GE PGP966DET1BB, PGP966SET1SS Installation Guide

I stallatio

36"SealedGasCooktop

I structio s

r_ In Canada, call 1.800.561.3344 or Visit our Website at: www.geappliances.ca

j Ouestions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

IN THE COMMONWEALTH OF

JGP633, JGP970, PGP966, ZGU36

FOR YOUR SAFETY:

MASSACH USETTS:

A WARNING - iftheinformation

, This product must be installed by a licensed

plumber or gas fitter.

, When using ball-type gas shut-off valves, they

shall be the T-handle type.

, A flexible gas connector, when used, must not

exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

.IMPORTANT - Savetheseinstructions

for local inspector's use.

, IMPORTANT - ObserveaUgoverning

codes and ordinances.

, Note to Installer- Be sure to leave these

instructions with the Consumer.

Note to Consumer - Keep these instructions for

future reference.

, Product failure due to improper installation is not

covered under the Warranty.

in this manual is not followed exactly, a fire,

explosion or gas leak may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance!

WHAT TO DO IFYOU SMELL

GAS:

Do not try to light any appliance. Do not touch

any electrical switch; do not use any phone in

your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

, If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

i

WARNING - Thisappliancemust be

properlygrounded.

. IMPORTANT - Leak testingof the

applianceshallbe conducted accordingto the

manufacturer's instructions.

, Proper installation is the responsibility

of the installer and product failure due to

improper installation is NOT covered under

warranty.

A WARNING - Disconnectallelectrical

power at the main circuit breaker

or fuse box before installing.

31-i0834 (ii-ii GE) i

This cooktop has been design certified

by CSA International. You'll find safety precautions

in your Owner's Manual.

Read them carefully.

Installation of this cooktop must conform with

local codes or, in the absence of local codes with

the National Fuel Gas Code, ANSI Z223.1/NFPA

54-Latest edition.

Be sure your cooktop is installed properly by a

qualified installer or service technician.

To eliminate reaching over surface burners,

cabinet storage above burner should be avoided.

Do not install the unit near an outside door or

where a draft may affect its use.

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the proper

voltage and frequency and connected to an

individual, properly grounded branch circuit,

protected by a circuit breaker or fuse having

amperage as noted on the rating plate.

We recommend you have the electrical wiring and

hookup of your cooktop connected by a qualified

electrician. After installation, have the electrician

show you where your main cooktop disconnect is

located.

Check with your local utilities for electrical codes

which apply in your area. Failure to wire your

cooktop according to governing codes could result

in a hazardous condition.

If there are no codes, your cooktop must be wired

and fused to meet the requirements of the National

Electrical Code, ANSI/NFPA No. 70--Latest edition.

You can get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, P1A 02269

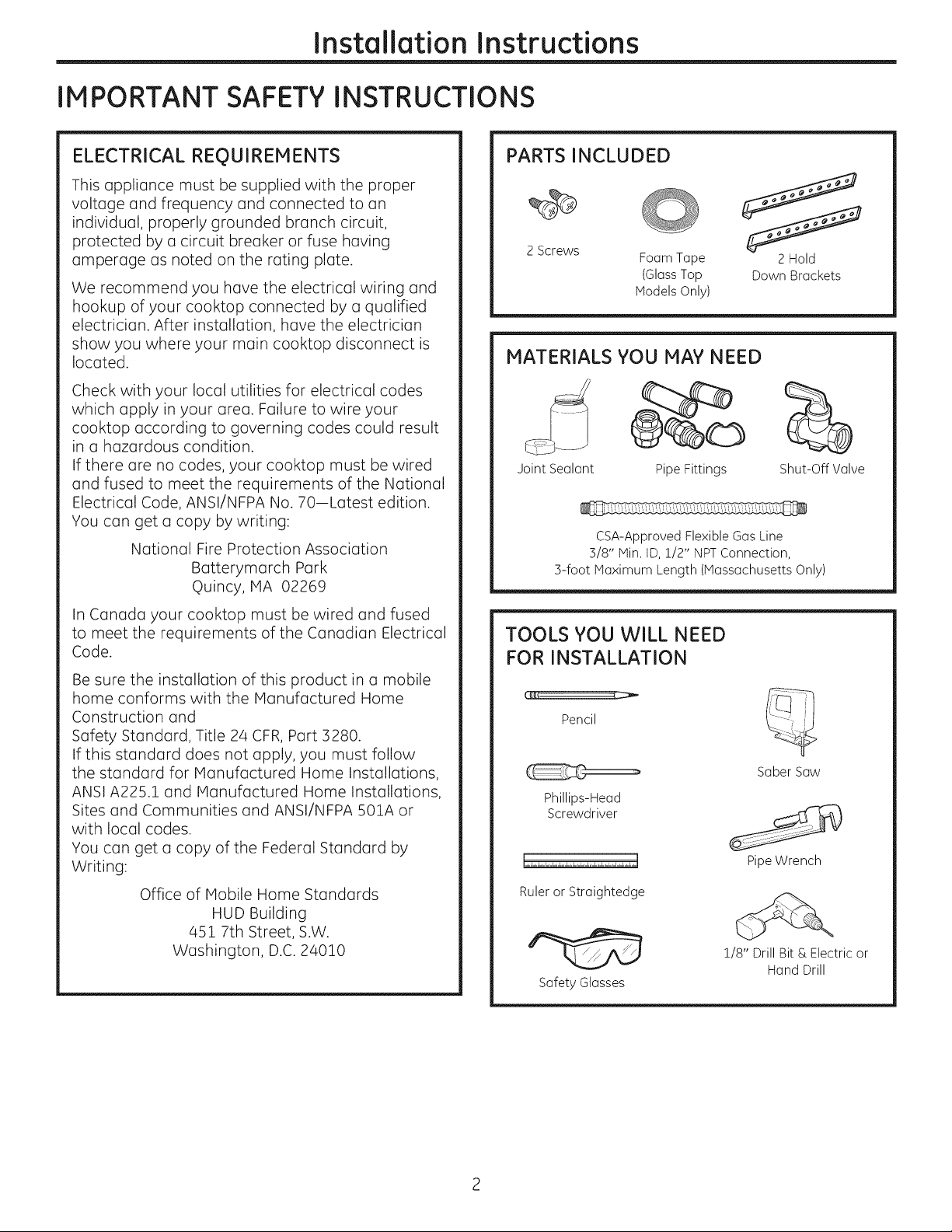

PARTS INCLUDED

2 Screws

Foam Tape

(GlassTop

Models Only)

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings

CSA-Approved Flexible Gas Line

3/8" Min. ID,1/2" NPTConnection,

3-foot Maximum Length (Massachusetts Only)

2 Hold

Down Brackets

Shut-Off Valve

In Canada your cooktop must be wired and fused

to meet the requirements of the Canadian Electrical

Code.

Be sure the installation of this product in a mobile

home conforms with the Manufactured Home

Construction and

Safety Standard, Title 24 CFR, Part 3280.

If this standard does not apply, you must follow

the standard for Manufactured Home Installations,

ANSI A225.1 and Manufactured Home Installations,

Sites and Communities and ANSI/NFPA 501A or

with local codes.

You can get a copy of the Federal Standard by

Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

TOOLS YOU WILL NEED

FOR INSTALLATION

Pencil

SaberSaw

Phillips-Head

Screwdriver

Pipe Wrench

Ruler or Straightedge

!/8" Drill Bit & Electric or

Hand Drill

Safety Glasses

Installation Instructions

PRE-INSTALLATION CHECKLIST

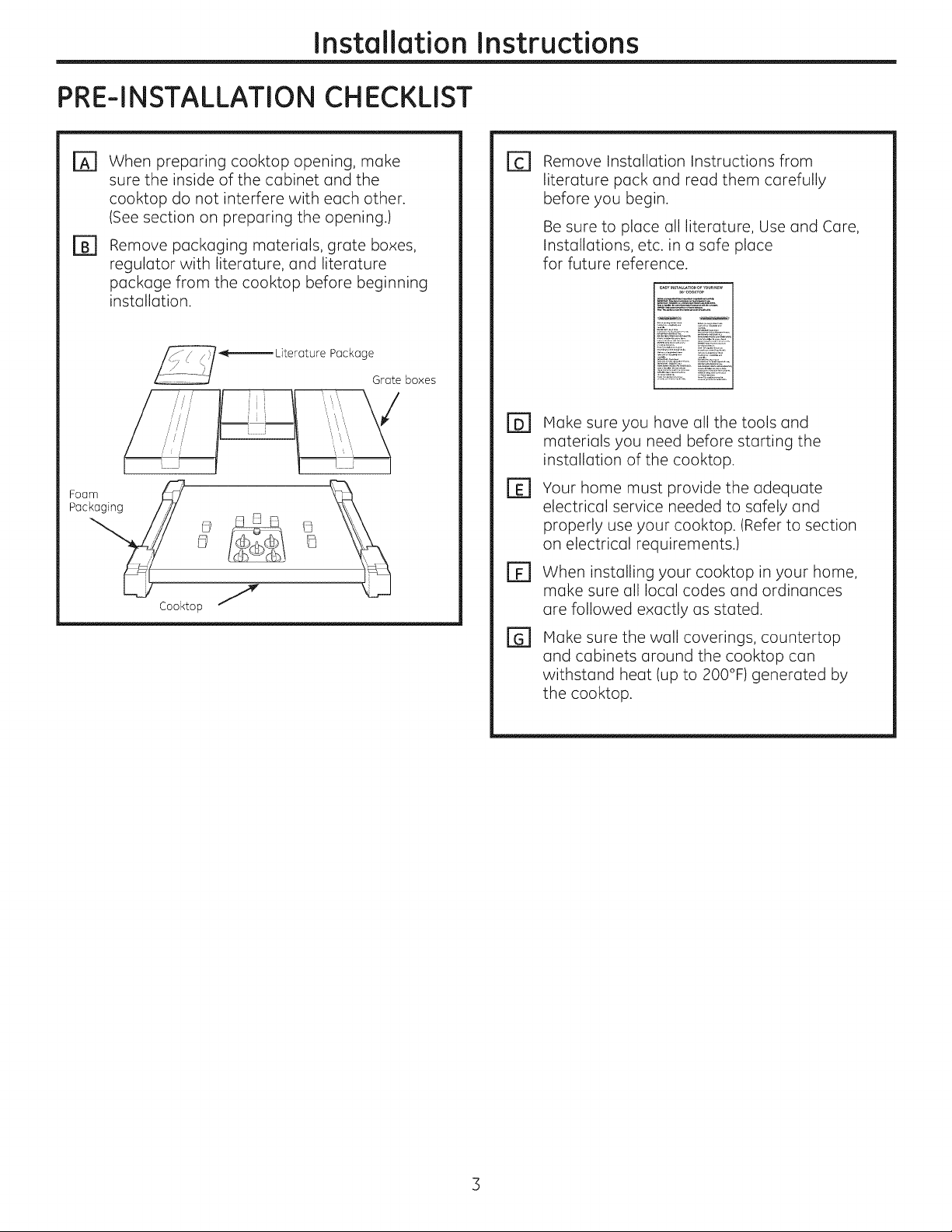

When preparing cooktop opening, make

[Z]

sure the inside of the cabinet and the

cooktop do not interfere with each other.

(See section on preparing the opening.)

Remove packaging materials, grote boxes,

@

regulator with literature, and literature

package from the cooktop before beginning

installation.

_-_ Literature PockOgGrot e boxes

Remove Installation Instructions from

E1

literature pack and read them carefully

before you begin.

Be sure to place all literature, Use and Care,

Installations, etc. in a safe place

for future reference.

Hake sure you have all the tools and

El

materials you need before starting the

installation of the cooktop.

Your home must provide the adequate

El

electrical service needed to safely and

properly use your cooktop. (Refer to section

on electrical requirements.)

When installing your cooktop in your home,

FF1

make sure all local codes and ordinances

are followed exactly as stated.

Hake sure the wall coverings, countertop

[]

and cabinets around the cooktop can

withstand heat (up to 200°F) generated by

the cooktop.

Instollotion Instructions

PREPARING THE OPENING

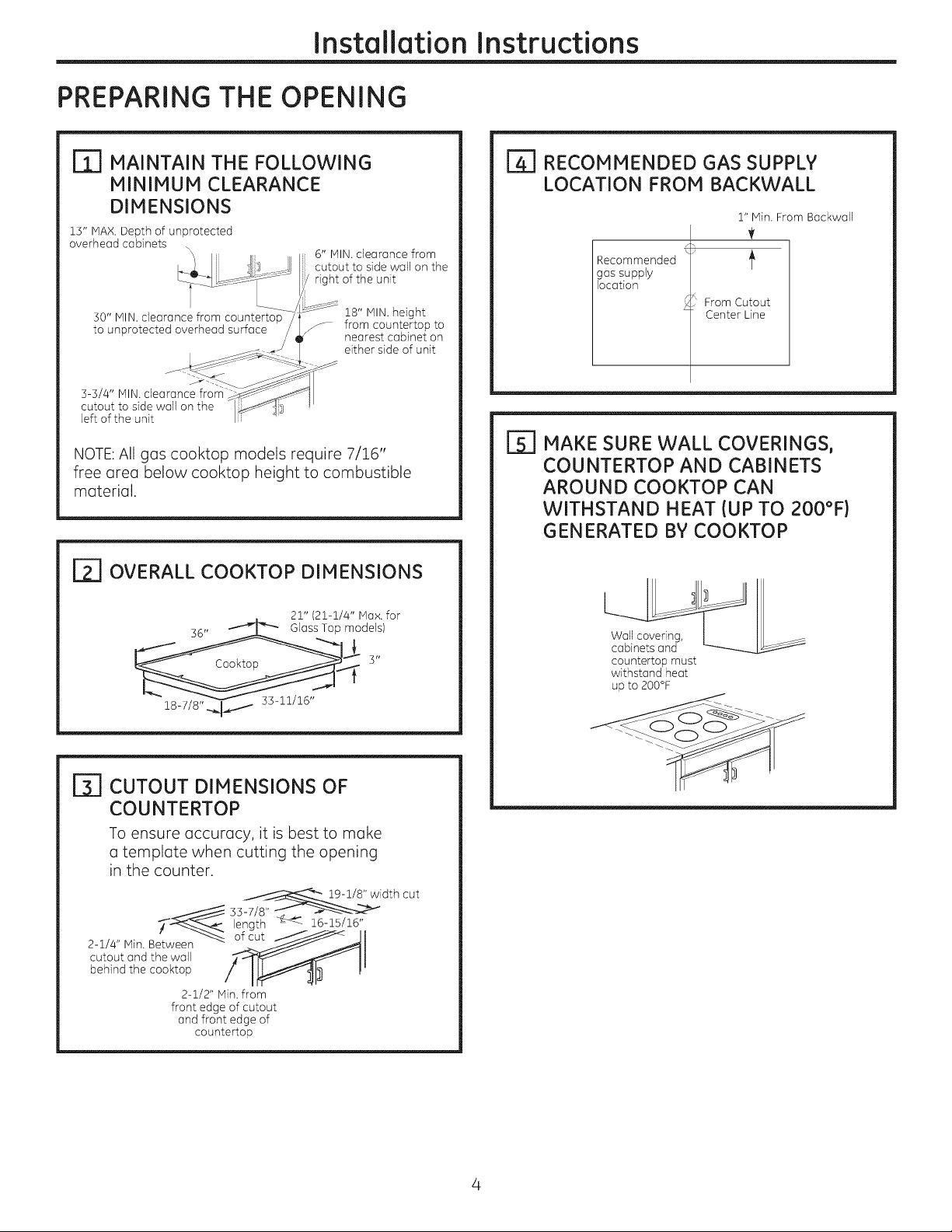

MAINTAIN THE FOLLOWING

MINIMUM CLEARANCE

DIMENSIONS

13" IVlAX. Depth of unprotected

overhead cabinets

30" MIN. clearance from countertop

to unprotected overhead surface

3-3/4" IVllN. clearance from

cutout to side wall on the

left of the unit

\\ B" MIN. clearance from

cutout to side wall on the

right of the unit

18" MIN. height

from countertop to

nearest cabinet on

either side of unit

NOTE:All gas cooktop models require 7/16"

free area below cooktop height to combustible

material.

OVERALL COOKTOP DIMENSIONS

. 21" (21-1/4" Max. for

18-7/8" ._I -_

| RECOMMENDED GAS SUPPLY

LOCATION FROM BACKWALL

1" Min. From Backwall

tr

Recommended

gas supply

location

From Cutout

Center Line

[_] MAKE SURE WALL COVERINGS,

COUNTERTOP AND CABINETS

AROUND COOKTOP CAN

WITHSTAND HEAT {UP TO 200°F)

GENERATED BY COOKTOP

Wall covering,

cabinets and

countertop must

withstand heat

up to 200°F

CUTOUT DIMENSIONS OF

COUNTERTOP

To ensure accuracy, it is best to make

o template when cutting the opening

in the counter.

_-1/_ width cut

?._ ss-7/8"_-c"_ >-_--_e _

2-1/4" Min. Between _ of cutcutout and the wall

behind the cooktop

2-1/2" Min. from

front edge of cutout

and front edge of

length _ 16-15/16"

countertop

Installation Instructions

iNSTALLiNG THE COOKTOP UNiT

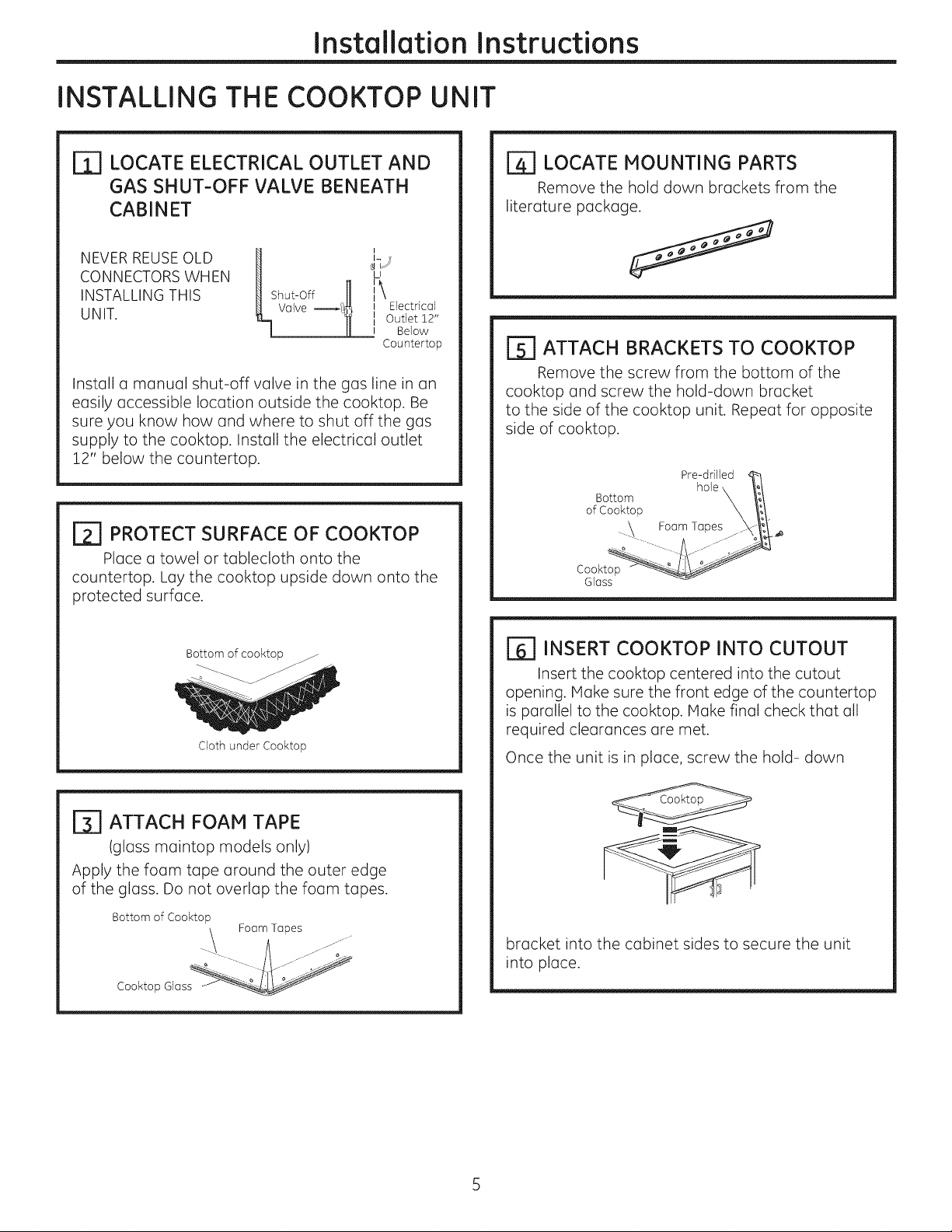

rT] LOCATE ELECTRICAL OUTLET AND

GAS SHUT-OFF VALVE BENEATH

CABINET

NEVER REUSEOLD

CONNECTORS WHEN

INSTALLING THIS

UNIT.

H I

Shut-Off I\

_Lj Valve _ t Electrical

Install a manual shut-off valve in the gas line in an

easily accessible location outside the cooktop. Be

sure you know how and where to shut off the gas

supply to the cooktop. Install the electrical outlet

12" below the countertop.

_1LS

I1 k'

tt Outlet 12"

t Below

Countertop

r_ PROTECT SURFACE OF COOKTOP

Place a towel or tablecloth onto the

countertop. Lay the cooktop upside down onto the

protected surface.

_-] LOCATE MOUNTING PARTS

Remove the hold down brackets from the

literature package.

ITi ATTACH BRACKETS TO COOKTOP

Remove the screw from the bottom of the

cooktop and screw the hold-down bracket

to the side of the cooktop unit. Repeat for opposite

side of cooktop.

Pre-drilled

Bottom

of Cooktop

Foam Tapes

--_..

Cooktop

Glass

Bottom of cooktop

Cloth under Cooktop

ATTACH FOAM TAPE

(glass maintop models only)

Apply the foam tape around the outer edge

of the glass. Do not overlap the foam tapes.

Bottom of Cooktop

.\_ Foam Tapes

Cooktop Glass

_] INSERT COOKTOP INTO CUTOUT

Insert the cooktop centered into the cutout

opening. Make sure the front edge of the countertop

is parallel to the cooktop. Make final check that all

required clearances are met.

Once the unit is in place, screw the hold- down

bracket into the cabinet sides to secure the unit

into place.

Installation Instructions

INSTALLATION--GAS CONNECTIONS

r_ PROVIDE ADEQUATE

GAS SUPPLY

This cooktop is designed to operate on natural gas

at 4" of water column manifold pressure and 7" of

water column (W.C.) supply pressure. It is shipped

from the factory set for natural gas. The convertible

pressure regulator supplied with the unit must

be connected in series with the manifold of the

cooktop and must remain in series with the supply

line regardless of whether natural or LP. gas is

being used.

FOR PROPEROPERATION, THE MAXIMUH INLET

PRESSURETO THE REGULATOR MUST BE NO HaRE

THAN 14" OF WATER COLUMN PRESSURE.For

checking the regulator, the inlet pressure must

be at least 1" W.C.. (or 3.4 KPA)greater than the

regulator output setting. If the regulator is set for 4"

W.C. of water column pressure, the inlet pressure

must be at least 5" W.C. If the regulator is set for

10" W.C., the inlet pressure must be at least 11"

W.C.. The gas supply line to the cooktop should be

1/2" or 3/4" pipe.

J_ INSTALL REGULATOR

NEVER REUSEOLD CONNECTORS WHEN

INSTALLING THIS COOKTOP.

WARNING: Neverreuseold

flexible connectors. The use of old flexible

connectors can cause gas leaks and personal

injury. Always use new flexible connectors when

installing a gas appliance.

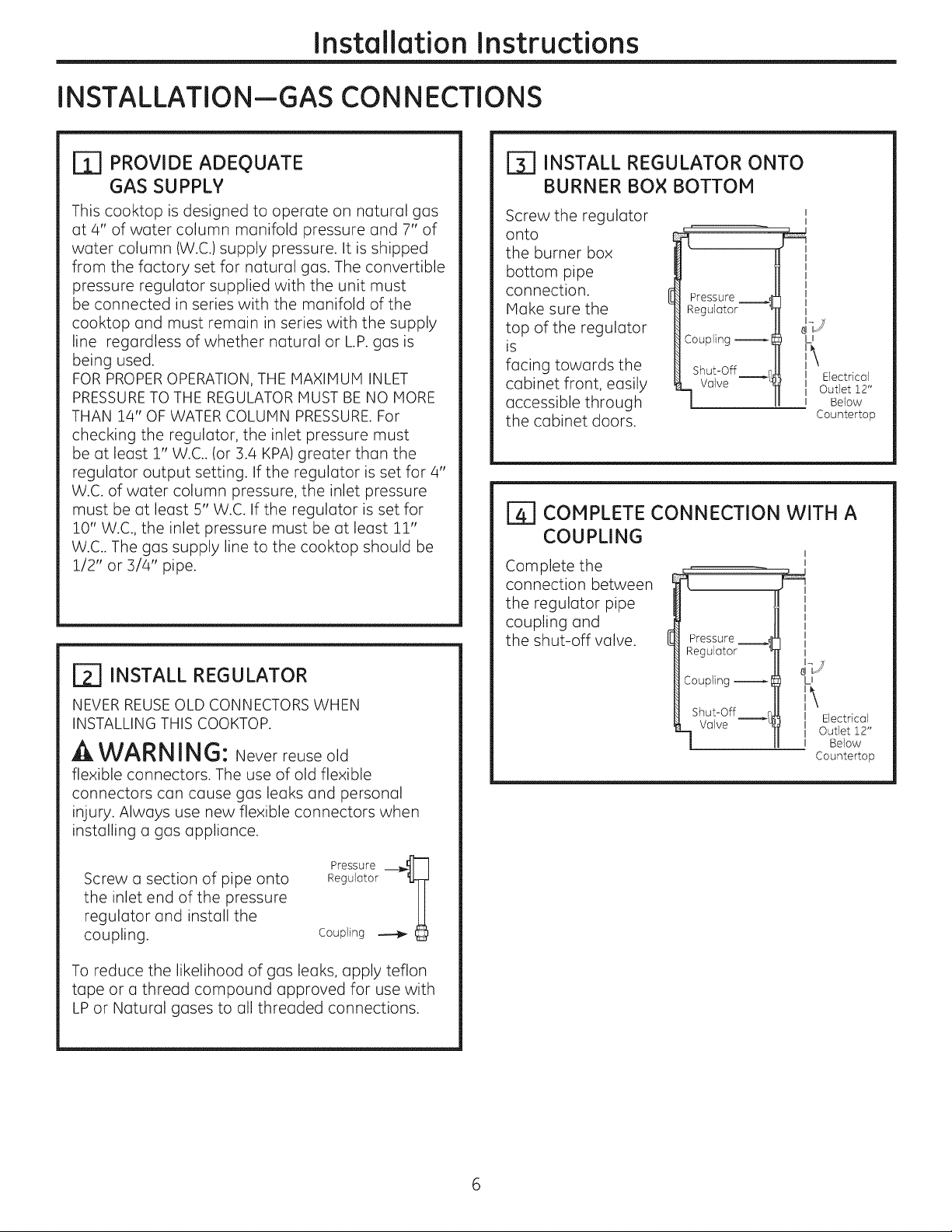

r_ INSTALL REGULATOR ONTO

BURNER BOX BOTTOM

Screw the regulator

onto

the burner box

bottom pipe

connection.

Hake sure the

top of the regulator

is

facing towards the

cabinet front, easily

accessible through

the cabinet doors.

Pressure ___

Regulator

Coupling _l

Shut-Off

_ Valve _'_

I

I

l]J

Li

1 Electrical

I Outlet 12"

I Below

Countertop

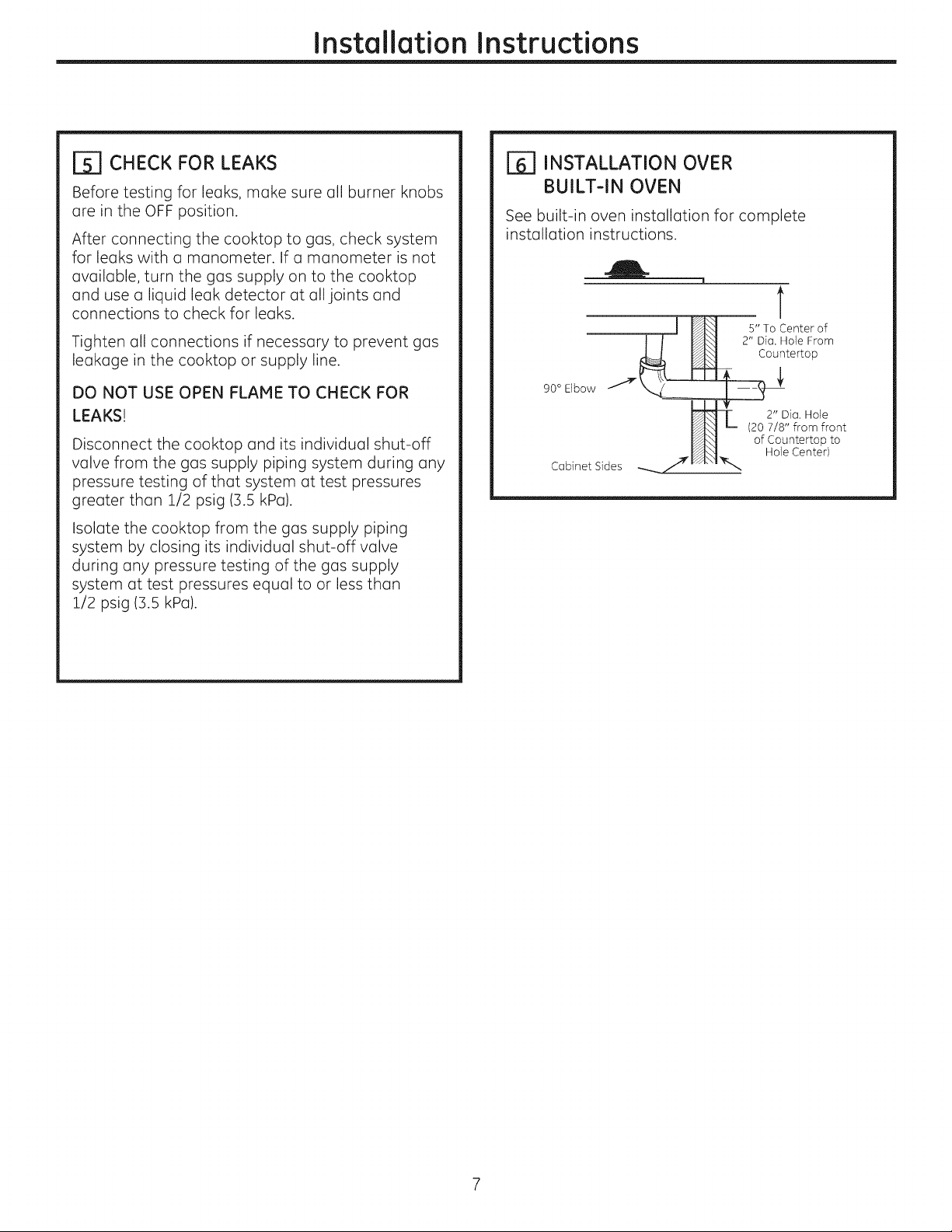

_] COMPLETE CONNECTION WITH A

COUPLING

I

Complete the

L--

I

connection between

the regulator pipe

coupling and

the shut-off valve.

Pressure _

Regulator

Coupling

U

i\

Shut-Off Q,

Valve _

II Electrical

I Outlet 12"

I Below

Countertop

Pressure -_l

Screw a section of pipe onto

the inlet end of the pressure

regulator and install the

coupling.

Regulator

Coupling _

To reduce the likelihood of gas leaks, apply teflon

tape or a thread compound approved for use with

LP or Natural gases to all threaded connections.

Installation Instructions

CHECK FOR LEAKS

Before testing for leaks, make sure all burner knobs

are in the OFF position.

After connecting the cooktop to gas, check system

for leaks with a manometer. If a manometer is not

available, turn the gas supply on to the cooktop

and use a liquid leak detector at all joints and

connections to check for leaks.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

DO NOT USE OPEN FLAME TO CHECK FOR

LEAKS!

Disconnect the cooktop and its individual shut-off

valve from the gas supply piping system during any

pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa).

Isolate the cooktop from the gas supply piping

system by closing its individual shut-off valve

during any pressure testing of the gas supply

system at test pressures equal to or less than

1/2 psig (3.5 kPa).

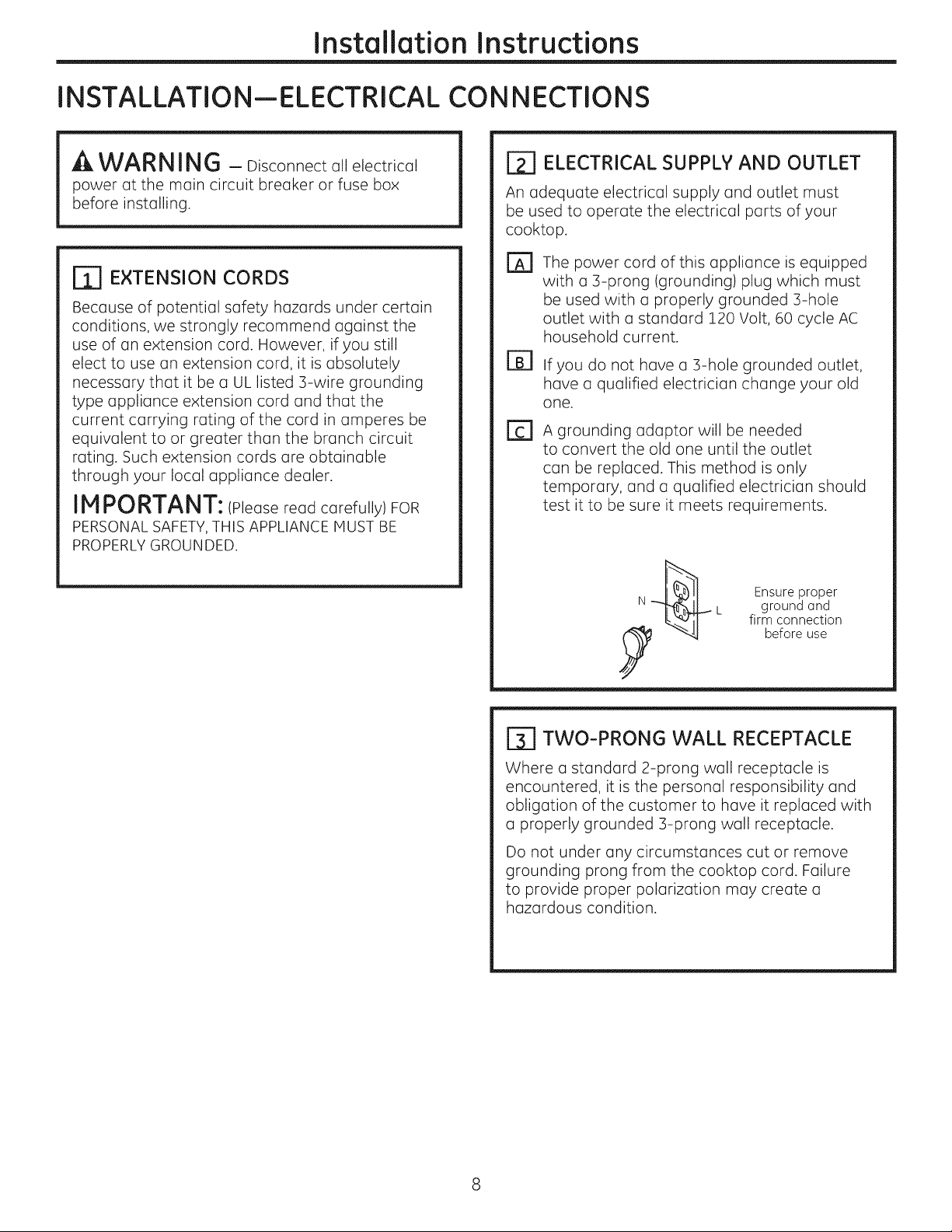

_] INSTALLATION OVER

BUILT-IN OVEN

See built-in oven installation for complete

installation instructions.

i

T

_1 ToCenterof

| I _ 2" Dia. Hole From

_ Countertop

90°E,bowj_t_ I-TT] _:_

1207/8" from front

of Countertop to

Cabinet Sides -__ ,

jl_-_,_ 2" Dia. Hole

Hole Center)

Installation Instructions

INSTALLATION--ELECTRICAL CONNECTIONS

WARNING - Disconnectallelectrical

power at the main circuit breaker or fuse box

before installing.

r_ EXTENSION CORDS

Because of potential safety hazards under certain

conditions, we strongly recommend against the

use of an extension cord. However, if you still

elect to use an extension cord, it is absolutely

necessary that it be a UL listed 3-wire grounding

type appliance extension cord and that the

current carrying rating of the cord in amperes be

equivalent to or greater than the branch circuit

rating. Such extension cords are obtainable

through your local appliance dealer.

IMPORTANT: (Pleaseread carefully)FOR

PERSONAL SAFETY,THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

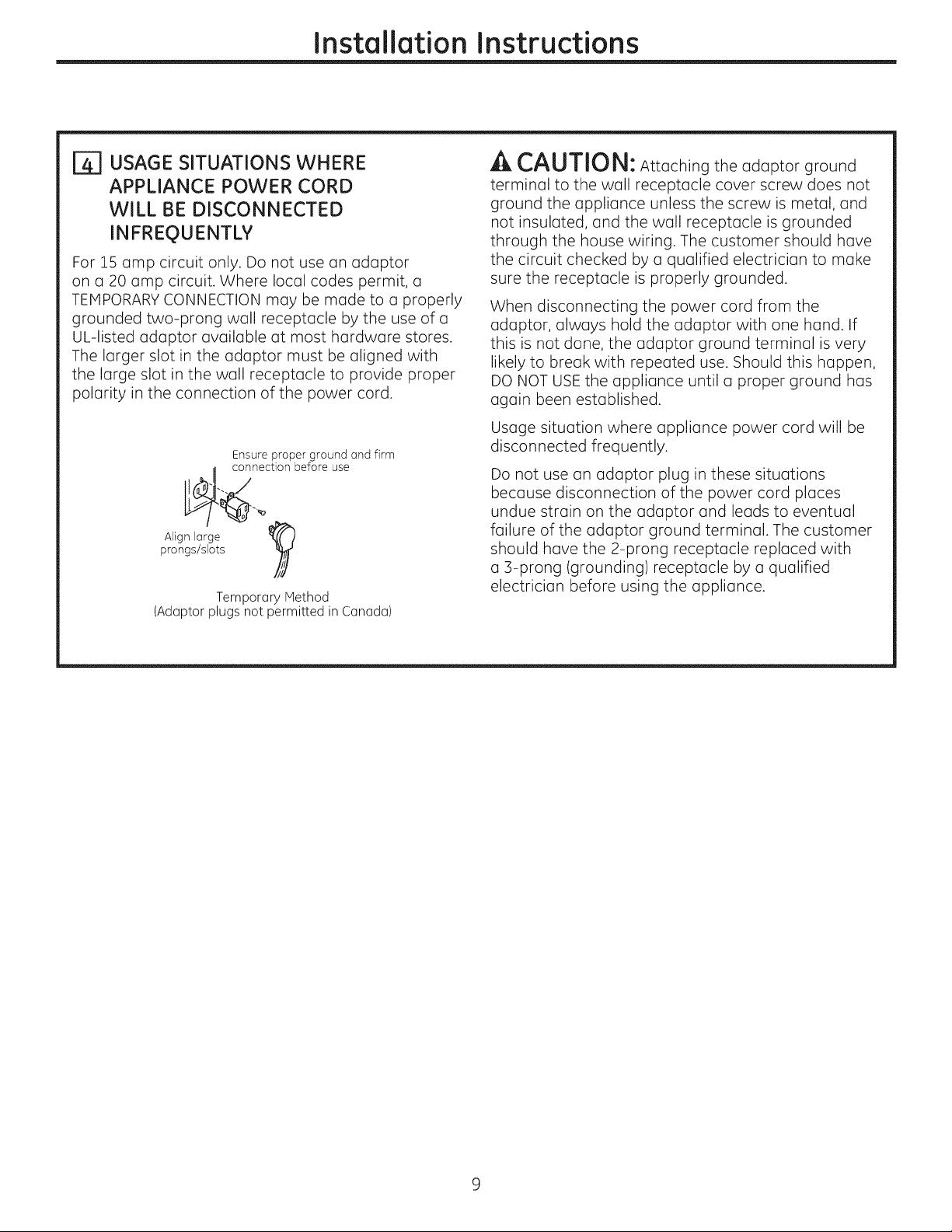

[Z] ELECTRICAL SUPPLY AND OUTLET

An adequate electrical supply and outlet must

be used to operate the electrical parts of your

cooktop.

[]

The power cord of this appliance is equipped

with a 3-prong (grounding) plug which must

be used with a properly grounded 3-hole

outlet with a standard 120 Volt, 60 cycle AC

household current.

B]

If you do not have a 3-hole grounded outlet,

have a qualified electrician change your old

one.

[] A grounding adaptor will be needed

to convert the old one until the outlet

can be replaced. This method is only

temporary, and a qualified electrician should

test it to be sure it meets requirements.

Ensure proper

L ground and

firmconnection

beforeuse

[_] TWO-PRONG WALL RECEPTACLE

Where a standard 2-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with

a properly grounded 3-prong wall receptacle.

Do not under any circumstances cut or remove

grounding prong from the cooktop cord. Failure

to provide proper polarization may create a

hazardous condition.

Installation Instructions

USAGE SITUATIONS WHERE

APPLIANCE POWER CORD

WILL BE DISCONNECTED

INFREOUENTLY

For 15 amp circuit only. Do not use Gn adaptor

on a 20 Gmp circuit. Where local codes permit, a

TEMPORARY CONNECTION may be made to G properly

grounded two-prong wGII receptacle by the use of a

UL-listed adaptor available at most hardware stores.

The larger slot in the adaptor must be Gligned with

the large slot in the wall receptacle to provide proper

polarity in the connection of the power cord.

Ensure proper ground and firm

II connection before use

prongs/slots

Align Iorge

(Adoptor plugs not permitted in Conodo)

Temporory Method

A CAUTION: Attaching the adaptor ground

terminal to the wall receptacle cover screw does not

ground the GppliGnce unless the screw is metal, and

not insulated, Gnd the wall receptacle is grounded

through the house wiring. The customer should have

the circuit checked by a qualified electrician to make

sure the receptacle is properly grounded.

When disconnecting the power cord from the

adaptor, always hold the adaptor with one hand. If

this is not done, the adaptor ground terminal is very

likely to break with repeated use. Should this happen,

DO NOT USE the appliance until a proper ground has

again been established.

Usage situation where appliance power cord will be

disconnected frequently.

Do not use an adaptor plug in these situations

because disconnection of the power cord places

undue strain on the adaptor and leads to eventual

failure of the adaptor ground terminal. The customer

should have the 2-prong receptacle replaced with

a 3-prong (grounding) receptacle by a qualified

electrician before using the appliance.

COOKTOP BURNERS

Installation Instructions

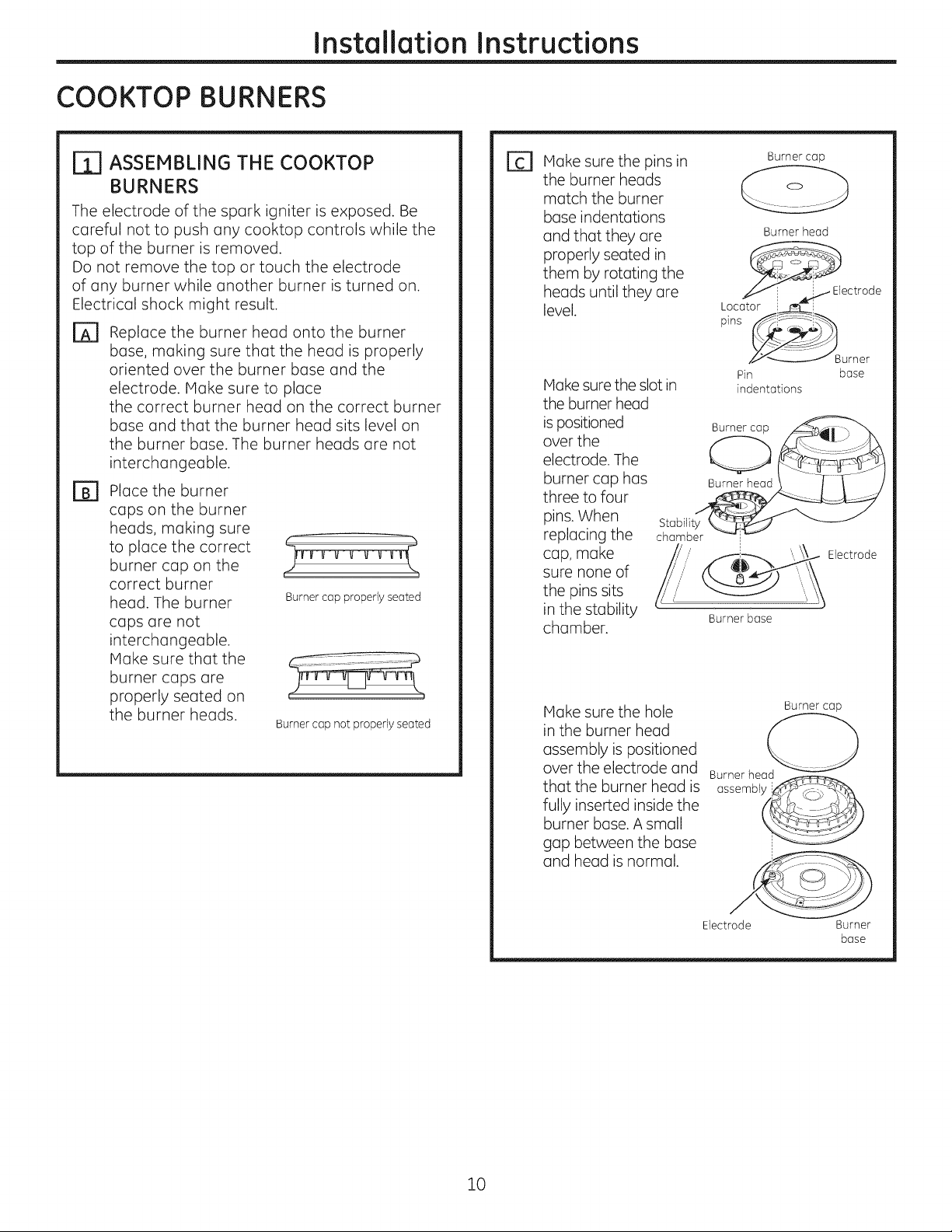

r_ ASSEMBLING THE COOKTOP

BURNERS

The electrode of the spark igniter is exposed. Be

careful not to push any cooktop controls while the

top of the burner is removed.

Do not remove the top or touch the electrode

of any burner while another burner is turned on.

Electrical shock might result.

D Replace the burner head onto the burner

base, making sure that the head is properly

oriented over the burner base and the

electrode. Make sure to place

the correct burner head on the correct burner

base and that the burner head sits level on

the burner base. The burner heads are not

interchangeable.

Place the burner

B]

caps on the burner

heads, making sure

to place the correct

burner cap on the

correct burner

head. The burner

caps are not

interchangeable.

Make sure that the

burner caps are

properly seated on

the burner heads.

Burner cap properly seated

Burner cap not properly seated

lake sure the pins in

E]

the burner heads

match the burner

base indentations

and that they are

properly seated in

them by rotating the

heads until they are

level.

lake sure the slot in

the burner head

is positioned

over the

electrode. The

burner cap has

three to four

pins. When

replacing the

cap, make

sure none of

the pins sits

in the stability

chamber.

Make sure the hole Burner cap

in the burner head f/ ",_

assembly is positioned

over the electrode and Burner head

that the burner head is assembly

fully inserted inside the

burner base. A small

gap between the base

and head is normal.

chamber ....

Burnerbase

Burner cop

Burner head

Locator i_i

__Burner

Pin base

indentations

q__j

,d,..i.- Electrod e

Electrode

10

Electrode Burner

base

Loading...

Loading...