Page 1

GE Energy Connections

Grid Solutions

MiCOM P40 Agile

P442, P444

Technical Manual

Numerical Distance Protection Relay

Hardware version: M

Publication reference: P44x/EN M/Hb6

Software version: 72

Page 2

Page 3

TD

IT

ST

GS

AP

PL

MR

FD

CM

MT

SC

SG

IN

CS

TS

VH

CONTENTS

Section 1 Introduction P44x/EN IT/Hb6

Section 2 Technical Data P44x/EN TD/Hb6

Section 3 Getting Started P44x/EN GS/Hb6

Section 4 Settings P44x/EN ST/Hb6

Section 5 Application Notes P44x/EN AP/Hb6

Section 6 Programmable Logic P44x/EN PL/Hb6

Section 7 Measurements and Recording P44x/EN MR/Hb6

Section 8 Firmware Design P44x/EN FD/Hb6

Section 9 Commissioning P44x/EN CM/Hb6

Section 10 Maintenance P44x/EN MT/Hb6

Section 11 Troubleshooting P44x/EN TS/Ha6

Section 12 SCADA Communications P44x/EN SC/Hb6

Section 13 Symbols and Glossary P44x/EN SG/Hb6

Section 14 Installation P44x/EN IN/Hb6

Section 15 Cyber Security P44x/EN CS/Hb6

Section 16 Firmware and Service Manual Version History P44x/EN VH/Hb6

Page 4

Page 5

Safety Section P44x/EN SS/H11

SAFETY SECTION

Page 6

P44x/EN SS/H11 Safety Section

Page 7

Safety Section P44x/EN SS/H11

(SS) - 1

CONTENTS

1. INTRODUCTION 3

2. HEALTH AND SAFETY 3

3. SYMBOLS AND EXTERNAL LABELS ON THE EQUIPMENT 4

3.1 Symbols 4

3.2 Labels 4

4. INSTALLING, COMMISSIONING AND SERVICING 4

5. DE-COMMISSIONING AND DISPOSAL 7

6. TECHNICAL SPECIFICATIONS FOR SAFETY 7

6.1 Protective fuse rating 7

6.2 Protective class 7

6.3 Installation category 7

6.4 Environment 8

Page 8

P44x/EN SS/H11 Safety Section

(SS) - 2

Page 9

Safety Section P44x/EN SS/H11

(SS) - 3

STANDARD SAFETY STATEMENTS AND EXTERNAL LABEL INFORMATION

FOR ALSTOM GRID EQUIPMENT

1. INTRODUCTION

This Safety Section and the relevant equipment documentation provide full information on

safe handling, commissioning and testing of this equipment. This Safety Section also

includes reference to typical equipment label markings.

The technical data in this Safety Section is typical only, see the technical data section of the

relevant equipment documentation for data specific to a particular equipment.

Before carrying out any work on the equipment the user should be familiar with

the contents of this Safety Section and the ratings on the equipment’s rating

label.

Reference should be made to the external connection diagram before the equipment is

installed, commissioned or serviced.

Language specific, self-adhesive User Interface labels are provided in a bag for some

equipment.

2. HEALTH AND SAFETY

The information in the Safety Section of the equipment documentation is intended to ensure

that equipment is properly installed and handled in order to maintain it in a safe condition.

It is assumed that everyone who will be associated with the equipment will be familiar with

the contents of this Safety Section, or the Safety Guide (SFTY/4L M).

When electrical equipment is in operation, dangerou s voltages will be present in certain parts

of the equipment. Failure to observe warning notices, incorrect use, or improper use may

endanger personnel and equipment and also cause personal injury or physical damage.

Before working in the terminal strip area, the equipment must be isolated.

Proper and safe operation of the equipment depends on appropriate shipping and handling,

proper storage, installation and commissioning, and on careful operation, maintenance and

servicing. For this reason only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

Are familiar with the installation, commissioning, and operation of the equipment and of

the system to which it is being connected;

Are able to safely perform switching operations in accordance with accepted safety

engineering practices and are authorized to energize and de-energize equipment and to

isolate, ground, and label it;

Are trained in the care and use of safety apparatus in accordance with safety

engineering practices;

Are trained in emergency procedures (first aid).

The equipment documentation gives instructions for its installation, commissioning, and

operation. However, the manuals cannot cover all conceivable circumstances or include

detailed information on all topics. In the event of questions or specific problems, do not take

any action without proper authorization. Contact the appropriate Alstom Grid technical sales

office and request the necessary information.

Page 10

P44x/EN SS/H11 Safety Section

(SS) - 4

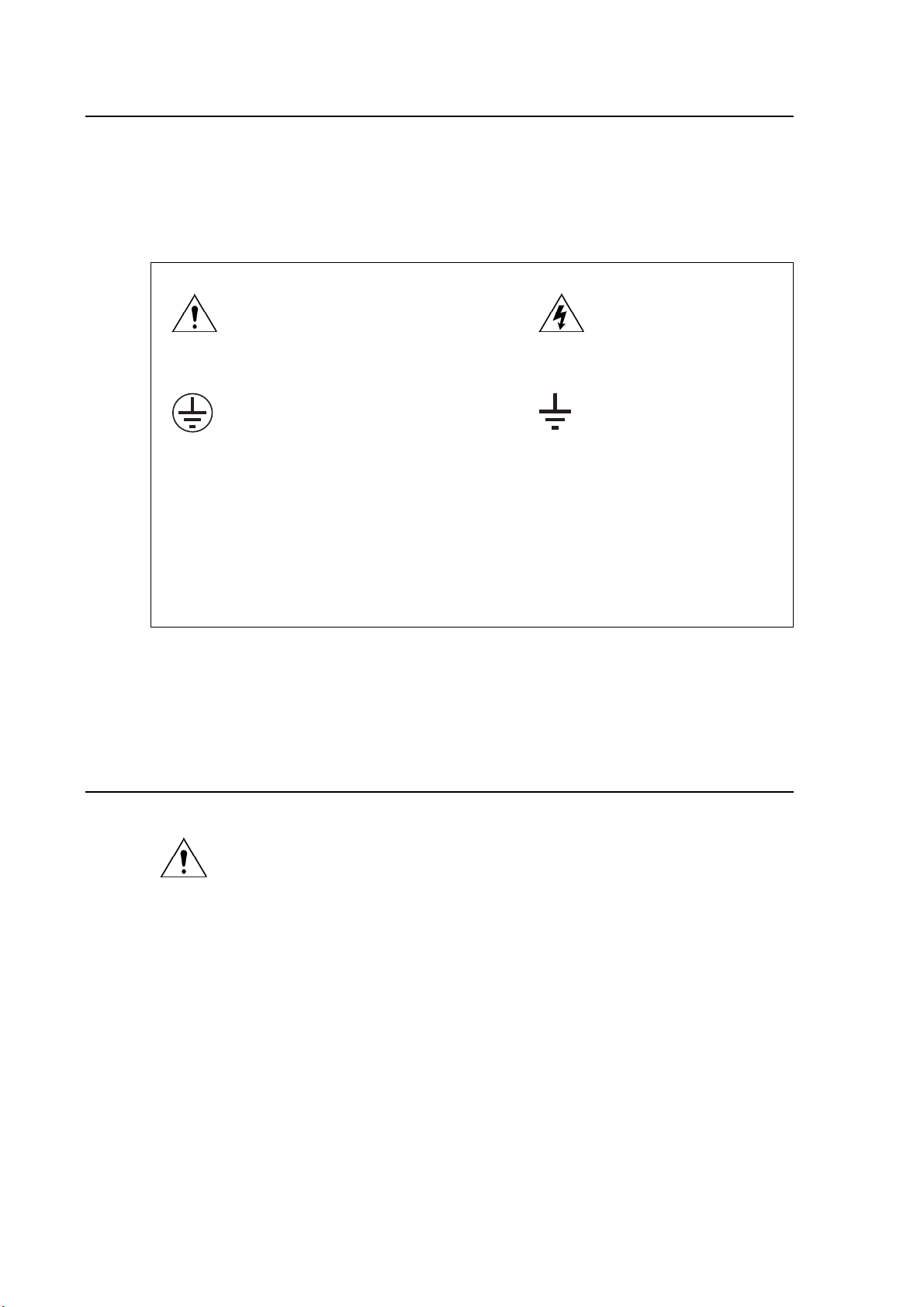

3. SYMBOLS AND LABELS ON THE EQUIPMENT

For safety reasons the following symbols which may be used on the equipment or referred to

in the equipment documentation, should be understood before it is installed or

commissioned.

3.1 Symbols

Cautio

Protective Conductor (*Earth) terminal

3.2 Labels

n: refer to equipment documentation

*NOTE: THE TERM EARTH USED THROUGHOUT THIS TECHNICAL

MANUAL IS THE DIRECT EQUIVALENT OF THE NORTH

AMERICAN TERM GROUND.

Caution: risk of electric shock

Functional/Protective Conductor

(*Earth) terminal.

Note: This symbol may also be used

for a Protective Conductor

(Earth) Terminal if that

terminal is part of a terminal

block or sub-assembly e.g.

power supply.

See Safety Guide (SFTY/4

L M) for typical equipment labeling information.

4. INSTALLING, COMMISSIONING AND SERVICING

Equipment connections

Personnel undertaking installation, commissioning or servicing work for this

equipment should be aware of the correct working procedures to ensure safety.

The equipment documentation should be consulted before installing,

commissioning, or servicing the equipment.

Terminals exposed during installation, commissioning and maintenance may

present a hazardous voltage unless the equipment is electrically isolated.

The clamping screws of all terminal block connectors, for field wiring, using M4

screws shall be tightened to a nominal torque of 1.3 Nm.

Equipment intended for rack or panel mounting is for use on a flat surface of a

Type 1 enclosure, as defined by Underwriters Laboratories (UL).

Any disassembly of the equipment may expose parts at hazardous voltage, also

electronic parts may be damaged if suitable electrostatic voltage discharge (ESD)

precautions are not taken.

If there is unlocked access to the rear of the equipment, care should be taken by

all personnel to avoid electric shock or energy hazards.

Voltage and current connections shall be made using insulated crimp terminations

to ensure that terminal block insulation requirements are maintained for safety.

Page 11

Safety Section P44x/EN SS/H11

(SS) - 5

Watchdog (self-monitoring) contacts are provided in numerical relays to indicate

the health of the device. Alstom Grid strongly recommends that these contacts

are hardwired into the substation's automation system, for alarm purposes.

To ensure that wires are correctly terminated the correct crimp terminal and tool

for the wire size should be used.

The equipment must be connected in accordance with the appropriate connection

diagram.

Protection Class I Equipment

- Before energizing the equipment it must be earthed using the protective

conductor terminal, if provided, or the appropriate termination of the

supply plug in the case of plug connected equipment.

- The protective conductor (earth) connection must not be removed since

the protection against electric shock provided by the equipment would be

lost.

- When the protective (earth) conductor terminal (PCT) is also used to

terminate cable screens, etc., it is essential that the integrity of the

protective (earth) conductor is checked after the addition or removal of

such functional earth connections. For M4 stud PCTs the integrity of the

protective (earth) connections should be ensured by use of a locknut or

similar.

The recommended minimum protective conductor (earth) wire size is 2.5 mm²

(3.3 mm² for North America) unless otherwise stated in the technical data section

of the equipment documentation, or otherwise required by local or country wiring

regulations.

The protective conductor (earth) connection must be low-inductance and as short

as possible.

All connections to the equipment must have a defined potential. Connections that

are pre-wired, but not used, should preferably be grounded when binary inputs

and output relays are isolated. When binary inputs and output relays are

connected to common potential, the pre-wired but unused connections should be

connected to the common potential of the grouped connections.

Before energizing the equipment, the following should be checked:

- Voltage rating/polarity (rating label/equipment documentation);

- CT circuit rating (rating label) and integrity of connections;

- Protective fuse rating;

- Integrity of the protective conductor (earth) connection (where

applicable);

- Voltage and current rating of external wiring, applicable to the application.

Accidental touching of exposed terminals

If working in an area of restricted space, such as a cubicle, where there is a risk of

electric shock due to accidental touching of terminals which do not comply with

IP20 rating, then a suitable protective barrier should be provided.

Equipment use

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Removal of the equipment front panel/cover

Removal of the equipment front panel/cover may expose hazardous live parts,

which must not be touched until the electrical power is removed.

Page 12

P44x/EN SS/H11 Safety Section

(SS) - 6

UL and CSA/CUL listed or recognized equipment

To maintain UL and CSA/CUL Listing/Recognized status for North America the

equipment should be installed using UL and/or CSA Listed or Recognized parts

for the following items: connection cables, protective fuses/fuseholders or circuit

breakers, insulation crimp terminals, and replacement internal battery, as

specified in the equipment documentation.

For external protective fuses a UL or CSA Listed fuse shall be used. The Listed

type shall be a Class J time delay fuse, with a maximum current rating of 15 A and

a minimum d.c. rating of 250 Vd.c. for example type AJT15.

Where UL or CSA Listing of the equipment is not required, a high rupture capacity

(HRC) fuse type with a maximum current rating of 16 Amps and a minimum d.c.

rating of 250 Vd.c. may be used, for example Red Spot type NIT or TIA.

Equipment operating conditions

The equipment should be operated within the specified electrical and

environmental limits.

Current transformer circuits

Do not open the secondary circuit of a live CT since the high voltage produced

may be lethal to personnel and could damage insulation. Generally, for safety,

the secondary of the line CT must be shorted before opening any connections to

it.

For most equipment with ring-terminal connections, the threaded terminal block

for current transformer termination has automatic CT shorting on removal of the

module. Therefore external shorting of the CTs may not be required, the

equipment documentation should be checked to see if this applies.

For equipment with pin-terminal connections, the threaded terminal block for

current transformer termination does NOT have automatic CT shorting on removal

of the module.

External resistors, including voltage dependent resistors (VDRs)

Where external resistors, including voltage dependent resistors (VDRs), are fitted

to the equipment, these may present a risk of electric shock or burns, if touched.

Battery replacement

Where internal batteries are fitted they should be replaced with the recommended

type and be installed with the correct polarity to avoid possible damage to the

equipment, buildings and persons.

Insulation and dielectric strength testing

Insulation testing may leave capacitors charged up to a hazardous voltage. At the

end of each part of the test, the voltage should be gradually reduced to zero, to

discharge capacitors, before the test leads are disconnected.

Insertion of modules and pcb cards

Modules and PCB cards must not be inserted into or withdrawn from the

equipment whilst it is energized, since this may result in damage.

Insertion and withdrawal of extender cards

Extender cards are available for some equipment. If an extender card is used,

this should not be inserted or withdrawn from the equipment whilst it is energized.

This is to avoid possible shock or damage hazards. Hazardous live voltages may

be accessible on the extender card.

Page 13

Safety Section P44x/EN SS/H11

External test blocks and test plugs

Great care should be taken when using external test blocks and test plugs such

as the MMLG, MMLB and MiCOM P990 types, hazardous voltages may be

accessible when using these. *CT shorting links must be in place before the

insertion or removal of MMLB test plugs, to avoid potentially lethal voltages.

*Note: When a MiCOM P992 Test Plug is inserted into the MiCOM P991 Test

Block, the secondaries of the line CTs are automatically shorted, making

them safe.

Fiber optic communication

Where fiber optic communication devices are fitted, these should not be viewed

directly. Optical power meters should be used to determine the operation or

signal level of the device.

Cleaning

The equipment may be cleaned using a lint free cloth dampened with clean water,

when no connections are energized. Contact fingers of test plugs are normally

protected by petroleum jelly, which should not be removed.

(SS) - 7

5. DE-COMMISSIONING AND DISPOSAL

De-commissioning

The supply input (auxiliary) for the equipment may include capacitors across the

supply or to earth. To avoid electric shock or energy hazards, after completely

isolating the supplies to the equipment (both poles of any dc supply), the

capacitors should be safely discharged via the external terminals prior to

de-commissioning.

Disposal

It is recommended that incineration and disposal to water courses is avoided.

The equipment should be disposed of in a safe manner. Any equipment

containing batteries should have them removed before disposal, taking

precautions to avoid short circuits. Particular regulations within the country of

operation, may apply to the disposal of the equipment.

6. TECHNICAL SPECIFICATIONS FOR SAFETY

Unless otherwise stated in the equipment technical manual, the following data is applicable.

6.1 Protective fuse rating

The

recommended maximum rating of the external protective fuse for equipments is 16A,

high rupture capacity (HRC) Red Spot type NIT, or TIA, or equivalent. The protective fuse

should be located as close to the unit as possible.

DANGER - CTs must NOT be fused since open circuiting them may

produce lethal hazardous voltages.

6.2 Protective class

IEC 60255

equipment documentation).

EN 60255-27: 2005 This equipment requires a protective

conductor (earth) connection to ensure user safety.

-27: 2005 Class I (unless otherwise specified in the

Page 14

P44x/EN SS/H11 Safety Section

(SS) - 8

6.3 Installation category

IEC 60255-27: 2005 Installation category III (Overvoltage Category III):

EN 60255-27: 2005 Distribution level, fixed installation.

Equipment in this category is qualification tested at

5 kV peak, 1.2/50 µs, 500 , 0.5 J, between all

supply circuits and earth and also between

independent circuits.

6.4 Environment

The equi

pment is intended for indoor installation and use only. If it is required for use in an

outdoor environment then it must be mounted in a specific cabinet of housing which will

enable it to meet the requirements of IEC 60529 with the classification of degree of

protection IP54 (dust and splashing water protected).

Pollution Degree - Pollution Degree 2 Compliance is demonstrated by reference to safety

Altitude - Operation up to 2000m standards.

IEC 60255-27:2005

EN 60255-27: 2005

Page 15

Introduction

6

MiCOM P40 Agile P442, P444

1

(IT) 1-

P44x/EN IT/Hb

INTRODUCTION

Date: 2017

Page 16

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

-2

Introductio

Page 17

Introduction

6

MiCOM P40 Agile P442, P444

3

(IT) 1-

P44x/EN IT/Hb

CONTENTS

1. INTRODUCTION TO MICOM GUIDES 5

2. INTRODUCTION TO MICOM 7

3. PRODUCT SCOPE 8

3.1 Ordering options 11

Page 18

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

-4

Introductio

Page 19

Introduction

6

MiCOM P40 Agile P442, P444

5

(IT) 1-

1 INTRODUCTION TO MiCOM GUIDES

This manual provides a functional and technical description of the MiCOM protection relay

and a comprehensive set of instructions for the relay ’s use and application.

The section contents are summarized below:

Safety Guide

P44x/EN IT Introduction

A guide to the MiCOM range of relays and the documentati on st ructure. General safety

aspects of handling Electronic Equipment is disc ussed with particular reference to relay

safety symbols. Also a general functional overview of the relay and brief application

summary is given.

P44x/EN TD Technical Data

Technical data including setting ranges, accuracy l i m its, recommended operating conditions,

ratings and performance data. Compliance with norms and i nt ernational standards is quoted

where appropriate.

P44x/EN GS Getting Started

P44x/EN IT/Hb

A guide to the different user interfaces of the protection relay describing how to start using it.

This section provides detailed information regarding the communication interfaces of the

relay, including a detailed description of how to access the settings database stored within

the relay.

P44x/EN ST Settings

List of all the relay settings, including ranges, step sizes and defaults, together with a brief

explanation of each setting.

P44x/EN AP Application Notes

This section includes a description of common power system applications of the relay,

calculation of suitable settings, some typical worked examples, and how to apply the settings

to the relay.

P44x/EN PL Programmable Logic

Overview of the programmable scheme logic a nd a description of each logical node. This

section includes the factory default (PSL) and an explanation of typical applications.

P44x/EN MR Measurements and Recording

Detailed description of the relays recording and measurements functions including the

configuration of the event and disturbance recorder a nd measurement functions.

P44x/EN FD Firmware Design

Overview of the operation of the relay’s hardware and software. This section includes

information on the self-checking features and di agnostics of the relay.

P44x/EN CM Commissioning

Instructions on how to commission the relay, comprising checks on the calibration and

functionality of the relay.

P44x/EN MT Maintenance

A general maintenance policy for the relay is out li ned.

P44x/EN TS Troubleshooting

Advice on how to recognize failure modes and the recommended course of action. Includes

guidance on who to contact for advice.

Page 20

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

Introductio

-6

P44x/EN SC SCADA Communications

This section provides an overview regarding the SCADA communication interfaces of the

relay. Detailed protocol mappings, semantics, profiles and interoperability tables are not

provided within this manual. Separate document s are available per protocol, available for

download from our website.

P44x/EN SG Symbols and Glossary

List of common technical abbreviations found within the product documentation.

P44x/EN IN Installation

Recommendations on unpacking, handling, inspect i on and storage of the relay. A guide to

the mechanical and electrical installation of t he relay is provided, incorporating earthing

recommendations. All external wiring connections to the relay are indicated.

P44x/EN CS Cyber Security (Software Version C7.x only, hardw are suffix K)

This section provides an overview about cyber security protection (to secure communication

and equipment within substations environment). Cy ber security standards and

implementation are described.

P44x/EN VH Firmware and Service Manual Version History

History of all hardware and software releases f or t he product.

Page 21

Introduction

6

MiCOM P40 Agile P442, P444

7

(IT) 1-

2 INTRODUCTION TO MiCOM

MiCOM is a comprehensive solution capable of meeting all electricity supply requirements. It

comprises a range of components, systems and services from General Electric.

Central to the MiCOM concept is flexibility.

MiCOM provides the ability to define an application solution and, through extensive

communication capabilities, to integrate it with your power supply control system.

The components in MiCOM are:

• P range protection relays;

• C range control products;

• M range measurement products for accurate metering and monitoring;

• S range versatile PC support and substation control packages.

MiCOM products include extensive facilities for recording information on the state and

behaviour of the power system using disturbance and fault records. They can also provide

measurements of the system at regular intervals to a cont rol centre enabling remote

monitoring and control to take place.

P44x/EN IT/Hb

For up-to-date information on any MiCOM product, visit our website:

http://www.gegridsolutions.com

Page 22

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

-8

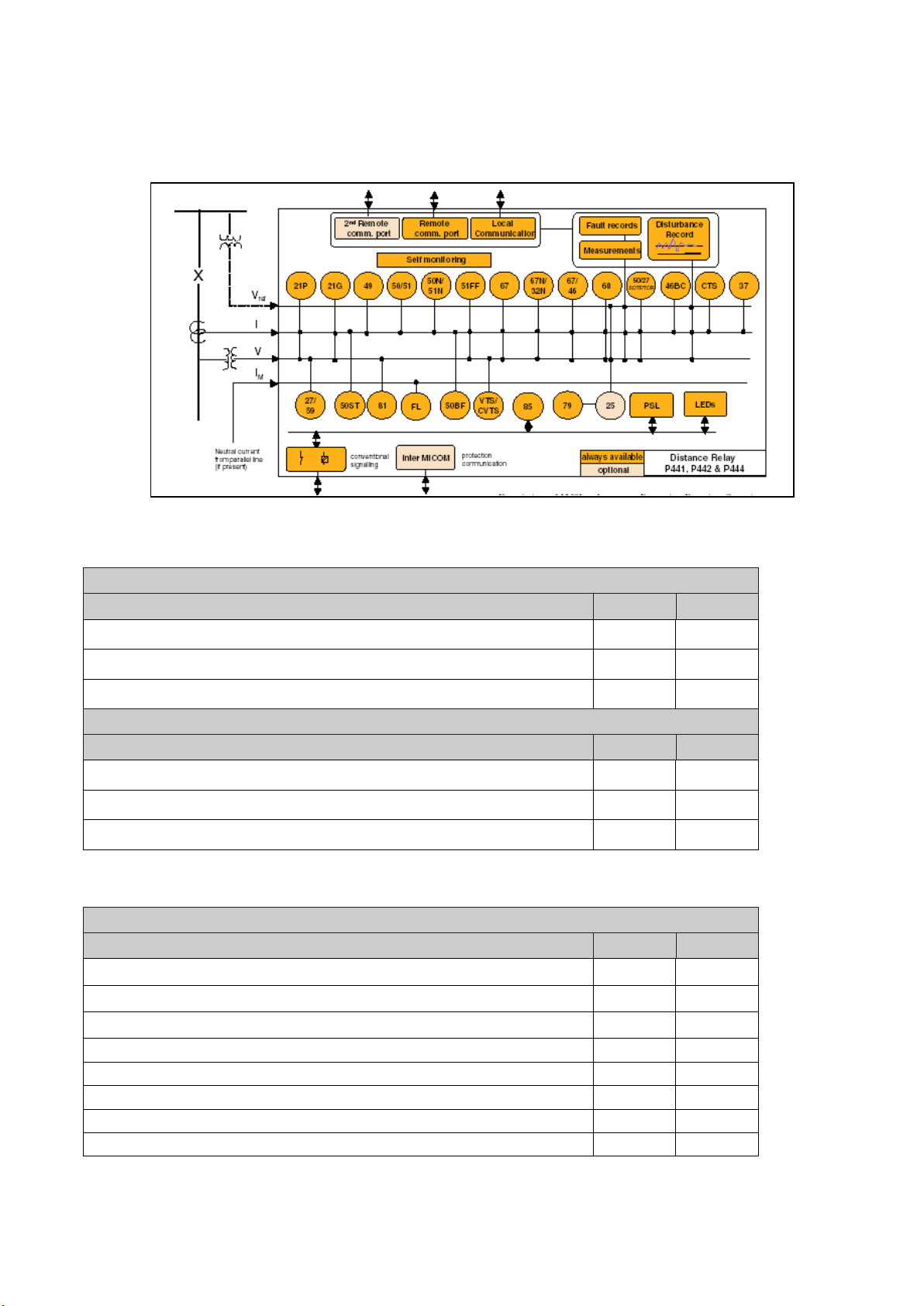

3 PRODUCT SCOPE

The MiCOM P442 and P444 Numerical Full Scheme Distance Relays provide

comprehensive distance protection for different applications like: lines, cables, tapped lines,

lines with multiple zero sequence sources, non-homogeneous lines, series compensated

lines and parallel lines.

The independently settable resistive reach for e ach zone allows easy application to short

lines and cable protection. Using well-proven, patented techniques to directionalise, and

making full use of digital memory, the relays can be appl i ed i n situations that can cause

classic distance implementations to maloperat e (crosscountry faults and close-up faults).

The MiCOM P442 and P444 are in-built with a library of channel aided scheme logic,

supplementary and back-up protection. It prov ides complete protection (4 alternative setting

groups) to solidly earthed systems from distribut ion t o transmission voltage levels.

Three phase tripping with faulted phase indication is provided for all protection functions. In

addition models P442 and P444 allow single-pha se t ripping for the distance protection and

the channel aided DEF protection (67N).

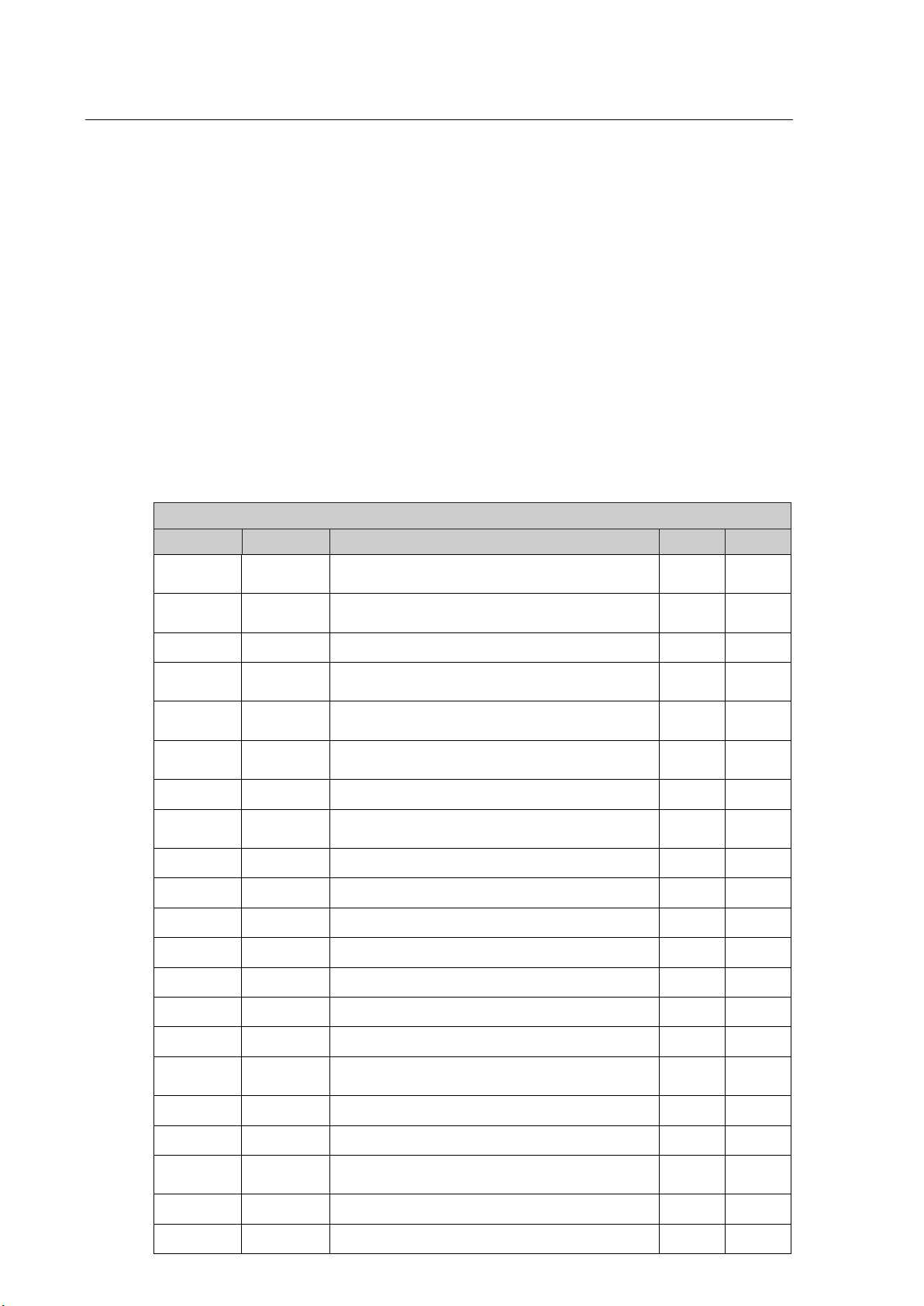

The P442 and P444 distance relays equipped with 150 MHz CPU and coprocessor board

have been enhanced as described in the following table:

Introductio

Protection Functions Overview

ANSI IEC 61850 Features P442 P444

21P PDIS

21G PDIS

Load Blinder

50/51/67

50N / 51N

/ 67N

67N EfaPSCH

32N Directional zero sequence power protecti on

67/46

27 PTUV Undervoltage (4 stages, 1st stage DT and IDMT)

59 PTOV Overvoltage (4 stages, 1st stage DT and IDMT)

37 3-phase undercurrent (2 stages)

81U Underfr equency (4 stages)

81O Overfrequency (2 stages)

49 PTTR Thermal overload protection

50 / 27 PSOF Switch on to fault / trip on r ec lose (SOTF/TOR)

78 / 68 RPSB

85 PSCH Channel aided schemes (PUP, POP, Blocking)

Weak Infeed (WI) Echo logic

46BC Broken conductor (open jumper)

50ST OcpPTOC Stub bus protection

OcpPTOC

/ RDIR

EfdPTOC /

RDIR

NgcPTOC

/ RDIR

Quadrilateral full scheme phase di s tance (6

zones)

Quadrilateral full scheme ground d istance (6

zones)

Directional / non-directional phase overcurrent (2

stages)

Directional / non-directional stand by earth fault (2

stages)

Channel aided directional earth fault protection

(DEF)

Directional / non-directional negat ive sequence

overcurrent

Power swing blocking & Out of step tripping

(using PSL)

Accelerated trip feature: Loss of Load - Zx

extension

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

Page 23

Introduction

6

MiCOM P40 Agile P442, P444

9

P44x/EN IT/Hb

(IT) 1-

Protection Functions Overview

ANSI IEC 61850 Features P442 P444

50BF RBRF Circuit breaker failure

PTRC Tripping 1/3p 1/3p

79 RREC Autoreclose (4 shots) 1/3p 1/3p

25 RSYN Check synchronism

VTS

CTS Current Transformer Supervision

CVTS Capacitive Voltage Transformer Supervision

51FF PTOC Emergency Overcurrent on VT failure

OptGGIO Digital inputs 16 24

RlyGGIO Output relays (fast output optional) 21

SV IEC 61850-9-2 sampled values

Front communication port (RS232/K-bus)

Time synchronisation port (IRI G-B) * option option

Voltage Transformer Supervision

(1, 2 & 3 phase fuse failure detection)

Rear communication port (RS485/Opt ic/Ethernet)

*

Second rear communication port

(RS232/RS485/K-Bus)*

IEC 61850-9-2-LE Sampled Analogue values

Ethernet board

• •

• •

• •

• •

• •

• •

32 or

46

• •

• •

• •

option option

option option

*It may be possible to get all in one particular model.

NA: Not applicable

To complement the wide range of protection functions listed in the table, the P442 and P444

relays are provided with the following measurement, control, monitoring, post fault

analysis and self-diagnostic functions.

• Fault locator

• Display of instantaneous measured and derived values

• Circuit breaker control, status & condition monitoring.

• Trip circuit and coil supervision

• 4 alternative setting groups

• Programmable scheme logic

• Sequence of event recording

• Comprehensive disturbance recording (waveform capture)

• User configurable LEDs

• Local and remote communication ports

• Multiple communication protocol and interface options

• Time synchronisation

• Fully customisable menu texts

• Multi level password protection

• Test facilities

• Power-up diagnostics and continuous self monitoring of the relay

Page 24

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

•

•

•

•

•

•

•

•

•

•

•

•

•

-10

• User friendly setting and analysis software (MiCOM S1 Agile)

Application overview

Introductio

Figure 1: Functional diagram

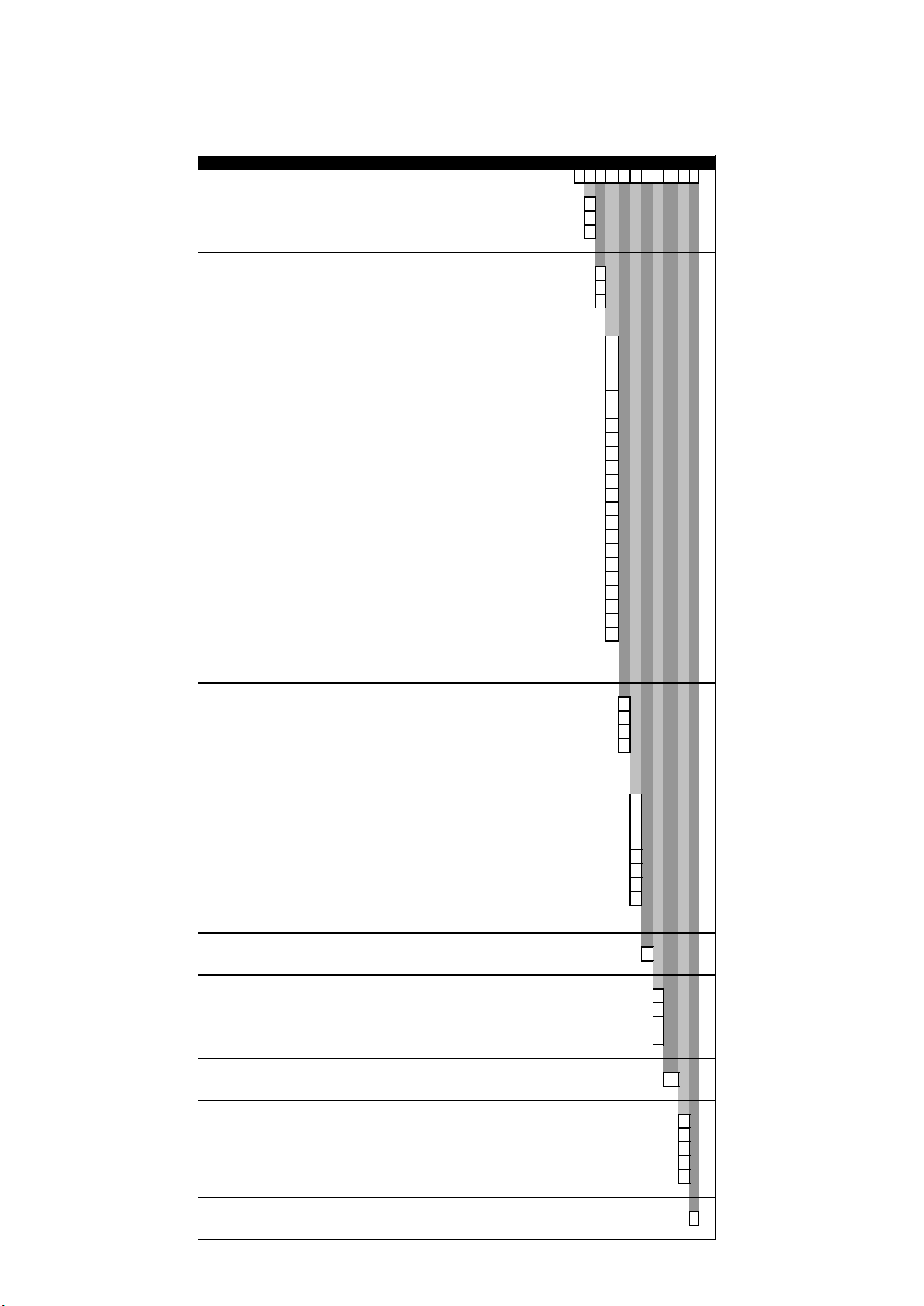

Rating options

Auxiliary Voltage Rating options

Features P442 P444

24 – 48 Vdc only

48 – 110 Vdc (30 – 100 Vac)

110 – 250 Vdc (100 – 240 Vac)

In/Vn Rating boards options

Features P442 P444

Dual rated CT (1&5A: 100-120 V)

Module Sum (Σ1A / PXDB)

IEC 61850-9-2-LE Sampled Analogue values Ethernet board

Communication protocol options

Communication protocol options

Features P442 P444

K-Bus / Courier

MODBUS

VDEW (IEC 60870-5-103) (RS485 or Fibre Optic)

DNP3.0

IEC 61850 + Courier via rear RS485 port

IEC 61850 + IEC 60870-5-103 via rear RS485 port

DNP3.0 over Ethernet and Courier via r ear K-Bus/RS485

IEC 61850-9-2-LE

• •

• •

• •

• •

• •

•

•

•

•

Page 25

Introduction

6

MiCOM P40 Agile P442, P444

11

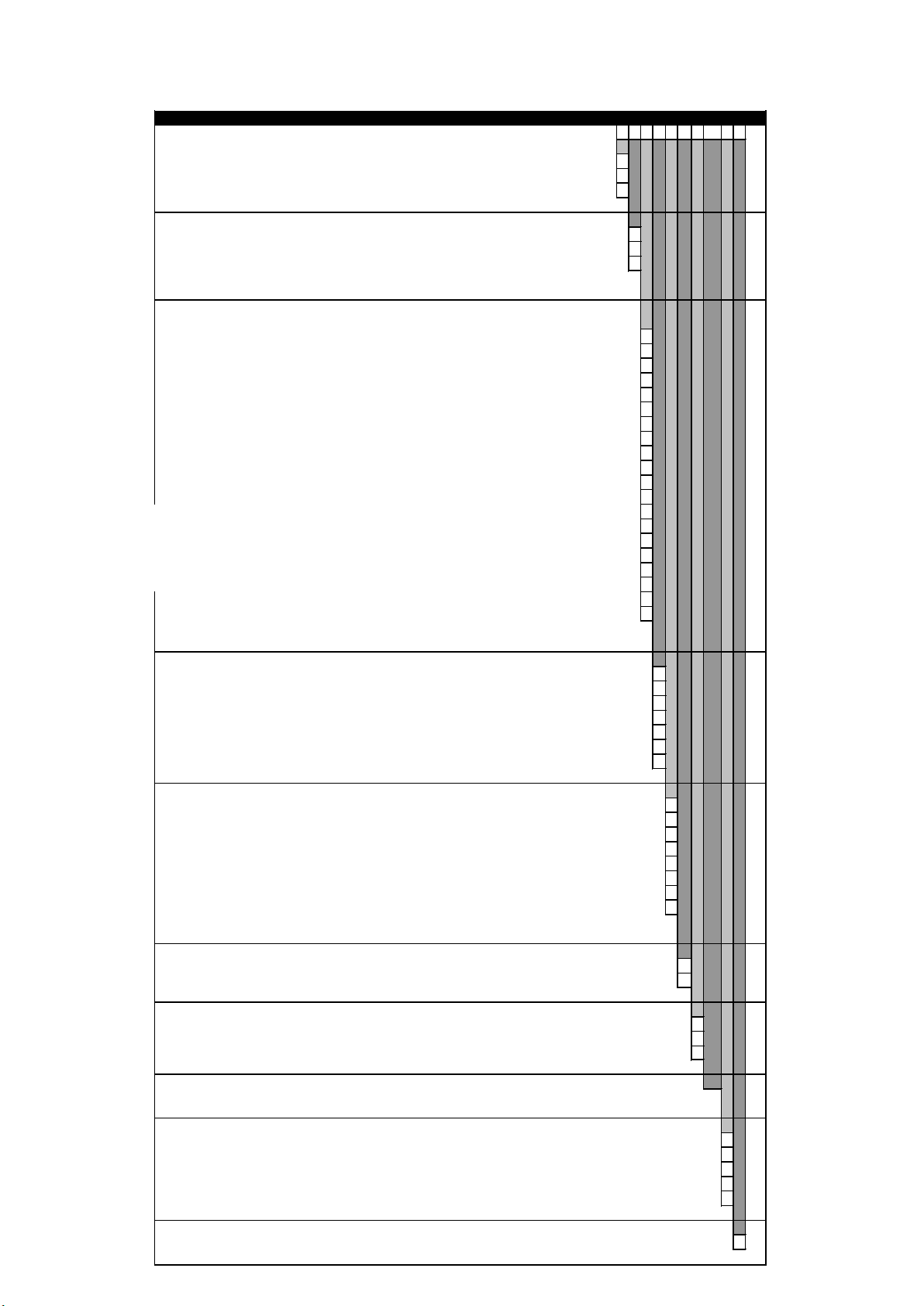

Dist ance Prot ection

P442 P44

2

**

Nominal auxiliary voltage

24-54 Vdc

7

48-125 Vdc (40-100 V ac)

8

110-250 Vdc (100-240 V ac)

9

In/Vn ra ting

Dual rated CT (1 & 5A : 100 - 120V ) 1

Module Sum

(∑

1A / PXDB)

5

C

Hardwa re options

Standard version

1

IRIG-B Only (Modul at ed) 2

3

4

Single Ethernet 100M bi t /s 6

Second Rear Comm s + Int erMi COM 7

IRIG-B (Modulated) + S econd Rear Comms + InterMiCOM 8

Single Ethernet (100Mbi t/s) plus IRIG-B (Modul ated) Software version '31' and later (S uffix J) A

Single Ethernet (100Mbi t/s) plus IRIG-B (Un-modul at ed) S oft ware version '31' and later (S uffix J) B

IRIG-B (Un-modulated) Soft ware version '31' and later (Suffix J) C

InterMiCOM + Courier Rear Port * E

InterMiCOM + Courier Rear Port + IRIG-B modulat ed *

F

Redundant Et hernet Self-Healing Ring, 2 m ul ti-mode fibre port s + Modul ated IRIG-B G

Redundant Et hernet Self-Healing Ring, 2 m ul ti-mode fibre port s + Un-modul at ed IRIG-B H

Redundant Et hernet RSTP, 2 mul t i -m ode fibre port s + M odul at ed IRIG-B J

Redundant Et hernet RSTP, 2 mul t i -m ode fibre port s + Un-modul ated IRIG-B K

Redundant Et hernet Dual -Homi ng Star, 2 m ul t i -m ode fibre port s + M odul at ed IRIG-B L

Redundant Et hernet Dual -Homi ng Star, 2 m ul t i -m ode fibre port s + Un-modul ated IRIG-B M

Redundant Et hernet PRP/ HS R**, 2 fibre port s + M odul at ed IRIG-B

N

Redundant Et hernet PRP/ HS R**

, 2 fibre ports + Unmodulat ed IRIG-B P

* NB: Options available wit h Software version 45 & lat er (Des i gn Suffix K)

** For HSR – c ont act Alstom for detai ls

Software options

16 Logic Inputs & 21 Relay Outputs B

16 Logic Inputs & 21 Relay Outputs (3 Fast trip) D

16 Logic Inputs & 21 Relay Outputs (6 Fast trip) E

16 Logic Inputs & 18 Relay Outputs (4 High Break) *

C

* NB: Option C is onl y available with Des i gn Suffix K & Software version 40 or lat er

Protocol options

K-Bus 1

Modbus

2

VDEW (IEC 60870-5-103)

3

DNP3.0 4

UCA2 + Courier via rear RS485 port (Ethernet hardware opti ons [i.e. 6] onl y) 5

IEC61850 + Courier via rear RS485 port * 6

IEC61850 + IEC60870-5-103 via rear RS485 port * 7

DNP3 over Ethernet wit h Courier rear port K-Bus /RS485 protocol

8

* NB: IEC61850 E di tion 2 available wit h '82' Software

Mounting

Flush Panel Mounting, wi t h Harsh Environment Coati ng M

Language

English, F renc h, German, S pani sh

0

English, F renc h, German, Ital i an 4

C

Software version

Date and application dependant **

Customer specific options

Standard version 0

Custom er engi neered version: ENEL 1

Custom er engi neered version: TERNA 2

Custom er engi neered version: RTE 4

Custom er engi neered version: general A

Hardware version

Model and hardware version dependant *

Chinese, E ngl i sh or French via HMI, wit h English or French onl y via

Communic ations port

Variants Order No.

Fibre opti c converter (Courier, Modbus,IEC60870-5-103 or DNP3)

(Note: c onverts RS 485 port to fibre optic; NOT ext ra port

)

IRIG-B input and Fibre optic converter (Courier, Modbus , IE C60870-5-103 or DNP3)

(

Note: converts RS485 port to fibre optic; NOT ext ra port)

Non-conventional input t ransformers NCIT (IEC 61850-9-2 LE)

(IT) 1-

3.1 Ordering options

P44x/EN IT/Hb

Page 26

P44x/EN IT/H

b6

n

(IT) 1

MiCOM P40 Agile P442, P444

Dist ance Protection P444 P444 **

Nominal auxiliary voltage

24-54 Vdc 7

48-125 Vdc (40-100 V ac) 8

110-250 Vdc (100-240 V ac) 9

In/Vn ra ting

Dual rated CT (1 & 5A : 100 - 120V ) 1

Module S um (∑1A / PXDB) 5

C

Hardware options

Standard version 1

IRIG-B input 2

Fibre opti c c onverter (IEC60870-5-103) 3

IRIG-B input and Fi bre opt i c converter (IEC60870-5-103) 4

Singl e E thernet 100M bi t /s 6

Rear Comms + InterMi COM 7

Rear Comms + IRIB-B + InterM i COM 8

Singl e E thernet (100M bit/s) plus IRIG-B (Modulat ed) S oft ware version '31' and later (Suffix J) A

Singl e E thernet (100M bit/s) plus IRIG-B (Un-modulated) S oft ware version '31' and later (S uffix J) B

IRIG-B (Un-modulated) (Soft ware version '31' and later) C

InterMiCOM + Couri er Rear Port * E

InterMiCOM + Couri er Rear Port + IRIG-B modulated

* F

Redundant Ethernet S el f-Healing Ri ng, 2 m ul ti-mode fibre port s + M odul at ed IRIG-B G

Redundant Ethernet S el f-Healing Ri ng, 2 m ul ti-mode fibre port s + Un-modul at ed IRIG-B H

Redundant Ethernet RS TP, 2 m ul ti-mode fibre port s + M odul ated IRIG-B J

Redundant Ethernet RS TP, 2 m ul ti-mode fibre port s + Un-m odul at ed IRIG-B K

Redundant Ethernet Dual-Hom i ng S tar, 2 m ul t i -m ode fibre port s + M odul ated IRIG-B L

Redundant Ethernet Dual-Hom i ng S tar, 2 m ul t i -m ode fibre port s + Un-m odulated IRIG-B M

Redundant Ethernet P RP /HSR, 2 fibre port s + M odul ated IRIG-B N

Redundant Ethernet P RP /HSR, 2 fibre port s + Unm odul at ed IRIG-B P

* NB: Opt i ons available with Software version 45 & later (Design Suffix K )

Models

1 & 3 Pol e tripping/recl osing with 24 input s & 32 out puts B

1 & 3 Pol e tripping/recl osing with 24 input s & 34 ouput s (12 high break ) C

1 & 3 Pol e tripping/recl osing with 24 input s & 32 out puts (4 fast output contac t s) D

1 & 3 Pol e tripping/recl osing with 24 input s & 32 out puts (8 fast output contac t s) E

1 & 3 Pol e tripping/recl osing with 24 input s & 46 out puts J

1 & 3 Pol e tripping/recl osing with 24 input s & 46 out puts (4 fast output contac t s) K

1 & 3 Pol e tripping/recl osing with 24 input s & 46 out puts (8 fast output contac t s) L

Protocol options

K-Bus 1

Modbus 2

VDEW (IEC 60870-5-103) (RS485 or Fibre O pt i c) 3

DNP3.0 4

UCA2 5

IEC61850 + Courier via rear RS485 port * 6

IEC61850 + IEC60870-5-103 via rear RS485 port

* 7

DNP3 over Ethernet wit h Courier rear port K -Bus/RS485 prot ocol

8

* NB: IEC61850 E di tion 2 available wit h '82' Software

Mounting

Flus h/Panel M ount i ng wi t h Hars h Environment Coati ng M

19" Rack Mounting wit h Harsh Environmental Coat i ng N

Language

Engli sh, F renc h, German, Spanis h 0

Engli sh, F renc h, German, It al i an 4

C

Software version

Date and applicat i on dependant

Customer specific options

Standard version 0

Customer engineered version: E NE L 1

Customer engineered version: TERNA 2

Customer engineered version: RTE 4

Customer engineered version: General A

Hardware version

Model and hardware version dependant *

Variant s Order No.

Chinese, English or Frenc h via HMI, wit h English or Frenc h onl y via Communic at i ons port

Non-conventional input transformers NCIT (IEC 61850-9-2 LE) NEW BO A RD

Introductio

-12

Page 27

Technical Data

6

MiCOM P40 Agile P442, P444

1

(TD) 2-

P44x/EN TD/Hb

TECHNICAL DATA

Date: 2017

Page 28

P44x/EN TD/H

b6

Technical Data

(TD)

MiCOM P40 Agile P442, P444

2-2

Page 29

Technical Data

6

MiCOM P40 Agile P442, P444

3

(TD) 2-

Technical Data

P442 & P444 Numerical Distance

Protection:

∗ 1 & 3 Pole tripping/reclosing (P442 & P444)

In/Vn rating (ordering option):

∗ Dual rated CT (1&5A: 100-120 V)

∗ Module sum (Σ1A / PXDB)

∗ IEC 61850-9-2LE Sampled Analogue

Values Ethernet board.

Input / Output (I/O)

P442 (with or without Check Synchronism):

∗ 16I/21O,

∗ 18I/18O (4 high break)

∗ 16I/21O (3 or 6 Fast Trip)

P444 (with or without Check Synchronism):

∗ 24I/32O,

∗ 24I/46O,

∗ 24I/34O (12 high break).

Protocol options:

∗ K-Bus

∗ Modbus,

∗ VDEW (IEC 60870-5-103)

∗ DNP3.0

+ (P442 and P444 only):

∗ IEC 61850 + Courier via rear RS485 port

∗ IEC 61850 + IEC 60870-5-103 via rear

RS485 port

∗ DNP3 over Ethernet with Courier rear port

K-Bus/RS485 protocol

Hardware options (P442 & P444):

∗ IRIG-B input

∗ Fibre optic converter (IEC 60870-5-103)

∗ IRIG-B input and Fibre optic converter

(IEC 60870-5-103)

∗ Single Ethernet 100 Mbit/s

∗ Rear Comms + InterMiCOM

∗ Rear Comms + IRIB-B + InterMiCOM

∗ Single Ethernet (100 Mbit/s) plus IRIG-B

(Modulated)

∗ Single Ethernet (100 Mbit/s) plus IRIG-B

(De-modulated)

∗ IRIG-B (De-modulated)

∗ InterMiCOM + Courier Rear Port *

∗ InterMiCOM + Courier Rear Port + IRIG-B

modulated *

∗ Redundant Ethernet Self-Healing Ring, 2

multi-mode fibre ports + Modulated IRIG-B

∗ Redundant Ethernet Self-Healing Ring, 2

multi-mode fibre ports + Un-modulated

IRIG-B

∗ Redundant Ethernet RSTP, 2 multi-mode

fibre ports + Modulated IRIG-B

∗ Redundant Ethernet RSTP, 2 multi-mode

fibre ports + Un-modulated IRIG-B

∗ Redundant Ethernet Dual-Homing Star, 2

multi-mode fibre ports + Modulated IRIG-B

∗ Redundant Ethernet Dual-Homing Star, 2

multi-mode fibre ports + Un-modulated

IRIG-B

P44x/EN TD/Hb

Mechanical Specification

Design

Modular MiCOM Px40 platform relay available

in three different case sizes:

∗ P442 60TE (12”),

∗ P444 80TE (16”).

Mounting:

∗ front of panel flush mounting,

∗ rack mounted (19” ordering option).

Enclosure Protection

Per IEC 60529: 1989

IP 52 Protection (front panel) against dust and

dripping water,

IP 50 Protection for the rear and sides of the

case against dust,

IP 10 Product safety protection for the rear due

to live connections on the terminal block.

Weight

40TE: approx. 7.3kg

60TE: approx. 9.2kg

80TE: approx. 11.0kg

Terminals

AC Current and Voltage Measuring Inputs

Located on heavy duty (black) terminal block:

Threaded M4 terminals, for ring lug

connection.

CT inputs have integral safety shorting, upon

removal of the terminal block.

General Input/Output Terminals

For power supply, opto inputs, output contacts

and COM1 & optional COM2 rear

communications.

Located on general purpose (grey) blocks:

Threaded M4 terminals, for ring lug

connection.

Case Protective Earth Connection

Rear stud connection, threaded M4.

Must be earthed (grounded) using the

protective (earth) conductor for safety,

minimum earth wire size 2.5 mm².

Front P

EIA RS232 DTE, 9 pin D-type female

connector.

Courier protocol for interface to MiCOM S1

Agile software.

PEB* rated Maximum cable length 15 m.

Front Download/Monitor Port

EIA RS232, 25 pin D-type female connector.

For firmware downloads. PEB* rated circuit.

Isolation to ELV level.

ort Serial PC Interface

Page 30

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

-4

Rear Communications Port

K-Bus/EIA(RS485) signal levels, two wire

Connections located on general purpose block,

M4 screw.

For screened twisted pair cable, multidrop,

1000 m max.

SELV* rated circuit.

Ethernet (copper & fibre)

Optional Rear IRIG-B Interface modulated

or un-modulated

BNC socket

SELV* rated circuit.

50 ohms coaxial cable.

Optional Rear Fiber Connection for

SCADA/DCS

BFOC 2.5-(ST®)-interface for multi-mode

glass fibre type 62.5, as per IEC874-10,

850 nm short-haul fibers, one Tx and one Rx.

Optical budget: 5.6 dB

Data rate: 2.5 Mbits

Max Length: 1000 m

Optional Rear Ethernet Connection for

IEC 61850

10 Base T / 100 Base TX Communications

Interface in accordance with IEEE802.3 and

IEC 61850

Isolation: 1.5 kV.

Connector type: RJ45

Cable type: Screened Twisted Pair (STP)

Max. cable length: 100 m

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC 61850

Wavelength: 1300 nm

Fiber: multi-mode 50/125 µm or 62.5/125 µm

Connector style: BFOC 2.5 - (ST®)

Optional Rear redundant Ethernet

connection for IEC 61850

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC 61850

Wavelength: 1300 nm

Fiber: multi-mode 50/125 µm or 62.5/125 µm

Connector style: BFOC 2.5 - (ST®)

Fiber defect connector (watchdog relay)

Redundant Ethernet board

Connector (3 terminals): 2NC contacts

Rated voltage: 250 V

Continuous current: 5 A

Short duration current: 30 A for 3 s

Breaking capacity

DC: 50 W resistive

DC: 25 W resistive

AC: 1500 VA resistive (cos φ = unity)

AC: 1500 VA inductive (cos φ = unity)

Subject to maxima of 5 A and 250 V

Optional Second Rear Communication Port

EIA(RS)

232, 9 pin D-type female connector,

socket SK4. Courier protocol: K-Bus, or

EIA(RS)485 or EIA(RS)232. Maximum cable

length: 15 m.

*: PEB = Protective equipotential bonded

*: SELV = Safety/Separated extra low voltage

Both PEB and SELV circuits are safe to touch

after a single fault condition.

Page 31

Technical Data

6

MiCOM P40 Agile P442, P444

5

Ratings

(TD) 2-

P44x/EN TD/Hb

Power supply

AC Measuring Inputs

Nominal frequency:

∗ 50 and 60 Hz (settable)

Operating range:

∗ 45 to 65 Hz

AC Current

Nominal current (In):

∗ 1 and 5 A dual rated (separate terminals

are provided for the 1A and 5A windings,

with the neutral input of each winding

sharing one terminal)

Nominal burden per phase 1 A:

∗ <0.04 VA at rated current

Impedance per phase 1 A:

∗ <40 mΩ over 0 – 30 In

Nominal burden per phase 5 A:

∗ <0.15 VA at rated current

Impedance per phase 5 A:

∗ <8 mΩ over 0 – 30 In

Thermal withstand:

∗ continuous 4 In

∗ for 10 s: 30 In

∗ for 1 s; 100 In

Linear to 64 In (non-offset AC current).

AC Voltage

Nominal voltage (Vn):

∗ 100 to 120 V phase-phase

Nominal burden per phase:

∗ < 0.02 VA at 110/√3 V

Thermal withstand:

∗ continuous 2 Vn

∗ for 10 s: 2.6 Vn

Auxiliary Voltage (Vx)

Three ordering options:

(i) Vx: 24 to 48 Vdc

(ii) Vx: 48 to 110 Vdc, and 40 to 100Vac (rms)

(iii) Vx: 110 to 250 Vdc, and 100 to 240 V ac (rms).

Operating Range

(i) 19 to 65 V (dc only for this variant)

(ii) 37 to 150 V (dc), 32 to 110 V (ac)

(iii) 87 to 300 V (dc), 80 to 265 V (ac).

With a tolerable ac ripple of up to 12% for a dc

supply, per IEC 60255-11: 1979.

Nominal Burden

Quiescent burden: 12 W

Additions for energized binary inputs/out put s:

Per opto input:

∗ 0.09 W…(24 to 54 V),

∗ 0.12 W...(110/125 V),

∗ 0.19 W...(220/250 V).

Per energized output relay: 0.13 W

Per energized high break output relay: 0.73 W

Power-up Time

Time to power up < 11 s.

Power Supply Interruption

Per IEC 60255-11: 1979

The relay will withstand a 20 ms interruption in

the DC auxiliary supply, without de-energizing.

Per IEC 61000-4-11: 1994

The relay will withstand a 20 ms interruption in

an AC auxiliary supply, without de-energizing.

Battery Backup

Front panel mounted Type ½ AA, 3.6 V

Field Voltage Output

Regulated 48 Vdc

Current limited at 112 mA maximum output

The operating range shall be 40 V to 60 V with

an alarm raised at <35 V

Digital (“Opto”) Inputs

Universal opto inputs with programmable

voltage thresholds. May be energized from the

48 V field voltage, or the external battery

supply.

Rated nominal voltage: 24 to 250 Vdc

Operating range: 19 to 265 Vdc

Withstand: 300 Vdc.

Nominal pick-up and reset thresholds:

∗ Pick-up: approx. 70% of

battery nominal set,

∗ Reset: approx. 64% of

battery nominal set.

Recognition time:

∗ <2 ms with long filter removed,

∗ <10 ms with half-cycle ac immunity filter on.

Page 32

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

-6

Output Contacts

Environmental Conditions

Standard Contacts

General purpose relay outputs for signalling,

tripping and alarming:

Rated voltage: 300 V

Continuous current: 10 A

Short-duration current:

∗ 30 A for 3 s

Making capacity:

∗ 250 A for 30 ms

∗ 10 A continuous.

Breaking capacity:

∗ DC: 50 W resistive

∗ DC: 62.5 W inductive (L/R = 50 ms)

∗ AC: 2500 VA resistive (cos φ = unity)

∗ AC: 2500VA inductive (cos φ = 0.7)

Response to command: < 5 ms

Durability:

∗ Loaded contact: 10000 operations

minimum,

∗ Unloaded contact: 100000 operations

minimum.

Fast operation and High Break Contacts

Dedicated purpose relay outputs for tripping:

∗ Uses IGBT technology

Make and Carry:

∗ 30 Amps for 3 sec, 30 A @ 250 V resistive

Carry:

∗ 250 Amps dc for 30 ms

Continuous Carry:

∗ 10 Amps dc

Break Capacity:

∗ 10 Amps @ 250 V resistive (10,000

operations) 10 Amps @ 250 V L/R=40 ms

Operating time:

∗ <200 µs & Reset time: 7.5 ms

Watchdog Contacts

Non-programmable contacts for relay

healthy/relay fail indication:

Breaking capacity:

∗ DC: 30 W resistive

∗ DC: 15 W inductive (L/R = 40 ms)

∗ AC: 375 VA inductive (cos φ = 0.7)

IRIG-B 12X Interface (Modulated)

External clock synchronization per IRIG

standard 200-98, format B12X.

Input impedance 6 kΩ at 1000 Hz

Modulation ratio:

∗ 3:1 to 6:1

Input signal, peak-peak:

∗ 200 mV to 20 V

Ambient Temperature Range

Ambient temperature range

Operating temperature range:

∗ –25°C to +55°C (or –13°F to +131°F)

Storage and transit:

∗ –25°C to +70°C (or –13°F to +158°F)

Tested as per IEC 60068-2-1: 2007:

∗ –25°C (–13°F) storage (96 hours)

∗ –40°C (–40°F) operation (96 hours)

IEC 60068-2-2: 2007:

∗ +70°C (+158°F) (storage (96 hours)

∗ +85°C (+185°F) operation (96 hours)

Ambient Humidity Range

Per IEC 60068-2-3: 1969:

∗ 56 days at 93% relative humidity and

+40 °C

Per IEC 60068-2-30: 1980:

∗ Damp heat cyclic, six (12 + 12) hour cycles,

93% RH, +25 to +55 °C

Pollution degree

Per IEC 61010-1:1990/A2:1995:

∗ Normally only non conductive pollution

occurs. Occasionally a temporary

conductivity caused by condensation mu st

be expected.

Corrosive Environments

Per IEC 60068-2-60: 1995, Part 2, Test Ke,

Method (class) 3

Industrial corrosive environment/poor

environmental control, mixed gas flow test.

21 days at 75% relative humidity and +30°C

Exposure to elevated concentrations of H

, Cl2 and SO2.

NO

2

2

S,

Type Tests

Insulation

Per IEC 60255-27: 2005,

∗ Insulation resistance > 100 M

(Using only electronic/brushless insulation

tester).

Creepage Distances and Clearances

Per IEC 60255-27: 2005

∗ Pollution degree 3,

∗ overvoltage category III,

∗ impulse test voltage 5 kV.

Ω at 500 Vdc

IRIG-B 00X Interface (Un-modulated)

External clock synchronization per IRIG

standard 200-98, format B00X.

Input signal TTL level

Input impedance at dc 10 kΩ

Page 33

Technical Data

6

MiCOM P40 Agile P442, P444

7

(TD) 2-

High Voltage (Dielectric) Wi th stand

(EIA RS232 ports excepted).

(i) Per IEC 60255-27: 2005, 2 kV rms, AC, 1

minute:

Between all case terminals connected togethe r

and the case earth.

Also, between all terminals of independent

circuits.

∗ 1 kV rms AC for 1 minute, across open

watchdog contacts and across open

contacts of changeover output relays.

(ii) Per ANSI/IEEE C37.90-1989 (reaffirmed

1994):

∗ 1.5 kV rms AC for 1 minute, across open

contacts of changeover output relays.

Impulse Voltage Withstand Test

Per IEC 60255-27: 2005

Front time: 1.2 µs, Time to half-value: 50 µs,

Peak value: 5 kV, 0.5J

Between all terminals, and all terminals and

case earth.

Electromagnetic Compatibility (EMC)

1 MHz Burst High Frequency Disturbance

Test

Per IEC 60255-22-1: 2008, Class III,

Common-mode test voltage: 2.5 kV,

Differential test voltage: 1.0 kV,

Test duration: 2 s, Source impedance: 200 Ω

(EIA RS232 ports excepted).

100 kHz Damped oscillatory Test

Per EN 61000-4-18: 2007, Level 3,

Common-mode test voltage: 2.5 kV,

Differential test voltage: 1.0 kV,

Immunity to Electrostatic Discharge

Per IEC 60255-22-2: 1997, Class 4,

∗ 15 kV discharge in air to user interface,

display, and exposed metalwork.

Per IEC 60255-22-2: 1997, Class 3,

∗ 8 kV discharge in air to all communication

ports.

∗ 6 kV point contact discharge to any part of

the front of the product.

Electrical Fast Transient or Burst

Requirements

Per IEC 60255-22-4: 2002 and EN 61000-4-4:

2004.

Test severity:

∗ Class III and IV:

Amplitude:

∗ 2 kV, burst frequency 5 kHz (Class III),

Amplitude:

∗ 4 kV, burst frequency 2.5 kHz (Class IV).

Applied directly to auxiliary supply, and applied

to all other inputs. (EIA RS232 ports

excepted).

Amplitude:

∗ 4 kV, burst frequency 5 kHz (Class IV).

Applied directly to auxiliary supply.

P44x/EN TD/Hb

Fast transient disturbances on power

supply (common mode only): 4 kV, 5 ns rise

time, 50 ns decay time, 5 kHz repetition

frequency, 15 ms burst, repeated every

300 ms for 1 min in each polarity, with a 50 Ω

source impedance

Fast transient disturbances on I/O signal,

data and control lines (common mode only):

4 kV, 5 ns rise time, 50 ns decay time, 5 kHz

repetition frequency, 15 ms burst, repeated

every 300 ms for 1 min in each polarity, with a

50 Ω source impedance.

Surge Withstand Capability

Per IEEE/ANSI C37.90.1: 2002:

4 kV fast transient and 2.5 kV oscillatory

applied directly across each output contact,

optically isolated input, and power supply

circuit.

Surge Immunity Test

(EIA RS232 ports excepted).

Per IEC 61000-4-5: 2006 Level 4,

Time to half-value: 1.2 / 50 µs,

∗ Amplitude: 4 kV between all groups and

case earth,

∗ Amplitude: 2 kV between terminals of each

group.

Immunity to Radiated Electromagnetic

Energy

Per IEC 60255-22-3: 2000, Class III:

Test field strength, frequency band 80 to 1000

MHz:

∗ 10 V/m,

∗ Test using AM: 1 kHz / 80%,

∗ Spot tests at 80, 160, 450, 900 MHz

Per IEEE/ANSI C37.90.2: 2004:

25 MHz to 1000 MHz, zero and 100% square

wave modulated.

Field strength of 35 V/m.

Radiated Immunity from Digital

Communications

Per EN61000-4-3: 2002, Level 4:

Test field strength, frequency band 800 to 960

MHz, and 1.4 to 2.0 GHz:

∗ 30 V/m,

Test using AM:

∗ 1 kHz / 80%.

Radiated Immunity from Digital Radio

Telephones

Per EN 61000-4-3: 2002

∗ 10 V/m, 900 MHz and 1.89 GHz.

Immunity to Conducted Disturbances

Induced by Radio Frequency Fields

Per IEC 61000-4-6: 1996, Level 3,

Disturbing test voltage: 10 Vrms at 1 kHz 80%

am., 0.15 to 80 MHz

Page 34

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

-8

Power Frequency Magnetic Field Immunity

Per IEC 61000-4-8: 2001, Level 5,

∗ 100 A/m applied continuously,

∗ 1000 A/m applied for 3 s.

Per IEC 61000-4-9: 2001, Level 5,

∗ 1000 A/m applied in all planes.

Per IEC 61000-4-10: 2001, Level 5,

∗ 100 A/m applied in all planes at

100 kHz/1MHz with a burst duration of 2 s.

Conducted Emissions

Per EN 55022: 1998:

∗ 0.15 – 0.5 MHz, 79 dBµV (quasi peak)

66 dBµV (average)

∗ 0.5 – 30 MHz, 73 dBµV (quasi peak)

60 dBµV (average).

Mechanical Robustness

Vibration Test

Per IEC 60255-21-1: 1996

Response Class 2

Endurance Class 2

Shock and Bump

Per IEC 60255-21-2: 1995

Shock response Class 2

Shock withstand Class 1

Bump Class 1

Seismic Test

Per IEC 60255-21-3: 1995

Class 2

Radiated Emissions

Per EN 55022: 1998:

∗ 30 – 230 MHz, 40 dBµV/m at 10 m

measurement distance

∗ 230 – 1 GHz, 47 dBµV/m at 10 m

measurement distance.

EU Directives

EMC Compliance

Per 2004/108/EC:

Compliance to the European Commission

Directive on EMC is claimed via the Technical

Construction File route. Product Specific

Standards were used to establish conformity :

∗ EN50263: 2000

Product Safety

Per 2006/95/EC:

Compliance with European Commission Low

Voltage Directive. Compliance is demonstrat ed

by reference to generic safety standards:

∗ IEC 60255-27:2005

CE

R&TTE compliance

Radio and telecommunication terminal

equipment (R&TTE) directive 99/5/EC.

Compliance demonstrated by compliance to

both the EMC directives on low voltage

directive down to 0 V.

Applicable to rear communication ports.

Cyber Security

(where applicable)

Implementation

Following measures have been implemented:

∗ Four level access,

∗ Password strengthening,

∗ Disabling of unused application and

physical ports,

∗ Inactivity timer,

∗ Storage of security events,

∗ NERC-compliant default display.

Standards

∗ NERC CIP (North American Electric

Reliability Corporation – Critical

Infrastructure Protection, USA):

CIP-002-1, CIP-003-1, CIP-004-1,

CIP-005-1, CIP-006-1, CIP-007-1,

CIP-008-1 and CIP-009-1

∗ BDEW (Germany),

∗ ANSI ISA 99 (USA), IEEE 1686,

∗ IEC 62351, ISO/IEC 27002,

∗ NIST SP800-53 (National Institute of

Standards and Technology, USA),

∗ CPNI Guidelines (Centre for the Protection

of National Infrastructure, UK).

IEC 61850-9-2 Ethernet board

(option)

∗ connexion RJ45 or optical fibre

∗ Antialiasing filter

∗ Number of logical nodes: up to 6

∗ Time-delay at message

reception: 0 to 3 ms

Safety control:

∗

- presence test alarm,

- synchronization alarm,

- quality alarm,

independent per logical node

Page 35

Technical Data

6

MiCOM P40 Agile P442, P444

9

(TD) 2-

Timing and Accuracy

PERFORMANCE DATA

For all accuracies specified, the repeatability is

±

5%, unless otherwise specified

P44x/EN TD/Hb

Transient Overreach: Additional tolerance due

to increasing X/R ratios:

±5% over the X/R ratio from 1 to 90

Breaker fail timers accuracy:

20 ms or ±2%, whichever is greater

DISTANCE PROTECTION

All quoted operating times include the closure

of the trip output contact.

50 Hz Operation

Minimum tripping time: 13 ms (SIR = 5)

14 ms (SIR = 30)

Maximum tripping time: 18 ms (SIR = 5)

21 ms (SIR = 30)

Typical tripping time: 17 ms (SIR = 5)

17.5 ms (SIR = 30)

100% of faults up to 75% of Zone 1 reach

setting trip subcycle at SIR=5.

99% of faults up to 75% of Zone 1 reach

setting trip subcycle at SIR=30.

60 Hz Operation

Minimum tripping time: 13 ms (SIR = 5)

13 ms (SIR = 30)

Maximum tripping time: 16.5 ms (SIR = 5)

18 ms (SIR = 30)

Typical tripping time: 14 ms (SIR = 5)

16 ms (SIR = 30)

100% of faults up to 75% of Zone 1 reach

setting trip subcycle at SIR=5.

88% of faults up to 75% of Zone 1 reach

setting trip subcycle at SIR=30.

Accuracy

Characteristic shape, up to SIR = 30:

±5% for on-angle fault (the set line angle)

±10% for off-angle

(Example: For a 70 degree set line angle,

injection testing at 40 degrees would be

referred to as “off-angle”).

Zone time delay deviations:

±20 ms or 2%, whichever is greater

DIRECTIONAL AND NON-DIRECTIONAL

OVERCURRENT

(I>1, I>2, I>3 or I>4)

Accuracy

DT Pick-up: Setting ±5%

IDMT Pick-up 1.05 × Setting ±5%

DT reset: 0.95 × Setting ±2%

IDMT reset: 0.95 × Setting ±5%

Definite time stages:

±20 ms or ±2%, whichever is greater

Inverse time stages:

±40 ms or ±5%, whichever is greater

NEGATIVE SEQUENCE

OVERCURRENT

(I2>1, I2>2, I2>3 or I2>4)

Accuracy

Zone 1:

Pick-up: Setting ±5%

Reset: 0.95 × Setting ±5%

Definite time stages:

±40 ms or ±5%, whichever is greater

BROKEN CONDUCTOR DETECTION

Accuracy

(I2/I1)

Pick-up: Setting ±2.5%

Reset: 0.95 × Setting ±2.5%

Definite time stages:

±20 ms or 2%, whichever is greater

Sensitivity

Settings < 5/In Ω: (0.05 In*5/(setting*In)) ±5%

Settings > 5/In Ω: 0.05 In ±5%

Distance elements

Pick-up: Setting ±5%

Zone timer deviation:

20 ms or ±2%, whichever is greater

Timer accuracy: ±2 ms

Minimum trip level for IDMT elements:

1.05 × Setting ± 5%

Inverse time stages:

±40 ms or 5%, whichever is greater

Definite time stages:

±40 ms or 2%, whichever is greater

Repeatability: 5%

Sensitivity

Settings < 5/In Ω: (0.05 In*5/(setting*In)) ±5%

Settings > 5/In Ω: 0.05 In ±5%

Page 36

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

-10

DIRECTIONAL AND NON-DIRECTIONAL

EARTH FAULT PROTECTION

(IN>1, IN>2, IN>3 or IN>4)

Accuracy

DT Pick-up: Setting ±5%

IDMT Pick-up 1.05 ×Setting ±5%

Drop-off: 0.95 × setting ±5%

Definite time stages:

±20 ms or ±2%, whichever is greater

DT reset: 0.95 × Setting ±2%

Inverse time stages:

40 ms or ±5%, whichever is greater

IDMT reset: 0.95 × Setting ±5%

AIDED DIRECTIONAL EARTH FAULT

(D.E.F.) PROTECTION

Accuracy

Zero Sequence Polarisation

pick-up: Setting ±10%

with relay characterist angle = ±90°

Negative Sequence Polarisation

pick-up: Setting ±5%

THERMAL OVERLOAD

Accuracy

Thermal alarm pick-up:

Calculated trip time ±10% ∗

Thermal overload pick-up:

Calculated trip time ±10% ∗

Cooling time accuracy

±15% of theoretical

Repeatability: <5%

∗ Operating time measured with applied

current of 20% above thermal setting.

UNDERCURRENT PROTECTION

(I<1,I<2)

Accuracy

Pick-up:

±10% or 0.025 In, whichever is greater

Drop-off: ±5%

Timer accuracy:

±40 ms or 2%, whichever is greater

Reset: <15 ms

UNDERVOLTAGE

(V<1, V<2, V<3 or V<4)

Accuracy

DT Pick-up: Setting ±2%

IDMT Pick-up: 0.95 × Setting ±2%

Definite time operation:

±20 ms or 2%, whichever is greater

IDMT characteristic shape:

±40 ms or 2%, whichever is greater

Reset: 1.05 × Setting ±5%

OVERVOLTAGE

(V>1, V>2, V>3 or V>4)

Accuracy

DT Pick-up: Setting ±1%

IDMT Pick-up: 1.05 x Setting ±2%

Definite time operation:

±20 ms or 2%, whichever is greater

IDMT characteristic shape:

±40 ms or 2%, whichever is greater

Reset: 0.98 to 0.995 × Setting ±5%

CIRCUIT BREAKER FAIL AND

UNDERCURRENT

NEUTRAL DISPLACEMENT/ RESIDUAL

OVERVOLTAGE

(VN>1, VN>2)

Accuracy

DT Pick-up: Setting ±5%

IDMT Pick-up: 1.05 x setting ±5%

Definite time operation:

±20 ms or 2%, whichever is greater

Instantaneous operation: <50 ms

IDMT characteristic shape:

±40 ms or 2%, whichever is greater

Reset: 0.95 × Setting ±5%

Accuracy

Pick-up:

±10% or 0.025

Operating time: <12 ms

Definite time operation:

±20 ms or 2%, whichever is greater

In, whichever is greater

VOLTAGE TRANSFORMER

SUPERVISION

Accuracy

Fast block operation: <1 cycle

Fast block reset: <1.5 cycles

Definite time operation:

±20 ms or 2%, whichever is greater

Page 37

Technical Data

6

MiCOM P40 Agile P442, P444

11

(TD) 2-

P44x/EN TD/Hb

CURRENT TRANSFORMER

SUPERVISION

Accuracy

IN> Pick-up: Setting ±5%

VN< Pick-up: Setting ±5%

IN> Drop-off: 0.9 × setting ±5%

VN< Drop-off:

(1.05 × settin g) ±5% or 1 V

whichever is greater

Time delay operation:

Setting ±2% or 20 ms

whichever is greater

CTS block operation: <1 cycle

CTS reset: <35 ms

CB STATE MONITORING AND

CONDITION MONITORING

Accuracy

Timers:

±20 ms or 2%, whichever is greater

Broken current accuracy: ±5%

PROGRAMMABLE SCHEME LOGIC

Accuracy

Output conditioner timer:

Setting ±20 ms or 2%, whichever is greater

Dwell conditioner timer:

Setting ±20 ms or 2%, whichever is greater

Pulse conditioner timer:

Setting ±20 ms or 2%, whichever is greater

AUTORECLOSE AND CHECK

SYNCHRONISM

Accuracy

Timers:

Setting ±20 ms or 2%, whichever is greater

MEASUREMENTS AND RECORDING

FACILITIES

Accuracy

Typically

0.2 - 2In/Vn

Current:

Range: 0.05 to 3 In

Accuracy: ±1.0% of reading

Voltage:

Range: 0.05 to 2 Vn

Accuracy: ±1.0% of reading

Power (W):

Range: 0.2 to 2 Vn and 0.05 to 3 In

Accuracy: ±5.0% of reading at

uni ty power factor

Reactive power (Vars):

Range: 0.2 to 2 Vn

and 0.05 to 3 In

Accuracy: ±5.0% of reading at

zero power factor

Apparent power (VA):

Range: 0.2 to 2 Vn

and 0.05 to 3 In

Accuracy: ±5.0% of reading

Energy (Wh):

Range: 0.2 to 2 Vn

and 0.2 to 3 In

Accuracy: ±5.0% of reading at

zero power factor

Energy (Varh):

Range: 0.2 to 2 Vn

and 0.2 to 3 In

Accuracy: ±5.0% of reading at

zero power factor

Phase accuracy:

Range: 0° to 360°

Accuracy: ±0.5%

Frequency:

Range: 45 t o 65 Hz

Accuracy: ±0.025 Hz

±

1%, but ±0.5% between

IRIG-B AND REAL TIME CLOCK

Performance

Real time clock accuracy:

< ±2 seconds/day

Modulation ratio: 1/3 or 1/6

Input signal peak-peak amplitude:

200 mV to 20 V

Input impedance at 1000 Hz: 6000 Ω External

clock synchronization:

Conforms to IRIG standard 200-98, format B

Page 38

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

Parameter

Sym

Min.

Typ.

Max

Unit

Output Optical

EOL

Output Optical

EOL

Ratio

10

-10

dB

Output Optical

Logic “0” State

Parameter

Sym

Min.

Typ.

Max.

Unit

PIN

(W)

dBm avg.

PIN

(C)

Input Optical

Power Maximum

PIN

Max.

dBm avg.

(ms)

Max (ms)

Direct fiber

3 to 7

9

No Noise

5 to 8

+ MUX

12

+ MUX

BER

10-3

Direct fiber

4 to 8

10

No Noise

6 to 8

+ MUX

13

+ MUX

BER

≤10-3

-12

FAULT AND DISTURBANCE RECORDS

Accuracy

Time and date stamping:

±2 ms of applied fault/event

Fault clearance time: ±2%

CB operating time: ±5ms

Protection operating time: ±2%

Waveshape:

Comparable with applied quantities,

±5% of applied quantities

Trigger positions: ±2%

Record length: 8 records each of 1.8 s

duration (1.5 s at 60 Hz)

FAULT LOCATOR

Accuracy

Fault location: ±2% of line length (under

reference conditions)*

* Reference conditions solid fault applied on

line.

REFERENCE CONDITIONS

Ambient temperature: 20°C

FREQUENCY TRACKING RANGE

45 to 65 Hz

Ethernet data

(where applicable)

10 Base T /100 Base TX Communications

Interface in accordance with IEEE802.3 and

IEC 61850

Isolation 1.5 kV

Cable type: Screened twisted pair STP

Max length: 100 m

100 Base FX Interface

Interface in accordance with IEEE802.3 and

IEC 61850

Wavelength: 1300 nm

Fibre: multi-mode 50/125 µm or 62.5/12 5 µm

Connector style: ST

Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

BOL= Beginning of Life, EOL= End of Life

Power

BOL 62.5/125 µm,

NA = 0.275 Fiber

Power

BOL 50/125 µm,

NA = 0.20 Fiber

Optical Extinction

-19

PO

-20

-22.5

PO

-23.5

-16.8 -14

-20.3 -14

dBm avg.

dBm avg.

%

BREAKER FAILURE

Accuracy

Reset time < 40 ms ±2%

Thresholds: settings ±5%

Power at

PO

(“0”)

-45

dBm avg.

BOL – Beginning of life

EOL – End of life

Receive Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Input Optical

Power Minimum at

Window Edge

Input Optical

Power Minimum at

Eye Center

Min.

Min.

-14 -11.8

-33.5 –31

-34.5 -31.8 Bm avg.

InterMiCOM64 fiber optic

teleprotection

(where applicable)

End-end operation: Table below shows bit

transfer time (for multiplexed links, ‘MUX’

denotes the multiplexer delay).

IM64 Cmd Applic.

Typical

Delay

Note

Permissive

Dir. Intertrip

Via MUX

Via MUX

≤

BER – Bit Error Rate for Channel

Page 39

Technical Data

6

MiCOM P40 Agile P442, P444

13

(TD) 2-

SETTINGS, MEASUREMENTS

AND RECORDS LIST

SETTINGS LIST

GLOBAL SETTINGS (SYSTEM DATA):

Language:

English/French/German/Spanish/Italian/

Chinese (ordering option)

Frequency: 50/60 Hz

CONFIGURATION

Setting Group:

Select via Menu

Select via Opto

Active Settings: Group 1/2/3/4

Setting Group 1: Disabled/Enabled

Setting Group 2: Disabled/Enabled

Setting Group 3: Disabled/Enabled

Setting Group 4: Disabled/Enabled

Distance Protection: Disabled/Enabled

Power Swing: Disabled/Enabled

Back-Up I>: Disabled/Enabled

Negative Sequence

overcurrent: Disabled/Enabled

Broken Conductor: Disabled/Enabled

Earth Fault overcurrent

protection: Disabled/

Zero sequence power/

Earth fault overcurrent

Aided Directional Earth

Fault (DEF): Disabled/Enabled

Voltage Protection: Disabled/Enabled

Circuit Breaker Fail & I<: Disabled/Enabled

Supervision (Voltage,

Current or Capacitive

Voltage Transformer): Disabled/Enabled

System Checks: Disabled/Enabled

Thermal Overload: Disabled/Enabled

I< Protection: Disabled/Enabled

Residual Overvoltage

protection: Disabled/Enabled

Frequency Protection: Disabled/Enabled

Internal Autoreclose: Disabled/Enabled

Input Labels: Invisible/Visible

Output Labels: Invisible/Visible

CT & VT Ratios: Invisible/Visible

Record Control: Invisible/Visible

Disturbance Recorder: Invisible/Visible

Measure't Setup: Invisible/Visible

Communication Settings: Invisible/Visible

Commission Tests: Invisible/Visible

Setting Values: Primary/Secondary

Control Input: Invisible/Visible

Control Input Config: Invisible/Visible

Control Input Labels: Invisible/Visible

Direct Acces: Disabled/Enabled

InterMiCOM: Disabled/Enabled

Ethernet NCIT: Invisible/Visible

Function key: Invisible/Visible

RP1 / RP2 Read only Disabled/Enabled

NIC Read only Disabled/Enabled

PSL Timers: Invisible/Visible

RearPortt1ReadOnly Disabled/Enabled

RearPort2ReadOnly Disabled/Enabled

RearNICReadOnly Disabled/Enabled

LCD Contrast: (Factory pre-set)

P44x/EN TD/Hb

DISTANCE PROTECTION

Line setting

Line Length (Ln): 0.3 to 1000 km (step 0.010)

or 0.2 to 625 miles (step 0.005)

Line Impedance:

0.001×I1 to 500×I1 (step 0.001×I1)

Positive sequence angle (Line Angle, ϑ

–90.0° to +90° (step 0.1°)

):

1

Zone setting

Zone Status:

∗ Z1X Enabled/Disabled

∗ Z2 Enabled/Disabled

∗ ZP Enabled/Disabled

∗ ZQ Enabled/Disabled

∗ Z3 Enabled/Disabled

∗ Z4 Enabled/Disabled

Z1 (Impedance reach:) 0.001/In to 500/In Ω

(step 0.001/In Ω)

Z1X 0.001/In to 500/In Ω

(step 0.001/In Ω)

kZ1 residual

compensation factor: 0 to 7 (step 0.001)

KZ1 residual

compensation angle: 0 to +360° (step 0.1

R1G (Resistive reach for

phase-earth fault):

0 Ω to 400/In Ω (step 0.01/In Ω)

R1Ph (Resistive reach

for phase-phasefault):

0 Ω to 400/In Ω (step 0.01/In Ω)

tZ1 (time-delay

for Zone 1): 0 to 10 s (step 0.002 s)

Z2: 0.001/In to 500/In Ω (step 0.001/In/Ω)

kZ2 res comp: 0 to 7 (step 0.001)

kZ2 Angle: 0 to 360° (step 0.1°)

R2G: 0 Ω to 400/In Ω (step 0.01/In Ω)

R2Ph: 0 Ω to 400/In Ω (step 0.01/In Ω)

tZ2: 0 to 10 s (step 0. 002 s)

Z3: 0.001/In to 500/In Ω (step 0.001/In/Ω)

kZ3/4 res comp: 0 to 7 (step 0.001)

kZ3/4 Angle: 0 to 360° (step 0.1°)

R3G-R4G: 0 Ω to 400/In Ω (step 0.01/In Ω)

R3Ph-R4Ph: 0 Ω to 400/In Ω (step 0.01/In Ω)

tZ3: 0 to 10 s (step 0.002 s)

Z4: 0.001/In to 500/In Ω (step 0.01/In Ω)

tZ4: 0 to 10 s (step 0.01 s)

Zone P – Directionality Forward/Reverse

Zp: 0.001/In to 500/In Ω (step 0.001/In/Ω)

kZp res comp: 0 to 7 (step 0.001)

kZp Angle: 0 to 360° (step 0.1°)

RpG: 0 Ω to 400/In Ω (step 0.01/In Ω)

RpPh: 0 Ω to 400/In Ω (step 0.01/In Ω)

tZp: 0 to 10 s (step 0.002 s)

Zone Q – Directionality Forward/Reverse

Zq: 0.001/In to 500/In Ω (step 0.001/In/Ω)

kZq res comp: 0 to 7 (step 0.001)

kZq Angle: 0 to 360° (step 0.1°)

RqG: 0 Ω to 400/In Ω (step 0.01/In Ω)

RqPh: 0 Ω to 400/In Ω (step 0.01/In Ω)

tZq: 0 to 10 s (step 0.002 s)

°)

Page 40

P44x/EN TD/

Hb6

Technical Data

(TD) 2

MiCOM P40 Agile P442, P444

-14

Zone Setting other parameters

Serial Compensated

Line: Enabled/Disabled

Overlap Z mode: Enabled/Disabled

Z1m Tilt Angle: –45° to +45° (step 1°)

Z1p Tilt Angle: –45° to +45° (step 1°)

Z2/Zp/Zq Tilt Angle –45° to +45° (step 1°)

Fwd Z Chgt Delay: 0 to 100ms (step 1ms)

Volt. Memory Validity: 0 to 10 s (step 10 ms)

Earth Current detection:

0 to 0.1×I1 (step 0.01×I1)

Fault locator:

∗ KZm mutual Comp: 0 to 7 (step1)

∗ KZm Angle: 0 to 360° (step 1°)

Load Blinder:

∗ R< Blinder Lim: 0.001/In to 500/In Ω

(step 0.001/In/Ω)

∗ Load/B Angle: 15° to 65° (step 1°)

∗ Load Blinder V: 1 V to 70 V (step 0.5 V)

∗ None,

∗ Loss of Guard mode,

∗ Loss of Carrier mode.

Distance Scheme setting

Program mode Standard or open scheme

Standard Modes:

∗ Basic + Z1X,

∗ POP Z1,

∗ POP Z2,

∗ PUP Z2,

∗ PUP Forward,

∗ BOP Z1,

∗ BOP Z2.

POP = Permissive Overreach Protection

PUP = Permissive Underreach Protection

BOP = Blocking Overreach Protection

Fault type:

∗ Phase to Ground,

∗ Phase to Phase,

∗ Both enabled.

Trip Mode:

∗ Force 3 Pole,

∗ 1 Pole Z1 and Carrier Received (CR),

∗ POP Z1 Z2 and CR.

Signal sent from a zone to the relays setting

(open scheme):

∗ CsZ1 (Carrier sent by Z1),

∗ CsZ2,

∗ CsZ4.

Aided scheme on Carrier receipt “Dist CR”

(open scheme):

∗ None,

∗ PermZ1: Permissive Z1 (Z1 can trip without

waiting the end of tZ1 timout),

∗ PermZ2,

∗ PermFwd (forward),

∗ Blocking Z1 (BlkZ1) (Z1 can only trip if a

Carrier is not received),

∗ BlkZ2.

Additional time-delay for PUP Z2, PUP FWD,

POP Z1 and POP Z2 schemes:

0 to 1 s (stem 2 ms)

tReversal Guard: 0 to 0.15 s (step 2 ms)

Unblocking schemes (with permissive

schemes):

Page 41

Technical Data

6

MiCOM P40 Agile P442, P444

15

(TD) 2-

TOR (Trip On Reclose)–SOTF (Switch On To

Fault) modes enabled or disabled for:

∗ TOR logic in case of fault in Z1, Z2, Z3 or

All Zones,

∗ SOTF logic in case of fault in Z1, Z2, Z3 or

All Zones,

∗ TOR or SOTF in Distance scheme,

∗ SOTF logic in case of fault Z1+Rev,

Z2+Rev or I>3 Enabled,

∗ SOTF initiated by level detectors,

SOTF Delay: 10 to 3600 s (step 1 s)

Z1X extension on channel fail:

Enabled/Disabled

Weak Infeed

Mode Status:

Disabled/Echo/WI Trip & Echo/PAP

Single Pole: Disabled/Enabled

V< Threshold: 10 to 70 V (step 5 V)

Trip time delay: 0 to 1 s (step 2 ms)

Loss of Load (LoL)

Mode Status:

Enabled/Disabled

LoL on Channel failed: Enabled/Disabled

I<: 0.05×In to 1×In (step 0.05×In)

LoL Window: 0.01 s to 0.1 s (step 0.01 s)

POWER SWING DETECTION AND

BLOCKING

Power Swing detection boundaries:

∗ Delta R: 0 to 400/ In Ω (step 0.01/In Ω)

∗ Delta X: 0 to 400/ In Ω (step 0.01/In Ω)

IN Status: Enabled/Disabled

∗ IN> (%max) 10% to 100% (step 1%)

I2> Status: Enabled/Disabled

∗ I2> (%max) 10% to 100% (step 1%)

Imax line Status: Enabled/Disabled

∗ Imax line> (%max):

1×In to 20×In (step 0.01×In)

Delta I Status: Enabled/Disabled

Unblocking time-delay: 0 to 30 s (step 0.1 s)

Blocking zones:

∗ Z1/Z1X Block: Yes/No

∗ Z2 Block: Yes/No

∗ Zp Block: yes/No

∗ Zq Block: Yes/No

∗ Z3 Block: Yes/No

∗ Z4 Block Yes/No

Out of Step (OOS): 1 to 255 (step 1)

Stable swing: 1 to 255 (step 1)

P44x/EN TD/Hb

DIRECTIONAL AND NON DIRECTIONAL

OVERCURRENT PROTECTION

(Back-up I>)

Directional and non directional

I> protections:

I>1, I>2 (range 0.08–10×In)

Non directional I> protections:

I>3, I>4 (range 0.08–32×In)

I>1 Function / I>2 Function:

∗ Disabled,

∗ Definite Time (DT),

∗ IEC Standard inverse

∗ IEC Very inverse