GE JGP989, Profile JGP989 Series Technical Service Manual

C

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Profile

Gas-on-Glass

Cooktop

MODEL SERIES:

JGP989

PUB # 31-9080 06/01

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major

appliance may result in personal injury and property damage. The

manufacturer or seller cannot be responsible for the interpretation

of this information, nor can it assume any liability in connection

with its use.

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death. If you smell gas:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in

the building.

- Immediately call the gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach the gas supplier, call the fire department.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers

used to complete a path to ground are removed for service, they

must be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2001

All rights reserved. This service guide may not be reproduced in whole or in

part in any form without written permission from the General Electric Company.

Table of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conversion to LP (Propane) Gas . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications and Nomenclature5 . . . . . . . . . . . . . . . . . . . . . . 8

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cooktop Features and Controls. . . . . . . . . . . . . . . . . . . . . . . . 10

Mechanical Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Component and Connector Locator Views . . . . . . . . . . . . . . . . . . 21

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

[[Title]]

– 1 –

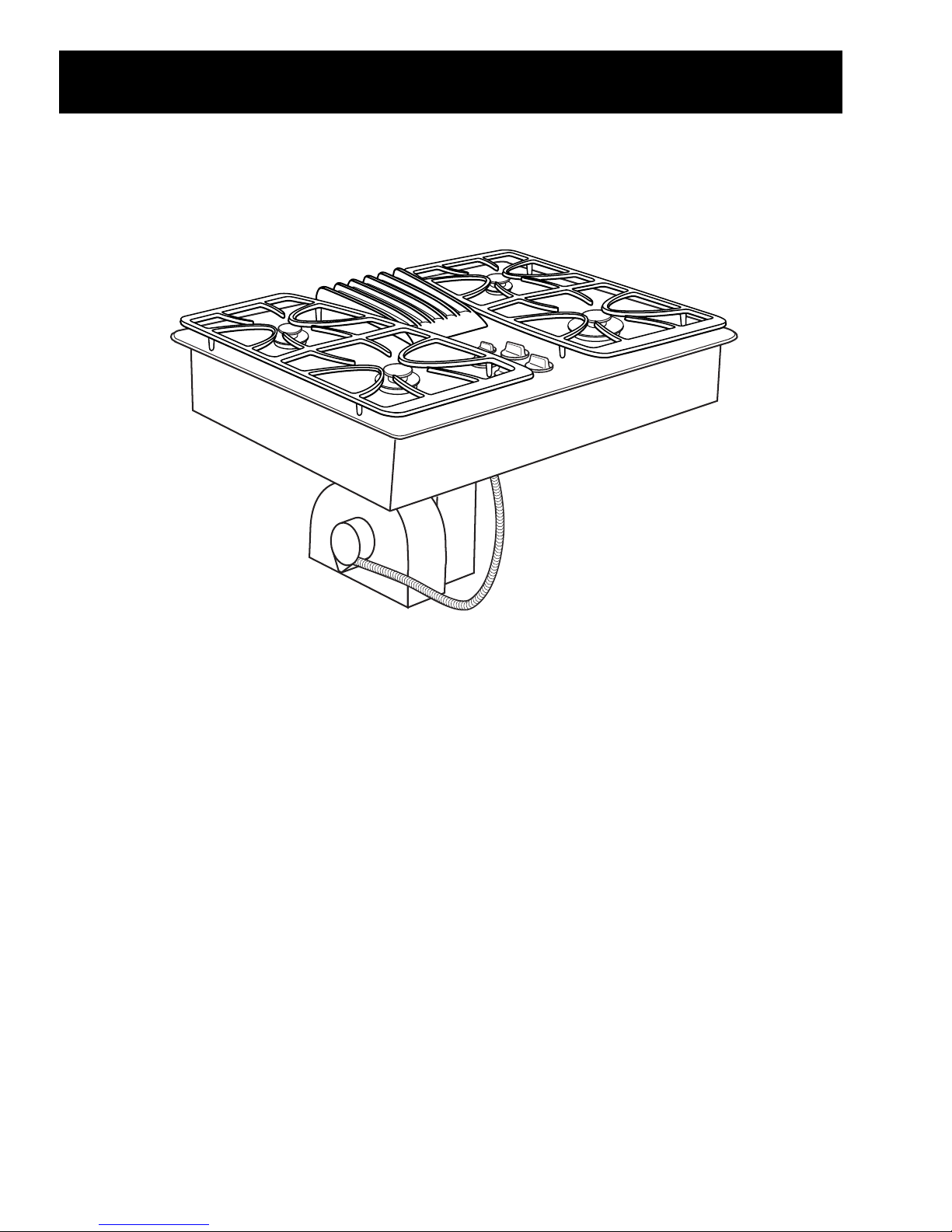

Introduction

The new Profile Gas-on-Glass Downdraft Model

cooktops make an eloquent statement of style,

convenience, and kitchen planning flexibility .

Whether chosen for its purity of design, attention

to detail, or both of these reasons–you’ll find these

downdraft gas cooktops’ superior blend of form

and function will be a delight for years to come.

These cooktops contain several new features,

such as glass cooktop surfaces, sealed burners,

and a 400-CFM downdraft venting system.

The information on the following pages will help

you service these cooktops effectively and

efficiently.

– 2 –

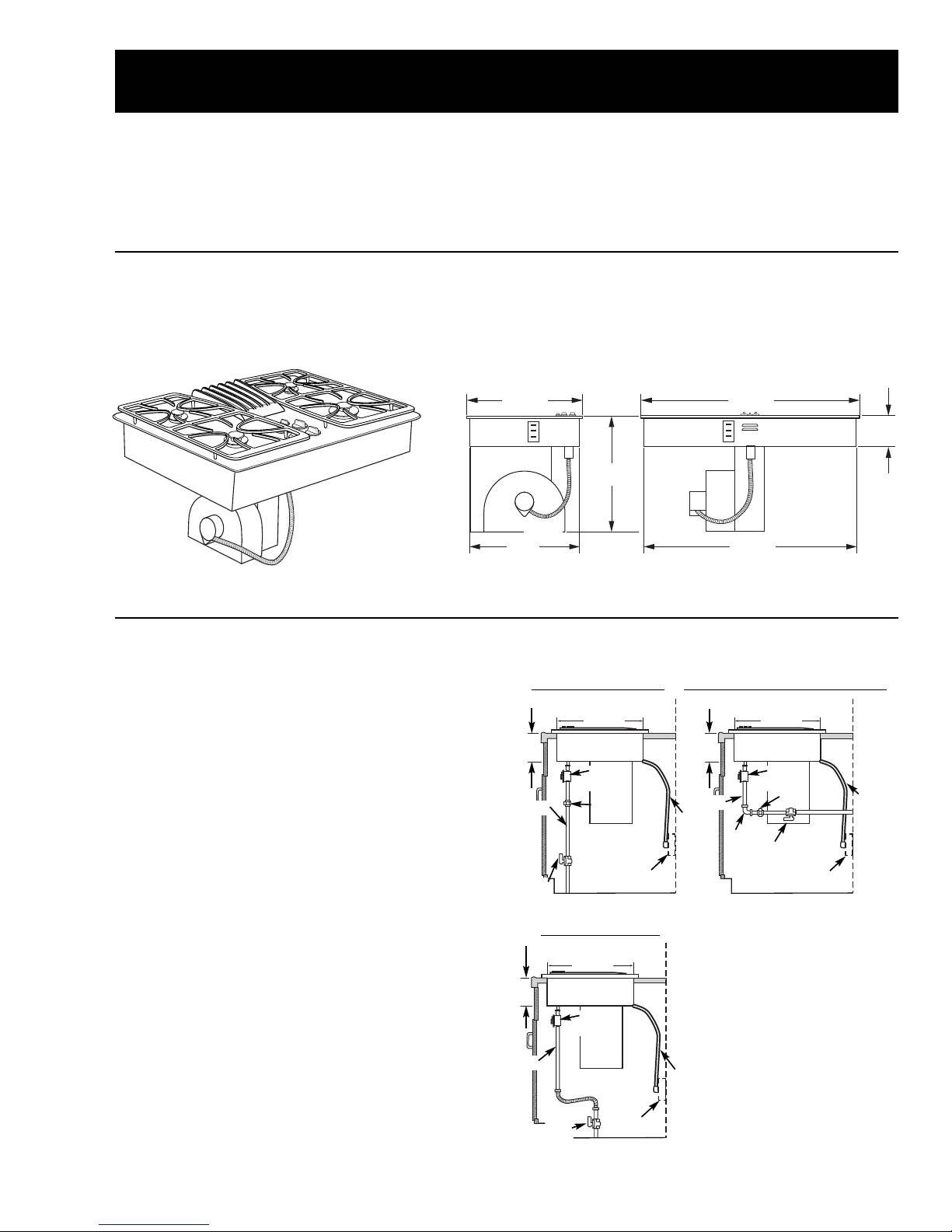

Installation

Never reuse old flexible

connectors. The use

of old flexible connectors

can cause gas leaks

and personal injury.

Always use NEW

flexible connectors

when installing a

gas appliance.

205⁄8″

Cutout

205⁄8″

Cutout

205⁄8″

Cutout

6″ Min.

Min.

Electrical

outlet:

12″ above

cabinet

floor

Electrical

outlet:

12″ above

cabinet

floor

Pressure

regulator

Pressure

regulator

Pressure

regulator

Electrical

outlet:

12″ above

cabinet

floor

6″ Min.

Shut-off

valve

Shut-off

valve

Shut-off

valve

″ Pipe

1

⁄2″ Pipe

1

⁄2″ Pipe

Electrical

cord

42″ long

Electrical

cord

42″ long

Electrical

cord

42″ long

Solid Pipe Connection

Solid Pipe Connection with Elbow

Union

Elbow

Union

Flexible Connection

217⁄8″

201⁄2″

19″

6″ Dia.

297⁄8″

6″

283⁄4″

WARNING: Before beginning the installation,

switch power off at the service panel and lock the

service disconnecting means. When the service

disconnecting means cannot be locked, securely

fasten a warning tag to the service panel.

30-in. Cooktop Dimensions

Dimensions for reference only .

Unit shown fully assembled.

Unit must be vented to the outside!

Gas Supply

These cooktops are designed to operate on natural

gas at 4 in. of water column pressure or on LP gas

at 10 in. of water column pressure. For proper

operation, the maximum inlet pressure to the

regulator must be no more than 10 in. of water

column pressure for natural gas and 14 in. of

water column pressure for LP gas.

Gas Supply Shutoff V alve

The cooktop itself is not equipped with a gas shutof f valve. If installed correctly, a shutoff valve will be

in the main gas supply line “upstream” of the

appliance pressure regulator .

Measuring the Gas Pressure

Supplied to the Burners

Connect the tubing supplied with a manometer

over one end of the manometer . Remove a burner

cap and head from the appliance and place the

other end of the tubing over the burner orifice. T u rn

on the gas to the orifice you are testing and light at

least one other burner to serve as a load.

Before You Begin...

Note: The complete installation instructions

are inclosed with the

Use and Care Manual

Carefully read and follow these instructions.

6”

1/2

– 3 –

.

PART QUANTITY

Brass orifices 4

Stick-on rating label 1

Installation instructions 1

Conversion to LP (Propane) Gas

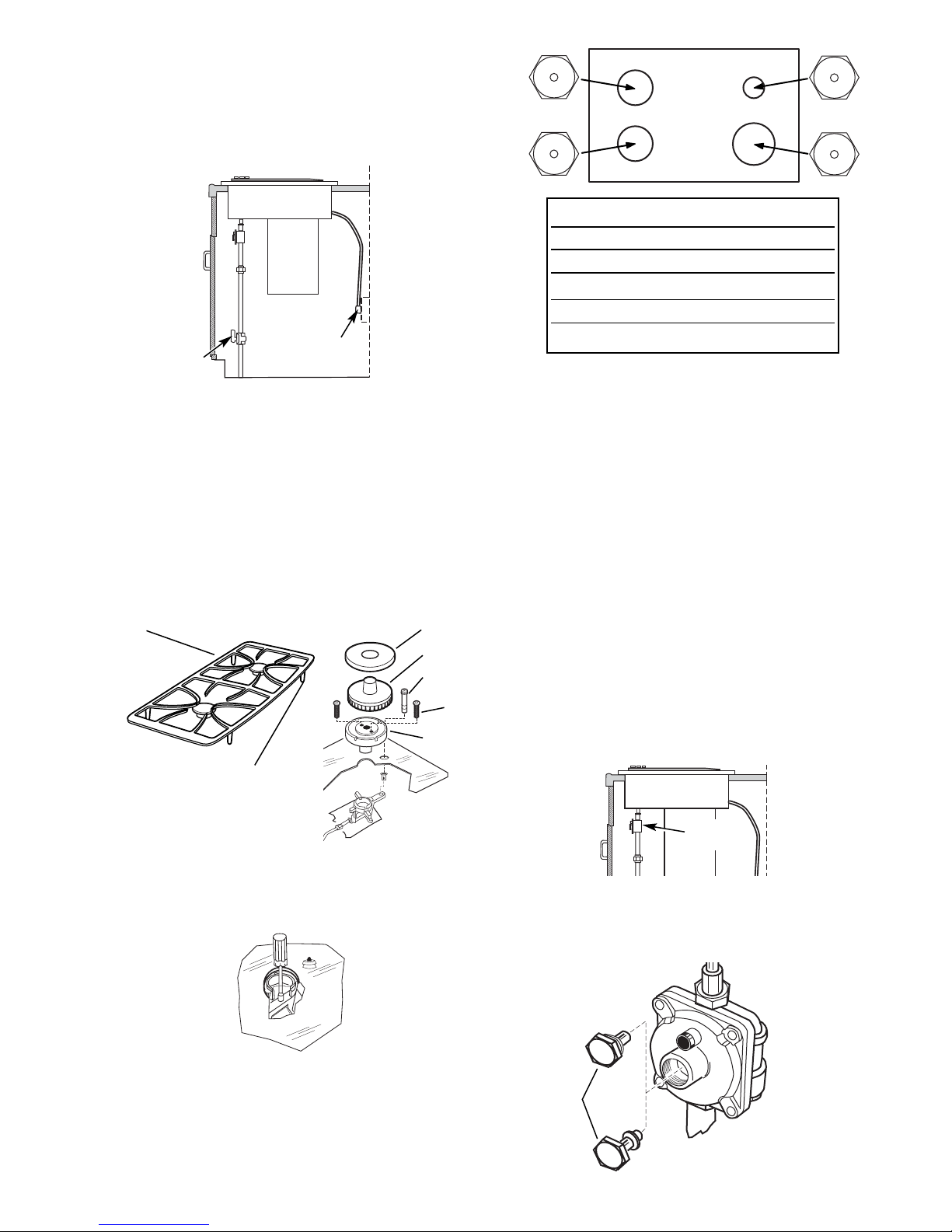

Adjustable wrench 9/32″ (7 mm) Nutdriver T15 Torx driver

Small, thin-blade flat screwdriver with approximately 1/8″

blade width is needed to access the calibration screw.

Note: Before you begin, read these

instructions completely and carefully.

The cooktop is factory set for natural gas

operation. T o use LP ( pr opane) gas, the regulator

and burner orifices must be converted. The LP

orifice spuds for the cooktop burners can be

located within the literature package shipped with

the unit.

If you convert to LP gas, keep instructions and

natural gas orifices to convert back for use with

natural gas.

Product failure due to improper installation is not

covered under the GE Appliances Warranty.

WARNING: If you are using LP (propane) gas, all

adjustments described in the following steps must

be made before attempting burner adjustments or

using the cooktop.

WARNING: This conversion kit shall be installed

by a qualified service agency in accordance with

the manufacturer’s instructions and all applicable

codes and requirements of the authority having

jurisdiction. If the information in these instructions

is not followed exactly , a fire, explosion, or

production of carbon monoxide may result,

causing property damage, personal injury , or loss

of life. The qualified service agency is responsible

for the proper installation of this kit. The installation

is not proper and complete until the operation of

the converted appliance is checked as specified in

the manufacturer’s instructions supplied with the

kit.

Parts Included

Gas Supply

With the installation of this conversion kit, the

cooktop should operate on LP gas at 10 in. of

water column pressure.

The pressure regulator must be connected in

series with the manifold of the cooktop and must

remain in series with the supply line. For proper

operation, the maximum inlet pressure to the

regulator must be no more than 14 in. water

column pressure for LP gas.

When checking the regulator , the inlet pressure

must be at least 1 in. greater than the regulator

output setting. If the regulator is set for 10 in. of

water column pressure, the inlet pressure must be

at least 1 1 in.

T ools You Will Need

Note: Disconnect the cooktop and the individual

shutoff valve from the gas supply piping system

during any pressure testing of that system at test

pressures greater than 1/2 psig. Isolate the

cooktop from the gas supply piping system by

closing the individual manual shutoff valve to the

cooktop during any pressure testing of the gas

supply piping system at test pressures equal to or

greater than 1/2 psig.

– 4 –

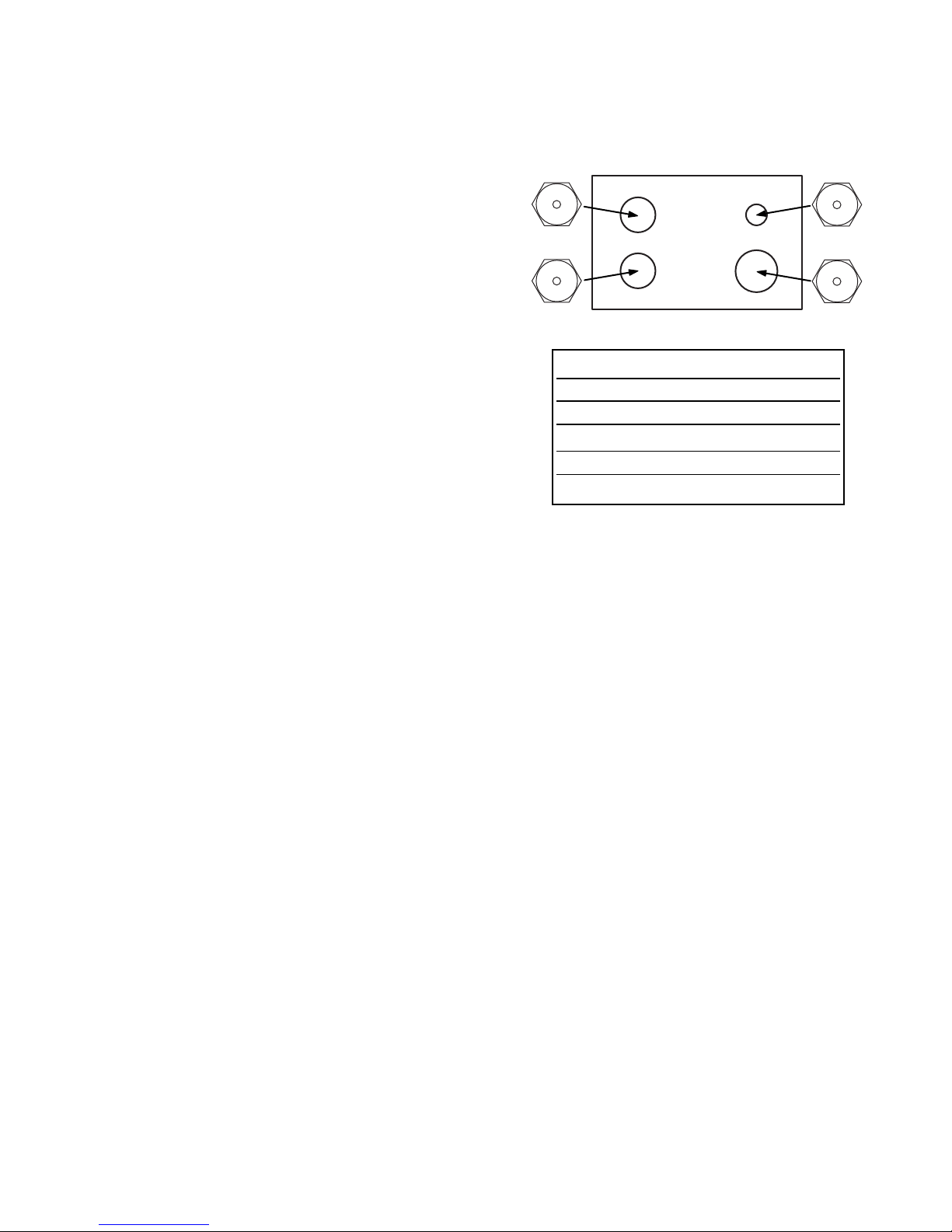

LP (Propane) Gas 10″ W. C . P.

Burner Output Rating in BTU/HR

Location BTUs Orifice Size

LF, LR 8,500 0.84 Lmm

RR 5,500 0.71 Lmm

RF 11,000 0.99 Lmm

Front

Pressure

regulator

Natural gas

LP gas

Nut

Turn OFF Gas and Electric Supply

Shut-off valve

Electrical supply

Grate

Brass

locator foot

Burner cap

Electrode

Burner base

Burner head

Burner

base

screw (2)

Before you begin, turn OFF the gas supply at the

shut-off valve. Disconnect the electrical supply

from the cooktop.

Convert Surface Burners

1. First remove, convert, and replace the left-side

surface burners and then the right-side surface

burners. Remove the grates, burner caps, and

burner heads. Remove the screws securing the

burner bases to the burners. Pull out the

electrodes without removing the electrode leads.

84

L

84

L

71

L

99

L

Note: For operation at elevations above 5000 ft.(1500 m),

equipment ratings shall be reduced at a rate of 2% for each

1000 ft. (300 m) above sea level before selecting

appropriately sized equipment, i.e., use smaller orifices.

Caution: When attaching the burner base to the

glasstop unit, tighten to 12 in./lbs max torque.

Overtightening will cause damage.

4. Replace the gaskets, burner bases, and

electrodes. Install the 2 screws in each burner

base. Do not overtighten. The maximum torque

is 10 in./lbs. Push the igniters all the way down

into the burner head.

2. Remove the brass orifice spud in the chimney

of each burner using a 9/32-in. (7 mm) nutdriver .

Note: The LP orifices are shorter than the natural

gas orifices.

3. Install the LP orifice spuds in their correct

positions by number .

5. Install the burner heads, burner caps, and

grates in their original burner positions.

Convert the Pressure Regulator

1. Locate the pressure regulator under the rear of

the cooktop.

2. Remove the nut from the pressure regulator

with an adjustable wrench.

– 5 –

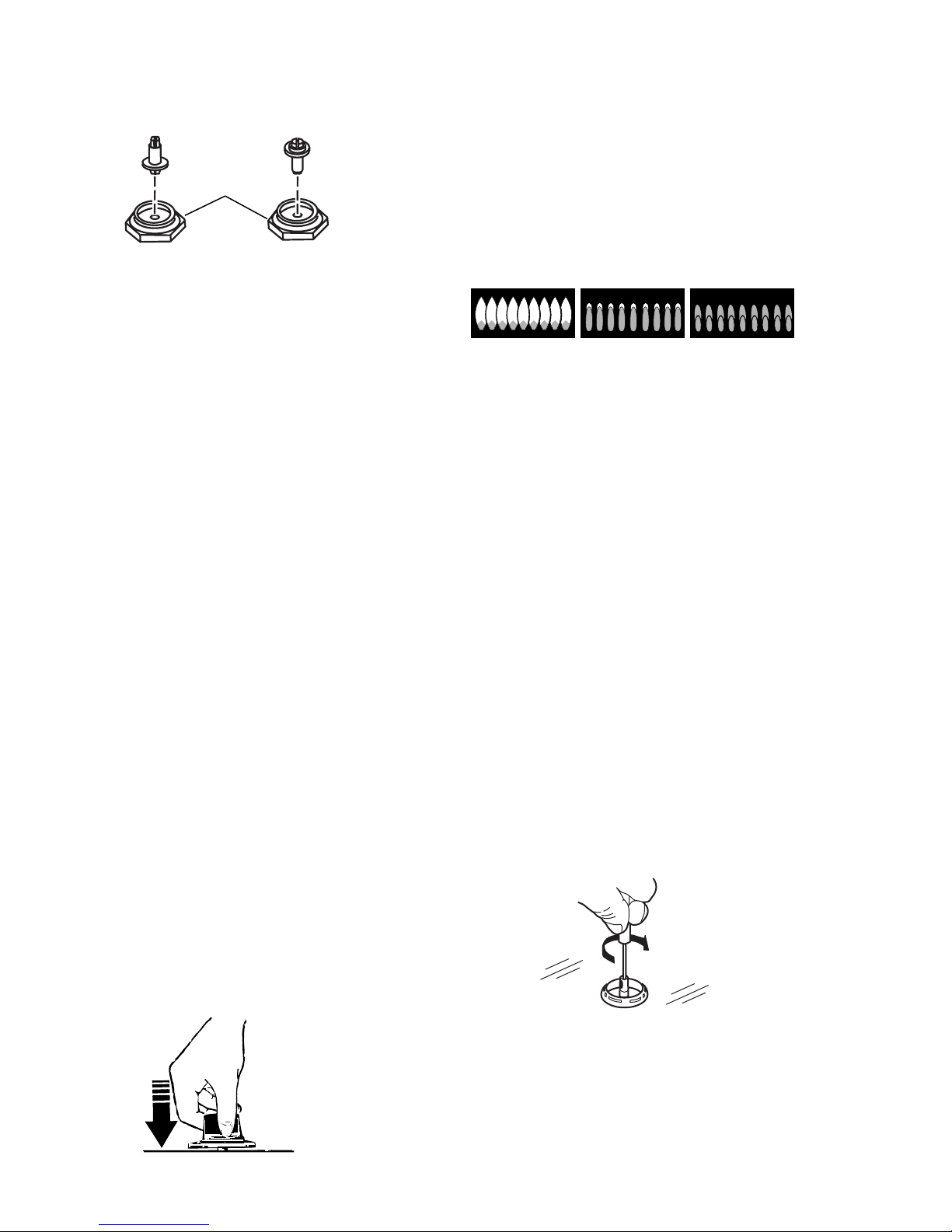

3. Remove the plastic pin from the inside of the

Natural gas LP gas

Nut

A–Yellow flames

Call for service

B–Yellow tips

Normal for

LP gas

C–Soft blue flames

Normal for

natural gas

nut, turn the pin 180 degrees and snap the pin

back into the nut.

4. Reinstall the nut onto the regulator .

5. Apply the LP conversion label next to the rating

plate.

T est for Leaks

2. Push down one control knob and turn to the

LITE position. The igniter will spark and the

burner will light. The first test may require some

time while air is flushed out of the gas line.

3. Check to determine if your burner flames are

normal. If burner flames look like A, call for

service. Normal burner flames should look like

B or C, depending on the type of gas you use.

With LP gas, some yellow tipping on outer

cones is normal.

WARNING: Do not use a flame to check for leaks!

Do not use the cooktop until all connections have

been leak tested.

Perform leak test per the following instructions:

1. Purchase a liquid leak detector or prepare a

soap solution of one part water , one part liquid

detergent.

2. When all connections have been made, make

sure all cooktop controls are turned to OFF and

turn the gas supply valve to ON.

3. Apply the liquid leak detector or the soap solution around all connections from the shutoff

valve to the cooktop.

4. A leak is identified by a flow of bubbles from the

area of the leak.

5. If a leak is detected, turn the gas supply off.

T ighten the fitting. T urn the gas ON and test

again. If the leak persists, turn the gas supply

OFF and contact your dealer for assistance.

Do not attempt to operate the cooktop if a leak

is present.

4. Turn the knob to OFF.

5. Repeat the procedure for each burner .

Adjusting Low Flame (Simmer) Setting

WARNING: The following adjustments must be

made before turning on the burner . Failure to do so

could result in serious injury . Be sure pressure

regulator has been converted.

Note: The top burner valves have low flame/

simmer adjustment screws in the center of the

control shafts. A flashlight may be needed to

locate the screw . A small thin-blade screwdriver

(approximately 1/8-in. blade width) is needed to

access the screw .

1. Light 2 other burners and set the knobs to a

MEDIUM to HI setting.

2. Light the burner to be adjusted and turn the

knob to LOW .

Check Ignition

1. Connect electrical supply cord.

3. Remove the knob and insert a screwdriver into

the valve shaft.

4. T urn the adjustment screw until the flame

– 6 –

reaches the desired size.

Front

Natural Gas 4″ W. C . P.

Burner Output Rating in BTU/HR

Location BTUs Orifice Size

LF, LR 9,100 1.50 Nmm

RR 5,500 1.22 Nmm

RF 11,500 1.69 Nmm

5. Perform a flame stability test with the downdraft

fan on HIGH.

Flame Adjustments

Note: The burners do not have air shutters adjust-

ments and use nonadjustable orifices. If the

flame lifts off the burner , or if you experience

yellow-tipped flames and/or soot in the flames,

be sure to check the following:

1. Gas pressure: 4-in. W .C.P. (natural) and 10-in.

W .C .P. (LP).

2. Inspect orifice to be sure it is drilled in the

center and free of debris or burrs.

3. Be sure the correct size orifice is in the proper

location.

4. Make sure the cooktop was properly converted

if on LP.

5. If the cause of sooting cannot be found in the

above checks, replace the orifice with one

having a smaller diameter opening.

Testing Flame Stability

1. With the downdraft vent fan on HI, turn the

burner knob from HI to LOW quickly . If the LOW

flame goes out, increase the flame size and

test again.

Converting Back to Natural Gas

Reverse the procedure for converting to LP ,

locating the orifices as follows:

150

N

150

N

Note: For operation at elevations above 5000 ft.

(1500 m), equipment ratings shall be reduced at a

rate of 2% for each 1000 ft. (300 m) above sea

level before selecting aproximately sized

equipment, ie., use smaller orifices.

122

169

N

N

2. With the burner on the LOW setting, open and

close the cabinet door under the cooktop. If the

flame is extinguished by the air currents created by the door movement, increase the flame

height and test again.

Flame Recheck

After the adjustment is made, turn all burners OFF .

Ignite each burner individually . Observe the flame

at the HI position. Rotate the valve to the LOW

position and be sure the flame size decreases as

the valve is rotated counterclockwise.

Note: Once the conversion is complete and

checked OK, fill out the LP sticker and include

your name, organization, and date conversion was

made. Apply the sticker near the cooktop gas inlet

opening to alert others in the future that this

appliance has been converted to LP . If converting

back to natural gas from LP, please remove the

sticker so others know the appliance is set to use

natural gas.

– 7 –

Loading...

Loading...