Page 1

GE Consumer & Industrial

TECHNICAL SERVICE GUIDE

Arctica Side-by-Side

Dual Evaporator Refrigerators with

Electronic Touch Controls

MODEL SERIES:

PSH23PGR

PSH23PSR

PUB # 31-9118 10/04

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2004

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2

Page 3

Table of Contents

3-Way Valve .....................................................................................................................27

Accumulator .....................................................................................................................40

Check Valve .....................................................................................................................40

Components .....................................................................................................................18

Components Locator Views .............................................................................................11

Condenser Fan ................................................................................................................21

Control Board Connector Locator ....................................................................................12

Control Features ..............................................................................................................7

Defrost Cycles ..................................................................................................................22

Dispenser Light ................................................................................................................10

Dispenser Lock ................................................................................................................10

Dispensing Functions .......................................................................................................10

Evacuation and Charging Procedure ...............................................................................17

Freezer Evaporator ..........................................................................................................31

Freezer Evaporator Fan ...................................................................................................20

Freezer Section Cooling ..................................................................................................15

Fresh Food and Freezer Section Cooling ........................................................................16

Fresh Food Evaporator ....................................................................................................37

Fresh Food Evaporator Fan .............................................................................................19

Fresh Food Section Cooling ............................................................................................14

Illustrated Parts ................................................................................................................44

Introduction ......................................................................................................................4

Inverter .............................................................................................................................24

Inverter Compressor ........................................................................................................26

Liner Protection Mode ......................................................................................................10

Nomenclature ...................................................................................................................6

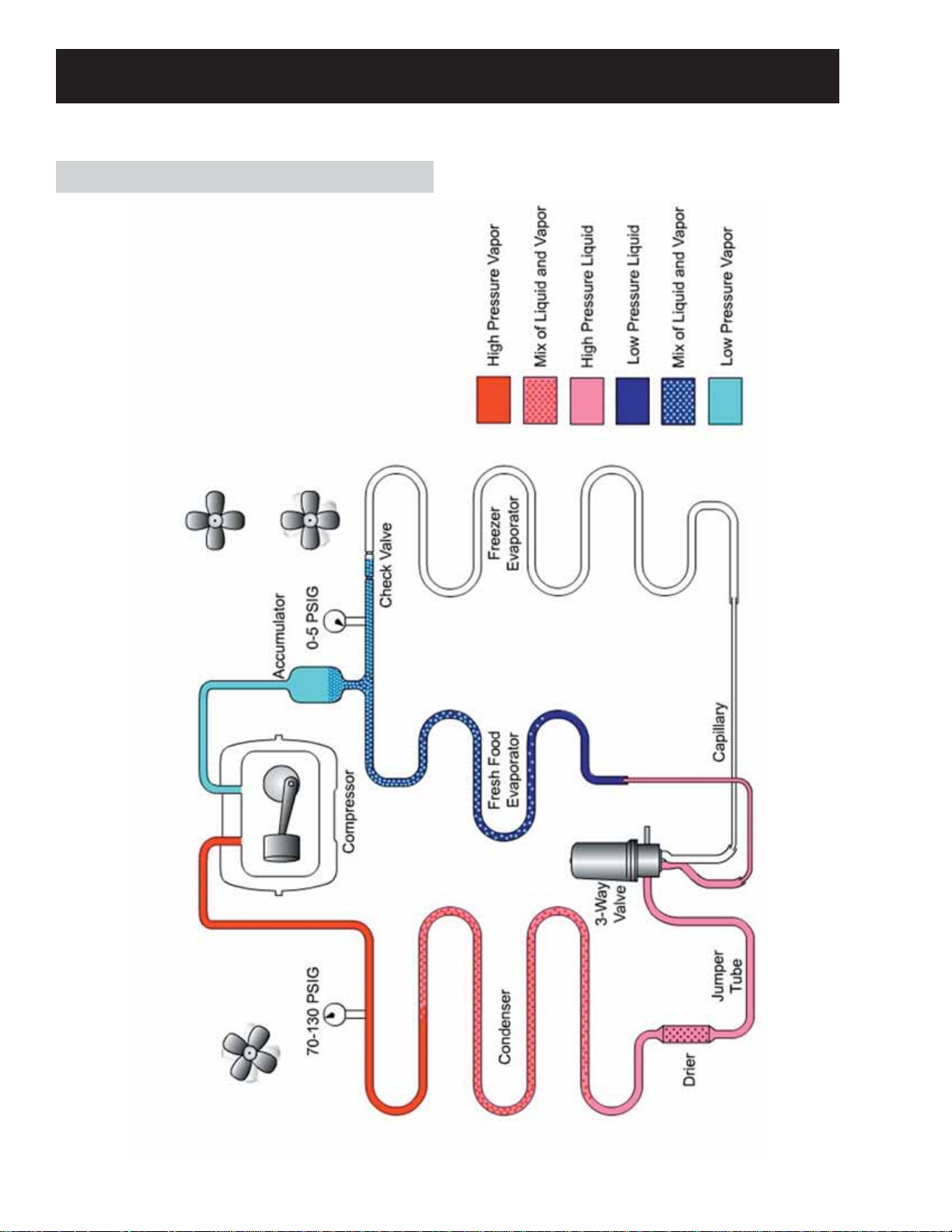

Refrigeration System .......................................................................................................14

Replacing Freezer Evaporator Using the Brazing Method ...............................................33

Replacing Freezer Evaporator Using the

Replacing Fresh Food Evaporator Using the Brazing Method .........................................38

Replacing Fresh Food Evaporator Using the

Replacing the 3-Way Valve ..............................................................................................29

LOKRING Method ............................................35

LOKRING Method ......................................39

Schematic ........................................................................................................................43

Technical Data .................................................................................................................5

Thermistors ......................................................................................................................18

Troubleshooting ...............................................................................................................41

Warranty ...........................................................................................................................62

– 3 –

Page 4

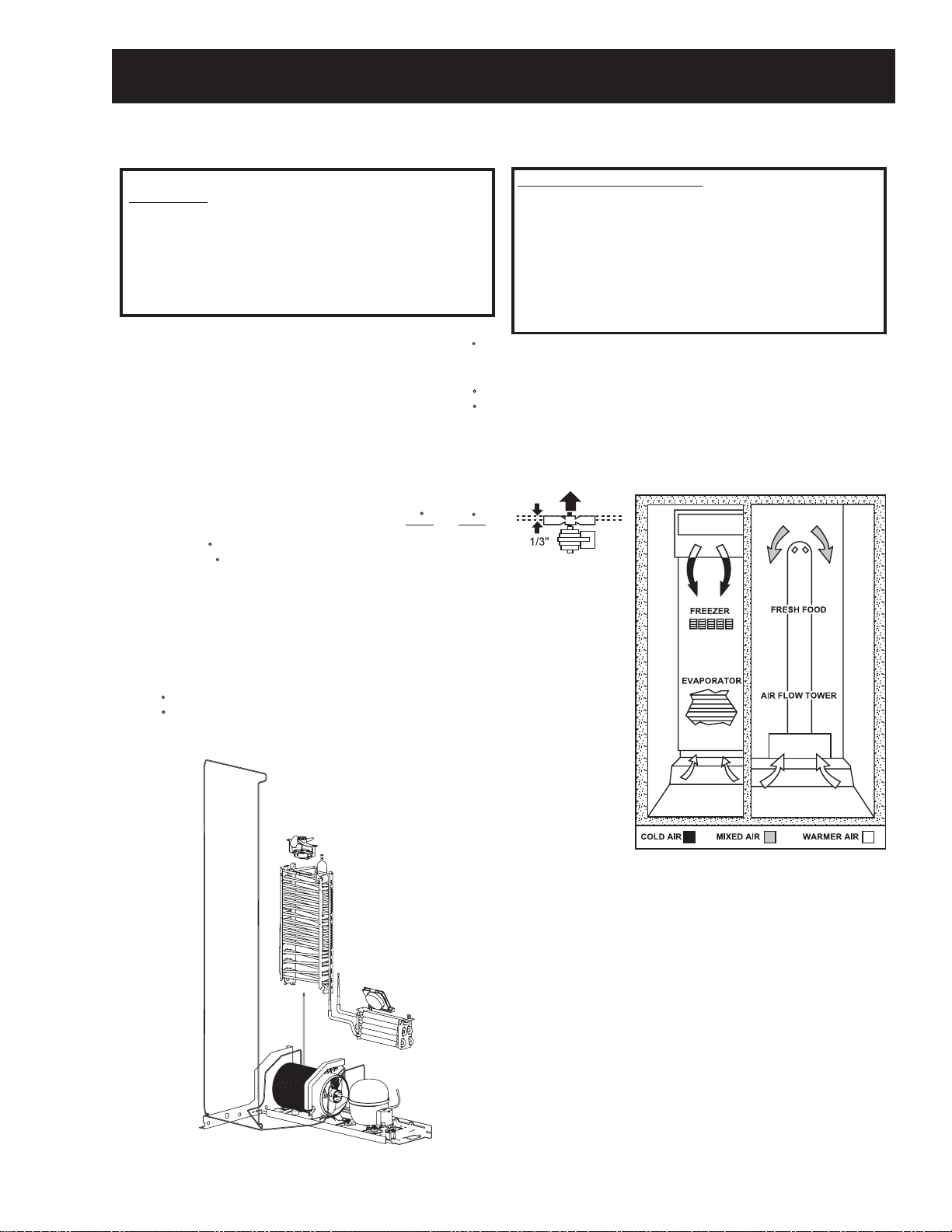

Introduction

This new Arctica dual evaporator refrigerator has the following features:

• Separate freezer and fresh food evaporators with independent cooling.

• No damper/air inlet assembly in the fresh food section creates more usuable space on the top shelf.

• Greater fresh food humidity to keep food

fresher, longer.

• 20% less freezer defrost for better food

preservation.

• 3-Way valve to direct refrigerant fl ow.

• Nearly silent, only 30 dBA.

The 3-speed compressor is controlled by

an inverter that receives input from the

low voltage DC side of the main control

board. The inverter always has 120 VAC

applied when the refrigerator is connected

to power. The main control board still makes

compressor decisions based on the input of

thermistors, door-open time, and input from

the temperature control panel. The main

control board also operates the condenser

fan, fresh food fan, freezer fan and adaptive

defrost.

The most signifi cant difference from previous

models is that the freezer and fresh food

evaporators are separate. The 3-way valve

directs refrigerant fl ow to each evaporator as needed. The fresh food section no longer relies on the

freezer evaporator for cooling. The evaporators are controlled separately by the main control board

through the 3-way valve.

– 4

Page 5

Technical Data

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNEC

T ALL GROUNDING DEVICE

S

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to

complete a path to ground are removed for service,

they must be returned to their original position and

properly fastened.

ELECTRICAL SPECIFIC

Temperature Control (Position 5) ......................... 7-(-11 ) F

Defrost Control .......................................... 60hrs @ 45 min

Overtemperature Thermostat .............................. 140-110 F

Defrost Thermistor ........................................................ 75 F

Electrical Rating: 115V AC 60 Hz ......................... 11.6 Amp

Maximum Current Leakage ................................... 0.75 mA

Maximum Ground Path Resistance .................. 0.14 Ohms

ATIONS

w/ no door openings

NO LOAD PERFORMANCE

Control Position MID/MID

and Ambient of:

Fresh Food, F ................................................ 34-40 34-40

Frozen Food, F .............................................. (-3) 3 (-3) 3

Run Time, % ...................................................... <80 80-100

REFRIGER

Refrigerant Charge (R134a) ............................... 6.5 ounces

Compressor ....................................................833 BTU/hr @

Minimum Compressor Capacity ......................... 22 inches

Minimum Equalized Pressure

@ 70 F ....................................................................... 40 PSIG

@ 90 F ....................................................................... 54 PSIG

...............................................70 F 90 F

ATION SYSTEM

3000 RPM

IMPORTANT SAFE

TY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation of

this information, nor can it assume any liability in

connection with its use.

INSTALLATION

Minimum clearance required for air circulation:

TOP ............................................................................................. 1"

SIDES ................................................................................... 0.125"

REAR ........................................................................................ 0.5"

AIR FLOW

EVAPOR

ATO

R

– 5 –

Page 6

P S H 23 P G R A F BB

Brand/Product

G - GE

H - Hotpoint

P - Profi le

E - Eterna

S - GE Select

Confi guration

S - Side by Side

T - Top Mount

Nomenclature

Exterior Color

WW - White on White

BB - Black on Black

CC - Bisque on Bisque

SV - Stainless Visor

Door Type

F - Flat

R - Right

L - Left Door Swing

Depth/Power

H - Inverter Compressor

S - Standard Depth

T - Tropical

G - Global

Capacity

(cubic feet) AHAM Rated Volume

Interior Features/Shelves

A - Leader Wire

D - Deluxe Wire

F - 6 Month Filter

I - Deluxe Glass

K - Spillproof/Slideout Glass

P - Dual Evaporator

S - Stainless Steel Doors

Q - Showcase Derivative

U - AVB Derivative

W - HPS Derivative

X - Regional Derivative

The nomenclature plate is located on the

upper right wall of the fresh food compartment.

It contains the following information:

Nomenclature

Mini-Manual Location

• Model and Serial

Number

• Minimum

Installation

Clearances

• Electrical Voltage,

Frequency

• Maximum

Amperage Rating

• Refrigerant Charge

and Type

Engineering

A - Initial Design

B - 1st Revision

Model Year

R - 2004

Icemaker/Exterior

B - Non Dispenser

IM Ready

D - Cubed Ice/Water

E - Cubed/Crushed/

Water

F - 6-Month Filter

Cubed/Crushed

G - 1-Year Filter

Cubed/Crushed

I - In-line Filter/Indicator

Cubed/Crushed

Water

S - Stainless steel

Dispenser Trim

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AG123456S = January, 2004

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

– 6

Page 7

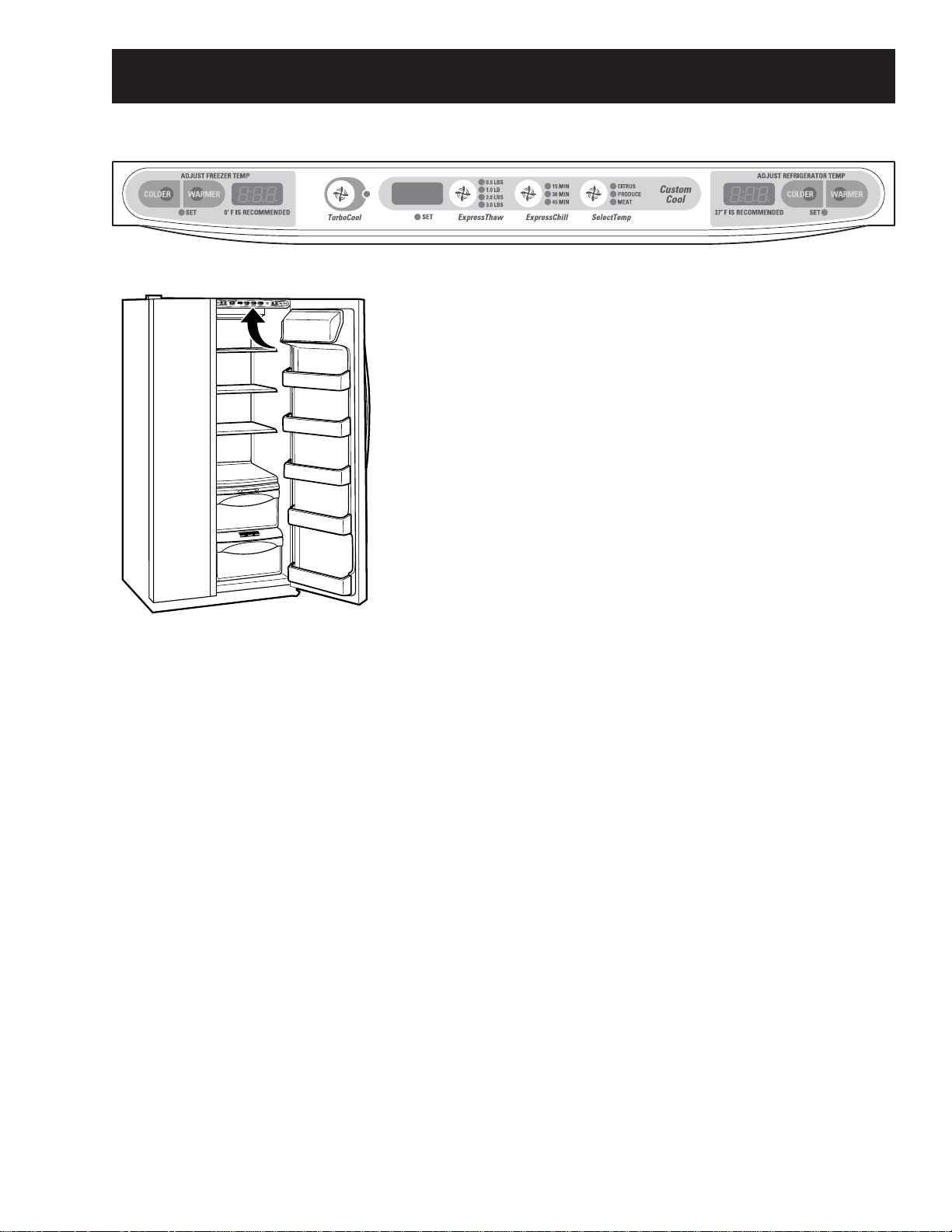

Control Features

• The temperature controls are preset in the factory at 37°F

for the refrigerator compartment and 0°F for the freezer

compartment.

• Allow 24 hours for the temperature to stabilize to the preset

recommended settings.

• The temperature controls can display both the SET

temperature as well as the actual temperature in the

refrigerator and freezer.

• The actual temperature may vary slightly from the SET

temperature based on usage and operating environment.

• Setting either or both controls to OFF stops cooling in both

the freezer and refrigerator compartments, but does not shut

off electrical power to the refrigerator.

• To change the temperature, press and release the WARMER or COLDER pad. The SET light will

come on and the display will show the set temperature.

• To change the temperature, tap either the WARMER or COLDER pad until the desired temperature

is displayed.

• Refrigerator temperatures can be adjusted between 34°F and 44°F and the freezer temperatures

can be adjusted between –6°F and +6°F.

• Once the desired temperature has been set, the temperature display will return to the actual

refrigerator and freezer temperatures after 5 seconds. Several adjustments may be required. Each

time you adjust controls, allow 24 hours for the refrigerator to reach the temperature you have set.

• To turn the cooling system off, tap the WARMER pad for either the refrigerator or the freezer until

the display shows OFF. To turn the unit back on, press the COLDER pad for either the refrigerator

or freezer. The SET light will illuminate on the side you selected. Then press the COLDER pad

again (on the side where the SET light is illuminated) and it will go to the preset points of 0°F for the

freezer and 37°F for the refrigerator.

• Setting either or both controls to OFF stops cooling in both the freezer and refrigerator

compartments, but does not shut off electrical power to the refrigerator.

– 7 –

Page 8

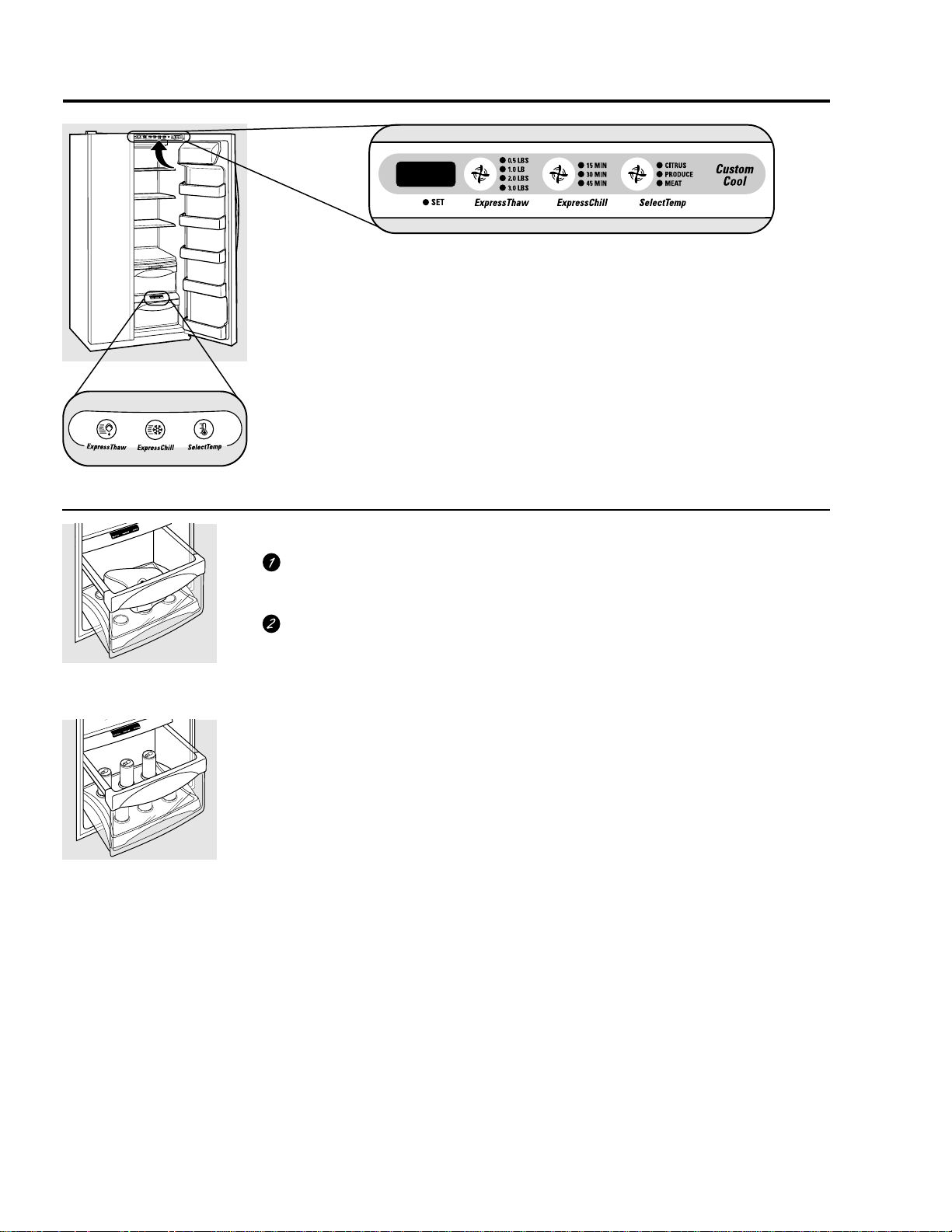

About CustomCool™.

How it Works

The CustomCool

dampers, a fan, a temperature thermistor

and a heater. Depending on the function

selected, a combination of these will be

used to quickly chill items, thaw items or

hold the pan at a specific temperature.

How to Use

ExpressThaw

ExpressChill

™

™

™

feature is a system of

Empty the pan. Place the Chill/Thaw

tray in the pan. Place the items on the

tray and close the pan completely.

Select the ExpressThaw,

™

ExpressChill

or SelectTemp™pad. The display and

SET light will come on. Tap the pad

until the light appears next to the

desired setting. Use the chart to

determine the best setting to use.

■ To stop a feature before it is

finished, tap that feature’s pad

until no options are selected and

the display is off.

■ During ExpressThaw

ExpressChill,

™

™

and

the display on the

controls will count down the time

in the cycle.

The pan is tightly sealed to prevent the pan’s

temperature from causing temperature

fluctuations in the rest of the refrigerator.

The controls for this pan are located at the

top of the refrigerator with the temperature

controls.

■ After the ExpressThaw

™

complete, the pan will reset to the

MEAT setting (31°F) to help preserve

™

thawed items until they are used.

■ The displayed actual temperature of

the CustomCool pan may vary slightly

from the SET temperature based on

usage and operating environment.

NOTE: For food safety reasons, it is

recommended that foods be wrapped

in plastic wrap when using ExpressThaw.

This will help contain meat juices and

improve thawing performance.

cycle is

™

– 8

Page 9

About TurboCool.

™

How it Works

TurboCool rapidly cools the refrigerator

compartment in order to more quickly

cool foods. Use TurboCool when adding a

large amount of food to the refrigerator

compartment, putting away foods after they

have been sitting out at room temperature

or when putting away warm leftovers. It can

also be used if the refrigerator has been

without power for an extended period.

Once activated, the compressor will turn on

immediately and the fans will cycle on and

off at high speed as needed for eight hours.

The compressor will continue to run until

the refrigerator compartment cools to

approximately 34°F (1°C), then it will cycle

on and off to maintain this setting. After 8

hours, or if TurboCool is pressed again, the

refrigerator compartment will return to

the original setting.

How to Use

Press TurboCool. The refrigerator

temperature display will show TC.

After TurboCool is complete, the

refrigerator compartment will return

to the original setting.

NOTES: The refrigerator temperature

cannot be changed during

TurboCool.

The freezer temperature is not

affected during TurboCool.

When opening the refrigerator

door during TurboCool, the fans

will continue to run if they have

cycled on.

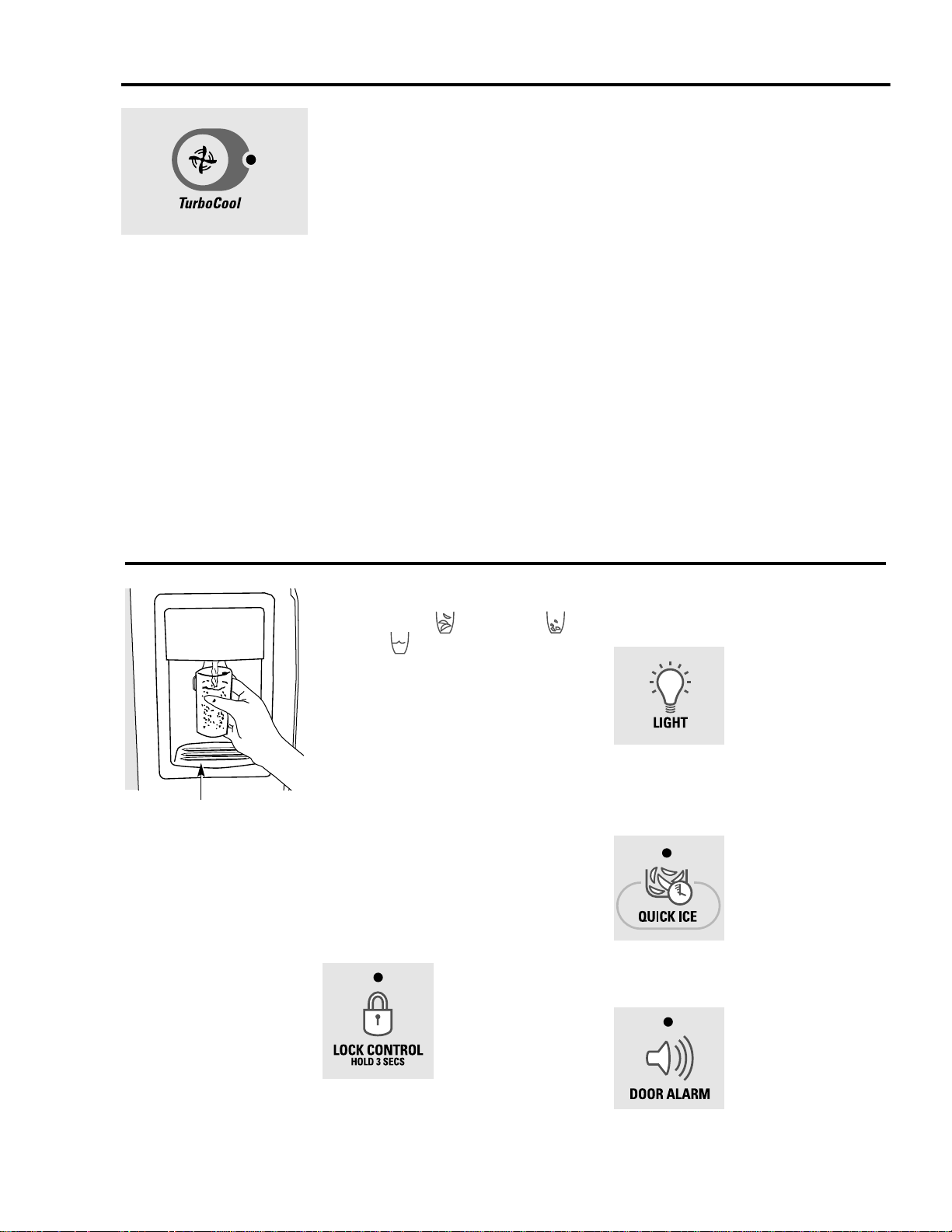

About the ice and water dispenser. (on some models)

To Use the Dispenser

Select CUBED ICE , CRUSHED ICE

or WATER .

Press the glass gently against the top of

the dispenser cradle.

The spill shelf is not self-draining.

To reduce water spotting, the shelf and

its grille should be cleaned regularly.

If no water is dispensed when the refrigerator is

first installed, there may be air in the water line

system. Press the dispenser arm for at least two

minutes to remove trapped air from the water

line and to fill the water system. To flush out

impurities in the water line, throw away the first

six glassfuls of water.

CAUTION: Never put fingers or any other

objects into the ice crusher discharge opening.

Locking the Dispenser

Press the LOCK CONTROL

pad for 3 seconds to

lock the dispenser and

control panel. To

unlock, press and

hold the pad again

for 3 seconds.

Dispenser Light

This pad turns the night

light in the dispenser

on and off. The light

also comes on when

the dispenser cradle is

pressed. If this light

burns out, it should be

replaced with a 6 watt

12V maximum bulb.

Quick Ice

When you need ice

in a hurry, press this

pad to speed up ice

production. This will

increase ice production

for the following

48 hours or until you

press the pad again.

Door Alarm

To set the alarm, press

this pad until the

indicator light comes

on. This alarm will

sound if either door is

open for more than

3 minutes. The light

goes out and the

beeping stops when

you close the door.

Spill Shelf

– 9 –

Page 10

Dispenser Light

The LIGHT pad turns the dispenser light on and

off. When the light is turned off, it will fade out.

The dispenser light will come on automatically

when the dispenser cradle is depressed and will

fade out 5 seconds after it is released. The LIGHT

pad will not turn off the light during dispensing.

Dispensing Functions

The water, crushed ice, and cubed ice functions

are controlled by the main control board. To

select a function, press the appropriate pad on

the dispenser. The LED will light to identify the

selection.

To dispense ice cubes or crushed ice, choose

the appropriate pad and depress the dispenser

cradle. The solenoid and linkage assembly will

open the ice chute duct door to dispense the

ice. If cubed ice is selected, a solenoid located

behind the ice bucket will lift a rod along the side

of the bucket. This rod pulls a fl apper away from

the cutter blades, allowing cubes to bypass the

ice crusher. The dispenser duct door will remain

open for 3 seconds after dispensing to allow all

ice to clear the chute.

The dispenser light will come on automatically

when the dispenser cradle is depressed and will

fade out 5 seconds after it is released.

Dispenser Lock

When the dispenser system is locked, no

dispenser command will be accepted. This

includes the dispenser cradle and will prevent

accidental dispensing that may be caused

by children or pets. If a pad or the cradle is

depressed with the system locked, it will be

acknowledged with three pulses of the LOCK

LED accompanied by an audible tone.

To lock or unlock communication between the

dispenser and main control board, press the

LOCK pad and hold it for 3 seconds. The LOCK

LED will fl ash while the LOCK pad is pressed.

When the communication is locked, the LOCK

LED will be illuminated.

The status of other functions selected prior to the

initiation of the lock feature will be displayed. If

the lock is engaged while a mode is active, the

LED will remain on until that mode times out.

If the lock is engaged when the fi lter timer

expires, the LED will come on but cannot be reset

until the lock is turned off.

The lock feature will be restored in the event of a

power disruption.

Liner Protection Mode

The dual evaporator model has separate liner

protection modes for each section. The specifi c

evaporator fan (freezer or fresh food) will start

and run on high speed if the door has been open

for 3 minutes.

This mode is controlled by 2 timers. Timer #1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If 3

minutes elapse before the door is closed, the liner

protection mode will become active. Once the

door is closed, timer #1 resets and liner protection

mode goes into standby. In standby, normal

fan operation resumes and timer #2 begins a

3-minute door-closed count. If 3 minutes elapse

without a door opening, liner protection mode will

completely deactivate. If a door is opened within

the timer #2 door-closed count, the remaining

time in the door-closed count will be deducted

from the timer #1 door-open count.

– 10

Page 11

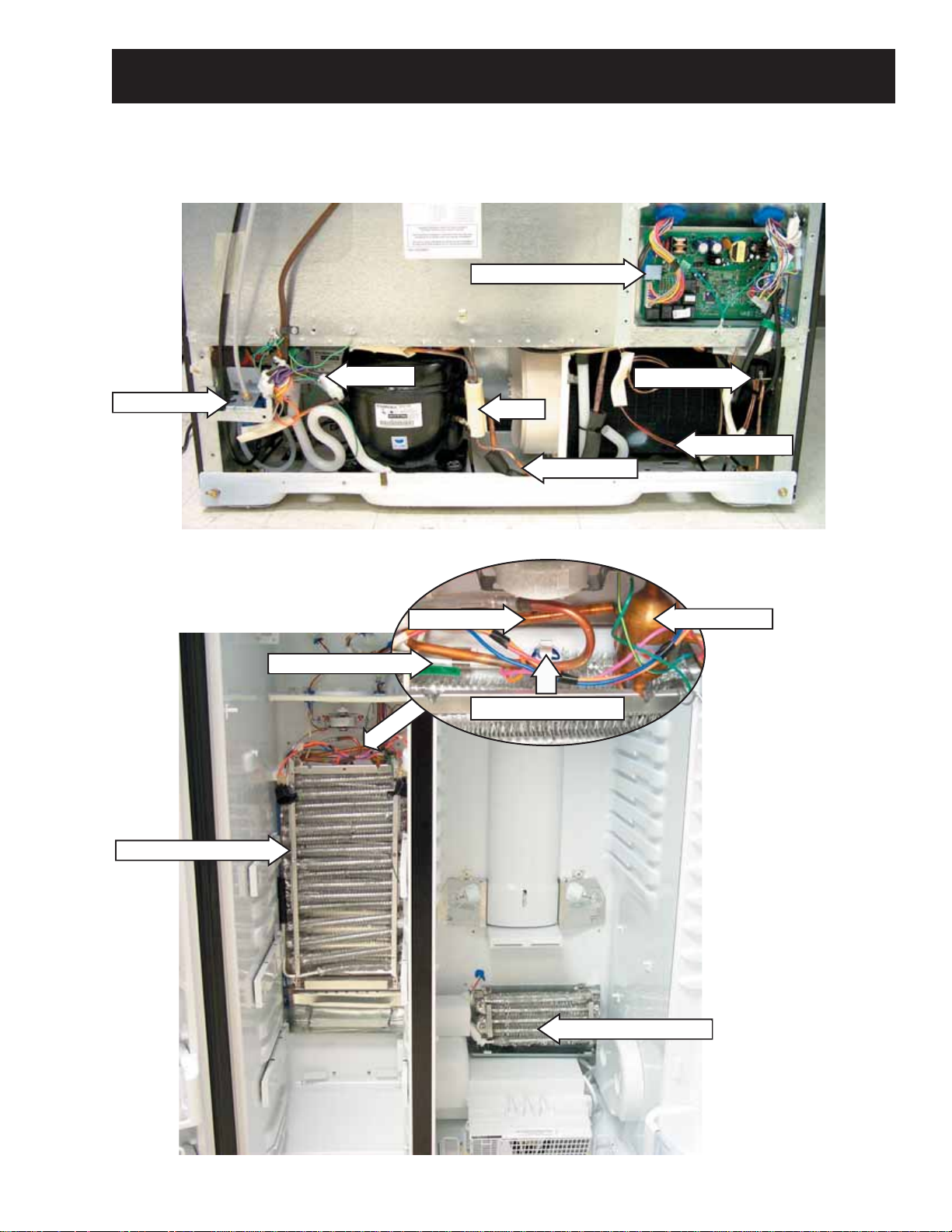

Rear View

Components Locator Views

Main Control Board

Water Valve

Front View

Inverter

Evaporator Thermistor

Check Valve

Over Temp Thermostat

3-Way Valve

Drier

Condenser

Jumper Tube

Accumulator

Note: The

check valve and

accumulator are

part of the freezer

evaporator and

are not available

separately.

Freezer Evaporator

Fresh Food Evaporator

– 11 –

Page 12

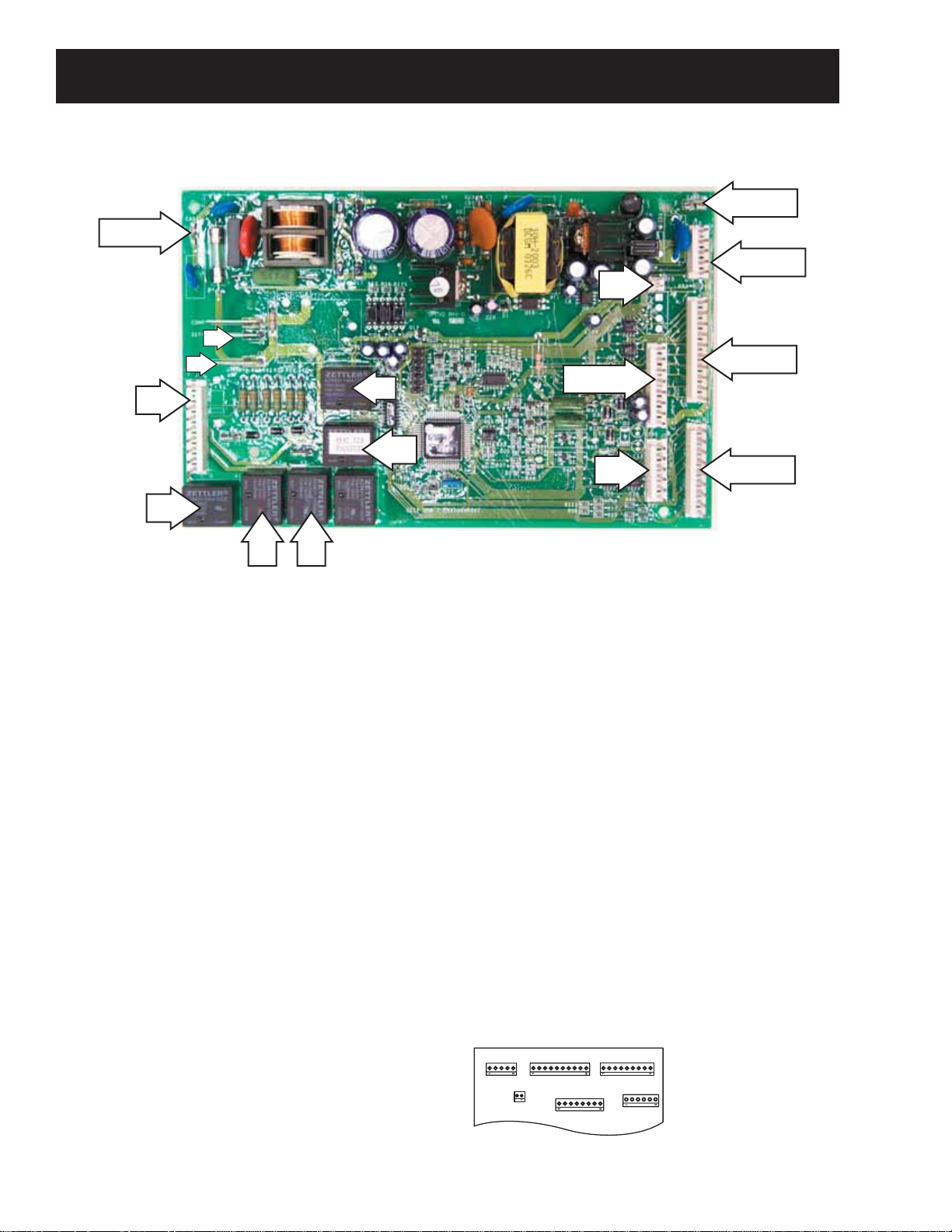

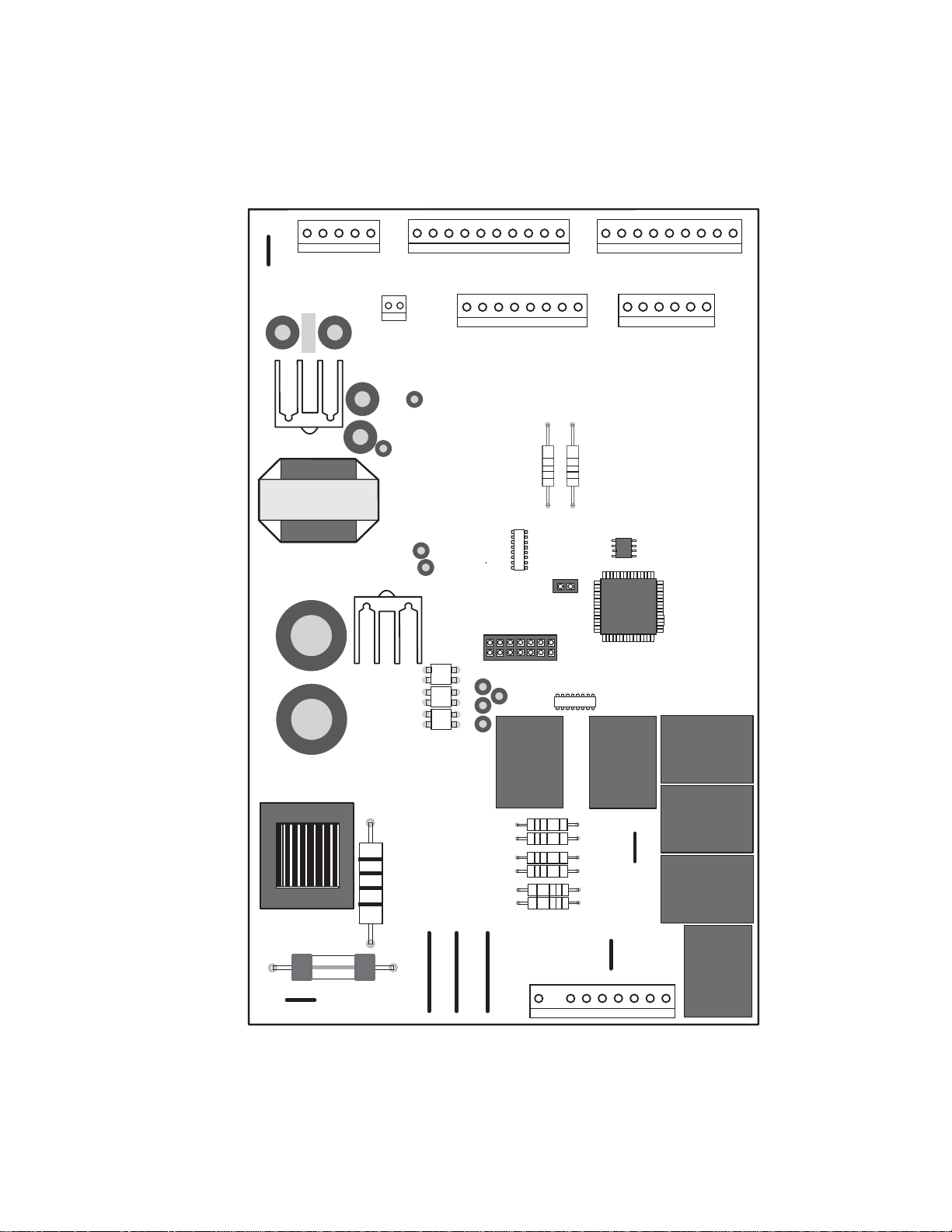

Main Control Board

J1 or J10

J9

J11

J7

Control Board Connector Locator

J15

K4

K5

J2 or J13

J5

J2 or J13

J4 or J16

J3 or J10

J1 or J14

K2K1K3

J1 or J10 - Earth (Ground)

J2 or J13 - Earth (Ground)

J5 - Custom Cool

J7 - Neutral, Door Switches, Custom Cool

Heater, Water Valve, Crusher Solenoid,

Auger Motor

J9 - Defrost Heater

J3 or J10 - 3-Way Valve

J11 - Line (L1)

J2 or J13 - Model Selector, Fan Common,

Evaporator Fan, Condenser Fan,

Fresh Food Fan, Custom Cool Fan

J1 or J14 - Fresh Food Thermistor, Freezer

Thermistor, Fresh Food Evaporator

Thermistor, Freezer Evaporator

Thermistor, Model Selector

J15 - Inverter

J4 or J16 - Temperature Control Board

K1 - Auger

K2 - Crusher

K3 - Water

K4 - Defrost

K5 - Custom Cool

Some of the low voltage DC

connector labeling on this model

may differ from other models. The

function and diagnostics for these

connectors are identical for all

models.

– 12

J4 or J16

J3 or J10

J2 OR J13

J1 or J14

Page 13

Comm. Common

Comm. +12V

Comm. 2-Way Digital

3-Way valve - Gray & White

3-Way valve - Black

3-Way valve - Red

3-Way valve - Yellow

3-Way valve - Orange

FF Thermistor

FF Evaporator Thermistor

Model Selector

+5V

FZ Thermistor

FZ Evaporator Thermistor

Model Selector

EARTH

J4 or J16

J2 or J13

5

1

1

J3 or J10

1

J15

1

J2 or J13

10

1

J1 or J14

8

J5

9

1

6

+5V

Fan +12V

Inverter Output

Inverter Common

Fan Common

Model Selector

Condenser Fan

Evaporator Fan

Fresh Food Fan

Custom Cool Fan

Evaporator Fan (RPM)

J19

1

J6

2

Custom Cool Thermistor

Custom Cool Dual Damper +

Custom Cool Dual Damper -

Custom Cool Single Damper -

Custom Cool Single Damper +

EARTH

J1 or J10

K4

DEFROST

Not Used (Wire ends in cabinet)

Defrost Heater

Line (L1)

J8

J9

J11

J7

Neutral

FZ Door Switch

K5

CUSTOM COOL

J12

Not Used

J18

Not Used

Water Valve

FF Door Switch

Custom Cool Heater

Crusher Solenoid

Auger Motor Interlock

K7

NOT

K3

WATER

K2

CRUSHER

K1

1

Auger Motor

USED

AUGER

– 13 –

Page 14

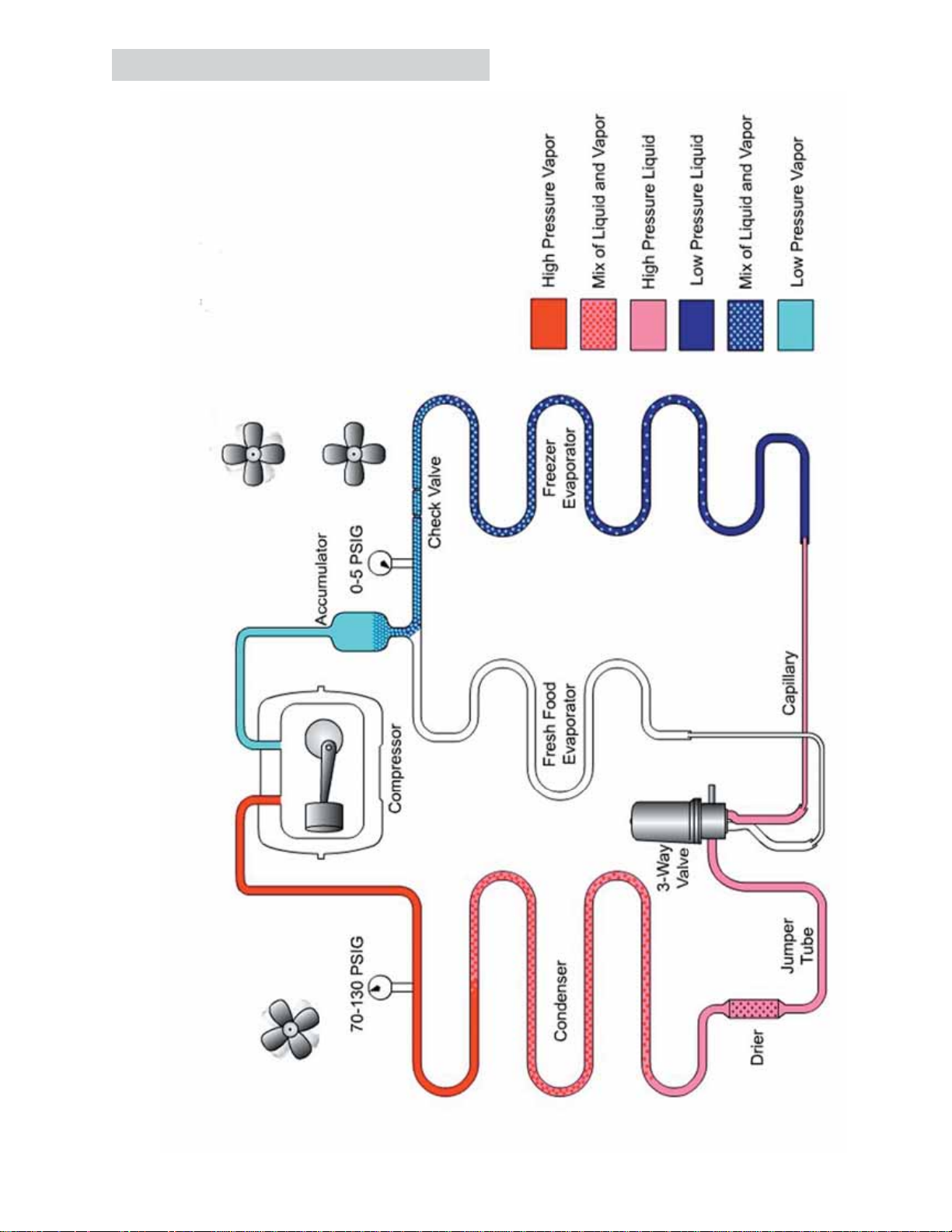

Fresh Food Section Cooling

Refrigeration System

Freezer Fan Off

Fresh Food Fan Running

Condenser Fan Running

– 14

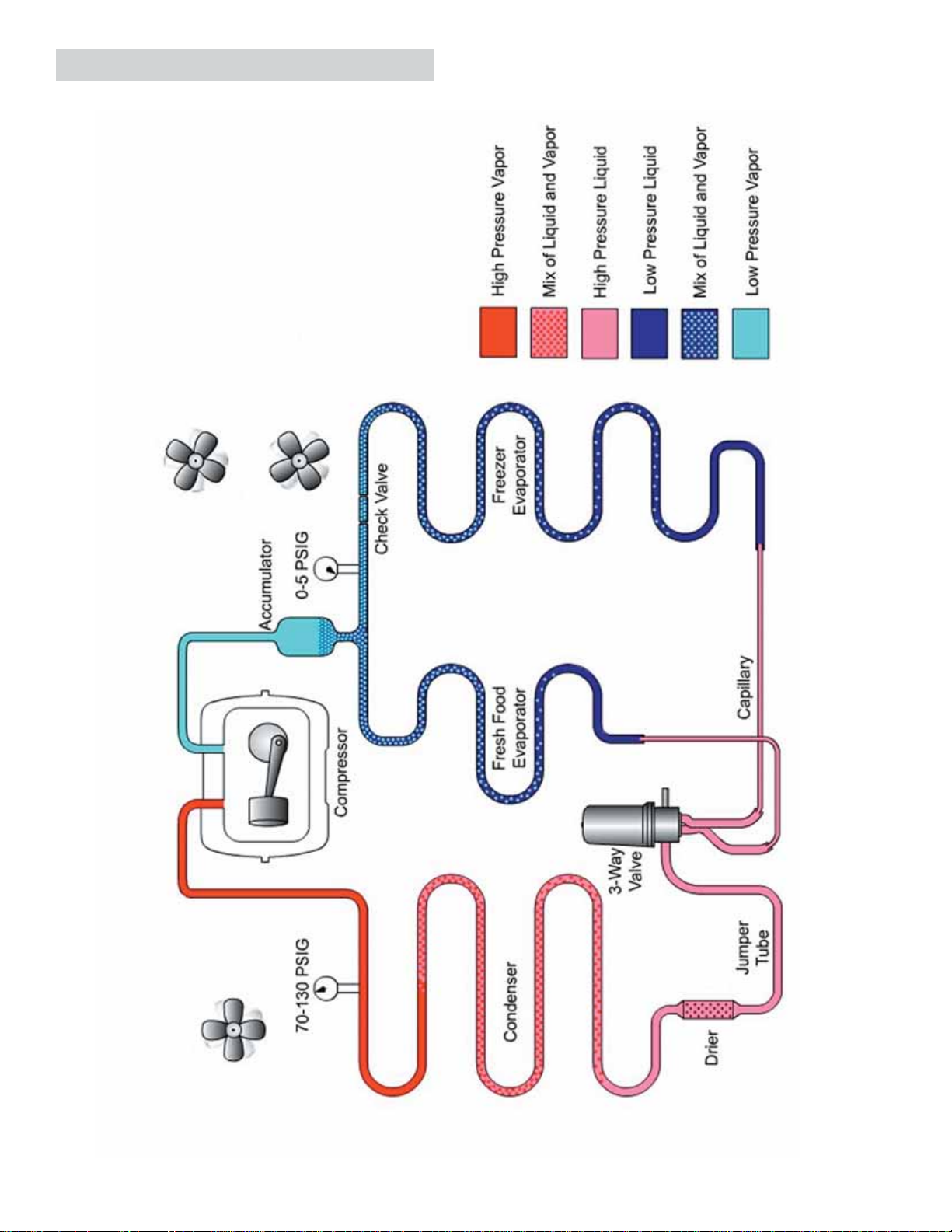

Page 15

Freezer Section Cooling

Freezer Fan Running

Fresh Food Fan Off

Condenser Fan Running

– 15 –

Page 16

Fresh Food and Freezer Section Cooling

Freezer Fan Running

Fresh Food Running

Condenser Fan Running

– 16

Page 17

Evacuation and Charging Procedure

WARNING:

• Before cutting or using a torch on

refrigerant tubes, recover the refrigerant

from the system using approved recovery

equipment.

4. Open the ball valve. Recover the purge/

sweep charge using the recovery pump and

the refrigerator compressor until a 20-in.

vacuum is attained. Close the ball valve and

remove the recovery hose.

5. Charge the system with the exact amount of

R-134a refrigerant specifi ed.

• Never charge new refrigerant through the

purge valve. This valve is always located

on the high pressure side of the system.

• Never apply heat from any source to a

container of refrigerant. Such action will

cause excessive pressure in the container.

• Always wear goggles when working with

refrigerants and nitrogen holding charge

in some replacement parts. Contact with

these gases may cause injury.

1. Attach the hose from the R-134a charging

cylinder to the process tube port on the

compressor.

2. Evacuate the system to a minimum 20-in.

vacuum using the refrigerator compressor and

recovery pump, which is attached to the new

drier assembly.

3. Turn off the recovery pump. Close the ball

valve on the hose connected to the high-side

port connection. Add 3 ounces of R-134a

refrigerant to the system. Let the refrigerator

operate and circulate the refrigerant for 5

minutes.

6. Disconnect the power cord to the refrigerator.

This allows the pressure to equalize. After

3 to 5 minutes, the low side pressure will be

positive and then the hose-to-charging port

can be disconnected.

7. Using an electronic leak detector, check

all brazed joints and both schrader ports.

Reinstall caps to schrader.

– 17 –

Page 18

Components

Thermistors

Temperature

(°F)

-40 -40 166.8 kΩ

-31 -35 120.5 kΩ

-22 -30 88 kΩ

-13 -25 65 kΩ

-4 -20 48.4 kΩ

5 -15 36.4 kΩ

14 -10 27.6 kΩ

23 -5 21 kΩ

32 0 16.3 kΩ

41 5 12.7 kΩ

Thermistor Resistance

Temperature

(°C)

Resistance in

Kilo-Ohms

Fresh Food and Freezer Thermistors

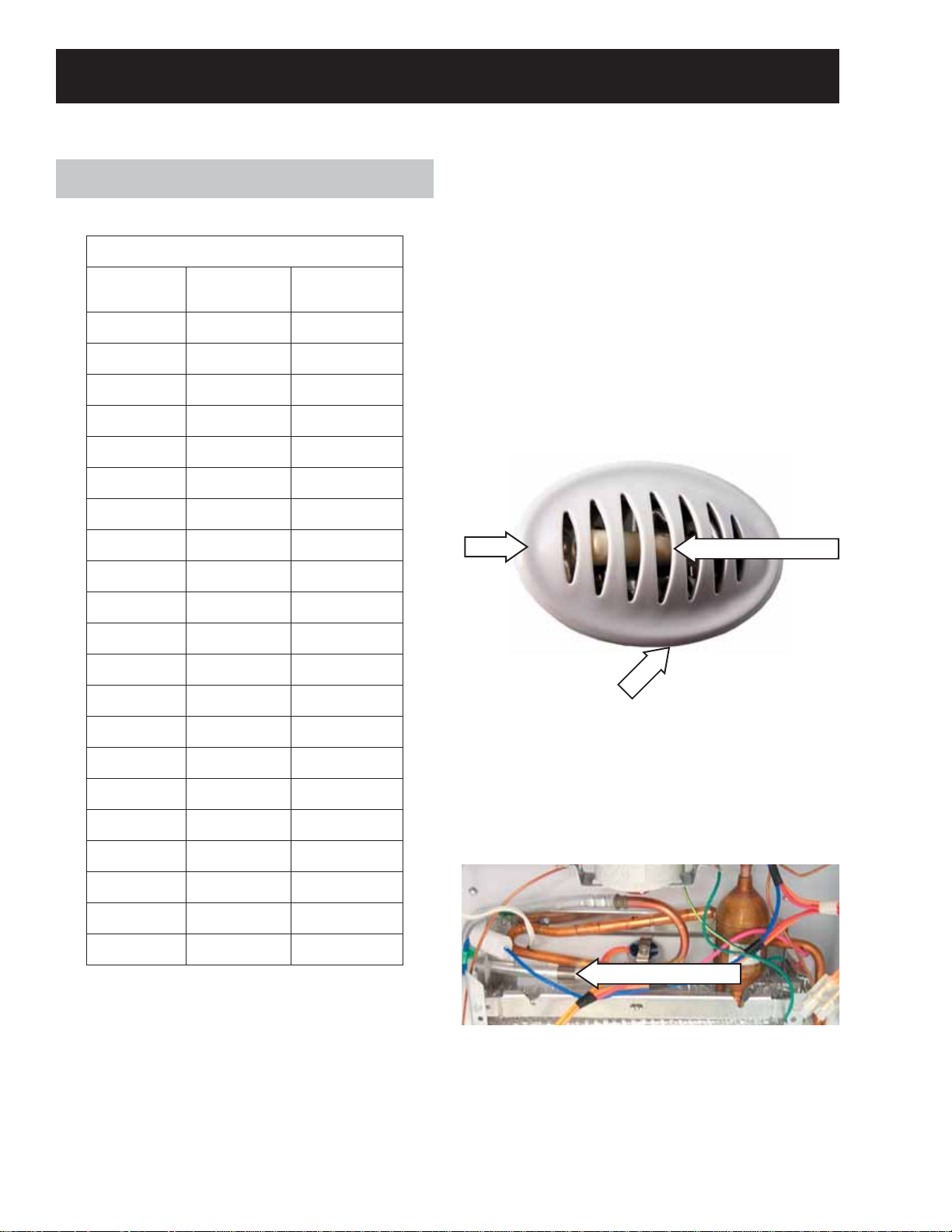

The fresh food and freezer thermistors (part #

WR55X10025) are located in the mullion dividing

the fresh food and freezer compartments.

Note: The fresh food and freezer thermistors are

removed in the same manner.

To remove the thermistor cover, insert a fl at-blade

screwdriver under the front of the cover and

gently lift at the bottom edge until it releases from

the compartment wall.

Insert

Thermistor Cover

50 10 10 kΩ

59 15 7.8 kΩ

68 20 6.2 kΩ

77 25 5 kΩ

86 30 4 kΩ

95 35 3.2 kΩ

104 40 2.6 kΩ

113 45 2.2 kΩ

122 50 1.8 kΩ

131 55 1.5 kΩ

140 60 1.2 kΩ

Note: To accurately test a thermistor, place the

thermistor in a glass of ice water (approximately

33°F) for several minutes and check for

approximately 16K Ω.

Lift

Freezer Evaporator Thermistor

The freezer evaporator thermistor (part #

WR55X10025) is clipped to the top coil of the

freezer evaporator. See Freezer Evaporator for

accessing instructions.

Evaporator Thermistor

– 18

Page 19

Fresh Food Evaporator Thermistor

The fresh food evaporator thermistor (part #

WR55X10025) is located in an aluminum thermal

block on the back of the evaporator. It is attached

to the fresh food evaporator by a wire tie. See

Fresh Food Evaporator for accessing instructions.

If the fresh food evaporator thermistor is either

open or shorted, the main control board defaults

to a fi xed defrost cycle of 1 hour at high speed

fan.

Thermal Block

Thermistor

Insert the new thermistor into the thermal block.

Add RTV102 silicone to hold the thermistor in

place. Make certain to wire tie the thermal block

back to the evaporator.

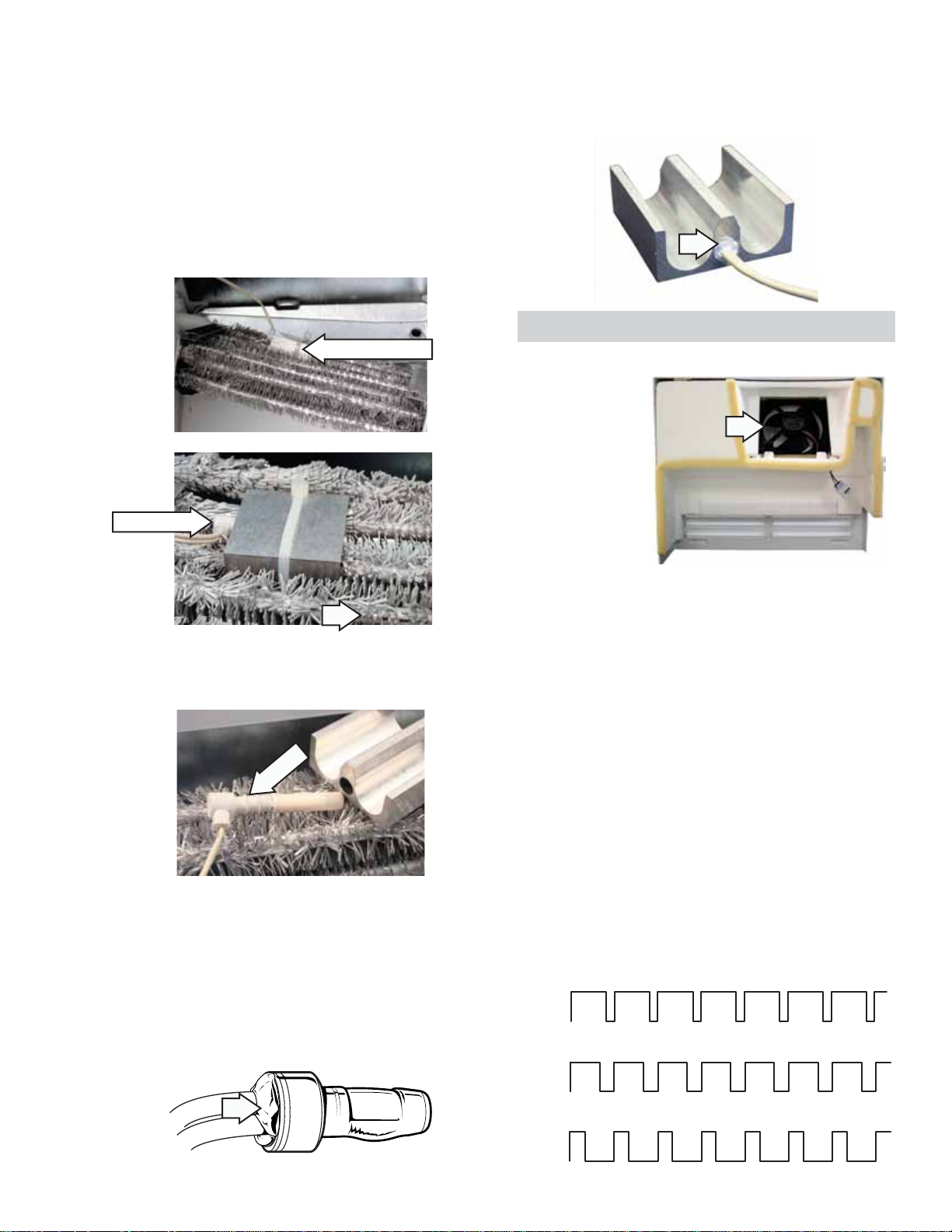

Fresh Food Evaporator Fan

A variable speed

12 VDC motor

is mounted in

front of the fresh

food evaporator.

The fan and

evaporator cover

are replaced

as a complete

assembly.

Barbs on the molded housing hold the thermistor

in the thermal block.

Barbs

Replacement

Should the evaporator thermistor require

replacement, splice a new thermistor into the

harness using plastic bell connectors (part #

WR01X10466). Fill the connector with RTV102

silicone as shown in the illustration.

When activated, the fresh food evaporator fan

recirculates the air in the fresh food compartment,

providing cooling independent of the freezer

evaporator fan.

The main control board gathers information from

the fresh food thermistors to determine when, and

at what speed, fan operation should occur.

A constant 13.6 VDC is provided to the fan from

the main control board and switching occurs on

the neutral side.

Speed is regulated by pulse width modulation on

the common side of the fan. When operating, the

common side of the circuit is pulsed open and

closed. This pulsing produces effective voltage

being received at the motor, which is equivalent to

a reduction in voltage. Fan speed is selected and

maintained by the main control board regulating

the length and frequency of the 13.6 VDC pulse.

13.6 VDC

12 VDC

0 VDC

High Speed (12 VDC measured)

– 19 –

13.6 VDC

10 VDC

13.6 VDC

9 VDC

0 VDC

0 VDC

Medium Speed (10 VDC measured)

Low Speed (9 VDC measured)

Page 20

Freezer Evaporator Fan

The position of the fan blade in relation to the

shroud is important.

5/16" ± 0.03

1.0" ± 0.05 Target

The evaporator fan is the same fan used on

previous models; however, a signifi cant difference

is that the main control board neither requires

nor receives input from the fan feedback/rpm

(blue) wire. The fan utilizes a permanent magnet,

4 pole, DC motor that operates at three different

speeds: high, medium, and low.

The speed of the fan is controlled by the voltage

output from the main control board. Voltage

output from the main control board to the fan

is 13.6 VDC; however, to regulate the speed of

the fan, the main control board uses pulse width

modulation (PWM).

When operating, voltage is sent in pulses (much

like a duty cycle) as opposed to an uninterrupted

fl ow. This pulsing of 13.6 VDC produces effective

voltage being received at the motor, which is

equivalent to a reduction in voltage.

13.6 VDC

9.5 VDC

0 VDC

13.6 VDC

8 VDC

0 VDC

13.6 VDC

6.5 VDC

0 VDC

Blade tip

Orifice

Air Flow

Motor

High Speed (9.5 VDC measured)

Medium Speed (8 VDC measured)

Low Speed (6.5 VDC measured)

Fan speed is selected and maintained by the

main control board regulating the length and

frequency of the 13.6 VDC pulse. Temperature

can cause some fan speed variation. Fan speed

can vary +/- 5%, depending on the temperature,

with higher temperatures causing slightly higher

speeds.

The evaporator fan has a 4-wire connection:

White Wire (DC Common)

The white wire is the DC common wire used

for testing. During repairs, DC polarity must be

observed. Reversing the DC polarity causes a

shorted motor and/or board.

Red Wire (Supply)

Each motor uses an internal electronic controller

to operate the motor. Supply voltage from

the main control board remains at a constant

13.6 VDC.

Blue Wire (Feedback/RPM)

On previous Arctica models, the blue wire

reported rpm (speed) information to the main

control board for speed control purposes. On this

model, the board does not require or read any

feedback information from the fan motor.

Yellow Wire (Signal)

The yellow wire is the input wire from the main

control board. The main control board provides

6.5 VDC effective voltage for low speed, 8 VDC

effective voltage for medium speed, and 9.5 VDC

effective voltage for high speed. The fan operates

in low speed only when the fresh food thermistor

is satisfi ed.

Note: When testing these motors:

• You cannot test with an ohmmeter.

• DC common is not AC common.

• Verify 2 voltage potentials:

a. Red to white - power for internal controller

b. Yellow to white - power for fan

• Observe circuit polarity.

• Motors can be run for short periods using a

9 volt battery. Connect the white wire to the

negative (-) battery terminal only. Connect

the red and yellow wires to the positive (+)

battery terminal.

– 20

Page 21

Condenser Fan

The fan is mounted in the machine compartment

with the no-clean condenser. The fan and

fan shroud are mounted on one end of the

condenser, and the other end of the condenser is

blocked.

When the fan is operating, air is pulled from

the center of the condenser, drawing air in

through the coils. The air is then exhausted over

the compressor and out the right side of the

refrigerator.

Inlet air is available through the left front

and left rear of the machine compartment. A

rubber divider strip underneath the refrigerator

divides the inlet and outlet sides of the machine

compartment.

Rear

Divider Strip

Front

1/2"

Fan

0.375"

Housing

Motor

The rear access cover must be tightly fi tted to

prevent air from being exhausted directly out of

the rear of the machine compartment, bypassing

the compressor.

The condenser fan is mounted with screws to a

fan shroud and mounting bracket that is attached

to the condenser.

Condenser fan speed corresponds with

compressor speed (low, medium, high) to

minimize pressure variations in the sealed

system except when the freezer temperature is

20°F above the set point. If this condition exists

(such as during initial startup), the condenser

fan operates at super high speed while the

compressor operates at medium speed.

The speed of the fan is controlled by the voltage

output from the main control board. Voltage

output from the control board to the fan is

13.6 VDC; however, to regulate the speed of

the fan, the main control board uses pulse width

modulation (PWM).

When operating, voltage is sent in pulses (much

like a duty cycle) as opposed to an uninterrupted

fl ow. This pulsing of 13.6 VDC produces effective

voltage being received at the motor, which is

equivalent to a reduction in voltage.

Fan speed is selected and maintained by the

main control board regulating the length and

frequency of the 13.6 VDC pulse.

Air Flow

0.50" ± 0.05

Bracket

– 21 –

Page 22

Temperature can cause some fan speed

variation. Fan speed can vary +/- 5%, depending

on the temperature, with higher temperatures

causing slightly higher speeds.

Condenser fan speed is controlled by Pulse

Width Modulation (PWM), the same method used

to control fan speeds for the evaporators.

13.6 VDC

12.0 VDC

0 VDC

Super High Speed (12.0 VDC measured)

13.6 VDC

10.5 VDC

0 VDC

High Speed (10.5 VDC measured)

Fresh Food Normal Defrost

The fresh food section cools until the fresh food

thermistor is satisfi ed.

13.6 VDC

7.5 VDC

0 VDC

Medium Speed (7.5 VDC measured)

13.6 VDC

5.5 VDC

0 VDC

Low Speed (5.5 VDC measured)

Defrost Cycles

Fresh Food Evaporator Defrost Cycle

The refrigerator utilizes a forced air cycle defrost

method (no electric heater) to remove frost from

the fresh food evaporator. Fresh food air that is

above freezing temperature circulates thru the

coil and melts any accumulated frost. Note that

during fresh food defrost, the compressor may

still be running, cooling only the freezer section.

If both freezer and fresh food thermistors are

satisfi ed, the compressor cycles off. If the freezer

still requires cooling, the main control board

rotates the 3-way valve to stop refrigerant fl ow to

the fresh food evaporator. Even though refrigerant

fl ow has stopped in the fresh food evaporator, the

fresh food fan continues to run at low speed.

The system is designed to run the fan until the

fresh food evaporator thermistor reaches 35°F.

Once this temperature is reached, the fan

continues to run for an additional 5 minutes.

Under normal conditions, the defrost time takes

approximately 30 minutes. The maximum time

the fan runs in low speed is 60 minutes. If the

evaporator thermistor has not reached 35°F after

60 minutes, the control switches to extended

defrost #1.

– 22

Page 23

Fresh Food Extended Defrost #1

Fresh Food Forced Defrost

Occasionally there may be excessive frost

on the evaporator coil. This can be attributed

to numerous door openings, extremely high

humidity, poor door gasket seal, etc. If the normal

defrost fan time exceeds 60 minutes, the fan

switches to high speed. The control continues to

monitor the fresh food evaporator thermistor for

35°F. When 35°F is reached, the fan runs for an

additional 5 minutes at high speed. The fan can

run up to an additional 30 minutes at high speed,

trying to reach 35°F. After 90 total minutes of fan

time (60 at low speed and 30 at high speed), if

the fresh food evaporator is still below 35°F, the

control will switch to extended defrost #2.

Fresh Food Extended Defrost #2

If the fresh food fan has been operating for 90

minutes, the main control searches for a fresh

food thermistor temperature above 52°F. If the

fresh food thermistor is above 52°F, the main

control board assumes there is a problem reading

the fresh food evaporator thermistor, ends the

defrost cycle and returns to normal cooling.

If the fresh food thermistor is less than 52°F, the

main control board assumes there is refrigerant

leaking through the 3-way valve, keeping the

fresh food evaporator cold during the defrost

process while the freezer evaporator is cooling.

The main control board shuts off the compressor

and runs the fresh food fan at high speed until

two conditions are met: the evaporator thermistor

reaches 35°F and the fresh food thermistor is

2½F° above the set point. As in the other cycles,

the fan continues to run for an additional 5

minutes after the 35°F evaporator temperature is

reached.

If the main control board senses the fresh food

section has been cooling for 45 minutes, it

immediately stops the refrigerant fl ow through

the fresh food evaporator. The main control

board changes the position of the 3-way valve

if cooling is still required in the freezer, or turns

the compressor off if the freezer is satisfi ed. The

fresh food fan operates on high speed until the

evaporator reaches 35°F, plus an additional 5

minutes after the evaporator reaches 35°F.

To prevent the refrigerator from going into forced

defrost when fi rst installed or after a power failure,

the control will disregard the 45 minute time limit

if the freezer temperature is above 20°F.

Note: If the fresh food evaporator thermistor is

either open or shorted and the 35°F cutoff cannot

be determined, the main control board defaults to

a fi xed defrost cycle of 1 hour at high-speed fan.

Freezer Defrost Cycle

The freezer evaporator utilizes a defrost heater

to remove frost from the coil. The control board

determines the length of time the heater is

energized. It does this by monitoring the freezer

evaporator thermistor. Once the temperature

of the thermistor reaches 75°F, the control

cycles the defrost heater off. A bi-metal safety

thermostat provides a backup in the event the

evaporator thermistor fails. The safety thermostat

prevents the temperature from exceeding 140°F.

Note: During the freezer defrost cycle, the

compressor does not operate, even if the fresh

food section is above the set point.

– 23 –

Page 24

Inverter

•

The inverter is accessed from the back of the

refrigerator.

•

It is located on the left side of the compressor

behind the water valve.

• The water valve must be removed to access

the inverter.

To remove the Inverter

1

1. Remove the

the inverter in place.

/4-in. hex-head screw that holds

Caution: It may be necessary to bend the

process tube in order to remove the inverter. If

it is necessary to bend the process tube, use

extreme caution.

Inverter Viewed From the Front

Inverter

2. Rotate the inverter counterclockwise and

slide it forward to release the tabs from the

mounting bracket.

Inverter Front

Process Tube

Inverter Shown with Cover Removed

Compressor Lead Wires

Line-In

N

Signal Wire Connector from Main Board

L1

WARNING: When the refrigerator is plugged in,

120 VAC is always present at the inverter.

Back Tab

Right Side Tab

Left Side View

Mounting Bracket

Back View

Back Tab

Note: Certain voltmeters will not be able to read

voltage output from the inverter. If no voltage

or erratic voltage is measured, it does not

necessarily indicate a faulty inverter.

The inverter receives 120 VAC line-in from the

power supply. The inverter converts this singlephase, 60 Hz, 120 VAC into 3-phase, 230 VAC,

with frequency variations between 57 Hz and 104

Hz. This voltage is delivered to the compressor

through 3 lead wires. Each wire will carry identical

voltage and frequency.

Note: The compressor leads must be connected

to measure voltage output. If the compressor

wires are not connected, or if an open occurs in

one of the 3 lead wires or in the compressor, the

inverter will stop voltage output.

– 24

Page 25

When checking inverter voltage output, connect

the test-meter leads to any 2 of the 3 compressor

lead wires at the inverter plug (plug should

be connected). The same reading should be

measured between any 2 of the 3 wires.

The inverter controls compressor speed

by frequency variation and by Pulse Width

Modulation (PWM). Changing frequency and

PWM will cause an effective voltage between 80

and 230 VAC to be received at the compressor.

• Low speed (1710 rpm) - 57 Hz

• Medium speed (2100 rpm) - 70 Hz

• High speed (3120 rpm) - 104 Hz

The inverter receives commands from the main

control board. The main control board will send

a PWM run signal from the J15 connector of

between 4-6 VDC effective voltage to the inverter

(all wires must be connected). The inverter will

select compressor speed (voltage output) based

on this signal.

The main control board will only send a run signal

to the inverter when the compressor should be

on.

Note: When measuring signal voltage (from the

main control board) at the inverter, a reading

of 4-6 VDC will be measured with all wires

connected. If the inverter wiring is disconnected,

the board output will measure between 10-12

VDC.

The inverter will monitor compressor operation

and if the compressor fails to start or excessive

current draw (4 amps maximum) is detected,

the inverter will briefl y stop voltage output.

The inverter will then make 12 consecutive

compressor start attempts (once every 12

seconds). After 12 attempts, if the compressor

has not started, an 8-minute count will initiate.

After the 8-minute count, the inverter will attempt

to start the compressor again. If the compressor

starts, normal operation will resume. If the

compressor fails to start, this process will be

repeated. Removing power to the unit will reset

the inverter count. When power is restored, the

inverter will attempt to start the compressor within

8 seconds.

The inverter has a built-in circuit protection to

guard against damage from a failed or shorted

compressor. However, if a failed compressor is

diagnosed, order a new compressor and inverter.

If the compressor fails to start after replacement,

replace the inverter.

– 25 –

Page 26

Inverter Compressor

Caution: Do not attempt to direct-start the

compressor. The compressor operates on a

3-phase power supply. Applying 120 VAC to the

compressor will permanently damage the unit. It

is not possible to start the compressor without an

inverter.

The compressor is a reciprocating, variable

speed, 4-pole type. It operates on 3-phase, 80 to

230 VAC within a range of 57 to 104 Hz.

Note: Certain voltmeters will not be able to read

voltage output or frequency from the inverter.

Compressor wattages at various speeds are:

• LOW - 65 watts

• MED - 100 watts

• HIGH - 150 watts

The compressor is controlled by the inverter,

which receives its signal from the main control

board. Varying the frequency to the inverter

changes the compressor speed.

• 3°F to 5°F above refrigerator set point medium speed.

• 5.5°F to°7 F above refrigerator set point - high

speed.

Note: The compressor will run at medium speed

if the freezer temperature is 20°F or more above

the setpoint.

The use of 3-phase power eliminates the need

for the PTCR relay, capacitor, and individual

start and run windings; therefore, the start,

run and common pins found on conventional

compressors are not applicable on this 3-phase

model. Compressor pin functions are identical

and compressor lead wire confi guration is of no

importance. A resistance of 9Ω to 11Ω should be

read between any 2 of the 3 pins. Should an open

occur in the compressor winding or should one

of the compressor lead wires become open or

disconnected, the inverter will stop voltage output

to the compressor.

High compressor torque enables the compressor

to start against high pressure in the sealed

system. When power has been disconnected

from an operating unit, the high torque will enable

the compressor to start immediately upon power

restoration.

AC

J15-2

J15-1

Main Control

Board

BROWN

BLACK

TAB 1

10

10

COMPRESSOR

BLACK

BLUE

10

BROWN

INVERTER

WHITE

RED

ORANGE

ORANGE

WHITE

Compressor speed is based on the temperature

set point in conjunction with the specifi c cabinet

temperature. Speeds are selected according to

the following cabinet temperatures, with freezer

temperature being the primary:

• 7°F to 19.5°F above freezer set point = high

speed.

• 4.5°F to 6.5°F above freezer set point =

medium speed.

• 1°F to 4°F above freezer set point = low

speed.

• 1°F to 2.5°F above refrigerator set point = low

speed.

Compressor and sealed system operation is

extremely smooth and cool. The compressor

exterior may be room temperature while

operating; therefore, a running unit may be

diffi cult to detect.

RED

To verify that the compressor is running:

Disconnect power from the unit and place a hand

on the compressor. Reconnect power and feel for

a vibration when the compressor tries to start. It

may take up to 8 seconds before the compressor

attempts to start.

Note:

When ordering a replacement compressor,

•

order both the compressor and inverter.

Replace the compressor fi rst. If, after

compressor installation, the compressor fails

to start, replace the inverter.

When servicing the compressor, it is important

•

to dress the wiring to keep low voltage DC

wiring and 120 VAC wiring separate.

– 26

Page 27

3-Way Valve

The 3-way valve is located beneath the main

control board in the machine compartment and

is accessed from the back of the refrigerator. It is

composed of a magnetic coil and a valve body.

Two ¼-in. hex-head screws mount the valve to

the cabinet.

Make certain that rubber gaskets are installed

•

on mounting bracket to reduce vibration.

3-Way Valve Coil

The 3-way valve coil receives 12 VDC pulses

from the main board to change the position of the

valve. The pulses come too quickly to measure

with a volt meter.

The 3-way valve coil has a resistance value of

approximately 46 ohms that can be measured

between the coil pins.

Rubber Gaskets

Three copper tubes connect to the 3-way

•

valve.

One jumper tube connects from the drier to

•

the inlet on the valve.

A freezer capillary and a fresh food capillary

•

connect to the other two tubes on the valve.

Coil

Jumper Tube to Drier

Capillary Tube to Fresh

Food

Valve Body

Capillary Tube to

Freezer

– 27 –

Page 28

3-Way Valve Body

The valve body contains a cam, rotor and

•

magnet.

The rotor and cam are grooved to rotate with

•

the magnet.

Valve Rotation

The pulses of the valve coil cause the magnet

•

to rotate inside the valve body.

As the magnet rotates, it moves the cam at

•

the bottom of the valve.

The entire valve body has refrigerant fl owing

•

through it when the compressor is operating.

Use care not to damage the top of the valve

•

body when installing the coil on the valve.

A locating pin is used to correctly align the

•

valve body in the valve coil.

Failure to fully seat the valve in the coil or to

•

align it correctly with the pin can cause the

system to stop cooling.

Rotor

Valve Body

Cam

Magnet

Stop Point

(Home Position)

Magnet

Note: The 3-way valve comes only as a complete

assembly. Exploded view is for reference only.

The cam opens or covers the ports to the

capillary tubes.

Capillary Tube

Ports

– 28

Page 29

Testing the 3-Way Valve

The valve returns to “home” at the end of

every freezer defrost cycle and whenever the

refrigerator is reconnected to power.

To test the valve, disconnect the refrigerator from

power for at least 10 seconds, place a fi nger on

top of the valve and reconnect power.

Replacing the 3-Way Valve

Parts Needed:

•

3-Way Valve (part # WR57X10053)

•

Thermal Paste (part # WX5X8927)

•

Drier Assembly (part # WR86X93)

•

Process valve (part # WJ56X61)

The main control overdrives the valve to the

“home” position.

You should be able to feel the valve move as it

returns to the home position .

If movement is present, the main board and valve

coil are operating correctly.

When replacing a 3-way valve, note the black

mark on the freezer outlet tube. Make certain to

mark the freezer capillary by placing a piece of

tape on the capillary, 6-8 inches from the valve.

This will aid in installing the capillaries in the

correct outlet tubes.

– 29 –

INLET

FRESH FOOD

OUTLET

FREEZER

OUTLET

Black Mark

Page 30

1. Unplug the refrigerator.

Fresh Food

Outlet

Black

Mark

Inlet

Freezer

Outlet

2. Remove the rear access cover and evacuate

the sealed system. (See Evacuation and

Charging Procedure.)

3. Remove the valve body from the valve coil by

carefully pressing down on top of the valve

body.

Press

Here

5. Connect the new jumper tube to the inlet tube

of the new 3-way valve.

6. Prepare the taped capillary tube, and insert

it into the 3-way valve freezer outlet port

(identifi ed with black mark or tape).

7. Prepare the remaining capillary tube and

insert it into the 3-way valve fresh food outlet

port.

4. Tape the freezer capillary tube 6 inches below

the brazing joint. Score and break the two

capillary tubes below the brazing joints.

Valve Body

Common

Tube

Black

Mark

Brazing

Joints

Jumper Tube

Two Capillary

Tubes

Tape Here

FF Capillary

Tube

Break

Here

Break

Here

FZ Capillary

Tube

8. Apply a liberal amount of thermal paste to

the base of the three tubes on the new valve.

Apply a wet cloth to the top of the valve to

help keep the valve cool.

Apply a Wet Cloth

to Top of Valve to

Help Keep Valve Cool

Thermal

Paste

– 30

Page 31

9. Angle the torch so the fl ame is not directed

towards the valve body when brazing the

three joints.

10. Remove the thermal paste residue and dry

the valve body thoroughly. Install the valve

body into the coil.

Freezer Evaporator

The following components must be removed

in the appropriate order to access the freezer

evaporator:

1. Remove the ice bucket, shelves, and drawers.

Note: If necessary, use an adjustable pliers to

carefully install the valve body into the coil. DO

NOT depress on the top of the valve body. See

photo.

11. Remove the old drier by un-brazing or

cutting the condenser loop (halo) as close

as possible to the drier. Install the new drier

assembly (part # WR86X93).

2. Slide the air duct panel upward to remove.

3. Remove the light bulb cover and light bulbs.

4. Remove the four 1/4-in. hex-head screws that

hold the auger assembly in place.

5. The auger motor wiring is connected in two

places:

Note: If necessary, use the condenser loop

extension tubing (part # WR97X238).

Jumper Tube

12. Install the process valve (part # WJ56X61).

Clean and inspect all joints.

13. Evacuate and charge the system. Use original

factory charge quantity of R-134a. (See

Evacuation and Charging Procedure.)

14. Reinstall the rear access cover.

a. Disconnect the top connector.

Disconnect

b. Pull the auger motor assembly forward

and disconnect the second connector.

Disconnect

– 31 –

Page 32

6. Loosen the 2 screws that hold the icemaker

assembly in place and slide it out of the

freezer compartment.

10. Remove the 4 hex-head screws that hold the

evaporator fan shroud in place ( Fig. 1 and

Fig. 2).

Top Hex-head Screws

Fig. 1

7. Loosen the 3 screws on the icemaker bracket,

and slide it out of the freezer compartment.

8. Unclip the light bulb sockets from their

mounting holes and disconnect the sockets.

Note: The bottom hex-head screws are hidden

under the bottom of the evaporator fan shroud.

Bottom Hex-head Screws

Fig. 2

11. Unclip the auger connector plug from the

evaporator fan shroud. Slide the evaporator

fan shroud down and out of the freezer

compartment.

9. Remove the 4 hex-head screws that hold the

freezer evaporator cover in place. Carefully

pull the evaporator cover out of the freezer

compartment.

Auger Connector Plug

– 32

Page 33

12. Disconnect the fan wiring harness

(Disconnect 1). Disconnect the over

temperature thermostat/light bulb wiring

harness (Disconnect 2).

13. Remove the 2 hex-head screws that hold the

fan bracket in place.

Replacing Freezer Evaporator Using the

Brazing Method

Parts Needed:

•

Freezer Evaporator (part # WR85X10061)

•

Drier Assembly (part # WR86X93)

•

Access Tube (part # WJ56X61)

•

Heat Shield Kit (part # WX5X8926)

Disconnect 1

Disconnect 2

Screw

Screw

14. Remove the ground clip from the evaporator

frame.

15. Unclip the evaporator thermistor.

16. Slide the over-temperature thermostat/light

bulb wiring harness out of the fan bracket.

17. Remove the fan bracket.

Caution: A heat shield kit is required for this

procedure to prevent damage to the plastic

interior (liner) of the freezer compartment.

Note: If it is determined that the epoxy joints (the

transition joint between the aluminum and copper

jumper) on the freezer evaporator assembly are

defective, then

LOKRING connectors can be used

to repair the joints. Refer to Pub. No. 31-9067 for

more LOKRING information.

1. Unplug the refrigerator.

2. Remove the rear access cover and evacuate

the sealed system.

3. Remove components necessary to expose

the evaporator. (See

Freezer Evaporator.)

4. Remove the ice bucket, icemaker, auger

assembly, fan motor housing, and fan motor.

5. Note the location of thermistor and thermostat

on top of old evaporator and remove.

6. Remove heater from bottom of evaporator

and discard. Bundle remaining wires and tape

high on the back wall of freezer.

Evaporator Thermistor

Ground Clip

Note: When replacing the evaporator thermistor,

cut the thermistor wires and splice the new

thermistor using bell connectors. Always use

RTV102 silicone to seal the end of the connector

from moisture.

7. Apply a liberal amount of thermal paste to

suction line where it enters the rear wall of

freezer.

8. Insert the brazing shield behind the joint of the

accumulator top and suction line to protect the

liner.

9. Use torch to heat the joint of the accumulator

top, separate the suction line and accumulator

top and clean the suction line surface (Fig. 1

and 2).

10. Using the tubing cutter, cut fresh food

evaporator jumper (right side) tube about 2

inches from the joint outlet end of the fresh

food evaporator. Score and break the capillary

tube about 2 inches from the end of freezer

evaporator inlet jumper (left side) (Fig. 1 and

2).

– 33 –

Page 34

r

FZ

Evaporator

Inlet

Jumper

Brazing Shield

Fig. 1

Top of

Accumulator

Evaporato

Jumper

12. Modify replacement evaporator to accept the

5

/

-in. fresh food evaporator jumper.

16

FF

Modify

Here

11. Loosen the hex-head screws that hold the

evaporator in place. Note locations of the

foam blocks at sides of old evaporator. These

are needed for proper airfl ow. Remove the

foam blocks and save for new evaporator

installation. Remove old evaporator.

Loosen Hex-

Head Screws

Suctio

n

Tube

Line

Capillary

Tube

Cut

Here

Heat

Here

2"

13. Install the new evaporator and tighten all

mounting screws.

14. Connect tubes between top of accumulator

and suction line. Connect tubes between

fresh food evaporator and freezer evaporator

(right side). Insert the capillary tube.

15. Check that the thermal paste is still on the

suction line where it enters the rear wall of the

freezer. If not, apply paste. In addition, apply

thermal paste around epoxy joints on the new

evaporator to prevent the heat from damaging

joint integrity.

16. Protect the freezer fl oor from molten

solder during brazing. Braze suction line to

accumulator on new evaporator. Angle torch

so that fl ame is directed away from rear wall

when brazing.

Remove

Screw

Fig. 2

FF

Evaporator

Outlet

Cut

Here

2"

17. Move the brazing shield behind the capillary

joint and braze the capillary tube.

– 34

Page 35

18. Move the brazing shield behind the fresh food

jumper to the freezer evaporator. Braze the

jumper tube joint. Remove the brazing shield.

Clean and inspect all joints.

19. Remove the old drier by cutting the halo loop

as close as possible to the drier. Install the

new drier assembly (part # WR86X93) making

sure that there is suffi cient space between the

tubing.

Replacing Freezer Evaporator Using the

LOKRING Method

Parts Needed:

Freezer Evaporator (part # WR85X10061)

•

Drier Assembly (part # WR86X93)

•

Access Tube (part # WJ56X61).)

•

LOKRING Connectors (part # WR97X10021)

•

20. Install the access tube. Clean and inspect

joints.

21. Replace the heater supplied with the

evaporator. Reinstall foam blocks, thermostat

and thermistors. Dress wiring.

22. Evacuate and charge the system. Use original

factory charge quantity of R-134a. (See

Evacuation and Charging Procedure.)

23. Replace all component parts in the freezer.

24. Reinstall the rear access cover.

Note: If it is determined that the epoxy joints (the

transition joint between the aluminum and copper

jumper) on the freezer evaporator assembly are

defective, then LOKRING connectors can be used

to repair the joints. Refer to Pub. No. 31-9067 for

more LOKRING information.

1. Follow steps 1 through 6 under

Freezer Evaporator Using the Brazing Method.

Replacing

2. Using the tubing cutter, cut the freezer

evaporator jumper of the check-valve

assembly (top) as close as possible to the

joint of the copper jumper. Cut the jumper

tube (left side) on the inlet of the freezer

evaporator (capillary joint) as close as

possible to the epoxy joint.

Suction

Cut

Here

Tube

Line

– 35 –

Capillary

Tube

Cut

Here

FF

Evaporator

Outlet

Page 36

3. Loosen the hex-head screws that hold the

evaporator in place. Note locations of the

foam blocks at sides of old evaporator. These

are needed for proper airfl ow. Remove the

foam blocks and save for new evaporator

installation. Remove old evaporator.

Loosen HexHead Screws

4. Modify replacement evaporator to use

LOKRING connectors.

a. Using the tubing cutter, cut the jumper

tube (top) at the outlet end of the freezer

evaporator. Leave as much of the straight

tube portion as possible from the joint of

the check-valve assembly. Discard the

check-valve assembly.

5. Install the new evaporator and tighten all

mounting screws.

6. Remove the old drier by cutting the halo

loop as close as possible to the drier. Install

the new drier assembly (make sure there is

suffi cient space between the tubing).

7. Install the access tube. Clean and inspect

joints.

8. Replace the heater supplied in the kit.

Reinstall foam blocks, thermostat and

thermistors. Dress the wiring.

9. Evacuate and charge the system. Use original

factory charge quantity of R-134a. (See

Evacuation and Charging Procedure.)

10. Replace all component parts in the freezer.

11. Reinstall the rear access cover.

b. Using the tubing cutter, cut the jumper

tube (left side) on the inlet end of the

evaporator (capillary joint) about 3 inches

from epoxy joint. Make two joints using

the LOKRING connectors for 5/

-in. copper

16

to copper joints.

Cut

Here

Cut

Here

– 36

Page 37

Fresh Food Evaporator

1. Remove the custom cool drawer and

necessary drawers and covers above the

custom cool drawer, to expose the evaporator

cover housing.

2. Remove the water line coil cover.

Note: The water line coil cover is slotted. To

remove it, slide the water line coil cover toward

the door opening.

3 Remove the 3 Philips-head screws that hold

the fresh food evaporator fan cover in place.

Screw

Screw

Screw

5. Loosen the 2 Phillips-head screws that hold

the fresh food evaporator in place.

Screw

Screw

6. Carefully lift and pull the fresh food evaporator

forward. Cut the tie strap that holds the

thermistor block in place.

7. Remove the evaporator thermistor and block

from the evaporator.

Evaporator Cover

Water Line Coil Cover

4. Carefully pull the cover forward, then

disconnect the fresh food evaporator fan.

Disconnect

FF Evaporator Fan

– 37 –

Page 38

Replacing Fresh Food Evaporator Using

the Brazing Method

7. Pull the evaporator away from the liner and

remove the thermistor from the aluminum

block attached to the rear of the evaporator.

Parts Needed:

•

Fresh Food Evaporator (part # WR85X10060)

•

Drier Assembly (part # WR86X93)

•

Access Tube (part # WJ56X61)

•

Heat Shield Kit (part # WX5X8926)

Caution: A heat shield kit is required for this

procedure to prevent damage to the plastic

interior (liner) of the freezer compartment.

Note: If it is determined that the epoxy joints (the

transition joint between the aluminum and copper

jumper) on the freezer evaporator assembly are

defective, then

to repair the joints. Refer to Pub. No. 31-9067 for

more LOKRING information.

1. Unplug the refrigerator.

2. Remove the rear access cover and evacuate

the sealed system. (See Evacuation and

Charging Procedure.)

3. Remove components necessary to expose

both the freezer and fresh food evaporators.

(See Freezer Evaporator and Fresh Food

Evaporator.)

LOKRING connectors can be used

8. Look into the freezer compartment and locate

the epoxy joints on the tubes leading to the

fresh food evaporator. (These joints will be

located on the right hand side of the freezer

evaporator.)

Epoxy

Joints

4. Remove the 2 foam tubes that are wire tied

to the inlet and outlet tubes of the fresh food

evaporator.

5. Remove the Styrofoam block that is inserted

into the opening in the mullion wall and

discard. A replacement is provided.

6. Loosen the 2 screws that attach the fresh

food evaporator to the liner.

Styrofoam

Block

Wire

Ti

Foam

T

ubes

e

Loosen 2 Screws

9. To allow easier access to the epoxy joints,

pull them away from the side of the freezer

evaporator into the freezer compartment.

10. Using the tube cutter, cut the 5/16 -in. OD

copper tube as close to the epoxy joint as

possible. Score and break the capillary tube

as close to the braze joint as possible.

11. Remove the fresh food evaporator.

12. Install new fresh food evaporator.

– 38

Page 39

13. Connect the capillary tube to the inlet tube

of the evaporator. Connect the 5/16 -in.

OD copper tube to the outlet tube of the

evaporator (remove any excess length as

required to obtain the correct fi t).

14. Apply a liberal amount of thermal paste

around both epoxy joints to prevent heat from

damaging joint integrity.

15. Install a metal brazing shield between the

joints and the plastic liner.

16. Protect the freezer fl oor from molten solder

during brazing.

17. Angle torch so that the fl ame is directed away

from the plastic liner. Braze both joints. Clean

and inspect joints. Remove the brazing shield.

18. Clean thermal paste off the joints. Dress the

joints to the right of the freezer evaporator

so the freezer evaporator cover can be

reinstalled without interference.

19. Reinsert the thermistor into the aluminum

block on the rear of the new fresh food

evaporator.

20. Attach the evaporator to the fresh food liner

using the original screws. Ensure that the

drain pan is properly positioned. Install a new

Styrofoam block into the hole of the mullion.

Attach foam tubes to evaporator inlet/outlet

tubes using wire tie provided.

21. Remove the old drier by cutting the condenser

loop as close as possible to the drier. Install

the new drier assembly, making sure that

there is suffi cient space between the tubing.

Install the access tube on the compressor.

22. Evacuate and charge the system. Use original

factory charge quantity of R-134a. (See

Evacuation and Charging Procedure.)

Replacing Fresh Food Evaporator Using

the

LOKRING Method

Parts Needed:

Drier Assembly (part # WR86X93)

•

Process Tube (part # WJ56X61

•

LOKRING Connectors (part # WR97X10021)

•

Note: If it is determined that the epoxy joints

(transition joint between the aluminum and copper

jumper) on the freezer evaporator assembly are

defective, then LOKRING connectors can be used

to repair the joints. Refer to Pub. No. 31-9067 for

more LOKRING information.

1. Follow steps 1 through 9 under Replacing

Fresh Food Evaporator Using the Brazing

Method.

2. Using the tube cutter, cut both copper tubes

as close to the epoxy joint as possible. Leave

as much 5/16 -in. tubing as possible for a good

LOKRING connection.

3. Remove the fresh food evaporator.

4. Modify replacement evaporator to use

LOKRING connectors.

a. Using the tubing cutter, cut the jumper

tube at the outlet end of the evaporator

2 inches from the epoxy joint.

b. Cut the jumper tube on the inlet end of the

evaporator (capillary joint) 11/2 inches from

the epoxy joint. Make two joints using the

LOKRING connectors for

copper joints.

Inlet Tube

Outlet Tube

5

/

-in. copper to

16

23. Replace all component parts in both the

freezer and the fresh food compartments.

24. Reinstall the rear access cover.

– 39 –

1-1/2"

Epoxy

Joints

2"

Page 40

5. Reinsert the thermistor into the aluminum

block on the rear of the new fresh food

evaporator.

6. Attach the evaporator to the fresh food liner

using the original screws. Ensure that drain

pan is properly positioned. Install a new

Styrofoam block into the hole of the mullion.

Attach foam tubes to the evaporator inlet/

outlet tubes using wire tie provided.

7. Remove the old drier by cutting the condenser

loop as close as possible to the drier. Install

the new drier assembly (make sure there is

suffi cient space between the tubing). Install

the process tube on the compressor.

8. Evacuate and charge the system. Use original

factory charge quantity of R-134a. (See

Evacuation and Charging Procedure.)

Check Valve

Check Valve

A nylon piston inside the check valve fl oats

•

back and forth, depending upon refrigerant

fl ow.

The check valve prevents refrigerant from

•

fl owing back into the freezer evaporator.

9. Replace all component parts in both the

freezer and the fresh food compartments.

10. Reinstall the rear access cover.

Accumulator

The accumulator collects any liquid refrigerant

•

left in the evaporator before it enters the

suction line.

The liquid refrigerant pools in the bottom

•

of the accumulator until it is drawn into the

compressor as a vapor.

The accumulator comes as a part of the

•

freezer evaporator. It is not available

separately.

When the main control rotates the 3-way

•

valve for fresh food only cooling, the check

valve will prevent refrigerant from fl owing

in the freezer evaporator (refrigerant will

naturally fl ow to the coldest area).

The check valve is only available with a new

•

freezer evaporator.

Caution: Do not attempt to replace only the

check valve. The nylon piston in the check valve

is extremely heat sensitive.

– 40

Page 41

Troubleshooting

Control Diagnostics

Enter the diagnostic mode by pressing both the freezer temperature (COLDER and WARMER) pads

and the refrigerator temperature (COLDER and WARMER) pads simultaneously. All four pads must

be held for approximately 3 seconds. Blinking "0"s in both displays indicate the refrigerator has

entered the test mode.

Enter the appropriate display numbers

as shown below and press any pad other

than the temperature pads to activate

that test mode. Not all test modes are

available on all models.

Freezer

Display

02

04

0 6 Temperature Control LED Test