Page 1

ISO9001:2000

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Instruction Manual

Manual P/N: 1601-0237-A1

Manual Order Code: GEK-113190

Copyright © 2005 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

T

E

S

I

R

E

G

D

E

R

G

E

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

UL # A3775

N

I

M

L

I

U

T

L

Page 2

Page 3

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Table of contents

INTRODUCTION Getting started........................................................................................................1–1

Inspecting the package and product.................................................................................................1–1

Contact information...................................................................................................................................1–1

Document conventions..........................................................................................1–2

Description .....................................................................................................................................................1–2

Glossary...........................................................................................................................................................1–2

About the P485 Modbus to Profibus Converter.................................................1–3

Application......................................................................................................................................................1–3

Features....................................................................................................................1–3

General features..........................................................................................................................................1–3

Modbus network..........................................................................................................................................1–3

Fieldbus interface features .....................................................................................................................1–3

Ordering ...................................................................................................................1–4

Order codes....................................................................................................................................................1–4

Specifications ..........................................................................................................1–4

Mechanical .....................................................................................................................................................1–4

Electrical characteristics..........................................................................................................................1–4

Communications .........................................................................................................................................1–4

Environmental...............................................................................................................................................1–4

EMC compliance ..........................................................................................................................................1–4

INSTALLATION Quick install .............................................................................................................2–1

Procedure........................................................................................................................................................2–1

Electrical installation .............................................................................................2–1

Overview..........................................................................................................................................................2–1

Profibus connector .....................................................................................................................................2–2

Configuration cable....................................................................................................................................2–3

Modbus connector......................................................................................................................................2–4

Power connector .........................................................................................................................................2–4

Mechanical installation .........................................................................................2–5

DIN-rail mounting........................................................................................................................................2–5

Indicators and switches ........................................................................................2–5

Status indicators..........................................................................................................................................2–5

Configuration switches.............................................................................................................................2–6

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE i

Page 4

TABLE OF CONTENTS

Profibus installation procedure ...........................................................................2–7

Profibus configuration tool.....................................................................................................................2–7

Profibus network termination ............................................................................................................... 2–7

Links ..................................................................................................................................................................2–7

Troubleshooting......................................................................................................2–8

dESCRIPTION ................................................................................................................................................. 2–8

DATA EXCHANGE Overview...................................................................................................................3–1

Description.....................................................................................................................................................3–1

Internal memory buffer structure.......................................................................................................3–1

Memory Map............................................................................................................3–2

Memory locations....................................................................................................................................... 3–2

Protocol configuration...........................................................................................3–3

Description.....................................................................................................................................................3–3

Communication mode..............................................................................................................................3–3

Protocol building blocks...........................................................................................................................3–3

SOFTWARE

OVERVIEW

Introduction .............................................................................................................4–1

Description.....................................................................................................................................................4–1

System requirements................................................................................................................................4–1

Installation procedure ...........................................................................................4–1

Description.....................................................................................................................................................4–1

Installing from EnerVista CD ..................................................................................................................4–1

Installing from the GE Multilin website.............................................................................................. 4–1

Using the EnerVista P485/D485 Setup software...............................................4–2

Description.....................................................................................................................................................4–2

Configuration wizard................................................................................................................................. 4–2

Select fieldbus type.................................................................................................................................... 4–3

Sub-network properties ...........................................................................................................................4–4

Device types..................................................................................................................................................4–5

Connecting devices....................................................................................................................................4–7

Selecting parameters for each node ................................................................................................. 4–8

Configuration report.................................................................................................................................. 4–8

Configuration main window .................................................................................4–9

Description.....................................................................................................................................................4–9

Navigation window ................................................................................................................................. 4–10

Parameter window.................................................................................................................................. 4–10

Information window ............................................................................................................................... 4–10

Configuration line indicator ................................................................................................................ 4–10

Options window........................................................................................................................................ 4–11

Fieldbus configuration........................................................................................ 4–11

Description.................................................................................................................................................. 4–11

P485/D485 configuration ................................................................................... 4–12

Parameter window.................................................................................................................................. 4–12

Modbus network configuration......................................................................... 4–13

Overview ...................................................................................................................................................... 4–13

Serial interface settings ........................................................................................................................ 4–13

COMMUNICATION

MODEL

ii P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Introduction .............................................................................................................5–1

Description.....................................................................................................................................................5–1

Scan list............................................................................................................................................................ 5–2

Page 5

TABLE OF CONTENTS

Basic settings ..........................................................................................................5–2

Parameter window .....................................................................................................................................5–2

Communication............................................................................................................................................5–2

Message delimiter.......................................................................................................................................5–2

Nodes ........................................................................................................................5–3

Description .....................................................................................................................................................5–3

Node parameters ........................................................................................................................................5–3

Modbus network menu.............................................................................................................................5–3

Node menu.....................................................................................................................................................5–3

Query parameters ......................................................................................................................................5–4

Response parameters...............................................................................................................................5–5

FRAME AND

COMMAND EDITORS

MODBUS NETWORK

AND NODE

MONITORS

ADVANCED

FUNCTIONS

Frame editor ............................................................................................................6–1

Description .....................................................................................................................................................6–1

Example ...........................................................................................................................................................6–1

Command editor .....................................................................................................6–2

General.............................................................................................................................................................6–2

Specifying a new command ..................................................................................................................6–3

Modbus network monitor......................................................................................7–1

General.............................................................................................................................................................7–1

Operation ........................................................................................................................................................7–2

Node monitor...........................................................................................................7–3

General.............................................................................................................................................................7–3

Operation ........................................................................................................................................................7–3

Control and status registers.................................................................................8–1

Description .....................................................................................................................................................8–1

Control register (Profibus control system to P485)......................................................................8–1

Control codes ................................................................................................................................................8–2

Status register (P485 to fieldbus control system).........................................................................8–2

Status codes ..................................................................................................................................................8–3

Handshaking procedure ..........................................................................................................................8–3

Input/output data during startup .......................................................................8–4

Description .....................................................................................................................................................8–4

Advanced fieldbus configuration.........................................................................8–5

Mailbox command......................................................................................................................................8–5

APPLICATION

EXAMPLE

Introduction.............................................................................................................9–1

Overview..........................................................................................................................................................9–1

Equipment and documents....................................................................................................................9–1

System setup.................................................................................................................................................9–2

Modbus user map setup ........................................................................................9–3

Description .....................................................................................................................................................9–3

PQMII user map............................................................................................................................................9–3

MM2 user map..............................................................................................................................................9–3

System configuration.............................................................................................9–5

Overview..........................................................................................................................................................9–5

Installing the Enervista P485/D485 Setup software ...................................................................9–6

Starting the configuration wizard........................................................................................................9–6

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE iii

Page 6

TABLE OF CONTENTS

Step 1: Selecting the fieldbus type...................................................................................................... 9–6

Step 2: Selecting the sub-network properties ...............................................................................9–7

Step 3: Include device types ..................................................................................................................9–7

Step 4: Connect devices to the sub-network .................................................................................9–9

Step 5: Select parameters for each node ..................................................................................... 9–10

Step 6: Configuration report ............................................................................................................... 9–11

Saving device data.................................................................................................................................. 9–12

Configuring the queries......................................................................................................................... 9–12

Downloading the configuration file................................................................................................. 9–15

Profibus network setup....................................................................................... 9–16

Description.................................................................................................................................................. 9–16

MISCELLANEOUS Revision history.................................................................................................... 10–1

Release dates............................................................................................................................................. 10–1

Changes to the manual ........................................................................................................................ 10–1

Warranty............................................................................................................... 10–1

GE Multilin warranty statement ........................................................................................................ 10–1

iv P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 7

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Chapter 1: Introduction

Introduction

Getting started

INSPECTING THE

PACKAGE AND PRODUCT

CONTACT INFORMATION GE Multilin contact information and call center for product support is shown below:

Examine the shipping container for obvious damage prior to installing this product; notify

the carrier of any damage that you believe occurred during shipment or delivery. Inspect

the contents of this package for any signs of damage and ensure that the items listed

below are included.

Remove the items from the shipping container. Be sure to keep the shipping container

should you need to re-ship the unit at a later date.

In the event there are items missing or damaged, contact the party from whom you

purchased the product. If the unit needs to be returned, please use the original shipping

container, if possible.

GE Multilin

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

• Telephone: 905-294-6222 or 1-800-547-8629 (North America),

+34 94 485 88 00 (Europe)

Fax: 905-201-2098 (North America),

+34 94 485 88 45 (Europe)

• E-mail: multilin.tech@ge.com

•Website: http://www.GEmultilin.com

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 1–1

Page 8

INTRODUCTION

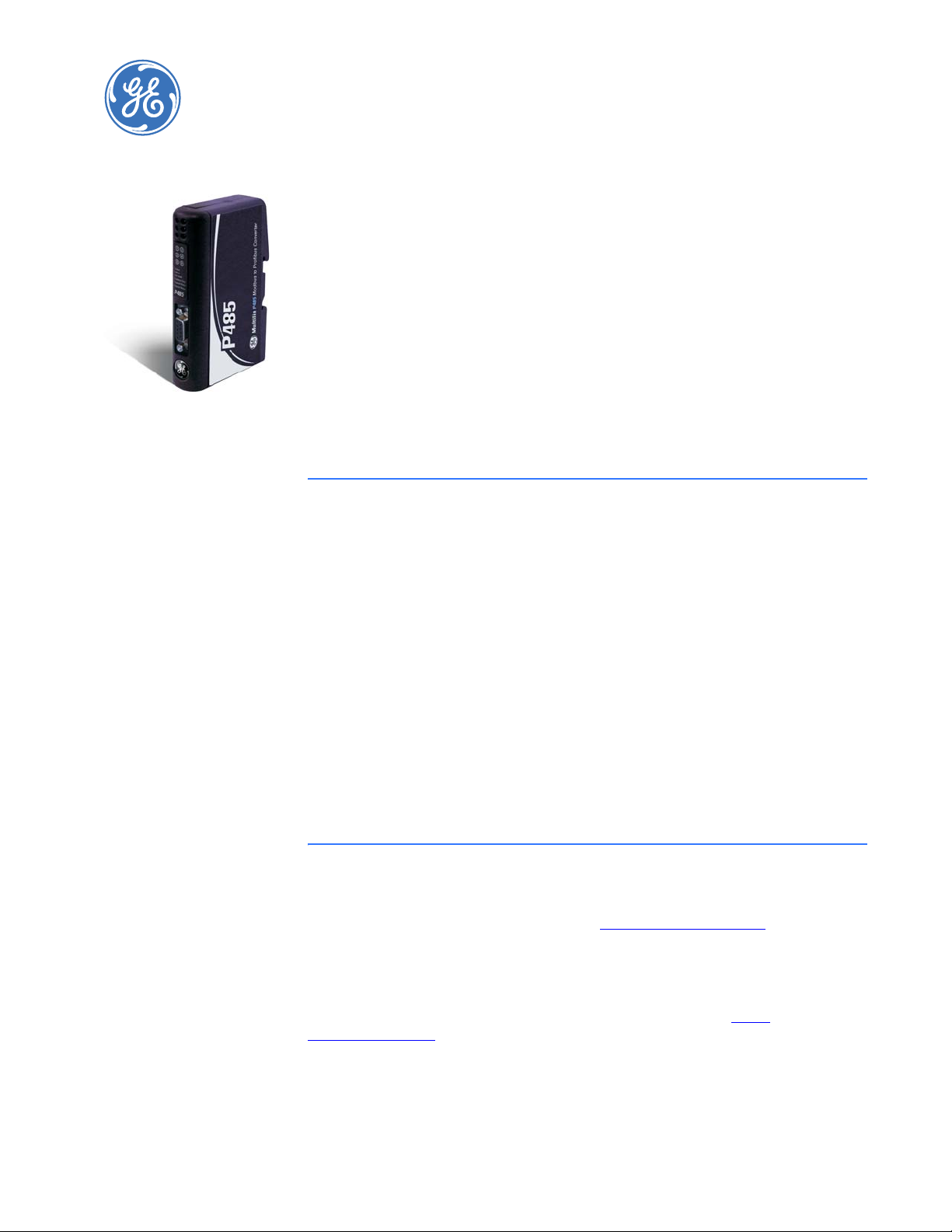

Profibus

master

Slave

GE Multilin

P485 Converter

Slave

Modbus

network

Profibus network

OUT

IN

OUT

IN

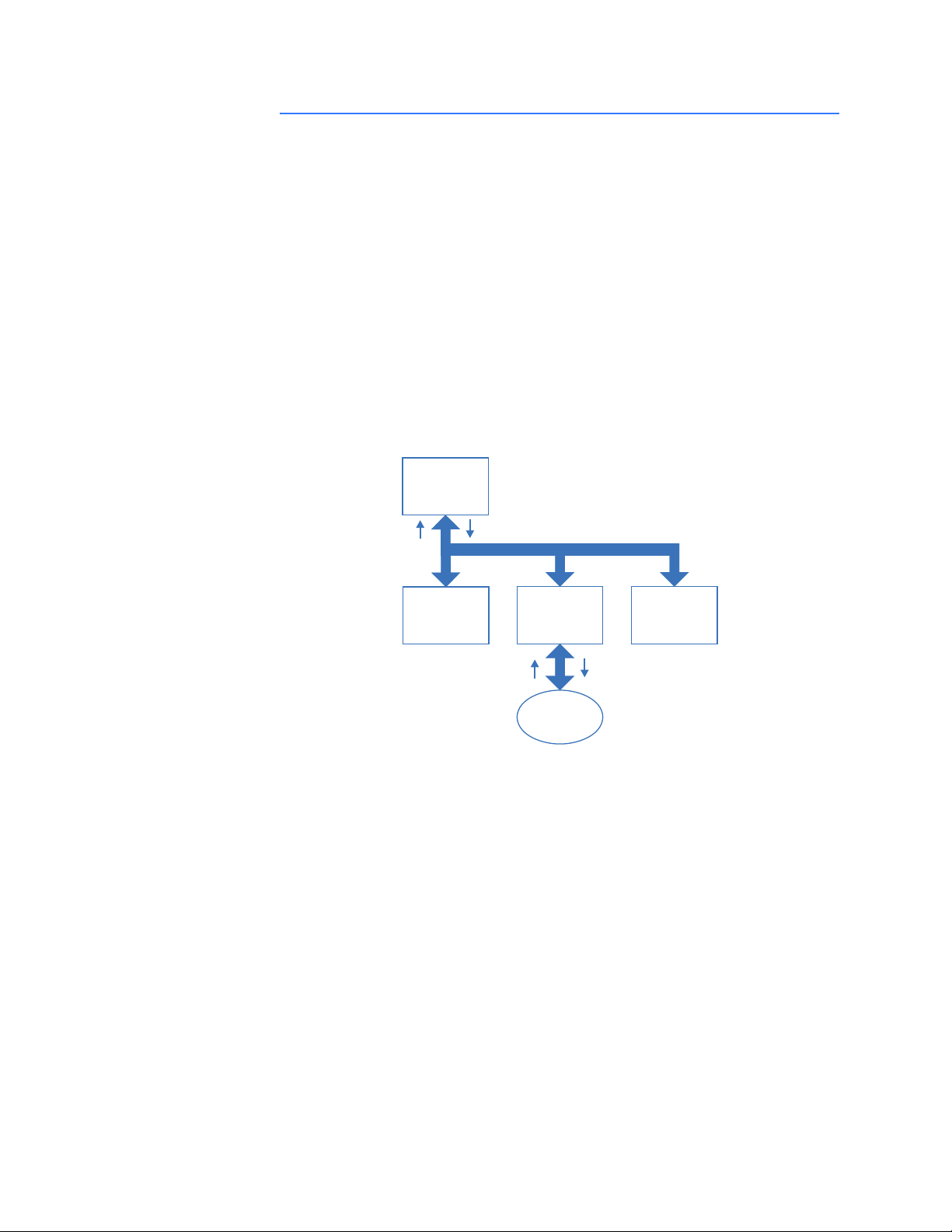

Document conventions

DESCRIPTION The following conventions are used throughout this document:

• Numbered lists provide sequential steps.

• Bulleted lists provide information, not procedural steps.

• The term ‘user’ refers to the person or persons responsible for installing the P485

Modbus to Profibus Converter in a network.

• Hexadecimal values are written in the format 0xNNNN, where NNNN is the

hexadecimal value.

• Decimal values are represented as NNNN, where NNNN is the decimal value.

• As in all communication systems, the terms “input” and “output” can be ambiguous,

since their meaning depends on which end of the link is being referenced. The

convention in this document is that “input” and “output” are always being referenced

to the master/scanner end of the link (see illustration below).

• The term “sub-network” is interchangeably used for “Modbus network”.

Figure 1-1: Input and output definition

GLOSSARY The following terminology is used in the P485 manual:

• Broadcaster: A protocol specific node in the sub-network scan that holds transactions

destined for all nodes.

• Command: A protocol specific transaction.

• Fieldbus: The network to which the converter is connected (Profibus for P485).

• Frame: A higher level series of bytes forming a complete telegram on the sub-network

(Modbus).

• Monitor: A tool for debugging the P485 and network connections.

• Node: A device in the scan list that defines the communication with a slave (GE relay)

on the Modbus sub-network.

• Scan list: List of configured slaves with transactions on the sub-network.

• Sub-network: Modbus network that logically is located on a subsidiary level with

respect to the fieldbus and to which the P485 acts as a gateway.

• Transaction: A generic building block that is used in the sub-network scan list and

1–2 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

defines the data that is sent out the sub-network.

Page 9

INTRODUCTION

Profibus

master (PLC)

HMI

Profibus

slave

Profibus network

P485

PC for configuration

and monitoring

Multi-drop

Multi-node Modbus network

Single-node Modbus network

RS232 port

PC for configuration

and monitoring

Profibus slave

HMI

Profibus

master (PLC)

Profibus network

P485

About the P485 Modbus to Profibus Converter

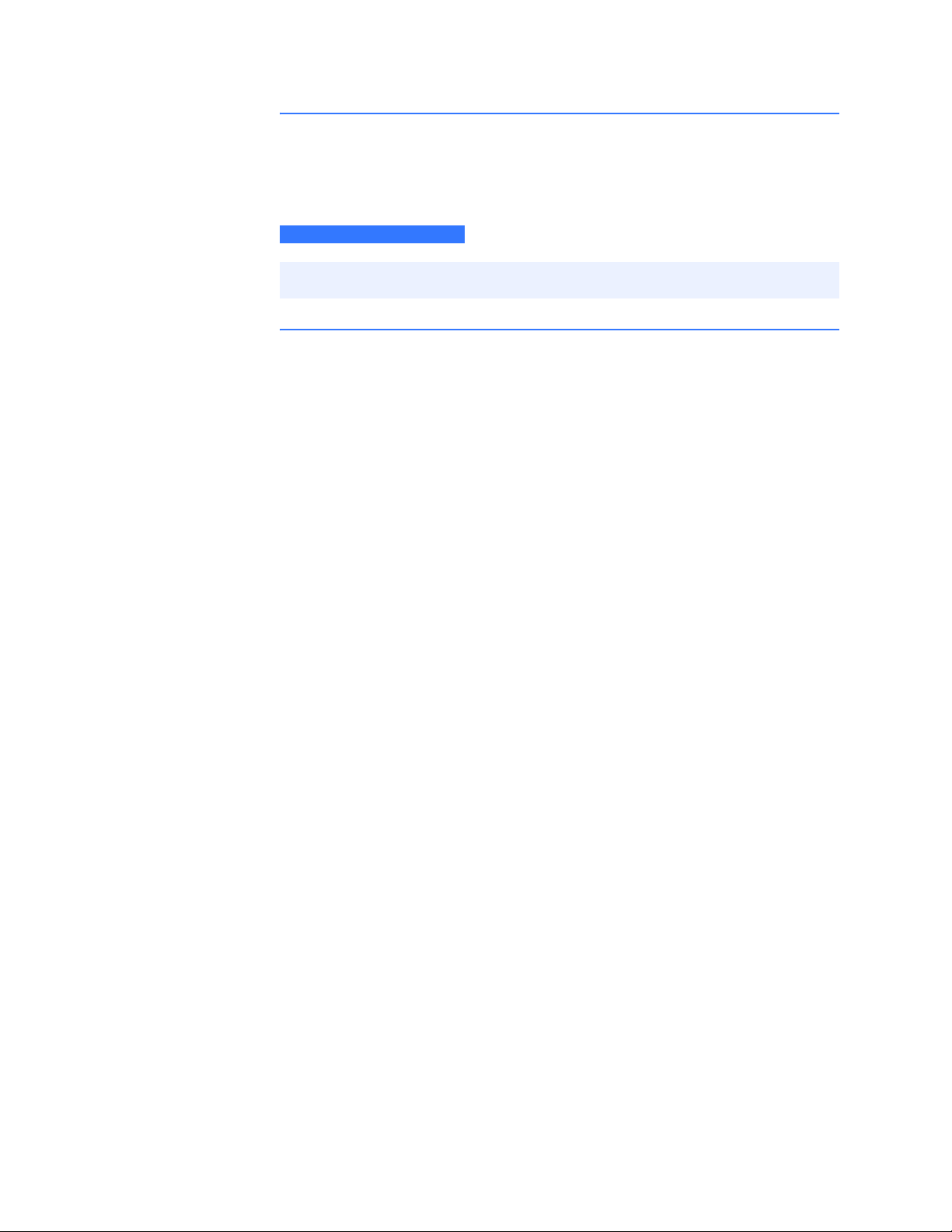

APPLICATION The P485 Modbus to Profibus Converter (or P485) acts as a gateway between the Modbus

protocol and a Profibus-DP network. Integration of industrial devices is enabled without

loss of functionality, control, and reliability, both when retrofitting to existing equipment as

well as when setting up new installations.

GENERAL FEATURES • DIN-rail mountable

MODBUS NETWORK • RS232/RS422/RS485 communications

FIELDBUS INTERFACE

FEATURES

Figure 1-2: Typical applications

Features

• Save/load configuration in flash

•CE, UL, and cUL marked

• Multi-drop or single-node configurations

• Modbus RTU Master mode

• Supports up to 50 commands

• Configuration via EnerVista P485/D485 Setup software

• Complete Profibus-DP slave functionality according to IEC 61158

• Node Address range: 1 to 99 using on board switches

• Baud rate range: 9.6 kbps to 12 Mbps. Auto baud rate detection supported.

• Transmission media: Profibus bus line, type A or B specified in IEC 61158

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 1–3

Page 10

INTRODUCTION

ORDER CODES The following table illustrates the order codes for the P485 Modbus to Profibus Converter.

Ordering

Table 1–1: P485 order codes

P485 – *

Base unit P485 | P485 Modbus to Profibus Converter

C With configuration cable

X No configuration cable

Specifications

MECHANICAL HOUSING

Plastic housing with snap-on connection to DIN-rail, protection class IP20

DIMENSIONS

L x W x H: 120 mm × 75 mm × 27 mm

(4.72-in × 2.95-in × 1.06-in)

PROTECTION CLASS

Protection class: IP20

ELECTRICAL

CHARACTERISTICS

POWER SUPPLY

Power: 24 V ±10% (for use in class 2 circuits)

POWER CONSUMPTION

Maximum power consumption: 280 mA on 24 V

Typically power consumption: approximately 100 mA

COMMUNICATIONS BAUD RATES

Baud rate (Profibus) 9.6, 19.2, 45.45, 93.75, 187.5, and 500 kbps; 1.5, 3, 6, and 12 Mbps

Baud rate (Modbus) 1200, 2400, 4800, 9600, 19200, 38400, and 57600 bps

I/O DATA

I/O input size: 244 bytes

I/O output size: 244 bytes

Total I/O size: 416 bytes

FEATURES AND INTERFACE

Communication profile: Profibus-DP

Supported features: synchronous, freeze, watchdog

Modbus interface: RS232, RS422, RS485

Profibus interface: RS485 (type A or B)

ENVIRONMENTAL RELATIVE HUMIDITY

The product is designed for a relative humidity of 0 to 95% non-condensing

TEMPERATURE

Operating: 0 to 55°C

Non Operating: –5 to 85°C

EMC COMPLIANCE CE-MARK

Certified according to European standards unless otherwise is stated

Emission: according to EN 50081-2:1993

Immunity: according to EN 61000-6-2:1999

UL/C-UL COMPLIANCE

This unit is an open type listed by the Underwriters Laboratories.

The certification has been documented by UL in file E214107.

1–4 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 11

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Chapter 2: Installation

Installation

Quick install

PROCEDURE 1. Snap the P485 on to the DIN-rail (see DIN-rail mounting on page 2–5).

2. Connect the Profibus cable (see Profibus connector on page 2–2).

3. Connect the serial Modbus network cable (see Modbus connector on page 2–4 for

details).

4. Connect a PC using the configuration cable (see Configuration cable on page 2–3).

5. Connect the power cable and apply power to the unit (see Power connector on page

2–4 for details).

6. Start the EnerVista P485/D485 Setup software.

7. Normally, the EnerVista P485/D485 Setup detects the correct serial port. If this does

not occur, select the correct port through the Port menu item.

8. Configure the P485 using EnerVista P485/D485 Setup and download the configuration

to the unit.

9. Configure and power-up the Modbus network device for communication.

Electrical installation

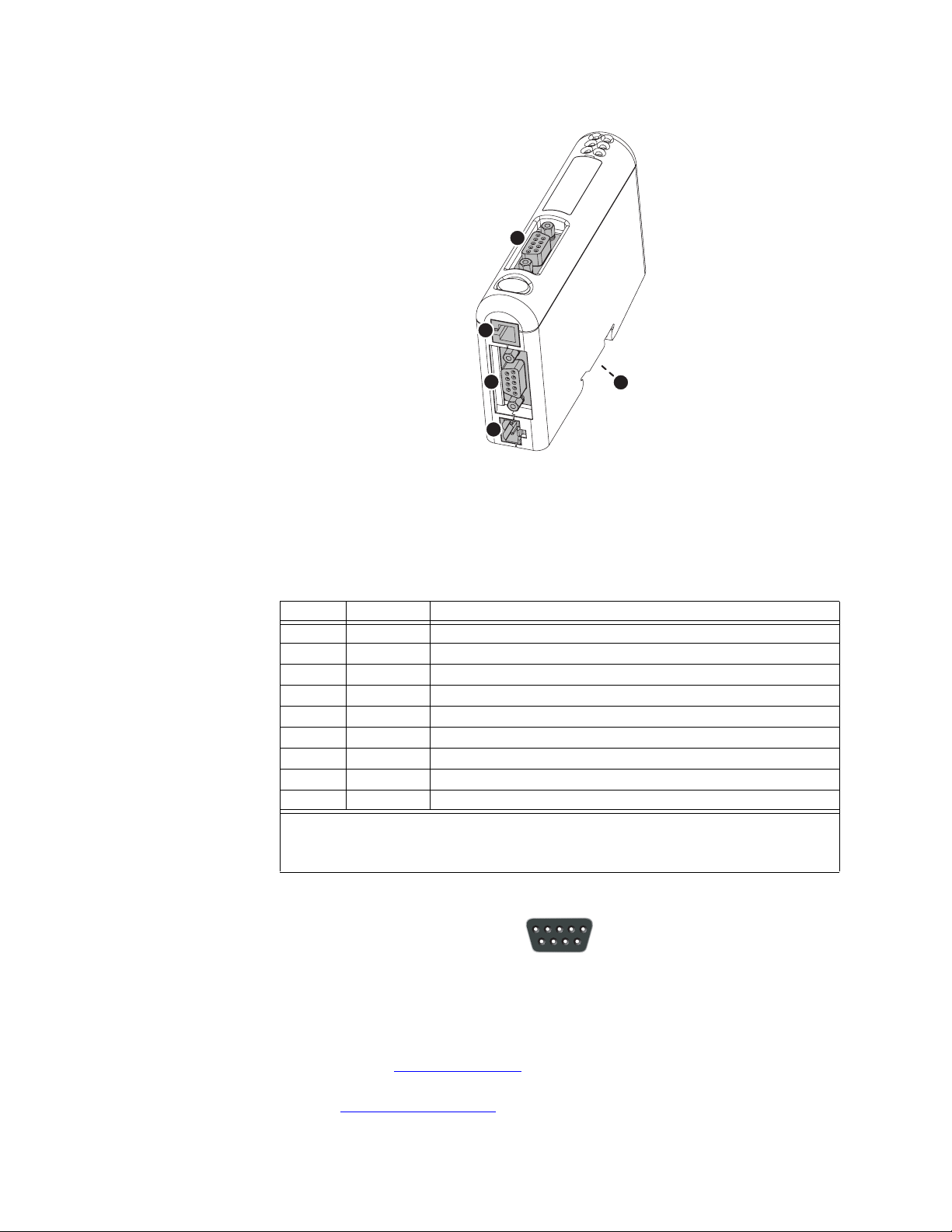

OVERVIEW The location of the various electrical connectors is shown below.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 2–1

Page 12

INSTALLATION

E

A

B

C

D

Figure 2-1: P485 electrical connections

PROFIBUS CONNECTOR The Profibus connector is indicated as A in the figure above. This connector is used to

connect the P485 to the Profibus network.

The pin assignments for the Profibus connector are shown below.

Table 2–1: Profibus connector pin assignments

Pin Signal Description

1- -

2- -

3 B-Line Positive RxD/TxD (RS485)

4 RTS * Request To Send

5 GNDBUS ** Isolated ground from the RS485 side

6 +5 V BUS ** Isolated +5V output from the RS485 side (80 mA maximum)

7- -

8 A-Line Negative RxD/TxD (RS485)

9- -

* Used in some equipment to determine the direction of transmission. However, in normal

applications only A-Line, B-Line and Shield are used.

** Used for bus termination. Some devices such as optical transceivers (RS485 to fibre optics) may

require power from these pins.

51

69

(female)

Figure 2-2: Profibus connector

The following Profibus connectors are recommended:

• Profibus Max standard, part number 134928 and Profibus reversed, part number

104577, from http://www.erni.com

• Fast connect bus connector, part number 6GK1500-0FC00 or 6ES7 972-0BA50-0XA0,

from http://www.siemens.com

2–2 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 13

INSTALLATION

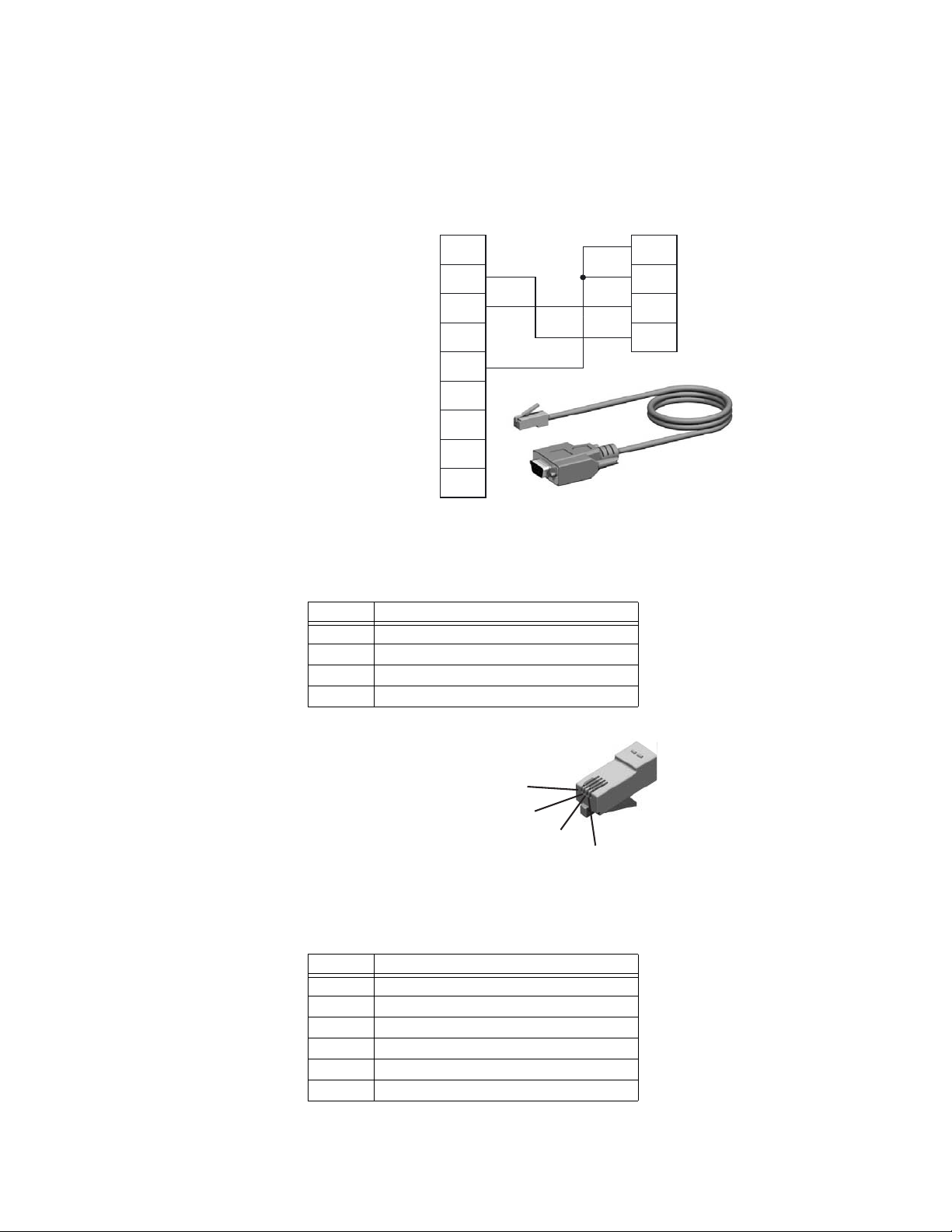

CONFIGURATION CABLE The PC connector is indicated as B in Figure 2-1: P485 electrical connections on page 2–2.

This connector is used to connect the P485 to a PC using the configuration cable for

configuration and monitoring purposes.

A P485/D485 configuration cable can be purchased from GE Multilin. The wiring for the

configuration cable is shown below.

D-sub 9 female (PC) Modular 4/4 RJ11 connector (P485)

RS232 Rx

RS232 Tx

Ground

1

2

3

4

5

6

7

8

9

Connects to P485

Connects to PC serial port

1

Ground

2

Ground

3

Rx

4

Tx

Figure 2-3: Configuration cable

The pinout for the modular 4/4 RJ11 connector (connects to the P485) is shown below.

Table 2–2: Configuration cable pin assignments (P485 end)

Pin Description

1 Signal ground

2 Signal ground

3 RS232 Rx, data input to P485

4 RS232 Tx, data output from P485

4

3

2

1

Figure 2-4: Configuration cable (P485 end)

The pinout for the DSUB 9-pin serial plug (connects to the PC) is shown below.

Table 2–3: Configuration cable pin assignments (PC end)

Pin Description

1 Not connected

2 RS232 Rx, data input to PC

3 RS232 Tx, data output from PC

4 Not connected

5 Ground

6 to 9 Not connected

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 2–3

Page 14

INSTALLATION

51

69

(female)

Figure 2-5: Configuration cable (PC end)

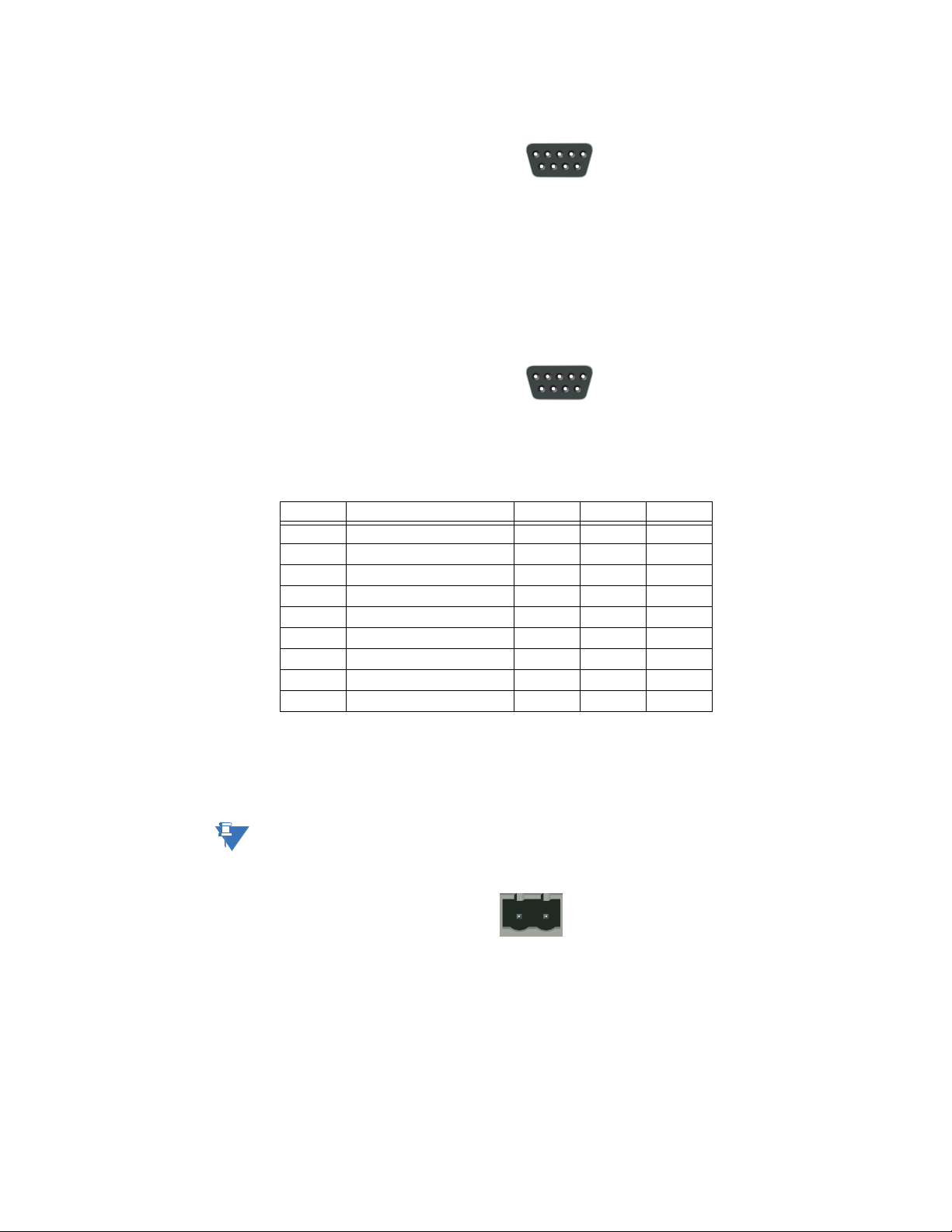

MODBUS CONNECTOR The Modbus connector is indicated as C in Figure 2-1: P485 electrical connections on page

2–2. This connector is used to connect the P485 to the serial network. Based on the

configuration selected in the EnerVista P485/D485 Setup software, the corresponding

signals are activated.

51

69

(female)

Figure 2-6: Modbus connector

Table 2–4: Modbus connector pin assignments

Pin Description RS232 RS422 RS485

1 +5 V output (50 mA max)

2 RS232 Rx 3

3 RS232 Tx 3

4 Not connected

5 Ground 333

6 RS422 Rx + 3

7 RS422 Rx – 3

8 RS485 + / RS422 Tx+ 33

9 RS485 – / RS422 Tx– 33

2–4 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

POWER CONNECTOR The power connector is indicated as D in Figure 2-1: P485 electrical connections on page

2–2. Use this connector to apply power to the P485.

Pin 1: +24 V DC;

Pin 2: ground

Use 60/75 or 75°C copper (CU) wire only. The terminal tightening torque must be between

5 to 7 lbs-in (0.5 to 0.8 nm).

NOTE

12

Figure 2-7: Power connector

Page 15

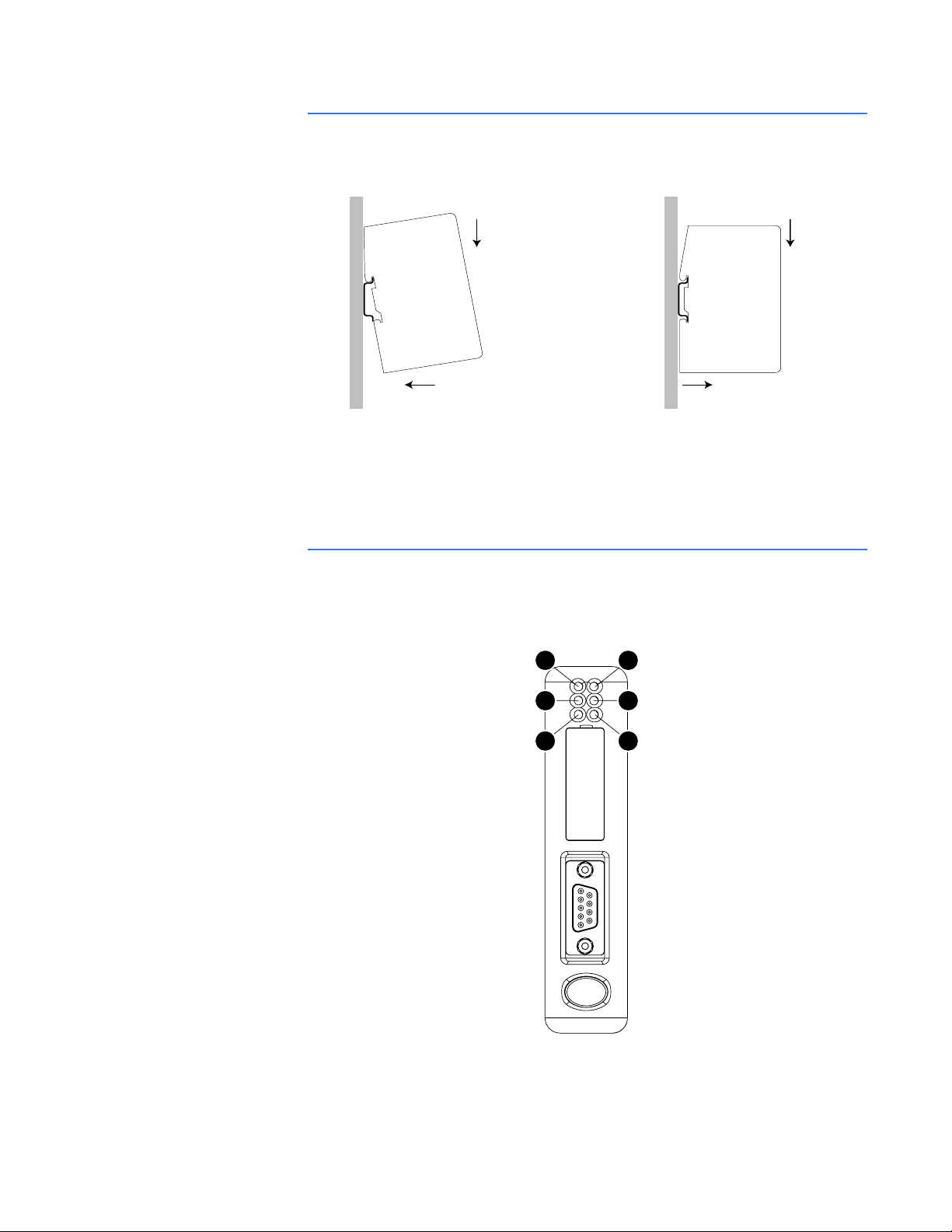

Mechanical installation

DIN-RAIL MOUNTING The DIN-rail connector is internally connected to the P485.

ON OFF

Figure 2-8: Mounting the P485 to the DIN-rail

To snap the P485 on, first press the P485 downwards (1) to compress the spring on the DINrail connector, then push the P485 against the DIN-rail as to make it snap on (2)

To snap the P485 off, push the P485 downwards (1) and pull it out from the DIN-rail (2), as to

make it snap off from the DIN-rail.

INSTALLATION

11

22

Indicators and switches

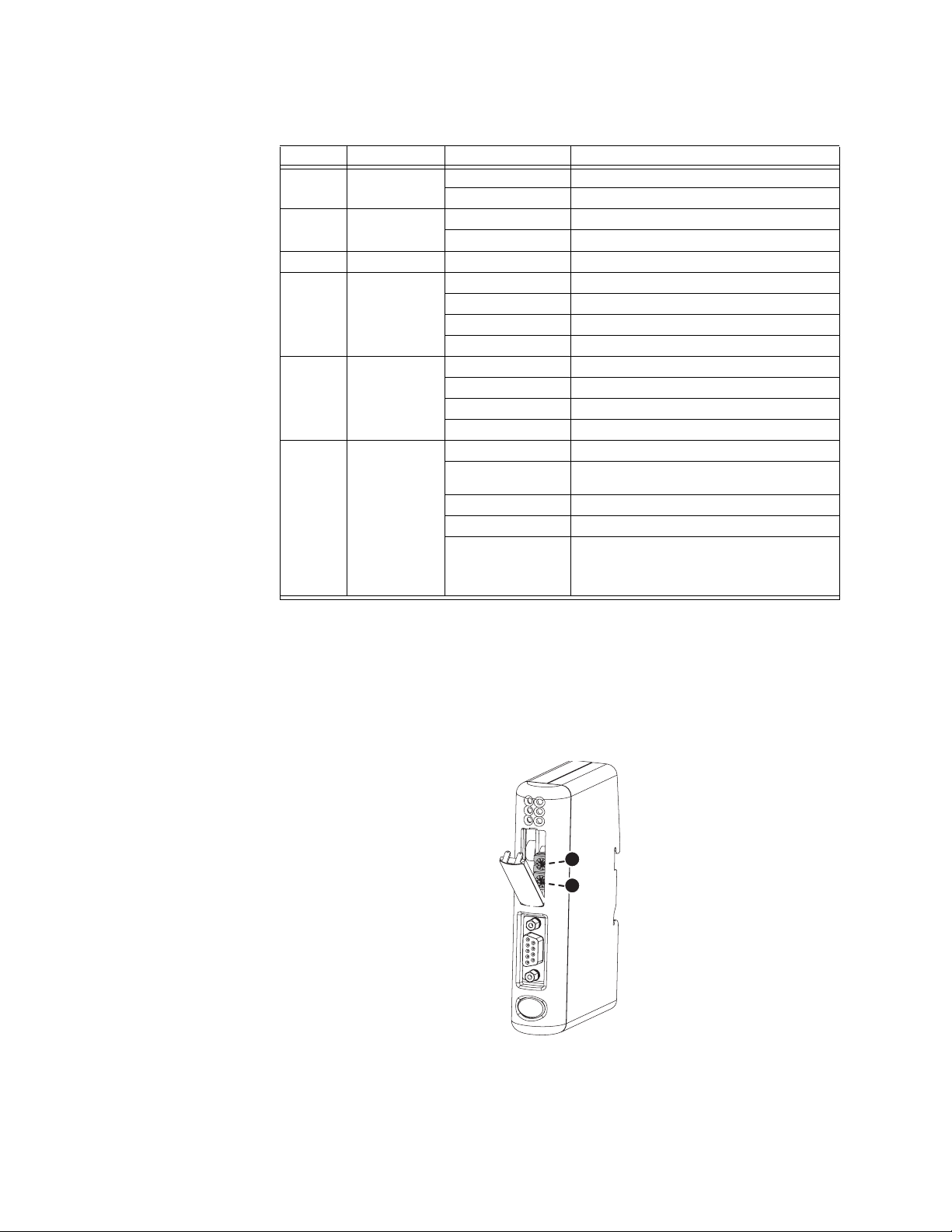

STATUS INDICATORS The status indicators for the P485 Modbus to Profibus Converter are indicated below.

1

3

5

2

4

6

Figure 2-9: P485 status indicators

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 2–5

Page 16

INSTALLATION

Table 2–5: P485 status indicators

Number Description State Status

1 Profibus online Off Not online

Green Online

2 Profibus offline Off Not offline

Red Offline

3Not used- -

4Profibus

diagnostics

5 Subnet status *

(Modbus)

6 Device status Off Power off

* This LED turns green when all transactions have been active at least once. This includes any

transactions using “change of state” or “change of state on trigger”. If a timeout occurs on a

transaction, this LED will turn red.

Off No diagnostics present

Red, flashing 1 Hz Error in configuration

Red, flashing 2 Hz Error in user parameter data

Red, flashing 4 Hz Error in initialisation

Off Power off

Green, flashing Initializing and not running

Green Running

Red Stopped or subnet error, or timeout

Alternating Red/

Green

Green Initializing

Green, flashing Running

Red, flashing If the device status LED is flashing in a

Invalid or missing configuration

sequence starting with one or more red

flashes, note the sequence pattern and

contact GE Multilin

CONFIGURATION

SWITCHES

The configuration switches are used to set the Profibus node address. Normally, these

switches are covered by a plastic hatch. Note that the node address can not be changed

during runtime, i.e. the P485 requires a reset for any changes to have effect. Recycle the

power supply to reset the module

A

B

Figure 2-10: P485 configuration switches

The node address is configured using two rotary switches as follows:

Profibus node address = (Switch B× 10) + (Switch A × 1)

2–6 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 17

NOTE

INSTALLATION

For example, to set the node address to 42, set switch A to “2” and switch B to “4”.

When removing the hatch, avoid touching the circuit boards and components. Exercise

caution when using tools to open the hatch.

Profibus installation procedure

PROFIBUS

CONFIGURATION TOOL

Each device on a Profibus-DP network is associated with a GSD file, which contains all

necessary information about the device. This file is used by the Profibus configuration tool

during configuration of the network. The file is available for download at the GE Multilin

website at http://www.GEmultilin.com

(the GSD file is named ‘P48509E5.GSD’).

It is necessary to import the GSD file in the Profibus configuration tool in order to

incorporate the P485 as a slave in the network. The properties for the P485 must then be

configured from the Profibus configuration tool. This includes setting up the node address,

input/output data areas and offset address.

• Node address: The node address in the Profibus configuration tool should be set to

match the one selected using the on board configuration switches of the P485 (see

Configuration switches on page 2–6).

• Setting up input/output data areas: Input/output data are arranged as logic modules

in the Profibus configuration tool. Which modules to use depends on the application.

The modules are composed together in the “module list” for the P485 device.

It is possible to select modules freely to compose the required input/output sizes, see

example below.

Input/output bytes required Modules

4 inputs and 2 outputs 4 inputs + 2 outputs

7 inputs and 12 outputs 4 inputs + 2 inputs + 1 input + 8 outputs + 4 outputs

68 inputs 64 inputs + 4 inputs

• Offset address: The offset addresses can be chosen freely. However, certain

restrictions may apply depending on what PLC/Profibus master is used.

PROFIBUS NETWORK

TERMINATION

If the P485 is the last node on a Profibus segment, it is necessary to use a Profibus

connector with integrated termination switch.

• The termination switch should be set to ‘ON’ if...

– The P485 is the last physical node on a network segment

– No other termination is used at this end of the network

• The termination switch should be set to ‘OFF’ if...

– There are other nodes on either side of the P485 in the network segment

LINKS Additional information about the Profibus fieldbus system can be found at http://

www.profibus.com.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 2–7

Page 18

INSTALLATION

Troubleshooting

DESCRIPTION Problem during configuration upload/download. The Config Line LED turns red.

• Serial communication failed – try again.

The serial port seems to be available, but it is not possible to connect to the P485.

• The serial port may be in use by another application. Exit EnerVista P485/D485 Setup

and close all other applications including the ones in the system tray and try again.

• Select another serial port and try again.

Poor performance.

• Right click ‘Modbus Network’ in the Navigation window and select ‘Modbus Network

Status’ to see status/diagnostic information about the Modbus network. If the P485

reports very many re-transmissions, check your cabling and / or try a lower baud rate

setting for the sub network (if possible).

• Is the Modbus Network Monitor in EnerVista P485/D485 Setup active? The Modbus

network monitor has a negative influence on the overall performance of the P485, and

should only be used when necessary.

• Is the Node Monitor in EnerVista P485/D485 Setup active? The node monitor has a

negative influence on the overall performance of the P485, and should only be used

when necessary.

2–8 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 19

GE Consumer & Industrial

Internal Memory Buffer

Output data

(up to 244 bytes)

Input data

(up to 244 bytes)

Sub Network

Fieldbus

General data

1024 bytes

P485 Modbus to Profibus

Converter

Chapter 3: Data exchange

Data exchange

Overview

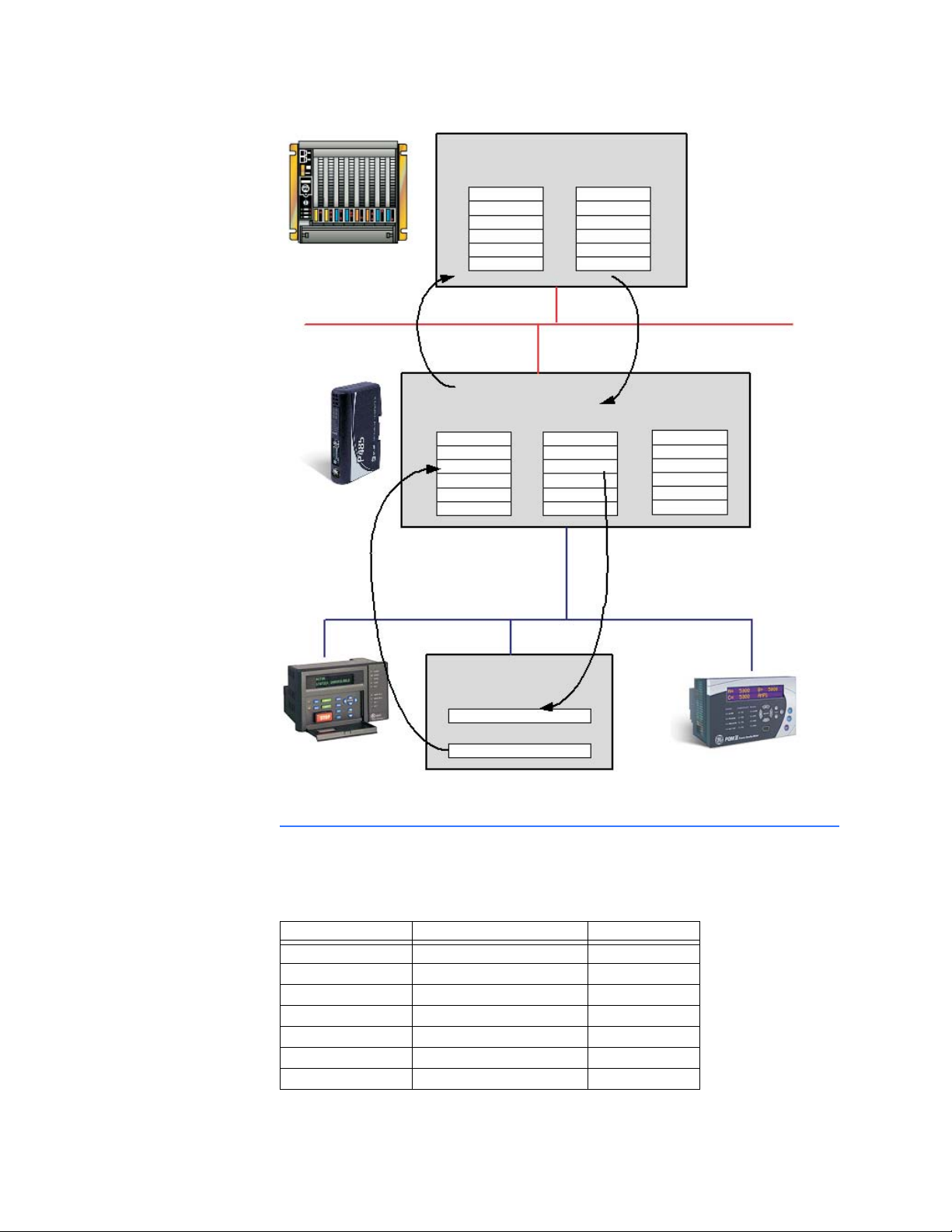

DESCRIPTION Data from the fieldbus (Profibus) and the sub network (Modbus) is stored in an internal

memory buffer. This is a easy method for data exchange where the fieldbus control

system simply reads and writes data to pre-defined memory locations, and the serial sub

network also use the same internal memory buffer to read and write data. Refer to Figure

3-2: Data exchange overview on page 3–2 for details.

INTERNAL MEMORY

BUFFER STRUCTURE

The internal memory buffer can be seen as a memory space with three different types of

data; input data, output data and general data.

• Input data: This is data that should be sent to the fieldbus. The P485 can handle up to

244 bytes of input data. The total input/output data must not exceed 416 bytes.

• Output data: this is data recieved from the fieldbus. The P485 can handle up to 244

bytes of output data.

• General data: This data cannot be accessed from the fieldbus, and is used for

transfers between nodes on the sub-network, or as a general “scratch pad” for data.

The P485 can handle up to 1024 bytes of general data.

Figure 3-1: Internal memory buffer

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 3–1

Page 20

DATA EXCHANGE

PLC memory

The PLC exchanges data

via the Profibus network

between its internal input

area and the input area

of the P485

I/O inputs

Current Ia

Profibus network

Internal memory buffer

of the P485

Input data area Output data area General data area

0x0000 0x0200 0x0400

Current Ia CT PRIMARY

The data in the input area of

the P485 contains data received

from nodes on the Modbus

sub-network (sent in to the P485

from the sub-network)

Modbus sub-network

I/O outputs

CT PRIMARY

The data in the output area of

the P485 contains data received

from Profibus. In this case, it is

the CT PRIMARY setting of the

PQMII meter.

The PLC exchanges data

via the Profibus network

between its internal output

area and the output area

of the P485

Modbus slave (e.g. PQMII)

CT PRIMARY setting

Current Ia actual value

Figure 3-2: Data exchange overview

Memory Map

MEMORY LOCATIONS When configuring the sub-network, use the memory locations shown below:

Address Contents Access

0x0000 to 0x0001 Status register read/write

0x0002 to 0x00F3 Input data area read/write

0x00F4 to 0x01FF Reserved -

0x0200 to 0x0201 Control register read only

0x0202 to 0x02F3 Output data area read only

0x02F4 to 0x03FF Reserved -

0x0400 to 0x7FF General data area read/write

3–2 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 21

DATA EXCHANGE

Node

Transaction

Transaction

Message frame

Byte

Word Data CRC Byte

Frame objects

Message frame

Byte Word Data CRC Byte

Frame objects

Message frame

Byte

Word Data CRC Byte

Frame objects

• Status register (0x0000 to 0x0001): If enabled, this register occupies the first two

bytes in the input data area. For more information, see Control and status registers on

page 8–1.

• Input data area (0x002 to 0x00F3): This area holds data that should be sent to the

fieldbus (see the status and control registers).

• Control register (0x0200 to 0x0201): If enabled, these register occupies the first two

bytes in the output data area. For more information, see Control and status registers

on page 8–1.

• Output data area (0x200 to 0x2F3): This area holds data received from the fieldbus.

Data cannot be written to this area.

• General data Area (0x0400 to 0x7FF): This data cannot be accessed from the fieldbus,

and should be used for transfers between nodes on the sub-network, or as a general

“scratch pad” for data.

Protocol configuration

DESCRIPTION In order to be able to communicate on the Modbus sub-network, the P485 must be

supplied with a description of the required sub-net protocol. To accomplish this, the

EnerVista P485/D485 Setup software features a flexible protocol-programming system,

allowing the P485 to interpret and exchange data with almost any serial device on the

Modbus sub-network.

COMMUNICATION MODE The P485 supports the Modbus Master communication mode. In this mode, the P485 is

setup to use the Modbus RTU protocol and implements a Modbus master for data

exchange between the fieldbus and one or more devices on the sub-network. Refer to

Chapter 5 for additional details.

PROTOCOL BUILDING

A description of the building blocks used to describe the sub-net protocol is shown below.

BLOCKS

Figure 3-3: Modbus protocol blocks

• Node: In the P485, a node holds all transactions and parameters for a particular

device on the sub network.

• Transaction: Transactions contains messages to be transmitted on the sub-network.

A transaction consists of one or more message frames (see figure above), and has a

few general parameters to specify how and when the transaction should be used on

the sub-network.

• Commands: A command is a pre-defined transaction that has been stored in a list in

the EnerVista P485/D485 Setup software. This improves readability as well as

simplifying common operations by allowing transactions to be stored and reused.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 3–3

Page 22

DATA EXCHANGE

• Message frame: The message frame contains a description of what is actually

transmitted on the sub-network and consists of frame objects (see figure above).

• Frame object: Frame objects are used to compose a message frame. Frame objects

include fixed values, dynamic values retrieved from a specified memory location in the

P485, or strings.

3–4 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 23

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Chapter 4: Software overview

Software overvie w

Introduction

DESCRIPTION EnerVista P485/D485 Setup is a PC-based configuration software used to describe the

protocol and communication properties for a serial network. When the configuration is

finished and the functionality is tested, it is possible to send memory allocation information

to a printer using EnerVista P485/D485 Setup.

EnerVista P485/D485 Setup can also be used for troubleshooting and diagnostic of the

P485 and the serial network during runtime.

SYSTEM REQUIREMENTS The following hardware and software is required to use the EnerVista P485/D485 Setup

software.

• Pentium 133 MHz or higher

• 10 MB of free space on the hard drive

•8 MB RAM

• Windows 95/98/NT/2000/XP

• Internet Explorer 4.01 SP1 or higher

Installation procedure

DESCRIPTION There are two different ways of installing EnerVista P485/D485 Setup; either via the GE

EnerVista CD or from the GE Multilin website at http://www.GEmultilin.com.

INSTALLING FROM

ENERVISTA CD

INSTALLING FROM THE

GE MULTILIN WEBSITE

Run ‘setup.exe’ and follow the on screen instructions

Download the self-extracting EXE file from the GE Multilin website at http://

www.GEmultilin.com.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–1

Page 24

SOFTWARE OVERVIEW

DESCRIPTION When creating a new sub network configuration, EnerVista P485/D485 Setup provides a

NOTE

Using the EnerVista P485/D485 Setup software

choice between starting out with a blank configuration, or using a predefined template

(configuration wizard).

• Configuration Wizard: The wizard option automatically creates a configuration based on information about the sub-network (Modbus) devices; that is, the user simply has to “fill in the blanks”.

• Blank Configuration: This option should be used when creating a new configuration

when the configuration wizard does not fit the application or to modify an existing

configuration for a new application. The following chapters will describe the

configuration process in detail.

It is recommended to use the configuration wizard for its simplicity of use with GE relays

and meters.

The online help system explains each configuration step in detail.

CONFIGURATION

WIZARD

The purpose of the configuration wizard is to help you through the process of creating a

project with a Modbus RTU sub-network. When the wizard is finished, it is possible to

continue editing the project in the configuration tool.

The EnerVista P485/D485 Setup software will open with following screen to select the

configuration.

Select Configuration Wizard and click on OK.

4–2 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 25

SOFTWARE OVERVIEW

Sub-Network (Modbus)

PC for configuration

and Monitoring

Fieldbus Network (P rofibus or DeviceNet)

Fieldbus

Master (PLC)

HMI

Fieldbus

Slave

GE Converter

(P485 or D485)

GE Relays & Meters

SELECT FIELDBUS TYPE The first step in the configuration wizard selects the fieldbus type. The fieldbus is the higher

layer network that communicates with the serial device(s) on the modbus sub-network via

the P485 converter.

Select “Profibus-DP” then click Next to continue. A typical Profibus-DP network

arrangement is shown below.

Figure 4-1: Typical network arrangement

In the event the wizard cannot handle the specific Modbus command(s) required by the

device, use the regular configuration tool or modify the commands produced by the

NOTE

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–3

wizard using the regular configuration tool.

Page 26

SOFTWARE OVERVIEW

SUB-NETWORK

PROPERTIES

NOTE

The second step in the configuration wizard selects the properties for the Modbus subnetwork. The data flow for the sub-network is shown below.

Fieldbus

Master

Fieldbus

Data Direction

In Out

Modbus

Sub-Network

GE

Converter

Figure 4-2: Sub-network data flow

Refer to the particular sub-network device manual(s) to determine the appropriate settings

and communication options. If multiple devices are being installed on the same subnetwork, they must be configurable for a common set of communication parameters.

All numerical values are entered and shown in decimal unless otherwise specified.

The sub-network properties window is shown below.

• Physical standard: The physical standard can be either RS232, RS485, or RS422.

RS232 is a point-to-point communication standard; that is, it is only possible to have one

sub-network node (Modbus device) connected to the P485 converter when using RS232.

RS232 supports a maximum cable length of 15 meters and is full duplex. It uses two signal

lines (Rx and Tx) and the signal is measured relative to ground.

RS485 is a common multi-drop communication standard. It is used with larger cable

distances with one or several sub-network nodes (Modbus devices) connected. RS485

supports a maximum of 31 nodes, with half duplex and a total cable length up to 1200

meters. It uses two signal lines (A-line and B-line, twisted pair) with the signal being

measured between the two lines.

RS422 is a common multi-drop communication standard. It is used with larger cable

distances with one or several sub-network nodes connected. RS422 supports a maximum

of 31 nodes, with full duplex and a total cable length up to 1200 meters. It uses four signal

lines (receive A1-B1 and transmit A2-B2, twisted pair) with the signals being measured

between the two signal lines A and B.

• Bitrate (bits/s): This parameters refers to the speed of the sub-network. Speeds are

1200 to 57600 bps in predefined steps. The bitrate is also referred to as baud rate.

4–4 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 27

SOFTWARE OVERVIEW

• Parity: The parity can be selected as "Odd", "Even", or "None". This is a simple error

check method capable of detecting single bit communication errors on a serial

network (i.e. the sub-network).

• Data bits: There can be "7" or "8" data bits. Generally, 8 data bits are used. This

parameter determines how many bits per byte of user data that is transmitted on the

sub-network, excluding start, stop and parity bits.

• Stop bits: There can be "1" or "2" stop bits. Determines the number of stop bits at the

end of each byte sent on the sub-network.

DEVICE TYPES The third step in the configuration wizard introduces device types into the project and

configures their parameters. Every device must be unique. Predefined devices can be

loaded from a file, and it is possible to connect devices to the sub-network at a later step in

the wizard. Additional devices can be created by editing previously saved devices.

The device types window is shown below.

The Modbus address range, including bit areas and register areas (words), is shown below.

The Modbus commands are also shown for the corresponding memory areas. Note that

many device manuals ignore the leading digit of the address (i.e. 0, 1, 3 or 4); as such, the

address 40001 is often referred to as 0001. The leading digit can be determined from the

Modbus command specified.

Address Command

0x Output coil (bits) 00001 to 09999 #1 (decimal): Read coil status

1x Inputs status (bits) 10001 to 19999 #2 (decimal): Read input status

3x Input status (word) 30001 to 39999 #4 (decimal): Read input registers

4x Output (word) 40001 to 49999 #3 (decimal): Read holding registers

#15 (decimal): Force multiple cells

#16 (decimal) Preset multiple registers

Users should consult the instruction manuals of the various network devices to determine

the actual Modbus command code(s) implemented or required. This will determine the

implied leading digit of the data address (i.e. 0, 1, 3 or 4).

In most GE Multilin relay and meter documentation, Modbus addresses are indicated in

hexadecimal form. For the Modicon format used for the P485, convert the hex address to

decimal, add 1, then append a prefix of 1, 2, 3, or 4, depending on the type of register. For

example, to convert the input register hexadecimal address 0x0300, we have:

1. 0300h = 0768 decimal

2. 0768 decimal + 1 = 0769 decimal

3. change 0769 → 30769 (prefix “3” for input registers)

Therefore, a Modbus hex address of 0x0300 is 30769 in Modicon format.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–5

Page 28

SOFTWARE OVERVIEW

NOTE

The wizard can accept memory addresses from 0 to 9999 (0x270F). For higher memory

addresses, please use the protocol building blocks (refer to Protocol building blocks on

page 3–3 for additional details).

The Create Device button creates a new empty device. A new Device tab will be created.

The new device can be named in the Device Name text box. The Remove Device button

removes the selected device.

The Load Device button opens the “open file” dialog box. Select a previously stored device

to include it into the project. Device files (extension D01) for the most commonly used GE

relays and meters are supplied with the EnerVista P485/D485 Setup software.

The Save Device button opens the “save device” dialog box. To create similar devices, click

on Save Device to save a particular device parameter list, then click Load Device to

recover a duplicate of the device. The duplicate device should be renamed and then

modified as required. Devices can also be saved for a use at a later stage. All parameters

and address settings are stored in the device file.

The Device tab shows the name of the device and the active node. The tab “in front” of the

other tabs is the active one. The active device's parameters are shown in the parameter list

below the tab list.

The Device Name is typically the technical name or designation of a device found on the

devices name plate. Examples are “MM2”, “469” and “PQMII”. Do not confuse the device

name with the node name, which is entered at a later stage. The node name is typically a

name that is used to identify the device in your application. Examples are “Lube Pump 1”,

“Production feeder” and “Main transformer”.

The Create Parameter button adds a new parameter to the parameter list. The loaded

device from previously saved devices can be modified for a new parameter or change in

the settings of the parameters. The Remove Parameter button removes the selected

parameter from the parameter list. To select a parameter simply click the desired

parameter in the list. Use the scroll bar to move the list up and down. Click the desired

parameter and enter the desired Parameter Name. It is recommended that you enter a

unique name here. Examples are “Phase A Current Ia”, “Voltage Vab”, and “VT ratio”.

The Data Direction column shows if data is read from or written to the device. The P485

converter is the one who reads or writes. It is only possible to read input data; output data

can be both read or written. Refer to Figure 4-2: Sub-network data flow on page 4–4 for

details.

The Register column is where the Modbus register number for the for the parameter in the

device is entered. Only register addresses can be entered here (the register address is the

absolute address +1). Most device manuals contain the register address but some may

provide an absolute address in hexadecimal format. In case absolute addresses are given,

the address must be incremented by 1. If the address range covers multiple coils, inputs, or

registers, only the start address is entered.

The Length column is where the total length of the parameter data is entered. The length is

given in bits for the 0x and 1xxxx areas and in words for the 3xxxx and 4xxxx areas. If the

parameter data for a device on the sub-network are linearly addressable, then

consecutive parameters may be addressed using a single Modbus command from the

P485. For example, five parameters each 2 words long can be addressed using a single

Modbus command (#16 Preset Multiple Registers) with a total length of 10 (5 × 2). Reducing

the number of transactions initiated by the P485 will optimize communications on the

Modbus sub-network.

The Type column shows the type of data that is referenced for the respective parameter.

Possible entries are bit(s) and word(s). This is automatically entered by the wizard based on

the selected address and selected direction.

4–6 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 29

SOFTWARE OVERVIEW

The Modbus Command column shows the Modbus command assigned by the wizard. The

Modbus command is automatically selected by the wizard based on the selected address

and direction.

CONNECTING DEVICES The fourth step in the configuration wizard connects one or more devices to the sub-

network. Devices on a sub-network are also known as nodes (Modbus slave devices) and

are the actual nodes that will be physically connected to the Modbus sub-network. It is

possible to connect devices of the same device type more than once. The created nodes

will be listed to the left.

The Node window is shown below:

The Create Node button adds a new node (Modbus slave) to the sub-network. A new row

will be added to the node list to the left. The Remove Node button to remove the selected

node. Select a node in the node list by clicking on the desired node.

When a new node is created, the wizard assigns it a default name. Enter the desired node

name in the Node Name column. The node name is typically a name that identifies the

device in your application. Examples are “Lube pump1”, “Production Feeder” and “Main

transformer “. Do not confuse the node name with the device name assigned at an earlier

stage – the device name is typically the technical name or designation of a device found

on the devices name plate (for example, “MM2”, “SR469” and “PQMII”).

Enter the Modbus slave address of the sub-network node in the Slave Address column. The

wizard automatically assigns a default address which can be changed as needed. The

node address must match the slave address setting of the device you are connecting. If

you only connect one node, this address setting might be irrelevant, depending on the

operation of the device.

The Device Type column is where previously configured devices are connected to the subnetwork. If you click a row in the device column, a list will appear containing all previously

configured device(s). Select the desired device from this list.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–7

Page 30

SOFTWARE OVERVIEW

SELECTING PARAMETERS

FOR EACH NODE

The fifth step in the configuration wizard selects the parameters that shall be mapped to

the Fieldbus Network. All previously configured parameters will appear at this point,

including parameters saved to a file. All previously configured nodes will appear in the

horizontal Node tab list in the upper left of the configuration wizard. Select the All

Parameters tab to view the complete list of parameters.

The Node tab in the foreground displays the active node. The number within brackets at

the end of the node name is the node Modbus slave address (1 to 255) on the sub-network.

Clicking a specific tab will display the parameters currently mapped to this node address.

For example, for “Lube Pump 1[1]”, the name of the node is “Lube Pump 1” and its slave

address is 1.

The All Parameters tab displays all parameters in the same list. This provides an overview

of data transmitted on the sub-network. It is also possible to add or remove parameters on

configured nodes in this list by using the Add Parameter or Remove Parameter buttons.

The Add Parameter button adds a new parameter to the selected node. The Remove

Parameter button remove the selected parameter from the selected node.

The Parameter Name column displays the user-assigned parameter name. When a new

parameter is inserted, it is named by the software as “Not Configured”. A list of available

parameters will appear when the you click the row. Select the desired parameter by

clicking on it in the list.

CONFIGURATION

REPORT

The sixth and final step in the configuration wizard displays a summary of the

configuration entries. This includes all configured devices, their parameters, and how they

are mapped to the internal memory of the P485. This report can be saved in rich text (RTF)

format or sent to a printer.

4–8 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 31

SOFTWARE OVERVIEW

If the Sub-net Overview button is pressed, a new window will appears that graphically

displays how the data is mapped to the internal memory of the P485.

Configuration main window

DESCRIPTION The main window is shown below. It is composed of the navigation window, parameter

window, information window, and configuration line indicator.

A

B

C

D

Figure 4-3: Configurator main window

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–9

Page 32

SOFTWARE OVERVIEW

NAVIGATION WINDOW The navigation window in EnerVista P485/D485 Setup is the main tool for selecting the

different levels of the configuration. There are three main levels in the navigation window,

namely fieldbus, P485, and Modbus network.

Menu entries preceded by a plus symbol (+) contain more configuration parameters or

sub-menus. To gain access to these parameters, the entry must be expanded by clicking

the ‘+’ symbol.

By right-clicking entries in this window, a popup menu with functions related to this entry

will appear. The options in this popup menu is often also available in the menu bar.

PARAMETER WINDOW The parameters available in this window is different depending on what is selected in the

navigation window. It consists of a grid with parameter names and, on the same row, a

field for editing.

The parameters can be displayed in two modes: alphabetic and categorized. Parameter

values are entered either using selection box or by entering a value. Values can be entered

either in decimal form (for example, 35) or in hexadecimal form (for example, 0x1A).

If a value is entered in decimal format, it will be converted automatically to the equivalent

hexadecimal value.

INFORMATION WINDOW In the right bottom corner of EnerVista P485/D485 Setup, below the parameter window,

lies the information window. It contains descriptions of currently marked parameter

instances.

Figure 4-4: Information window

CONFIGURATION LINE

INDICATOR

In the lower-right corner of the main window, two lights indicate if a connection has been

established between the PC running EnerVista P485/D485 Setup and P485. A green light

indicates that the connection is OK, and a red light indicates no connection.

4–10 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 33

OPTIONS WINDOW In the main window under tools, select options.

Table 4–1: Options window functions

Function Description

Warning on delete When something is to be deleted, a warning window will appear.

Warning on unsaved

data

Show Wizard when

“New” menu is selected

Language next time the

program is launched

Size of log buffer Set the size of the log buffer (0 to 512 bytes).

Firmware download Download the firmware to the

Factory restore Restores the software on the P485 carrier board, to it´s original state.

Block configuration Use with caution. When this button is pressed, the configuration will

Create error log Creates an error log file.

When closing EnerVista P485/D485 Setup with unsaved data, a

warning window will appear.

Each time a new configuration is to be made, the Wizard window will

appear.

Select which language the program should use the next time the

program is launched. Presently, only English is supported.

not be accessible and a new configuration has to be downloaded to

the module.

Fieldbus configuration

SOFTWARE OVERVIEW

P485. Use with caution.

DESCRIPTION During start-up, the fieldbus interface is initialized to fit the configuration created in the

EnerVista P485/D485 Setup software. Since EnerVista P485/D485 Setup supports both the

P485 and D485 converters, the user must verify that the 'Fieldbus' parameter indicates the

correct converter. Additionally, it is possible for advanced users to customize the network

interface inside the converter to meet specific application demands (see Advanced fieldbus

configuration on page 8–5 for details).

Figure 4-5: Fieldbus configuration

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–11

Page 34

SOFTWARE OVERVIEW

P485/D485 configuration

PARAMETER WINDOW By selecting 'P485/D485 ' in the Navigation window, basic configuration options for the

sub-net will appear in the Parameter window.

Figure 4-6: P485/D485 configuration

• Physical interface: Currently, the P485 supports only a serial interface. The

communication settings for the selected interface are available under 'Modbus

Network (see Serial interface settings on page 4–13 for details).

• Control/status byte: This parameter is used to enable/disable the control/status

registers (see Control and status registers on page 8–1 for details).

– Enable: enable control/status registers. The “Data Valid” parameter (bit 13 in the

control register) must be set by the fieldbus control system to start the sub

network communication.

– Disable: Disables control/status registers.

– Enable but no start up lock: The control/status registers are enabled, but the

fieldbus control system is not required to set the “Data Valid” parameter (bit 13 in

the control register).

• Module Reset: This parameter defines how the module should behave in the event of

a fatal error. If Enabled, the module will reset and restart on a fatal error event, and no

error will be indicated to the user. If Disabled, the module will halt and indicate an error.

• Protocol: The P485 supports Modbus RTU master mode.

• Statistics: If enabled, the receive counter location indicates the number of valid

messages received from the subnet. If enabled, the transmit counter location

indicates the number of messages sent to the sub network. This function is used

primarily for debugging purposes.

4–12 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 35

SOFTWARE OVERVIEW

Modbus network configuration

OVERVIEW When controlling a Modbus sub-network with the P485 it is important to understand

functions during starting up. If the P485 starts scanning nodes on the sub-network, before

data is received from the fieldbus control system (fieldbus master), values of ‘00’ may be

transmitted to the nodes before data is updated the first time from the fieldbus.

See Input/output data during startup on page 8–4 for information on how to block

transactions until valid data is received.

SERIAL INTERFACE

SETTINGS

To be able to communicate on the Modbus network, various communication settings

needs to be configured. To gain access to these settings, select ‘Modbus Network’ in the

Navigation window.

Parameter Description Range

Bit rate Selects the bit rate. 1200 to 57600

Data bits Selects the number of data bits. 7, 8

Parity Selects the parity. None, Odd, Even

Physical standard Selects the physical standard. This setting

activates the corresponding signals on the subnet

connector.

Start bits Only one start bit is supported. 1

Stop bits Either one or two stop bits can be selected. 1, 2

RS232, RS422, RS485

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 4–13

Page 36

SOFTWARE OVERVIEW

4–14 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 37

GE Consumer & Industrial

P485 Modbus to Profibus

Converter

Chapter 5: Communication model

Communicatio n model

Introduction

DESCRIPTION In master mode, the P485 is configured to run as a master on the Modbus sub-network,

using a scan-list for communication with the Modbus slave devices. The scan-list is created

using EnerVista P485/D485 Setup and can consist of multiple nodes with multiple

transactions.

Communications between the P485 and the sub-net nodes (Modbus slaves) is based on

transactions with a query/response architecture. The P485 sends out a query on the

Modbus sub-network, and the addressed node is expected to send a response to this

query. Slave nodes are not allowed to respond without first receiving a query.

An exception to this is broadcaster functionality. Most protocols offer some way of

accessing all network nodes. In the P485, this is called a ‘broadcaster’. The broadcaster can

transmit messages to all nodes on the sub-network without expecting a response.

In Modbus, it is possible to broadcast a message to all nodes by sending a message to

node address 0. The Modbus slaves will receive the message, but not Respond to it.

P485

Query

Response

Broadcast

Fieldbus Master

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 5–1

Fieldbus slave

and

Modbus master

Figure 5-1: Master mode overview

Query

Response

Query

Response

Modbus devicesPLC

Node 1

(Modbus Slave)

Node 2

(Modbus Slave)

Page 38

COMMUNICATION MODEL

SCAN LIST Once the configuration has been downloaded to the P485, the P485 firmware searches the

The P485 uses pre-configured Modbus RTU commands, acting as a Modbus RTU master.

With Modbus RTU, each transaction is substituted with a pre-defined command that can

be selected from a list of available commands.

It is still possible, though, to define custom message frames by creating a transaction

instead of selecting a pre-defined command. A command is actually a transaction that has

been defined in advance and stored in a list.

scan-list, using the defined transactions for communication with the slave-devices.

Each node in the scan-list represents a slave device on the Modbus network. In EnerVista

P485/D485 Setup, each node is given a specific name and assigned an address in standard

Modbus RTU commands. The address must match the internal setting on the slave device.

Figure 5-2: P485 scan list

Basic settings

PARAMETER WINDOW Select ‘Modbus Network’ in the Navigation window to gain access to basic settings in the

Parameter window.

Figure 5-3: Parameter window

COMMUNICATION Refer to Serial interface settings on page 4–13 for details.

MESSAGE DELIMITER The message delimiter value is the minimum time in steps of 10 ms separating the

messages. According to the Modbus specification, the message delimiter has a default

setting of 3.5 characters.If this value is set to “0”, the P485 will use the Modbus standard 3.5

character message delimiter. The time in milliseconds is then dependent on the selected

baud rate, but this is all handled by the P485.

Due to its impact on subnet functionality, use caution when changing this parameter.

NOTE

5–2 P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE

Page 39

COMMUNICATION MODEL

Nodes

DESCRIPTION A node in the EnerVista P485/D485 Setup software represents a device on the Modbus

sub-network. In it’s simplest form, a Node contains of a single transaction, that consists of

a Query and a Response.

NODE PARAMETERS To gain access to these parameters, select the desired node in the navigation window.

• Slave address: This setting shall be set to match the Modbus address setting of the

destination device.

• Name: Node Name. This name will appear in the navigation window.

MODBUS NETWORK

MENU

NODE MENU Right-click on a node in the Navigation window to gain access to these functions.

Right-click “Modbus Network” in the Navigation window to gain access to these functions.

Figure 5-4: Modbus network menu

• Paste: Paste a node from the clipboard.

• Modbus Network Monitor: Launches the Modbus network monitor. Refer to Modbus

network monitor on page 7–1 for details.

• Add Node: Adds a node to the scanlist.

• Add Broadcaster: Adds a broadcaster node to the scanlist.

• Load Node: Loads a node previously saved using “Save Node” from the Node menu

(see details below).

• Modbus Network Status: Displays status/diagnostic information about the Modbus

network.

Figure 5-5: Node menu

• Cut: Cuts a node to the clipboard.

• Copy: Copies a node to the clipboard.

P485 MODBUS TO PROFIBUS CONVERTER – USER GUIDE 5–3

Page 40

COMMUNICATION MODEL

• Insert: Insert a node from the clipboard.

• Delete: Deletes a node and its configuration from the scan list.

• Monitor: Activates the node monitor.

• Add command: Adds a pre-defined protocol specific command to the scan list. The list