Page 1

GE

Automation & Controls

Programmable Control Products

PACSystems* IC695CPE400

RX3i 1.2GHz 64MB

Rackless CPU w/Field Agent

Quick Start Guide

GFK-3002A

October 2017

g

Page 2

Page 3

i IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Contents

User Features ................................................................................................................. 1

Switches ........................................................................................................... 4

Displays and Indicators (LEDs) ......................................................................... 4

Front-Panel Ethernet Ports ............................................................................... 7

Serial COM Port ................................................................................................ 8

Video Display Port ............................................................................................ 8

Field Agent Port ................................................................................................ 8

Energy Pack Connector .................................................................................... 9

Input Power Connector ..................................................................................... 9

Removable Data Storage Device (RDSD) ......................................................... 9

Hardware Installation................................................................................................. 10

Initial Checks ...................................................................................................10

Installation .......................................................................................................10

Installation in Hazardous Areas ........................................................................12

Connect to Power Supply .................................................................................13

Grounding ........................................................................................................14

Module Start-up ........................................................................................................... 15

You Will Need: .................................................................................................15

Basic Start-up Steps: .......................................................................................16

Configuration ............................................................................................................... 17

Backwards Compatibility ..................................................................................17

PROFINET Controller Configuration ................................................................17

Field Agent Configuration .................................................................................18

4.3.1. Start the Embedded Field Agent (EFA) ............................................................18

4.3.2. Log into the Web Console ................................................................................18

4.3.3. Configure the Network .....................................................................................20

Redundancy Configuration ...............................................................................24

Additional Information ............................................................................................... 25

Page 4

Page 5

1 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

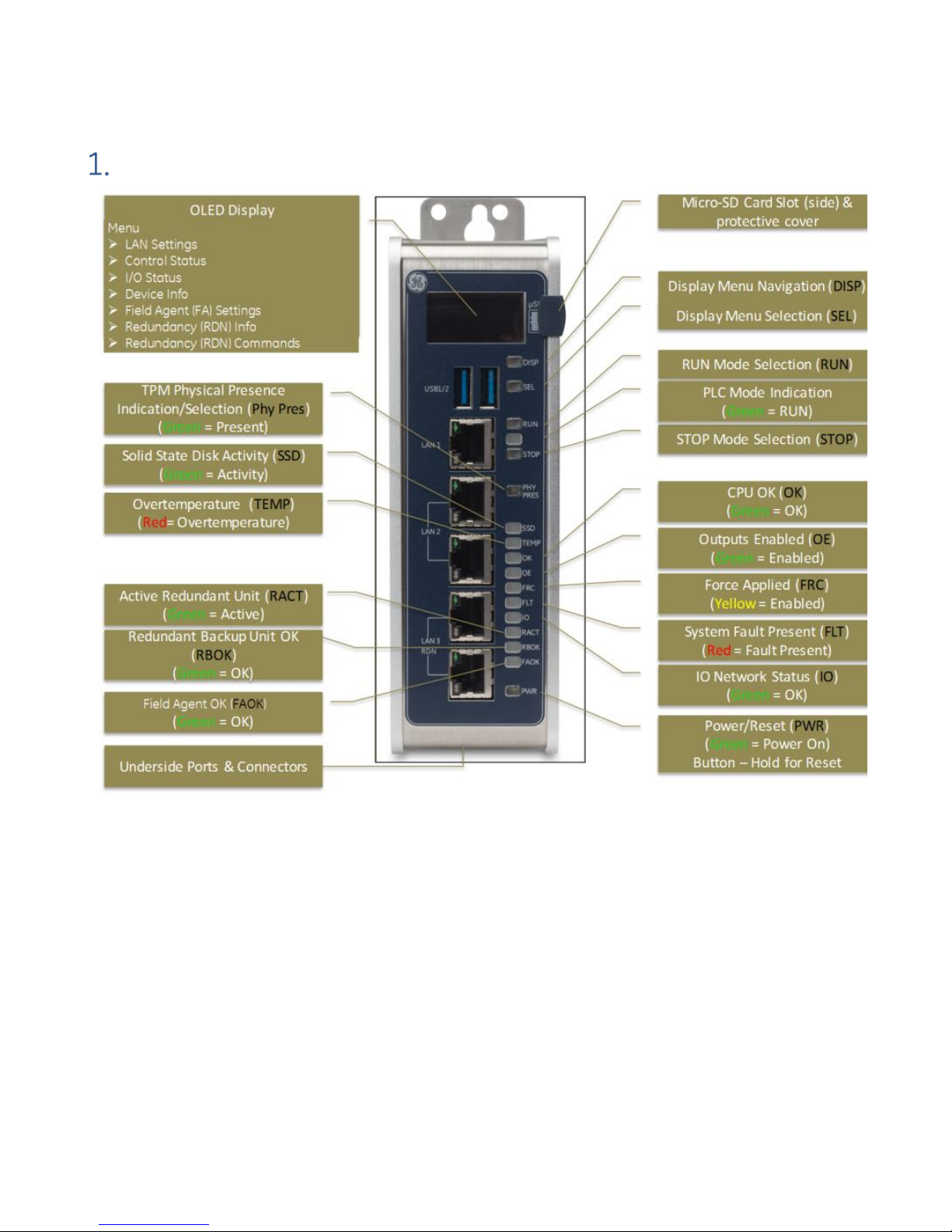

User Features

Figure 1: CPE400 Features at a Glance

The PACSystems* RX3i CPE400, part of GE’s Industrial Internet Control System, is the

industry’s first outcome optimizing controller. It augments real-time deterministic

control with Field Agent technology, delivering near real time advice through market

analysis, fleet and enterprise data, or asset/process knowledge to optimize the

outcomes that today’s businesses require. The Predix™ enabled CPE400 provides

reliable, secure communication and analytics using either cloud-based or edgebased outcome optimizing apps. Controls can now be programmed to dynamically

influence business outcomes, generate new forms of revenue, and improve

profitability.

Page 6

GFK-3002A October 2017 2

• The stand-alone CPE400 uses a 1.2GHz quad-core microprocessor and real-time

hypervisor technology to run real time deterministic control applications

concurrently with Field Agent technology without any adverse impact of one

over the other.

• A built-in RX3i PLC:

o User may program in Ladder Diagram, Structured Text, Function Block

Diagram, or C.

o Contains 64Mbytes of configurable data and program memory.

o Supports auto-located Symbolic Variables that can use any amount of user

memory.

o Reference table sizes include 32k bits for discrete %I and %Q and up to 32k

words each for analog %AI and %AQ. Bulk memory (%W) also supported for

data exchanges.

o Supports up to 512 program blocks. Maximum size for a block is 128KB.

• Field Agent technology is a platform for securely applying Predix applications

and secure connectivity to the Predix Cloud as well as running edge apps.

Running the Field Agent concurrently with the real-time control applications

allows the CPE400 to rapidly leverage external data. External monitoring may be

used to analyze and optimize entire business operations. The analysis can then

be used to dynamically adjust real-time industrial controls to align with changing

business objectives in today’s Industrial Internet age.

• Supports four independent 10/100/1000 Ethernet LANs. Three are located on the

front panel, as shown in Figure 1. LAN1 attaches via the upper, dedicated RJ 45

connector. LAN2 and LAN3 each attach via a pair of internally-switched RJ 45

connectors. The fourth LAN, labeled EFA (Embedded Field Agent), is located on

the underside (Figure 2), and is specifically used for Field Agent connectivity (see

Field Agent bullet just above).

• The embedded communications interface has dedicated processing capability,

which permits the CPU to independently support LAN1 and LAN2 with:

o up to 48 simultaneous SRTP Server connections;

o up to 16 simultaneous Modbus/TCP Server connections;

o 32 Clients are permitted; each may be SRTP or Modbus/TCP.

o OPC UA Server with support for up to 5 concurrent sessions with up to

10 concurrent variable subscriptions and up to 12,500 variables;

o up to 255 simultaneous Class 1 Ethernet Global Data (EGD) exchanges.

Page 7

3 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

• The embedded PLC may use one or both of the Ethernet LAN2 ports to support

the embedded Simplex PROFINET I/O Controller. PROFINET supports up to 32 I/O

devices with update rates of 1 – 512ms. I/O device update rates of 8ms and

faster are possible with 16 or fewer devices. Update rates of 16ms and higher

result whenever more than 16 devices are configured.

• Media Redundancy Protocol (MRP) allows the CPE400 to participate in a

PROFINET I/O network with MRP ring technology. This eliminates the I/O network

as a single point of failure. The CPE400 may be used as either a Media

Redundancy Manager or Media Redundancy Client.

• Effective with firmware release 9.30, the CPE400 supports Hot Standby

Redundancy with PROFINET IO. In this configuration, LAN3 is used as a highspeed data synchronization link between the two redundant CPUs. Only the

Primary and Secondary CPUs may be attached to LAN3. Two OLED menu items

support Redundancy operation: RDN Info and RDN Command. The RACT and

RBOK LEDs reflect the status of the Redundant CPUs.

• Effective with firmware release 9.30, the CPE400 supports two independent

Redundant IP addresses, one for LAN1 and one for LAN2. LAN2 Redundant IP is

supported when configured for Ethernet mode only. Redundant IP is supported

by the SRTP Server, Modbus TCP Server, and EGD protocols. It is not possible to

use Redundant IP with the OPC UA Server or with the Ethernet firmware update

web page.

• The CPE400 is secure by design, incorporating technologies such as Trusted

Platform Modules, secure boot, and encrypted firmware updates.

• Optional Energy Pack, IC695ACC403, allows CPE400 to instantly save user

memory to non-volatile storage in the event of loss of power.

• OPC UA Sweep Mode & Sweep Time: The CPE400’s sweep mode and sweep time

are available through the OPC UA server. The Sweep Mode variable reports the

controller’s current mode: Stop Disabled, Run Enabled, Stop Enabled,

Run Disabled, Stop Faulted, and Stop Halted. The Sweep Time variable reports

the sweep time in seconds. These variables are located under

GE Device Information -> PACSystems RX3i -> Controller.

• An OLED display that provides access to basic CPE400 status and control

information including each LAN’s configured IP Address.

• Operating temperature range -40C to 70C (-40F to 158F).

• Alternate panel-mount adaptor plate included.

Page 8

GFK-3002A October 2017 4

Switches

All user-accessible switches are provided as pushbuttons on the front panel (Figure 1)

as described below.

Pushbutton

Function

DISP

Permits user to navigate menus in the OLED display.

SEL

Permits user to select the menu item on the OLED display.

RUN

Activates OLED Menu to select RUN/Enabled or RUN/Disabled

Mode for the embedded PLC.

STOP

Activates OLED Menu to select STOP/Enabled or STOP/Disabled

Mode for the embedded PLC.

PHY PRES

Not functional.

PWR

Hold down for brief period to induce CPU Reset.

Note that this does not turn unit power off, but only holds unit in Reset

Displays and Indicators (LEDs)

OLED Display

The monochrome organic light-emitting diode (OLED) display (Figure 1) is used to

display CPE400 system menus. It interacts with the DISP pushbutton, which jogs the

cursor from one menu item to the next, and with the SEL pushbutton, which activates

the currently indicated menu item for further action.

The OLED display permits the user to:

• Display Ethernet LAN Settings: IPv4 address.

• Display the PLC firmware revision.

• Set/view PLC mode and view sweep time.

• Set the PLC mode to RUN/STOP with I/O Enabled/Disabled via the display.

Note: the RUN and STOP pushbuttons activate the PLC Mode menu items per

Section 1.1.

• View whether all, some, or none of the PROFINET I/O devices are connected.

• Display EFA Settings: IPv4 address, subnet mask, gateway, MAC address,

IPv6 address.

• Issue Field Agent Commands: Enter/Exit Configuration mode, Clear

Configuration, Perform factory reset.

• View Field Agent Status: Off, Starting, Connecting, Connected, Connected-ACT.

• View HSB Redundancy Mode and State (Release 9.30 and later)

• Command an HSB Redundancy Role Switch (Release 9.30 and later)

Page 9

5 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

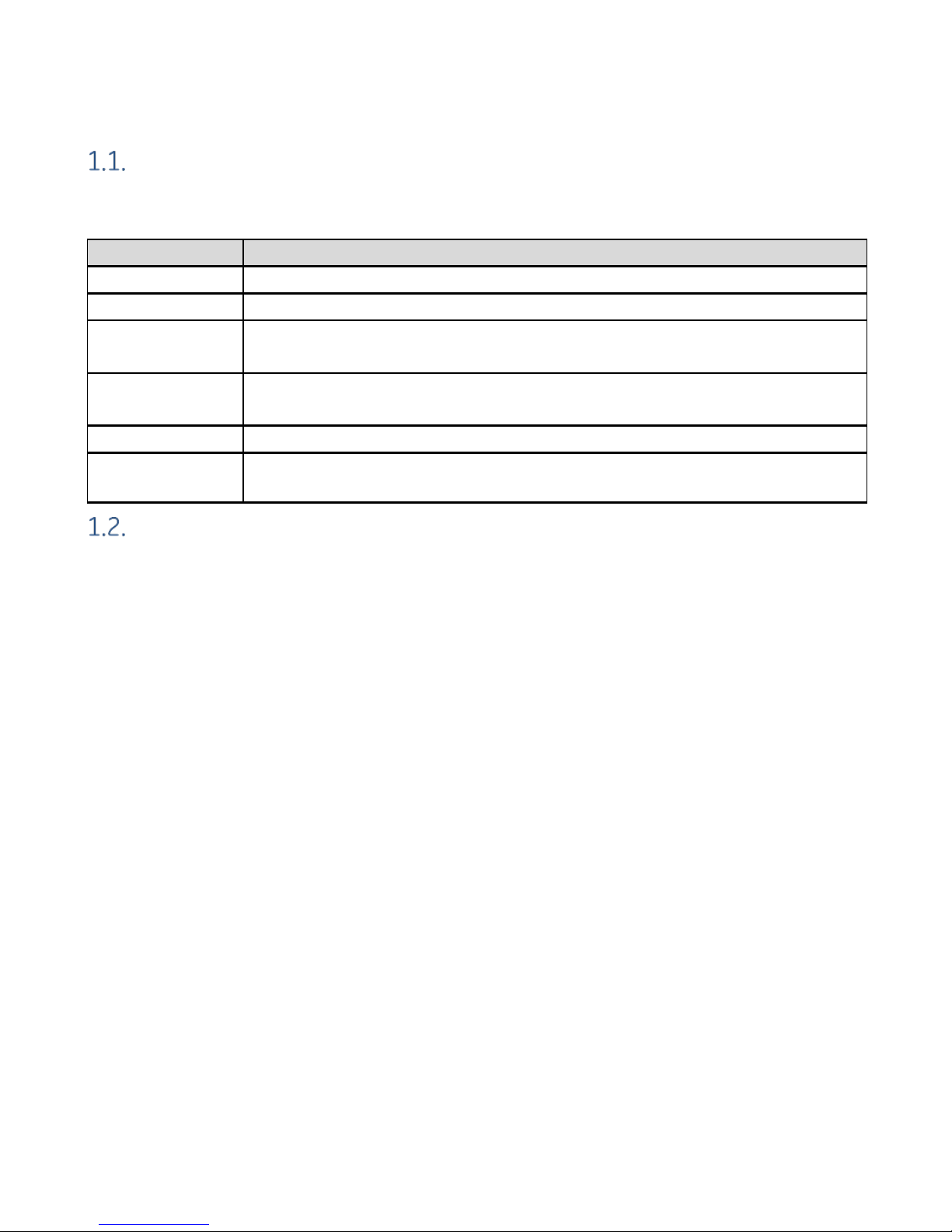

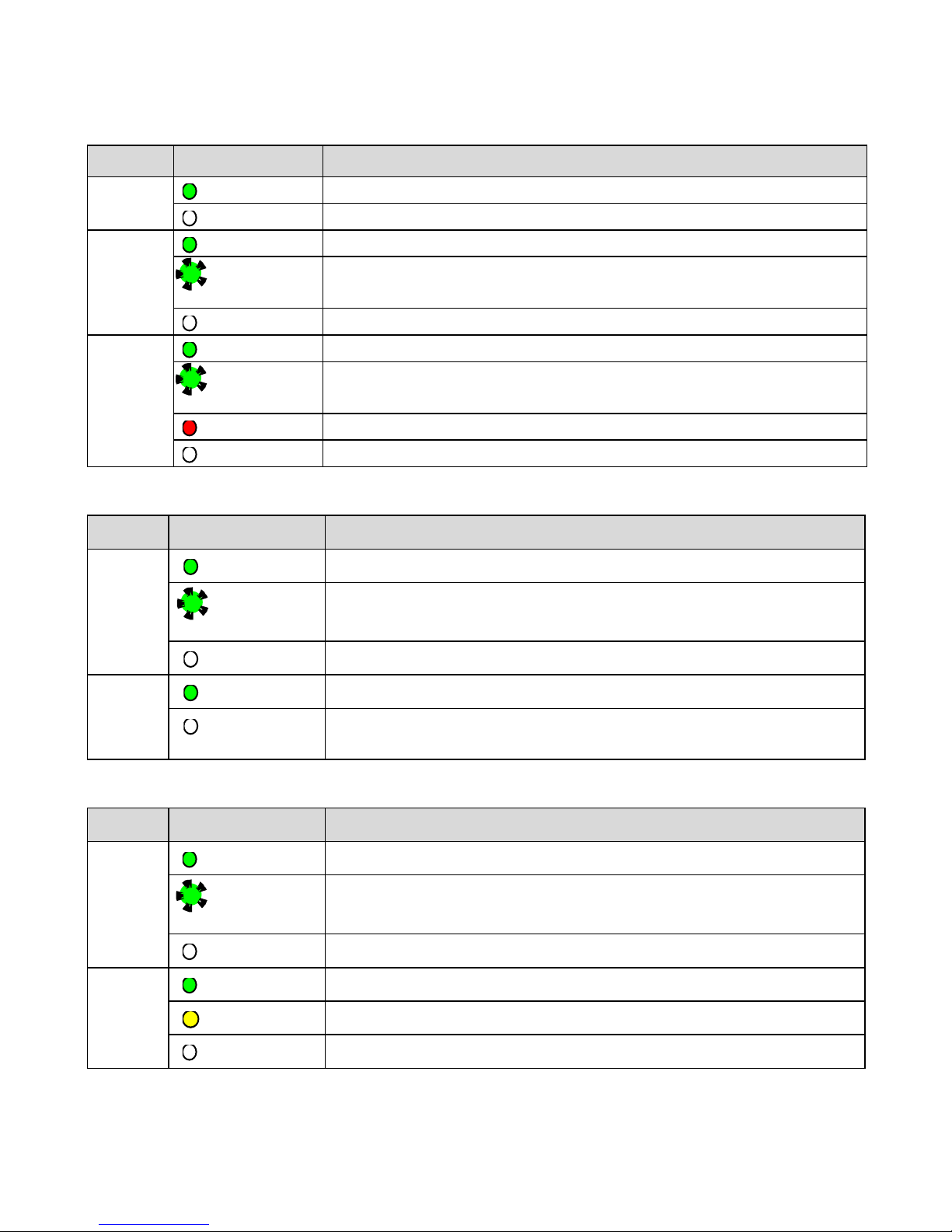

Status Indicators (LEDs)

LED

LED State

Operating State

PLC

MODE1

On Green

PLC is in RUN mode.

Off

PLC is in STOP mode.

RUN

Blinking in

unison

CPU is updating an internal programmable hardware

device.

OE

PHY

PRES

On Green

TPM Physical Presence (not functional).

Off

SSD

On Green

Activity detected on Solid State Disk.

Off

No activity detected on Solid State Disk.

TEMP

On Red

CPU Overtemperature condition detected.

Off

Overtemperature condition not detected.

OK

On Green

CPU has passed its power-up diagnostics and is

functioning properly. (Following initialization sequence.)

Off

Power is not applied or CPU has a problem.

Blinking;

All other

LEDs off

PLC in STOP/Halt state; possible watchdog timer fault.

If the programmer cannot connect, cycle power with

charged Energy Pack attached and refer to fault tables.

OK

Blinking

alternately

CPU encountered a Secure Boot Error.

OE

OE

On Green

Output scan is enabled.

Off

Output scan is disabled.

FRC

On Yellow

One or more Overrides active in I/O Reference Table(s).

Off

No Overrides active in any I/O Reference Table.

FLT

On Red

PLC is in STOP/Faulted mode: a fatal fault has occurred.

Off

No fatal faults detected.

IO

On Green

PROFINET Connection Status = OK.

Off

PROFINET Connection Status not OK.

RACT

On Green

Local Redundant CPU is Ready & Active.

Off

Local Redundant CPU is not Ready.

1

This LED is located between the RUN and STOP pushbuttons. It indicates the PLC Mode.

Page 10

GFK-3002A October 2017 6

LED

LED State

Operating State

RBOK

On Green

Remote Redundant CPU is Ready.

Off

Remote Redundant CPU is not Ready.

FAOK

On Green

Field Agent Running and Connected to Cloud.

Blinking

Green

Blink at 0.5 Hz: Field Agent Starting.

Blink at 1 Hz: Field Agent Running.

Off

Field Agent Off.

PWR

On Green

CPU running.

Blinking

Green

Booting up – diagnostics in progress.

On Red

Off

Off

Reset / Power not detected.

Front Ethernet Indicators (LAN1, LAN2, LAN3 RJ45 Built-in LEDs)

LED

LED State

Operating State

Link

Status

(upper)

On Green

The corresponding link has been established.

Blinking

Green

Traffic is detected at the corresponding port.

Off

No connection established at corresponding port.

Link

Speed

(lower)

On Green

Corresponding data speed is 1 Gbps or 100 Mbps.

Off

Corresponding network data speed is 10 Mbps

Bottom Ethernet Indicators (EFA RJ45 Built-in LED)

LED

LED State

Operating State

Link

Status

(upper)

On Green

The corresponding link has been established.

Blinking

Green

Traffic is detected at the corresponding port.

Off

No connection established at corresponding port.

Link

Speed

(lower)

On Green

Corresponding network data speed is 1 Gbps.

On Yellow

EFA port only: network data speed is 100 Mbps

Off

Corresponding network data speed is 10 Mbps

Page 11

7 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Front-Panel Ethernet Ports

LAN1 connects to the uppermost RJ45 connector (Figure 1). It is not switched.

LAN2 connects to the middle two RJ45 connectors (Figure 1). These two ports are

switched internally.

LAN3 connects to the two lower RJ45 connectors (Figure 1). These two ports are

switched internally. LAN3 may only be used to supply a high-speed synchronization

link between the Primary and Secondary CPUs in Hot Standby Redundancy. Both

ports are typically used, as described in the PACSystems Hot Standby CPU

Redundancy User Manual, GFK-2308 (revision L or later).

Each of the embedded Ethernet interfaces automatically senses the data rate

(10 Mbps or 100 Mbps or 1 Gbps), communications mode (half-duplex or full-duplex),

and cabling arrangement (straight-through or crossover) of the attached link. LEDs

embedded in each RJ45 connector provide indications per the table above.

LAN1 or LAN2 may be used to communicate with the PME programming software

using the Service Request Transport Protocol (SRTP, a proprietary GE protocol, used

primarily for communication with the programmer).

To establish Ethernet communications between the PME programming and

configuration software and the CPU, you first need to know the target IP address. Use

the OLED menu function to check the IP Address. The factory-shipped default settings

are:

CPE400 LAN1

CPE400 LAN2

CPE400 LAN3

IP Address:

192.168.0.100

10.10.0.100

N/A

Subnet Mask:

255.255.255.0

255.255.255.0

N/A

Gateway:

0.0.0.0

0.0.0.0

N/A

Page 12

GFK-3002A October 2017 8

Serial COM Port

The RJ45 port marked COM is located on

the underside of the CPE400, as shown

in Figure 2. This port is not currently

supported.

Video Display Port

The Display Port is located on the

underside of the CPE400, as shown in

Figure 2. It provides signals for

connecting either a suitable monitor or

video adapter to the unit. This port is

not currently supported.

Figure 2: Underside Ports & Connectors2

Field Agent Port

The RJ45 port marked EFA is located on the underside of the CPE400, as shown in

Figure 2. This is an Ethernet port pre-configured to connect securely to the Predix

cloud environment. For additional information concerning use of this port, refer to the

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual, GFK-2222Y or later. For

more detailed information regarding Field Agent, refer to the Field Agent User’s Guide,

GFK-2993.

The FAOK LED, located on the front panel, indicates the status (page 6) of the Field

Agent interface.

2

Only the 24Vdc In Connector is shipped with the CPE400.

Page 13

9 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Energy Pack Connector

The CPE400 compatible Energy Pack, IC695ACC403, is supplied with a purpose-built

cable, IC695CBL003, which installs in the 24Vdc In and Energy Pack Control & Status

connectors shown in Figure 2. Use of the Energy Pack is optional. When used, it

allows the CPE400 to save its current state upon loss of power. Refer to the

PACSystems RX3i Rackless Energy Pack IC695ACC403 Quick Start Guide, GFK-3000, for

complete wiring and grounding instructions.

Input Power Connector

If no Energy Pack is to be connected, refer to Section 2.4. Otherwise, refer to the

PACSystems RX3i Rackless Energy Pack IC695ACC403 Quick Start Guide, GFK-3000.

Removable Data Storage Device (RDSD)

The CPE400 is equipped with a micro-SD card slot and two USB ports (Figure 1). These

are not currently supported.

Page 14

GFK-3002A October 2017 10

Hardware Installation

Initial Checks

Upon receiving your equipment, carefully inspect all shipping containers for damage.

If any part of the system is damaged, notify the carrier immediately. The damaged

shipping container should be saved as evidence for inspection by the carrier.

As the consignee, it is your responsibility to register a claim with the carrier for

damage incurred during shipment. GE will fully cooperate with you, however, should

such action be necessary.

After unpacking the equipment, record all serial numbers. Serial numbers are

required if you should need to contact Customer Care during the warranty period. All

shipping containers and all packing material should be saved should it be necessary

to transport or ship any part of the system.

Verify that all components of the system have been received and that they agree

with your order. If the system received does not agree with your order, contact

Customer Care.

Installation

As shipped, the CPE400 is intended for mounting on a DIN rail. A panel-mount

adaptor is also available. If panel-mounting is required, replace the DIN-rail adaptor

with the panel-mount adaptor using the screws supplied with that adaptor. Both

adaptors attach to the rear of the CPE400 chassis using four Torx M3 screws. Torque

newly-installed screws to 5.3 in-Ibs (0.6 Nm) if installing a new adaptor plate.

For installation to standards, refer to the Installation and Maintenance Requirements

document, GFK-3004.

Note the thermal requirements for mounting the equipment (Figure 3).

Mount on the DIN rail per Figure 4. (1) Incline the unit so that the upper hooks of the

DIN rail adaptor engage with the upper edge of the DIN rail. (2) Press on the lower

part of the unit until you hear a click. The click indicates that the lower hooks of the

DIN rail adaptor have engaged with the lower edge of the DIN rail.

Dismount from the DIN rail per Figure 5. (1) Grasp the unit securely. (2) Press down on

the release bar as indicated. (3) Swivel the unit away from the DIN rail, then remove.

Page 15

11 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

50mm 50mm

100

mm

100

mm

Air flow

adjacent device right

adjacent device left

adjacent device below

adjacent device above

25mm

Air flow

max. 70°C

Figure 3: Thermal Requirements

Figure 4: Mounting on DIN Rail

Figure 5: Dismounting from DIN Rail

Page 16

GFK-3002A October 2017 12

If using the panel-mount adaptor, two options are available: mount using two screws

(Figure 6) or, for more secure mounting, mount using four screws (Figure 7).

Figure 6: 2-screw panel mount

Figure 7: 4-screw panel mount

Installation in Hazardous Areas

Refer to the Installation and Maintenance Requirements document, GFK-3004.

Page 17

13 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Connect to Power Supply

The 24Vdc power input connector is located on

the underside of the CPE400, as shown in Figure 8.

The signal pinouts are also indicated.

The mating connector for the CPE400 24Vdc

power input is the 3-pin Phoenix 1827716 shown

in Figure 9. The power supply cable prepared by

the user must use the specified mating connector.

The positive “+” and negative “-“ signals are

required. FGND is optional, but recommended.

For the mating connector, the compatible

conductor size is from 24AWG to 16AWG. Strip the

wires back 7mm before inserting into the

connector. Tightening torque for the three signal

screws is 2.2 in-Ibs (0.248Nm). Secure the mating

connector to the power input connector via the

two captive screws provided.

The user-supplied SELV3 power supply must

supply voltage in the range of 18Vdc to 30Vdc.

Once the power supply cable (or compatible

Energy Pack ACC403) has been attached to the

CPE400 and the power supply has been turned on,

the unit will start booting. There is no need to push

any button.

The unit is equipped with built-in reverse polarity

protection. If + and - are swapped the unit will not

power-up. If + is connected to FGND, this will

cause a short. The power supply needs to protect

itself against this condition.

Figure 8: 24Vdc Power Input

Connector

Figure 9: 24Vdc Power Input

Mating Connector

Inrush Current

The CPE400 may experience an inrush current of up to 49A for 15µs.

3

SELV = Safety Extra Low Voltage

Page 18

GFK-3002A October 2017 14

Overvoltage protection

In the CPE400, the voltage to the inner loads is clamped to 33Vdc. At 33Vdc, the

internal clamping diode starts conducting at 1mA. Any further increase in the voltage

will cause the internal current fuse to blow and/or the clamping diode to break.

• CAUTION – EQUIPMENT REPAIR REQUIRED – Internal components must be

repaired at the factory; they are not field replaceable. Contact the GE

support team at https://ge-ip.force.com/communities/CC_Contact

Overcurrent protection

The function protects the internal circuitry from overcurrent conditions before serious

damage can occur, such as overheating of the equipment. The fuse is rated for 4A

continuous current. Once the sensed current reaches 40A, the fuse will blow after a

period of 10ms to 100ms.

• CAUTION – EQUIPMENT REPAIR REQUIRED – Internal components must be

repaired at the factory; they are not field replaceable. Contact the GE

support team at https://ge-ip.force.com/communities/CC_Contact

Grounding

Grounding via the FGND connection on the 3-pin 24Vdc In power header is

recommended (see section 2.4), but is not required if the CPE400 is mounted to a

grounded metal panel. Furthermore, if an Energy Pack is connected, be sure to

comply with grounding procedures as described in PACSystems RX3i Rackless Energy

Pack IC695ACC403 Quick Start Guide, GFK-3000.

Page 19

15 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Module Start-up

You Will Need:

• This PACSystems Rackless RX3i CPU.

• A compatible SELV 24Vdc, 48W power supply (72W if Energy Pack attached).

• (Optionally) A compatible Energy Pack, IC695ACC403, and corresponding cable.

• If no Energy Pack is to be attached, use the power supply cable described in

Section 2.4.

• A DIN rail, typically mounted in an enclosure, as discussed above. Alternately,

mount the unit using the compatible panel-mount adaptor.

• A computer running Proficy Machine Edition (PME) configuration and

programming software. PME Version 9.00 SIM 8 or later supports the CPE400.

Version 9.50 SIM 5 is required for Hot Standby Redundancy.

• Ethernet cable for connecting the PME programmer computer to the CPE400.

• Additional cables, as needed, to connect each port employed in the application.

• A very small slotted screwdriver to secure the 24Vdc mating connector.

• A T8 Torx screwdriver, if the micro-SD slot cover is to be removed. Note that the

cover must be replaced to achieve immunity from electrical noise.

• A T10 Torx screwdriver, if exchanging the mounting adaptors.

Page 20

GFK-3002A October 2017 16

Basic Start-up Steps:

For startup and configuration of the CPE400, complete the following steps. For full

details on CPE400 operation, refer to the PACSystems RX3i and RX7i CPU Reference

Manual, GFK-2222Y or later.

1. Mount the CPE400, as described in Section 2.2 and per the Installation and

Maintenance Requirements document, GFK-3004.

2. Attach the user-supplied power supply cable as described in Section 2.4 if no

Energy Pack is being used.

3. (optionally) Mount and attach the compatible Energy Pack, IC695ACC403, as

described in the PACSystems RX3i Rackless Energy Pack IC695ACC403 Quick Start

Guide, GFK-3000.

4. Turn on the power supply unit: the unit should then run without the need to press

any buttons.

5. If not previously configured, configure the RX3i PLC using PME 9.00 SIM 8 or later,

as described in the Configuration section below.

Note: When the ACC403 Energy Pack is powered up, a finite period is required to

charge it up to its operating level. During this time, the Energy Pack will

indicate this condition via its LEDs (refer to the PACSystems RX3i Rackless

Energy Pack IC695ACC403 Quick Start Guide, GFK-3000).

The CPE400 will begin its boot cycle immediately upon power application.

However, the embedded controller will not start its control until the ACC403 is

charged. This typically takes 45 seconds or less. In the event the ACC403 is

faulty or is not communicating, CPE400 commences operation without the

Energy Pack.

Note: In the event of loss of power, with the ACC403 Energy Pack connected and

charged up, the CPE400 remains on for 4 seconds to backup user memory

into its non-volatile memory.

Page 21

17 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Configuration

To configure, the CPE400, connect the computer running the PME programming

software to any of the front-panel Ethernet ports. PME 9.00 SIM 8 or later is required

The CPE400 is the first controller available in the PACSystems RX3i Rackless family.

Configuration will either start out using the RX3i Rackless CPE400 template when

creating a new project, or will convert an existing project to the CPE400 using the

Family Conversion feature in PME.

Backwards Compatibility

To convert an existing project which uses any other PLC, use the Family Conversion

feature in PME. Be aware of the constraints involved, as will be notified in PME. For

instance, the first PROFINET Controller in an RX3i CPU320 application will be assigned

to the embedded PROFINET Controller feature of the CPE400.

PROFINET Controller Configuration

An Embedded PROFINET Controller may be configured on LAN2. To enable the

PROFINET Controller in a CPE400 project, select the CPE400 target in the PME

Navigator (Figure 10) and open the Hardware Configuration. On the Settings tab,

change the designated LAN Mode of the selected port to PROFINET. The PROFINET

Controller node description then displays that a PROFINET node exists on the selected

LAN (under the CPE400). For further details, refer to the PACSystems RX3i PROFINET IO

Controller User Manual, GFK-2571.

Figure 10: PME Navigator showing PROFINET node on LAN2

Page 22

GFK-3002A October 2017 18

Field Agent Configuration

4.3.1. Start the Embedded Field Agent (EFA)

After providing the CPE400 with power, the Embedded Field Agent (EFA) application

will begin to boot. The FAOK LED will start blinking to indicate when the EFA has

booted and is ready for user logins. (This may take about two minutes.)

4.3.2. Log into the Web Console

To log into the Web Console:

1. Connect a computer to the EFA’s IICS Cloud Port or EFA Port.

2. Configure the computer’s network adapter to be an address on the Field Agent

network.

• The EFA’s default IICS Cloud Port or EFA Port is assigned 172.31.0.100

with subnet mask 255.255.0.0. Set your computer’s network adapter to

any other IP address on the 172.31.x.x network. For example,

172.31.0.101 with subnet mask 255.255.0.0.

3. Use the OLED Menu to enable Configuration Mode as follows:

• From the Main Menu, select the “FA Settings” menu item.

• From the FA Settings Menus, select the “Commands” menu item.

• From the Commands Menus, select the “Config Mode” menu item.

• Confirm entering Config Mode.

• Configuration Mode will remain active for one hour or until the above

steps are repeated to disable Configuration Mode.

Note: Browsing to the Web Console too soon may result in seeing an

Authentication Required or similar drop-down/pop-up dialog. Entering a

user name and password into this dialog will not permit a log-in to the Web

Console. Wait for the Field Agent to fully boot as indicated by the FAOK LED

and re-attempt to browse to the Web Console. Closing the current browser

tab or window may also be required.

4. Using Google Chrome (recommended), browse to the Field Agent’s Web Console

at https://172.31.0.100:8443/system/console.

5. Since the Web Console uses a self-signed certificate, the browser will warn that

the connection is not private. When prompted, accept the connection.

Page 23

19 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

6. Login using the default credentials.

• Default User Name: predix

• Default Password: predix2machine

7. A prompt to change the default password displays. Complete the form to

change the default password.

8. The password complexity requirements display if the chosen password is not

sufficiently complex. After changing the password, log in using the new

password.

Page 24

GFK-3002A October 2017 20

9. Verify that the Log Service page displays, which indicates a successful login.

Note: After some idle time, the Web Console will time out. If this occurs, the user

will need to return to the main page to log back into the console. Session

timeout does not automatically redirect the console back to the login

page.

4.3.3. Configure the Network

4.3.3.1. EFA IP Addresses

By default, the Embedded Field Agent’s WAN interface is set to a static address of

172.31.0.100 with a subnet mask of 255.255.0.0.

To change the WAN IP address

1. Verify that the WAN Ethernet cable is connected to the IICS Cloud port / EFA Port.

If a network proxy is needed to connect the field agent to the WAN, refer to the

section Configure a Network Proxy.

2. From the Web Console, navigate to the Technician Console, Network

Configuration page.

Page 25

21 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

3. Set the WAN interface settings appropriately for the Field Agent’s network. DHCP

can be used for networks where a DHCP server is available, and a static IP

address for networks where each device is manually assigned an address. Click

the Save button to accept the changes.

Note: The DNS servers can also be configured to be obtained automatically or

specified statically. When using a static IP address, DNS servers must also

be specified statically.

4.3.3.2. Configure a Network Proxy

A Network Proxy is only required when your network architecture is configured to

restrict access directly to the Internet. Contact your network administrator for the

Network Proxy information.

If a network HTTP/HTTPS proxy server is used to route traffic from the intranet to the

Internet, the network proxy must be configured in the Web Console under Technician

Console, Network Configuration. To add or update a network proxy server, check the

Page 26

GFK-3002A October 2017 22

“Enable HTTP/HTTPS Proxy” check box, enter the proxy server’s address and port in

the form “proxy:port” into the Proxy Settings text box, and press the Save button.

To verify the Field Agent can successfully use the newly configured network proxy to

reach the Internet, use the Test Connection feature of the Field Agent Updater page

in the Web Console under Technician Console, Field Agent Updater. Internet

reachability can be tested by using either the default Update URL or any other

desired URL and pressing the Test Connection button.

If the URL is reachable, a Test Connection Succeeded message is displayed below the

Test Connection button after the button is pressed. Otherwise, a message will appear

indicating that the Test Connection attempt failed.

4.3.3.3. Configure Time Synchronization

In order for industrial data time-stamping and Field Agent diagnostic information to

operate reliably, it is important for the Field Agent to have an accurate time source.

The Field Agent has two methods of synchronizing time – either by using a Network

Time Protocol (NTP) server or by pulling time from a web page hosted by an HTTPS

web server with its own reliable time source. Either method can be configured in the

Web Console under Technician Console, Time Sync Configuration.

Page 27

23 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

4.3.3.3.1. Using NTP Time Synchronization

By default, time synchronization is configured to use the time.windows.com NTP

Server. If a valid network path to the Internet exists, time will be synchronized when

the Field Agent boots and continuously while running. The current date and time on

the Field Agent is displayed above the Save button on the Time Sync Configuration

page when the page loads, and can be updated by pressing the Save button or

reloading the page.

To change the NTP server to use for time synchronization enter the new NTP server

URL in the NTP Server textbox and press the Save button. If the new server was

successfully configured, a success statement will be displayed and the updated time

will be displayed. If the time and date was more than 20 minutes out of date prior to

time synchronization occurring after pressing the Save button, the Web Console

session may end and an error message may be presented indicating that the

session’s timeout had been reached. Log back into the Web Console to verify the time

was updated as expected.

4.3.3.3.2. Using HTTPS Time Synchronization

Time synchronization can also be configured to use an HTTPS web server's time by

pulling it from the header of the web page it serves. To configure HTTPS time

synchronization, select the HTTPS Server radio button on the Time Sync Configuration

page, enter a valid HTTPS URL, and press the Save button. If a network proxy is in use,

this time synchronization method will only work with HTTPS URLs that do not require

a network proxy in order to reach them.

Page 28

GFK-3002A October 2017 24

If the new HTTPS URL was successfully configured after pressing the Save button, a

success statement will be displayed and the updated time will be displayed. If the

time and date was more than 20 minutes out of date prior to time synchronization

occurring after pressing the Save button, the Web Console session may end and an

error message may be presented indicating that the session’s timeout had been

reached. Log back into the Web Console to verify the time was updated as expected.

Redundancy Configuration

With firmware version 9.30 or later, it is possible to configure the CPE400 as a Hot

Standby Redundancy CPU with PROFINET IO. The two ports on LAN3 are used

exclusively for this purpose: they provide a high-speed data synchronization link

between the two CPUs. Connect the upper LAN3 port of the Primary CPU to the upper

LAN3 port of the Secondary CPU and connect the lower LAN3 port of the Primary to

the lower LAN3 port of the Secondary. Note that no additional hardware, other than

the two redundant CPUs, may be connected to LAN3.

To enable redundancy in a CPE400 project, select the CPE400 target in the PME

Navigator and use the Property Inspector to change the Enable Redundancy target

property to True.

Important: Set the Background Window Timer to a minimum of 5ms in both the

Primary and Backup CPE400 hardware configurations. The Background Window

Timer setting may be found on the Scan Tab in the CPE400’s hardware configuration.

Once configured for HSB Redundancy, the RACT and RBOK LEDs (Figure 1) become

functional. RACT indicates the Local CPU is Ready & Active; RBOK indicates the

Remote CPU is Ready. These two LEDs are also reflected in the Status Data of the CPU

and are presented as OPC UA Variables.

The OLED display includes two menu items used in conjunction with Redundancy:

• RDN Info provides status information via the OLED display.

• RDN Command permits the operator to perform a Role Switch.

For further details, refer to the PACSystems Hot Standby CPU Redundancy User

Manual, GFK-2308 (rev L or later).

Page 29

25 IC695CPE400 Rackless CPU w/Field Agent Quick Start Guide GFK-3002A

Additional Information

Proficy Logic Developer-PLC Getting Started

GFK-1918

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User’s

Manual

GFK-2224

PACSystems TCP/IP Ethernet Communications Station Manager Manual

GFK-2225

PACSystems Hot Standby CPU Redundancy User Manual

GFK-2308

PACSystems RX3i System Manual

GFK-2314

PACSystems RXi, RX7i, RX3i and RSTi-EP Controller Secure Deployment Guide

GFK-2830

PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference Manual

GFK-2950

PACSystems HART Pass Through User Manual

GFK-2929

PACSystems RX3i PROFINET IO Controller User Manual

GFK-2571

PROFINET I/O Devices Secure Deployment Guide

GFK-2904

PACSystems RX3i Rackless Energy Pack IC695ACC403 Quick Start Guide

GFK-3000

IC695CPE400 RX3i 1.2GHz 64MB Rackless CPU w/Field Agent

Important Product Information

GFK-3003

IC695CPE400 RX3i 1.2GHz 64MB Rackless CPU w/Field Agent

Installation and Maintenance Requirements

GFK-3004

Field Agent User’s Guide

GFK-2993

User manuals, product updates and other information sources are available on the

Support website, www.geautomation.com under Controllers and IO, RX3i Controllers.

Page 30

GFK-3002A October 2017 26

For binaries that you receive in this distribution that are licensed under any version of the GNU

General Public License (GPL) or the GNU Library/Lesser General Public License (LGPL), you can

receive, for a fee of no more than our cost of physically performing the distribution, a complete

machine-readable copy of the source code by sending a written request to:

Automation & Controls

GE

Attn: General Counsel

2500 Austin Drive

Charlottesville, VA 22911

Your request should include: (i) the name of the covered binary, (ii) the version number of the

product containing the covered binary, (iii) your name, (iv) your company name (if applicable)

and (v) your return mailing and email address.

This offer is valid for three (3) years after the date of the last distribution of this particular version

of this product. For any code in this product covered by version 3 of the GNU General Public

License (GPL), then this offer is valid for those who possess the object code for either i) for the

aforementioned three (3) years, or ii) until the date on which we cease offering both spare parts

and customer support for this particular version of this product, whichever occurs last.

https://digitalsupport.ge.com/communities/en_US/Documentation/PACSystemsIC695CPE400-Open-Source-Software-information

Page 31

GE

Contact Information

Americas: 1-800-433-2682 or 1-434-978-5100

Global regional phone numbers are available on our web site

www.geautomation.com

Copyright © 2016-2017 General Electric Company.

All Rights Reserved.

* Trademark of General Electric Company and/or its subsidiaries.

All other trademarks are property of their respective holders

GFK-3002A

g

Loading...

Loading...