GE PDW7900P - Profile: Full Console Dishwasher, PDW7980PSS - 6 LEVEL 12 TOUCHPADS CONTOCONTOUR DOOR 5, GSD6000 Series, PDW7000 Series Installation Instructions Manual

/_ ¢,* i¢_¸ _._

Appliances

i< i i,3Lft_LlIL,

nstallation

instructions

Built-In Dishwasher

If you have questions, call 800.GE.CARES 1800.432.2737} or visit our website at: www.ge.com

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

IMPORTANT.ThedishwasherMUST be installed

to oliow for future removal from the enclosure if service is

required.

,,,A,,_iPORTANT - Observeallgoverningcodesand

ordinances.

• Note to Installer - Be sure to leave these instructions for the

consumer's and local inspector's use,

• Note to Consumer - Keep these instructions with gour

Owner's Manuo! for future reference.

• Skill Level - Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills. Proper

installation is the responsibility of the installer. Product

failui;e due to improper installation is not covered under

the GE Appliance warrontg, See warrantg information.

• Completion Time - 2 to 3 Hours, New installations require

more time than replacement installations.

If gOu received o damaged dishwasher, gou should

immediately contact gout dealer or builder.

Optional Accessories- Seethe 0wner!s Manual for available

custom panel kits,

FOR YOUR SAFETY

Read and observe all CAUTIONS and WARNINGS shown

throughout these instructions, While performing

installations described in this booklet, gloves, safetg glasses

or goggles should be worn.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

GSD6000 Series

PDW7000 Series

imagination at work

Installation Preparation

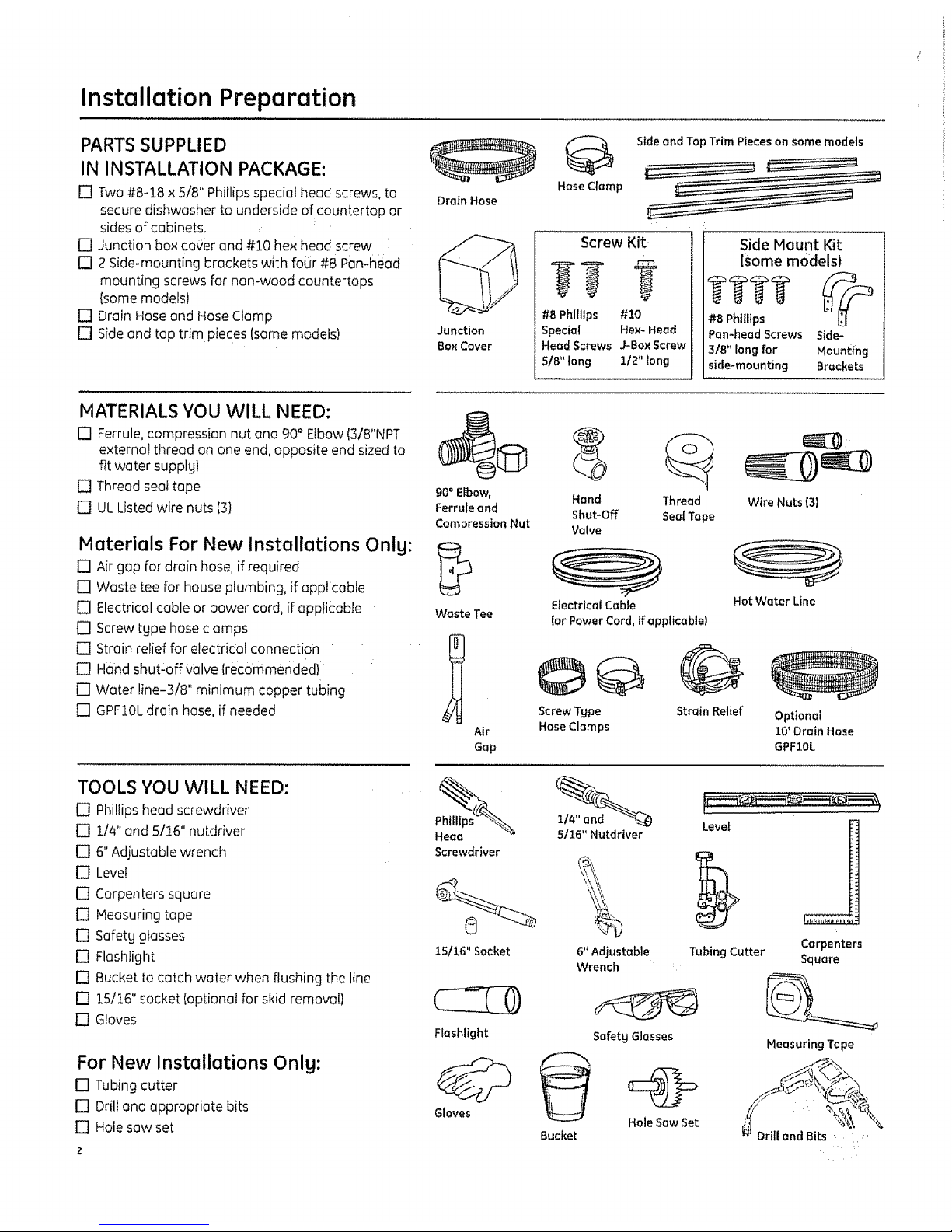

PARTS SUPPLIED

IN INSTALLATION PACKAGE:

[] Two #8-18 × 5/8" Phillips special head screws, to

secure dishwasher to underside of countertop or

sides of cabinets,

[] Junction box cover and #10 he× head screw

[] 2 Side-mounting brackets with four #8 Pan-head

mounting screws for non-wood countertops

{some models)

[] Drain Hose and Hose Clamp

[] Side and top trim pieces (some models)

DrainHose

Junction

Box Cover

Side and Top Trim Pieces on some models

Hose Clamp

Screw Kit

#8 Phillips #10

Special Hex-Head

HeadScrews J-Bo_Screw

SIB"long 1/2" long

SideMount Kit

(some models)

#8 Phillips

Pan-head Screws

3/8" long for

side-mounting

Side- :

Mounting

Brackets

MATERIALS YOU WILL NEED:

[] Ferrule, compression nut and 90° Elbow (3/8"NPT

externet thread on one end, opposite end sized to

fit water supply)

[] Thread seal tape

[] UL Listed wire nuts (3)

Materials For New Installations Only:

[] Air gap for drain hose, if required

[] Waste tee for house plumbing, if applicable

[] Electrical cable or power cord, if appficable

[] Screw tgpe hose clamps

[] Strain relief for electrical Connection

[] Hand shut:off V01ve{recommended}

D Water line-3!8" minimum copper tubing

[] GPF10L drain hose, if needed

TOOLS YOU WILL NEED:

[] Phillips head screwdriver

[] 114" and 5/16" nutdriver

[] 6" Adjustable wrench

[] Level

[] Carpenters square

[] Heasuring tope

[] Safetg gtasses

[] Flashlight

[] Bucket to catch water when flushing the line

[] 15/16" socket (optional for skid removal}

[] Gloves

For New Installations Only:

[] Tubing cutter

[] Drill and appropriate bits

[] Hole sow set

90° Elbow,

Ferrule and

Compression Nut

Waste Tee

Air

Gap

Screwdriver

°,3

"_r--

15116"Socket

Flashlight

Gloves

Hand Thread Wire Nuts 13)

Shut-Off SealTape

Valve

Electrical Cable

!or Power Cord, if applicable)

Hot Water Line

©@

ScrewType

HoseClamps

@

Strain Relief

Optional

10'Drain Hose

GPFZ0L

5116"Nutdriver

i)

6"Adjustable

Wrench

Safety Glasses

Bucket

Hole Saw Set

Level

Tubing Cutter

!

j

Carpenters

Square

MeasuringTape

n Drill and Bits

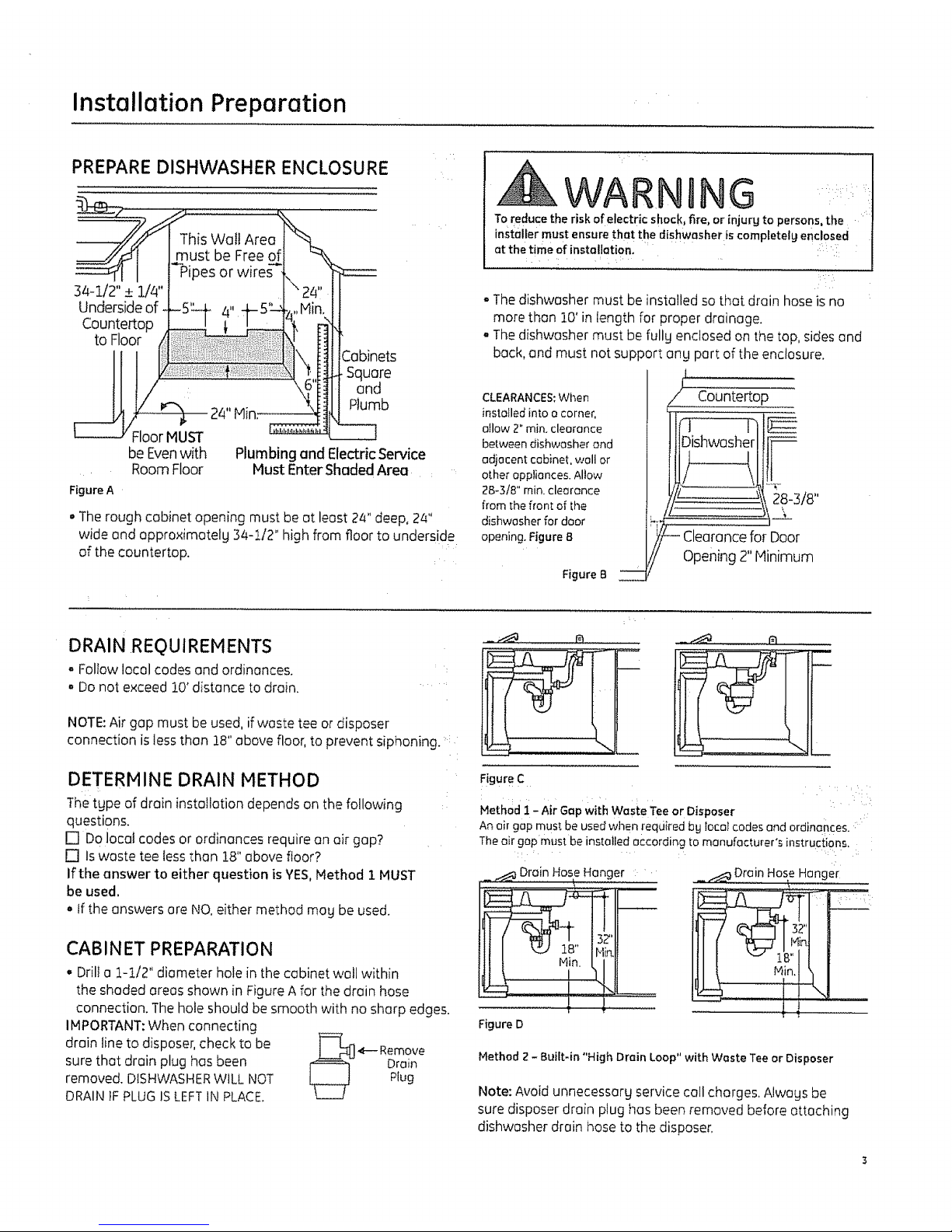

Installation Preparation

PREPARE DISHWASHER ENCLOSURE

34-1/2"_+ 1//4"

Underside of

Countertop

to Floor

Floor MUST

Figure A

This Wall Area

must be Free

_Pipes or wires

2abinets

Square

and

Plumb

24" Hin:

--q

be Evenwith Plumbing and Electric Service

Room Floor Must Enter Shaded Area

• The rough cabinet opening must be at least 24" deep, 2_"

wide and approximotelg 34-1/2" high from floor to underside

of the countertop.

WARNING

Toreduce the risk ofelectric shock, fire, or injurg to persons,the

installer must ensure that the dishwasher is completely enclosed

at the time of installation, ....

(V::

- The dishwasher must be installed so that drain hose is no

more than 10' in length for proper drainage.

• The dishwasher must be fullg enclosed on the top, sides and

back, and must not support and part of the enclosure.

I

Countertop

Dishwasher F

t.........!

28-3/8"

\

n Clearance for Door

opening 2" Hinimum

CLEARANCES:When

installed into a corner,

atlow 2" min. clearance

between dishwasher and

adjacent cabinet, wall or

other appliances. Allow

28_3/8" min. clearance

from the fron; of tile

dishwasher for door

opening. Figure B

Figure B

DRAIN REQUIREMENTS

a Follow local codes and ordinances.

Do not exceed 10' distance to drain.

NOTE: Air gap must be used, if waste tee or disposer

connection is less than 18" above floor, to prevent siphoning. ....

DETERMINE DRAIN METHOD

The type of drain installation depends on the following

questions.

[] Do local codes or ordinances require an air gap?

[] Is waste tee tess than 18" above floor?

If the answer to either question isYES, Method 1 MUST

be used.

o If the answers are NO. either method mad be used.

CABINET PREPARATION

• Drill a t-112" diameter hole in the cabinet wail within

the shaded areas shown in Figure A for the drain hose

connection. The hole should be smooth with no sharp edges.

IMPORTANT: When connecting

drain line to disposer, check to be ]==_

4--- Remove

sure that drain plug has been L__.Z--U_ Drain

removed. DISHWASHER WILL NOT _ Plug

DRAIN 1FPLUG IS LEFTIN PLACE.

L__J

FigureC .... :

MethodI - Air Gapwith Waste Teeor Disposer

Anair gap must beusedwhen {eqciiredbg Ioco_codesand ordin0nces.:

Theair gap must be installed accordingto manufacturer's instructions.

_ _ Drain Has? Hanger

I 2 i ,

3Z'

Hir_

Figure D

_ _ Drain HoseHanger

Method Z- Built-in "High Drain Loop" with Waste Tee or Disposer

Note: Avoidunnecessary service call charges.Alwags be

sure disposer drain plug has been removed before attaching

dishwasher drain hoseto the disposer,

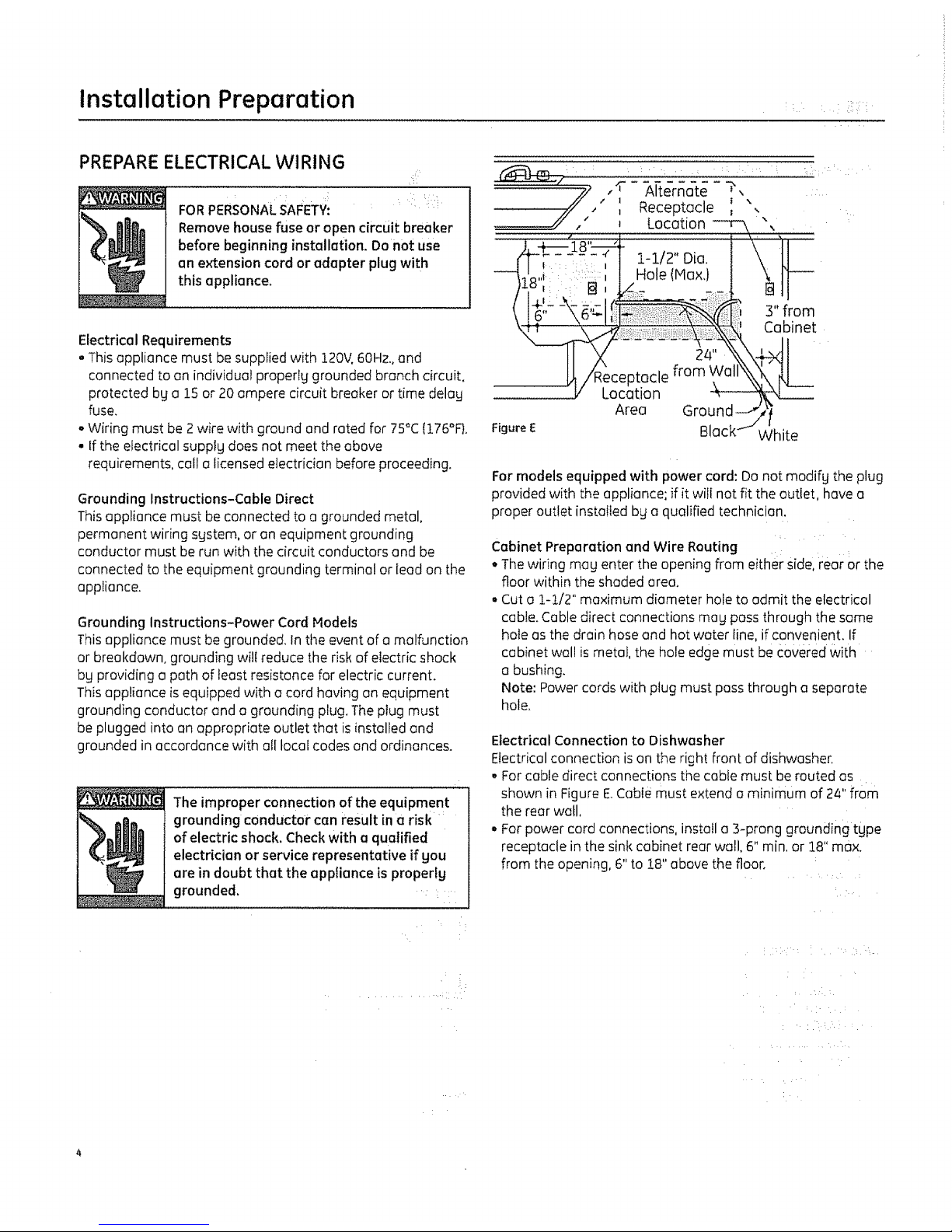

Installation Preparation

PREPARE ELECTRICAL WIRING

FORPERSONALSAFETVI " ' Receptacle : ",

_Ji Remove house fuse or open circuit breaker ' Location --r-k ",,

before beginning installation. Donot use

an extension cord or adapter plug with

this appliance, 8''ill ::

I ,:i

!

Electrical Requirements

• This appliance must be supplied with 120V, 60Hz.. and

connected to on individual properlg grounded branch circuit.

protected bg a 15 or 20 ampere circuit breaker or time delay

fuse.

oWiring must be 2 wire with ground and rated for 75°C {176%}.

• If the electrical supply does not meet the above

requirements, call a licensed electrician before proceeding.

8. /

:::::\ ; ! Hole(Max,} \ t]---

_,-F_ 3'from

! _: :':::: Ca,b',inet

/Receptacle from Wakkx_x_k

V Location

Area Ground-_' i

Figure E Black-" VVhite

Grounding Instructions-Cable Direct

This appliance must be connected to a grounded metal,

permanent wiring sgstem, or an equipment grounding

conductor must be run with the circuit conductors and be

connected to the equipment grounding terminal or lead on the

appliance.

Grounding Instructions-Power Cord Models

This appliance must be grounded. In tile event of o malfunction

or breakdown, grounding will reduce the risk of electric shock

bg providing a path of least resistance for electric current.

This appliance is equipped with o cord having an equipment

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is installed and

grounded in accordance with at! local codes end ordinances.

The improper connection of the equipment

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service representative if gou

are in doubt that the appliance is propertg

grounded.

For models equipped with power cord: Do not modifg the plug

provided with the appliance; if it will not fit the outlet hove a

proper outlet installed by a qualified technician.

Cabinet Preparation and Wire Routing

• The wiring meg enter the opening from efther side, rear or the

floor within the shaded area.

° Cut o 1-t/2" maximum diameter hole to admit the electrical

cable. Cable direct connections meg pass through the same

hole as the drain hose and hot water line, if convenient. If

cabinet wal! is metal, the hole edge must be €overed With

a bushing.

Note: Power cords with plug must pass through a separate

hole.

Electrical Connection to Dishwasher

Electrical connection is on the right front of dishwasher.

• For cable direct connections the cable must be routed as

shown in Figure E Cable must extend a minimum of 24" from

the rear wall.

° For power cord connections, install a 3-prong grounding tgpe

receptacle in the sink cabinet rear wall. 6" min, or !8" max.

from the opening, 6" to 18" above the floor.

..... --iii //

Loading...

Loading...