnocdeepsrosserpmocrofretrevnI

.sesaerced

rooddnadraoblortnocniamneewtebnoitacinummoclatigidyaw-2

llihCkciuQdna,)draob(lortnocerutarepmet,draobyalpsidresnepsid

.)draob(lortnocerutarepmet)looCmotsuC(

5J1 .repmad)looCmotsuC(llihCkciuQ

5J2 .repmad)looCmotsuC(llihCkciuQ

5J3 .repmad)looCmotsuC(llihCkciuQ

5J4 .repmad)looCmotsuC(llihCkciuQ

5J5 CDV .rotsimreht)looCmotsuC(llihCkciuQrofCDV5sedivorP

5J6CDV

– 24 –

erutarepmetnehw,CTNsirotsimrehT.rotsimreht)looCmotsuC(llihCkciuQfokcabdeeF

.egatlovnruterninoitcuderagnisuac,sesaercnieulavecnatsiser,spord

Page 27

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

7J1 CAV .CAV021-rotomreguaehtotegatlov1LdehctiwS

7J2 CAV .CAV021-dionelosrehsurcehtotegatlov1LdehctiwS

7J3 CAV .CAV021-evlavretawehtotegatlov1LdehctiwS

7J4CAV .desolcsiroodrezeerfnehwhctiwsroodrezeerfmorftupni1LsevieceR

7J5 CAV .CAV021-retaeh)looCmotsuC(lllihCkciuQehtotegatlov1LdehctiwS

7J6CAV

7J7CAV

7J9CAV.nilartuenCA

SNOITINIFEDNIPDRAOBLORTNOC

rofdesusitupnisihT.neposiroodnehwhctiwsrooddoofhserfmorftupni1LsevieceR

dna,snoitaluclacmralarood,snoitaluclacedomnoitcetorprenil,lortnocnafrotaropave

.snoitaluclactsorfedevitpada

rofdesusitupnisihT.neposiroodnehwhctiwsroodrezeerfmorftupni1LsevieceR

,snoitaluclactsorfedevitpada,snoitaluclacedomnoitcetorprenil,lortnocnafrotaropave

nidesolcebtsumhctiwS.snoitcnufkcolretniroodemosdna,snoitaluclacmralarood

ottengamroodtcuddnathgilresnepsidrof)desserpedhctiws(noitisopdesolcrood

.ezigrene

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

)2baT(9J1 CAV

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

)4baT(11J1CAV

SNOITINIFEDNIPDRAOBLORTNOC

tiucricsihtgnolwohstnuocremitA.CAV021-tiucrictsorfedehtotegatlov1LdehctiwS

evitpadasielcyctsorfedtxenehtfienimretedotnoitamrofnisihtsesudnadezigrenesi

.evitpadanonro

SNOITINIFEDNIPDRAOBLORTNOC

1LdehctiwsroflaitnetoptupniCAV021-stiucricdraoblortnocotegatlov1LtnatsnoC

.slanimret

– 25 –

Page 28

draoBlortnoCniaM

niP roloCeriW

1eulB

tnenopmoC

noitanimreT

nafrotaropavE

retemohcat

/tupnI

tuptuO

tupnI.ledomsihtotelbacilppatoN

2etihW/eulBledoMtupnICDV21=3nipot2nip2J

3revliS/etihWnommocnaFnommoCCDV21=3nipot8nip2J

)ediSCDegatloV-woL(rotcennoC2J

gnidaeRegatloVniP-ot-niP

4kcalB/wolleYnafrotaropavEtuptuO

5wolleYnafresnednoCtuptuO

6etihW/kcalBnafdoofhserFnommoC

7naTnaflooCmotsuCnommoCCDV21=8nipot7nip2J

8deR

120 VAC

GEA01195

Evaporator Fan Tach.

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

FF Fan

QuickChill Fan

Fan +12V

Low Voltage DC

QuickChill Damper1 +

QuickChill Damper1 QuickChill Damper2 +

QuickChill Damper2 +5V

QuickChill Thermistor

J2 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

J5 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

egatlovylppusnaF

)CDV21(

Comm. Tx/Rx

Comm. +12V

Comm. Common

Discrete Disp. Input 1

Discrete Disp. Input 2

Damper - Blue

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

FF1 Thermistor

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

J4 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

J3 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

J1 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

tuptuOCDV21=3nipot8nip2J

CDV5.9=3nipot4nip2J

,)dem(CDV8,)hgih(

)wol(CDV5.6

CDV5.01=3nipot5nip2J

,)dem(CDV5.7,)hgih(

)wol(CDV5.5

CDV21=6nipot8nip2J

CDV9,)dem(CDV01,)hgih(

)wol(

niP roloCeriW

1wolleYrotoMreppetSrepmaD

2kcalB/deRrotoMreppetSrepmaD

3nworB/etihWrotoMreppetSrepmaD

4wolleY/eulBrotoMreppetSrepmaD

01neerG/eulBretrevnItuptuO

tnenopmoC

noitanimreT

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC3J

/tupnI

tuptuO

gnidaeRegatloVniP-ot-niP

=3nip4Jot1nip3J

CDV3.1nahtssel-egatloVgnidnatS

CDV5.6.xorppa-egatloVgnilevarT

=3nip4Jot2nip3J

CDV3.1nahtssel-egatloVgnidnatS

CDV5.6.xorppa-egatloVgnilevarT

=3nip4Jot3nip3J

CDV3.1nahtssel-egatloVgnidnatS

CDV5.6.xorppa-egatloVgnilevarT

=3nip4Jot4nip3J

CDV3.1nahtssel-egatloVgnidnatS

CDV5.6.xorppa-egatloVgnilevarT

=3nip2Jot01nip3J

CDV5.3ot5.1

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC1J

niP roloCeriW

1deR/eulB

2wolleY

tnenopmoC

noitanimreT

doofhserF

1rotsimreht

doofhserF

2rotsimreht

/tupnI

tuptuO

tupnIA/N

tupnIA/N

3etihW/deRrotsimrehtrezeerFtupnIA/N

4etihW/eulB

5eulB

rotaropavE

rotsimreht

ylppusrotsimrehT

)CDV5(egatlov

tupnIA/N

tuptuOCDV5=3nip2Jot5nip1J

6eulBnipytilanosrePtupnICDV5=3nip2Jot6nip1J

8eulBnipytilanosrePtupnICDV5=3nip2Jot8nip1J

9eulBnipytilanosrePtupnICDV5=3nip2Jot9nip1J

– 26 –

gnidaeRegatloVniP-ot-niP

Page 29

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC4J

niP roloCeriW

1kcalB

2deR

3eulB

GEA01195

120 VA C

Evaporator Fan Tach.

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

FF Fan

QuickChill Fan

Fan +12V

Low Voltage DC

QuickChill Damper1 +

QuickChill Damper1 QuickChill Damper2 +

QuickChill Damper2 +5V

QuickChill Thermistor

tnenopmoC

noitanimreT

erutarepmeT

lortnoc

erutarepmeT

lortnoc

erutarepmeT

lortnoc

Comm. Tx/Rx

Comm. +12V

Comm. Common

Discrete Disp. Input 1

Discrete Disp. Input 2

Damper - Blue

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

J5 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

FZ Encoder Select

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

FF1 Thermistor

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

J2 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

tuptuO/tupnI

noitacinummoC

tuptuOCDV21=3nipot2nip4J

nommoCCDV21=3nipot2nip4J

J4 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

J3 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

J1 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

egatloVniP-ot-niP

gnidaeR

latigidyaw-2

.noitacinummoc

niP

1kniP

2wolleY

3nworB

4

5

6

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC5J

eriW

roloC

/wolleY

kcalB

tnenopmoC

noitanimreT

llihCkciuQ

)looCmotsuC(

repmaD

llihCkciuQ

)looCmotsuC(

repmaD

llihCkciuQ

)looCmotsuC(

repmaD

llihCkciuQ

)looCmotsuC(

repmaD

egatloVylppuS

)CDV5(

/tupnI

tuptuO

/tupnI

tuptuO

/tupnI

tuptuO

/tupnI

tuptuO

/tupnI

tuptuO

tuptuOCDV5=3nip2Jot01nip5J

gnidaeRegatloVniP-ot-niP

)ytiralopgnisrever(CDV21=2nipot1nip5J

)ytiralopgnisrever(CDV21=1nipot2nip5J

)ytiralopgnisrever(CDV21=4nipot3nip5J

)ytiralopgnisrever(CDV21=3nipot4nip5J

llihCkciuQ

)looCmotsuC(

tupnIA/N

rotsimrehT

– 27 –

Page 30

,11J,9JdraoBlortnoCniaM

)ediSegatloV-hgiH(srotcennoC

niP roloCeriW

9J

)2baT(

11J

)4baT(

tnenopmoC

noitanimreT

-ptuO/tupnI

tu

eulBretaeHtsorfeDtuptuOCAV021=9nip7Jot9J

nworBrekamecItupnICAV021=9nip7Jot11J

Pin 1 J8

Compressor

Pin 1 J9

Defrost Heater

Pin 1 J11

Line

Pin 1 J12

Monogram Drain Pan Heater

Pin 9 J7

Neutral

Pin 8

NIC

Pin 7

FZ Door Switch

Pin 6

FF Door Switch

Pin 5

QuickChill Heater

Pin 4

Auger Motor Interlock

Pin 3

Water Valve

Pin 2

Crusher Solenoid

Pin 1

Auger Motor

Pin 1

QuickChill Htr.

gnidaeRegatloVniPotniP

Pin 2

QuickChill Htr.

GEA01194

draoBlortnoCniaM

niP roloCeriW

tnenopmoC

noitanimreT

/tupnI

tuptuO

1 egieB reguA tuptuO CAV021=9nip7Jot1nip7J

2revliSdoineloSebuCtuptuOCAV021=9nip7Jot2nip7J

3wolleYevlaVretaWtuptuOCAV021=9nip7Jot3nip7J

4etihW/deRhctiwSrooDZFtupnI

5etihW/eulBllihCkciuQtuptuOCAV021=9nip7Jot5nip7J

6elpruP

7deR

thgilroodFF

hctiws

thgilroodrezeerF

hctiws

tupnI

tupnI

Low V oltage DC

120 VA C

)ediSCAV021(rotcennoC7J

gnidaeRegatloVniP-ot-niP

CAV021=9nip7Jot4nip7J

)desolcroodZF(

CAV021=9nip7Jot6nip7J

)neporoodFF(

CAV021=9nip7Jot7nip7J

)neporoodZF(

9egnarOlartueNlartueNlartueN

– 28 –

Page 31

Unplug refrigerator. Warm

freezer thermistor to 70 ˚F.

Connect power and set

temperature controls to

maximum settings.

Does compressor start?

YES

Adjust settings and

allow 24 hours to

stabilize.

Diagnostics

Compressor Not Running

Check condenser

fan for operation.

NO

Fan operating?

YES

Note: A signal voltage from the

main board to the inverter of less

than 1.5 VDC or greater than 3.5

VDC indicates a bad main board.

Verify signal voltage of 1.5 to

3.5 VDC at the main control

board connector J3-10 to J4-3.

Is voltage OK?

NO

NO

YES

Go to Condenser

Fan Not Running

flowchart.

Replace main

control board.

Verify freezer

thermisor is within

proper range using

thermistor values

chart. Is thermsitor

within proper range

NO

Check wiring

connections. If

wiring is OK, replace

thermsitor.

YES

Disconnect the main control

board signal wire at the inverter

and verify signal voltage.

Note: Voltage should be

higher at the inverter than at

the main board.

Voltage OK?

YES

Check compressor for

proper resistance.

9 to 11 should be

measured between all

pins.

Resistance OK?

YES

Check for 120 VAC

(L1) at inverter.

Voltage present?

YES

Replace wiring

harness from main

NO

NO

NO

control board to

inverter.

Replace compressor.

Note: When ordering a replacement

compressor, order the compressor and

inverter. Replace the compressor first.

If the compressor does not start

replace the inverter.

Repair inverter

wiring.

YES

Replace inverter.

Check compressor

lead wires and

connections.

Wires and

connections OK?

NO

Repair lead wire or

connection.

– 29 –

Page 32

Fresh Food Warm - Freezer Normal

Check control settings and temperatures.

Food at setting of 5 and 5 with no door

openings for 12 hours should be:

Fresh food 34 ˚F to 40 ˚F

Freezer -3 ˚F to +3 ˚F

Control settings OK

Control settings

require adjustment

Adjust settings and allow

24 hours to stabilize.

Basic refrigerator checks:

Door gasket seal OK?

Door switch - light turning off with door closed?

YES

Is evaporator fan running?

YES

Set temperature controls to 5 and 5. Unplug

Refrigerator.

Reconnect power.

Does damper door open immediately after

reconnecting power?

Yes

Is the airflow within the fresh food normal?

YES

NO

NO

NO

NO

Look for blockage at vents

Not Running flowchart.

or heavy frost on

evaporator cover.

Heavy frost

Repair as

necessary.

Go to Evaporator Fan

Go to Damper Not Operating

flowchart.

Blockage

Go to Heavy Frost on Evaporator

Remove blockage

from vent area.

flowchart.

Verify thermistors are within proper range

using the thermistor values chart.

Is the resistance within range?

YES

Check sealed system.

Does sealed system check OK?

Yes

Unit tests OK.

Run checks again.

Reset electronics by unplugging

refrigerator for 15 seconds.

Look for usage problem.

NO

NO

Check wiring connections.

If wiring is OK, replace

thermistor.

Repair

sealed system.

– 30 –

Page 33

Fresh Food Too Cold - Freezer Normal

Check control settings and temperatures.

Food at a setting of 5 and 5 with no door

openings for 12 hours should be:

Fresh food 34 ˚F to 40 ˚F

Freezer -3 ˚F to +3 ˚F

Control settings OK

Room temperature

must be above 55 ˚F

to avoid low ambient

condition.

Room temperature

above 55 ˚F?

YES

NO

Controls require

adjustment

Advise consumer of

refrigeration installation

requirements.

Adjust setting and allow

24 hours to stabilize.

Is the damper closed?

YES

Verify thermistors are

within proper range

using thermistor values

chart.

Is the resistance within

proper range?

YES

Unit tests OK.

Run checks again.

Reset electronics by

unplugging refrigerator for 15

seconds.

Look for usage problem.

NO

Go to Damper Not

Operating flowchart.

NO

Check wiring

connections. If

OK, replace

thermistor.

– 31 –

Page 34

Check control settings and

temperatures.

Food at setting of 5 and 5 with no door

openings for 12 hours should be:

Fresh food 34 ˚F to 40 ˚F

Freezer -3 ˚F to +3 ˚F

Control settings OK

Fresh Food Warm - Freezer W arm

Control setting

require adjustment

Adjust setting and allow

24 hours to stabilize.

Basic refrigerator checks:

Door gasket seal OK?

Door switch - light turning off with door closed?

YES

Is the condenser fan running?

YES

Is the evaporator fan running?

YES

Is the compressor running?

YES

Is the airflow within the freezer normal? NO

NO

NO

NO

NO

Repair as

necessary.

Condenser Fan Not Running flowchart.

Evaporator Fan Not Running flowchart.

Compressor Not Running flowchart.

Look for blockage

at vents or heavy

frost on evaporator

Go to

Go to

Go to

Blockage

cover.

Remove blockage

from evaporator cover

vent area.

YES

Verify thermistors are within proper range using

thermistor values chart.

Is the resistance within range?

YES

Check sealed system.

Does system check OK?

YES

Unit tests OK.

Run checks again.

Reset electronics by unplugging refrigerator

for 15 seconds.

Look for usage problem.

NO

NO

Check wiring

connections.

IF OK, replace

thermistor.

Repair

sealed system.

Heavy frost

Go to Heavy Frost on

Evaporator flowchart.

– 32 –

Page 35

Freezer Warm - Fresh Food Normal

Check control settings and temperatures.

Food at a setting of 5 and 5 with no

door openings for 12 hours should be:

Fresh food 34 ˚F to 40 ˚F.

Freezer -3 ˚F to +3 ˚F.

Control settings OK.

Control settings

require adjustment.

Adjust settings and allow

24 hours to stabilize.

Basic refrigerator checks:

Door switch - light turning off with drawer closed?

Door gasket seal OK?

YES

Is the evaporator fan running?

YES

Is the condenser fan running? NO

YES

Is the airflow within the

freezer normal?

YES

Verify thermistors are within proper

range using thermistor values chart.

Is the resistance within range?

NO Blockage

NO

NO

Look for blockage at vents

or heavy frost on

evaporator cover.

NO

Repair as

necessary.

Evaporator Fan Not Running flowchart.

Condenser Fan Not Running flowchart.

Heavy Frost

Check wiring

connections.

If OK, replace

thermistor.

Go to

Go to

Remove blockage

from vent area.

Go to Heavy Frost on Evaporator

flowchart.

YES

Check sealed system.

Does sealed system check OK?

YES

Unit tests OK.

Run checks again.

Reset electronics by unplugging

refrigerator for 15 seconds.

Look for usage problem.

NO

Repair

sealed system.

– 33 –

Page 36

Refrigerator Dead - No Sound, No Cooling

Are the interior lights on?

YES

Unplug J2 connector

from main control

board.

Check for 12 VDC at

main control board

pins J2-8 to J2-3.

Voltage present?

NO

NO

Check house supply voltage.

Check for 120 VAC at 3-pin

connector at the rear of the

Unplug J4 connector from

main control board.

Check for 12 VDC at

control board pins J4-2 to

Voltage present?

Is 120 VAC present?

YES

unit.

Is 120 VAC present?

YES

Repair wiring

connections at

3-pin connector.

J4-3.

NO

NO

NO

Replace main

control board.

House wiring

Problem.

Repair or replace

power cord.

YES

Short in fan motor circuit.

Go to Fan flowchart.

YES

Unplug the temperature

control harness.

Does the refrigerator

start once the harness is

unplugged.

YES

Replace temperature

control board.

NO

Verify thermistors are

within proper range

using the thermistor

values chart.

Is the resistance

within range?

YES

Replace main

control board.

NO

Check wiring

connections. If wiring

is OK, replace

thermistor.

– 34 –

Page 37

Damper Not Operating

Note: The damper will cycle open and closed every 1/2 hour.

Replace main

control board.

Remove blockage or

replace damper.

Verify thermistors are

within proper range

using thermistor

values chart.

Is the resistance

within range?

NO

Check wiring

connections. If

OK, replace

thermistor.

YES

Push on damper door to check manual

Push damper door halfway closed.

Unplug refrigerator to reset main control board.

Set temperature controls to 37 ˚F and 0 ˚F.

YESYES

immediately after reconnecting

(You have 10 seconds to check.)

Unplug harness connector at damper.

Measure resistance between the

blue and red wires and between the

Do you measure approximately 420 ohms for

movement.

Is the damper door stuck?

NO

Reconnect power.

Does damper door move

power?

NO

white and blue wires.

both readings?

Replace damper.NO

YES

Look for wiring

problem between

main control board

and damper. If

wiring is OK, replace

damper.

YES

Unplug J3 connector from main

control board. Unplug the refrigerator

to reset, then reconnect power.

Are there 6 VDC between pins J4-3

(common) and pins J3-1, J3-2, J3-3,

and J3-4?

Note: After reconnecting power, you

have 10 seconds to check.

NO

Replace main

control board.

– 35 –

Page 38

Always check door ajar,

customer usage -

numerous door

openings, etc.

Heavy Frost on Evaporator

Unplug refrigerator. Unplug connector J9

from the main control board. Measure

between blue wire on connector and

orange (neutral) wire on main control

board J7 pin 9.

Are there approximately 37 ohms?

NO

Check wiring harness,

defrost heater, and

defrost overtemperature

thermostat.

YES

Verify thermistors are within

proper range using

thermistor values chart.

Is resistance within range?

YES

Replace main

board.

NO

Check wiring

connections. If

OK, replace

thermistor.

– 36 –

Page 39

Always check fan for obstruction first.

Unplug refrigerator to reset

main control board.

Warm freezer thermistor to 70 ˚F.

Set temperature controls to 5 and 5.

Reconnect power.

Evaporator Fan Not Running

At the evaporator fan connector, check for

13 VDC from the red to white/silver wire

and 8 to 13 VDC from the

yellow/black to white/silver wire.

Is the voltage correct for both?

YES

Replace

evaporator fan

motor.

Unplug J2 connector on the main control board.

NO

Check for 13 VDC between pins J2-8 and J2-3

and 8 to 13 VDC between pins J2-4 and J2-3.

Is the voltage correct for both?

YES

Repair wiring between main control

board and evaporator fan motor.

NO

Replace main

control board.

– 37 –

Page 40

Always check for obstruction first.

Unplug refrigerator to reset

main control board.

Warm freezer thermistor to

70 ˚F and set temperature

controls to 5 and 5.

Reconnect power.

Condenser Fan Not Running

At the condenser fan connector,

check for 13 VDC from the red to

white/silver wire and 11 to 13 VDC

from the yellow to white/silver wire.

Is the voltage correct for both?

YES

Replace the condenser

fan motor.

NO

Unplug J2 connector on the main control

board. Check for 13 VDC between pins

J2-3 and J2-8 and 11 to 13 VDC between

pins J2-3 and J2-5.

Is the voltage correct for both?

YES

Repair wiring between

main control board and

condenser fan.

NO

Replace main

control board.

– 38 –

Page 41

Thermistors

This main control board uses input from 4 thermistors. These thermistors are located in the fresh food

section, the freezer section, and on the evaporator. The main control board monitors the thermistors to

determine the temperature in these areas of the unit and determines which components to run and