Page 1

GFK-2892B

Programmable Control Products

PACSystems* RX3i

Genius* Communications Gateway

User Manual

August

2016

Public

Page 2

Legal Information

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met during installation, operation, and maintenance. The information is supplied for

informational purposes only, and GE makes no warranty as to the accuracy of the information included herein.

Changes, modifications, and/or improvements to equipment and specifications are made periodically and these

changes may or may not be reflected herein. It is understood that GE may make changes, modifications, or

improvements to the equipment referenced herein or to the document itself at any time. This document is

intended for trained personnel familiar with the GE products referenced herein.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing of

this document does not provide any license whatsoever to any of these patents.

Public - This document is approved for public disclosure.

GE provides the following document and the information included therein as is and without warranty of

any kind, expressed or implied, including but not limited to any implied statutory warranty of

merchantability or fitness for particular purpose.

For further assistance or technical information, contact the nearest GE Sales or Service Office, or an authorized

GE Sales Representative.

Revised: Aug 2016

Issued: June 2014

© 2014 - 2016 by General Electric Company.

* indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

Public

Page 3

Safety Symbol Legend

Warning

Caution

Attention

Indicates a procedure or condition that, if not strictly observed, could result in

personal injury or death.

Indicates a procedure or condition that, if not strictly observed, could result in

damage to or destruction of equipment.

Indicates a procedure or condition that should be strictly followed to improve these

applications.

Public

Page 4

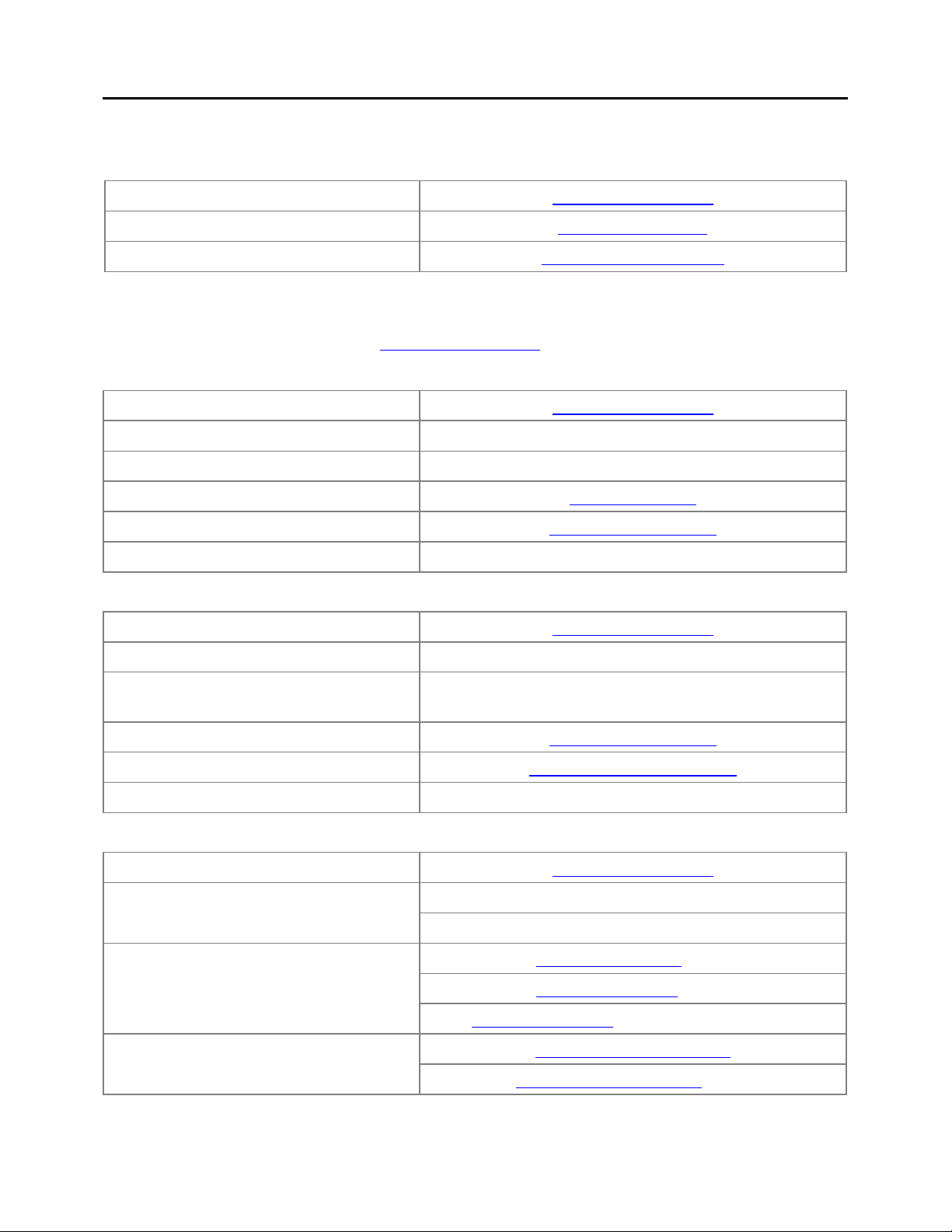

Contact Information

If you purchased this product through an Authorized Channel Partner, contact the seller directly.

General Contact Information

Online technical support and GlobalCare http://support.ge-ip.com

Additional information http://www.ge-ip.com/

Solution Provider solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, contact us by

telephone or email, or on the web at http://support.ge-ip.com

Americas

Online Technical Support http://support.ge-ip.com

Phone 1-800-433-2682

International Americas Direct Dial 1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email support.ip@ge.com

Customer Care Email customercare.ip@ge.com

Primary language of support English

Europe, the Middle East, and Africa

Online Technical Support http://support.ge-ip.com

Phone

EMEA Direct Dial

Technical Support Email support.emea.ip@ge.com

Customer Care Email customercare.emea.ip@ge.com

Primary languages of support English, French, German, Italian, Czech, Spanish

+

420-23-901-5850 (if toll free 800 option is unavailable or

dialing from a mobile telephone)

+

800-1-433-2682

Asia Pacific

Online Technical Support http://support.ge-ip.com

+

Phone

Technical Support Email

+

86-21-3217-4826 (India, Indonesia, and Pakistan)

support.in.ip@ge.com (remaining Asia customers)

86-400-820-8208

support.cn.ip@ge.com

support.jp.ip@ge.com (Japan)

(China)

Customer Care Email

Public

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

Page 5

Contents

Contents

INTRODUCTION ..................................................................................................................7 CHAPTER 1

1.1 DESCRIPTION ..................................................................................................................................................... 7

1.2 PRODUCT OVERVIEW ........................................................................................................................................... 8

1.3 SPECIFICATIONS .................................................................................................................................................. 9

1.4 CONTROLS AND INDICATORS ............................................................................................................................... 10

1.4.1 Mounting ............................................................................................................................................. 11

1.5 PROFINET OPERATION OVERVIEW ..................................................................................................................... 12

1.6 SYSTEM LIMITS ................................................................................................................................................. 15

1.7 OPERATIONAL DIFFERENCES VS. GENIUS BUS CONTROLLER ....................................................................................... 16

1.8 SUPPORTED GENIUS DEVICES .............................................................................................................................. 17

I

NSTALLATION ................................................................................................................. 19 CHAPTER 2

2.1 PRE-INSTALLATION CHECK .................................................................................................................................. 19

2.2 INSTALLATION LOCATION .................................................................................................................................... 19

2.3 INSTALLATION IN HAZARDOUS AREAS ................................................................................................................... 20

2.3.1 ATEX Zone 2 ......................................................................................................................................... 20

2.3.2 ATEX Marking ...................................................................................................................................... 20

2.4 MODULE INSTALLATION ..................................................................................................................................... 21

2.4.1 Install SD Card ...................................................................................................................................... 21

2.4.2 Mounting the GCG001 ......................................................................................................................... 21

2.4.3 GCG001 Module Removal .................................................................................................................... 23

2.4.4 Light-Emitting Diode (LED) Indications ................................................................................................ 24

2.4.5 Fault Notifications ................................................................................................................................ 25

2.5 CONFIGURING THE GENIUS GATEWAY TO OPERATE WITH THE RX3I CPU .................................................................... 25

2.6 ETHERNET PORT CONNECTIONS ........................................................................................................................... 25

2.6.1 RJ-45 Port Connections ........................................................................................................................ 26

2.7 FIRMWARE UPDATES ......................................................................................................................................... 26

2.8 SPARE PARTS ................................................................................................................................................... 27

GFK-2892B Public i

C

ONFIGURATION .............................................................................................................. 29 CHAPTER 3

3.1 CONFIGURATION TOOLS ..................................................................................................................................... 29

3.2 CONFIGURATION OVERVIEW ............................................................................................................................... 29

S

YSTEM OPERATION ......................................................................................................... 33 CHAPTER 4

4.1 SYSTEM OVERVIEW ........................................................................................................................................... 33

4.1.1 Communications .................................................................................................................................. 33

4.1.2 Redundancy ......................................................................................................................................... 34

4.1.3 I/O Scans .............................................................................................................................................. 35

4.1.4 Alarms .................................................................................................................................................. 36

D

IAGNOSTICS .................................................................................................................. 37 CHAPTER 5

5.1 STATUS DATA .................................................................................................................................................. 37

5.1.1 PROFINET Status Data ......................................................................................................................... 37

5.1.2 Genius Status Data .............................................................................................................................. 38

5.2 MODULE LED INDICATORS ................................................................................................................................. 38

5.3 POWER-UP ..................................................................................................................................................... 39

5.3.1 Problems during Power-up .................................................................................................................. 39

5.3.2 Transitioning from Firmware Update Mode to Operational Mode ..................................................... 39

Page 6

Contents

5.4 MODULE FAULTS IN THE RX3I I/O FAULT TABLES ................................................................................................... 40

5.4.1 Fault Types Reported to the RX3i Controller I/O Fault Table ............................................................... 41

5.4.2 Clearing the RX3i Fault Tables ............................................................................................................. 43

COMMREQ/D

ATA_INIT_COMM PROGRAMMING ................................................................. 45 CHAPTER 6

6.1 COMMREQS AND PASSWORDS ......................................................................................................................... 45

6.2 PROGRAMMING FOR A COMMREQ COMMUNICATION REQUEST ............................................................................. 45

6.3 COMMREQ COMMAND BLOCK FORMAT ............................................................................................................ 46

6.3.1 COMMREQ Command Block Contents ................................................................................................. 47

6.3.2 COMMREQ Commands Supported by the Genius Gateway (GCG001) ................................................ 48

6.3.3 COMMREQ Command Block Quick Reference ..................................................................................... 49

6.3.4 Mechanics of the COMMREQ Instruction ............................................................................................ 50

6.3.5 Comparison: COMMREQ vs Data_Init_Comm ..................................................................................... 55

6.3.6 COMMREQ Differences: Genius Bus Controllers and Genius Gateway ................................................ 56

6.4 COMMREQ DESCRIPTIONS AND FORMATS .......................................................................................................... 57

6.4.1 COMMREQ #1: Pulse Test Command ................................................................................................... 57

6.4.2 COMMREQ #2: Read Configuration Command .................................................................................... 58

6.4.3 COMMREQ #3: Write Configuration Command ................................................................................... 59

6.4.4 COMMREQ #4: Read Diagnostics Command ....................................................................................... 60

6.4.5 COMMREQ #5: Clear Circuit Fault Command ...................................................................................... 61

6.4.6 COMMREQ #6: Clear All Circuit Faults Command ................................................................................ 61

6.4.7 COMMREQ #7: Assign Monitor Command .......................................................................................... 62

6.4.8 COMMREQ #11: Read Device Command ............................................................................................. 63

6.4.9 COMMREQ #12: Write Device Command ............................................................................................ 64

6.4.10 COMMREQ #19: Read Identification .................................................................................................... 65

6.4.11 COMMREQ #20: Write Point Command .............................................................................................. 66

6.4.12 COMMREQ #21: Read Block I/O Command ......................................................................................... 67

6.4.13 COMMREQ #22: Read Map Command ................................................................................................ 71

6.4.14 COMMREQ #23: Write Map Command ............................................................................................... 72

6.4.15 COMMREQ #24: Read Data Command ................................................................................................ 73

6.4.16 COMMREQ #25: Write Data Command ............................................................................................... 73

ii Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 7

Contents

Figures

Figure 1: PLC System Using Genius Gateway GCG001 ............................................................................................................................. 7

Figure 2: GCG001 Module ......................................................................................................................................................................................... 8

Figure 3: Genius Gateway GCG001 Front Panel View ............................................................................................................................ 10

Figure 4: GCG001 Panel Mount Diagram ...................................................................................................................................................... 11

Figure 5: Application Relationships between PROFINET Controller & Genius Gateway ....................................................... 12

Figure 6: Real-Time & Non-Real-Time Data Types ................................................................................................................................... 13

Figure 7: PLC - GCG - Genius Scan Cycles .................................................................................................................................................... 14

Figure 8: Rear View of GCG001 .......................................................................................................................................................................... 21

Figure 9: GCG001 Power Connector ................................................................................................................................................................ 21

Figure 10: Daisy Chain Genius Bus Wiring.................................................................................................................................................... 22

Figure 11: Genius Bus Wiring for Bus Termination .................................................................................................................................. 22

Figure 12: PROFINET Discovery Screenshot ................................................................................................................................................ 23

Figure 13: GCG001 Firmware Upgrade ZIP File UnZIPped to SD Card .......................................................................................... 26

Figure 14: Hardware Configuration Expanded Tree ............................................................................................................................... 29

Figure 15: Change Module List for Genius Gateway GCG001 ............................................................................................................ 30

Figure 16: Populating the Genius IO Devices to be Controlled by the Genius Gateway ...................................................... 31

Figure 17: Populating Slots in S90-70 Rack Controlled by Remote I/O Scanner (BEM733) ................................................ 31

Figure 18: Genius Gateway Configuration Example ............................................................................................................................... 32

Figure 19: Genius Hot Standby Redundancy .............................................................................................................................................. 34

Figure 20: PROFINET Media Redundancy...................................................................................................................................................... 35

Figure 21: Gateway Status Data ........................................................................................................................................................................ 37

Figure 22: Genius Status Data ............................................................................................................................................................................ 38

Figure 23: Genius Discrete Block "No Load Present" Fault Display (Example) ........................................................................... 42

Figure 24: Genius Analog Block "Over Range" Fault Display (Example) ........................................................................................ 43

Figure 25: Ladder Logic to Clear Circuit Fault ............................................................................................................................................ 54

Figure 26: Data_Init_Comm to Clear Circuit Fault ................................................................................................................................... 55

GFK-2892B Public iii

Page 8

Contents

AR

PROFINET Application Relationship

CR

PROFINET Communication Relationship

DCP

PROFINET Discovery & Configuration Protocol

GCG

Genius Communications Gateway (specifically GCG001)

GENA

Genius Network Adaptor

GENI

Genius Network Interface

GNIU

Genius Network Interface Unit

GR7

Series 90-70 Remote I/O Scanner (IC697BEM733)

GSDML

General Station Description Markup Language

HHM

Genius Hand-Held Monitor

LAN

Local Area Network

LED

Light Emitting Diode

MRC

Ethernet Media Redundancy Client

MRM

Ethernet Media Redundancy Manager

MRP

Ethernet Media Redundancy Protocol

NRT

Non-Real-Time PROFINET Communication

PCIM

Personal Computer Interface Module

PME

Proficy Machine Edition

PNC

PROFINET Controller

PPV

PLC Protocol Variables

RT

Real-Time PROFINET Communication

SBA

Genius Serial Bus Address

SD

Secure Digital Card Slot

STP

Shielded Twisted Pair

UTP

Unshielded Twisted Pair

GEK-90486-1

Genius I/O System and Communications User's Manual

GEK-90486-2

Genius I/O Discrete and Analog Blocks User’s Manual

GFK–0579

Series 90-70 Remote I/O Scanner User’s Manual

GFK-1535

VersaMax System Genius Network Interface Unit User’s Manual

GFK-2222

PACSystems RX3i and RX7i CPU Reference Manual

GFK-2314

PACSystems RX3i System Manual

GFK-2571

PACSystems RX3i PROFINET IO-Controller Manual

GFK-2892

PACSystems RX3i Genius Communications Gateway Module User Manual

GFK-2900

PACSystems RX3i Genius Communications Gateway Module Important Product

Information

Acronyms and Abbreviations

Related Documents

User manuals, product updates and other information sources are available on the Support website,

http://www.ge-ip.com/support

4 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

, under Controllers and IO, RX3i Controllers.

Page 9

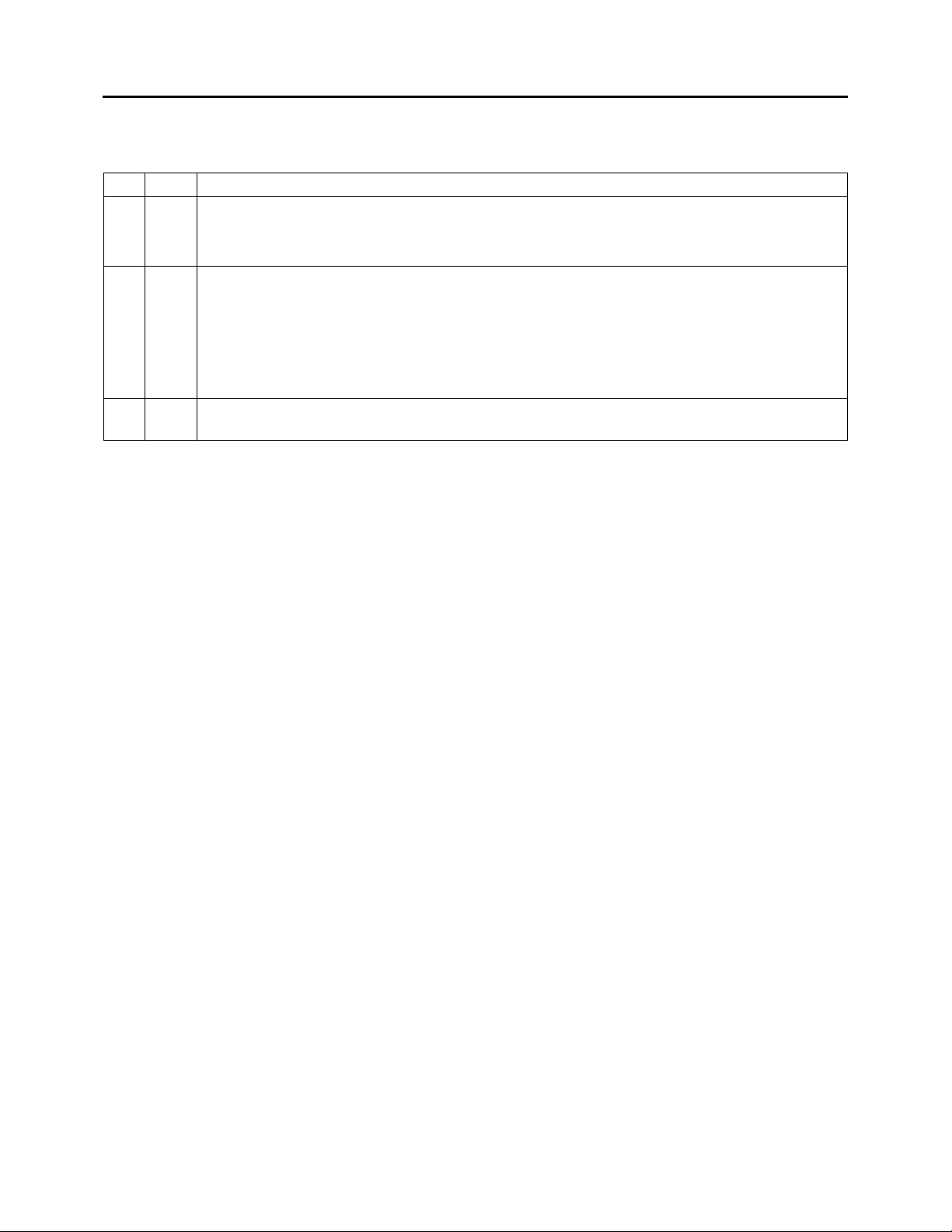

Contents

Rev

Date

Description

• Added support for VersaMax Genius Network Interface

• Behavior of GCG001 with respect to input references associated with a faulted block is

Jun

Document Updates

B

A

Aug

2016

Mar

2015

2014

• Added IC660BSS101 isolated I/O block

• Added additional Genius baud rates

described in Section 1.8, with workaround in Section 4.1.4.

• Correction to Figure 19: Genius Hot Standby Redundancy to indicate CPU type is CRU and

RMX modules are required.

• Clear All Faults can now be dispatched to all blocks on the bus in a single command. See

Section 6.4.6.

Initial release

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 5

Page 10

Contents

Notes

6 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 11

Chapter 1. Introduction

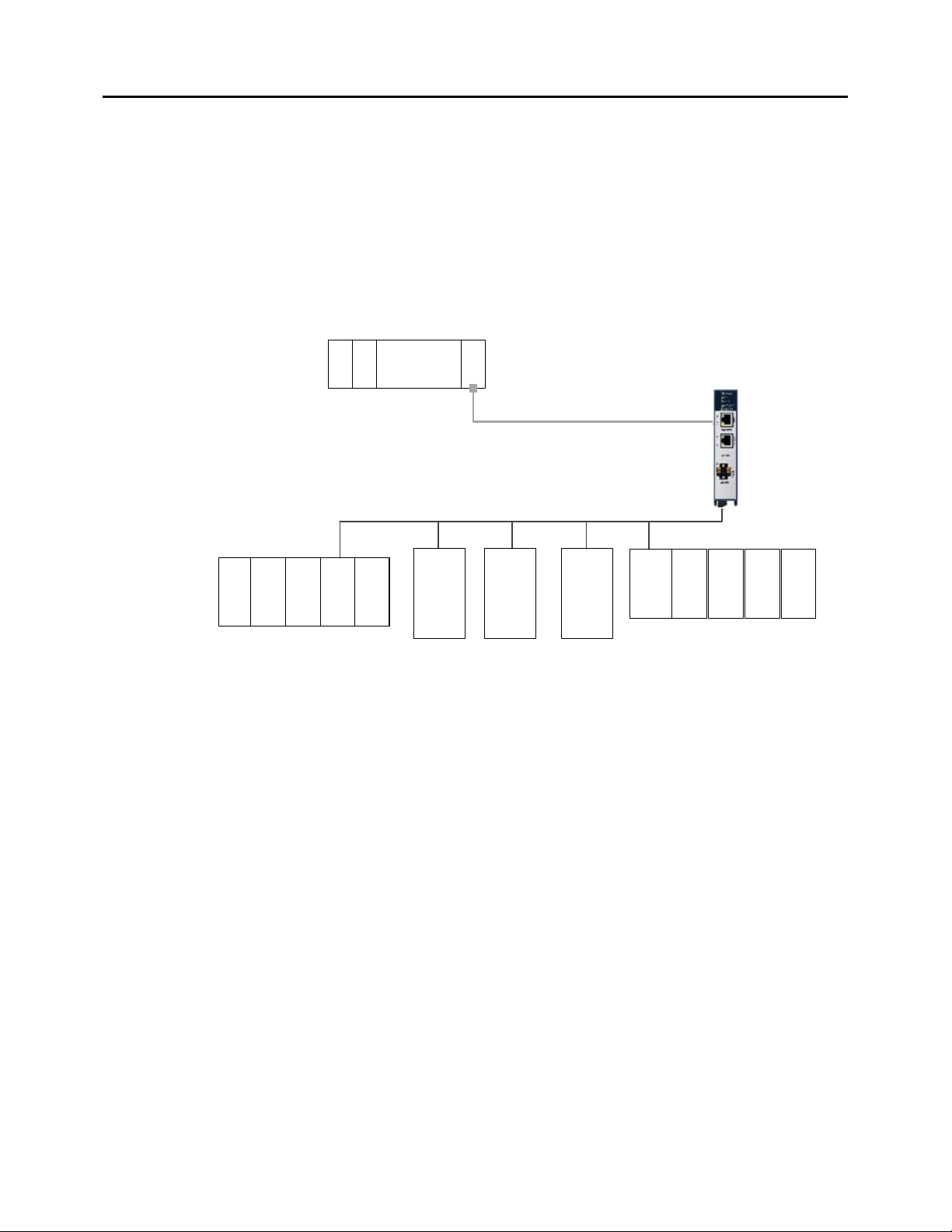

P

S

C

P

U

P

N

C

Genius

I/O

G

R

7

I OI OI

O

Vmax

NIUI OI OI OI O

Genius

I/

O

Genius

I/O

PROFINET I

/

O

Genius I/O

Introduction Chapter 1

This manual describes the RX3i Genius Communications Gateway, which acts as a gateway

between PROFINET and Genius I/O. Introductory material may be found in this chapter.

Chapter 2 provides installation and set-up information. Chapter 3 provides configuration

instructions. Chapter 4 describes system operation. Chapter 5 provides diagnostic

information. Chapter 6 covers the use and format of ladder logic COMMREQ instructions.

1.1 Description

The RX3i Genius Communications Gateway, IC695GCG001 (or GCG001), interfaces Genius IO

devices on a Simplex Genius Serial Bus to a GE Intelligent Platforms PROFINET IO Controller.

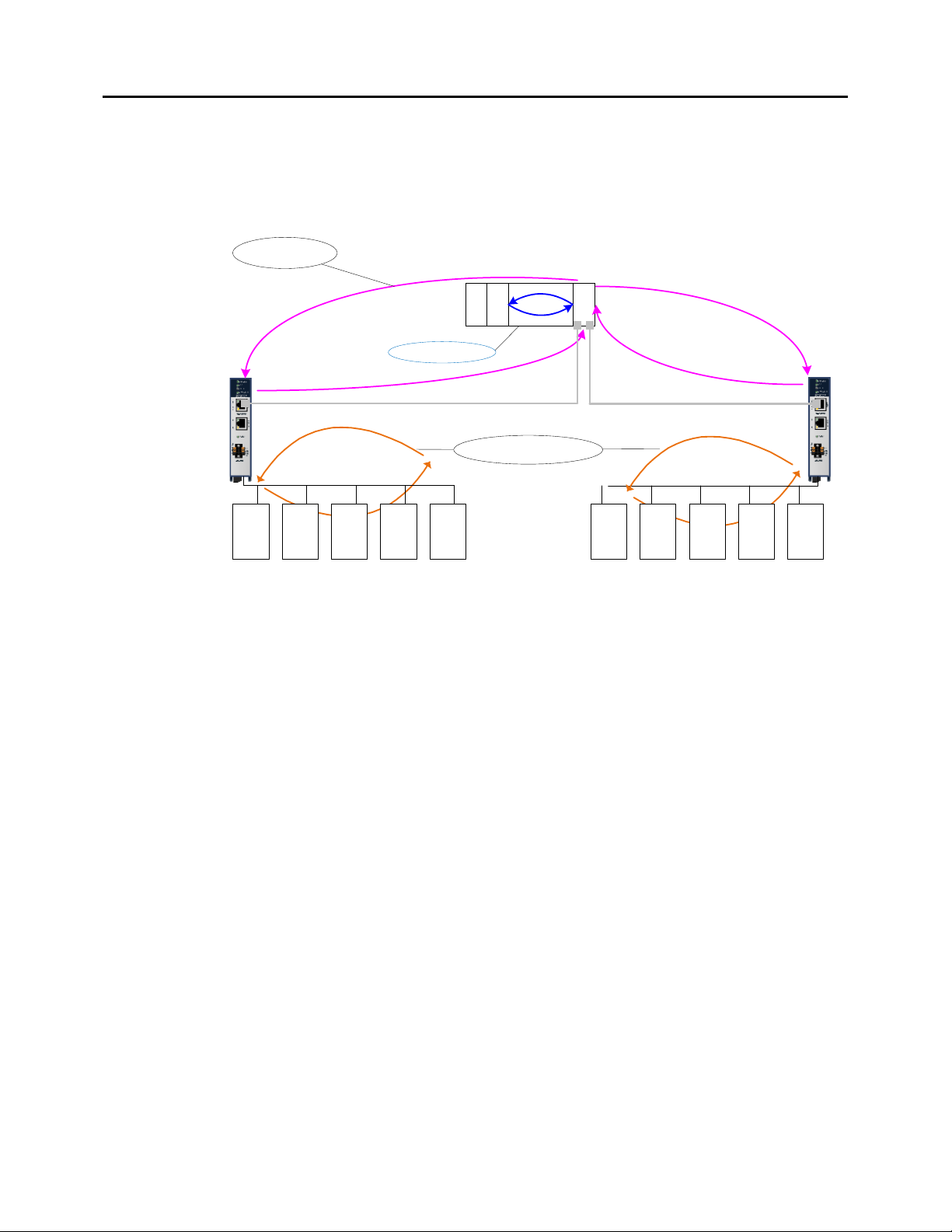

Figure 1: PLC System Using Genius Gateway GCG001

The GCG001 operates as a Genius Bus Controller on a Genius network. It scans the Genius IO

devices configured to it, retrieving input data and providing output data. It then exchanges

that data with its configured PROFINET IO Controller over its Ethernet interfaces at the

configured production rate. The GCG001 can manage communications for up to 31 Genius IO

devices on a single Genius Serial Bus.

The GCG001 also operates as an “IO Device” on PROFINET, controlled by the PROFINET IO

Controller (PNC001 or CPE330 LAN 2) to which it is attached. Thus, when correctly configured,

the entire Genius Bus, including the GCG001 itself, becomes visible to the controlling PLC. Note

that the GCG001 operates only with GE PLC PROFINET IO Controllers.

PROFINET operates on an Ethernet network. If the Ethernet network or Genius serial bus

communications are lost, the GCG001 manages I/O states according to the individual module

configurations.

Both PROFINET and Genius may be set up in Redundant configurations. These are discussed

later in this manual.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 7

Page 12

Chapter 1. Introduction

ETHERNET

ACT

LINK

PORT 1

PORT 2

COM

POWER

FAULT

CONNECT

OK

GCG001

LINK

ACT

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

1.2 Product Overview

Features of the GCG001 module include:

• Attachment of two RJ-45 Ethernet connections (Ports 1 & 2)

• Support for both star (switched) and linear (daisy-chained) network

topologies

• Supports Ethernet Media Redundancy Protocol (MRP)

• LEDs to indicate Ethernet status (ACT & LINK)

• Attachment Genius bus connections

• Supports Genius Redundancy consisting of a single Genius bus with

two GCG001 Gateways, one at SBA #30 and the other at SBA #31.

No other form of Genius redundancy is supported.

• LED to indicate Genius Communications Status (COM)

• LEDs to indicate module status (refer to module header)

• Panel-mount (typical)

• Optional mounting in RX3i expansion slot

• Cable tie-down loop on underside of module (at front)

• 24Vdc power connector on underside of module

• 0.2A maximum current draw

• Secure Digital (SD) Card Slot, accessible at rear of module

• Firmware load pushbutton, accessible at rear of module

8 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Figure 2: GCG001 Module

Note: Although the hardware supports the 10/100BASE TX Ethernet standard, PROFINET I/O

over wired infrastructure must be 100Mbps full-duplex or faster. 10Mbps should not be

used for PROFINET.

Page 13

Chapter 1. Introduction

RX3i Genius Communications Gateway Specifications

RX3i CPE330

PNC001 Compatibility

Firmware version 2.05 or later

RX3i CPE330 embedded PROFINET with firmware version 8.90 or

Operating Temperature Range

Number of Port Connectors

IEEE 802.2 Logical Link Control Class I

Status Data

64 (two banks of 32 bits)

Supports One Genius Bus.

HHM Compatibility

IC66* HHM501

Other Genius Compatibility

See table in Section 1.9

SD Card

The Genius Gateway requires an external 24Vdc power

1.3 Specifications

PROFINET Support

CPU Compatibility

Embedded PROFINET Compatibility

Proficy* Machine Edition Compatibility

Power Requirements

Local Area Network (LAN)

Genius Bus Support

Configuration

PROFINET version 2.3 Class A IO-Device

RX3i CPE305/CPE310 with firmware version 8.15 or later

RX3i CPU315/CPU320/CRU320 with firmware version 8.15 or later

later

Machine Edition 8.0 or later

External 24Vdc: (±10%) 0.2A

0 to 60°C

Two RJ-45

IEEE 802.3 CSMA/CD Medium Access Control 10/100 Mbps

Serial 1, Serial 2, Shield In and Shield Out, as marked.

Up to 31 additional devices supported per Genius Bus.

Selectable Baud Rate, per Genius specifications.

Genius Hot Standby and Duplex Redundancy supported.

2GB or smaller. Not compatible with SDHC or SDXC cards.

GSDML file is available on the Support website for download

and import into Proficy Machine Edition. The GSDML

supporting a firmware release is part of the firmware

upgrade kit available on the Support website.

supply and does not draw power from the Rx3i backplane.

Hot Swappable

For system standards, general operating specifications, and installation requirements, refer to

the PACSystems RX3i System Manual, GFK-2314.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 9

Swapping out the GCG001 will therefore not impact the PLC.

However, this cannot be performed without disconnecting its

power supply. If configured to support Genius Hot Standby,

the loss of a single GCG001 will be tolerated; otherwise not.

Page 14

Chapter 1. Introduction

ETHERNET

ACT

LINK

PORT 1

PORT 2

COM

POWER

FAULT

CONNECT

OK

GCG001

LINK

ACT

GENIUS A

SER 1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

Module Status

Indicator LEDs:

POWER, OK,

FAULT,

CONNECT

Ethernet Port

Indicator LEDs:

LINK,

ACT

24 V dc

Power

Connector

Genius Bus

Indicator LEDs:

COM

PROFINET

Ports

Genius Bus

Connector

1.4 Controls and Indicators

The following figure shows the front of the module and identifies the controls and indicators.

Figure 3: Genius Gateway GCG001 Front Panel View

10 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 15

Chapter 1. Introduction

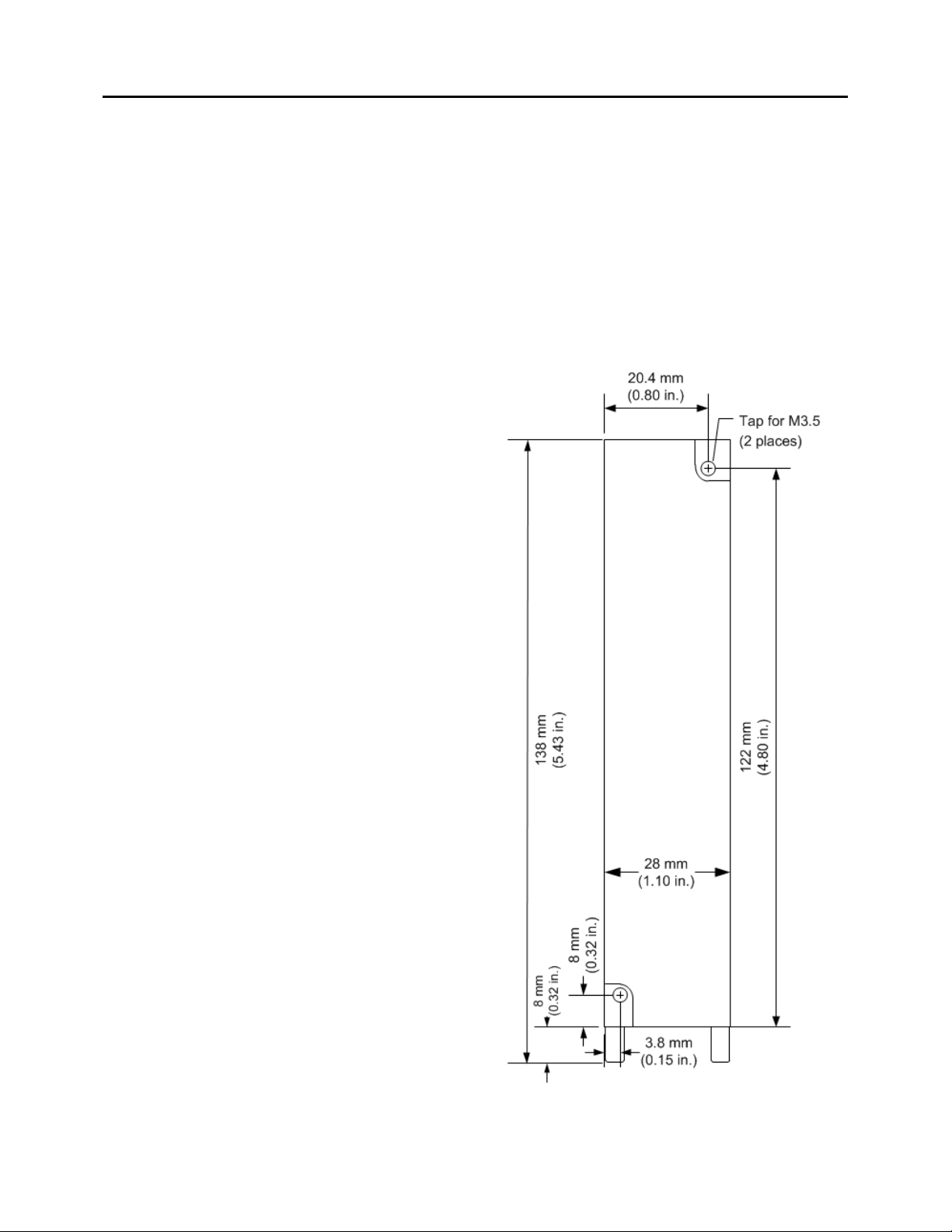

1.4.1 Mounting

The GCG001 may either be panel-mounted or mounted in the rightmost slot (expansion slot)

of an RX3i rack (IC695CHS012, IC695CHS016).

Note: The SD Card supplied with the GCG001 will have been installed at the factory. See

section 2.4.1 for instructions for installing the SD Card when doing a retrofit. The presence of

the SD Card should be checked before mounting the module.

Note: Clearance of 3 inches (75mm) must be provided above and below the module for

proper ventilation and to permit cable access.

Note: External power must always be supplied to the module, regardless of which

mounting arrangement is chosen. When rack-mounted, the GCG001 does not draw power

from the RX3i Universal Backplane.

RX3i Backplane Mounting

The GCG001 may be mounted in the

rightmost slot (expansion slot) of an RX3i

Universal Backplane.

The two captive M3.5 screws at the rear

of the GCG001 align with mating tapped

holes on the right side of the backplane,

providing a convenient mounting

location. When rack-mounted, the

module does not make contact with the

backplane connector.

Panel-Mounting

Panel-mounting allows for mounting

where no RX3i backplane slot is

available. The two captive M3.5 machine

screws on the GCG001 can be used for

attaching the unit to a panel.

Note: The panel must have a

minimum thickness of 2.4mm (0.094in).

1. Drill two mounting holes using the

spacing shown in the drawing (at

right) and tap for M3.5 (3.5 x 0.6mm).

2. Align the two mounting screws of the

module with the mounting holes in

the panel.

3. Using a Philips screwdriver, tighten

the two screws to a maximum torque

of 0.5 Nm (4.4 in-lbs).

Figure 4: GCG001 Panel Mount Diagram

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 11

Page 16

Chapter 1. Introduction

Record Data Communication Relationship

I/O Data Communication Relationship

Alarm Communication Relationship

Application Relationship

Genius Gateway (GCG001)

1

2

3

4

PNS001

ACTIVE

USB

OK

LAN

STATUS

CONN

USB

IP ADDRESS

MAC ADDRESS

PORTS

TO INSTALL,

TORQUE TO

6 IN-LB.

IO DEVICE

FRONT

3 4

1 2

SD CARD

!

RX3i with PROFINET Controller (PNC)

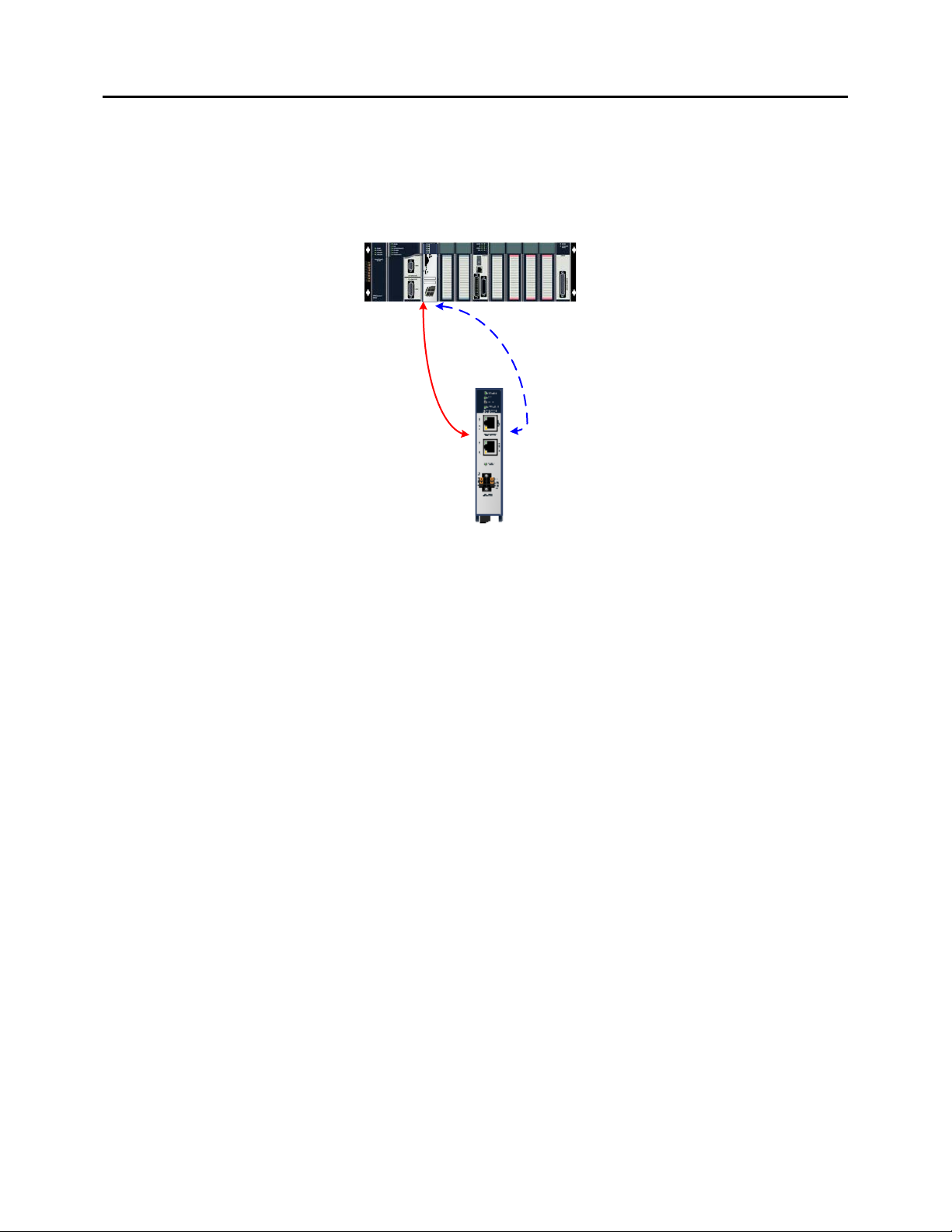

1.5 PROFINET Operation Overview

An RX3i Genius Communications Gateway (GCG001) uses PROFINET communications for data

exchange with the PLC. As noted above, the data rate must be 100Mbps full-duplex or faster.

The same network may be used for basic Ethernet communications, but use of a separate

Ethernet network and RX3i Ethernet interface is recommended.

PROFINET Communications

Communications on an RX3i PROFINET network use the standard PROFINET communications

described in this section. Note, however, that the Genius Gateway GCG001 is constrained to

work only with GE PROFINET PLC products.

Application Relationships

Before a PROFINET IO-Controller can exchange data with a PROFINET IO-Device such as the

GCG001, an Application Relationship (connection) must be established between the devices.

The PROFINET IO-Controller automatically sets up the correct number and types of Application

Relationship and Communication Relationship channels (see below) based on its Proficy

Machine Edition (PME) configuration. Usually, only one Application Relationship is established

per IO-Device.

Communication Relationships within an Application Relationship

Within each Application Relationship, the PROFINET IO-Controller establishes the following

types of Communication Relationships (CRs):

• Record Data CRs – always the first to be established within an Application Relationship.

Record Data Communication Relationships are used for non-real-time transfers of data

records such as startup parameter data, diagnostics data, identification data, and

configuration data.

• IO CRs – used for the real-time, cyclic transfer of IO data

• Alarm CR – used for real-time, acyclic transfer of alarms and events

The following illustration represents an Application Relationship between an RX3i PROFINET

Controller and an RX3i Genius Gateway GCG001.

12 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Figure 5: Application Relationships between PROFINET Controller & Genius Gateway

Page 17

Chapter 1. Introduction

1

2

3

4

PNS001

ACTIVE

USB

OK

LAN

STATUS

CONN

USB

IP ADDRESS

MAC ADDRESS

PORTS

TO INSTALL,

TORQUE TO

6

IN-

LB.

IO DEVICE

FRONT

3 4

1 2

SD CARD

!

RX3i with PROFINET Controller (PNC)

Real-Time Data

Inputs

Outputs

Alarms

Non Real-Time

Data

Parameters

Configuration Data

Types of PROFINET Communications

Genius Communications Gateways use two types of PROFINET communication transfers: realtime and non-real-time. The illustration below shows real-time communications as solid lines

and non-real-time communications as dashed lines.

Figure 6: Real-Time & Non-Real-Time Data Types

• Real-Time (RT) communication: PROFINET real-time communication is used for time-sensitive

data. A PROFINET IO-Controller (PROFINET Controller) and PROFINET IO-Device use two types

of real-time communications to exchange data: cyclic communication and acyclic

communication:

• Real-time Cyclic communication is used to periodically transfer the application’s input

and output data. Cyclic communication occurs each PROFINET IO production cycle.

• Real-time Acyclic communication is used to transfer non-periodic data such as alarms.

Acyclic communication occurs only when needed.

• Non-Real-Time (NRT) communication: PROFINET non-real-time communication is used for

less time-sensitive data such as configuration, parameterization, diagnostics, and

identification data.

Operations of the Genius Communications Gateway

The Genius Communications Gateway performs the following operations:

• Consumes PROFINET IO-Device configuration from the PROFINET IO-Controller over the

PROFINET network.

• Scans input data from each Genius device it manages and produces that data to the

PROFINET IO-Controller.

• Consumes the output data that it receives from the PROFINET IO-Controller and applies it

to each Genius device it manages.

• Where needed, translates Genius Datagrams (background traffic) into PROFINET

packages that are sent to the PROFINET Controller. This includes Datagrams that

originated at the Genius Devices, such as Fault Reports.

• Translates PROFINET packages that are sent by the PROFINET Controller into Genius

Datagrams. This includes Datagrams that originated at the PLC through use of COMMREQ

or Data_Init_Comm instructions. For example, a COMMREQ is used to generate a Clear

Fault Report datagram.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 13

Page 18

Chapter 1. Introduction

Genius

I/

O

Genius

I/O

Genius

I/O

Genius

I/

O

Genius

I/O

PROFINET I/O

Genius

I/O

Genius

I/

O

Genius

I/O

Genius

I/O

Genius

I/O

Genius Bus Scans

P

S

C

P

U

P

N

C

PROFINET IO

Production Cycle

RX3i CPU Sweep

IO Scanning

In the PACSystems RX3i PROFINET network, multiple IO cycles run asynchronously and

independently. Figure 7) illustrates typical cycles in a system with an RX3i CPU with a

PROFINET Controller module communicating with a Genius Communications Gateway. Cycles

may be different for third-party devices.

Figure 7: PLC - GCG - Genius Scan Cycles

• Genius IO-Device Scan: In this example, each GCG scans all of its Genius devices. The GCG

stores the devices’ input data into its internal memory. Every time the GCG gets a turn on the

Genius bus, it transmits the output data from its internal memory to each of the Genius

devices.

rd

party devices: The transfer of IO data between an IO module and the PROFINET IO network

• 3

is device dependent. Refer to the third party manufacturer documentation for specifics for a

particular device.

• PROFINET IO Production Cycle: Each PROFINET Controller and IO-Device publishes data from

its internal memory onto the network at its scheduled PROFINET production cycle (Note:

Production cycles between IO-Controllers and IO-Devices are not synchronized; each

publishes at its configured update rate independently). The PROFINET Controller publishes

output data received from the RX3i CPU to each IO-Device, and the IO-Device publishes input

data from its memory to the PROFINET Controller.

• RX3i CPU Sweep: The RX3i CPU Sweep includes both an input scan and an output scan. The

CPU input scan retrieves the current input data being stored within the PROFINET Controller

module. This input data is then available for use by the application logic. After the logic

solution, the CPU output scan writes the outputs to the PROFINET Controller.

14 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 19

Chapter 1. Introduction

Media Redundancy Protocol Support

PROFINET Media Redundancy Protocol (MRP) supports devices configured in a ring topology.

MRP is specified as part of IEC62439 and has been adopted by the PROFINET specification,

which provides for convenient configuration of the ring topology and necessary parameters.

Like PROFINET IO data, Media Redundancy Protocol operations are not routable between

different IP subnets.

Each device within an MRP ring has two physical pathways to the IO-Controller. To connect to

the ring, each device requires an integrated switch with at least two external ports (ring ports)

that support MRP. Devices that are not MRP-capable can be connected to a device in the ring

(i.e., an MRP-capable switch in the ring), but they should not be in the ring themselves. The

redundancy capability offered by the ring topology only extends to the devices on the ring

that are MRP-capable and enabled.

One of the devices on the ring must be configured as the Media Redundancy Manager (MRM),

and all the other devices must be configured as Media Redundancy Clients (MRCs). The

GCG001 can be configured as an MRC. Configuring the GCG as an MRC alters how the

Ethernet ports connect to the network. They attempt to indicate their state to the MRM before

allowing traffic to flow between the ports and close the ring topology through the internal

switch. They also send out notifications to the MRM when a port is lost. Operation of the

GCG001 is otherwise unchanged.

The MRP configuration is stored in non-volatile storage in the GCG001 and activated

immediately upon powering up. Non-volatile storage is updated as part of a connection with

the IO-Controller. A PROFINET Discovery & Configuration Protocol (DCP) Reset disables MRP

Client operation and updates non-volatile storage. The current state of the MRP configuration

is provided as part of the GCG’s Gateway Status Bits which are accessible to user application

logic. Refer to the description of Gateway Status Bits in Section 5.1.1 for further details.

Fast ring-break detection is not fully functional until all MRP clients have received their MRP

configuration. For a discussion of ring-break detection, refer to the following section,

Bumpless Operation with MRP.

Bumpless Operation with MRP

The GCG001 supports bumpless operation under MRP.

1.6 System Limits

IO-Controllers have limitations on the size of the system they support. One of these limits is

the number of PROFINET sub-modules supported. The GCG001 uses four sub-modules: two

for basic operation and two built-in port sub-modules that are always configured. Each

Genius device attached to a GCG001 uses one additional sub-module.

Other limitations, such as the configuration and IO sizes are specific to the configuration

options chosen. Note that not every combination of options is supported in every system. If

the configuration uses all Genius bus slots with a corresponding large device count, the

memory of the IO-Controller system will be a limiting resource.

See GFK-2571 for actual limits in the RX3i PROFINET Controller (PNC001).

See GEK-90486, Genius I/O System and Communications User's Manual for information on how

much I/O, and which type of I/O, need to be allocated to Genius devices,

Machine Edition (v8.0 or later) takes into account both system limits and I/O allocation.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 15

Page 20

Chapter 1. Introduction

1.7 Operational Differences vs. Genius Bus Controller

Persons migrating from a Genius environment where the Genius Bus Controller performs

functions similar to those of the GCG001 will want to be aware of the following differences:

1. COMMREQ function block SYSID and Task parameters change. SYSID is now the rack &

slot of the PNC connected to the GCG001. Task is now 132.

2. COMMREQ data blocks are different, mainly due to added PROFINET Device Number and

expansion of memory address fields from one word to two words. See COMMREQ

summary in Section 6.3.3.

3. Pulse Test and Assign Monitor COMMREQs do not support Genius bus address of 255 to

send messages to all blocks.

4. COMMREQ commands: GCG001 does not support all datagrams. See section 6.3.2 for a

corresponding list of supported COMMREQs.

5. GCG001 supports hot-standby and duplex redundancy modes only. No support for dual-

bus redundancy.

6. GCG001 can be assigned to bus addresses 30 and 31 only.

7. GCG001 does not support Field Control, GENI, GENA, or PCIM.

8. Prior to V2.0.0, GCG001 did not support 76.8K and 38.4K baud rates. Beginning with

V2.0.0, all Genius baud rates are supported.

9. Prior to V1.1.1, fault contact operation has changed. Whenever there is a fault on a single

channel of a Genius block, all fault contacts associated with that Genius block will

become active. All faults on that device must be cleared before any of the fault contacts

will de-energize. Beginning with V1.1.1, when there is a fault on a single channel, none of

the fault contacts will become active.

10. Genius faults routed through a GCG001 appear as PROFINET faults to the CPU. The same

fault routed through a Genius Bus Controller will present a different error code.

11. Prior to V1.1.1, when a Genius block encounters a circuit fault on one or more points or

channels, the GCG001 causes all of the input references associated with that block to

either hold last state or go to default values until such time as the fault is cleared. See the

Alarms discussion in section 4.1.4 for a work-around to this behavior. However, beginning

with V1.1.1, when a Genius block encounters a circuit fault on one or more points or

channels, the GCG will cause only the faulted input references to hold the last state or go

to default values. The other points or channels on the block will continue to operate

normally.

16 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 21

Chapter 1. Introduction

1.8 Supported Genius Devices

The following Genius devices are compatible with the GCG001 Genius Communications Gateway.

Catalog Number Description

IC200GBI001† VersaMax Genius Network Interface Unit (GNIU)

IC660BBA020 24/48Vdc 4-Input/2-Output Analog Block

IC660BBA021 24/48Vdc RTD Input Block

IC660BBA023 24/48Vdc Thermocouple Input Block

IC660BBA024 24/48Vdc Current–Source Analog Block

IC660BBA025 24/48Vdc Current–Source Output Block

IC660BBA026 24/48Vdc Current–Source Input Block

IC660BBA100 115Vac 4-Input/2-Output Analog Block

IC660BBA101 115Vac RTD Input Block

IC660BBA103 115Vac/125Vdc Thermocouple Input Block

IC660BBA104 115Vac/125Vdc Current–Source Analog Block

IC660BBA105 115Vac/125Vdc Current–Source Output Block

IC660BBA106 115Vac/125Vdc Current–Source Input Block

IC660BBD020 24/48Vdc 16-Circuit Source I/O Block

IC660BBD021 24/48Vdc 16-Circuit Sink I/O Block

IC660BBD022 24Vdc 16-Circuit Source I/O Block

IC660BBD023 24Vdc 16-Circuit Sink I/O Block

IC660BBD024 12/24Vdc 32-Circuit Source I/O Block

IC660BBD025 5/12/24Vdc 32-Circuit Sink I/O Block

IC660BBD101 115Vac Low–Leakage 8-Circuit Grouped Block

IC660BBD110 115Vac 16-Circuit Input Block

IC660BBD120 High–Speed Counter Block

IC660BBR100 16-Circuit Relay Block, Normally–Closed

IC660BBR101 16-Circuit Relay Block, Normally–Open

IC660BBS100 115Vac/125Vdc 8-Circuit Isolated I/O Block

IC660BBS101 115Vac/125Vdc 8-Circuit Isolated I/O Block Without Failed Switch Diagnostic

IC660BBS102 115Vac/125Vdc 8-Circuit Isolated I/O Block

IC660BBS103 115Vac/125Vdc 8-Circuit Isolated I/O Block Without Failed Switch Diagnostic

IC697BEM733 ‡ Series 90-70 Remote I/O Scanner (GR7)

†

Refer to GFK-1535 Chapter 1 for a list of VersaMax modules supported by GBI001.

‡

Refer to GFK–0579, Chapter 1 for a list of S90-70 modules supported by BEM733.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 17

Page 22

Chapter 1. Introduction

Notes

18 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 23

Chapter 2. Installation

Installation Chapter 2

This chapter provides instructions for installing the module. The following topics are covered.

• Pre-Installation check

• Module installation and removal

• Port connections

• LED indications

• Firmware updates

For additional information about RX3i system installation, see the PACSystems RX3i System

Manual, catalog number GFK-2314.

For additional information about PROFINET installation and configuration, see GFK-2571 for

the RX3i PROFINET Controller. You will also need Proficy Machine Edition (PME) configuration

and programming software, version 8.0 or later.

2.1 Pre-Installation Check

Upon receiving your RX3i equipment, carefully inspect all shipping containers for damage. If

any part of the system is damaged, notify the carrier immediately. The damaged shipping

container should be saved as evidence for inspection by the carrier.

As the consignee, it is your responsibility to register a claim with the carrier for damage

incurred during shipment. GE Intelligent Platforms will cooperate fully with you, however,

should such action be necessary.

After unpacking the RX3i equipment, record all serial numbers. Serial numbers are required if

you should need to contact Customer Care during the warranty period. All shipping containers

and all packing material should be saved should it be necessary to transport or ship any part

of the system.

Verify that all components of the system have been received and that they agree with your

order. If the system received does not agree with your order, contact Customer Care.

If you need technical help, contact Technical Support. For phone numbers and email

addresses, see the Contact Information page in the front of this manual.

2.2 Installation Location

This product is primarily intended for use with the RX3i system. Its components are considered

open equipment (having live electrical parts that may be accessible to users) and must be

installed in an ultimate enclosure that is manufactured to provide safety. At a minimum, the

enclosure shall provide a degree of protection against solid objects as small as 12mm (e.g.

fingers). This equates to a NEMA/UL Type 1 enclosure or an IP20 rating (IEC 60529) providing at

least a pollution degree 2 environment. For details about installing RX3i rack systems, refer to

GFK-2314, PACSystems RX3i System Manual.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 19

Page 24

Chapter 2. Installation

Warning

2.3 Installation in Hazardous Areas

The following information is for products bearing the UL marking for Hazardous Areas or ATEX

marking for explosive atmospheres:

CLASS 1 DIVISION 2 GROUPS ABCD

• This equipment is an open-type device and is meant to be installed in an enclosure

suitable for the environment that is only accessible with the use of a tool.

• Suitable for use in Class I, Division 2, Groups A, B, C and D Hazardous Locations, or

nonhazardous locations only.

EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS I, DIVISION 2.

WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES; AND

DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NONHAZARDOUS.

Warning

2.3.1 ATEX Zone 2

The module must be mounted in an enclosure certified in accordance with EN60079-15 for

use in Zone 2, Group IIC and rated IP54. The enclosure shall only be able to be opened with the

use of a tool.

2.3.2 ATEX Marking

II 3 G Ex nA IIC T4 X Ta: 0 - 60C

EXPLOSION HAZARD - USB PORT IS ONLY FOR USE IN

NONHAZARDOUS LOCATIONS, DO NOT USE UNLESS AREA IS KNOWN

TO BE NON-HAZARDOUS.

20 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 25

Chapter 2. Installation

+24 VDC

RTN

24 Vdc Power

Connector

(Use for cable

tie-downs)

2.4 Module Installation

2.4.1 Install SD Card

The SD card slot is designed to support a Secure Digital (SD) non-volatile memory card in

standard capacity format. This optional card has two distinct uses: (1) backup storage of some

key PROFINET configuration data and (2) loading new GCG001 module firmware. Insert the SD

Card into its slot at the rear of the GCG001 before mounting the module, as shown in Figure 8.

When shipped from the factory, the SD card will have been pre-installed. It will have been

programmed with the then-current version of the firmware for the GCG001. In the event the

firmware on the SD card needs to be updated, see section 2.7. Note that the firmware

upgrade should be performed before mounting the module.

Figure 8: Rear View of GCG001

2.4.2 Mounting the GCG001

The GCG001 is designed to mounted in one of the following ways:

a. In the expansion slot of an RX3i Universal Backplane

b. Panel-mounted

In both cases, at least 75 mm (3 in.) must remain clear above and below the module to allow

for convection cooling. See section 1.5.1 for mounting details.

Once the module has been mounted, connect 24Vdc power via the connector on the

underside of the module, connect PROFINET via the RJ-45 connectors and the Genius bus via

twisted pair cable. Each connection is described in the following section.

Once all connections are in place, it will be necessary to configure PROFINET. This is also

discussed in the following sections.

Power Connection

The module requires a user-supplied

24Vdc (±10%) power source wired to the

removable screw-terminal block located

on the bottom of the module. Connector

pin-outs are identified on the module, as

indicated at right. The module draws

0.2 A maximum current.

Figure 9: GCG001 Power Connector

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 21

Page 26

Chapter 2. Installation

COM

GENIUS A

SER

1

SER 2

SHLD

IN

GENIUS

SHLD

OUT

COM

GENIUS A

SER 1

SER

2

SHLD

IN

GENIUS

SHLD

OUT

Bus

termination

resistor

Grounding

For proper operation, always connect the GCG001 ground terminal (see Figure 9) to earth

ground. The panel to which the GCG001 module is mounted, or the RX3i Universal Backplane

to which it is mounted, must have a safety ground connection to protective earth. This ground

2

wire must be at least 1.5 mm

(16 AWG).

• Connect the frame ground connection on the power plug to protective earth.

• Terminate all ground wires at the same grounding point.

• Make all ground wires as short as possible.

• Where the grounding terminal contacts a painted enclosure panel, scrape the paint

away down to clean, bare metal to ensure good contact.

PROFINET Connection

Attach the PROFINET via one or both of the RJ-45 connectors provided (Port 1 & Port 2).

Various configurations are possible. Refer to the manual for the PROFINET controller used in

the application (GFK-2571 for the RX3i PROFINET Controller).

Genius Bus Connection

The GCG module is equipped with one active six-terminal Genius Serial Bus connector.

22 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Figure 10: Daisy Chain Genius Bus Wiring

Two terminals each are provided on a removable terminal block for Serial 1, Serial 2, and

Shield connections. The figure (above left) shows the Genius connection continuing through

the connector block (daisy chain).

Whenever the Genius bus is terminated at the GCG001, a bus termination resistor should

connect Serial 1 to Serial 2, with SHLD IN unterminated, (as shown above right). The value of

the termination resistor must match the impedance of the Genius Bus cable.

Note that whenever the GCG001 Genius terminal blocks are removed from the faceplate, the

continuity of the Genius Bus is disrupted.

Figure 11: Genius Bus Wiring for Bus Termination

Page 27

Chapter 2. Installation

PROFINET Configuration

Once all connections are in place, it will be necessary to set up the PROFINET configuration.

This requires use of the PC-based PROFINET Discovery tool. Be sure your PC is connected to

the same PROFINET network and interrogate the network to discover what is connected, as

shown in the following screen-shot.

Figure 12: PROFINET Discovery Screenshot

Initially, the out-of-the box GCG001 will not have a name assigned. Select the row containing

the GCG001, then click on the Edit Device button in order to assign a unique name.

Configuration tools and procedures are discussed in detail in Chapter 3.

2.4.3 GCG001 Module Removal

• Power down the external 24Vdc source

• Remove the Power connector from the underside of the GCG001 module

• Disconnect the RJ-45 PROFNET connector(s)

• Remove the Genius terminal block

• While holding the GCG001, loosen the two captive M3.5 screws that hold the module

in place, then pull away from the mounting surface. Note that, if mounted to an RX3i

rack, there is no pivot attachment or backplane connection to the rack.

• The SD Card may be transferred from the removed GCG001 to another (successor)

GCG001. This permits the PROFINET configuration of the removed module to be

transferred to the successor module.

• Once the successor module has been mounted, the original Power, PROFINET and

Genius connections may be restored to it.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 23

Page 28

Chapter 2. Installation

2.4.4 Light-Emitting Diode (LED) Indications

The four LEDs in the module header provide a visual indication of the GCG001 module status.

POWER — indicates the presence of power to the module.

Green, ON steady

OFF

OK — indicates GCG001 readiness to perform normal module operations.

Green, ON steady

Power supply is good.

Power supply is off or not good.

Module able to perform normal operations.

Green/Amber,

blinking

Amber, ON steady

OFF

FAULT — indicates the detection of faults by the module.

OFF No faults present.

Red, blinking 2Hz DCP Device Identification Signal received on PROFINET.

Red, ON

CONNECT — indicates status of the connection to a PROFINET controller.

OFF

Red, blinking

Red, ON No PROFINET Controller connection

The two LEDs associated with each Ethernet port (used here as PROFINET ports) are labelled ACT and LINK. These LEDs provide information about activity on that particular port.

PORT 1, PORT 2 LINK — indicates connection status on Ethernet ports.

Green, ON steady

Module loading main operating system

Module loading boot-loader operating system

Module has an unrecoverable fault or power is not applied.

A fault or other PROFINET diagnostic data exists on the

Gateway

One or more connections with GE Intelligent Platforms

PROFINET Controllers have been established to this device.

Device trying to connect to a controller.

Continuous if device has not been assigned a valid station

name.

Ethernet connection established

24 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

OFF

PORT 1, PORT 2 ACT — indicates activity on PROFINET ports.

Amber, blinking Communications occurring on port

OFF No communication

No Ethernet connection

Page 29

Chapter 2. Installation

The LED located directly above the Genius connector provides information about the Genius bus.

COM — indicates the status of Genius Bus communications.

Green, ON steady

The Genius Bus is configured and operating properly.

Green, blinking

OFF

A Genius Bus error has been detected.

The Genius Bus has failed or no Genius Bus configuration

has been received.

2.4.5 Fault Notifications

Powering up or down, or connecting/disconnecting the GCG001 from the controlling

PROFINET device will have effects specific to the particular controlling device. The discussion

below relates to using the RX3i PROFINET Controller as the controlling device.

Removing a GCG001 from the PROFINET network causes a Loss of Device fault for the GCG001

itself and all Genius devices connected via that GCG001.

Adding a GCG001 to the PROFINET network causes an Addition of Device fault for the GCG001

itself and all Genius devices connected via that GCG001.

Note that when a GCG001 is replaced by a successor GCG001, it is important to ensure that

the successor is configured for PROFINET in the same manner as its predecessor. The quickest

way to ensure this is to remove the SD Card from the original and insert it into the successor

GCG001.

2.5 Configuring the Genius Gateway to Operate with the RX3i CPU

1) Start the Machine Edition application, then open or create the project which will contain

the GCG001 module.

2) Configuring the rack, power supply, CPU and PROFINET Controller in the Project tab of the

Navigator

3) Follow the instructions in the RX3i PROFINET Controller System Manual GFK-2571 for

adding devices to the PROFINET IO Network. The GCG001 will be one of those devices.

4) Note that each IO Device connected to the GCG001 will be mapped per the RX3i

PROFINET Controller configuration.

2.6 Ethernet Port Connections

As noted earlier, PROFINET IO operates at 100Mbps or higher (full duplex). The GCG001 Genius

Gateway cannot operate at a data rate greater than 100Mbps. Thus, for normal operation, at

least one port must be operated at 100Mbps. Other devices operating at 10Mbps may co-exist

on that network, though this would not be typical.

Each Ethernet port on the GCG001 module (see Figure 3) operates independently, so devices

that operate at different speeds and/or duplex modes may be attached to the ports. Each port

automatically detects the attached cable and functions properly with either straight-through

or crossover cables.

Note: The module operates only in auto-negotiate mode. All PROFINET devices

and switches that are connected to the module should be configured to

use auto-negotiation.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 25

Page 30

Chapter 2. Installation

2.6.1 RJ-45 Port Connections

The two RJ-45 ports on the GCG001 Genius Gateway can be used for PROFINET network

connections or for general Ethernet communications on a 10BaseT or 100BaseTX IEEE 802.3

network; 1000BaseTX is not supported. If the port is connected to an external switch, hub, or

repeater, up to 12 PROFINET nodes may be connected in a star wiring topology. Cables may

be up to 100 meters in length. Cables for 100BaseTX must be data grade Category 5 or better

unshielded twisted pair (UTP) or shielded twisted pair (STP). 10BaseT may be used for the

general Ethernet traffic, but not for PROFINET communications.

2.7 Firmware Updates

Refer to the rear view of the GCG001 module shown in Figure 8 (above). Whenever the

GCG001 firmware needs to be updated, remove the SD card from its slot at the rear of the

module, then install the SD Card in your PC and copy the new firmware to the SD Card. The ZIP

file containing the GCG001 firmware upgrade may be found on the GE Intelligent Platforms

Product Support web-site http://www.ge-ip.com/support

following figure.

. Unzip the file as shown in the

Figure 13: GCG001 Firmware Upgrade ZIP File UnZIPped to SD Card

After the SD card has received an update of the GCG001 firmware, install the SD card in its

slot (see Figure 8). Note that the GCG001 must not be powered up while installing the SD Card.

Next, while holding down the Firmware Load Pushbutton (see Figure 8), apply power to the

module. This action causes the firmware to be copied from the SD Card to the GCG001

module itself. Continue holding the pushbutton until the OK LED turns amber, then release the

pushbutton. When the OK LED turns green, the firmware has been loaded. Cycle power on the

module and wait for the OK LED to turn green and steady. The module is then ready to be

properly mounted (see section 1.5.1) .

26 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 31

Chapter 2. Installation

GCG001

Usage

Manufacturer

Power

Phoenix

Genius

Terminal

Block

Config

Backup

2.8 Spare Parts

The following spare parts may be obtained directly from the indicated vendors:

Manufacturer

Contact

Weidmueller 127787000

Verbatim 44015 SD CARD, 2GB www.verbatim.com

P/N

1763180 CONN TB PLUG 1X3 3.81MM TIN SCW LCKS BLK www.phoenixcontact.com

Description Contact Information

CON,3X2,PLUG,W/SCREWS,SPRING CONN, TERM

BLOCK

www.wiedmueller.com

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 27

Page 32

Chapter 2. Installation

Notes

28 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Page 33

Chapter 3. Configuration

Configuration Chapter 3

The RX3i GCG001 Genius Gateway receives its configuration via its connected PROFINET I/O

Controller (PROFINET Controller). The PROFINET Controller, in turn, is configured by a PROFINET

I/O configuration tool. This tool will require a GSDML file for the GCG001 Genius Gateway. The

RX3i GCG001 GSDML can be obtained from GE’s Automation and Controls support website,

http://www.geautomation.com

import the RX3i GCG001 GSDML file into the Tool Chest of Proficy Machine Edition.

3.1 Configuration Tools

• PACSystems RX3i CPU Firmware 8.00 or later.

• Proficy Machine Edition configuration and programming software, version 8.0 or later.

• Serial or Ethernet cable for connecting the Proficy Machine Edition programmer computer

to the RX3i CPU.

• General Station Description Markup Language (GSDML) file for the GCG001, available from

GE’s Automation and Controls support website, http://www.geautomation.com

3.2 Configuration Overview

The steps involved in configuring a GCG001 Genius Gateway are as follows:

1. If you haven’t already done so, use Machine Edition to add a PROFINET IO-Controller

(IC695PNC001) to the Hardware Configuration of the target control system.

2. Select the PNC001 in the Navigator window, then browse the module and the Local Area

Network (LAN) configuration in the Inspector window, changing parameters as necessary

for your system. Note that the GCG001 will operate at 100Mbps, and will cause the

Network Speed to be auto-negotiated to this speed.

3. Right-click the PNC001, then select Add IO-Device to add the GCG001 as a connected

device on the PROFINET LAN. In the PROFINET Device Catalog dialog that subsequently

appears, select Have GSDML…, then browse to the location on your computer where the

file is located, select it, and Open. As mentioned above, the GSDML can be conveniently

stored in the PME Tool Chest.

4. Use PROFINET/DCP tool in Machine Edition to assign a name to the GCG001 Gateway so

that the PROFINET Controller can connect to it and send its configuration. To do this, rightclick the PNC001, then select Launch Discovery Tool GCG001.The tool will appear in a

new InfoViewer tab entitled PROFINET DCP – Direct Connection (see Figure 12).

, using GCG001 as your search term. For subsequent use,

.

Note: This tool can also be activated from the Utilities tab in the Navigation pane

by selecting PROFINET DCP.

5. With the GCG001 connected to the PNC001 via Ethernet cables, and both the RX3i rack

and the GCG001 powered up, select Refresh Device List. Find the GCG001 in the list. If its

Device Name does not match the Device Name configured on the PNC001 , select the

GCG001 , then select Edit Device, change the Device Name, then Exit.

6. GeniusGateway… appears in the Device Catalog tree.

Select GeniusGateway, then OK.

7. geniusgateway…

now appears

(Figure 14) as an

IO device in the

Hardware

Configuration

tree under the

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 29

Figure 14: Hardware Configuration

Expanded Tree

Page 34

Chapter 3. Configuration

PNC001. Within the geniusgateway branch, two daughter devices are displayed by

default: the GCG (shown at slot 0 with its connected PNC) and the Gateway module itself

at slot 31. You may drag the gateway to slot 30, if desired.

Note that slot 0, normally used by the Genius HHM, is not really consumed by the GCG001.

The slot 0 indication for the GCG001 in the ME display should be ignored: it does not

impact the SBA assignments on the Genius Bus.

Note: geniusgateway… is the default PROFINET Device Name that Machine Edition

gives to a GCG001 in the Hardware Configuration under a PNC001. This

Device Name must match that given to the module itself using the

PROFINET/DCP (Discovery and Configuration Protocol) tool (see below). If

there are multiple GCG001s on a PROFINET bus, each of the modules’ Device

Names must be unique. You can change it by selecting the device in the

Navigator, then typing in a new name in the Inspector.

Example: GCG_inside and GCG_outside are acceptable Device Names.

8. Add Genius I/O devices to the Genius Bus by right-clicking geniusgateway… and selecting

Change Module List…. (see Figure 15). If the application is a retrofit of an existing Genius

solution, be sure to set all I/O reference addresses to match those of the Genius

configuration being incorporated. To ease confusion, it is also recommended that the

Genius Devices be assigned the same serial bus addresses (Location column) as had

been assigned in the system under retrofit.

30 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Figure 15: Change Module List for Genius Gateway GCG001

Page 35

Chapter 3. Configuration

9. Select individual Genius I/O devices from the right-hand panel of Figure 15 and then drop

them into the appropriate location row on the left-hand side, resulting in Figure 16.

Figure 16: Populating the Genius IO Devices to be Controlled by the Genius Gateway

10. Special consideration needs to be given to the configuration of a Series 90-70 Remote I/O

Scanner (BEM733) device on the Genius Bus, since this device is capable of controlling a

rack filled with I/O modules, each of which needs to be suitably configured.

a. Add the BEM733 to the Genius Bus configuration as described above.

b. Drill down into the BEM733. A display of rack I/O will be presented (Figure 17).

Figure 17: Populating Slots in S90-70 Rack Controlled by Remote I/O Scanner (BEM733)

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 31

Page 36

Chapter 3. Configuration

c. For each slot in the BEM733-controlled rack, select a generic I/O device (such as a 16-

point discrete input module or a 4-channel analog output module) and attach that to

its corresponding slot in the I/O rack. Note that actual part numbers have not been

assigned for this procedure. If in doubt, check the data sheet related to each product

number to determine the type of I/O it consumes (Analog or Discrete / Input or

Output) and the number of I/O points it requires.

d. Once all BEM733-controlled rack slots have been suitably populated, save that

portion of the configuration.

11. Configuration of a VersaMax Genius Network Interface Unit (GNIU) is similar to the

process described for the Series 90-70 Remote I/O Scanner.

a. Add a GBI001 to the Genius Bus configuration as described above.

b. Drill down into the GBI001. A display of VersaMax I/O will be presented.

c. For each rack and slot controlled by the GBI001, select the VersaMax I/O device that

corresponds with the actual VersaMax device that is in use.

12. Once all the Genius Devices have been “populated” onto the Genius Bus topology as

shown in Figure 16, click the OK button to save that portion of the configuration.

13. Note that the I/O addresses associated with each Genius Device will have been provided

with default assignments by Machine Edition. Double-click on each Genius device to

examine its properties, and change the I/O assignments where needed. In retrofits, for

example, it will likely be crucial to keep the same I/O assignments from the earlier

implementation so that the controller logic can operate with the same I/O allocations as

before. For each “location” on the Genius Bus, keep a note of the assigned I/O addresses.

14. In Machine Edition, store the Hardware Configuration to the RX3i CPU, which also stores

the GCG001 configuration data to the PNC001.

The following screenshot shows a completed configuration.

32 Public PACSystems RX3i Genius Communications Gateway User Manual GFK-2892B

Figure 18: Genius Gateway Configuration Example

Page 37

Chapter 4. System Operation

System Operation Chapter 4

This chapter provides a System Overview and describes:

• Communications

• Redundancy

• I/O Scans

• Alarms

4.1 System Overview

4.1.1 Communications

As shown in Figure 7, the Genius Gateway (GCG001) sits on a PROFINET network which is

connected to a PROFINET Controller (PNC001, for instance). The PROFINET Controller is

mounted in an RX3i rack. This aspect of the architecture allows the RX3i to interact with the

GCG001.

The PROFINET network to which the GCG001 is connected operates at 100Mbps only. The

Network Speed will be set through auto-negotiation if necessary. Details of PROFINET

communications may be found in the RX3i PROFINET Controller System Manual GFK-2571.

The GCG001 is also connected to a Genius Bus. It takes the place of a traditional Genius Bus

Controller, meaning it is capable of communicating with up to 31 other Genius Devices.

The Genius Bus operates as a Local Area Network (LAN) using twisted pair wiring. The wiring is

daisy-chained via the terminal strips on each device, as shown in Figure 10. The Genius LAN

will not be disrupted if power is lost on one its networked devices, since the wiring passes

through each device without requiring any active electronics to be present. The LAN cabling

must be terminated at one end of the cable run, using a resistor, the value of which matches

the impedance of the cable used in the application. See Figure 11 for terminating the bus at

the GCG001.

The Genius Bus is capable of operating at a number of different baud rates. All devices on the

bus must operate at the same agreed baud rate. For further details, refer to the Genius I/O

System and Communications User's Manual (GEK-90486). The default baud rate of the GCG001,

when shipped from the factory is 153.6 kBaud. This may be changed via the Machine Edition

configuration software.

In the event the baud rate needs to be changed, the following sequence is recommended:

1. Disconnect the GCG001 module from the Genius bus.

2. Change the baud rate to the new value on all Genius devices connected to that bus.

3. Cycle power to all Genius devices on which the baud rate has just been changed.

4. Use the HHM to verify the baud rate was successfully changed on each device.

5. Retry the above steps on any devices that failed to switch over to the new baud rate.

6. Using Machine Edition, configure the GCG001 module to operate at the new baud rate.

7. Reconnect the GCG001 to the Genius bus.

8. Note that the HHM will not work reliably on a mixed baud rate bus. Connect the HHM

directly to any device under these circumstances and disconnect that device from the

Genius bus temporarily. The baud rate of the HHM can be altered (via the HHM keyboard)

to match the configured baud rate of the device (which may be unknown). Once both the

HHM and target device are set to the same baud rate, the HHM can command the target

device to change to a new baud rate, which will take effect upon power cycling the

device. Remember to then change the baud rate of the HHM to the new baud rate.

GFK-2892B PACSystems RX3i Genius Communications Gateway User Manual Public 33

Page 38

Chapter 4. System Operation

Genius

I/O

Genius

I/O

Genius

I/O

PROFINET I/O

Genius IO Bus

G