Page 1

GEAppliances.com

Profile

Safety Instructions ........... 2–4

Operating Instructions

Controls ........................... 5–8

Cycle Options ....................9, 10

Smart Appliance ....................13

Dryer Features ..................10, 11

Quick Start Guide ....................5

Settings Option ......................10

Using the Dryer .....................11

Installation Instructions

Before You Begin ................14, 15

Connecting the Inlet Hoses .........17

Connecting a Gas Dryer .........18–21

Connecting an

Electric Dryer ....................22–24

Exhausting the Dryer ............25–31

Final Setup ..........................32

Installing the Pedestal ...........43–45

Location of your Dryer ..........15, 16

Reversing the Door Swing .......33–39

Stacking the Washer

and Dryer .......................40–42

Owner’s Manual &

Installation Instructions

PFDS450

PFDS455

PFDN440

PFDN445

PFMS450

PFMS455

PFMN440

PFMN445

Sécheuses

Profile

Manuel d’utilisation et

d’installation

La section française commence à la page 52

Printed in Mexico

Troubleshooting Tips .......46–49

Consumer Support

Dryers

Consumer Support ........ Back Cover

Warranty (Canada) ................. 51

Warranty (U.S.) ..................... 50

SAVE THESE INSTRUCTIONS

Write the model and serial

numbers here:

Model # ______________

Serial # _______________

They are on the label on the front

of the dryer behind the door.

Secadoras

Profile

Manual del propietario e

instalación

La sección en español empieza en la página 104

234D2010P001 49-90472 03-13 GE

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk

of fire or explosion, electric shock, or to prevent property damage, personal injury, or

death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light a match, or cigarette,

1

or turn on any gas or electrical

appliance.

Do not touch any electrical switch; do

2

not use any phone in your building.

Clear the room, building or area of all

3

occupants.

California Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires businesses to warn customers of potential exposure to

such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be minimized

further by properly venting the dryer to the outdoors.

Immediately call your gas supplier

4

from a neighbor’s phone. Follow the

gas supplier’s instructions carefully.

If you cannot reach your gas supplier,

5

call the fire department.

PROPER INSTALLATION

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used. Installation Instructions are included in the back of this manual.

Properly ground dryer to conform with all governing

codes and ordinances. Follow details in Installation

Instructions.

Install or store where it will not be exposed to

temperatures below freezing or exposed to water or

weather.

Connect to a properly rated, protected and sized

power supply circuit to avoid electrical overload.

Remove all sharp packing items and dispose of all

shipping materials properly.

2

Exhaust/Ducting

Dryers MUST be exhausted to the outside to prevent

1

large amounts of moisture and lint from being blown

into the room.

Use only rigid metal 4” diameter ductwork inside the

2

dryer cabinet. Use only UL approved rigid metal or

flexible metal 4-in diameter ductwork for exhausting

to the outdoors. Never use plastic or other

combustible, easy-to-puncture ductwork. USE OF

PLASTIC OR OTHER COMBUSTIBLE DUCTWORK CAN

CAUSE A FIRE. PUNCTURED DUCTWORK CAN CAUSE

A FIRE IF IT COLLAPSES OR BECOMES OTHERWISE

RESTRICTED IN USE OR DURING INSTALLATION.

For complete details, follow the Installation Instructions.

Page 3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING. GEAppliances.com

WARNING!

YOUR LAUNDRY AREA

Keep the area underneath and around your

appliances free of combustible materials, (lint, paper,

rags, etc.), gasoline, chemicals and other flammable

vapors and liquids.

Keep the floor around your appliances clean and dry

to reduce the possibility of slipping.

Close supervision is necessary if this appliance is

used by or near children. Do not allow children to play

on, with or inside this or any other appliance.

WHEN USING YOUR DRYER

Keep the area around the exhaust opening

and adjacent surrounding areas free from the

accumulation of lint, dust and dirt.

Keep all laundry aids (such as detergents, bleaches,

etc.) out of the reach of children, preferably in a

locked cabinet. Observe all warnings on container

labels to avoid injury.

Never climb on or stand on the dryer top.

Never reach into the dryer while the drum is moving.

Before loading, unloading or adding clothes, wait until

the drum has completely stopped.

Clean the lint filter before each load to prevent lint

accumulation inside the dryer or in the room. DO NOT

OPERATE THE DRYER WITHOUT THE LINT FILTER IN

PLACE.

Do not wash or dry articles that have been cleaned in,

washed in, soaked in or spotted with combustible or

explosive substances (such as wax, oil, paint, gasoline,

degreasers, dry-cleaning solvents, kerosene, etc.).

These substances give off vapors that may ignite or

explode. Do not add these substances to the wash

water. Do not use or place these substances around

your washer or dryer during operation.

Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

clothes load to catch fire.

Any article on which you have used a cleaning

solvent or that contains flammable materials (such

as cleaning cloths, mops, towels used in beauty

salons, restaurants or barber shops, etc.) must not

be placed in or near the dryer until solvents or

flammable materials have been removed. There are

many highly flammable items used in homes such

as acetone, denatured alcohol, gasoline, kerosene,

some household cleaners, some spot removers,

turpentines, waxes, wax removers and products

containing petroleum distillates.

The laundry process can reduce the flame retardancy

of fabrics. To avoid such a result, carefully follow the

garment manufacturer’s care instructions.

Do not dry articles containing rubber, plastic or

similar materials such as padded bras, tennis

shoes, galoshes, bath mats, rugs, bibs, baby pants,

plastic bags, pillows, etc. that may melt or burn.

Some rubber materials, when heated, can under

certain circumstances produce fire by spontaneous

combustion.

Do not store plastic, paper or clothing that may burn

or melt on top of the dryer during operation.

Garments labeled Dry Away from Heat or Do Not

Tumble Dry (such as life jackets containing Kapok)

must not be put in your dryer.

Do not dry fiberglass articles in your dryer. Skin

irritation could result from the remaining particles

that may be picked up by clothing during subsequent

dryer uses.

To minimize the possibility of electric shock, unplug

this appliance from the power supply or disconnect

the dryer at the household distribution panel by

removing the fuse or switching off the circuit breaker

before attempting any maintenance or cleaning

(except the removal and cleaning of the lint filter).

NOTE: Pressing START/PAUSE or POWER does NOT

disconnect the appliance from the power supply.

If you see water on the floor around the dryer, call for

service.

Do not obstruct the flow of ventilating air. Do not

stack or place laundry or throw rugs against the front

or back of the dryer.

3

Page 4

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

WHEN USING YOUR DRYER (cont.)

Never attempt to operate this appliance if it is damaged,

malfunctioning, partially disassembled, or has missing

or broken parts, including a damaged cord or plug.

The interior of the machine and the exhaust duct

connection inside the dryer should be cleaned at least

once a year by a qualified technician. See the Sorting

and Loading Hints section on page 12.

If yours is a gas dryer, it is equipped with an

automatic electric ignition and does not have

a pilot light. DO NOT ATTEMPT TO LIGHT WITH A

MATCH. Burns may result from having your hand in

the vicinity of the burner when the automatic ignition

turns on.

Do not open the dryer door during steam cycles. The

steam is very hot and it will continue to exhaust from

the port for several seconds after opening. Do not

touch the steam port after a steam cycle.

Do not use a steam cycle with items such as wool,

leather, silk, lingerie, foam products or electric blankets.

Do not use steam cycles on new clothes without first

washing.

You may wish to soften your laundered fabrics or

reduce the static electricity in them by using a dryerapplied fabric softener or an anti-static conditioner.

We recommend you use either a fabric softener

in the wash cycle, according to the manufacturer’s

instructions for those products, or try a dryer-added

product for which the manufacturer gives written

assurance on the package that their product can

be safely used in your dryer. Service or performance

problems caused by use of these products are the

responsibility of the manufacturers of those products

and are not covered under the warranty of this

appliance.

Never attempt to use the Steam Dewrinkle or Steam

Refresh cycles without clothes in the drum. Additionally,

it is highly recommended to select the appropriate

load size for best results. Selecting large load cycles

for small loads may result in wetting of clothes, and

selecting small load cycles for large loads may result

in poor dewrinkling performance.

Do not spray any type of aerosol into, on, or near dryer

at any trime. Do not use any type of spray cleaner

when cleaning dryer interior. Hazardous fumes or

electrical shock could occur.

WHEN NOT USING YOUR DRYER

Grasp the plug firmly when disconnecting this

appliance to avoid damage to the cord while pulling.

Place the cord away from traffic areas so it will not be

stepped on, tripped over or subjected to damage.

Do not attempt to repair or replace any part of this

appliance or attempt any servicing unless specifically

recommended in this Owner’s Manual or in published

user-repair instructions that you understand and have

the skills to carry out.

Before discarding a dryer, or removing it from service,

remove the dryer door to prevent children from hiding

inside.

Do not tamper with controls.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

4

Page 5

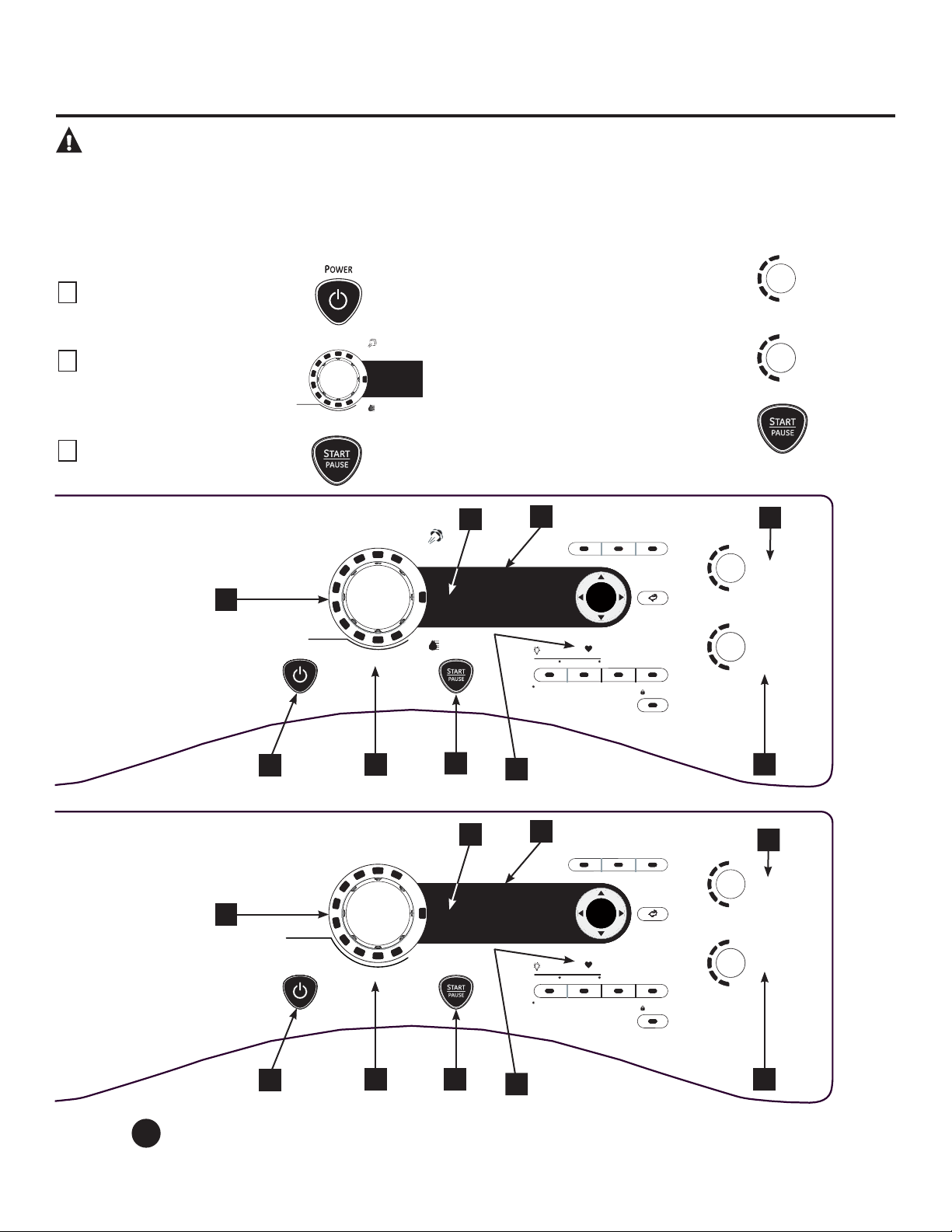

About the dryer control panel.

M

WARNING! To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS before operating this appliance.

Throughout this manual, features and appearance may vary from your model.

Quick Start

If the screen is dark, press the POWER button to “wake up”

the display.

Press the

1

Select a cycle by turning the

2

Cycle Knob.

If you selected a SENSOR CYCLE –

3

just press the START/PAUSE button.

POWER

button.

SENSOR DRY

W

A

CTIVE WEAR

TIME DRY

RINKLE FREE

D

ELICATES

S

PEED DRY

N

M

IXED LOADS

ORMAL /

W

ARM UP

C

T

IMED DRY

OTTONS

S

TEAMREFRESH

S

TEAM

D

EWRINKLE

SPECIALTY

CYCLES

If you selected a TIME DRY CYCLE

-select your heat setting and the

amount of time you want your items

to dry by using the cursor buttons.

Then press the START/PAUSE button.

ORE DRY

LESS DRY

MEDIUM

EXTRA DRY

DRY

DAMP

ANTI -

BACTERIAL

HIGH

LOW

EXTRA LOW

GEAppliances.com

SENSOR

DRY

DRY

TEMP

Models: PFDS450 / PFDS455 / PFMS450 / PFMS455

SENSOR DRY

2

TIME DRY

MIXED LOADS

WRINKLE FREE

ACTIVE WEAR

DELICATES

SPEED DRY

POWER

NORMAL /

1

Models: PFDN440 / PFDN445 / PFMN440 / PFMN445

SENSOR DRY

2

TIME DRY

WRINKLE FREE

ACTIVE WEAR

DELICATES

SPEED DRY

AIR FLUFF

NO HEAT

POWER

WARM UP

WARM UP

COTTONS

TIMED DRY

3

NORMAL /

MIXED LOADS

DEWRINKLE

STEAMREFRESH

STEAM

DEWRINKLE

COTTONS

TIMED DRY

SPECIALTY

CYCLES

SPECIALTY

CYCLES

9

6

9

8

DRUM

LIGHT

STORE MY CYCLE

SETTINGS

PRESS & HOLD 3 seconds for secondary OPTIONS

7

8

DRUM

LIGHT

STORE MY CYCLE

SETTINGS

PRESS & HOLD 3 seconds for secondary OPTIONS

e

DRY

MY

CYCLE

e

DRY

MY

CYCLE

ENTER

ENTER

DELAY

S

TART

EXTENDED

TUMBLE

DELAY

START

EXTENDED

TUMBLE

DRYER

RACK

BACKBACK

DAMP

ALERT

LOCK

Push to Lock Control

Hold 3 Secs to Unlock

DRYER

RACK

BACKBACK

DAMP

ALERT

LOCK

Push to Lock Control

Hold 3 Secs to Unlock

EXTRA DRY

MORE DRY

DRY

LESS DRY

BACTERIAL

HIGH

MEDIUM

LOW

EXTRA LOW

EXTRA DRY

MORE DRY

DRY

LESS DRY

BACTERIAL

HIGH

MEDIUM

LOW

EXTRA LOW

DAMP

ANTI -

DAMP

ANTI -

4

SENSOR

DRY

DRY

TEMP

5

4

SENSOR

DRY

DRY

TEMP

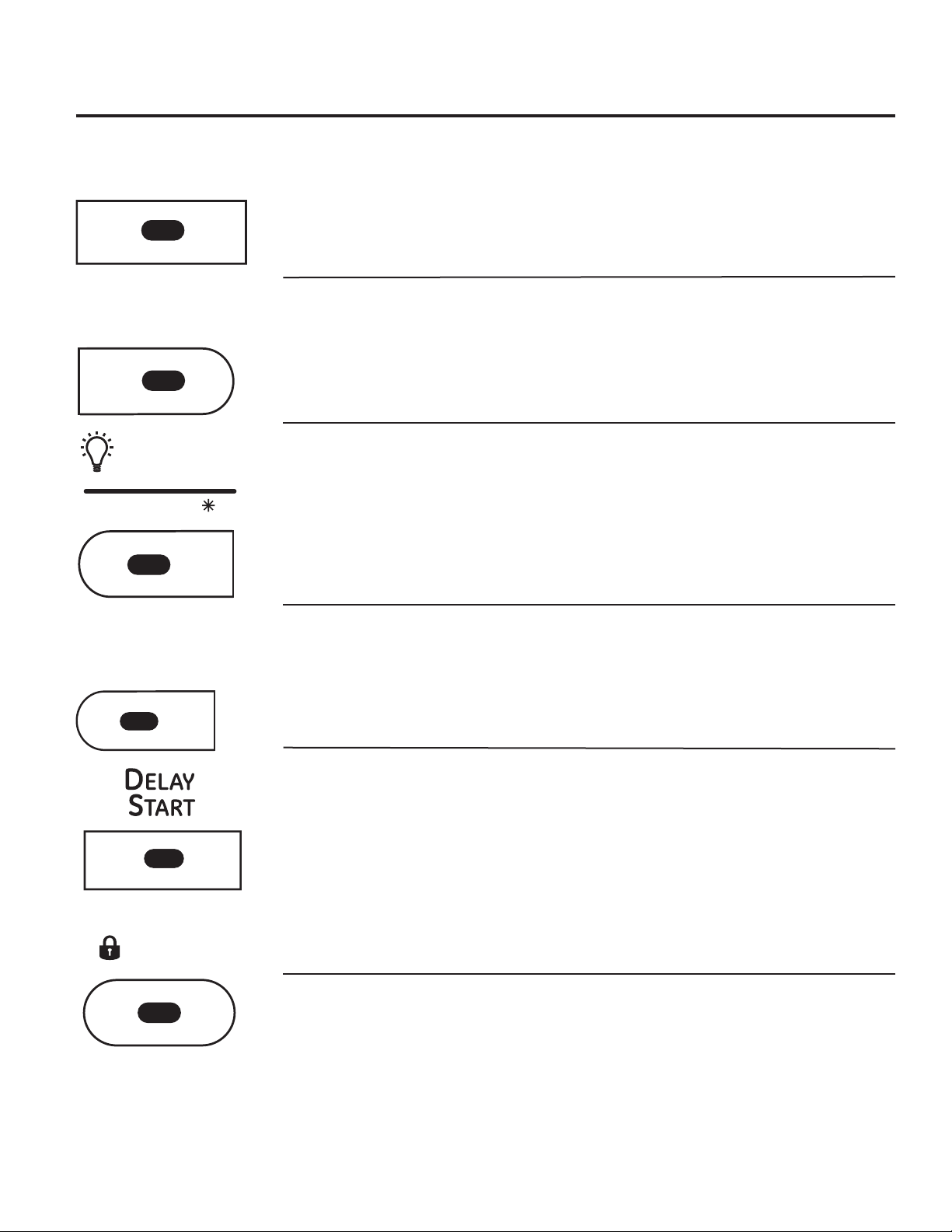

Power

1

Press to “wake up” the display. If the display is active, press to turn the dryer off.

1

3

6

7

NOTE: Pressing POWER does not disconnect the appliance from the power supply.

5

5

Page 6

About the dryer control panel.

Dry Cycles

The dry cycle controls the cycle time for the drying process. The chart below will help you match the dry setting with the

loads.

Sensor Cycles

2

COTTONS For cottons and most linens.

NORMAL/ For loads consisting of cottons and poly-blends.

MIXED LOAD

WRINKLE FREE For wrinkle-free/easy care and permanent press items.

ACTIVE WEAR Clothing worn for active sports exercise and some casual wear. Fabrics include new

technology finishes and stretch fibers such as Spandex.

DELICATES For lingerie and special-care fabrics.

SPEED DRY For small loads that are needed in a hurry, such as sports or school uniforms. Can also be

used if the previous cycle left some items damp, such as collars or waistbands.

Timed Dry Cycles

STEAM For slightly wrinkled dry garments. Significantly reduces wrinkles on 1–5 garments.

REFRESH Selecting a higher number of garments for the cycle (e.g., selecting 5-garment load for a 1-garment load) may result in excessive wetting

(on some models)

A single extremely light fabric item may need to have an additional item included in the steam refresh cycle to achieve optimum results.

DEWRINKLE For removing wrinkles from items that are dry or slightly damp. This cycle is not reccomended for delicate

(on some models) fabrics.

STEAM For use with larger loads than STEAM REFRESH. Ideal for loads left in dryer for an extended

DEWRINKLE time. Selecting a larger cycle than needed (e.g., selecting Large Load for a half-full dryer)

(on some models) may result in excessive wetting of clothes.

WARM UP Provides 10 minutes of warming time to warm up clothes.

My Cycle (on some models)

MY CYCLE Press to use, create or modify custom dry cycles.

of clothes. After the STEAM REFRESH Cycle, the unit will beep and display “Garments Ready” and “0:00.” If the unit is not turned off or if the

door is not opened, the dryer will continue to tumble for 30 minutes. At the end of 30 minutes, it will display “0:00” and “Cycle Complete.”

NOTE: When STEAM REFRESH is selected, “EXTENDED TUMBLE” will automatically turn on and cannot be turned off.

Timed Dry

3

Use to set your own dry time. TIMED DRY is also recommended for small loads.

To use TIMED DRY:

1. Turn dry cycle dial to TIMED DRY.

2. Select the drying time by pressing the S and T buttons. You can increase the time in 10-minute increments up to 2 hours, 5 minutes.

3. Select the DRY TEMP.

4. Close the door.

5. Press START/PAUSE.

Sensor Dry

4

The sensor continuously monitors the amount of moisture in the load. When the moisture in your clothes reaches your selected dry level, the dryer will stop.

EXTRA DRY Use for heavy-duty fabrics or items that should be very dry, such as towels.

MORE DRY Use for heavy or mixed type of fabrics.

DRY Use for normal dryness level suitable for most loads. This is the preferred cycle

for energy saving.

LESS DRY Use for lighter fabric (ideal for ironing).

DAMP For leaving items partially damp.

6

Page 7

Dry Temp

5

You can change the temperature of your dry cycle.

GEAppliances.com

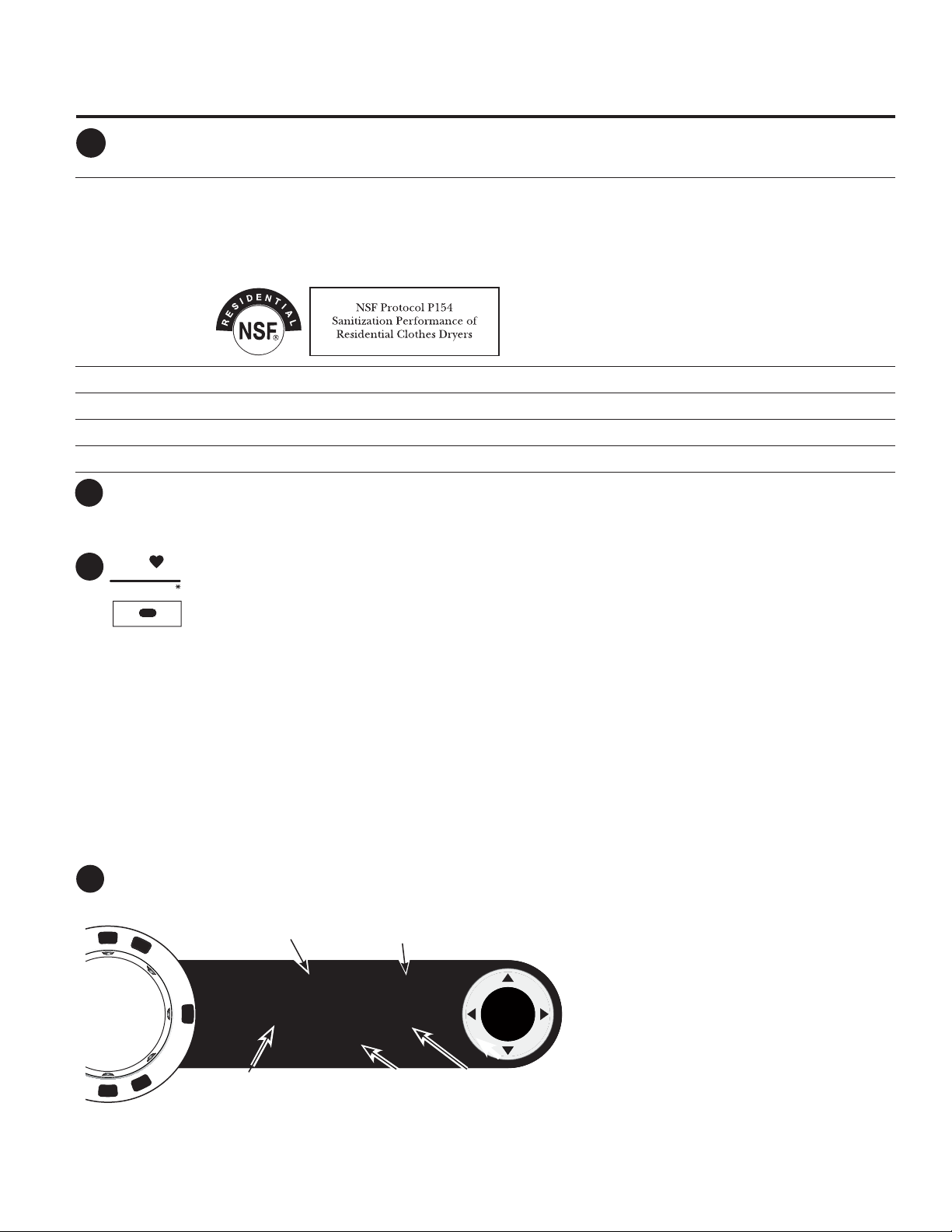

ANTI-BACTERIAL This option may only be used with COTTONS or MIXED LOAD cycles. This option reduces certain types of bacteria by

NOTE: Do not use this cycle on delicate fabrics.

* The Anti-Bacterial Cycle is Certified by NSF International (formerly National Sanitation Foundation) to NSF Protocol

HIGH For regular to heavy cottons.

MEDIUM For synthetics, blends and items labeled permanent press.

LOW For delicates, synthetics and items labeled Tumble Dry Low.

EXTRA LOW For lingerie and special-care fabrics.

START/PAUSE

6

Press to start a dry cycle. If the dryer is running, press it once and it will pause the dryer. Press it again to resume the dry

cycle.

MY

7

CYCLE

STORE MY CYCLE

99.9%, including: Staphylococcus aureus, Pseudomonas aeruginosa and Klebsiella pneumoniae*. The anti-bacterial

process occurs when high heat is used during a portion of this drying cycle.

P154 Sanitization Performance of Residential Clothes Dryers.

My Cycle (on some models)

Set up your favorite combination of settings and save them here for one touch recall. These custom

settings can be set while a cycle is in progress.

To store a MY CYCLE combination of settings:

1. Select your drying cycle.

2. Change DRY TEMP and SENSOR DRY settings to fit your needs.

3. Select any drying OPTIONS you want.

4. Press and hold the MY CYCLE button for 3 seconds to store your selection. A beep will sound the button will light up, and

the unit will display “My cycle is now programed with the current cycle settings”.

To recall your stored MY CYCLE combination:

Press the MY CYCLE button before drying a load. The light in the center of the button will light up when MY CYCLE is selected.

To change your stored MY CYCLE combination:

Follow Steps 1–4 in “To store a MY CYCLE combination of settings.”

8

Display

Special Cycle Status OR

Dryer Rack OR Timed Dry

SPECIALTY CYCLE 1:10

SPECIALTY

CYCLES

Comforters

Delay Time 1:00

Clean Lint Filter

Delay Time

Status

Est. Cycle Time

OR Time to Dry

0

Lint Filter Status

Screen

ENTER

DELAY TIME

After the POWER button is pressed, the CLEAN

LINT FILTER message could appear if the

previous cycle was not finished. This message

will disappear after the START button is pressed.

Even though you have already cleaned the

filter (before the POWER button was pressed),

the CLEAN LINT FILTER message will still be

displayed until the START button is activated.

“CLEAN LINT FILTER” (message)

This message appears periodically. It is only a reminder.

7

Page 8

About the dryer control panel.

Specialty Cycles

9

1. Turn the CYCLE knob to SPECIALTY CYCLES. A list of cycle options will appear in the display.

2. Using the cursor buttons, select a CATEGORY.

3. Using the cursor buttons, select a CYCLE.

Press the BACK button to take you back to the CATEGORIES.

4. Press ENTER to select.

5. Press the START/PAUSE button.

SPECIALTY CYCLES include:

Garment

Coats

Hosiery/Bras (use mesh bag)

Jeans

Khakis

Bed and Bath

Blankets (Cotton)

Comforters

Sheets

Towels

Specialty Cycles

Air Fluff

Dryel

Fleece

Fragile Cottons

Performance Fabrics

Pet Bedding

Play Clothes

Rack Dry

Sleeping Bag

Throw Rugs

Washer Communicated Cycles

To turn on communication, press the SETTINGS button

on the washer control panel. When “DRYER LINK”

appears in the display, press ENTER. Using the arrow

keys, select ON; then press ENTER.

When the washer cycle is completed, the washer will

communicate with the dryer when any button on the

control panel is touched or the door is opened.

The washer will display, “TRANSFERRING CYCLE

INFORMATION TO THE DRYER” and the dryer will

display, “RECEIVING CYCLE INFORMATION TO THE

DRYER”.

The dryer will only communicate with the washer if

the dryer is not running a cycle.

If the washer starts a new cycle before the dryer has

a chance to communicate with it, the information will

be lost.

8

Page 9

About cycle options.

D

NOTE: Not all features are available on all dryer models.

EXTENDED

TUMBLE

AMP

ALERT

DRUM

LIGHT

SETTINGS

Extended Tumble

Minimizes wrinkles by adding approximately 60

minutes of no-heat tumbling after clothes are

dry.

The light in center of the button will light up

when EXTENDED TUMBLE is on.

Damp Alert

This option causes the dryer to beep when

clothes have dried to a damp level. Remove

items that you wish to hang dry. The DAMP

ALERT will only beep when this option is selected.

Drum Light

Press this button to turn on the light in the dryer.

Press the button again to turn the light off.

This only controls the light when the door is shut.

NOTE: The light will turn off by itself after one

minute when the door is shut.

When the door is opened, the light comes on

automatically.

Extended Tumble is automatically selected for the

SteamRefresh cycle and cannot be deselected.

Dryer will beep and display “Garments Ready”

when SteamRefresh is complete. The dryer will

continue in Extended Tumble until the door is

opened.

Removing clothes and hanging them when they

are damp can reduce the need to iron some

items.

The light in center of the button will light up

when DAMP ALERT is on.

The light in center of the button will light up

when DRUM LIGHT is on.

NOTE: Hold down the DRUM LIGHT button for

3 seconds to access the SETTINGS menu. (See

page 10 for more details)

GEAppliances.com

e

DRY

LOCK

Push to Lock Control

Hold 3 Secs to Unlock

e-Dry

Reduces the total energy consumption of

specific dryer cycles by adjusting certain heat

settings.

NOTE: Cycle times will change when e-DRY is

selected

Delay Start

Use to delay the start of your dryer.

1. Choose your dry cycle and any options.

2. Press DELAY START. You can change the

delay time in 1/2-hour increments, using the

S or T arrow pads.

3. Press the START/PAUSE button to start the

countdown.

The countdown time will be shown in the

ESTIMATED TIME REMAINING display.

Lock

You can lock the controls to prevent any

selections from being made. Or you can lock

the controls after you have started a cycle.

Children cannot accidentally start the dryer by

touching pads with this option selected.

This cycle can be used with DELICATES, ACTIVE

WEAR, EASY CARE, NORMAL/MIXED LOADS

and COTTONS.

NOTES:

If the door is opened while the dryer is

in DELAY, the countdown time will not

restart unless the door is closed and

START/PAUSE button has been pressed

again.

You can delay the start of a dry cycle up

to 24 hours.

The light in center of the button will light up

when DELAY START is on.

To lock the dryer, press the LOCK button. To

unlock the dryer, press and hold the LOCK

button for 3 seconds.

The light in center of the LOCK button will light

up when the controls are locked.

Even though the controls are locked, the POWER

button is still active in case you have to turn the

unit off.

9

Page 10

About cycle options.

NOTE: Not all features are available on all dryer models.

DRUM

LIGHT

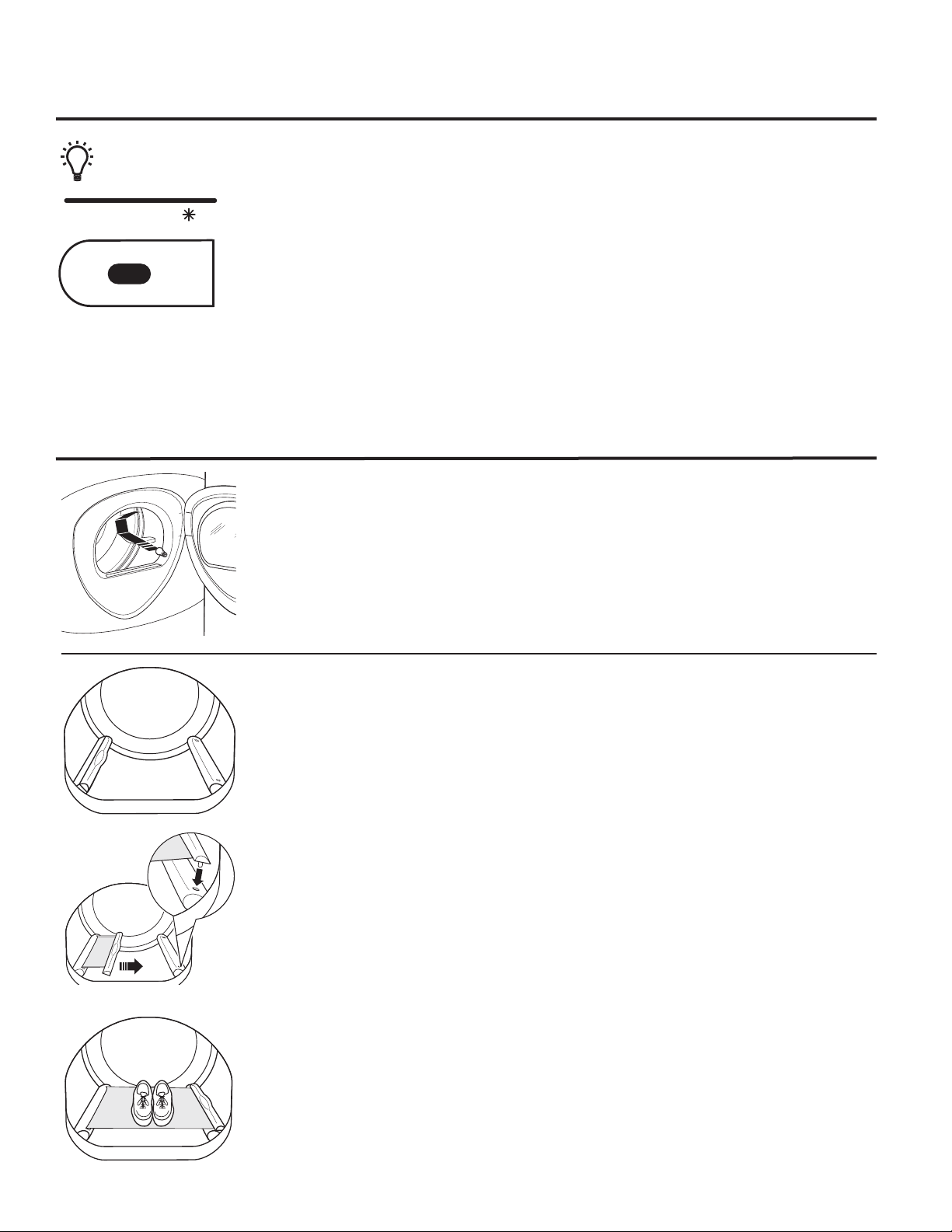

Settings

Under the SETTINGS option, you can

adjust the volume or the brightness of

the display.

SETTINGS

VOLUME

End of Cycle (signal) volume can be set from

HIGH, MED, LOW or OFF.

Control Sounds volume can be set from

Press & hold for 3

HIGH, MED, LOW or OFF.

seconds for secondary

options

About dryer features.

Drum Lamp

Before replacing the light bulb, be sure to unplug the dryer power cord or disconnect the dryer at

the household distribution panel by removing the fuse or switching off the circuit breaker. Reach

above dryer

DISPLAY BRIGHTNESS can be set from HIGH,

MED or LOW.

After you have made your selection, press

ENTER.

NOTE: To access the SETTINGS menu, hold

down the DRUM LIGHT button for 3 seconds.

opening from inside the drum. Remove the

bulb and replace with the same size bulb.

Engage the handle posts

Built-In Rack Dry System

A handy drying rack may be used for drying items such as tennis shoes. Place items flat on the

drying rack and block such items as wool sweaters and delicate fabrics. Dry with low heat.

To install the Built-In Rack Dry System

1. Make sure the drum of the dryer is oriented so the rack drying system is on the left side of the

dryer.

2. Pull the drying rack screen out from the left side and engage the handle “posts” in the

opposite baffle slots.

3. Place the garment on the rack and close the door.

4. Press the DRYER RACK button.

5. Select desired time.

6. Press the START/PAUSE button.

NOTE:

Do not use this drying rack when there are other clothes in the dryer.

Make sure to detach the drying rack at the end of the cycle and fully retract the screen back

into the baffle.

10

Page 11

About dryer features (cont.).

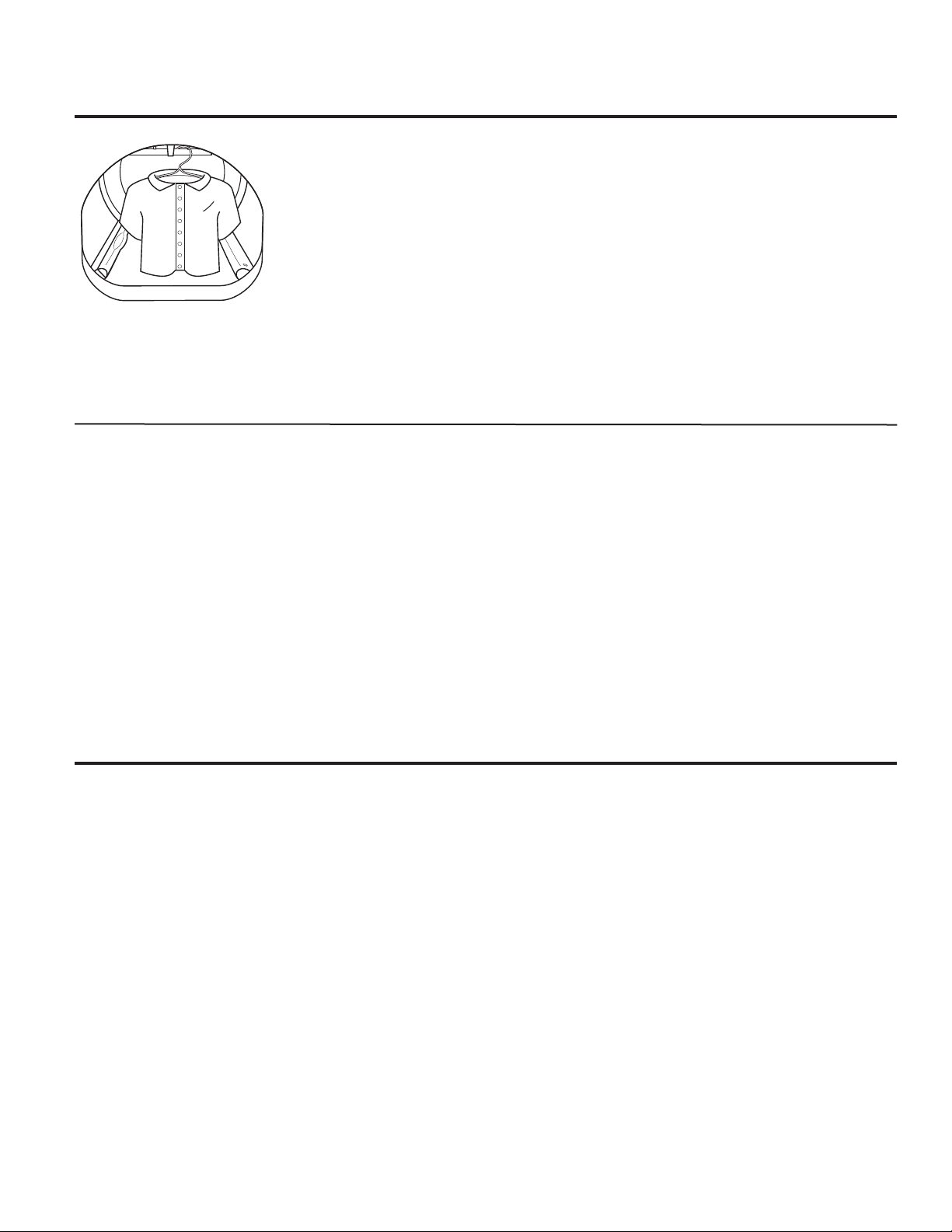

To Use the Built-In Hook for

Hanging Garments

1. Make sure the drum of the dryer is

oriented so the hook is on the top

center of the dryer.

2. Using your finger, pull the hook out of

the baffle.

3. Hang the garment on a hanger, hang

the hanger on the hook and close the

door.

4. Press the DRYER RACK button.

5. Select the desired time.

6. Press the START/PAUSE button.

GEAppliances.com

Reverse Tumble

All Profile front-load matching dryers are equipped with the Reverse Tumble™ feature,

as part of the Duo Dry Plus system™. By reversing the direction of drum rotation during

the drying cycle, your dryer will tangle the clothes load less, dry more evenly and

improve drying times. Typical loads such as bed and bath mixed loads, where sheets,

towels and pillow cases are laundered together, benefit from this capability. When

the dryer reverses direction, there will be a slight pause and sound change. This is

normal. All dryer cycles utilize this feature, except when the rack dry option is selected,

in which case the drum does not tumble.

™

Using the dryer.

Always follow fabric manufacturer’s care label when laundering.

Sorting and Loading Hints

As a general rule, if clothes are sorted

properly for the washer, they are sorted

properly for the dryer. Try also to sort items

according to size. For example, do not dry a

sheet with socks or other small items.

Do not add fabric softener sheets once

the load has become warm. They may

cause fabric softener stains. Bounce®

Fabric Conditioner Dryer Sheets have been

approved for use in this dryer when used

in accordance with the manufacturer’s

instructions.

See below for lint filter cleaning instructions.

Do not overload. This wastes energy and

causes wrinkling.

Do not dry the following items: fiberglass

items, woolens, rubber-coated items, plastics,

items with plastic trim and foam-filled items.

11

Page 12

Using the dryer.

Fabric Care Labels

Below are fabric care label “symbols” that affect the clothing you will be laundering.

Wash Labels

Machine

wash

cycle

Front load

target water

temperature

Normal

Permanent Press/

wrinkle resistant

Target Automatic

Category Water Temperature Temperature Control

Tap Cold Inlet Water Temperature Not used

Cold 27°C/80°F Used

Warm 40°C/105°F Used

Hot 50°C/120°F Used

Sanitize 70°C/160°F Used

Gentle/

delicate

Hand wash

Do not wash Do not wring

Dry Labels

Tumble

dry

Dry

Normal

Permanent Press/

wrinkle resistant

Gentle/

delicate

Do not tumble dry

Do not dry

(used with

do not wash)

Heat

setting

High

Medium

Low

No heat/air

12

Special

instructions

Line dry/

hang to dry

Drip dry

Bleach Labels

Bleach

symbols

Any bleach

(when needed)

Only non-chlorine bleach

(when needed)

Care and Cleaning of the Dryer

Dryer Interior and Duct: The interior of

the appliance and exhaust duct should be

cleaned once a year by qualified service

personnel.

The Exterior: Wipe or dust any spills or

washing compounds with a damp cloth.

Dryer control panel and finishes may be

damaged by some laundry pretreatment

soil and stain remover products. Apply these

products away from the dryer. The fabric

may then be washed and dried normally.

Damage to your dryer caused by these

products is not covered by your warranty.

Do not touch the surface or the display with

sharp objects.

The Lint Filter: Clean the lint filter before

each use. Remove by pulling straight up.

Run your fingers across the filter. A waxy

buildup may form on the lint filter from

using dryer-added fabric softener sheets.

To remove this buildup, wash the lint screen

Dry flat

Do not bleach

In the shade

in warm, soapy water. Dry thoroughly and

replace. Do not operate the dryer without the

lint filter in place.

Vacuum the lint from the dryer lint filter if you

notice a change in dryer performance.

Stainless Steel: To clean stainless steel

surfaces, use a damp cloth with a mild,

nonabrasive cleaner suitable for stainless

steel surfaces. Remove the cleaner residue,

and then dry with a clean cloth.

The stainless steel used to make the dryer drum

provides the highest reliability available in a GE

dryer. If the dryer drum should be scratched or

dented during normal use, the drum will not rust

or corrode. These surface blemishes will not affect

the function or durability of the drum.

The Exhaust Hood: Check with a mirror that

the inside flaps of the hood move freely

when operating. Make sure that there is no

wildlife (birds, insects, etc.) nesting inside the

duct or hood.

Page 13

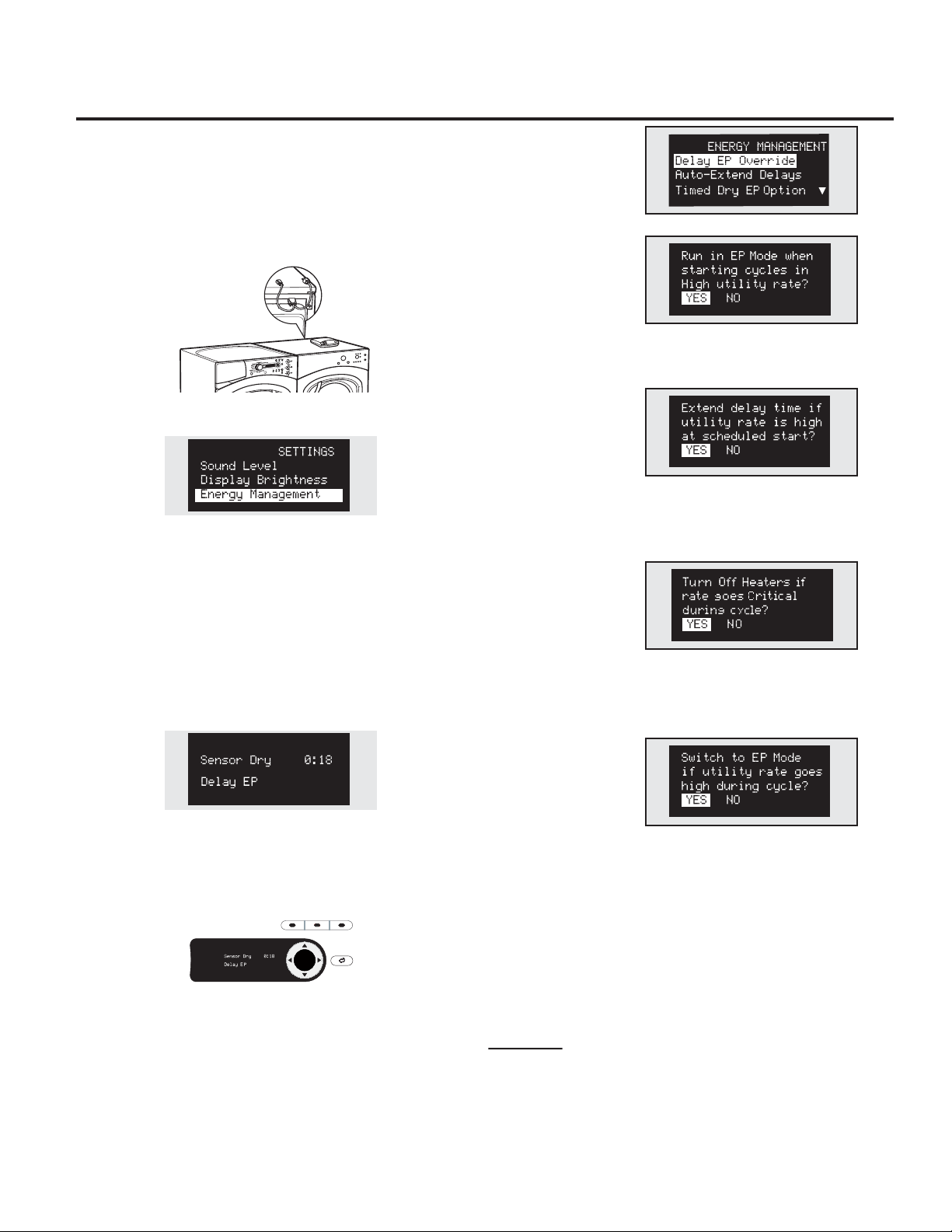

SMART APPLIANCE (on some models) GEAppliances.com

Models PFDS450, PFDS455, PFDN440, PFDN445 are compatible with the

GE Smart Appliance Module (SAM) which can be purchased separately.

Contact your local utility or visit www.GEAppliances.com/smart-appliances

to see if your area is using Demand Response (DR) technology.

Installation

The preferred location for the module installation is on top of the clothes

dryer. Details on how to connect the cables to the module are in the

instructions that come with the module.

Wait 5 minutes; then press the Settings button. Scroll and look for the

energy management screen as seen below.

This screen means the module is attached correctly and you can begin to

use your Smart Appliance following the instructions below.

If the Energy Management Screen is not available, refer to the SAM module

troubleshooting guide.

Quick Guide

There are 4 power levels available: Critical, High, Medium and Low. On the

Medium and Low levels, the unit runs as normal. The following steps show

how the unit reacts during startup at Critical and High power levels.

Option 1 (Delay EP)

During startups at Critical and High levels, the unit will delay

starting until the level becomes Medium or Low. Press the START/PAUSE

button.

Settings Menu

Press SETTINGS; then select

Energy Management.

Delay EP Override

If you are starting a cycle in

a Critical or High utility rate,

this option allows the unit

to automatically run on an

EP Cycle. This setting will

operate with less energy than normal cycles. Default setting is YES.

Auto-Extend Delays

If a timed delay is selected,

this option allows for the

scheduled start to extend

if the utility rate is Critical or

High at the scheduled start. The default setting will automatically extend

these cycles.

Critical Rate Option

This option allows your smart

appliance to respond to

Critical Rate information by

automatically engaging the

Critical Response Mode. The

Critical Response Mode is designed to maximize energy savings when a

cycle is run during a Critical Rate period. The default setting is YES. Setting

this option to NO will disable the Critical Response Mode.

Option 2 (Override Delay EP)

To start the unit when Delay EP is shown, press the DELAY START button to

turn the delay off. Then press START/PAUSE to begin the cycle.

During a Critical Rate period, the Critical Response Mode** will also be

activated to maximize energy savings. EP will be displayed.

DELAY

e

DRY

DRYER

START

RACK

BACKBACK

ENTER

Option 3 (Override “e” DRY)

After overriding the delay function, pressing the “e”DRY button will disable

the “e”DRY setting. Pressing the START/PAUSE key will begin the selected

cycle.

During a Critical Rate period, the Critical Response Mode** will be activated

to maximize energy savings. EP will be displayed.

**Note: The Critical Response Mode can be disabled at any time by

pressing and holding the “e”DRY Button for 3 seconds. EP will be removed

from the display

Timed Dry EP Option

If the unit is running in Timed

Dry Mode and the utility rate

switches to Critical or High,

the unit will conserve energy

by decreasing heat if YES (default) is selected. If NO is selected, the unit will

operate normally.

NOTE: When YES (default) is selected, your load may be damp

at the end of the cycle.

In order for the Smart Appliance features on the appliance to work,

additional equipment is required to be installed to interface with the local

utility. Such equipment may be sold separately and/or is available through

your utility as part of the pilot test program. Check with your utility company

to see if a pilot test program is available in your area and for full details.

PLEASE NOTE: If you move to an area where the program is not available,

the demand response features cannot be activated and utilized on the

appliance. The appliance will function as normal after the demand response

equipment has been deactivated or disconnected.

13

Page 14

Installation Dryer

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

PFDS450 / PFDS455 /PFDN440 / PFDN445 /

PFMS450 / PFMS455 / PFMN440 / PFMN445

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these instructions for local

electrical inspector’s use.

IMPORTANT – Observe all governing codes and

•

ordinances.

•

Install the clothes dryer according to the manufacturer’s

instructions and local codes.

•

Note to Installer – Be sure to leave these instructions

with the Consumer.

•

Note to Consumer – Keep these instructions for future

reference.

•

Clothes dryer installation must be performed by a

qualified installer.

•

This dryer must be exhausted to the outdoors.

•

Before the old dryer is removed from service or

discarded, remove the dryer door.

•

Service information and the wiring diagram are located

in the control console.

•

Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance

is used near children.

•

Proper installation is the responsibility of the installer.

•

Product failure due to improper installation is not

covered under the Warranty

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Remove and discard existing plastic or metal foil duct

and replace with UL-listed duct.

.

CALIFORNIA SAFE DRINKING WATER AND

TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a

list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires

businesses to warn customers of potential exposure to such

substances. Gas appliances can cause minor exposure to

four of these substances, namely benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete

combustion of natural gas or LP fuels. Properly adjusted

dryers will minimize incomplete combustion. Exposure to

these substances can be minimized further by properly

venting the dryer to the outdoors.

14

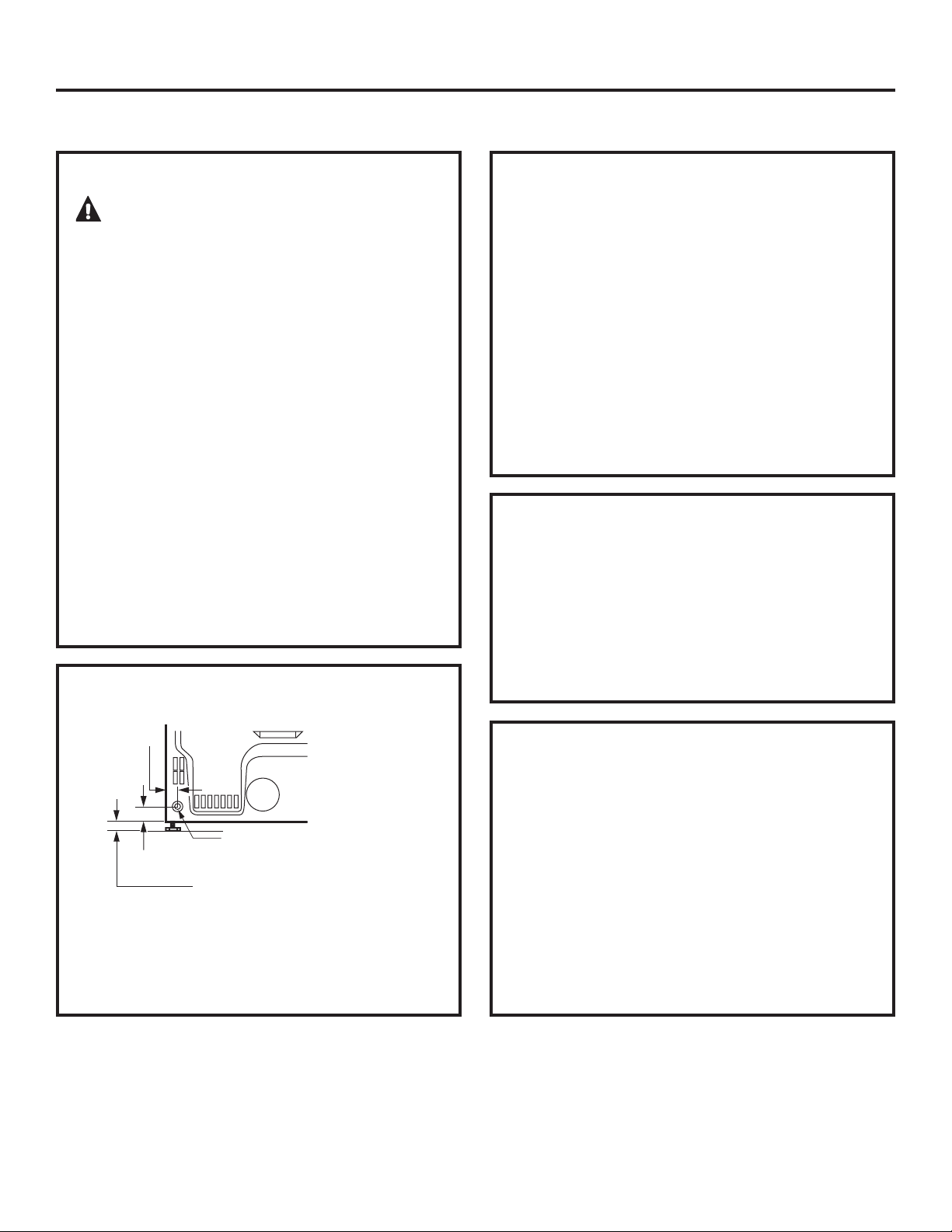

FOR YOUR SAFETY:

WARNING –

To reduce the risk of severe injury or death, follow all

•

installation instructions.

•

Clothes dryer installation must be performed by a

qualified installer.

•

Install the clothes dryer according to these

instructions and in accordance with local codes.

•

This dryer must be exhausted to the outdoors.

•

Use only rigid metal 4

dryer cabinet and use only UL approved transition

ducting between the dryer and the home duct.

•

DO NOT install a clothes dryer with flexible plastic

ducting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in “Connecting the Dryer to House Vent” on page 26

of this manual. Flexible ducting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

•

Do not install or store this appliance in any location

where it could be exposed to water and/or weather.

•

Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

”

diameter ductwork inside the

Risk of Fire

FOR GAS MODELS ONLY:

NOTE: Installation and service of this dryer must be

performed by a qualified installer, service agency or

the gas supplier.

In the Commonwealth of Massachusetts:

•

This product must be installed by a licensed

plumber or gas fitter.

•

When using ball-type gas shut-off valves, they

shall be T-handle-type.

•

A flexible gas connector, when used, must not

exceed 3 feet.

Page 15

Installation Instructions

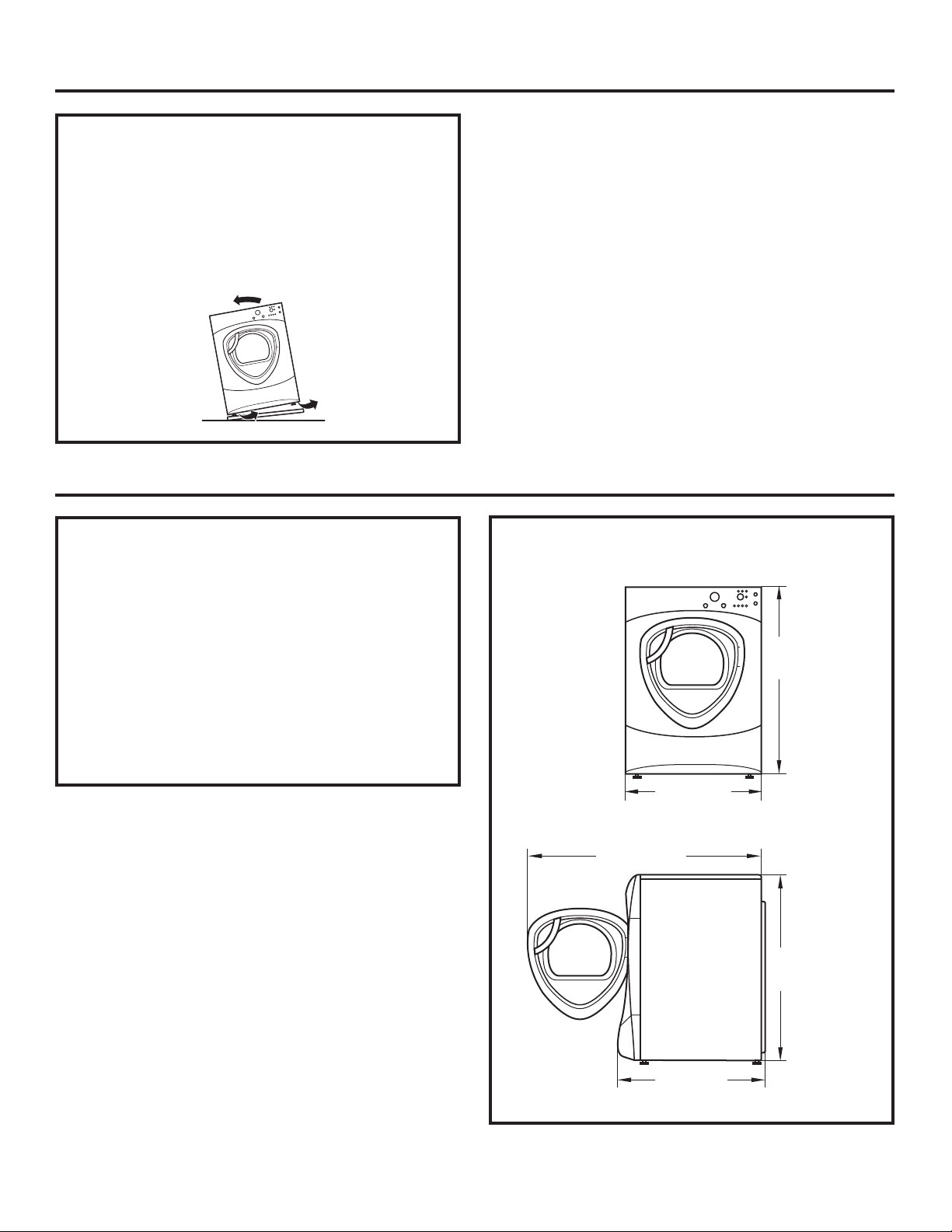

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove

all of the foam pieces around the legs.

Remove the bag containing the literature and serial

cable.

LOCATION OF YOUR DRYER

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and for

air openings are:

•

0 inch clearance both sides

•

1 inch front

•

3 inches rear

Consideration must be given to provide adequate

clearance for proper operation and service.

DRYER DIMENSIONS

Front View

27″

27”

(68.6 cm)

(68.6 cm)

53”

51″

(134.6 cm)

(129.5 cm)

39.5”

39.1″

(993 cm)

(100.3 cm)

39.5”

39.1″

(100.3 cm)

(993 cm)

15

Side View

32.34″

33.5”

(847 cm)

(85.1 cm)

Page 16

Installation Instructions

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

• Your dryer is approved for installation in an

alcove or closet, as stated on a label on the dryer

back.

The dryer MUST be vented to the outdoors. See

•

the EXHAUSTING THE DRYER section.

Minimum clearance between dryer cabinet and

•

adjacent walls or other surfaces is:

0” either side

3” front and rear

Minimum vertical space from floor to overhead

•

shelves, cabinets, ceilings, etc., is 52”.

Closet doors must be louvered or otherwise

•

ventilated and have at least 60 square inches

of open area equally distributed. If the closet

contains both a washer and a dryer, doors must

contain a minimum of 120 square inches of open

area equally distributed.

The closet should be vented to the outdoors to

•

prevent gas pocketing in case of gas in the supply

line.

No other fuel-burning appliance shall be installed

•

in the same closet with the dryer (gas models

only).

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL IS 5.5 INCHES.

BATHROOM OR BEDROOM INSTALLATION

• The dryer MUST be vented to the outdoors. See

EXHAUSTING THE DRYER.

The installation must conform with local codes or,

•

in the absence of local codes, with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70 (for electric

dryers) or NATIONAL FUEL GAS CODE, ANSI Z223

(for gas dryers).

MOBILE OR MANUFACTURED HOME

INSTALLATION

• The installation must conform to the

MANUFACTURED HOME CONSTRUCTION &

SAFETY STANDARD, TITLE 24, PART 32–80 or, when

such standard is not applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME, NO.

501B.

The dryer MUST be vented to the outdoors with

•

the termination securely fastened to the mobile

home structure. (See EXHAUSTING THE DRYER.)

The vent MUST NOT be terminated beneath a

•

mobile or manufactured home.

The vent duct material MUST BE METAL.

•

FOR GAS MODELS ONLY: KIT 14-D346-33 MUST be

•

used to attach the dryer securely to the structure.

FOR GAS MODELS ONLY: The vent MUST NOT be

•

connected to any other duct, vent or chimney.

Do not use sheet metal screws or other refastening

•

devices which extend into the interior of the

exhaust vent.

Provide an opening with a free area of at least 25

•

sq. in. for introduction of outside air into the dryer

room.

GARAGE INSTALLATION (IF ALLOWED

BY LOCAL CODES)

• Dryers installed in garages must be elevated 18

inches (46cm) above the floor.

16

Page 17

Installation Instructions

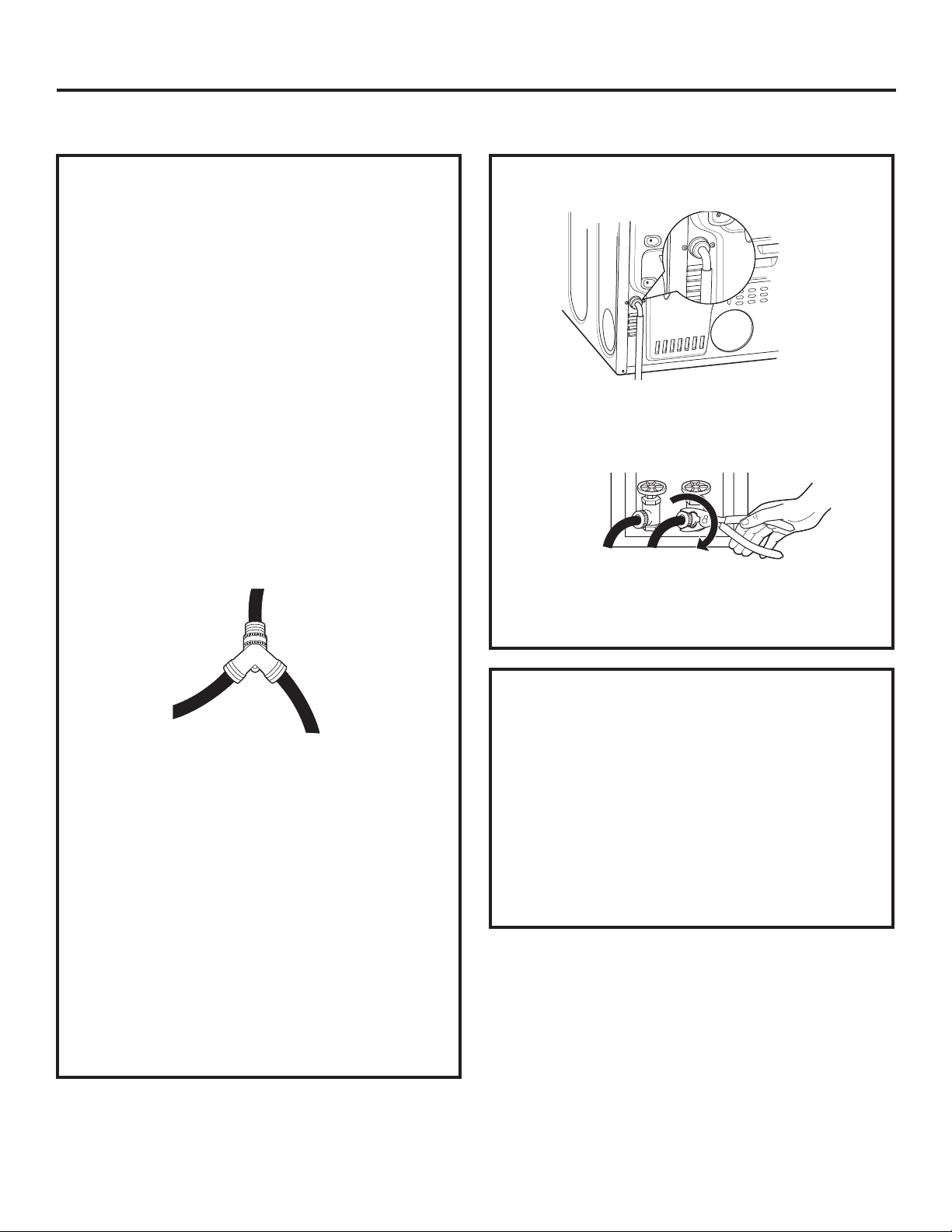

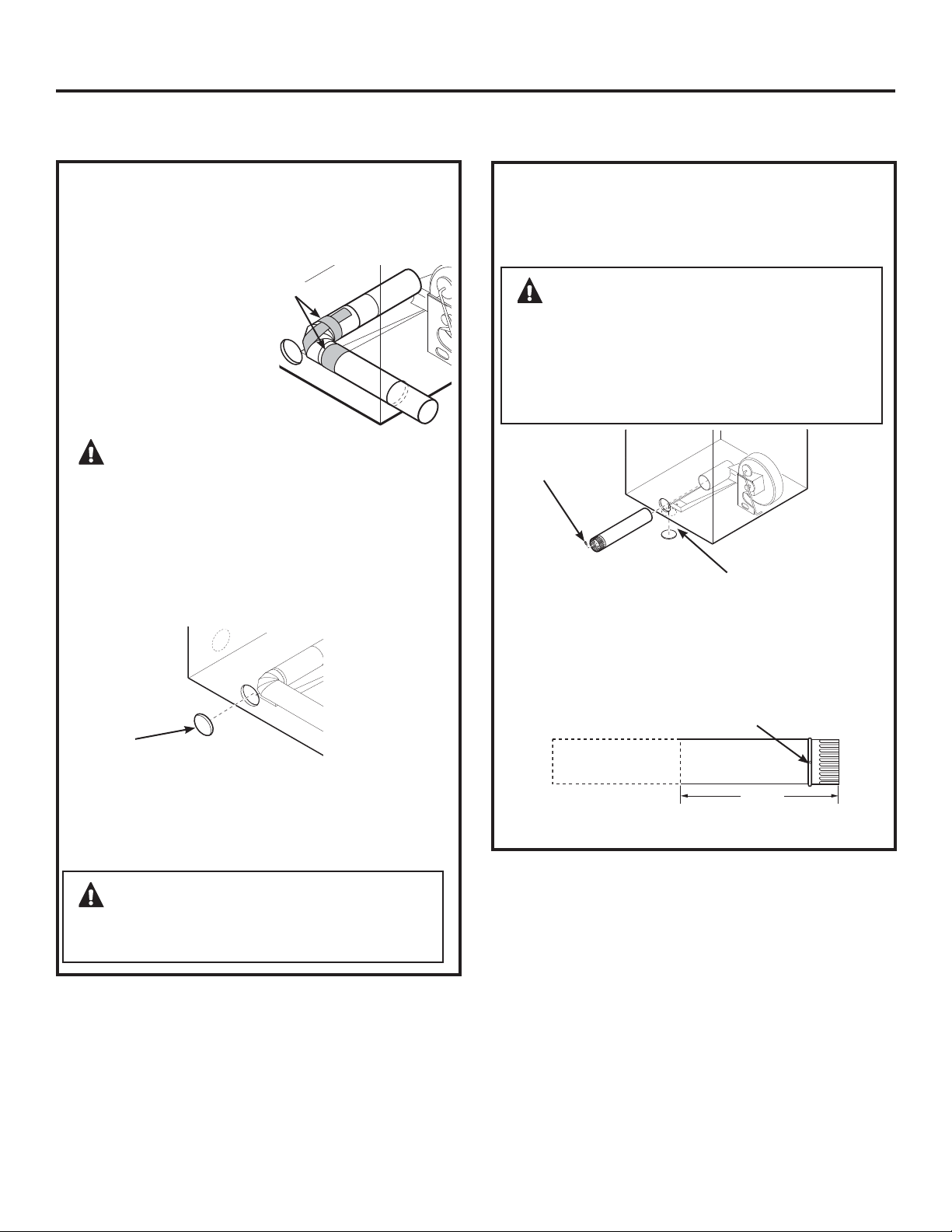

CONNECTING INLET HOSES

CONNECTING INLET HOSES

To produce steam, the dryer must connect to

the cold water supply. Since the washer must

also connect to the cold water, a “Y” connector

is inserted to allow both inlet hoses to make that

connection at the same time.

NOTE: Use the new inlet hoses provided; never use

old hoses.

1. Turn the cold water faucet off. Remove the

washer inlet hose from the washer fill valve

connector (cold).

2. Ensure the rubber flat washer is in place and

screw the female coupling of the short hose onto

the washer fill valve connector. Tighten by hand

until firmly seated.

3. Attach the female end of the ‘’Y’’ connector to

the male coupling of the short hose. Ensure the

rubber flat washer is in place. Tighten by hand

until firmly seated.

CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten all the couplings with an

additional two–thirds turn.

NOTE: Do not overtighten. Damage to the couplings

may result.

8. Turn the water faucet on.

9. Check for leaks around the ‘’Y’’ connector, faucet

and hose couplings.

4. Insert the filter screen in the coupling of the

washer’s inlet hose. If a rubber flat washer is

already in place remove it before installing the

filter screen. Attach this coupling to one male end

of the ‘’Y’’ connector. Tighten by hand until firmly

seated.

5. Ensure the rubber flat washer is in place and

attach the dryer’s long inlet hose to the other

male end of the ‘’Y’’ connector. Tighten by hand

until firmly seated.

6. Ensure the rubber flat washer is in place and

attach the other end of the dryer’s long inlet

hose to the fill valve connector at the bottom of

the dryer back panel. Tighten by hand until firmly

seated.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed

within 42 in. (107 cm) of your washer’s water

inlet. The faucets MUST be 3/4 in. (1.9 cm) garden

hose-type so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds per

square inch. Your water department can advise you

of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the steam generator if the

home water supply is very hard.

17

Page 18

Installation Instructions

CONNECTING A GAS DRYER (skip for electric dryers)

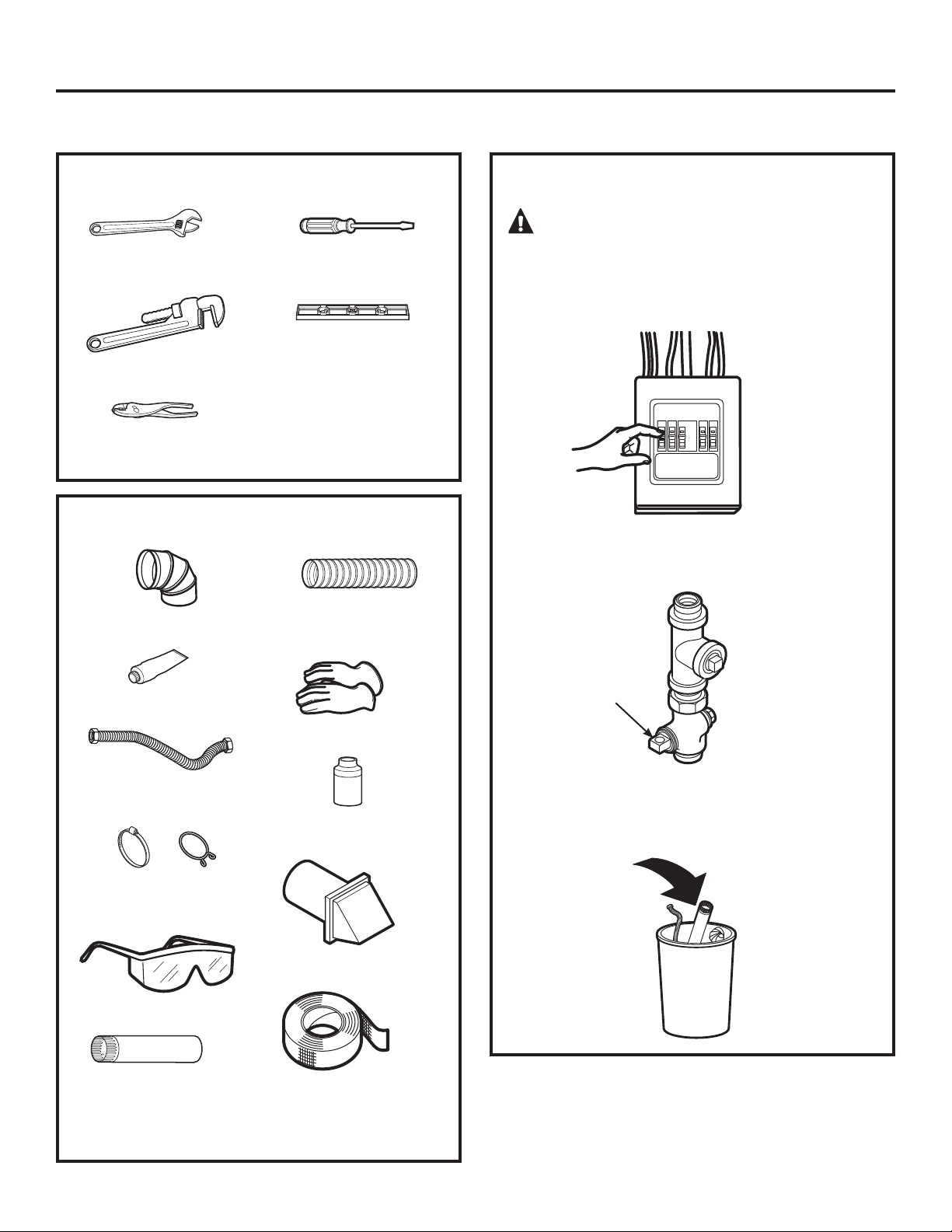

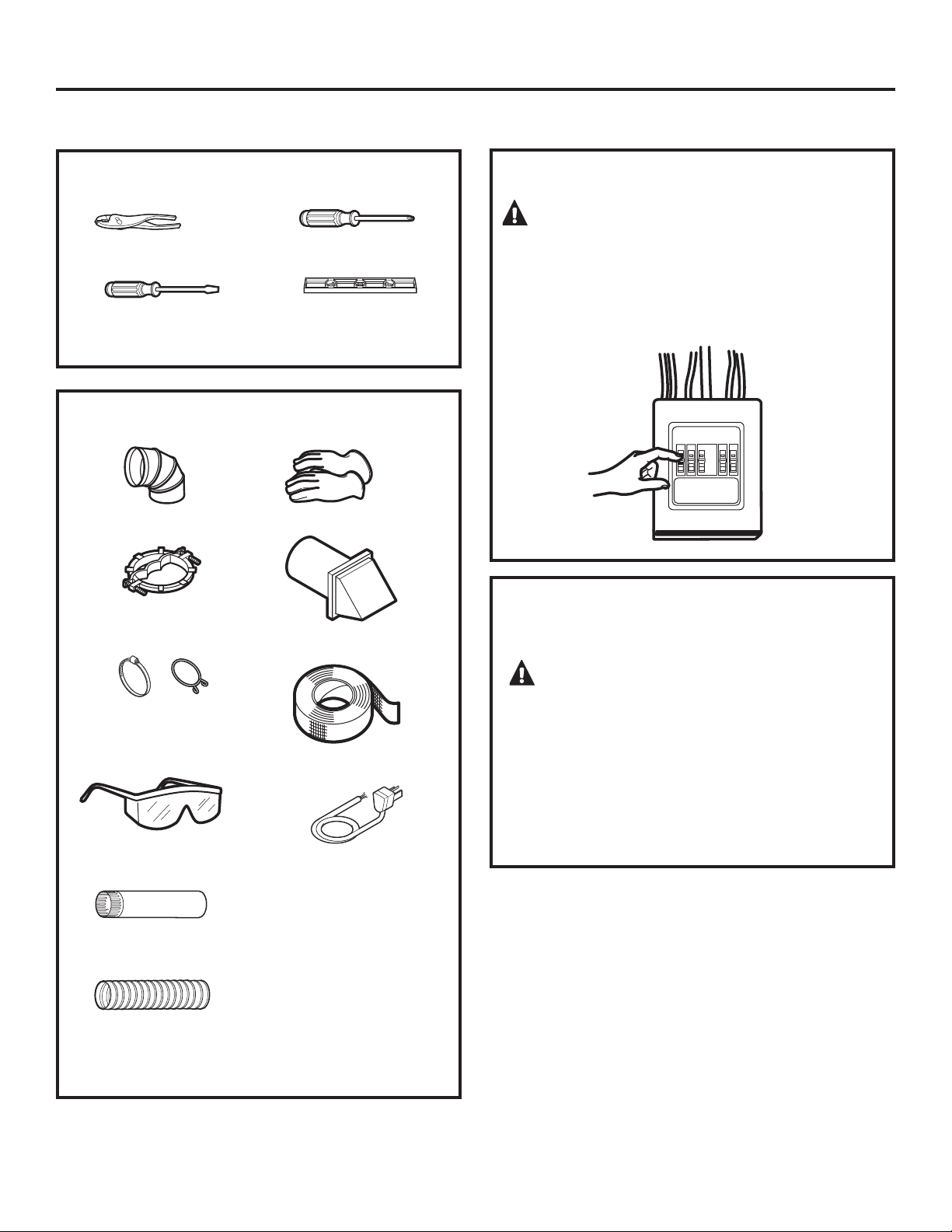

TOOLS YOU WILL NEED

Flat-blade

10” Adjustable

wrenches (2)

8” Pipe wrench

Slip-joint pliers

screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

4” dia., UL-listed

flexible metal duct (if

needed)

FOR YOUR SAFETY:

WARNING

Before beginning the installation, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

Turn the dryer’s gas shut-off valve in the supply

line to the OFF position.

Pipe compound

Flexible gas line

connector

Duct clamps (2) or

Spring clamps (2)

Safety glasses

4” dia. metal duct

(recommended)

Gloves

Soap solution for

leak detection

Exhaust hood

Duct tape

Shut-off

Valve

Disconnect and discard old flexible gas connector

and ducting material.

18

Page 19

Installation Instructions

GAS REQUIREMENTS

WARNING

• Installation must conform to local codes and

ordinances, or in their absence, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CSA B149.1.

This gas dryer is equipped with a Valve and

•

Burner Assembly for use only with natural gas.

Using conversion kit 14-A048, your local service

organization can convert this dryer for use with

propane (LP) gas. ALL CONVERSIONS MUST BE MADE

BY PROPERLY TRAINED AND QUALIFIED PERSONNEL

AND IN ACCORDANCE WITH LOCAL CODES AND

ORDINANCE REQUIREMENTS.

The dryer must be disconnected from the gas supply

•

piping system during any pressure testing of that

system at a test pressure in excess of 0.5 PSI (3.4

KPa).

The dryer must be isolated from the gas supply

•

piping system by closing the equipment shut-off

valve during any pressure testing of the gas supply

piping of test pressure equal to or less than 0.5 PSI

(3.4KPa).

DRYER GAS SUPPLY CONNECTION

GAS SUPPLY

• A 1/8” National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact

your local gas utility should you have questions

on the installation of the plugged tapping.

Supply line is to be 1/2” rigid pipe and equipped

•

with an accessible shutoff within 6 feet of, and

in the same room with, the dryer.

Use pipe thread compound appropriate for

•

natural or LP gas or use Teflon

Connect flexible metal connector to dryer and

•

gas supply.

®

tape.

IN THE COMMONWEALTH OF

MASSACHUSETTS

• This product must be installed by a licensed

plumber or gas fitter.

When using ball-type gas shut-off valves, they

•

shall be the T-handle type.

A flexible gas connector, when used, must not

•

exceed 3 feet.

2” (5.1 cm)

3/8” NPT MALE THREAD GAS SUPPLY

25ø8” (6.7 cm)

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

You must use with this dryer a flexible metal

connector (listed connector ANSI Z21.24 / CSA 6.10).

The length of the connect shall not exceed 3 ft.

ADJUSTING FOR ELEVATION

• Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation. For

operation at elevations above 2000 ft., input

ratings should be reduced at a rate of 4 percent

for each 1000 ft. above sea level.

Installation must conform to local codes and

•

ordinances or, in their absence, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA

B149.1

19

Page 20

Installation Instructions

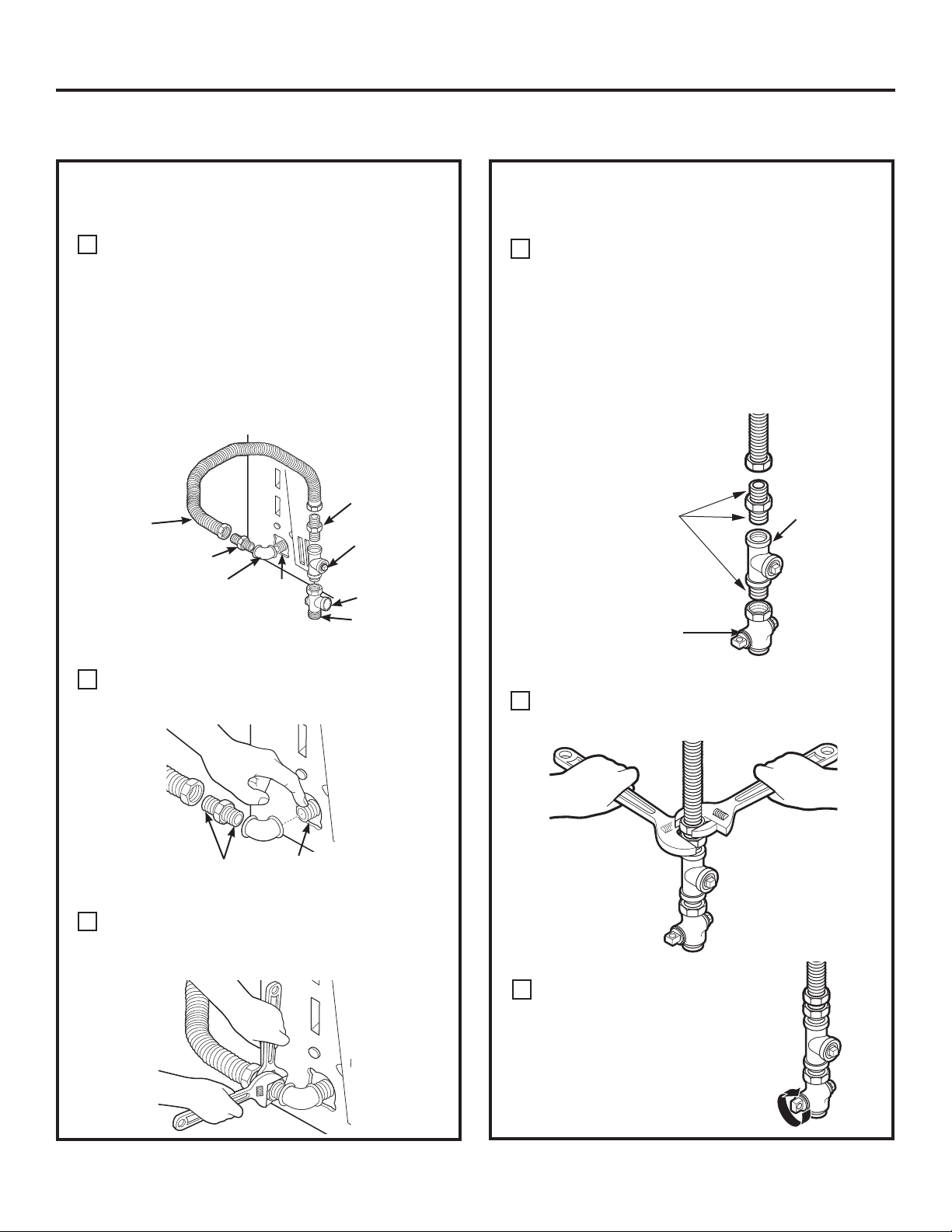

CONNECTING A GAS DRYER (cont.)

CONNECTING THE DRYER TO THE GAS

SUPPLY

Install a female 3/8” NPT elbow at the end of the

A

dryer gas inlet.

Install a 3/8” flare union adapter to the female

elbow.

IMPORTANT: Use a pipe wrench to securely

hold on to the end of the dryer gas inlet to

prevent twisting the inlet.

®

NOTE: Apply pipe compound or Teflon

the threads of the adapter and dryer gas inlet.

New Metal

Flexible Gas

Line Connector

Adapter

Elbow

Items not supplied

3/8” NPT

tape to

Adapter

1/8” NPT

Pipe Plug for

Checking Gas

Inlet Pressure

Shut-Off Valve

Pipe size at

least 1/2”

CONNECTING THE DRYER TO THE GAS

SUPPLY (cont.)

Install a 1/8” NPT plugged tapping to the dryer

D

gas line shut-off valve for checking gas inlet

pressure.

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or Teflon

to the threads of the adapter and plugged

tapping.

Apply pipe compound

or Teflon

male threads.

®

tape to all

Shut-Off

Valve

®

tape

Plugged

Tapping

Attach the flexible metal gas line connector to

B

the adapter.

Apply pipe compound to the

adapter and dryer gas inlet.

Tighten the flexible gas line connection, using

C

two adjustable wrenches.

Tighten all connections, using two adjustable

E

wrenches. Do not overtighten.

Open the gas shut-off valve.

F

20

Page 21

Installation Instructions

TEST FOR LEAKS

WARNING – Never use an open

flame to test for gas leaks.

Check all connections for leaks with soapy solution

or equivalent.

Apply a soap solution. The leak test solution must

not contain ammonia, which could cause damage

to the brass fittings.

If leaks are found, close the valve, retighten the joint

and repeat the soap test.

Open Gas

Valve

ELECTRICAL REQUIREMENTS FOR GAS

DRYERS

This appliance must be supplied with 120V, 60Hz,

and connected to a properly grounded branch

circuit, protected by a 15- or 20-amp circuit breaker

or time-delay fuse.

If electrical supply provided does not meet the

above specifications, it is recommended that a

licensed electrician install an approved outlet.

WARNING – This dryer is equipped

with a three-prong (grounding) plug for your

protection against shock hazard and should be

plugged directly into a properly grounded

three-prong receptacle. Do not cut or remove the

grounding terminal from this plug.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

WARNING – To reduce the risk of

fire, electrical shock and personal injury:

•

Do not use an extension cord or an adapter plug

with this appliance.

The dryer must be electrically grounded in

•

accordance with local codes and ordinances, or

in the absence of local codes, in accordance with

the NATIONAL ELECTRICAL CODE, ANSI/NFPA NO.

70 or Canadian Electrical Code, CSA C22.1

Ensure proper

ground exists

before use.

If local codes permit, an external ground wire (not

provided), which meets local codes, may be added

by attaching to the green ground screw on the rear

of the dryer, and to an alternate established ground.

Ensure proper ground exists before use.

Ground

Screw

21

Page 22

Installation Instructions

CONNECTING AN ELECTRIC DRYER (skip for gas dryers)

TOOLS YOU WILL NEED

Slip-joint pliers

Flat-blade crewdriver

Phillips screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

3/4” strain relief

(UL recognized)

Gloves

Exhaust hood

FOR YOUR SAFETY:

WARNING

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall. NEVER LEAVE THE

ACCESS COVER OFF THE TERMINAL BLOCK.

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

4”duct clamps (2) or

4”spring clamps (2)

Safety glasses

4” dia. metal duct

(recommended)

4” dia., UL-listed

flexible metal duct (if

needed)

Duct tape

Dryer power cord kit

(not provided with

dryer)

UL rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type

as per the house

receptacle before

purchasing line cord.

WARNING – To reduce the risk of

fire, electrical shock and personal injury:

•

Do not use an extension cord or an adapter plug

with this appliance.

The dryer must be electrically grounded in

•

accordance with local codes, or in the absence

of local codes, with the National Electrical Code,

ANSI/NFPA NO. 70 or Canadian Electrical Code,

CSA C22.1.

22

Page 23

Installation Instructions

ELECTRICAL REQUIREMENTS FOR

ELECTRIC DRYERS

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. A three- or four-wire,

single-phase, 120/240V or 120/208V, 60Hz, 30-amp

circuit is required.

If the electric supply does not meet the above

specifications, then call a licensed electrician.

ELECTRICAL REQUIREMENTS FOR

ELECTRIC DRYERS (CANADA)

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. The power supply must

be of 120/240 volts, 60Hz circuit with the wall

receptacle as shown below.

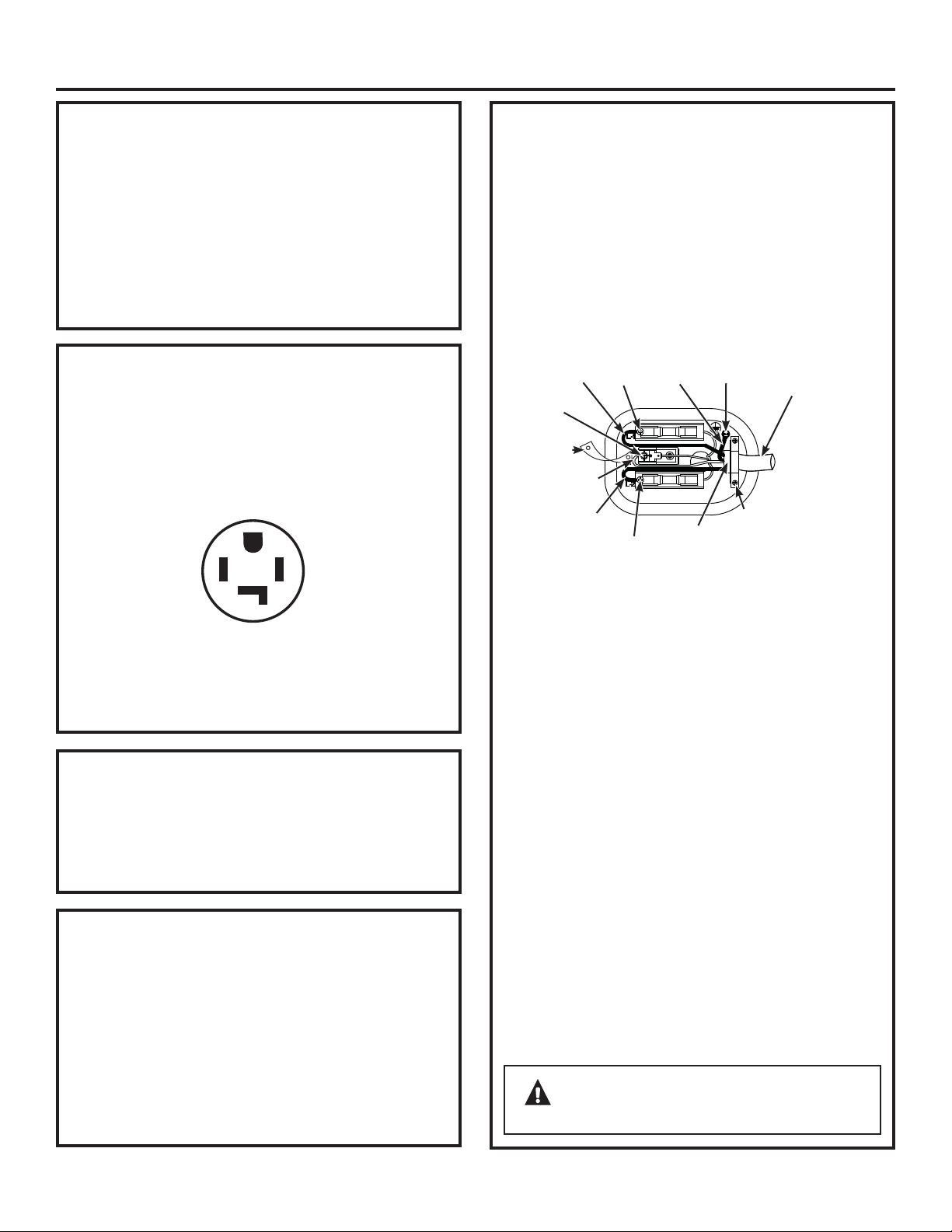

G

XY

W

TYPICAL 30 AMP

RECEPTACLE FOR DRYER

The power supply must be protected with 30 Amp

fuses or breakers. It must be well grounded and

conform to local codes.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded

metal, permanent wiring system, or an equipmentgrounding conductor must be run with the circuit

conductors and connected to the equipment

grounding terminal on the appliance.

GROUNDING INSTRUCTIONS

(CANADA)

This appliance must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electrical shock by providing

a path of least resistance for electrical current.

This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

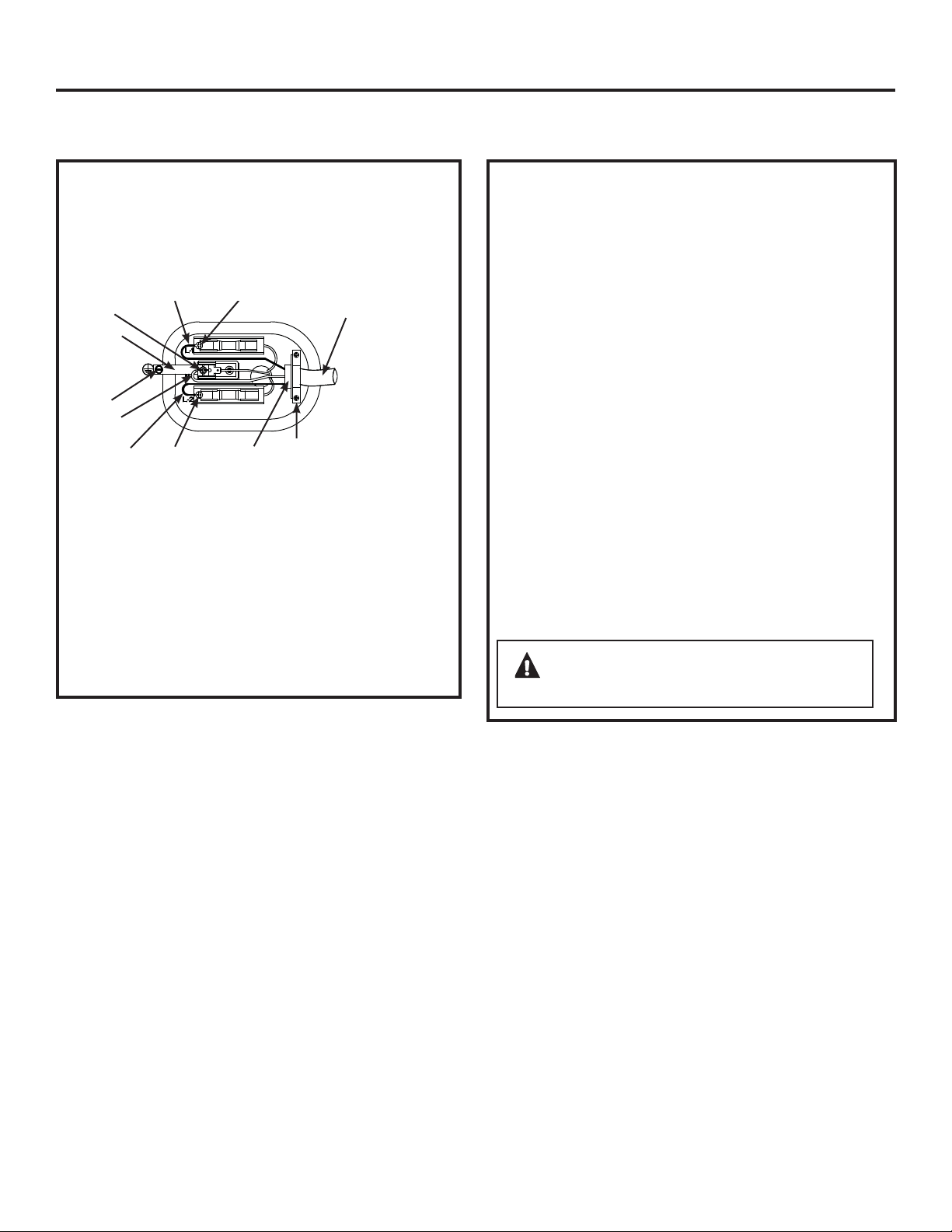

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE: Since January 1, 1996, the National Electrical

Code requires that new constructions utilize a

4-wire connection to an electric dryer. A 4-wire cord

must also be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new

construction.

Relocatre

green ground

screw here

3/4” UL

Recognized

Strain Relief

Strain

Relief

Bracket

4 #10 AWG

minimum

copper

conductors

or 120/240V

30A

power

supply cord

marked for use

with dryers

and provided

with closed

loop or spade

terminals with

upturned ends

(not supplied)

kit

Hot Wire

Screw

Remove

ground strap

and discard.

Keep green

ground

screw.

Neutral

(white)

Screw

Hot Wire

Green

Wire

Screw

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

Be sure the dryer cord is unplugged from the wall

2.

receptacle.

Remove the power cord cover located at the

3.

lower back.

Remove and discard ground strap. Keep the

4.

green ground screw for Step 7.

Install 3/4 in. UL-recognized strain relief to power

5.

cord entry hole. Bring power cord through strain

relief.

Connect power cord as follows:

6.

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

Attach ground wire of power cord with the green

7.

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) securely.

Properly secure power cord to strain relief.

8.

Reinstall the cover.

9.

WARNING – NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

23

Page 24

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

CONNECTING DRYER USING 3-WIRE

CONNECTION

If required, by local code, install external ground (not

provided) to grounded metal, cold water pipe, or other

established ground determined by a qualified electrician.

Hot Wire

Screw

Ground

Strap

Green

ground

screw

Neutral

(white)

Hot Wire

Screw

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations.

NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit

grounding through the neutral conduction.

Screw

3/4” UL

Recognized

Strain Relief

Strain

Relief

Bracket

3 #10 AWG

minimum

copper

conductors or

120/240V 30A

power supply

cord kit marked

for use with

dryers and

provided with

closed loop or

spade terminals

with upturned

ends (not

supplied)

CONNECTING DRYER USING 3-WIRE

CONNECTION (cont.)

Turn off the circuit breaker(s) (30 amp) or remove

1.

the dryer’s circuit fuse at the electrical box.

Be sure the dryer cord is unplugged from the wall

2.

receptacle.

Remove the power cord cover located at the lower

3.

back.

Install 3/4-in. UL-recognized strain relief to power

4.

cord entry hole. Bring power cord through strain

relief.

Connect power cord as follows:

5.

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

Be sure ground strap is connected to neutral

6.

(center) terminal of block and to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) securely.

Properly secure power cord to strain relief.

7.

Reinstall the cover.

8.

WARNING – NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

24

Page 25

Installation Instructions

EXHAUSTING THE DRYER

WARNING – To reduce the risk of fire

or personal injury:

This clothes dryer must be exhausted to the outdoors.

•

Use only 4” rigid metal ducting for the home exhaust

•

duct.

Use only 4” rigid metal or UL-listed flexible metal

•

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed

in accordance with the instructions found in

“Connecting the Dryer to House Vent” on page 26 of

this manual.

Do not terminate exhaust in a chimney, a wall,

•

a ceiling, gas vent, crawl space, attic, under an

enclosed floor, or in any other concealed space

of a building. The accumulated lint could cause a

potential fire hazard.

Never terminate the exhaust into a common duct

•

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

Do not use duct longer than specified in the exhaust

•

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

Never install a screen in or over the exhaust duct. This

•

will cause lint to accumulate, creating a potential fire

hazard.

Do not assemble ductwork with any fasteners

•

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

Do not obstruct incoming or exhausted air.

•

Provide an access for inspection and cleaning of

•

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

This dryer comes ready for rear exhausting. If space

•

is limited, use the instructions on pages 29–31 to

exhaust directly from the sides or bottom of the

cabinet.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

•

Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

•

Termination should present minimal resistance to

the exhaust airflow and should require little or no

maintenance to prevent clogging.

•

Never install a screen in or over the exhaust duct.

•

Wall caps must be installed at least 12” above ground

level or any other obstruction with the opening pointed

down.

SEPARATION OF TURNS

•

For best performance, separate all turns by at least 4

ft. of straight duct, including distance between last turn

and dampened wall cap.

SEALING OF JOINTS

•

All joints should be tight to avoid leaks. The male end of

each section of duct must point away from the dryer.

•

Do not assemble the ductwork with fasteners that

extend into the duct. They will serve as a collection

point for lint.

•

Duct joints should be made air- and moisture-tight

by wrapping the overlapped joints with duct tape or

aluminum tape.

•

Horizontal runs should slope down towards the

outdoors 1/4” per foot.

INSULATION

•

Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint buildup.

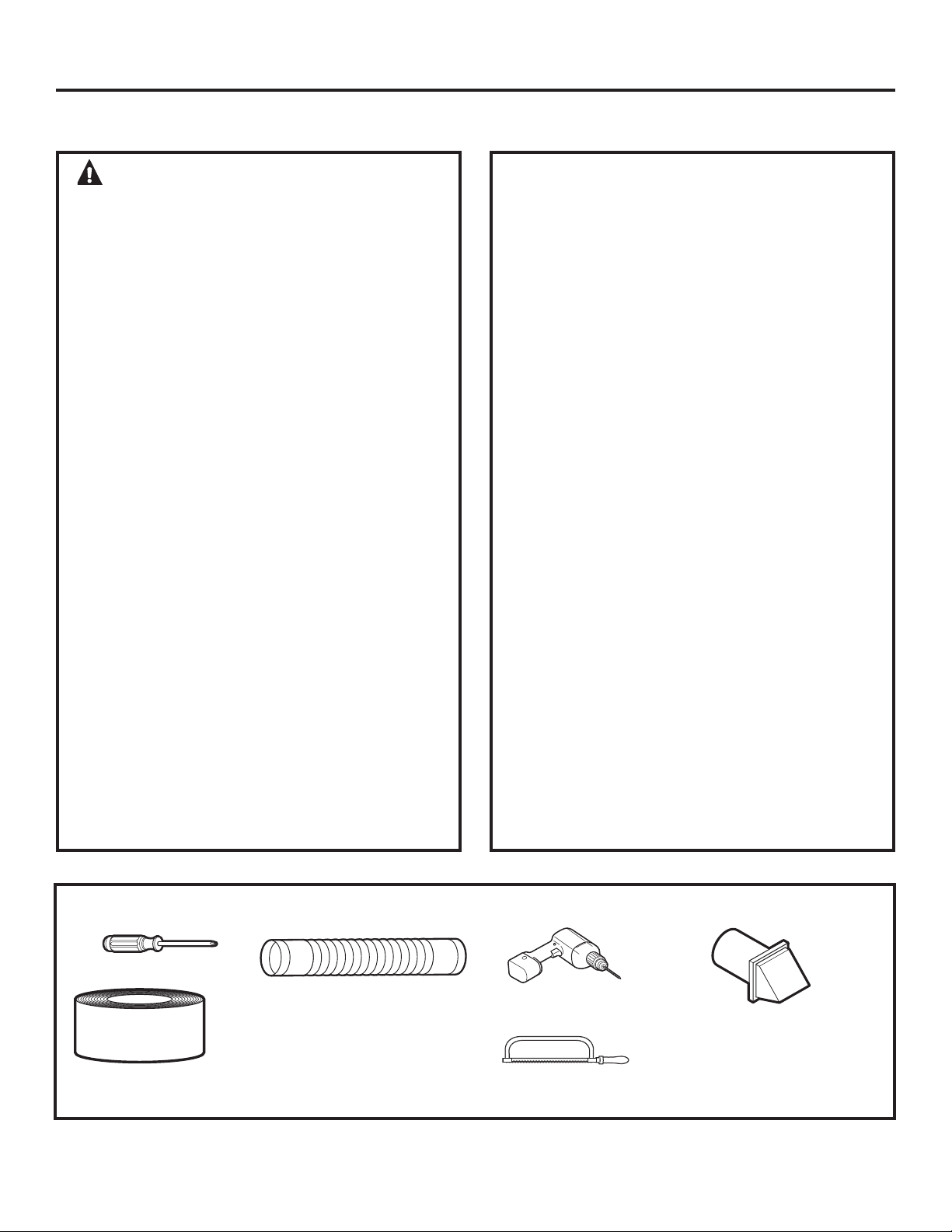

TOOLS AND MATERIALS YOU WILL NEED TO INSTALL EXHAUST DUCT

Phillips-head screwdriver

Drill with 1/8” drill bit

(for bottom venting)

Hacksaw

25

Duct tape or duct

clamp

Rigid or UL-listed

flexible metal 4” (10.2

cm) duct

Vent hood

Page 26

Installation Instructions

EXHAUSTING THE DRYER (cont.)

CONNECTING THE DRYER TO HOUSE

VENT

RIGID METAL TRANSITION DUCT

For best drying performance, a rigid metal transition

•

duct is recommended.

Rigid metal transition ducts reduce the risk of crushing

•

and kinking.

UL-LISTED FLEXIBLE METAL (SEMI-RIGID) TRANSITION

DUCT

•

If rigid metal duct cannot be used, then UL-listed

flexible metal (semi-rigid) ducting can be used (Kit

WX08X10077).

Never install flexible metal duct in walls, ceilings, floors

•

or other enclosed spaces.

Total length of flexible metal duct should not exceed 8

•

feet (2.4 m).

For many applications, installing elbows at both

•

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing the

transition duct, maximizing drying performance.

Avoid resting the duct on sharp objects.

•

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION

DUCT

•

In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal

(foil-type) duct. A UL-listed flexible metal (foil-type) duct

may be used ONLY in installations where rigid metal or

flexible metal (semi-rigid) ducting cannot be used AND

where a 4” diameter can be maintained throughout

the entire length of the transition duct.

In Canada and the United States, only the flexible

•

metal (foil-type) ducts that comply with the “Outline for

Clothes Dryer Transition Duct Subject 2158A” shall be

used.

Never install flexible metal duct in walls, ceilings, floors

•

or other enclosed spaces.

Total length of flexible metal duct should not exceed 8

•

feet (2.4 m).

Avoid resting the duct on sharp objects.

•

For best drying performance:

•

1. Slide one end of the duct over the clothes dryer

outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position, extend

”

the duct to its full length. Allow 2

overlap the exhaust pipe. Cut off and remove

excess duct. Keep the duct as straight as possible

for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

of duct to

FOR TRANSITION VENTING (DRYER TO

WALL), DO:

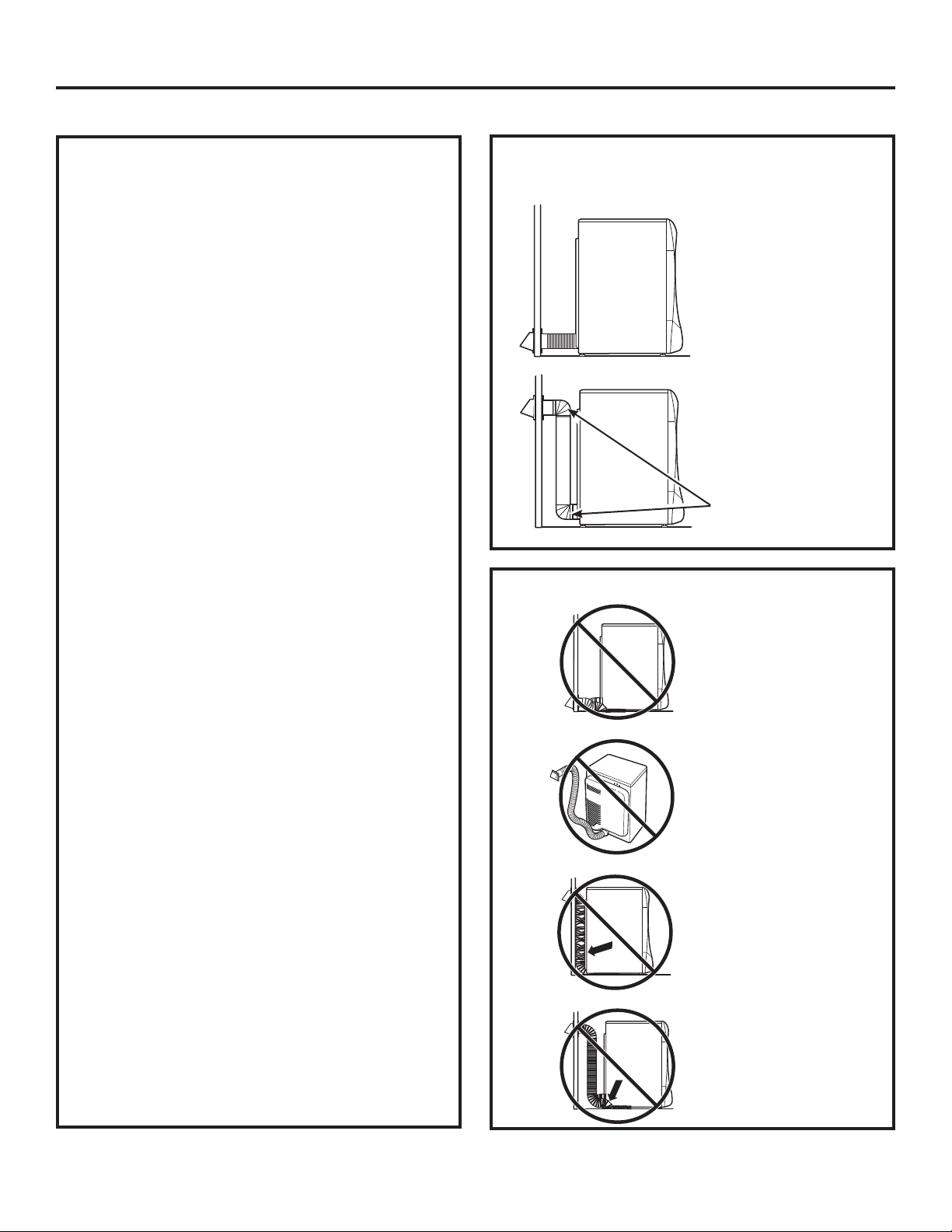

• DO cut duct as

short as possible

and install

straight into wall.

DO use elbows

•

when turns are

necessary.

Elbows

DO NOT:

• DO NOT bend or

collapse ducting.

Use elbows

if turns are

necessary.

•

DO NOT use

excessive

exhaust length.

Cut duct as short

as possible.

• DO NOT crush

duct against the

wall.

DO NOT set

•

dryer on duct.

26

Page 27

Installation Instructions

WARNING – USE ONLY METAL 4”

DUCT. DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

•

Increase the drying times and the energy cost.

Reduce the dryer life.

•

Accumulate lint, creating a potential fire

•

hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation are not

covered by the warranty.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

•

Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

Termination should present minimal resistance

•

to the exhaust airflow and should require little or

no maintenance to prevent clogging.

Never install a screen in or over the exhaust

•

duct. This could cause lint buildup.

Wall caps must be installed at least 12” above

•

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

The MAXIMUM ALLOWABLE length of the

exhaust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall

cap) and all conditions noted below.

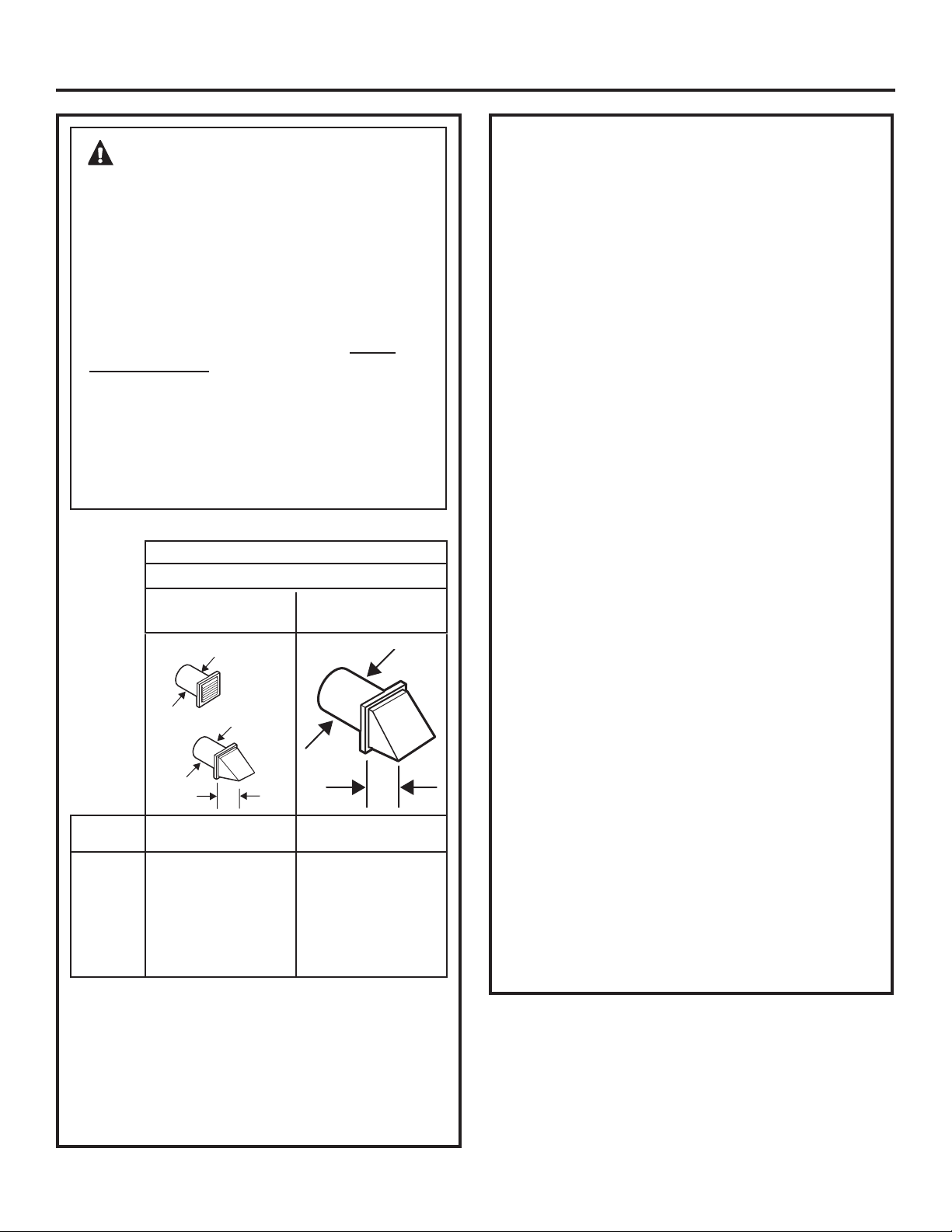

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Use only for short- run

installations

4

”

4” DIA

4” DIA

”

4

No. of 90º Rigid Rigid

Elbows Metal Metal

0 150 Feet 125 Feet

1 135 Feet 115 Feet

2 125 Feet 105 Feet

3 115 Feet 95 Feet

4 105 Feet 85 Feet

5 95 Feet 75 Feet

• For every extra 90° elbow, reduce the allowable vent

system length by 10 ft.

• Two 45° elbows will be treated like one 90° elbow.

• For the side exhaust installations, add one 90° elbow to

the chart.

• The total vent system length includes all the straight

portions and elbows of the system (transition duct

included).

DIA

1

ø2”

2

27

For best performance, separate all turns by at

least 4 ft. of straight duct, including the distance

between the last turn and the exhaust hood.

TURNS OTHER THAN 90º

• One turn of 45º or less may be ignored.

Two 45º turns should be treated as one 90º turn.

•

Each turn over 45º should be treated as one 90º

•

turn.

SEALING OF JOINTS

•

All joints should be tight to avoid leaks. The male

end of each section of duct must point away

from the dryer.

Do not assemble the ductwork with fasteners

•

that extend into the duct. They will serve as a

collection point for lint.

Duct joints can be made air- and moisture-tight

•

by wrapping the overlapped joints with duct

tape.

Horizontal runs should slope down toward the

•

outdoors 1/4” per foot.

INSULATION

Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint buildup.

Page 28

Installation Instructions

EXHAUSTING THE DRYER (cont.)

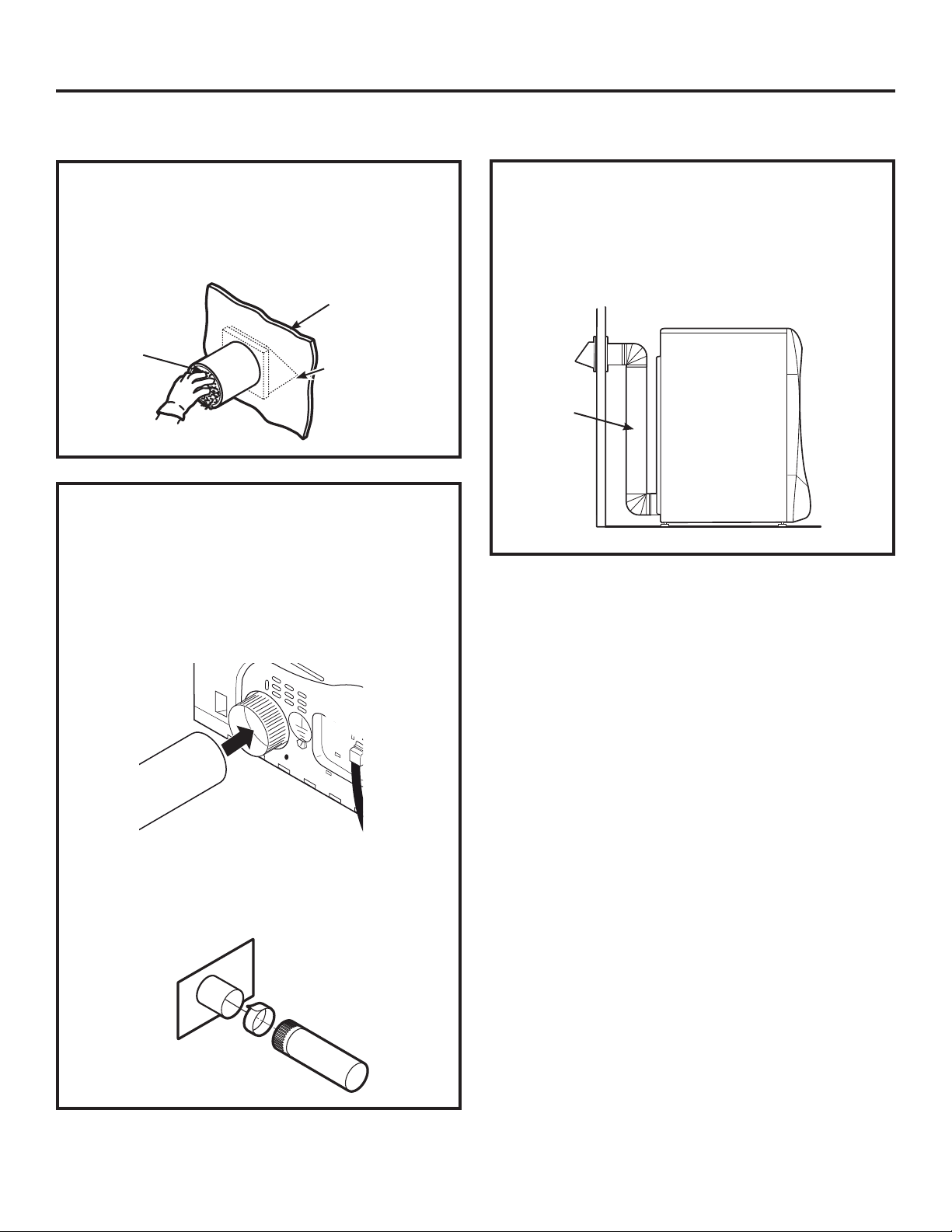

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

Remove any lint from the wall exhaust opening.

•

Wall

Internal

Duct

Opening

Check that exhaust

hood damper opens

and closes freely.

STANDARD REAR EXHAUST

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the

dryer and secure with duct tape or a hose clamp.

RECOMMENDED CONFIGURATION TO

MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Transition

Ducting

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct.

•

For straight-line installation, connect the dryer

exhaust to the wall, using duct tape.

Wall Side

Dryer

Side

28

Page 29

Installation Instructions

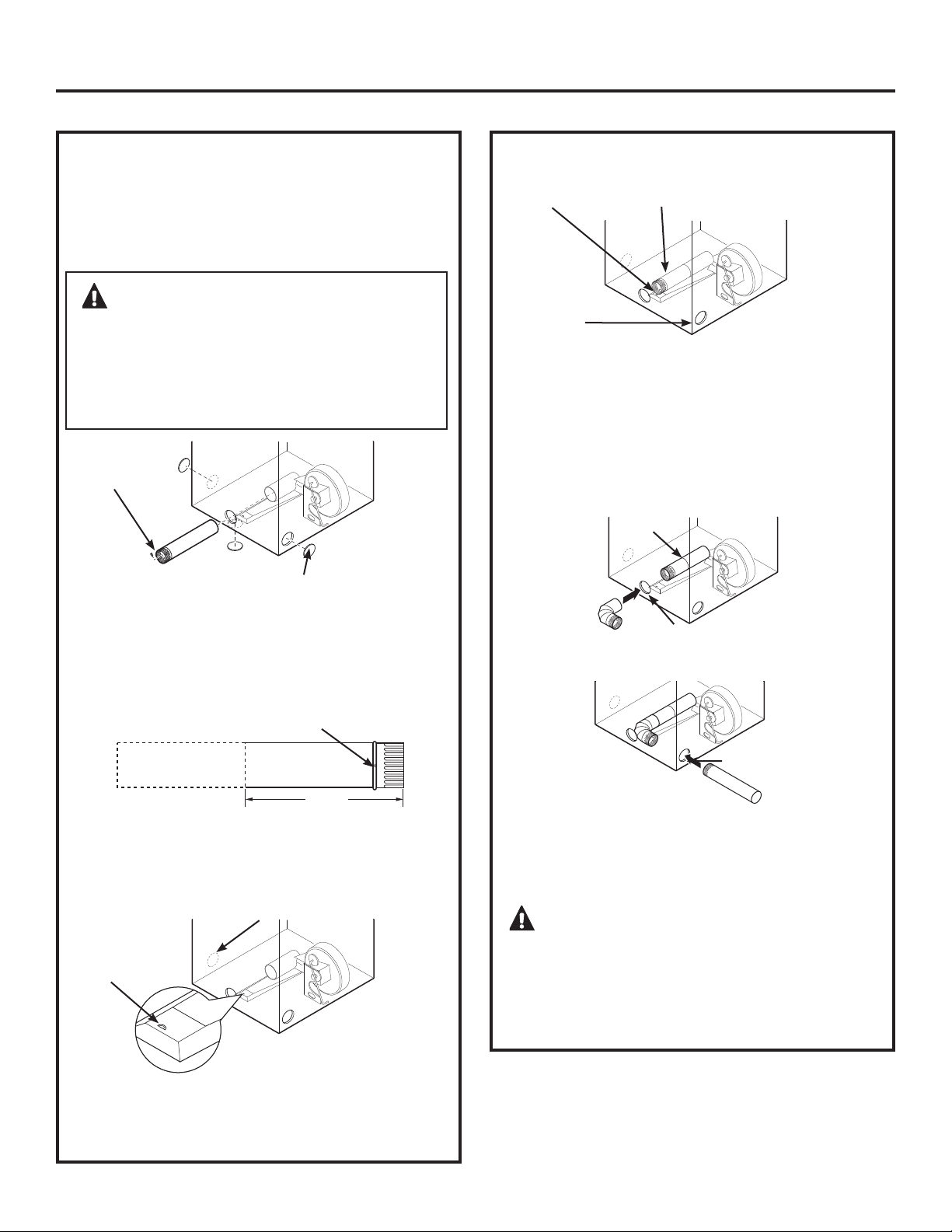

SIDE VENTING:

Dryer Exhaust to right of cabinet for Electric

models only.

Dryer Exhaust to left of cabinet for Gas and

Electric models.

WARNING – BEFORE PERFORMING

THIS EXHAUST INSTALLATION, BE SURE TO

DISCONNECT THE DRYER FROM ITS ELECTRICAL

SUPPLY. PROTECT YOUR HANDS AND ARMS

FROM SHARP EDGES WHEN WORKING INSIDE

THE CABINET. BE SURE TO WEAR GLOVES.

Remove

screw

and save

Right

Left

Bottom

Remove desired

knockout (one only)

ADDING A NEW DUCT

Fixing hole

Left side

exhaust

Reconnect the cut portion (A) of the duct to the

blower housing. Make sure that the shortened

duct is aligned with the tab in the base. Use the

screw saved previously to secure the duct in place

through the tab on the appliance base.

Portion “A”

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET

Internal duct

Detach and remove the bottom, right or left side

knockout as desired. Remove the screw inside the

dryer exhaust duct and save. Pull the duct out of

the dryer.

Fixing hole

A

13 1ø2”

Cut the duct as shown and keep portion A.

TAB LOCATION

Not for gas

Bend tab

up 45°

Rear opening

Side opening

• Insert the 4” elbow through the rear opening and

connect the elbow to the dryer internal duct.

Insert the 4” duct through the side opening and

•

connect it to the elbow.

CAUTION: Do not pull or damage the

electrical wires and do not remove the vinyl cover

from the electrical components inside the dryer

when inserting the duct. A slight interference may

occur between the exhaust and the wire

components.

Through the rear opening, locate the tab in the