Page 1

GE

Grid Solutions

P50 Agile

P253

Technical Manual

Motor Protection Relay

Hardware version: A

Software version: 01

Publication reference: P253/EN M/C

Page 2

Conformity

This product complies with the directive of the Council of the European Communities relating to electromagnetic

compatibility (EMC directive 2014/30/EU) and product safety (Low-voltage directive 2014/30/EU). This conformity is the result

of a test conducted in accordance with the product standard EN 60255- 26 for the EMC directive, and with the product

standard EN 60255-27 for the low voltage directive. The IED is designed in accordance with the international standards of the

IEC 60255 series.

Page 3

P50 Agile P253

1 Introduction

P253/EN M/C

1-1

INTRODUCTION

CHAPTER 1

Page 4

1 Introduction

P50 Agile P253

1-2

P253/EN M/C

Page 5

P50 Agile P253

1 Introduction

P253/EN M/C

1-3

1 CHAPTER OVERVIEW

This chapter consists of the following sections:

1

Chapter Overview

2 Introduction

2.1 Features

2.1.1 Protection & Control

2.1.2 Measurement, Recording & Post Fault A nalysis

2.1.3 Front Panel Interface

2.1.4 Communications

2.2 Functional Overview

2.3 Ordering Information

Page 6

1 Introduction

P50 Agile P253

1-4

P253/EN M/C

2 INTRODUCTION

2.1 Features

The P253 is a dedicated motor protection relay desi gned to protect motors in industrial networks and

power plants. It offers essential protection f unct i ons for motors deployed in installations from LV t o M V

voltage levels. The P253 relay performs an important rol e i n m any industrial processes with its

diagnostic features improving asset health monitoring.

The principal protection functions in the relay include thermal overload, negative sequence

overcurrent, loss of load, prolonged start, locke d rot or (starting/normal running), restricted earth fault,

excessive no. of starts and speed switch input for stall rotor detection. Additional versatility is provided

thanks to the inclusion of backup overcurrent and earth fault protection, with up to 3 independent

stages (IEC and IEEE curve types are provided for IDMT f unct i on), breaker fail and trip circuit

supervision functions. Multiple setting groups are included. The hardware capability is broadened by a

sensitive earth fault CT option, and a universal auxiliary power supply range to permit standardisation

in procurement and inventories.

The user can assign any of the logical/physical statuses to binary inputs, binary outputs and

programmable LEDs. This provides flexibility to program the relay as per the application requirements.

All the output contacts are changeover type for ease of i m pl ementing the desired wiring schematic.

The P253 offers supervision functions including measurement, monitoring and recording. The P 253

records the starting current which is very helpful in m onitoring motor performance during the critical

starting period. Industry and utility protocols such as MODBUS, IEC 60870-5-103 and DNP3.0 are

available for transmitting relay data to a supervisory control system via communication networks. The

intuitive operator interface facilitates easy reading of measured values and simple configuration of t he

relay.

2.1.1 Protection & Control

• Thermal overload

• Speed switch input (for stall rotor detection)

• Prolonged start (excessive long start)

• Locked rotor (during starting)

• Locked rotor (during normal running)

• Excessive number of starts

• Loss of load detection

• Negative sequence overcurrent

• Emergency restart

• Timed and instantaneous phase and earth fault prot ection (3 independent stages)

• Wide range of IEC/IEEE curves

• Inrush blocking

• Circuit breaker Fail

• Restricted earth Fault

• Trip circuit supervision

• 6 Digital inputs

• 6 Digital output (c/o)

Page 7

P50 Agile P253

1 Introduction

P253/EN M/C

1-5

• 1A/5A CTs selection

• SEF option

• Latching of output contacts

• Universal auxiliary power supply range

• 2 Setting groups

• Password protection

• Self-supervision & internal diagnostics

2.1.2 Measurement, Recording & Post Fault Analysis

• Metering of Phase currents

• Metering of Neutral currents-derived and measured

• Measurement of thermal state

• Positive, Negative and Zero sequence current

• Load Current

• Time to Thermal trip

• Last starting current and time

• Time before a permitted start

• Authorised hot start number

• Authorised cold start number

• Motor running hours

• Total number of starts

• Total number of emergency starts

• Number of Thermal Trip

• Breaker operation counter

• Breaker trip counter

• Breaker operating time

• Up to 512 time tagged event records

• Up to 5 Fault records

• Up to 5 disturbance records

• 1 start-up current record

2.1.3 Front Panel Interface

• 8 LEDs for status indication

• Backlit LCD display (16 x 2)

• 8 navigation keys for setting and interrogation

2.1.4 Communications

• Front USB port for real-time data viewing, device setting, and upload/download.

Page 8

1 Introduction

P50 Agile P253

1-6

P253/EN M/C

• Rear EIA (RS) 485 port for SCADA communication

• Multiple protocols - Modbus/ IEC60870-5-103 or DNP 3.0 (orderi ng option)

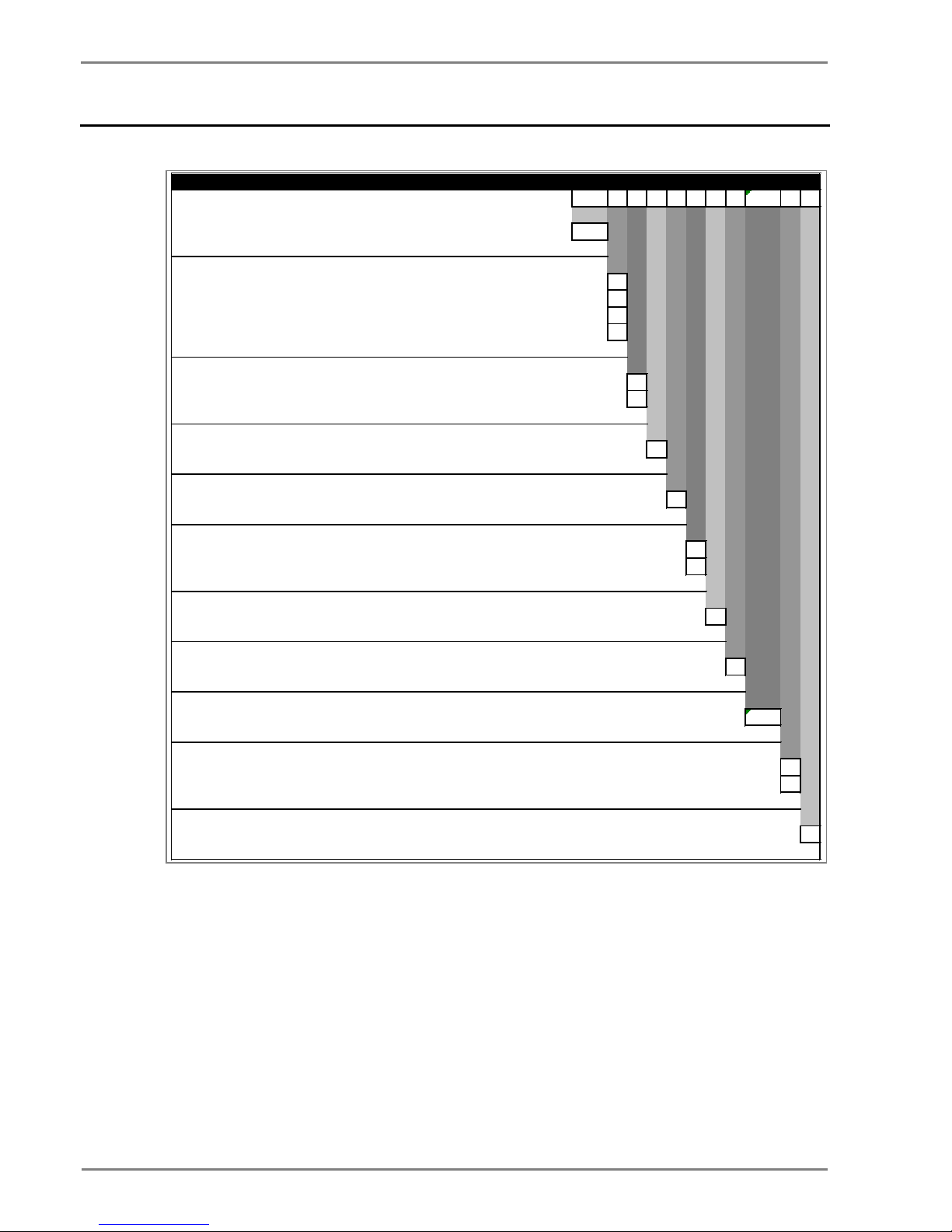

2.2 Functional Overview

ANSI FUNCTION P253

14 Speed switch input (for stall rotor detection)

•

48 Prolonged start (excessive long start)

•

51S Locked rotor (during starting)

•

51L Locked rotor (during normal running)

•

66 Excessive number of starts

•

49 Thermal Overload

•

37 Loss of load

•

46 Negative sequence overcurrent

•

50 Definite time overcurrent (short circuit protection)

•

50N Neutral/Earth definite time overcurrent

•

51 IDMT overcurrent (short circuit protection)

•

51N Neutral/Earth IDMT overcurrent

•

68 Inrush Blocking

•

50BF Circuit breaker fail

•

64R Restricted earth fault

•

86 Latching of output contacts (Lockout)

•

Control Functions

74 Trip circuit supervision

•

Watchdog function

•

Self monitoring & diagnostics

•

Test/Commissioning facilities

•

Emergency restart

•

HMI

Back-Lit LCD display

•

8 x Touch Keys

•

8 x status LEDs

•

Communication

USB port

•

Modbus/IEC 60870-5-103 (RS485) (or)

DNP3.0

•

Binary Input/Output

Binary Input

6

Binary Output

6 (c/o)

Analogue Input

Phase current input 3x1 ph

•

Page 9

P50 Agile P253

1 Introduction

P253/EN M/C

1-7

ANSI FUNCTION P253

Earth current input 1x1 ph (or)

SEF current input 1x1 ph

•

General

Setting Groups 2

Self diagnostics

•

Measurements

•

Event records

•

Fault records

•

Disturbance records

•

Start-up current record

•

Configurable BI/BO/LEDs

•

Hardware

Auxiliary supply 24-230 V AC/DC

Climatic conditions

Operating:

- 25

o

C to + 55

o

C

Storage:

-25oC to + 70oC

Housing

Front IP 52

Rear IP 20

Page 10

1 Introduction

P50 Agile P253

1-8

P253/EN M/C

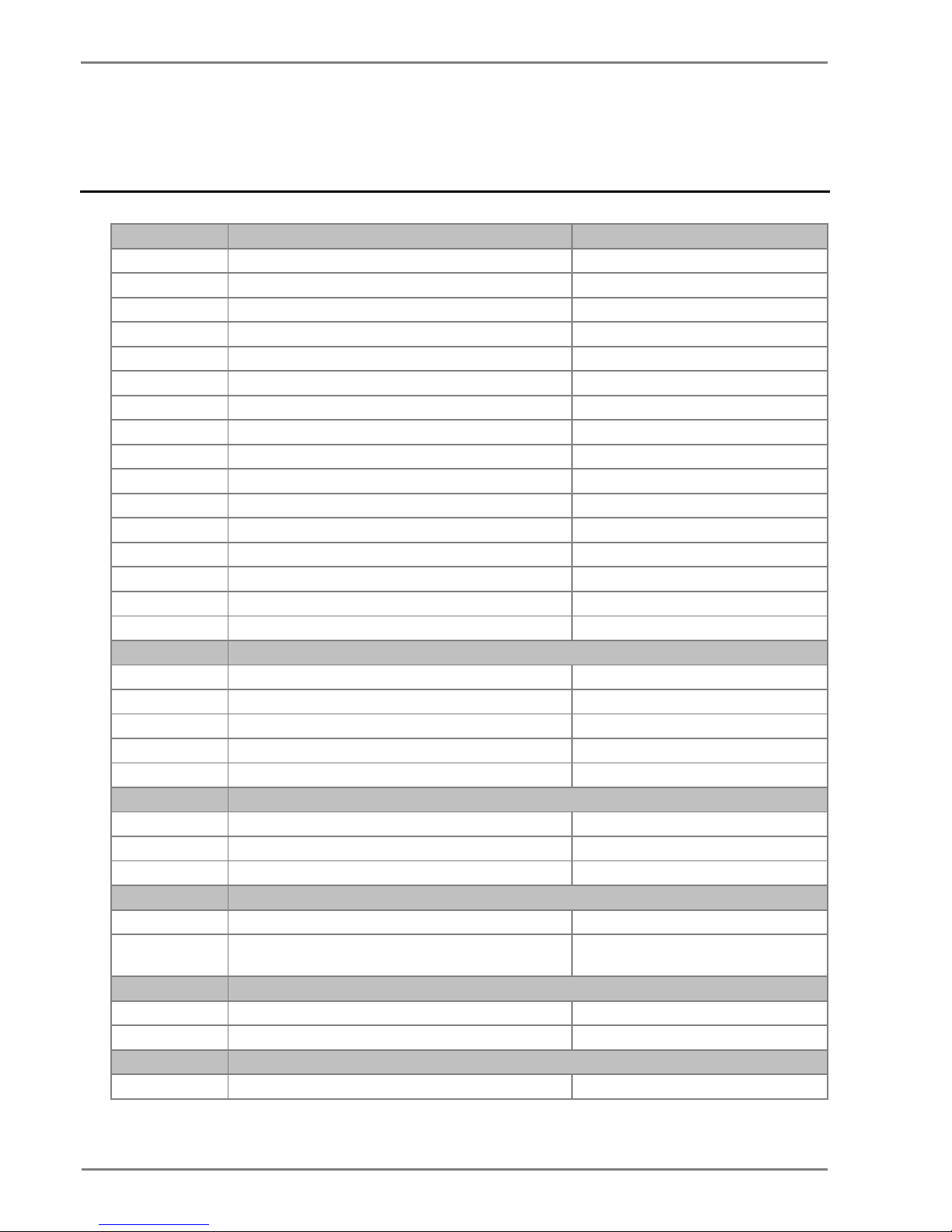

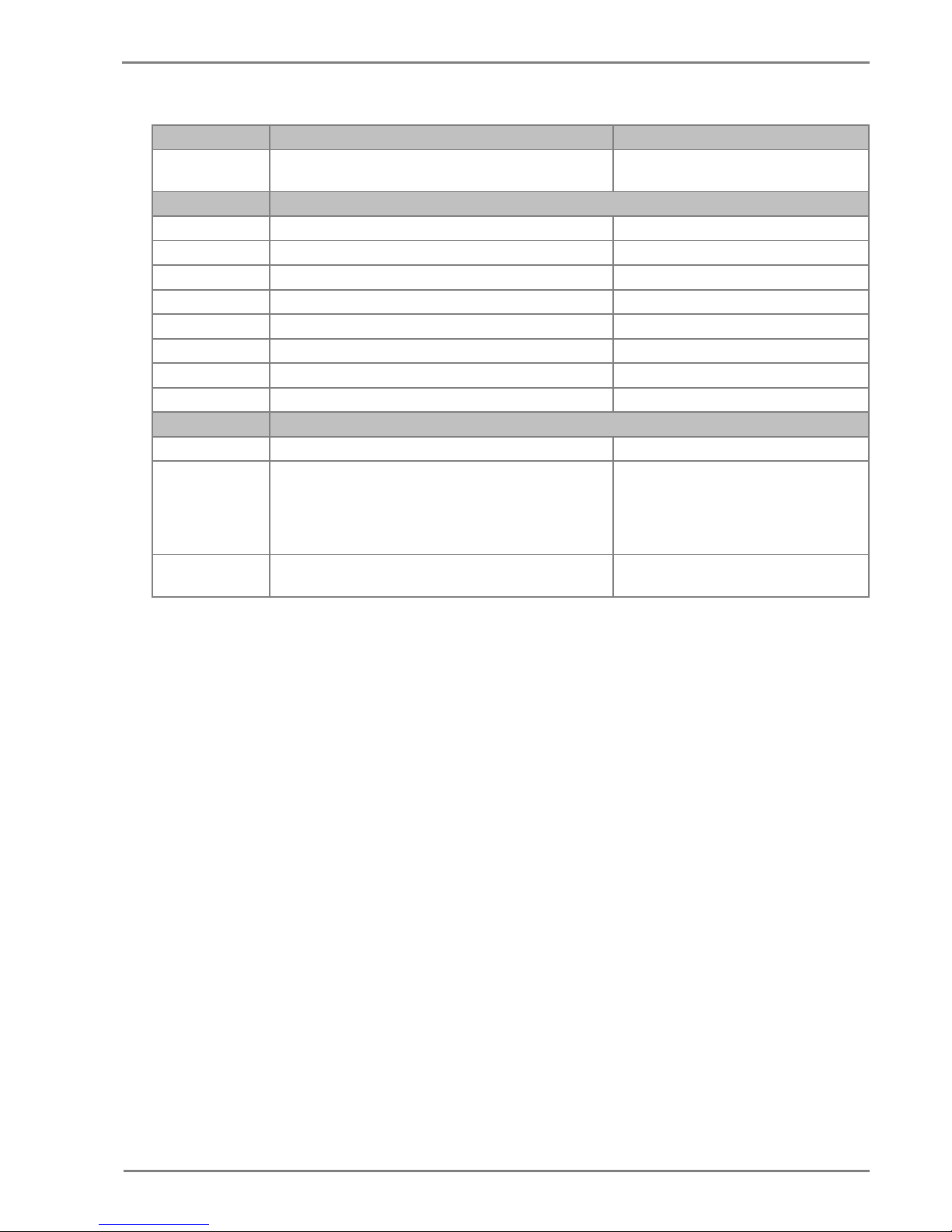

2.3 Ordering Information

Variants

1 - 4 5 6 7 8 9 10 11 12-13 14 15

Model Type

Bas i c Motor Protec t i on Rel ay P253

Auxilliary Voltage Bina ry Input Threshold Voltage

24 – 230 V DC/AC 18V DC / 16V AC

1

24 – 230 V DC/AC 35V DC / 33V A C

2

24 – 230 V DC/AC 77V DC / 75V A C

3

24 – 230 V DC/AC 154V DC / 152V A C

4

Current Transformer

St andard CT 1

SEF CT 2

Hardware Options

EIA RS 485 onl y 1

I/O Options

St andard ( 6 logi c inputs + 6 relay output s ) A

Communication protocol

Modbus / IE C 60870-5-103

1

DNP3.0 2

Ca se

Non drawout A

Language

English 0

Software Reference

Initial rel ease (v1.xx ) 01

Customisation / Regionali sation

Default 0

Cust om er spec i fic A

Hardware design suffix

Initial rel ease A

Order Number

Figure 1: Ordering Information

Page 11

SAFETY INFORMATION

CHAPTER 2

Page 12

Safety Information

Pxxx

2

Page 13

Pxxx

Safety Information

3

1 HEALTH AND SAFETY

Personnel associated with the equipment must be famil i ar wit h the contents of this Safety Information.

When electrical equipment is in operation, dangerous voltages are present in certain parts of the equipment.

Improper use of the equipment and failure to observ e war ni ng notices will endanger personnel.

Only qualified personnel may work on or operate the equi pment. Qualified personnel are individuals who are:

● familiar with the installation, commissioning, and operation of the equipment and the system t o which it

is being connected.

● familiar with accepted safety engineering practises and are authorised to energise and de-energise

equipment in the correct manner.

● trained in the care and use of safety apparatus in accordance with safety engineering practises

● trained in emergency procedures (first aid).

The documentation provides instructions for installing, commissioning and operating the equipment . It

cannot, however cover all conceivable circumstances. In the event of questions or problems, do not take any

action without proper authorisation. Please contact your local sales office and request the necessary

information.

Page 14

Safety Information

Pxxx

4

2 SYMBOLS

Throughout this manual you will come across the foll owing symbols. You will also see these symbols on

parts of the equipment.

Caution:

Refer to equipment documentation. Failure to do so could result in damage to

the equipment

Warning:

Risk of electric shock

Earth terminal. Note: This symbol may also be used for a protective conductor (earth) terminal if that

terminal is part of a terminal block or s ub-assembly.

Protective conductor (earth) terminal

Instructions on disposal requirements

Note:

The term 'Earth' used in this manual is t he direct equivalent of the North Americ an term 'Ground'.

Page 15

Pxxx

Safety Information

5

Caution:

All personnel involved in installing, commissioning, or servicing this equipment

must be familiar with the correct working procedures.

Caution:

Consult the equipment documentation before installing, commissioning, or

servicing the equipment.

Caution:

Always use the equipment as specified. Failure to do so will jeopardise the

protection provided by the equipment.

Warning:

Removal of equipment panels or covers may expose hazardous live parts. Do

not touch until the electrical power is removed. Take care when there is

unlocked access to the rear of the equipment.

Warning:

Isolate the equipment before working on the terminal strips.

Warning:

Use a suitable protective barrier for areas with restri cted space, where there is a

risk of electric shock due to exposed terminals.

Caution:

Disconnect power before disassembling. Disassembly of the equ ipment may

expose sensitive electronic circuitry. Take suitable precautions against

electrostatic voltage discharge (ESD) to avoid damage to the equipment.

3 INSTALLATION, COMMISSIONING AND SERVICING

3.1 LIFTING HAZARDS

Many injuries are caused by:

● Lifting heavy objects

● Lifting things incorrectly

● Pushing or pulling heavy objects

● Using the same muscles repetitively

Plan carefully, identify any possible hazards and det ermine how best to move the product. Look at other

ways of moving the load to avoid manual handling. Use the correct lifting techniques and Personal Protective

Equipment (PPE) to reduce the risk of injury.

3.2 ELECTRICAL HAZARDS

Page 16

Safety Information

Pxxx

6

Caution:

NEVER look into optical fibres or optical output connections. Always use optical

power meters to determine operation or signal level.

Caution:

Testing may leave capacitors charged to dangerous voltage levels. Discharge

capacitors by rediucing test voltages to zero before disconnecting test leads.

Caution:

Operate the equipment within the specified el ectrical and environmental limits.

Caution:

Before cleaning the equipment, ensure that no connections are energised. Use a

lint free cloth dampened with clean water.

Note:

Contact fingers of test plugs are normally protected by petroleum jelly, which should not be removed.

3.3 UL/CSA/CUL REQUIREMENTS

The information in this section is applicable only to equipm ent carrying UL/CSA/CUL markings.

Caution:

Equipment intended for rack or panel mounting is for use on a flat surface of a

Type 1 enclosure, as defined by Underwriters Laboratories (UL).

Caution:

To maintain compliance with UL and CSA/CUL, install the equipment using UL/

CSA-recognised parts for: cables, protective fuses, fuse holders and circuit

breakers, insulation crimp terminals, and replacement internal batteries.

3.4 FUSING REQUIREMENTS

Caution:

Where UL/CSA listing of the equipment is required for external fuse protection, a

UL or CSA Listed fuse must be used for the auxiliary supply. The listed

protective fuse type is: Class J time delay fuse, with a maximum current rating

of 15 A and a minimum DC rating of 250 V dc (for example type AJT15).

Page 17

Pxxx

Safety Information

7

Caution:

Where UL/CSA listing of the equipment is not required, a high rupture capacity

(HRC) fuse type with a maximum current rating of 16 Amps and a minimum dc

rating of 250 V dc may be used for the auxiliary supply (for example Red Spot

type NIT or TIA).

For P50 models, use a 1A maximum T-type fuse.

For P60 models, use a 4A maximum T-type fuse.

Caution:

Digital input circuits should be protected by a high rupture capacity NIT or TIA

fuse with maximum rating of 16 A. for safety reasons, current transformer

circuits must never be fused. Other circuits should be appropriately fused to

protect the wire used.

Caution:

CTs must NOT be fused since open circuiting them may produce lethal

hazardous voltages

Warning:

Terminals exposed during installation, commissioning and maintenance may

present a hazardous voltage unless the equipment is electrically isolated.

Caution:

Tighten M4 clamping screws of heavy duty terminal block connectors to a

nominal torque of 1.3 Nm.

Tighten captive screws of terminal blocks to 0.5 Nm minimum and 0.6 Nm

maximum.

Caution:

Always use insulated crimp terminations for voltage and current connections.

Caution:

Always use the correct crimp terminal and tool according to the wire size.

Caution:

Watchdog (self-monitoring) contacts are provided to indicate the health of the

device on some products. We strongly recommend that you hard wire these

contacts into the substation's automation system, for alarm purposes.

3.5 EQUIPMENT CONNECTIONS

Page 18

Safety Information

Pxxx

8

Caution:

Earth the equipment with the supplied PCT (Protective Conductor Terminal).

Caution:

Do not remove the PCT.

Caution:

The PCT is sometimes used to terminate cable screen s. Always check the PCT’s

integrity after adding or removing such earth connections.

Caution:

Use a locknut or similar mechanism to ensure the integrity of stud-connected

PCTs.

Caution:

The recommended minimum PCT wire size is 2.5 mm² for countries whose

mains supply is 230 V (e.g. Europe) and 3.3 mm² for coun tries whose mains

supply is 110 V (e.g. North America). This may be superseded by local or

country wiring regulations.

For P60 products, the recommended minimum PCT wire size is 6 mm². See

product documentation for details.

Caution:

The PCT connection must have low-inductance and be as short as pos sible.

Caution:

All connections to the equipment must have a defined potential. Connections

that are pre-wired, but not used, should be earthed, or connected to a common

grouped potential.

Caution:

Check voltage rating/polarity (rating label/equipment documentation).

Caution:

Check CT circuit rating (rating label) and integrity of connections.

Caution:

Check protective fuse or miniature circuit breaker (MCB) rating.

3.6 PROTECTION CLASS 1 EQUIPMENT REQUIREMENTS

3.7 PRE-ENERGISATION CHECKLIST

Page 19

Pxxx

Safety Information

9

Caution:

Check integrity of the PCT connection.

Caution:

Check voltage and current rating of external wiring, ensuring it is appropriate for

the application.

3.8 PERIPHERAL CIRCUITRY

Warning:

Do not open the secondary circuit of a live CT since the high voltage produced

may be lethal to personnel and could damage insulation. Short the secondary of

the line CT before opening any connections to it.

Note:

For most General Electric equipment with ring-terminal connections, the threaded terminal block for current

transformer termination is automatically shorted if the module is remov ed. Therefore external shorting of the CTs

may not be required. Check the equip ment documentation and wiring diag r ams first to see if this applies.

Caution:

Where external components such as resistors or voltage dependent resistors

(VDRs) are used, these may present a risk of electric shock or burns if touched.

Warning:

Take extreme care when using external test blocks and test plugs such as the

MMLG, MMLB and P990, as hazardous voltages may be exposed. Ensure that CT

shorting links are in place before removing test plugs, to avoid potentially lethal

voltages.

3.9 UPGRADING/SERVICING

Warning:

Do not insert or withdraw modules, PCBs or expansion boards from the

equipment while energised, as this may result in damage to the equipment.

Hazardous live voltages would also be exposed, endangering personnel.

Caution:

Internal modules and assemblies can be heav y and may have sharp edges. Take

care when inserting or removing modules into or out of the IED.

Page 20

Safety Information

Pxxx

10

4 DECOMMISSIONING AND DISPOSAL

Caution:

Before decommissioning, completely isolate the equipment power supplies

(both poles of any dc supply). The auxiliary supply input may have capacitors in

parallel, which may still be charged. To avo id electric shock, discharge the

capacitors using the external terminals before decommissioning.

Caution:

Avoid incineration or disposal to water courses. Dispose of the equipment in a

safe, responsible and environmentally friendly manner, and if applicable, in

accordance with country-specific regulations.

Page 21

Pxxx

Safety Information

11

5 STANDARDS COMPLIANCE

Compliance with the European Commission Directive on EMC and LVD is demonstrated using a Technical

File.

5.1 EMC COMPLIANCE: 2014/30/EU

Compliance with EN60255-26:2009 was used to establish co nformity.

5.2 PRODUCT SAFETY: 2014/30/EU

Compliance with EN60255-27:2005 was used to establish co nformity.

Protective Class

IEC 60255-27: 2005 Class 1 (unless otherwise specifi ed i n equipment documentation). This equipment

requires a protective conductor (earth) to ensure use r safety.

Installation category

IEC 60255-27: 2005 Overvoltage Category 3. Equipment i n this category is qualification tested at 5kV peak,

1.2/50

m

S,

500 Ohms, 0.5 J, between all supply circuits and earth and also between independent circuits.

Environment

IEC 60255-27: 2005, IEC 60255-26:2009. The equipm ent is intended for indoor use only. If it is required for

use in an outdoor environment, it must be mounted i n a specific cabinet or housing which will enable it to

meet the requirements of IEC 60529 with the classification of degree of protection IP54.

5.3 UL/CUL COMPLIANCE

If marked with this logo, the product is compliant with the requirements of the Canadian and USA

Underwriters Laboratories.

The relevant UL file number and ID is shown on the equipment.

Page 22

Safety Information

Pxxx

12

Equipment with this marking is not itself suitable for operation within a potentially explosive

atmosphere.

Compliance demonstrated by Notified Body Type Ex am i nation Certificate.

ATEX Potentially Explosive Atmospheres directive 94/9/EC for equipment.

Page 23

P50 Agile P253

3 Hardware Design

P253/EN M/C

3-1

HARDWARE DESIGN

CHAPTER 3

Page 24

3 Hardware Design

P50 Agile P253253

3-2

P253/EN M/C

Page 25

P50 Agile P253

3 Hardware Design

P253/EN M/C

3-3

1 CHAPTER OVERVIEW

This chapter consists of the following sections:

1

Chapter Overview

2 Hardware Design

2.1 Overview of Hardware Design

2.2 Microcontroller with DSP Module

2.2.1 Microcontroller Module (processor board) Features

2.3 Microcontroller and Analog Measurement

2.4 Digital Input/Output Module

2.5 Power Supply Module

2.6 Communication Module

2.7 Human Machine Interface Module

Page 26

3 Hardware Design

P50 Agile P253253

3-4

P253/EN M/C

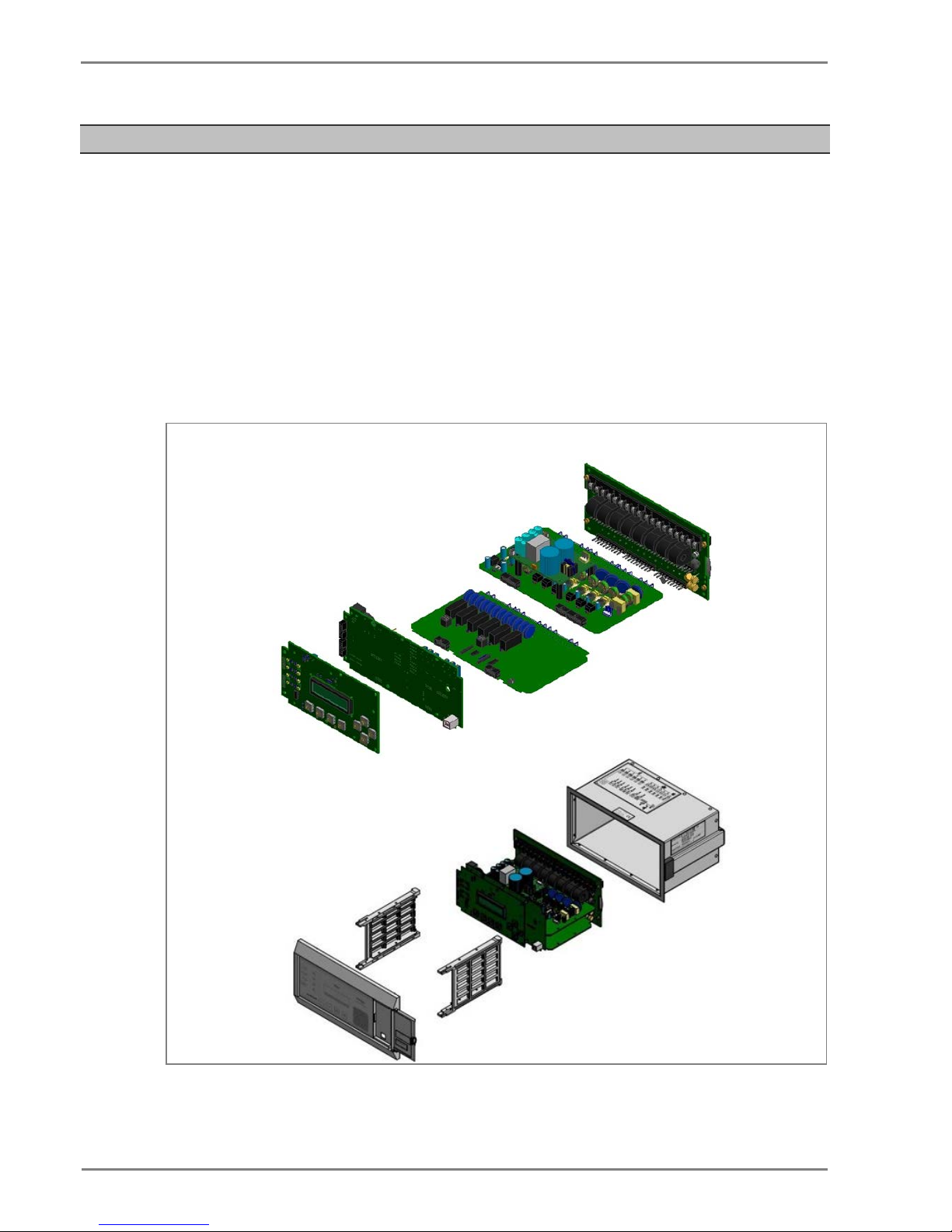

2 HARDWARE DESIGN

The P253 hardware comprises of the following main components:

• Housing, consisting of a front panel and connections at the rear

• Microcontroller module

• Analogue input module

• Digital input module

• Digital output module

• Communication module

• Power supply unit

• Human machine interface (HMI) module

Figure 1: P253 general assembly

Page 27

P50 Agile P253

3 Hardware Design

P253/EN M/C

3-5

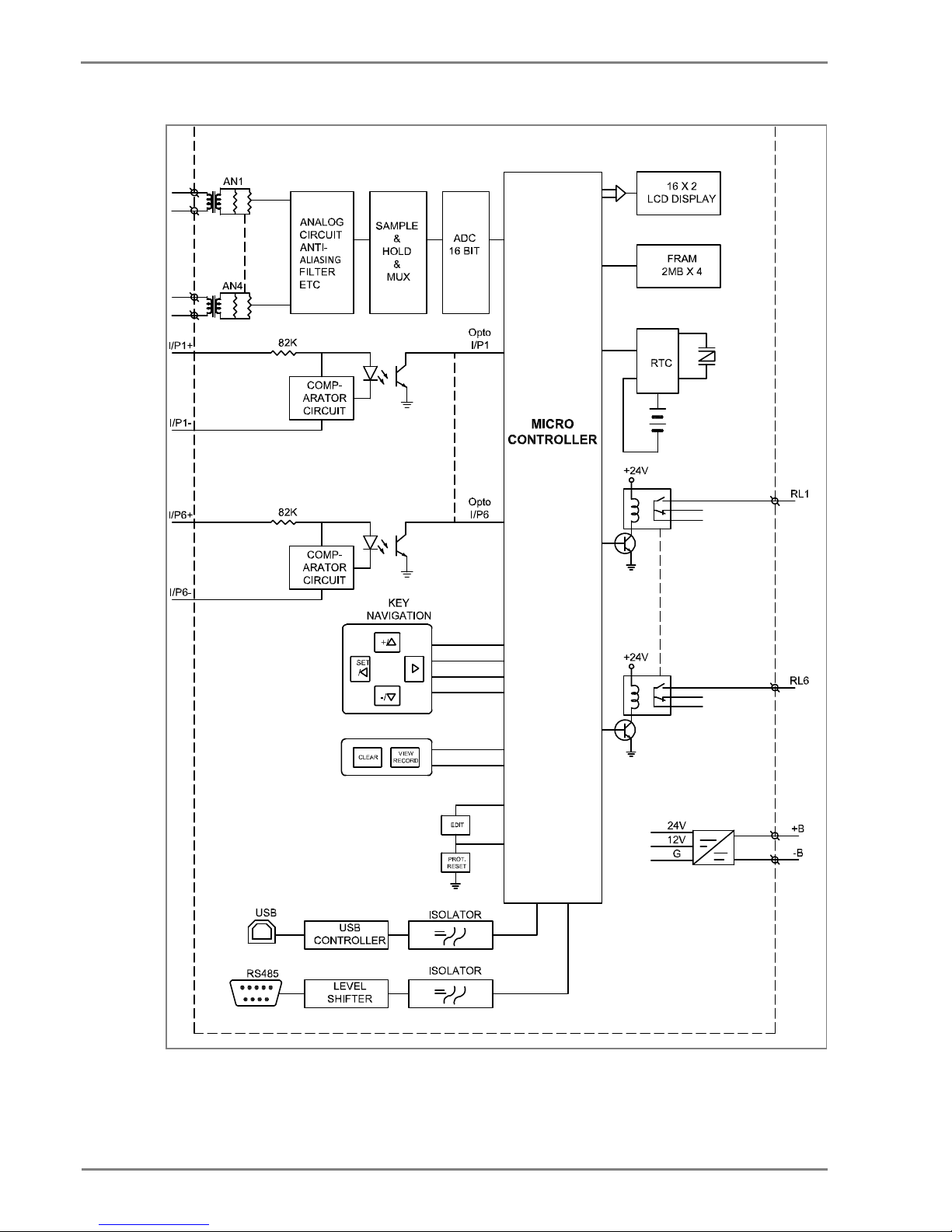

2.1 Overview of Hardware Design

The P253 hardware design overview is explained with the help of the schematic diagram. The P253

hardware consists of three sets of internal Current Transformers (CTs). These internal CTs are

designed to cater to protection & metering requirements. Dedicated CT is available for the earth fault

protection requirements. The relay also has provision for the built-in SMPS unit which accepts power

supply input of 24-230 V AC/DC from external source and outputs 12 V and 24 V DC for internal

circuitry. The current signals acquired as analogue inputs get pr ocessed through operational amplifier,

filter circuit, multiplexer, ADC (Analog to digital converter) and finally fed to CPU.

The CPU design is a hybrid of the digital signal process or (DSP) and high speed microcontroller which

runs complex algorithm for deriving the fundamental & harmonic component from the input current

signals. The digital inputs and outputs modules are designed to interface the monitoring, control and

protection signals through optically isolated circuit as per the field requirements. The other peripherals

modules like 16x2 LCD display, feather touch keys, USB and RS485 communication interfaces,

battery backup for RTC and built in memory circuits are int egrated as per the schematic diagram and

enclosed in the IP-52 enclosure.

Page 28

3 Hardware Design

P50 Agile P253253

3-6

P253/EN M/C

E00276

Figure 2: Hardware design overview

Page 29

P50 Agile P253

3 Hardware Design

P253/EN M/C

3-7

2.2 Microcontroller with DSP Module

The hardware is designed around 32 bit controller housed in small 100 pin SMD package. It is a high

speed fix point controller having MIPS’s M4K® 32-bit core with 5-stage pipeline capable of operating

up to 80 MHz.This controller is referred to as MCU (Microcontroller unit).

2.2.1 Microcontroller Module (processor board) Features

• 512K Flash memory (plus an additional 12 KB of Boot Flash)

• 128K on chip SRAM memory

• Multiple interrupt vectors with individually programmable priority

• Fail-Safe Clock Monitor mode

• Configurable Watchdog Timer with on-chip Low-Po wer RC oscillator for reliable operation

• Internal 8 MHz and 32 kHz oscillators

• Six UART modules with:

• RS-232, RS-485, USB and LIN support

• Four SPI modules

• Five I2C™ modules

• Hardware Real-Time Clock and Calendar (RTCC)

• Five 16-bit Timers/Counters

2.3 Microcontroller and Analog Measurement

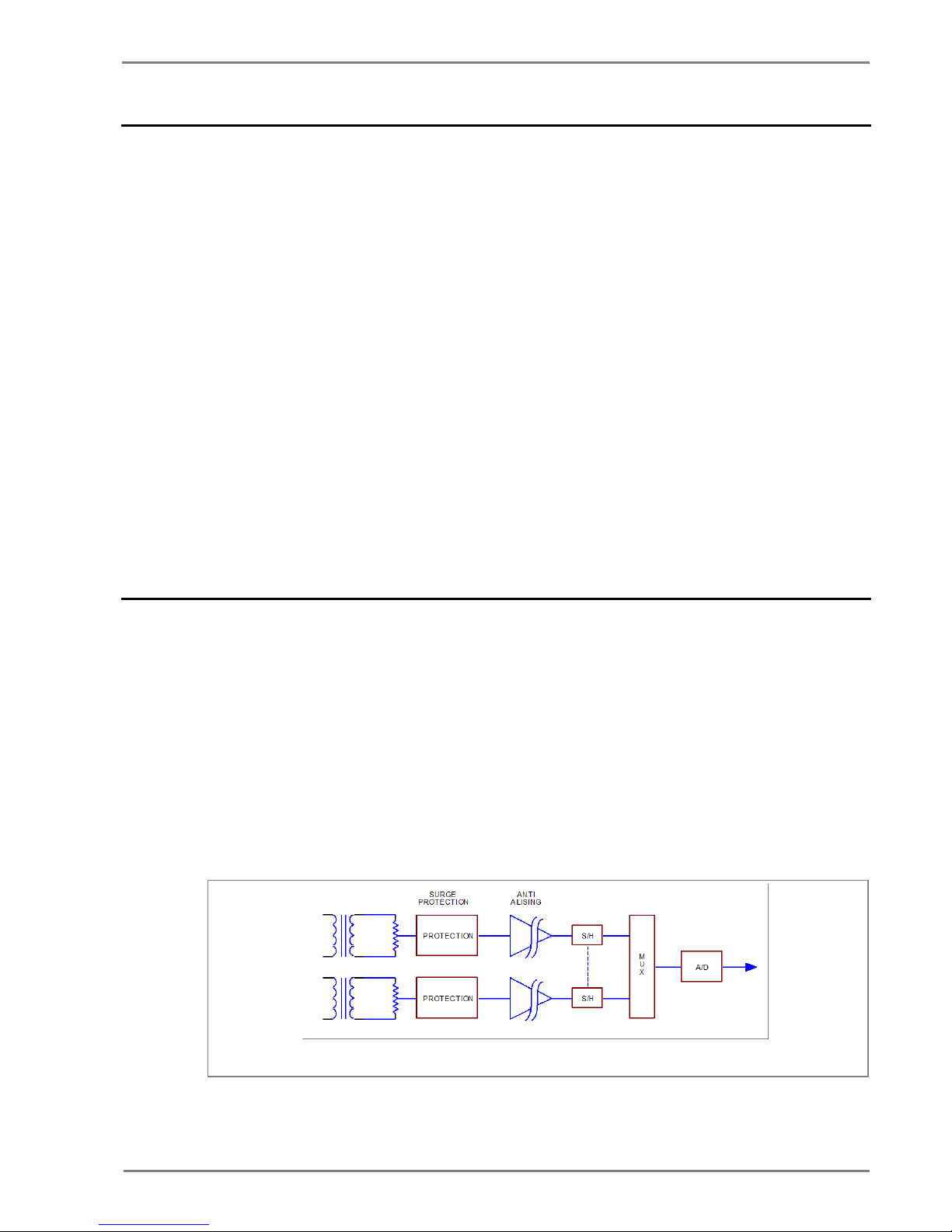

P253 hardware supports 4 analog inputs. The relay hardware uses an external 16 bit ADC converter

with capability to sample 8 signals simultaneously to avoid any phase angle error and achieve higher

accuracy. In P253, only 4 channels of ADC converter are used. This external ADC can measure input

in a range of – 10 V to +10 V. The ADC interface uses a SPI serial interface to avoid any software

delays. The MCU continuously monitors different analog signals like line and E/F currents through

CTs, multiplexer and ADC.

The relay is designed for 5 amp and 1 amp CT secondary cu rr ent signal. These inputs are further

scaled down to low voltage signal by using an internal cur rent and transformer. The internal current

transformer converts nominal current signal to 3.3 mA. These analog signals are then passed through

protection circuit, anti aliasing filter and amplifier which scales analogue signal to required ADC range.

This anti aliasing filter blocks all high frequency components and surges to avoid measurement error.

The sample and hold (S/H) circuit and multiplexer sample all analog signals at same instant to avoid

and phase angle error and give maximum accuracy.

V00277

Figure 3: Analog signal processing

Page 30

3 Hardware Design

P50 Agile P253253

3-8

P253/EN M/C

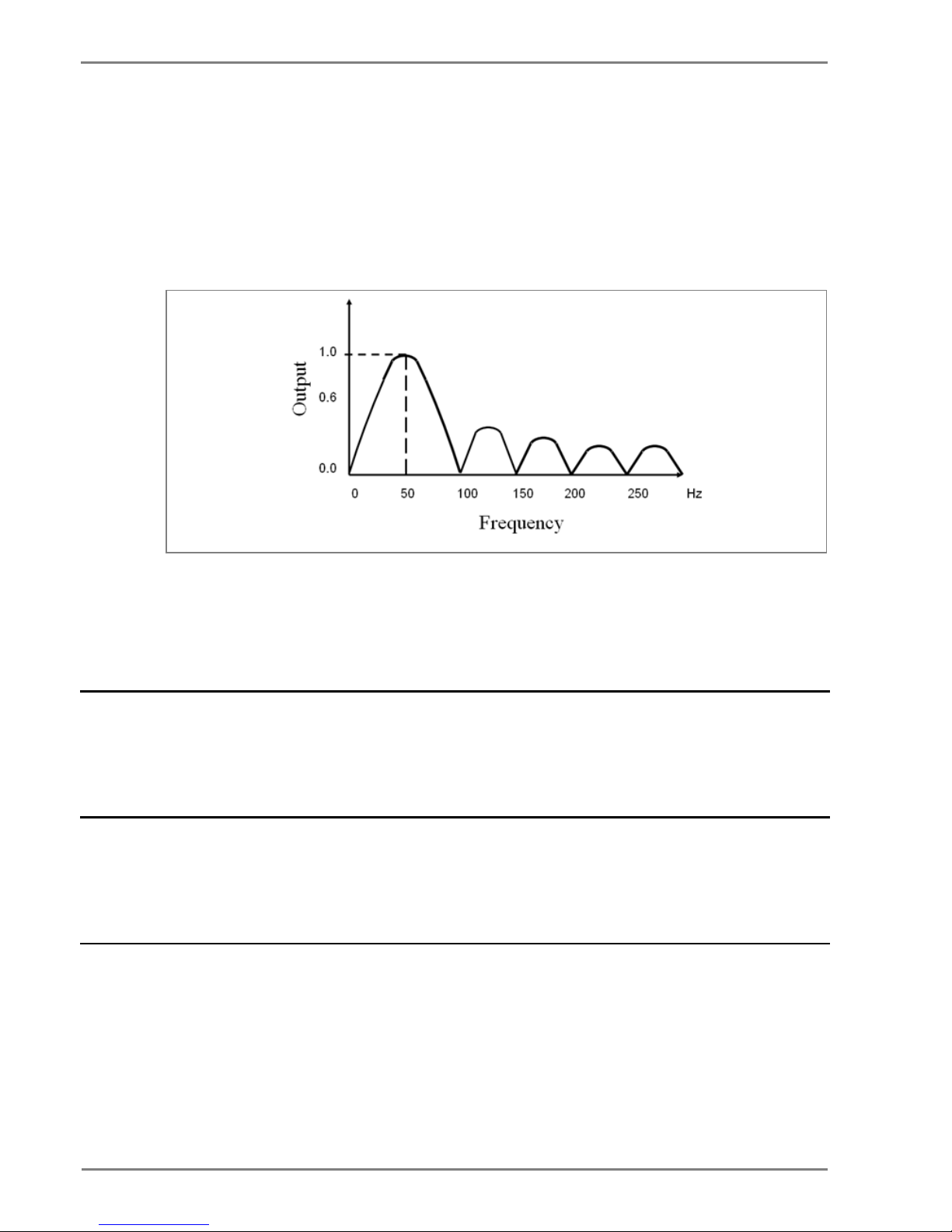

The MCU acquires analog values at the rate of 16 sam pl es per cycle. Digital signal processing (DSP)

performs powerful numerical algorithms which converts this signal in to equivalent vectors. Once the

signal is converted into vectors, number of parameters are derived from it such as phase currents (Ia,

Ib, Ic), positive sequence current (I1) and negative sequence current (I2). The MCU also calculates

harmonic contents of the current signals (actual harmonics depend upon type of relay). All

measurements are tuned to fundamental frequency i.e. 50 Hz or 60 Hz, so that the relay will remain

stable during distorted waveform generated by modern electronics load.

The typical frequency response of tuned filter for 50 Hz is shown in figure 4.

V00278

Figure 4: Frequency response of tuned filter for 50 Hz

The measurement is totally immune to all higher harm onics which makes relay operation reliable. All

these measured values are then used for different prot ect i on functions such as over current/Earth

Fault and negative phase sequences. The actual prot ection function depends on type of relay and

described in the rest of the document.

2.4 Digital Input/Output Module

This module supports 6 numbers of Digital input DI and 6 number s of Digital output DO channels for

acquiring filed signals or controlling field devices respectively. The DIs are isolated f rom other circuits

by using Opto isolators. The threshold voltage at which Opt o coupler turns ON is controlled by

comparator based on the voltage range selected duri ng device ordering.

2.5 Power Supply Module

The power supply module is a designed using modern PWM based switching mode technique. It

converts input supply to the 12 V and 24 Vdc low voltage su ppl y for relay electronics and control

circuit. It also provides necessary isolation from input power supply. The normal operating voltage

range is 24 V – 230 VAC/DC.

2.6 Communication Module

The P253 supports 2 numbers of isolated ports for communication.

• (a) USB port provided on front of the relay

• (b) RS 485 (2 wired) port provided on the rear side of relay.

The relay can be accessed using the P50 Agile Configurator. Rear port supports open protocols like

IEC60870-5-103/MODBUS or DNP3.0 (ordering option) and is used for external communication.

Page 31

P50 Agile P253

3 Hardware Design

P253/EN M/C

3-9

2.7 Human Machine Interface Module

The HMI module is provided with 16x2 LCD, 8 numbers of soft feather touch keys and 8 numbers of

LEDs for indication. The cover at right side of the fron t panel houses following:

• Female USB connector

• Serial number of relay

• Model number of relay

• Voltage and Current ratings

Figure 5: Front panel of P253 relay

Page 32

3 Hardware Design

P50 Agile P253253

3-10

P253/EN M/C

Page 33

P50 Agile P253

4 Front Panel

P253/EN M/C

4-1

FRONT PANEL

CHAPTER 4

Page 34

4 Front Panel

P50 Agile P253

4-2

P253/EN M/C

Page 35

P50 Agile P253

4 Front Panel

P253/EN M/C

4-3

1 CHAPTER OVERVIEW

This chapter consists of the following sections:

1

Chapter Overview

2 Front Panel

2.1 User Interface

2.1.1 LCD Display

2.1.2 Touch Keys

2.1.3 LEDs

2.1.4 RS 485 Port

2.1.5 USB Port

Page 36

4 Front Panel

P50 Agile P253

4-4

P253/EN M/C

2 FRONT PANEL

Figure 1: Front panel

SL no Label Function

1 ON

The green LED indicates that the IED is in correct working order. T he gr een LE D should be ON

at all times. If there is an error in the hardware or software t he LE D will turn red.

2

START

The amber LED flashes when the IED registers an alarm. This can be triggered by a fault or an

event or maintenance record. The LED will flash until the alarms have been accepted (read).

Press the VIEW RECORD function key and it will change to ON. When the alarms have been

cleared, press the CLEAR key and the LED will switch OFF.

3 TRIP

The red LED switches ON when the IED issues a trip signal. When the faults have been cleared

,

press the CLEAR key and the LED will switch OFF.

4

OUT OF SERVICE

The amber LED flashes when the IED's protection is unavailable (eg. Setting Error, ADC Error

detected by unit’s self-test etc).

5

L5

Programmable dual colour LED

6 L6 Programmable dual colour LED

7 L7 Programmable dual colour LED

8 L8 Programmable dual colour LED

9

LCD Display

The LCD display is used to view the settings and parameters of the relay.

10

EDIT

Feather touch key to edit parameter settings.

11

CLEAR

Feather touch key to clear the fault LED indications.

Also used to discard the setting changes.

12

VIEW RECORD

Feather touch key to view fault records.

13

PROT. RESET

Feather touch key to reset the hardware. This key should be be used alongside the EDIT key.

The relay will reboot when ‘PROT. RESET’ + EDIT are pressed simultaneously.

14

SET

/ ◄

Feather touch key SET to save the settings and /◄ is used for navigating through the

menus/submenus.

15 + /▲

Feather touch key [+] is used to INCREASE the values and [▲] is used to change the menu

level or change between settings in a particular menu.

16 - /▼ Feather touch key [-] is used to DECREASE the values and [▼] is used to change the menu

level or change between settings in a particular menu.

Page 37

P50 Agile P253

4 Front Panel

P253/EN M/C

4-5

SL no

Label

Function

17 ►

Feather touch key [►] is used to view the settings and to navigate through the menus and

submenus.

2.1 User Interface

2.1.1 LCD Display

A backlit LCD display of 16 x 2 characters is provided for param eter and setting display. It also

provides easy viewing of measurement, setting, f aul t records, date & time and error messages. The

backlit display will switch off automatically after 100 seconds if no key is pressed. The backlit display

will turn ON automatically if any tripping occurs.

2.1.2 Touch Keys

The function of the relay is controlled by the following key s on the front panel.

(+) key is used to INCREASE the values

(▲) key is used to change the menu level or change between settings in a particular menu.

SET key is used to save the settings

(◄) key is used for navigating through the menus/submenus.

(►) key is used to view the settings and to navigate through the menus and submenus.

(-) key is used to DECREASE the values

(▼) key is used to change the menu level or change between settings in a particular menu.

EDIT key is used to edit the setting

CLEAR key is used to clear the fault LED indications. This key is also used to discard the setting

changes.

VIEW RECORD key is used to view the Fault, Maintenance and Event Records.

PROT. RESET key is used for Hardware reset. This key is interlocked with the EDIT key. This

key is not required to be pressed in normal operation, but is used to reset the hardware of relay

during a relay firmware update.

Note: If you edit the settings you have 100 s to make the changes. After 100 s the display will reset itself

and return to the Main Menu.

Page 38

4 Front Panel

P50 Agile P253

4-6

P253/EN M/C

2.1.3 LEDs

The P253 relay has 8 high-intensity LEDs for easy identification of fault type and ease of user

interface.

SL no

Label

Function

LED 1

ON

The green LED indicates that the IED is in correct working order. The gr een LE D should be ON

at all times. If there is an error in the hardware or software t he LE D will turn red.

LED 2

START

The amber LED flashes when the IED registers an alarm. This can be triggered by a fault or an

event or maintenance record. The LED will flash until the alarms have been accepted (read).

Press the VIEW RECORD function key and it will change to ON. When the alarms have been

cleared, press the CLEAR key and the LED will switch OFF.

LED 3

TRIP

The red LED switches ON when the IED issues a trip signal. When the faults have been cleared,

press the CLEAR key and the LED will switch OFF.

LED 4

OUT OF SERVICE

The amber LED flashes when the IED's protection is unavailable (eg. Setting Error, ADC Error

detected by unit’s self-test etc).

LED 5,6,7,8

-

Programmable dual colour LED

2.1.4 RS 485 Port

The RS485 port is provided at the rear of relay (near to terminal block) for permanent SCADA

connectivity. The separate 5 Pin connector is used to avoid accidental connection of power wiring to

communication input. The RS485 port can be used to download Settings, Fault data, Live Event and

Disturbance Records.

2.1.5 USB Port

The USB port is situated on the front panel in the bottom right hand corner, and can be accessed by

opening the flap on the front of the relay. This port is used to communicate with a locally connected

PC.

It has three main purposes:

• Transferring settings information to/from the P C from/to the device.

• Downloading firmware updates.

• Downloading relay data for analysis.

The port is intended for temporary connection during testing, installation and commissioning. It is not

intended to be used for permanent SCADA communicati ons.

You can connect the unit to a PC with a USB cable up to 15 m in l engt h.

The USB port includes a USB full-speed function controller, USB transceiver, oscillator, EEPROM, and

synchronous serial data bus (UART). No other extern al US B components are required.

For configuration/setting the appropriate ‘config port’ has to be selected from the SYSTEM DATA

menu.

Page 39

P50 Agile P253

4 Front Panel

P253/EN M/C

4-7

Figure 2: USB port

Page 40

4 Front Panel

P50 Agile P253

4-8

P253/EN M/C

Page 41

P50 Agile P253

5 Configuration

P253/EN M/C

5-1

CONFIGURATION

CHAPTER 5

Page 42

5 Configuration

P50 Agile P253

5-2

P253/EN M/C

Page 43

P50 Agile P253

5 Configuration

P253/EN M/C

5-3

1 CHAPTER OVERVIEW

This chapter consists of the following sections:

1

Chapter Overview

2 Configuration

2.1 Changing the Settings

2.2 Password Entry

2.3 Menus

2.3.1 Default Display

2.3.2 Main Menu Contents

2.3.3 System Data Menu

2.3.3.1 View / Edit Settings

2.3.4 View Records Menu

2.3.4.1 View Records Menu Contents

2.3.4.2 View Fault Records

2.3.4.3 View Event Records

2.3.4.4 View Maintenance Records

2.3.4.5 View Alarm Records

2.3.5 Measurement Menu

2.3.5.1 View Contents- Measurement 1 Submenu

2.3.5.2 View Contents- Measurement 2 Submenu

2.3.6 CB Control Menu

2.3.6.1 View / Edit Settings (if all settings are disabled)

2.3.6.2 View / Edit settings (if all settings are enabled)

2.3.7 Date and Time Menu

2.3.7.1 Edit Settings (if the settings are disabled)

2.3.7.2 Edit Settings (if the settings are enabled)

2.3.8 Configuration Menu

2.3.8.1 View / Edit Settings

2.3.9 Transformer Ratios Menu

2.3.9.1 View / Edit Settings

2.3.10 Record Control Menu

2.3.10.1 View / Edit Settings

2.3.11 Communication Menu

2.3.11.1 View / Edit Settings

2.3.12 I/O Configuration Menu

2.3.12.1 View / Edit Settings

2.3.12.2 List of the submenus for Relay Output, LEDs and AND Logic configuration

2.3.13 O/P Relay Configuration Menu

2.3.13.1 View / Edit Settings

2.3.14 Disturbance Record Menu

2.3.14.1 View / Edit Settings

2.3.15 Commissioning Test Menu

2.3.15.1 View / Edit Settings

2.3.16 Group 1 Menu

2.3.16.1 Edit Settings

2.3.16.2 Group 1 –System Configuration Submenu

2.3.16.3 Group 1 – Overcurrent Submenu

2.3.16.4 Group 1 –Negative Sequence Overcurrent Submenu

2.3.16.5 Group 1 – Earth Fault 1 Submenu

2.3.16.6 Group 1 – Earth Fault 2 Submenu

2.3.16.7 Group 1 –Thermal Overload Submenu

2.3.16.8 Group 1 – Loss of Load Submenu

2.3.16.9 Group 1 –CB Fail Submenu

2.3.16.10 Group1 –Stall Detection Submenu

Page 44

5 Configuration

P50 Agile P253

5-4

P253/EN M/C

2.3.16.11 Group1 –Limit Nb Starts Submenu

2.3.17 Group 2 Menu

2.3.17.1

Edit Settings

2.4 Configuration Flowcharts

2.4.1 Main Menu

2.4.2 View and Edit Settings

2.4.3 View System Data Menu Settings

2.4.4 Records Menu

2.4.4.1 View Records

2.4.4.2 View Fault Records

2.4.4.3 View Event Records

2.4.4.4 View Maintenance Records

2.4.4.5 View Alarm Records

2.4.5 Measurement Menu

2.4.5.1 View Measurement 1 Submenu

2.4.5.2 View Measurement 2 Submenu

2.4.6 CB Control Menu

2.4.6.1 View / Edit Settings (if all settings are disabled)

2.4.6.2 View / Edit Settings (if all settings are enabled)

2.4.7 Date and Time Menu

2.4.7.1 View / Edit Settings (if all settings are disabled)

2.4.7.2 View / Edit Settings (if all settings are enabled)

2.4.8 Configuration Menu

2.4.8.1 View / Edit Settings

2.4.9 Transformer Ratios Menu

2.4.9.1 View / Edit Settings

2.4.10 Record Control Menu

2.4.10.1 View / Edit Settings

2.4.11 Communication Menu

2.4.12 View / Edit Settings

2.4.13 I/O Configuration Menu

2.4.14 View / Edit Settings

2.4.15 O/P Relay Configuration Menu

2.4.15.1 View / Edit Settings

2.4.16 Disturbance Record Menu

2.4.16.1 View / Edit Settings

2.4.17 Commissioning Test Menu

2.4.17.1 View / Edit Settings

2.4.18 Group 1 Menu

2.4.18.1 View / Edit Settings

2.4.18.2 Group 1- System Configuration Submenu

2.4.18.3 Group 1- Overcurrent Submenu

2.4.19 Group 1- Negative Sequence Overcurrent Menu

2.4.19.1 View / Edit Settings (If setting is disabled)

2.4.19.2 View / Edit Settings (For all types of IEC curves)

2.4.19.3 View / Edit Settings (For all types of IEEE curves)

2.4.19.4 View / Edit Settings (For DT)

2.4.20 Group 1- Earth Fault 1 Submenu

2.4.20.1 View / Edit Settings (If setting is disabled)

2.4.20.2 View / Edit Settings (For all types of IEC curves)

2.4.20.3 View / Edit Settings (For all types of IEEE curves)

2.4.20.4 View / Edit Settings (For DT)

2.4.21 Group 1- Earth Fault 2 Submenu

2.4.21.1 View / Edit Settings (If setting is disabled)

2.4.21.2 View / Edit Settings (For all types of IEC curves)

2.4.21.3 View / Edit Settings (For all types of IEEE curves)

2.4.21.4 View / Edit Settings (For DT)

Page 45

P50 Agile P253

5 Configuration

P253/EN M/C

5-5

2.4.22 Group 1- Thermal Overload Submenu

2.4.22.1 View / Edit Settings (If setting is disabled)

2.4.22.2 View / Edit Settings (If setting is disabled)

2.4.22.3 View / Edit Settings (If setting is enabled)

2.4.23 Group 1- Loss of Load Submenu

2.4.23.1 View / Edit Settings (If setting is disabled)

2.4.23.2 View / Edit Settings (If the setting is enabled)

2.4.24 Group 1- CB Fail Submenu

2.4.24.1 View / Edit Settings (If setting is disabled)

2.4.24.2 View / Edit Settings (If setting is enabled)

2.4.25 Group 1- Stall Detection Submenu

2.4.25.1 View / Edit Settings (If setting is disabled)

2.4.25.2 View / Edit Settings (If setting is enabled)

2.4.26 Group 1- Limit Nb Starts Submenu

2.4.26.1 View / Edit Settings (If setting is disabled)

2.4.26.2 View / Edit Settings (If setting is enabled)

2.4.27 Group 2 Menu

2.4.27.1 View / Edit Settings

Page 46

5 Configuration

P50 Agile P253

5-6

P253/EN M/C

2 CONFIGURATION

Each product has different configuration parameter s according to the functions it has been

designed to perform. There is, however, a common m ethodology used across the entire product

to set these parameters.

This chapter describes an overview of this common methodology, as well as providing concise

instructions of how to configure the device.

Using the HMI you can:

• Display and modify settings

• View the digital I/O signal status

• Display measurements

• Display fault records

• Reset fault and alarm indications

The keypad provides full access to the device functionality by means of a range of menu options.

Information is displayed on the LCD.

Figure 1: P253 menu/function keys

Page 47

P50 Agile P253

5 Configuration

P253/EN M/C

5-7

2.1 Changing the Settings

SYSTEM DATA

Step 1: Press the (4) key to move to the next option.

Language

English

Step 2: Press the (- /6) key to move to the next option till the relay

displays CB Open/Close setting

: : :

: : :

CB Open/Close

Open

Step 3:

Once the relay displays this option, press

EDIT

key to edit the

setting.

Password = 0001

[All editable settings are password protected. So when the EDIT key is

pressed, it will display the password and the settable number/text will

start blinking].

Step 4: Enter the password by using the (+ /5) or the (- /6) key. The

Password is four (4) digits alpha numeric.

Password = 0000

** Password OK **

Step 5: After editing the Password, press the EDIT key, the **Password

OK** message is displayed and settable number/text will start blinking

and the relay will move to the next option.

Note: When the password is set, modification can be done in any

settings within 15 minutes. After the lapse of 15 minutes, the relay will

once again ask to re-enter the password.

CB Open/Close

Open

Step 6: By using the (+ /5) or (- /6) key, the desired selection can be

set as shown in the display.

CB Open/Close

Close

Step 7:

After setting, press the

EDIT

key, the text will stop blinking and

move to the next option.

Step 8: Press the (3) / (4) key, it will ask if you want to save the

settings and move to the next option.

SET For Save

CLEAR For Cancel

Step 9: When the SET key is pressed again, it will save the changes

and move to the next option.

SAVE Settings

This window will flash for a moment and the control will return to the

main menu.

Page 48

5 Configuration

P50 Agile P253

5-8

P253/EN M/C

SYSTEM DATA

Note: Press the CLEAR Key to DISCARD settings.

SET For Save

CLEAR For Cancel

Step 10: When the CLEAR key is pressed, it will discard the changes

and the relay will move to the next option.

DISCARD Settings

This window will flash for a moment and the control will return to the

main menu.

SYSTEM DATA

2.2 Password Entry

To modifiy the settings you will need password access. You will be asked for a password before

you can make any of the following changes. The defaul t password is 0000.

1. When you press the EDIT key a flashing cursor appears at the right most character field

of the password by default. Press the up or down cursor key s t o change each character.

2. Use the left and right cursor keys to move between the character fields of t he password.

3. Press the SET key to confirm the password. After entering a valid password the

Password OK message appears indicating that the password is correct. The user can

now start editing the settings. If the correct password has not been entered, the password

prompt page appears again. To stop this prompt press the CLEAR key.

4. A new password c an be set using the Password cell in the SYSTEM DATA menu.

5. If the keypad is inactive for 15 minutes the user will again be prompted for a password

entry.

Page 49

P50 Agile P253

5 Configuration

P253/EN M/C

5-9

2.3 Menus

2.3.1 Default Display

After Power ON or when the PROT.RESET + EDIT keys are pressed the relay will display the

following message.

P50 Agile P253

Motor Protect’n

This window will flash momentarily showing the following.

Relay Name: P50 Agile P253,

Relay Type : Motor Protection

Then the control will automatically move to next option.

ID = 1

SW = V1.04

This window will flash momentarily showing the following :-

Unit ID = 1

Software Version =V1.04

Then the control will automatically move to the default window.

SYSTEM DATA

2.3.2 Main Menu Contents

SYSTEM DATA

Password protected window for “SYSTEM DATA’’ setting i.e. Language,

Description, Model Number, Serial Number, Software Version,

Frequency, USB Address, USB Parity, USB Baud Rate, Password,

Active Group, Opto I/P Status, R elay O/P S tatus. CB Open/ Close, Opto

I/P and Config Port.

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

records.

MEASUREMENTS

This menu displays the measurements values of various parameters

under submenu Measurement 1 and 2

Measurement 1 (i.e. Phase current, measured and derived earth

current, negative, positive phase sequence current and zero s equence

current) as per phase/earth C T ratio, rms value of phase current, BOC

(Breaker Operation Counter), TC (Trip Counter), BOT (Breaker

Operating Time), and

Measurement 2 (i.e. Thermal State, Load Current, T ime to Th Trip, Nb

of Th Trip, Last Start Time, Last St Current, Nb Hot St Allow, Nb Cold St

Allow, Time to Next St, Tot al Nb of Strt, Nb Emergency Rst and Motor

Run Time)

CB CONTROL

Password protected window for “CB CONTROL” settings

i.e. TCS

Alarm, TCS Timer, CB Open S ’vision (Enabled / Disabled), CB Open

Time, CB Open Alarm (Enabled / Disabled), CB Open Oper, CB Control

By, Close Pulse Time, Open Pulse Time and Emergency Rest. (Yes/No).

Page 50

5 Configuration

P50 Agile P253

5-10

P253/EN M/C

DATE AND TIME

Password protected window for “DATE AND TIME’’ settings i.e. Local

Time Enable, Local Time Offset. DST Enable, DST Offset, DST Start,

DST Start Day, DST Start Mont h, DST Start Mins, DST End, D ST End

Day, DST End Month, DST End Mins, RP Time Zone, S ET Hours, SET

Minutes, SET Seconds, SET Date, SET Month and SET Year.

CONFIGURATION

Password protected window for “CONFIGURATION’’ settings i.e.

Restore Defaults, Active Sett ings , Copy From, Copy To, S etting G roup 1

(Enabled/Disabled), Setting Group 2 (Enabled/Disabled), System Conf ig

(Enabled/Disabled), Overcurrent (Enabled/Disabled)

, Neg Sequence

O/C (Enabled/Disabled), E arth Fault 1 (Enabled/Disabled), Earth Fault 2

(Enabled/Disabled), Thermal Overlo ad (Enabled/Disabled), Loss of Lo ad

(Enabled/Disabled), CB Fail (Enabled/Disabled), Stall Detection

(Enabled/Disabled), Limit NB Starts (Enabled/Disabled), IFL, Measure’t

Setup, and Setting Values.

TRANS. RATIOS

Password protected window for

“TRANS. RATIO ’’

settings i.e Phase

CT Primary, Phase CT Sec’y, E/F CT Primary and E/F CT Secondary.

RECORD CONTROL

Password protected window for “RECORD CONTROL’’ settings i.e.

Clear Events (Yes/No), Clear F aults (Yes/No), Clear Dist Recs (Yes/No),

Clear Maint (Yes/No), Thermal Reset (Yes/No), Reset Nb Em Rst

(Yes/No), Reset Nb of St (Yes/No), Reset Motor RunT (Yes/No) and

Reset CB Data (Yes/No).

COMMUNICATION

Password protected window for

“COMMUNICATION’’

settings i.e. RP1

Address, RP1 Baud Rate, RP1 Parity and RP1 Timesync.

IO CONFIGURATION

Password protected window for “IO CONFIGURATION’’ settings i.e.

Relay, LED G, LED R, AND Logic and Opto I/P.

O/P RELAY CONFIG

Password protected window for “O/P RELAY CONFIGURATION’’

setting i.e. Contact HR/SR, O/P-1 Open Ti me, O/P -2 Open Time, O/ P-3

Open Time, O/P-4 Open Time, O/P -5 Op en T ime and O/P-6 Open Ti me,

LED G HR/SR, LED R HR/SR, ANDEQ A Op Time, ANDEQ A Rst Time,

ANDEQ B Op Time, ANDEQ B Rst Time, ANDEQ C Op Time, ANDEQ C

Rst Time, ANDEQ D Op Time and ANDEQ D Rst Time.

DISTURBANCE REC

Password protected window for

“DISTURBANCE RECORD”

setting i.e.

Trigger Position.

COMMISSION. TEST

Password protected window for “COMMISSIONING TEST” setting i.e.

Test Mode, Test Pattern, Contact Test and Test LEDs.

Page 51

P50 Agile P253

5 Configuration

P253/EN M/C

5-11

GROUP 1

Password protected window for

“GROUP 1’’

settings

i.e. SYSTEM

CONFIG, OVERCURRENT, NEG SEQUENCE O/C, EARTH FAULT 1,

EARTH FAULT 2, THERMAL OVERLOAD, LOSS OF LOAD, CB FAIL

STALL DETECTION and LIMIT NB STARTS.

Note: Group 1 settings will be seen only when it is enabled and set

under Active Settings in Configuration menu.

GROUP 2

Password protected window for “GROUP 2’’ settings

i.e. SYSTEM

CONFIG, OVERCURRENT, NEG SEQUENCE O/C, EARTH FAULT 1,

EARTH FAULT 2, THERMAL OVERLOAD, LOSS OF LOAD, CB FAIL

STALL DETECTION and LIMIT NB STARTS.

Note: Group 2 settings will be seen only when it is enabled and set

under Active Settings in Configuration menu.

2.3.3 System Data Menu

2.3.3.1 View / Edit Settings

SYSTEM DATA

Password protected window for “SYSTEM DATA’’ settings i.e.

Language, Description, Model Number, Serial Number, Software

Ve

rsion, Frequency, USB Address, USB Parity, USB Baud Rate,

Password, Active Group, Opto I/P Status, Relay O/P Status. CB

Open/Close, Opto I/P and Config Port.

Language

English

Read-only

This window shows user interface is in English Language.

Description

P50 Agile P253

Read-only

This window shows Description of the relay.

Model Number

P253121A1A0010A

Read-only

This window shows the Model Number of the relay.

Serial Number

xxxP253xxxx

Read-only

This window shows the Serial Number of the relay.

Software Version

P253_1__1_0V1.04

Read-only

This window shows the Software Version of the relay.

Frequency

50Hz

Editable setting

This window shows the setting for System Frequency.

The desired Frequency can be selected to either 50 / 60 Hz.

Page 52

5 Configuration

P50 Agile P253

5-12

P253/EN M/C

USB Address

1

Read-only

This window shows the USB Address.

USB Parity

None

Read-only

This window shows the USB Parity.

USB Baud Rate

57600

Read-only

This window shows the USB Baud Rate

Password

****

Editable setting

This window is for setting the new Password of the relay. The desired

alpha numeric case sensitive password can be selected from 0000 to

zzzz and each digit can be set i.e. 0 to 9 / A to Z / a to z.

Active Group

Group 1

Read-only

This window shows the Active Group selected in configuration.

Opto I/P 654321

Status 000000

Read-only

This window shows the Opto Input status.

Relay O/P 654321

Status 000000

Read-only

This window shows the Relay Output status.

CB Open / Close

No operation

Editable setting

This window allows selection of the desired CB operation i.e. Open,

Close and No operation.

Opto I/P

DC

Editable setting

This window allows selection of voltage input type for the Opto I/P i.e.

AC / DC

Config Port

USB

Editable setting

This window allows selection of the Configuration Port of the relay

i.e. USB / RP

Page 53

P50 Agile P253

5 Configuration

P253/EN M/C

5-13

2.3.4 View Records Menu

2.3.4.1 View Records Menu Contents

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

record.

Fault Record

This window is to view the Fault Record

Event Record

This window is to view the Event Record

Maint Record

This window is to view the Maint Record

Alarm Record

This window is to view the

Alarm Record

2.3.4.2 View Fault Records

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

record.

Fault Record

This window shows the Fault Record

Fault Num = 1

This window shows the Fault Number of latest fault.

I>1: I<:

IN1>1: IN2>1: I2>1:

This window displays trip flag of stage 1: O/C, E/F-1 and E/F-2, Neg

Sequence O/C, Under Current, Thermal Trip.

Note: This window is seen when relay operates for respective protection

function.

Page 54

5 Configuration

P50 Agile P253

5-14

P253/EN M/C

I>2:

IN1>2: IN2>2: I2>2:

This window displays trip flag of stage 2: O/C, E/F-1 and E/F-2, Neg

Sequence O/C, Lock Rotor, Stall trip.

Note: This window is seen when relay operates for respective protection

function.

I>3:

IN1>3: IN2>3: I2>3:

This window displays trip flag of stage 3: O/C, E/F-1 and E/F-2, Neg

Sequence O/C, Prolong Start.

Note: This window is seen when relay operates for respective protection

function.

S1 S3 S5 CBF

S2 S4 S6 EXT TR

This window displays status flag (S1 – Opto Input 1, S2 – Opto Input 2,

S3 – Opto Input 3, S4 – Opto Input 4, S5 – Opto Input 5, and S6 – Opto

Input 6, CBF – CB Fail, EXT TR – External Trip)

Note: This window is seen when status flag operates

ia = 0.00 A

ib = 0.00 A

This window displays secondary fault current values.

ic = 0.00 A

in1= 0.00 A

This window displays secondary fault current values.

in2 = 0.00 A

i2 = 0.00 A

This window displays secondary fault current values.

i1 = 0.00 A

i0 =0.00

This window displays secondary fault current values.

Thermal State

0%

This window displays Thermal State.

Trip Counter

0

This window displays Trip counter.

Trip Timing (Sec)

0.000

This window displays Trip time.

Page 55

P50 Agile P253

5 Configuration

P253/EN M/C

5-15

17/11/14

16:15:30.225

This window displays date & time of fault.

2.3.4.3 View Event Records

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

record.

Fault Record

This window shows the Fault Record

Event Record

This window shows the Event Record

Event Num = 1

This window shows the Event number of latest event.

By using the (+ /5) or (- /6) key, the relay will scroll between Event

numbers 1 to 512.

Dt: 21/02/2014

Tm: 16:15:30:225

This window will show date & time of Event.

Event Num = 1

Trip IN1>

This window shows the latest Event and Event number.

2.3.4.4 View Maintenance Records

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

record.

Fault Record

This window shows the Fault Record

Page 56

5 Configuration

P50 Agile P253

5-16

P253/EN M/C

Event Record

This window will show Event Record

Maint Record

This window will show Maintenance Record contents

Main’t Rec Num =

1

This window shows Maintenance Record 1

Errorcode : 0004

RTC Error

This window shows the contents of the Maintenance Record 1.

07/06/2014

17:20:30.596

This window shows the date and time of error.

2.3.4.5 View Alarm Records

VIEW RECORDS

Menu to view Fault Record, Event Record, Maint Record and Alarm

record.

Fault Record

This window will show the Fault Record

Event Record

This window will show Event Record

Maint Record

This window will show Maintenance Record

Page 57

P50 Agile P253

5 Configuration

P253/EN M/C

5-17

Alarm Record

This window will show Alarm Record

TCS Al a rm

This window shows latest alarm.

24/09/2014

12:35:40:025

This window shows the date and time of alarm.

2.3.5 Measurement Menu

2.3.5.1 View Contents- Measurement 1 Submenu

MEASUREMENTS

Menu to view the Measurement 1 & Measurement 2

Measurement 1

Submenu to view following measurements :

Phase current, Measured and derived earth c

urrent, Negative and

Positive phase sequence curr ent and zero sequence curr ent) as per CT

Primary and Secondary current s election, RMS value of Phase Current,

BOC (Breaker Operation Counter), TC (Trip Counter), BOT (Breaker

Operating Time),

IA = 0 A

IB = 0 A

This window shows primary value of current in phase A and B taking in

to account phase CT ratio.

IC = 0 A

IN1 = 0 A

This window shows primary value of current in phase C and measured

earth current taking in account phase CT and earth CT ratio respectively.

IN2 = 0 A

I0 = 0 A

This window shows primary value of internally derived earth current and

zero sequence current.

I1 = 0 A

I2 = 0 A

This window shows primary value of positive sequence current and

negative sequence current.

Page 58

5 Configuration

P50 Agile P253

5-18

P253/EN M/C

ia = 0.00 A

ib = 0.00 A

This window shows secondary value of current in phase A and phase B.

ic = 0.00 A

in1 = 0.00 A

This window shows secondary value of current in phase C and

measured earth current.

in2 = 0.00 A

i0 = 0.00 A

This window shows secondary value of internally derived earth current

and zero sequence current.

i1 = 0.00 A

i2 = 0.00 A

This window shows secondary value of positive sequence current and

negative sequence current.

Irms A = 0.00 A

Irms B = 0.00 A

This window shows secondary value of RMS current in phase A and

Phase B.

Irms C = 0.00 A

BOC : 0

This window shows secondary value of RMS current in phase C and

Breaker operation counter.

TC : 0

BOT : 0 msec

This window shows Trip Counter and Breaker Operating Time

2.3.5.2 View Contents- Measurement 2 Submenu

MEASUREMENTS

This menu is to view the Measurement 1 & Measurement 2

Measurement 1

Submenu to view measurements related to phase current, earth current,

breaker operation, trip counter and breaker operating time.

Page 59

P50 Agile P253

5 Configuration

P253/EN M/C

5-19

Measurement 2

Submenu to view measurements related to motor :

Thermal State, Load Current, Time to Th Trip, Nb of Th Trip, Last Start

Time, Last St current, Nb Hot st Allow, Nb Cold St Allow, Time to Next

St, Total Nb of Strt, Nb of Emergency Rst, and Motor Run Time.

Thermal State

0 %

This window shows Thermal state o f the motor

Load Current

0 %

This window shows load current value in % (maximum value of three

phase currents in % of IFL setting)

Time to Th Trip

0 S

This window shows Time to Thermal Trip.

Nb of Th Trip

0

This window shows counter for number of Thermal Trip.

Last Start Time

0.00 S

This window shows the duration of the last start.

Last St Current

0.00 A

This window shows the current value of last start.

Nb Hot St Allow

2

This window shows the number of motor hot start allowed

Nb Cold St Allow

3

This window shows the number of motor cold start allowed

Page 60

5 Configuration

P50 Agile P253

5-20

P253/EN M/C

Time to Next St

0 S

This window shows time before permitted start

Total Nb of Strt

0

This window shows the number of starts of the motor

Nb Emergency Rst

0

This window shows number of emergency starts

Motor Run Time

0.000 hrs

This window shows total motor running hours

2.3.6 CB Control Menu

2.3.6.1 View / Edit Settings (if all settings are disabled)

CB CONTROL

Password protected window for “CB CONTROL” settings: TCS Alarm,

TCS Timer, CB Open S’visio n , CB Open Time, CB Open Alarm , C B

Open Oper, CB Control By, Close Plus Time, Open pulse Time and

Emergency Rest.

TCS Al a rm

NO

Editable setting

By using the (+ /5) or (- /6) key, TCS Alarm can be set as Yes / No.

CB Open S’vision

Disabled

Editable setting

By using the (+ /5) or (- /6) key , CB Open Supervision can be

Enabled or Disabled.

CB Open Alarm

Disabled

Editable setting

By using the (+ /5) or (- /6) key, CB Open Alarm can be Enabled or

Disabled.

CB Control by

Disabled

Editable setting

By using the (+ /5) or (- /6) key, CB Control By can be set as

Disabled / Local / Remote / Local + Remote.

Page 61

P50 Agile P253

5 Configuration

P253/EN M/C

5-21

Emergency Rest

No

Editable setting

By using the (+ /5) or (- /6) key, Emergency Restar t can be set as

Yes / No.

2.3.6.2 View / Edit settings (if all settings are enabled)

CB CONTROL

Password protected window for “CB CONTROL” settings:

TCS Alarm, TCS Timer, CB O pen S ’v ision (Enabled/Disabled), CB O pen

Time, CB Open Alarm (Enabled/Disabled), CB Open Oper, CB Control

By, Close Plus Time, Open Pulse Time and Emergency Rest (Yes/No).

TCS Al a rm

Yes

Editable setting

By using the (+ /5) or (- /6) key, TCS Alarm can be set as Yes / No.

TCS Timer

5.00S

Editable setting

By using the (+ /5) or (- /6) key, TCS Timer can be set. The setting

range is from 0.1s to 10s in steps of 10ms.

CB Open S’vision

Enabled

Editable setting

By using the (+ /5) or (- /6) key, CB Open Supervision can be

Enabled or Disabled.

CB Open Time

0.30S

Editable setting

By using the (+ /5) or (- /6) key, CB Open Time can be set. The

setting range is from 50ms to 1s in steps of 10ms

CB Open Alarm

Enabled

Editable setting

By using the (+ /5) or (- /6) key, CB Open Alarm can be Enabled or

Disabled.

CB Open Oper

2000

Editable setting

By using the (+ /5) or (- /6) key, CB Open operations can be set. The

setting range is from 1 to 30000 in steps of 1.

CB Control by

Local + Remote

Editable setting

By using the (+ /5) or (- /6) key, CB Control By can be set as

Disabled/Local/Remote /Local + Remote.

Page 62

5 Configuration

P50 Agile P253

5-22

P253/EN M/C

Close Pulse Time

0.50S

Editable setting

By using the Plus / Up arrow key (+ /5) or the Minus / Down arrow key

(- /6) key, the desired Close Pulse Time can be set. The setting range

is from 0.1s to 50s in steps of 0.01s

Open Pulse Time

0.50S

Editable setting

By using the Plus / Up arrow key (+ /5) or the Minus / Down arrow key

(- /6) key, the desired Open Pulse Time can be set. The setting range

is from 0.1s to 50s in steps of 0.01s

Emergency Rest

Yes

Editable setting

By using the (+ /5) or (- /6), Emergency Restart can be set as Yes /

No

2.3.7 Date and Time Menu

2.3.7.1 Edit Settings (if the settings ar e d isabled)

DATE AND TIME

Password protected window for “DATE AND TIME” settings:

Local Time Enable, Local Time Off set, DST Enable, DST Offset, DST

Start, DST Start Day, DST Start Month, DST Start minutes, DST End,

DST End Day, DST End Month, DST End minutes, RP Tim e Zone, SET

Hours, SET Minutes, SET Seconds, SET Date, SET Month and SET

Year.

Tm: 17:21:50

Dt : 14/11/14 Fri

Read-only

This window shows the set Date & Time

Local Time Enable

Disabled

Editable setting

By using the (+ /5) or (- /6) key, Local Time Enable can be set as

Disabled / Fixed / Flexible.

DST Enable

Disabled

Editable setting

By using the (+ /5) or (- /6) key, DST Enable can be set as

Enabled/Disabled.

RP Time Zone

Local

Editable setting

By using the (+ /5) or (- /6) key, RP Time Zone can be set as Local /

UTC

Page 63

P50 Agile P253

5 Configuration

P253/EN M/C

5-23

SET Hours

17

Editable setting

By using the (+ /5) or (- /6) key, the desired SET Hours can be set.

The setting range is from 00 to 23 in steps of 1.

SET Minutes

21

Editable setting

By using the (+ /5) or (- /6) key, the desired SET Minutes can be set.

The setting range is from 00 to 59 in steps of 1.

SET Seconds

50

Editable setting

By using the (+ /5) (- /6) key, the desired SET Seconds can be set.

The setting range is from 00 to 59 in steps of 1.

SET Date

14

Editable setting

By using the Plus / Up arrow key (+ /5) or the Minus / Down arrow key

(- /6) key, the desired SET Date can be set. The setting range is from 1

to 31 in steps of 1.

SET Month

11

Editable setting

By using the (+ /5) or (- /6) key, the desired SET Month can be set.

The setting range is from 1 to 12 in steps of 1.

SET Year

14

Editable setting

By using the (+ /5) or (- /6) key, the desired SET Year can be set. The

setting range is from 00 to 99 in steps of 1.

2.3.7.2 Edit Settings (if the settings are en abled)

DATE AND TIME

Password protected window for “DATE AND TIME” settings:

Local Time Enable, Local Time Offset, DST Enable, DST Offset, DST

Start, DST Start Day, DST Start Month, DST Start minutes, DST End,

DST End Day, DST End Month, DST End minutes, RP Time Zone, SET

Hours, SET Minutes, SET Seconds, SET Date, SET Month and SET

Year.

Tm: 17:21:50

Dt : 14/11/14 Fri

Read-only

This window shows the set Date & Time

Local Time Enable

Fixed

Editable setting

By using the (+ /5) or (- /6) key, Local Time Enable can be set as

Disabled / Fixed / Flexible.

Page 64

5 Configuration

P50 Agile P253

5-24

P253/EN M/C

Local Time Offset

0 Mins

Editable setting

By using the (+ /5) or (- /6) key, Local Time Offset can be set. The

setting range is from -720 mins to 720 mins in steps of 15 mins

DST Enable

Enabled

Editable setting

By using the (+ /5) or (- /6) key, DST Enable can be

Enabled/Disabled.

DST Offset

60 Mins

Editable setting

By using the (+ /5) or (- /6) key, DST Offset can be set as 30Mins /

60Mins.

DST Start

Last

Editable setting

By using the (+ /5) or (- /6) key, DST Start can be set as First /

Second/ Third / Fourth / Last.

DST Start Day

Sunday

Editable setting

By using the (+ /5) or (- /6) key, DST Start Day can be set from

Sunday to Saturday.

DST Start Month

March

Editable setting

By using the (+ /5) or (- /6) key, DST Start Month can be set from

January to December

DST Start Mins

60 Mins

Editable setting

By using the (+ /5) or (- /6) key, DST Start minutes can be set. The

setting range is from 0 to 1425 mins in steps of 15 mins.

DST End

Last

Editable setting

By using the (+ /5) or (- /6) key, DST End can be set as First /

Second/ Third / Fourth / Last.

DST End Day

Sunday

Editable setting

By using the (+ /5) or (- /6) key, DST End Day can be set from

Sunday to Saturday.

DST End Month

October

Editable setting

By using the (+ /5) or (- /6) key, DST End Month can be set from

January to December

Page 65

P50 Agile P253

5 Configuration

P253/EN M/C

5-25

DST End Mins

60 Mins

Editable setting

By using the (+ /5) or (- /6) key, DST End minutes can be set. The

setting range is from 0 to 1425 mins in steps of 15 mins.

RP Time Zone

Local

Editable setting

By using the (+ /5) or (- /6) key, RP Time Zone can be set as Local /

UTC

SET Hours

17

Editable setting

By using the (+ /5) or (- /6) key, SET Hours can be set from 00 to 23

in steps of 1.

SET Minutes

21

Editable setting

By using the (+ /5) or (- /6) key, SET Minutes can be set. The setting

range is from 00 to 59 in steps of 1.

SET Seconds

50

Editable setting

By using the (+ /5) or (- /6) key, SET Seconds can be set. The setting

range is from 00 to 59 in steps of 1.

SET Date

14

Editable setting

By using the (+ /5) or (- /6) key, SET Date can be set. The setting

range is from 1 to 31 in steps of 1.

SET Month

11

Editable setting

By using the (+ /5) or (- /6) key, SET Month can be set. The setting

range is from 1 to 12 in steps of 1.

SET Year

14

Editable setting

By using the (+ /5) or (- /6) key, SET Year can be set. The setting

range is from 00 to 99 in steps of 1.

Page 66

5 Configuration

P50 Agile P253

5-26

P253/EN M/C

2.3.8 Configuration Menu

2.3.8.1 View / Edit Settings

CONFIGURATION

Password protected window for “CONFIGURATION’’ settings:

Restore Defaults, Active Settings, Copy From, Copy To, Setting Group 1

(Enabled/Disabled), Setting Group 2 (Enabled/Disabled), System Config

(Enabled/Disabled), Overcurrent (Enabled/Disabled), Neg Sequence

O/C (Enabled/Disabled), Earth Fault 1 (Enabled/Disabled), Earth Fault 2

(Enabled/Disabled), Thermal Overload (Enabled/Disabled), Los s of Lo ad

(Enabled/Disabled), CB Fail (Enabled/Disabled), Stall Detection

(Enabled/Disabled), Limit NB Starts (Enabled/Disabled), IFL, Measure’t

Setup, and Setting Values.

Restore Defaults

No Operation

Editable setting

By using the (+ /5) or (- /6) key, Restore Defaults can be set as

No Operation / All Settings / Setting Group 1 / Setting Group 2.

Active Settings

Group 1

Editable setting

By using the (+ /5) or (- /6) key, Active Setting can be set as Group 1

/ Group 2.

Copy From

Group 1

Editable setting

By using the (+ /5) or (- /6) key, Copy From can be set as Group 1 /

Group 2.

Copy To

No Operation

Editable setting

By using the (+ /5) or (- /6) key, Copy To can be set as No Operation

/ Group 1 / Group 2.

Setting Group 1

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Setting Group 1 can be Enabled /

Disabled.

Setting Group 2

Disabled

Editable setting

By using the (+ /5) or (- /6) key, Setting Group 2 can be Enabled /

Disabled.

System Config

Enabled

Editable setting

By using the (+ /5) or (- /6) key, System Configuration can be

Enabled / Disabled.

Page 67

P50 Agile P253

5 Configuration

P253/EN M/C

5-27

Overcurrent

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Overcurrent can be Enabled /

Disabled.

Neg Sequence O/C

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Neg Sequence O/C can be Enabled /

Disabled.

Earth Fault 1

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Earth Fault 1 can be Enabled /

Disabled.

Earth Fault 2

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Earth Fault 2 can be Enabled /

Disabled.

Thermal Overload

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Thermal Overload can be Enabled /

Disabled.

Loss of Load

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Loss of Load can be Enabled /

Disabled.

CB Fail

Enabled

Editable setting

By using the (+ /5) or (- /6) key, CB Fail can be Enabled / Disabled.

Stall Detection

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Stall Detection can be Enabled /

Disabled.

Limit NB Starts

Enabled

Editable setting

By using the (+ /5) or (- /6) key, Limit NB Starts can be Enabled /

Disabled.

IFL

1.00

Editable setting

By using the (+ /5) or (- /6) key, the desired IFL (Full Load Current)

can be set. The setting range is 0.2 In – 4 In step 0.01 In

Page 68

5 Configuration

P50 Agile P253

5-28

P253/EN M/C

Measure’t setup

ABC

Editable setting

By using the (+ /5) or (- /6) key, Measurement Setup can be set as

ABC / RYB.

Setting Values

Secondary

Editable setting

By using the (+ /5) or (- /6) key, Setting Values can be set as Primary

/ Secondary.

2.3.9 Transformer Ratios Menu

2.3.9.1 View / Edit Settings

TRANS. RATIOS

Password protected window for “TRANS. RATIOS settings:

Phase CT Primary, Phase CT Secondary, E/F CT Primary and E/F CT

Secondary.