GE PFDS450EL3WW, PFDS450EL2WW Owner’s Manual

GEAppliances.com

Safety Instructions ........... 2-4

oi

L_

Operating Instructions

Controls ........................... 5-8

Cycle Options .................... 9, 10

Smart Appliance .................... 15

Dryer Features .................. 10, 11

.

Ouick Start Guide .................... 5

Settings Option ...................... 10

Using the Dryer ..................... 11

Installation Instructions

Before You Begin ................ 14, 15

Connecting the Inlet Hoses ......... 17

Connecting a Gas Dryer ......... 18-21

Connecting an

Electric Dryer .................... 22-24

Exhausting the Dryer ............ 25-31

Final Setup .......................... 32

Installing the Pedestal ........... 43-45

Location of your Dryer .......... 1S,16

Reversing the Door Swing ....... 33-39

Stacking the Washer

and Dryer ....................... 40-42

La section frangaise commence la page 52

S cheuses

PFDS450

PFDS455

PFDN440

PFDN445

PFMS450

PFMS455

PFMN440

PFMN445

Profile

Troubleshooting Tips....... 46-49

Secadoras

Profile

Consumer Support

Consumer Support ........ Back Cover

Warranty (Canada) ................. 51

Warranty (U.S.)..................... 50

La secci6n en espafiol empieza en la p6gina i04

SAVE THESEINSTRUCTIONS

Write the model and serial

numbers here:

Model #

Serial #

They are on the label on the front

of the dryer behind the door.

PrintedinMexico 234D2020PO02 49-90472 03-23 GE

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

A WARNING!

Foryour safety, the information in this manual must be followed to minimize the risk

of fire or explosion, electric shock, or to prevent property damage, personal inJury, or

death.

m Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

m Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS"

[-_ Do not try to light a match, or cigarette,

or turn on any gas or electrical

appliance.

[_ Do not touch any electrical switch; do

not use any phone in your building.

F_ Clear the room, building or area of all

occupants.

California Safe Drinking Water and Toxic Enforcement Act

Thisact requiresthe governor of California to publish a list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires businessesto warn customers of potential exposure to

such substances.

Gasappliances cancause minor exposureto four ofthese substances,namely benzene,carbon monoxide,

formaldehyde and soot, caused primarily by the incompletecombustion of natural gas or LPfuels.

[] immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions carefully.

F-_if you cannot reach your gas supplier,

call the fire department.

Properlyadjusted dryers will minimize incomplete combustion. Exposureto these substances can be minimized

further by properlyventing the dryer to the outdoors.

PROPERINSTALLAWON

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used. Installation Instructions are included in the back of this manual.

[]

Properlyground dryer to conform with oil governing

codes and ordinances. Follow details in Installation

Instructions.

[]

Install or store where it will not be exposed to

temperatures below freezing or exposed to water or

weather.

[] Connect to u properly rated, protected and sized

power supply circuit to avoid electrical overload.

[] Remove all sharp packing items and dispose of all

shipping materials properly.

2 For complete details, follow the Installation Instructions.

Exhaust/Ducting

[_] DryersMUSTbeexhausted to the outside to prevent

large amounts of moisture and lintfrom being blown

intothe room.

Useonly rigid metal 4" diameter ductwork inside the

[]

dryer cabinet. Useonly UL approved rigid metal or

flexible metal 4-in diameter ductwork for exhausting

to the outdoors. Never use plastic or other

combustible, easy-to-puncture ductwork. USE OF

PLASTICOROTHERCOMBUSTIBLEDUCTWORKCAN

CAUSEA FIRE.PUNCTUREDDUCTWORKCANCAUSE

A FIREIF IT COLLAPSESOR BECOMESOTHERWISE

RESTRICTEDIN USEORDURINGINSTALLATION.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING. GEApUioncescom

WARNING!

YOUR LAUNDRY AREA

[] Keep the area underneath and around your

appliances free of combustible materials, (lint,paper,

rags, etc.),gasoline, chemicals and other flammable

vapors and liquids.

[]

Keepthe floor around your appliances clean and dry

to reducethe possibility of slipping.

[]

Close supervision is necessary if this appliance is

used byor near children. Do not allow children to play

on,with or inside this or any other appliance.

WHEN USING YOURDRYER

[]

Never reach into the dryer while the drum is moving.

Beforeloading,unloading or adding clothes,wait until

the drumhascompletelystopped.

[]

Clean the lint filter before each load to prevent lint

accumulation insidethe dryeror inthe room.DO NOT

OPERATETHEDRYERWITHOUTTHELINTFILTERIN

PLACE.

[]

Donotwash or dry articlesthat havebeen cleaned in,

washed in,soaked in or spotted with combustible or

explosivesubstances(suchaswax, oil,paint,gasoline, []

degreasers, dry-cleaning solvents, kerosene, etc.).

These substances give off vapors that may ignite or

explode. Do not add these substances to the wash

water. Do not use or place these substances around

your washer or dryer during operation.

[]

Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

clothes load to catch fire.

[]

Any article on which you have used a cleaning

solvent or that contains flammable materials (such

as cleaning cloths, mops, towels used in beauty

salons, restaurants or barber shops, etc.) must not

be placed in or near the dryer until solvents or

flammable materials have been removed. There are

many highly flammable items used in homes such

as acetone, denatured alcohol, gasoline, kerosene,

some household cleaners, some spot removers,

turpentines, waxes, wax removers and products

containing petroleum distillates.

[]

Thelaundry processcan reducethe flame retardancy

of fabrics. Toavoid such a result,carefully follow the

garment manufacturer's care instructions.

Keep the area around the exhaust opening

and adjacent surrounding areas free from the

accumulation of lint, dust and dirt.

Keep all laundry aids (such as detergents, bleaches,

etc.) out of the reach of children, preferably in a

locked cabinet. Observe all warnings on container

labelsto avoid injury.

[] Neverclimb on or stand on the dryer top.

Do not dry articles containing rubber, plastic or

similar materials such as padded bras, tennis

shoes, galoshes, bath mats, rugs, bibs, baby pants,

plastic bags, pillows, etc. that may melt or burn.

Some rubber materials, when heated, can under

certain circumstances produce fire by spontaneous

combustion.

Donot store plastic, paper or clothing that may burn

or melt on top of the dryer during operation.

Garments labeled Dry Away from Heat or Do Not

Tumble Dry (such as life jackets containing Kapok)

must not be put inyour dryer.

[]

Do not dry fiberglass articles in your dryer. Skin

irritation could result from the remaining particles

that may be picked up by clothing during subsequent

dryer uses.

To minimize the possibility of electric shock, unplug

this appliance from the power supply or disconnect

the dryer at the household distribution panel by

removing the fuse or switching off the circuit breaker

before attempting any maintenance or cleaning

(except the removal and cleaning of the lint filter).

NOTE:PressingSTART/PAUSEor POWERdoes NOT

disconnect the appliance from the power supply.

Ifyou seewater on the floor around the dryer, call for

service.

Do not obstruct the flow of ventilating air. Do not

stack or place laundry or throw rugs against the front

or back ofthe dryer.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

WHEN USINGYOURDRYER(cont.)

[] Neverattempttooperatethisapplianceifitisdamaged, []

malfunctioning, partially disassembled,or has missing

or broken parts, including a damaged cord or plug.

[]

The interior of the machine and the exhaust duct

connection insidethe dryer should be cleaned at least

once a year by a qualified technician. Seethe Sorting

and Loading Hints section on page 12.

[]

If yours is a gas dryer, it is equipped with an

automatic electric ignition and does not have

a pilot light. DO NOT ATTEHPT TO LIGHT WITH A

MATCH.Burns may result from having your hand in

the vicinity of the burner when the automatic ignition

turns on.

[]

Do not open the dryer door during steam cycles. The

steam is very hot and it will continue to exhaust from

the port for several seconds after opening. Do not

touch the steam port after a steam cycle.

[]

Do not use a steam cycle with items such as wool,

leather,silk,lingerie,foam products or electric blankets.

[]

Do not use steam cycles on new clothes without first

washing.

You may wish to soften your laundered fabrics or

reduce the static electricity in them by using a dryer-

applied fabric softener or an anti-static conditioner.

We recommend you use either a fabric softener

in the wash cycle, according to the manufacturer's

instructions for those products, or try a dryer-added

product for which the manufacturer gives written

assurance on the package that their product can

be safely used in your dryer. Service or performance

problems caused by use of these products are the

responsibility of the manufacturers of those products

and are not covered under the warranty of this

appliance.

[]

Never attempt to use the Steam Dewrinkle or Steam

Refreshcycleswithout clothesinthe drum. Additionally,

it is highly recommended to select the appropriate

load size for best results. Selecting large load cycles

for small loads may result in wetting of clothes, and

selecting small load cycles for large loads may result

in poor dewrinkling performance.

[]

Donot spray any type of aerosol into,on, or near dryer

at any trime. Do not use any type of spray cleaner

when cleaning dryer interior. Hazardous fumes or

electrical shock could occur.

--'- Grasp the plug firmly when disconnecting this Beforediscarding a dryer, or removing itfrom service,

appliance to avoid damage to the cord while pulling, remove the dryer door to prevent children from hiding

Placethe cord away from traffic areas so it will not be inside.

stepped on, tripped over or subjected to damage.

[]

Do not attempt to repair or replace any part of this

appliance or attempt any servicing unless specifically

recommended in this Owner's Manual or in published

user-repair instructionsthat you understand and have

the skillsto carry out.

[] Do not tamper with controls.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

THESEINSTRUCTIONS

4

About the dryer control panel. GEAppliances.com

A WARNING!

SAFETYINSTRUCTIONS before operating this appliance.

Throughout this manual, features and appearance may vary from your model.

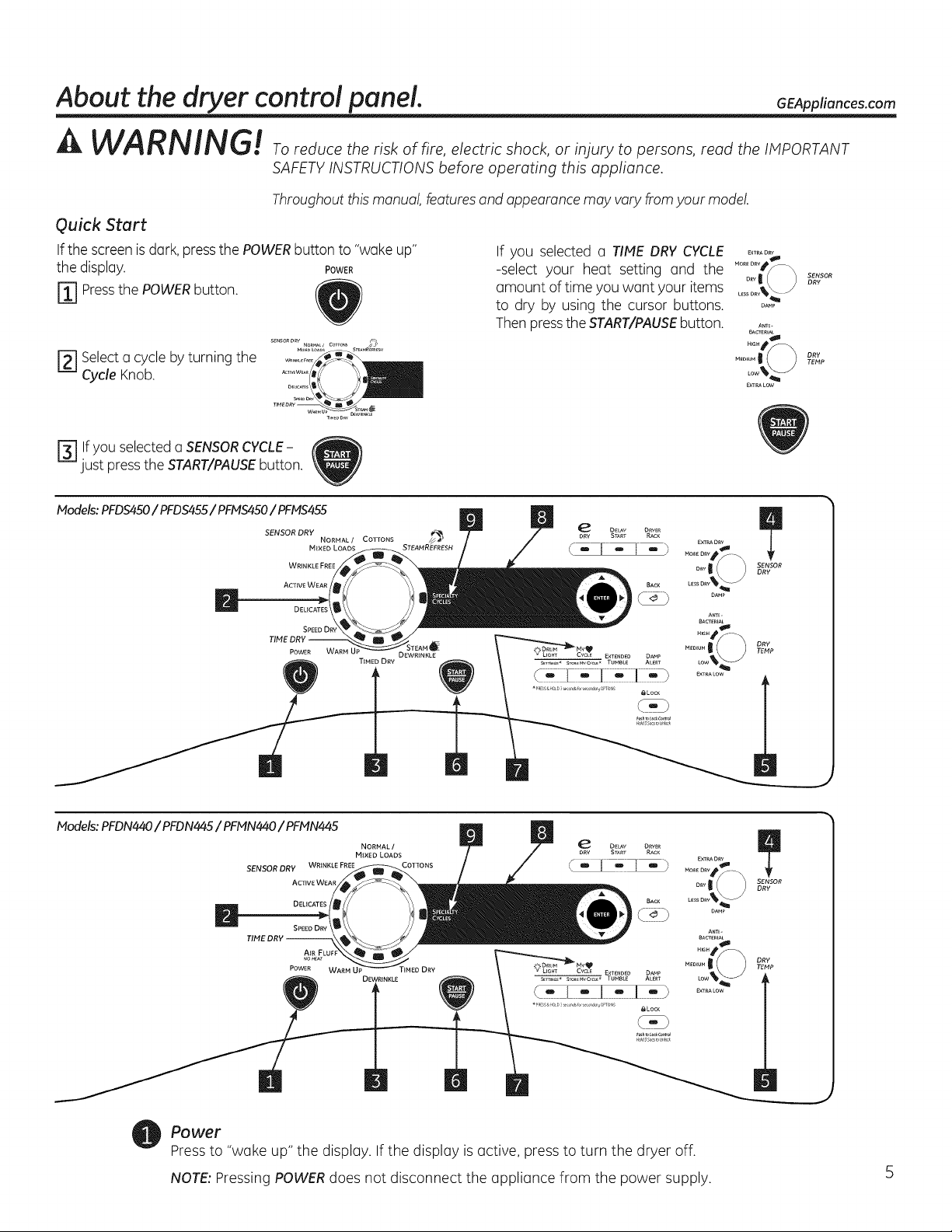

Quick Start

Ifthe screenis dark,pressthe POWERbutton to "woke up"

the disphy. POWER

[_] Pressthe POWERbutton.

SENSORORVNORMA_/COTTO_Sr_A_/S_+j

r_ Selectu cycle byturning the

Cycle Knob.

T,MEOD_

F_lf you selecteda SENSORCYCLE-

just pressthe START/PAUSEbutton.

Models: PFDS450 / PFDS455 / PFMS450 / PFMS455

SENSOR DRY

NORMAL/ COTTONS _

MINED LOADS STEAMRE'FRESH

WRINKLE FREE

ACTIVEWEAR

DEUCATES

SPEEDDRY

POWER WARM U_ OEWR_NKLE

TSMED DRY

If you selected o TIME DRY CYCLE .......

-select your heat setting and the

amount of time you want your items

to dry by using the cursor buttons, oA.,

Then pressthe START/PAUSEbutton.

A_E-

BACTERIAL

......I/ _ oRYTEHP

Low%_J

EXT_LOW

_XTRAORV

BACrEmAL

A_l- /

...... '} TEHP I

SENSOR

DRY

Models: PFDN440 / PFDN445 / PFMN440 / PFMN445

SENSOR DRY WRJNKLE FREE COTTONS

ACTIVE WEAR

DELICATES

SPEEODRY

Po we r

Pressto "woke up" the display. Ifthe display is active, press to turn the dryer off.

NOTE: Pressing POWERdoes not disconnect the appliance from the power supply.

NORMAL /

M{×EO LOADS

WARM UP TIMED DRY

DEWRiNRLE

DELAy O_VER

START RACK

_XTRADRY _

LE v

DAMP

Am_-

BACrEmAL

......|/ ) oRYTEHP

_XTRALOW

About the dryer control panel.

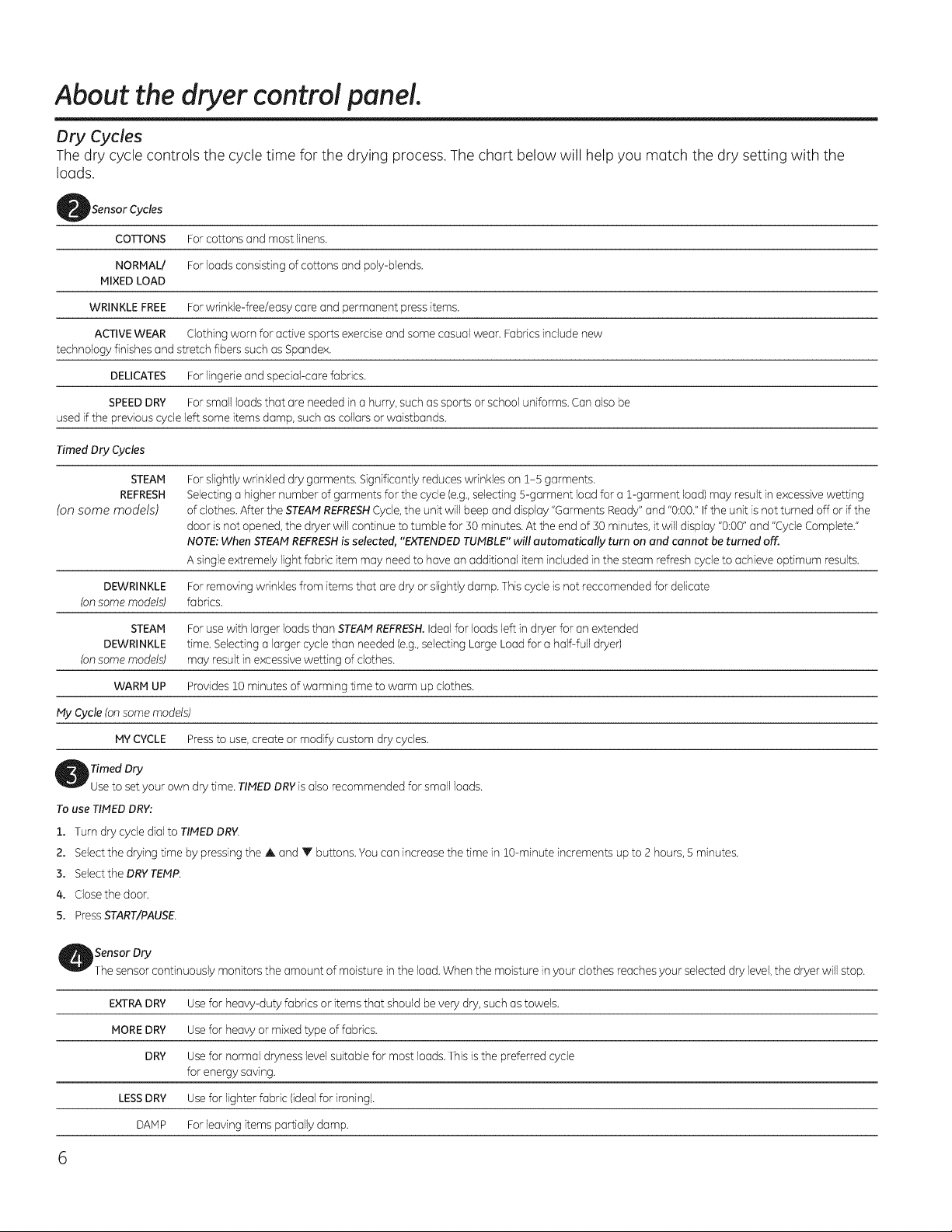

Dry Cycles

The dry cycle controls the cycle time for the drying process. The chart below will help you match the dry setting with the

loads.

iSensor Cycles

COTTONS For cottons and most linens.

NORMAL/ Forloads consisting of cottons and poly-blends.

MIXED LOAD

WRINKLEFREE For wrinkle-free/easy care and permanent press items.

ACTIVEWEAR Clothing worn for active sports exercise and some casual wear. Fabricsinclude new

technology finishes and stretch fibers such as Spandex.

DELICATES For lingerie and spedaFcare fabrics.

SPEEDDRY Forsmall loads that are needed ina hurry, such assports or school uniforms. Can also be

used if the previous cycle left some items damp, such ascollars or waistbands.

Timed Dry Cycles

STEAM

REFRESH

(on some models)

DEWRINKLE Forremoving wrinkles from items that are dry or slightly damp. This cycle is not reccomended for delicate

(onsome models) fabrics.

STEAM For use with larger loads than STEAMREFRESH.Ideal for loads left in dryer for an extended

DEWRINKLE time. Selectinga larger cycle than needed (e.g.,selecting Large Load for a half-full dryer)

(onsome models) may result in excessivewetting of clothes.

WARM UP Provides10 minutes of warming time to warm up clothes.

My Cycle (onsome models)

MYCYCLE Press to use, create or modify custom dry cycles.

Timed Dry

Use to setyour own dry time. TIMEDDRYis also recommended for small loads.

To use TIMED DRY:

l. Turn dry cycle dial to TIMEDDRY

2. Select the drying time by pressing the A and Y buttons. You can increase the time in 10-minute increments up to 2 hours, 5 minutes.

3. Select the DRYTEMP.

4. CIosethe door.

5. Press START/PAUSE.

For slightly wrinkled dry garments. Significantly reduces wrinkles on 1-S garments.

Selecting a higher number of garments for the cycle (e.g.,selecting S-garment load for a 1-garment load) may result in excessive wetting

of clothes. After the STEAMREFRESHCycle,the unit will beep and display "Garments Ready" and "0:00."Ifthe unit is not turned off orif the

door isnot opened, the dryer will continue to tumble for 30 minutes. At the end of 30 minutes, it will display "0:00"and "CycleComplete."

NOTE:When STEAMREFRESHis selected, "EXTENDEDTUMBLE" will automatically turn on and cannot be turned off.

Asingle extremely light fabric item may need to have an additional item included in the steam refresh cycle to achieve optimum results.

,Sensor Dry

Thesensor continuously monitors the amount of moisture in the load.When the moisture in your clothes reaches your selected dry level,the dryer will stop.

EXTRADRY Use for heavy-duty fabrics or items that should be verydry,such as towels.

MOREDRY Usefor heavy or mixed type of fabrics.

DRY Usefor normal dryness level suitable for most loads.Thisis the preferred cycle

for energy saving.

LESSDRY Use for lighter fabric (ideal for ironing).

DAMP For leaving items partially damp.

6

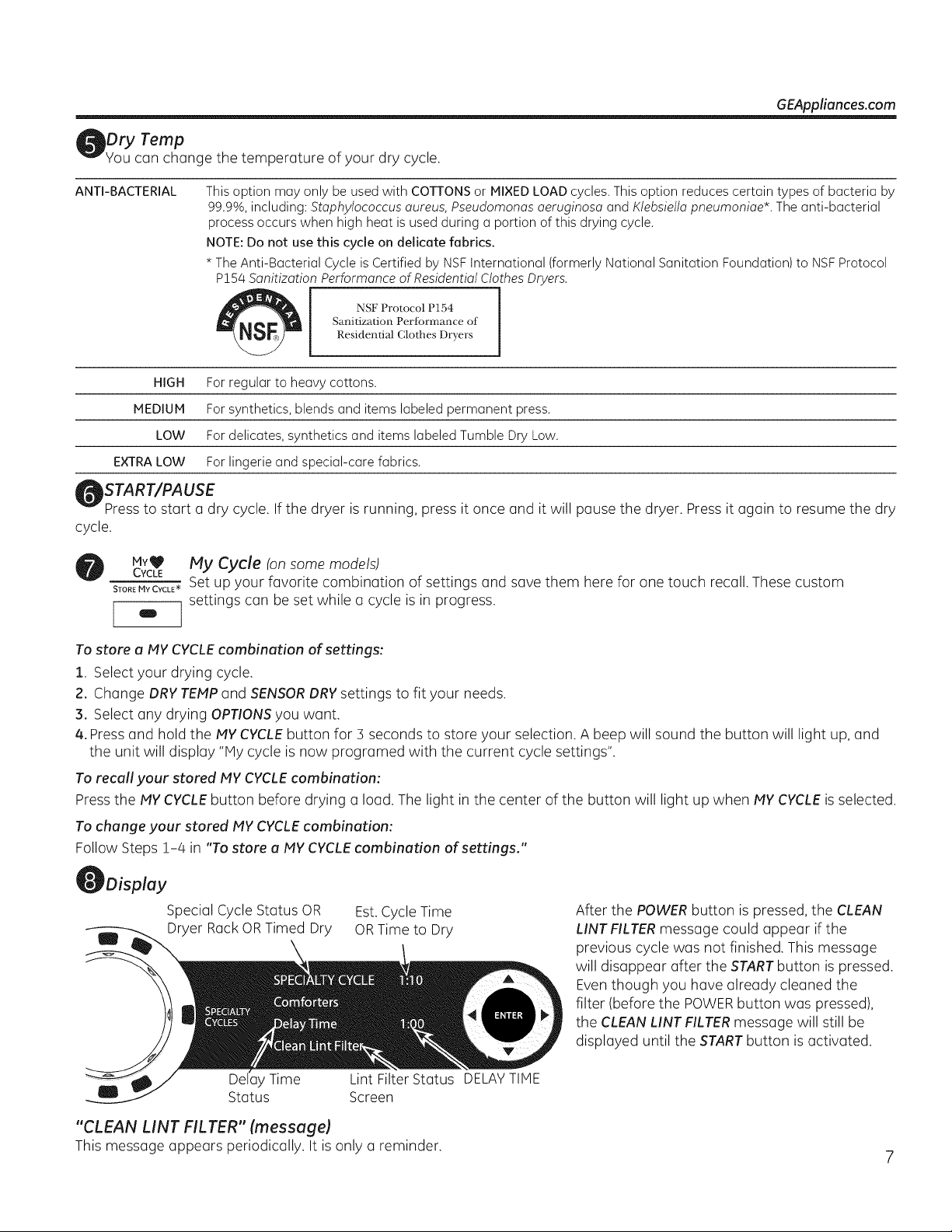

tDry Tamp

¢ou can change the temperature of your dry cycle.

GEAppliances.com

ANTI-BACTERIAL

HIGH For regular to heavy cottons.

MEDIUM For synthetics, blends and items labeled permanent press.

LOW For delicates, synthetics and items labeled Tumble Dry Low.

EXTRALOW For lingerie and special-care fabrics.

This option may only be used with COTTONS or MIXED LOAD cycles. This option reduces certain types of bacteria by

99.9%, including: Staphylococcus oureus, Pseudomonas aeruginosa and Ktebsiella pneumoniae*. The anti-bacterial

process occurs when high heat is used during a portion of this drying cycle.

NOTE: Do not use this cycle on delicate fabrics.

* The Anti-Bacterial Cycle is Certified by NSFInternational (formerly National Sanitation Foundation) to NSFProtocol

P!54 Sanitization Performance of Residential Clothes Dryers.

NSF Protocol P154

Sanitization Periormance of

Residential Clothes Dryers

START/PAUSE

Press to start a dry cycle. If the dryer is running, press it once and it will pause the dryer. Press it again to resume the dry

cycle.

Mv_ My Cycle (onsomemodels)

YCLE

S*o._MvCvcLE*Set up your favorite combination of settings and save them here for one touch recall. These custom

settings can be set while a cycle is in progress.

To store a NY CYCLE combination of settings:

1. Select your drying cycle.

2. Change DRY TEMP and SENSOR DRY settings to fit your needs.

21.Select any drying OPTIONS you want.

4. Press and hold the MY CYCLE button for 5 seconds to store your selection. A beep will sound the button will light up, and

the unit will display "Hy cycle is now programed with the current cycle settings".

To recall your stored NY CYCLE combination:

Press the NY CYCLE button before drying a load. The light in the center of the button will light up when MY CYCLE is selected.

To change your stored MY CYCLE combination:

Follow Steps 1-4 in "To store a MY CYCLE combination of settings."

ODisplay

Special Cycle Status OR Est. Cycle Time

g Dryer Rack OR Timed Dry OR Time to Dry

Del ]y Time Lint Filter Status DELAYTIME

Status Screen

After the POWERbutton is pressed, the CLEAN

LINT FILTERmessage could appear if the

previous cycle was not finished. This message

will disappear after the STARTbutton is pressed.

Eventhough you have already cleaned the

filter (before the POWERbutton was pressed),

the CLEAN LINT FILTERmessage will still be

displayed until the STARTbutton is activated.

"CLEAN LINT FILTER" (message)

This message appears periodically. It is only a reminder.

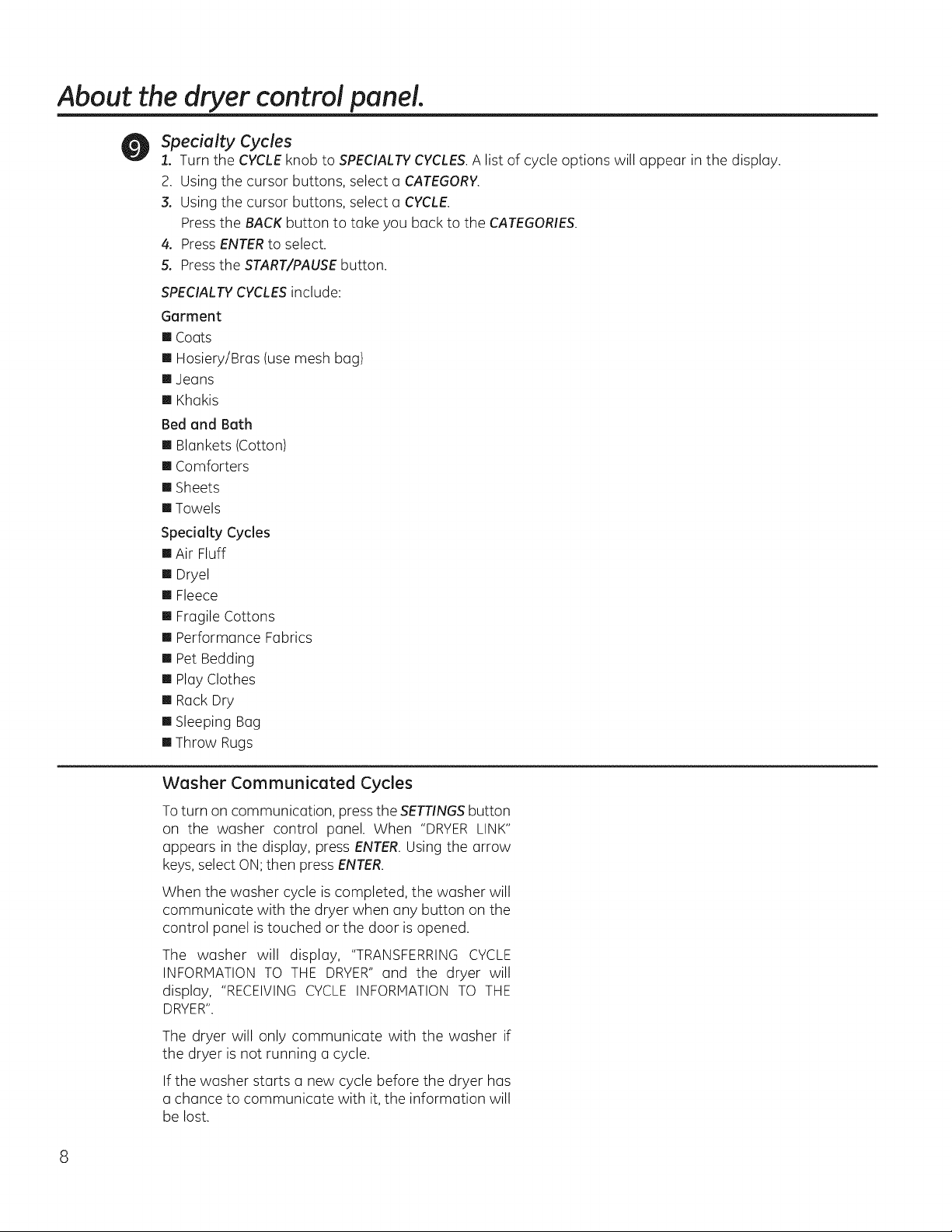

About the dryer control panel.

Specialty Cycles

1. Turn the CYCLEknob to SPECIALTYCYCLES.A list of cycle options will appear in the display.

2. Using the cursor buttons, select a CATEGORY.

3. Using the cursor buttons, select a CYCLE.

Pressthe BACK button to take you back to the CATEGORIES.

4. PressENTERto select.

5. Press the START/PAUSEbutton.

SPECIALTYCYCLESinclude:

Garment

[] Coats

[] Hosiery/Bras (use mesh bag)

[] Jeans

[] Khakis

Bed and Bath

[] Blankets (Cotton)

[] Comforters

[] Sheets

[] Towels

Specialty Cycles

[] Air Fluff

[] Dryel

[] Fleece

[] Fragile Cottons

[] Performance Fabrics

[] Pet Bedding

[] Play Clothes

[] Rack Dry

[] Sleeping Bag

[] Throw Rugs

Washer Communicated Cycles

Toturn on communication, pressthe SETTINGSbutton

on the washer control panel. When "DRYERLINK"

appears in the display, press ENTER.Using the arrow

keys,select ON;then press ENTER.

When the washer cycle is completed, the washer will

communicate with the dryer when any button on the

control panel is touched or the door is opened.

The washer will display, "TRANSFERRINGCYCLE

INFORMATION TO THE DRYER"and the dryer will

display, "RECEIVINGCYCLE INFORMATION TO THE

DRYER".

The dryer will only communicate with the washer if

the dryer is not running a cycle.

If the washer starts a new cycle before the dryer has

a chance to communicate with it, the information will

be lost.

About cycle options.

NOTE: Not all features are available on all dryer models. GEAppliances.com

EXTENDED

TUMBLE

O

DAMP

ALERT

'01 DRUM

LIGHT

SETTINGS ÷

(

O

Extended Tumble

Hinimizes wrinkles by adding approximately 60

minutes of no-heat tumbling after clothes are

dry.

The light in center of the button will light up

when EXTENDEDTUMBLEison.

Damp Alert

This option causes the dryer to beep when

clothes have dried to a damp level. Remove

items that you wish to hang dry. The DAMP

ALERTwillonly beepwhen this option is selected.

Drum Light

Pressthis button to turn on the light in the dryer.

Pressthe button again to turn the light off.

Thisonlycontrols the light when the door isshut.

NOTE:The light will turn offby itself after one

minute when the door is shut.

When the door is opened, the light comes on

automatically.

ExtendedTumble isautomatically selectedforthe

SteamRefreshcycle and cannot be deselected.

Dryer will beep and display "Garments Ready"

when SteamRefresh is complete. The dryer will

continue in Extended Tumble until the door is

opened.

Removingclothesand hanging them when they

are damp can reduce the need to iron some

items.

The light in center of the button will light up

when DAHP ALERTison.

The light in center of the button will light up

when DRUMLIGHT is on.

NOTE:Hold down the DRUM LIGHTbutton for

3 seconds to access the SETTINGSmenu. (See

page 10 for more details)

e

DRY

- I

DELAY

START

O

LOCK

Pushto LockControl

Hold3SecstoUnlock

e-Dry

Reduces the total energy consumption of

specific dryer cycles by adjusting certain heat

settings.

NOTE:Cycle times will change when e-DRYis

selected

Delay Start

Useto delay the start of your dryer.

1. Chooseyour dry cycleand any options.

2. PressDELAYSTART.Youcan change the

delay time in 1/2-hour increments, using the

or V arrow pads.

3. Pressthe START/PAUSEbutton to start the

countdown.

Thecountdown time will be shown in the

ESTIMATEDTIMEREMAININGdisplay.

Lock

You can lock the controls to prevent any

selections from being made. Or you can lock

the controls after you have started a cycle.

Children cannot accidentally start the dryer by

touching padswith this option selected.

This cycle can be used with DELICATE& ACTIVE

WEAR, EASY CARE, NORtfAL/HIXED LOADS

and COTTONS.

NOTES:

[] If the door is opened while the dryer is

in DELAY,the countdown time will not

restart unless the door is closed and

START/PAUSEbutton has been pressed

again.

[] You can delay the start of a dry cycle up

to 2/4hours.

Thelight in center of the button will light up

when DELAYSTARTison.

To lock the dryer, press the LOCK button. To

unlock the dryer, press and hold the LOCK

button for 3 seconds.

The light in center of the LOCKbutton will light

up when the controls are locked.

Eventhough the controls are locked,the POWER

button isstill active in caseyou have to turn the

unit off.

About cycleoptions.

NOTE: Not all features are available on all dryer models.

Settings

.Lg:-DRUM

LIGHT

SETTINGS ÷

Under the

adjust the

the display.

VOLUME

SETTINGS option, you can

volume or the brightness of

DISPLAY BRIGHTNESS can be set from HIGH,

HED or LOW.

After you have made your selection, press

ENTER.

[] End of Cycle (signal) volume can be set from

(

Press & hold for 3

seconds for secondary

options

HIGH, MED, LOW or OFF.

[] Control Sounds volume can be set from

HIGH, MED, LOW or OFF.

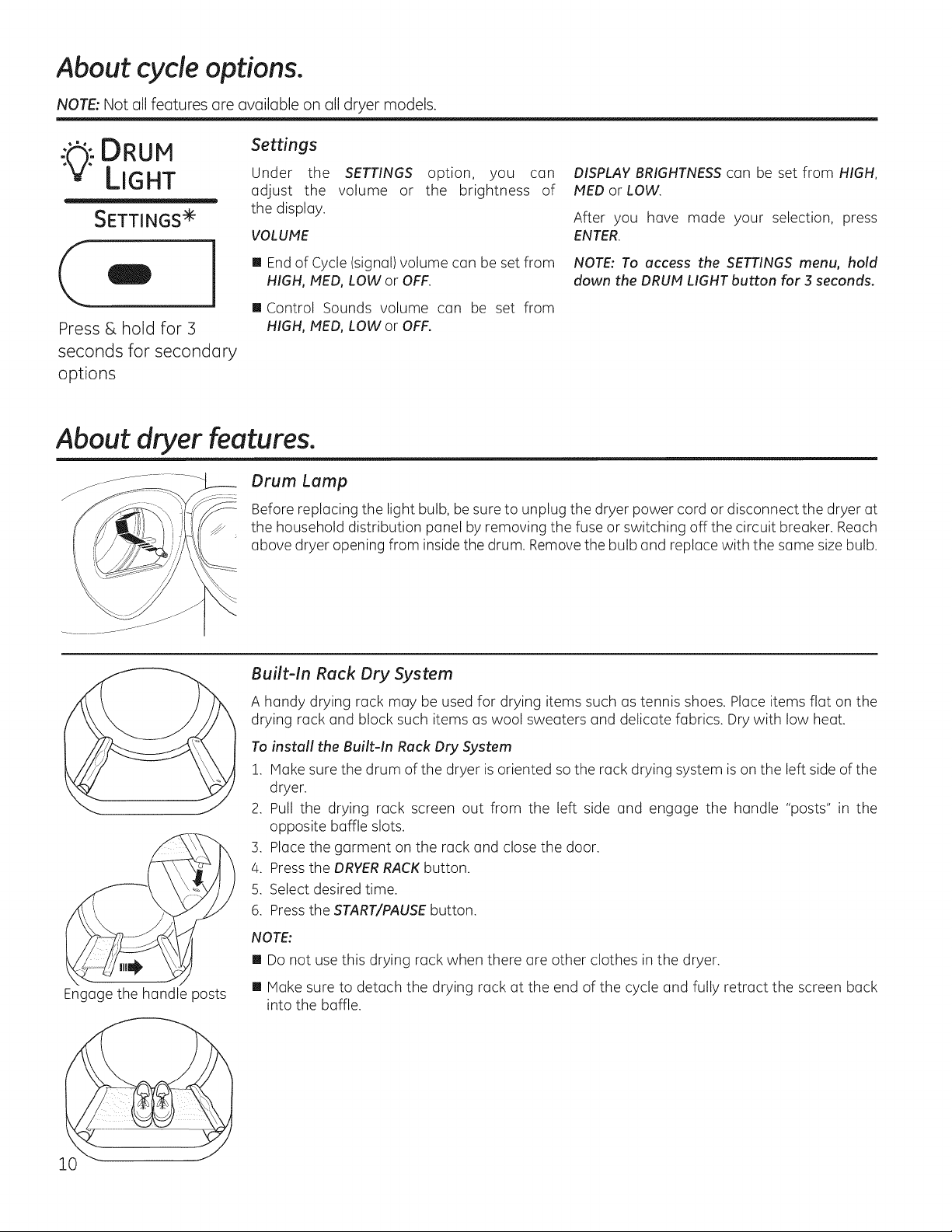

About dryer features.

Drum Lump

Before replacing the light bulb, be sure to unplug the dryer power cord or disconnect the dryer at

the household distribution panel by removing the fuse or switching off the circuit breaker. Reach

above dryer opening from inside the drum. Removethe bulb and replace with the same size bulb.

Built-In Rack Dry System

A handy drying rack may be used for drying items such as tennis shoes. Place items flat on the

drying rack and block such items as wool sweaters and delicate fabrics. Dry with low heat.

Toinstall the Built-In Rack Dry System

1. Hake sure the drum of the dryer is oriented so the rack drying system is on the left side of the

dryer.

2. Pull the drying rack screen out from the left side and engage the handle "posts" in the

opposite baffle slots.

3. Place the garment on the rack and close the door.

4. Pressthe DRYERRACKbutton.

5. Select desired time.

6. Pressthe START/PAUSEbutton.

NOTE:

[] Do not use this drying rack when there are other clothes in the dryer.

NOTE: To access the SETTINGS menu, hold

down the DRUM LIGHT button for 3 seconds.

Engage the handle posts

[] Hake sure to detach the drying rack at the end of the cycle and fully retract the screen back

into the baffle.

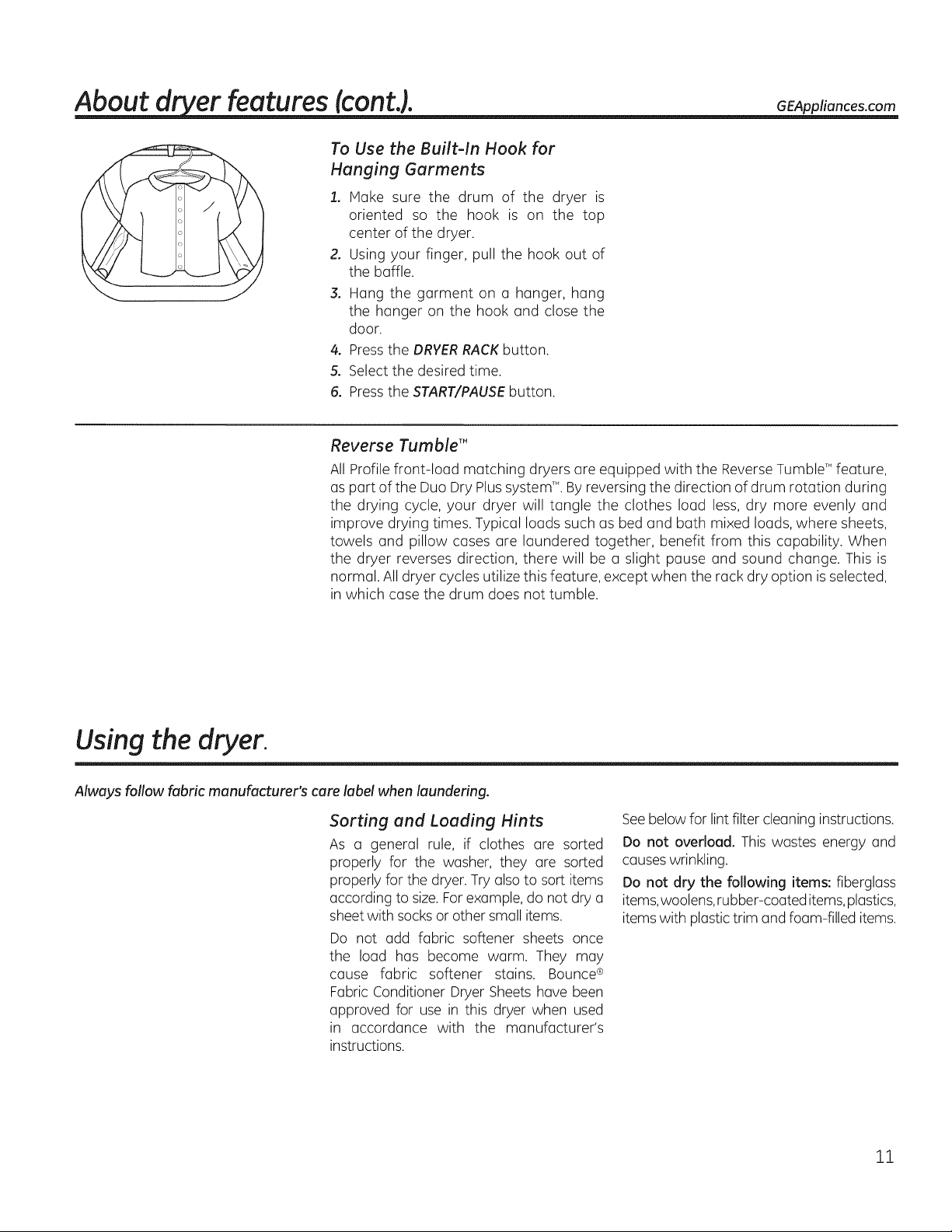

About d er features (cont.). GEAppliances.com

To Use the Built-In Hook for

Hanging Garments

1. Make sure the drum of the dryer is

oriented so the hook is on the top

center of the dryer.

2. Using your finger, pull the hook out of

the baffle.

3. Hang the garment on a hanger, hang

the hanger on the hook and close the

door.

4. Pressthe DRYERRACKbutton.

5. Select the desired time.

6. Press the START/PAUSE button.

Reverse Tumble'"

AllProfile front-loud matching dryers are equipped with the Reverse mumbW" feature,

as part of the Duo Dry Plus system'L By reversing the direction of drum rotation during

the drying cycle, your dryer will tangle the clothes loud less, dry more evenly and

improve drying times. Typical loads such as bed and bath mixed loads, where sheets,

towels and pillow cases are laundered together, benefit from this capability. When

the dryer reverses direction, there will be a slight pause and sound change. This is

normal. Alldryer cycles utilize this feature, except when the rack dry option is selected,

in which case the drum does not tumble.

Using the dryer.

Always follow fabric manufacturer's care label when laundering.

Sorting and Loading Hints

As u general rule, if clothes are sorted

properly for the washer, they are sorted

properly for the dryer. Try also to sort items

according to size. For example, do not dry a

sheet with socks or other small items.

Do not add fabric softener sheets once

the load has become warm. They may

cause fabric softener stains. Bounce ®

Fabric Conditioner Dryer Sheets have been

approved for use in this dryer when used

in accordance with the manufacturer's

instructions.

Seebelow for lint filter cleaning instructions.

Do not overload. This wastes energy and

causeswrinkling.

Do not dry the following items: fiberglass

items,woolens,rubber-coated items,plastics,

items with plastictrim and foam-filled items.

11

Using the dryer.

Fabric Care Labels

Below are fabric care label "symbols" that affect the clothing you willbe laundering.

Wash Labels

cycle No_molP............tP,es_/ Ge,,tl_'_/ Do,,otwo_h Do,,otw,i,,g

Front load Target

target water Category Water Temperature

temperature Co_d 27°C/80°F

wrinkle resistant delicate Hand wash

Tap Cold Inlet Water Temperature

Warm 40°C/105°F

Hot 50°C/120°F

Sanitize 70°C/160°F

Automatic

Temperature Control

Not used

Used

Used

Used

Used

Dry Labels

dry

Dry Normal Permanent Press/

wrinkle resistant

bq

Gentle/

delicate

.eat ® ®

setting

High Medium Low No heat/air

nPsetCiu°cltions

Line dry/ Drip dry Dry fiat In the shade

hang to dry

Bleach Labels

Do not tumble dry

Do not dry

(used with

do not wash)

12

Bleach £ £

symbols AnybJeGch Only ...... hlorine bleach Do not bleach

(when needed) (when needed)

Care and Cleaning of the Dryer

Dryer Interior end Duct: The interior of

the appliance and exhaust duct should be

cleaned once a year by qualified service

personnel.

The Exterior: Wipe or dust any spills or

washing compounds with a damp cloth.

Dryer control panel and finishes may be

damaged by some laundry pretreatment

soil and stain remover products. Apply these

products away from the dryer. The fabric

may then be washed and dried normally.

Damage to your dryer caused by these

products is not covered by your warranty.

Do not touch the surface or the display with

sharp objects.

The Lint Filter: Clean the lint filter before

each use. Remove by pulling straight up.

Run your fingers across the filter. A waxy

buildup may form on the lint filter from

using dryer-added fabric softener sheets.

To remove this buildup, wash the lint screen

in warm, soapy water. Dry thoroughly and

replace. Donot operate the dryer without the

lint filter in place.

Vacuum the lint from the dryer lint filter if you

notice a change in dryer performance.

Stainless Steel: To clean stainless steel

surfaces, use a damp cloth with a mild,

nonabrasive cleaner suitable for stainless

steel surfaces. Remove the cleaner residue,

and then dry with a clean cloth.

Thestainlesssteel used to make the dryer drum

provides the highest reliabilityavailable in a GE

dryer. If the dryer drum should be scratched or

dented during normal use,the drum will not rust

or corrode.Thesesurfaceblemisheswillnot affect

thefunction or durabilityofthe drum.

The Exhaust Hood: Check with a mirror that

the inside flaps of the hood move freely

when operating. Make sure that there is no

wildlife (birds, insects, etc.) nesting inside the

duct or hood.

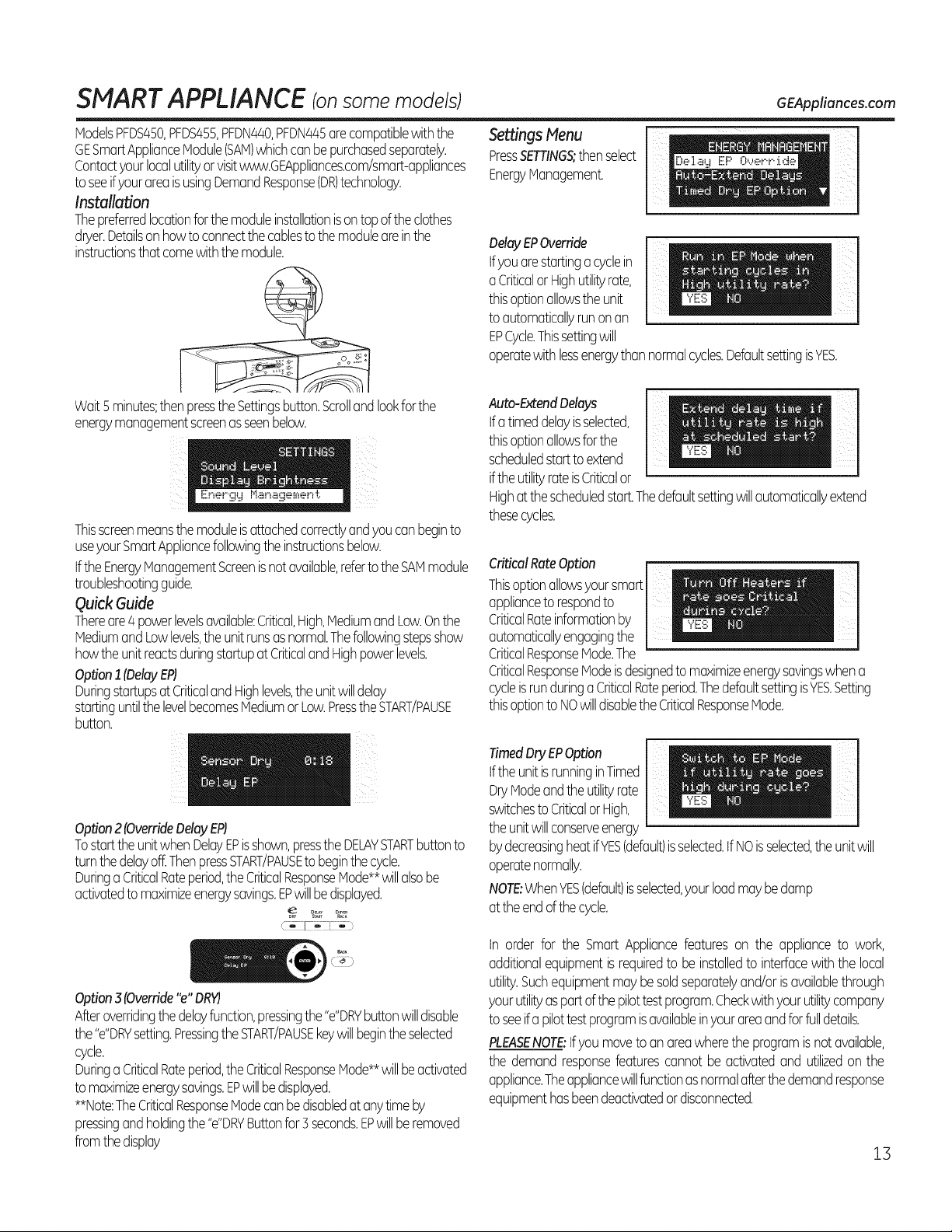

SMART APPLIANCE tonsome models) GEAppliances.com

ModelsPFDS450,PFDS455,PFDN440,PFDN4V45orecompatiblewiththe

GESmartApplianceModule(SAM)whichconbepurchasedseparately.

Contactyourlocalutilityorvisitwww.GEApplionces.com/smort-opplionces

toseeifyourareaisusingDemandResponse(DR)technology.

Installation

Thepreferredlocationforthemoduleinstallationisontop oftheclothes

dryer.Detailsonhowtoconnectthecablestothemoduleareinthe

instructionsthatcomewiththemodule.

Wait5minutes;thenpresstheSettingsbutton.Scrollandlookforthe

energymanagementscreenasseenbelow.

Thisscreenmeansthemoduleisattachedcorrectlyandyouconbeginto

useyourSmartAppliancefollowingtheinstructionsbelow.

tftheEnergyManagementScreenisnotavailable,refertotheSAMmodule

troubleshootingguide.

Quick Guide

Thereore4powerlevelsavailable:Critical,High,MediumandLow.Onthe

MediumandLowlevels,theunitrunsasnormal.Thefollowingstepsshow

howtheunitreactsduringstortupatCriticalandHighpowerlevels.

Option1(DelayEP)

DuringstortupsatCriticalandHighlevels,theunitwilldelay

startinguntilthelevelbecomesMediumorLow.PresstheSTART/PAUSE

button.

PressSETTINGS;thenselect

EnergyManagement.

Settings Nenu r

DelayEPOverride

tfyouorestartingocyclein

oCriticalorHighutilityrate,

thisoptionallowstheunit

toautomaticallyrunonon

EPCycle.Thissettingwill

operatewithlessenergythannormalcycles.DefaultsettingisYES.

tfatimeddelayisselected,

thisoptionallowsforthe

Auto-ExtendDelays

scheduledstarttoextend

ifthe utilityrateisCriticalor

Highatthescheduledstart.Thedefaultsettingwillautomaticallyextend

thesecycles.

CriticalRateOption

Thisoptionallowsyoursmart

appliancetorespondto

CriticalRateinformationby

automaticallyengagingthe

CriticalResponseMode.The

CriticalResponseModeisdesignedtomaximizeenergysavingswhena

cycleisrunduringaCriticalRateperiod.ThedefaultsettingisYES.Setting

thisoptiontoNOwilldisablethe CriticalResponseMode.

Option2(OverrideDelayEPJ

TostarttheunitwhenDelayEPisshown,presstheDELAYSTARTbuttonto

turnthedelayoff.ThenpressSTART/PAUSEto beginthecycle.

DuringaCriticalRateperiod,theCriticalResponseMode**willalsobe

activatedto maximizeenergysavings.EPwillbedisplayed.

Option3(Override"e"DRY}

Afteroverridingthedelayfunction,pressingthe"e"DRYbuttonwilldisable

the"e"DRYsetting.PressingtheSTART/PAUSEkeywillbeginthe selected

cycle.

DuringoCriticalRateperiod,theCriticalResponseMode**willbeactivated

tomaximizeenergysavings.EPwillbedisplayed.

**Note:TheCriticalResponseModeconbedisabledat anytimeby

pressingandholdingthe"e"DRYButtonfor5seconds.EPwillberemoved

fromthedisplay

tftheunitisrunninginTimedDryModeandtheutilityrate

TimedDryEPOption

switchestoCriticalorHigh,

theunitwillconserveenergy

bydecreasingheatifYES(default)isselected,tfNOisselected,the unitwill

operatenormally.

NOTE:WhenYES(default)isselected,yourloadmaybedamp

atthe endofthecycle.

tn orderfor the SmartAppliancefeatureson the applianceto work,

additionalequipmentisrequiredto be installedto interfacewiththelocal

utility.Suchequipmentmaybesoldseparatelyand/orisavailablethrough

yourutilityaspartofthepilottestprogram.Checkwithyourutilitycompany

toseeifapilottestprogramisavailableinyourareaandforfulldetails.

PLEASENOTE:tfyou movetoan areawheretheprogramisnotavailable,

the demandresponsefeaturescannotbeactivatedand utilizedon the

appliance.Theappliancewillfunctionasnormalafterthedemandresponse

equipmenthasbeendeactivatedordisconnected.

13

stall ti

I

Dryer

I

structi

Questions? Call 800.GE.CARES {800.432.2737) or visit our Web site at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

ns

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

• IMPORTANT- Savethese instructions for local

electrical inspector's use.

• IHPORTANT-Observeallgoverning codesand

ordinances.

• Installthe clothes dryer according to the manufacturer's

instructions and local codes.

• Note to Installer - Be sure to leave these instructions

with the Consumer.

• Note to Consumer - Keepthese instructions for future

reference.

• Clothes dryer installation must be performed by a

qualified installer.

• Thisdryer must be exhausted to the outdoors.

° Beforethe old dryer is removed from service or

discarded, remove the dryer door.

° Service information and the wiring diagram are located

in the control console.

° Donot allow children on or in the appliance. Close

supervision of children isnecessary when the appliance

is used near children.

° Proper installation isthe responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

° Removeand discard existing plastic or metal foil duct

and replace with UL-listed duct.

CALIFORNIA SAFE DRINKING WATER AND

TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a

list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires

businessesto warn customers of potential exposureto such

substances. Gas appliances can cause minor exposure to

four ofthese substances,namely benzene,carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete

combustion of natural gas or LP fuels. Properly adjusted

dryers will minimize incomplete combustion. Exposure to

these substances can be minimized further by properly

venting the dryerto the outdoors.

PFDS450 / PFDS455/PFDN440 / PFDN445 /

PFMS450 / PFMS455 / PFMN440 / PFMN445

i

FOR YOUR SAFETY:

I G -- Risk of Fire

• To reduce the risk of severe injury or death, follow all

installation instructions.

• Clothes dryer installation must be performed by a

qualified installer.

Install the clothes dryer according to these

instructions and in accordance with local codes.

This dryer must be exhausted to the outdoors.

Use only rigid metal 4" diameter ductwork inside the

dryer cabinet and use only UL approved transition

ducting between the dryer and the home duct.

DO NOT install a clothes dryer with flexible plastic

ducting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in "Connecting the Dryer to House Vent" on page 26

of this manual. Flexible ducting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

Do not install or store this appliance in any location

where it could be exposed to water and/or weather.

Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

FOR GAS MODELS ONLY:

NOTE: Installation and service of this dryer must be

performed by a qualified installer, service agency or

the gas supplier.

In the Commonwealth of Massachusetts:

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-offvalves, they

shall be T-handle-type.

• A flexible gas connector, when used, must not

exceed 3 feet.

14

Installation Instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove

all of the foam pieces around the legs.

Remove the bag containing the literature and serial

cable.

LOCATION OF YOUR DRYER

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and for

air openings are:

, 0 inch clearance both sides

, 1 inch front

, 3 inches rear

Consideration must be given to provide adequate

clearance for proper operation and service.

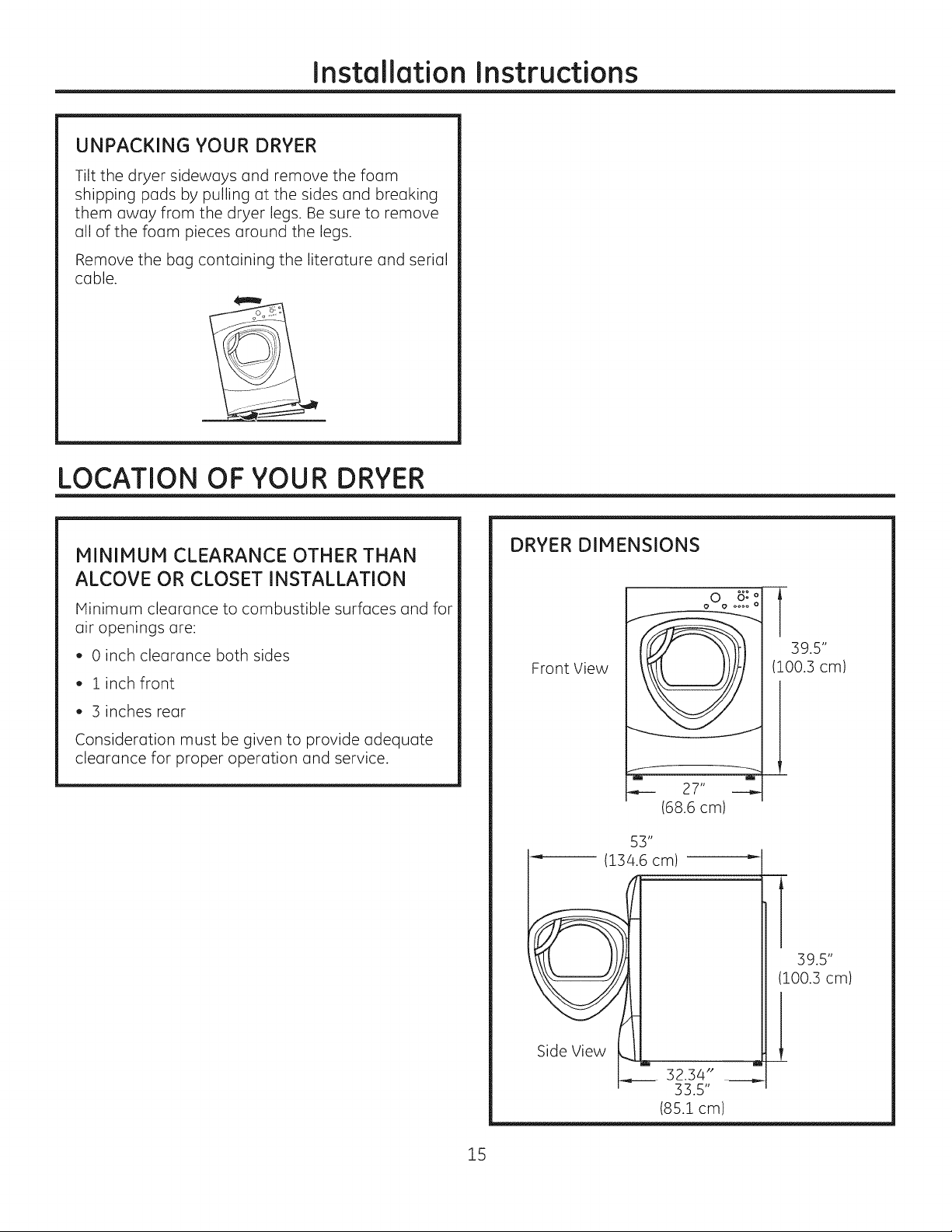

DRYER DIMENSIONS

oOo2!

Front View

27"

(68.6 cm)

53"

I------- 1134.6cm) "

T

39.5"

100.3 cm)

39.5"

(100.3 cm)

15

.!

4-- 32.34"

33.5"

(85.1 cm)

Installation Instructions

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

. Your dryer is approved for installation in an

alcove or closet, as stated on a label on the dryer

back.

. The dryer MUST be vented to the outdoors. See

the EXHAUSTING THE DRYERsection.

. Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0" either side

3"frontand rear

. Minimum vertical space from floor to overhead

shelves, cabinets, ceilings, etc., is 52".

. Closet doors must be Iouvered or otherwise

ventilated and have at least 60 square inches

of open area equally distributed. If the closet

contains both a washer and a dryer, doors must

contain a minimum of 120 square inches of open

area equally distributed.

. The closet should be vented to the outdoors to

prevent gas pocketing in case of gas in the supply

line.

. No other fuel-burning appliance shall be installed

in the same closet with the dryer (gas models

only).

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL IS5.5 INCHES.

BATHROOM OR BEDROOM INSTALLATION

. The dryer MUST be vented to the outdoors. See

EXHAUSTING THE DRYER.

. The installation must conform with local codes or,

in the absence of local codes, with the NATIONAL

ELECTRICALCODE, ANSI/NFPA NO. 70 (for electric

dryers) or NATIONAL FUEL GAS CODE, ANSI Z223

(for gas dryers).

MOBILE OR MANUFACTURED HOME

INSTALLATION

. The installation must conform to the

MANUFACTURED HOME CONSTRUCTION &

SAFETYSTANDARD, TITLE 24, PART32-80 or, when

such standard is not applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME, NO.

50lB.

. The dryer MUST be vented to the outdoors with

the termination securely fastened to the mobile

home structure. (See EXHAUSTING THE DRYER.)

. The vent MUST NOT be terminated beneath a

mobile or manufactured home.

. The vent duct material MUST BE METAL.

. FOR GAS MODELS ONLY: KIT 14-D346-33 MUST be

used to attach the dryer securely to the structure.

. FOR GAS MODELS ONLY: The vent MUST NOT be

connected to any other duct, vent or chimney.

. Do not use sheet metal screws or other refastening

devices which extend into the interior of the

exhaust vent.

. Provide an opening with a free area of at least 25

sq. in. for introduction of outside air into the dryer

room.

GARAGE INSTALLATION (IF ALLOWED

BY LOCAL CODES}

. Dryers installed in garages must be elevated 18

inches (46cm) above the floor.

16

Installation Instructions

CONNECTING iNLET HOSES

CONNECTING INLET HOSES

To produce steam, the dryer must connect to

the cold water supply. Since the washer must

also connect to the cold water, a "Y" connector

is inserted to allow both inlet hoses to make that

connection at the same time.

NOTE: Use the new inlet hoses provided; never use

old hoses.

1. Turn the cold water faucet off. Remove the

washer inlet hose from the washer fill valve

connector (cold).

2. Ensure the rubber flat washer is in place and

screw the female coupling of the short hose onto

the washer fill valve connector. Tighten by hand

until firmly seated.

3. Attach the female end of the "Y" connector to

the male coupling of the short hose. Ensure the

rubber flat washer is in place. Tighten by hand

until firmly seated.

CONNECTING INLET HOSES (cont.)

J

7. Using pliers, tighten all the couplings with an

additional two-thirds turn.

NOTE: Do not overtighten. Damage to the couplings

may result.

8, Turn the water faucet on.

9. Check for leaks around the "Y" connector, faucet

and hose couplings.

.

Insert the filter screen in the coupling of the

washer's inlet hose. If a rubber flat washer is

already in place remove it before installing the

filter screen. Attach this coupling to one male end

of the "Y" connector. Tighten by hand until firmly

seated.

S.

Ensure the rubber flat washer is in place and

attach the dryer's long inlet hose to the other

male end of the "Y" connector. Tighten by hand

until firmly seated.

.

Ensure the rubber flat washer is in place and

attach the other end of the dryer's long inlet

hose to the fill valve connector at the bottom of

the dryer back panel. Tighten by hand until firmly

seated.

WATER SUPPLY REOUIREMENTS

Hot and cold water faucets MUST be installed

within 42 in. (107 cm) of your washer's water

inlet. The faucets MUST be 3/4 in. (1.9 cm) garden

hose-type so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds per

square inch. Your water department can advise you

of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the steam generator if the

home water supply is very hard.

17

Installation Instructions

CONNECTING A GAS

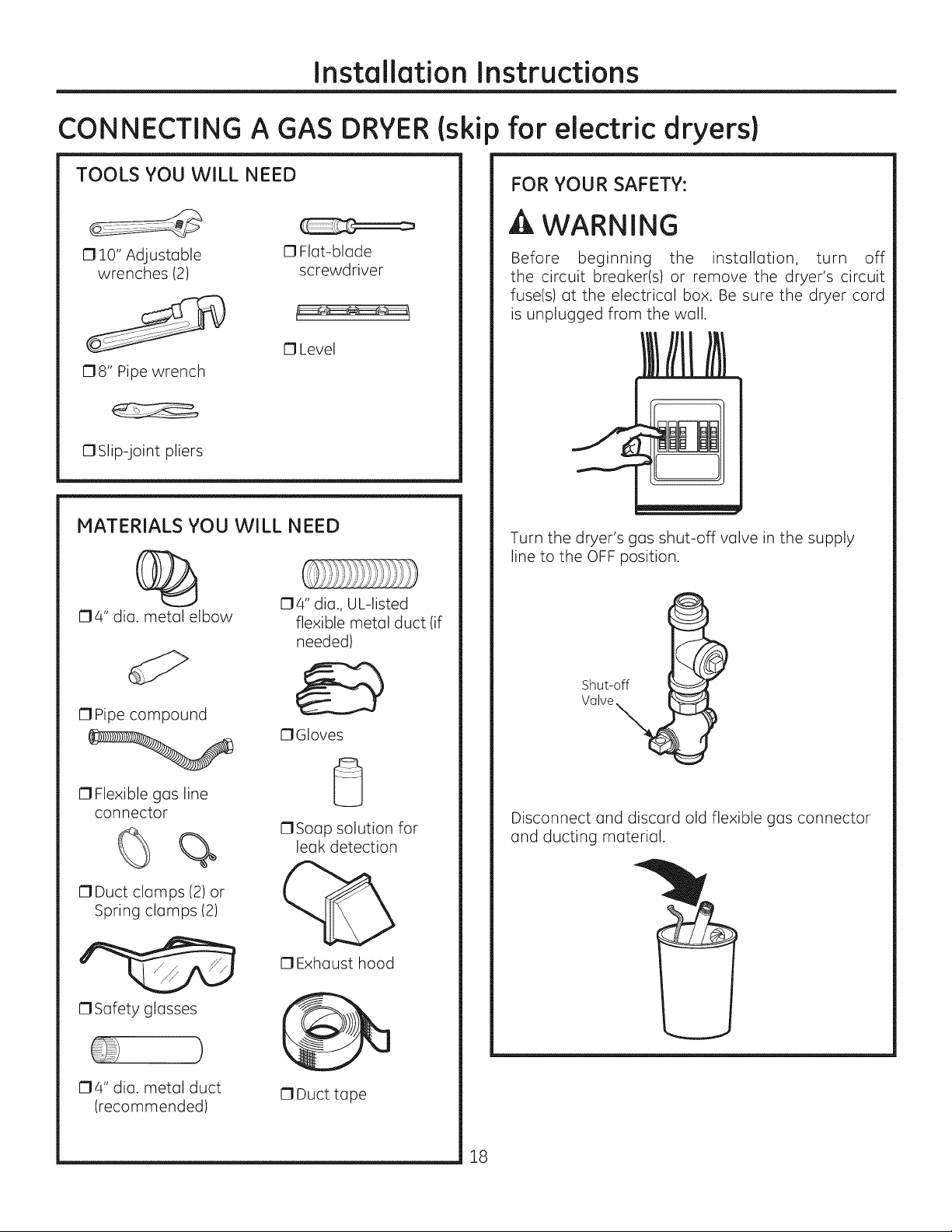

TOOLS YOU WILL NEED

1710" Adjustable

wrenches (2)

C18" Pipe wrench

17Slip-joint pliers

MATERIALS YOU WILL NEED

0 Flat-blade

screwdriver

C1Level

DRYER(ski

) for electric dryersl

FOR YOUR SAFETY:

A WARNING

Before beginning the installation, turn off

the circuit breaker(s) or remove the dryer's circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

Turn the dryer's gas shut-off valve in the supply

line to the OFF position.

174" dia. metal elbow

17Pipe compound

17Flexible gas line

connector

%

17Duct clamps (2) or

Spring clamps (2)

17Safety glasses

174" dia., UL-listed

flexible metal duct (if

needed)

17Gloves

C1Soap solution for

leak detection

17Exhaust hood

Shut-off

Valve

Disconnect and discard old flexible gas connector

and ducting material.

174" dia. metal duct

(recommended)

17Duct tape

18

Installation Instructions

GAS REQUIREMENTS

A WARNING

. Installation must conform to local codes and

ordinances, or in their absence, with the National

Fuel Gas Code, ANSI Z223.Z/NFPA 54, or the Natural

Gas and Propane Installation Code, CSA B149.1.

. This gas dryer is equipped with a Valve and

Burner Assembly for use only with natural gas.

Using conversion kit 14-A048, your local service

organization can convert this dryer for use with

propane (LP)gas. ALL CONVERSIONSMUST BEMADE

BY PROPERLYTRAINEDAND QUALIFIED PERSONNEL

AND IN ACCORDANCE WITH LOCAL CODES AND

ORDINANCE REQUIREMENTS.

, The dryer must be disconnected from the gas supply

piping system during any pressure testing of that

system at a test pressure in excess of 0.5 PSI (3.4

KPa).

, The dryer must be isolated from the gas supply

piping system by closing the equipment shut-off

valve during any pressure testing of the gas supply

piping of test pressure equal to or less than 0.5 PSI

(3.4KPa).

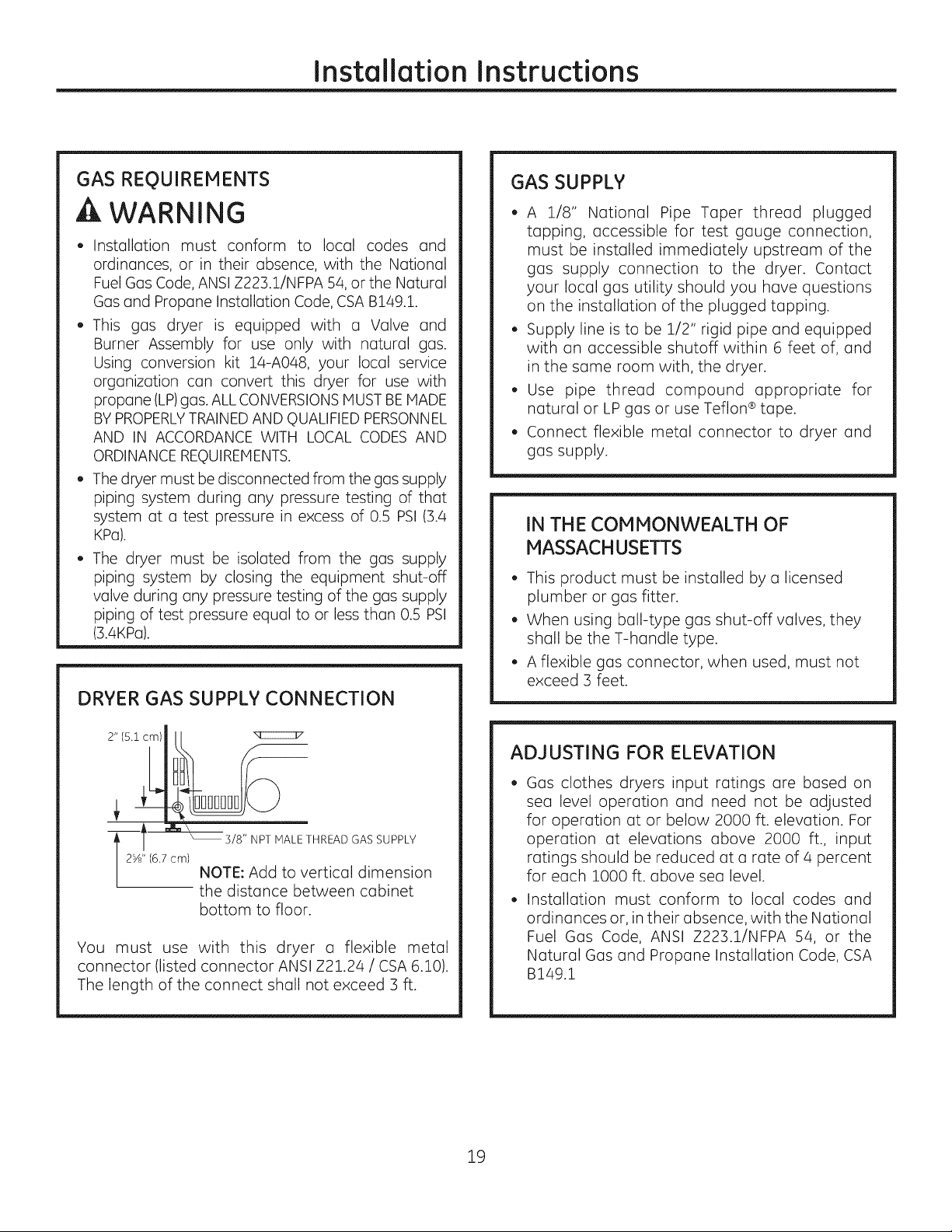

DRYER GAS SUPPLY CONNECTION

GAS SUPPLY

. A 1/8" National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact

your local gas utility should you have questions

on the installation of the plugged tapping.

. Supply line is to be 1/2" rigid pipe and equipped

with an accessible shutoff within 6 feet of, and

in the same room with, the dryer.

. Use pipe thread compound appropriate for

natural or LP gas or use Teflon ®tape.

, Connect flexible metal connector to dryer and

gas supply.

IN THE COMMONWEALTH OF

MASSACHUSETTS

. This product must be installed by a licensed

plumber or gas fitter.

. When using ball-type gas shut-off valves, they

shall be the T-handle type.

. A flexible gas connector, when used, must not

exceed 3 feet.

2" 15.1 cm)

3/8" NPT MALE THREAD GAS SUPPLY

I 2Yd' (6.7 cm)

You must use with this dryer a flexible metal

connector (listed connector ANSI Z21.24 / CSA 6.10).

The length of the connect shall not exceed 3 ft.

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

ADJUSTING FOR ELEVATION

Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation. For

operation at elevations above 2000 ft., input

ratings should be reduced at a rate of a percent

for each 1000 ft. above sea level.

Installation must conform to local codes and

ordinances or, in their absence, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA

B149.1

19

Installation Instructions

CONNECTING A GAS DRYER (cont,)

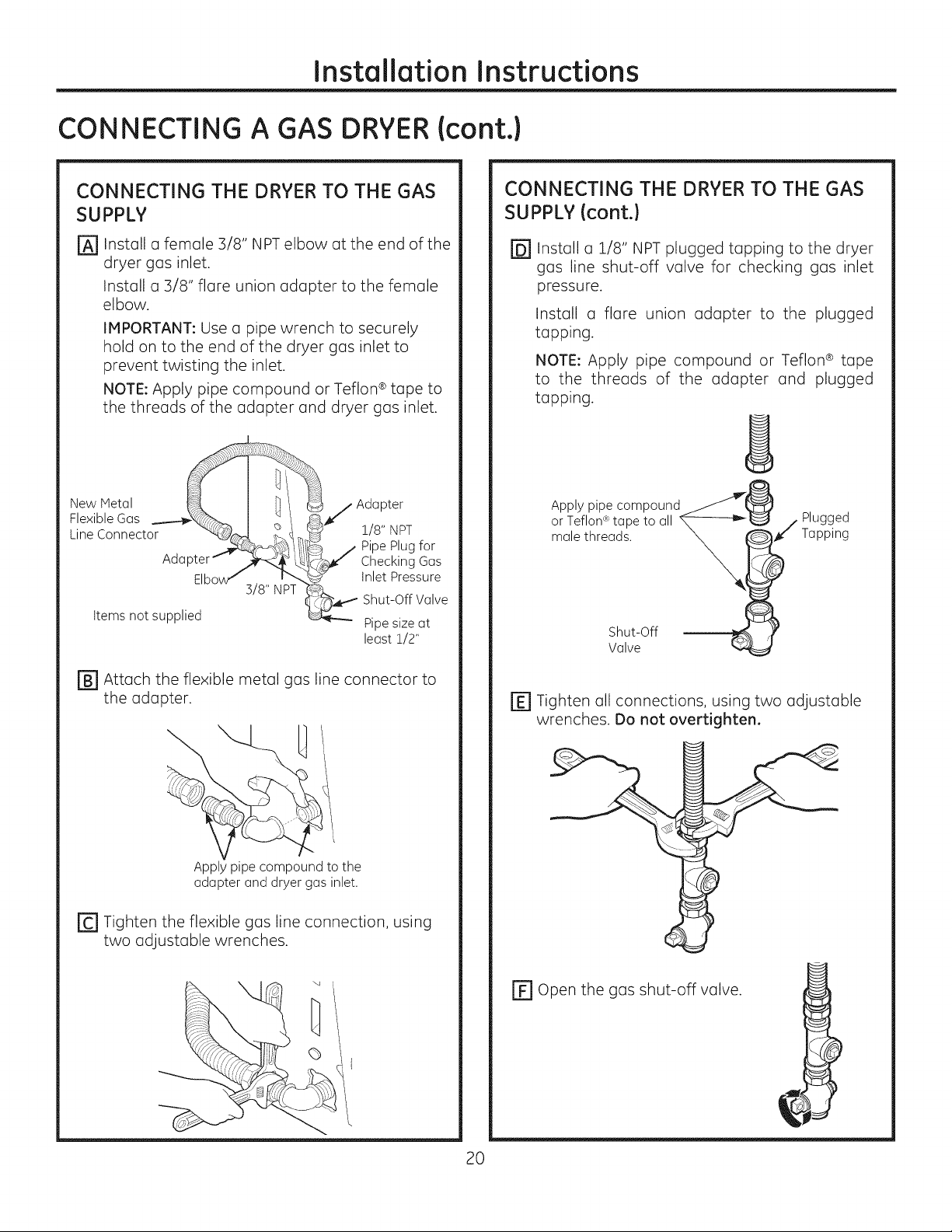

CONNECTING THE DRYER TO THE GAS

SUPPLY

Install a female 3/8" NPTelbow at the end of the

@

dryer gas inlet.

Install a 3/8" flare union adapter to the female

elbow.

IMPORTANT: Use a pipe wrench to securely

hold on to the end of the dryer gas inlet to

prevent twisting the inlet.

NOTE: Apply pipe compound or Teflon ®tape to

the threads of the adapter and dryer gas inlet.

New Metal _¢_

Flexible Gas __...--._x_7_ I &I

Line Connector "*<__,

Adapter"*-" ./_-_ _.

Elbow/ i _.

Items not supplied

3/8" NPT

_/Adapter

_¢" 1/8" NPT

/ Pipe Plug for

]q_ Checking Gas

_ Inlet Pressure

O,, a e

_-'_q_'- Pipe size at

least 1/2"

CONNECTING THE DRYERTO THE GAS

SUPPLY(cont.)

Install a 1/8" NPT plugged tapping to the dryer

@

gas line shut-off valve for checking gas inlet

pressure.

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or Teflon ® tape

to the threads of the adapter and plugged

tapping.

Apply pipe compound

or Teflon¢_tape to all

male threads.

Shut-Off

Valve

Plugged

Tapping

rB1 Attach the flexible metal gas line connector to

the adapter.

Apply pipe compound to the

adapter and dryer gas inlet.

rc1 Tighten the flexible gas line connection, using

two adjustable wrenches.

x,,

• -.q

r_ Tighten all connections, using two adjustable

wrenches. Do not overtighten.

[] Open the gas shut-off valve.

20

Installation Instructions

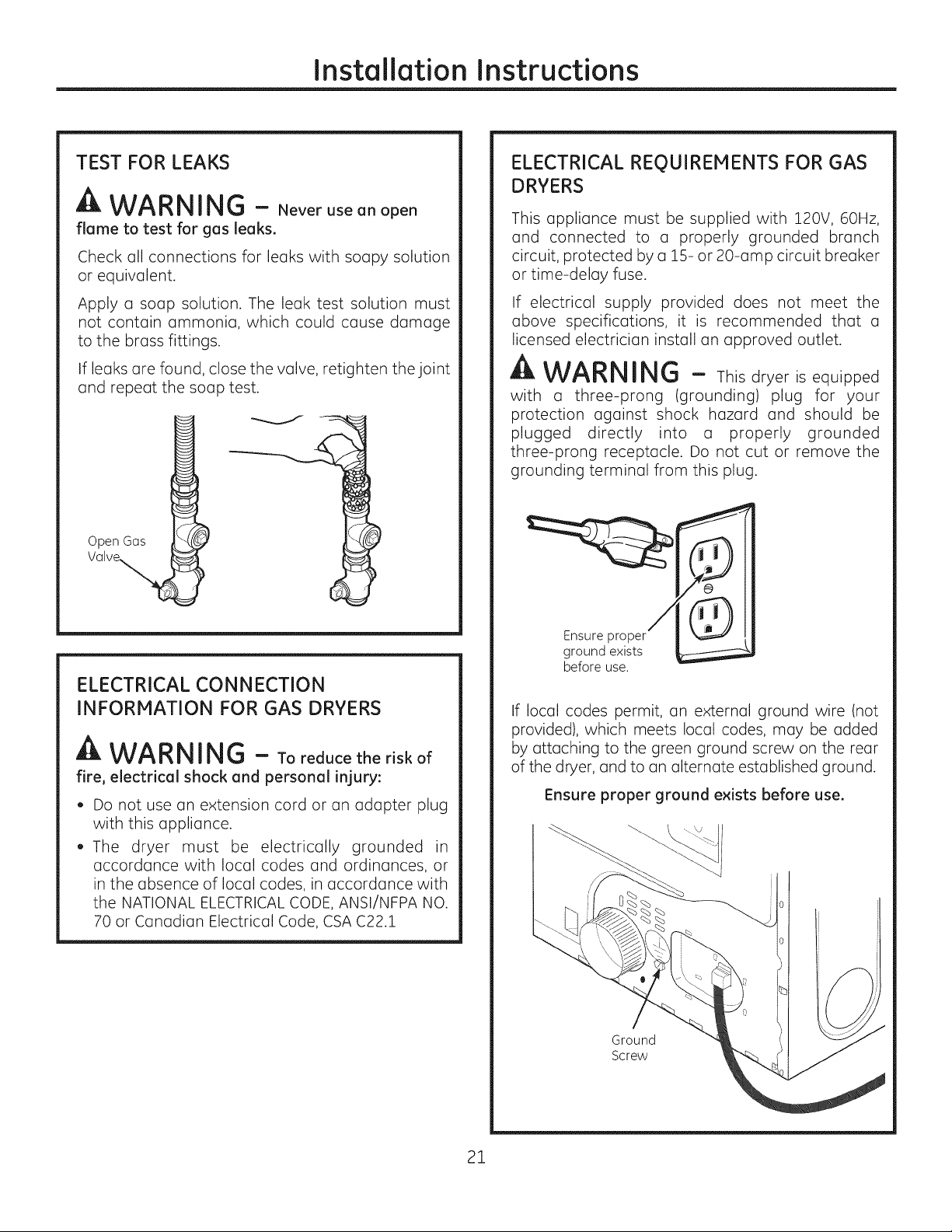

TEST FOR LEAKS

WARNING - Never useanopen

flame to test for gas leaks.

Check all connections for leaks with soapy solution

or equivalent.

Apply a soap solution. The leak test solution must

not contain ammonia, which could cause damage

to the brass fittings.

If leaks are found, close the valve, retighten the joint

and repeat the soap test.

Open Gas

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

A WARNING - Toreducetheriskof

fire, electrical shock and personal injury:

. Do not use an extension cord or an adapter plug

with this appliance.

. The dryer must be electrically grounded in

accordance with local codes and ordinances, or

in the absence of local codes, in accordance with

the NATIONAL ELECTRICAL CODE, ANSI/NFPA NO.

70 or Canadian Electrical Code, CSA C22.1

ELECTRICAL REQUIREMENTS FOR GAS

DRYERS

This appliance must be supplied with 120V, 60Hz,

and connected to a properly grounded branch

circuit, protected by a 15- or 20-amp circuit breaker

or time-delay fuse.

If electrical supply provided does not meet the

above specifications, it is recommended that a

licensed electrician install an approved outlet.

A WARNING - Thisdryerisequipped

with a three-prong (grounding) plug for your

protectionagainst shock hazard and should be

plugged directly into a properly grounded

three-prongreceptacle.Do not cut or remove the

groundingterminalfrom thisplug.

/II IIII

Ensure proper

ground exists

before use.

If local codes permit, an external ground wire (not

provided), which meets local codes, may be added

by attaching to the green ground screw on the rear

of the dryer, and to an alternate established ground.

Ensure proper ground exists before use.

21

Ground

Screw

InstallationInstructions

CONNECTING AN ELECTRIC DRYER {skipfor gas dryers)

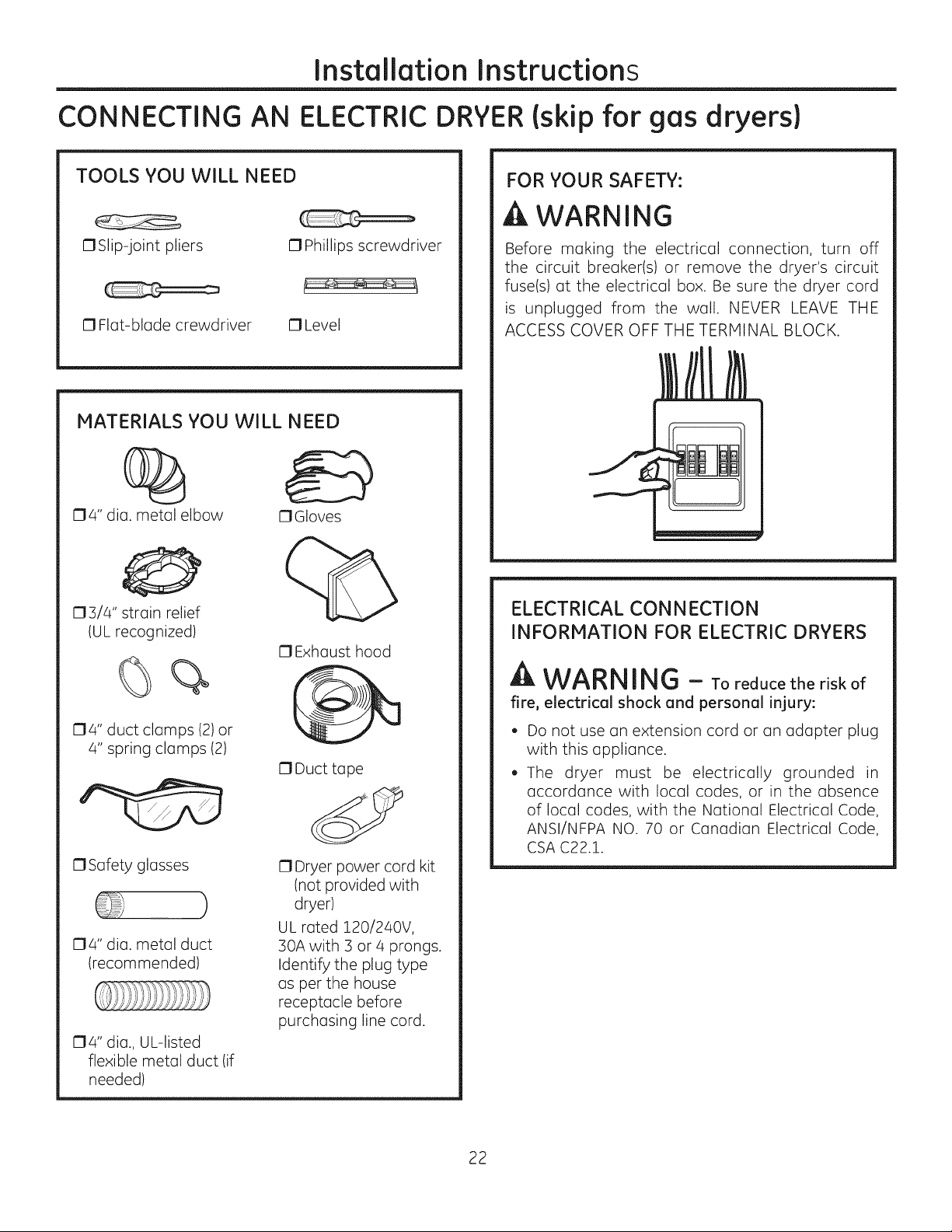

TOOLS YOU WILL NEED

OSlip-joint pliers

O Phillips screwdriver

__,====_

O Flat-blade crewdriver

MATERIALS YOU WILL NEED

O4" dia. metal elbow

O Level

OGIoves

%

O3/4" strain relief

(UL recognized)

0 Exhaust hood

FOR YOUR SAFETY:

A WARNING

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer's circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall. NEVER LEAVE THE

ACCESS COVER OFF THE TERMINAL BLOCK.

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

%

04" duct clamps (2)or

4" spring clamps (2)

0 Safety glasses

04" dia. metal duct

(recommended)

04" dia., UL-listed

flexible metal duct (if

needed)

O Duct tape

0 Dryer power cord kit

(not provided with

dryer)

UL rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type

as per the house

receptacle before

purchasing line cord.

A WARNING - Toreducetheriskof

fire, electrical shock and personal injury:

. Do not use an extension cord or an adapter plug

with this appliance.

. The dryer must be electrically grounded in

accordance with local codes, or in the absence

of local codes, with the National Electrical Code,

ANSI/NFPA NO. 70 or Canadian Electrical Code,

CSA C22.1.

22

Installation Instructions

ELECTRICAL REOUIREMENTS FOR

ELECTRIC DRYERS

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. A three- or four-wire,

single-phase, 120/240V or 120/208V, 60Hz, 30-amp

circuit is required.

If the electric supply does not meet the above

specifications, then call a licensed electrician.

ELECTRICAL REQUIREMENTS FOR

ELECTRIC DRYERS (CANADA)

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. The power supply must

be of 120/240 volts, 60Hz circuit with the wall

receptacle as shown below.

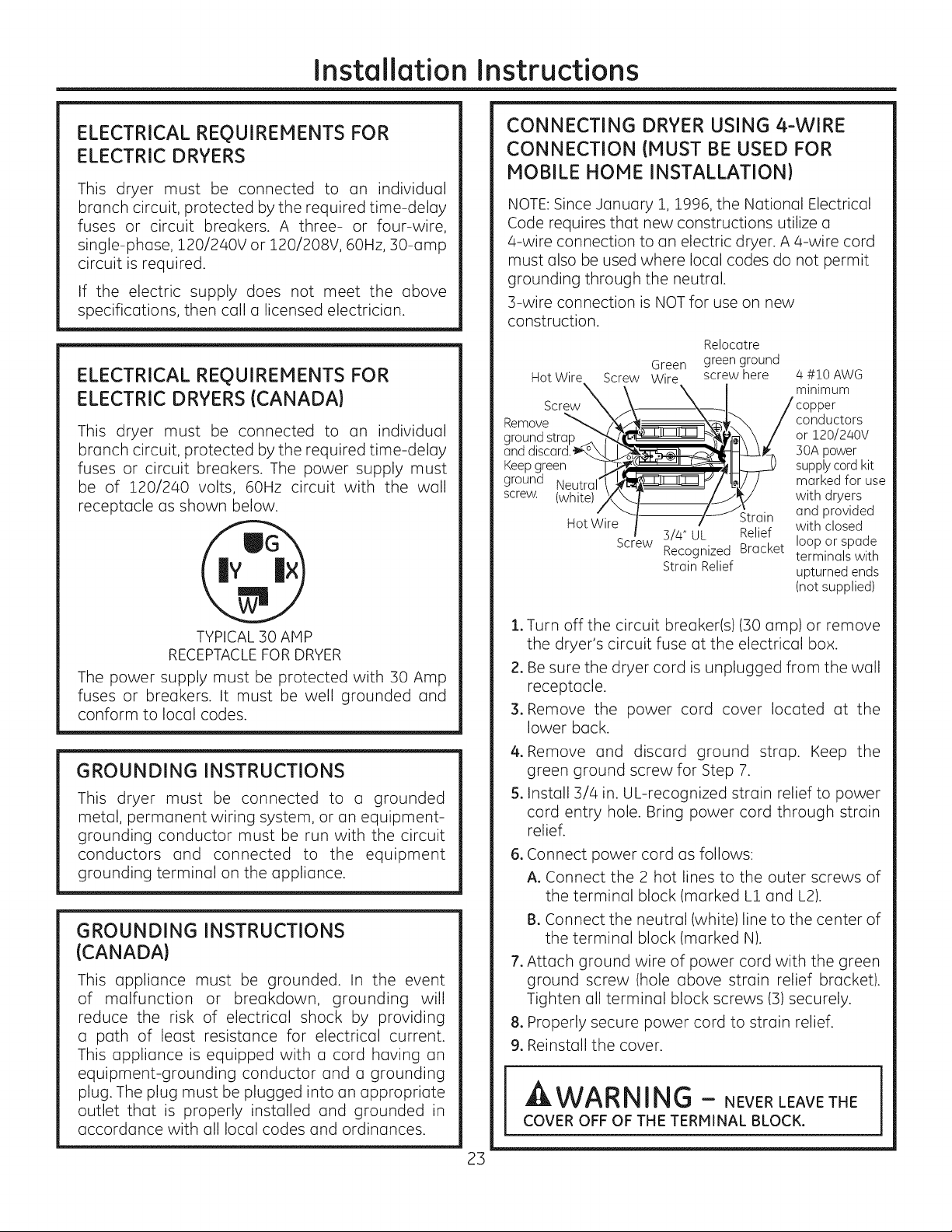

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE:Since January 1, 1996, the National Electrical

Code requires that new constructions utilize a

4-wire connection to an electric dryer. A 4-wire cord

must also be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new

construction.

Relocatre

Green green ground

Hot Wire Screw Wire screw here /4#10 AWG

Screw I minimum

Remove

ground strap

and

Keepgreen

ground Neutral

screw. (white)

Hot Wire Strain

Screw 3//4" UL Relief

Recognized Bracket

Strain Relief

conductors

or 120/2/40V

30A power

supply cord kit

marked for use

with dryers

and provided

with closed

loop or spade

terminals with

upturned ends

(not supplied)

TYPICAL 30 AMP

RECEPTACLEFOR DRYER

The power supply must be protected with 30 Amp

fuses or breakers. It must be well grounded and

conform to local codes.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded

metal, permanent wiring system, or an equipment-

grounding conductor must be run with the circuit

conductors and connected to the equipment

grounding terminal on the appliance.

GROUNDING INSTRUCTIONS

(CANADA)

This appliance must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electrical shock by providing

a path of least resistance for electrical current.

This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

.

Turn off the circuit breaker(s) (30 amp) or remove

the dryer's circuit fuse at the electrical box.

2.

Be sure the dryer cord is unplugged from the wall

receptacle.

3.

Remove the power cord cover located at the

lower back.

4.

Remove and discard ground strap. Keep the

green ground screw for Step 7.

5.

Install 3/4 in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

.

Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

.

Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) securely.

.

Properly secure power cord to strain relief.

9.

Reinstall the cover.

A,WARNING - NEVERLEAVETHE

COVER OFF OF THE TERMINAL BLOCK.

23

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

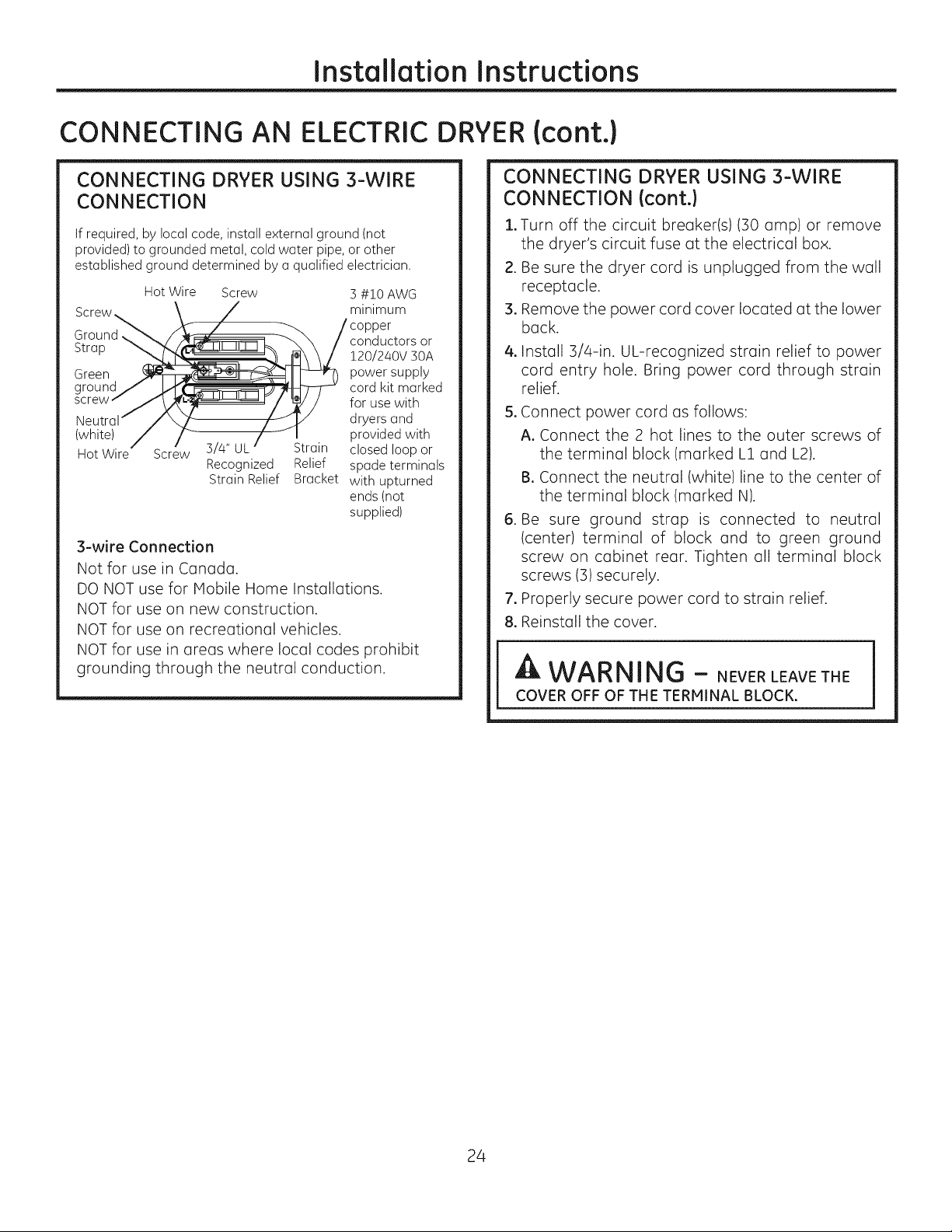

CONNECTING DRYER USING 3-WIRE

CONNECTION

If required, by local code, install external ground (not

provided) to grounded metal, cold water pipe, or other

established ground determined by a qualified electrician.

Hot Wire Screw 3 #10 AWG

minimum

Ground,

Strap

Green

(white)

Hot Screw

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations.

NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit

grounding through the neutral conduction.

3/4" UL Strain

Recognized Relief

Strain Relief Bracket

conductors or

120/240V 50A

power supply

cord kit marked

for use with

dryers and

provided with

closed loop or

spade terminals

with upturned

ends (not

supplied)

CONNECTING DRYER USING 3-WIRE

CONNECTION (cont.)

1oTurn off the circuit breaker(s) (30 amp) or remove

the dryer's circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall

receptacle.

3, Remove the power cord cover located at the lower

back.

4, Install 3/4-in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

5oConnect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

BoConnect the neutral (white) line to the center of

the terminal block (marked N).

6. Be sure ground strap is connected to neutral

(center) terminal of block and to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) securely.

7, Properly secure power cord to strain relief.

8, Reinstall the cover.

WARNING - NEVERLEAVETHE

COVER OFF OF THE TERMINAL BLOCK.

24

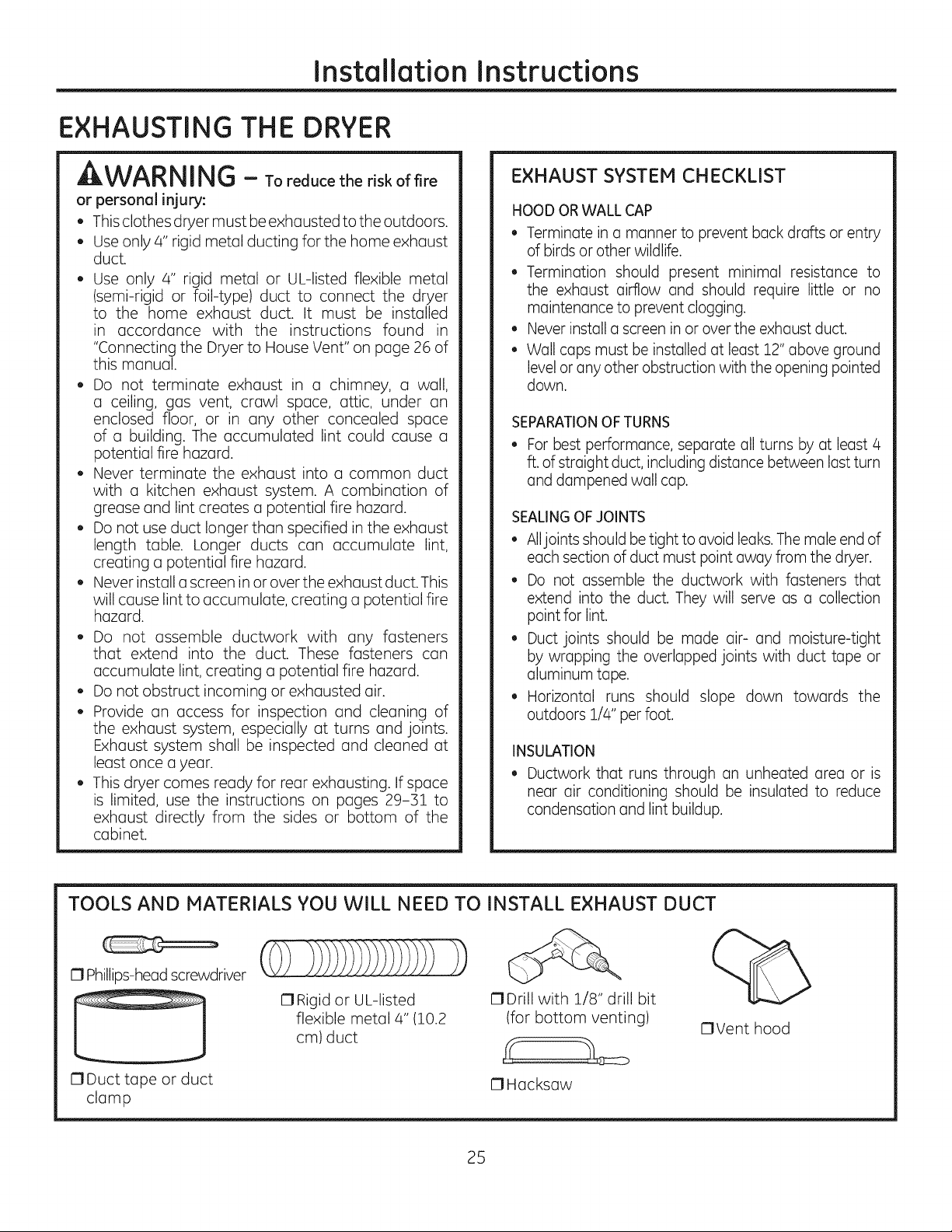

Installation Instructions

EXHAUSTING THE DRYER

WARNING - To reduce the risk of fire

or personal injury:

, This clothes dryer must be exhausted to the outdoors.

, Use only 4" rigid metal ducting for the home exhaust

duct.

, Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

"Connecting the Dryer to House Vent" on page 26 of

this manual.

, Do not terminate exhaust in a chimney, a wall,

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space

of a building. The accumulated lint could cause a

potential fire hazard.

, Never terminate the exhaust into a common duct

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

, Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

, Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

, Do not assemble ductwork with any fasteners

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

, Do not obstruct incoming or exhausted air.

, Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

, This dryer comes ready for rear exhausting. If space

is limited, use the instructions on pages 29-31 to

exhaust directly from the sides or bottom of the

cabinet.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

• Termination should present minimal resistance to

the exhaust airflow and should require little or no

maintenance to prevent clogging.

• Never install a screen in or over the exhaust duct.

• Wall caps must be installed at least 12" above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOF TURNS

Forbest performance,separateallturns by at least/4

ft.of straightduct,includingdistancebetweenlastturn

anddampenedwall cap.

SEALINGOFJOINTS

• Alljoints should be tight to avoid leaks. The male end of

each section of duct must point away from the dryer.

• Do not assemble the ductwork with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints should be made air- and moisture-tight

by wrapping the overlapped joints with duct tape or

aluminum tape.

• Horizontal runs should slope down towards the

outdoors 1/4" per foot.

INSULATION

Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint buildup.

TOOLS AND MATERIALS YOU WILL NEED TO INSTALL EXHAUST DUCT

17Phillips-head screwdriver

17Rigid or UL-listed

flexible metal 4" (10.2

cm) duct

C1Duct tape or duct

clamp

17Drill with 1/8" drill bit

(for bottom venting)

17Hacksaw

25

C1Vent hood

Installation Instructions

EXHAUSTING THE DRYERIcont.)

CONNECTING THE DRYER TO HOUSE

VENT

RIGID METALTRANSITIONDUCT

• For best drying performance, a rigid metal transition

duct is recommended.

• Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTED FLEXIBLEMETAL ISEMI-RIGID) TRANSITION

DUCT

• If rigid metal duct cannot be used, then UL-listed

flexible metal (semi-rigid)ducting can be used (Kit

WXO8XlO077).

• Never install flexible metal duct in walls, ceilings, floors

or other enclosed spaces.

• Total length of flexible metal duct should not exceed 8

feet (2./4m).

• For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing the

transition duct, maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL IFOIL-TYPE) TRANSITION

DUCT

• In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal

(foil-type) duct. A UL-listed flexible metal (foil-type)duct

may be used ONLYin installations where rigid metal or

flexible metal (semi-rigid) ducting cannot be used AND

where a 4" diameter can be maintained throughout

the entire length of the transition duct.

• In Canada and the United States, only the flexible

metal (foil-type) ducts that comply with the "Outline for

Clothes Dryer Transition Duct Subject 2158A" shall be

used.

Never install flexible metal duct in walls, ceilings, floors

or other enclosed spaces.

Total length of flexible metal duct should not exceed 8

feet (2./4m).

Avoid resting the duct on sharp objects.

For best drying performance:

1.Slide one end of the duct over the clothes dryer

outlet pipe.

2.Secure the duct with a clamp.

3.With the dryer in its permanent position, extend

the duct to its full length. Allow 2" of duct to

overlap the exhaust pipe. Cut off and remove

excess duct. Keepthe duct asstraight aspossible

for maximum aidlow.

/4.Secure the duct to the exhaust pipe with the

other clamp.

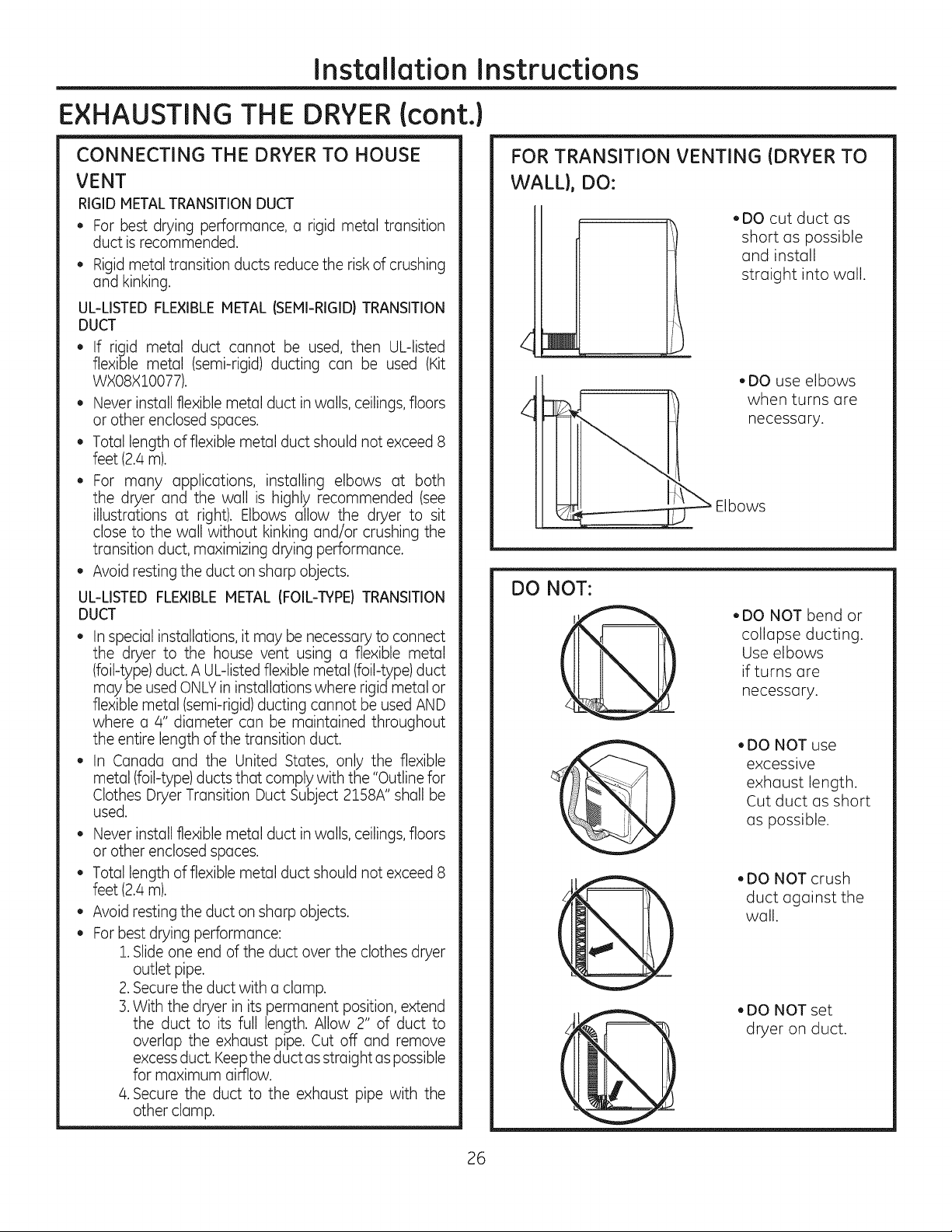

FOR TRANSITION VENTING (DRYER TO

WALL), DO:

,DO cut duct as

short as possible

and install

straight into wall.

,DO use elbows

when turns are

necessary.

bows

DO NOT:

• DO NOT bend or

collapse ducting.

Use elbows

if turns are

'@

necessary.

. DO NOT use

excessive

exhaust length.

Cut duct as short

as possible.

. DO NOT crush

duct against the

wall.

. DO NOT set

dryer on duct.

26

Installation Instructions

WARNING - USEONLYMETAL4"

DUCT. DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

, Increase the drying times and the energy cost.

, Reduce the dryer life.

, Accumulate lint, creating a potential fire

hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation are not

covered by the warranty.

The MAXIMUM ALLOWABLE length of the

exhaust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall

cap) and all conditions noted below.

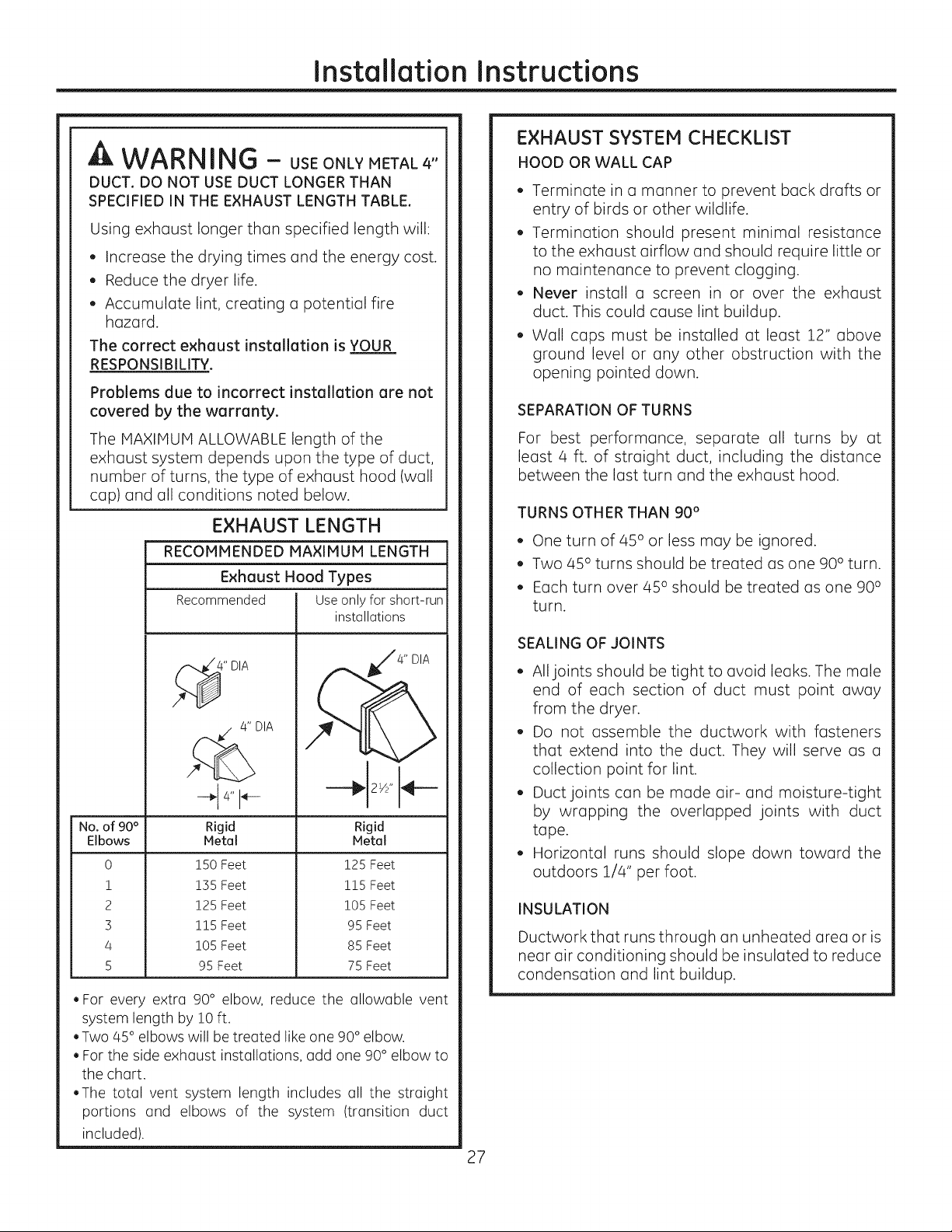

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Useonly for short-run

4" DIA

4" DIA

No. of 90°

Elbows

0

1

2

3

4

5

Rigid

Metal

150 Feet

155 Feet

125 Feet

115 Feet

105 Feet

95 Feet

. For every extra 90° elbow, reduce the allowable vent

system length by !0 ft.

.Two 45° elbows will betreated like one 90° elbow.

. For the side exhaust installations, add one 90° elbow to

the chart.

.The total vent system length includes all the straight

portions and elbows of the system (transition duct

included).

installations

_,,,'/4" DIA

Rigid

Metal

125 Feet

115 Feet

105 Feet

95 Feet

85 Feet

75 Feet

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

, Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

, Termination should present minimal resistance

to the exhaust airflow and should require little or

no maintenance to prevent clogging.

, Never install a screen in or over the exhaust

duct. This could cause lint buildup.

, Wall caps must be installed at least 12" above

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

For best performance, separate all turns by at

least 4 ft. of straight duct, including the distance

between the last turn and the exhaust hood.

TURNS OTHER THAN 90°

, One turn of 45 ° or less may be ignored.

, Two 45 ° turns should be treated as one 90° turn.

, Each turn over 45 ° should be treated as one 90°

turn.

SEALING OF JOINTS

, All joints should be tight to avoid leaks. The male

end of each section of duct must point away

from the dryer.

, Do not assemble the ductwork with fasteners

that extend into the duct. They will serve as a

collection point for lint.

, Duct joints can be made air- and moisture-tight

by wrapping the overlapped joints with duct

tape.

, Horizontal runs should slope down toward the

outdoors 1/4" per foot.

INSULATION

Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint buildup.

27

Installation Instructions

EXHAUSTING THE DRYER{cont.)

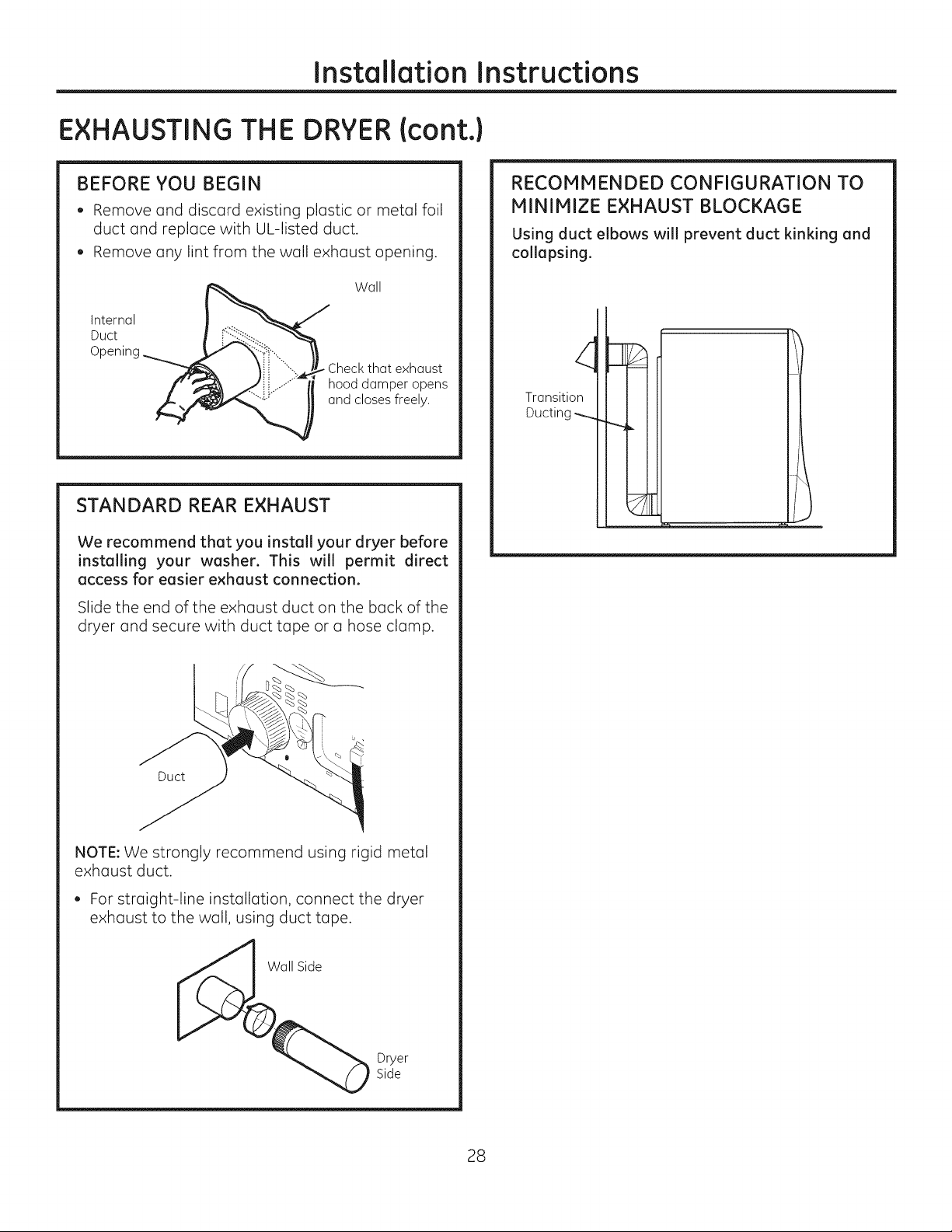

BEFORE YOU BEGIN

, Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

, Remove any lint from the wall exhaust opening.

Wall

Internal

Duct

Check that exhaust

hood damper opens

and closes freely.

STANDARD REAR EXHAUST

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the

dryer and secure with duct tape or a hose clamp.

RECOMMENDED CONFIGURATION TO

MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Transition

Ducting

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct.

, For straight-line installation, connect the dryer

exhaust to the wall, using duct tape.

all Side

Dryer

Side

28

Installation Instructions

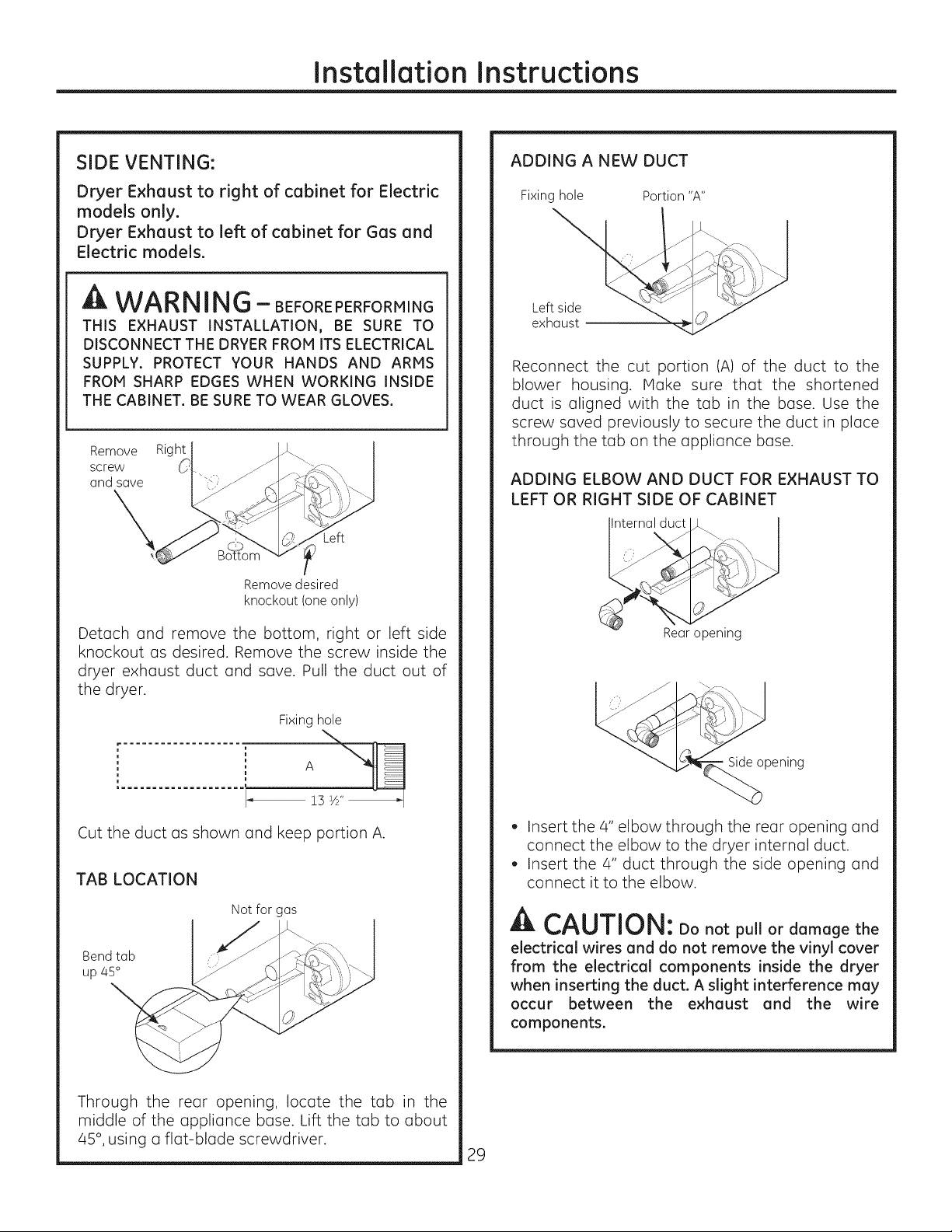

SIDE VENTING:

Dryer Exhaust to right of cabinet for Electric

models only.

Dryer Exhaust to left of cabinet for Gas and

Electric models.

WARNING- BEFOREPERFORMING

THiS EXHAUST INSTALLATION, BE SURE TO

DISCONNECT THE DRYER FROM iTS ELECTRICAL

SUPPLY. PROTECT YOUR HANDS AND ARMS

FROM SHARP EDGES WHEN WORKING INSIDE

THE CABINET. BE SURE TO WEAR GLOVES.

Remove Right

screw

and save

Left

Remove desired

knockout (one only)

ADDING A NEW DUCT

Fixing hole Portion "A"

Lef _..., _"_

exhaust ,..._

Reconnect the cut portion (A) of the duct to the

blower housing. Make sure that the shortened

duct is aligned with the tab in the base. Use the

screw saved previously to secure the duct in place

through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET

nternal duct

Detach and remove the bottom, right or left side

knockout as desired. Remove the screw inside the

dryer exhaust duct and save. Pull the duct out of

the dryer.

Fixing hole

Cut the duct as shown and keep portion A.

TAB LOCATION

Notfor gas

Bend tab

up 45 °

Rear opening

Side opening

, Insert the 4" elbow through the rear opening and

connect the elbow to the dryer internal duct.

, Insert the 4" duct through the side opening and

connect it to the elbow.

A CAUTION: Donotpu,or damage the

electrical wires and do not remove the vinyl cover

from the electrical components inside the dryer

when inserting the duct. A slight interference may

occur between the exhaust and the wire

components.

Through the rear opening, locate the tab in the

middle of the appliance base. Lift the tab to about

45°, using a flat-blade screwdriver.

29

Installation Instructions

EXHAUSTING THE DRYER(cont.)

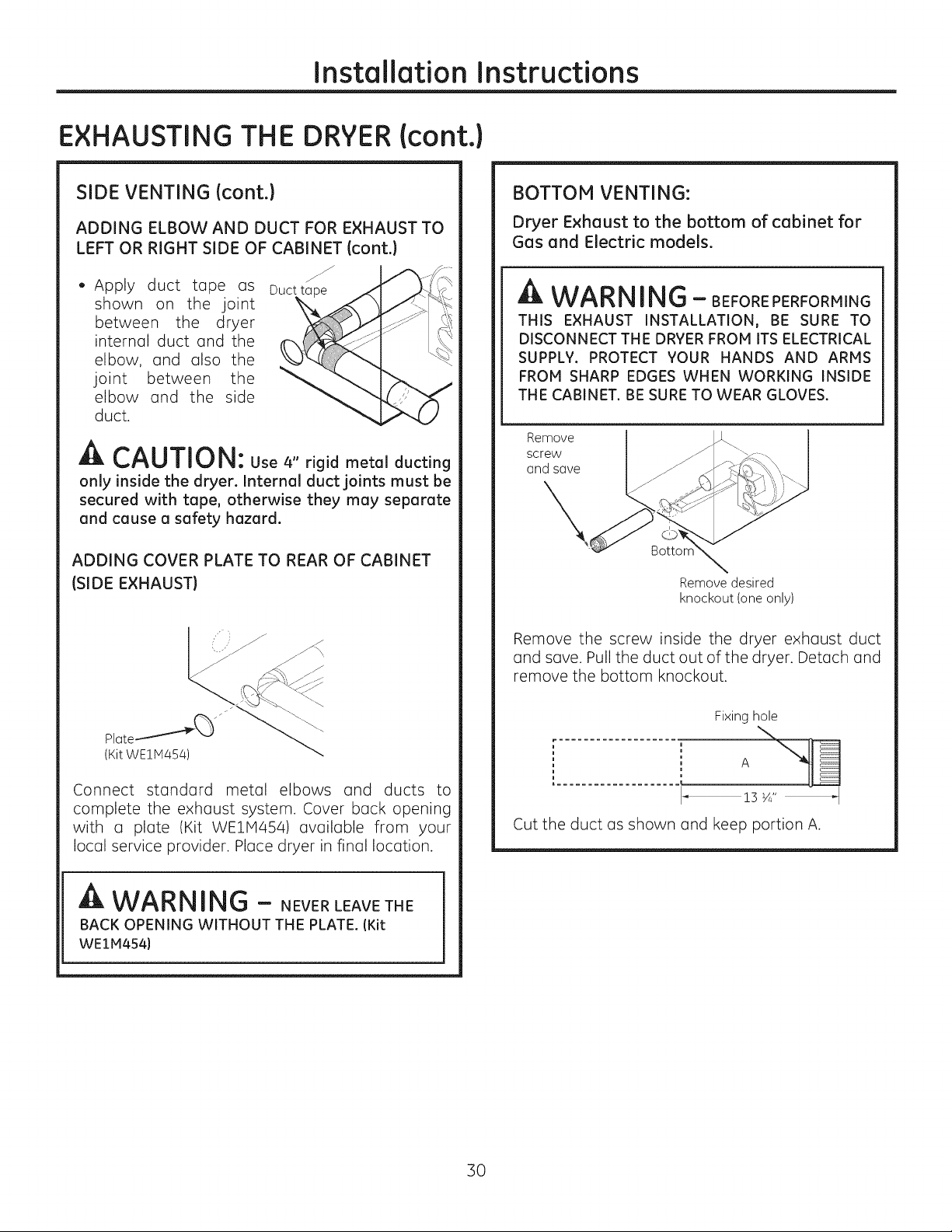

SIDE VENTING (cont.)

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET (cont.}

, Apply duct tope as

shown on the joint

between the dryer

internal duct and the

elbow, and also the

joint between the

elbow and the side

duct.

jJ

Duct ta

A CAUTION: Use 4" rigid metal ducting

only inside the dryer. Internal duct joints must be

secured with tope, otherwise they may separate

and cause a safety hazard.

ADDING COVER PLATE TO REAR OF CABINET

(SIDE EXHAUST}

j zf

BOTTOH VENTING:

Dryer Exhaust to the bottom of cabinet for

Gas and Electric models.

_k WA RNING- BEFOREPERFORMING

THIS EXHAUST INSTALLATION, BE SURE TO

DISCONNECT THE DRYER FROM ITS ELECTRICAL

SUPPLY. PROTECT YOUR HANDS AND ARMS

FROM SHARP EDGES WHEN WORKING INSIDE

THE CABINET. BE SURE TO WEAR GLOVES.

Remove

screw

and save

Bottor

Remove desired

knockout (one only)

Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer. Detach and

remove the bottom knockout.

(Kit WE1M454)

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with u plate (Kit WEIM454) available from your

local service provider. Place dryer in final location.

WARNING - NEVERLEAVETHE

BACK OPENING WITHOUT THE PLATE. (Kit

WE1M454}

Fixing hole

L.................... _

!3 Y4"_1

Cut the duct as shown and keep portion A.

30

Loading...

Loading...