Page 1

GE

For Public Disclosure

Programmable Control Products

RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

PACSystems*

RX7i, RX3i and RSTi-EP

CPU Reference Manual

GFK-2222AD

April 2018

Page 2

Legal Information

Warnings, Cautions, and Notes as Used in this Publication GFL-002

Warning

Warning notices are used in this publication to emphasize that hazardous

voltages, currents, temperatures, or other conditions that could cause personal

injury exist in this equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is

not taken.

Note: Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met during installation, operation, and maintenance. The information is

supplied for informational purposes only, and GE makes no warranty as to the accuracy of the information

included herein. Changes, modifications, and/or improvements to equipment and specifications are made

periodically and these changes may or may not be reflected herein. It is understood that GE may make

changes, modifications, or improvements to the equipment referenced herein or to the document itself

at any time. This document is intended for trained personnel familiar with the GE products referenced

herein.

GE may have patents or pending patent applications covering subject matter in this document. The

furnishing of this document does not provide any license whatsoever to any of these patents.

GE PROVIDES THE FOLLOWING DOCUMENT AND THE INFORMATION INCLUDED THEREIN AS-IS AND

WITHOUT WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

* indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

©Copyright 2003-2018 General Electric Company.

All Rights Reserved

Page 3

Contact Information

If you purchased this product through an Authorized Channel Partner, please contact the seller directly.

General Contact Information

Online technical support and GlobalCare

www.geautomation.com/support

Additional information

www.geautomation.com

Solution Provider

solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please

contact us by telephone or email, or on the web at www.geautomation.com/support

Americas

Phone

1-800-433-2682

780-420-2010 (if toll free 800-option is unavailable)

Email

digitalsupport@ge.com

Primary language of support

English

Europe, Middle East, & Africa

Phone

+800-1-433-2682

+ 420-296-183-331 (if toll free 800-option is unavailable or

if dialing from a mobile telephone)

Email

digitalsupport.emea@ge.com

Primary languages of support

English, French, German, Italian, Spanish

Asia

Phone

+86-400-820-8208

+86-21-3877-7006 (India, Indonesia & Pakistan)

Email

digitalsupport.apac@ge.com

Primary languages of support

Chinese, English

Page 4

GFK-2222AD April 2018 i

Table of Contents

RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

Table of Contents ....................................................................................................................................... i

Table of Figures ........................................................................................................................................ vi

Chapter 1 Introduction .................................................................................................................... 1

1.1 Revisions in this Manual ....................................................................................................... 2

1.2 PACSystems Control System Overview ............................................................................. 5

1.2.1 Programming and Configuration .................................................................................................................................... 5

1.2.2 Process Systems .................................................................................................................................................................... 5

1.2.3 PACSystems CPU Models ................................................................................................................................................... 6

1.3 RX3i Overview ....................................................................................................................... 8

1.4 RX7i Overview .....................................................................................................................11

1.5 RSTi-EP Overview ................................................................................................................12

1.6 Migrating Series 90 Applications to PACSystems ..........................................................13

1.7 Documentation ....................................................................................................................14

Chapter 2 CPU Features & Specifications ...................................................................................17

2.1 Common CPU Features .......................................................................................................18

2.1.1 Features Shared by All PACSystems CPU Models ............................................................................................... 18

2.1.2 Features Shared by Certain PACSystems CPU Models..................................................................................... 19

2.1.3 Firmware Storage in Flash Memory ........................................................................................................................... 20

2.1.4 Operation, Protection, and Module Status ............................................................................................................. 20

2.1.5 Ethernet Global Data ........................................................................................................................................................ 20

2.1.6 Embedded PROFINET Controller ................................................................................................................................. 21

2.1.7 OPC UA..................................................................................................................................................................................... 22

2.1.8 Removable Data Storage Devices (RDSDs) ............................................................................................................. 23

2.1.9 CPU Over-Temperature Monitoring and Behavior .............................................................................................. 28

2.2 RX3i CPU Features and Specifications .............................................................................29

2.2.1 CPE400 ..................................................................................................................................................................................... 35

2.2.2 CPE330 ..................................................................................................................................................................................... 61

2.2.3 CPE302, CPE305 and CPE310 ....................................................................................................................................... 70

2.2.4 CPU315 and CPU320/CRU320 ...................................................................................................................................... 79

2.2.5 CPU310 .................................................................................................................................................................................... 82

Page 5

Contents

ii PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

2.3 RX7i CPU Features and Specifications ............................................................................. 84

2.3.1 CPE030/CRE030 and CPE040/CRE040...................................................................................................................... 89

2.3.2 CPE010, CPE020 and CRE020 ....................................................................................................................................... 91

2.3.3 RX7i Embedded Ethernet Interface ............................................................................................................................ 93

2.4 RSTi-EP CPU Features and Specifications ....................................................................... 98

2.4.1 CPE100/CPE115 ................................................................................................................................................................ 101

Chapter 3 CPU Configuration ..................................................................................................... 109

3.1 Configuring the CPU ......................................................................................................... 110

3.2 Configuration Parameters ............................................................................................... 111

3.2.1 Settings Parameters ....................................................................................................................................................... 111

3.2.2 Modbus TCP Address Map ........................................................................................................................................... 114

3.2.3 SNTP ....................................................................................................................................................................................... 115

3.2.4 Time ........................................................................................................................................................................................ 116

3.2.5 Scan Parameters .............................................................................................................................................................. 117

3.2.6 Memory Parameters ....................................................................................................................................................... 120

3.2.7 Fault Parameters .............................................................................................................................................................. 123

3.2.8 Redundancy Parameters (Redundancy CPUs Only) ......................................................................................... 125

3.2.9 Transfer List ........................................................................................................................................................................ 125

3.2.10 COM1 and COM2 Parameters .................................................................................................................................... 126

3.2.11 Scan Sets Parameters .................................................................................................................................................... 130

3.2.12 Power Consumption Parameters ............................................................................................................................. 130

3.2.13 Access Control ................................................................................................................................................................... 131

3.2.14 OPC UA Parameters ........................................................................................................................................................ 132

3.3 Storing (Downloading) Hardware Configuration ......................................................... 133

3.4 Configuring the Embedded Ethernet Interface ............................................................ 134

3.4.1 Establishing Initial Ethernet Communications .................................................................................................. 135

3.4.2 Setting a Temporary IP Address ................................................................................................................................ 137

Chapter 4 CPU Operation ............................................................................................................ 139

4.1 CPU Sweep ......................................................................................................................... 140

4.1.1 Parts of the CPU Sweep ................................................................................................................................................ 141

4.1.2 CPU Sweep Modes ........................................................................................................................................................... 144

4.2 Program Scheduling Modes ............................................................................................. 146

4.3 Window Modes ................................................................................................................. 147

4.4 Data Coherency in Communications Windows ............................................................ 148

4.5 Run/Stop Operations ....................................................................................................... 149

4.5.1 CPU STOP Modes .............................................................................................................................................................. 150

4.5.2 STOP-to-RUN Mode Transition .................................................................................................................................. 152

Page 6

Contents

GFK-2222AD April 2018 iii

4.5.3 RUN/STOP Switch Operation ...................................................................................................................................... 152

4.6 Flash Memory Operation ................................................................................................. 153

4.7 Logic/Configuration Source and CPU Operating Mode at Power-Up ........................ 154

4.7.1 CPU Mode when Memory Not Preserved/Power-up Source is Flash ....................................................... 155

4.7.2 CPU Mode when Memory Preserved ....................................................................................................................... 156

4.8 Clocks and Timers ............................................................................................................ 157

4.8.1 Elapsed Time Clock .......................................................................................................................................................... 157

4.8.2 Time-of-Day Clock ............................................................................................................................................................ 158

4.8.3 Watchdog Timer ................................................................................................................................................................ 159

4.9 System Security ................................................................................................................ 161

4.9.1 Passwords and Privilege Levels - Legacy Mode .................................................................................................. 162

4.9.2 OEM Protection – Legacy Mode ................................................................................................................................. 164

4.9.3 Enhanced Security for Passwords and OEM Protection ................................................................................. 165

4.9.4 Legacy/Enhanced Security Comparison................................................................................................................. 166

4.10 PACSystems I/O System .................................................................................................. 167

4.10.1 I/O Configuration ............................................................................................................................................................... 168

4.10.2 Genius I/O ............................................................................................................................................................................. 170

4.10.3 I/O System Diagnostic Data Collection ................................................................................................................... 172

4.11 Power-Up and Power-Down Sequences ....................................................................... 174

4.11.1 Power-Up Sequence ........................................................................................................................................................ 174

4.11.2 Power-Down Sequence.................................................................................................................................................. 175

4.11.3 Power Cycle Operation with an Energy Pack....................................................................................................... 176

4.11.4 Retention of Data Memory Across Power Failure ............................................................................................. 179

Chapter 5 Communications ........................................................................................................ 181

5.1 Ethernet Communications .............................................................................................. 182

5.1.1 Embedded Ethernet Interface .................................................................................................................................... 182

5.1.2 Ethernet Interface Modules ......................................................................................................................................... 187

5.2 Serial Communications ................................................................................................... 188

5.2.1 Serial Port Communications Capabilities .............................................................................................................. 188

5.2.2 Configurable STOP Mode Protocols ......................................................................................................................... 190

5.2.3 Serial Port Pin Assignments ......................................................................................................................................... 191

5.2.4 Serial Port Electrical Isolation ..................................................................................................................................... 195

5.2.5 Serial Cable Lengths and Shielding .......................................................................................................................... 196

5.2.6 Serial Port Baud Rates .................................................................................................................................................... 197

5.3 Series 90-70 Communications and Intelligent Option Modules ............................... 198

5.3.1 Communications Coprocessor Module (CMM) ................................................................................................... 198

5.3.2 Programmable Coprocessor Module (PCM) ......................................................................................................... 199

5.3.3 DLAN/DLAN+ (Drives Local Area Network) Interface ...................................................................................... 200

Page 7

Contents

iv PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

Chapter 6 Serial I/O, SNP & RTU Protocols ............................................................................... 201

6.1 Configuring Serial Ports Using COMMREQ Function 65520 ....................................... 202

6.1.1 COMMREQ Function Example .................................................................................................................................... 202

6.1.2 Timing .................................................................................................................................................................................... 202

6.1.3 Sending Another COMMREQ to the Same Port ................................................................................................. 202

6.1.4 Invalid Port Configuration Combinations ............................................................................................................. 203

6.1.5 COMMREQ Command Block Parameter Values ................................................................................................ 204

6.1.6 Example COMMREQ Command Blocks for Serial Port Setup function ................................................... 205

6.2 Serial I/O Protocol ............................................................................................................. 208

6.2.1 Calling Serial I/O COMMREQs from the CPU Sweep ........................................................................................ 208

6.2.2 Compatibility ...................................................................................................................................................................... 208

6.2.3 Status Word for Serial I/O COMMREQs ................................................................................................................. 208

6.2.4 Serial I/O COMMREQ Commands ............................................................................................................................. 210

6.2.5 Overlapping COMMREQs .............................................................................................................................................. 211

6.2.6 Initialize Port Function (4300) .................................................................................................................................... 212

6.2.7 Set Up Input Buffer Function (4301) ....................................................................................................................... 213

6.2.8 Flush Input Buffer Function (4302) .......................................................................................................................... 214

6.2.9 Read Port Status Function (4303) ............................................................................................................................ 215

6.2.10 Write Port Control Function (4304) ......................................................................................................................... 217

6.2.11 Cancel COMMREQ Function (4399) ......................................................................................................................... 218

6.2.12 Autodial Function (4400) .............................................................................................................................................. 219

6.2.13 Write Bytes Function (4401) ....................................................................................................................................... 221

6.2.14 Read Bytes Function (4402) ........................................................................................................................................ 222

6.2.15 Read String Function (4403) ....................................................................................................................................... 224

6.3 RTU Slave Protocol ........................................................................................................... 226

6.3.1 Message Format ............................................................................................................................................................... 227

6.3.2 Cyclic Redundancy Check (CRC) ................................................................................................................................ 232

6.3.3 RTU Message Descriptions .......................................................................................................................................... 236

6.3.4 RTU Scratch Pad ............................................................................................................................................................... 252

6.3.5 Communication Errors .................................................................................................................................................. 253

6.3.6 RTU Slave/SNP Slave Operation with Programmer Attached ..................................................................... 256

6.4 SNP Slave Protocol ........................................................................................................... 257

6.4.1 Permanent Datagrams .................................................................................................................................................. 257

6.4.2 Communication Requests (COMMREQs) for SNP ............................................................................................. 257

Appendix A Performance Data ........................................................................................................... 259

A-1 Boolean Execution Times ............................................................................................................. 260

A-1.1 Boolean Execution Measurements (ms per 1000 Boolean executions) ................................................. 260

A-2 Instruction Timing ......................................................................................................................... 261

A-2.1 Overview .............................................................................................................................................................................. 261

A-2.2 PLC Version Information ............................................................................................................................................... 262

Page 8

Contents

GFK-2222AD April 2018 v

A-2.3 RX3i & RSTi-EP Instruction Times ............................................................................................................................. 263

A-2.4 RX7i Instruction Times ................................................................................................................................................... 264

A-3 Overhead Sweep Impact Times .................................................................................................. 275

A-3.1 Base Sweep Times ............................................................................................................................................................ 276

A-3.2 What the Sweep Impact Tables Contain ............................................................................................................... 278

A-3.3 Programmer Sweep Impact Times ........................................................................................................................... 279

A-3.4 I/O Scan and I/O Fault Sweep Impact ...................................................................................................................... 280

A-3.5 Ethernet Global Data Sweep Impact ....................................................................................................................... 287

A-3.6 EGD Sweep Impact for Embedded Ethernet Interface on RX3i & RSTi-EP CPE Models .................. 290

A-3.7 Sweep Impact of Intelligent Option Modules ...................................................................................................... 294

A-3.8 I/O Interrupt Performance and Sweep Impact.................................................................................................... 297

A-3.9 Timed Interrupt Performance ..................................................................................................................................... 300

A-3.10 Example of Predicted Sweep Time Calculation ................................................................................................. 301

Appendix B User Memory Allocation ................................................................................................ 303

B-1 Items that Count Against User Memory .................................................................................... 304

B-2 User Program Memory Usage ...................................................................................................... 305

B-2.1 %L and %P Program Memory ...................................................................................................................................... 305

B-2.2 Program Logic and Overhead ...................................................................................................................................... 305

Page 9

Contents

vi PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

Table of Figures

Figure 1: Configuring an Embedded PROFINET Controller _____________________________________________ 21

Figure 2: CPE400 Front View and Features ________________________________________________________ 35

Figure 3: CPE400 Underside Ports & Connectors ____________________________________________________ 39

Figure 4: CPE400 Micro-SD & USB Pinouts _________________________________________________________ 41

Figure 5: Typical Field Agent Application __________________________________________________________ 45

Figure 6: Login to Predix _______________________________________________________________________ 46

Figure 7: Predix Change Password _______________________________________________________________ 47

Figure 8: Log Service Page _____________________________________________________________________ 47

Figure 9: Technician Console, Network Configuration page ___________________________________________ 48

Figure 10: Enter Proxy Server Address ____________________________________________________________ 49

Figure 11: Test Connection _____________________________________________________________________ 49

Figure 12: Technician Console, Time Sync Configuration ______________________________________________ 50

Figure 13: LAN3 Interconnects for Hot Standby Redundancy __________________________________________ 53

Figure 14: Display Port Connector _______________________________________________________________ 55

Figure 15: Location of RTC battery on CPE400 ______________________________________________________ 57

Figure 16: DIN-Rail Mount Bracket Assembly CPE400 _______________________________________________ 60

Figure 17: Panel-Mount Bracket Assembly CPE400 _________________________________________________ 60

Figure 18: CPE330 Front View & Features _________________________________________________________ 61

Figure 19: CPE330 RUN/STOP Switch and RDSD Switches _____________________________________________ 63

Figure 20: Location and Orientation of Real-Time Clock Battery in CPE330 _______________________________ 66

Figure 21: IC695CPE302/CPE305 Front View _______________________________________________________ 70

Figure 22: IC695CPE310 Front View ______________________________________________________________ 70

Figure 23: External Features of CPE302/CPE305 ____________________________________________________ 72

Figure 24: External Features of CPE310 ___________________________________________________________ 72

Figure 25: Accessing Real-Time Clock Battery (CPE302, CPE305 and CPE310) _____________________________ 75

Figure 26: Sample Tool for Coin Battery Extraction __________________________________________________ 76

Figure 27: IC695CPU320 Front View ______________________________________________________________ 79

Figure 28: IC695CPU310 Front View ______________________________________________________________ 82

Figure 29: CPE040 Front View ___________________________________________________________________ 89

Figure 30: CPE010 Front View ___________________________________________________________________ 91

Figure 31: CPE100/CPE115 Front, Top and Bottom Views and Features ________________________________ 101

Figure 32: CPE100/CPE115 Membrane Pushbutton and Module Status LEDs ____________________________ 103

Figure 33: State Diagram for CPE100/CPE115 Run/Stop Operation ____________________________________ 103

Figure 34: Typical Multi-Tier LAN Application (Star/Bus Topology) ____________________________________ 106

Figure 35: Typical Multi-Tier LAN Application (Ring Topology) ________________________________________ 106

Figure 36: PME Expansion of PACSystems Target __________________________________________________ 110

Figure 37: Downloading Hardware Config to CPU __________________________________________________ 133

Figure 38: Selecting Embedded Ethernet for Configuration __________________________________________ 134

Figure 39: Set Temporary IP Address ____________________________________________________________ 137

Figure 40: Major Phases of a Typical CPU Sweep __________________________________________________ 141

Figure 41: Typical Sweeps in Normal Sweep Mode _________________________________________________ 144

Figure 42: Typical Sweeps in Constant Sweep Mode ________________________________________________ 145

Figure 43: Typical Sweeps in Constant Window Mode ______________________________________________ 146

Figure 44: CPU Sweep in Stop-I/O Disabled and Stop-I/O Enabled Modes _______________________________ 150

Figure 45: CPE330 Overlapping Local IP Subnet Example ____________________________________________ 183

Figure 46: Expected Response Path _____________________________________________________________ 184

Figure 47: Actual Response Path _______________________________________________________________ 184

Figure 48: COM1 Port CPE400 _________________________________________________________________ 192

Figure 49: RTU Message Transactions ___________________________________________________________ 227

Page 10

Contents

GFK-2222AD April 2018 vii

Figure 50: RTU Read Output Table Example _______________________________________________________ 230

Figure 51: CRC Register Operation ______________________________________________________________ 232

Figure 52: RTU Read Output Table Message Format ________________________________________________ 236

Figure 53: RTU Read Input Table Message Format _________________________________________________ 237

Figure 54: RTU Read Registers Message Format ___________________________________________________ 238

Figure 55: RTU Read Analog Inputs Message Format _______________________________________________ 239

Figure 56: RTU Force Single Output Message Format _______________________________________________ 240

Figure 57: RTU Preset Single Register Message Format _____________________________________________ 241

Figure 58: RTU Read Exception Status Message Format _____________________________________________ 242

Figure 59: RTU Loopback/Maintenance Message Format ____________________________________________ 243

Figure 60: RTU Force Multiple Outputs Message Format ____________________________________________ 245

Figure 61: RTU Preset Multiple Registers Message Format ___________________________________________ 246

Figure 62: RTU Report Device Type Message Format _______________________________________________ 247

Figure 63: RTU Read Scratch Pad Memory Message Format _________________________________________ 251

Figure 64: RTU Error Response Format ___________________________________________________________ 253

Figure 65: Interrupt Execution Considerations _____________________________________________________ 298

Page 11

Page 12

GFK-2222AD April 2018 1

Chapter 1 Introduction

This manual contains general information about PACSystems CPU operation and product features.

Chapter 1 provides a general introduction to the PACSystems family of products, including new

features, product overviews, and a list of related documentation.

CPU Features & Specifications are provided in Chapter 2.

Installation procedures for the different platforms are described in their respective manuals as given

below:

1. PACSystems RX7i Installation Manual, GFK-2223.

2. PACSystems RX3i System Manual, GFK-2314.

3. RSTi-EP User Manual, GFK-2958.

CPU Programming is covered in PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference

Manual, GFK-2950. It provides an overview of program structure and describes the various languages

which may be used, their syntax and operation, and provides examples.

CPU Configuration is described in Chapter 3. Configuration using the proprietary Proficy Machine Edition

(PME) programming and configuration software package determines characteristics of CPU, System and

module operation. It also establishes the program references used by each module in the system. For

details on configuration of the embedded RX7i Ethernet interface as well as the rack-based RX7i and

RX3i Ethernet Interface modules, refer to PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet

Communications User Manual, GFK-2224.

CPU Operation is described in Chapter 4.

Ethernet Communications and Serial Communications are described in Chapter 5.

Serial I/O, SNP & RTU Protocols are described in Chapter 6.

Performance Data, including Instruction Timing, is provided in Appendix A.

User Memory Allocation is described in Appendix B.

Page 13

Chapter 1. Introduction

2 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

1.1 Revisions in this Manual

Note: A given feature may not be implemented on all PACSystems CPUs. To determine whether a

feature is available on a given CPU model and firmware version, please refer to the Important

Product Information (IPI) document provided for the CPU version that you are using.

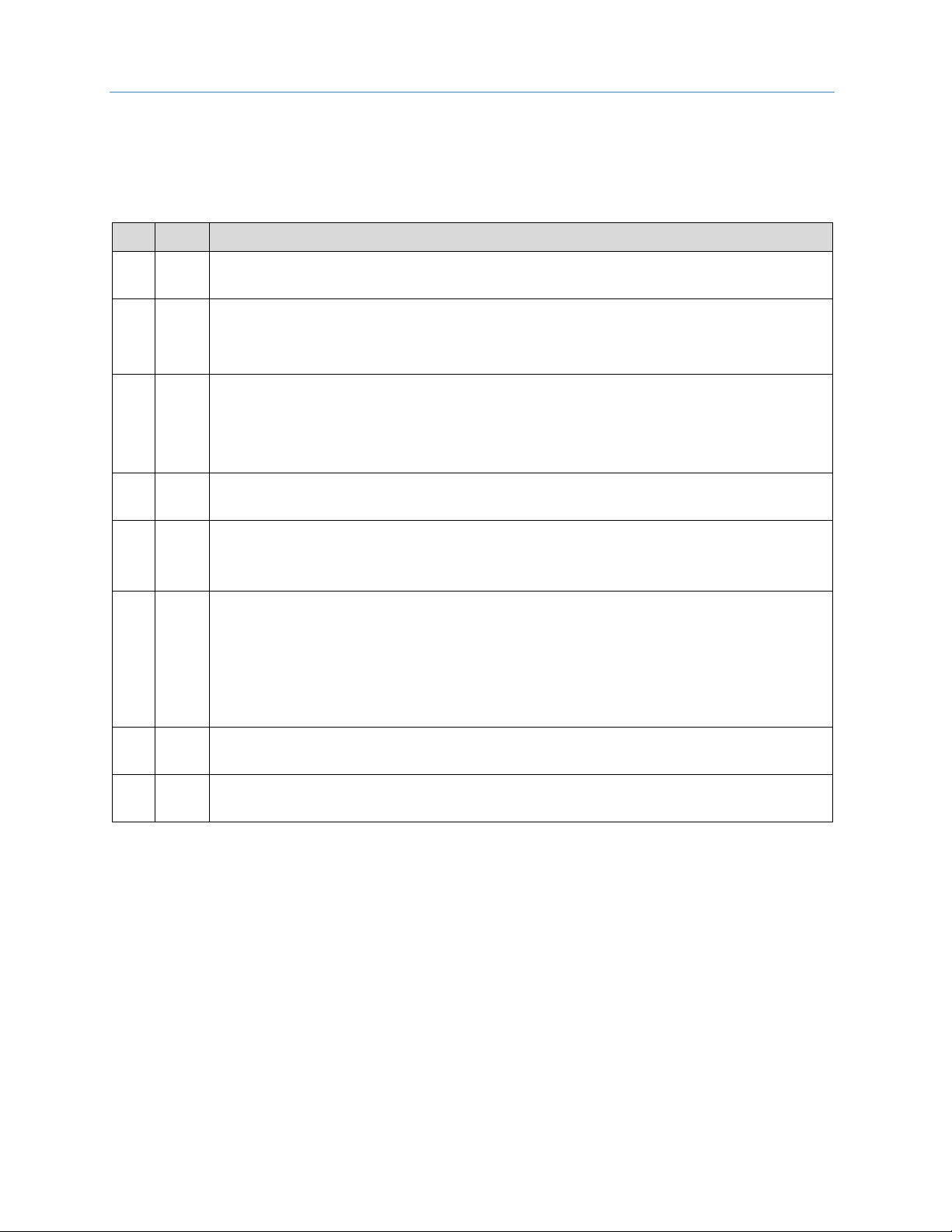

Rev

Date

Description

AD

Apr2018

▪ Added CPE115 module

AC

Feb2018

▪ Updated throughout for addition of CPE302 (initial firmware version 9.40).

▪ CPE400 Serial IO feature added

▪ New Authorized Firmware Update feature noted (part of RX3i firmware version 9.40).

AB

Oct2017

▪ Added Redundancy features for CPE400

▪ Updated Field Agent information for CPE400.

▪ Updated Section 2.2 for new features of CPE400.

▪ Added Section 2.1.9 on CPU Over-Temperature behavior.

AA

Sep2017

▪ Addition of support for Media Redundancy Protocol (MRP) on CPE100.

Z

May2017

▪ Addition of RSTi-EP EPSCPE100 (new product) and updated other relevant sections.

▪ Addition of Simple Network Time Protocol (SNTP), Coordinated Universal Time (UTC), and

Daylight Savings Time (DST) features forCPE305, CPE310, CPE330, and CPE400.

Y

Dec2016

▪ Added section on CPE400 and incorporated into CPU comparison table (section 2.2). This

section also introduces Field Agent and documents how to set up Embedded Field Agent for

the CPE400 (section 2.2.1.8).

▪ Added section 2.1.6, Embedded PROFINET Controller.

▪ Update of Energy Pack Section 4.11.3 to include ACC403 and compatibility matrix.

▪ Added compatibility mode information for CPE330 with CPU320 & CRU320

X

Feb2016

▪ Corrected Ethernet Indicators CPE305 & CPE310 table.

W

Aug2015

▪ Addition of support for Ethernet Global Data (Class 1) on CPE330

Page 14

Chapter 1. Introduction

GFK-2222AD April 2018 3

Rev

Date

Description

V

Jun2015

▪ Addition of RX3i CPE330 (new product) and related Ethernet considerations.

▪ Update of Energy Pack Section 4.11.3 to include ACC402 and compatibility matrix.

▪ Addition of HART

®

Pass Through feature (see page 10).

▪ Addition of CPU Comparison Charts (Section 2.2 and Section 2.3).

▪ Update of Communications Section (Chapter 5). Added

▪ RSTi-EP CPE100/CPE115 : RS232, RS485 Signals

▪ Serial Port Electrical Isolation.

▪ Removed original Chapters 5-11 (chapters dealing with CPU programming) and Chapter 14

(Diagnostics). These are now in PACSystems RX7i and RX3i CPU Programmer’s Reference

Manual, GFK-2950 (Chapters 2-8 and Chapter 9 respectively).

U

Nov2014

▪ New Section, A-3.6 for EGD Sweep Impact for RX3i CPE302/CPE305/CPE310 and RSTi-EP

CPE100/CPE115 Embedded Ethernet Interface.

T

Oct2014

▪ Support for OPC UA using embedded Ethernet port in CPE305/CPE310 with CPU firmware

8.20.

▪ Support for Ethernet Global Data (EGD Class 1) using embedded Ethernet port in

CPE305/CPE310 with CPU firmware 8.30 Sweep impact of EGD on Embedded Ethernet

interface. Direct replacement for S90-30 IC693CPU374.

▪ New communications capabilities provided by:

o IC695PNS001 – PROFINET Scanner Module

o IC695GCG001 – Genius Communications Gateway via PROFINET

o IC695EDS001 – Ethernet based DNP3 Outstation

RS-232 Signals

RS-485 Pins

Signals

TX Y

TX+

RX Z

TX-

GND A

RX+

RTS B

RX-

CTS

Page 15

Chapter 1. Introduction

4 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

Rev

Date

Description

S

July2013

▪ Support for Modbus/TCP Server, SRTP channels and Modbus/TCP client channels on RX3i

CPE305/CPE310 embedded Ethernet interface – Chapter 2 & Chapter 5

▪ Support for Access Control List – Chapter 3

▪ Modbus TCP/IP mapping for CPE305/CPE310 – Chapter 30

▪ Enhanced Security Passwords and OEM Protection – Chapter 4

▪ Serial I/O protocol enhancements (Data Set Ready, Ring Indicator, and Data Carrier Detect)

– Chapter 6

▪ Diagnostics for PROFINET alarms and PROFINET network faults, including #PNIO_ALARM,

SA0030 – refer to PACSystems RX7i and RX3i CPU Programmer’s Reference Manual,

GFK-2950 Chapter 3 & Chapter 9.

▪ Instruction executions times measured for RX3i CPU320/CRU320 – Appendix A

▪ Sweep impact times for new modules: IC694MDL758, IC694APU300-CA and later,

IC695PNS001, IC694ALG442, IC694ALG220, IC694MDL645 and IC694MDL740–Appendix A

earlier

▪ Added instructions for replacing the RX3i CPE305/CPE310 real-time clock battery: Chapter

2.

▪ Corrected definitions of reverse acting and direct acting modes for PID functions: refer to

PACSystems RX7i and RX3i CPU Programmer’s Reference Manual, GFK-2950 Chapter 7.

▪ Expanded data for Boolean execution measurements – Appendix A

▪ Re-instated instruction times for RX7i CPE030/CRE030/CPE040 release 6.0 as published in

version Q of the manual (unintentionally omitted from version R) – Appendix A

▪ Compatibility information for volatile memory backup batteries has been consolidated in the

PACSystems Battery and Energy Pack Manual, GFK-2741 – throughout

Page 16

Chapter 1. Introduction

GFK-2222AD April 2018 5

1.2 PACSystems Control System Overview

The PACSystems controller environment combines performance, productivity, openness and flexibility.

The PACSystems control system integrates advanced technology with existing systems. The result is

seamless migration that protects your investment in I/O and application development.

1.2.1 Programming and Configuration

Proficy* Machine Edition programming software provides a universal engineering development

environment for all programming, configuration and diagnostics of PACSystems. A PACSystems CPU is

programmed and configured using the programming software to perform process and discrete

automation for various applications. The CPU communicates with I/O and smart option modules through

a rack-mounted backplane. It communicates with the programmer and/or HMI devices via the Ethernet

ports or via the serial ports COM1 and COM2 using Serial I/O, or Modbus RTU slave protocols.

1.2.2 Process Systems

PACSystems CPUs with firmware version 5.0 and later support Proficy Process Systems (PPS). PPS is a

complete, tightly integrated, seamless process control system using PACSystems, Proficy HMI/SCADA,

and Proficy Production Management Software to provide control, optimization, and performance

management to manage and monitor batch or continuous manufacturing. It delivers the tools required

to design, implement, document, and maintain an automated process. For information about purchasing

PPS software, refer to the Support website.

Page 17

Chapter 1. Introduction

6 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

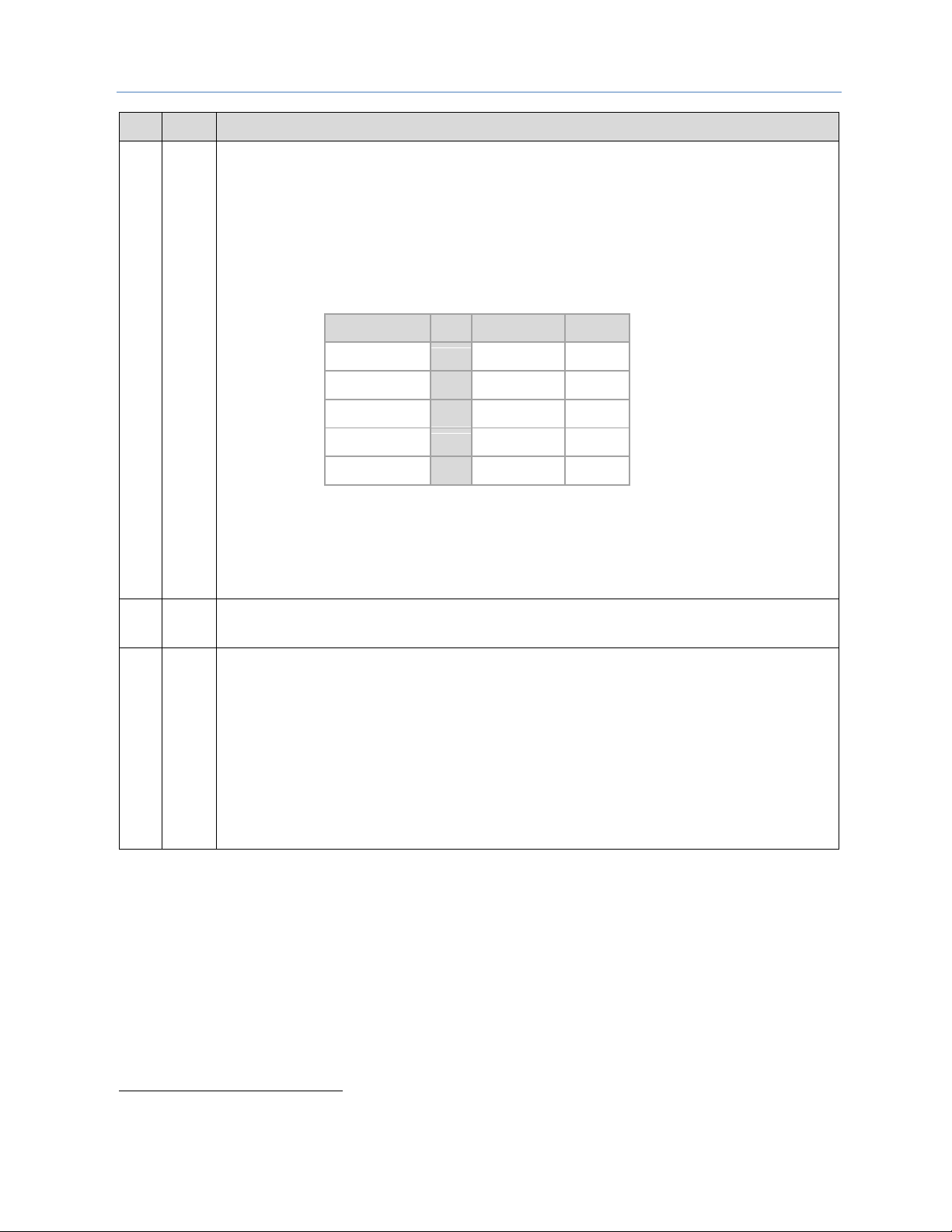

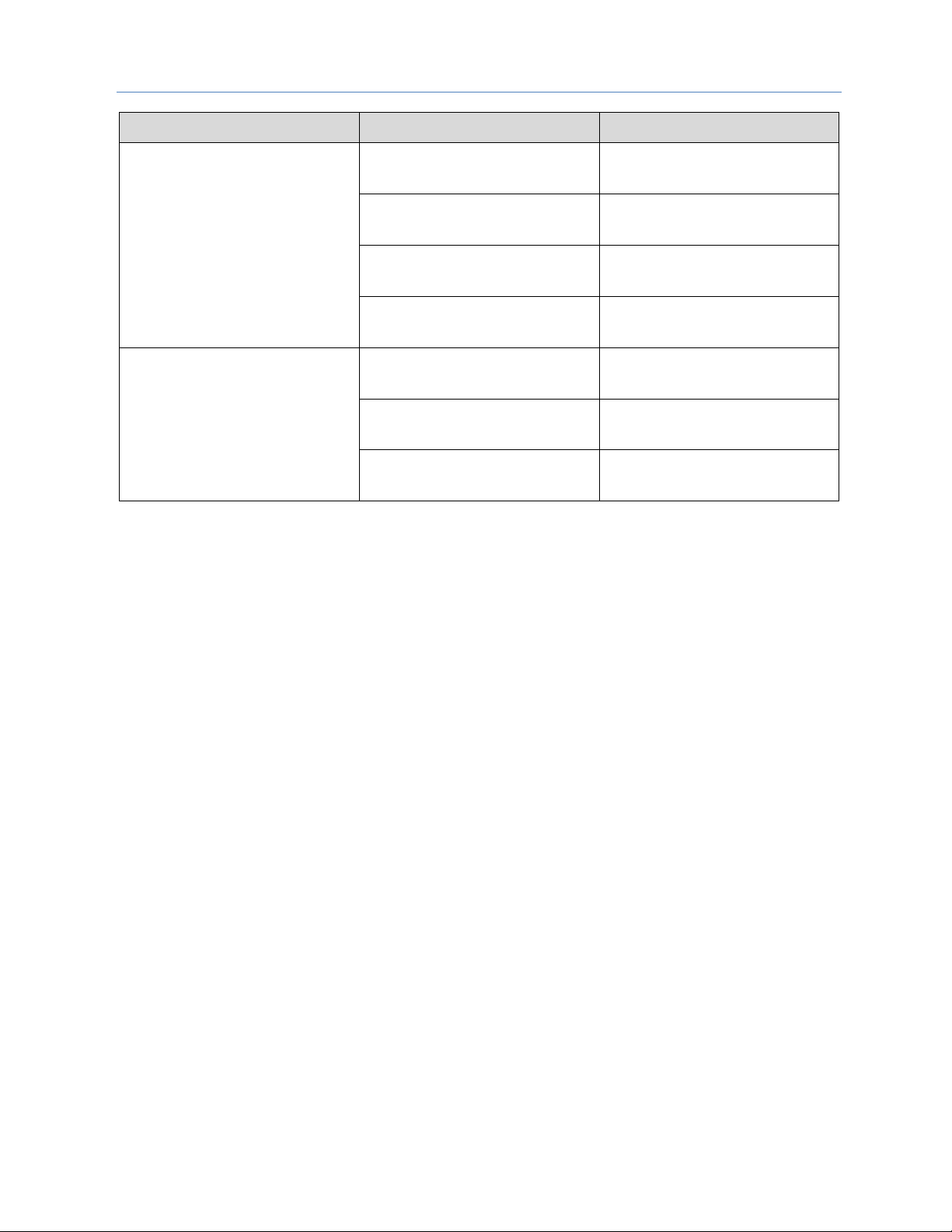

1.2.3 PACSystems CPU Models

Family

Catalog Number

Description

RSTi-EP Standalone CPUs

EPSCPE100

1 GHz AM335x CPU, 1 MB user

memory.

EPSCPE115

1 GHz AM335x CPU, 1.5 MB

user memory.

RX3i Standalone CPUs with

embedded Ethernet Interface

IC695CPE400

1.2 GHz AMD G-Series Quad

Core, 64 MB user memory with

Field Agent

RX3i CPUs with embedded

Ethernet Interface1

IC695CPE302

1.1GHz Atom CPU, 2 MB user

memory

IC695CPE305

1.1GHz Atom CPU, 5 MB user

memory

IC695CPE310

1.1GHz Atom CPU, 10 MB user

memory

IC695CPE330

1 GHz AMD G-Series Dual Core,

64 MB user memory

RX3i CPUs

IC695CPU310

300MHz Celeron CPU, 10 MB

user memory

IC695CPU315

1 GHz Celeron-M CPU, 20 MB

user memory

IC695CPU320

1 GHz Celeron-M CPU, 64 MB

user memory

IC695NIU001+

versions –AAAA & later

1.1 GHz Atom 510 NIU. For

information, refer to the

PACSystems RX3i Ethernet

Network Interface Unit User’s

Manual, GFK-2439

IC695NIU001

300MHz Celeron NIU. For

information, refer to the

PACSystems RX3i Ethernet

Network Interface Unit User’s

Manual, GFK-2439

RX3i Redundancy CPU

IC695CRU320

1 GHz Celeron-M CPU, 64 MB

user memory

1

The RX3i CPE302/CPE305/CPE310 embedded Ethernet interface provides a maximum of two programmer connections. It

does not support the full set of Ethernet interface features described in this manual. For a summary of RX3i embedded

Ethernet interface features, refer to PACSystems RX7i & RX3i TCP/IP Ethernet Communications User Manual, GFK-2224K or

later.

Page 18

Chapter 1. Introduction

GFK-2222AD April 2018 7

Family

Catalog Number

Description

RX7i CPUs with embedded

Ethernet Interface

IC698CPE010

300MHz, Celeron CPU, 10MB

user memory

IC698CPE020

700MHz, Pentium CPU, 10 MB

user memory

IC698CPE030

600MHz, Pentium-M CPU,

64MB user memory

IC698CPE040

1800MHz, Pentium-M CPU,

64MB user memory

RX7i Redundancy CPUs with

embedded Ethernet Interface

IC698CRE020

700MHz, Pentium CPU, 10 MB

user memory

IC698CRE030

600MHz, Pentium-M CPU,

64MB user memory

IC698CRE040

1800MHz, Pentium-M CPU,

64MB user memory

Page 19

Chapter 1. Introduction

8 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

1.3 RX3i Overview

The RX3i control system hardware consists of an RX3i universal backplane and up to seven Series 90-30

expansion or remote racks. The CPU can be in any slot in the universal backplane except the last slot,

which is reserved for the serial bus transmitter, IC695LRE001.

The RX3i supports user defined Function Blocks (LD logic only) and Structured Text programming.

The RX3i universal backplane uses a dual bus that provides both:

▪ High-speed PCI for fast throughput of new advanced I/O.

▪ Serial backplane for easy migration of existing Series 90-30 I/O

The RX3i universal backplane and Series 90-30 expansion/remote racks support the Series 90-30 Genius

Bus Controller and Motion Control modules, and most Series 90-30/RX3i discrete and analog I/O with

catalog prefixes IC693 and IC694. RX3i modules with catalog prefixes IC695, including the Ethernet and

other communications modules can only be installed in the universal backplane. See the PACSystems

RX3i System Manual, GFK-2314 for a list of supported modules.

RX3i supports hot standby (HSB) CPU redundancy, which allows a critical application or process to

continue operating if a failure occurs in any single component. A CPU redundancy system consists of an

active unit that actively controls the process and a backup unit that is synchronized with the active unit

and can take over the process if it becomes necessary. Each unit must have a redundancy CPU,

(IC695CRU320). The redundancy communication path is provided by IC695RMX128 Redundancy Memory

Xchange (RMX) modules set up as redundancy links. For details on the operation of PACSystems

redundancy systems, refer to the PACSystems Hot Standby CPU Redundancy User Manual, GFK-2308.

RX3i communications features include:

▪ Open communications support includes Ethernet, PROFIBUS, PROFINET, Modbus TCP, Ethernet

Global Data (EGD), DNP3 and serial protocols.

▪ On the CPE400 one of its embedded Ethernet ports is set up as a dedicated Field Agent port.

▪ The CPE302, CPE305

9

, CPE310, and CPE330 and CPE400 CPUs provide an embedded Ethernet

interface which is used to connect to the programmer (Proficy Machine Edition).

▪ Effective with RX3i CPE310/CPE305 firmware version 7.30, or CPE330 firmware version 8.50, the

embedded Ethernet port on the CPU provides support for Service Request Transfer Protocol (SRTP)

channels and for Modbus TCP. This feature is available on all firmware versions of CPE400.

▪ Effective with CPE310/CPE305 firmware version 8.20, or CPE330 firmware version 8.45, the CPE

embedded Ethernet port supports OPC UA Server. This feature is available on all firmware versions

of CPE400. Refer to PACSystems RX7i & RX3i TCP/IP Ethernet Communications User Manual, GFK2224 version M or higher (Chapter 10).

▪ Effective with RX3i firmware version 8.30

2

, the CPE310/CPE305 CPUs also support Ethernet Global

Data (EGD). Prior to that firmware version, EGD was only available in the RX3i via the RX3i Ethernet

Interface Module (IC695ETM001). With this upgrade, these CPUs are positioned as a direct

replacement for S90-30 IC693CPU374.

▪ Effective with RX3i firmware version 8.60

3

, the CPE330 supports Ethernet Global Data (EGD) Class 1.

This feature is available on all firmware versions of CPE4004 and CPE3029.

2

Proficy Machine Edition Release 8.50 SIM 7 is required for EGD Class 1 on Embedded Ethernet interface of CPE305/CPE310.

3

Proficy Machine Edition Release 8.60 SIM 5 is required for EGD Class 1 on both LAN1 and LAN2 of CPE330. This PME version

also supports Advanced Configuration Parameters for EGD on CPE330. Alternately, PME Release 8.60 (not SIM 5) supports

EGD on CPE330 LAN1 only, and does not support Advanced Configuration Parameters for EGD.

4

Proficy Machine Edition Release 9.00 SIM 8 or later is required for native configuration support of the CPE400.

Page 20

Chapter 1. Introduction

GFK-2222AD April 2018 9

▪ The rack-based IC695ETM001 Ethernet Interface has dual RJ45 ports connected through an auto-

sensing switch. This eliminates the need for rack-to-rack switches or hubs. The ETM001 supports

upload, download and online monitoring, and provides 32 SRTP channels with a maximum of 48

simultaneous SRTP server connections. It also supports Modbus TCP. For details on Ethernet

Interface capabilities, refer to PACSystems RX7i & RX3i TCP/IP Ethernet Communications User

Manual, GFK-2224.

▪ PROFIBUS communications via the PROFIBUS Master module, IC695PBM300. For details, refer to the

PACSystems RX3i PROFIBUS Modules User’s Manual, GFK-2301.

▪ PROFINET communications via any supported PROFINET Controller and any supported PROFINET

Scanner.

o Supported PROFINET Controllers include the embedded PROFINET Controller function

offered by IC695CPE400 and IC695CPE330, and the rack-mounted PROFINET Controller

module IC695PNC001.

o Supported PROFINET Scanners include the RX3i PROFINET Scanner module IC695PNS001

5

,

the RX3i IC695CEP001, and the VersaMax PROFINET Scanner modules IC200PNS001 &

IC200PNS002.

For details, refer to the PACSystems RX3i PROFINET IO-Controller Manual, GFK-2571F or later and

PACSystems RX3i PROFINET Scanner Manual, GFK-2737F or later.

▪ Effective with the release of IC695CEP001 and IC694CEE001, the RX3i may be configured to control

a remote drop consisting of one or two I/O modules. The RX3i interface to the remote drop is

managed by the PROFINET Controller, IC695PNC001. Refer to PACSystems RX3i CEP

▪ Effective with the release of IC695GCG001, the RX3i may be equipped to control a Genius Bus. The

RX3i interface to the Genius Gateway is managed by the PROFINET Controller, IC695PNC001. Refer

to PACSystems RX3i Genius Communications Gateway User Manual, GFK-2892.

▪ Effective with the release of IC695EDS001, the RX3i may be configured as a DNP3 Outstation. Refer

to PACSystems RX3i DNP3 Outstation Module IC695EDS001User’s Manual, GFK-2911.

▪ Effective with the release of IC695EIS001, the RX3i may be configured to act as an IEC 104 Server.

Refer to PACSystems RX3i IEC 104 Server Module IC695EIS001 User’s Manual, GFK-2949.

▪ PROFINET Scanner User Manual, GFK-2883.

5

IC695PNS001 firmware version 2.40 added support for a number of I/O modules not previously supported, as documented in

PACSystems RX3i PROFINET Scanner Important Product Information, GFK-2738L.

Page 21

Chapter 1. Introduction

10 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

▪ HART Pass Through allows an RX3i CPU to communicate HART asset management data between

HART-capable I/O modules and PC-based asset management tools. This entails usage of PC-based

applications, RX3i Analog modules with HART functionality and (optionally) supporting PROFINET

products. HART Pass Through operation is described in the PACSystems HART Pass Through User

Manual, GFK-2929.

The following RX3i CPUs support HART Pass Through: IC695CPE305, IC695CPE310, IC695CPU315,

IC695CPU320, IC695CRU320, IC695CPE330

6,7

(firmware version 8.50 or later). All versions of

IC695CPE3029 support this feature.

The following RX3i analog modules support HART:

IC695ALG626

IC695ALG628

IC695ALG728

If used for HART Pass Through, the supporting RX3i PROFINET Controller and PROFINET Scanner

must also contain HART-compatible firmware:

IC695PNC001-AK firmware version 2.20

IC695PNS001-ABAH firmware version 2.308

IC695CEP001-AAAD firmware version 2.30.

▪ IC695CMM002 and IC695CMM004 expand the serial communications capability of the RX3i system.

Refer to PACSystems RX3i Serial Communications Modules User’s Manual, GFK-2460.

▪ CPE310, CPU310, CPU315, CPU/CRU320 and NIU001 provide two serial ports, one RS-232 and one

RS-485.

▪ CPE400 (firmware version 9.40), CPE302 and CPE305 each provides one RS-232 serial port.

▪ CPE330 provides no serial ports.

▪ Effective with CPE302 firmware version 9.40

9

, CPE305/CPE310/CPE40010 firmware version 9.20, or

CPE330 firmware version 9.21, the CPE embedded Ethernet interface supports Simple Network Time

Protocol (SNTP) Client, Coordinated Universal Time (UTC), and Daylight Savings Time (DST). Refer to

PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual, GFK-2224

version Q or higher.

▪ Effective with RX3i firmware version 9.40, the Authorized Firmware Update functionality is available.

Users may now authorize access to firmware updates using a custom password. Details are included

in the revised firmware update instructions.

6

When used to support HART Pass Through, CPE330 must do so via a PNC001 and cannot employ its embedded PROFINET

feature for this purpose.

7

IC695CPE330 firmware version 8.95 added support for the Remote Get HART Device Information COMMREQ.

8

IC695PNS001 firmware version 2.41 added support for the Remote Get HART Device Information COMMREQ not previously

supported, as documented in PACSystems RX3i PROFINET Scanner Important Product Information, GFK-2738L. The syntax

and usage for this COMMREQ are described in the PACSystems RX3i System Manual, GFK-2314M or later.

9

Proficy Machine Edition Release 9.50 SIM 7 or later is required for CPE302 configuration.

10

Proficy Machine Edition Release 9.00 SIM 10, or 9.50 SIM 2, or later is required for SNTP Client, UTC, and DST support.

Page 22

Chapter 1. Introduction

GFK-2222AD April 2018 11

1.4 RX7i Overview

The RX7i control system hardware consists of an RX7i rack and up to seven Series 90-70 expansion racks.

The CPU resides in slot 1 of the main rack. RX7i racks use a VME64 backplane that provides up to four

times the bandwidth of existing VME based systems, including the current Series 90-70 systems for

faster I/O throughput. The VME64 base supports all standard VME modules including Series 90-70 I/O

and VMIC modules.

Expansion racks support Series 90-70 discrete and analog I/O, the Genius Bus Controller, and the HighSpeed Counter. The CPU provides an embedded auto-sensing 10/100 Mbps half/full duplex Ethernet

interface.

RX7i supports hot standby (HSB) CPU redundancy, which allows a critical application or process to

continue operating if a failure occurs in any single component. A CPU redundancy system consists of an

active unit that actively controls the process and a backup unit that is synchronized with the active unit

and can take over the process if it becomes necessary. Each unit must have a redundancy CPU,

(IC698CRE020, CRE030 or CRE040). The redundancy communication path is provided by IC698RMX016

Redundancy Memory Xchange (RMX) modules set up as redundancy links. For details on the operation of

PACSystems redundancy systems, refer to the PACSystems Hot Standby CPU Redundancy User Manual,

GFK-2308.

Note: Extended operation with dissimilar CPU types is not allowed. During normal operation, the

primary and secondary units in an HSB redundancy system must have the same CPU model

type.

The primary and secondary units of an HSB redundancy system can have dissimilar model types for a

limited time, for the purpose of system upgrade only. Fail wait times for the higher performance CPU in

a dissimilar redundant pair may need to be increased to allow synchronization.

RX7i communications features include:

▪ Open communications support includes Ethernet, Genius, and serial protocols.

▪ A built-in 10/100mb Ethernet interface that has dual RJ45 ports connected through an auto-

sensing switch for upload, download and online monitoring. This eliminates the need for rackto-rack switches or hubs. The CPU Ethernet Interface provides basic remote control system

monitoring from a web browser and allows a combined total of up to 16 web server and FTP

connections. For details on Ethernet Interface capabilities, refer to PACSystems RX7i & RX3i

TCP/IP Ethernet Communications User Manual, GFK-2224.

▪ Two serial ports, one RS-232 and one RS-485.

▪ An RS-232 isolated Ethernet Station Manager serial port.

Page 23

Chapter 1. Introduction

12 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

1.5 RSTi-EP Overview

RSTi-EP CPUs make it possible to incorporate the entire PACSystems programming suite in stand-alone

applications or as auxiliary control in larger process applications that use RX3i. They allow the User to

leverage the power and flexibility of PACSystems in smaller applications.

At a high level, CPE100/CPE115 supports real-time application status, remote diagnostics and:

• Dual LAN interfaces with four Ethernet ports

• Built-in RS-232 serial port

• Support for a range of communications protocols, including PROFINET

• CPE100/115 supports 1 MB /1.5MB of non-volatile user memory.

All in just 1.5” (38.1mm) of DIN rail space.

CPE100/CPE115 supports two independent 10/100 Ethernet LANs. LAN1 has only one port and is

dedicated to highspeed Ethernet and whereas LAN2 is comprised of three switched ports (labelled as 2,

3 & 4) configurable as either a second embedded Ethernet controller or an embedded PROFINET

controller. All four ports are located on the front panel of the CPU.

The Ethernet controller Interface of CPE100/CPE115 provides Transmission Control Protocol and

Internet Protocol (TCP/IP) communications with other control systems, host computers running the Host

Communications Toolkit or programmer software, and computers running the TCP/IP version of the

programming software. These communications use the Service Request Transport Protocol (SRTP),

Modbus TCP, and Ethernet Global Data (EGD) protocols over a four-layer TCP/IP (Internet) stack.

The RSTi-EP CPE100/CPE115 also embeds an industry standard PROFINET controller that allows it to

connect to any type of PROFINET I/O solutions either from GE or any third party. It offers enhanced

productivity, flexibility and performance advantages for virtually any type of control application in a range

of industries. PROFINET supports a variety of I/O without compromising system performance and can

operate in high-noise environments.

The RSTi-EP CPE100/CPE115 is secure by design, incorporating technologies such as Trusted Platform

Modules (currently disabled) and verified boot. Centralized configuration allows encrypted firmware

updates to be executed from a secure central location.

Page 24

Chapter 1. Introduction

GFK-2222AD April 2018 13

1.6 Migrating Series 90 Applications to PACSystems

The PACSystems control system provides cost-effective expansion of existing systems. Support for

existing Series 90 modules, expansion racks and remote racks protects your hardware investment. You

can upgrade on your timetable without disturbing panel wiring.

▪ The RX3i supports most Series 90-30 modules, expansion racks, and remote racks. For a list of

supported I/O, Communications, Motion, and Intelligent modules, see the PACSystems RX3i System

Manual, GFK-2314.

▪ The RX7i supports most existing Series 90-70 modules, expansion racks and Genius networks. For a

list of supported I/O, Communications, and Intelligent modules, see the PACSystems RX7i

Installation Manual, GFK-2223.

▪ Conversion of Series 90-70 and Series 90-30 programs preserves existing development effort.

▪ Conversion of VersaPro and Logicmaster applications to Machine Edition allows smooth transition

to PACSystems.

Page 25

Chapter 1. Introduction

14 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

1.7 Documentation

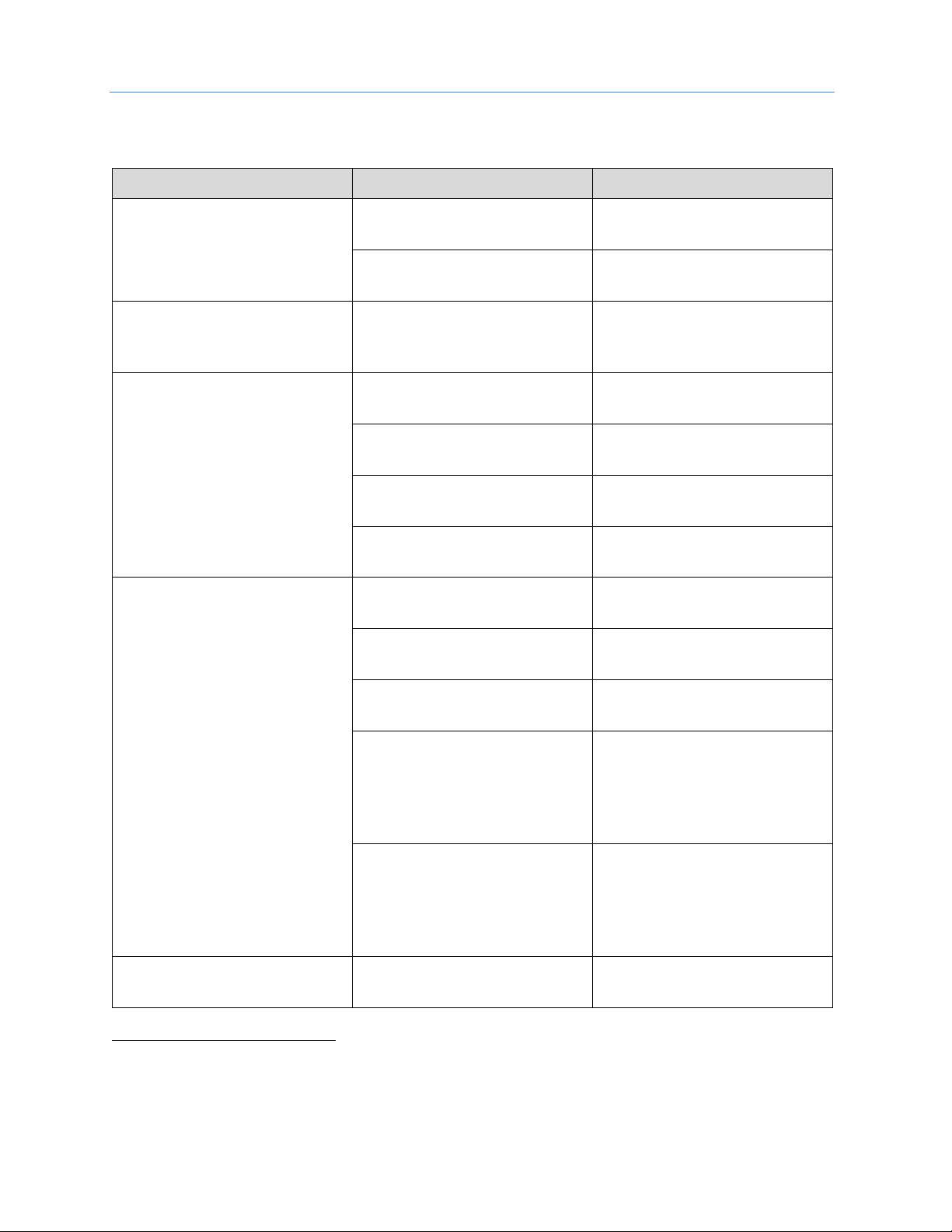

PACSystems Manuals

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference Manual

GFK-2950

PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual

GFK-2224

PACSystems TCP/IP Ethernet Communications Station Manager User Manual

GFK-2225

C Programmer’s Toolkit for PACSystems

GFK-2259

PACSystems Memory Xchange Modules User’s Manual

GFK-2300

PACSystems Hot Standby CPU Redundancy User Manual

GFK-2308

PACSystems Battery and Energy Pack Manual

GFK-2741

Proficy Machine Edition Logic Developer Getting Started

GFK-1918

Proficy Process Systems Getting Started Guide

GFK-2487

PACSystems RXi, RX3i, and RX7i Controller Secure Deployment Guide

GFK-2830

RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i IC695CPE400 1.2GHz 64MB Rackless CPU w/Field Agent QSG

GFK-3002

PACSystems RX3i IC695ACC403 Rackless Energy Pack Quick Start Guide

GFK-3000

PACSystems RX3i IC695CPE330 1GHz 64MB CPU w/Ethernet Quick Start Guide

GFK-2941

PACSystems RX3i IC695ACC402 Energy Pack Quick Start Guide

GFK-2939

PACSystems RX3i IC695ACC400 Energy Pack Data Sheet

GFK-2724

DSM324i Motion Controller for PACSystems RX3i and Series 90-30 User’s Manual

GFK-2347

PACSystems RX3i PROFIBUS Modules User’s Manual

GFK-2301

PACSystems RX3i Max-On Hot Standby Redundancy User’s Manual

GFK-2409

PACSystems RX3i Ethernet Network Interface Unit User’s Manual

GFK-2439

PACMotion Multi-Axis Motion Controller User’s Manual

GFK-2448

PACSystems RX3i & RSTi-EP PROFINET IO-Controller Manual

GFK-2571

PACSystems RX3i PROFINET Scanner Manual

GFK-2737

PACSystems RX3i CEP PROFINET Scanner User Manual

GFK-2883

PACSystems RX3i Serial Communications Modules User’s Manual

GFK-2460

PACSystems RX3i Genius Communications Gateway User Manual

GFK-2892

PACSystems RX3i DNP3 Outstation Module IC695EDS001User’s Manual

GFK-2911

PACSystems RX3i IEC 104 Server Module IC695EIS001User’s Manual

GFK-2949

PACSystems HART Pass Through User Manual

GFK-2929

Field Agent Manuals

Field Agent User’s Guide

GFK-2993

Page 26

Chapter 1. Introduction

GFK-2222AD April 2018 15

RX7i Manuals

PACSystems RX7i Installation Manual

GFK-2223

PACSystems RX7i User's Guide to Integration of VME Modules

GFK-2235

Series 90-70 Genius Bus Controller User’s Manual

GFK-2017

RSTi-EP Manuals

RSTi-EP User’s Manual

GFK-2958

Series 90 Manuals

Series 90 Programmable Coprocessor Module and Support Software

GFK-0255

Series 90 PLC Serial Communications User’s Manual

GFK-0582

Series 90-70 DLAN/DLAN+ Interface Module User’s Manual

GFK-0729

Series 90-30 Genius Bus Controller User’s Manual

GFK-1034

Distributed I/O Systems Manuals

Genius I/O System User’s Manual

GEK-90486-1

Genius I/O Analog and Discrete Blocks User’s Manual

GEK-90486-2

In addition to these manuals, datasheets and product update documents describe individual modules

and product revisions. The most recent PACSystems documentation is available on GE’s Automation and

Controls support website www.geautomation.com.

Page 27

Page 28

GFK-2222AD April 2018 17

Chapter 2 CPU Features & Specifications

This chapter provides details on the hardware features of the PACSystems CPUs and their specifications.

▪ Common CPU Features

▪ RX3i CPU Features and Specifications

▪ RX7i CPU Features and Specifications

▪ RSTi-EP CPU Features and Specifications

Page 29

Chapter 2. CPU Features & Specifications

18 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

2.1 Common CPU Features

2.1.1 Features Shared by All PACSystems CPU Models

▪ Programming in Ladder Diagram, Function Block Diagram, Structured Text and C.

▪ Floating point (real) data functions.

▪ Configurable data and program memory.

▪ Non-volatile built-in flash memory for user data (program, configuration, register data, and

symbolic variable) storage. Use of this flash memory is optional.

▪ Configurable RUN/STOP Mode switch.

▪ Embedded serial and/or Ethernet communications (refer to comparison charts in RX3i CPU

Features and Specifications, RX7i CPU Features and Specifications and RSTi-EP CPU Features and

Specifications).

▪ Up to 512 program blocks. Maximum size for a block is 128KB.

▪ Auto Located Symbolic Variables, which allows you to create a variable without specifying a

reference address.

▪ Bulk memory area accessed via reference table %W. The upper limit of this memory area can be

configured to the maximum available user RAM.

▪ Larger reference table sizes, compared to Series 90* CPUs: 32Kbits for discrete %I and %Q and

up to 32K words each for analog %AI and %AQ.

▪ Online Editing mode that allows you to easily test modifications to a running program. (For

details on using this feature, refer to the programming software online help and Proficy Logic

Developer Getting Started, GFK-1918.)

▪ Bit in word referencing that allows you to specify individual bits in a WORD reference in retentive

memory as inputs and outputs of Boolean expressions, function blocks, and calls that accept bit

parameters.

▪ In-system upgradeable firmware for CPU

▪ Indirect mechanism for upgrading firmware in backplane modules via the CPU.

Page 30

Chapter 2. CPU Features & Specifications

GFK-2222AD April 2018 19

2.1.2 Features Shared by Certain PACSystems CPU Models

▪ Rx3i CPE302, CPE305, CPE310, CPE330 and CPE400 offer battery-less retention of user memory

when each is connected to its compatible Energy Pack.

▪ RSTi-EP CPE100/CPE115 offers battery-less retention of user memory with the support of

internal super capacitors.

▪ All prior RX3i models have battery-backed RAM for user data (program, configuration, register

data, and symbolic variable) storage and clocks.

▪ Rx3i CPE302, CPE305, CPE310, CPE330 and CPE400 and RSTi-EP CPE100/CPE115 models have

coin battery backup for their real-time clocks (elapsed time clock).

▪ RX3i CPE302, CPE305, CPE310 and CPE330 models have the ability to upload and download data

from a Removable Data Storage Device (RDSD). This feature is not yet available on RX3i CPE400

and RSTi-EP CPE100/CPE115.

▪ RX3i CPE302, CPE305, CPE310, CPE330 , CPE400 and RSTi-EP CPE100/CPE115 models support

OPC-UA..

▪ RX3i CPE302, CPE305, CPE310, CPE330, CPE400 and RSTi-EP CPE100/CPE115 models support

Ethernet Global Data Class 1.

▪ RX3i CPE302, CPE305, CPE310, CPE330, and CPE400 models support Simple Network Time

Protocol (SNTP) Client, Coordinated Universal Time (UTC), and Daylight Savings Time (DST).

▪ RX3i CPE330 and CPE400 and RSTi-EP CPE100/CPE115 permit LAN2 to be configured as an

Embedded PROFINET Controller. Refer to Section 2.1.6, Embedded PROFINET Controller.

▪ RX3i CPE302, CPE305, CPE310, CPE330, and CPE400 models monitor the internal temperature

of the CPU hardware. CPU behavior under these conditions is documented in Section 2.1.9.

For a comparative review of CPU features, refer to RX3i CPU Features and Specifications, RX7i CPU

Features and Specifications and RSTi-EP CPU Features and Specifications. Note that each specific feature

may require a corresponding firmware version of the CPU firmware.

Page 31

Chapter 2. CPU Features & Specifications

20 PACSystems* RX7i, RX3i and RSTi-EP CPU Reference Manual GFK-2222AD

2.1.3 Firmware Storage in Flash Memory

The CPU uses non-volatile flash memory for storing the operating system firmware. This allows firmware

to be updated without disassembling the module or replacing EPROMs. The operating system firmware

is updated by connecting to the CPU with a PC compatible computer and running the software included

with the firmware upgrade kit.

Each upgrade kit contains specific instructions for performing the upgrade. Depending on the CPU Model

and firmware version, the method employed is one of the following:

a) Use a serial port and the WinLoader utility (applies to CPU310, CPU315 & CPU320 models and

to CPE305/CPE310 models containing firmware versions prior to v7.30)

b) Use a USB port and memory stick for CPE302 (with firmware version 9.40 and later) or for

CPE305/CPE310 models (with firmware version 7.30 and later)

c) Use an Ethernet port and a Web-based mechanism for RXi CPUs, RX3i CPE330, CPE400 and RSTi-

EP CPE100/CPE115.

2.1.4 Operation, Protection, and Module Status

Operation of the CPU can be controlled by the three-position RUN/STOP Switch or remotely by an

attached programmer and programming software. Program and configuration data can be locked

through software passwords. The status of the CPU is indicated by the CPU LEDs on the front of the

module. For details, see Indicators for each PACSystems family.

Note: The RESET pushbutton is provided to support future features and has no effect on CPU

operation in the current version

2.1.5 Ethernet Global Data

Notes: Effective with RX3i firmware version 8.302, the CPE310/CPE305 CPUs also support EGD Class 1.

Prior to that firmware version, EGD was only available in the RX3i via the RX3i Ethernet Interface

Module (ETM001).

Effective with RX3i firmware version 8.603, CPE330 also supports EGD Class 1. This feature is

available on all firmware versions of RX3i CPE400, CPE302 and RSTi-EP CPE100/CPE115.

Each PACSystems CPU supports up to 255 simultaneous EGD pages across all Ethernet interfaces in the

Controller. EGD pages must be configured in the programming software and stored into the CPU. The

EGD configuration can also be loaded from the CPU into the programming software. Both produced and

consumed pages can be configured. PACSystems CPUs support the use of only part of a consumed EGD

page, and EGD page production and consumption to the broadcast IP address of the local subnet.

The PACSystems CPU supports 2ms EGD page production and timeout resolution. EGD pages can be

configured for a production period of 0, indicating the page is to be produced every output scan. The

minimum period for these “as fast as possible” pages is 2 ms. Refer to the Section, A-3.6 for EGD Sweep

Impact for RX3i CPE302/CPE305/CPE310 and RSTi-EP CPE100/CPE115 Embedded Ethernet Interface.

During EGD configuration, PACSystems Ethernet interfaces are identified by their Rack/Slot location.

Page 32

Chapter 2. CPU Features & Specifications

GFK-2222AD April 2018 21

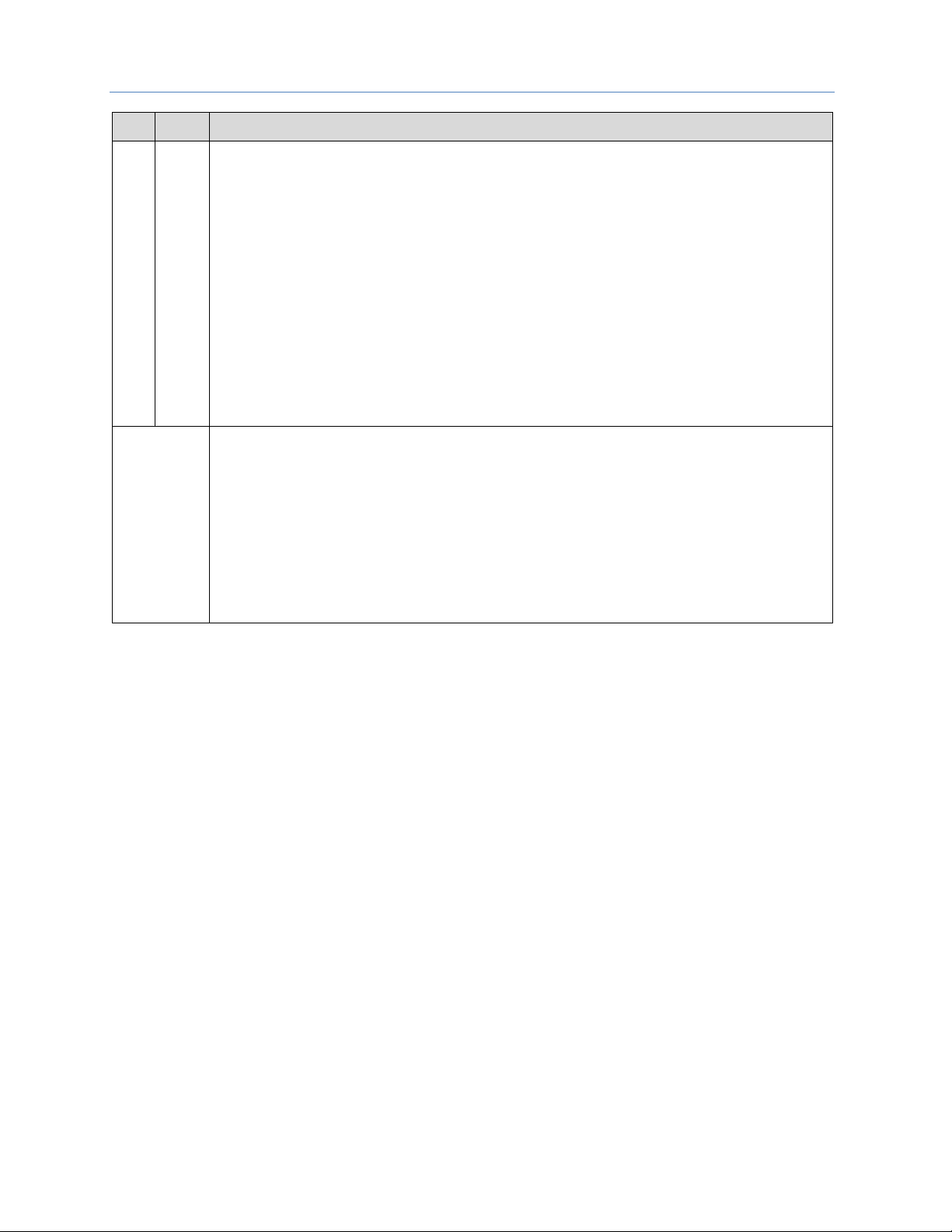

2.1.6 Embedded PROFINET Controller

The following CPUs support a feature that permits an Ethernet LAN to be configured for use as a

PROFINET Controller:

• RX3i CPE400

11

• Rx3i CPE330

12

• RSTi-EP CPE100/CPE115

13

If the Embedded PROFINET Controller feature is to be configured, it must be configured on LAN2 for the

CPUs listed above. In the case of RX3i CPE400 and RSTi-EP CPE100/CPE115, which are Standalone CPU’s,

this will be its only PROFINET Controller. In the case of CPE330, the Embedded PROFINET Controller can

co-exist with any rack-mounted PROFINET Controllers (IC695PNC001) present in its CPU rack.

To enable the Embedded PROFINET Controller in a project in Proficy Machine Edition14, select the RX3i

CPE400 (or CPE330) or RSTi-EP CPE100/CPE115 target in the PME Navigator (Figure 1) and open the

Hardware Configuration. On the Settings tab, change the designated LAN Mode of the selected port to

PROFINET. The PROFINET Controller node description then displays that a PROFINET node exists on the

selected LAN.

For further details, refer to the PACSystems RX3i & RSTi-EP PROFINET IO-Controller User Manual,

GFK-2571G or later.

Figure 1: Configuring an Embedded PROFINET Controller

A PROFINET configuration may be transferred between a PROFINET Controller module (IC695PNC001)

and the target Embedded PROFINET IO-Controller using the cut / copy / paste or equivalent drag and

drop functions in Proficy Machine Edition.

Note: If the PME Project has PROFINET redundant devices, you must record any unique Secondary

Target information and disable Redundancy before cut / copy / paste functions on PROFINET

Controller modules will work. Then, re-enable Redundancy, mirror, and restore your unique

Secondary Target information.

11

CPE400 firmware version 9.00 or later is required for the embedded PROFINET Controller feature.

12

CPE330 firmware version 8.90 or later is required for the embedded PROFINET Controller feature.

13