Page 1

GE

Intelligent Platforms

Programmable Control Products

PAC8000* IO

PROFINET Scanner

User’s Manual, GFK-2839B

September 2017

Page 2

2 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

GFL-002

Warnings, Cautions and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that

hazardous voltages, currents, temperatures, or other conditions

that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury

or damage to equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if

care is not taken.

Note: Notes merely call attention to information that is especially significant to

understanding and operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover

all details or variations in hardware or software, nor to provide for every possible contingency

in connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Intelligent Platforms

assumes no obligation of notice to holders of this document with respect to changes

subsequently made.

GE Intelligent Platforms makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

* indicates a trademark of GE Intelligent Platforms, Inc. and/or its affiliates. All

other trademarks are the property of their respective owners.

©Copyright 2013 GE Intelligent Platforms, Inc.

All Rights Reserved

Page 3

Contact Information

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual –September 2017 3

If you purchased this product through an Authorized Channel Partner, please contact the

seller directly.

General Contact Information

Online technical support and GlobalCare

http://www.ge-ip.com/support

Additional information

http://www.ge-ip.com/

Solution Provider

solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this guide,

please contact us by telephone or email, or on the web at www.ge-ip.com/support

Americas

Online Technical Support

www.ge-ip.com/support

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email

support.ip@ge.com

Customer Care Email

customercare.ip@ge.com

Primary language of support

English

Europe, the Middle East, and Africa

Online Technical Support

www.ge-ip.com/support

Phone

+800-1-433-2682

EMEA Direct Dial

+420-23-901-5850 (if toll free 800 option is unavailable

or dialing from a mobile telephone)

Technical Support Email

support.emea.ip@ge.com

Customer Care Email

customercare.emea.ip@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Asia Pacific

Online Technical Support

www.ge-ip.com/support

Phone

+86-400-820-8208

+86-21-3217-4826 (India, Indonesia, and Pakistan)

Technical Support Email

support.cn.ip@ge.com (China)

support.jp.ip@ge.com (Japan)

support.in.ip@ge.com (remaining Asia customers)

Customer Care Email

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

Page 4

Page 5

Contents

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 5

Chapter 1. Introduction ...................................................................................... 7

1.1 PAC8000 PROFINET Scanner Overview ..................................................................7

1.2 PAC8000 PROFINET Scanner Versions ...................................................................8

1.3 PAC8000 PROFINET Scanner Specifications ...........................................................9

1.4 PAC8000 PROFINET Scanner Controls and Indicators ......................................... 10

1.4.1 PAC8000 PROFINET Scanner LEDs ............................................................ 10

1.4.2 Power Supplies .............................................................................................. 11

1.4.3 External BFP (Bussed Field Power Supply) Monitoring ................................ 12

1.4.4 12V DC HVCC/PNS Power supply monitoring .............................................. 12

1.4.5 Ethernet Network Ports .................................................................................. 13

1.4.6 USB Port ........................................................................................................ 16

1.5 Compatible PAC8000 IO Modules, Carriers, and Power Supplies ......................... 17

1.5.1 IO Modules ..................................................................................................... 17

1.5.2 IO Carrier ....................................................................................................... 17

1.5.3 PNS Carrier .................................................................................................... 17

1.5.4 Power Supply Requirements ......................................................................... 18

Chapter 2. Hardware Installation ..................................................................... 19

2.1 Module Installation .................................................................................................. 19

2.2 Cable and Connector Clearance Requirements ..................................................... 21

2.3 Installation in Hazardous Areas ............................................................................... 22

2.3.1 ATEX Marking ................................................................................................ 22

2.3.2 CE Marking .................................................................................................... 22

2.4 Installing the Module on a DIN Rail ......................................................................... 23

2.5 Removing the Module from the DIN Rail ................................................................. 24

2.6 Panel Mounting........................................................................................................ 24

2.7 Grounding ................................................................................................................ 25

2.8 Connecting Power Supplies to PAC8000 PROFINET Scanner .............................. 25

2.9 PAC8000 PROFINET Scanner Power-up and Restart ........................................... 26

2.10 LED Operation ......................................................................................................... 27

2.10.1 Special LED Blink Patterns ............................................................................ 28

2.11 Firmware Updates ................................................................................................... 29

2.11.1 Firmware Update for IO Modules in the PNS ................................................ 29

2.12 Installing the USB Port Driver .................................................................................. 30

Chapter 3. Configuration ................................................................................. 31

3.1 Configuration Overview ........................................................................................... 31

3.1.1 Basic Configuration Steps .............................................................................. 32

3.1.2 Configuration Tool .......................................................................................... 32

3.2 Adding a PAC8000 PROFINET Scanner to a LAN ................................................. 33

3.2.1 Configuring PAC8000 PROFINET Scanner Parameters ............................... 33

3.2.2 Configuring PAC8000 PROFINET Scanner Parameters ............................... 36

3.3 Assigning IO-Device Names ................................................................................... 37

Page 6

Contents

6 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

3.4 Clearing the IO-Controller Configuration ................................................................. 37

3.5 Replacing PAC8000 PROFINET Scanner Hardware.............................................. 37

Chapter 4. Diagnostics .................................................................................... 38

4.1 PNS Status and Control Data .................................................................................. 38

4.1.1 Output Control Register ................................................................................. 38

4.1.2 Input Status Registers .................................................................................... 39

4.2 Error Handling ......................................................................................................... 41

4.2.1 Fatal Error Handling ....................................................................................... 41

4.2.2 PROFINET Diagnostics ................................................................................. 42

4.2.3 Clearing Faults on PAC8000 Modules ........................................................... 45

4.2.4 PROFINET Module Loss, Add and Mismatch Faults .................................... 46

Chapter 5. PROFINET Specifications .............................................................. 47

5.1 PROFINET Protocol Support .................................................................................. 47

5.2 Technical Data......................................................................................................... 47

5.3 Limitations ............................................................................................................... 48

Page 7

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 7

Chapter 1. Introduction

This chapter provides an overview of the PAC8000 PROFINET Scanner (PNS) module and

its operation. This chapter also includes a list of the PAC8000 IO modules that can be

included in the PAC8000 PROFINET Scanner IO-Device.

Chapter 2, Installation, gives instructions for PNS installation, panel-mounting, grounding,

installing power supplies, and updating firmware. It also describes powerup and restart, and

LED operation.

Chapter 3, Configuration, describes how to configure the PNS and its IO modules.

Chapter 4, Diagnostics, describes the input and output data that can be used to monitor and

control the PNS. This chapter also explains how the PNS reports errors to the control system.

Chapter 5, PROFINET Specifications, summarizes the features specified for PROFINET

v2.3 Class A IO-Devices that are supported by the PAC8000 PROFINET Scanner module.

1.1 PAC8000 PROFINET Scanner Overview

The PAC8000 PROFINET Scanner (PNS) module interfaces PAC8000 IO modules to a

PROFINET IO network. The PNS scans the input modules in the node (retrieving input data

and providing output data), publishes input data on the PROFINET network at the configured

update rate, and receives data for output module outputs.

The PNS manages PROFINET communication and IO module configuration between an IOController and IO modules of PNS. If network communications are lost, the PNS manages I/O

states according to the individual module configurations.

Input and Output data are coherent over a full scan of the IO modules. All input data read

from one scan of the IO modules is kept together and then sent over the PROFINET network.

Similarly, outputs delivered on the network are sent to the IO modules as a unit. If new

outputs arrive during the writing of data to the output modules, the PNS continues to write to

the outputs using the previous data until all IO modules have been updated before switching

to the newly delivered data.

Page 8

Contents

8 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

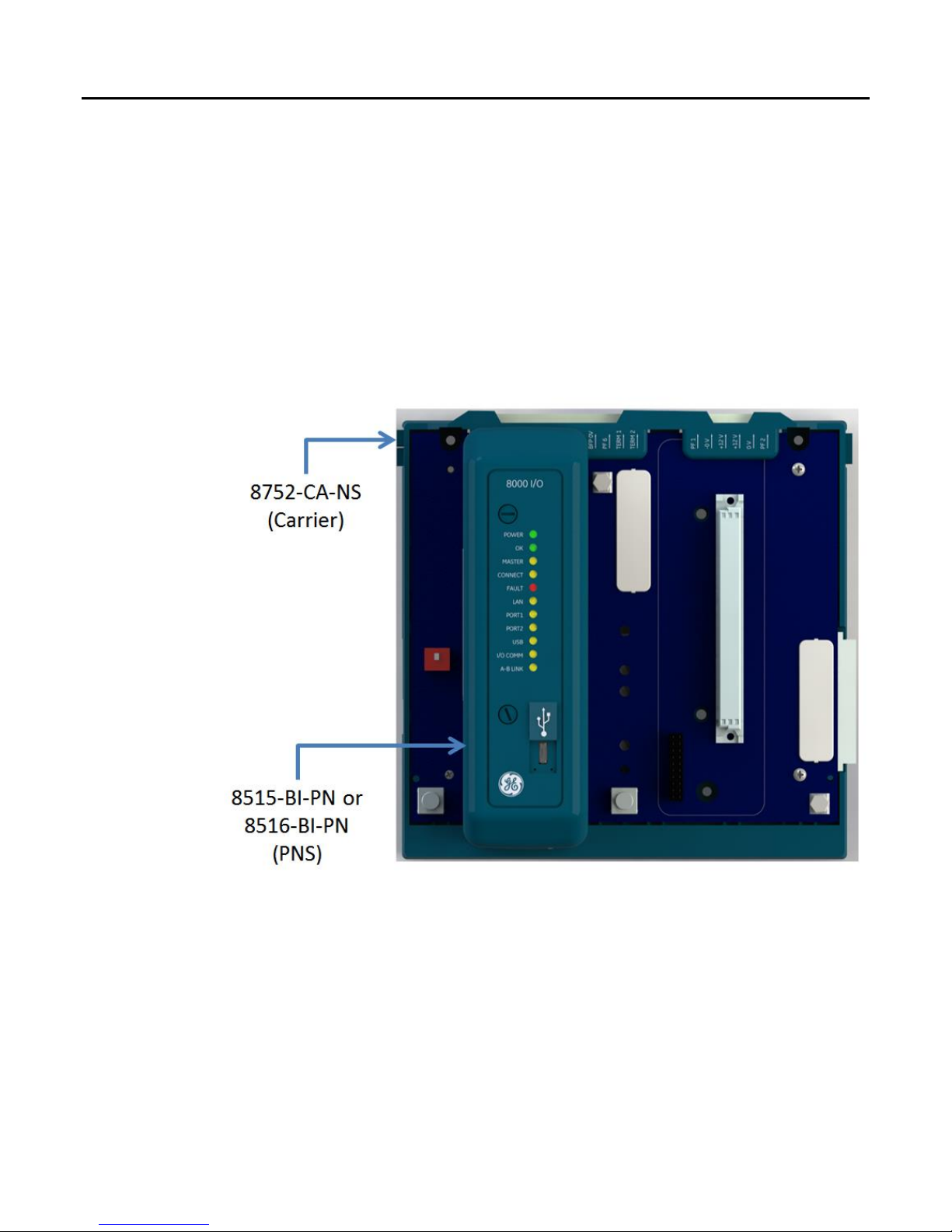

1.2 PAC8000 PROFINET Scanner Versions

The PNS network interface module is available in two versions to allow you to use the

network media that meet the requirements of your application.

8515-BI-PN: Two 10/100 Mbps copper RJ-45 media connectors supporting shielded

(refer Note below) and unshielded cables (CAT 5 and above)

8516-BI-PN: Two 100Mbps Multimode SC–Duplex fiber optic media connectors

The above PNS modules require the following carrier.

8752-CA-NS: PAC8000 Node Service Carrier

The PNS uses external 12V DC power supply. Optionally user can use two power supplies

having redundancy feature.

Note: The shield connections of RJ45 connectors on 8515-BI-PN module get connected to

the system ground through a capacitor internally, when the module is installed on the carrier.

Page 9

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 9

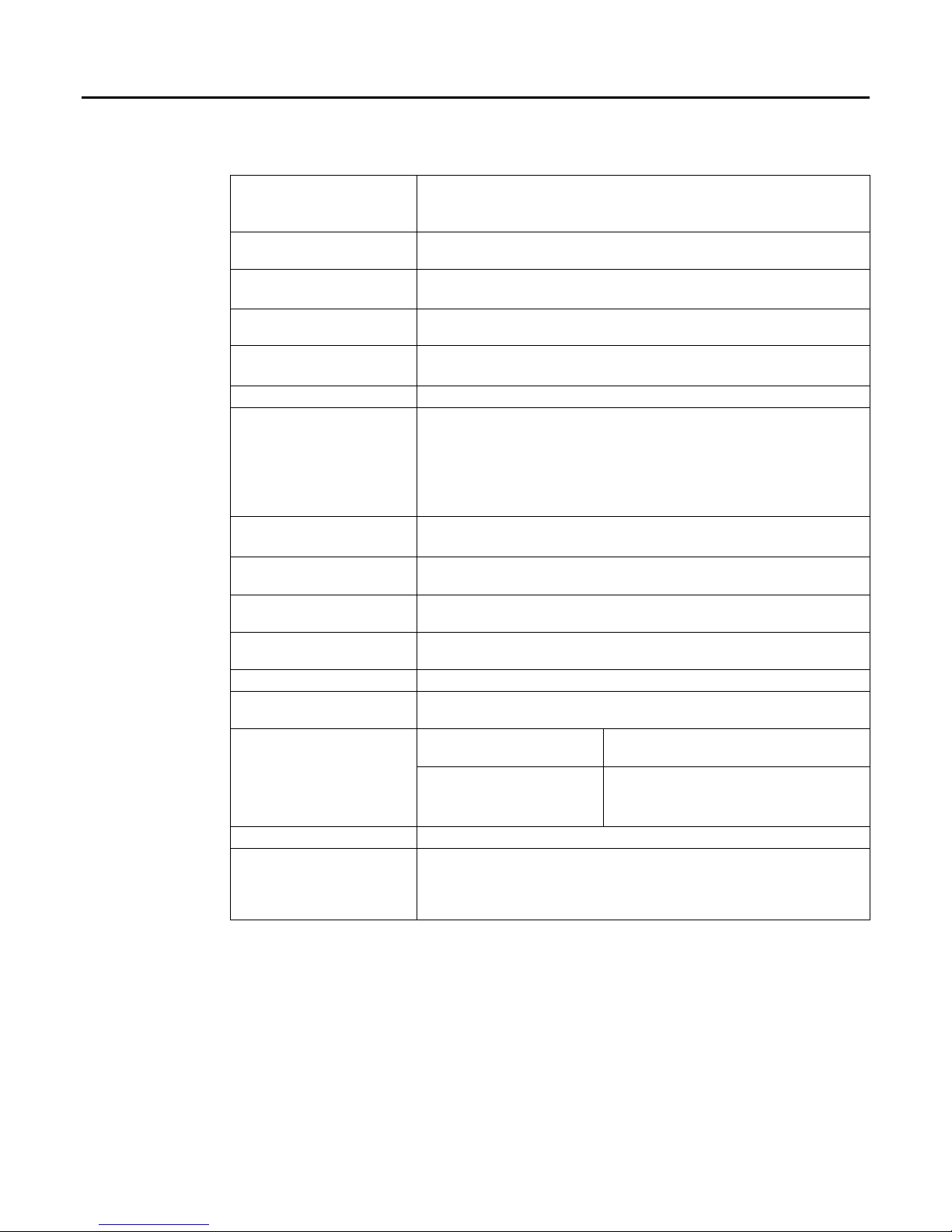

1.3 PAC8000 PROFINET Scanner Specifications

PROFINET Support

PROFINET Version 2.3 Class A IO-Device

Redundantly controlled operation conforms to PROFINET V2.3 Type

S2 System Redundancy.

RX3i PLC CPU Version

Required

Firmware version 7.0 or later

Proficy Machine Edition

Version Required

Version 7.5 SIM 3 or later

V2.3 GSDML and Proficy Machine Edition/3rd-Party tools.

Power Requirements

8515-BI-PN 4.5 Watts (5.5 Watts Max)

8516-BI-PN 6.0 Watts (7.2 Watts Max)

Module Dimensions

Length: 160.3mm (6.31”), Width: 128.3mm (5.05")

Thickness 47.78mm (1.88”)

Carrier Required

8752-CA-NS : PAC8000 Node Service Carrier

Operating Temperature

Range

8515-BI-PN -40˚C to +70˚C

8516-BI-PN -40˚C to +70˚C

Horizontal DIN rail mounting.

Optimum orientation is when the carrier is mounted in a vertical plane

with field terminals for communication cables located below the

modules.

Number of Port

Connectors

8515-BI-PN : Two RJ-45

8516-BI-PN : Two SC-Duplex

USB Connector (for

firmware upgrades)

One Micro-B connector. USB 2.0 compliant running at full speed

(12 MHz)

PNS Status and Control

Bits

64 input status bits and 48 output control bits

I/O Data Update on the

PROFINET LAN

Configurable: 1ms, 2ms, 4ms, 8ms, 16ms, 32ms, 64ms, 128ms, 256ms

and 512ms (Recommended is 4 ms and above)

Number of IP addresses

One. Supports Classless Inter-Domain Routing (CIDR)

Number of MAC

Addresses

Three. One per external port and one internal. External MAC addresses

are only used for specialized Ethernet protocols such as MRP or LLDP

I/O Station Maximum

Limits

Number of IO Modules per

Node

32

IO data per station

2880 bytes total

1440 bytes of input data

1440 bytes of output data

RoHS Compliance

Yes

Configuration

Configured using Proficy Machine Edition when used with a

PACSystems RX3i PROFINET Controller (PNC) module, as part of an

RX3i PROFINET network.

V2.3 GSDML file is available for import into 3rd-Party tools.

For product standards, general operating specifications, and installation requirements, refer

to the PAC8000 IO modules Manual, INM8200.pdf.

Page 10

Contents

10 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

1.4 PAC8000 PROFINET Scanner Controls and Indicators

The illustration below shows a PAC8000 PROFINET Scanner.

1.4.1 PAC8000 PROFINET Scanner LEDs

POWER LED

Power Supply LED is ON solid green when power is being supplied on the power supply

connector.

OK LED

The OK LED is solid green ON for normal operation.

MASTER LED

This LED is reserved.

CONNECT LED

When a new PNS module powers up for the first time, it has no network name. The

CONNECT LED slowly blinks to indicate that the module is not ready to use. After a name is

assigned, the CONNECT LED goes OFF.

If the PNS has an assigned network name, the CONNECT LED is OFF after a successful

power up. It turns ON solid when the IO-Controller has established communications with the

PNS module. It turns OFF when communications are terminated.

Page 11

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 11

FAULT LED

The FAULT LED remains OFF during normal operation when no PROFINET Diagnosis

conditions are present on the PNS itself or any IO module in the node. When a PROFINET

Diagnosis condition exists, the FAULT LED turns solid red. When all diagnosis conditions

have disappeared, the FAULT LED is OFF.

The FAULT LED blinks red (0.5 seconds ON/0.5 seconds OFF) if any of the MAC addresses

read from non-volatile memory on power-up are invalid. The PNS remains disconnected from

the Ethernet network if any of its MAC addresses are invalid.

Missing or mismatched IO modules in the PNS node do not affect the PNS FAULT LED.

LAN LED

The LAN LED blinks ON when the PNS module is actively processing Ethernet packets

(Tx/Rx). The LAN LED is OFF if there is no activity.

Port LEDs (10/100 Mbps and Link/Activity)

The two Port LEDs indicate link connection and link activity on the Ethernet ports. If a PORT

LED is solid ON, the port is connected but is not currently receiving or transmitting Ethernet

frames. A Port LED blinks when Ethernet frames are actively being transmitted or received.

USB LED

The USB LED is OFF when a USB connection is not established and ON when the link with a

computer is ready. The USB LED flashes when there is traffic such as Winloader activity on

the port.

I/O COMM

This LED turns ON when all IO module commands were successful in the last two seconds. It

blinks when at least one IO module command failed in the last two seconds. It remains OFF

when no IO module command was sent in the last two seconds.

A-B LINK

This LED is reserved.

1.4.2 Power Supplies

The PAC8000 PROFINET Scanner can be connected with either one power supply or dual

redundant power supplies. If two power supplies are installed, they serve as redundant

backups for each other.

Page 12

Contents

12 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

1.4.3 External BFP (Bussed Field Power Supply) Monitoring

The status of up to four Bussed Field Power supplies can be monitored through the status

bits of the PNS. For details, see 4.1.2.3, “PNS Power Status Register (PPSR).” The Bussed

Field Power monitoring connector is shown in the picture below. There are two terminal

marked as 24VA and 24VB provided for connecting the 24V terminal (+) of the power supply.

There are four terminals marked as BFP0V are provided to connect the 0V terminal (-). The

power status signals from the power supplies are required to be connected to terminals

marked as PF3, PF4, PF5 and PF6. Please note that this functionality shall only work if the

power status signal is “open-collector” type: low impedance to BFP0V when power is OK and

high impedance if power fails.

The terminal marked as “TERM1” & “TERM2” are reserved for future use.

1.4.4 12V DC HVCC/PNS Power supply monitoring

The status of up to two redundant 12V Power supplies (HVCC and/or PNS power) can be

monitored through the status bits of the PNS. For details, see 4.1.2.3, “PNS Power Status

Register (PPSR).” The HVCC connector is shown in the picture below. The power status

signals from the power supplies are required to be connected to terminals marked as PF1

and PF2. Please note that this functionality shall only work if the power status signal is “opencollector” type: low impedance to GND when power is OK and high impedance if power fails

Page 13

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 13

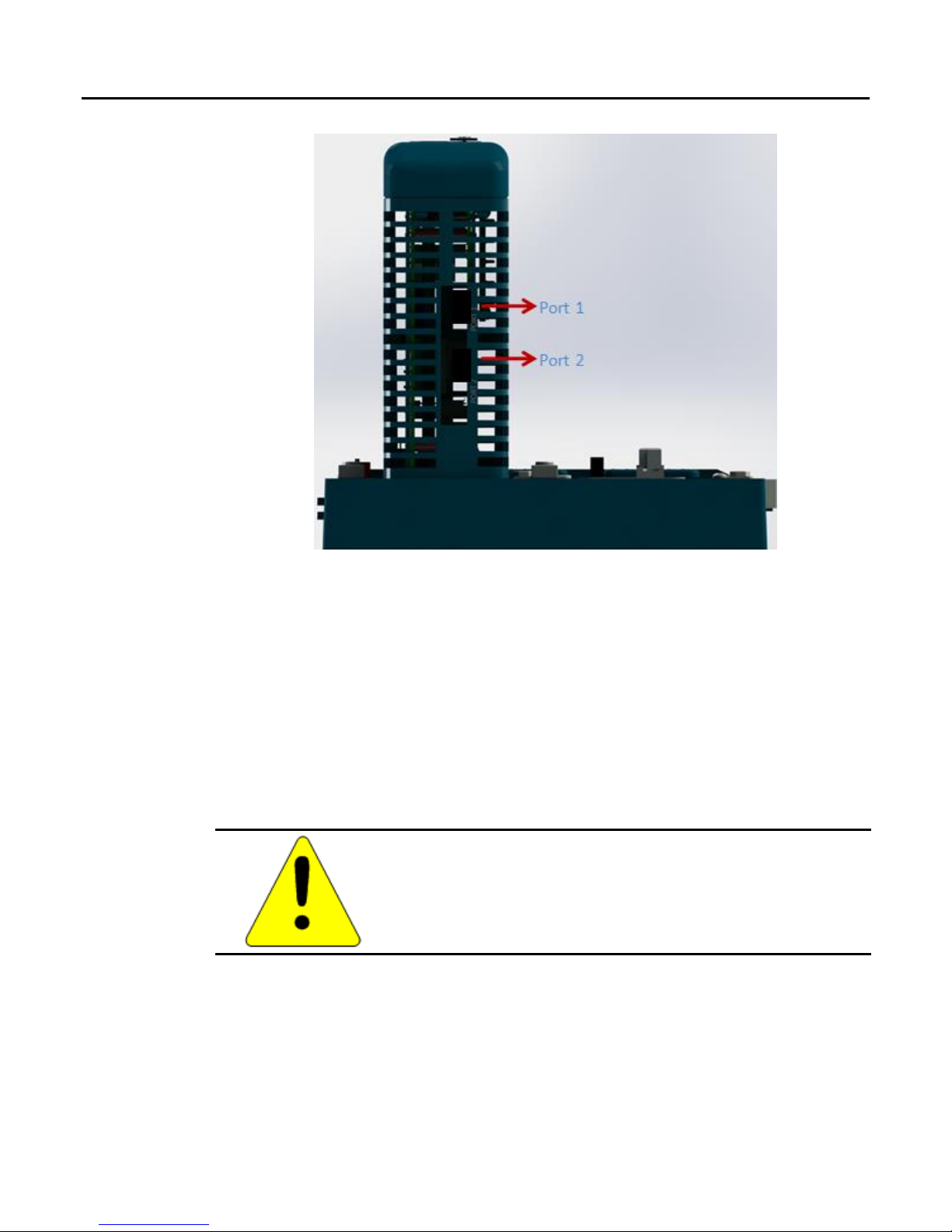

1.4.5 Ethernet Network Ports

The two external Ethernet ports are on the bottom of the module. The illustration below is a

side view of 8515-BI-PN with its two RJ-45 ports.

8515-BI-PN (Copper)

RJ-45 Port

SC-Duplex Port

Page 14

Contents

14 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

8516-BI-PN (Fiber)

Model 8515-BI-PN has two RJ-45 ports, providing 10/100 Mbps copper interfaces. Model

8516-BI-PN has two SC-Duplex ports, providing 100Mbps Multimode fiber interfaces. Each

Ethernet port automatically senses the type of network and adjusts speed and connection

parameters. The PNS requires at least one port be operating at full duplex for a connection to

remain established. The PROFINET protocol may be sent and received over either or both of

the two external ports.

Devices connected to the PNS ports should have Ethernet Autonegotiation enabled unless

the IO-Controller supports configuring the port operation mode. If the IO-Controller configures

the PNS port to a specific setting with autonegotiation disabled, the device connected to the

PNS must be configured for the exact same setting.

Caution

Both ports on the Ethernet Interface must not be connected,

directly or indirectly, to the same device so as to form a circular

network unless Media Redundancy is enabled with one node

actively set up as the Media Redundancy Manager.

Page 15

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 15

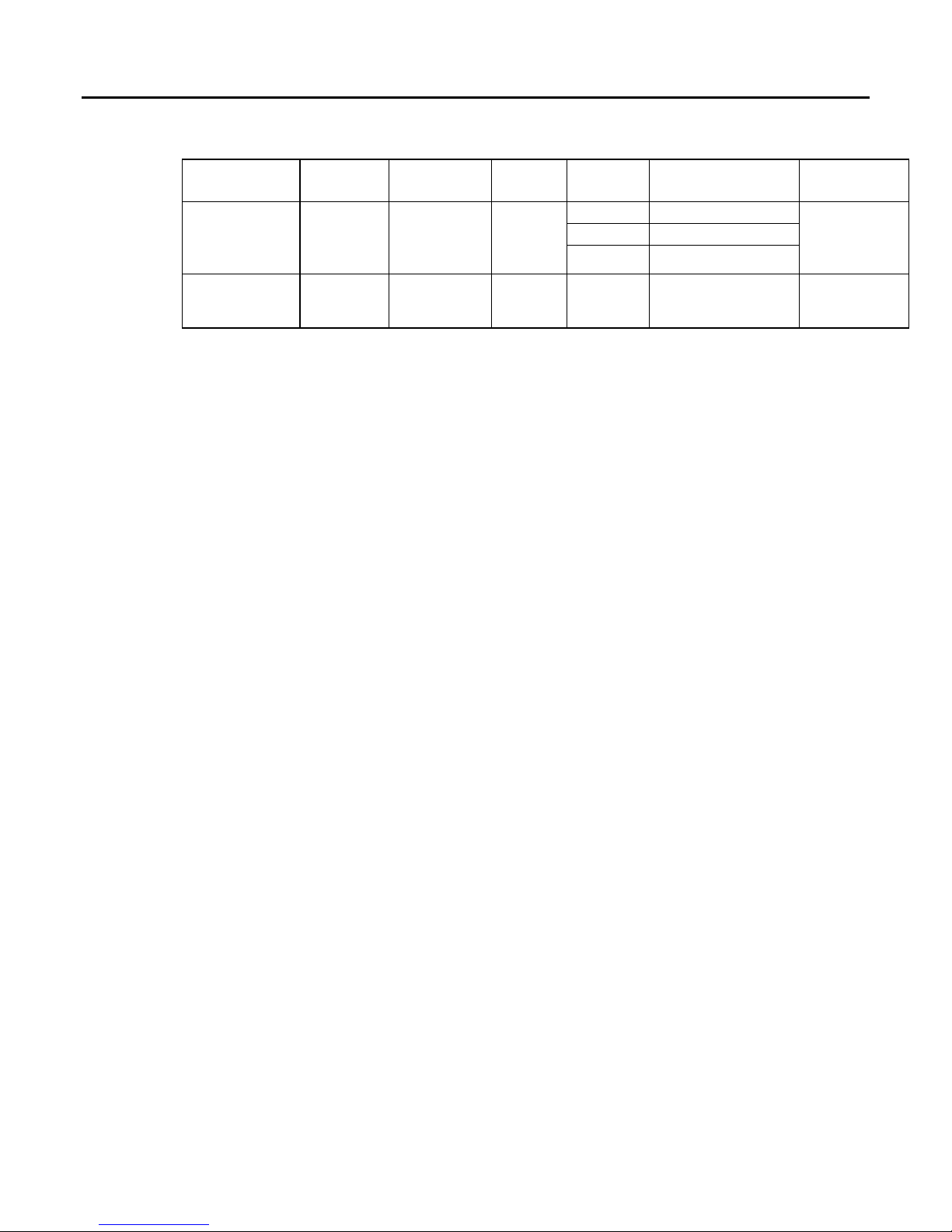

The PNS supports the following network media type and distances.

Media Type

Connector

Type

Wavelength

(nm)

Media

Type

Core

Size(μm)

Modal Bandwidth

(MHz – Km)

Distance (m)

100BASE-FX

SC or

SC-Duplex

1300

MMF

62.5

500

2 – 2,000

(Full Duplex)

2 – 400

(Half Duplex)

50

400

50

500

10/100BASE-T

RJ45

-

CAT5/

CAT5e/

CAT6

- - 100

(maximum)

PAC8000 PNS modules and other participating modules can be connected in a

daisy-chain/line, star, or ring (redundant media) topology.

Page 16

Contents

16 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

1.4.5.1 Media Redundancy Protocol Support

PROFINET Media Redundancy Protocol (MRP) supports devices configured in a ring

topology. It is based on the functions of IEC62439. Media Redundancy Protocol is not

routable between different IP subnets.

Each device within a Redundant Media network has at least two physical pathways to two

other devices on the network. To connect to the ring, each device requires an integrated

switch with at least two external ports (ring ports) that support Media Redundancy Protocol.

Devices that are not MRP-capable can be connected to a device like an MRP-capable switch

in the ring, but they cannot be in the ring themselves. The redundant paths only extend to the

devices on the ring that are MRP-capable and enabled.

One of the devices on the ring must be configured as the Media Redundancy Manager

(MRM), and all the other devices must be configured as Media Redundancy Clients (MRCs).

The PNS can be configured to be an MRC. Configuring the PNS as an MRC alters how the

Ethernet ports connect to the network. They attempt to indicate their state to the MRM before

allowing traffic to flow between the ports and close the ring topology through the internal

switch. They also send out notifications to the MRM when a port is lost. Operation of the PNS

is otherwise unchanged.

1.4.6 USB Port

The USB port, below LEDs, on the faceplate behind the cover on PNS, can be used to

connect a computer for firmware updates of the PAC8000 PNS. The USB port accepts a

standard USB cable (USB Micro B Male to USB Type A Male, not included). The port must

be set up before using it, as described in chapter 2.

Note: The USB port is for firmware upgrades only. It is not intended for permanent

connection.

Page 17

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 17

1.5 Compatible PAC8000 IO Modules, Carriers, and Power Supplies

1.5.1 IO Modules

The following modules can be used in a PAC8000 PROFINET Scanner IO-Device:

Module

Type

Catalog No.

Description

Standard Modules

8101-HI-TX

8-channel Analog Input Module, 4–20 mA

8102-HO-IP

8-channel Analog Output Module, 4–20 mA

8103-AI-TX

8-channel Analog Input Module, 4–20 mA

8104-AO-IP

8-channel Analog Output Module, 4–20 mA

8109-DI-DC

8-channel Discrete Input Module, 24 V dc, isolated, sinking

8110-DI-DC

8-channel Discrete Input Module, 24 V dc, non-isolated, module powered

8111-DI-AC

8-channel Discrete Input Module, 115 V ac, isolated, sinking

8112-DI-AC

8-channel Discrete Input Module, 115 V ac, non-isolated, module powered

8113-DI-AC

8-channel Discrete Input Module, 230 V ac, isolated, sinking

8114-DI-AC

8-channel Discrete Input Module, 230 V ac, non-isolated, module powered

8115-DO-DC

8-channel Discrete Output Module, 2–60 V dc, non-isolated, module powered

8116-DO-AC

8-channel Discrete Output Module, 20–265 V ac, non-isolated, module powered

8117-DO-DC

8-channel Discrete Output Module, 2–60 V dc, isolated, unpowered

8118-DO-AC

8-channel Discrete Output Module, 20–265 V ac, isolated, unpowered

8119-VI-05

8-channel Analog Input Module, 1–5 V

8121-DI-DC

16-channel Discrete Input Module, 24 V dc, non-isolated, module powered

8122-DI-DC

16-channel Discrete Input Module, 24 V dc, isolated, sinking

8125-DI-DC

32-channel Discrete Input Module, Switch/Proximity Detector Inputs, Module

Powered

8132-AI-UN

8-channel, 4-20mA, Thermocouple, RTD and Voltage isolated, universal input

8140-DI-AC

16-channel Discrete Input Module, 115 V ac, block-isolated, sinking

8142-DO-DC

16-channel Discrete Output Module, 12-42 V dc, non-isolated, module powered

Intrinsic Safe Modules

8201-HI-IS

8-channel Analog Input Module, 4–20 mA

8202-HO-IS

8-channel Analog Output Module, 4–20 mA

8204-AO-IS

8-channel Analog Output Module, 4–20 mA

8215-DO-IS

4-channel Discrete Output Module, solenoid driver, IIC gas groups

8230-AI-IS

8-channel, intrinsic Analog input module (Voltage/Potentiometer)

8206-TI-IS

8-channel, intrinsic Temperature input module (RTD/Ohms)

8220-16-DI-IS

16-channel, intrinsic Digital input module, Proximity Detector

1.5.2 IO Carrier

8709-CA-08, 8729-CA-08

1.5.3 PNS Carrier

8752-CA-NS: Node Service Carrier

Page 18

Contents

18 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

1.5.4 Power Supply Requirements

1. The power supply shall have output ratings of 12V DC, 5 A with power fail signal.

2. The power supply shall be current limited and shall meet the output entity parameter

requirements as per our drawing no. SCI-1520 / SCI-1526.

3. It shall comply to class A emission requirements as per CISPR-11.

4. It shall comply to EMC immunity requirements such as surge (2kV) and EFT (2kV).

5. It shall be ATEX marked, CE marked and UL or CSA listed to Class 1 Division 2, Group

A, B, C, D.

6. The power-fail output of the power supply shall be an open-collector output only, capable

of working with maximum 15V pull-up externally connected

For power supply cable and connector for the PAC8000 PNS, refer to part number

8421-CC-PS.

Page 19

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 19

Chapter 2. Hardware Installation

This chapter describes:

■ Module Installation

o Installing the Module on a DIN Rail

o Removing the Module from the DIN Rail

o Panel-Mounting

o Grounding

o Installing Power Supplies

■ PNS Powerup and Restart

■ LED Operation

o Special LED Blink Patterns

■ Firmware Updates

o Installing the USB Port Driver

2.1 Module Installation

PNS module must be mounted on a horizontal DIN rail. The PNS module fits into a 156mm

deep enclosure.

Rated thermal specifications are based on a minimum clearance of 5.1cm (2 inch) above and

below the module.

In addition to clearances required for cooling, space must be allowed for the following

requirements:

Allow adequate clearance for communications port cables. For an example, see

below sections.

Allow adequate clearance for power wiring.

1

2

Page 20

Contents

20 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

Page 21

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 21

2.2 Cable and Connector Clearance Requirements

You may need to allow more space for installation of cables and connectors than what is

required for heat dissipation. To avoid impacting mechanical reliability and signal quality,

cable installation must comply with the minimum bend radius specified by the cable

manufacturer.

Cable Clearance Example

In this example, an 8516-BI-PN module is installed with a fiber optic cable that has the

following characteristics:

SC-Duplex connector length: 27mm (1.07 inches)

Manufacturer-recommended long-term minimum bend radius: 30mm (1.2 inches)

The minimum clearance required to insert the connector into a port is 57mm (2.27 inches).

Additional clearance is recommended to provide physical access. In the case of the

8516-BI-PN, the space required for cabling will be greater than the space required to meet

thermal ratings.

1

2

Page 22

Contents

22 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

2.3 Installation in Hazardous Areas

The following information is for products bearing the UL marking for Hazardous

Locations or ATEX marking for explosive atmospheres:

• EQUIPMENT LABELED WITH REFERENCE TO CLASS I, DIVISION 2, GROUPS A,

B, C & D, HAZARDOUS LOCATIONS (ALTERNATIVELY MARKED AS CLASS I

ZONE 2, GROUP IIC) IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS

A, B, C, D OR NON-HAZARDOUS LOCATIONS ONLY

▪ Equipment labeled with II 3 G is suitable for use in Group 2 Category 3

environments.

▪ Connectors P1, J101 & HVCC shall be secured properly with the mechanical latch

provided for the purpose.

• WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

• WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN

OFF POWER BEFORE REPLACING OR WIRING MODULES; AND

• WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NONHAZARDOUS.

• WARNING - EXPLOSION HAZARD - USB PORT IS ONLY FOR USE IN

NONHAZARDOUS LOCATIONS, DO NOT USE UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

2.3.1 ATEX Marking

II 3 G Ex nA IIC T5 -40ºC Ta +70C

(Ref. ATEX Cat-3 certificate# GE13ATEX8515X & GE13ATEX8516X from our support

website for details of marking and installation guidelines.)

2.3.2 CE Marking

CE (EMC & ATEX Directives)

(Ref. Declaration of Conformity from our support website for details)

UL Marking

cULus

LISTED FOR US and CANADA FOR HAZLOC & PROCESS

CONTROL INSTRUMENTS CATEGORY

HAZLOC Classification

Class I Zone 2 Group IIC

Alternate Classification: Class I Division 2 Groups A, B, C, D

Page 23

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 23

2.4 Installing the Module on a DIN Rail

The PNS and connecting carriers must be installed on the same section of 35mm x 7.5mm

DIN rail. The rail must have a conductive (unpainted) finish for proper grounding. For best

resistance to vibration, the DIN rail should be installed on a panel using screws spaced

approximately 6 inches (5.24cm) apart.

Step 1 Slide the Carrier module onto the DIN rail thru the recess provided on the carrier plastic

Step 2: Lock the carrier in place with four screws marked through the hole on module

Page 24

Contents

24 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

Step 3: Guide the module into the connectors and lock them with two plastic screws with 4.5 N-m

2.5 Removing the Module from the DIN Rail

1. Remove the screws of PNS and pull the module from the carrier.

2. Unlock four screws with a small flathead screw driver, shown in step 2 of installation

instruction.

3. Slide the module along the DIN rail away from the other modules until the connector

disengages

2.6 Panel Mounting

For applications requiring maximum resistance to mechanical vibration and shock, the PNS

must also be panel-mounted.

Tolerances on all dimensions are ±0.13mm (0.005 in) non-cumulative.

1.1–1.4Nm (10–12 in/lbs) of torque should be applied to M3.5 (#6-32) steel screw threaded

into material containing internal threads and having a minimum thickness of 2.4mm (.093in).

Page 25

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 25

2.7 Grounding

The PAC8000 PROFINET Scanner has one system ground for which the ground terminal is

available on the carrier as shown below. The carrier also has provision for a BFP (expand)

ground.

2.8 Connecting Power Supplies to PAC8000 PROFINET Scanner

The PAC8000 PROFINET Scanner has connectors for either one or two power supplies.

Power connector with cable can be ordered using 8421-CC-PS part number.

The carrier needs +12V and GND for the module and +12V and GND for the carrier. It also

has provision to monitor external power fail status. 12 V DC and 24 V DC power fail status

can be monitored through the pins shown below.

Please ensure the following requirements are met for the power-fail signals:

Requirement for 12V supply power-fail signal:

The power-fail output of the power supply shall be an open-collector output only, capable of

working with maximum 15V pull-up externally connected.”

Requirement for 24V supply power-fail signal:

“The power-fail output of the power supply shall be an open-collector output only, capable of

working with maximum 30V pull-up externally connected.”

Page 26

Contents

26 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

2.9 PAC8000 PROFINET Scanner Power-up and Restart

Once PNS is powered up, the OK LED remains ON. If a fatal error occurs during powerup,

the LED blinks instead.

If the module encounters a hardware failure, invalid firmware image, or the powerup

diagnostics fail, the module will not become operational; it may enter firmware update mode.

Cycling power to the module should restore operation.

Page 27

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 27

2.10 LED Operation

The following table summarizes the operation of the PAC8000 PROFINET Scanner’s LEDs:

Name

Color

Description

POWER

Green

ON = Power OK

OFF = No power

OK

Green

ON = PNS is OK and has completed system boot up successfully

FAST BLINK pattern: See 2.10.1, “Special LED Blink Patterns” for

definitions.

MASTER

Yellow

Reserved

CONNECT

Yellow

ON = One or more PROFINET application relationships (ARs) has been

established

OFF = No PROFINET application relationships (ARs) are established

SLOW BLINK = The PNS has not been assigned a device name.

FAULT

Red

ON = One of the configured IO module or the PNS itself is in fault state

SLOW BLINK = Invalid MAC addresses

OFF = All configured modules are in healthy state

LAN

Yellow

IRREGULAR BLINK = Node is processing the packets addressed to it

OFF = No activity

PORT 1

Yellow

ON = Link connected

OFF = Link failure

IRREGULAR BLINK = Activity on this port.

PORT 2

Yellow

ON = Link connected

OFF = Link failure

IRREGULAR BLINK = Activity on this port.

USB

Yellow

ON = USB connection is active, but no data is being transferred

OFF = No activity on USB

IRREGULAR BLINK = Activity on USB

I/O COMM

Yellow

ON = All IO module commands sent in the last two seconds were

successful

OFF = No IO module command was sent in last two seconds

IRREGULAR BLINK = At least one IO module command failed in last two

seconds

A-B LINK

Yellow

Reserved

Note: Slow Blinking is ON for 0.5 second then OFF for 0.5 second.

Fast Blinking is ON for 0.1 second then OFF for 0.1 second.

Irregular Blinking has no regular pattern. It reflects data transmission traffic.

Page 28

Contents

28 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

2.10.1 Special LED Blink Patterns

Multiple LEDs can blink in patterns that indicate special conditions:

LEDs Involved

Pattern Displayed

Description

CONNECT, FAULT,

LAN, PORT 1,

PORT 2

CONNECT, FAULT, LAN, PORT 1, PORT

2 LED's go ON in order, from bottom to

top. After the CONNECT LED has been

ON for approximately 45 ms, the LEDs go

OFF from top to bottom, until all of the

LEDs are OFF. After all of the LEDs have

been OFF for approximately 45 ms, the

pattern is repeated.

Module identification requested

(Initiated by PME or any DCP

client and is used to locate

and/or identify a PNS)

CONNECT, FAULT,

LAN, PORT 1,

PORT 2

These LEDs blink slowly (ON for 0.5

seconds, OFF for 0.5 seconds) in unison.

Firmware update mode

(Application/FPGA)

MASTER,

CONNECT, FAULT,

LAN, PORT 1,

PORT 2

These LEDs blink slowly (ON for 0.5

seconds, OFF for 0.5 seconds) in unison.

Firmware update mode (Boot

loader)

OK, CONNECT,

FAULT, LAN,

PORT 1, PORT 2

The CONNECT, FAULT, LAN, PORT 1

and PORT 2 LEDs flash once. The OK

LED blinks an (2-digit hexadecimal) error

code. The pattern is repeated until the

module is reset or power-cycled.

Fatal error detected

Fatal Error Blink Pattern

If the PNS detects a fatal error, it attempts to write diagnostic data to nonvolatile storage. The

OK LED blinks rapidly if the module has been configured to blink fatal error codes. It starts

blinking the error code after writing the diagnostic data to nonvolatile storage. The

CONNECT, FAULT, LAN, Port 1 and Port 2 LEDs flash once to indicate the start of the error

code. After a pause, the OK LED blinks a 2-digit hexadecimal error code. The OK LED first

blinks to indicate the most significant error digit, then after a one-second pause blinks again

to indicate the least significant error digit. Repetitions continue until the module is reset or

power-cycled.

Module Identification LED Pattern

The Module Identification LED blink pattern described above can be used to locate and/or

identify a PNS, for example, when assigning its Device Name. PROFICY Machine Edition or

any DCP client can be used to command the module to begin or end the blink pattern.

Firmware Update Mode Blink Patterns

Blink patterns described in the table above indicate that a firmware update of the PNS is

underway. Because the update is being done through the USB port, the USB LED also blinks

to indicate activity on the USB port.

Page 29

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 29

2.11 Firmware Updates

The PAC8000 PROFINET Scanner enters firmware update mode when commanded to do so

from the Winloader update utility, or if a firmware component is corrupted or invalid.

In firmware update mode, the PNS module blinks its LEDs in a special pattern as described

previously, and its Ethernet ports are not operational.

If the PNS is currently in use by an IO-Controller and the controller is in Run mode, all

attempts to update the PNS firmware are rejected.

If the PNS has experienced a fatal error, the module goes to an LED blink code error

condition and does not communicate with Winloader, causing Winloader to return a timeout

failure indication. The module must be restarted or power-cycled before reattempting the

update.

When the firmware update is completed and the PNS is rebooted, its previous connections

are re-established and control resumes.

2.11.1 Firmware Update for IO Modules in the PNS

PAC8000 PROFINET Scanner does not support firmware updates for IO modules.

Page 30

Contents

30 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

2.12 Installing the USB Port Driver

The USB port is only used for firmware updates. USB driver files are provided as part of

upgrade packages compatible with the PNS.

With the provided installation files accessible on either a local or network drive, connect the

computer’s USB port to the PAC8000 PROFINET Scanner’s USB port. When requested,

direct the installation to the proper location of the installation files.

The serial port name is COM followed by the next available number from 1 to 256. After the

computer assigns the USB port a COM port number, that computer uses the same COM port

number each time it connects to that Scanner module.

During firmware upgrades, Winloader will display the COM port name followed by the serial

number of the PNS:

In this example, Winloader shows that COM34 is a PAC8000 PROFINET IO Scanner with

serial number 0015.

Note: When connecting the USB cable to the PNS, you may receive a warning for installing

a driver that has not passed Windows Logo testing. Because each Scanner has a

different serial number, the operating system recognizes each module installation as

different.

Page 31

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 31

Chapter 3. Configuration

This chapter provides general information for configuring a PAC8000 PNS and its IO modules

in a PROFINET-IO network. For information on configuring the PROFINET IO-Controller and

its network, refer to the IO-Controller manufacturer’s documentation.

Note: To configure RX3i Controller, refer to the PACSystems RX3i PROFINET Controller

Manual, GFK-2571.

This chapter discusses the following topics:

■ Configuration Overview

o Basic Configuration Steps

o Configuration Tool

■ Adding a PAC8000 PROFINET Scanner to a LAN

o Configuring PAC8000 PROFINET Scanner Parameters

o Configuring PAC8000 Module Parameters

■ Assigning IO-Device Names

■ Clearing the PROFINET IO-Controller Configuration

■ Replacing PAC8000 PROFINET Scanner Hardware

3.1 Configuration Overview

The PAC8000 PNS receives its configuration from a PROFINET IO-Controller, which is

configured by a PROFINET IO configuration tool. The GSDML file provided with the PNS

must be imported into the PROFINET IO configuration tool.

Note: For details on using the Proficy Machine Edition PLC Logic Developer programmer to

create and download the configuration for a PAC8000 PNS in an RX3i PROFINET

network, refer to the PACSystems RX3i PROFINET IO-Controller Manual,

GFK-2571.

Page 32

Contents

32 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

3.1.1 Basic Configuration Steps

The basic configuration steps are:

■ Configure a PROFINET IO-Controller and its PROFINET LAN using the Controller

manufacturer’s recommended PROFINET IO configuration tool.

■ Configure the parameters of the PROFINET IO-Controller.

■ Add IO-Devices to the LAN. These IO-Devices can be PAC8000 PROFINET Scanner

modules or third-party IO-Devices. PAC8000 PROFINET Scanners and other types

of IO-Devices use GSDML files to describe their capabilities. The PROFINET IO

configuration tool imports these GSDML files and incorporates the devices into the

configuration.

■ Configure the parameters of the PAC8000 PROFINET Scanners and other

IO-Devices.

■ Configure the communications properties of the PROFINET IO-Controller, PAC8000

PROFINET Scanners, and other IO-Devices.

■ Add PAC8000 IO modules to the PAC8000 PROFINET Scanner..

■ Configure the parameters of the PAC8000 IO modules and other devices in the PNS.

■ When the configuration is ready, use a DCP tool to assign a name to each IO-Device

so the PROFINET IO-Controller can connect to the devices and deliver their

configuration.

■ Store the configuration data from the configuration tool to the PROFINET

IO-Controller.

Note: When the connection between IO-Controller and PNS is in progress, and if a new

configuration download initiated, first the existing connection breaks and the output

modules go into failsafe state (if configured so). Otherwise output modules hold the

last values. This output state continues till a valid output data received from IOController.

3.1.2 Configuration Tool

The configuration tool used to configure the PROFINET LAN containing the PNS module

must support PROFINET V2.3 IO Devices.

Page 33

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 33

3.2 Adding a PAC8000 PROFINET Scanner to a LAN

Use the PROFINET IO configuration tool to add a PNS module to the LAN. This process may

include importing the PNS module’s GSDML files. If necessary for your application, change

the settings of the PNS module’s configurable parameters listed below.

3.2.1 Configuring PAC8000 PROFINET Scanner Parameters

The PROFINET IO Scanner provides 64-bits of status data and receives 16-bits of output

control data. These should be mapped to the IO-Controller’s memory.

The IO-Controller determines the operation of inputs when the PNS is unable to provide

them. This typically happens when the PNS is not powered on, connected to the network, or

there is a network or configuration issue such that the IO-Controller cannot reach the PNS.

The IO-Controller may support defaulting inputs to fixed or configurable values or holding the

last known good state of inputs until connectivity is restored (Based on controller

configuration parameters).

The PNS has a single parameter on slot 0, subslot 1 that specifies the action the PNS will

take if a fatal error occurs. By default, the PNS module LEDs blinks a fault code if a fatal error

occurs and the output modules are forced to go into failsafe state (if configured so). This can

be changed to cause the PNS to restart instead.

The network parameters of the PNS (IP Address, subnet mask, and gateway IP) should

either be configured to match the fixed parameters assigned to the PNS using a DCP Tool or

to what the IO-Controller should assign during the startup of communications between the

PNS and IO-Controller. If the network parameters assigned by the DCP tool are different from

the configuration in the IO-Controller and the IO-Controller is configured to assign them to IODevices, then when the IO-Controller assigns them as a temporary setting, the settings

previously stored from the DCP tool are lost. On a reset, the IO-Device is set to factory

default values (0.0.0.0/0.0.0.0/0.0.0.0).

The rate of data exchange is usually configured on the PNS in configuration tools. The PNS

supports update rates from 1ms to 512ms. The correct setting for each device can depend on

the dynamics of the equipment being controlled, the network loading on the PROFINET-IO

LAN, and the loading of the IO-Controller. It is possible to have better performance at 4ms or

greater periods than at 1ms, depending on the overall system requirements, design, and

loading.

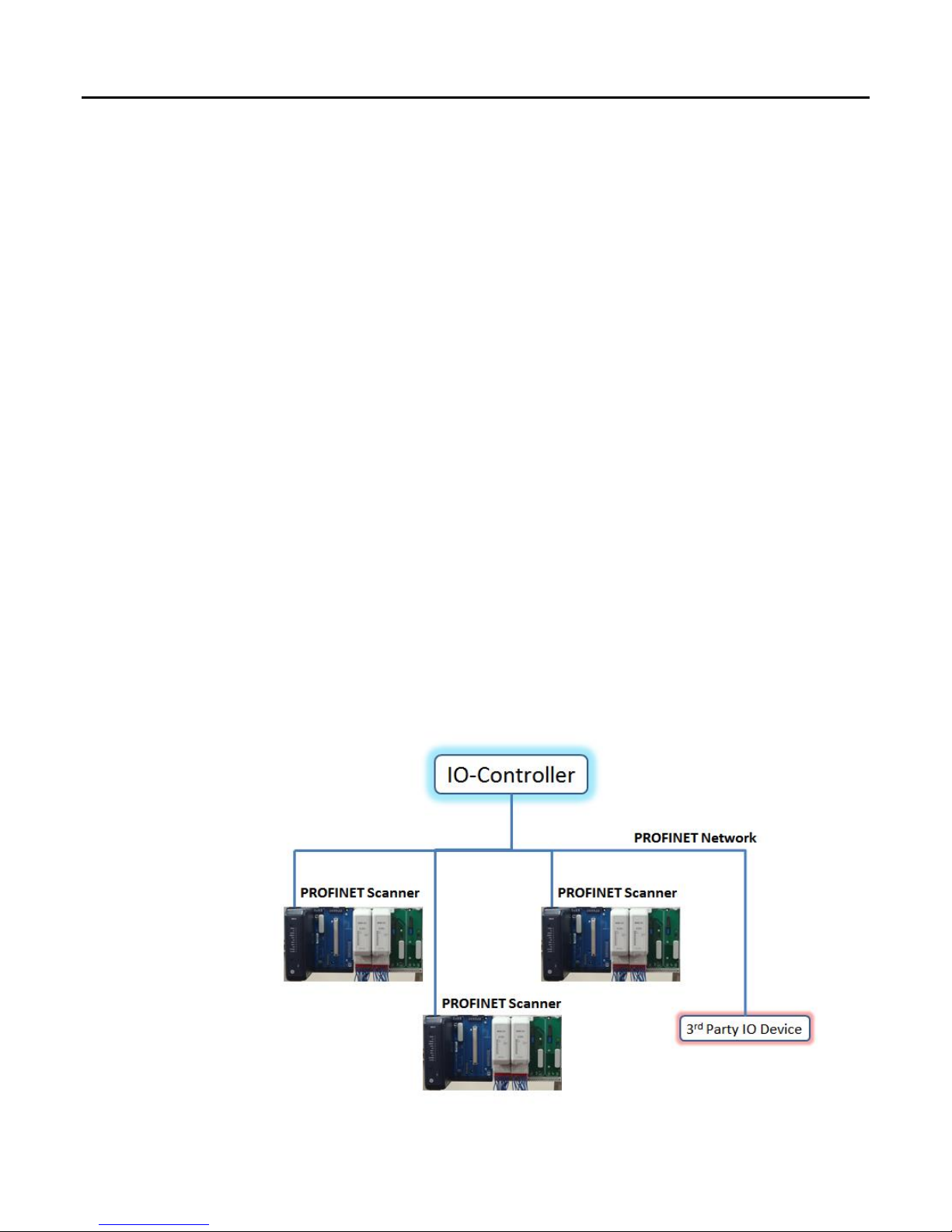

3.2.1.1 Configuring PAC8000 PROFINET Scanner for PROFINET System Redundancy

The PAC8000 PNS supports PROFINET System Redundancy feature (PROFINET V2.3

Type S2 System Redundancy). This feature allows PNS to be part of a Hot-Standby (HSB)

CPU Redundancy system as shown below. In the HSB redundancy system, the two IO

controllers, based on their mutual agreement, makes primary and backup AR (application

relationship) connections with the PNS. One controller acts as a primary and the other acts

as backup. Once the connection is made, the PNS exchanges data only with the primary

controller.

In the HSB system, the CPUs/HOSTs continuously monitors the health status of connection

between the primary controller and PNS. If the CPUs finds the primary connection unreliable

at any point of time, it switches over the primary connection ownership to the backup

controller and commands PNS to recognize this change. The PNS then recognizes this

change and will immediately start the data exchange with the new primary controller

(previously backup controller).

Page 34

Contents

34 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

HOSTHOST

Profinet

Controller

IOC

Profinet

Controller

IOC

Profinet

Device

NAP

IO Module

Profinet

Device

NAP

IO Module

PROFINET IO

SR-ARa

SR-ARb

The “Redundancy mode” tab in the configuration tool selects whether or not the PNS to be

redundantly controlled.

When it is configured for “HSB CPU Redundancy”, the PROFINET System Redundancy

feature in PNS gets enabled. This causes the PNS to accept redundant PROFINET SR-AR

connections (primary and backup) from the controllers.

When it is configured for “None”, the PROFINET System Redundancy feature in PNS gets

disabled. This causes PNS to accept only one AR connection from the controller (simplex

operation).

3.2.1.2 Media Redundancy Parameters

By default, the PNS is not set up for Media Redundancy. If the PNS will be a Media

Redundancy Client, select the PNS ports that will be used for Ring Port 1 and Ring Port 2,

and the MRP Domain. The MRP Domain name is used to assign MRP Clients to the media

redundancy manager (MRM) for the network ring.

Media Redundancy = None (Media redundancy Disabled).

Media Redundancy = Client (Media redundancy Enabled).

3.2.1.3 Module Parameters

Fatal Error Action

If a fatal error occurs, the PNS either blinks an error code on its LEDs and sets the modules

into fail safe state or Gets restarted based on the configuration.

Apply Failsafe = PNS blinks an error code on the LEDs

Auto Restart = PNS Restarts

Page 35

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 35

Communication Timeout

Control application (PROFINET Controller) should toggle Heartbeat bit (refer Output Control

Register) to indicate it is alive. When there is no update to this bit for more than configured

communication timeout time, the PNS treats it as a communication/application failure and

goes to failsafe state.

0 = Disabled.

Values for communication timeout range 50 ms, 100ms, 200 ms, 500 ms, 1 Sec, 2 Sec, 5

Sec, 10 Sec, 20 Sec, 50 Sec.

SNMP Configuration

From release 2.00 onwards PNS supports SNMP protocol.

Enable SNMP Service = Enables SNMP protocol services in the PNS

Disable SNMP Service = Disables SNMP protocol services in the PNS

Page 36

Contents

36 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

3.2.2 Configuring PAC8000 PROFINET Scanner Parameters

After adding PAC8000 PROFINET scanner(s) to the PROFINET IO Controller in the

programmer, their parameters must be configured. Configuration details for basic parameters

are given in the following pages.

3.2.2.1 Basic Module Parameters

The PNS parameters define how the IO-Controller scans and stores the PNS data.

Default values are provided by the module’s GSDML file.

Input Data / Output Data: The address in the IO-Controller’s reference memory for the

module’s data.

Length: The length of the input /output data is fixed and cannot be edited (Non

Configurable).

3.2.2.2 Additional Module Parameters

Additional module parameters vary, depending on the module type. Some modules have only

a few parameters. Others have several. The additional parameters that must be configured

for more complex modules are explained in the individual module documentation.

On Failsafe: When the module has outputs, this field specifies how the PNS will handle the

module’s output data if it loses communication with the IO-Controller. Select either Hold Last

State or Failsafe Value (For Analog modules) or ON/OFF (For Digital modules). This

selection has to be made for each channel in the module. If Failsafe Value is chosen, failsafe

values can be set up on a per-channel basis. If the Failsafe time out is set to ‘0’, Failsafe is

disabled.

Note: PAC8000 analog and digital modules latch their last outputs when configured for

Hold Last State and hold that value as long as field power remains on to the module.

Clear Latch: These control bits of the module clears the Latch of the selected channel. If the

channel’s Latch is enabled in the configuration and got Latched to an input, by using the

corresponding bit user can clear the Latch. As long as the Latch Bit is set to 1 the Latch on

that channel will be disabled. This control bit is available to DI modules with pulse counters

enabled.

Clear Counter: These control bits of the module clears the Counter of the selected channel. If

the channel’s Counter is enabled in the configuration and has been counting the pulses, by

using the corresponding bit user can clear the Counter. As long as the Clear Counter Bit is

set to 1 the Counting on that channel will be disabled.

3.2.2.3 Configuring the Module Parameters

Please refer to the PAC8000 IO module’s manual (8000-2/x Series Modular I/O GFA-1779)

for configuration details

Page 37

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 37

3.3 Assigning IO-Device Names

After the PNS and other IO-Devices on the LAN have been entered into the configuration, a

Discovery and Configuration Protocol (DCP) tool must be used to assign a name to each IODevice. The Name of each device on the LAN must match the configuration. This step is

required before downloading the configuration from the PROFINET IO-Controller, otherwise

the PROFINET IO-Controller will be unable to connect to the devices and deliver their

configuration.

The DCP tool must be connected to PROFINET IO LAN, either through the PROFINET

IO-Controller or directly to the LAN depending on whether it operates through the

IO-Controller or directly to IO-Devices.

3.4 Clearing the IO-Controller Configuration

The PAC8000 PROFINET Scanner reacts to clearing the PROFINET IO-Controller as a loss

of connectivity, and takes appropriate actions such as setting outputs to the failsafe state.

Clearing the IO-Controller does not typically cause a clearing action on all connected

IO-Devices.

3.5 Replacing PAC8000 PROFINET Scanner Hardware

If a PNS module needs to be replaced for any reason, the steps to commission a new

hardware module are below.

If the replacement PNS module has no assigned name (the CONNECT LED blinks slowly),

the network cabling can be plugged back in and the name assigned over the IO network. If

there is a possibility of duplicate names existing on the network due to a pre-existing IODevice name assigned in the replacement module, the IO-Device Name should be assigned

before inserting it into a working IO network. The IO-Device Name and IP Address settings

can be updated offline (for example, in an office setting).

1. Power down the PNS.

2. Remove network cabling from the module.

3. Remove the old module.

4. Insert the new PNS module.

5. Connect network cabling to the new PNS module.

6. Apply power to the new PNS module hardware.

7. Optional: Assign IP address settings to the new PNS module using the DCP tool if

this was not done offline. The IO-Controller will update any IP address settings

automatically when it connects if this step is skipped.

8. If an IO-Device Name was not assigned to the new PNS module, assign it now.

Page 38

Contents

38 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

Chapter 4. Diagnostics

This chapter describes:

■ PNS Status and Control Data

o Output Control Register

o Input Status Registers

o PNS Status register

o PNS Network port status register

o PNS Power status register

o PNS Module health status register

■ Error Handling

o Fatal Error Handling

o PROFINET Alarms

o PROFINET Module Loss, Add & Mismatch Faults

4.1 PNS Status and Control Data

The PAC8000 PROFINET Scanner provides 64 bits of input status data and receives 16 bits

of output control data. The application program in the IO-Controller system can monitor the

input status bits and can perform some control operations using the output control bits. This

data is associated with slot 0 submodule 1 in the configuration.

4.1.1 Output Control Register

The PNS’s 16 bits of output control data can be used to trigger module actions.

Output

Bits

Name

Description

1 (LSB)

Reset

0 to 1 transition resets the PNS.

1 to 0 transition has no effect.

2

Set Failsafe

0 to 1 transition sets the PNS to failsafe state.

1 to 0 transition has no effect.

3

Clear Failsafe

0 to 1 transition commands the PNS to clear failsafe state

1 to 0 transition has no effect.

4

Heartbeat Enable

1 = Enable Heartbeat feature.

0 = Disable Heartbeat feature.

5

Heartbeat

Remote application (host) should toggle this bit to indicate it is

alive. When there is no update to this bit for more than

configured communication timeout, the PNS treats it as a

communication/application failure and goes to failsafe state.

Applicable only when “Heartbeat Enable” in output control

register is ‘1’.

6 – 16

Reserved

Page 39

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 39

4.1.2 Input Status Registers

Byte

Register

Description

1

PNS Status Register (PSR)

Device/Scanner Status

2

3

PNS Network Port Status Register (PNSR)

Network Status

4

PNS Power Status Register (PPSR)

Power Status

5

Module Health Status Register (MHSR)

IO module Health Status

6

7

8

4.1.2.1 PNS Status Register (PSR)

The PSR provides 16 bits of information about the PNS module. All status bits are active

high.

Status

Bits

Name

Description

1 (LSB)

PNS OK

1 = PAC8000 PNS is up and running

0 = Unrecoverable fault detected during power up

2

PNS Fault

1 = Alarm generated by PNS

0 = All alarms are cleared.

3

PNS Failsafe

1 = PNS is in failsafe state

0 = PNS is not in failsafe state

4

Heartbeat Echo

IO-Controller sets “Heartbeat” in output control register and

when PNS receives it, it echoes back that value in

“Heartbeat Echo”. Echoing before the configured

communication timeout confirms communication between

IO-Controller and PNS is healthy.

5

Heartbeat Status

1 = Heartbeat failure

0 = Heartbeat OK

6-16

Reserved

4.1.2.2 PNS Network Port Status Register (PNSR)

The PNSR provides 8 bits of information about the network. All status bits are active high.

Status

Bits

Name

Description

1(LSB)

Port 1 Link Status

1 = Link detected at port 1 of PNS

0 = Link failure at port 1 of PNS

2

Port 2 Link Status

1 = Link detected at port 2 of PNS

0 = Link failure at port 2 of PNS

3-8

Reserved

Reserved for future use

Page 40

Contents

40 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

4.1.2.3 PNS Power Status Register (PPSR)

The PPSR provides 8 bits of information about the power supply. All status bits are active

high.

Status

Bits

Name

Description

1 (LSB)

Power Line 1 Status

1 = Power supply is healthy

0 = Power supply failed

2

Power Line 2 Status

1 = Power supply healthy

0 = Power supply failed

3

Power Line 3 Status

1 = Power supply is healthy

0 = Power supply failed

4

Power Line 4 Status

1 = Power supply is healthy

0 = Power supply failed

5

Power Line 5 Status

1 = Power supply is healthy

0 = Power supply failed

6

Power Line 6 Status

1 = Power supply is healthy

0 = Power supply failed

7-8

Reserved

Reserved for future use

4.1.2.4 Module Health Status Register (MHSR)

The MHSR provides 32 bits of information about the module’s health. All status bits are active

high.

Status

Bits

Name

Description

1(LSB)

Module in slot 1

1 = Module Healthy

0 = Module not Healthy

2

Module in slot 2

1 = Module Healthy

0 = Module not Healthy

3

Module in slot 3

1 = Module Healthy

0 = Module not Healthy

4

Module in slot 4

1 = Module Healthy

0 = Module not Healthy

…

…

32

Module in slot 32

1 = Module Healthy

0 = Module not Healthy

Page 41

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 41

4.2 Error Handling

The PNS has two error-handling methods: fatal error handling and PROFINET diagnostics.

4.2.1 Fatal Error Handling

Any failures that occur during powerup or firmware update mode are considered fatal errors.

This includes faults detected on non-critical devices such as the USB port. After successful

power-up of the PNS, only catastrophic errors are treated as fatal.

If a fatal error occurs, the PNS either blinks an error code on its LEDs and sets the modules

into fail safe state (If the modules are configured for failsafe), or restarts automatically,

depending on its configured Fatal Error Action.

When the PNS detects a catastrophic failure it tries to save diagnostic information to nonvolatile storage. This information overwrites any previous diagnostic information in storage.

Only information about the most recent fatal error is retained. This information is available on

future power cycles to be retrieved and sent to GE Intelligent Platforms for analysis.

While diagnostic information is being saved, the PNS blinks its OK LED. The PNS disables

Ethernet and USB communications, so communication with the module is not possible. If the

PNS cannot save the diagnostic information it is considered a failed Save attempt.

After the attempt to store the information has completed (whether it succeeded or failed), the

module either blinks an error code or restarts, depending on how it is configured.

4.2.1.1 Automatic Restart

If the PNS is configured to automatically restart after a fatal error, on the next successful

power-up, a diagnosis alarm is generated to indicate the PNS reset. This alarm turns the

Fault LED on and persists until the PNS is power-cycled. There is no way to clear this fault

other than a second successful restart.

A persistent fatal error that occurs after the PNS has successfully powered up can cause the

module to continually reset itself.

4.2.1.2 Apply Failsafe operation

If the PNS is configured to put the PNS into failsafe when a fatal errors, the PNS goes into

failsafe state. All output modules will also go into failsafe state (if they are configured so).

Page 42

Contents

42 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

4.2.2 PROFINET Diagnostics

The PNS reports its own non-fatal errors and errors on modules using PROFINET Diagnosis

or PROFINET Pull/Plug alarms.

4.2.2.1 PROFINET Diagnosis Alarms

Diagnosis Alarms indicate any fault conditions other than a module add, loss, or mismatch

that a PAC8000 PROFINET Scanner needs to communicate to the PROFINET IO-Controller.

Most faults generate Diagnosis alarms. Situations that do not send a PROFINET Diagnosis

are covered in a later section.

When the PAC8000 PROFINET Scanner detects a fault condition, it sends a Diagnosis alarm

to the IO-Controller. If there is an Application Relationship (AR) currently active, the PAC8000

PNS sends the Diagnosis alarm over that AR. Otherwise, the alarm is placed in diagnosis

memory in the PNS to be read later, and no alarm is sent. The Scanner’s FAULT LED is ON

and the FAULT status bit (see bit definitions of PNS status register mentioned earlier in this

chapter) is set to 1. An alarm is not generated on subsequent connections.

The PNS automatically clears (and sends Diagnosis Disappears alarms for) these diagnosis

faults after the fault condition has been corrected. If no additional conditions exist in memory,

the FAULT LED is turned OFF and the FAULT status bit is set to 0.

The table on the next page lists the faults reported to the IO-Controller. The PAC8000 PNS

generates all of its application faults as channel diagnosis faults. The AlarmType is Diagnosis

Appears or Diagnosis Disappears. The left column lists the Channel Error Type in

PROFINET.

Page 43

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 43

PNS Diagnosis Alarms

Channel

Error

Type

Diagnosis Alarm

Type

Module

or

Channe

l Error

Cause

Fault Text

Recommendation

6

Channel Diagnosis

Appears / Disappears:

Line Break

Channel

Open Wire/Line break

detected on a channel

Line Break

Verify wiring of the channel

16

Channel Diagnosis

Appears/Disappears

Module

Module not Configured

The module rejected

the configuration

parameters.

Verify the configuration

parameters against their

allowable ranges for the

operation

17

Channel Diagnosis

Appears/Disappears

Module

Loss of User Power

The module has lost

field power.

Check power supplies and

wiring

256

Channel Diagnosis

Appears/Disappears

Channel

Line Fault detected on

a channel.

Line Fault Detected

Verify wiring of the channel

257

Channel Diagnosis

Appears/Disappears

Channel

Channel value is above

configured Hi Alarm

High alarm detected

Bring process value on the

channel below configured high

alarm level

258

Channel Diagnosis

Appears/Disappears

Channel

Channel value is above

configured Hi-Hi Alarm

High High alarm

detected

Bring process value below

configured high high alarm

level

259

Channel Diagnosis

Appears/Disappears

Channel

Channel value is below

configured Low Alarm

Low alarm detected

Bring process value above

configured low alarm level

260

Channel Diagnosis

Appears/Disappears

Channel

Channel value is above

configured Lo-Lo Alarm

Low Low alarm

detected

Bring process value above

configured low low alarm

level

261

Channel Diagnosis

Appears/Disappears

Channel

Channel detected fault

in ADC

ADC Error Detected

Check the Bused Field Power

of the IO carrier . If it is ok,

contact GE-IP support team

for help.

262

Channel Diagnosis

Appears/Disappears

Channel

Channel configuration

has invalid alarm

settings. This fault

occurs after

configuration download,

when following

condition is NOT met

Lo-Lo alarm <= Lo

Alarm < Hi Alarm <= HiHi Alarm

Parameterization

error in alarm setting

In configuration tool adjust the

alarm settings so that they

meet the condition Lo-Lo

alarm <= Lo Alarm < Hi Alarm

<= Hi-Hi Alarm and download

the configuration again.

Page 44

Contents

44 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

Channel

Error

Type

Diagnosis Alarm

Type

Module

or

Channe

l Error

Cause

Fault Text

Recommendation

263

Channel Diagnosis

Appears/Disappears

Channel

Channel configuration

has invalid pulse

settings. This fault

occurs after

configuration download,

when following

condition is NOT met

(1) If Operation mode is

Single Pulse (Static),

failsafe value should be

OFF, pulse period

should be 0

(2) If Operation mode is

Continuous Pulse

(Static), failsafe value

should be OFF/Hold

Last State, pulse period

>= 6ms and pulse

period > on time

Parameterization

error in failsafe

value/Pulse

period/Pulse on time

In the configuration tool, set

the parameters properly and

download the configuration

again.

264

Channel Diagnosis

Appears/Disappears

Channel

Channel configuration

has invalid settings.

This fault occurs after

configuration download,

when any of the

parameters are out of

expected range.

TI Alarms/Dead zone

range fault

In the configuration tool, set

the parameters properly and

download the configuration

again.

268

Channel Diagnosis

Appears/Disappears

Channel

Open Sensor detected

on a channel

Open circuit fault for

the sensor on channel

Verify wiring of the channel

269

Channel Diagnosis

Appears/Disappears

Channel

Cold Junction

Compensation Fault

detected

Cold Junction

Compensation Fault

Check if either of the (two)

cold junction compensation

elements have gone open

circuit or out of range

270

Channel Diagnosis

Appears/Disappears

Channel

The Dynamic pulse on

time or period is not in

range. Or difference

between Period and On

Time is less than 5ms

The Dynamic pulse

on time or period is

not in range. Or

difference between

Period and On Time

is less than 5ms

Check if the Dynamic pulse on

time or period is not in range

(valid range Period: 10 –

60000, and 65530, 65531,

65532, 65533, 65534, 65535,

On Time : 5 - 60000). Period

must be at least 5 ms greater

than On Time

271

Channel Diagnosis

Appears/Disappears

Channel

The Thermocouple

compensation fault

The Thermocouple

compensation fault

Check if the Thermocouple

compensation is selected

correctly and values are within

range

272

Channel Diagnosis

Appears/Disappears

Channel

The Thermocouple HH,

H, L, LL fault

The Thermocouple /

RTD Parameterization

error.

Verify LL alarm <= L Alarm

< H Alarm <= HH Alarm.

Verify alarms between Min

and Max temp. Deadband and

Deadzone are between Min +

Max temp

Page 45

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 45

Channel

Error

Type

Diagnosis Alarm

Type

Module

or

Channe

l Error

Cause

Fault Text

Recommendation

273

Channel Diagnosis

Appears/Disappears

Channel

Channel fault

Channel fault

Verify Channel fault

274

Channel Diagnosis

Appears/Disappears

Channel

Secondary data fault

Secondary data fault

Verify Secondary data fault

4096

Channel Diagnosis

Appears/Disappears

Module

Module is in fault state

Module Fault

Detected

Contact GE-IP support team

4097

Channel Diagnosis

Appears/Disappears

Module

Parameterization error

due to Configurator or

Corrupted GSDML file

used for configuration

Module fatal

parameterization error

Verify that Configuration tool

is working properly and

GSDML file is not modified or

corrupted.

4098

Channel Diagnosis

Appears/Disappears

Module

Module not in a position

to accept the

configuration.

Module rejected

configuration

Power cycle the module. If the

problem still persists may be

module replacement required.

4099

Channel Diagnosis

Appears/Disappears

Module

A fatal error reset

happened (when

PNS is configured to

automatically restart

after a fatal error)

Auto-Restart event

occurred

Contact GE-IP support team

4.2.3 Clearing Faults on PAC8000 Modules

The PAC8000 PROFINET Scanner clears alarms as soon as the underlying condition returns

to normal.

Page 46

Contents

46 PAC8000* IO PROFINET Scanner User’s Manual–September 2017 GFK-2839B

4.2.4 PROFINET Module Loss, Add and Mismatch Faults

The PAC8000 PROFINET Scanner uses standard PROFINET Pull/Plug alarms to indicate

differences between the configured modules and the actual modules present in the PNS.

■ If a module is configured, but is not present or not operating correctly, the PNS

indicates the module as removed via a Pull Alarm.

■ If a different IO module is hot-inserted than configured while an Application

Relationship is active, the PAC8000 PROFINET Scanner reports the mismatch using

a Plug Wrong Submodule alarm.

■ PNS does not generate alarms for an un-configured slots. The module is ignored by

the PNS and remains at its module defaults.

■ When a configured IO module is plugged into a configured slot, PNS sends a Plug

Alarm.

■ Configuration related alarms are generated when user configuration is not valid. For

each invalid configuration of a IO module, an alarm is generated. If all modules have

invalid configuration, 32 alarms will be generated. Note that only one alarm per IO

module is generated (even though more than one invalid configuration exists on a

module). If an IO module has an invalid configuration, an alarm is generated and that

IO module will not be put under IO scan.

Page 47

Index

GFK-2839B PAC8000* IO PROFINET Scanner User’s Manual–September 2017 47

Chapter 5. PROFINET Specifications

Release 2.00 of the PAC8000 PROFINET Scanner supports PROFINET v2.3 Class A

IO-Device with the clarifications listed below. For version-specific updates, refer to the

Important Product Information document provided with your module.

5.1 PROFINET Protocol Support

RTC – Real time Cyclic Protocol: RT_CLASS_1 & RT_CLASS_2

RTA – Real time Acyclic Protocol

DCP – Discovery and Configuration Protocol