Page 1

GE Zoneline® packaged

terminal air conditioners

Page 2

2

Page 3

Zoneline®. Efficient. Quiet.

Reliable. Innovative.

Versatile Zoneline® Packaged Terminal Air Conditioners provide year-round comfort

with individual heating and cooling temperature controls. Designed for a wide range of

applications, these units are ideal for hotels and motels, office buildings, schools and

apartments. All Zoneline units feature the exclusive GE® “Superseal” system which

ge.com

minimizes energy usage by reducing air infiltration. The result is maximum operating

efficiency and a more comfortable room. All Zoneline units are also very quiet thanks to a

lower sound level and lower sound transmission. The newest innovation in Zoneline units

is the Dry Air 25 Series. Similar to our Deluxe 2900 Series, the Dry Air 25 removes 25%

more moisture from the air than standard GE packaged terminal air conditioners.

3

Page 4

Zoneline® features and benefits

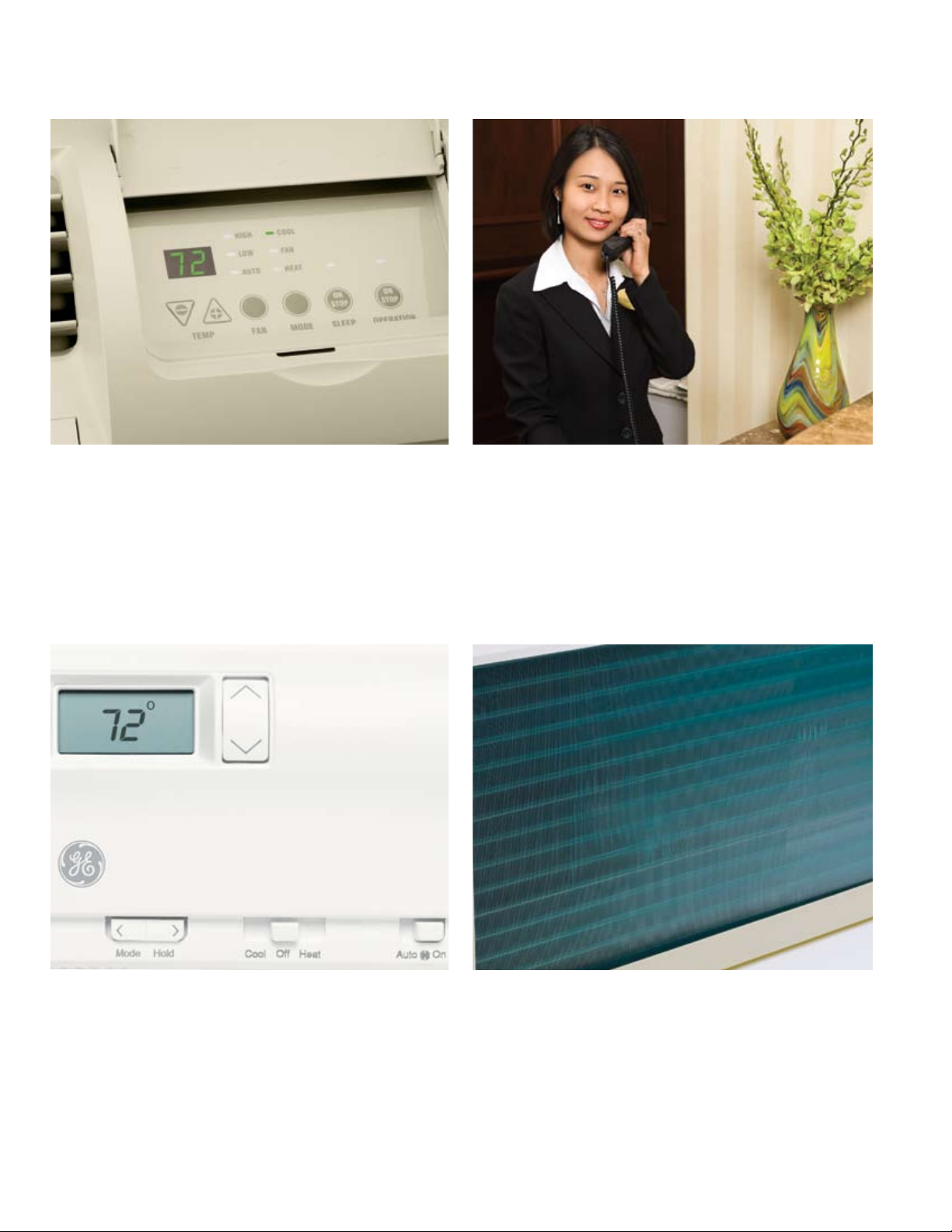

Electronic touch controls

The 2900, 3900 and 5800 Series Zoneline® units are

equipped with microcomputer touch controls. This

feature gives the user better control over the temperature

with a touch pad and an LED readout.

Central desk control

All Zoneline units are compatible with two-wire central

desk ON/OFF controls, including many computerized

control systems. They can also be wired directly to

infrared sensors and door switches to maximize efficiency.

Remote installation capability

All Zoneline units are compatible with GE® wall-mounted

remote thermostats. Mechanical, digital and programmable

thermostats are available.

4

Optional corrosion treatment

Deluxe Zoneline units can be ordered with special

treatment to reduce the effects of corrosive

environments. Special treatments are placed on

the outdoor coil and other components to extend

the life of the unit.

Model shown: PDW9880J

Page 5

ge.com

The Dry Air 25

The Dry Air 25 Series centers around GE’s exclusive use of

the patented Dinh® Dehumidifier Heat Pipe from Heat Pipe

Technology, Inc. This innovative technology enables the

Dry Air 25 to remove 25% more moisture from the air than

standard GE packaged terminal air conditioners. The Dry Air

25 is perfect for high-humidity climates. Available on 7000,

9000 and 12000 BTU models.

Freeze Sentinel

All Zoneline units are equipped with Freeze Sentinel to

provide protection against damage caused by freezing

temperatures in unoccupied rooms, regardless of unit

setting. In installations where freezing temperature is

not a concern, the owner has the option of disabling

the Freeze Sentinel.

™

Heat Sentinel

Provides automatic protection against overheating by

switching on the unit to cool should the temperature

of an unoccupied room reach 85°F.

Upfront filters

For ease of cleaning, all Zoneline units have interchangeable,

removable upfront filters made of long-lasting nylon mesh,

thus assuring high performance and long life.

Electronic temperature limiting

Heating and cooling temperatures may be electronically

limited on all series to prevent expensive overcooling or

overheating. Heating and cooling limits are independently

set so seasonal adjustment is unnecessary.

5

Page 6

Easy installation and flexibility of design

Zoneline® units are designed with innovative, universal

components, and offer even greater installation flexibility

than ever, whether in new construction, renovation or

for replacement of old units. Unless specified by code,

they require no sub-base and may be installed flush with

finished floor. All models are adaptable to remote and

central desk control. Zoneline units may even be placed

in unusual locations, such as transom or common-area

installations. The two lines, Deluxe and Premium, each

with its own special blend of features, offer flexibility to

meet each zone application. All units come with

microcomputer controls.

Room cabinet

Wall sleeve (optional)

RAB71A (Shown)

RAB77A4 (SMC) (Not Shown)

Deluxe 2900 series

cooling with resistance heat

• Digital controls

- LED temperature display

- Easy temperature selection

- Tactile touch pads

• Two fan motors

- Improved quiet sound levels

- Higher efficiency

• Electronic temperature limiting

- Helps reduce operating costs

• Optional corrosion treatment

- Reduces the effects of coastal

environments

• Freeze Sentinel

- Protects unoccupied rooms from

damage by freezing temperatures

• Heat Sentinel

- Reduces excessive temperatures

in unoccupied room

• GE-exclusive Superseal

- Increased room comfort

- Energy savings

• Upfront filters

- Ease of cleaning

- Long-lasting nylon mesh

• Central desk control compatibility

• Remote thermostat capability

• Smartfan

- Fan cycle operation based on

heat/cool selection

6

™

Deluxe Dry Air 25 series

cooling with resistance heat

Includes all features of 2900 series, plus:

• Removes 25% more moisture from the

air than standard GE packaged terminal

air conditioners

• Cool and dry air in less time than standard

Zoneline models

• Maintains comfort at slightly higher room

temperatures

- Helps reduce operating costs

- Provides comfort without overcooling

• Corrosion treatment is standard

• Heat pipe is a separate sealed

refrigerant system

- No mechanical parts

- No special maintenance required

• Helps maintain lower relative humidity

in rooms

• Best suited for humid climates

Deluxe 3900 series

cooling with heat pump

and resistance heat

Includes all features of 2900 series, plus:

• Reverse cycle heating

- Energy savings over electric

resistance heat

- Significantly lower operating costs

• Heat pump operation down to 25°F

outdoor temperature

• Three-stage thermostat for quicker

heat recovery

• Optional factory-installed internal

condensate removal (ICR)

- Minimizes need for drain systems

• Heat pump and resistance heat can

operate together

- Better room comfort

- Helps reduce operating costs over

all standard heat pump systems

• Reverse cycle defrost

- Extends heat pump operation

- May help lower operating costs

• Electric resistance heat lockout

- Lowers operating costs by restricting

electric heat operation when outdoor

temperature is above 46°F.

Page 7

Grille options

Extruded aluminum:

RAG67 (Shown)

Stamped aluminum grille

RAG60

Exterior architectural louvers

Durable polycarbonate:

RAG61 (Warm Grey Beige)

RAG62 (Maple)

RAG63 (Bittersweet Chocolate)

Retrofit kits (not shown)

RAK901L - Wall Case Insulation for use

with Heat Pumps

RAK40 - Deflector Kit to adapt chassis for

use with existing exterior architectural

louvered grilles

ge.com

Chassis

Premium 5800 series

cooling with heat pump

and resistance heat

Includes all features of 3900 series, plus:

• Two-fan-motor system with indoor

cross flow blower

- For quieter operation

• Corrosion treatment is standard

• Self-diagnostics

• Connections for infrared/door

switch sensors

Grille

Requires power connection kit

Resistance heat Heat pump

Deluxe

Features

Highly featured

microcomputer controls

Tactile touch pad controls with LED Standard Standard Standard Standard

Universal heaters Standard Standard Standard Standard

Solid-state thermostat Standard Standard Standard Standard

3-position vent control

Upfront filter (interchangeable) Standard Standard Standard Standard

Automatic indoor frost control Standard Standard Standard Standard

Sleep function Standard Standard Standard Standard

Corrosion-treated chassis Optional Standard Optional Standard

2-position discharge grille Standard Standard Standard Standard

Fan motors 2 2 2 2

“SmartFan” Fan cycle control Standard Standard Standard Standard

Fan Only setting—2-speed Hi/Low Hi/Low Hi/Low Hi/Low

Indoor fan speed Hi/Low Hi/Low Hi/Low Hi/Low

Cool & heat only settings Hi/Low/Auto Hi/Low/Auto Hi/Low/Auto Hi/Low/Auto

Staged heating — — 3-stage 3-stage

Freeze Sentinel™ Standard Standard Standard Standard

Heat Sentinel Standard Standard Standard Standard

Temperature limiting

Remote control compatibility Standard Standard Standard Standard

Central desk control compatibility Standard Standard Standard Standard

Service indicator — — — Standard

Heat pump with resistance

heat back-up

Heat pump with supplemental

resistance heat

Automatic emergency heat Standard Standard Standard Standard

Electric resistance heat lock-out — — Standard Standard

Heat pump defrost system — — Reverse cycle Reverse cycle

Internal condensate removal (ICR)* — — Optional Optional

Quick heat recovery — — Standard Standard

Self-diagnostics — — — Standard

Auto power recovery Standard Standard Standard Standard

*Not for use in corrosive environments

2900 Series

Standard Standard Standard Standard

Standard Standard Standard Standard

Electronic 7-step Electronic 7-step Electronic 7-step Electronic 7-step

—

—

Deluxe

Dry Air 25

—

—

Deluxe

3900 Series

Standard Standard

Standard Standard

Premium

5800 Series

7

Page 8

Deluxe models

2900 series and Dry Air 25 series – heat/cool units

3900 series – heat pump unit

Highly featured microcomputer controls

Central desk control

compatible

Ability to turn the unit

“on” or "off" from a

remote location.

Two fan motors

(not visible)

Separate motors for

indoor and outdoor fans

to assure quiet operation.

Reversible louver

(not shown)

May be reversed to

provide an air discharge

angle of 40 or 50 degrees

off vertical with the simple

removal of six screws.

3-Position vent control

(not shown)

Opens vent. Provides up

to 75 cfm of outdoor air.

The closed position saves

energy by recirculating

conditioned room air.

Reverse cycle defrost

(not shown)

Solid-state sensor

monitors frost build-up

on outdoor coil. When

frost is detected, the

refrigerant flow is reversed

to melt frost build-up.

When completed, the

refrigerant is reversed to

the normal energy-saving

heat pump operation for

additional heat pump

operating hours.

Easy-access filter

(not shown)

Two upfront interchangeable

filters are part of roomside

cabinet for easy access

and maintenance.

Remote control

compatible

Ability to be controlled

by a wall-mounted

thermostat with high

or low fan speed.

Solid-state

thermostat control

Provides better room

temperature control

vs. electromechanical

temperature control

device.

Freeze Sentinel™

Provides automatic

protection against

freezing by switching

the unit to heat should

the temperature of an

unoccupied room drop

to 41°F.

Heat Sentinel

Provides automatic

protection against

overheating by switching

on the unit to cool should

the temperature of

an unoccupied room

reach 85°F.

Auto frost control

A special sensor monitors

the roomside coil to

prevent efficiency-robbing

accumulation of frost

during cooling operation.

GE Dry Air 25

(not shown)

Innovative technology from

Heat Pipe Technology, Inc

enables the DryAir 25 to

remove 25% more moisture

from the air than standard

GE packaged terminal air

conditioners.

Electronic

temperature limiting

Preset cooling and heating

limits with 7 independent

cooling and 7 heating

limits—saves energy by

preventing over-cooling

or over-heating of rooms.

“Smartfan”

fan cycle selection

Select fan cycle or fan

continuous independently

for heating and cooling.

Universal power cord

Flexibility of heat

applications. All

Zonelines contain a

bank of 3 heaters.

Rotary compressor

Fewer moving parts

than reciprocating models

for quiet, reliable operation

and longer life.

Touch pad controls

With electronic control

temperature display. Gives

the user finer control over

the temperature.

The Dry Air 25

The Dry Air 25 features innovative technology from Heat Pipe

Technology, Inc., an addition which enables this unit to remove 25%

more moisture from the air than standard GE Zoneline® models. The

Dry Air 25 system, Heat Pipe, is a hermetically sealed heat transfer

surface that is saddlebagged around the indoor coil (evaporator) of

the Zoneline. This coil arrangement will transfer heat from one coil to

another without power consumption. This assembly uses R-22 as the

refrigerant and is isolated from the regular Zoneline refrigerant circuit.

As warm humid air is pulled through the pre-cool section of the Heat

Pipe, the heat removed from the air is absorbed by the refrigerant,

causing the refrigerant to boil. As the pre-cooled air passes through

the Zoneline evaporator, the air is further cooled (colder than it would

be normally), removing 25% more moisture from the air than standard

GE packaged terminal air conditioners.

As the cold air passes through the reheat section of the Heat Pipe, the

refrigerant condenses and the liquid flows back to the pre-cool section

to be reheated again. The air discharged into the room by this process

is much drier, creating a more comfortable room condition.

8

Special corrosion-protected units

To help extend the life of the Zoneline unit in seacoast areas, some

Deluxe Zoneline units may be ordered with a special corrosion

protection treatment on outdoor components and use stainless

steel hardware. Zoneline units with optional corrosion protection

have a ‘C’ in the 10th character of the model number.

Internal condensate removal

Available on the 3900 and 5800 heat pumps, this feature drips the

heat pump condensate over the warm indoor coil to help dissipate

water from heat pump operation and associated defrost cycles. The

installation of an internal or external drain system is recommended if

no dripping of condensate to the outdoors is desired. ICR must not be

installed in seacoast or corrosive applications.

Page 9

Premium models

5800 series

Highly featured microcomputer controls

Cross-flow blower

Quiet blower reduces

annoying “Air rush” noise.

Reversible louver

(not shown)

May be reversed to

provide an air discharge

angle of 40 or 50 degrees

off vertical with the

removal of six screws.

3 position vent control

(not shown)

Opens vent. Provides up

to 70 cfm of outdoor air.

The closed position saves

energy by recirculating

conditioned room air.

Solid state

thermostat control

Provides better room

temperature control

vs. electromechanical

temperature control

device.

Freeze Sentinel™

Provides automatic

protection against

freezing by switching

the unit to heat should

the temperature of an

unoccupied room drop

to 41°F.

Heat Sentinel

Provides automatic

protection against

overheating by switching

on the unit to cool should

the temperature of

an unoccupied room

reach 85°F.

Room occupancy

sensor compatible

Ready for connection

to room occupancy

sensor system.

Weather-protected

electrical components

On inside of barrier.

Auto frost

control monitor

A special sensor monitors

the roomside coil to

prevent efficiency-robbing

accumulation of frost

during cooling cycle.

Electronic

temperature limiting

Preset cooling and heating

limits with 7 independent

cooling and 7 heating

limits—saves energy by

preventing over-cooling or

over-heating of rooms.

“Smartfan”

fan cycle selection

Select fan cycle or fan

continuous independently

for heating and cooling.

Universal power cord

Flexibility of heat

applications. Each

premium line Zoneline

contains a bank of

3 heaters.

Microcomputer controls

Electronic components

for fast response and

accuracy.

Rotary compressor

With fewer moving

parts than reciprocating

models for quiet,

reliable operation.

Easy-access filter

(not shown)

Two upfront filters

are part of roomside

cabinet for easy access

and maintenance.

ge.com

Two fan motors

(not visible)

Separate motors for

indoor and outdoor fans

to assure quiet operation.

Touch pad controls

With electronic control

temperature display.

Gives the user finer

control over the

temperature.

Reverse cycle defrost

(not shown)

Solid state sensor

monitors frost build-up

on outdoor coil. When

frost is detected, the

refrigerant flow is reversed

to melt frost build-up.

When completed, the

refrigerant is reversed

to the normal energy

saving heat pump

operation for additional

heat pump operating hours.

Central desk

control compatible

Ability to turn the unit

“on” or “off” from a

remote location.

Remote control

compatible

Ability to be controlled

by a wall-mounted

thermostat with high

or low fan speed.

Wall sleeve dimensions

Heavy-gauge galvanized

steel with a baked enamel

finish for outstanding

protection and appearance.

RAB71A wall sleeve

Heavy-gauge galvanized steel, with insulation.

A-42", B-13 3/4", C-16"

RAB77A4 wall sleeve (shown above)

Molded SMC fiberglass-reinforced polyester compound.

A-42 1/8", B-13 7/8", C-16 1/4"

Wall opening dimensions

Add 1/4" to A and C dimensions for all cutout sizes.

RAB71 16 1/4" min. H. x 42 1/4" min. W.

RAB71 available in 16", 24", 28" and 31" depths.

RAB77A4 16 1/2" min. H. x 42 3/8" min. W.

A

Electrical connection

230/208 volt units may be plugged into

a receptacle. 265 volt units are provided

with a junction box and require direct

C

connection. (NEC Requires 265V Direct

Connection.) See Architects and Engineers

Design Data Manual for electrical

B

connection information including use of

sub-base for direct-connected units. Installation

must comply with local electrical codes and regulations.

Ducted applications

2900 and 3900 series can be used with ductwork to heat or cool more

than one room. RAK6052 Duct Adapter is applied to top of case over air

discharge. RAK601 Duct Extension is applied to right or left of adapter.

Locally fabricated ductwork may be added to extend to maximum

recommended distance of 15 feet.

For additional information on ducted applications, including special

adapters for replacement units, refer to Architects and Engineers Design

Data Manual.

9

Page 10

Receptacles/Sub-bases

Tandem

230/208V 15 Amp

NEMA6-15R

Sub-bases

RAK204U RAK204D15P RAK204D20P RAK204D30P RAK204E15 RAK204E20 RAK204E30

Voltage N/A 230/208 230/208 230/208 265 265 265

Amps N/A 15 20 30 15 20 30

Receptacle N/A NEMA6-20R NEMA6-20R NEMA6-30R NEMA7-15R NEMA7-20R NEMA7-30R

230/208 Volt sub-bases include appropriate power cord kit .

265 Volt units are to be direct connected. Cordset through enclosed chaseway into interior sub-base receptacle meets the NEC requirements.

Perpendicular

230/208V 20 Amp

NEMA6-20R

Large tandem

230/208V 30 Amp

NEMA6-30R

265V 15 Amp

NEMA7-15R

265V 20 Amp

NEMA7-20R;

receptacle used

On 265V sub-base

GE0720-3

265V 30 Amp

NEMA7-30R;

receptacle used

On 265V sub-base

GE073

Power connection kits are required on all Zoneline® chassis (see chart below).

The correct kit for the installation is determined by the voltage and amperage of the electrical circuit and the means of connecting the unit to the

building wiring. If the unit is to be plugged into a receptacle, a line cord kit would be used; if the unit is to be permanently connected, a permanent

connection kit would be used. 265 volt cord set units must be installed in compliance with National Electrical Code

Power connection kits

Required on all models.

See specification sheet

for heater KW and branch

circuit ampacity.

®

.

RAK3153/3203

230/208 volt line cord

connection kit

RAK4157/4207/4307

230/208 volt universal

power supply kit

230/208 volt Line cord connected units

LCDI Power Connection Kit RAK3153 RAK3203 RAK3303

Heater KW 2.55/2.09 3.45/2.82 5.00/4.09

Watts 2,550/2,090 3,450/2,820 5,000/4,090

BTUH 8,600/7,100 11,700/9,600 17,000/13,900

Amps 11.6/10.6 15.6/14.2 22.4/20.4

Min. circuit amps 15 20 30

Recommended

protective

device

15 amp

time delay

fuse or breaker

20 amp

time delay

fuse or breaker

30 amp

time delay

fuse or breaker

230/208 volt Direct connection kit**

RAK4157 RAK4207 RAK4307

Heater KW 2.55/2.09 3.45/2.82 5.00/4.09

Watts 2,550/2,090 3,450/2,820 5,000/4,090

BTUH 8,600/7,100 11,700/9,600 17,000/13,900

Amps 11.6/10.6 15.6/14.2 22.4/20.4

Min. circuit amps 15 20 30

Recommended

protective

device

**To be used with sub-base or connection to building wiring

15 amp

time delay

fuse or breaker

20 amp

time delay

fuse or breaker

30 amp

time delay

fuse or breaker

RAK5157/5207/5307

265 volt universal power

supply kit

265 volt Permanent connected units* (Cord set)

RAK5172 RAK5202 RAK5302

2.55 3.45 5.0

2,550 3,450

8,600

10.3 13.8 19.6

15 20 30

15 amp

time delay fuse

*To be used with sub-base

11,700 17,000

20 amp

time delay fuse

5,000

30 amp

time delay fuse

265 volt Direct connection kit**

RAK5157 RAK5207 RAK5307

2.55 3.45 5.0

2,550 3,450

8,600

10.3 13.8 19.6

15 20 30

15 amp

time delay fuse

**To be used with sub-base or connection to building wiring

11,700 17,000

20 amp

time delay fuse

5,000

30 amp

time delay fuse

10

Page 11

Preliminary specifications

ge.com

Deluxe series – cooling & electric heat Dry Air 25

2900 series units Dry Air 25

230/208V Models AZ29E07D AZ29E09D AZ29E12D AZ29E15D AZ29E07DAP AZ29E09DAP AZ29E12DAP

Capacity

Cooling BTUH 7,100/6,900 9,300/8,900 11,700/11,500 14,600/14,300 6,800/6,600 8,800/8,500 11,200/11,000

EER (BTU/Watt) 12.7/12.7 12.0/12.0 11.5/11.5 10.2/10.2 12.1/12.1 11.5/11.5 11.0/11.0

Dehumidification Pts/Hr 1.7 2.7 3.6 4.6 2.3 3.4 4.5

Features

CFM, indoor fan high 250 270 290 310 210 230 240

CFM, indoor fan low 215 235 240 280 175 200 210

Vent CFM (full open/partial open) 50/40 70/45 75/45 75/45 50/40 70/45 75/45

Power/Ratings

Power factor 86/87 86/87 91/91 89/90 87/87 86/86 91/91

Sensible heat ratio @ 230 volts 75% 68% 67% 67% 66% 58% 57%

Watts 560/545 775/745 1,020/1,000 1430/1405 560/545 765/740 1,020/1,000

Amperes, F.L. 2.8/3.0 3.8/4.1 4.9/5.3 7.0/7.5 2.8/3.0 3.8/4.1 4.9/5.3

Amperes, L.R. 19.0 21.0 31.0 38.0 19.0 21.0 31.0

Weight (Net/Ship) 100/115 101/116 105/120 115/130 100/115 101/116 105/120

Sound Transmission Class (STC) 29 29 29 29 29 29 29

265V Models AZ29E07E AZ29E09E AZ29E12E AZ29E15E AZ29E07EAP AZ29E09EAP AZ29E12EAP

Capacity

Cooling BTUH 7,100 9,000 11,700 14,600 6,800 8,600 11,200

EER (BTU/Watt) 12.7 12.0 11.5 10.2 12.1 11.5 11.0

Dehumidification Pts/Hr 1.7 2.7 3.6 4.6 2.3 3.4 4.4

Features

CFM, indoor fan high 250 270 290 310 210 235 240

CFM, indoor fan low 215 235 240 280 175 200 210

Vent CFM (full open/partial open) 50/40 70/45 75/45 75/45 50/40 70/45 75/45

Power/Ratings

Power factor 87 86 87 90 88 86 87

Sensible heat ratio @ 265 volts 75% 68% 67% 67% 66% 58% 57%

Watts 560 750 1,020 1435 560 750 1,020

Amperes, F.L. 2.4 3.3 4.4 6.0 2.4 3.3 4.4

Amperes, L.R. 16.0 18.0 24.0 31.0 16.0 18.0 24.0

Weight (Net/Ship) 100/115 100/115 105/120 115/130 100/115 101/116 105/120

Sound Transmission Class (STC) 29 29 29 29 29 29 29

Deluxe series – heat pump units** Premium series – heat pump units

230/208V Models AZ39H07D AZ39H09D AZ39H12D AZ39H15D AZ58H07D A Z58H09D AZ58H12D AZ58H15D

Capacity

Cooling BTUH 7,100/6,900 9,400/9,150 11,850/11,500 14,750/14,350 7,300/7,000 9,300/9,050 11,800/11,600 14,700/14,400

EER (BTU/Watt) 12.7/12.7 12.0/12.0 11.5/11.5 10.0/10.0 13.0/13.0 12.0/12.0 11.7/11.7 10.3/10.3

Dehumidification Pts/Hr 1.7 2.7 3.6 4.5 2.1 3.0 4.0 4.8

Features

CFM, indoor fan high 250 270 300 310 250 265 350 365

CFM, indoor fan low 215 235 260 260 230 245 330 345

Vent CFM (full open/partial open) 50/40 70/45 75/45 75/45 40/35 65/60 70/65 70/65

Power/Ratings

Power factor 87 88 91 92 95 96 94 95

Sensible heat ratio @ 230 volts

Watts 560/545 785/765 1030/1000 1480/1440 560/540 760/735 1010/990 1425/1400

Amperes, F.L. 2.8/3.0 3.8/4.1 4.9/5.3 7.0/7.5 2.7/2.8 3.6/3.8 4.6/5.0 6.5/7.0

Amperes, L.R. 19.0 21.0 31.0 38.0 19.0 21.0 33.0 38.0

Reverse cycle heat BTUH 6,400/6,200 8,500/8,250 10,900/10,700 13,750/13,400 6,400/6,200 8,400/8,200 10,900/10,700 13,800/13,800

COP 3.6/3.6 3.6/3.6 3.4/3.4 3.2/3.2 3.7/3.7 3.6/3.6 3.4/3.4 3.2/3.2

Watts 520/505 695/675 950/925 1,275/1,245 505/490 685/670 940/920 1,265/1,235

Amps 2.4/2.6 3.2/3.5 4.3/4.7 5.8/6.3 2.4/2.5 3.2/3.4 4.3/4.7 5.7/6.2

Weight (Net/Ship) 102/117 105/120 113/128 123/138 108/122 113/128 118/133 127/142

Sound Transmission Class (STC) 29 29 29 29 29 29 29 29

265V Models AZ39H07E A Z39H09E AZ39H12E AZ39H15E AZ58H07E AZ58H09E AZ58H12E AZ58H15E

Capacity

Cooling BTUH 7,100 9,400 11,700 14,750 7,300 9,300 11,800 14,700

EER (BTU/Watt) 12.7 12.0 11.5 10.0 13.0 12.0 11.7 10.3

Dehumidification Pts/Hr 1.7 2.7 3.6 4.5 2.1 3.0 4.0 4.8

Features

CFM, indoor fan high 250 270 300 310 250 265 350 365

CFM, indoor fan low 215 235 260 260 220 270 310 330

Vent CFM (full open/partial open) 50/40 70/45 75/45 75/45 40/35 65/60 70/65 70/65

Power/Ratings

Power factor 88 88 87 92 95 96 94 95

Sensible heat ratio @ 265 volts 75% 68% 67% 67% 75% 67% 68% 65%

Watts 560 785 1020 1480 560 760 1010 1425

Amperes, F.L. 2.4 3.3 4.4 6.0 2.2 3.2 4.4 5.8

Amperes, L.R. 16.0 18.0 24.0 31.0 16.0 18.0 24.0 31.0

Reverse cycle heat BTUH 6,400 8,550 10,900 13,750 6,400 8,400 10,900 13,800

COP 3.6 3.6 3.4 3.2 3.7 3.6 3.4 3.2

Watts 520 700 940 1,275 505 685 940 1,265

Amps 2.2 2.8 3.9 5.0 2.2 2.7 3.9 5.0

Weight (Net/Ship)* 102/117 109/124 113/128 123/138 108/122 113/128 118/133 127/142

Sound Transmission Class (STC) 29 29 29 29 29 29 29 29

**ICR adds 3 pounds to unit weight

**Corrosion model BTUH and watts may vary.

3900 series units 5800 series units

75% 68% 67% 67% 75% 67% 68% 65%

11

Page 12

Zoneline® chassis nomenclature

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

A

R

I

S

T

A

N

D

A

R

D

3

1

0

P

A

C

K

A

G

E

D

T

E

R

M

I

N

A

L

A

I

R

-

C

O

N

D

I

T

I

O

N

E

R

S

R

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

A

R

I

S

T

A

N

D

A

R

D

3

8

0

P

A

C

K

A

G

E

D

T

E

R

M

I

N

A

L

H

E

A

T

P

U

M

P

S

R

GE Consumer & Industrial

Appliances

General Electric Company

Louisville, KY 40225

ge.com

Zoneline warranty*

The Zoneline® chassis is identified by a model number defining the type

of unit, cooling capacity, electrical information and optional features

included on the unit. When specifying or ordering the Zoneline chassis,

use of this nomenclature will assure receiving the correct unit.

A Z 5 8 H 1 2 D A D

Zoneline

packaged

terminal

chassis

Chassis series

29= deluxe line cool/

electric heat

39=deluxe line heat pump

58= premium line

heat pump

Unit type

E= cooling with electric

resistance heat

H= heat pump with electric

resistance heat

Nominal cooling capacity

07=7,000 BTUH cooling

09=9,000 BTUH cooling

12=12,000 BTUH cooling

15=15,000 BTUH cooling

Voltage/Phase/

Frequency

D= 230/208 Volt, single

phase, 60 Hz

E= 265 Volt, single phase,

60 Hz

Universal

power connection

Special Features

B=base unit

C=corrosion treated

D= internal

condensate

removal (ICR)

system (heat

pump models

only) (not for

coastal areas)

P=Dry Air 25

What is covered

Limited one-year warranty

For one year from the date of the original purchase, GE will repair or

replace any part of the air conditioner which fails due to a defect in

materials or workmanship. During this limited one-year warranty, GE

will provide, free of charge, all labor and related service costs to repair

or replace the defective part.

Limited five-year warranty

For five years from the date of the original purchase, GE will repair

or replace the Sealed Refrigerating System if any part of the Sealed

Refrigerating System (the compressor, condenser, evaporator, and

all connecting tubing) should fail due to a defect in materials or

workmanship. During this limited five-year warranty, GE will provide, free

of charge, all labor and related service costs to repair or replace

the defective part.

Limited second through fifth year parts warranty

From the second through the fifth year from the date of the original

purchase, GE will replace the Fan Motors, Switches, Thermostat, Heater,

Heater Protectors, Compressor Overload, Solenoids, Circuit Boards,

Auxiliary Controls, Thermistors, Freeze Sentinel, Frost Controls, ICR Pump,

Capacitors, Varistors and Indoor Blower Bearing, if any of these parts

should fail due to a defect in materials or workmanship. During this

additional four-year limited warranty, you will be responsible for any

labor and related service costs.

*See written warranty for details

Listed by

Underwriters

Laboratories.

For detailed information on operating specifications, installation data and accessories,

see the GE Zoneline Architects and Engineers Design Data Manual.

A century of quality and innovation

For more than a century, GE has been committed to producing innovative products

that change the way people live. The result of thorough research and rigorous testing,

GE appliances are designed for years of dependable performance.

Today, the GE tradition of quality and innovation continues.

For GE appliance service in the US, call

1-800-GE CARES. In Canada call 1-888-209-0999.

zoneline.com

GE has a policy of continuous improvement of

its products and reserves the right to change

materials and specifications without notice.

© 2008 GE Company

Pub. No. 20-S097 PC51902

Loading...

Loading...