Page 1

GE Energy Connections

Grid Solutions

MiCOM P40 Agile

P741, P742, P743

Technical Manual

Busbar Differential Protection Relay

Hardware version: J and K

Publication reference: P74x/EN M/Na7

Software version: 51

Page 2

Page 3

CONTENTS

TD

IT

ST

GS

OP

AP

PL

MR

FD

CM

VH

TS

SC

SG

IN

MT

Safety Section

Section 1 I

Section 2 T

Section 3 G

Section 4 S

Section 5 O

on 6 Application Notes P74x/EN AP/Na7

Secti

Section 7 P

Section 8 M

ntroduction P74x/EN IT/Na7

echnical Data P74x/EN TD/Na7

etting Started P74x/EN GS/Na7

ettings P74x/EN ST/Na7

peration P74x/EN OP/Na7

rogrammable Logic P74x/EN PL/Na7

easurements and Recording P74x/EN MR/Na7

Section 9 F

Section 10 C

Section 11 M

Section 12 T

Section 13 S

Section 14 S

Section 15 In

Section 16 F

irmware Design P74x/EN FD/Na7

ommissioning P74x/EN CM/Na7

aintenance P74x/EN MT/Na7

roubleshooting P74x/EN TS/Na7

CADA Communications P74x/EN SC/Na7

ymbols and Glossary P74xEN SG/Na7

stallation P74x/EN IN/Na7

irmware and Service Manual Version History P74xEN VH/Na7

Appendix A

Page 4

Page 5

Introduction

a7

MiCOM P74

IT

1, P742, P743

P74x/EN IT/N

INTRODUCTION

Hardware Suffix: J and K

Software Version: 51

Page 6

P74

x/EN IT/Na7

Introduction

MiCOM P741, P742, P743

Page 7

Introduction

a7

MiCOM P741, P742, P743

1

IT

(IT) 1-

P74x/EN IT/N

CONTENTS

1. DOCUMENTATION STRUCTURE 3

2. INTRODUCTION TO MiCOM 5

3. PRODUCT SCOPE 6

3.1 Functional overview 6

3.2 Ordering options 8

FIGURES

FIGURE 1: FUNCTIONAL DIAGRAM 7

Page 8

P74

x/EN IT/Na7

Introduction

(IT) 1

MiCOM P741, P742, P743

IT

-2

Page 9

Introduction

a7

MiCOM P741, P742, P743

3

IT

(IT) 1-

1. DOCUMENTATION STRUCTURE

The manual provides a f unctional and technical description of the MiCOM protection relay

and a comprehensive set of instructions for the relay’s use and application.

The section contents are summarized below:

P74x/EN IT Introduction

A guide to the MiCOM range of relays and the documentation structure. General safety

aspects of handling Electronic Equipment is discussed with particular reference to relay

safety symbols. Also a general functional overview of the relay and brief application

summary is given.

P74x/EN TD Technical Data

Technical data inc luding s ettin g ran ges, accurac y lim its, r ecommended operating condit ions ,

ratings and perform ance data. C omplianc e with n orms and internat ional stand ards is quoted

where appropriate.

P74x /EN GS Getting Started

A guide to the different us er interf aces of the protec tion rela y descr ibing ho w to st art using it .

This section provides detailed information regarding the communication interfaces of the

relay, including a detailed description of how to access the sett ings database stored with in

the relay.

P74x/EN IT/N

P74x /EN ST Settings

List of all relay settings, including ranges, step sizes and defaults, together with a brief

explanation of each setting.

P74x /EN OP Operation

A comprehensive and detailed functional description of all protection and non-protection

functions.

P74x /E N AP Application Notes

This section includes a description of common power system applications of the relay,

calculation of suitabl e s etti n gs , some typical worked examples, and how to apply the settings

to the relay.

P74x /EN PL Programmable Logic

Overview of the programmable scheme logic and a description of each logical node. This

section includes the factory default (PSL) and an explanation of typical applications.

P74x /EN MR Measurements and Recording

Detailed description of the relays recording and measurements functions including the

configuration of the event and disturbance recorder and measurement functions.

P74x /EN FD Firmware Design

Overview of the operation of the relay’s hardware and software. This section includes

information on the self-checking features and diagnostics of the relay.

P74x /EN CM Commissioning

Instructions on how to commission the relay, comprising checks on the calibration and

functionality of the relay.

P74x /EN MT Maintenance

A general maintenance policy for the relay is outlined.

P74x /EN TS Troubleshooting

Advice on how to r ecognize f ailure modes and the re commended co urse of act ion. Includes

guidance on who in General Electric to contact for advice.

Page 10

P74

x/EN IT/Na7

Introduction

(IT) 1

MiCOM P741, P742, P743

IT

-4

P74x /EN SC SCADA Communications

This section provides an overview regarding the SCADA communication interfaces of the

relay. Detailed protocol mappings, semantics, profiles and interoperability tables are not

provided within this manual. Separate documents are available per protocol, available for

download from our website.

P74x /EN SG Symbols and Glossary

List of common technical abbreviations found within the product documentation.

P74x /EN IN Installation

Recommendations on u npacking, handling, inspecti on and storage of the rela y. A guide to

the mechanical and electrical installation of the relay is provided, incorporating earthing

recommendations. All external wiring connections to the relay are indicated.

P74x /EN VH Firmware and Service Manual Version History

History of all hardware and software releases for the product.

Page 11

Introduction

a7

MiCOM P741, P742, P743

5

IT

(IT) 1-

2. INTRODUCTION TO MiCOM

MiCOM is a comprehens ive solut ion capab le of meet ing all electr icit y suppl y requirem ents . It

comprises a range of components, systems and services from General Electric.

Central to the MiCOM concept is flexibility.

MiCOM provides the ability to define an application solution and, through extensive

communication capabilities, integrate it with your power supply control system.

The components within MiCOM are:

− P range protection relays;

− C range control products;

− M range measurement products for accurate metering and monitoring;

− S range versatile PC support and substation control packages.

MiCOM products include extensive facilities for recording information on the state and

behaviour of the p ower system using dis turbance and fault recor ds. They can also prov ide

measurements of the system at regular intervals to a control centre enabling remote

monitoring and control to take place.

P74x/EN IT/N

For up-to-date inform ation on an y MiCOM pro duc t, vis it our webs ite:

www.gegridsolutions.com

Page 12

P74

x/EN IT/Na7

Introduction

(IT) 1

MiCOM P741, P742, P743

IT

•

•

•

•

•

•

•

•

• •

• •

• • •

• • •

• •

• • •

• • •

• • •

• - •

-6

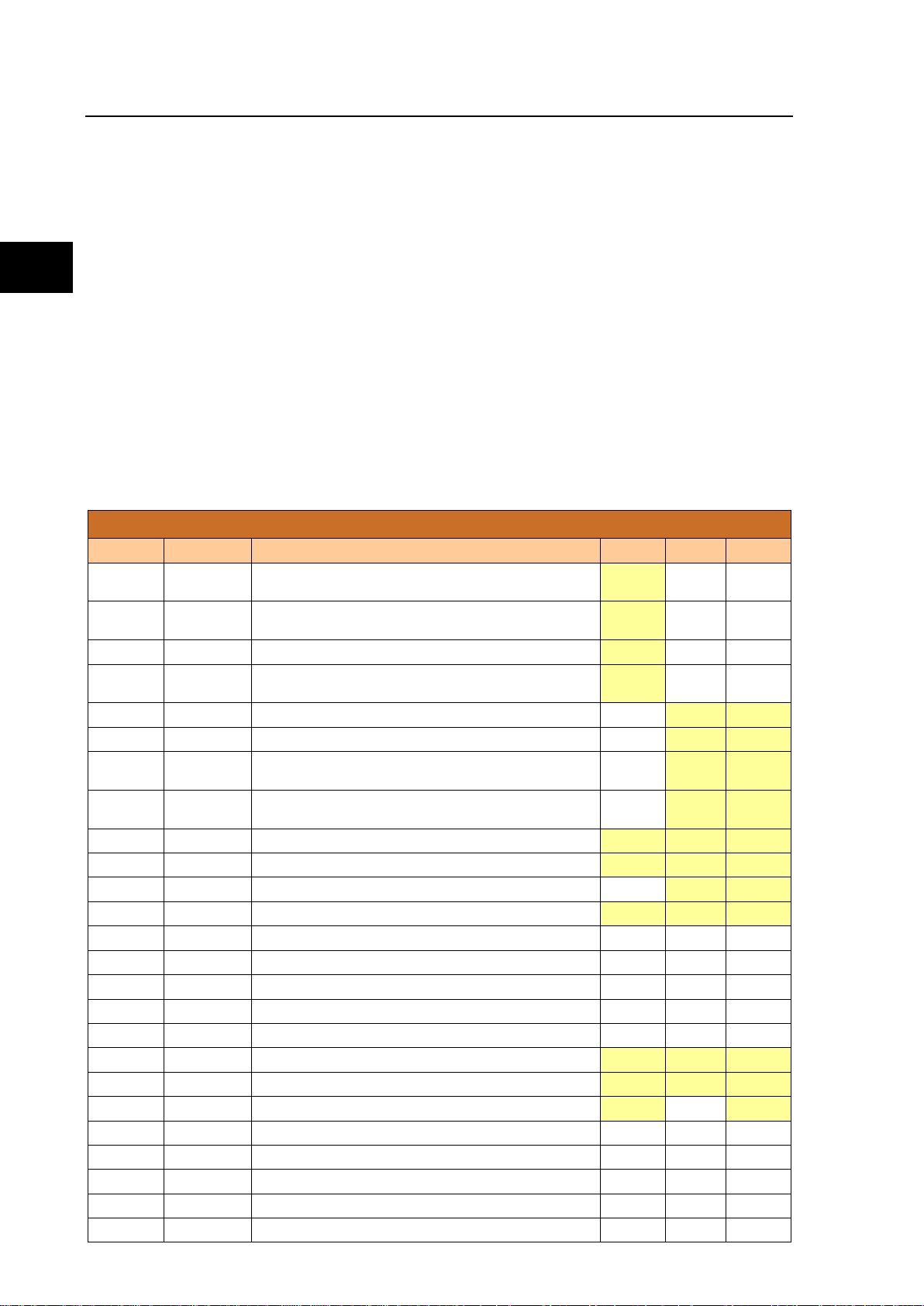

3. PRODUCT SCOPE

The P74x differential busbar protection relays have been designed for the protection of a

wide range of subs tation b usbars f rom distr ibution t o transm ission vo ltage le vels. The r ela ys

include a comprehens ive range of non-pro tection features to a id with system dia gnosis and

fault analysis. The P74x offers integral b iased diff erential bus bar, br eak er failure, dead zo ne,

overcurrent and earth-fault protection and is suitable for application on solidly grounded,

impedance grounded, Petersen coil grounded and isolated systems. The relays are

especially suitable where a complete scheme solution is required.

The scheme comprises of three relays:

• The P741 (Central Unit),

• The P742 and P743 (Peripheral Units).

Which, together with the topology configuration software and the dynamic synoptic

monitoring tool, allow full flexibility for all configurations.

3.1 Functional overview

The P74x Busbar protection contains a wide variety of protection func tions. The protection

features are summarized below:

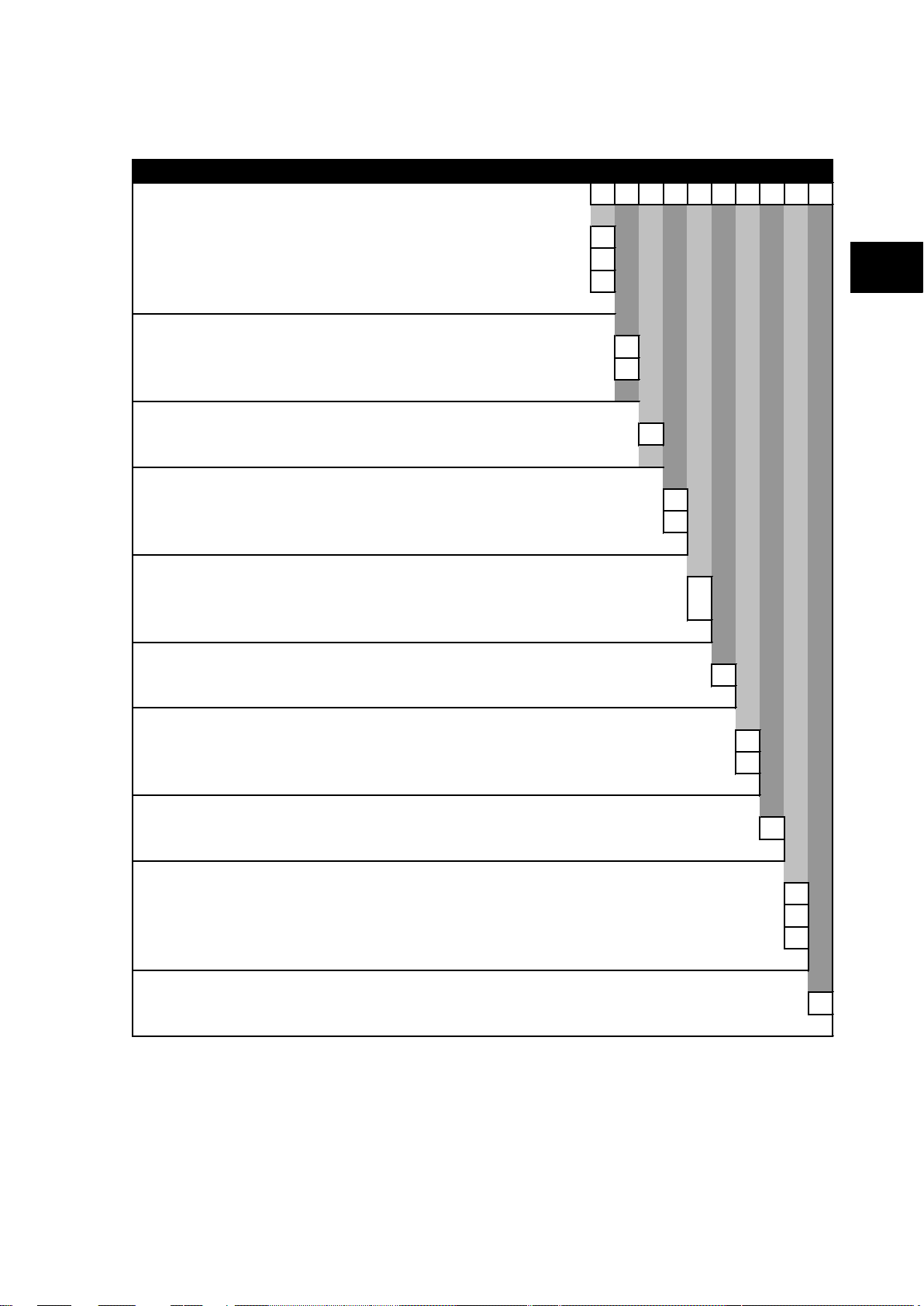

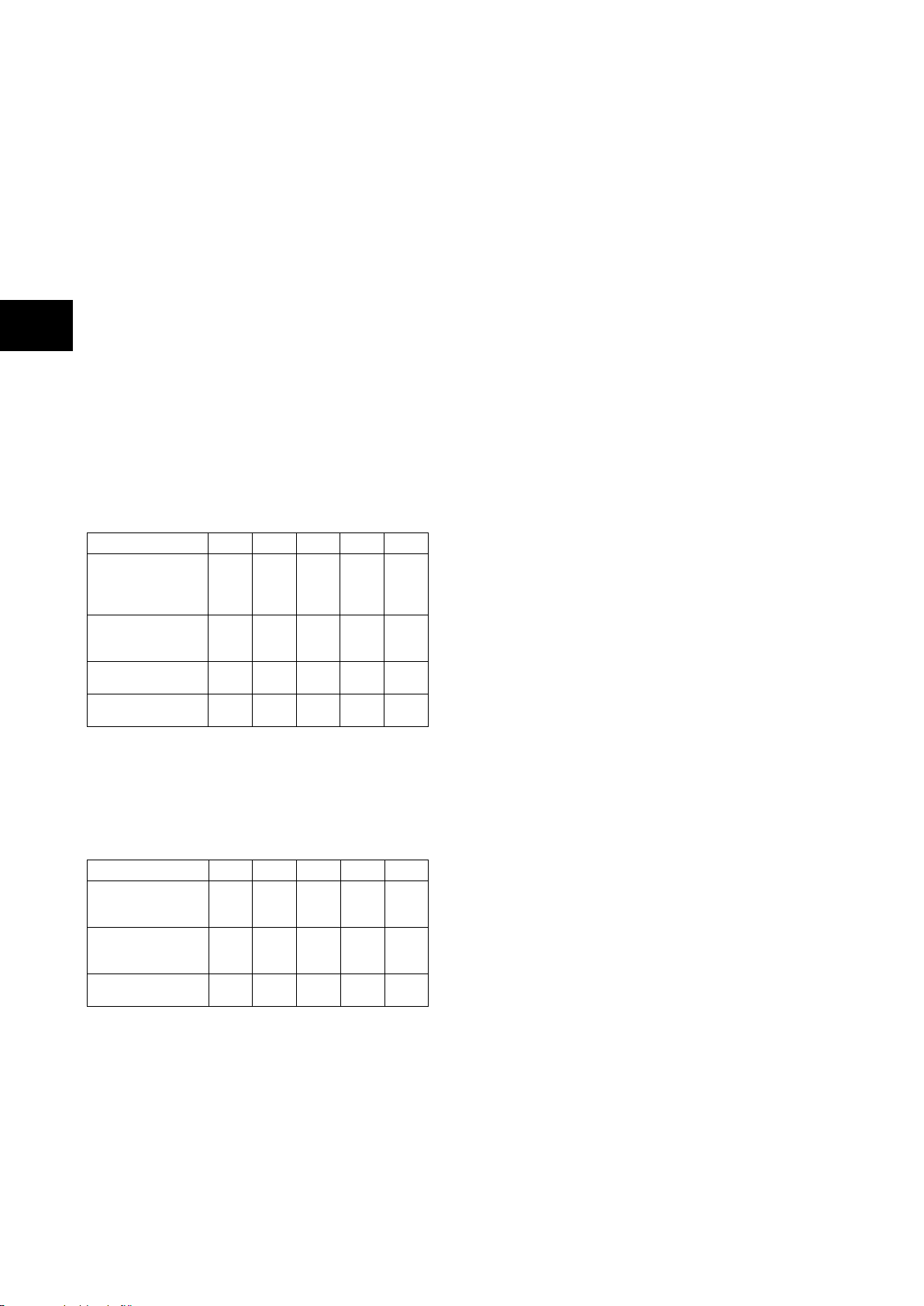

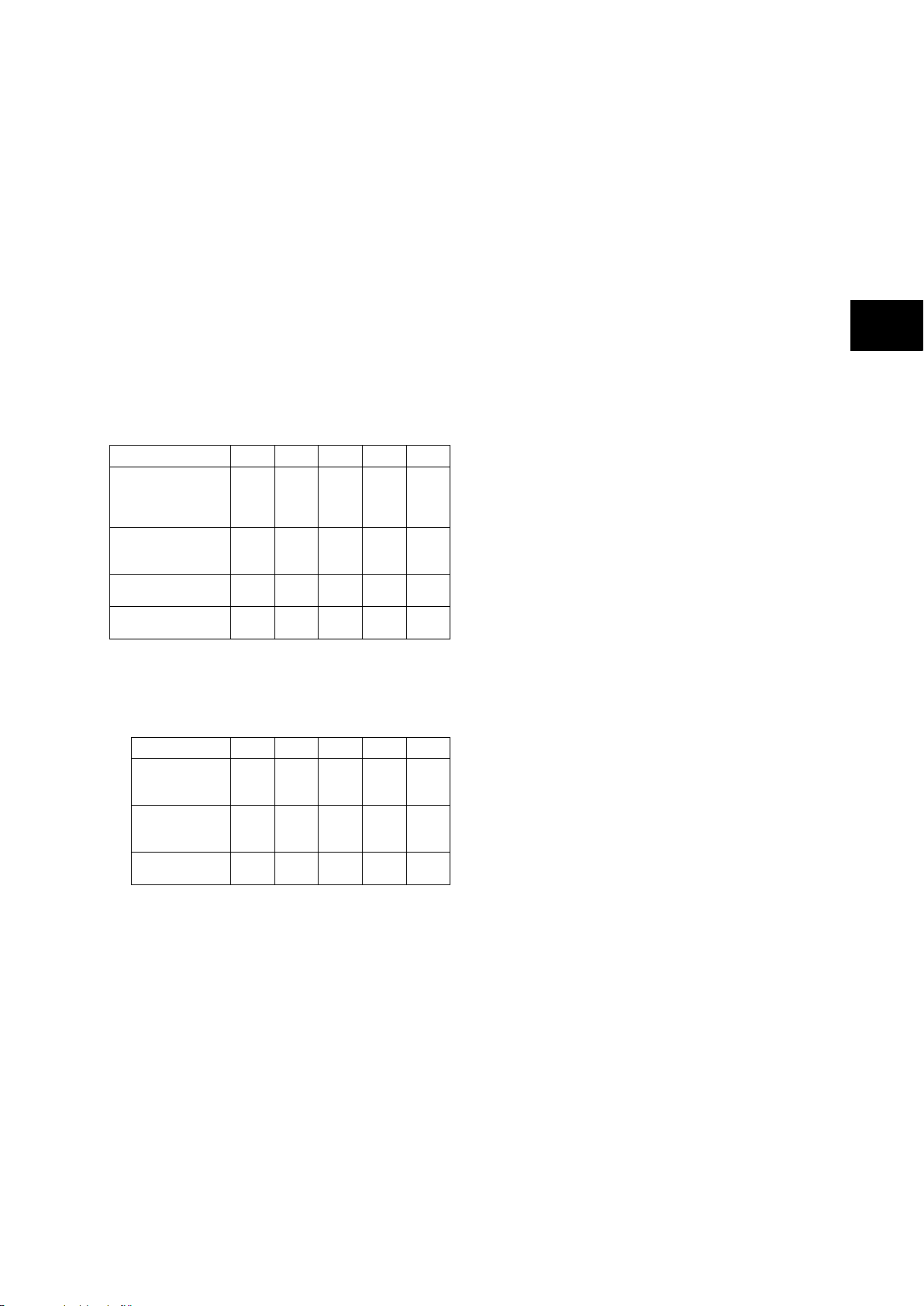

Protection Functions Overview

ANSI IEC 61850 Function P741 P742 P743

87BB / P PhsPDIF Phase segregated biased current differential high speed and

87CZ / P CzPPDIF Check Zone segregated biased phase current differential

87BB / N NeuPDIF Sensitive earth fault bias current controlled busbar protection

87 CZ/ N CzNPDIF Check Zone segregated biased earth current controlled

50 / 51 / P OcpPTOC Phase overcurrent protection (2 stages) 50 / 51 / N EfmPTOC Eart h overc urrent protecti on (2 st ages) -

50ST / P DzpPhsPTOC Dead zone phase protection (short zone between CTs and

50ST / N DzpEfmPTOC Dead zone earth protection (short zone between CTs and

CTS Current transformer supervision

50BF RBRF Breaker failure protection (LBB)

ISL Isolator discrepancy alarm Fibre optic signalling channel

OptGGIO Digital inputs (according to product) * 8 8/16 16/24

RlyGGIO Output relays (according to product) * 8 8/12 12/16/20

High Break relays (according to product) * 4 4/8

Virtual Digital inputs (via fibre communication) 16 16 16

Virtual Output relays (via fibre communication) 16 16 16

Front communication port (RS232)

Rear communication port (Kbus/EIA(RS)485)

Second Rear communication port (Kbus/EIA(RS)485)

Rear communication port (Ethernet) * Option - Option

Time synchronisation port (IRIG-B) * Option Via CU Via CU

Redundant Ethernet port Option - Option

FnkGGIO Function keys 10 - 10

LedGGIO Programmable tri-colour LEDs 18 - 18

* Refer to the data sheet for model selection

delayed busbar protection

high speed and delayed busbar protection

busbar protection

open CBs)

open CBs)

-

-

- -

- -

- -

- -

Page 13

Introduction

a7

MiCOM P741, P742, P743

7

IT

(IT) 1-

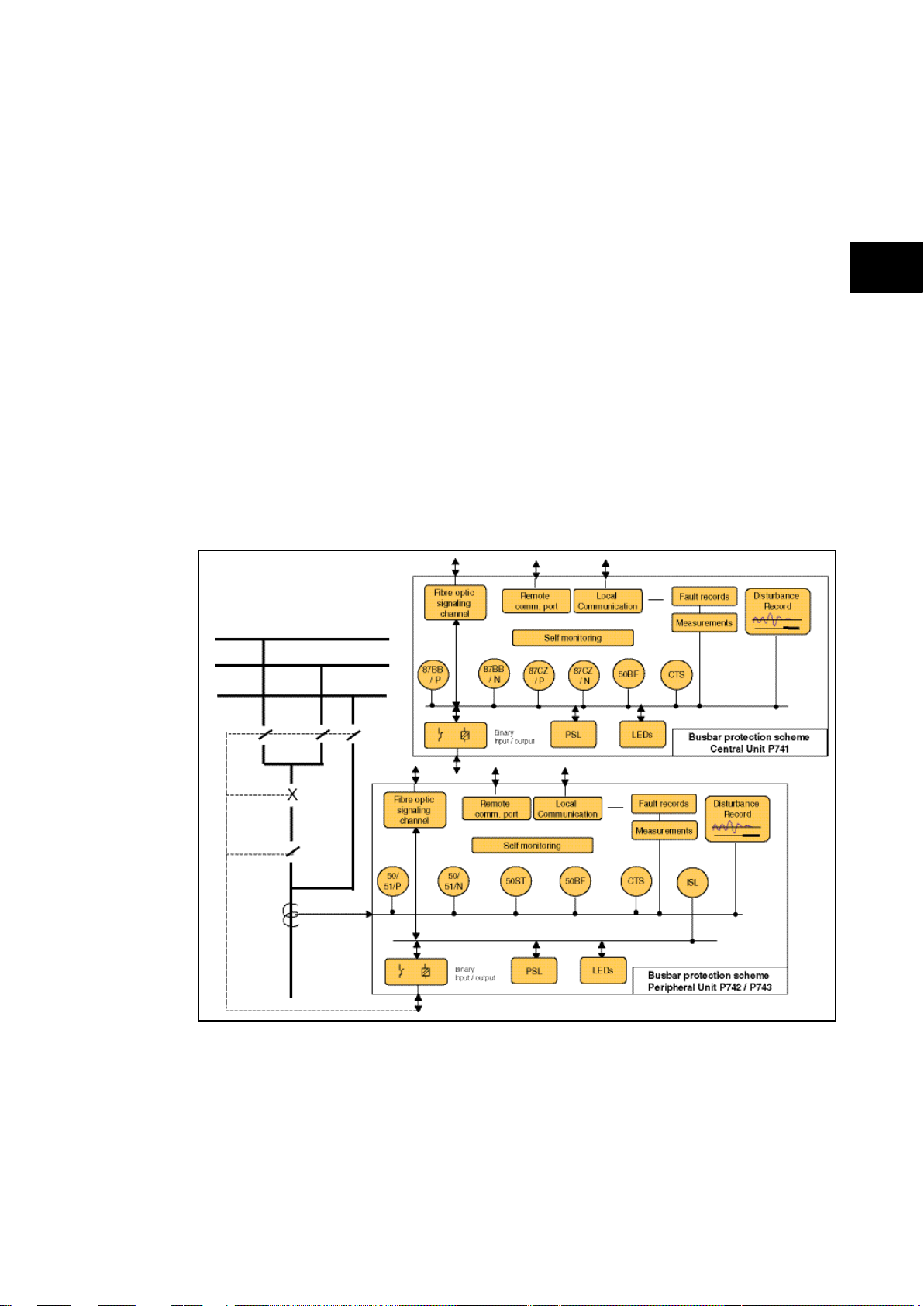

The P74x supports the following relay management functions in addition to the functions

illustrated above.

• Trip circuit and coil supervision

• 4 Alternative setting groups

• Programmable function keys (P741 and P743)

• Control inputs

• Programmable scheme logic

• Programmable allocation of digital inputs and outputs

• Sequence of event recording

• Comprehensive disturbance recording (waveform capture)

• Fully customizable menu texts

• Multi-level password protection

• Power-up diagnostics and continuous self-monitoring of relay

P74x/EN IT/N

Application overview

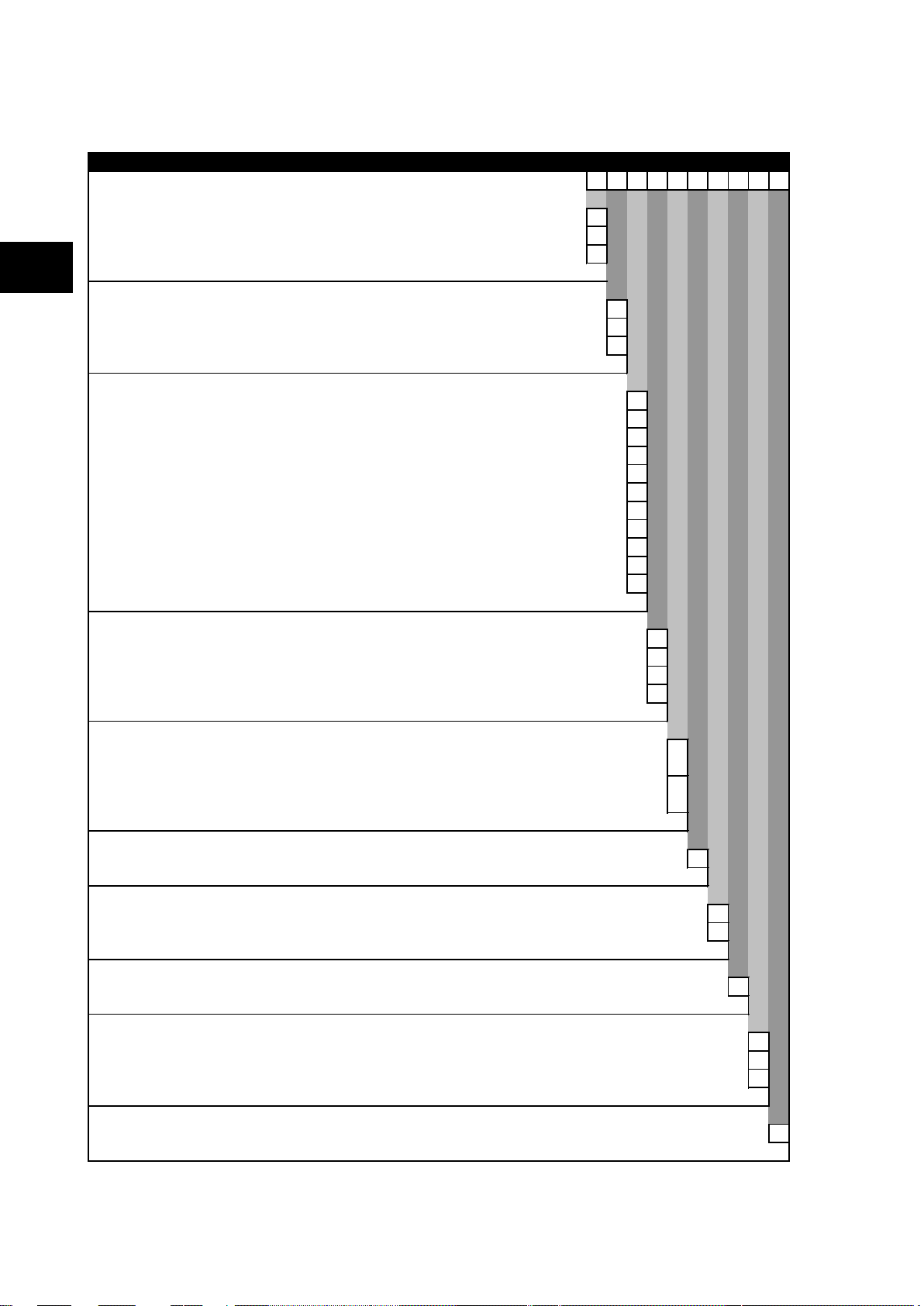

FIGURE 1: FUNCTIONAL DIAGRAM

Page 14

P74

x/EN IT/Na7

Introduction

(IT) 1

MiCOM P741, P742, P743

IT

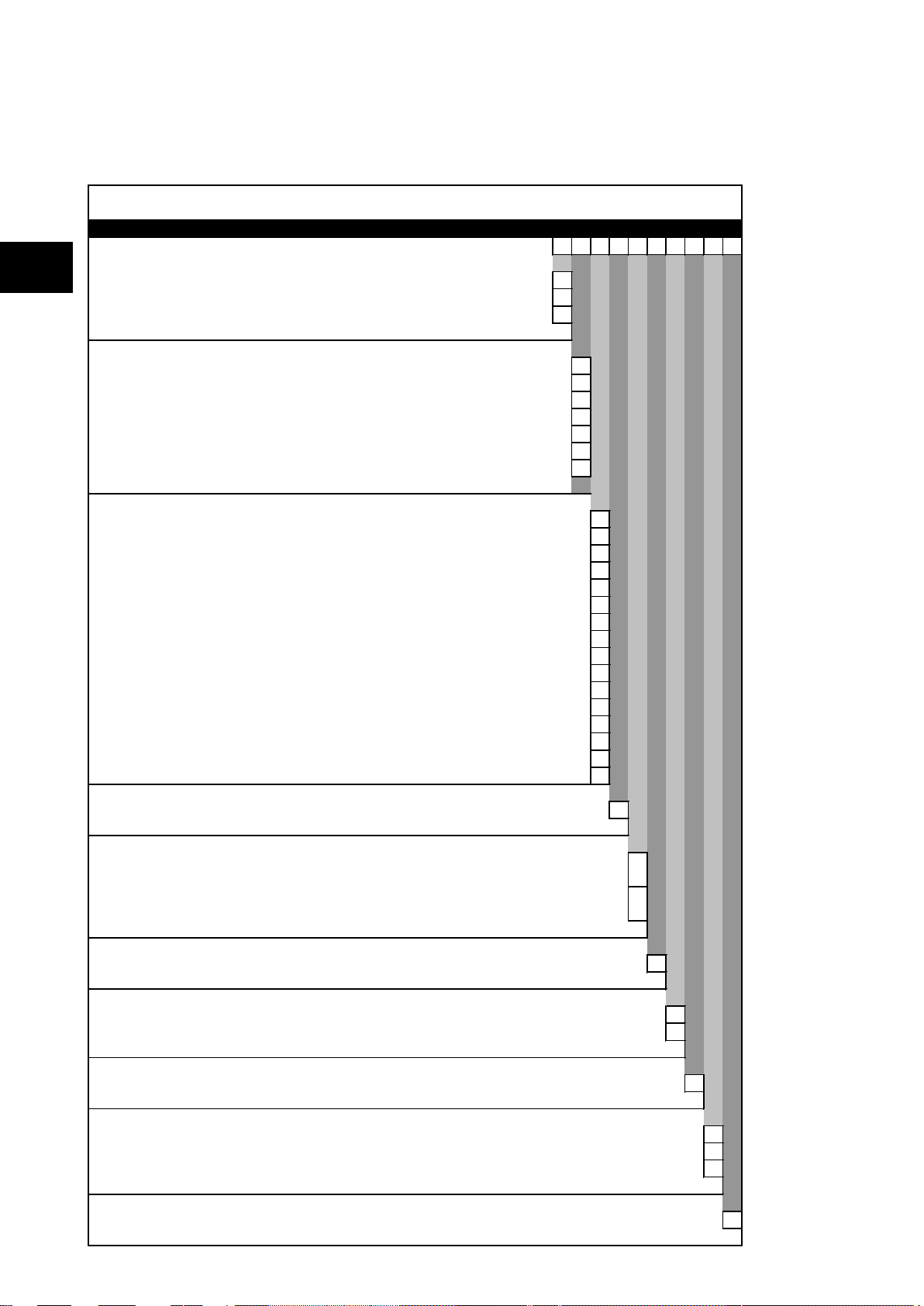

Information Required wit h O rder

Variants

P741 Bus bar P rot ect ion Rel ay P741

Vx Aux Rating

24 - 48 Vdc 7

48 - 125 Vdc (40 - 100 V ac ) 8

110 - 250 Vdc (100 - 240 V ac ) 9

Communication Boa rds

1 communic ation board (1 to 4 Peripheral Unit) 1

2 communic ation board (to 8 Peripheral Unit) 2

3 communic ation board (to 12 Peripheral Unit) 3

4 communic ation board (to 16 Peripheral Unit) 4

5 communic ation board (to 20 Peripheral Unit) 5

6 communic ation board (to 24 Peripheral Unit) 6

7 communic ation board ( to 28 Peripheral Unit) 7

Hardware Options

St andard - None 1

IRIG-B Only (m odulated) 2

IRIG-B (Demodulated) C

Et hernet (100 M bi t s/s) wit hout IRIG-B 6

Et hernet (100M bi t /s) pl us IRIG-B (Modulat ed) A

Et hernet (100M bi t /s) pl us IRIG-B (Un-modulated) B

2nd Rear Port & Int erM iCOM E

2nd Rear Port & Int erM iCOM & IRIG-B (Modulat ed) F

Redundant Ethernet S el f-Healing Ri ng, 2 m ul ti-mode fibre port s + M odul at ed IRIG-B G

Redundant Ethernet S el f-Healing Ri ng, 2 m ul ti-mode fibre port s + Un-modul at ed IRIG-B H

Redundant Ethernet RS TP, 2 m ul ti-mode fibre port s + M odul ated IRIG-B J

Redundant Ethernet RS TP, 2 m ul ti-mode fibre port s + Un-m odul at ed IRIG-B K

Redundant Ethernet Dual-Hom i ng S tar, 2 m ul t i -m ode fibre port s + M odul ated IRIG-B L

Redundant Ethernet Dual-Hom i ng S tar, 2 m ul t i -m ode fibre port s + Un-m odulated IRIG-B M

Redundant Ethernet P RP /HSR, 2 fibre port s + M odul ated IRIG-B N

Redundant Ethernet P RP /HSR, 2 fibre port s + Unm odul at ed IRIG-B P

Product Specific

Fixed A

Protocol Options

K-Bus/Courier

IEC60870-5-103 (Via K ITZ274)

Courier (K-Bus), IEC60870-5-103 via KITZ274 (Supplied as Courier. KITZ274 to be ordered)

Addit i onal IE C61850

Mounting

Panel M ounting, with harsh environment coati ng M

Language

Mult i l i ngual - E ngl i sh, F renc h, German, Spanis h 0

Mult i l i ngual - E ngl i sh, F renc h, German, Russi an 5

Sof twa re Issue

Unless specified t he l atest version will be del i vered **

Customisation

Default 0

Cust om er s pecific A

Central Net work s Version 5

Design Suffix

Order Number

1

6

-8

3.2 Ordering options Information Required with Order

Page 15

Introduction

a7

MiCOM P741, P742, P743

9

IT

Information Required with Order

Variants

P742 Busbar P rot ect i on P eri pheral Uni t (40TE) P742

Vx Aux Rating

24 - 54Vdc 7

48 - 125Vdc (40 - 100V ac) 8

110 - 250Vdc (100 - 240V ac) 9

Hardw a re Options

W i t hout CT Input 0

W i t h In = 1/ 5A CT Input 1

Hardw a re Options

St andard - None 1

Product Specific

8 Relay s O ut puts and 16 St at us Inputs A

8 Relay s O ut puts , 4 High B reak and 8 S t atus Input s B

Protocol Options

K-Bus/Courier

IEC60870-5-103 (Via K ITZ274)

Mounting

Flush P anel Mount ing, with Harsh Environment Coating M

Language

Multil i ngual - E ngl i sh, French, Germ an, S panish 0

Multil i ngual - E ngl i sh, French, Germ an, Rus s i an 5

Softw are Issue

Unles s specified t he l ates t versi on wil l be del i vered **

Customisation

Default 0

Cust om er spec i fic A

Central Net work s V ersion 5

Design Suffix

Order Number

1

(IT) 1-

P74x/EN IT/N

Page 16

P74

x/EN IT/Na7

Introduction

(IT) 1

MiCOM P741, P742, P743

IT

Information Required wit h O rder

Variants

P743 Busbar P rotec t i on Peripheral Unit (60TE) P743

Vx Aux Rating

24 - 54Vdc 7

48 - 125Vdc (40 - 100V ac) 8

110 - 250Vdc (100 - 240V ac)

9

Hardware Options

Wi thout CT Input 0

Wi th In = 1/ 5A CT Input 1

IEC 61850-9-2LE Sam pl ed Analogue V al ues Ethernet board *

C

Hardware Options

St andard - None 1

Et hernet (100 M bi t s/ s) without IRIG-B

6

2nd Rear Port & Int erM i COM & IRIG-B (Modul ated)

E

Redundant Ethernet Self-Healing Ring, 2 mul t i -m ode fibre port s + M odul ated IRIG-B G

Redundant Ethernet Self-Healing Ring, 2 mul t i -m ode fibre port s + Un-m odul at ed IRIG-B

H

Redundant Ethernet RS TP, 2 multi-m ode fibre port s + Modul ated IRIG-B J

Redundant Ethernet RS TP, 2 multi-m ode fibre port s + Un-modulated IRIG-B

K

Redundant Ethernet Dual -Homi ng S tar, 2 m ul ti-mode fibre ports + Modul at ed IRIG-B

L

Redundant Ethernet Dual -Homi ng S tar, 2 m ul ti-mode fibre ports + Un-modulated IRIG-B M

Redundant Ethernet PRP/ HS R, 2 fibre ports + Modul ated IRIG-B

N

Redundant Ethernet PRP/ HS R, 2 fibre ports + Unmodul at ed IRIG-B

P

Product Specific

16 Relays Out put s and 24 S t atus Inputs ** A

16 Relays Out put s, 4 High Break and 16 Status Inputs B

8 Relays Out put s, 4 High Break and 24 Status Inputs C

8 Relays Out put s, 8 High Break and 16 Status Inputs D

Protocol Options

K-Bus/Courier

IEC60870-5-103 (Via K ITZ274)

Courier (K-Bus), IE C60870-5-103 via KITZ274 (Supplied as Courier. KITZ274 to be ordered)

Additional IE C61850

Mounting

Panel M ounting, wi t h Hars h Environment Coati ng M

Language

Mult i l i ngual - E ngl i sh, F rench, Germ an, Spani sh 0

Mult i l i ngual - E ngl i sh, F rench, Germ an, Russian 5

Sof tw are Issue

Unless s pecified t he l atest version will be del i vered **

Customisation

Default 0

Cust om er speci fic A

Central Net work s Version 5

Design Suffix

* Only available wit h '60' s oftware

** 21 Relay Output s and 24 Status Inputs For S uffix 'B ' devices

Order Number

1

6

-10

Page 17

Technical Data

a7

MiCOM P74

TD

1, P742, P743

P74x/EN TD/N

TECHNICAL DATA

Hardware Suffix: J and K

Software Version: 51

Page 18

P74

x/EN TD/Na7

Technical Data

1, P742, P743

MiCOM P74

Page 19

Technical Data

a7

MiCOM P74

3

TD

1, P742, P743 (TD) 2-

Technical Data

Mechanical Specification

Design

Modular Px40 platform relay:

P741: Size 16“ case (80TE)

P742: Size 8“ case (40TE)

P743: Size 12“ case (60TE)

Mounting is front of panel flush mounting.

Enclosure Protection

Per IEC 60529: 1992:

IP 52 Protection (front panel) against dust and

dripping water,

IP 50 Protection for the rear and sides of the

case against dust,

IP 10 Product safety protection for the rear due

to live connections on the terminal block

Weight

P741 with 7 comm. boards 7.4 kg

with 1 comm. board 6.2 kg

P742 7.5 kg

P743 9.2 kg

P74x/EN TD/N

Front Download/Monitor Port

EIA RS232, 25 pin D-type female connector.

For firmware downloads.

PEB* rated circuit.

Rear Communications Port

K-Bus/EIA (RS)485 signal levels, two wire

Connections located on general pur p os e block,

M4 screw.

For screened twisted pair cable, multidrop,

1000 m max.

Courier protocol

SELV* rated circuit

Optional Second Rear Communication Port

EIA(RS)232, 9 pin D-type female connector,

socket SK4.

Courier protocol: K-Bu s, EI A( RS) 2 3 2, or

EIA(RS)485 connection.

Maximum cable run length: 15m.

Optional Rear EIA(RS)232 InterMiCOM Port

For “MODEM” InterMiCOM teleprotection

schemes.

EIA(RS)232, 9 pin D-type female connector,

socket SK5.

Isolation to SELV* level.

Maximum cable run length to MODEM 15m.

Terminals

AC Current and Voltage Measuring Inputs

P742 and P743 only

Located on heavy duty (black) terminal block:

Threaded M4 terminals, for ring lug

connection.

CT inputs have integral safety shorting, upon

removal of the terminal block.

General Input/Output Terminals

For power supply, opto inputs, output contacts

and COM1 rear communications.

Located on general purpose (grey) blocks:

Threaded M4 terminals, for ring lug

connection.

Case Protective Earth Connection

Two rear stud connections (2 P741, 1 P742/3),

threaded M4.

Must be earthed (grounded) using the

protective (earth) conductor for safety,

minimum wire size 2.5mm

Front Port Serial PC Interface

EIA RS232 DTE, 9 pin D-type female

connector.

Courier protocol for interface to S1 software.

PEB* rated Maximum cable length 15 m.

2

.

Optional Rear IRIG-B Interface modulated

or un-modulated

P741 only

(P742 & P743 synchronized by the P741)

BNC socket

SELV* rated circuit

50 ohm coaxial cable.

*: PEB = Protective equipotential bon ded

*: SELV = Safety/Separated extra low voltage

Both PEB and SELV circuits are safe to touch

after a single fault condition.

Optical Fiber Connection

BFOC 2.5 (ST®) interface for multi-mode glass

fibre type 62.5/125 µm, as per IEC 874-10, 850

nm short-haul fibres, one Tx and one Rx.

Optical budget: 5.6 dB

Data rate:2.5 Mbits

Max Length: 1000 m

Optional Rear Ethernet Connection for IEC

61850

10BaseT / 100BaseTX Communications

Interface in accordance with IEEE802.3 and

IEC61850

Isolation: 1.5kV

Connector type: RJ45

Cable type: Screened Twisted Pair (STP)

Max. cable length: 100m

Page 20

P74

Technical Data

(TD) 2

1, P742, P743

TD

Parameter

Sym

Min.

Typ.

Max

Unit

Output Optical Power

BOL: 62.5/125 µm,

NA = 0.275 Fiber

EOL

Output Optical Power

BOL: 50/125 µm,

NA = 0.20 Fiber EOL

Optical Extinction

Ratio

10

–10 % dB

Output Optical Power

at Logic “0” State

(“0”)

avg.

Input Optical Power

Minimum at Window

Edge

P

Min.

Input Optical Power

Minimum at Eye

Center

P

Min.

Input Optical Power

Maximum

PIN

dBm

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC61850

Wavelength: 1300nm

Fiber: multi-mode 50/125µm or 62.5/125µm

Connector style: BFOC 2.5 -(ST®)

Optional Rear redundant Ethernet

connection for IEC 61850

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC61850

Wavelength: 1300nm

Fiber: multi-mode 50/125µm or 62.5/125µm

Connector style: BFOC 2.5 -(ST®)

Transmitter optical characteristics 100 base FX

interface

Transmitter Optical Characteristics – 100

base FX interface

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

BOL – Beginning of life

EOL – End of life

Receiver Optical Characteristics – 100 base

FX interface

A = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

(T

Fiber defect connector (watchdog relay) –

Redundant Ethernet board

Connector (3 terminals): 2NC contacts

Rated voltage: 250 V

Continuous current: 5 A

Short duration current: 30 A for 3 s

Breaking capacity

Subject to maxima of 5 A and 250 V

x/EN TD/Na7

-4 MiCOM P74

Ratings

AC Measuring Inputs

Nominal frequency: 50 and 60 Hz (settable)

Operating range: 45 to 65 Hz

Phase rotation: ABC or ACB

AC Current

Nominal current (In): 1 and 5 A dual rated.

(1A and 5A inputs use different transformer tap

connections, check correct terminals are

wired).

Nominal burden per phase

1 A: <0.04VA at rated current

Impedance per phase

1 A: <40mΩ over 0 - 30In

Nominal burden per phase

5 A: <0.15VA at rated current

Impedance per phase

5 A: <8mΩ over 0 - 30In

Thermal withstand:

continuous 4 In

for 10 s: 30 In

for 1 s; 100 In

Linear to 64 In (non-offset AC current).

–19

P

OUT

–20

–16.8 –14

dBm

avg.

Power supply

Parameter Sym Min. Typ. Max. Unit

–22.5

P

OUT

–23.5

P

OUT

IN

(W)

IN

(C)

Max.

–45

–33.5 –31

–34.5 –31.8

–14 –11.8

–20.3 –14

dBm

avg.

dBm

dBm

avg.

dBm

avg.

avg.

DC: 50 W resistive

DC: 25 W resistive

AC: 1500 VA resistive (cos φ = un i ty)

AC: 1500 VA inductive (cos φ = unity)

Auxiliary Voltage (Vx)

Three ordering options:

(i) Vx: 24 to 48 Vdc

(ii) Vx: 48 to 110 Vdc,

and 40 to 100 Vac (rms.)

(iii) Vx: 110 to 250 Vdc,

and 100 to 240 Vac (rms.).

Operating Range

(i) 19 to 65 V (dc only for this variant)

(ii) 37 to 150 V(dc), 32 to 110 V (ac)

(iii) 87 to 300 V(dc), 80 to 265 V (ac).

With a tolerable ac ripple of up to 12 % for a dc

supply, per IEC 60255-11: 1979.

Nominal Burden

Quiescent burden:

P741: 37 to 41 W

P742: 16 to 23 W

P743: 22 to 32 W

Additions for energised binary inputs/outputs:

Per opto input:

0.09 W…(24 to 54 V),

0.12 W…(110/125 V),

0.19 W…(220/250 V).

Per energised output relay: 0.13 W

Per energised high break output relay: * 0.73W

Power-up Time

Time to power up < 30 s.

Page 21

Technical Data

a7

MiCOM P74

5

TD

1, P742, P743 (TD) 2-

Power Supply Interruption

Per IEC 60255-11: 1979

The relay will withstand a 20ms interruption in

the DC auxiliary supply, without

de-energising.

Per IEC 61000-4-11: 1994

The relay will withstand a 20ms interruption in

an AC auxiliary supply, without de-

energising.

Note: the use of a E124 extends these limits

Battery Backup

Front panel mounted

Type ½ AA, 3.6 V

Field Voltage Output

Regulated 48 Vdc

Current limited at 112 mA maximum output

Digital (“Opto”) Inputs

Universal opto inputs with programmable

voltage thresholds. May be energised from the

48 V field voltage, or the external battery

supply.

Rated nominal voltage: 24 to 250 Vdc

Operating range: 19 to 265 Vdc

Withstand: 300 Vdc.

Nominal pick-up and reset thresholds:

Pick-up: approx. 70 % of battery nominal set,

Reset: approx. 66 % of battery nominal set.

Recognition time: 7 ms

Output Contacts

Standard Contacts

General purpose relay outputs for signalling,

tripping and alarming:

Rated voltage: 300V

Continuous current: 10A

Short-duration current: 30A for 3s

Making capacity: 250A for 30ms

Breaking capacity:

DC: 50W resistive

DC: 62.5W inductive (L/R = 50ms)

AC: 2500VA resistive (cos φ = unity)

AC: 2500VA inductive (cos φ = 0.7)

Response to command: < 5 ms

Durability:

Loaded contact: 10 000 operations

minimum,

Unloaded contact: 100 000 operations

minimum.

Fast operation and High Break Contacts

Dedicated purpose relay outputs for tripping:

Uses IGBT technology

Make and Carry: 30 Amps for 3 sec,

30A @ 250V resistive

Carry: 250 Amps dc for 30ms

Continuous Carry: 10 Amps dc

Break Capacity:

– 10A @ 250V resistive (10,000 operations)

– 10A @ 250V L/R=40ms

P74x/EN TD/N

Operating time:

<200µs

& Reset time: 7.5ms

Watchdog Contacts

Non-programmable contacts for relay

healthy/relay fail indication:

Breaking capacity:

DC: 30 W resistive

DC: 15 W inductive (L/R = 40 ms)

AC: 375 VA inductive (cos φ = 0.7)

IRIG-B 12X Interface (Modulated)

External clock synchronization per IRIG

standard 200-98, format B12X.

Input impedance 6kΩ at 1000Hz

Modulation ratio: 3:1 to 6:1

Input signal, peak-peak: 200mV to 20V

IRIG-B 00X Interface (Un-modulated)

External clock synchronization per IRIG

standard 200-98, format B00X.

Input signal TTL level

Input impedance at dc 10kΩ

Environmental Conditions

Ambient Temperature Range

Ambient temperature range

Operating temperature range:

–25°C to +55°C

(or –13°F to +131°F)

Storage and transit:

–25°C to +70°C

(or –13°F to +158°F)

Tested as per

IEC 60068-2-1: 2007:

storage (96 hours) –25°C (–13°F)

operation (96 hours) –40°C (–40°F)

IEC 60068-2-2: 2007:

storage (96 hours) +85°C (+185°F)

operation (96 hours) +85°C (+185°F)

Ambient Humidity Range

Per IEC 60068-2-3: 196 9:

56 days at 93 % relative humidity

and +40 °C

Per IEC 60068-2-30: 1980:

Damp heat cyclic, six (12 + 12) hour cycles,

93 % RH, +25 to +55 °C

Corrosive Environments

Per IEC 60068-2-60: 1995, Part 2, Test Ke,

Method (class) 3

Industrial corrosive environment/poor

environmental control, mixed gas flow test.

21 days at 75% relative humidity and +30°C

Exposure to elevated concentrations of H

NO

, Cl2 and SO2.

2

2

S,

Page 22

P74

x/EN TD/Na7

Technical Data

(TD) 2

1, P742, P743

TD

-6 MiCOM P74

Type Tests

Insulation

Per IEC 60255-5: 2000,

Insulation resistance > 100 MΩ at 500 Vdc

(Using only electronic/brushless insulation

tester).

Creepage Distances and Clearances

Per IEC 60255-27:2005

Pollution degree 3,

Overvoltage category III,

Impulse test voltage 5 kV.

High Voltage (Dielectric) Withstand

(EIA RS232 ports excepted).

(i) Per IEC 60255-27:2005, 2 kV rms. AC, 1

min.

Between all case terminals connected

together, and the case earth.

Also, between all terminals of independent

circuits.

1 kV rms. AC for 1 minute, across open

watchdog contacts.

1 kV rms. AC for 1 minute, across open

contacts of changeover output relays.

(ii) Per ANSI/IEEE C37.90-1989 (reaffirmed

1994):

1.5 kV rms. AC for 1 minute, across open

contacts of changeover output relays.

Impulse Voltage Withstand Test

Per IEC 60255-27: 2005

Front time: 1.2 µs,

Time to half-value: 50 µs,

Peak value: 5 kV, 0.5 J

Between all terminals, and all terminals and

case earth.

Electrical Fast Transient or Burst

Requirements

Per IEC 60255-22-4: 2002. Test severity Class

III and IV:

Amplitude: 2 kV, burst frequency 5 kHz

(Class III),

Amplitude: 4 kV, burst frequency 2.5 kHz

(Class IV).

Applied directly to auxiliar y suppl y, and appli ed

to all other inputs. (EIA RS232 ports

excepted).

Electromagnetic Compatibility (EMC)

1 MHz Burst High Frequency Disturbance

Test

Per IEC 60255-22-1: 1988, Class III,

Common-mode test voltage: 2.5 kV,

Differential test voltage: 1.0 kV,

Test duration: 2 s, Source impedance: 200 Ω

(EIA RS232 ports excepted).

Immunity to Electrostatic Discharge

Per IEC 60255-22-2: 1996, Class 4,

15 kV discharge in air to user interface,

display, and exposed metalwork.

Per IEC 60255-22-2: 1996, Class 3,

8 kV discharge in air to all communication

ports.

6 kV point contact discharge to any part of

the front of the product.

Page 23

Technical Data

a7

MiCOM P74

7

TD

1, P742, P743 (TD) 2-

Surge Immunity Test

(EIA RS232 ports excepted).

Per IEC 61000-4-5: 2002 Level 4,

Time to half-value: 1.2 / 50 µs,

Amplitude: 4 kV between all groups and

case earth,

Amplitude: 2 kV between terminals of each

group.

Immunity to Radiated Electromagnetic

Energy

Per IEC 60255-22-3: 2000, Class III:

Test field strength, frequency band 80 to

1000 MHz: 10 V/m,

Test using AM: 1kHz / 80%,

Spot tests at 80, 160, 450, 900 MHz

Per IEEE/ANSI C37.90.2: 1995:

25 MHz to 1000 MHz, zero and 100%

square wave modulated.

Field strength of 35 V/m.

Radiated Immunity from Digital

Communications

Per EN61000-4-3: 2002, Level 4:

Test field strength, frequency band 800 to

960 MHz, and 1.4 to 2.0 GHz:

30 V/m,

Test using AM: 1 kHz / 80%.

Radiated Immunity from Digital Radio

Telephones

Per ENV 50204: 1995

10 V/m, 900 MHz and 1.89 GHz.

Immunity to Conducted Disturbances

Induced by Radio Frequency Fields

Per IEC 61000-4-6: 1996, Level 3,

Disturbing test voltage: 10 V

Power Frequency Magnetic Field Immunity

Per IEC 61000-4-8: 1994, Level 5,

100 A/m applied continuously,

1000 A/m applied for 3 s.

Per IEC 61000-4-9: 1993, Level 5,

1000 A/m applied in all planes.

Per IEC 61000-4-10: 1993, Lev el 5,

100 A/m applied in all planes at 100 kHz/1

MHz with a burst duration of 2 s.

Conducted Emissions

Per EN 55022: 1998:

0.15 – 0.5 MHz, 79 dBµV (quasi peak) 66

dBµV (average)

0.5 – 30 MHz, 73 dBµV (quasi peak) 60

dBµV (average).

Radiated Emissions

Per EN 55022: 1998:

30 – 230 MHz, 40 dBµV/m at 10 m

measurement distance

230 MHz – 1 GHz, 47 dBµV/m at 10 m

measurement distance.

P74x/EN TD/N

EU Directives

EMC Compliance

Per 89/336/EEC:

Compliance to the European Commission

Directive on EMC is claimed via the

Technical Construction File route. Product

Specific Standards were used to establish

conformity:

EN50263: 2000

Product Safety

Per 2006/95/EC:

Compliance with European Commission Low

Voltage Directive. Compliance is demonstrated

by reference to generic safety standards:

IEC 60255-27:2005

EN 60255-5:2001.

Mechanical Robustness

Vibration Test

Per IEC 60255-21-1: 1996

Response Class 2

Endurance Class 2

Shock and Bump

Per IEC 60255-21-2: 1995

Shock response Class 2

Shock withstand Class 1

Bump Class 1

Seismic Test

Per IEC 60255-21-3: 1995

Class 2

Timings and Accuracy

All quoted operating times include the closure

of the trip output contact.

Page 24

P74

x/EN TD/Na7

Technical Data

(TD) 2

1, P742, P743

TD

-8 MiCOM P74

Performance Data

Busbar Protection

Busbar fault Accuracy

Pick-up: Setting ± 5% or 20 A up to 8 Pus, or

50 A from 8 Pus, Whichever Is Greater (WIG)

Drop-off: >0.95 x Setting or 20 A up to 8 Pus,

or 50 A from 8 Pus, WIG

Busbar trip:11 ms (min) & 13 ms (typical) at

1.4 x tripping threshold at 50Hz and at 1.7 x

tripping threshold at 60Hz

Circuitry fault Accuracy

Pick-up: Setting ± 5% or 20 A up to 8 Pus, or

50 A from 8 Pus, Whichever Is Greater (WIG)

Drop-off: >0.95 x Setting or 20 A up to 8 Pus,

or 50 A from 8 Pus, WIG

DT operation: ±5 % or 40 ms WIG

Dead Zone Protection

Accuracy

Pick-up: Setting ± 5% or 10 mA Whichever Is

Greater (WIG)

Drop-off: >0.95 x Setting or 10 mA WIG

Min. trip level: 1. 05 x Setting ± 5% or 10 mA

WIG

DT operation: ±5 % or 20 ms WIG

Three phase overcurrent protection

Accuracy

Pick-up: Setting ±5 % or 10 mA Whichever Is

Greater (WIG)

Drop-off: 0.95 x Setting ±5 % or 10 mA WIG

Min. trip level of IDMT elements:

1.05 x Setting ±5 % or 10 mA WIG

IDMT shape: ±5 % or 40 ms WIG (under

reference conditions)*

IEEE reset: ±5 % or 40 ms WIG

DT operation: ±5 % or 50 ms WIG

DT reset: Setting ±5 % or 20 ms WIG

Characteristic

UK curves: IEC 60255-3 …1998

US curves: IEEE C37.112 …1996

Earth Fault Protection

Accuracy

Pick-up: Setting ± 5% or 10 mA Whichever Is

Greater (WIG)

Drop-off: >0.95 x Setting or 10 mA WIG

Min. trip level of IDMT elements: 1.05 x Setting

± 5% or 10 mA WIG

IDMT characteristic shape: ± 5 % or 40 ms

WIG (under reference conditions)*

IEEE reset: ±10 % or 40 ms WIG

DT operation: ±5 % or 50 ms WIG

DT reset: ± 5% or 50 ms WIG

Transient overreach and overshoot

Accuracy

Additional tolerance due to increas i ng X/R

ratios: ± 5% over the X/R ratio of 1 to 90

Overshoot of overcurrent elements: < 40 ms

Programmable scheme logic

Accuracy

Output conditioner timer:

Setting ±2 % or 50ms whichever is greater

Dwell conditioner timer:

Setting ±2 % or 50ms whichever is greater

Pulse conditioner timer:

Setting ±2 % or 50 ms whichever is greater

IRIG-B and Real Time Clock

Modulated IRIG-B:

Modulation ratio: 1/3 or 1/6

Input signal peak-peak amplitude:

200 mV to 20 V

Input impedance at 1000Hz: 6000 Ω

External clock synchronization:

Conforms to IRIG standard 200-98, format B

Un-modulated IRIG-B:

Input signal TTL level

Input impedance at dc 10kΩ

External clock synchronization per IRIG

standard 200-98, format B00X.

Performance Accuracy (for modulated and

un-modulated versions)

Real time clock accuracy: < ±2 seconds/day

Measurements

Accuracy

Phase current: ±1.0 % of Reading or ±1.0%

CT Ratio (RorCTR)

Phase local current: ±1.0 % of RorCTR

or ±(f-fn)/fn %

Phase remote current: ±1.0 % of RorCTR

or ±(f-fn)/fn %

Phase differential current: ±5.0 %

Bias current: ±5.0 %

Frequency: ±1 %

Disturbance records

Accuracy

Waveshape : Compar abl e with app li ed

quantities

Magnitude and relative phases : ±5 % of

applied quantities

Duration: ±2 %

Trigger position: ±2 %

(minimum trigger 100 ms)

Page 25

Technical Data

a7

MiCOM P74

9

TD

Output Optical Power

BOL: 62.5/125 µm,

NA = 0.275 Fiber

EOL

Output Optical Power

BOL: 50/125 µm,

NA = 0.20 Fiber EOL

Optical Extinction

Ratio

–10 % dB

Output Optical Power

at Logic “0” State

P

dBm

Input Optical

Power Minimum

at Window Edge

P

Min.

Input Optical

Power Minimum

at Eye Center

P

Min.

Input Optical

Power Maximum

PIN

Max.

dBm

avg.

1, P742, P743 (TD) 2-

IEC 61850 Ethernet data

P74x/EN TD/N

Protection functions

10 Base T/100 Base TX Communications

Interface in accordance with IEEE802.3 and

IEC61850

Isolation 1.5kV

Cable type: Screened twisted pair STP

Max length: 100m

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC61850

Wavelength: 1300nm

Fibre: multi-mode 50/125µm or 62.5/125µm

Connector style: ST

Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Sym Min. Typ. Max Unit

–19

P

OUT

–20

–22.5

P

OUT

–23.5

OUT

(“0”)

–45

–16.8 –14

–20.3 –14

10

dBm

avg.

dBm

avg.

avg.

BOL – Beginning of life

EOL – End of life

Receiver Optical Characteristics

A = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

(T

Parameter Sym Min. Typ. Max. Unit

IN

(W)

IN

(C)

–33.5 –31

–34.5 –31.8

–14 –11.8

dBm

avg.

dBm

avg.

Note: The 10BaseFL connection will no

longer be supported as IEC 61850

does not specify this interface

Reference conditions

Ambient temperature: 20 °C

Frequency Tracking Range

45 to 65 Hz

Global Settings (System Data)

Language: English/Frenc h/ G erm an/Spa nis h

Frequency: 50/60 Hz

Common conventional ratios (CU)

Primary basis current (virtual)

Ibp: 1000A

Current transformers (PU)

Phase CT Primary: 1…30.000A (step 1A)

Phase CT Secondary In: 1A or 5A

Phase Fault elements (CU)

Phase current slope adjustment

k2: 0.20…0.90 (step 0.1)

Phase differential current threshold

ID>2: 50A…30kA (step 10A)

Check Zone slope adjustment

kCZ: 0.00…0.90 (step 0.01)

Check Zone differential current threshold

IDCZ >2: 50A…30kA (step 10A)

Circuitry fault slope adjustment

ID>1: 10…500A (step 10A)

Circuitry fault threshold

k1: 0.00…0.50 (step 0.01)

Circuitry fault alarm timer

ID>1 tCF: 0.1…600.0s (step 0.1s)

Sensitive earth fault

Option for high neutral impedance:

Disabled/Enabled

Threshold for sensitive Earth fault with flowing

current control:

IbiasPh>Cur.: 50A…30kA (step 10A)

Residual current slope adjustment

kN2: 0.00…0.90 (step 0.01)

Residual differential current threshold:

IDN>2: 10A…30kA (step 10A)

Residual Check Zone current slope adjustment

kNCZ: 0.00…0.90 (step 0.01)

Residual Check Zone differential current

threshold:

IDNCZ>2: 10A…30kA (step 10A)

Circuitry fault slope adjustment

kN1: 0.00…0.50 (step 0.01)

Circuitry fault threshold:

IDN>1: 10…500A (step 10A)

Circuitry fault alarm timer

IDN>1 tCF: 0.1…600.0s (step 0.1s)

Breaker failure

Accuracy

Reset time

= 25 ms from:

start to [(TBF2 or TBF4) - 30ms]

= 15 ms from:

[(TBF2 or TBF4) - 30ms] to [TBF2 or TBF4]

±2 % or 10 ms whichever is greater

Thresholds: settings ±5 % or 10 mA Whichever

Is Greater

Page 26

P74

x/EN TD/Na7

Technical Data

(TD) 2

1, P742, P743

TD

-10 MiCOM P74

Current transformer and feeder

characteristics

Class: 5P (IEC185)

X (BS3958)

TPX (IEC 44-6)

TPY (IEC 44-6)

TPZ (IEC 44-6)

Min. Knee point voltage (BS 3958):

Vk: 100/I

V…5k/In V (step 10/In V)

n

Rated Burden (IEC 44-6):

S: 5VA…100VA (step 1VA)

Rated Resistive Burden (IEC 44-6):

5…100/I

2

Ω (step 1/I

n

2

Ω)

n

rRB: data calculated from rated burden

Rated short-circuit current factor:

Kscc: 10…50 (step 5)

Secondary resistance (Ω)

: 0.1…50.0 Ω (step 0.1Ω)

R

CT

External loop resistance Eff. Burden (Ω):

RB: 0.1…200.0/ I

2

Ω (step 1/ I

n

2

Ω)

n

External loop resistance Eff. Burden VA

(Data calculated from Eff. Burden Ohm)

Blocking of 87BB on phase-phase feeder fault

for external ph-ph fault detection - (>1.5 max

ph-ph fault current infeed) with Ultra high

speed detection <1 ms:

I>BB: 0.05…4×I

(step 0.01×In)

n

Blocking of 87BB on earth/feeder fault

(external earth fault detecti on) - (>1.5 max

earth fault current infeed. Ultra high speed

detection required <1 ms):

IN>BB: 0.05…4×I

(step 0.01×In)

n

Supervision of I0 calculation

Kce: 0.01…1.00 (step 0.01)

I0 error alarm time delay

Tce: 0.0…10.0s (step 0.1s)

I0 supervision blocking : 87BB (P&N) / N on e

CTS Timer alarm : 0.1s…10.0s (step 0.1s)

Note: I

is the CT nominal current

n

Dead Zone protection (PU)

Phase threshold

I>DZ: 0.05…4.00×I

Time delay: 0.00…100.00s (step 10ms)

Dead Zone Earth: Disabled/Enabled

Neutral threshold:

IN>DZ: 0.05…4.00×I

Time delay: 0.00…100.00 s (step 10ms)

Note: I

is the CT nominal current

n

(step 0.01×In)

n

(step 0.01×In)

n

Breaker failure protection (PU)

Caution: the following current set values are

expressed in multiple of the local CT’s nominal

rated current Inp (primary) or Ins (secondary).

Breaker Failure

st

phase O/C threshold

1

(dead pole detection for 50BF):

I<: 0.05…4.00×I

Confirmation I>: Disabled/Enabled

nd

phase O/C threshold:

2

I>: 0.05…4.00×I

Confirmation IN>: Disabled/Enabled

nd

residual O/C threshold:

2

IN>: 0.05…4.00×I

Timers for 50BF internal tripping

CB fail 1 timer:

tBF1: 0.00…10.00s (step 10ms)

CB fail 2 timer:

tBF2: 0.00…10.00s (step 10ms)

Timers for 50BF external tripping

(orders from 21 or 87T etc.)

CB fail 3 timer:

TBF3: 0.00…10.00 s (step 10ms)

CB fail 4 timer:

TBF4: 0.00…10.00 s (step 10ms)

Overcurrent Protection (PU)

Phase Fault Protection (50/51)

3 phase Overcurrent Function Status I>1:

0. Disabled

1. DT

2. IEC S Inverse

3. IEC V Inverse

4. IEC E Inverse

5. UK LT Inverse

6. IEEE M Inverse

7. IEEE V Inverse

8. IEEE E Inverse

9. US Inverse

10. US ST Inverse

If “function status” ≠0

I>1 Current Set: 0.10…32.00×In

(step 0.01×In)

If “function status” =1

I>1 Time delay: 0.00…100.00s (step 10ms)

If ”function status” ≤5

I>1: 0.025…1.200 (step 0.025)

(step 0.01×In)

n

(step 0.01×In)

n

(step 0.01×In)

n

If “function status” ≥6

I>1 time Dial: 0.5…15.0 (step 0.1)

I>1 Reset Char: DT or inverse

If ”function status” ≤5

or

“I>1 Reset Char.”=DT and “function status” ≥6

I>1: 0.0…100.0 (step 0.1)

Page 27

Technical Data

a7

MiCOM P74

11

TD

1, P742, P743 (TD) 2-

I>2 Function:

Disabled, 87BBP&N blocking, High Set I>2,

I>2 & 87BBP&N, 87BB/P blocking, 87BB/N

blocking, I>2 & 87BB/P or I>2 & 87BB/N

I>2 Current Set (if “I>2 function” enabled)

0.10…32.00×In (step 0.01×In)

If “I>2 function” = high set I>2

I>2 Time Delay: 0.00…100.00s (step 10ms)

If “I>2 function” = 87BB (P and/or N)

I>2 Time Delay: 0.2…6.00s (step 0.1s)

Earth Fault Protection (50N/51N)

Residual Overcurrent Function Status IN>1:

0. Disabled

1. DT

2. IEC S Inverse

3. IEC V Inverse

4. IEC E Inverse

5. UK LT Inverse

6. IEEE M Inverse

7. IEEE V Inverse

8. IEEE E Inverse

9. US Inverse

10. US ST Inverse

If “function status” ≠0

“IN >1 current set”: 0.10…32.00×In

(step 0.01×In)

If “function status” =1

“IN >1 Time delay”: 0.00…100.00s

(step 10ms)

If “function status” ≤5

“IN >1 TMS”: 0.025…1.200 (step 0.025)

If “function status” ≥6

“IN >1 Time Dial”: 0.5…15.0 (step 0.1)

“IN >1 Reset Char”: DT or Inverse

If “function status” ≤5

or

“IN>1 Reset Char.”=DT & “function status” ≥6

IN >1 tReset: 0.0…100.0 (step 0.1)

P74x/EN TD/N

CB Control (PU)

Prot Trip Pulse: 0.05…2.00s (step 10mss)

Trip Latched: Disabled/Enabled

Rest Trip Latch: Yes/No

CB Control by: Disabled, Local and/or

Remote and /or Opto

Man Close Pulse: 0.1…10.0s (step 10ms)

Man Trip Pulse: 0.1…5.0s (step 10ms)

Man Close Delay: 0…600s (step 10ms)

87BB Trip Delay: 0…400ms (step 5ms)

CB Superv Timer: 10…400ms (step 5ms)

Date and Time

IRIG-B Sync: Disabled/Enabled

Battery Alarm: Disabled/Enabled

LocalTime Enable: Disabled/Fixed/Flexible

DST Enable: Disabled/Enabled

Configuration

Setting Group:

Select via Menu or Select via Opto

Active Settings: Group 1/2/3/4

Setting Group 1: Disabled/Enabled

Setting Group 2: Disabled/Enabled

Setting Group 3: Disabled/Enabled

Setting Group 4: Disabled/Enabled

CU Only

Diff Busbar Prot: Disabled/Enabled

– Differential phase fault

– Sensitive earth fault

PU Only

Dead Zone Prot: Disabled/Enabled

CB Fail & I>: Disabled/Enabled

BB Trip Confirm: Disabled/Enabled

Overcurrent Prot: Disabled/Enabled

Earth Fault Prot: Disabled/Enabled

CU & PU

Setting Values: Primary/Secondary

LCD Contrast: (Factory pre-set)

IN >2 Function:

Disabled, 87BBP&N blocking, High Set I>2,

I>2 & 87BBP&N, 87BB/P blocking, 87BB/N

blocking, I>2 & 87BB/P or I>2 & 87BB/N

IN>2 Current Set (if “IN>2 function” enabled):

0.10…32.00 xIn (step 0.01×In)

If “IN>2 function” = high set I>2

IN>2 Time Delay:

0.00…100.00s (step 10ms)

If “IN>2 function” = 87BB (P and/or N)

IN>2 Time Delay: 0.2…6.00 s (step 0.1s)

Page 28

P74

x/EN TD/Na7

Technical Data

(TD) 2

1, P742, P743

TD

-12 MiCOM P74

Measurements and records List

Fault Recorder

Records for the last 5 faults

Central Unit:

• Active Setting group

• Faulty phase

• Protection started/operated (87BB, 50BF,

Dead Zone…)

• Fault occurrence time and duration

• Check Zone values (Diff. & Bias for A, B, C,

N)

• Faulty zone(s)

• Topology prior the fault occurrence

Peripheral Unit:

• Active setting group

• Indication of the tripped phases

• Protection started/operated (87BB, 50BF,

Dead Zone…)

• Relay Trip Time and duration

• Relay Trip Time

• Faulty phase currents (A, B, C, N)

Event Recorder

Records for the last 512 events

Communications

RP1 Protocol: Courier

RP1 Address (courier): 6…34

Inactivity Timer: 1…30 minutes

RP1 Port Config (Courier):

K Bus / EIA485 (RS485)

RP1 Comms Mode (EIA485 (RS485)):

IEC60870 FT1.2 Frame

10-Bit NoParity

RP1 Baud Rate (EIA485 (RS485)):

9600 / 19200 / 38400 bits/s

RP1 Read Only: Disabled/Enabled

Optional Second Rear

Communication

RP2 Protocol: Courier (fixed)

RP2 Port Config:

Courier over EIA(RS)232

Courier over EIA(RS)485

K-Bus

RP2 Comms. Mode:

IEC60870 FT1.2 Frame

10-Bit NoParity

RP2 Address: 0…255

RP2 InactivTimer: 1…30mins

RP2 Baud Rate:

9600 / 19200 / 38400 bits/s

RP2 Read Only: Disabled/Enabled

Oscillography

(Disturbance Recorder)

Central Unit:

Duration: Fixed value 1.2 s

Trigger Position: 0…100% (step 33.3%)

Analogue Channel 1: (up to 8)

Digital Input 1: (up to 32)

Peripheral Unit:

Duration: Settable from 1.2 to 10.5s

Trigger Position: 0…100% (step 0.1%)

Trigger Mode: Single / Extended

Analogue Channel 1: (up to 4):

Digital Input 1: (up to 32):

Selected binary channel assignment from

any DDB status point within the relay (opto

input, output contact, alarms, starts, trips,

controls, logic…).

Sampling frequency: 600Hz

Optional Ethernet Port

NIC Tunl Timeout: 1…30mins

NIC Link Report: Alarm / Event / None

NIC Link Timeout: 0.1…60s

NIC Read Only: Disabled/Enabled

Page 29

Technical Data

a7

MiCOM P74

13

TD

1, P742, P743 (TD) 2-

COMMISSION TESTS

Monitor Bit 1(up to 8):

Binary function link strings, selecting which

DDB signals have their status visible in the

Commissioning menu, for test purposes

Test Mode: (CU)

Test Mode: Enabled or Out of Service

• 87BB trip blocked but 50BF (back trip)

enable per zone

• 87BB and 50BF trip blocked per zone

• All the protections (87BB, Dead Zone,

General 50BF, Local 50BF, O/C) disabled

• 87BB disable but 50BF (back trip) enable

for all zones

Test Mode: (PU)

Test mode: Disabled / 50BF Disabled /

Overhaul

Test Pattern:

Configuration of which output contacts are

to be energised when the contact test is

applied.

Static Test Mode: Disabled/Enabled

Opto input voltage range:

24-27 V

30-34 V

48-54 V

110-125 V

220-250 V

Custom Opto Input 1

(up to # = max. opto no. fitted)

Custom options allow independent

thresholds to be set per opto, from the

same range as above

Filter Control:

P74x/EN TD/N

Opto Input Labels

Opto Input 1 up to: 8 for P741

16 for P742

24 for P743

User defined text string to describe the

function of the particular opto input.

Outputs Labels

Relay 1 up to: 8 for P741 & P742

16 for P743

User defined text string to describe the

function of the particular relay output

contact.

IED CONFIGURATOR

Switch Conf.Bank:

No Action / Switch Banks

IEC61850 GOOSE

GoEna: Disabled/Enabled

Test Mode: Disabled / Enabled

VOP Test Pattern: 0x00000000 / 0xFFFFFFFF

Ignore Test Flag: No/Yes

Page 30

P74

x/EN TD/Na7

Technical Data

(TD) 2

1, P742, P743

TD

-14 MiCOM P74

Page 31

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

GS

GETTING STARTED

Hardware Suffix: J and K

Software Version: 51

Page 32

P74x/EN GS/Na7

Getting Started

MiCOM P741, P742, P743

Page 33

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

1

GS

(GS) 3-

CONTENTS

1. GETTING STARTED 3

1.1 User interfaces and menu structure 3

1.2 Introduction to the relay 3

1.2.1 Front panel 3

1.2.2 Relay rear panel 9

1.3 Relay connection and power-up 11

1.4 Introduction to the user interfaces and settings options 11

1.5 Menu structure 12

1.5.1 Protection settings 13

1.5.2 Disturbance recorder settings 13

1.5.3 Control and support settings 13

1.6 Password protection 13

1.7 Relay configuration 14

1.8 Front panel user interface (keypad and LCD) 14

1.8.1 Default display and menu time-out 15

1.8.2 Menu navigation and setting browsing 16

1.8.3 Hotkey menu navigation 16

1.8.4 Password entry 17

1.8.5 Reading and clearing of alarm messages and fault records 17

1.8.6 Setting changes 18

1.9 Front communication port user interface 18

1.9.1 Front courier port 20

1.10 S1 Agile relay communications basics 20

1.10.1 Off-line use of S1 Agile 21

2. CO NFIGURING THE ETHERNET INTERFACE 22

2.1 Configuring the Ethernet Interface for IEC 61850 22

3. CO NFIGURING THE REDUNDANT ETHERNET BOARD 24

3.1 Configuring the IED IP Address 24

3.2 Configuring the Board IP Address 24

3.3 RSTP Configuration 25

4. CO NFIGURING THE DATA PROTOCOLS 30

4.1 Courier Configuration 30

4.2 IEC 61850 Configuration 31

4.3 IEC 61850 Configuration 31

4.3.1 IEC 61850 Configuration Banks 32

4.3.2 IEC 61850 Network Connectivity 32

5. P RP/HSR CONFIGURATOR 33

5.1 Connecting the IED to a PC 33

5.2 Installing the Configurator 33

5.3 Starting the Configurator 33

5.4 PRP/HSR device identification 34

5.5 Selecting the device mode 34

Page 34

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-2

5.6 PRP/HSR IP Address Configuration 34

5.7 SNTP IP Address Configuration 34

5.8 Check for connected equipment 34

5.9 PRP Configuration 34

5.10 HSR CONFIGURATION 35

5.11 Filtering Database 35

5.12 End of session 36

FIGURES

FIGURE 1: RELAY FRONT VIEW (EXAMPLE FOR P742 – 40 TE) 3

FIGURE 2: RELAY FRONT VIEW (EXAMPLE FOR P743 – 60 TE) 4

FIGURE 3: P742 RELAY REAR VIEW 40 TE 9

FIGURE 4: P743 RELAY REAR VIEW 60 TE 10

FIGURE 5: P741 RELAY REAR VIEW 80 TE 10

FIGURE 6: MENU STRUCTURE 12

FIGURE 7: FRONT PANEL USER INTERFACE 15

FIGURE 8: HOTKEY MENU NAVIGATION 17

FIGURE 9: FRONT PORT CONNECTION 19

FIGURE 10: PC – RELAY SIGNAL CONNECTION 20

FIGURE 11: IED AND REB IP ADDRESS CONFIGURATION 24

FIGURE 12: REB ADDRESS SWITCHES (SW2) 25

Page 35

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

3

GS

1. GETTING STARTED

BEFORE CARRYING OUT ANY WORK ON THE EQUIPMENT, THE USER

SHOULD BE FAMILIAR WITH THE CONTENTS OF THE SAFETY

SECTION/SAFETY GUIDE PXXX-4LM-2 OR LATER ISSUE, THE

TECHNICAL DATA SECTION AND THE RATINGS ON THE EQUIPMENT

RATING LABEL.

1.1 User interfaces and menu structure

The settings and f unctions of the pr otection r elay can be access ed both f rom the front pan el

keypad and LCD, and via the front and rear com munication ports. Information on each of

these methods is given in this section to describe how to start using the relay.

1.2 Introduction to the relay

1.2.1 Front panel

The front panel of the rela y is shown in F igure 1 (P7 42) or 2 (P741 or P7 43), with the hinge d

covers at the top and botto m of the relay shown o pen. Extra ph ysical protection f or the front

panel can be provide d by an optional transpare nt front cover. With the co ver in place read

only access to the user inte rf ace is pos sible. Rem oval of the c over does not com prom is e the

environmental withstand capability of the product, but allows access to the relay settings.

When full access to the relay keypad is required, for editing the settings, the transparent

cover can be unclipped a nd rem oved when the t op and bottom covers ar e open. If the lo wer

cover is secured with a wir e seal, this will need to be rem oved. Using the sid e flanges of the

transparent cover, pu ll the bottom edge a way from the relay fr ont panel unt il it is clear of the

seal tab. The co ver can then be moved vert ically down to release t he two fixing lugs from

their recesses in the front panel.

(GS) 3-

FIGURE 1: RELAY FRONT VIEW (EXAMPLE FOR P742 – 40 TE)

The front panel of the relay includes the following, as indicated in Figure 1:

Page 36

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-4

• a 16-character by 3-line alphanumeric liquid crystal display (LCD).

• a 9-key keypad com prising 4 arrow keys

clear key (

• 12 LEDs; 4 fixed function LEDs on the left-hand side of the front panel and 8

programmable function LEDs on the right-hand side.

Under the top hinged cover:

• the relay serial number, and the relay’s current and voltage rating information*.

Under the bottom hinged cover:

• battery compartment to hold the

back-up for the real time clock, event, fault and disturbance records.

• a 9-pin female D-t ype front port for comm unication with a PC locall y to the relay (up to

15m distance) via an RS232 serial data connection.

• a 25-pin female D-type port providing internal signal monitoring and high speed local

downloading of software and language text via a parallel data connection.

), a read key () and 2 hot keys ().

( , , and ), an enter key (), a

1

/2 AA size battery which is used for memory

FIGURE 2: RELAY FRONT VIEW (EXAMPLE FOR P743 – 60 TE)

The front panel of the relay includes the following, as indicated in Figure 2:

− a 16-character by 3-line alphanumeric liquid crystal display (LCD)

− a 19-key keypad comprising 4 arrow keys (, , and ), an enter key

(), a clear key (), a read key (), 2 hot keys () and 10 ( − )

programmable function keys

− Function key functionality:

− The relay front panel f eatures control pushbutton s witches with programmable

LEDs that facilitate local control. Factory default settings associate specific relay

functions with these 10 direct-action pushbuttons and LEDs e.g. reset

indications. Using pr ogram m able sc hem e logic, the us er can rea dil y change t he

default direct-action pushbutton functions and LED indications to fit specific

control and operational needs .

− Hotkey functionality: When the functionality is disabled:

− SCROLL

Starts scrolling through the various default displays.

− STOP

Stops scrolling the default display.

Page 37

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

5

GS

When the functionality is disabled:

− For control of setting groups, control inputs and circuit breaker operation

− 22 LEDs; 4 fixed func tion LEDs, 8 tri-colour pro grammable function LEDs on th e left

hand side of the front pane l and 1 0 tr i-colour programm able f unc tion L EDs on t h e r ight

hand side associated with the function keys

− Under the top hinged cover:

− The relay serial number, and the relay’s current and voltage rating information

− Under the bottom hinged cover:

− Battery compartm ent to hold the 1/2 AA size bat tery which is used for m emory

back-up for the real time clock, event, fault and disturbance records

− A 9-pin fem ale D -type front port for c om munication with a PC loca lly to the rela y

(up to 15m distance) via an EIA(RS)232 serial data connection

− A 25-pin female D-t ype port providing internal signal m onitoring and high s peed

local downloading of software and language text via a parallel data connection

(GS) 3-

1.2.1.1 LED indications Fixed Function The 4 fixed function L EDs on the left-hand side of the front panel are used to indicate the

following conditions:

Trip (Red) indicates that t he relay has issued a trip signal. It is r eset when the associated

fault record is cleared from the front display.

Alarm (Yellow) flashes to indicate that the relay has registered an alarm. This may be

triggered by a fault, event or maintena nce record. The LED will f lash until the alarms have

been accepted (read), after which the LED will change to constant illumination, and will

extinguish, when the alarms have been cleared.

Out of service (Ye llow) can indicat e that the re lay’s protecti on is unavail able or a test m ode

is selected.

Healthy (Green) ind icates that the relay is in correct working order, and should be on at al l

times. It will be extin guishe d if the r ela y’s self -test f aciliti es indic ate tha t ther e is an er ror with

the relay’s hard ware or softwar e. The state of the health y LED is reflected by the watch dog

contact at the back of the relay.

To improve the visibi lity of t he settings via the f ront panel, the LCD c ontrast c an be a djusted

using the “LCD Contrast” setting in the CONFIGURATION column. This should only be

necessary in very hot or cold ambient temperatures.

Programmable LEDs

All the programmable LEDs are tri-colour and can be programmed to indicate RED,

YELLOW or GREEN depe nding on the requir ements. T he 8 programm able LEDs on the lef t

are suitable for program ming alarm indicati ons and the defaul t indications and fu nctions are

indicated in the table below. The 10 programmable LEDs physically associated with the

function keys, are us ed to i ndicate the status of the associated pushbutt on ’s function and the

default indications are shown below:

Page 38

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-6

The default mappings for each of the programmable LEDs are as shown in the following

table:

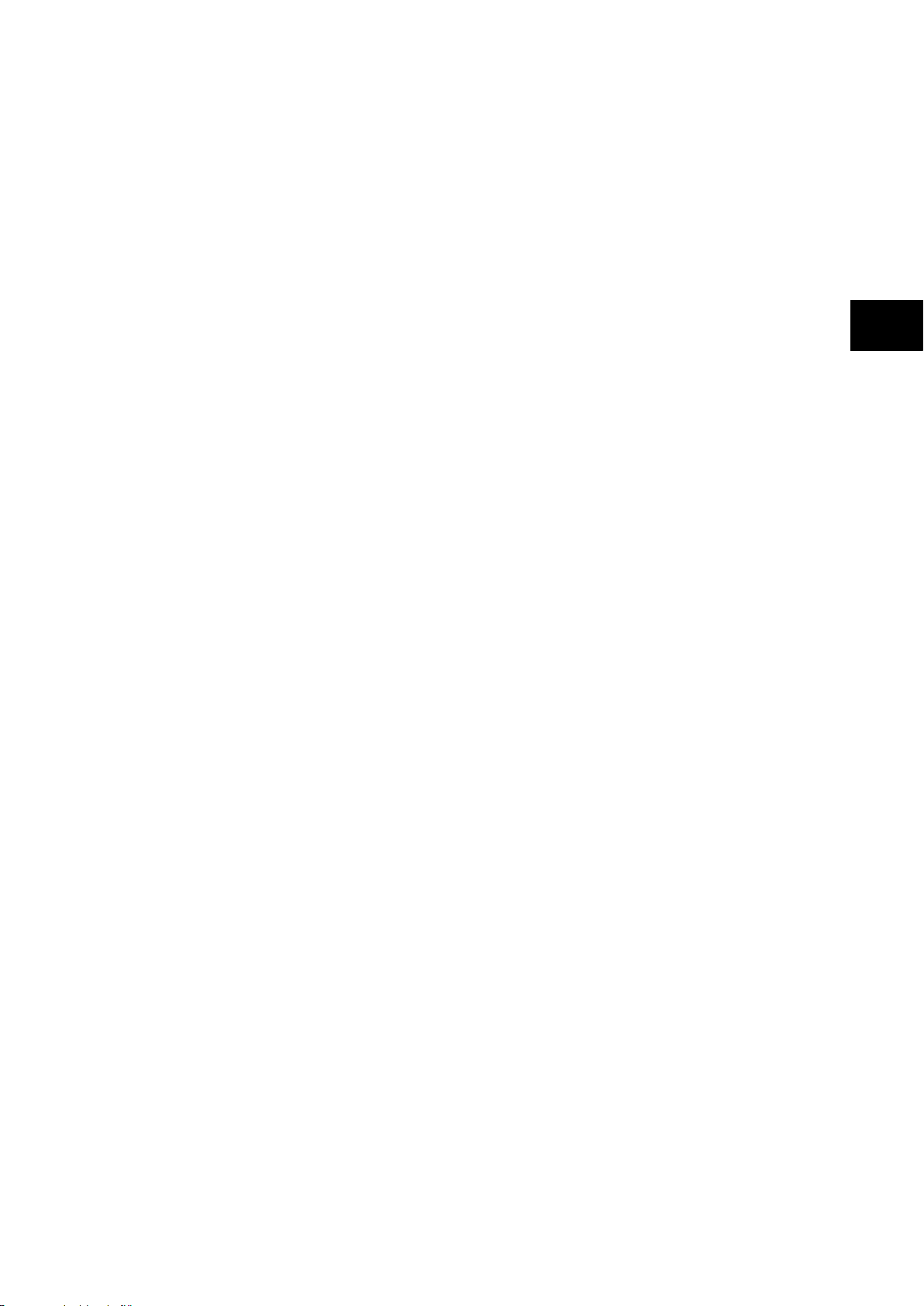

Central Unit P741:

LED

Number

1

2

3

4

5

LED Input Connection/Text Latched P74x LED Function Indication

LED1 Red

LED1 Yellow

LED1 Green

LED2 Red

LED2 Yellow

LED2 Green

LED3 Red

LED3 Yellow

LED3 Green

LED4 Red

LED4 Yellow

LED4 Green

LED5 Red

LED5 Yellow

LED5 Green

Yes

Yes

Yes

Yes

Yes

87BB fault on phase A

Not used

Not used

87BB fault on phase B

Not used

Not used

87BB fault on phase C

Not used

Not used

50BF Trip Zone 1

87BB & 50BF Trip Zone 1

87BB Trip Zone 1

50BF Trip Zone 2

87BB & 50BF Trip Zone 2

87BB Trip Zone 2

6

7

8

9

10

11

LED6 Red

LED6 Yellow

LED6 Green

LED7 Red

LED7 Yellow

LED7 Green

LED8 Red

LED8 Yellow

LED8 Green

FnKey LED1 Red

FnKey LED1 Yellow

FnKey LED1 Green

FnKey LED2 Red

FnKey LED2 Yellow

FnKey LED2 Green

FnKey LED3 Red

FnKey LED3 Yellow

No

No

No

No

No

No

Zone 1 blocked by itself

Zone 1 blocked by Check Zone

Zone 1 protected

Zone 2 blocked by itself

Zone 2 blocked by Check Zone

Zone 2 protected

Fiber communication Error

Fiber communication to change

Fiber communication healthy

Zone or CZ circuitry fault block.

Zone or CZ circuitry fault alarm

No Zone or CZ circuitry fault

Zone or CZ PU error fault block.

Zone or CZ PU error fault alarm

No Zone or CZ PU error fault

All protections Disabled

Not used

FnKey LED3 Green

FnKey LED4 Red

12

FnKey LED4 Yellow

FnKey LED4 Green

No

All protections Not Disabled

Zone 1: 87BB & 50BF blocked

Zone 1: 50BF blocked

Zone 1: protected

Page 39

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

7

GS

LED

Number

LED Input Connection/Text Latched P74x LED Function Indication

(GS) 3-

13

14

15

16

17

18

FnKey LED5 Red

FnKey LED5 Yellow

FnKey LED5 Green

FnKey LED6 Red

FnKey LED6 Yellow

FnKey LED6 Green

FnKey LED7 Red

FnKey LED7 Yellow

FnKey LED7 Green

FnKey LED8 Red

FnKey LED8 Yellow

FnKey LED8 Green

FnKey LED9 Red

FnKey LED9 Yellow

FnKey LED9 Green

FnKey LED10 Red

FnKey LED10 Yellow

No

No

No

No

No

No

Zone 2: 87BB & 50BF blocked

Zone 2: 50BF blocked

Zone 2: protected

Not used

Not used

Reset CU Indications

Not used

Not used

Reset CU & PU Indications

Not used

Not used

Reset PU Trip Latch

Not used

Not used

Manual DR trigger

Not used

Dead Zone fault

FnKey LED10 Green

Peripheral Unit P742:

LED

Number

1 LED 1 Red No Isolator 1 Closed

2 LED 2 Red No Isolator 2 Closed

3 LED 3 Red No Isolator 3 Closed

4 LED 4 Red Yes Trip on CU 50BF backtrip order

5 LED 5 Red Yes Trip on CU 87BB trip order

6 LED 6 Red Yes Dead Zone fault

7 LED 7 Red No Circuit Breaker out of service

8 LED 8 Red No Fiber communication Error

LED Input Connection/Text Latched P74x LED Function Indication

Not used

Page 40

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-8

Peripheral Unit P743:

LED

Number

1

2

3

4

5

LED Input Connection/Text Latched P74x LED Function Indication

LED1 Red

LED1 Yellow

LED1 Green

LED2 Red

LED2 Yellow

LED2 Green

LED3 Red

LED3 Yellow

LED3 Green

LED4 Red

LED4 Yellow

LED4 Green

LED5 Red

LED5 Yellow

LED5 Green

No

No

No

Yes

Yes

Isolator 1 Closed

Isolator 1 Status Alarm

Isolator 1 Open

Isolator 2 Closed

Isolator 2 Status Alarm

Isolator 2 Open

Isolator 3 Closed

Isolator 3 Status Alarm

Isolator 3 Open

Trip on CU 50BF backtrip order

Not used

Not used

Trip on CU 87BB trip order

Not used

Not used

6

7

8

9

10

11

LED6 Red

LED6 Yellow

LED6 Green

LED7 Red

LED7 Yellow

LED7 Green

LED8 Red

LED8 Yellow

LED8 Green

FnKey LED1 Red

FnKey LED1 Yellow

FnKey LED1 Green

FnKey LED2 Red

FnKey LED2 Yellow

FnKey LED2 Green

FnKey LED3 Red

FnKey LED3 Yellow

Dead Zone fault

Yes

No

No

No

No

No Not used

Not used

Not used

Circuit Breaker out of service

Not used

Circuit Breaker healthy

Fiber communication Error

Fiber communication to change

Fiber communication healthy

Not used

Not used

Reset PU Indications

Not used

Not used

Reset PU Trip Latch

FnKey LED3 Green

FnKey LED4 Red

12

13

FnKey LED4 Yellow

FnKey LED4 Green

FnKey LED5 Red

FnKey LED5 Yellow

FnKey LED5 Green

No

No

Not used

Mode 50BF disabled

Mode normal

Mode overhaul

Not used

Mode normal

Page 41

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

9

GS

LED

Number

LED Input Connection/Text Latched P74x LED Function Indication

FnKey LED6 Red

(GS) 3-

14

15

16

17

18

1.2.2 Relay rear panel Examples of the rear panel of the relay are s hown in Figures 3, 4 a nd 5. All curr ent signals ,

digital logic input signals and ou tput contacts are connected at the rear of the relay. Also

connected at the rear is the twist ed pair wiring f or the rear EIA(RS)485 c ommunic ation port;

the IRIG-B time synchronising input is op tio na l in t he P 741, the E ther n et r e ar c om munication

board with copper and fiber optic connections or the second communication and InterMiCOM

board are optional in the P741 and P743.

FnKey LED6 Yellow

FnKey LED6 Green

FnKey LED7 Red

FnKey LED7 Yellow

FnKey LED7 Green

FnKey LED8 Red

FnKey LED8 Yellow

FnKey LED8 Green

FnKey LED9 Red

FnKey LED9 Yellow

FnKey LED9 Green

FnKey LED10 Red

FnKey LED10 Yellow

FnKey LED10 Green

No Not used

No Not used

No Not used

No Not used

No Not used

FIGURE 3: P742 RELAY REAR VIEW 40TE

Page 42

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-10

FIGURE 4: P743 RELAY REAR VIEW 60TE

FIGURE 5: P741 RELAY REAR VIEW 80TE

Refer to the wiring diagram in the ‘Installation Chapter’ (P74x/EN IN) for the complete

connection details.

Page 43

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

11

GS

1.3 Relay connection and power-up

Before powering-up the relay, confirm that the relay power supply voltage and nominal ac

signal magnitudes are appropriate for your application. The relay serial number, and the

relay’s current and voltage rating, power rating information can be viewed under the top

hinged cover. The rel ay is availab le in the following a uxiliary volt age versions and these are

specified in the table below:

(GS) 3-

Nominal Ranges

24 - 48V dc 19 to 65V -

48 - 110V dc (30 - 100V ac rms) ** 37 to 150V 24 to 110V

110 - 250V dc (100 - 240V ac rms) ** 87 to 300V 80 to 265V

** rated for ac or dc operation

Please note that the label does not s pecif y the logic input r atings. T he P74x relays ar e fitted

with universal opto isolated logic inputs that can be programmed for the nominal battery

voltage of the circuit of which they are a part. See ‘Universal Opto input’ in the Firmware

section for m ore information on logic input specifications. Please note that the opto inputs

have a maximum input voltage rating of 300V dc at any setting.

Once the ratings have bee n verified for the application, connec t external power capable of

delivering the power r equirements specif ied on the label to perf orm the relay familiari zation

procedures. Figures 3, 4 an d 5 ind ic ate the location of the power s up ply terminals but please

refer to the wiring diagrams in the Installation section for complete installation details

ensuring that the correct polarities are observed in the case of dc supply.

1.4 Introduction to the user interfaces and settings options

The relay has three user interfaces:

− The front panel user interface via the LCD and keypad

Operative dc

Range

Operative ac

Range

− The front port which supports Courier communication

− The rear port which supports one protocol: Courier. (IEC 60870-5-103 is converted

from Courier using a KITZ274).

− The optional Ethernet port which supports IEC 61850

The measurement information and relay settings that can be accessed from the four

interfaces are summarized in Table 1.

Page 44

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

dat a

settings

Column header

Contr ol&suppor t

Group 1

Group 4

Up to4protectionsettinggroups

System dat a

V

iew records

DIFF

BUSBARPROT

BUSBAR

OPTION

P0106ENb

INP UTS

LABELS

OUTPUT

LABELS

DIFF

BUSBARPROT

BUSBAR

OPTION

INP UTS

LABELS

OUTPUT

LABELS

-12

Keypad/

LCD

Display & modification of

all settings

Digital I/O signal status

Display/extraction of

measurements

Display/extraction of fault

records

Extraction of disturbance

records

Programmable scheme

logic settings

Reset of fault & alarm

records

Clear event & fault

records

Time synchronization

Control commands

Courier

• •

IEC870-5-

103

IEC

61850

• • • •

• • • •

• •

• • •

•

• • •

• •

• • •

• • •

•

Table 1

1.5 Menu structure

The relay’s menu is arran ged in a tabular structur e. Each setting in the menu is referred to

as a cell, and each cell in t he menu may be accessed by reference to a row and column

address. The settings are arranged so that each column contains related settings, for

example all of the disturbance recorder set tings are contained with in the same column. As

shown in Figure 6, the top row of each column contains the heading that describes the

settings contained with in that c olumn. Mov em ent bet ween the c olumns of the m enu can onl y

be made at the c olum n hea ding level. F or a complete list of all of t he m enu se ttin gs, s ee th e

Settings chapter P74x/EN ST.

FIGURE 6: MENU STRUCTURE

Page 45

Getting Started

P74x/EN GS/Na7

MiCOM P741, P742, P743

13

GS

Read access to all settings, alarms, event

All of the settings in the menu fall into one of three categories; protection settings,

disturbance recorder settings, or control and support (C&S) settings. One of two different

methods is used to change a setting depending on which category the setting falls into.

Control and support settings are stored and used by the relay immediately after they are

entered. For either protection setti ngs or disturbance r ecorder settings, the relay stores the

new setting values in a temporar y ‘scratchp ad’. It activ ates all t he new s ettings together , but

only after it has been co nfirmed that the new settings are to be adopted. This techniq ue is

employed to provide extr a sec urit y, and so that s ever al sett ing ch anges that ar e m ade within

a group of protection settings will all take effect at the same time.

1.5.1 Protection settings The protection settings include the following items:

− Protection element settings

− Scheme logic settings

There are four groups of protection settings, with each group containing the same setting

cells. One group of pr otection settings is selected as the active group, and is used b y the

protection elements.

(GS) 3-

1.5.2 Disturbance recorder settings The disturbance recor der settings inclu de the record durati on and trigger posit ion, selection

of analogue and digital signals to record, and the signal sources that trigger the recording.

1.5.3 Control and support settings The control and support settings include:

− Relay configuration settings

− Open/close circuit breaker

− CT & VT ratio settings

− Reset LEDs

− Active protection setting group

− Password & language settings

− Communications settings

− Measurement settings

− Event & fault record settings

− User interface settings

− Commissioning settings

1.6 Password protection

The menu structure contains three levels of access. The level of access that is enabled

determines which of the re lay’s settings can be changed and is contro lled by entry of two

different passwords. The levels of access are summarized in Table 2.

Access level Operations enabled

Level 0

No password required

records and fault records

Page 46

P74x/EN GS/Na7

Getting Started

(GS) 3

MiCOM P741, P742, P743

GS

-14

Access level Operations enabled

As level 0 plus:

Control commands, e.g.

Level 1