Page 1

GE

Measurement & Control Flow

PanaFlow™ MV80 & MV82

Vortex Volumetric and Mass Flowmeters

User’s Manual

910-292 Rev. C

January 2016

Page 2

Page 3

PanaFlow™ MV80 & MV82

Vortex Volumetric and Mass Flowmeters

User’s Manual

910-292 Rev. C

January 2016

www.gemeasurement.com

©2016 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

CUSTOMER NOTICE FOR OXYGEN SERVICE! Unless you have specifically ordered optional

cleaning, this flow meter may not be fit for oxygen service. Some models can only be properly

O

2

cleaned during the manufacturing process. GE Measurement & Control is not liable for any damage

or personal injury, whatsoever, resulting from the use of the MV80 or MV 82 standard mass flow

meters for oxygen gas.

ii

Page 5

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation. The safety of any system incorporating the equipment is the responsibility of the

assembler of the system.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on the equipment.

PanaFlow™ MV80 & MV82 User’s Manual iii

Page 6

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE)

take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit www.gemeasurement.com/environmental-health-safety-ehs

information about this initiative.

for take-back instructions and more

iv PanaFlow™ MV80 & MV82 User’s Manual

Page 7

Contents

Chapter 1. Introduction

1.1 Multi-Parameter Vortex Mass Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Multi-Parameter Mass Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1.2 Volumetric Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3 Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 How the PanaFlow Vortex Mass Flowmeter Operates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Velocity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3.1 Vortex Shedding Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.2 Vortex Frequency Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.3 Flow Velocity Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5 Pressure Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.6 Flowmeter Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6.1 Multivariable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6.2 Line Size, Process Connections and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.6.3 Flowmeter Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 2. Installation

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.1 Flowmeter Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Unobstructed Flow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2 Series MV80 In-Line Flowmeter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2.1 Flange Bolt Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2.2 Installing Wafer-Style Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.2.3 Installing Flange-Style Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.3 Series MV82 Insertion Flowmeter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3.1 General Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3.1a Electronics Enclosure Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3.1b Isolation Valve Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3.1c Cold Tap Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.3.1d Hot Tap Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.3.1e Insertion Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.3.1f Selecting the Correct Insertion Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.3.2 Installing Flowmeters with a Compression Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.3.3 Installing Flowmeters with a Packing Gland Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.3.4 Insertion Procedure for Flowmeters with Permanent Insertion Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.3.5 Insertion Procedure for Flowmeters with Removable Insertion Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2.3.6 Installing Flowmeters with a Packing Gland Connection (No Insertion Tool). . . . . . . . . . . . . . . . . . . . . . . . . .28

PanaFlow™ MV80 & MV82 User’s Manual v

Page 8

Contents

2.4 Adjusting the Meter Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.4.1 Display/Keypad Adjustment (All Meters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2.4.2 Enclosure Adjustment (Series MV80 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.5 Loop Power Flowmeter Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2.5.1 DC Input Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.5.2 4-20 mA Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.5.3 Pulse Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.5.4 Frequency Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.5.5 Optional Backlight Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.5.6 Remote Electronics Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

2.6 Line Power Meter Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2.6.1 Input Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2.6.1a AC Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2.6.1b DC Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2.6.2 4-20 mA Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

2.6.3 Frequency Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2.6.4 Pulse Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2.6.5 Alarm Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.6.6 Remote Electronics Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2.6.7 Optional Input Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.6.7a Optional Energy EMS RTD Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.6.7b Optional External 4-20 mA Input Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2.6.7c Optional Contact Closure Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Chapter 3. Operating Instructions

3.1 Flowmeter Display/Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

3.2 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

vi PanaFlow™ MV80 & MV82 User’s Manual

Page 9

Contents

3.3 Using the Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

3.3.1 A Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

3.3.2 Programming the Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

3.3.3 The Output Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

3.3.4 The Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

3.3.5 The Alarms Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

3.3.6 The Totalizer #1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

3.3.7 The Totalizer #2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

3.3.8 The Energy Menu for EMS Energy Meters Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

3.3.9 The Fluid Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

3.3.10 The Units Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

3.3.11 The Time & Date Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

3.3.12 The Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

3.3.13 The Calibration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

3.3.14 The Password Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Chapter 4. Serial Communications

4.1 HART Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4.1.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4.1.1a HART Loop Powered Meter Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4.1.1b HART DC Powered Meter Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

4.1.1c HART AC Powered Meter Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

4.1.2 HART Commands with the Digital Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

4.1.3 HART Commands with the Generic Digital Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

4.1.4 Fast Key Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

4.2 Modbus Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4.2.1 Applicable Flowmeter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4.2.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4.2.3 Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4.2.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.2.5 Pin Labeling Among Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.2.6 Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.2.6a Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.2.6b Comm Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.2.6c Modbus Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.2.6d Modbus Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.2.6e Modbus Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

4.2.6f Register Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

4.2.6g Exception Status Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

4.2.6h Discrete Input Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

PanaFlow™ MV80 & MV82 User’s Manual vii

Page 10

Contents

4.2.6i Control Register Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

4.2.6j Error Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

4.2.6k Command Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

4.2.6l Normal Response Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2.6m Exception Response Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

4.2.6n Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

4.3 BACnet MS/TP Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.3.1 BACnet MS/TP Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

4.3.2 Baud Rates on the MS/TP Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.3.3 Baud Rate and MAC Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.3.4 Supported BACnet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

4.3.4a Device Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

4.3.4b Analog Input Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

4.3.4c Binary Input Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.3.4d Binary Value Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.3.5 ANNEX - BACnet Protocol Implementation Conformance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.3.6 Acronyms and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Chapter 5. Troubleshooting and Repair

5.1 Hidden Diagnostics Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.1.1 Level One Hidden Diagnostics Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.1.2 Column Two Hidden Diagnostics Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.2 Analog Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.3 Troubleshooting the Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.4 Determine the Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.4.1 Symptom: Output at No Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.4.2 Symptom: Erratic Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.4.3 Symptom: No Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.4.4 Symptom: Meter Displays Temperature Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.4.5 Symptom: Meter Displays Pressure Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

5.5 Electronics Assembly Replacement (All Meters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5.6 Pressure Sensor Replacement (Series MV80 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5.7 Returning Equipment to the Factory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

viii PanaFlow™ MV80 & MV82 User’s Manual

Page 11

Contents

Appendix A. Product Specifications

Appendix B. Approvals

Appendix C. Flowmeter Calculations

C.1 In-Line Flowmeter Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C.1.1 Volume Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C.1.2 Mass Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C.1.3 Flowing Velocity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C.2 Insertion Flowmeter Calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

C.2.1 Flowing Velocity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

C.2.2 Volume Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

C.2.3 Mass Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

C.3 Fluid Calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

C.3.1 Calculations for Steam T & P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

C.3.1a Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

C.3.1b Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

C.3.2 Calculations for Gas (“Real Gas” and “Other Gas”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

C.3.2a Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

C.3.2b Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

C.3.3 Calculations for Liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

C.3.3a Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

C.3.3b Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Appendix D. Glossary

PanaFlow™ MV80 & MV82 User’s Manual ix

Page 12

Contents

[no content intended for this page]

x PanaFlow™ MV80 & MV82 User’s Manual

Page 13

Chapter 1. Introduction

Chapter 1. Introduction

1.1 Multi-Parameter Vortex Mass Flowmeters

The GE PanaFlow™ MV80 & MV82 Vortex Flowmeters provide a reliable solution for process flow measurement.

From a single entry point in the pipeline, MV80 & MV82 meters offer precise measurements of mass or volumetric

flow rates.

1.1.1 Multi-Parameter Mass Flowmeters

Mass flowmeters utilize three primary sensing elements: a vortex shedding velocity sensor, an RTD temperature sensor

and a solid state pressure sensor to measure the mass flow rate of gases, liquids, and steam.

Meters are available as loop powered devices or with up to three 4-20 mA analog output signals for monitoring your

choice of the five process variables (mass flow, volumetric flow, temperature, pressure and fluid density). The Energy

Monitoring option permits real-time calculation of energy consumption for a facility or process.

1.1.2 Volumetric Flowmeters

The primary sensing element of a volumetric flowmeter is a vortex shedding velocity sensor. The analog 4-20 mA

output signal offers your choice of volumetric or mass flow rate. Mass flow rate is based on a constant value for fluid

density stored in the instrument's memory.

Both the mass and volumetric flowmeters can be ordered with a local keypad/display which provides instantaneous

flow rate, total, and process parameters in engineering units. A pulse output signal for remote totalization and

MODBUS, BACNET or HART communications are also available. PanaFlow digital electronics allows for easy

reconfiguration for most gases, liquids and steam. The PanaFlow MV80 & MV82 Meters' simple installation combines

with an easy-to-use interface that provides quick set up, long term reliability and accurate mass flow measurement over

a wide range of flows, pressures and temperatures.

1.1.3 Using This Manual

This manual discusses how to install and operate both the MV80 In-Line and MV82 Insertion Flow Meters:

• Chapter 1 includes an introduction and product description

• Chapter 2 provides information needed for installation

• Chapter 3 describes system operation and programming

• Chapter 4 provides information on HART and MODBUS protocols

• Chapter 5 covers troubleshooting and repair

• Appendix A lists the product specifications

• Appendix B shows current agency approvals

• Appendix C Discusses flow meter calculations

• Appendix D lists a glossary of terms

PanaFlow™ MV80 & MV82 User’s Manual 1

Page 14

Chapter 1. Introduction

F

LOW

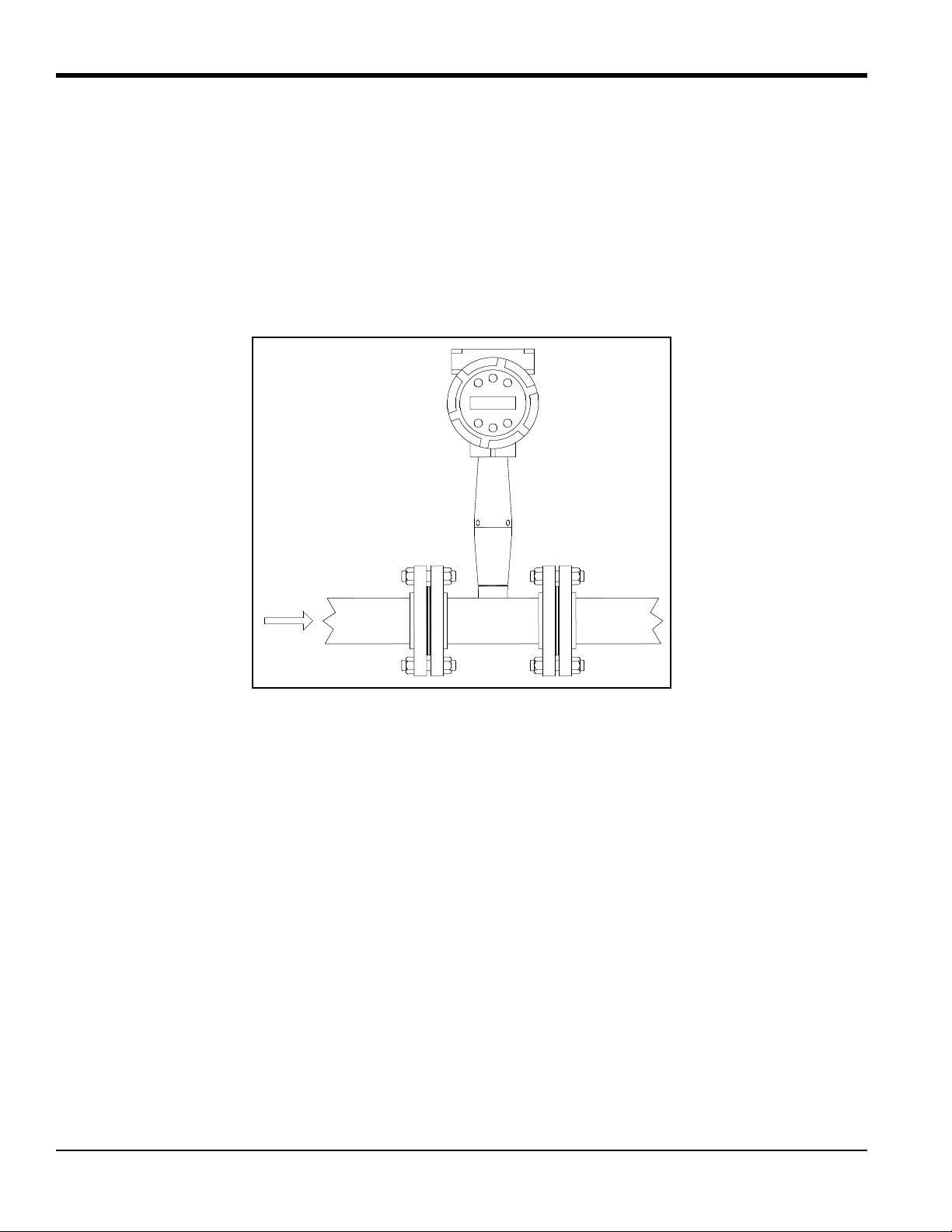

1.2 How the PanaFlow Vortex Mass Flowmeter Operates

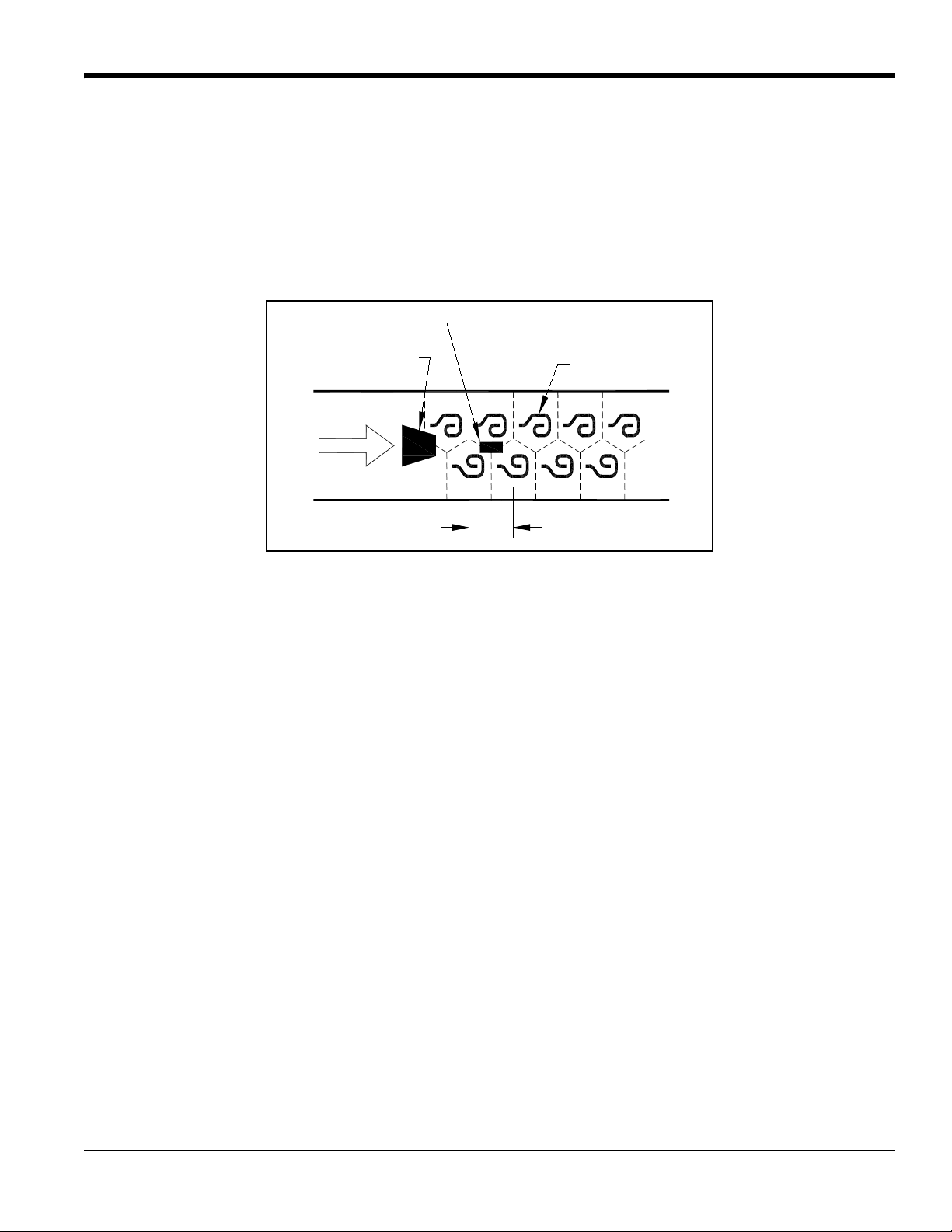

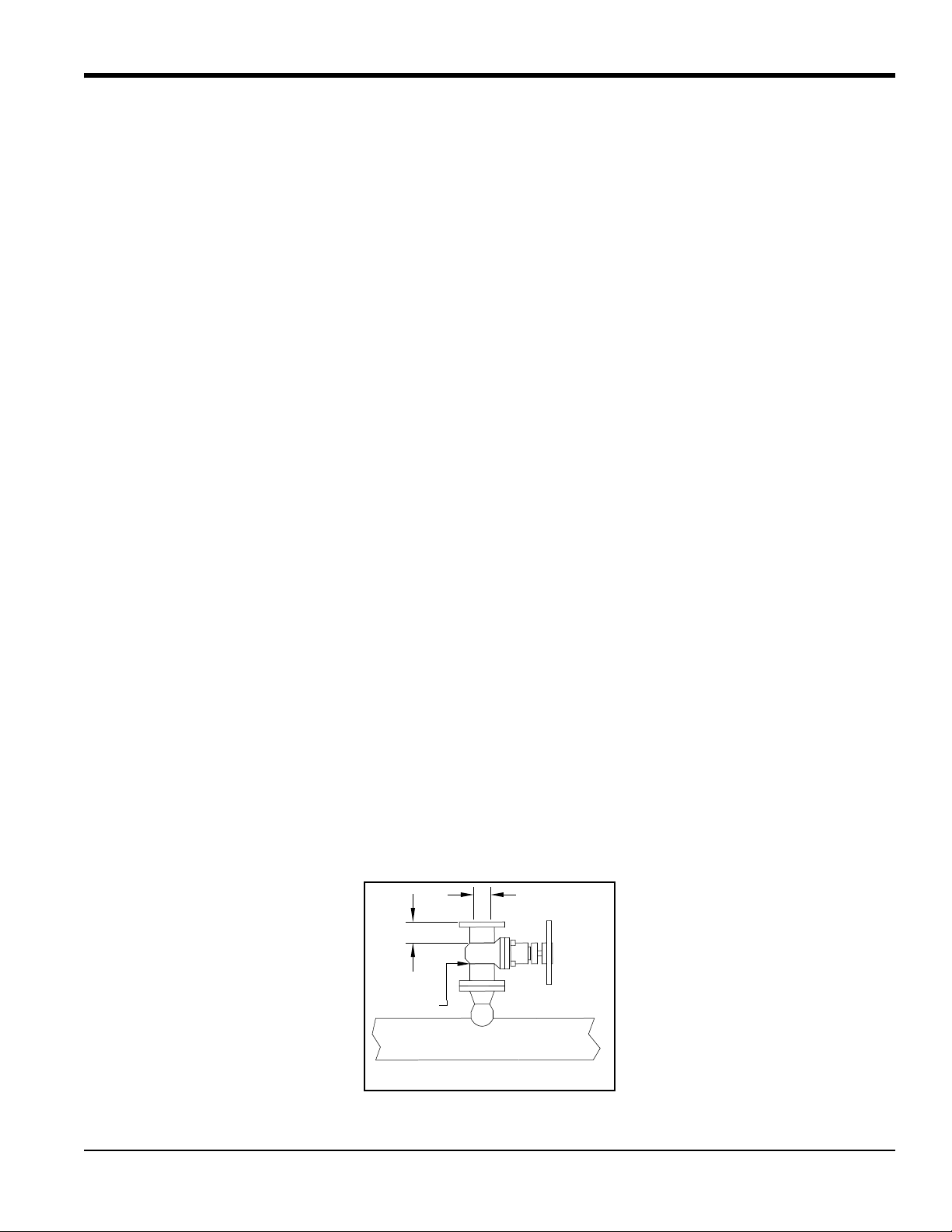

PanaFlow MV80 and MV82 Mass Flowmeters (see Figure 1 below) use a unique sensor head to monitor mass flow

rate by directly measuring three variables-fluid velocity, temperature and pressure. The built-in flow computer

calculates the mass flow rate and volumetric flow rate based on these three direct measurements. The velocity,

temperature and pressure sensing head is built into the vortex meter's flow body. To measure fluid velocity, the

flowmeter incorporates a bluff body (shedder bar) in the flow stream and measures the frequency of vortices created by

the shedder bar. Temperature is measured using a platinum resistance temperature detector (PRTD). Pressure

measurement is achieved using a solid-state pressure transducer. All three elements are combined into an integrated

sensor head assembly located downstream of the shedder bar within the flow body.

Figure 1: In-Line Vortex Multi-Parameter Mass Flowmeter

1.3 Velocity Measurement

The PanaFlow vortex velocity sensor is a patented mechanical design that minimizes the effects of pipeline vibration

and pump noise, both of which are common error sources in flow measurement with vortex flowmeters. The velocity

measurement is based on the well-known Von Karman vortex shedding phenomenon. Vortices are shed from a shedder

bar, and the vortex velocity sensor located downstream of the shedder bar senses the passage of these vortices. This

method of velocity measurement has many advantages including inherent linearity, high turndown, reliability and

simplicity.

2 PanaFlow™ MV80 & MV82 User’s Manual

Page 15

Chapter 1. Introduction

Vortex Shedder Bar

Velocity Sensor

Vortices

Constant Wave Length

Flow

1.3.1 Vortex Shedding Frequency

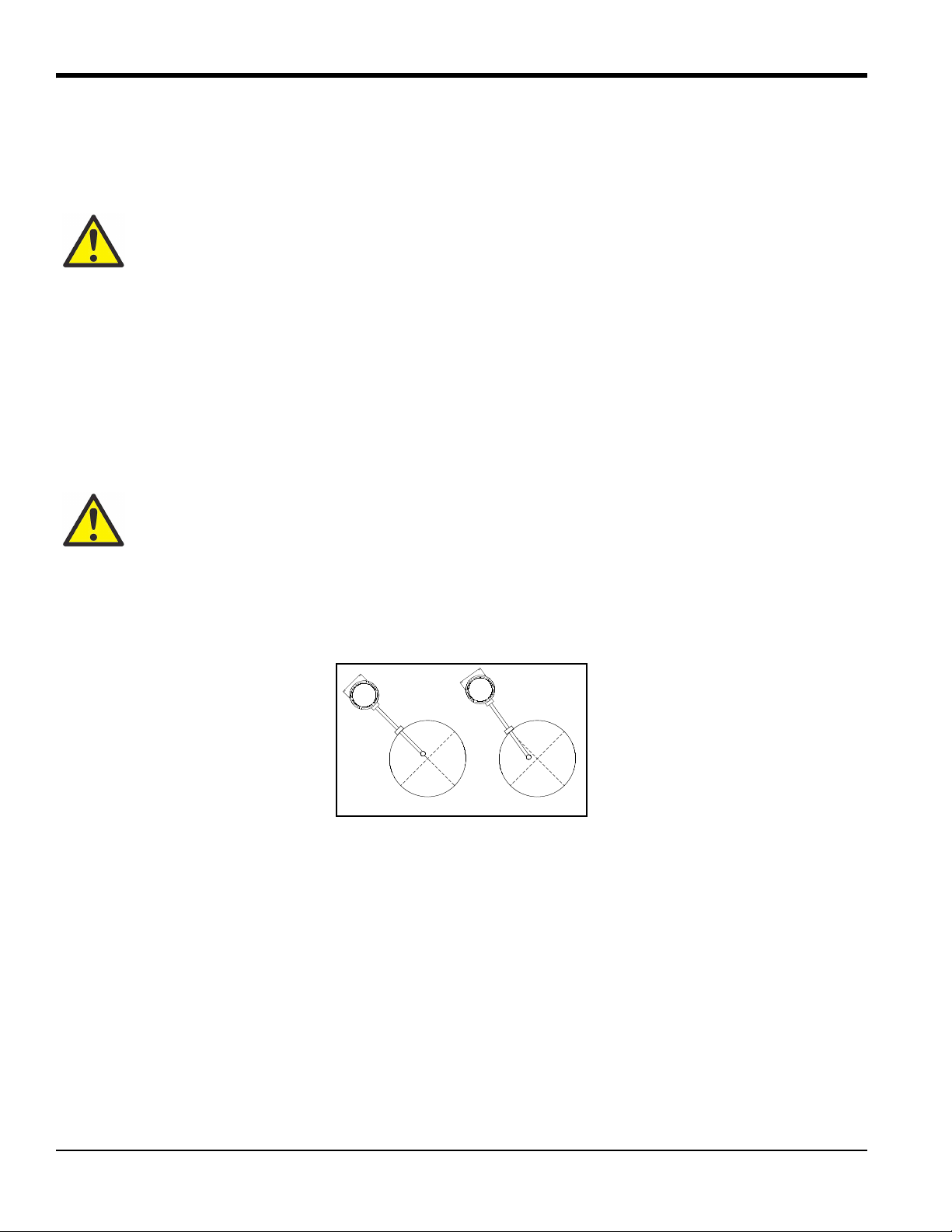

Von Karman vortices form downstream of a shedder bar into two distinct wakes. The vortices of one wake rotate

clockwise while those of the other wake rotate counterclockwise. Vortices generate one at a time, alternating from the

left side to the right side of the shedder bar. Vortices interact with their surrounding space by over-powering every other

nearby swirl on the verge of development. Close to the shedder bar, the distance (or wave length) between vortices is

always constant and measurable. Therefore, the volume encompassed by each vortex remains constant, as shown in

Figure 2 below. By sensing the number of vortices passing by the velocity sensor, the PanaFlow™ Flowmeter

computes the total fluid volume.

Figure 2: Measurement Principle of Vortex Flowmeters

1.3.2 Vortex Frequency Sensing

The velocity sensor incorporates a piezoelectric element that senses the vortex frequency. This element detects the

alternating lift forces produced by the Von Karman vortices flowing downstream of the vortex shedder bar. The

alternating electric charge generated by the piezoelectric element is processed by the transmitter's electronic circuit to

obtain the vortex shedding frequency. The piezoelectric element is highly sensitive and operates over a wide range of

flows, pressures and temperatures.

PanaFlow™ MV80 & MV82 User’s Manual 3

Page 16

Chapter 1. Introduction

25ft/s

ρ

---------------

37m/s

ρ

----------------

Re

ρVD

μ

----------

=

St

fd

V

-----=

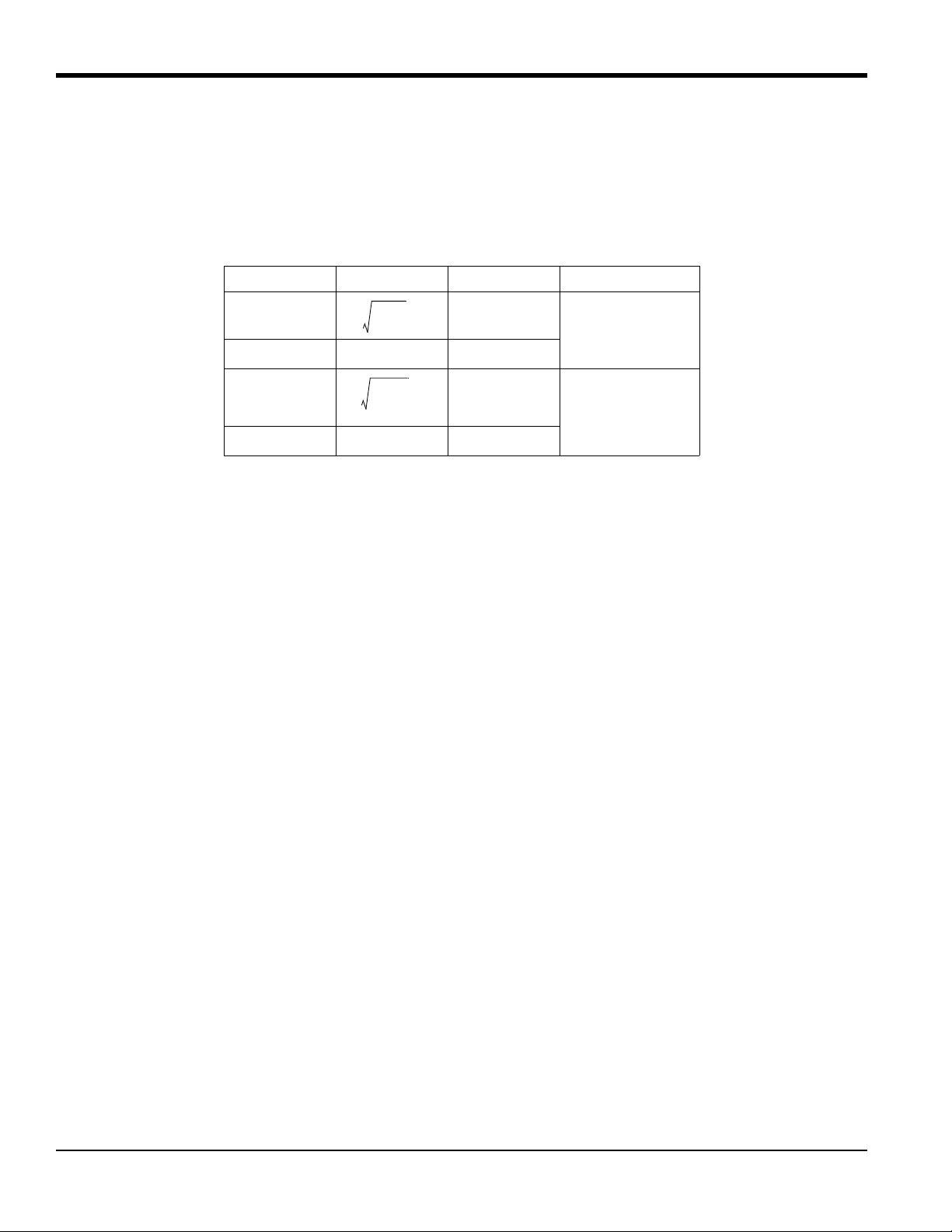

1.3.3 Flow Velocity Range

To ensure trouble-free operation, vortex flowmeters must be correctly sized so that the flow velocity range through the

meter lies within the measurable velocity range (with acceptable pressure drop) and the linear range.

The measurable range is defined by the minimum and maximum velocity using Table 1 below.

Table 1: Measurable Ranges

Parameter Gas Liquid Units for ρ

V

min

1 ft/s

English

ρ (lb/ft

3

)

V

max

V

min

V

max

300 ft/s 30 ft/s

0.3 m/s

91 m/s 9.1 m/s

Metric

ρ (kg/m

3

)

The pressure drop for series MV82 insertion meters is negligible. The pressure drop for series MV80 in-line meters is

defined as:

ΔP = .00024

ΔP = .000011

2

ρV

English units (ΔP in psi, ρ in lb/ft

2

ρV

Metric units (ΔP in bar, ρ in kg/m

3

, V in ft/sec)

3

, V in m/sec)

The linear range is defined by the Reynolds number. The Reynolds number is the ratio of the inertial forces to the

viscous forces in a flowing fluid and is defined as:

Where,

Re = Reynolds Number

ρ = mass density of the fluid being measured

V = velocity of the fluid being measured

D = internal diameter of the flow channel

μ = viscosity of the fluid being measured

The Strouhal number is the other dimensionless number that quantifies the vortex phenomenon. The Strouhal number

is defined as:

Where,

St = Strouhal Number

f = frequency of vortex shedding

d = shedder bar width

V = fluid velocity

4 PanaFlow™ MV80 & MV82 User’s Manual

Page 17

Chapter 1. Introduction

0.0

0.1

0.2

0.3

10

3

10

4

10

5

10

6

10

7

10

8

Linear Range

Reynolds Number, Re

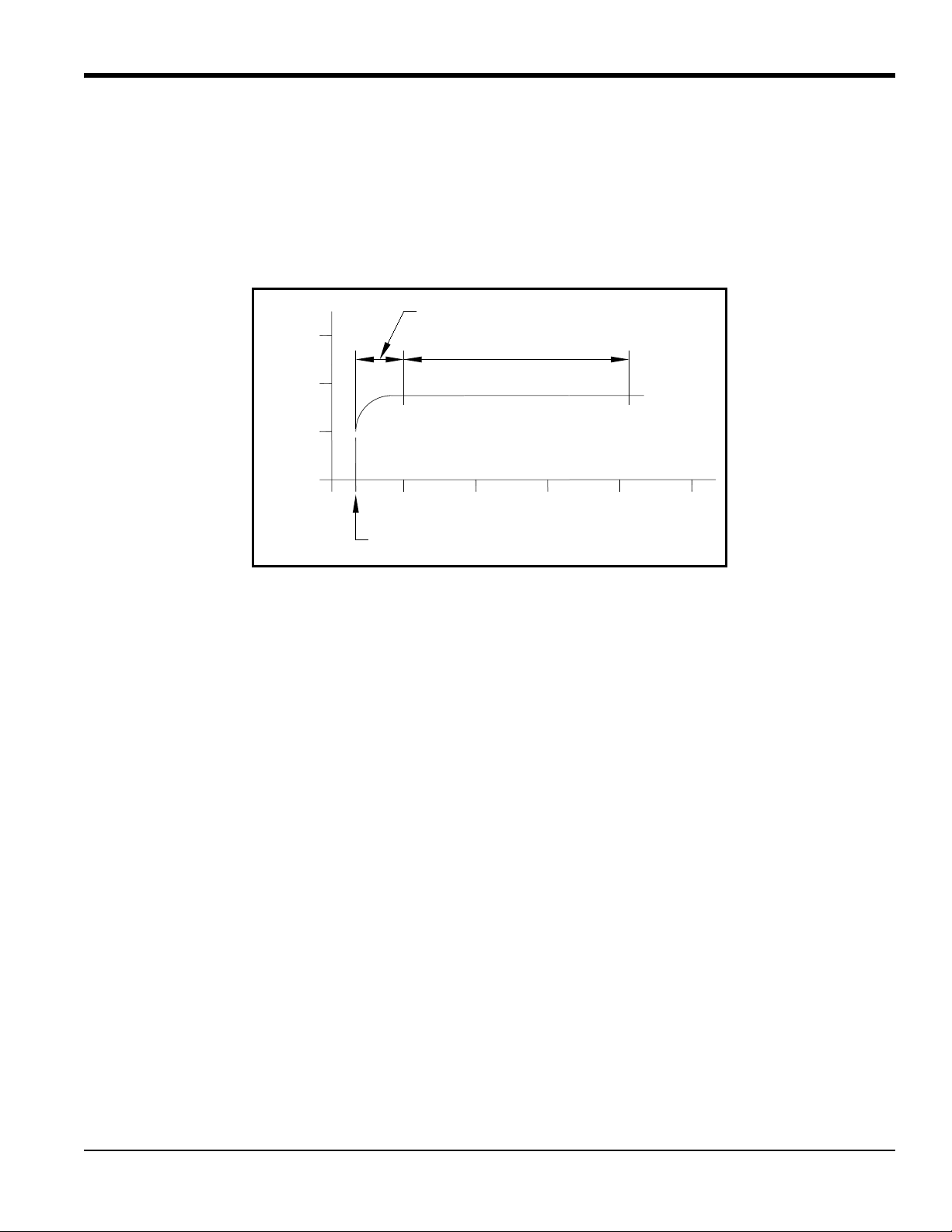

1.3.3 Flow Velocity Range (cont.)

As shown in Figure 3 below, PanaFlow meters exhibit a constant Strouhal number across a large range of Reynolds

numbers, indicating a consistent linear output over a wide range of flows and fluid types. Below this linear range, the

intelligent electronics in PanaFlow automatically corrects for the variation in the Strouhal number with the Reynolds

number. The meter's smart electronics corrects for this non-linearity via its simultaneous measurements of the process

fluid temperature and pressure. This data is then used to calculate the Reynolds number in real time. PanaFlow meters

automatically correct down to a Reynolds number of 5,000.

Corrected Range

Strouhal Number, St

5000

Figure 3: Reynolds Number Range for the PanaFlow MV

1.4 Temperature Measurement

PanaFlow Flowmeters use a 1000 ohm platinum resistance temperature detector (PRTD) to measure fluid temperature.

1.5 Pressure Measurement

PanaFlow Flowmeters incorporate a solid-state pressure transducer isolated by a 316 stainless steel diaphragm. The

transducer itself is micro-machined silicon, fabricated using integrated circuit processing technology. A nine-point

pressure/temperature calibration is performed on every sensor. Digital compensation allows these transducers to

operate within a 0.3% of full scale accuracy band within the entire ambient temperature range of –40°F to 140°F

(–40 to 60°C). Thermal isolation of the pressure transducer ensures the same accuracy across the allowable process

fluid temperature range of –330°F to 750°F (–200 to 400°C).

PanaFlow™ MV80 & MV82 User’s Manual 5

Page 18

Chapter 1. Introduction

1.6 Flowmeter Configurations

PanaFlow Vortex Mass Flowmeters are available in two model configurations:

• Series MV80 in-line flowmeter (replaces a section of the pipeline)

• Series MV82 insertion flowmeter (requires a “cold” tap or a “hot” tap into an existing pipeline)

Both the in-line and insertion configurations are similar in that they both use identical electronics and have similar

sensor heads. Besides installation differences, the main difference between an in-line flowmeter and an insertion

flowmeter is their method of measurement.

For an in-line vortex flowmeter, the shedder bar is located across the entire diameter of the flow body. Thus, the entire

pipeline flow is included in the vortex formation and measurement. The sensing head, which directly measures

velocity, temperature and pressure is located just downstream of the shedder bar.

Insertion vortex flowmeters have a shedder bar located across the diameter of a short tube. The velocity, temperature

and pressure sensor are located within this tube just downstream of a built-in shedder bar. This entire assembly is called

the insertion sensing head. It fits through any entry port with a 1.875 inch minimum internal diameter.

The sensing head of an insertion vortex flowmeter directly monitors the velocity at a point in the cross-sectional area of

a pipe, duct, or stack (referred to as “channels”). The velocity at a point in the pipe varies as a function of the Reynolds

number. The insertion vortex flowmeter computes the Reynolds number and then computes the total flow rate in the

channel. The output signal of insertion meters is the total flow rate in the channel. The accuracy of the total flow rate

computation depends on adherence to the piping installation requirements given in Chapter 2. If adherence to those

guidelines cannot be met, contact GE for specific installation advice.

1.6.1 Multivariable Options

The MV80 or MV82 models are available with the following options:

• V = volumetric flowmeter

• VT = velocity and temperature sensors

• VTP = velocity, temperature, and pressure sensors

• VT-EM = energy output options

• VTP-EM = energy options with pressure

• VT-EP = external pressure transmitter input.

6 PanaFlow™ MV80 & MV82 User’s Manual

Page 19

Chapter 1. Introduction

1.6.2 Line Size, Process Connections and Materials

The MV80 In-line model is built for line sizes ½ through 4 inch wafer or ½ through 8 inch flanged design using

ANSI 150, 300, 600, PN16, 40, or 64 class flanges.

The MV82 Insertion model can be used in line sizes 2 inch and greater and is built with a compression fitting or

packing gland design using 2 inch NPT, or 2 inch flanged connections (ANSI 150, 300, 600, PN16, 40, or 64 class

flanges). The packing gland design can be ordered with a permanent or removable retractor.

The MV80 In-line model can be built with A105 carbon steel, 316L stainless steel, or Hastelloy C-276. The MV82

Insertion model can be built with 316L stainless steel or Hastelloy C-276.

1.6.3 Flowmeter Electronics

PanaFlow flowmeter electronics are available mounted directly to the flow body, or remotely mounted. The electronics

housing may be used indoors or outdoors, including wet environments. Available input power options are: DC loop

powered (2-wire), DC powered or AC powered. Three analog output signals are available for your choice of three of

the five process variables: mass flow rate, volumetric flow rate, temperature, pressure or fluid density. A pulse output

signal for remote totalization and MODBUS or HART communications are also available.

PanaFlow flowmeters include a local 2 x16 character LCD display housed within the enclosure. Local operation and

reconfiguration is accomplished using six push buttons operated via finger touch. For hazardous locations, the six

buttons can be operated with the electronics enclosure sealed using a hand-held magnet, thereby not compromising the

integrity of the hazardous location certification.

The electronics include nonvolatile memory that stores all configuration information. The nonvolatile memory allows

the flowmeter to function immediately upon power up, or after an interruption in power. All flowmeters are calibrated

and configured for the customer's flow application.

PanaFlow™ MV80 & MV82 User’s Manual 7

Page 20

Chapter 1. Introduction

[no content intended for this page]

8 PanaFlow™ MV80 & MV82 User’s Manual

Page 21

Chapter 2. Installation

Chapter 2. Installation

2.1 Installation Overview

PanaFlow Vortex Flowmeter installations are simple and straightforward. Both the Series MV80 In-Line and Series

MV82 Insertion type flowmeter installations are covered in this chapter. After reviewing the installation requirements

given below, see page 11 for Series MV80 installation instructions. See “Series MV82 Insertion Flowmeter

Installation” on page 15 for Series MV82 installation instructions. Wiring instructions begin in “Loop Power

Flowmeter Wiring Connections” on page 32.

2.1.1 Flowmeter Installation Requirements

WARNING! Consult the flowmeter nameplate for specific flowmeter approvals before any

hazardous location installation.

Before installing the flowmeter, verify that the installation site allows for these considerations:

1. Line pressure and temperature will not exceed the flowmeter rating.

2. The location meets the required minimum number of pipe diameters upstream and downstream of the sensor

head as illustrated in Figure 4 on page 10.

3. Safe and convenient access with adequate overhead clearance for maintenance purposes.

4. Verify that the cable entry into the instrument meets the specific standard required for hazardous area

installations.

5. For remote installations, verify the supplied cable length is sufficient to connect the flowmeter sensor to the

remote electronics.

Also, before installation, check your flow system for anomalies such as:

• Leaks

• Valves or restrictions in the flow path which could create disturbances in the flow profile that might cause

unexpected flow rate indications

PanaFlow™ MV80 & MV82 User’s Manual 9

Page 22

Chapter 2. Installation

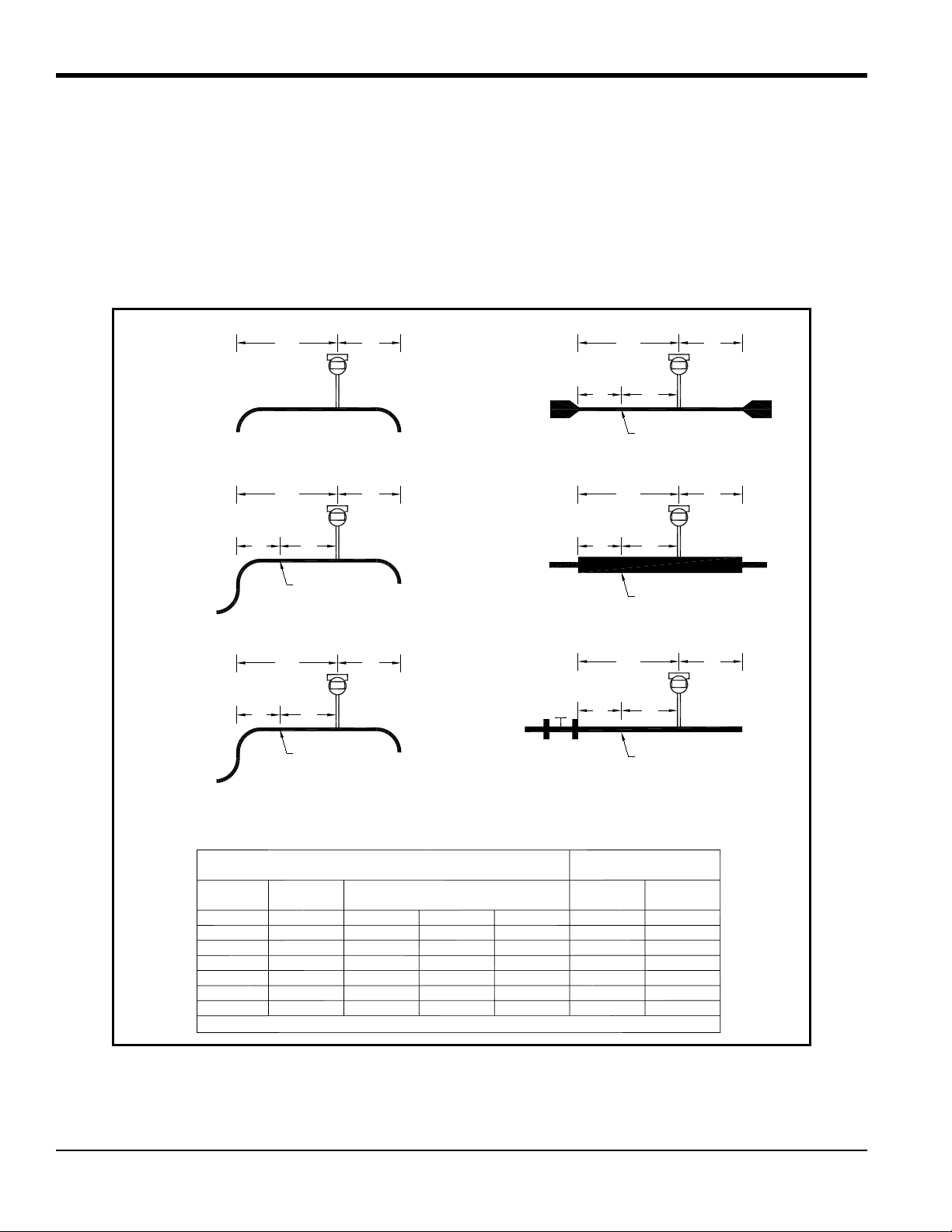

Flowmeter

AB

Example 1.

One 90° elbow before meter

Flowmeter

AB

Example 2.

Two 90° elbows before meter in one plane

C' C

Flow Conditioner

(if used)

Flowmeter

AB

Example 3.

Two 90° elbows before meter out of plane (if three

C' C

Flow Conditioner

(if used)

90° bends present, double recommended length)

Flowmeter

AB

Example 4.

Reduction before meter

Flowmeter

AB

Example 5.

Expansion before meter

C' C

Flow Conditioner

(if used)

C' C

Flow Conditioner

(if used)

Flowmeter

AB

Example 6.

Regulator or valve partially closed before meter

C' C

Flow Conditioner

(if used)

(If valve is always wide open, base length

requirements on fitting directly preceding it)

Example

1

2

3

4

5

6

A

10D

15D

25D

10D

20D

25D

No Flow

Conditioner

A

N/A

10D

10D

10D

10D

10D

With Flow Conditioner

C

N/A

5D

5D

5D

5D

5D

C'

N/A

5D

5D

5D

5D

5D

No Flow

Conditioner

With Flow

Conditioner

Minimum Required

Downstream Diameters

Minimum Required

Upstream Diameters

D = Internal diameter of channel. N/A = Not applicable.

B

5D

5D

10D

5D

5D

10D

B

5D

5D

5D

5D

5D

5D

2.1.2 Unobstructed Flow Requirements

Select an installation site that will minimize possible distortion in the flow profile. Valves, elbows, control valves and

other piping components may cause flow disturbances. Check your specific piping condition against the examples

shown in Figure 4 below. In order to achieve accurate and repeatable performance install the flowmeter using the

recommended number of straight run pipe diameters upstream and downstream of the sensor.

Note: For liquid applications in vertical pipes, avoid installing with flow in the downward direction because the pipe

may not be full at all points. Choose to install the meter with flow in the upward direction if possible.

Figure 4: Recommended Pipe Length Requirements for Installation of Series MV80 & MV82

10 PanaFlow™ MV80 & MV82 User’s Manual

Page 23

Chapter 2. Installation

1

2

34

1

2

34

1

2

34

8

67

5

8

12 5

9

7

116

10

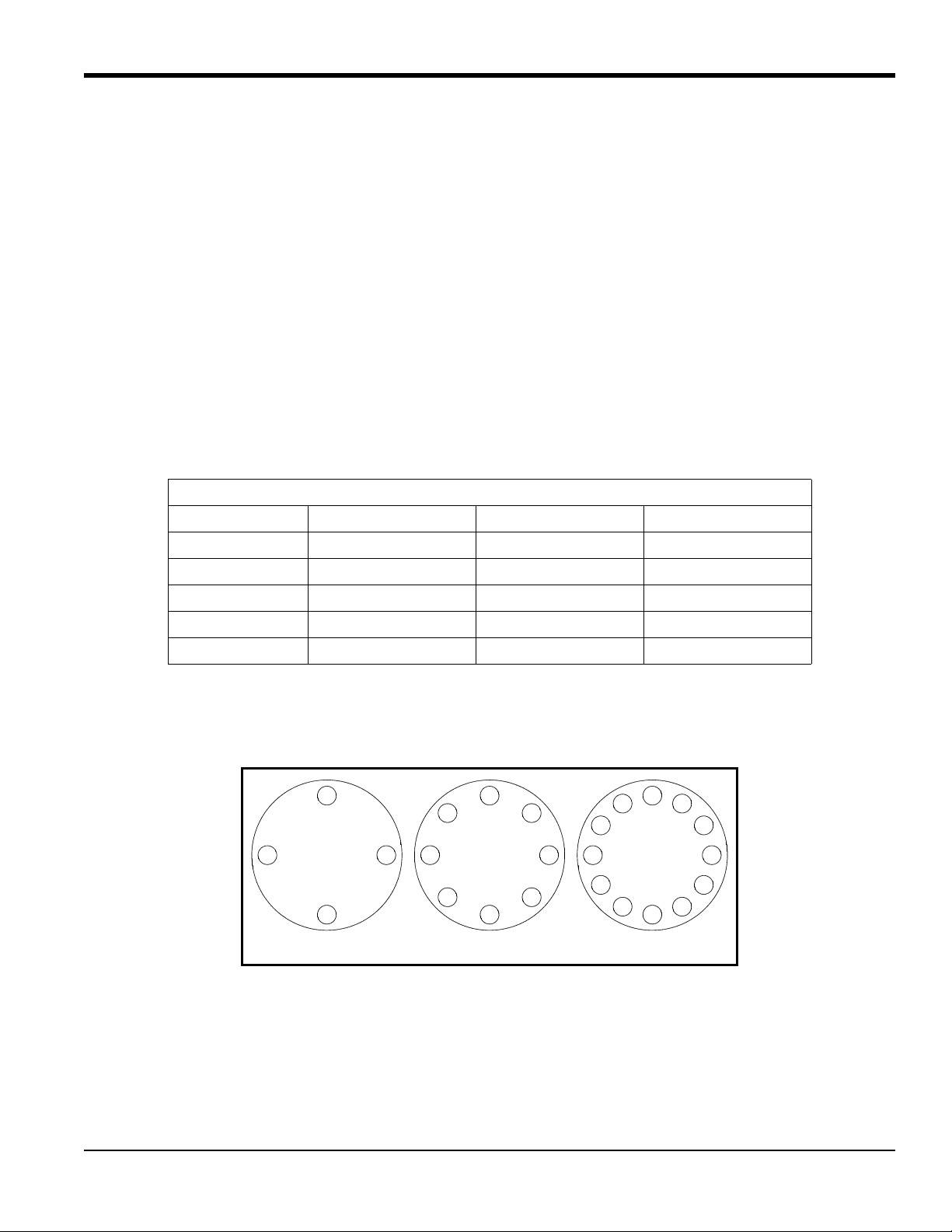

2.2 Series MV80 In-Line Flowmeter Installation

Install the Series MV80 In-Line Flowmeter between two conventional pipe flanges as shown in Figure 6 on page 12

and Figure 7 on page 14. Table 2 below provides the recommended minimum stud bolt lengths for wafer-style meter

body size and different flange ratings.

The meter inside diameter is equal to the same size nominal pipe ID in schedule 80. For example, a 2" meter has an ID

of 1.939" (2" schedule 80). Do not install the meter in a pipe with an inside diameter smaller than the inside diameter of

the meter. For schedule 160 and higher pipe, a special meter is required. Consult GE before purchasing the meter.

Series MV80 Meters require customer-supplied gaskets. When selecting gasket material make sure that it is compatible

with the process fluid and pressure ratings of the specific installation. Verify that the inside diameter of the gasket is

larger than the inside diameter of the flowmeter and adjacent piping. If the gasket material extends into the flow stream,

it will disturb the flow and cause inaccurate measurements.

2.2.1 Flange Bolt Specifications

Table 2: Minimum Recommended Stud Bolt Lengths for Wafer Meters

Stud Bolt Lengths for Each Flange Rating (inches)

Line Size Class 150 and PN16 Class 300 and PN40 Class 600 and PN64

1 inch 6.00 7.00 7.50

1.5 inch 6.25 8.50 9.00

2 inch 8.50 8.75 9.50

3 inch 9.00 10.00 10.50

4 inch 9.50 10.75 12.25

The required bolt load for sealing the gasket joint is affected by several application-dependent factors. Therefore the

required torque for each application may be different. Refer to the ASME Pressure Vessel Code guidelines for bolt

tightening standards and refer to Figure 5 below for the proper bolt tightening sequence.

4-bolt 8-bolt 12-bolt

Figure 5: Flange Bolt Torquing Sequence

PanaFlow™ MV80 & MV82 User’s Manual 11

Page 24

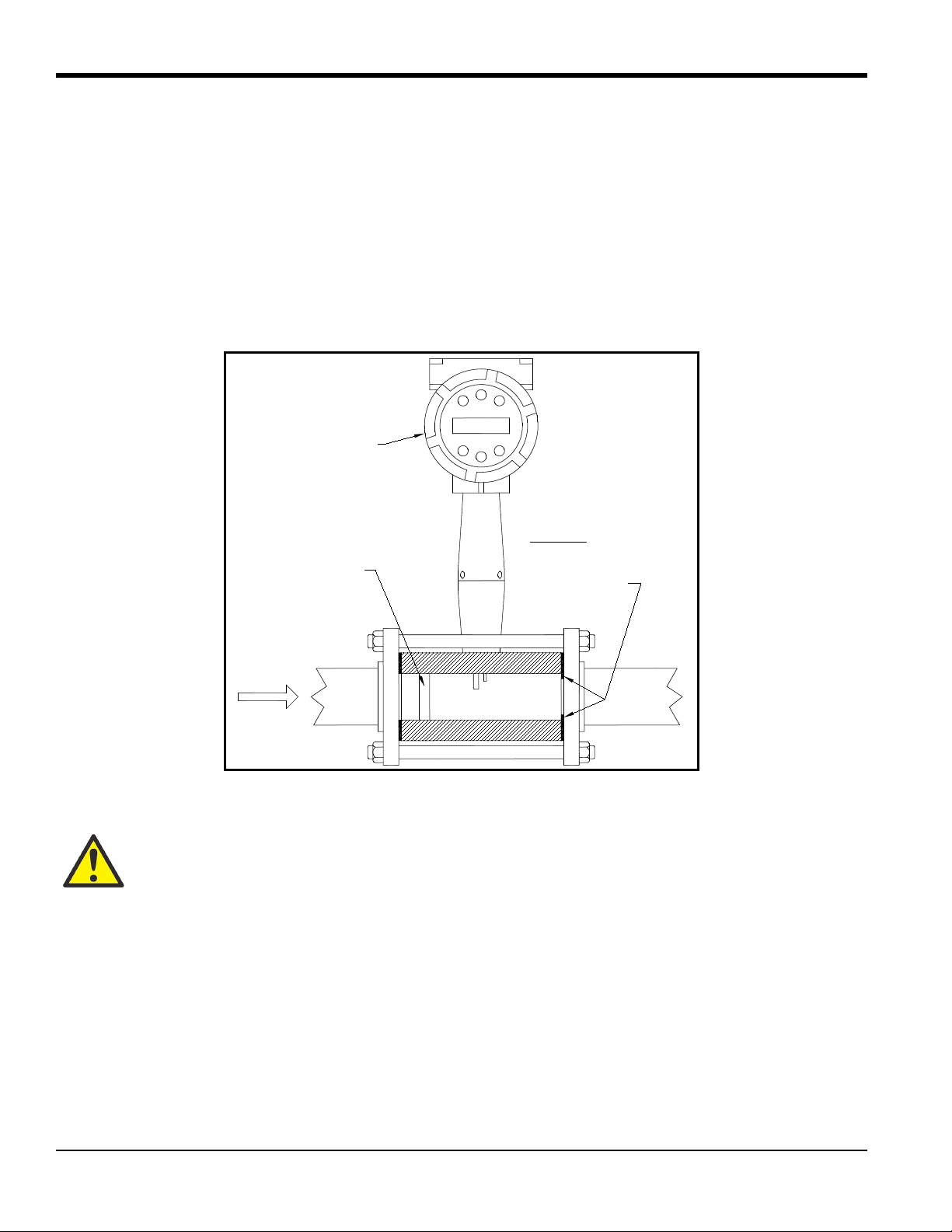

Chapter 2. Installation

F

LOW

Enclosure and

display/keypad

are adjustable to suit

most viewing angles.

Incorrect gasket position!

Do not allow any gasket

material to extend into

the flow profile.

Shedder bar (bluff body)

is positioned upstream

of the sensor.

2.2.2 Installing Wafer-Style Flowmeters

Install the wafer-style meter between two conventional pipe flanges of the same nominal size as the flowmeter (see

Figure 6 below). If the process fluid is a liquid, make sure the meter is located where the pipe is always full. This may

require locating the meter at a low point in the piping system.

Note: Vortex flowmeters are not suitable for two-phase flows, such as liquid and gas mixtures.

For horizontal pipelines having a process temperature above 300° F, mount the meter at a 45 or 90-degree angle to

avoid overheating the electronics enclosure. To adjust the viewing angle of the enclosure or display/keypad, see

“Display/Keypad Adjustment (All Meters)” on page 30 and “Enclosure Adjustment (Series MV80 Only)” on page 31.

When installing the meter make sure the section marked with a flow arrow is positioned upstream of the outlet, with the

arrow head pointing in the direction of flow. (The mark is on the wafer adjacent to the enclosure mounting neck.) This

ensures that the sensor head is positioned downstream of the vortex shedder bar and is correctly aligned to the flow.

Installing the meter opposite this direction will result in completely inaccurate flow measurement.

12 PanaFlow™ MV80 & MV82 User’s Manual

Figure 6: Wafer-Style Flowmeter Installation

CAUTION! When using toxic or corrosive gases, purge the line with inert gas for a minimum of four

hours at full gas flow before installing the flowmeter.

Page 25

Chapter 2. Installation

2.2.2 Installing Wafer-Style Flowmeters (cont.)

To install the meter, complete the following steps:

1. Turn off the flow of process gas, liquid or steam. Verify that the line is not pressurized. Confirm that the

installation site meets the required minimum upstream and downstream pipe diameters.

2. Insert the studs for the bottom side of the meter body between the pipe flanges. Place the wafer-style meter

body between the flanges with the end stamped with a flow arrow on the upstream side, with the arrow head

pointing in the direction of flow. Center the meter body inside the diameter with respect to the inside diameter

of the adjoining piping.

3. Position the gasket material between the mating surfaces. Make sure both gaskets are smooth and even with no

gasket material extending into the flow profile. Obstructions in the pipeline will disturb the flow and cause

inaccurate measurements.

4. Place the remaining studs between the pipe flanges. Tighten the nuts in the sequence shown in Figure 5 on

page 11. Check for leaks after tightening the flange bolts.

PanaFlow™ MV80 & MV82 User’s Manual 13

Page 26

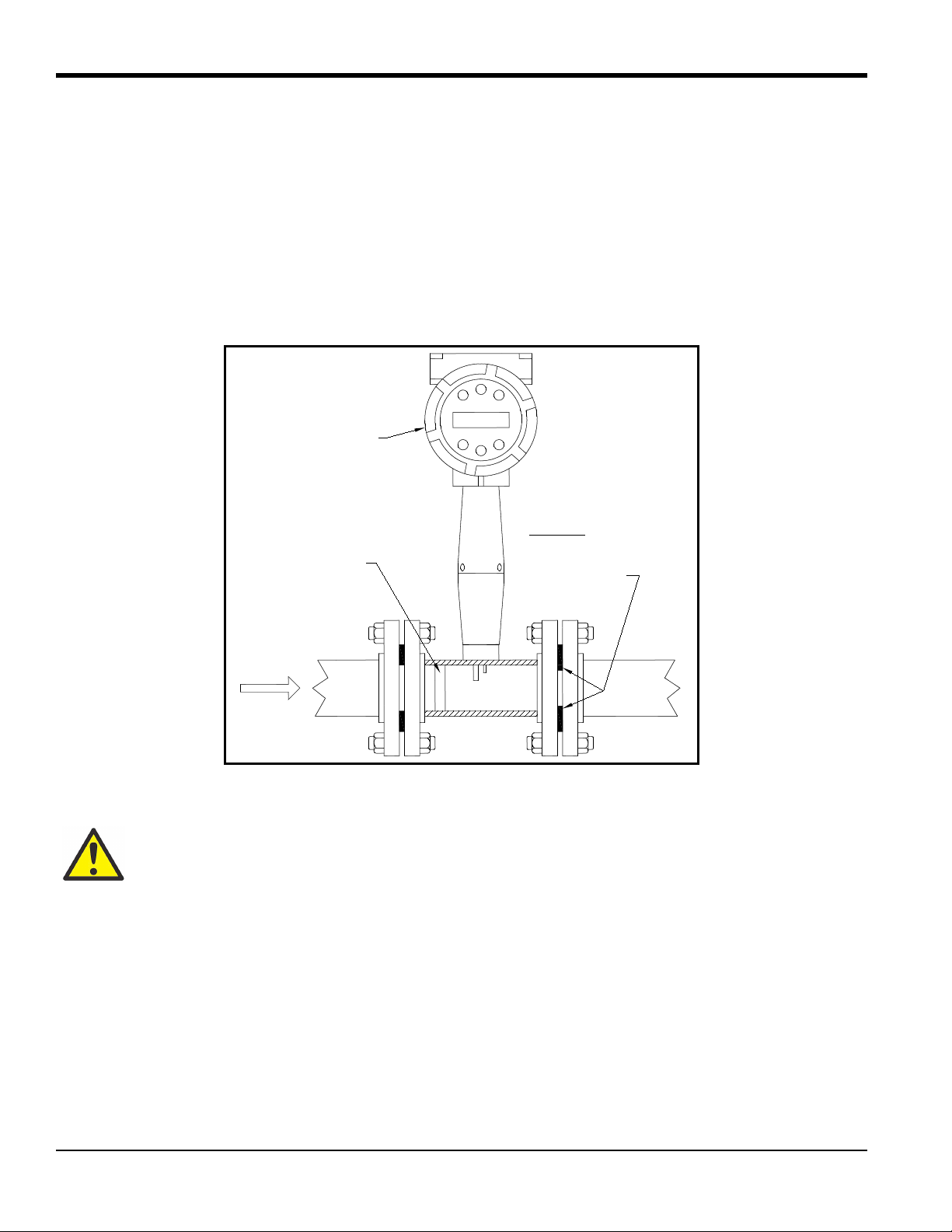

Chapter 2. Installation

LOW

Enclosure and

display/keypad

are adjustable to suit

most viewing angles.

Incorrect gasket position!

Do not allow any gasket

material to extend into

the flow profile.

Shedder bar (bluff body)

is positioned upstream

of the sensor.

2.2.3 Installing Flange-Style Flowmeters

Install the flange-style meter between two conventional pipe flanges of the same nominal size as the flowmeter (see

Figure 7 below). If the process fluid is a liquid, make sure the meter is located where the pipe is always full. This may

require locating the meter at a low point in the piping system.

Note: Vortex flowmeters are not suitable for two-phase flows, such as liquid and gas mixtures.

For horizontal pipelines having a process temperature above 300° F, mount the meter at a 45 or 90-degree angle to

avoid overheating the electronics enclosure. To adjust the viewing angle of the enclosure or display/keypad, see

“Display/Keypad Adjustment (All Meters)” on page 30 and “Enclosure Adjustment (Series MV80 Only)” on page 31.

F

Figure 7: Flange-Style Flowmeter Installation

CAUTION! When using toxic or corrosive gases, purge the line with inert gas for a minimum of four

hours at full gas flow before installing the flowmeter.

When installing the meter make sure the flange marked with a flow arrow is positioned upstream of the outlet flange,

with the arrow head pointing in the direction of flow. The mark is on the flange adjacent to the enclosure mounting

neck. This ensures that the sensor head is positioned downstream of the vortex shedder bar and is correctly aligned to

the flow. Installing the meter opposite this direction will result in completely inaccurate flow measurement.

14 PanaFlow™ MV80 & MV82 User’s Manual

Page 27

Chapter 2. Installation

valve bore

2-inch min.

2-inch

valve size

2.2.3 Installing Flange-Style Flowmeters (cont.)

To install the meter, complete the following steps:

1. Turn off the flow of process gas, liquid or steam. Verify that the line is not pressurized. Confirm that the

installation site meets the required minimum upstream and downstream pipe diameters.

2. Seat the meter level and square on the mating connections with the flange stamped with a flow arrow on the

upstream side, with the arrow head pointing in the direction of flow. Position a gasket in place for each side.

Make sure both gaskets are smooth and even with no gasket material extending into the flow profile.

Obstructions in the pipeline will disturb the flow and cause inaccurate measurements.

3. Install bolts in both process connections. Tighten the nuts in the sequence shown in Figure 5 on page 11. Check

for leaks after tightening the flange bolts.

2.3 Series MV82 Insertion Flowmeter Installation

2.3.1 General Installation Guidelines

Prepare the pipeline for installation using either a cold tap or hot tap method described in this section. Refer to a

standard code for all pipe tapping operations. The following tapping instructions are general in nature and intended for

guideline purposes only. Before installing the meter, review the mounting position and isolation value requirements

given in the following sub-sections.

2.3.1a Electronics Enclosure Clearance

Allow clearance between the electronics enclosure top and any obstruction when the meter is fully retracted.

2.3.1b Isolation Valve Selection

An isolation valve is available as an option with Series MV82 meters. If you supply the isolation valve, refer to

Figure 8 below and verify that it meets the following requirements:

1. A minimum valve bore diameter of 1.875 inches is required, and the valve’s body size should be two inches.

Normally, gate valves are used.

2. Verify that the valve’s body and flange rating are within the flowmeter’s maximum operating pressure and

temperature.

3. Choose an isolation valve with at least a two inch distance between the flange face and the gate portion of the

valve. This ensures that the flowmeter’s sensor head will not interfere with the operation of the isolation valve.

1.875-inch min.

Isolation Valve Requirements

Figure 8: Isolation Valve Dimensions

PanaFlow™ MV80 & MV82 User’s Manual 15

Page 28

Chapter 2. Installation

Incorrect AlignmentCorrect Alignment

2.3.1c Cold Tap Guidelines

Refer to a standard code for all pipe tapping operations. The following tapping instructions are general in nature and

intended for guideline purposes only. Proceed as follows:

CAUTION! When using toxic or corrosive gases, purge the line with inert gas for a minimum of four

hours at full gas flow before installing the flowmeter.

1. Turn off the flow of process gas, liquid or steam. Verify that the line is not pressurized.

2. Confirm that the installation site meets the minimum upstream and downstream pipe diameter requirements.

See Figure 4 on page 10.

3. Use a cutting torch or sharp cutting tool to tap into the pipe. The pipe opening must be at least 1.875 inches in

diameter. (Do not attempt to insert the sensor probe through a smaller hole.)

4. Remove all burrs from the tap. Rough edges may cause flow profile distortions that could affect flowmeter

accuracy. Also, obstructions could damage the sensor assembly when inserting into the pipe.

WARNING! All flowmeter connections, isolation valves and fittings for cold tapping must have the

same or higher pressure rating as the main pipeline.

5. After cutting, measure the thickness of the cut-out and record this number for calculating the insertion depth.

6. Weld the flowmeter pipe connection on the pipe. Make sure this connection is within ± 5° perpendicular to the

pipe centerline (see Figure 9 below).

Figure 9: Connection Alignment

7. Install the isolation valve (if used).

8. When welding is complete and all fittings are installed, close the isolation valve or cap the line. Run a static

pressure check on the welds. If pressure loss or leaks are detected, repair the joint and retest.

9. Connect the meter to the pipe process connection.

10. Calculate the sensor probe insertion depth and insert the sensor probe into the pipe as described on the

following pages.

16 PanaFlow™ MV80 & MV82 User’s Manual

Page 29

Chapter 2. Installation

FLOW

Check upstream and

downstream piping

requirements.

Weld mounting

adapter.

Connect process

connection

(flange or NPT)

Connect

isolation valve.

Hot tap pipe

Test for leaks,

purge pipe.

Connect meter to

valve, calculate

insertion depth,

install flowmeter.

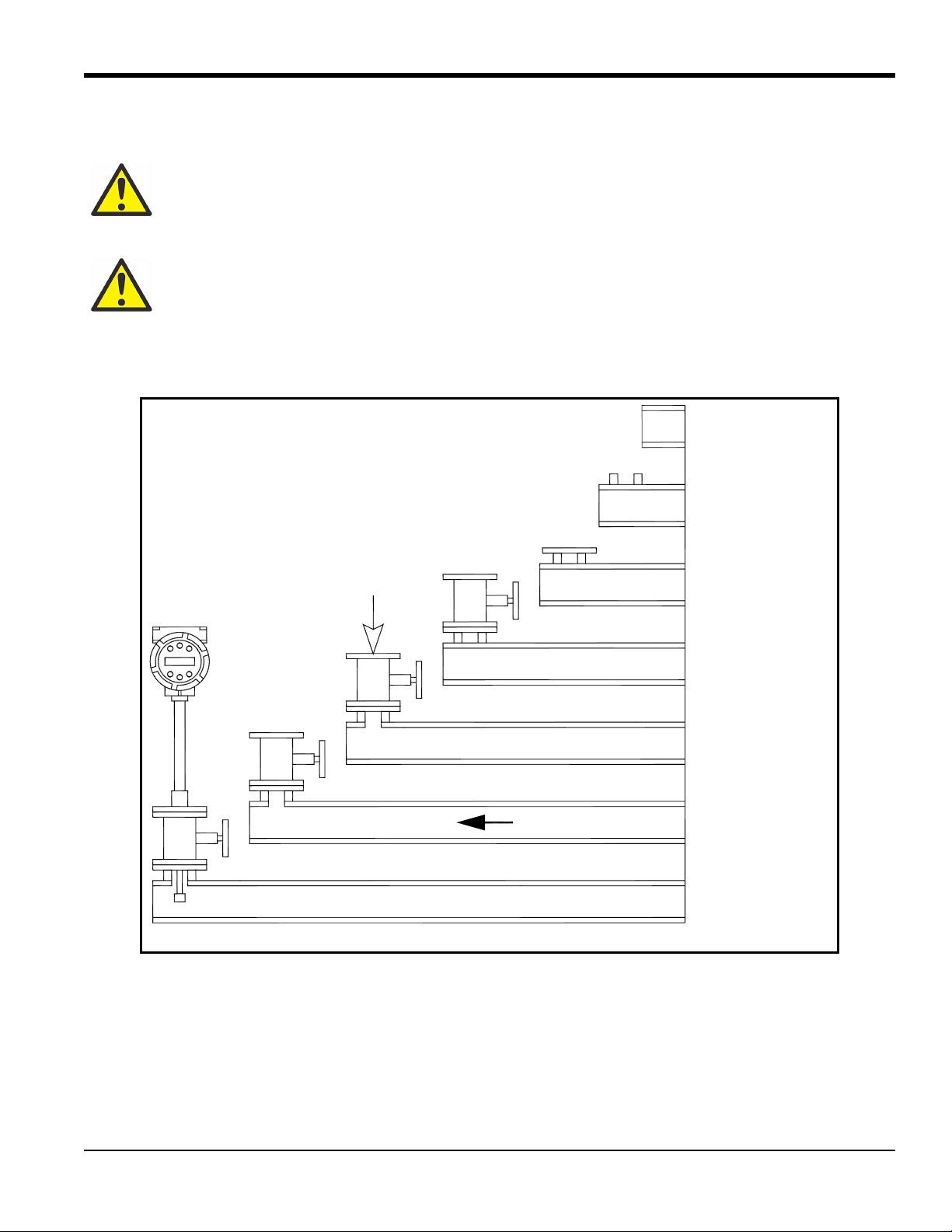

2.3.1d Hot Tap Guidelines

WARNING! Hot tapping must be performed by a trained professional. US. regulations often require

a hot tap permit. The manufacturer of the hot tap equipment and/or the contractor performing the

hot tap is responsible for providing proof of such a permit.

WARNING! All flowmeter connections, isolation valves, and fittings for hot tapping must have the

same pressure rating as the main pipeline or higher.

Refer to a standard code for all pipe tapping operations. The following tapping instructions and Figure 10 below are

general in nature and are intended for guideline purposes only.

Figure 10: Hot Tap Sequence

PanaFlow™ MV80 & MV82 User’s Manual 17

Page 30

Chapter 2. Installation

2.3.1d Hot Tap Guidelines (cont.)

Proceed as follows:

1. Confirm that the installation site meets the minimum upstream and downstream pipe diameter requirements.

2. Weld a two inch mounting adapter on the pipe. Make sure the mounting adapter is within ± 5° perpendicular to

the pipe centerline (see Figure 9 on page 16). The pipe opening must be at least 1.875 inches in diameter.

3. Connect a two inch process connection on the mounting adapter.

4. Connect an isolation valve on the process connection. The valve's full open bore must be at least 1.875 inches

in diameter.

5. Run a static pressure check on the welds. If pressure loss or leaks are detected, repair the joint and re-test.

6. Connect the hot tapping equipment to the isolation valve, open the isolation valve and drill at least a 1.875 inch

diameter hole.

7. Retract the drill, close the isolation valve, and remove the hot tapping equipment.

8. Connect the flowmeter to the isolation valve and open the isolation valve.

9. Calculate the sensor probe insertion depth and insert the sensor probe into the pipe as described on the

following pages.

18 PanaFlow™ MV80 & MV82 User’s Manual

Page 31

Chapter 2. Installation

2.3.1e Insertion Guidelines

The sensor head must be properly positioned in the pipe. For this reason, it is important that insertion length

calculations are carefully followed. A sensor probe inserted at the wrong depth in the pipe will result in inaccurate

readings.

Insertion flowmeters are applicable to pipes 2 inch and larger. For pipe sizes ten inches and smaller, the centerline of

the meter's sensing head is located at the pipe's centerline. For pipe sizes larger than ten inches, the centerline of the

sensing head is located in the pipe's cross section five inches from the inner wall of the pipe. That is, its “wetted” depth

from the wall to the centerline of the sensing head is five inches.

Insertion flowmeters are available in three probe lengths:

• Standard Probe configuration is used with most flowmeter process connections. The length (S) of the stem is

29.47 inches.

• Compact Probe configuration is used with compression fitting process connections. The length (S) of the stem

is 13.1 inches.

• 12-Inch Extended Probe configuration is used with exceptionally lengthy flowmeter process connections. The

length (

S) of the stem is 41.47 inches.

2.3.1f Selecting the Correct Insertion Formula

WARNING! An insertion tool must be used for any installation where a flowmeter is inserted under

pressure greater than 50 psig.

Depending on your flowmeter's process connection, use the applicable insertion length formula and installation

procedure as follows:

• For flowmeters with a compression type connection (NPT or flanged), follow the instructions beginning in

“Installing Flowmeters with a Compression Connection” on page 20.

• For flowmeters with a packing gland type connection (NPT or flanged), configured with an insertion tool,

follow the instructions in “Installing Flowmeters with a Packing Gland Connection” on page 23.

• For flowmeters with a packing gland type connection (NPT or flanged), configured without an insertion tool,

follow the instructions in “Installing Flowmeters with a Packing Gland Connection (No Insertion Tool)” on

page 28.

PanaFlow™ MV80 & MV82 User’s Manual 19

Page 32

Chapter 2. Installation

I

F

t

R

S

I

F

t

R

S

Flow

Flow

Insertion Length Formula

I = S – F – R – t

Where:

I = Insertion Length.

= Stem length - the distance from the center of the sensor head to the base of the enclosure adapter

(S = 29.47" for standard probes; S = 13.1" for compact; S = 41.47" for 12-inch extended).

F = Distance from the raised face of the flange or top of NPT stem housing to the outside of the pipe wall.

R = Pipe inside diameter + 2 for pipes ten inches and smaller.

R = Five inches for pipe diameters larger than ten inches

t = Thickness of the pipe wall. (Measure the disk cut-out from the tapping procedure or check a piping

2.3.2 Installing Flowmeters with a Compression Connection

Refer to Figure 11 below, and use the formula shown to determine insertion length for flowmeters (NPT and flanged)

with a compression process connection.

S

handbook for thickness.)

Figure 11: Insertion Calculation (Compression Type)

20 PanaFlow™ MV80 & MV82 User’s Manual

Page 33

Chapter 2. Installation

Compression Nut

Stem Housing

2-inch NPT

Connection

Compression Nut

Sensor Head

Flange

Connection

Sensor Alignment

Pointer

Encloser Adapter

Stem

Stem Housing

2.3.2 Installing Flowmeters with a Compression Connection (cont.)

Example:

To install a Series MV82 meter with a standard probe (S = 29.47 inches) into a 14 inch schedule 40 pipe, the following

measurements (in inches) are taken:

• F = 3 inches

• R = 5 inches

• t = 0.438 inches

Then, using the formula given in Figure 11 on page 20, the insertion length for this example is 21.03 inches. Insert the

stem through the fitting until an insertion length of 21.03 inches is measured with a ruler.

PanaFlow™ MV80 & MV82 User’s Manual 21

Figure 12: Flowmeter with a Compression Type Fitting

Page 34

Chapter 2. Installation

2.3.2 Installing Flowmeters with a Compression Connection (cont.)

CAUTION! The sensor alignment pointer must point downstream, in the direction of flow.

WARNING! To avoid serious injury, DO NOT loosen the compression fitting under pressure.

Refer to Figure 12 on page 21 and complete the following steps:

1. Refer to Figure 11 on page 20 and calculate the required sensor probe insertion length for your system.

2. Fully retract the stem until the sensor head is touching the bottom of the stem housing. Slightly tighten the

compression nut to prevent slippage.

3. Bolt or screw the flowmeter assembly into the process connection. Use PTFE tape or pipe sealant to improve

the seal and prevent seizing on NPT styles.

4. Hold the meter securely while loosening the compression fitting. Insert the sensor into the pipe until the

calculated insertion length (

housing, or to the raised face of the flanged version. Do not force the stem into the pipe.

I) is measured between the base of the enclosure adapter and the top of the stem

5. Align the sensor head using the sensor alignment pointer. Adjust the alignment pointer parallel to the pipe and

pointing downstream.

6. Tighten the compression fitting to lock the stem in position.

IMPORTANT: After the compression fitting is tightened, the position is permanent.

22 PanaFlow™ MV80 & MV82 User’s Manual

Page 35

Chapter 2. Installation

t

R

low

Insertion Length Formula

I = F + R + t –1.35

Where:

I = Insertion length.

F = Distance from the raised face of the flange or top of the process

connection for NPT style meters to the top outside of the process pipe.

R = Pipe inside diameter ÷ 2 for pipe diameters 10 inches and smaller.

R = Five inches for pipe diameters larger than 10 inches.

t = Thickness of the pipe wall. (Measure the disk cut-

out from the tapping

procedure or check a piping handbook for thickness.)

I

F

2.3.3 Installing Flowmeters with a Packing Gland Connection

Use the formula in Figure 13 below to determine the insertion depth for flowmeters (NPT and flanged) equipped with

an insertion tool. To install, see “Insertion Procedure for Flowmeters with Permanent Insertion Tool” on page 24 for

instructions for meters with a permanent insertion tool. For meters with a removable insertion tool, see “Insertion

Procedure for Flowmeters with Removable Insertion Tool” on page 26.

F

Figure 13: Insertion Length Calculation for Meters with an Insertion Tool

Example 1 - Flange Style Meters:

To install a Series MV82 Flowmeter into a 14 inch schedule 40 pipe, the following measurements are taken:

• F = 12 inches

• R = 5 inches

• t = 0.438 inches

Then, using the formula given in Figure 13 above, the insertion length for this example is 16.09 inches.

PanaFlow™ MV80 & MV82 User’s Manual 23

Page 36

Chapter 2. Installation

Flow

Sensor Head

Stem Housing

Packing Gland Nuts

Stem

Sensor Alignment

Pointer

Stem Lock Bolt

(center)

Upper Retractor Bracket

Depth Marker Arrow

Stanchion

Scribe Mark

Permanent

Insertion Tool

2.3.3 Installing Flowmeters with a Packing Gland Connection (cont.)

Example 2 - NPT Style Meters:

In this example, the length of thread engagement on the NPT style meters must also subtracted in the equation shown in

Figure 13 on page 23. The length of the threaded portion of the NPT meter is 1.18 inches. Measure the threaded

portion still visible after the installation and subtract that amount from 1.18 inches. This gives you the thread

engagement length. If this cannot be measured, use 0.55 inch for this amount.

• F = 12 inches

• R = 5 inches

• t = 0.438 inches

• thread engagement = 1.18 inches - visible thread length (or 0.55 inches nominal value)

For this example, the equation yields an insertion length of 15.54 inches.

2.3.4 Insertion Procedure for Flowmeters with Permanent Insertion Tool

Refer to Figure 14 below, and follow the instructions on the next page.

24 PanaFlow™ MV80 & MV82 User’s Manual

Figure 14: Flowmeter with Permanent Insertion Tool

Page 37

Chapter 2. Installation

2.3.4 Insertion Procedure for Flowmeters with Permanent Insertion Tool (cont.)

CAUTION! The sensor alignment pointer must point downstream, in the direction of flow.

Note: If line pressure is above 500 psig, it could require up to 25 ft-lb of torque to insert the flowmeter. Do not

confuse this with possible interference in the pipe.

1. Calculate the required sensor probe insertion length (see

Example 1 on page 23). Measure from the depth

marker arrow down the stanchion and scribe a mark at the calculated insertion depth.

2. Fully retract the flowmeter until the sensor head is touching the bottom of the stem housing. Attach the meter

assembly to the two inch full-port isolation valve, if used. Use PTFE tape or pipe sealant to improve the seal

and prevent seizing on NPT style meters.

3. Loosen the two packing gland nuts on the stem housing of the meter. Loosen the stem lock bolt adjacent to the

sensor alignment pointer. Align the sensor head using the sensor alignment pointer. Adjust the alignment

pointer parallel to the pipe and pointing downstream. Tighten the stem lock bolt to secure the sensor position.

4. Slowly open the isolation valve to the full open position. If necessary, slightly tighten the two packing gland

nuts to reduce the leakage around the stem.

5. Turn the insertion tool handle clockwise to insert the sensor head into the pipe. Continue until the top of the

upper retractor bracket aligns with the insertion length position scribed on the stanchion. Do not force the stem

into the pipe.

6. Tighten the packing gland nuts to stop leakage around the stem. Do not use a torque over 20 ft-lb.

PanaFlow™ MV80 & MV82 User’s Manual 25

Page 38

Chapter 2. Installation

Flow

Sensor Head

Stem Housing

Stem Clamp Bolts

Stem

Sensor Alignment

Pointer

Stem Lock Bolt

(center)

Upper Retractor Bracket

Depth Marker Arrow

Stanchion

Scribe Mark

Removable

Insertion Tool

Lower Retractor Bracket

Packing Gland Nuts

(covered by stem clamp)

Stem Clamp Nuts

2.3.5 Insertion Procedure for Flowmeters with Removable Insertion Tool

Refer to Figure 15 below, and follow the instructions on the next page.

Figure 15: Flowmeter with Removable Insertion Tool

26 PanaFlow™ MV80 & MV82 User’s Manual

Page 39

Chapter 2. Installation

2.3.5 Insertion Procedure for Flowmeters with Removable Insertion Tool (cont.)

CAUTION! The sensor alignment pointer must point downstream, in the direction of flow.

Note: If line pressure is above 500 psig, it could require up to 25 ft-lb of torque to insert the flowmeter. Do not

confuse this with possible interference in the pipe.

1. Calculate the required sensor probe insertion length. Measure from the depth marker arrow down the stanchion

and scribe a mark at the calculated insertion depth.

2. Fully retract the flowmeter until the sensor head is touching the bottom of the stem housing. Attach the meter

assembly to the two inch full-port isolation valve, if used. Use PTFE tape or pipe sealant to improve the seal

and prevent seizing on NPT style meters.

3. Remove the two top stem clamp nuts and loosen two stem clamp bolts. Slide the stem clamp away to expose

the packing gland nuts.

4. Loosen the two packing gland nuts. Loosen the stem lock bolt adjacent to the sensor alignment pointer. Align

the sensor head using the sensor alignment pointer. Adjust the alignment pointer parallel to the pipe and

pointing downstream. Tighten the stem lock bolt to secure the sensor position.

5. Slowly open the isolation valve to the full open position. If necessary, slightly tighten the two packing gland

nuts to reduce the leakage around the stem.

6. Turn the insertion tool handle clockwise to insert the stem into the pipe. Continue until the top of the upper

retractor bracket lines up with the insertion length mark scribed on the stanchion. Do not force the stem into the

pipe.

7. Tighten the packing gland nuts to stop leakage around the stem. Do not use a torque over 20 ft-lb.

8. Slide the stem clamp back into position, and torque stem clamp bolts to 15 ft-lb. Replace the stem clamp nuts

and torque them to 10-15 ft-lb.

9. To separate the insertion tool from the flowmeter, remove the four socket head cap bolts securing the upper and

lower retractor brackets. Then, remove the insertion tool.

PanaFlow™ MV80 & MV82 User’s Manual 27

Page 40

Chapter 2. Installation

t

R

F

low

Insertion Length Formula

I = S – F – R – t

Where:

I = Insertion length.

S = Stem length - the distance from the center of the sensor head

to the base of the enclosure adapter (S = 41.47 inches for

12 inch extended probes).

F = Distance from the raised face of the flange or top of NPT stem

housing to the outside of the pipe wall.

R = Pipe inside diameter ÷ 2 for pipes ten inches and sma

ller.

R = Five inches for pipe diameters larger than ten inches.

t = Thickness of the pipe wall. (Measure the disk cut-out from the

tapping procedure or check a piping handbook for thickness.)

I

F

S

2.3.6 Installing Flowmeters with a Packing Gland Connection (No Insertion Tool)