GE PDS22xxP series, GBS20xxP series, GBS22xxP series, PDS20xxP series Technical Service Manual

GE Consumer & Industrial

TECHNICAL SERVICE GUIDE

2003 Electronic Bottom-Mount

Refrigerators

MODEL SERIES:

GBS22_ _P

GBS20_ _P

PDS22_ _P

PDS20_ _P

PUB # 31-9112 1/04

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

W ARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in

part in any form without written permission from the General Electric Company.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2004

– 2 –

Table of Contents

Airflow (Cabinet Interior).................................................................................................................. 6

Air Flow Tower and Damper ........................................................................................................ 11

Component Locator Views ............................................................................................................ 9

Components................................................................................................................................10

Control Diagnostics ..................................................................................................................... 18

Control Features ........................................................................................................................... 8

Diagnostics Chart ....................................................................................................................... 19

Doors ............................................................................................................................................ 4

Door Gaskets .............................................................................................................................. 17

Door Handles ................................................................................................................................ 4

Electronic Control Panel................................................................................................................8

Evaporator Fan ............................................................................................................................ 13

Evaporator Thermistor ................................................................................................................ 13

Evaporator Thermostat ...............................................................................................................14

Freezer Drawer and Slides .........................................................................................................16

Fresh Food and Freezer Thermistors ......................................................................................... 12

Fresh Food and Freezer Light Thermostats ............................................................................... 15

Icemaker Ready Models .............................................................................................................. 12

Illustrated Parts Catalog .............................................................................................................. 24

Installation .....................................................................................................................................4

(Encoder) .............................................................................................................................10

Knob

(Encoder) Control Panel ........................................................................................................ 8

Knob

Nomenclature ................................................................................................................................7

Schematics ................................................................................................................................. 22

Strip Circuits ................................................................................................................................ 20

Technical Data...............................................................................................................................6

Troubleshooting ........................................................................................................................... 18

Warranty......................................................................................................................................30

Water Filter................................................................................................................................. 11

– 3 –

Installation

Doors

The swing direction of the fresh food door and the

freezer door can be reversed on all models except

stainless steel.

Stainless steel models must be ordered as left or

right door swing.

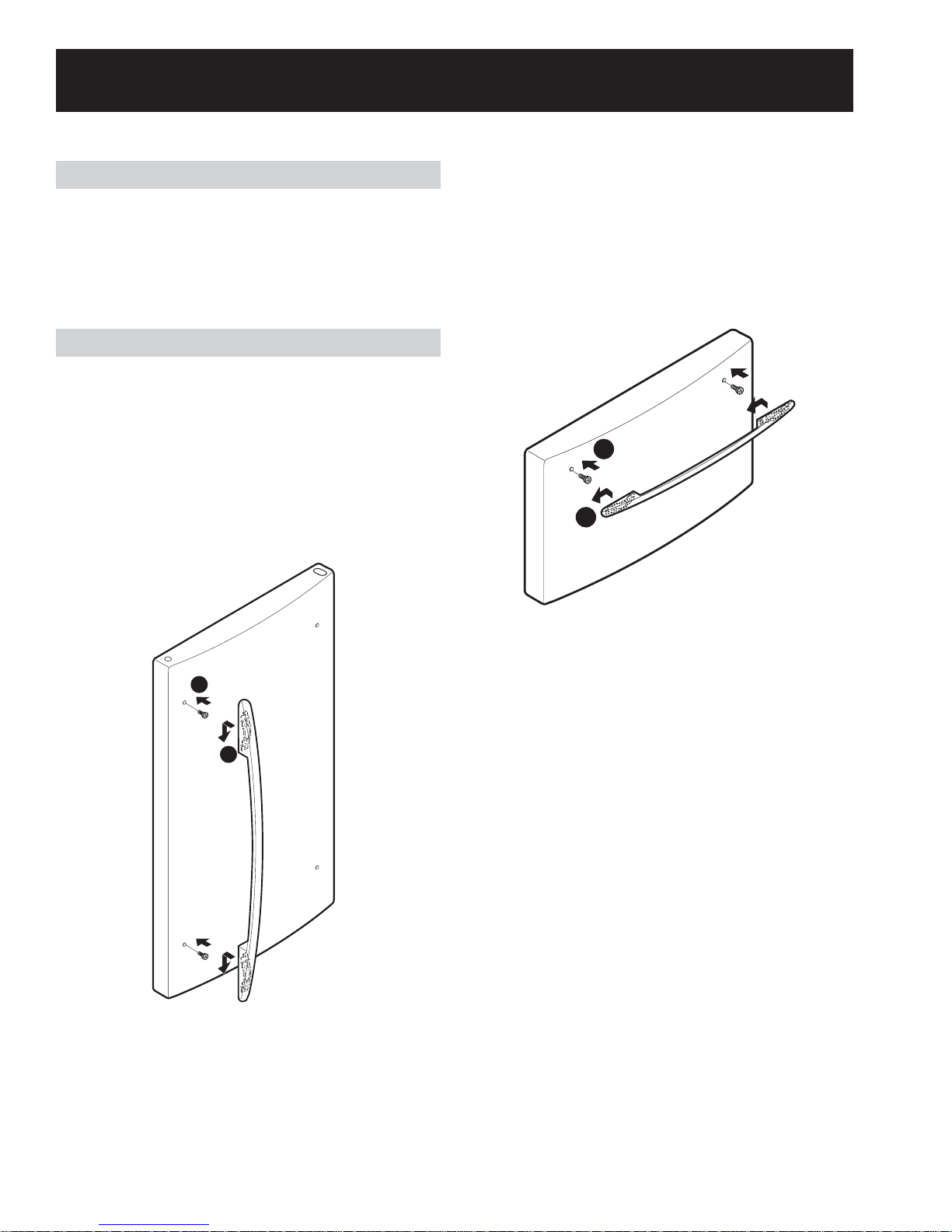

Door Handles

Removal and Replacement

Fresh Food Door

1. Lift the fresh food compartment door handle

firmly upward and off of the 2 door mounting

screws.

2. Reverse the above procedure to reinstall.

Freezer Door

1. Install 2 door mounting screws on the freezer

compartment door.

2. Insert the door handle onto the door mount

screws and pull the handle firmly to the left.

1

2

1

2

Note: The door handle can be installed

incorrectly. Make sure the curved side of the

handle is toward the outside edge of the door.

Note: The door handle can be installed

incorrectly. Make sure the handle is curved

upward and is locked in place. A properly installed

handle will be centered on the door.

– 4 –

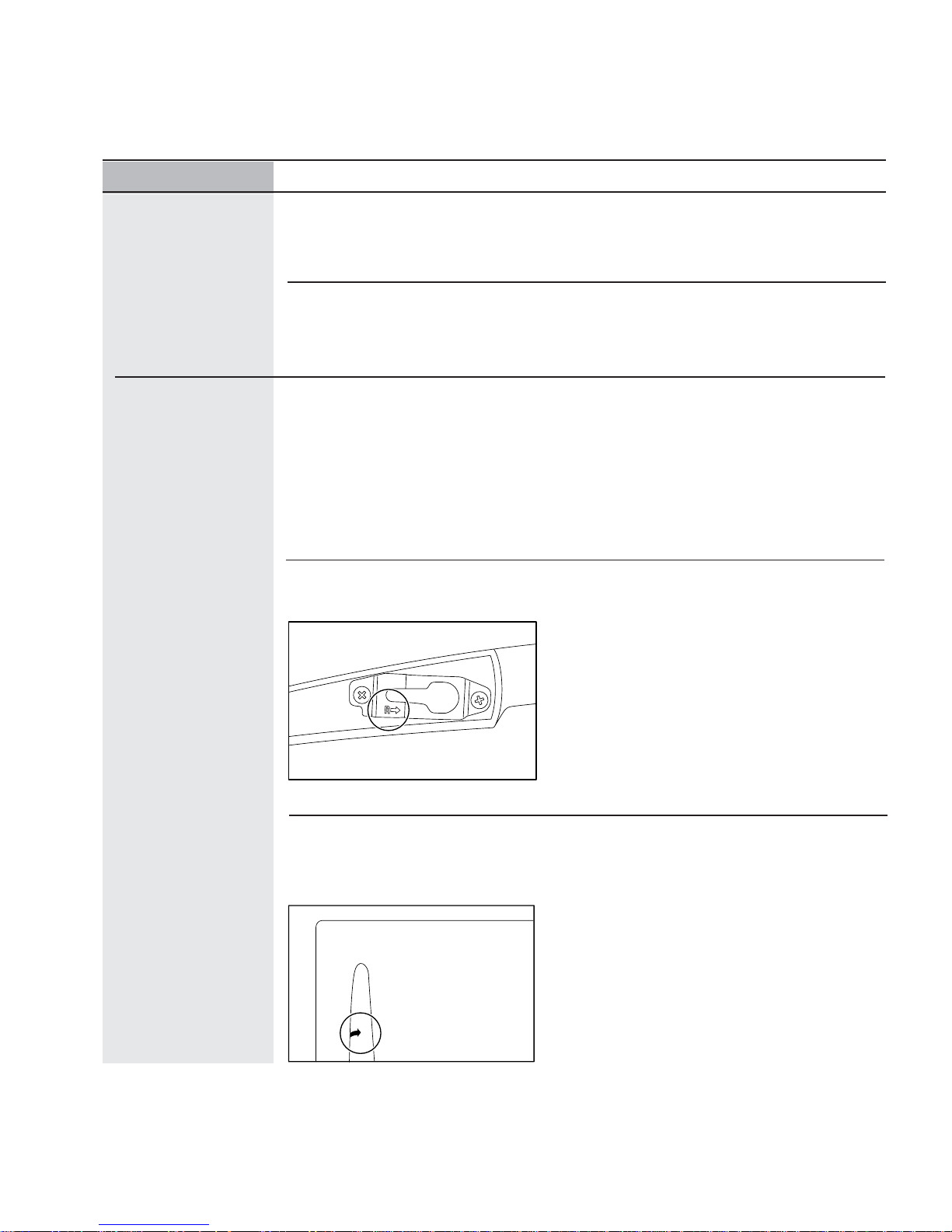

Troubleshooting Tips - Handle Installation

Problem Possible Causes What To Do

Handle too hard to

install/Handle requires

excessive force to

install

Loose handle/Handle

makes rattling noise at

attachment

Mounting bolts too tight. Remove the handle. Loosen the mounting bolts

slightly so that the handle will snap into place

when installed.

Defective mounting bracket or

bolts.

Loose mounting bolts.

Freezer handle is installed

backwards.

Remove handle. Check for defective mounting

brackets or bolts. If defective, replace. Install

handle according to Installation Instructions.

If the handle installs properly (slides on and

locks/snaps into place) but is loose, remove the

handle and tighten the mounting bolts. Use a

10mm socket and ratchet or wrench. Do not use a

screwdriver as it will not provide enough torque

for proper tightening. Reinstall handle according

to Installation Instructions included with the

handle.

Remove handle. Check for correct mounting

brackets on the handle. There is a right bracket

(R) and a left bracket (L). The handle has the

word “RIGHT” printed in the bracket cavity. The

“R” bracket should be installed in the bracket

cavity marked “RIGHT”. The “L” bracket should

be installed on the opposite side. Reinstall handle

according to Installation Instructions.

Fresh Food handle is mounted upside

down or incorrectly relative to the

curve of the Fresh Food door.

Make certain that the arrow label on the handle

is pointing at the center of the unit. To verify, the

handle should look straight from a distance (not

slanted to the side).

– 5 –

Technical Data

ELECTRICAL SPECIFICA TIONS

Temperature Control (Position 5)....................... 32 - 4°F

Defrost Control... 60 hrs @ 40 mins with no door opening

Overtemperature Thermostat....................... 140 - 110°F

Defrost Thermistor.................................................70°F

Electrical Rating: 115V. AC, 60 Hz.................1 - 5 Amp.

Maximum Current Leakage................................0.5 mA

Maximum Ground Path Resistance...............0.14 Ohms

Energy Consumption.......507 kWh/yr for 20 cu/ft models

Energy Consumption.......520 kWh/yr for 22 cu/ft models

NO LOAD PERFORMANCE

Control Position: 5-5

And Ambient of:................................................... 90°F

Fresh Food, °F..................................................32 - 42

Frozen Food, °F.................................................. -5 - 5

Percent Running Time....................................... 45 - 65

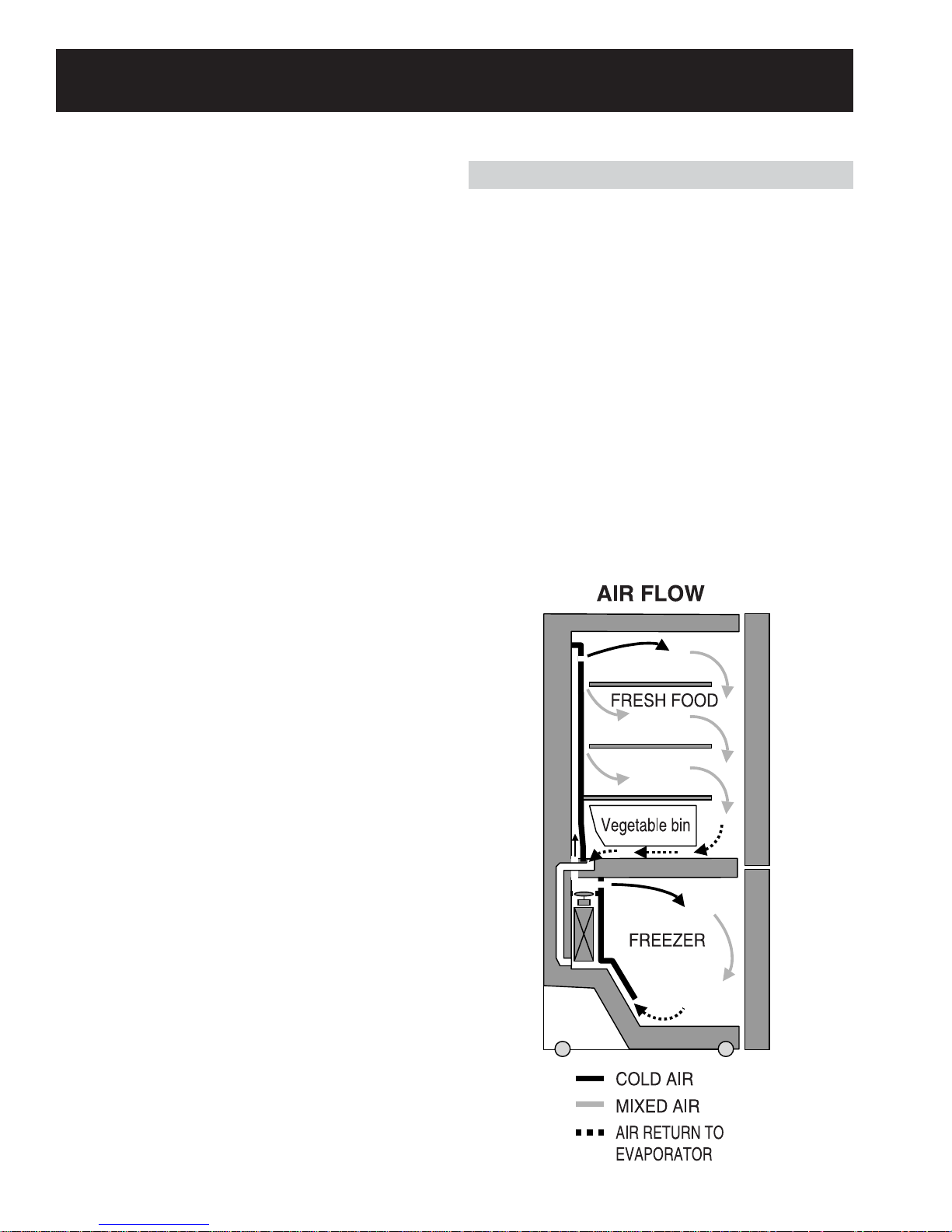

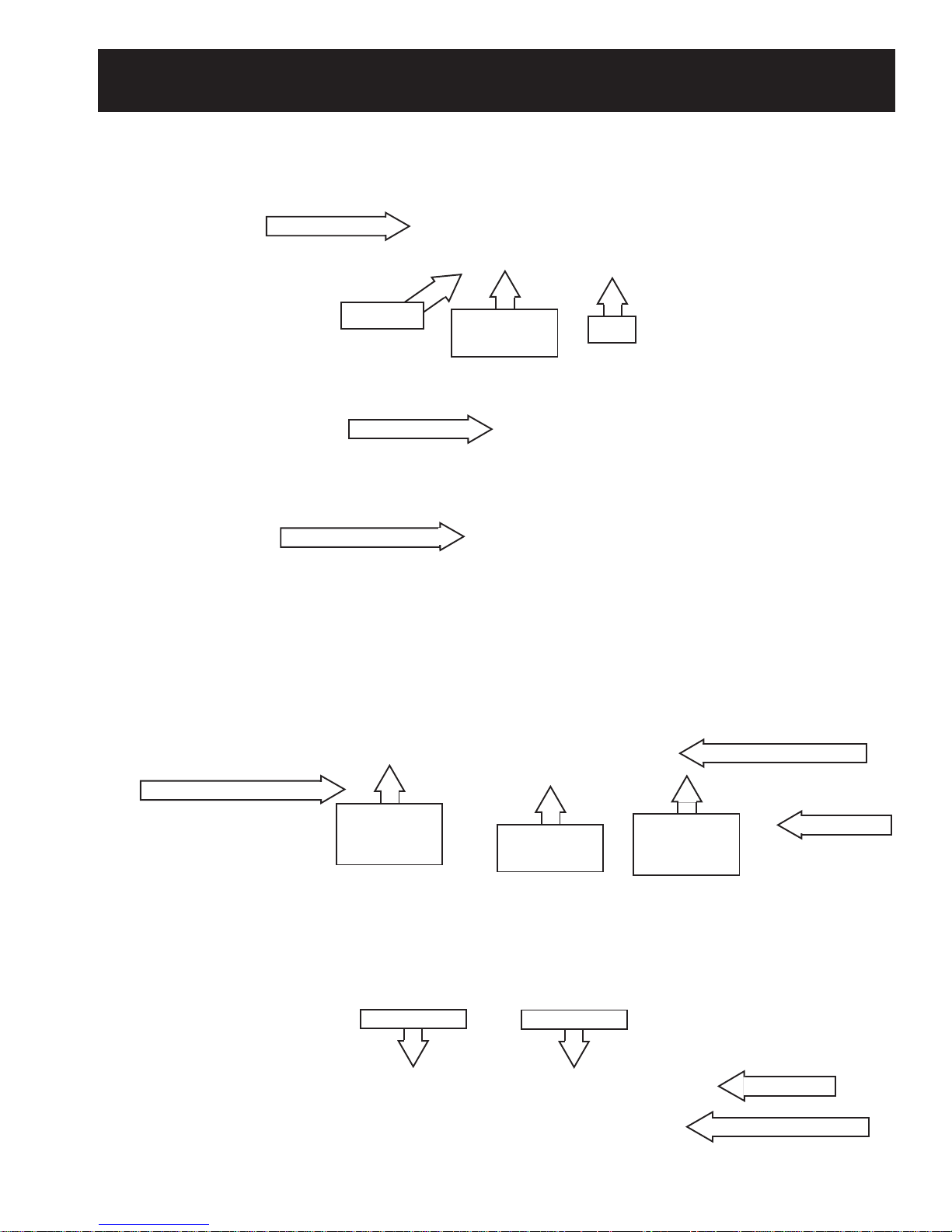

Airflow (Cabinet Interior)

The evaporator fan forces air through the

evaporator into the freezer compartment.

Air from the evaporator is also forced through the

electronic damper to the top of the air tunnel,

through the fresh food compartment, and returns

to the evaporator.

The fresh food compartment receives chilled air

through an electronic damper at the bottom, rear

of the fresh food compartment. The damper is

controlled by the main control board. When open,

the damper allows chilled air from the freezer to

move into the fresh food compartment.

Air returns from the fresh food compartment to the

freezer compartment via two vents located to the

left and right of the air tunnel.

REFRIGERA TION SYSTEM

Minimum Compressor Capacity Vacuum.............. 22 in.

Minimum Equalized Pressure

@ 70°F ................................................... 38 PSIG

@ 90°F.................................................... 49 PSIG

Refrigerant - R - 134a...................................... 4.06 oz.

Compressor .............................................. 690 BTU/hr

INSTALLATION

Clearance must be provided at top, sides and rear of the

refrigerator for air circulation.

AT TOP............................................................. 1 inch

AT SIDES................................................... 0.125 inch

AT REAR.......................................................... 1 inch

– 6 –

Model Number

Nomenclature

CONFIGURATION

B = DOOR

D = DRAWER

CUBIC FEET

20 or 22

ICEMAKER

B = ICEMAKER READY

C = FACTORY ICEMAKER

ENGINEERING NOMENCLA TURE

A = CONVERSION KIT

P D S 2 2 M C P A W W

BRAND/PRODUCT

G = GE

P = PROFILE (GE)

DEPTH/POWER

S = STANDARD

INTERIOR/SHELVES

H = UPGRADE GLASS

K = SPILL-PROOF GLASS

M = SPILL-PROOF/SLIDE-OUT GLASS

S = STAINLESS STEEL DOORS

MODEL YEAR

P = 2003

EXTERIOR COLOR

WW = WHITE/WHITE

SS = STAINLESS/STAINLESS

CC = BISQUE/BISQUE

BB = BLACK/BLACK

Serial Number

The first two characters of the serial number

identify the month and year of manufacture.

Example: AG123456S = January, 2004

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter

designating the

year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Nomenclature

The nomenclature

plate is located on the

upper left wall of the

fresh food

compartment.

Mini-Manual

(Behind Base Grille)

– 7 –

Electronic Control Panel

Control Features

Knob (Encoder) Control Panel

– 8 –

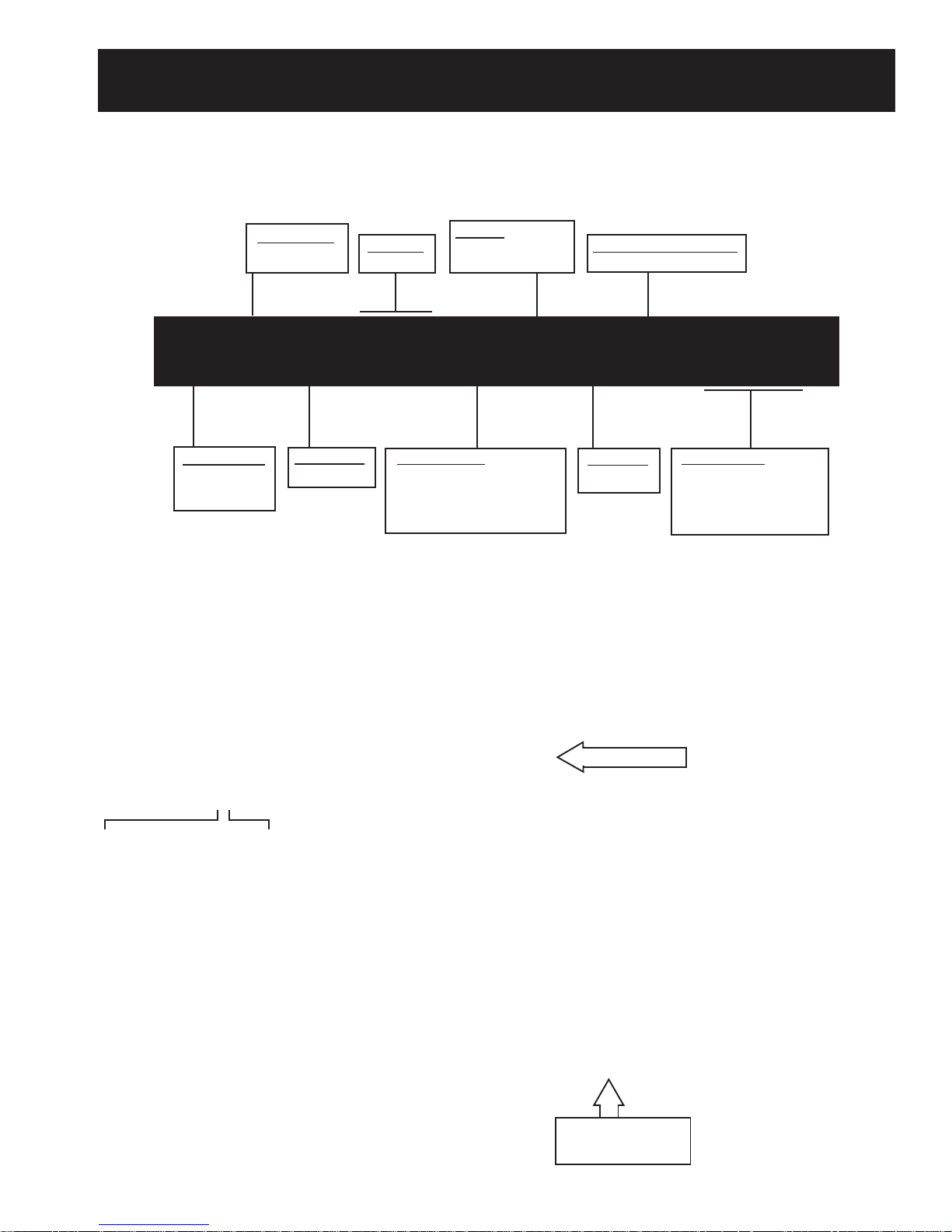

Fresh Food Section

Component Locator Views

Control Panel

Freezer Section

Thermistor

Air Flow Tower

Damper (Inside Tower)

Lights and

Thermostat

Filter

Light and Thermostat

Icemaker (When Installed)

Machine Compartment

Evaporator

Thermostat

(Behind Panel)

Compressor

Evaporator

(Behind Panel)

Condenser

– 9 –

Evaporator

Thermistor

(Behind Panel)

Condenser Fan Motor

Thermistor

Water Valve

Loading...

Loading...